High polymer material sample preparation system and sample preparation method

A polymer material and sample preparation system technology, applied in the polymer material sample preparation system and the field of sample preparation, can solve problems such as rubber blocks, uneven plate thickness, waste of manpower, time and resources, and high labor intensity, to avoid Pollution, improved efficiency and quality, good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

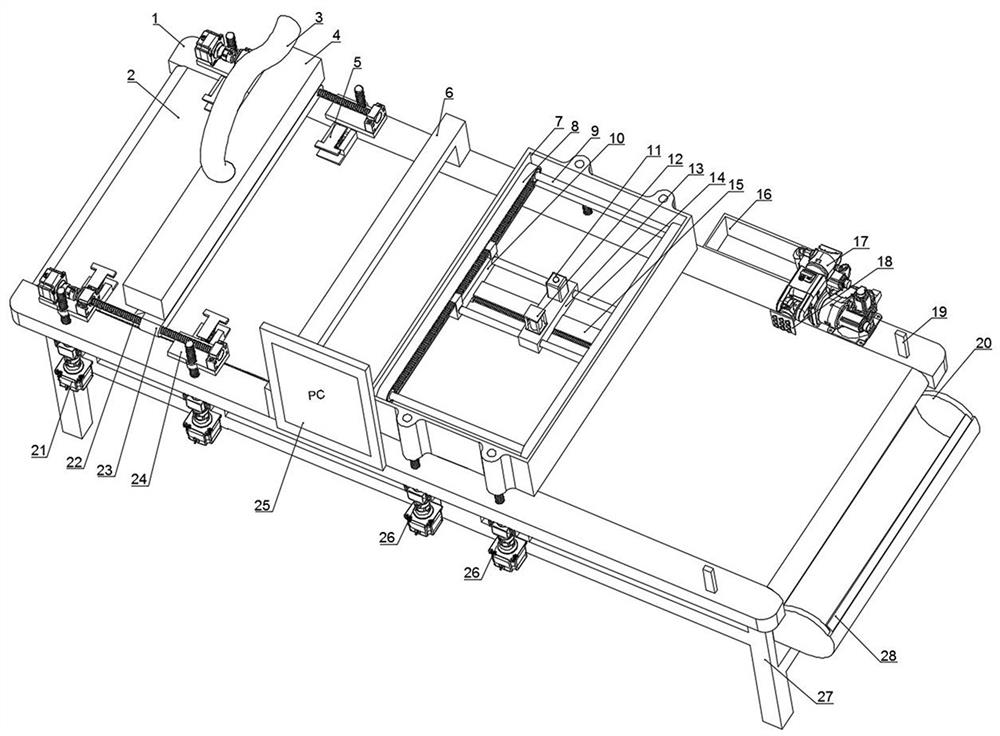

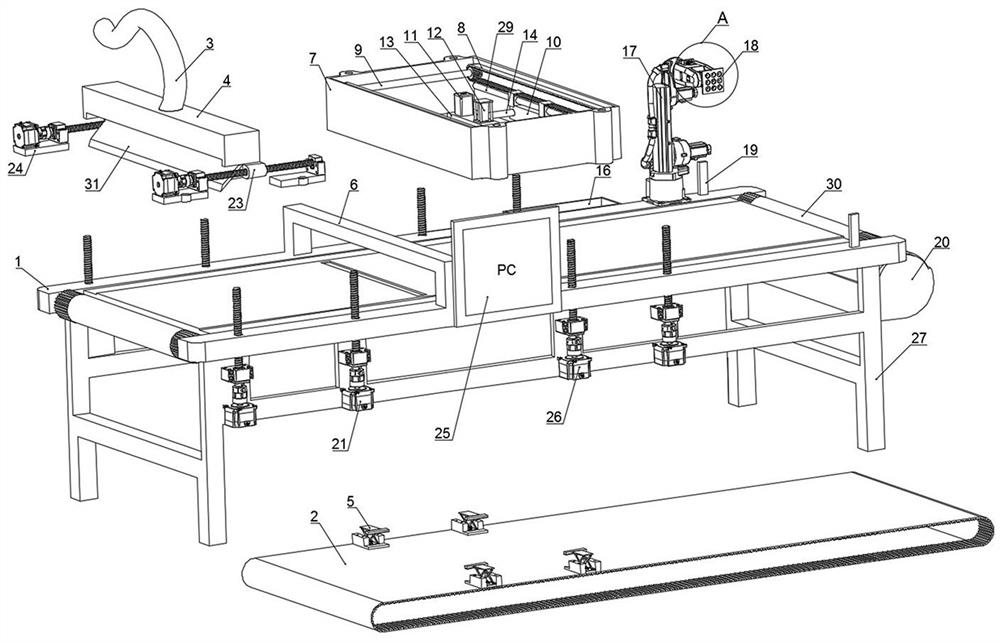

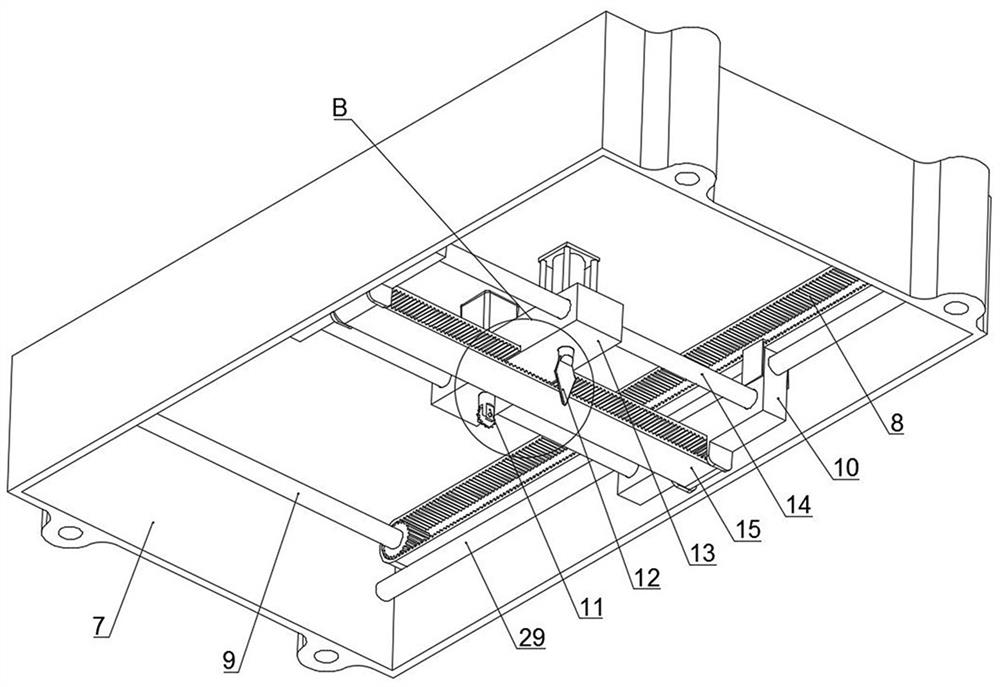

[0041] see Figure 1-Figure 8 , a polymer material sample preparation system, comprising a base, the base includes a top plate 1 and support legs 27 arranged under the top plate 1, along the length direction of the top plate 1, one end of the top plate 1 is the head end, and the other end is the tail end; There is a pair of rectangular grooves, and a pair of driving rollers 30 are provided at both ends of the top plate 1. The driving roller 30 is a cylindrical structure arranged along the width direction of the top plate 1. Bar teeth are arranged on the outer walls of the two sides of the driving roller 30. The top plate 1 There is also an endless conveyor belt 2 that cooperates with the driving drum 30. The conveyor belt 2 is a synchronous belt with teeth on the inside and smooth outside. The teeth on the inside of the conveyor belt 2 are arranged on both sides of the conveyor belt 2 in the width direction. The inner teeth cooperate with the teeth on the driving drum 30 and a...

Embodiment 2

[0047] A polymer material sample preparation method adopts a polymer material sample preparation system. First, the top surface of the conveyor belt 2 is used as the coordinate plane, the length direction of the conveyor belt 2 is the X-axis direction, and the conveyor belt 2 width direction is the Y axis. Axis direction, with the vertical direction as the Z-axis direction, the length and width of the top plate 1 limit a rectangular area, take the center point of the conveyor belt 2 top surface as the origin to establish a space coordinate system, and determine the coordinates of each device in the coordinate system, The control module accurately controls the relative position of each device by controlling the coordinates of each device in the space coordinate system. The method mainly includes the following steps:

[0048] S1: Cut the sample from the product, and fix the cut sample on the conveyor belt 2 through the clamping device 5;

[0049] S2: Start the system, the convey...

Embodiment 3

[0055] see Figure 9 , a polymer material sample preparation system, the only difference from Embodiment 1 is that the third ball screw device 26 is provided with a pair, and the pair of third ball screw devices 26 are symmetrically arranged on both sides of the top plate 1, and the housing 7 A pair of vertically arranged threaded holes are provided on both sides to cooperate with the third ball screw device 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com