Patents

Literature

42results about How to "Convenient flaw detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powerful paint stripper

ActiveCN101629036AConvenient flaw detectionEasy to repaintChemical paints/ink removersParaffin waxLacquer

The invention relates to a powerful paint stripper comprising the following components by weight percent: 0-5 percent of surface active agent, 72-78 percent of dichloromethane, 0-3 percent of ethylacetate, 0.78-0.8 percent of thickener, 0.6-0.7 percent of ceresin wax, 4.85-10 percent of phenol, 5-9 percent of alcohol, 0-6 percent of methanoic acid, 0-6 percent of ammonia water and 0-1 percent of sodium nitrite. The invention can effectively remove paint on the metal surface of planes and on the train wheel surface so as to perform flaw detection and repaint on the metal materials without damaging metal and wood surfaces, and has excellent depainting performance, low use amount and low depainting cost.

Owner:长沙艾森设备维护技术有限公司

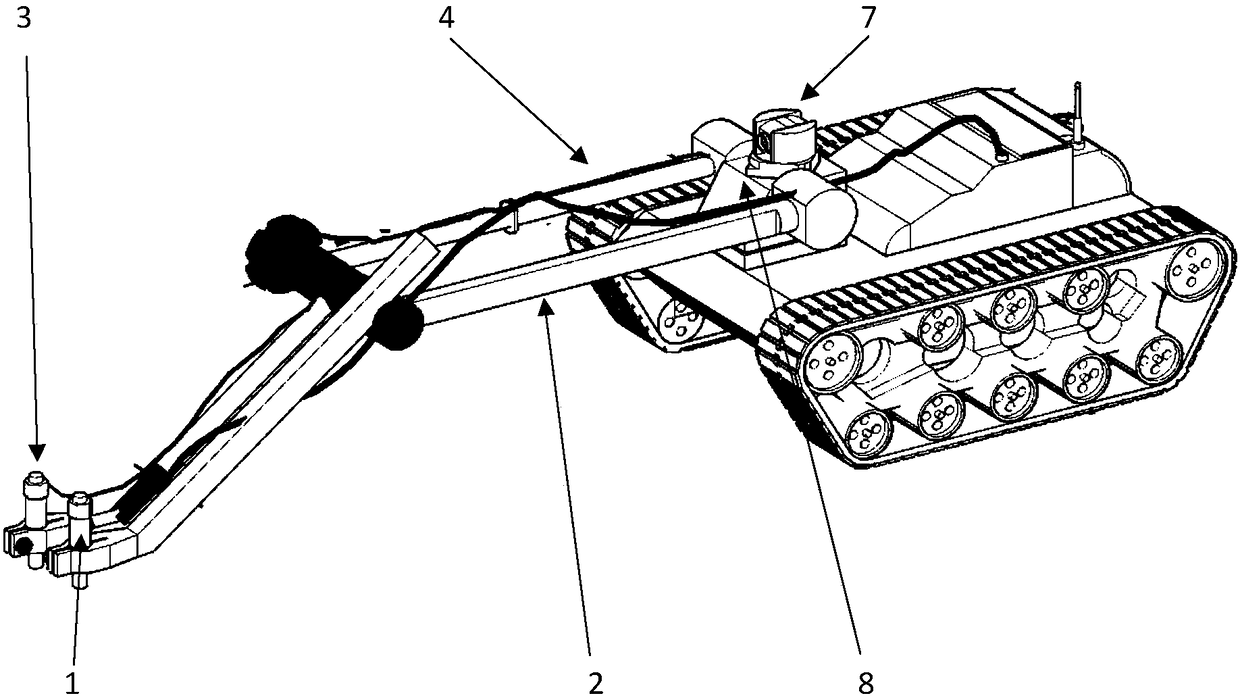

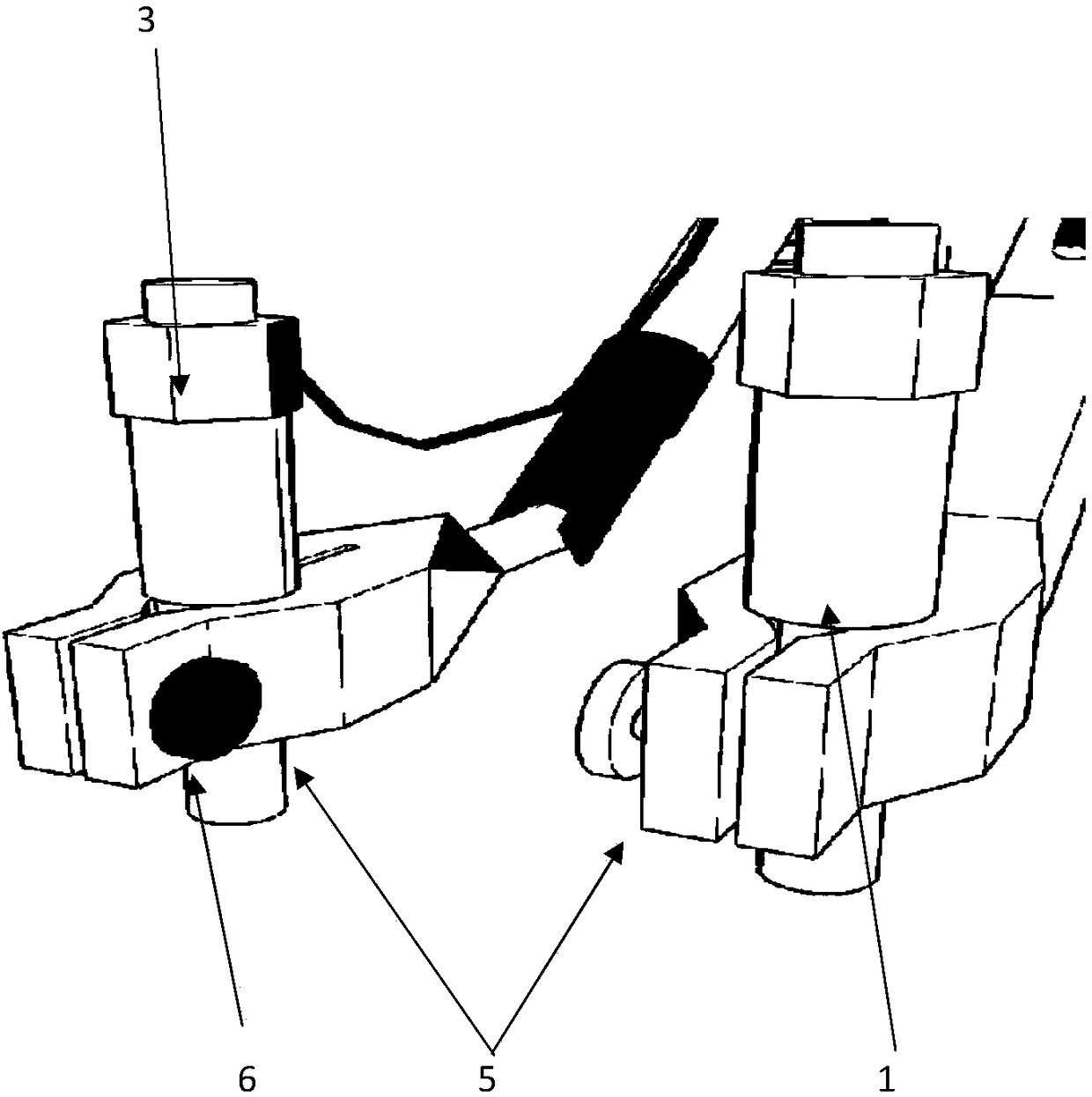

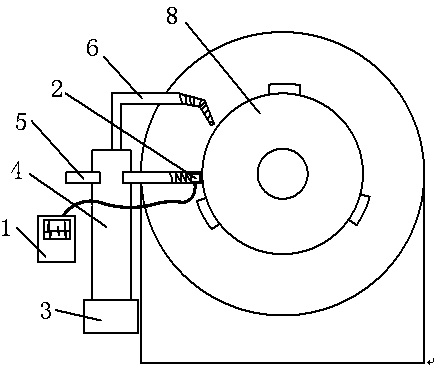

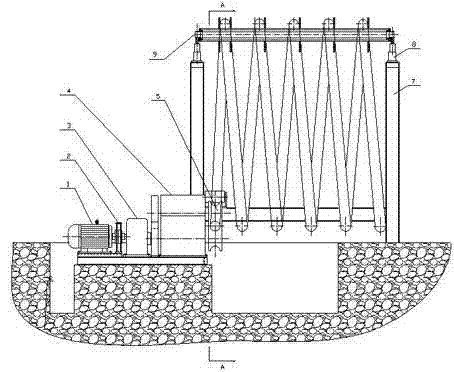

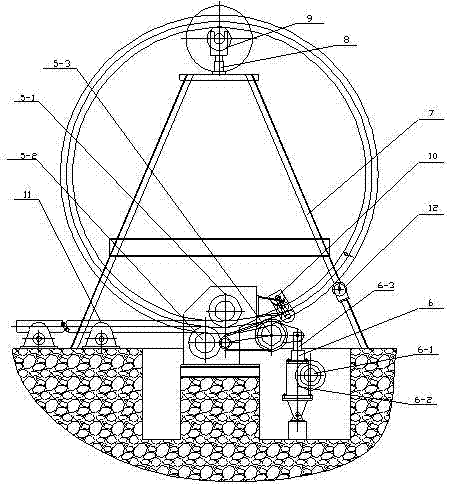

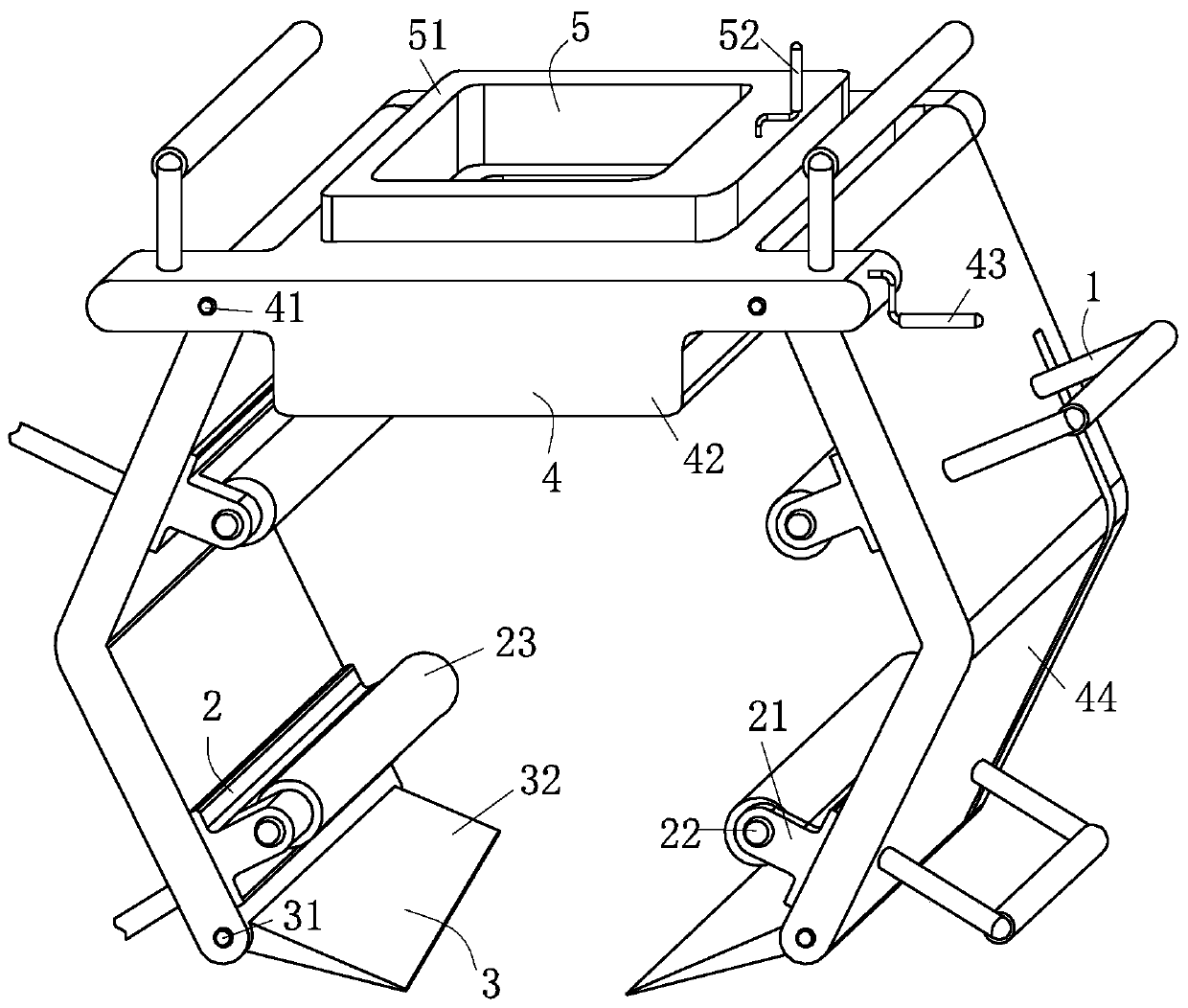

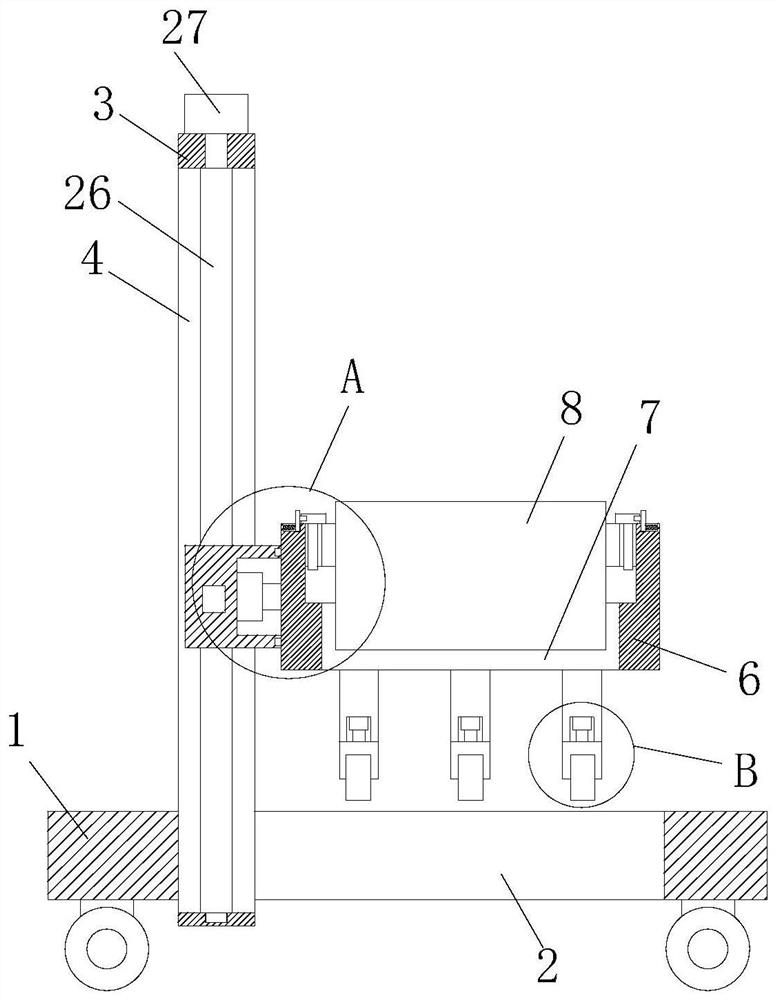

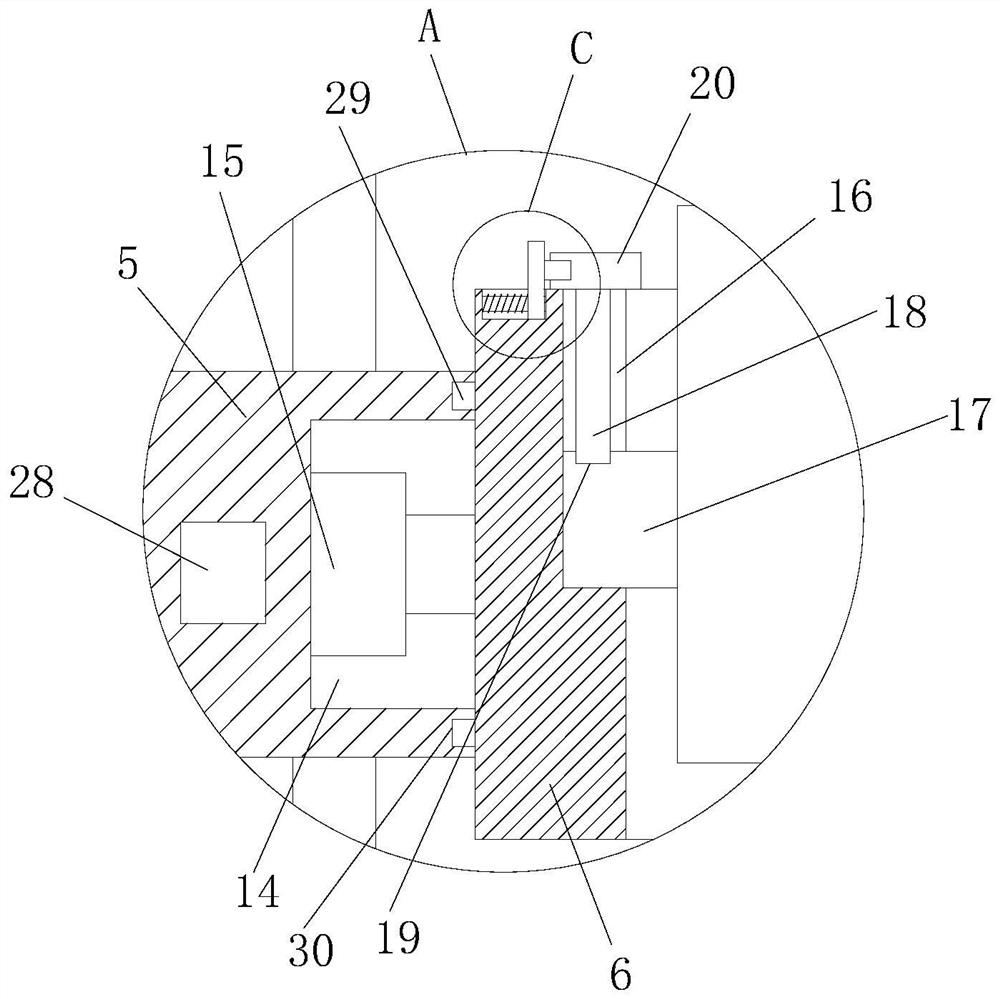

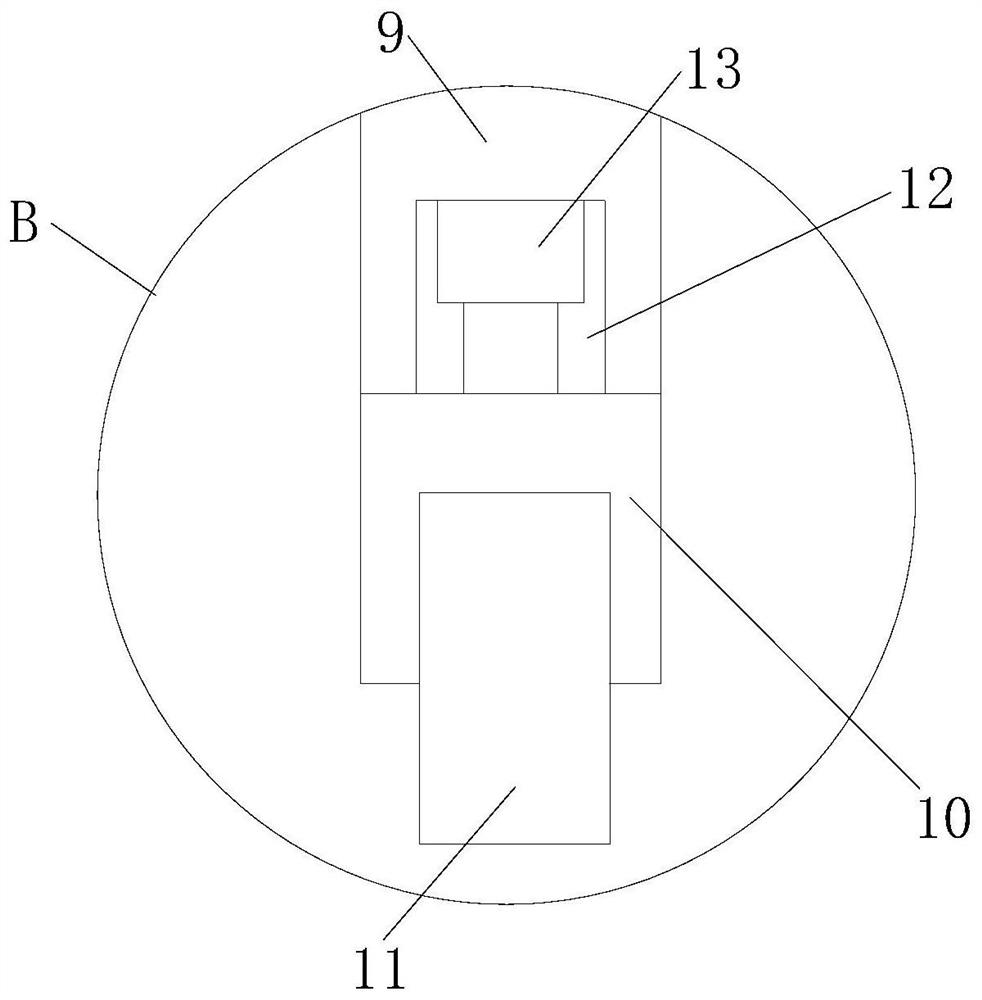

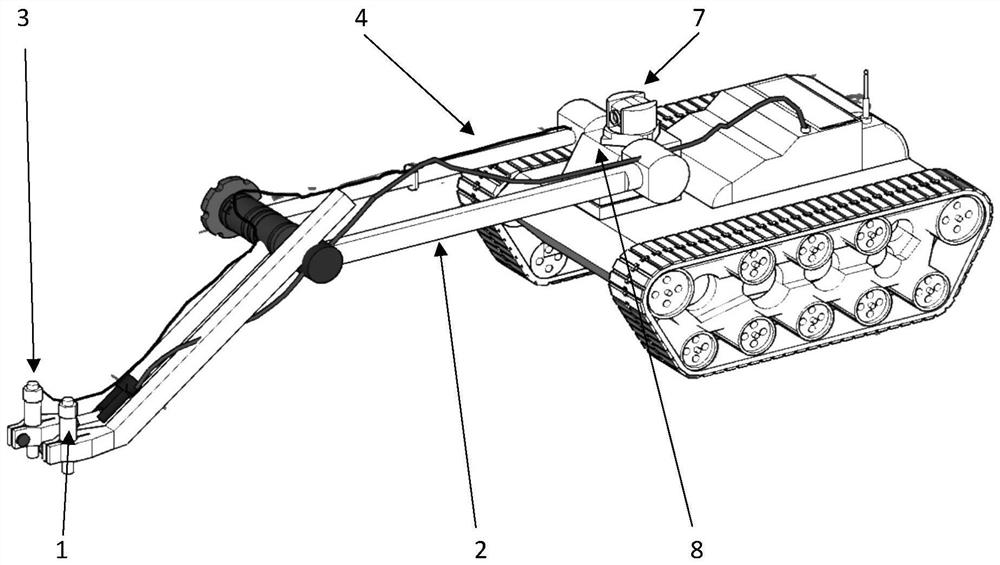

