Patents

Literature

131results about How to "Automatic cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

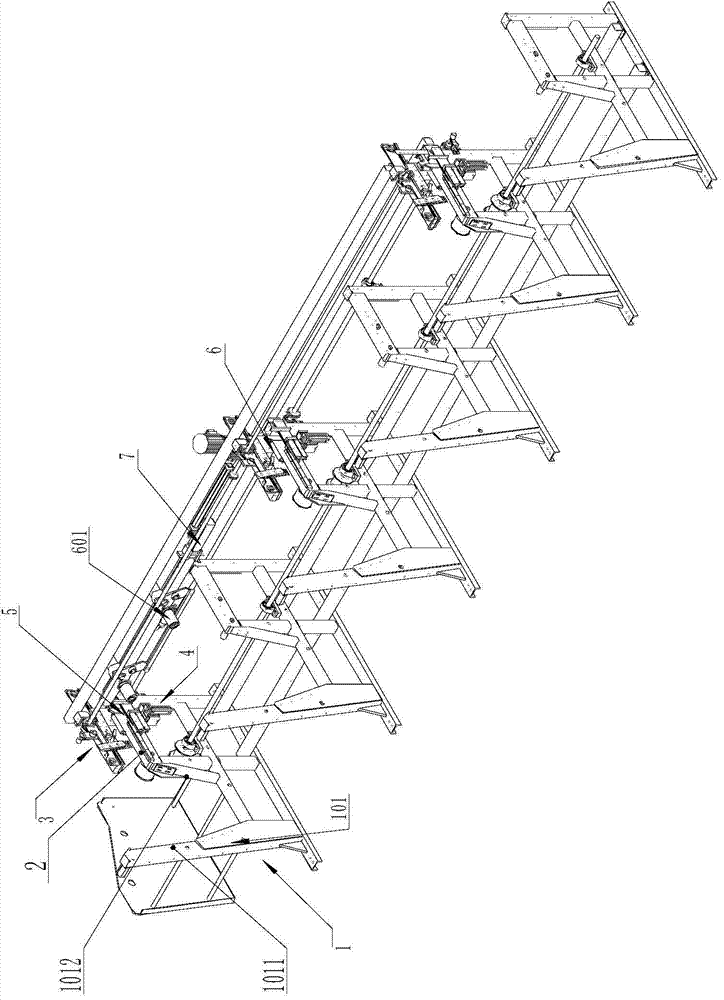

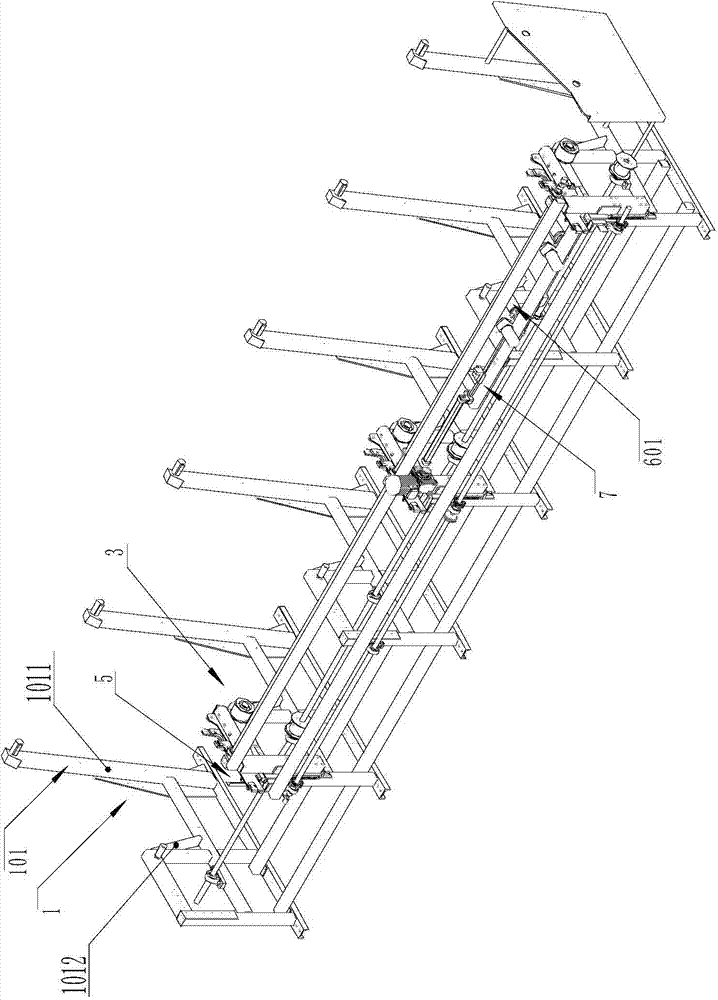

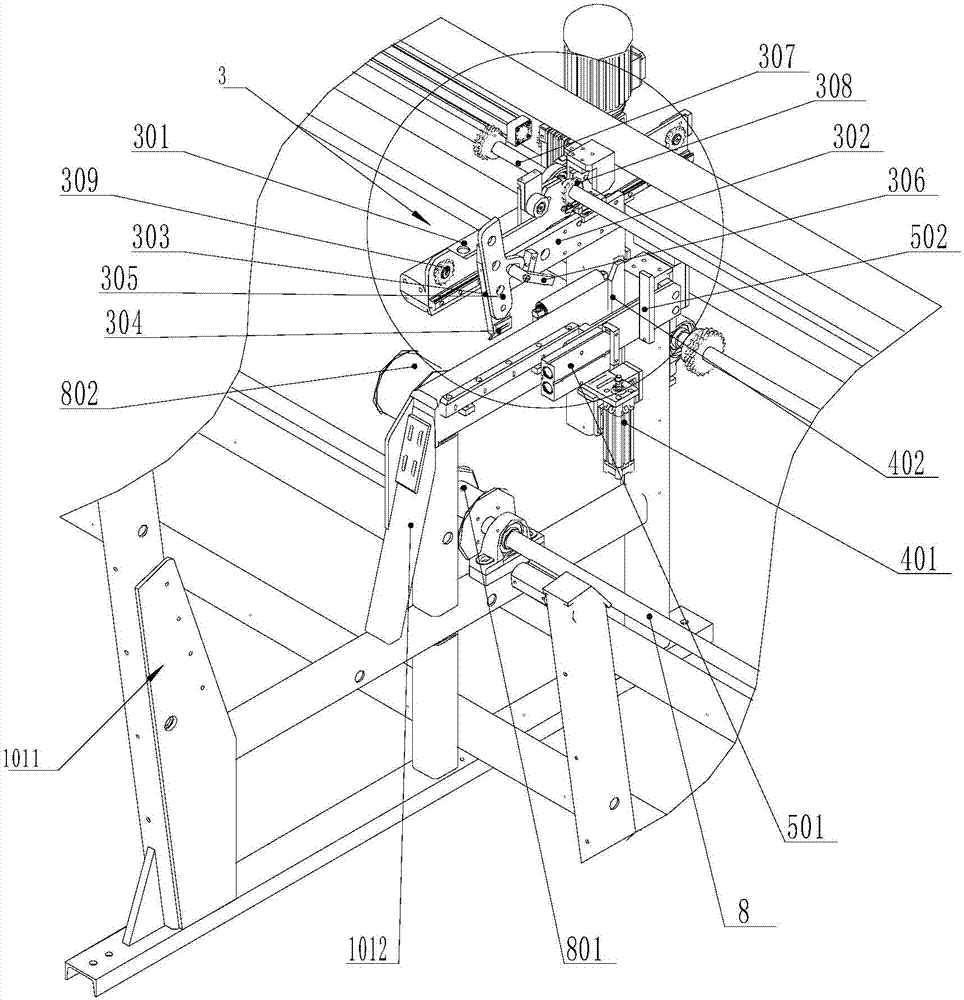

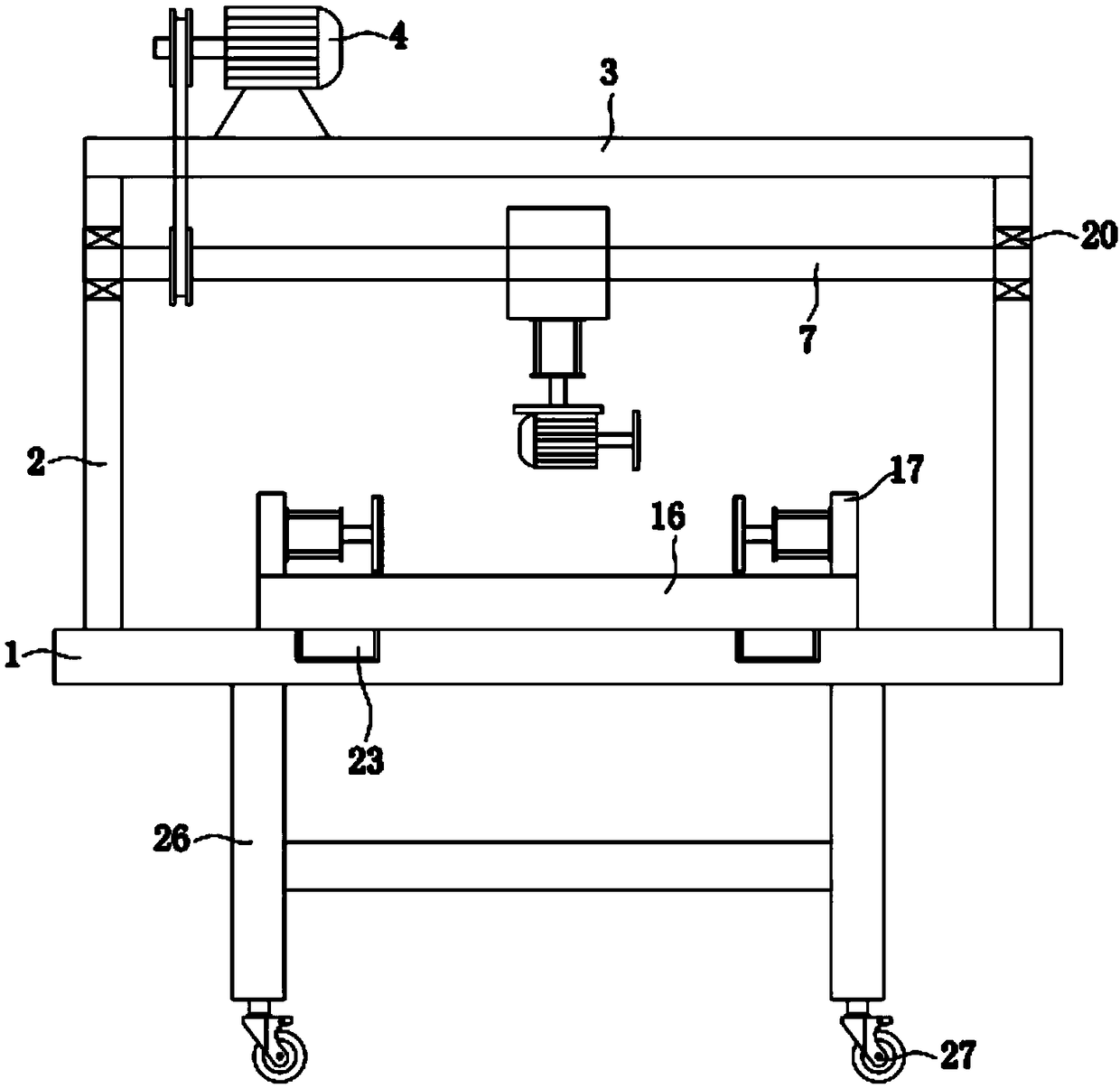

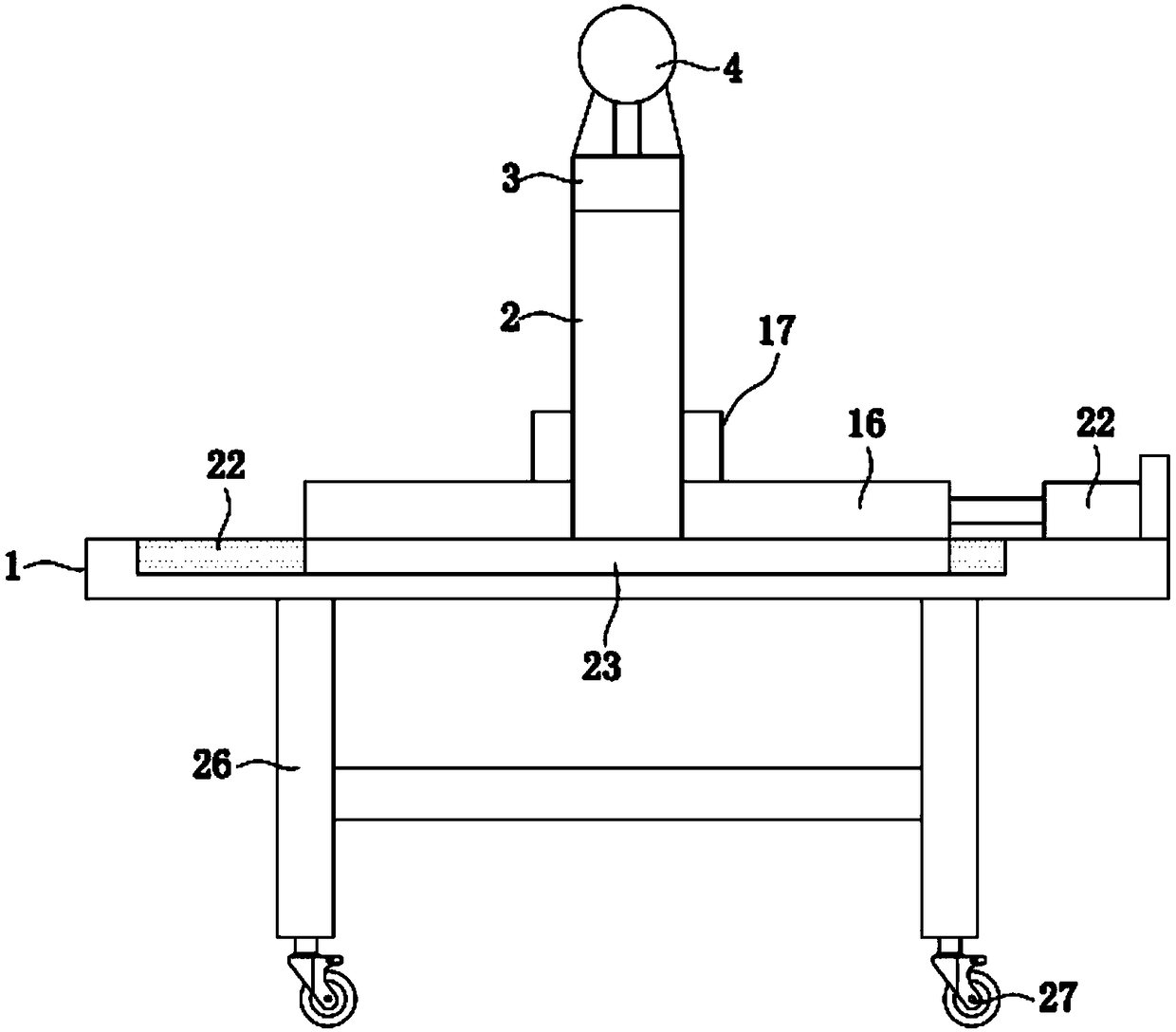

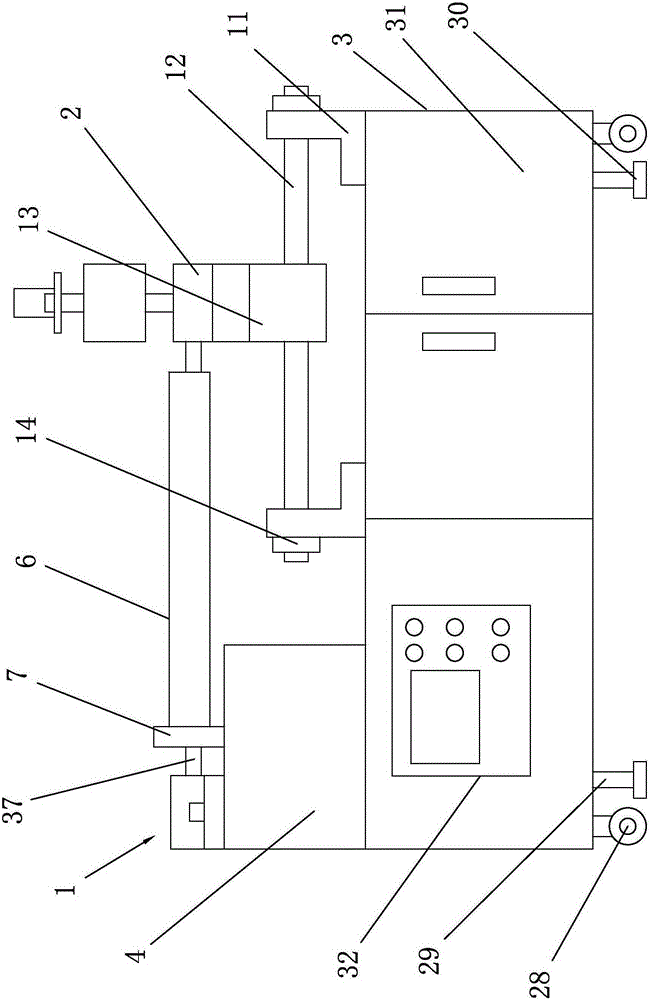

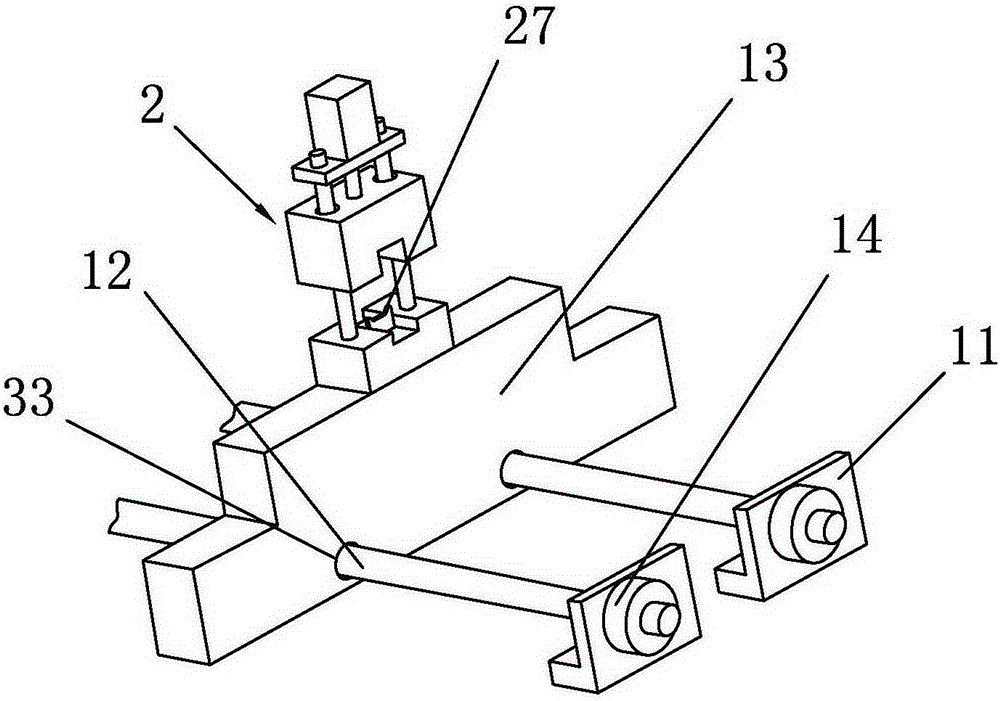

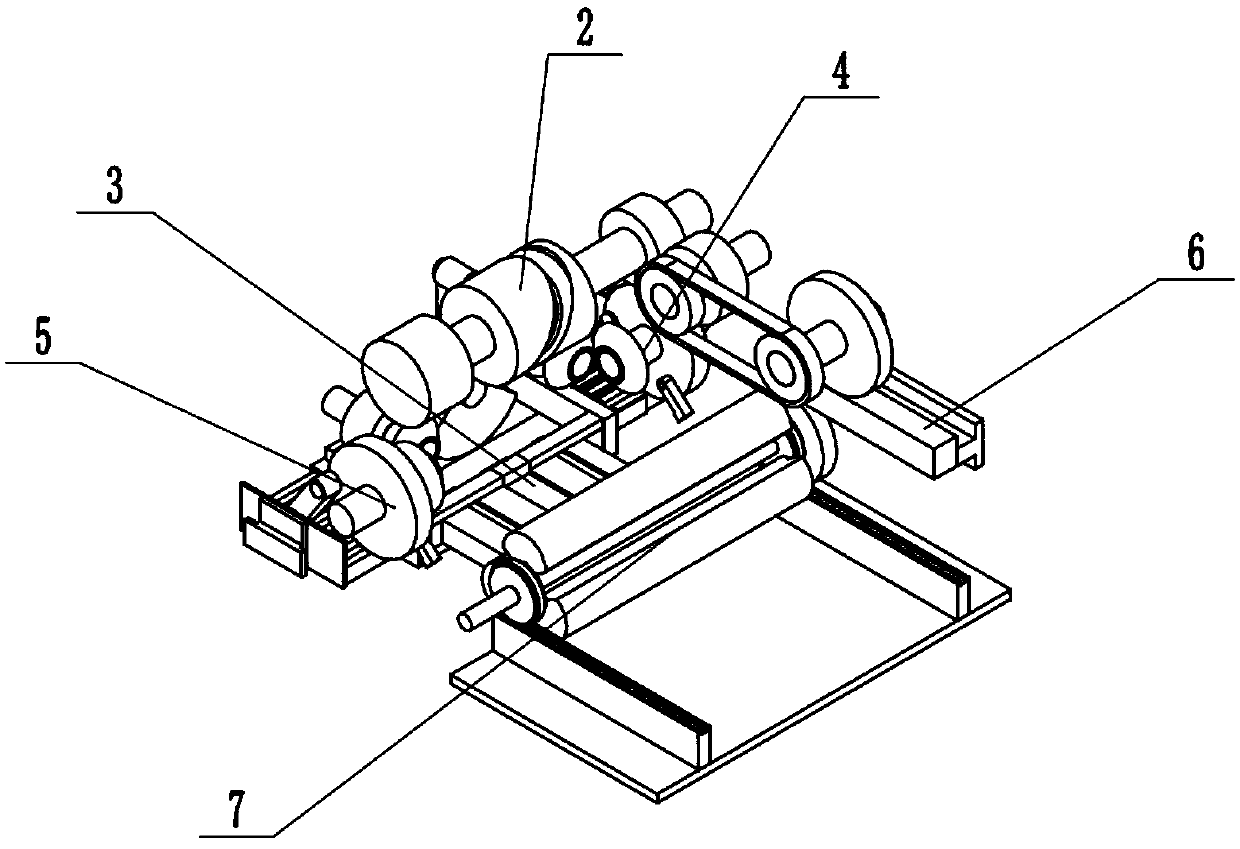

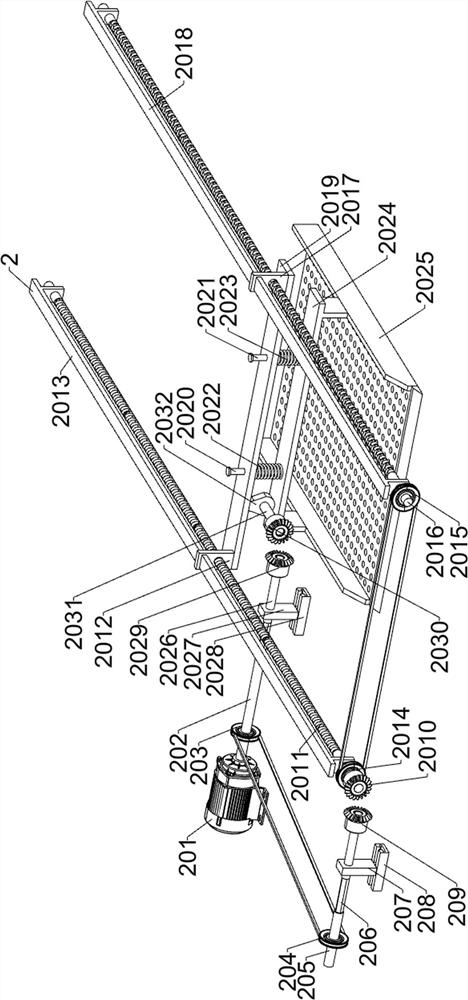

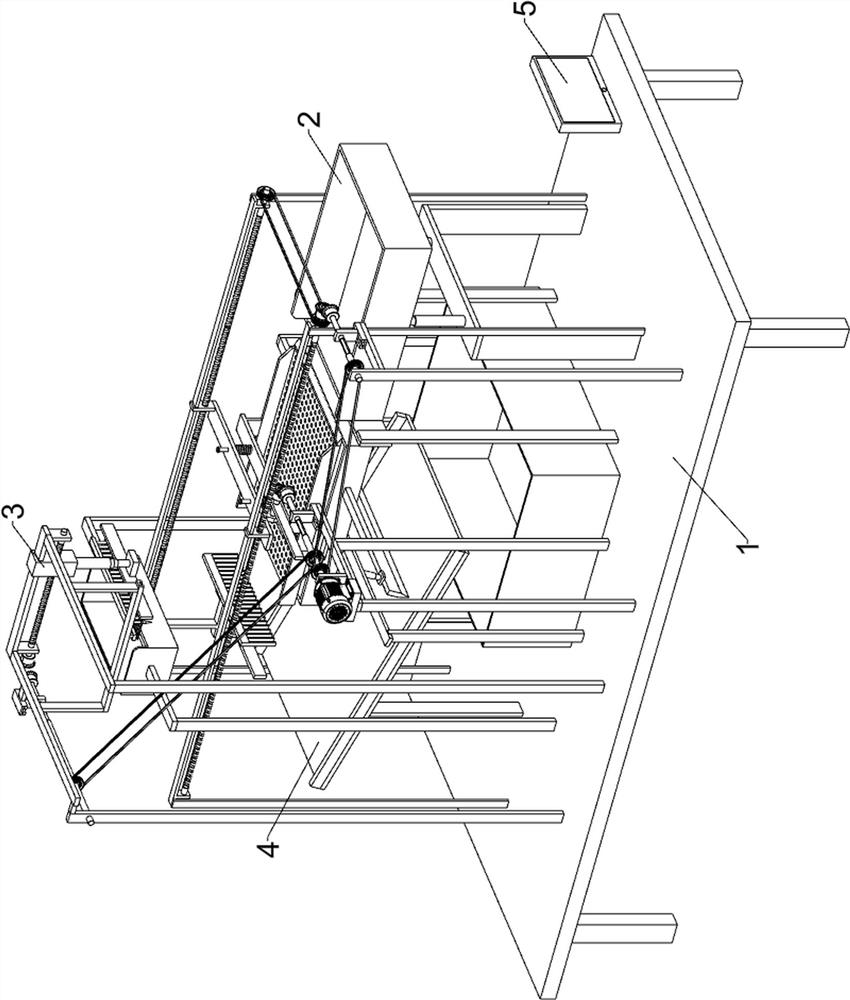

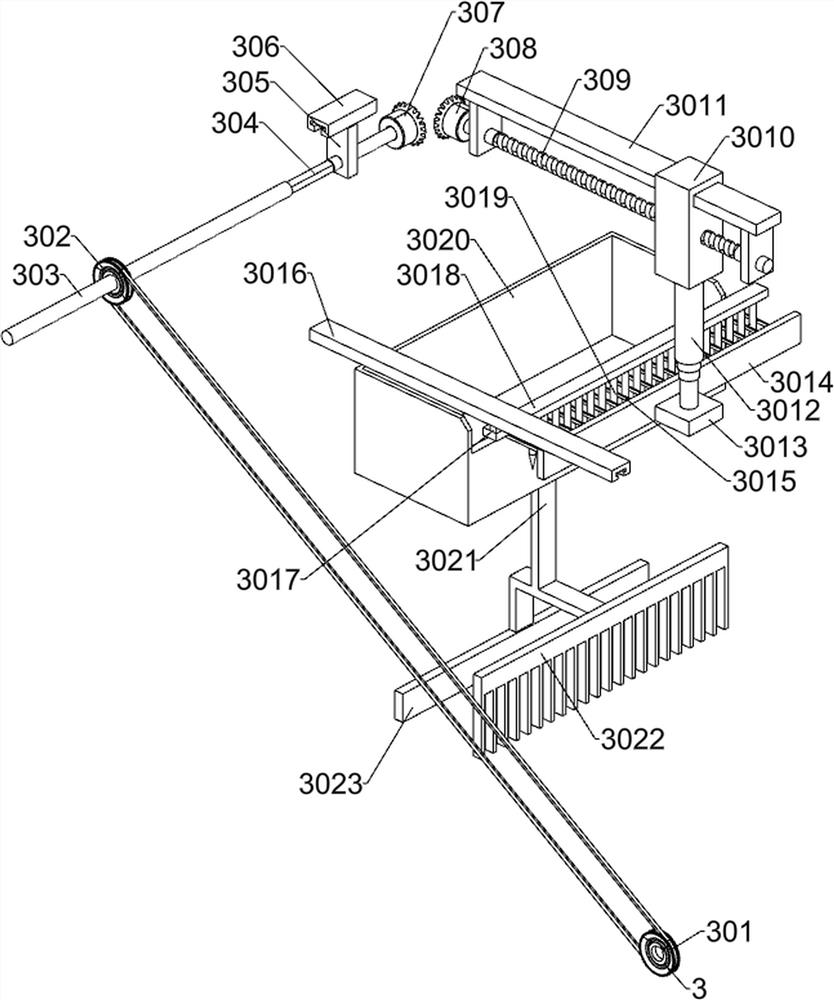

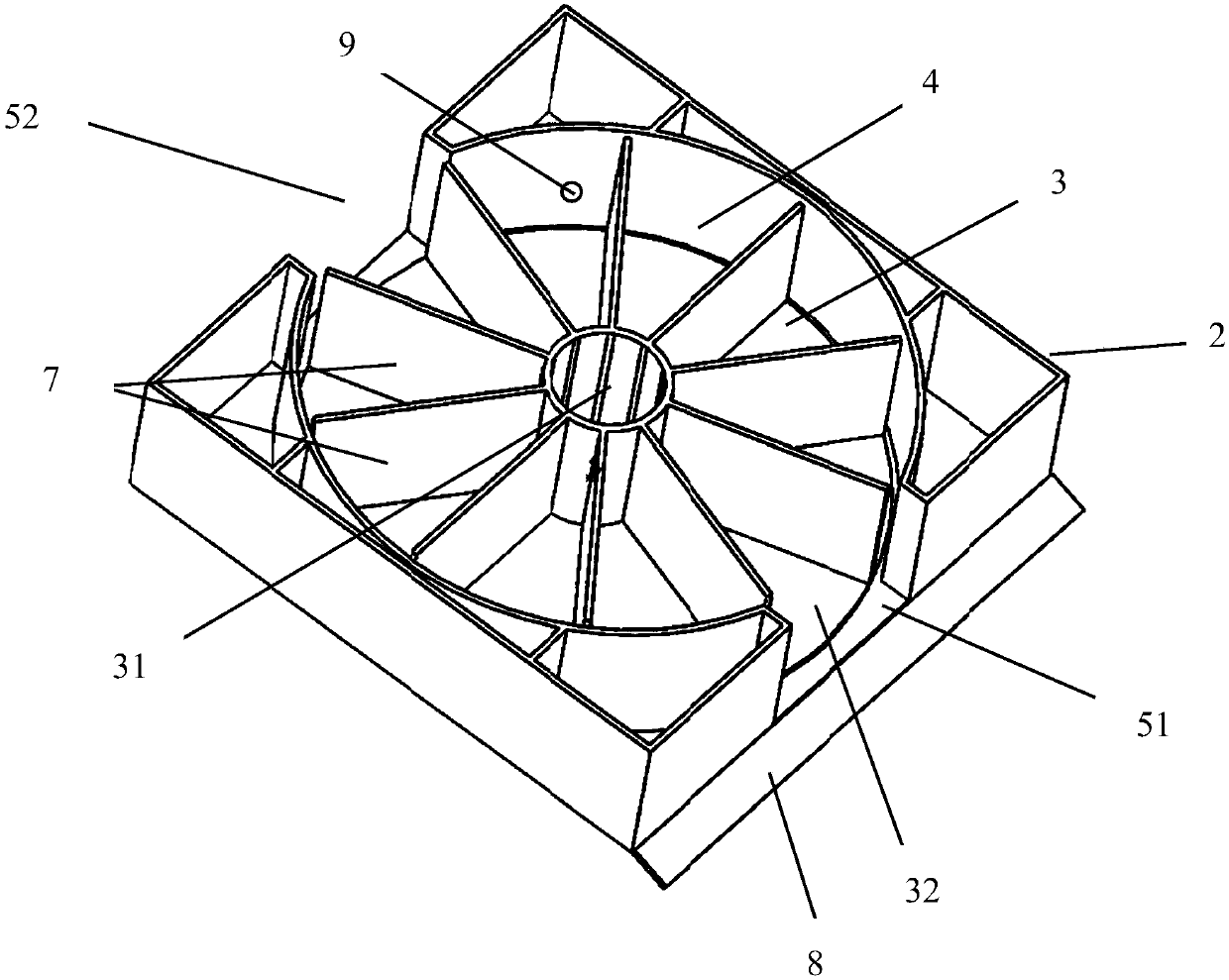

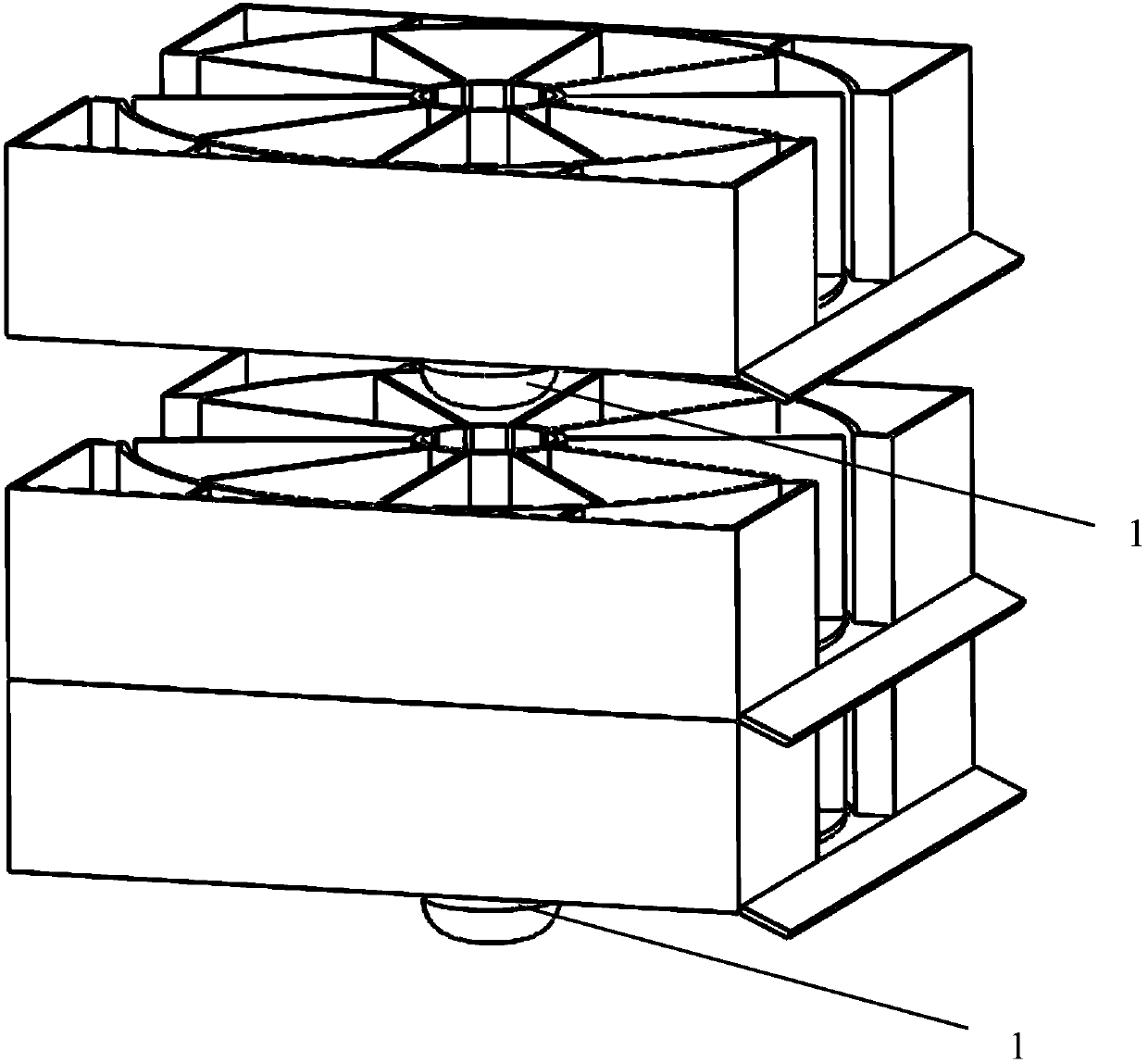

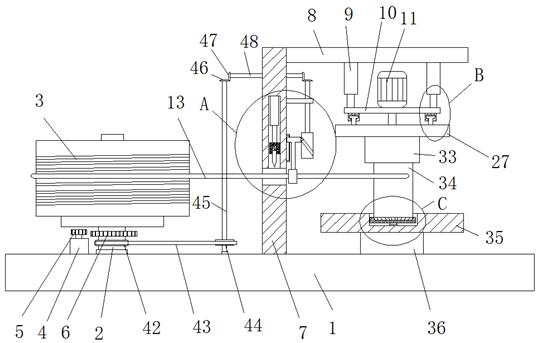

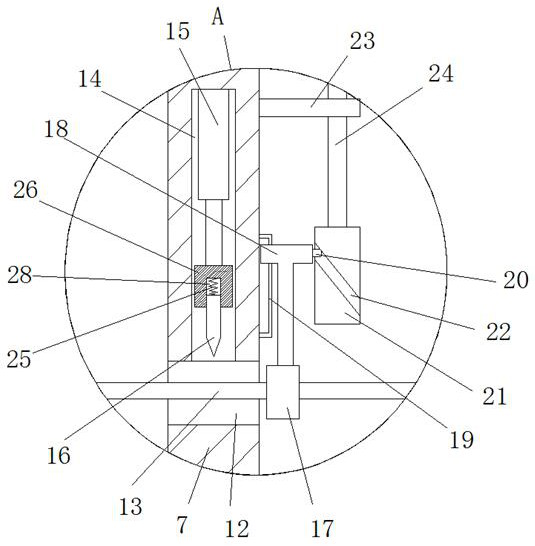

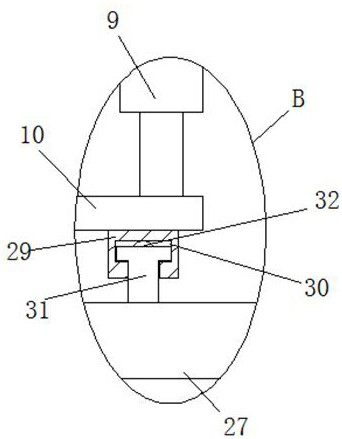

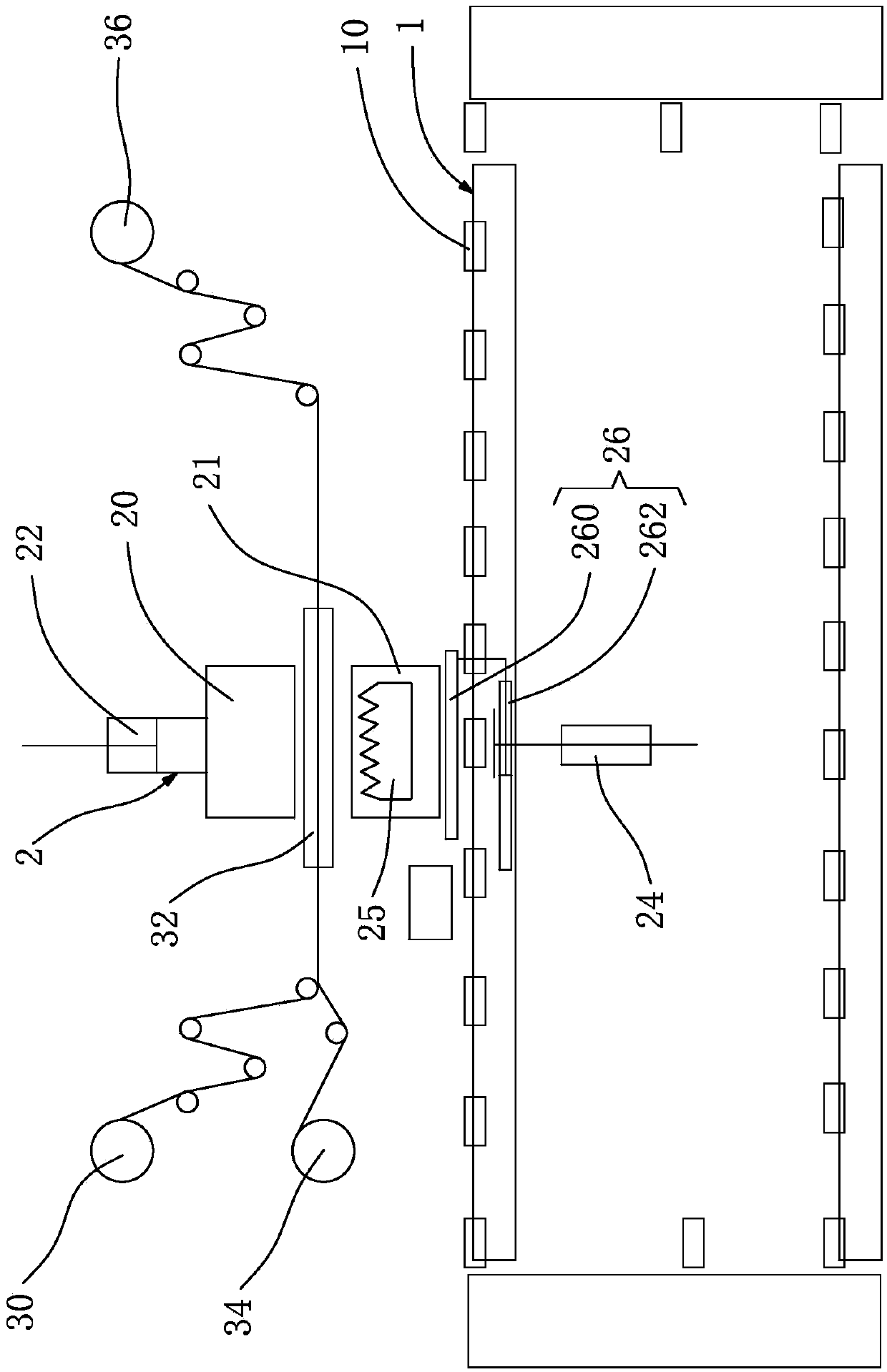

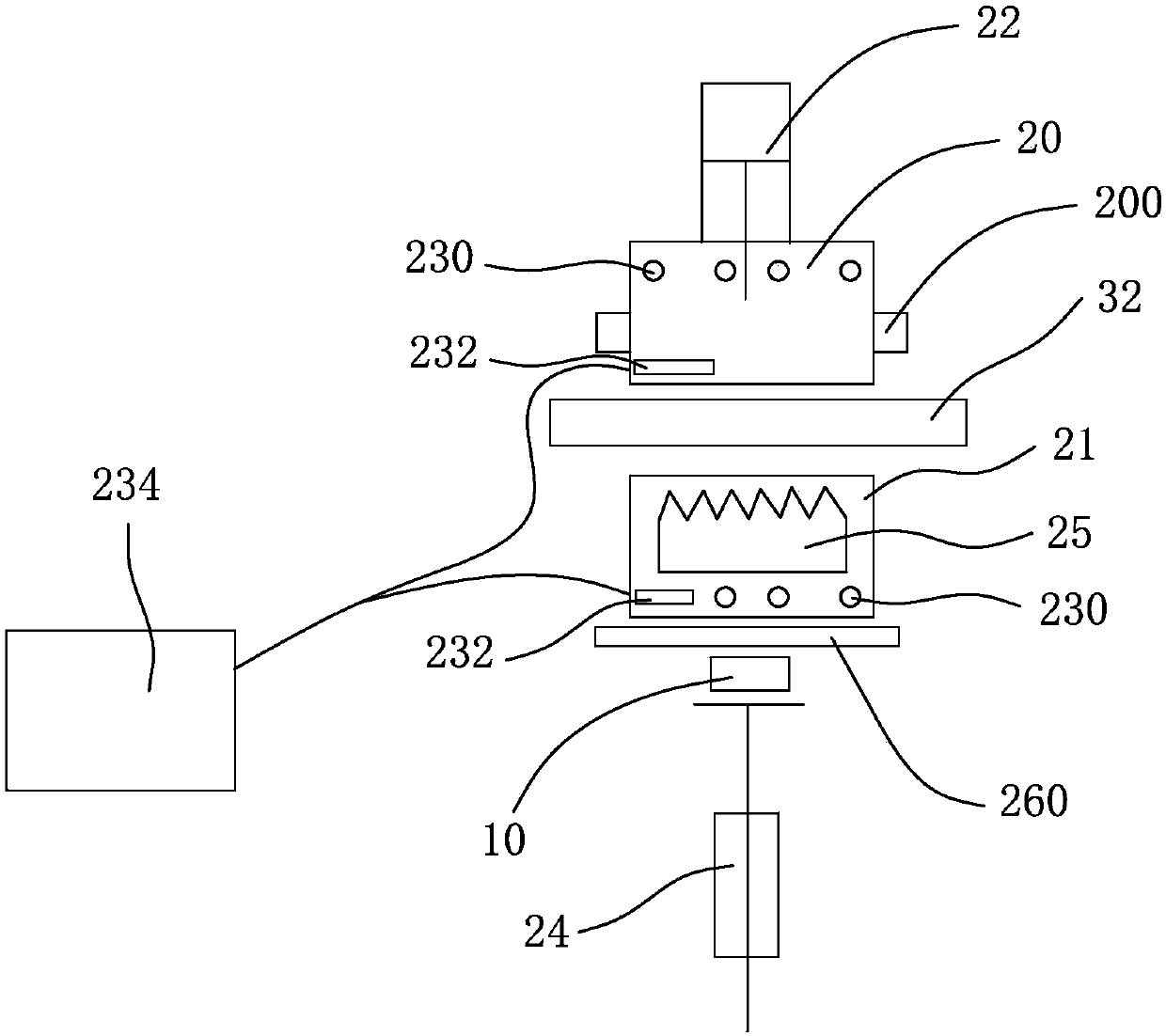

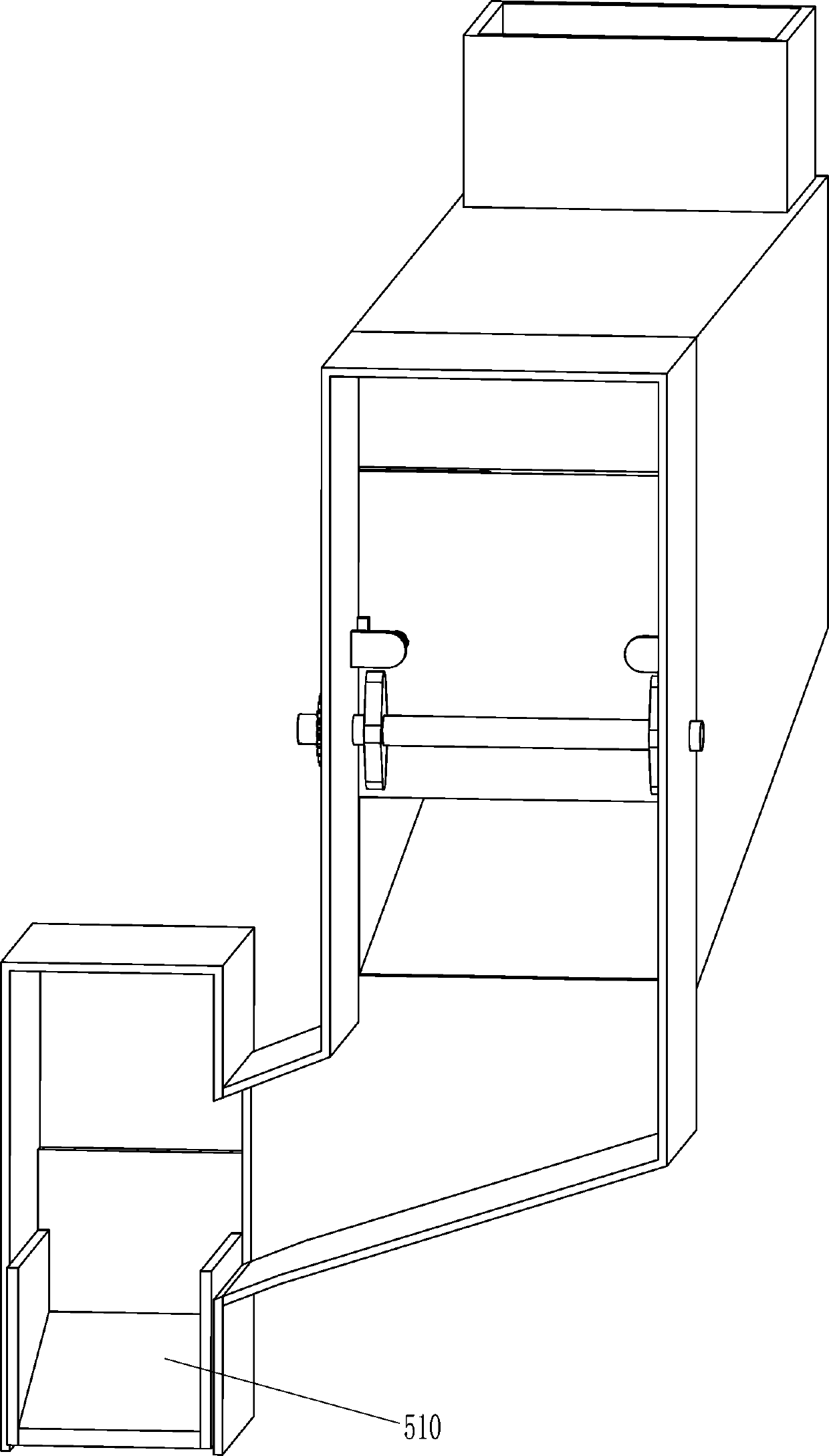

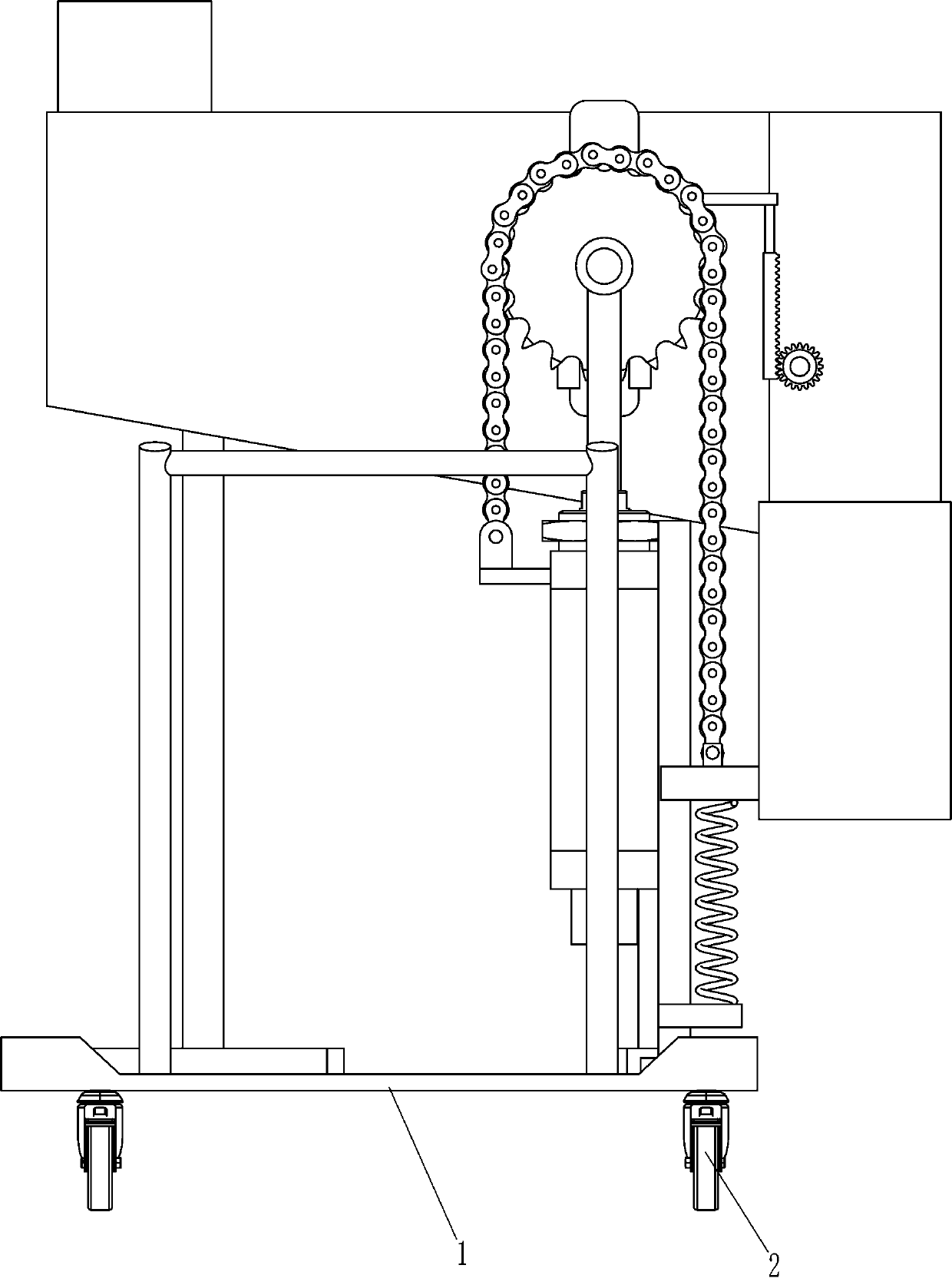

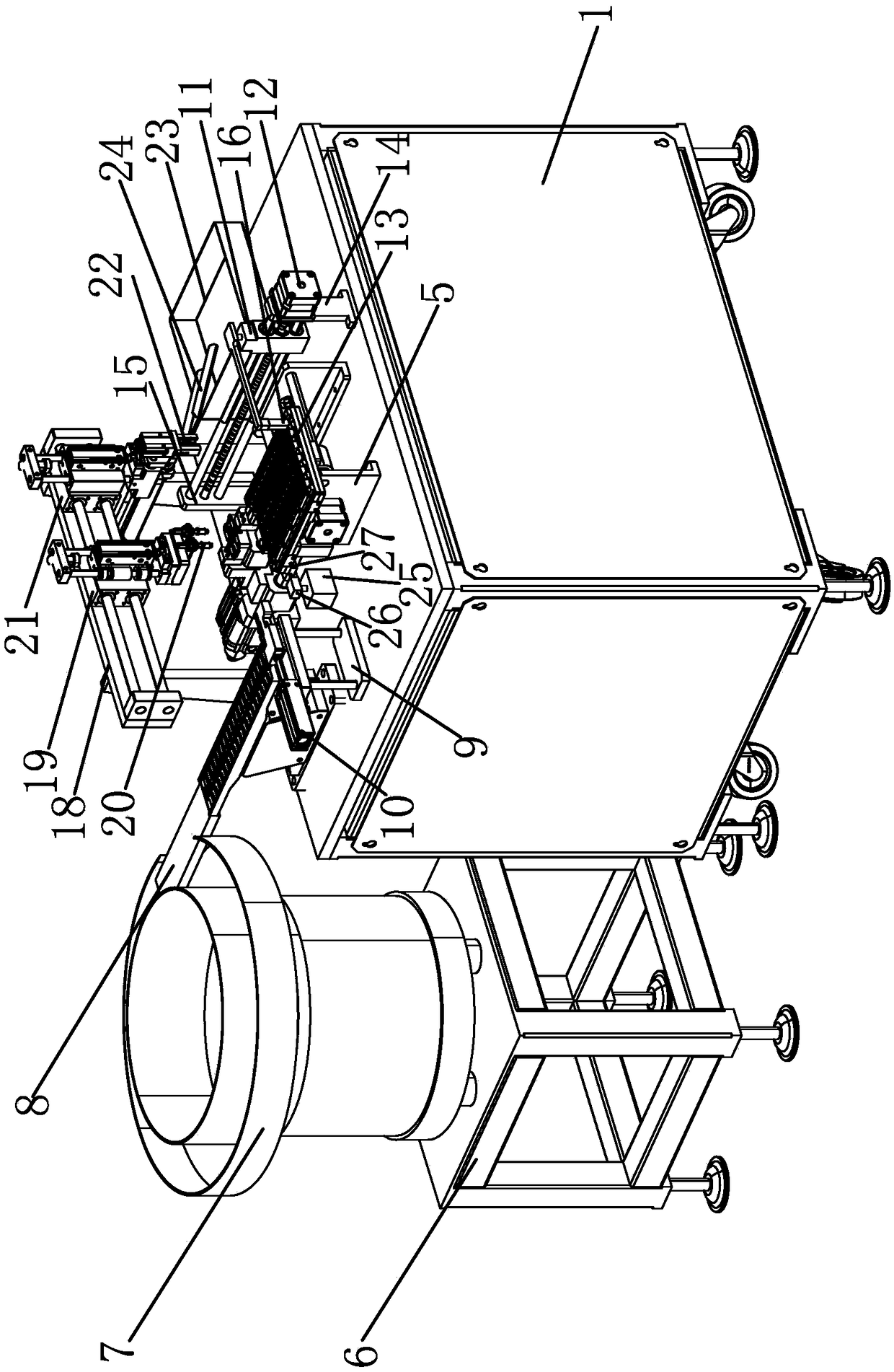

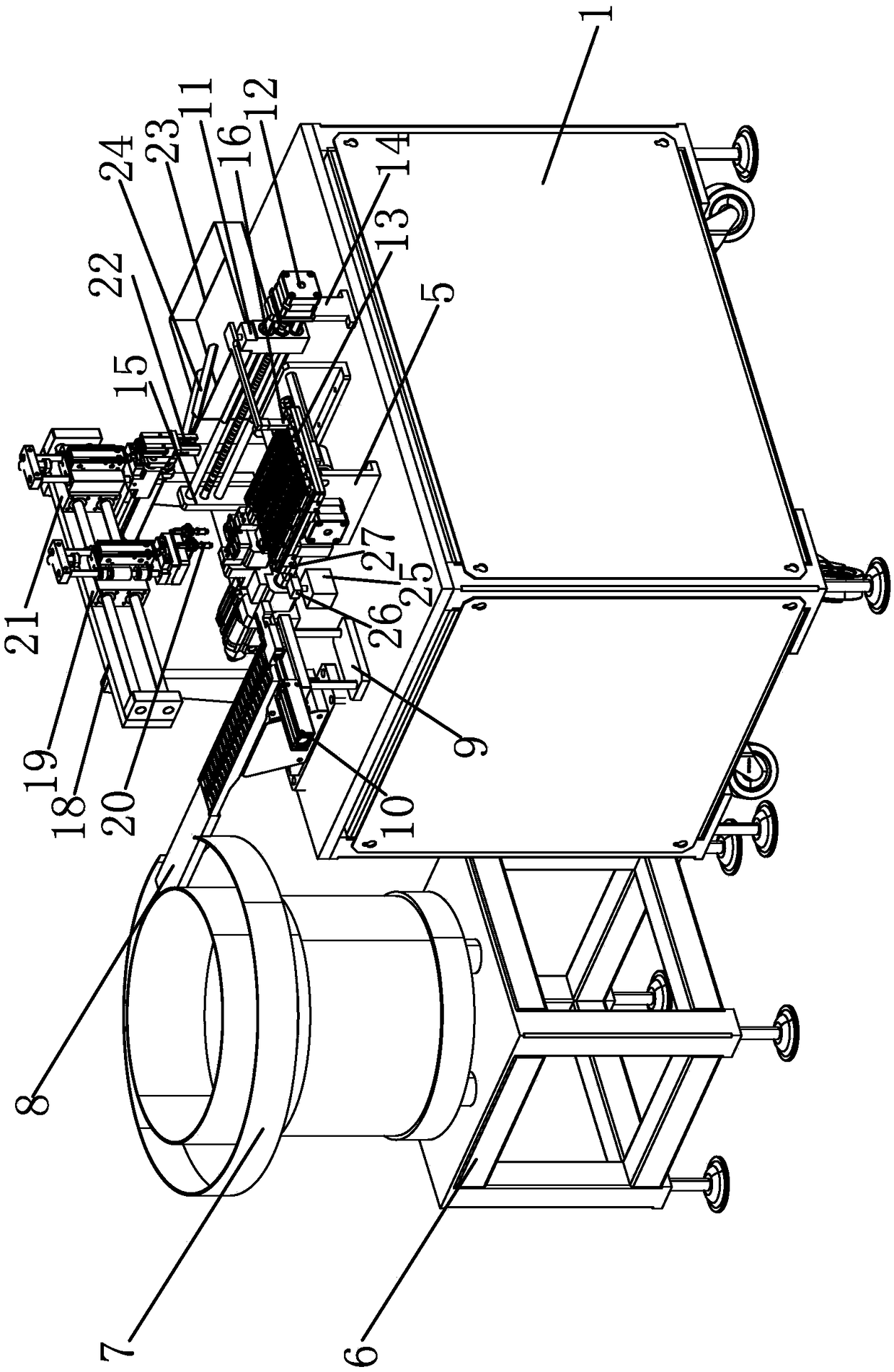

Automatic rectangular tube feeding device

ActiveCN104722831AGuaranteed accuracyImprove overall efficiencyShearing machine accessoriesEngineeringMechanical engineering

