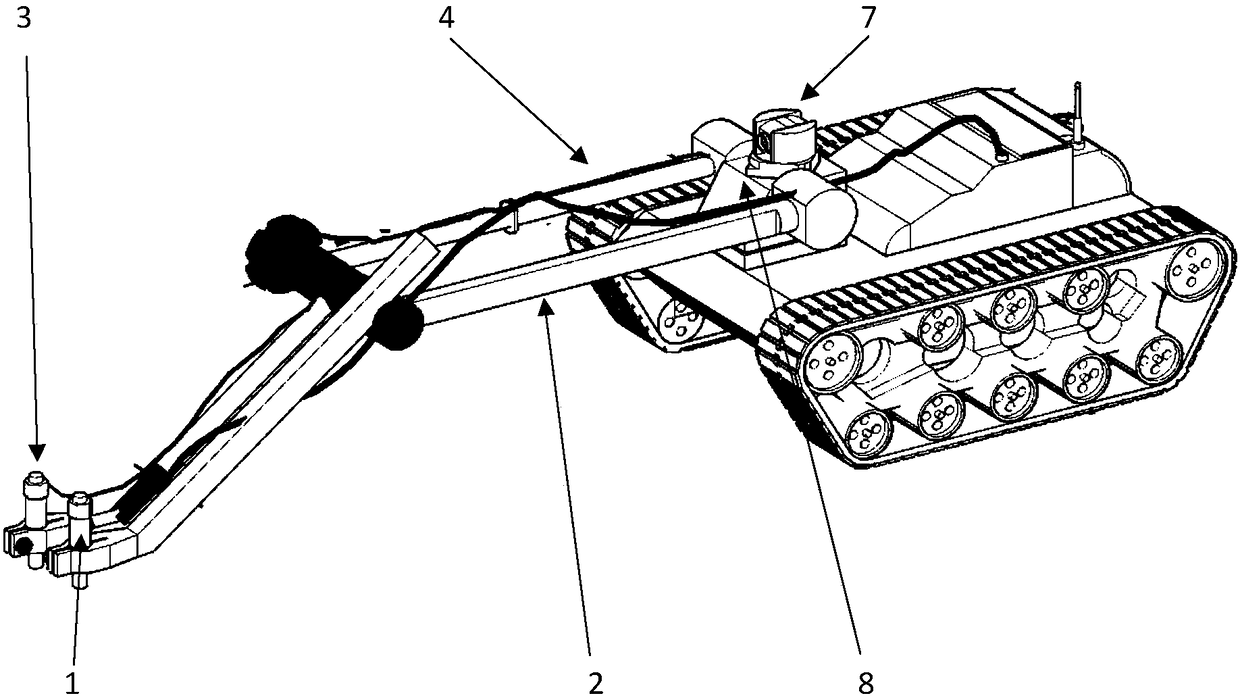

Detection robot and method for detecting pouring quality of concrete filled steel tube by using detection robot

A robot and concrete technology, applied in measuring devices, processing response signals of detection, and analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of difficulty in detection and observation, and achieve high-precision flaw detection, fast and convenient flaw detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

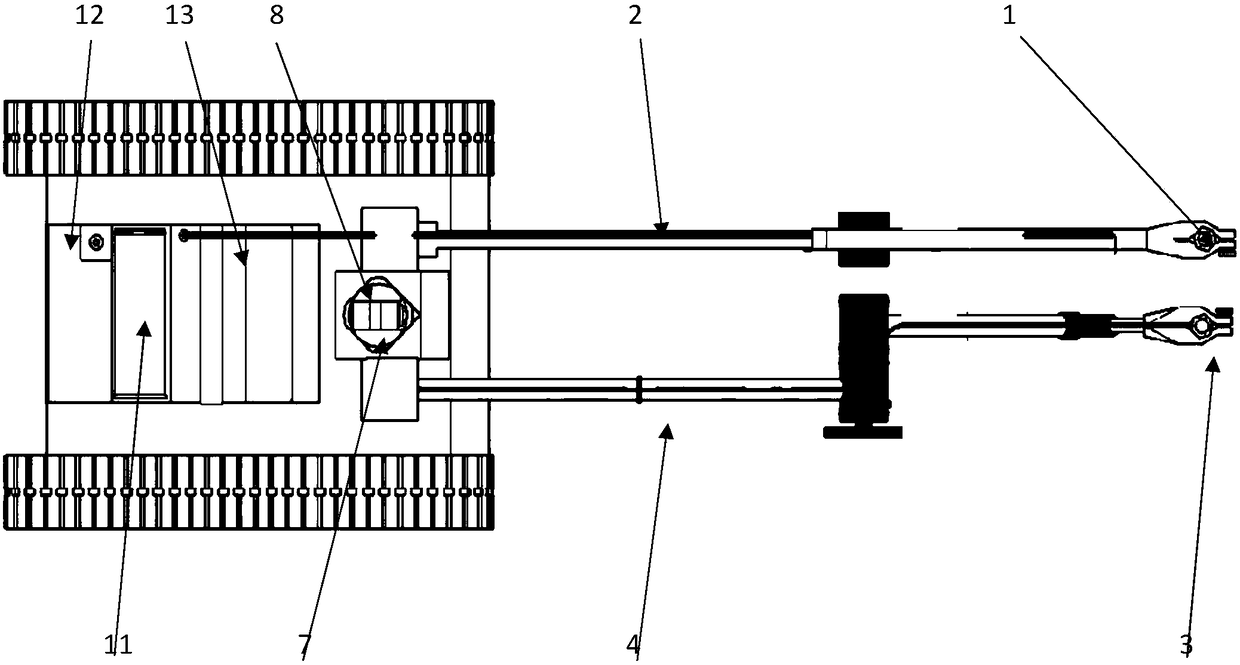

[0046] Use artificial percussion listening method or infrared thermal imaging technology to quickly detect the overall structure of the steel pipe concrete to be detected, and initially determine the area where local void damage may occur;