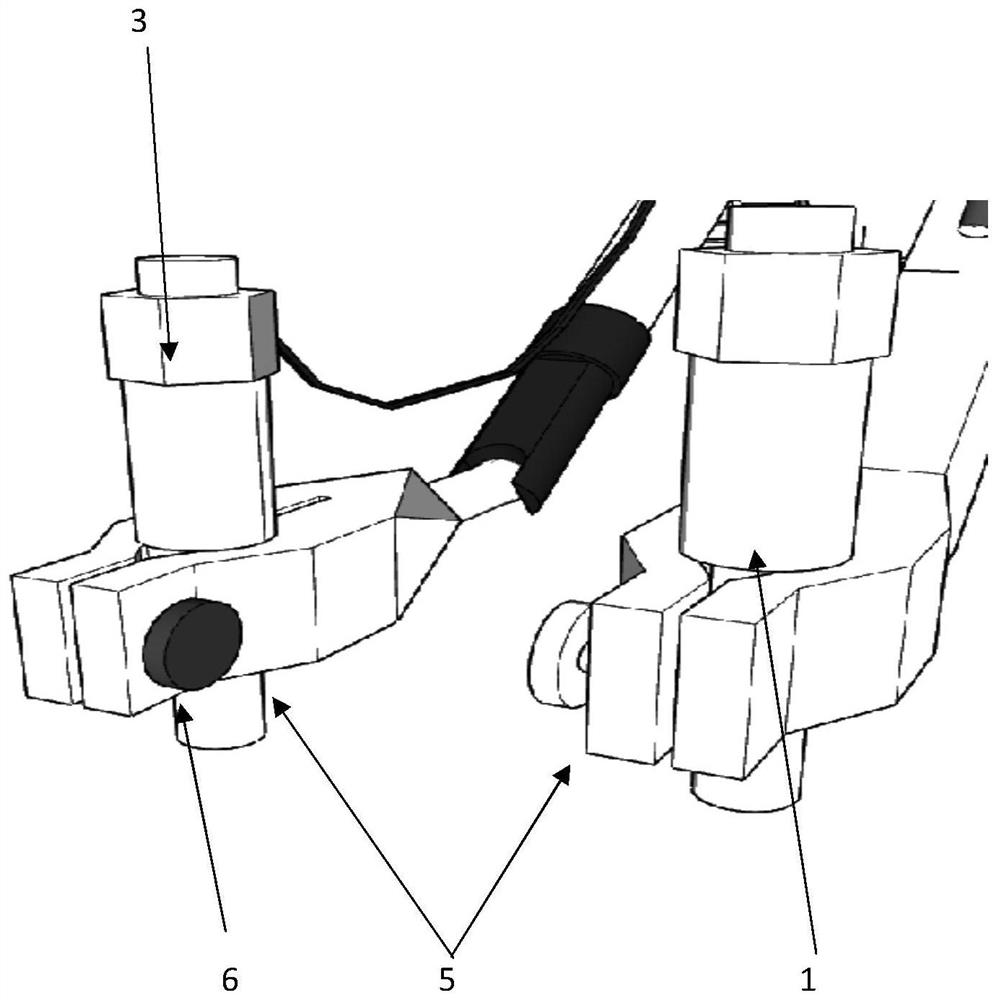

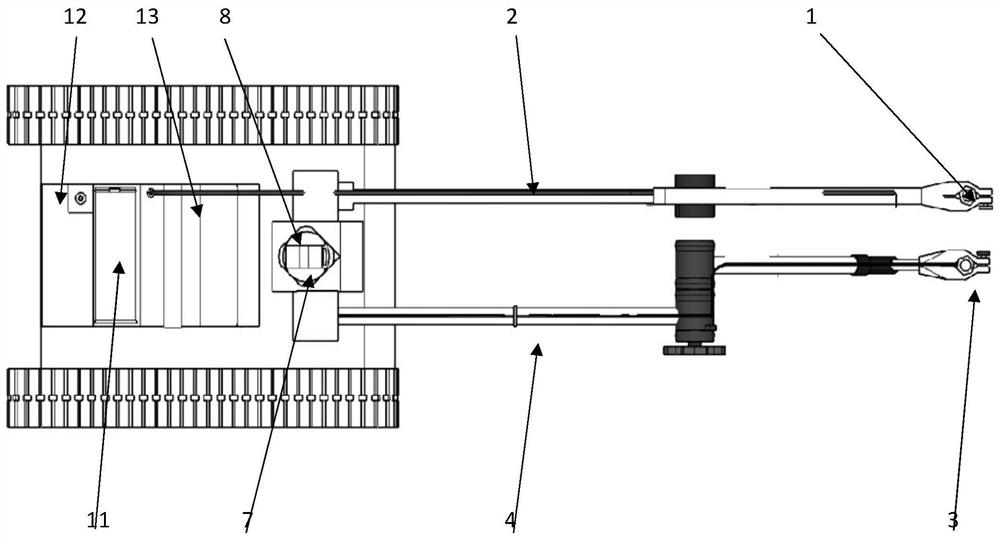

Detection robot and method for detecting pouring quality of concrete filled steel tube by using detection robot

ActiveCN108254440ARealize instant transmissionRealize high-precision flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesTransmission systemsControl theorySteel tube

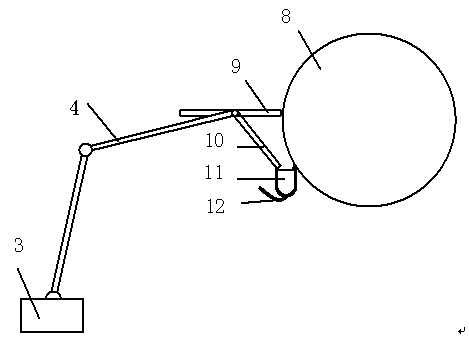

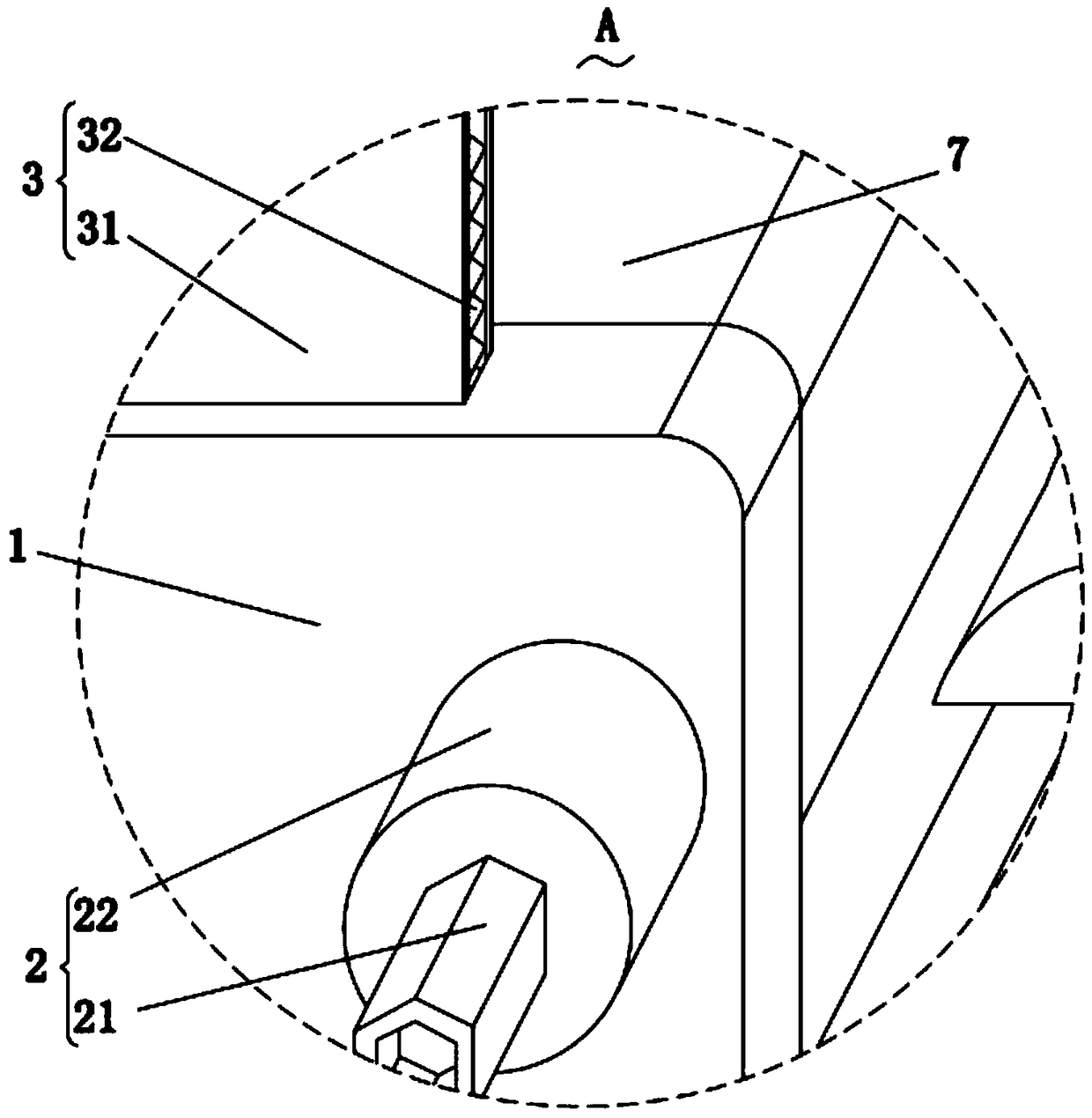

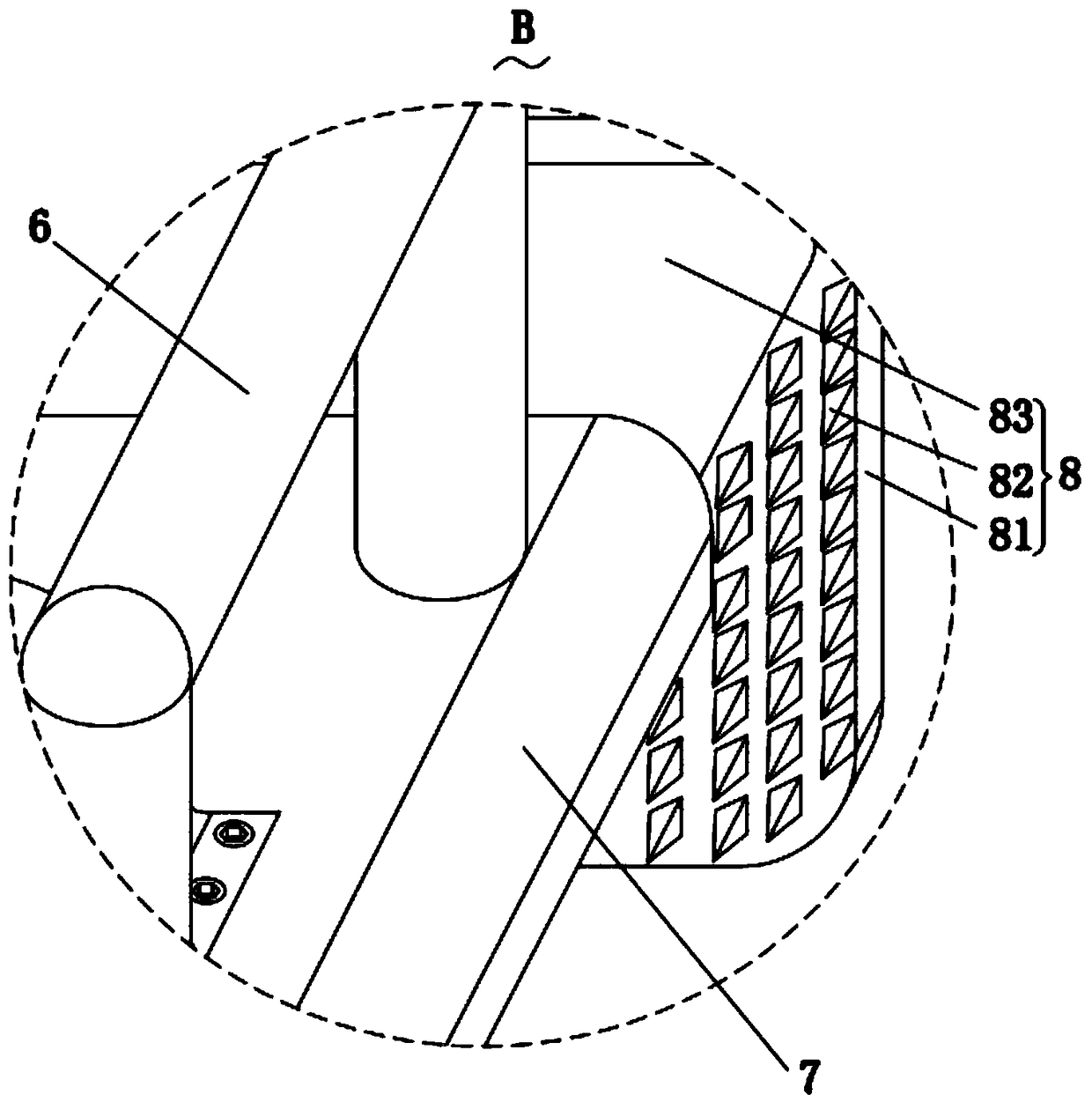

The invention provides a detection robot and a method for detecting the pouring quality of a concrete filled steel tube by using the detection robot. The detection robot comprises a mechanical electromagnetic mixing knocking hammer (1), a microphone (3) and a camera (7), wherein both the mechanical electromagnetic mixing knocking hammer (1) and the microphone (3) are respectively fixed on certainends of a knocking hammer mechanical arm (2) and a microphone mechanical arm (4) on the robot by virtue of an adjustable clamp (5), the other ends of the knocking hammer mechanical arm (2) and the microphone mechanical arm (4) are fixed on a control rotating stack (8) on the robot, the control rotating stack (8) is provided with a foundation support (9), the foundation support (9) is provided witha steering device (10), and the steering device (10) is provided with the camera (7).