The invention discloses an automatic rectangular tube feeding device which comprises a rack, a feeding box, horizontal sorting platforms, at least two sets of material poking devices arranged on the rack, at least two sets of overturning mechanisms arranged on the rack and a horizontal conveying roller set arranged on the rack and used for longitudinally conveying rectangular tubes. Each material poking device set comprises a material poking lifting frame arranged on the rack in a vertically lifting mode. The material poking lifting frames are driven by a material poking lifting power device and arranged on horizontal material poking frames in a horizontally sliding mode. The horizontal material poking frames are driven by a horizontal material poking power device and provided with material poking rods. The overturning mechanisms comprise jacking rods, and the jacking rods are driven by an overturning lifting power device. The horizontal conveying roller set is arranged on the rack. By means of the automatic feeding device, automatic feeding of the rectangular tunes can be achieved, and the rectangular tubes are turned over and conveyed out according to the actual requirements, so that the rectangular tubes can be cut by a downstream process conveniently, rectangular tube cutting is more automated, and overall efficiency is higher.

Owner:SUZHOU KINKALTECK MACHINERY TECH

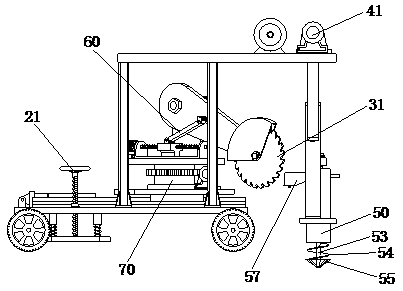

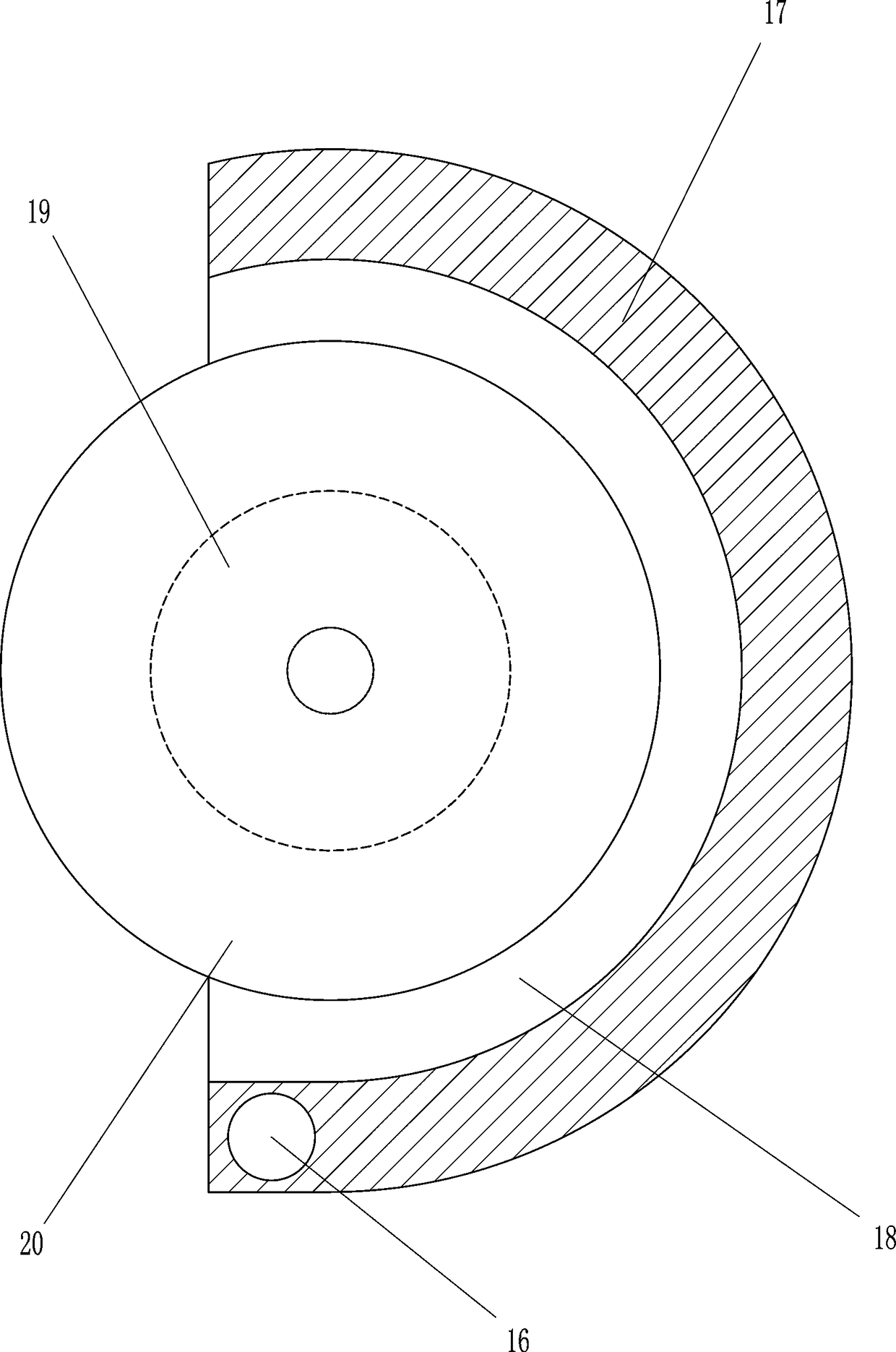

Sampling device for geotechnical exploration

InactiveCN110308010AAutomatic cuttingAutomatic crushing operationWithdrawing sample devicesDrive wheelSpiral blade

The invention discloses a sampling device for geotechnical exploration, and belongs to the technical field of geological exploration equipment. The sampling device comprises a base, a stabilizing mechanism, a rock cutting mechanism and a drilling and sampling mechanism; four driving wheels are arranged at the bottom of the base; a supporting frame is arranged on the top of the base; the drilling and sampling mechanism comprises a lifting assembly, a lifting plate and a drilling and sampling assembly; the drilling and sampling assembly comprises a sampling barrel and a connecting frame; a rotating shaft is arranged on the connecting frame; a spiral blade is arranged on the rotating