Technology for reducing harmful ingredients in smoke

A technology of harmful components and processes, applied in the field of new tobacco processing technology, can solve the problems of breaking the balance of tobacco chemical components, reducing the sensory quality of smoke, and reducing the processing resistance, so as to ensure the quality of smoke, ensure processing performance, and restore processing. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

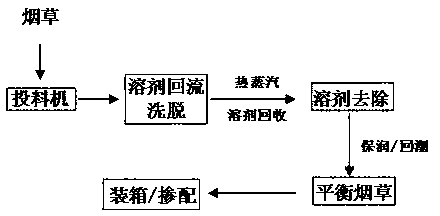

Image

Examples

Embodiment 1

[0018] Tobacco is transported through the conveyor belt to the solvent reflux elution process, the solvent is n-hexane, and the reflux time is 10 minutes; then the solvent on the tobacco is removed by hot steam, and the solvent is recovered; finally, the structure of the tobacco is repaired, and the glycerin or propylene glycol is mixed with water or ethanol Blended into repairing liquid, the consumption of glycerol or propylene glycol is 1% of the tobacco weight percentage, the repairing liquid is evenly sprayed on the tobacco, and the repairing time is 72 hours.

Embodiment 2

[0020] Tobacco is transported through the conveyor belt to the solvent reflux elution process, the solvent is n-hexane, and the reflux time is 30 minutes; then the solvent on the tobacco is removed by hot steam, and the solvent is recovered; finally, the structure of the tobacco is repaired, and the glycerin or propylene glycol is mixed with water or ethanol Blended into repairing liquid, the consumption of glycerin or propylene glycol is 10% of tobacco weight percent, the repairing liquid is evenly sprayed on the tobacco, and the repairing time is 36 hours.

Embodiment 3

[0022] Tobacco is transported through the conveyor belt to the solvent reflux elution process, the solvent is n-hexane, and the reflux time is 60 minutes; then the solvent on the tobacco is removed by hot steam, and the solvent is recovered; finally, the tobacco structure is repaired, and glycerin or propylene glycol is mixed with water or ethanol Mix and make repairing liquid, the consumption of glycerin or propylene glycol is 15% of tobacco weight percentage, the repairing liquid is evenly sprayed on the tobacco, and the repairing time is 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com