Owner:HUNAN UNIV

Method for determining flaw detection benchmark sensitivity of steel plate by single crystal probe

InactiveCN103293226AConvenient flaw detectionAvoid frequent measurementsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringSingle crystal

The invention provides the technical scheme of a method for determining flaw detection benchmark sensitivity of a steel plate by a single crystal probe. According to the technical scheme, the method comprises the following steps of: selecting a flat-bottomed test block with specified burial depth according to the thickness of a steel plate to be measured, detecting the largest wave height Delta 1dB of a flat bottom hole and the Delta 2dB value of the large flat bottom position of the test block by the single crystal probe, and determining the correction value delta; adjusting the bottom wave height on the intact steel plate part to be 50 percent of full scales of a flaw detector display screen in the process of performing flaw detection on the steel plate, gaining by delta dB, and determining the benchmark sensitivity of the steel plate, thus performing flaw detection on the steel plate on the basis of the benchmark sensitivity. A standard specified measuring defect is discovered in the detection process, the defect boundary is determined in a standard specified mode, the size or area of the defect is measured, and whether the steel plate is qualified or not is judged according to the length, the area and the area percent of the defect.

Owner:JIGANG GRP

Efficient paint remover and preparation process thereof

ActiveCN102344712AConvenient flaw detectionEasy to repaintChemical paints/ink removersHexamethylenetetramineMetallic materials

The invention discloses a novel powerful paint remover capable of removing paint on surfaces of oilfield oil pipelines and paint on surfaces of other equipment efficiently. The preparation process comprises the steps of: taking dichloromethane, benzyl alcohol, ethyl acetate, ethylene glycol monobutyl ether, paraffin, ethanol, lactic acid, formic acid, urotropine, JFC and OP-10 according to weight parts; stirring the JFC, the OP-10, the benzyl alcohol, the ethyl acetate, the ethylene glycol monobutyl ether, the paraffin, the ethanol, the lactic acid, the formic acid and the urotropine in a reaction kettle at a temperature of 45-50 DEG C for 1.5-2 hours until the paraffin is completely dissolved; adding the dichloromethane and stirring for 20-30 min; and stirring uniformly in the reaction kettle to obtain the paint remover. The invention provides a paint remover which can efficiently remove old and shabby paint films on surfaces of various mechanical equipment and paint on surfaces of mechanical equipment, such as paint on metal surfaces of airplanes, paint on surfaces of train wheels and the like, brings convenience for fault detection and recoating on metal materials, has no damage to metal and wood surfaces, and has excellent paint removal performance.

Owner:扬州润达油田化学剂有限公司

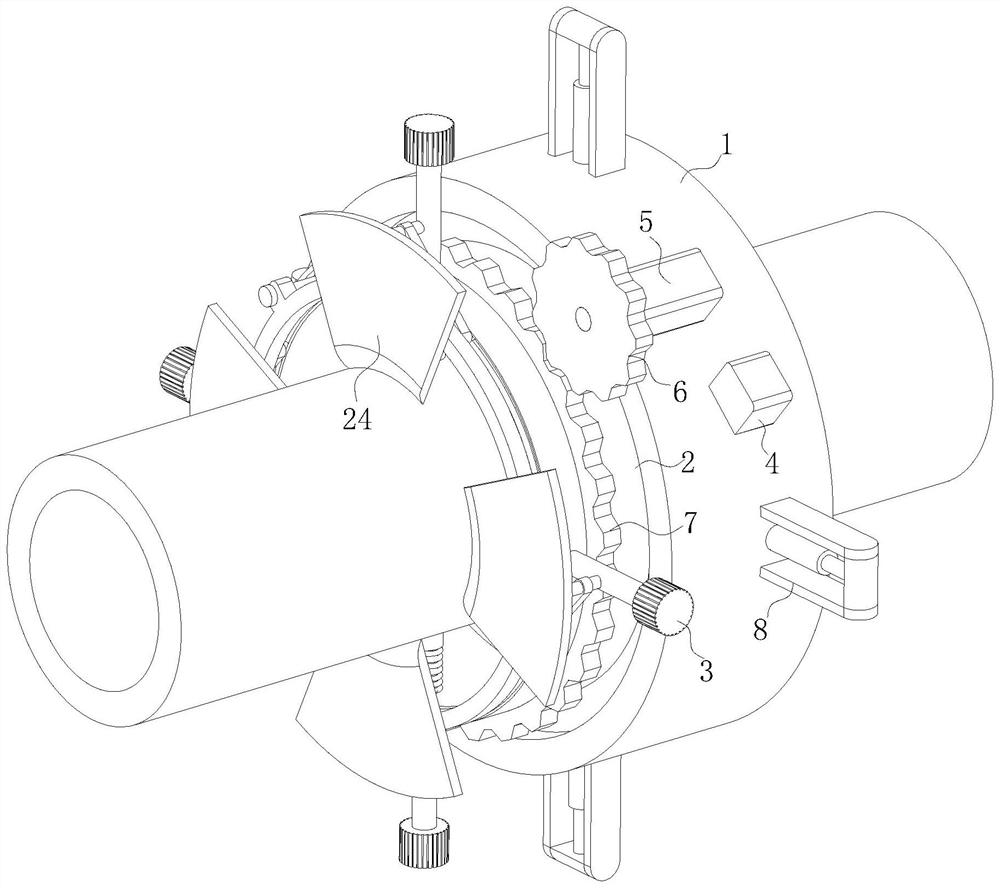

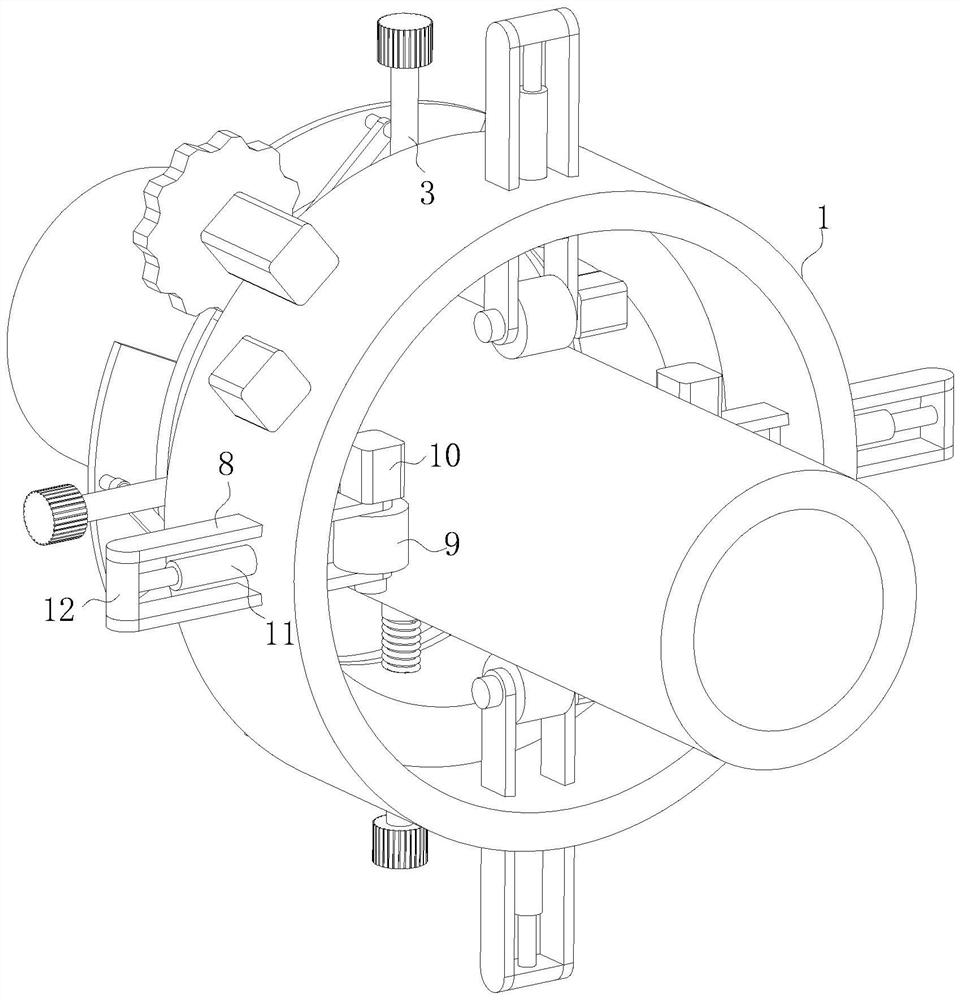

Online nondestructive flaw detector for pressure pipeline detection

PendingCN114166940AAccurate detectionAutomatically realize segmented intermittent flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesStructural engineeringElectrical and Electronics engineering

The invention discloses an online nondestructive flaw detector for pressure pipeline detection in the technical field of pipeline flaw detection, and the online nondestructive flaw detector comprises a fixing ring, the interior of the fixing ring is connected with a driving mechanism for driving the fixing ring to move along a pipeline, and the driving mechanism can move along pipelines with different diameters; when the pipeline is subjected to flaw detection every time, the driving mechanism and the adjusting mechanism are used for detecting the diameter of the self-adaptive pipeline, the driving mechanism can meet the driving effect on pipelines with different diameters, and the adjusting mechanism can adjust the distance between the flaw detector and the outer surface of the pipeline; the flaw detector can accurately detect cracks in the pipeline, the rotating mechanism is used for driving the flaw detector to conduct circumferential rotation flaw detection, full-coverage flaw detection is conducted on the outer surface of the pipeline, detection is more accurate, the controller is used for controlling the driving mechanism and the rotating mechanism in a staggered mode, and segmented intermittent flaw detection is automatically achieved.

Owner:淄博市特种设备检验研究院

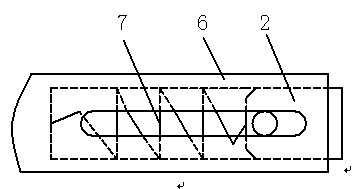

Ultrasonic flaw detection apparatus

InactiveCN104020219AMeet the needs of flaw detectionSimple structureAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringPortable ultrasound

The invention relates to the technical field of ultrasonic flaw detection equipment. An ultrasonic flaw detection apparatus comprises a portable ultrasonic detector and a detection probe, and also comprises a magnetic gauge stand and a movable support installed on the upper end face of the magnetic gauge stand; a free end of the movable support is provided with a clamping device; one end of the detection probe is installed in a chute at the end of the clamping device and is connected with an adjusting spring; and the periphery of a working end of the detection probe is provided with a plurality of spray pipes which are fixedly connected with the movable support and communicated with an automatic water tank. The ultrasonic flaw detection apparatus is simple in structure, convenient to adjust and rapid in mounting and dismounting, and is capable of satisfying requirements of most of working conditions, especially flaw detection requirements of relatively large specification aluminium rods.

Owner:广西南南铝加工有限公司

Ultrasonic flaw detection device and flaw detection method thereof

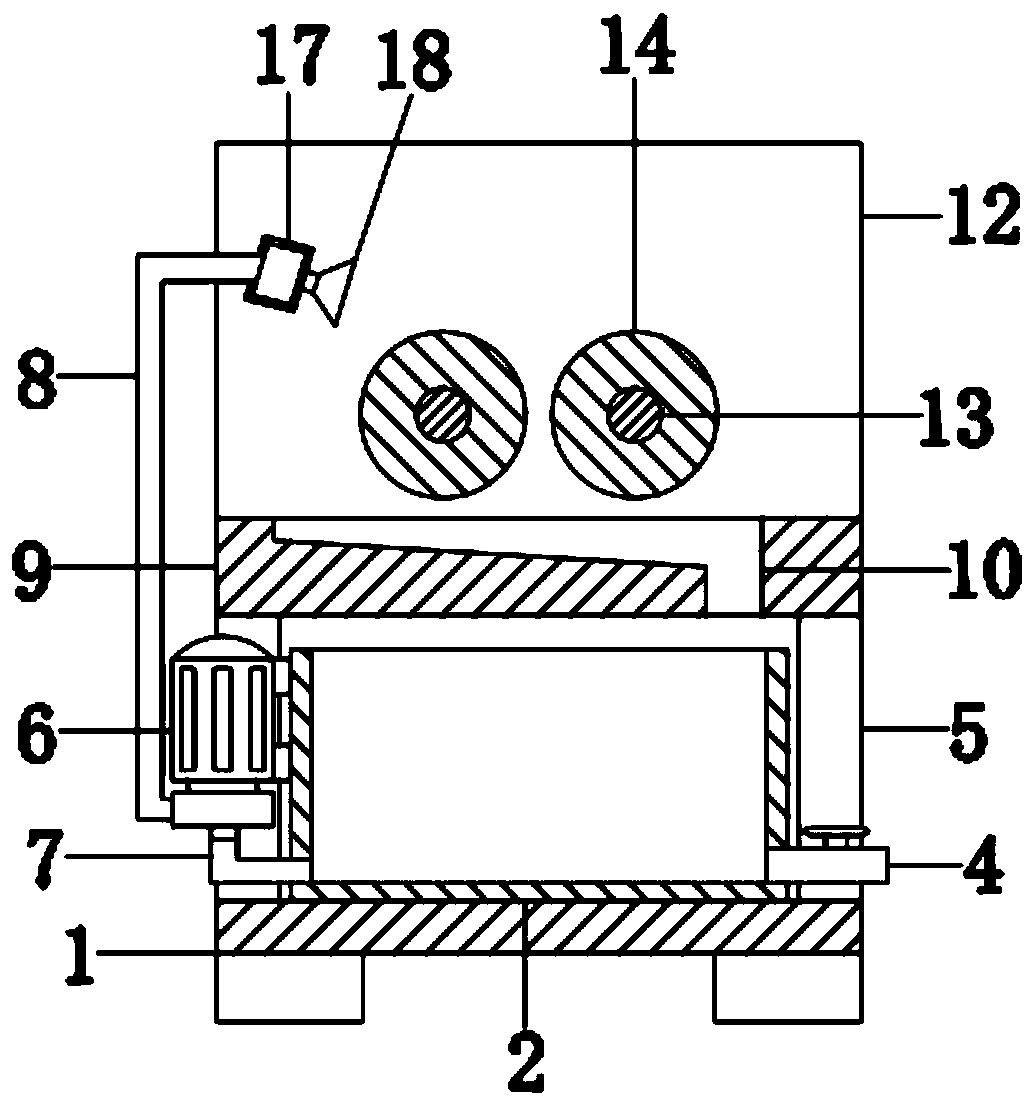

InactiveCN110133109ASmooth rotationConvenient flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringSteel tube

The invention discloses an ultrasonic flaw detection device. The ultrasonic flaw detection device comprises a base, wherein a top end of the base is connected with a box body through screws; a right end of a front side of the box body is connected with a controller; a valve is connected to the center of a bottom end of a front side of the box body in a threaded manner; support legs are welded at the four corners of the top end of the base; a rotary mechanism is welded at the top ends of the support legs; a water pump is connected to the center of the back side of the box body through screws; the water pump is electrically connected with the controller; the water inlet of the water pump is in threaded connection with one end of a water inlet pipe; the other end of the water inlet pipe is inthreaded connection with the center of the bottom end of the back side of the box body; a water outlet of the water pump is in threaded connection with one end of a water outlet pipe; and the other end of the water outlet pipe is connected with the rotary mechanism. During use of the ultrasonic flaw detection device, steel tubes of different thicknesses can be detected, and the steel tubes can rotate uniformly to prevent missing of detection. The ultrasonic flaw detection device has the advantages of high automation degree, high detection efficiency and convenience in popularization.

Owner:XIAN TECHNOLOGICAL UNIV

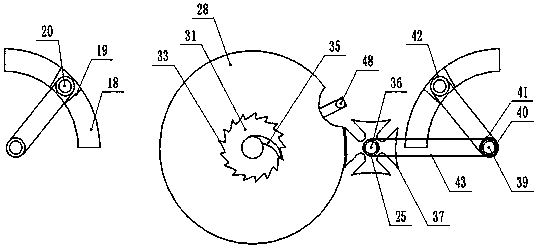

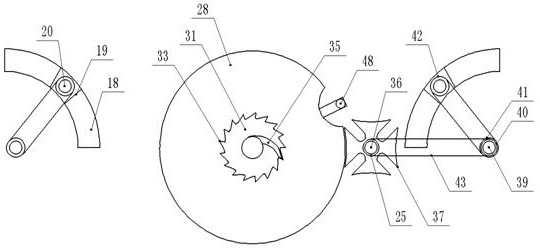

Once hot-forging shaping process for manufacturing joint hinge

ActiveCN101574721AHigh precisionConvenient flaw detectionMetal-working apparatusHingesIntermediate frequencyEngineering

The invention relates to the technical field of joint hinge manufacturing, in particular to a once hot-forging shaping process for manufacturing a joint hinge. The once hot-forging shaping process is characterized by adopting the following steps of: (1) adopting an intermediate frequency heating furnace to heat blanked material to 1050 to 1150 DEG C; (2) adopting a pneumatic hammer to directly and lightly upset the material heated by the intermediate frequency heating furnace to remove roll scale on the surface of the material; (3) adopting a friction press blocker to mould unfolding sheet of the joint hinge; (4) utilizing a friction press finisher provided with a V-shaped lower die to mould the unfolding sheet into the joint hinge; (5) adopting a hydraulic shape-adjuster to adjust the shape of the joint hinge; and (6) adopting a metal steel-shot to carry out shot blasting so as to lead the surface of forgeable piece to become silvery white. Compared with the prior art, the invention adopting the once hot-forging shaping process has high efficiency. The roll scale is so thin that the roll scale can be removed before forging so as to obtain excellent surface quality; and after the forgeable piece is shaped, the metal steel-shot is adopted to lead the surface of the forgeable piece to become silvery white through shot blasting so as to bring convenience for metal surface fault detection and to avoid painting treatment; and compared with the cost of flat die forging, the cost of the once hot-forging shaping process can be reduced at least by three times.

Owner:SHANGHAI CHANGQIANG POWER

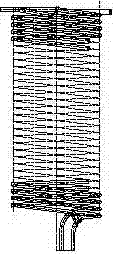

Start-up heating furnace coil pipe production method of synthetic ammonia device

InactiveCN103240313AImprove ergonomicsManufacturing Quality Assurance and EnhancementStraight tubeProcess engineering

The invention relates to a start-up heating furnace coil pipe production method of a synthetic ammonia device. The start-up heating furnace coil pipe production method includes welding and installing materials straight pipes one by one, and then processing the welded and installed straight pipes into coil pipes by a spiral coiler. Compared with the existing method of producing single coil pipe and then welding and installing, the start-up heating furnace coil pipe production method of the synthetic ammonia device greatly improves processing quality and working efficiency, and reduces production cost.