shaft in a sleeved mode; and a drilling head is arranged at the bottom end of the rotating shaft in a sleevedmode. The sampling device has the beneficial effects that the lifting operation of the drilling and sampling assembly can be realized, and the sample can be conveyed to a material collecting hopper byvirtue of the drilling and sampling mechanism; the automatic cutting assembly can be used for cutting and crushing rock samples; and a rotary assembly can drive the automatic cutting assembly to rotate to a proper position, so that the interference of the automatic cutting assembly on the operation of the drilling and sampling mechanism is avoided.

Owner:胡立宇

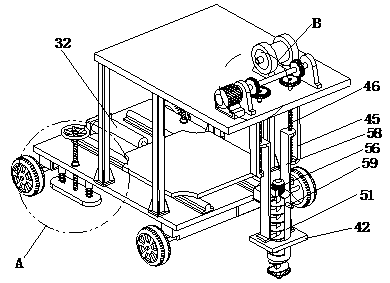

Building cutting device and using method thereof

InactiveCN109262069APrevents affecting cut qualityEasy to adjustWork clamping meansLarge fixed membersHydraulic cylinderEngineering

The invention discloses a building cutting device. The building cutting device comprises a workbench, supporting plates are arranged at the left and right sides of the upper end of the workbench, a top plate is arranged at the upper ends of the supporting plates, a through hole is formed in the top plate, and a first motor is arranged at the left side of the upper end of the top plate; a first rotary shaft is arranged at the output end of the first motor, a driving belt pulley is arranged on the first rotary shaft, a lead screw is arranged at the lower end of the top plate, and a driven belt pulley is arranged on the lead screw; through outstretching and back-drawing of the output end of an air cylinder, an abutting plate is driven to move left and right, and thus materials are clamped toprevent the situation that the materials move in the cutting process and the cutting quality is influenced; through the arrangement of an antiskid rubber pad, the antiskid effect can be achieved; through outstretching and back-drawing of the output end of a second hydraulic cylinder, a placement plate can be driven to slide in a slide groove through a slide block, thus the placement plate moves front and back, and the positions of the materials and a cutting blade are convenient to adjust, so that the cutting process is more automatic; the cutting position is convenient to adjust, the labor ofworkers is reduced, and the working efficiency is improved.