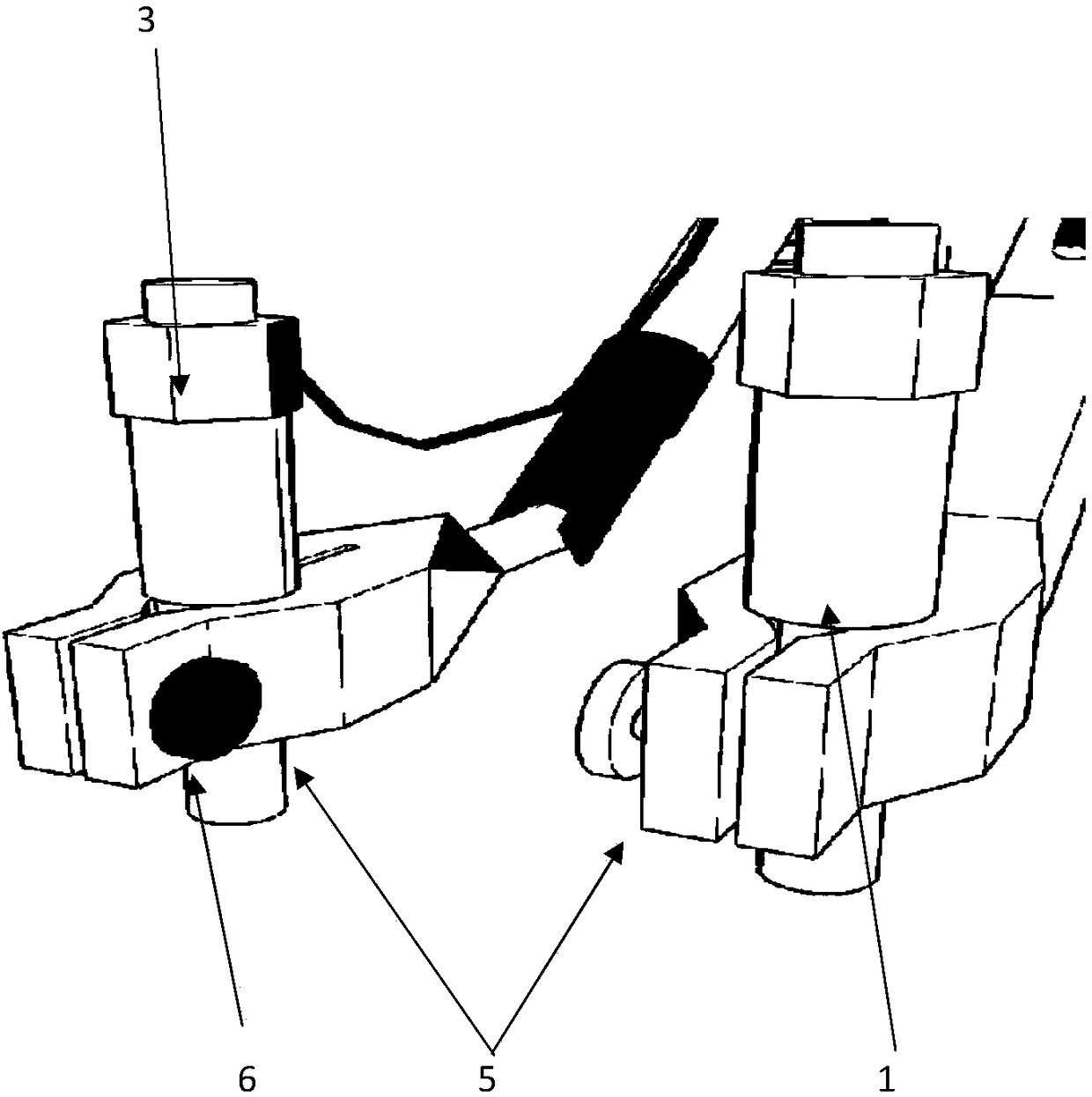

[0047] Such as Figure 7 As shown in , the surface of the steel shell in the area where local void damage may occur is divided into 10×10 grids with a spacing of 25mm, and the microphones are placed 50mm above the intersection points of each column of grids in turn;

[0048] Tap each grid intersection point in each row and column in turn, pick up the sound pressure signal of the microphone directly above the point, and make a frequency response function with the force signal of the hammer, and extract its frequency response by CMIF method For the first obvious frequency peak, calculate the modal compliance sound pressure form at this order frequency. For the above grid, obtain the modal compliance values at each point, as shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com