Once hot-forging shaping process for manufacturing joint hinge

A preparation process and intermediate frequency technology, applied in mechanical equipment, metal processing equipment, folding boards, etc., can solve the problems of low efficiency, difficulty in uniform control, high manufacturing cost, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below.

[0014] 1. Heat the fallen material to 1050-1150°C in an intermediate frequency heating furnace, the heating speed is set at 1-2 minutes per piece according to the size of the workpiece, and the power of the intermediate frequency heating furnace is 100-500KV;

[0015] Use a 750KG air hammer to lightly upset the workpiece vertically for 5-10 seconds, shorten the length by about 5%, and remove the surface oxide skin with a thickness of about 0.1mm;

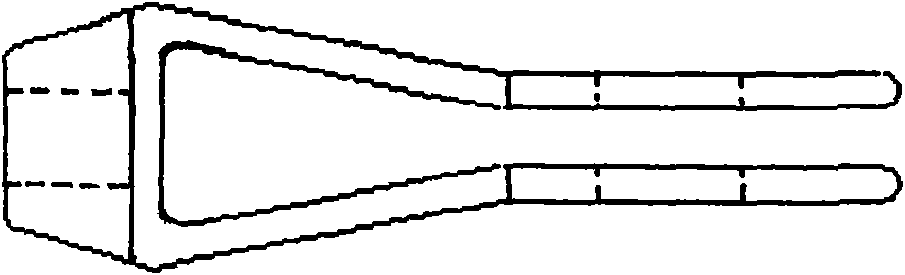

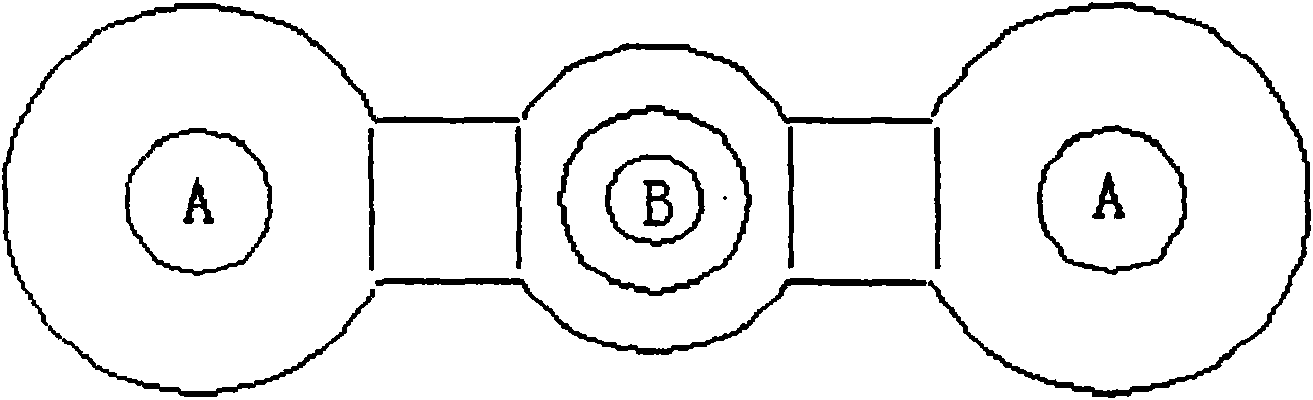

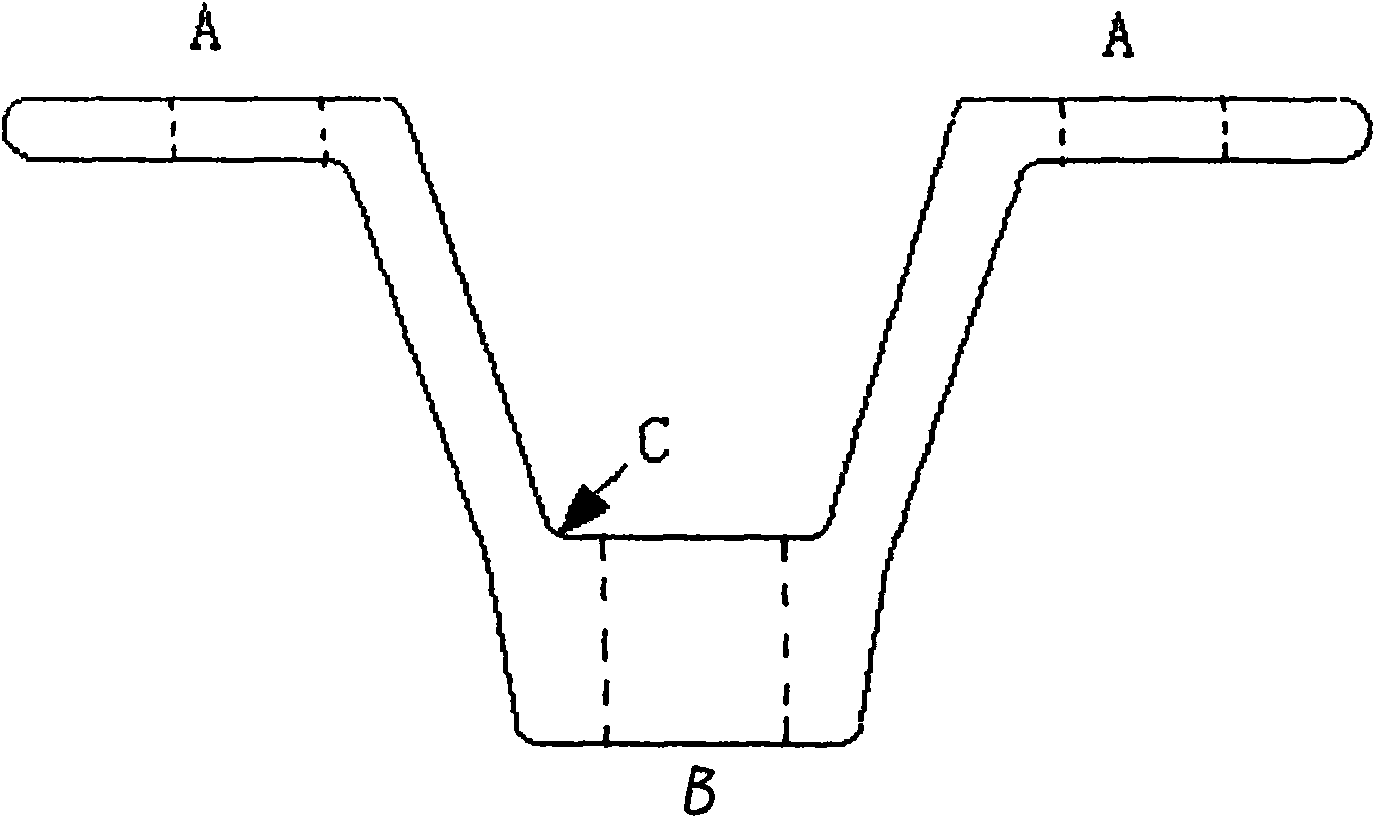

[0016] 2. Then process it in a 560T or 1600T friction press. According to the size of the workpiece, workpieces less than 16KG are processed in a 560T press, and workpieces larger than 16KG are processed in a 1600T press. The pre-forging die is basically flat, and the main distribution Material operation time is 10-20 seconds. see figure 2 , the feature of this process is to punch and forge the three holes A and B. Because the workpieces A and B have the largest external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com