Owner:淮北辰威科技有限公司

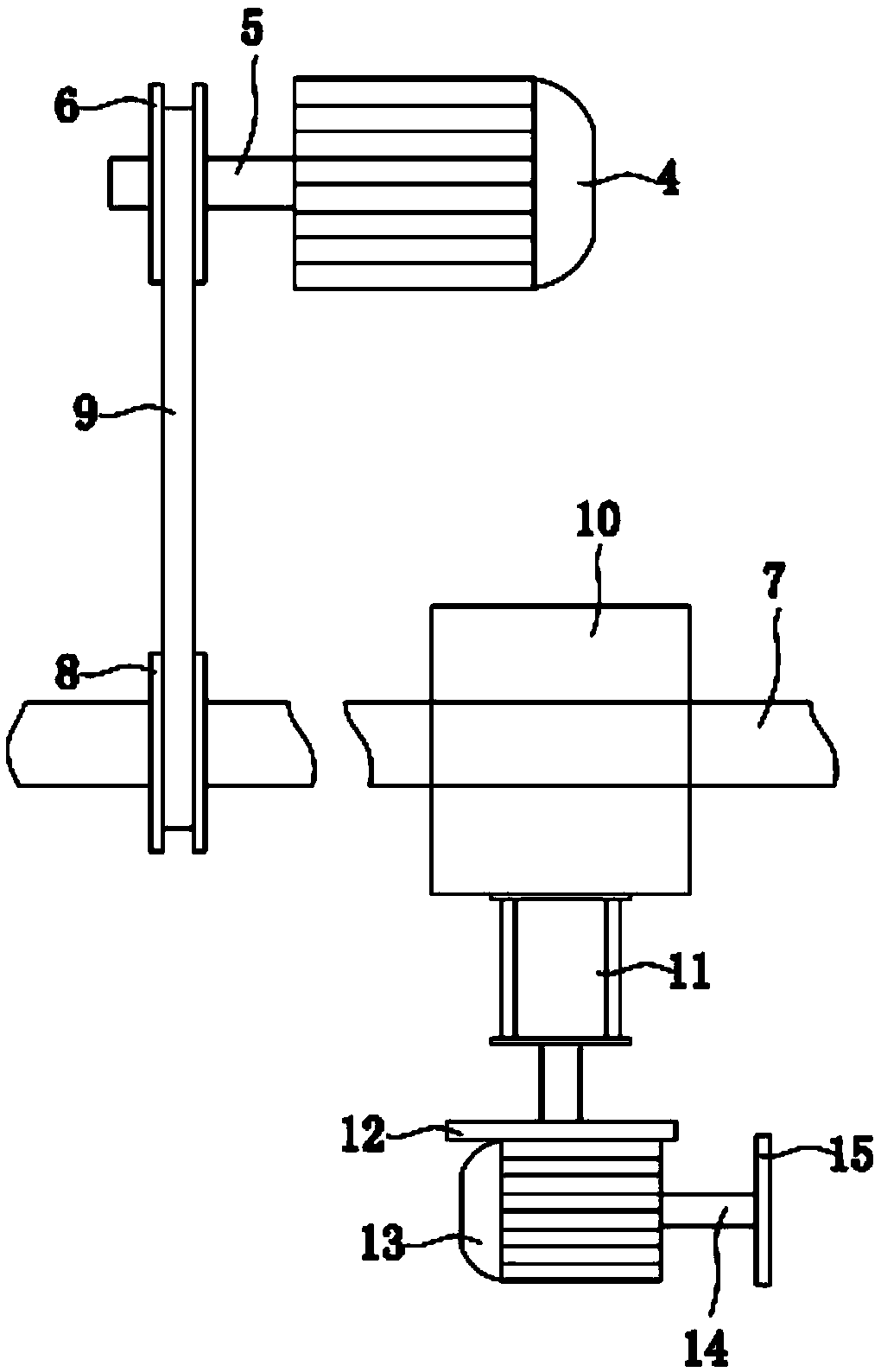

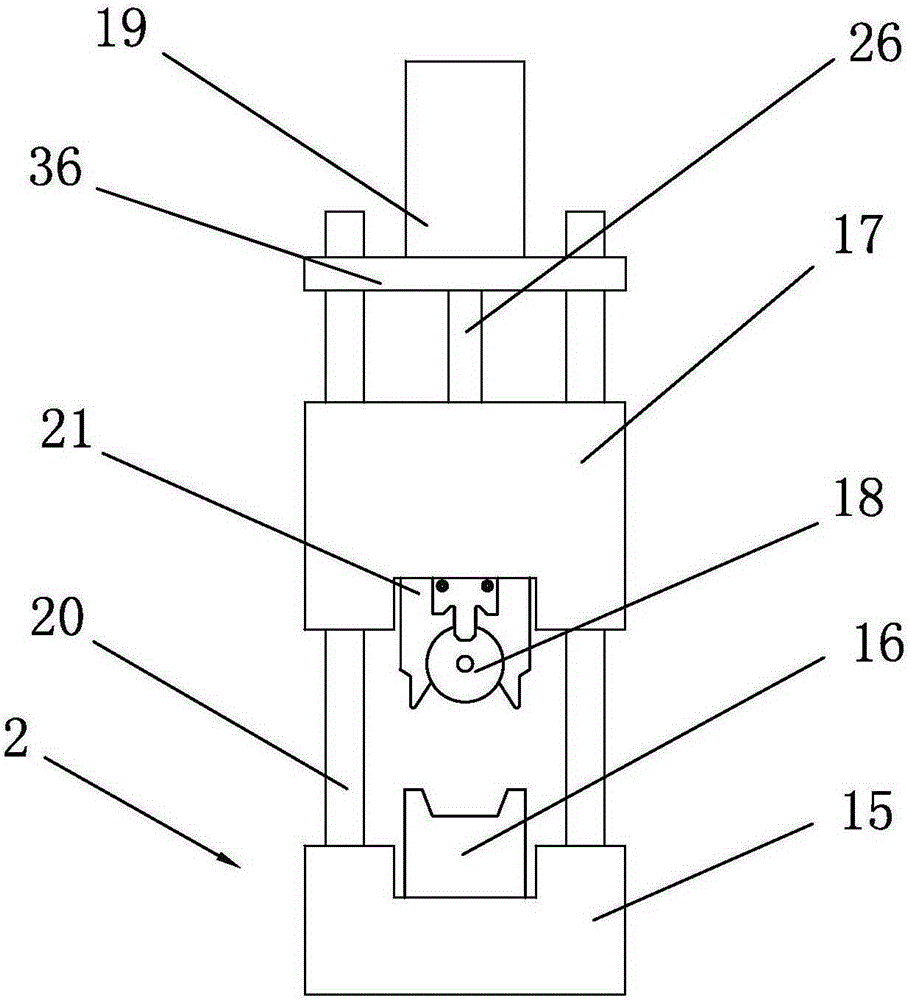

Auto part unloading mechanism

The invention discloses an auto part unloading mechanism. The auto part unloading mechanism comprises a vertically arranged fixed rack. A baffle plate is fixed at the upper portion of the fixed rack; a driving wheel is fixed at the lower portion of the fixed rack; the driving wheel drives a driven wheel to rotate; the driven wheel is composed of a gear I and a cam; the driving wheel drives the gear I to rotate; the gear I drives the cam to rotate; the cam drives a swing arm to swing; a rocker is also hinged to the fixed rack; the swing arm drives the rocker to swing through a connecting rod; a supporting plate is also horizontally arranged on the fixed rack; a rotary shaft is arranged on the right end of the supporting plate; the rocker drives the rotary shaft to drive the supporting plate to reciprocate; the auto part unloading mechanism also comprises a clamping mechanism arranged on the supporting plate. By means of the reciprocating motion of the supporting plate, the clamping mechanism can clamp and unload auto parts automatically. As a special clamping mechanism is adopted, the auto part unloading mechanism can clamp and unload auto parts automatically.

Owner:浙江康意智能科技有限公司

Cutting device applied to production and processing of tubular glass

InactiveCN105271686AEasy to installEasy to fixGlass severing apparatusMechanical engineeringEngineering

The invention discloses a cutting device applied to production and processing of tubular glass. The cutting device comprises a workbench, a clamping device, a sliding component and a cutting component, wherein the workbench comprises a first workbench and a second workbench; the clamping device comprises clamping blocks and clamping air cylinders; the sliding component comprises a support frame, a sliding bar and a sliding block; and the cutting component comprises a fixing block, a bracket, a moving block, a cutting knife and a telescopic air cylinder. The cutting device is simple in structure and strong in practicability; with the design of the clamping device, the tubular glass is more convenient and simpler to fix and clamp; the cutting stability of the tubular glass is improved; a cut surface after cutting is smoother; then, with the design of the sliding block component and the cutting component, the tubular glass is cut more automatically; furthermore, the position of the cutting knife can be adjusted by the sliding block component and the cutting component, so that the cutting device is applicable to cutting the tubular glass with different diameters; the application scope of the cutting device is enlarged; and the comprehensive utilization efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

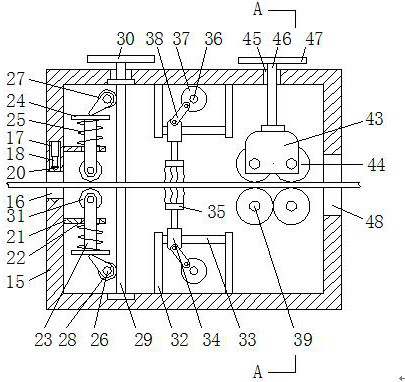

Spinning machine discharging mechanism with tailoring structure

ActiveCN111648009AReduced chance of wrinklingImprove applicabilityMechanical cleaningPressure cleaningTextile technologySpinning

The invention relates to the technical field of spinning, in particular to a spinning machine discharging mechanism with a tailoring structure. A base is included. The upper end of the base is sequentially fixedly connected with two support columns, a tensioning device, a first framework, a conveying device and a box from left to right. The upper portion and the lower portion of the left side of the inner wall of the box are symmetrically fixedly connected with second connecting plates. The second connecting plates are provided with through grooves. Movable rods are movably connected in the through grooves. The opposite sides of the two movable rods are fixedly connected with movable plates. Rotation shafts are symmetrically and rotationally connected between the left portions of the frontside and the rear side of the inner wall of the box. Worm gears are fixedly in cup joint to the rear sides of the outer portions of the rotation shafts. Worms engaged with the worm gears are rotationally connected between the upper end and the lower end of the inner wall of the box. By means of the spinning machine discharging mechanism, wrinkles of cloth in the conveying process can be avoided,dust on the cloth is removed, practicability and functionality of the device are greatly improved, and the spinning machine discharging mechanism is worthy of popularization and usage.

