Synchronizing mechanism for automatic feeder

A synchronous mechanism, automatic feeding technology, applied in metal processing machinery parts, metal processing, measuring/indicating equipment, etc., can solve the problems of complex structure, easy failure, low synchronization, etc., to achieve low drop probability and response Fast, highly synchronized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing description and specific embodiment, the present invention will be described in further detail:

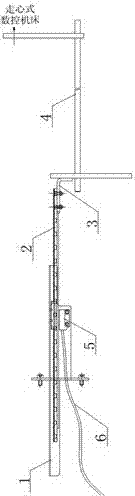

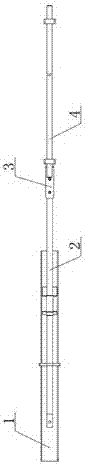

[0017] see Figure 1-Figure 2 , a synchronous mechanism for an automatic feeder, comprising a fixed bracket 1, a linear slide rail 2 and a machine tool connection bracket 4, the linear slide rail 2 is fixed on the fixed bracket 1, and between the machine tool connection bracket 4 and the linear slide rail 2 Connected by the connecting piece 3, the shape of the connecting piece 3 is L-shaped, one side of the connecting piece 3 is fixed on the linear slide rail 2 with a connecting nut, and the other side is fixed on the machine tool connection bracket 4, the linear slide rail 2 A position measuring device 5 is arranged at the bottom, and the position measuring device 5 is a grating ruler displacement sensor, and a data feedback signal line 6 is connected to the position measuring device 5 .

[0018] During installation, the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com