Owner:SHIFANG TONGJIA MACHINERY

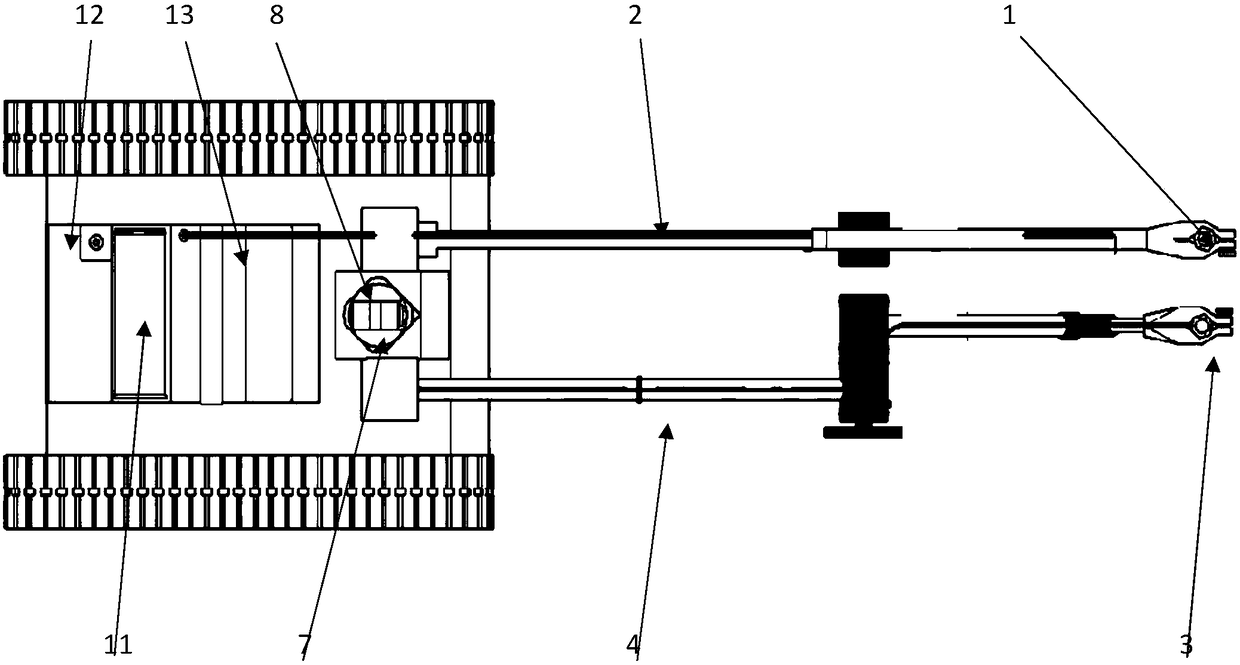

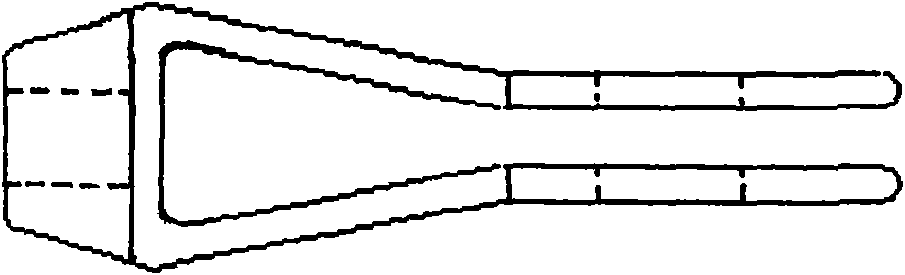

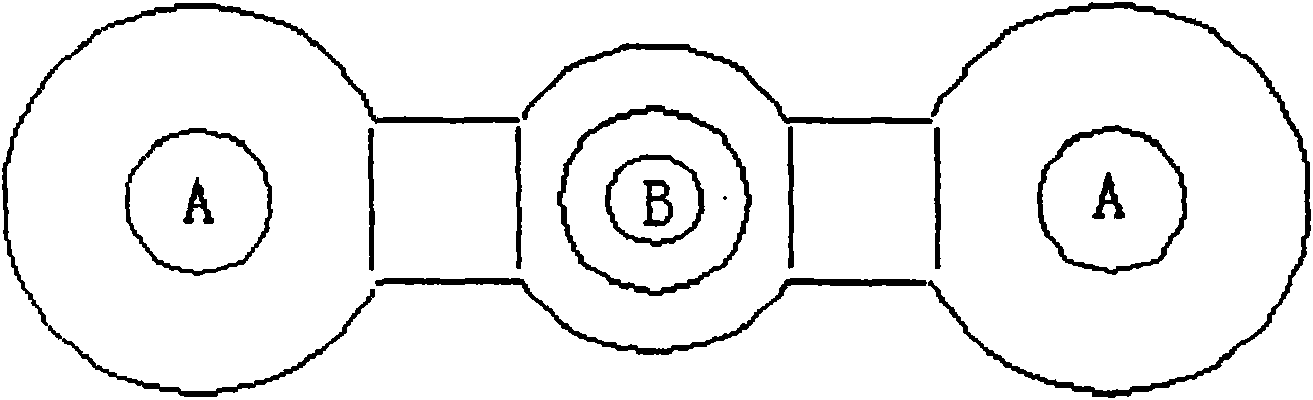

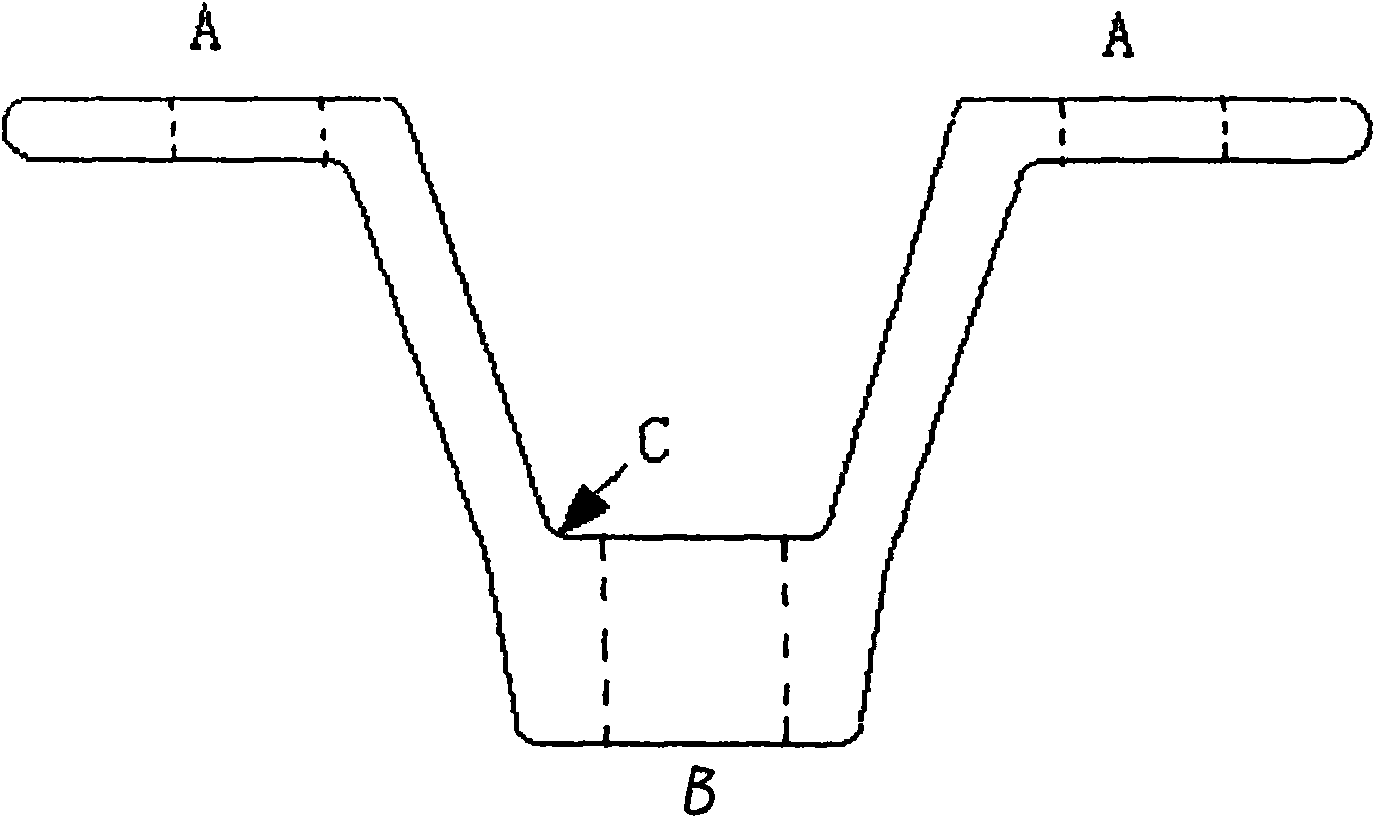

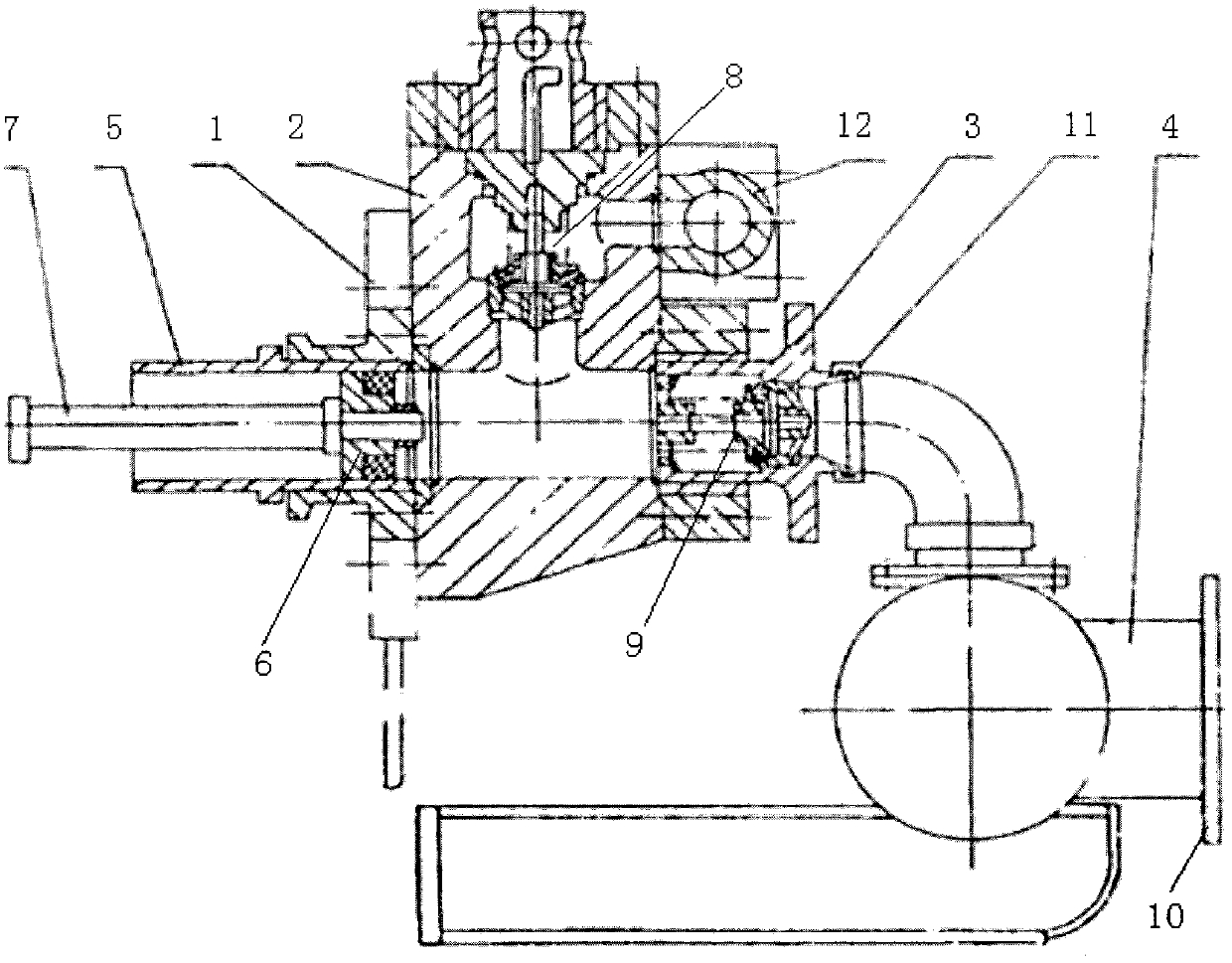

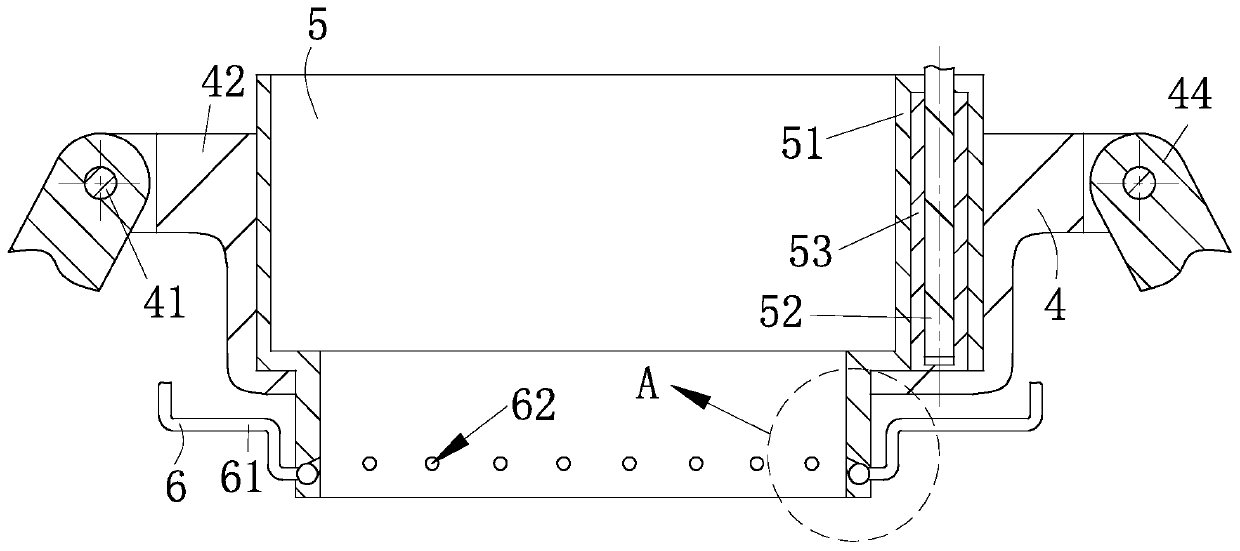

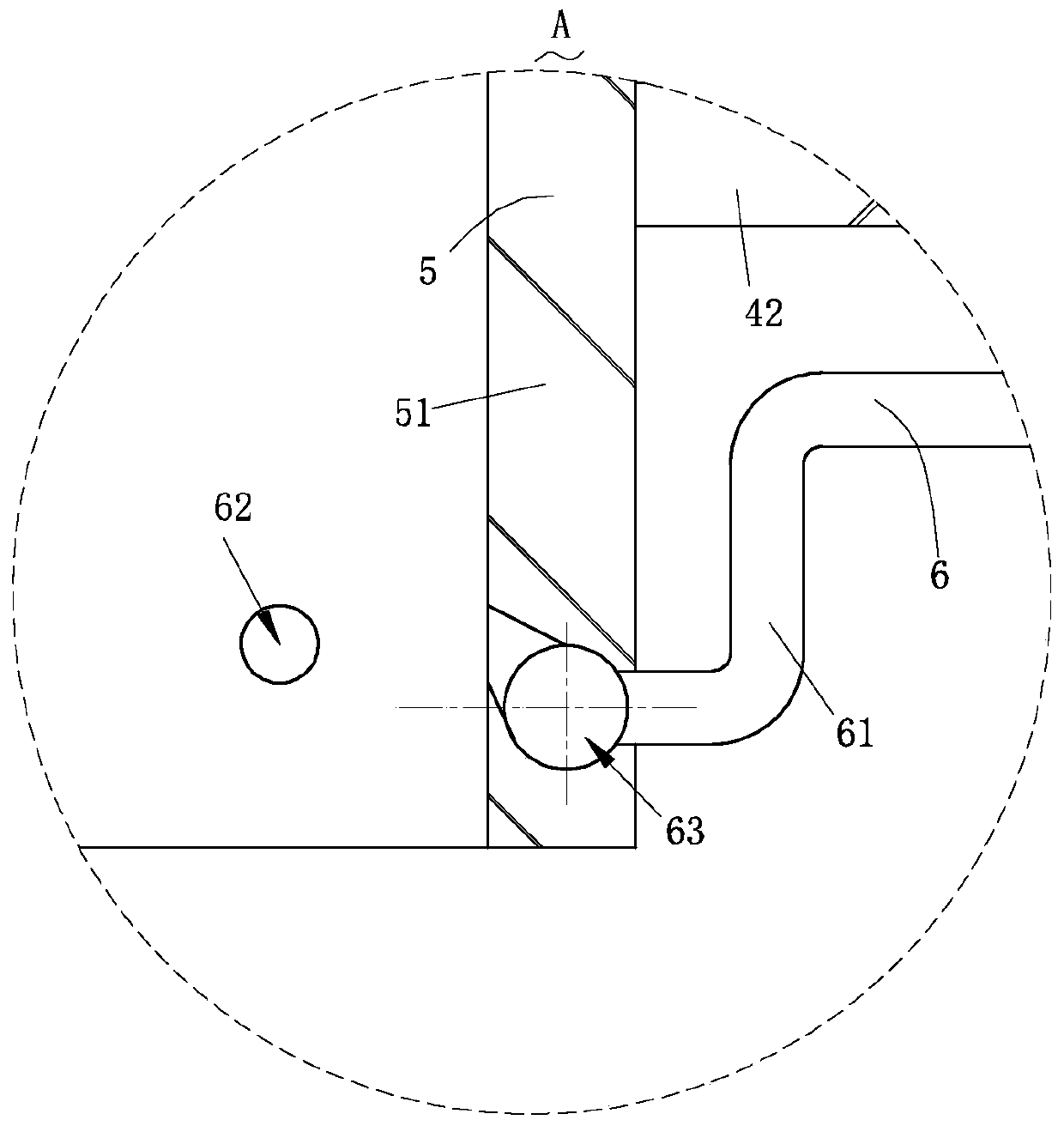

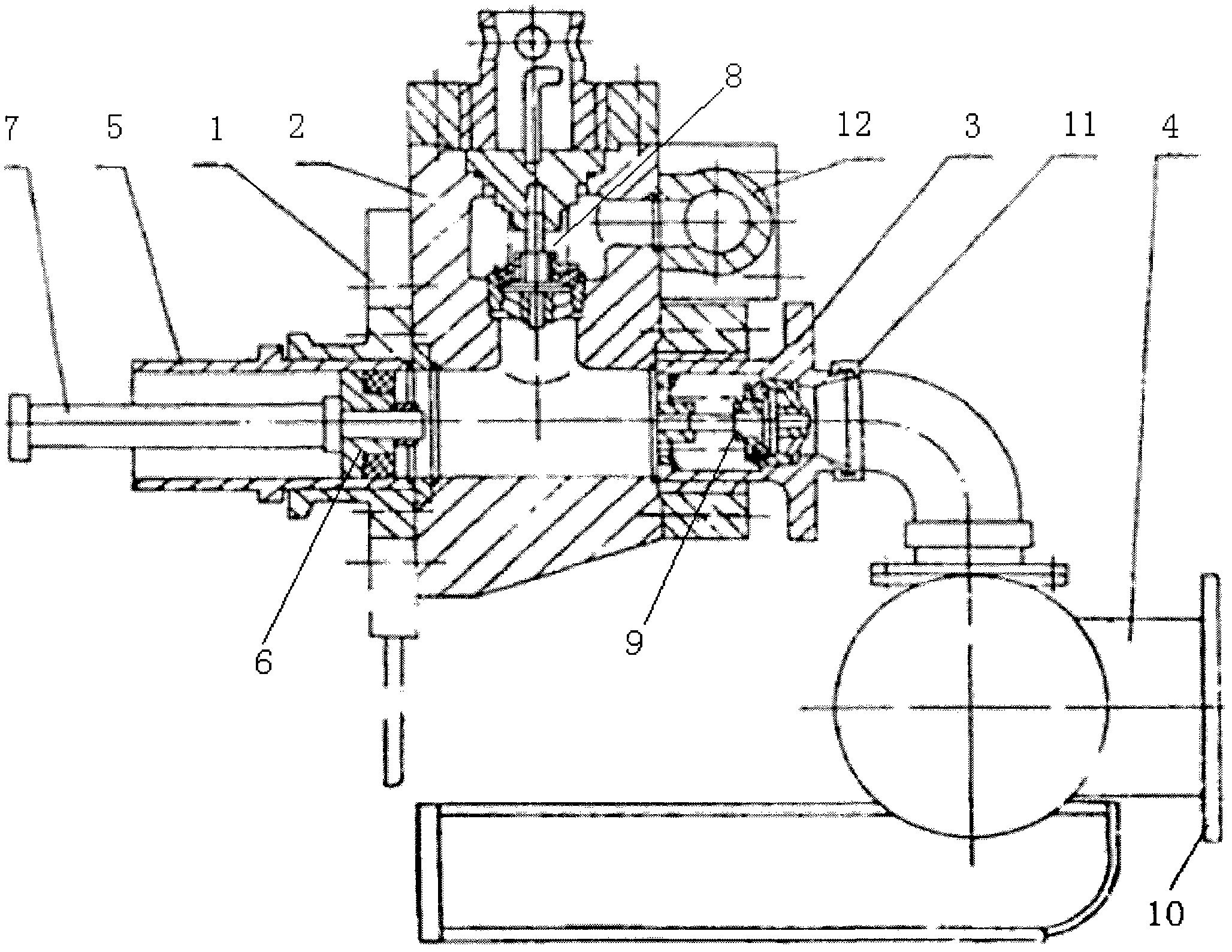

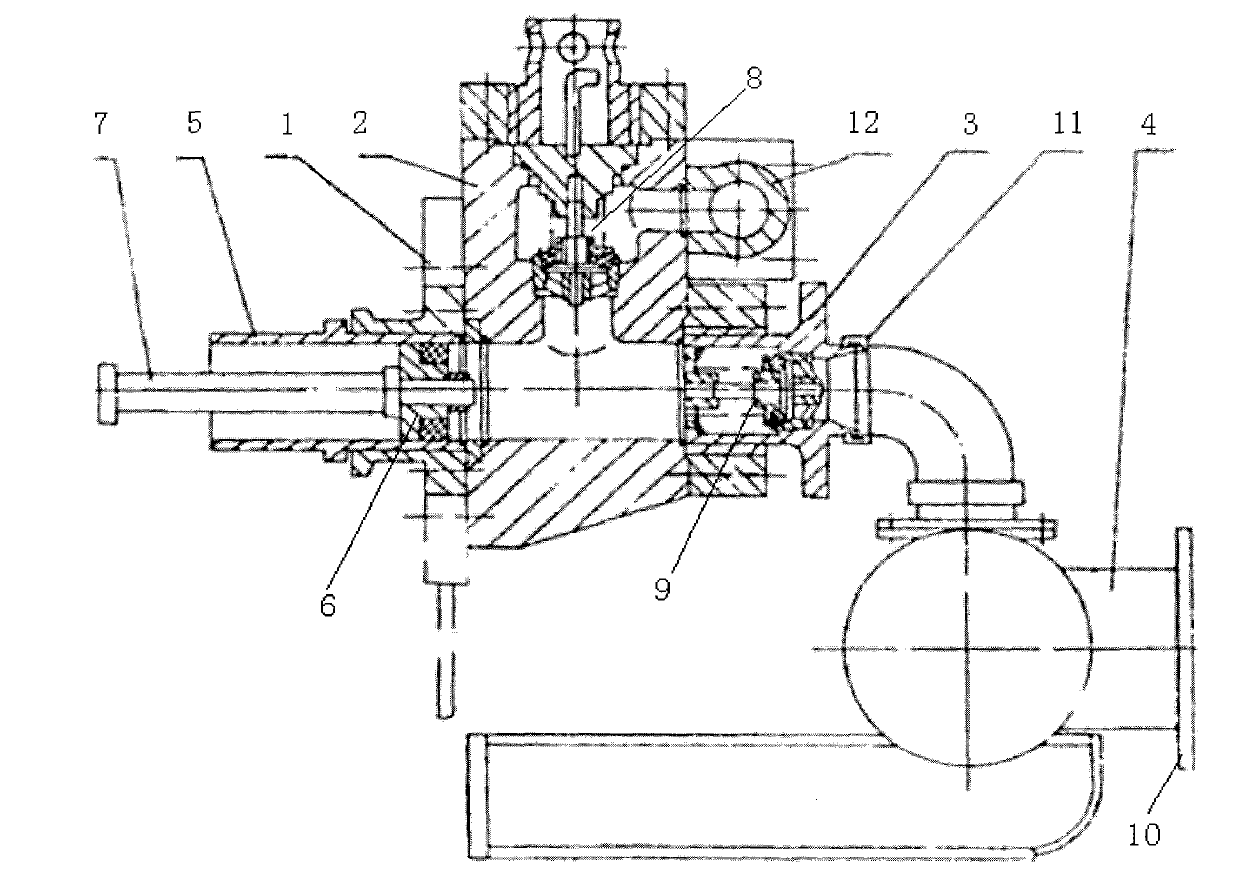

Drilling pump with T-type pump head and supercharging method thereof

InactiveCN103104473ACompact structureReduce size and massPositive displacement pump componentsLiquid fuel engine componentsPistonEngineering

The invention discloses a drilling pump with a T-type pump head. The drilling pump with the T-type pump head is mainly formed by a shell body, a discharge liquor cylinder arranged on the shell body, a discharging pipe connected and communicated with the discharge liquor cylinder, a suction liquor cylinder connected and communicated with the discharge liquor cylinder, and a suction pipe connected and communicated with the liquid suction cylinder. A piston device communicated with the discharge liquor cylinder is arranged inside the shell body. The invention further discloses a supercharging method based on the drilling pump. The drilling pump with the T-type pump head is in a compact structure and a suction chamber is canceled, the volume and the quality of the drilling pump with the T-type pump head are both reduced by 25% - 30%. The drilling pump with the T-type pump head is easy to process and manufacture, convenience is brought to flaw detect and inspection, and can ensure the quality of pump head products. Slurry is sucked horizontally, the clearance volume in the pump head cylinder is small, the suction efficiency and the volumetric efficiency of the drilling pump are improved; liquid flow is smooth, pressure fluctuation and pressure vibration are reduced, and drilling pump impact loads are also reduced. The change of a suction valve is very convenient and time-saving, and the workload of dismounting and changing is little.