Owner:嘉兴如运建筑科技有限公司

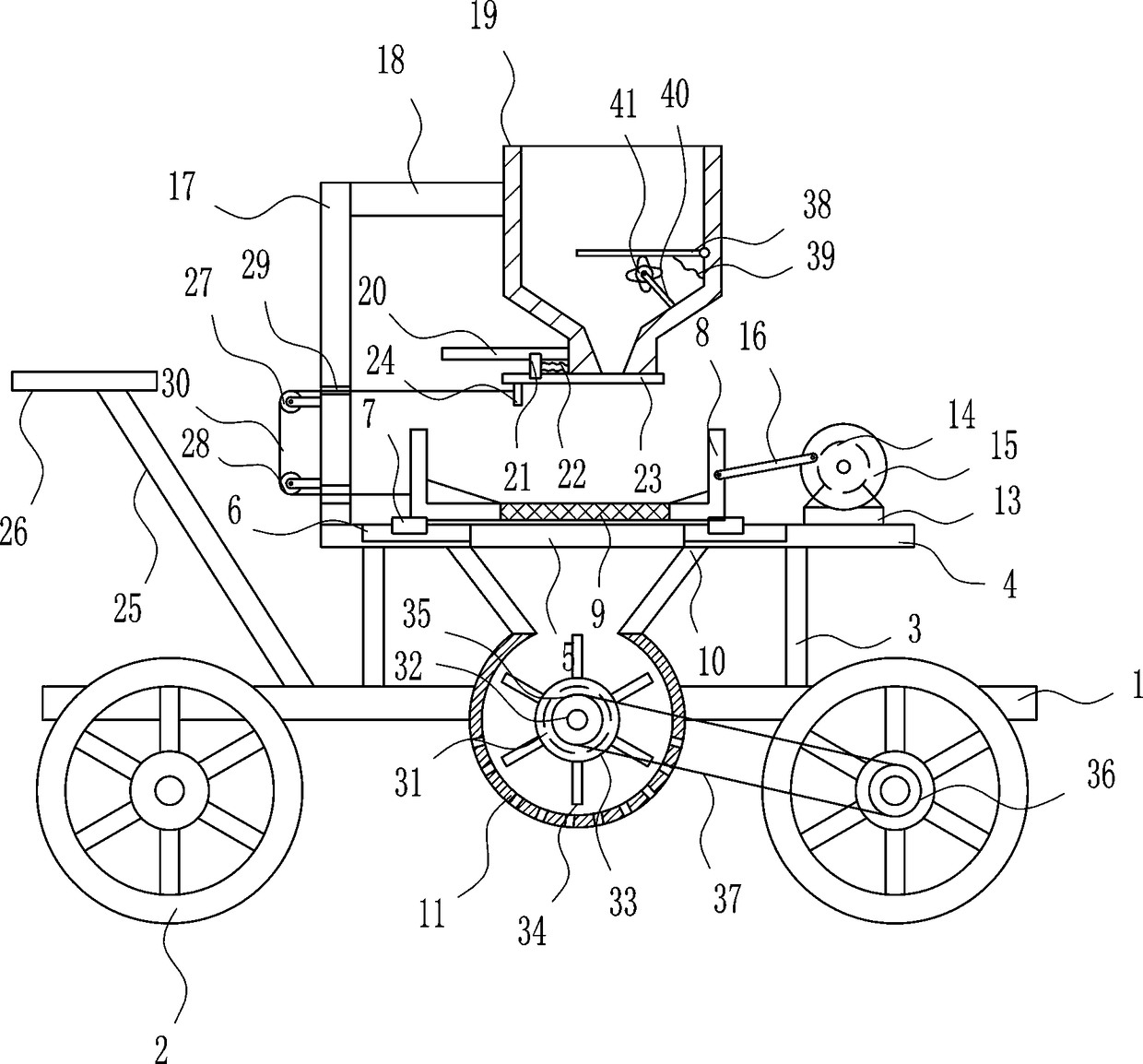

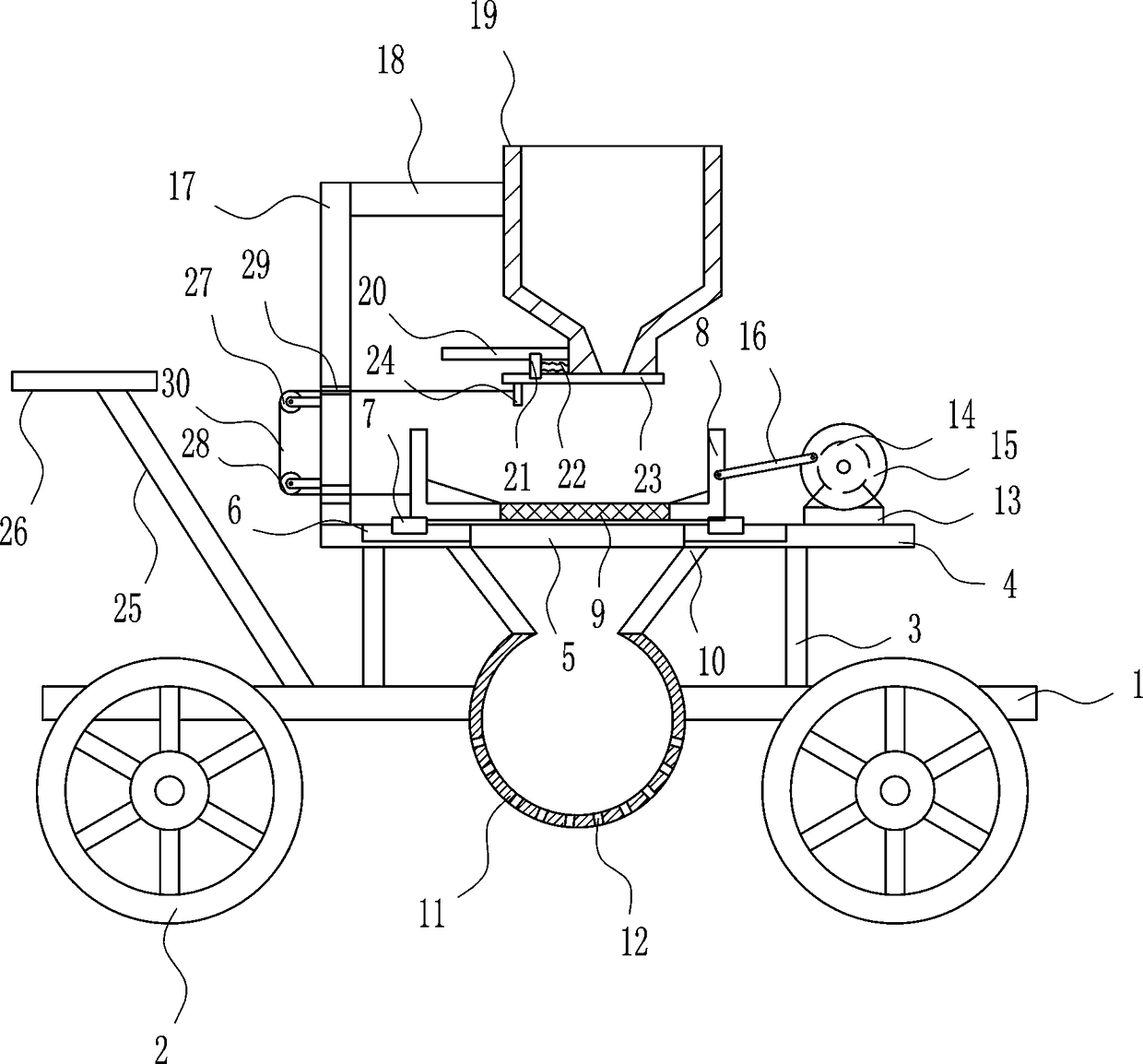

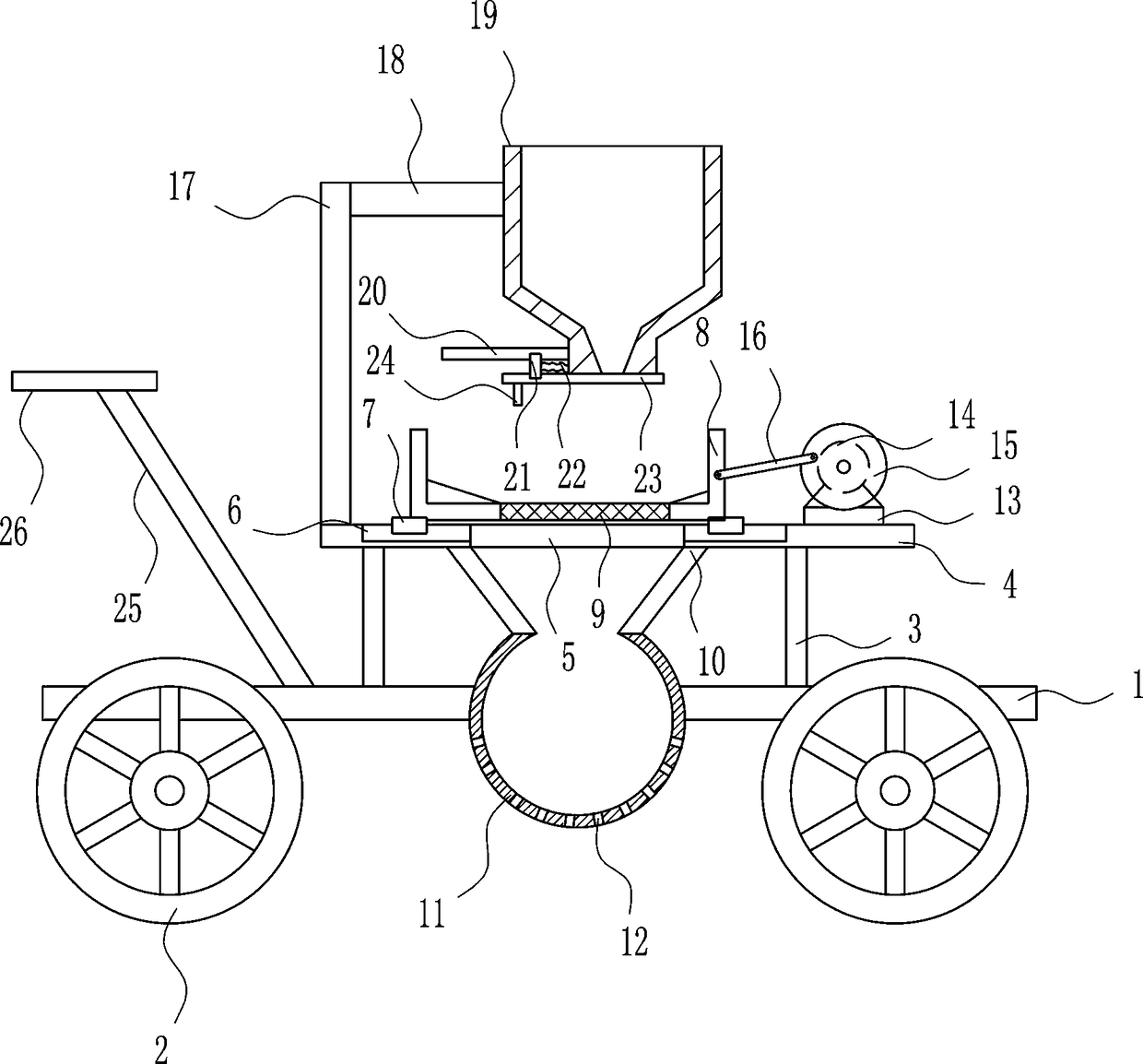

Efficient powder spreading equipment for road construction

ActiveCN108487000AAutomatic cuttingShorten the timeRoads maintainenceArchitectural engineeringRoad construction

The invention relates to efficient powder spreading equipment for construction, in particular to efficient powder spreading equipment for road construction. According to the efficient powder spreadingequipment for road construction, the construction quality can be ensured, the working conditions are improved, and the working efficiency is improved. The efficient powder spreading equipment for road construction comprises a bottom plate, wheels, first brackets, a mounting plate, a first sliding rail, a first sliding block, a screening box, a net plate, a material falling hopper, a material dividing barrel, a first mounting seat, a rotating motor and the like; and the wheels are symmetrically arranged at the bottom of the bottom plate, the first brackets are symmetrically arranged on the topof the bottom plate, and the mounting plate is arranged at the top ends of the first brackets. According to the efficient powder spreading equipment for road construction, a baffle is driven to movethrough a first fixed pulley, a second fixed pulley and a pulling line under working of the rotating motor, thus, the safety of the equipment is greatly improved, a lot of time is saved, and the working efficiency is improved.

Owner:广西现代路桥工程有限责任公司

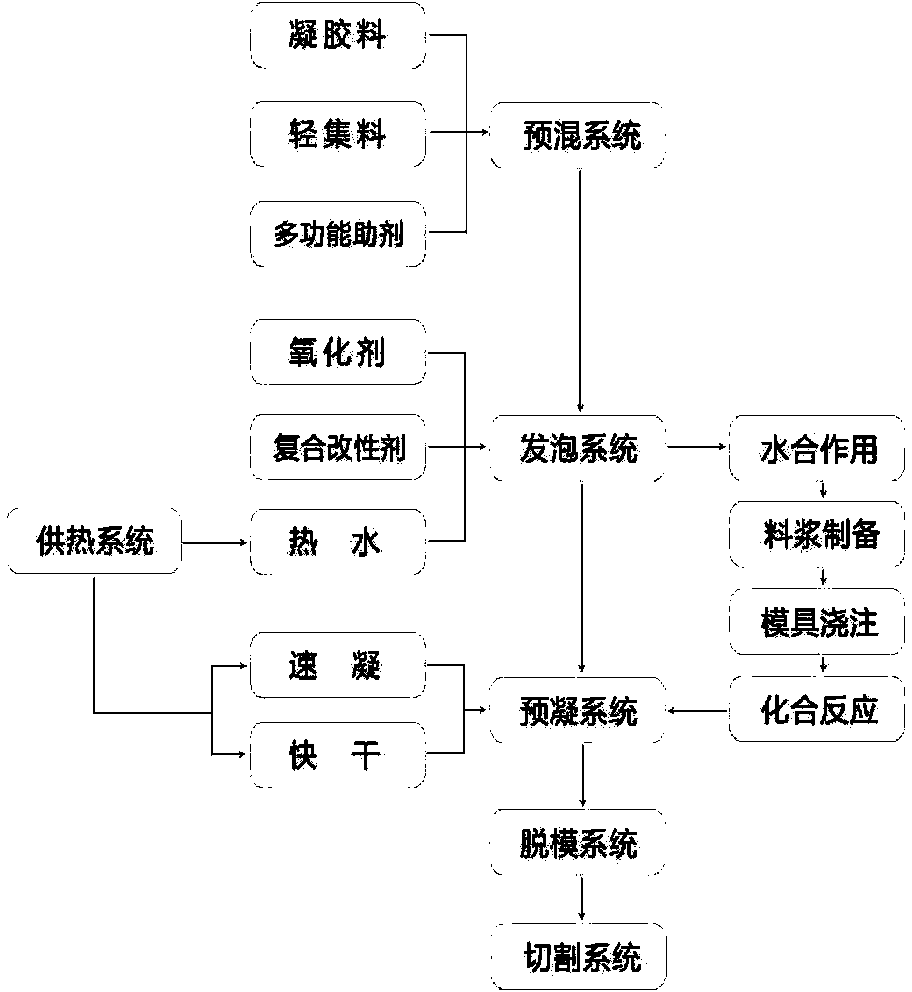

Process for preparing composite foamed cement

ActiveCN104193385AHigh degree of automationStrong capacityCeramicwareProcess engineeringManufacturing engineering

The invention discloses a process for preparing composite foamed cement. The process comprises the following steps: premixing, namely, uniformly mixing a gel material, lightweight aggregate and a multifunctional additive, subsequently preparing the above components into premix, and storing the premix in a storage tank for later use; foaming, namely, feeding the premixed premix and hot water into a stirring tank, stirring for 5 minutes, sequentially adding a composite modifier and an oxidant into the stirring tank, and continuously stirring for 5 minutes, thereby obtaining slurry; pre-coagulating, namely, filling the foamed slurry into a mold box of a pre-coagulating kiln, simultaneously supplying hot water into the pre-coagulating kiln continuously so as to foam and expand the slurry inside the mold box, thereby preparing the composite foamed cement, and standing the composite foamed cement in the mold box for 6-8 minutes, thereby forming a composite foamed cement initial set object; and demolding and cutting, namely, demolding and cutting the pre-coagulated composite foamed cement initial set object into a plate material, thereby preparing the formed composite foamed cement. The composite foamed cement prepared by using the process is high in mechanical strength, free of foaming, high in foaming strength, rapid to coagulate and dry, short in demolding time and free of maintenance period, can save the space, the energy, the labor and the time, and can be cut in a wet manner.