Owner:谢月

Automatic flaw detection device for cracks of bridge concrete barrier

Owner:山东水发市政建设有限公司

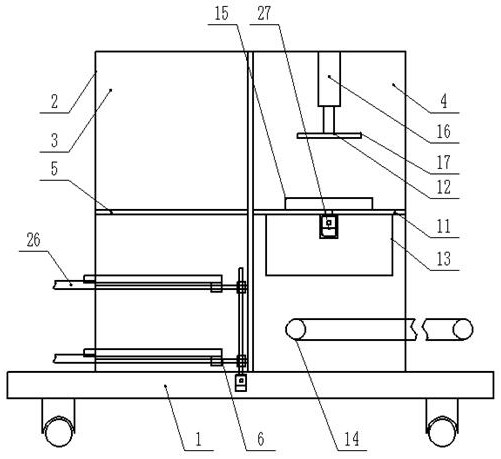

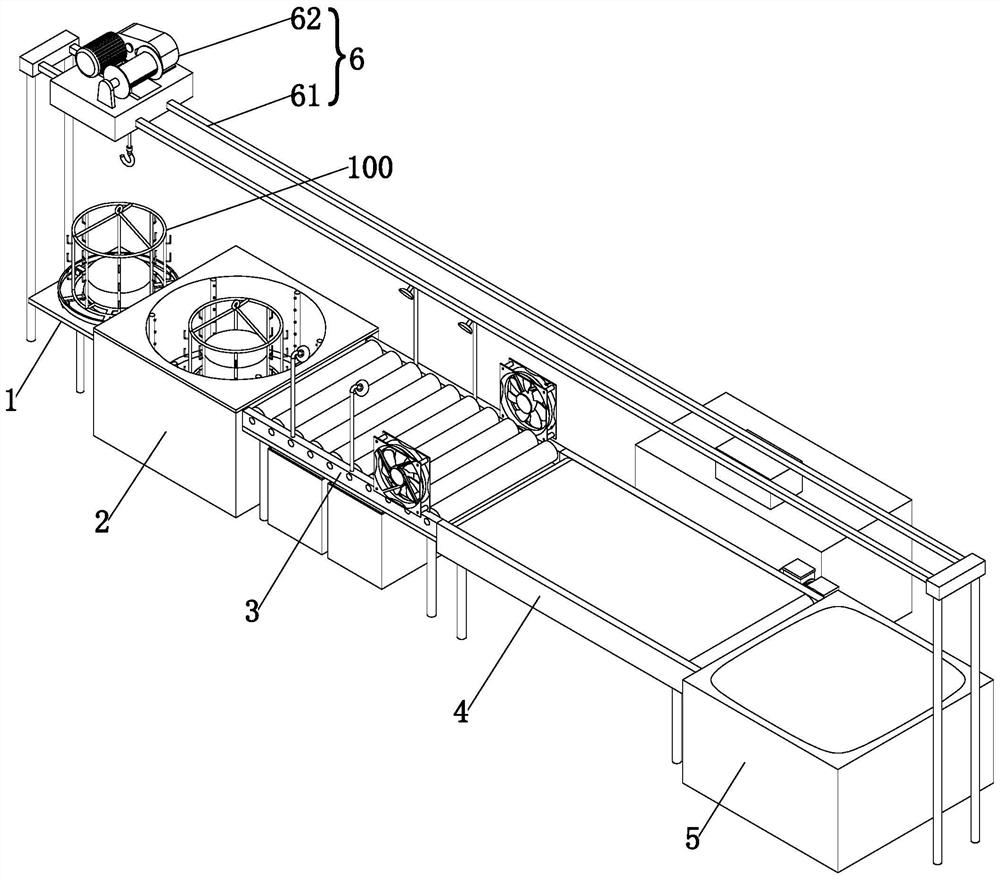

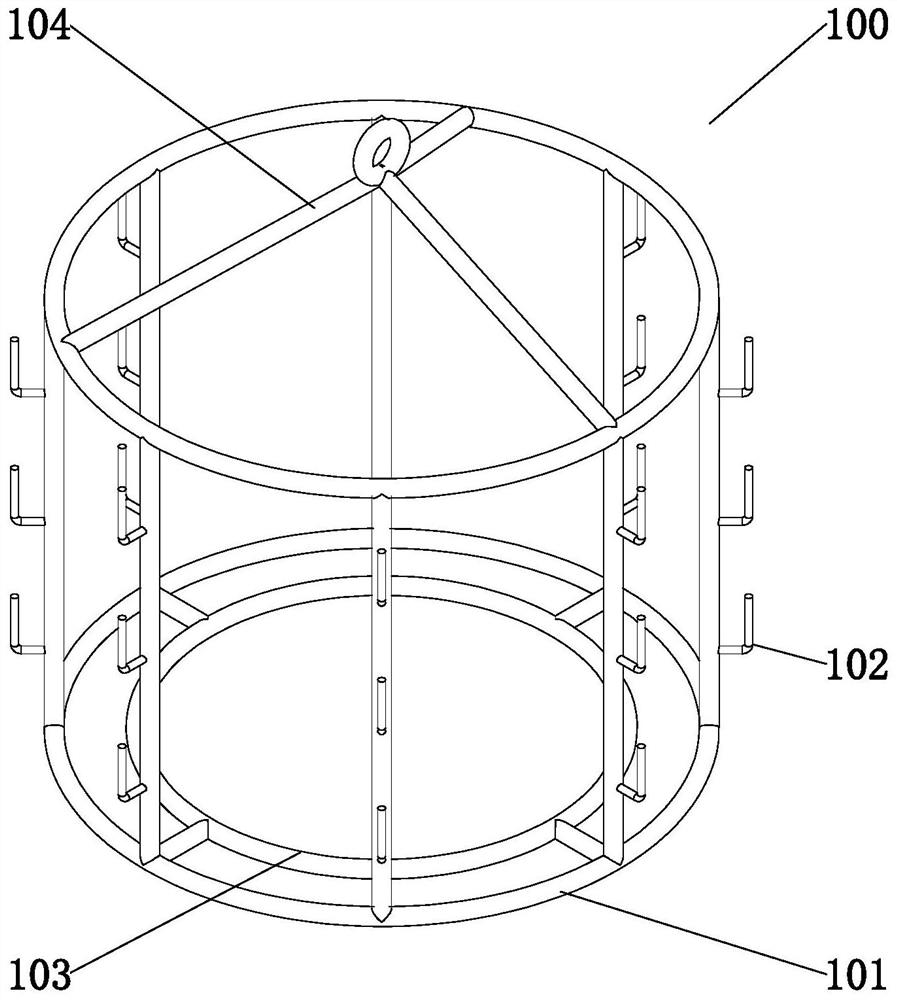

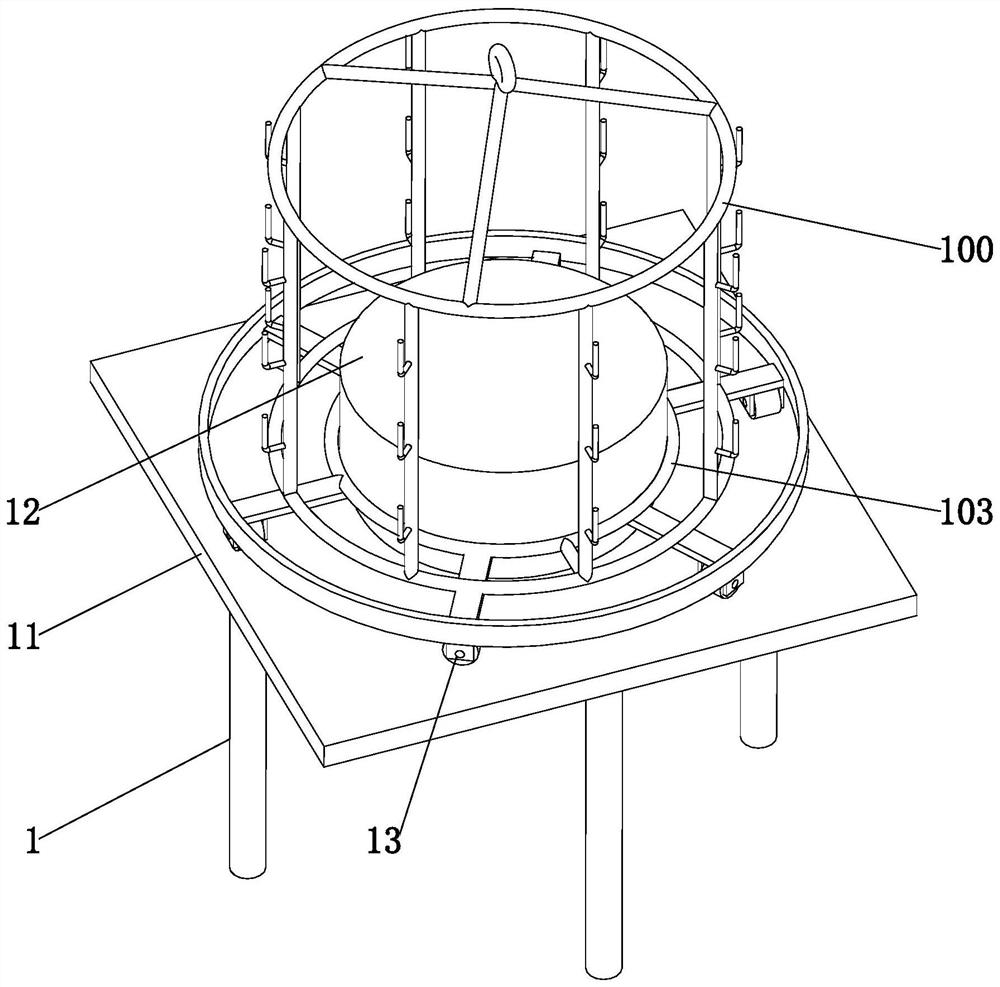

Pump part machining and flaw detection equipment

ActiveCN109632956AReduce occupancyComprehensive cleaningAnalysing solids using sonic/ultrasonic/infrasonic wavesOther manufacturing equipments/toolsEngineeringWater spray

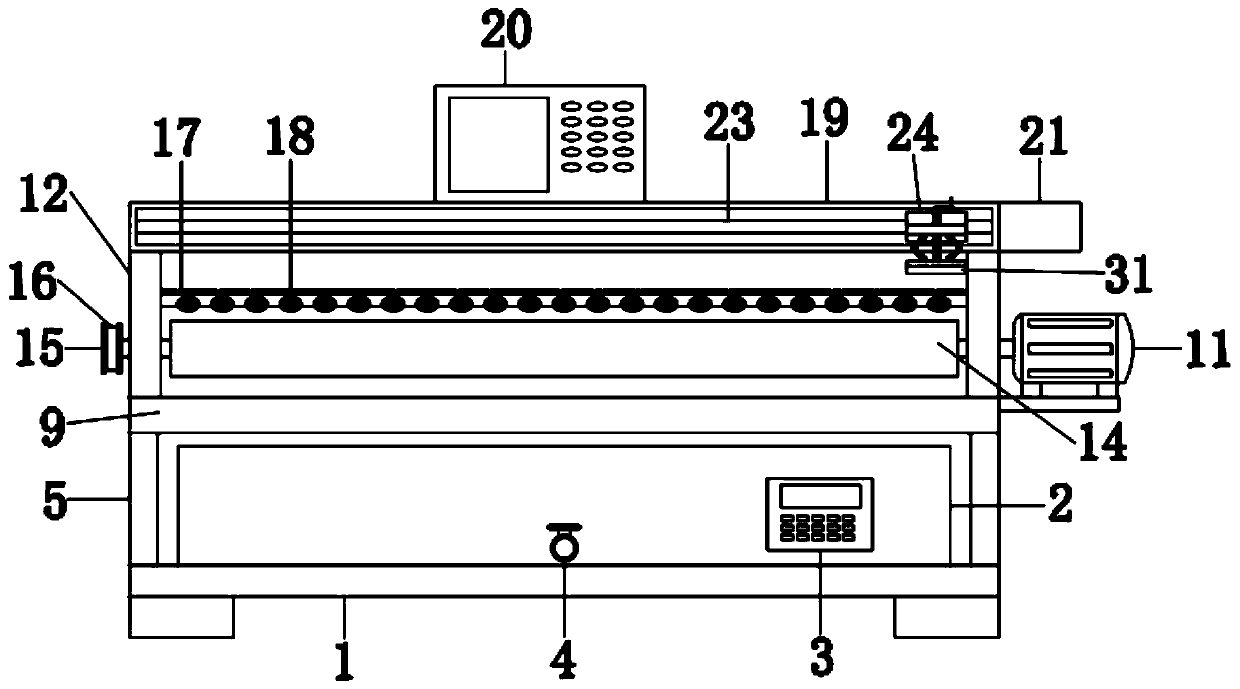

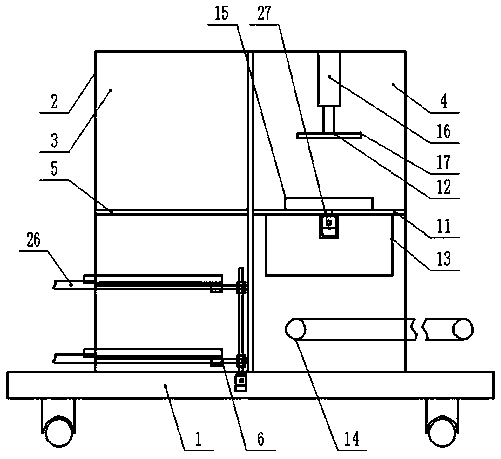

The invention discloses pump part machining and flaw detection equipment. The pump part machining and flaw detection equipment comprises a machine base, universal wheels and a machining and a flaw detection box body, wherein the inner cavity of the machining and flaw detection box body is divided into a left side machining chamber and a right side cleaning and flaw detection chamber through a partition plate, a first supporting plate is arranged in the middle of the left side machining chamber cavity, a pump part intelligent machining device is arranged at the upper end of the first supportingplate, a feeding mechanism is arranged at the lower end of the left side machining chamber cavity, the feeding mechanism is composed of first screw rods, feeding plates, a worm and worm wheels, the right side cleaning and flaw detection chamber is provided with a second supporting plate, a cleaning and flaw detection assembly, a water collecting tank and a belt conveyor, and the cleaning and flawdetection assembly is composed of a disc shaped placing frame, an air cylinder, a pressing plate, an arc-shaped groove, an arc-shaped seat, a second screw rod, a sliding seat, a water spraying head,a drying head, an ultrasonic flaw detector and a transmission assembly.

Owner:ANHUI YINLONG PUMP VALVE

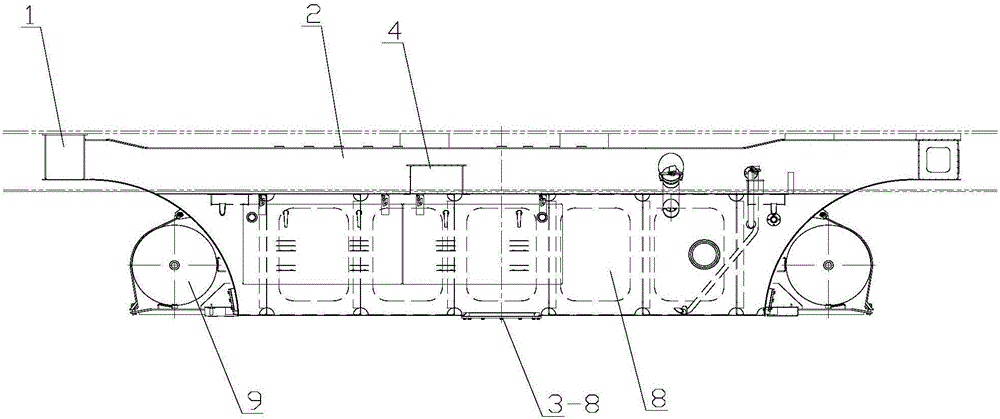

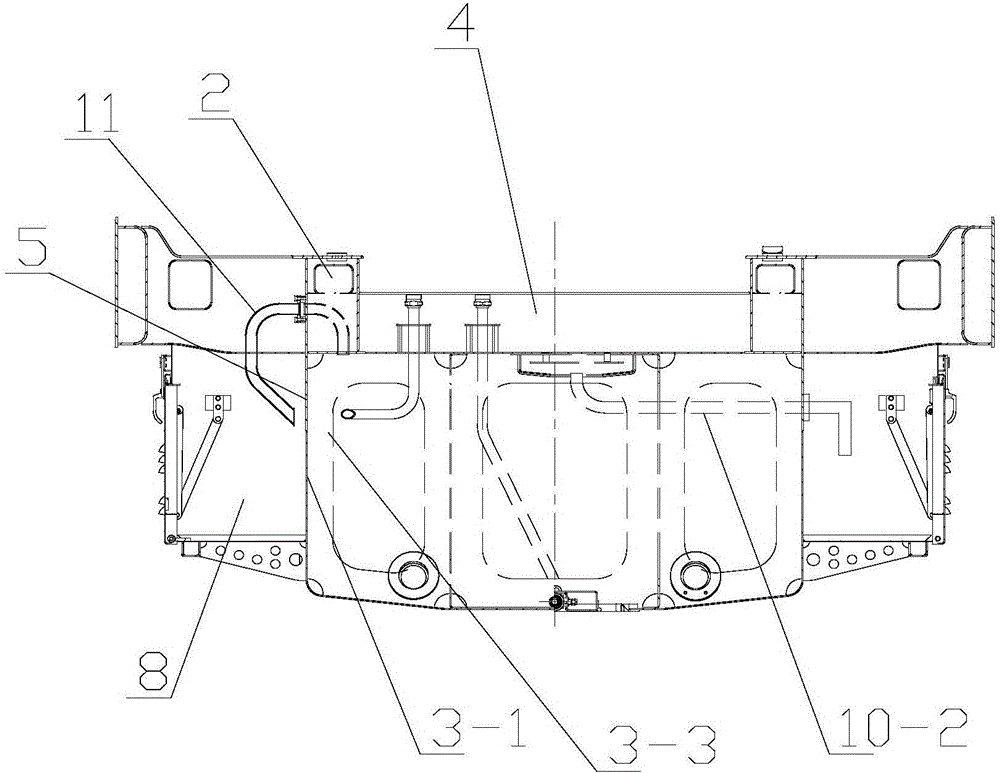

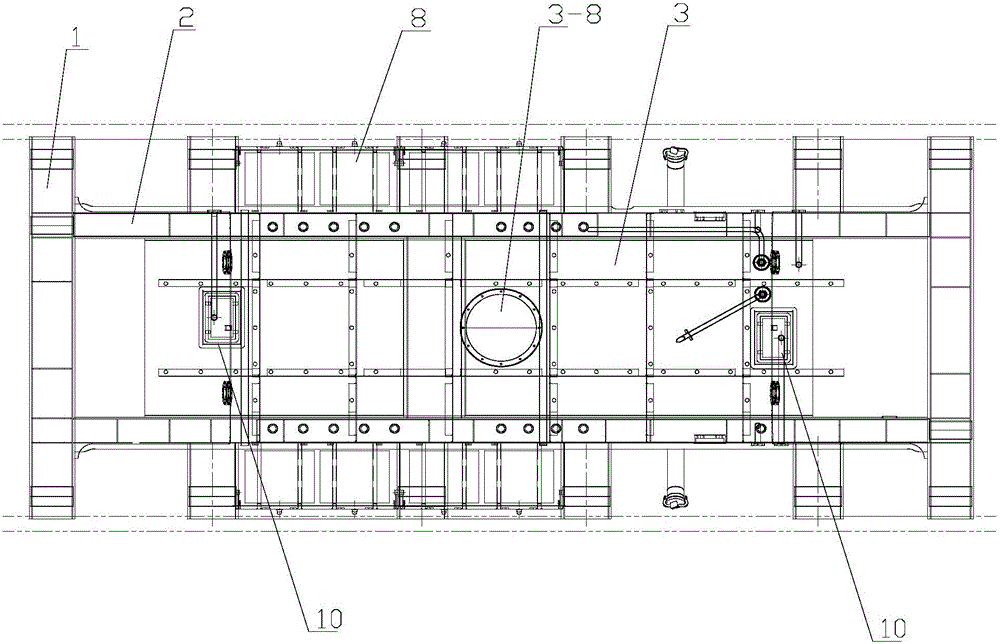

Vehicle-body loading type vehicle whole fuel tank structure

ActiveCN105109502APlay the role of positive pressure ventilationPositive pressure preventionLocomotivesWhole bodyFuel tank

The invention discloses a vehicle-body loading type vehicle whole fuel tank structure. The whole fuel tank comprises horizontal beams, vertical beams and a fuel tank, wherein the horizontal beams are connected between the two vertical beams, outer side plates vertically downwards extending are arranged on the outer sides of the vertical beams, the fuel tank is arranged between the two vertical beams, and the two sides of the fuel tank are welded and fixed with the outer side plates. A sewage tank is mounted in the fuel tank, a cover plate of the fuel tank covers a cover plate of the sewage tank, the size of the opening of a fuel hole is larger than that of a fuel leakage hole, and the cover plates of the fuel tank and the sewage tank are welded and fixed along the edge of the fuel hole. The outer side plates of the vertical beams are used as the main vertical plate of the fuel tank, and welded with the outer wall of the fuel tank, and thus the rigidity of the whole fuel tank is increased. The welded fuel tank is welded with the vertical beams, the horizontal beams and a reinforced horizontal beam to form a whole body, and thus the whole fuel tank is formed, the bearing capability of the fuel tank is increased, the rigidity of the middle structure is increased, and under the requirement of the same load, the weight of the vehicle body is obviously reduced and the requirement of light-weight design of the vehicle body is satisfied.

Owner:CRRC ZIYANG CO LTD

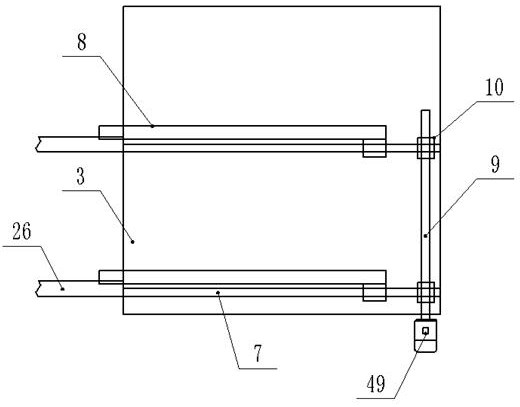

Ultrasonic flaw detection tooling for direct-axis parts

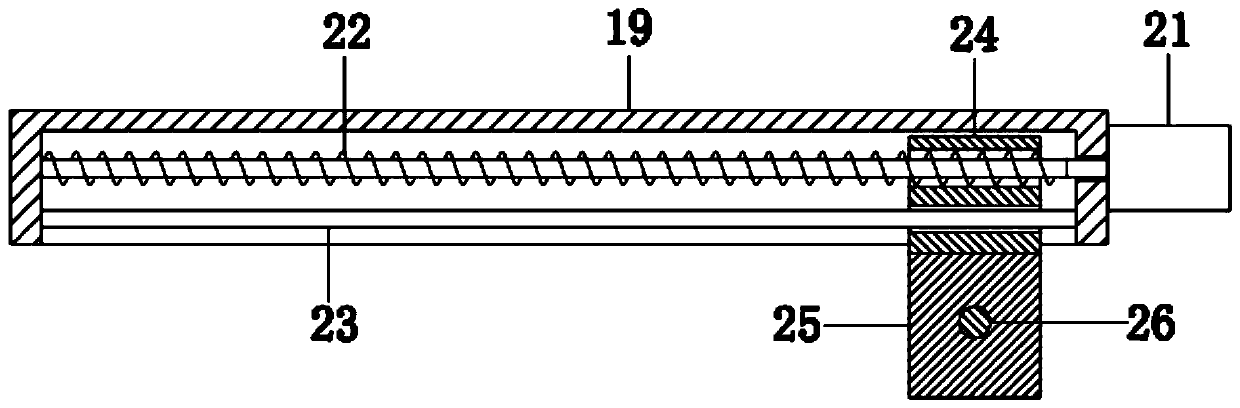

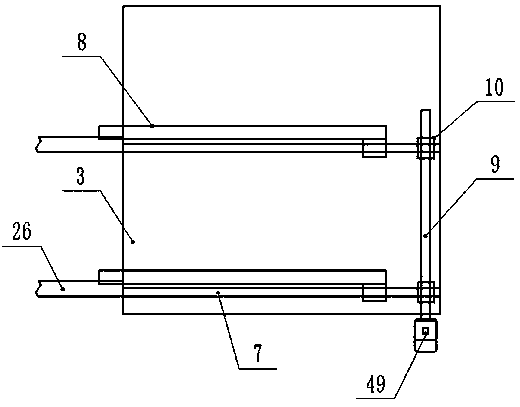

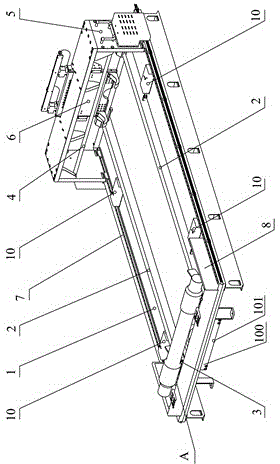

ActiveCN103558287AFully automatedReduce dependenceAnalysing solids using sonic/ultrasonic/infrasonic wavesIndustrial engineeringUltrasound

The invention provides an ultrasonic flaw detection tooling for direct-axis parts. The ultrasonic flaw detection tooling comprises a working table board, a workpiece support track arranged at the middle position of the working table board, a workpiece rotating device arranged at one end of the working table board, an oil sprinkling system, a workpiece translating mechanism in sliding connection with the working table board and a workpiece lifting mechanism arranged on the workpiece translating mechanism. Multiple direct-axis parts to be subjected to flaw detection can be arranged on the workpiece support track of the ultrasonic flaw detection tooling for one time by a crown block, for instance, two flaw detection toolings can be used for performing flaw detection on 15 axles or so for half a day through statistics, so that the axles can be hoisted on the workpiece support track for one time in the morning and then hoisted down from the workpiece support track for one time in the afternoon, and no crown block is required during the operation, therefore, the ultrasonic flaw detection tooling for the direct-axis parts is less dependent on the crown block, and the labor cost and the using cost of the crown block are reduced.

Owner:ZHUZHOU TIANLI FORGING IND

Adjustable protecting device for pipeline flaw detector

ActiveCN110886969AQuality improvementImprove efficiencyPipeline systemsMaterial analysisEngineeringStructural engineering

The invention relates to the field of pipeline flaw defectors and in particular to an adjustable protecting device for a pipeline flaw detector. The protecting device comprises a handle, four guidingstructures, a cleaning structure, a limiting structure, a fixing structure, an ash removing structure and a transmission structure. The positions of the four guiding structures are adjusted by the limiting structure conveniently, so that the four guiding structures determine a circle and lean against a pipeline to be applied to flaw detection of pipelines with different diameters conveniently, andtherefore, the operating flexibility is improved greatly. The four guiding structures are symmetrically arranged on the limiting structure in pairs, so that it is more convenient and rapid to drive rotation between the limiting structure and the pipeline. Flaws in different positions of the pipeline are detected conveniently. After flaw detection, the guiding structures are positioned conveniently, so that the flaw detection quality is improved greatly. The ash removing structure is connected to the fixing structure, so that the guiding structures drive the transmission structure to compressthe ash removing structure during guiding, and therefore, the ash removing structure cleans ash on the flaw detector on the fixing structure by means of gas.

Owner:响水县正响建设发展有限公司

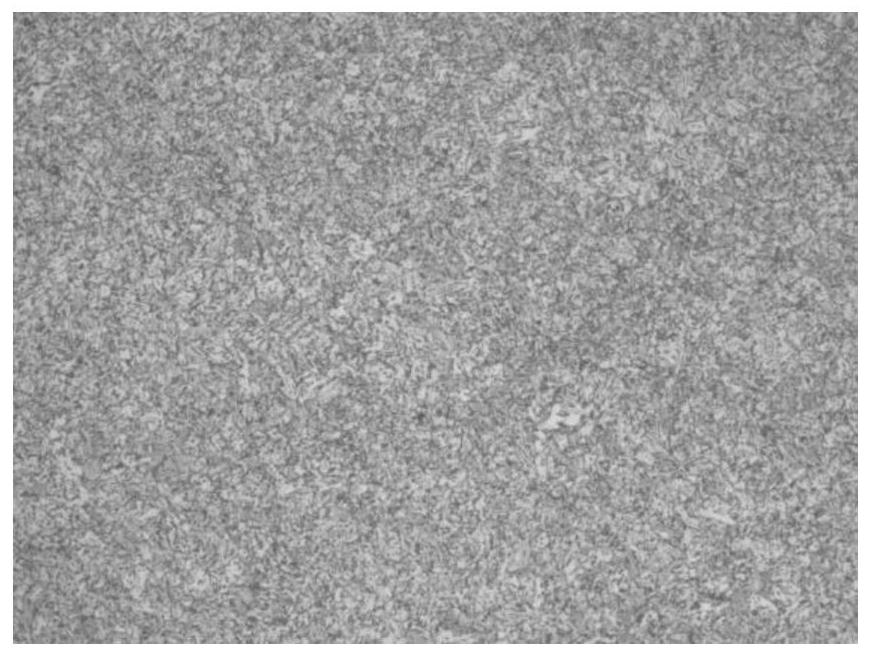

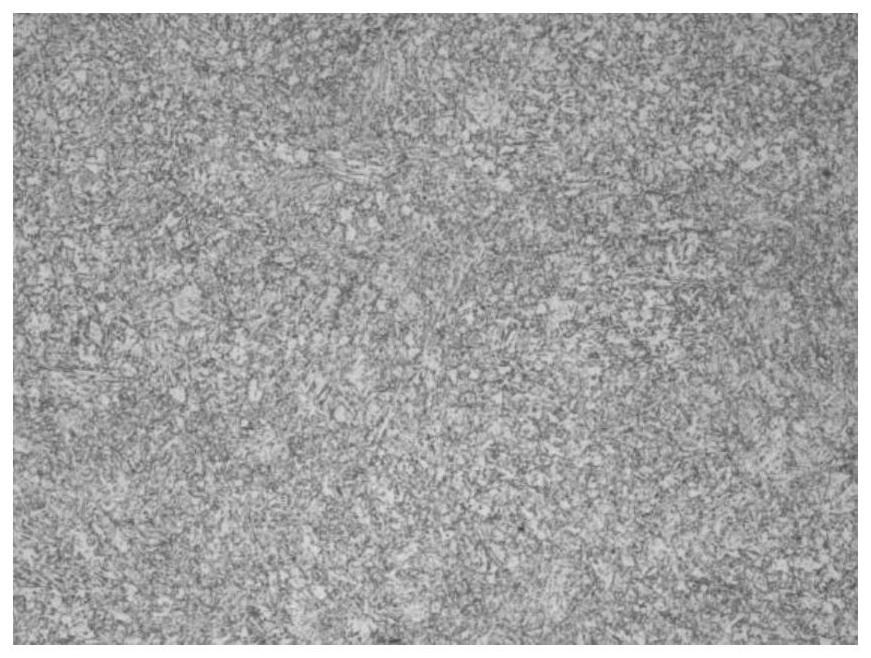

Large-thickness high-toughness S500QL1 steel plate and production method thereof

The invention discloses a large-thickness high-toughness S500QL1 steel plate and a production method thereof. The steel plate comprises chemical components: by mass, 0.12-0.14% of C, 0.20-0.40% of Si,1.00-1.25% of Mn, 0.80-1.10% of Ni, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.020-0.040% of Nb, 0.30-0.50% of Cr, 0.40-0.50% of Mo, 0.020-0.045% of Al during preparationof steel ingots, 0.060-0.090% of Al during preparation of electroslag ingots, and the balance Fe and inevitable impurities. The preparation method comprises the steps of heating, rolling and heat treatment. By adjusting the design of the chemical components of the steel plate and through cooperation of high-temperature large-reduction rolling and the reasonable heat treatment regime, it is guaranteed that the steel plate has the good structural and comprehensive properties and welding performance, and the production cost is reduced.

Owner:WUYANG IRON & STEEL

Preparation method of special coupling agent for ultrasonic flaw detection on rough surface

ActiveCN106770687AEasy to useConvenient flaw detectionMaterial analysis using sonic/ultrasonic/infrasonic wavesFilter cakeWater quality

The invention discloses a preparation method of a special coupling agent for ultrasonic flaw detection on a rough surface, belonging to the technical field of preparation of coupling agents. The preparation method comprises the following steps: firstly, soaking wheat straws in biogas broth to initially degrade and activate wheat straw fibers; secondly, cutting the straws, soaking the straws in lime water, digesting the straws, then putting the straws in a stone mortar, beating the straws, then putting short straws in a sodium hydroxide solution, and dissolving lignin in the straw fibers by using microwave heating combined with high-pressure heating treatment; and finally, mixing filter cakes with chloroacetic acid, performing centrifugal separation after heating reaction, and drying a precipitate into powder, thereby obtaining the special coupling agent for ultrasonic flaw detection on the rough surface. According to the preparation method provided by the invention, the wheat straws, which are low in price and easy to obtain, are used as a raw material, the obtained product only needs to be confected to be with different viscosities for direct use, the product is green and nontoxic, the surface of a workpiece can be washed directly with water after completion of flaw detection, and soil and water are not polluted. By use of the coupling agent, the problems that a conventional coupling agent for ultrasonic flaw detection on the rough surface pollutes a workpiece after use and is difficult to clean and recover are effectively solved.

Owner:JIANGSU SANHE SOUND SOURCE ULTRASONIC TECH

Heat-insulated protective garment

This invention relates to a heat insulation protecting coat composed of an inlay made of anti-high temperature, wear resisting, anti-shake and tensible fiber fabrics, a middle layer made of high-temperature resisting, low conduction of heat of inorganic cotton felts and a surface layer of strong hydrophobic fabrics.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

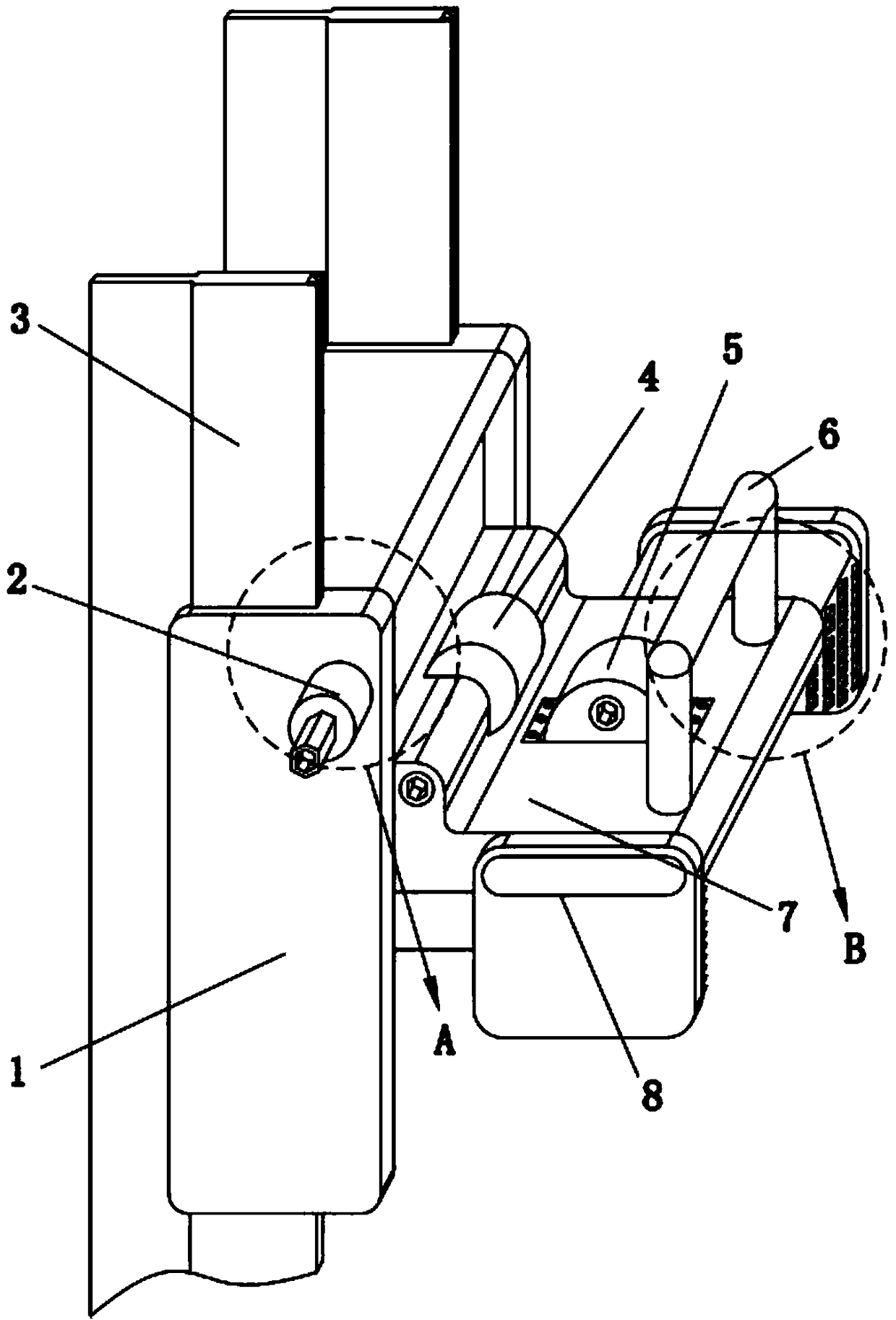

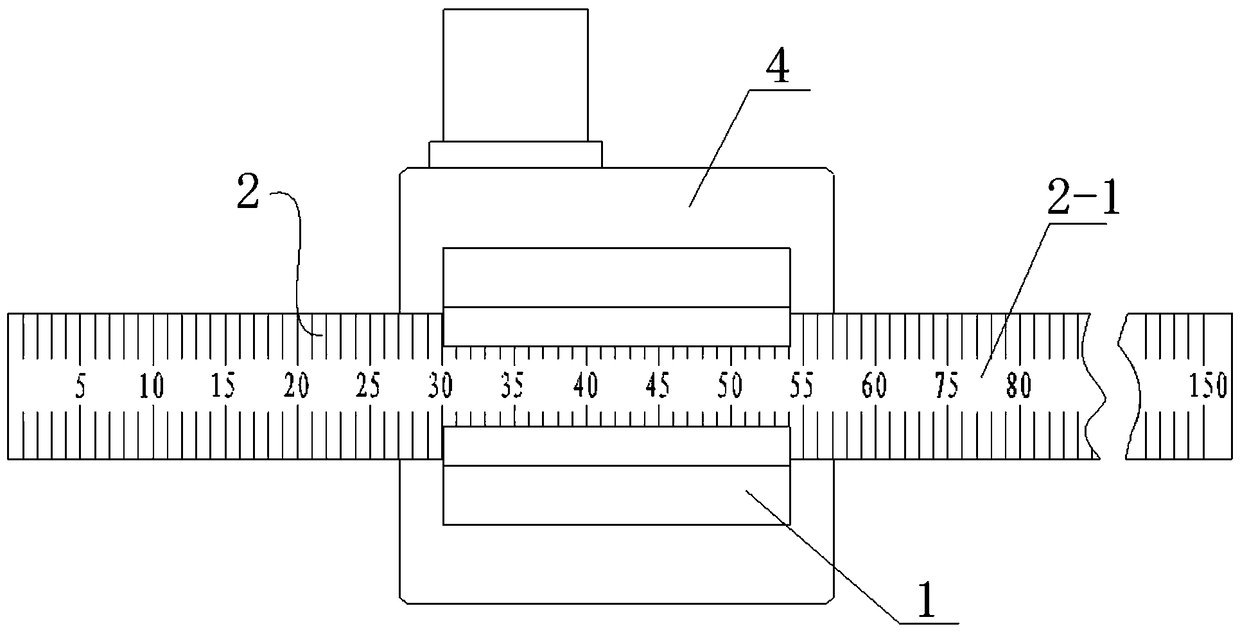

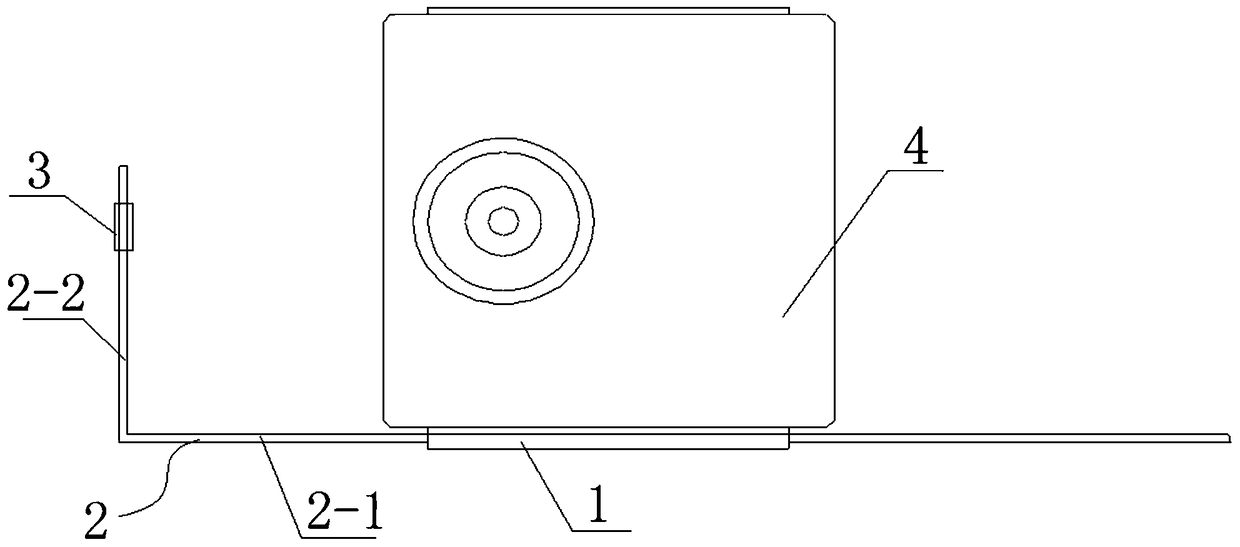

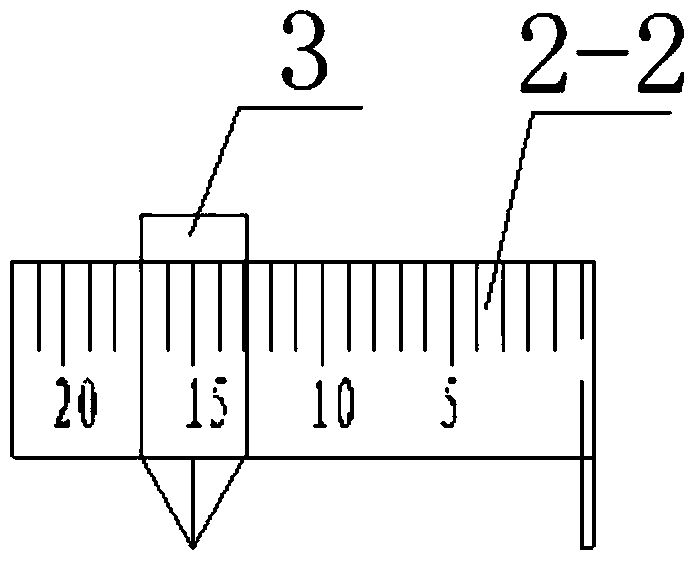

A defect location device for ultrasonic testing

ActiveCN105445373BAccurate judgmentEasy to useAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasoundUltrasonic detection

A related defect positioning apparatus applied to ultrasonic detection is characterized in that the apparatus comprises an installation mounting base and a right-angle measuring scale; the right-angle measuring scale comprises a first measuring scale and a second measuring scale fixedly connected with one end of the first measuring scale, and the scale surface of the first measuring scale is perpendicular to the scale surface of the second measuring scale; a slideway is disposed on the installation mounting base, and the first measuring scale is connected in the slideway in a sliding way; and the second measuring scale is provided with a flexible arrowhead in a sliding way. A double positioning manner in a plane is employed, and a point in a plane can be precisely positioned, a defect position is facilitated to be precisely determined, and defects are facilitated to be timely cleared and repaired.

Owner:CRRC QIQIHAR ROLLING CO LTD

Drilling pump with T-type pump head

InactiveCN103104447AReduce volatilityReduce vibrationPositive displacement pump componentsFlexible member pumpsSlurryPump head

The invention discloses a drilling pump with a T-type pump head, and the drilling pump with the T-type pump head is substantially formed by a shell body (1), a discharge liquor cylinder (2) arranged on the shell body (1), a discharging pipe (12) connected and communicated with the discharge liquor cylinder (2), a liquid suction cylinder (3) connected and communicated with the discharge liquor cylinder (2), and a suction pipe (4) connected and communicated with the liquid suction cylinder (3). A piston device communicated with the discharge liquor cylinder (2) is arranged inside the shell body (1). The drilling pump with the T-type pump head is in a compact structure and cancels a suction chamber, the volume and the quality of the drilling pump with the T-type pump head are reduced by 25% - 30%. The drilling pump with the T-type pump head is easy to process and manufacture, convenient to flaw detect and inspect, and can ensure the quality of the pump head products. Slurry is sucked in a horizontal mode, the clearance volume in the pump head cylinder is small, the suction efficiency and the volumetric efficiency of the drilling pump are improved; liquid flow is smooth, the pressure fluctuation and vibration is reduced, and the drilling pump impact load is also reduced. The change of a suction valve is very convenient and time-saving, and the workload of dismounting and changing is little.

Owner:谢月

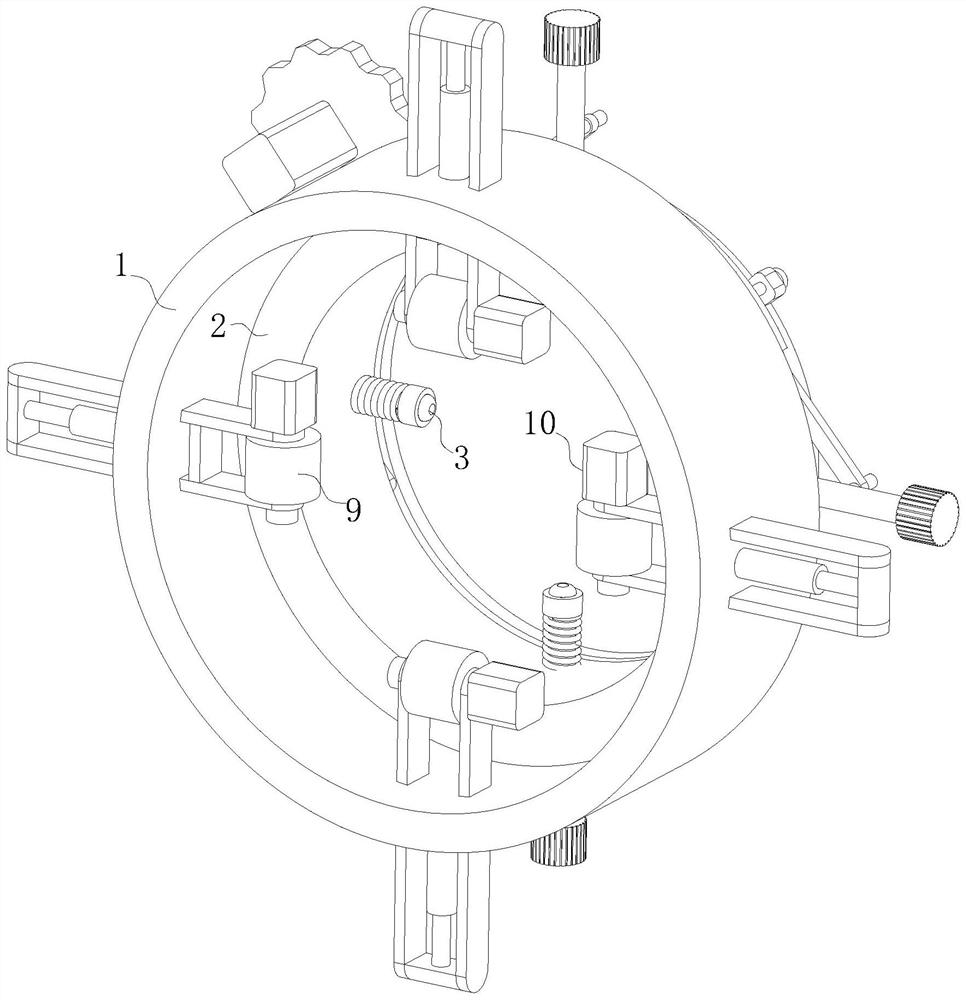

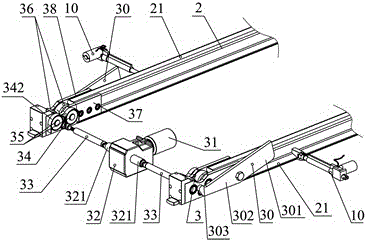

An Ultrasonic Flaw Detection System for Pipelines

ActiveCN109324118BPromote repairEasy to adjustAnalysing solids using sonic/ultrasonic/infrasonic wavesStructural engineeringAcoustics

Owner:孙中

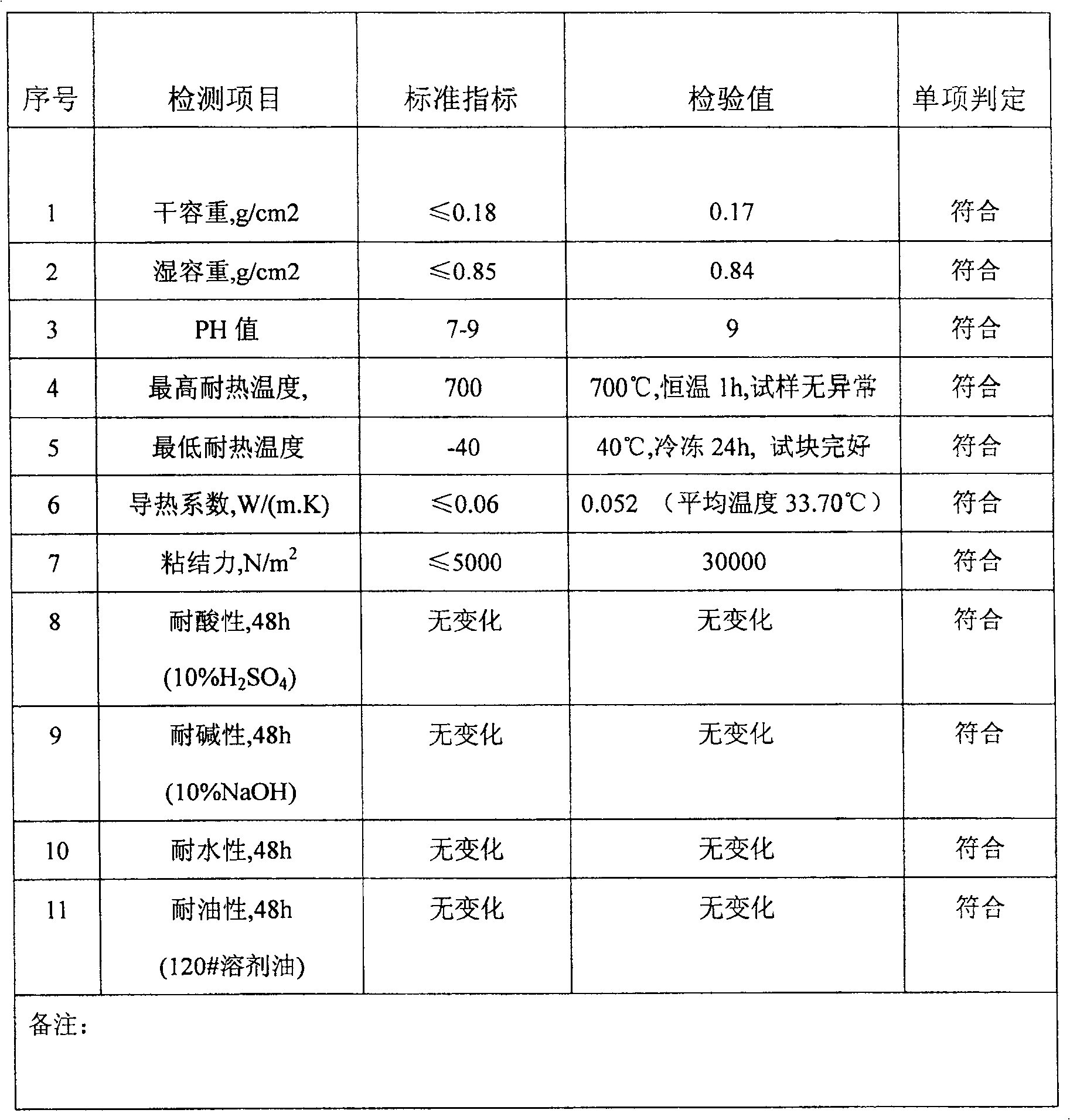

Composite silicate high-viscosity cold-hot coating heat preservation slurry

InactiveCN101245235BLow densityBlock deliveryFireproof paintsOther chemical processesFiberSodium Bentonite

Owner:格尚穆阳新材料(深圳)有限责任公司

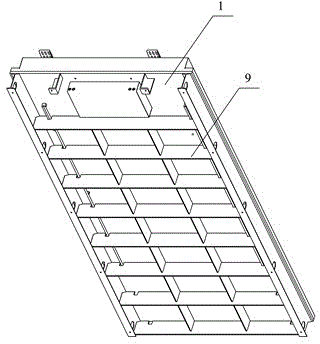

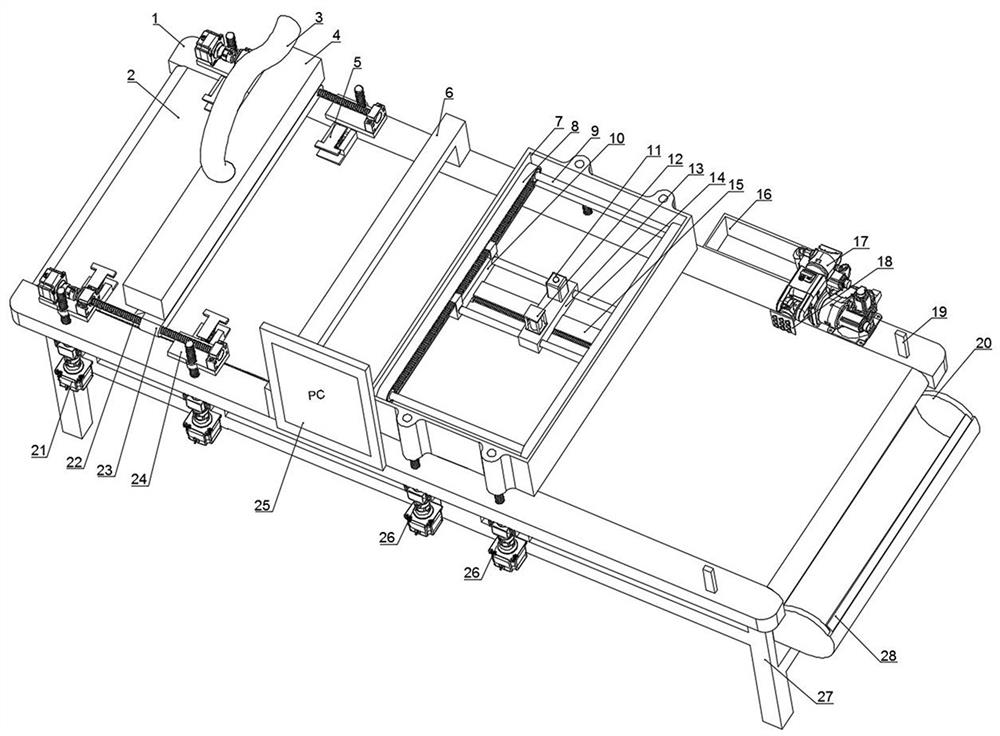

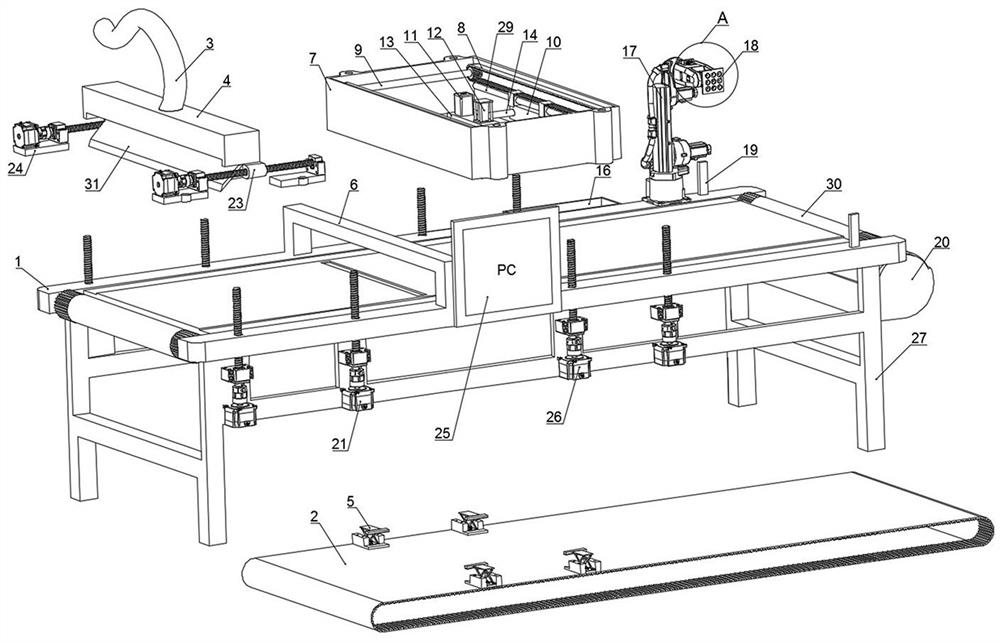

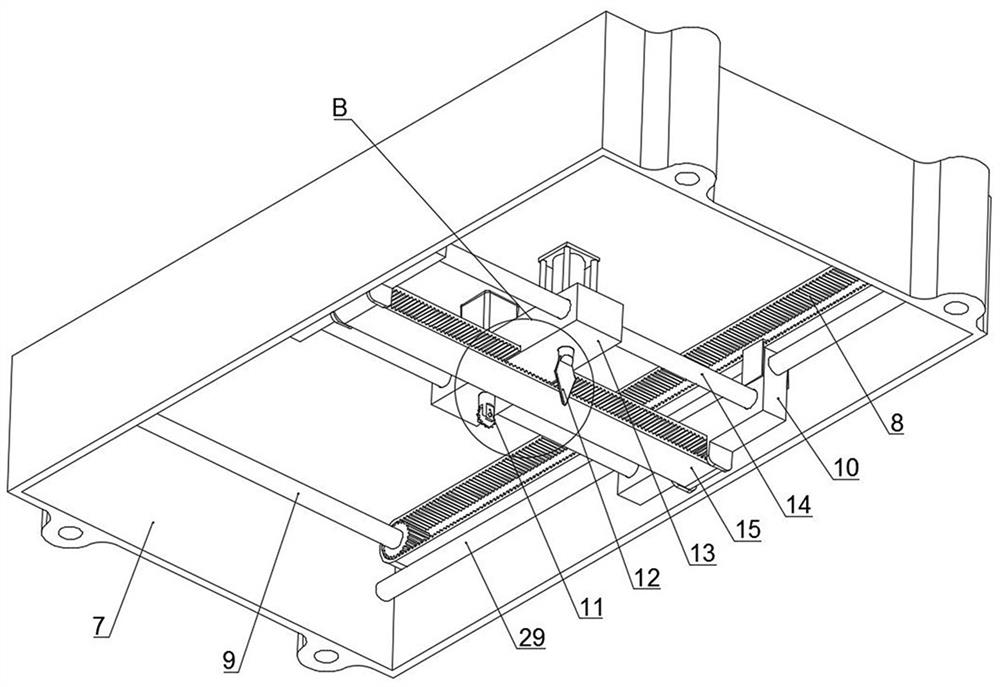

High polymer material sample preparation system and sample preparation method

InactiveCN112964531AAutomatic defect avoidanceImprove efficiencyPreparing sample for investigationMolecular materialsStructural engineering

The invention belongs to the technical field of high polymer material testing, and discloses a high polymer material sample preparation system and a sample preparation method. The system comprises a base, the base comprises a top plate and supporting legs arranged below the top plate, in the length direction of the top plate, one end of the top plate is the head end, the other end of the top plate is the tail end, a pair of driving rollers is arranged at the two ends of the top plate, an annular conveying belt matched with the driving rollers is further arranged on the top plate, and a clamping device is arranged on the conveying belt; a thinning device, a flaw detection device, a blanking device, a material picking device and a waste recovery device are sequentially arranged on the top plate from the head end to the tail end of the top plate. The system further comprises a control module for controlling linkage of the material clamping device, the thinning device, the flaw detection device, the blanking device, the material picking device and the waste recovery device. The problems that in the prior art, the automation degree is low during sample strip preparation, internal defects of sample strips are difficult to detect, cut-off knife storage is not changed, and manpower and resource waste is serious are solved.

Owner:XUZHOU COLLEGE OF INDAL TECH

Preparation method of a special couplant for rough surface ultrasonic flaw detection

ActiveCN106770687BEasy to useConvenient flaw detectionMaterial analysis using sonic/ultrasonic/infrasonic wavesFiberWater quality

The invention discloses a preparation method of a special coupling agent for ultrasonic flaw detection on a rough surface, belonging to the technical field of preparation of coupling agents. The preparation method comprises the following steps: firstly, soaking wheat straws in biogas broth to initially degrade and activate wheat straw fibers; secondly, cutting the straws, soaking the straws in lime water, digesting the straws, then putting the straws in a stone mortar, beating the straws, then putting short straws in a sodium hydroxide solution, and dissolving lignin in the straw fibers by using microwave heating combined with high-pressure heating treatment; and finally, mixing filter cakes with chloroacetic acid, performing centrifugal separation after heating reaction, and drying a precipitate into powder, thereby obtaining the special coupling agent for ultrasonic flaw detection on the rough surface. According to the preparation method provided by the invention, the wheat straws, which are low in price and easy to obtain, are used as a raw material, the obtained product only needs to be confected to be with different viscosities for direct use, the product is green and nontoxic, the surface of a workpiece can be washed directly with water after completion of flaw detection, and soil and water are not polluted. By use of the coupling agent, the problems that a conventional coupling agent for ultrasonic flaw detection on the rough surface pollutes a workpiece after use and is difficult to clean and recover are effectively solved.

Owner:JIANGSU SANHE SOUND SOURCE ULTRASONIC TECH

Pressurization method based on drilling pump provided with T-shaped pump head

InactiveCN103104471AReduce volatilityReduce vibrationPositive displacement pump componentsLiquid fuel engine componentsHydraulic cylinderEngineering

The invention discloses a pressurization method based on a drilling pump provided with a T-shaped pump head. The pressurization method comprises that (a) a suction tube is installed on a suction hydraulic cylinder, and the facts that the suction tube is communicated with the inside of the suction hydraulic cylinder and connecting ports of the suction tube and the suction hydraulic cylinder are sealed are guaranteed; (b) a suction valve and a discharge valve are opened, and a piston device is started; (c) liquid is sucked into the suction hydraulic cylinder from a suction flange and enters into a discharge hydraulic cylinder through the suction valve; (d) through reciprocating movement of the piston device, pressurization is carried out on liquid entering into the discharge hydraulic cylinder; and (e) the pressurized liquid is finally discharged through the discharge valve. According to the pressurization method, the structure is compact, and the size and mass are both reduced by 25%-30%; machining and manufacturing are easy, crack detection and inspection are convenient, and quality of pump head products can be guaranteed; slurry is horizontally sucked, and suction efficiency and volume efficiency of the drilling pump are improved; liquid flow is stable, fluctuation and vibration or pressure are reduced, and impact load of the drilling pump is reduced; and replacement of the suction valve is very convenient, time is saved, and workload of disassembling, installation and replacement is little.

Owner:谢月

Flaw detection equipment for pump parts processing

ActiveCN109632956BReduce occupancyComprehensive cleaningAnalysing solids using sonic/ultrasonic/infrasonic wavesOther manufacturing equipments/toolsCircular discStructural engineering

Owner:ANHUI YINLONG PUMP VALVE

Powerful paint stripper

ActiveCN101629036BConvenient flaw detectionEasy to repaintChemical paints/ink removersLacquerMetallic materials

The invention relates to a powerful paint stripper comprising the following components by weight percent: 0-5 percent of surface active agent, 72-78 percent of dichloromethane, 0-3 percent of ethylacetate, 0.78-0.8 percent of thickener, 0.6-0.7 percent of ceresin wax, 4.85-10 percent of phenol, 5-9 percent of alcohol, 0-6 percent of methanoic acid, 0-6 percent of ammonia water and 0-1 percent of sodium nitrite. The invention can effectively remove paint on the metal surface of planes and on the train wheel surface so as to perform flaw detection and repaint on the metal materials without damaging metal and wood surfaces, and has excellent depainting performance, low use amount and low depainting cost.

Owner:长沙艾森设备维护技术有限公司

A detection robot and a method for detecting the pouring quality of steel pipe concrete using the detection robot

ActiveCN108254440BRealize instant transmissionRealize high-precision flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesTransmission systemsClassical mechanicsEngineering

The invention provides a detection robot and a method for detecting the pouring quality of a concrete filled steel tube by using the detection robot. The detection robot comprises a mechanical electromagnetic mixing knocking hammer (1), a microphone (3) and a camera (7), wherein both the mechanical electromagnetic mixing knocking hammer (1) and the microphone (3) are respectively fixed on certainends of a knocking hammer mechanical arm (2) and a microphone mechanical arm (4) on the robot by virtue of an adjustable clamp (5), the other ends of the knocking hammer mechanical arm (2) and the microphone mechanical arm (4) are fixed on a control rotating stack (8) on the robot, the control rotating stack (8) is provided with a foundation support (9), the foundation support (9) is provided witha steering device (10), and the steering device (10) is provided with the camera (7).

Owner:HUNAN UNIV

MT U-shaped magnetizer device

PendingCN112345627AConvenient flaw detectionMagnetic bodiesMaterial magnetic variablesMagnetizationElectrical polarity

The invention is suitable for the technical field of magnetization flaw detection, and provides an MT U-shaped magnetizer device which is characterized in that a first flaw detection assembly comprises a first red copper bar set and a second red copper bar set which are arranged in parallel, a second flaw detection assembly and a third flaw detection assembly are symmetrically and obliquely arranged at the two ends of the first red copper bar set and the two ends of the second red copper bar set correspondingly and fixedly connected with the first red copper bar set and the second red copper bar set, and the cross sections of the first flaw detection assembly, the second flaw detection assembly and the third flaw detection assembly are in a U shape. By adopting the longitudinal U-shaped magnetizer device, three-dimensional magnetic field magnetization in the X direction, the Y direction and the Z direction can be achieved, and meanwhile, polarity-changing attenuation demagnetization can be tangentially carried out on the inner hole end face, the sharp corner, the periphery of a hole, the abrupt change part of the cross section, steps, the edge of a plate wall and magnetic fields deep in different directions of the special-shaped part through the longitudinal U-shaped coil.

Owner:江苏梁宸科技有限公司

Cleaning process and equipment for bearing repair

ActiveCN110899203BImprove cleaning efficiencyImprove repair efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesDrying gas arrangementsMechanical engineeringIndustrial engineering

The invention relates to a cleaning process for bearing repairing. The cleaning process comprises the following steps: a bearing is disassembled into single parts, and the single parts are placed on acommodity shelf in classified and layered modes; the commodity shelf is hoisted into a degreasing cleaning pool to degrease the bearing parts; the degreased bearing parts and the commodity shelf aresubjected to still standing, and a rust remover is sprayed on the surfaces of the bearing parts; the rust remover and rust stains on the surfaces of the bearing parts and the commodity shelf are rinsed off with clear water, and the bearing parts and the commodity shelf are dried; appearance flaw detection is conducted firstly through manual work, then internal flaw detection is conducted through aflaw detector, and the bearing parts with repairing value are screened to enter into the next procedure; and the bearing parts are immersed into rust-proof liquid to be subjected to rust-proof treatment, and after being taken out, the bearing parts are subjected to a bearing repairing process of the next step. According to the cleaning process and equipment, equipment for bearing cleaning can bereduced, the cleaning step is simplified, and the cleaning efficiency and the repairing efficiency of the bearing are improved.

Owner:北京宗合铁路轴承有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com