Owner:HUBEI KAILIFENG GREEN BUILDING MATERIALS DEV CO LTD

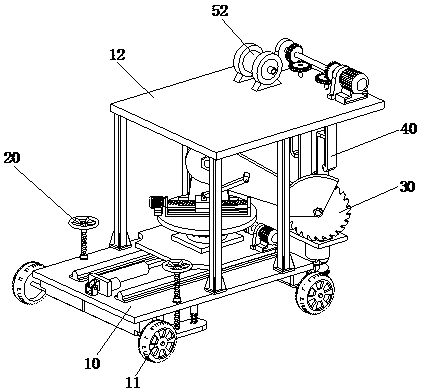

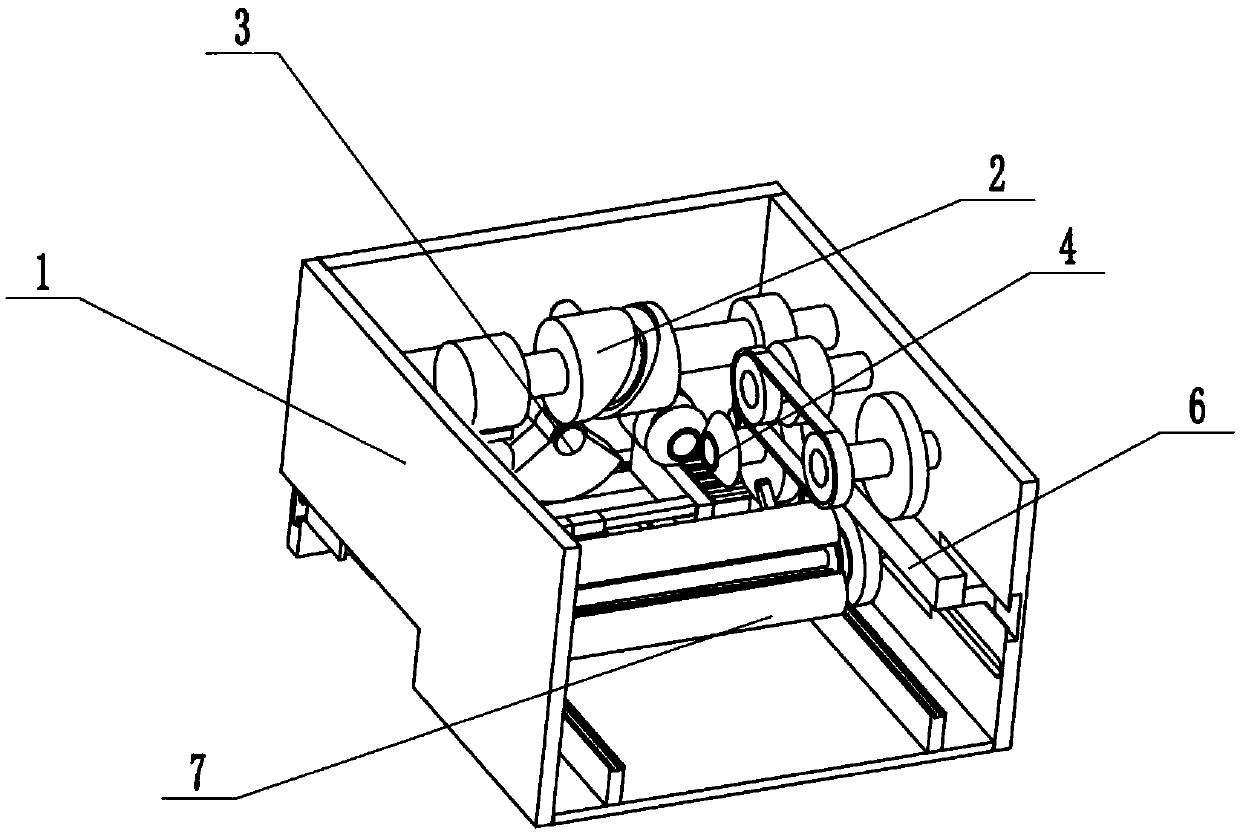

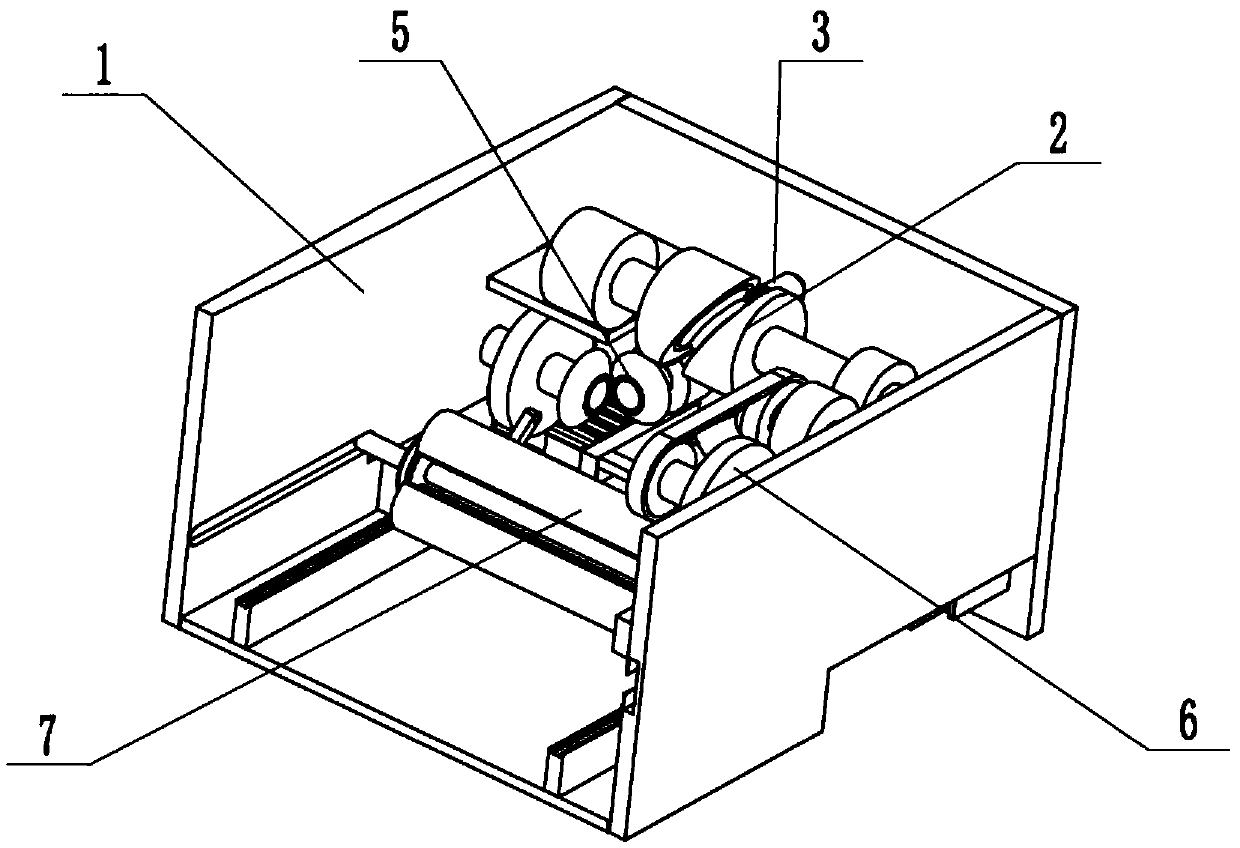

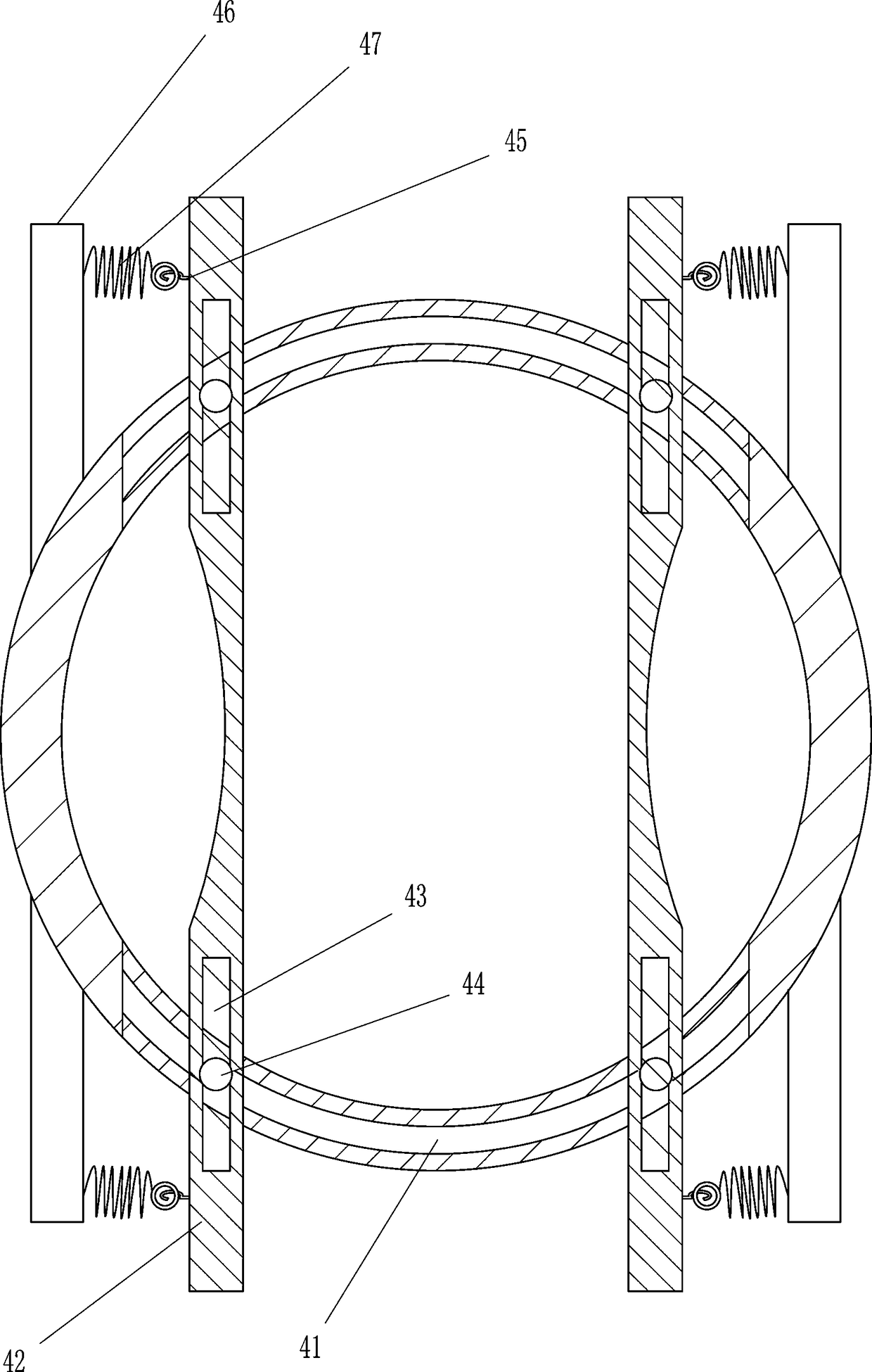

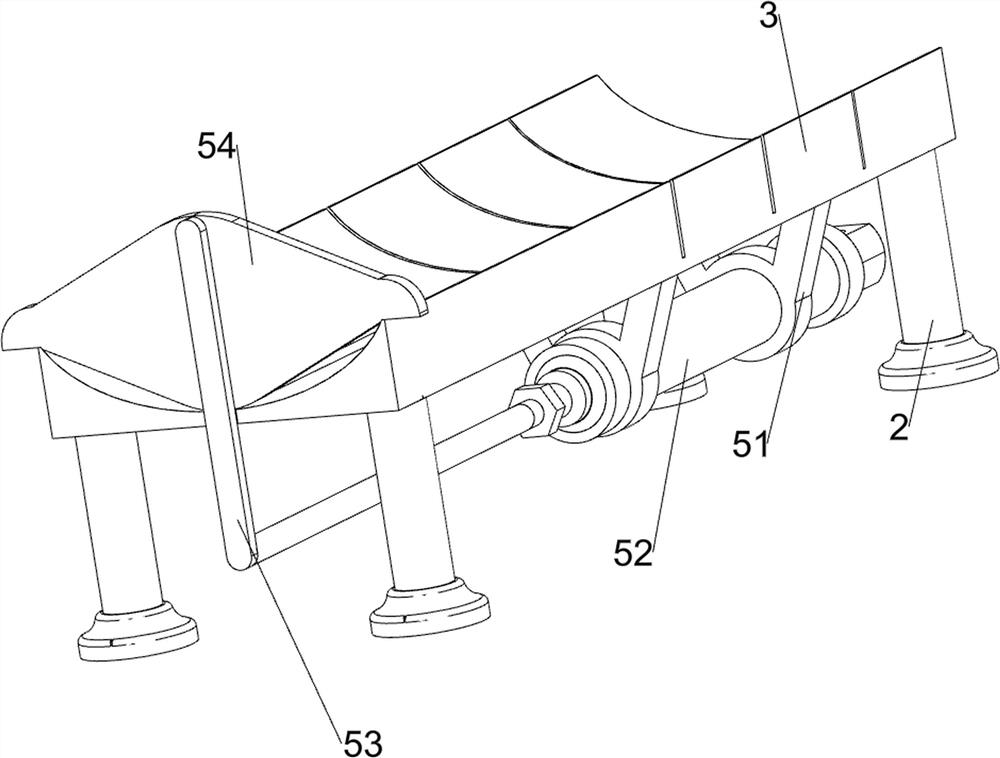

Industrial automatic slitting device for batch potato powder

The invention relates to the field of potato powder cutting, in particular to an industrial automatic slitting device for batch potato powder. The device comprises a bracket support, a driver, an intermittent propulsion cutter, a right pushing tightening device, a left pushing tightening device, a clamping propeller and a clamp, wherein the driver is fixedly connected to the bracket support, the upper end of the intermittent propulsion cutter is connected to the interior of the driver in a sliding manner, and the lower end of the intermittent propulsion cutter is connected to the rear end of the inner wall of the bracket support in a sliding manner; the right pushing tightening device and the left pushing tightening device are respectively connected to the left end and the right end of theinner wall of the bracket support in a sliding manner; and the clamping propeller is meshed with the driver in a transmission manner. The device has the beneficial effects that the tiled potato powder produced by a traditional production process can be automatically and rapidly cut into specified strips, manpower is saved through the safe, hygienic and rapid cutting, and application is convenient.

Owner:CHANGSHA CHUANGHONG AGRI TECH DEV

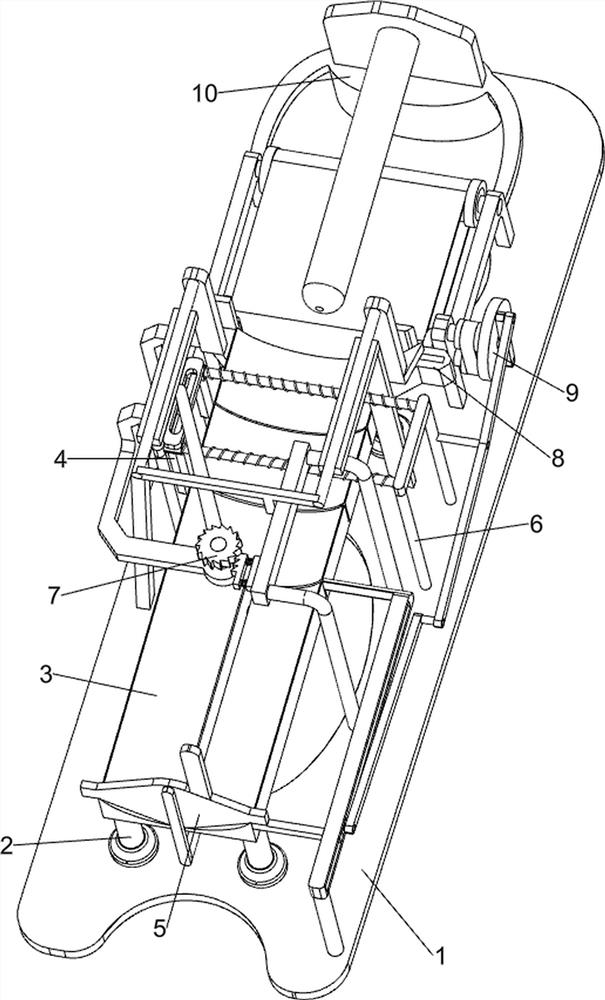

Pine needle treatment device capable of removing dead leaves

InactiveCN112715320AAutomatic cuttingAchieve removalSievingScreeningEngineeringMechanical engineering

The invention relates to the field of flowers, in particular to a pine needle treatment device capable of removing dead leaves. The technical problem is to provide the pine needle treatment device capable of removing dead leaves. According to the technical scheme, the pine needle treatment device capable of removing dead leaves comprises a bottom frame, a stone removing assembly, a dead leaf removing assembly, a cutting assembly and a control screen, wherein the bottom frame is connected with the stone removing assembly; the bottom frame is connected with the dead leaf removing assembly; the bottom frame is connected with the cutting assembly; the upper part of the bottom frame is connected with the control screen; and the stone removing assembly is connected with the dead leaf removing assembly. When the pine needle treatment device is used, a pile of pine needles are automatically treated in batches, the treatment effect and efficiency are greatly improved, meanwhile, stones in the pine needles are automatically removed through vibration, then dead leaves in the pine needles are removed, the separated dead leaves are screened again, residual pine needles are separated out, and the pine needles can be automatically cut into small sections.

Owner:张改凡

Rubber seal ring vulcanizing machine

ActiveCN111438857AImprove processing efficiencyAutomatic cuttingDomestic articlesVulcanizationEngineering

The invention discloses a rubber seal ring vulcanizing machine, and relates to the technical field of seal ring machining. According to the technical scheme, the rubber seal ring vulcanizing machine comprises a vulcanizing machine body, the vulcanizing machine body is provided with an upper heating flat plate, a lower heating flat plate, a hydraulic mechanism and a main vulcanizing box mold, the main vulcanizing box mold comprises an upper mold and a lower mold, the vulcanizing machine body is provided with a mold pushing device, the vulcanizing machine body is provided with a mold opening rail, the vulcanizing machine body comprises a sliding base, the sliding base is provided with a secondary vulcanizing box mold, lower molds of the main vulcanizing box mold and the secondary vulcanizingbox mold are provided with embedding grooves and limiting devices, the sliding base is provided with an upper table and a lower table, the lower table is provided with a discharging air cylinder, anejecting-out part is slidingly mounted in the lower mold, through a pushing air cylinder, and the mold opening guide rail, the vulcanizing machine can achieve automatic mold opening, machining efficiency of the vulcanizing machine can be improved, through the sliding base and the secondary vulcanizing box mold, the machining efficiency of the vulcanizing machine can be further improved, through the discharging air cylinder and the ejecting-out part, the vulcanizing machine can achieve automatic discharging, and convenience is achieved.

Owner:台州市杰剑华塑胶有限公司

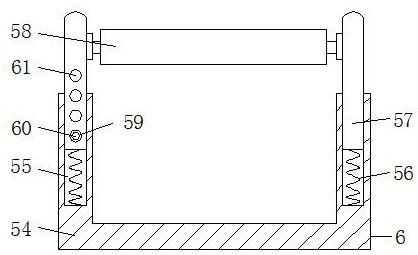

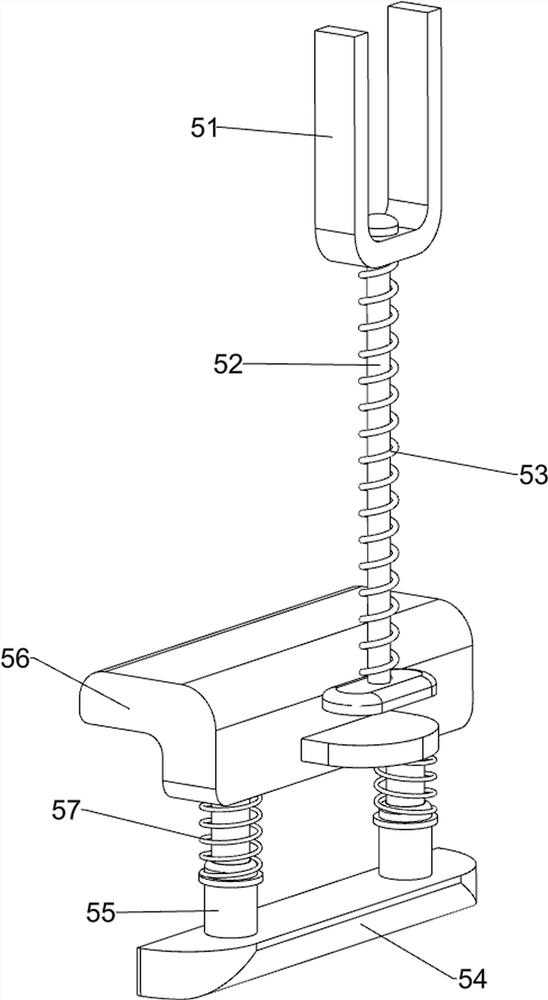

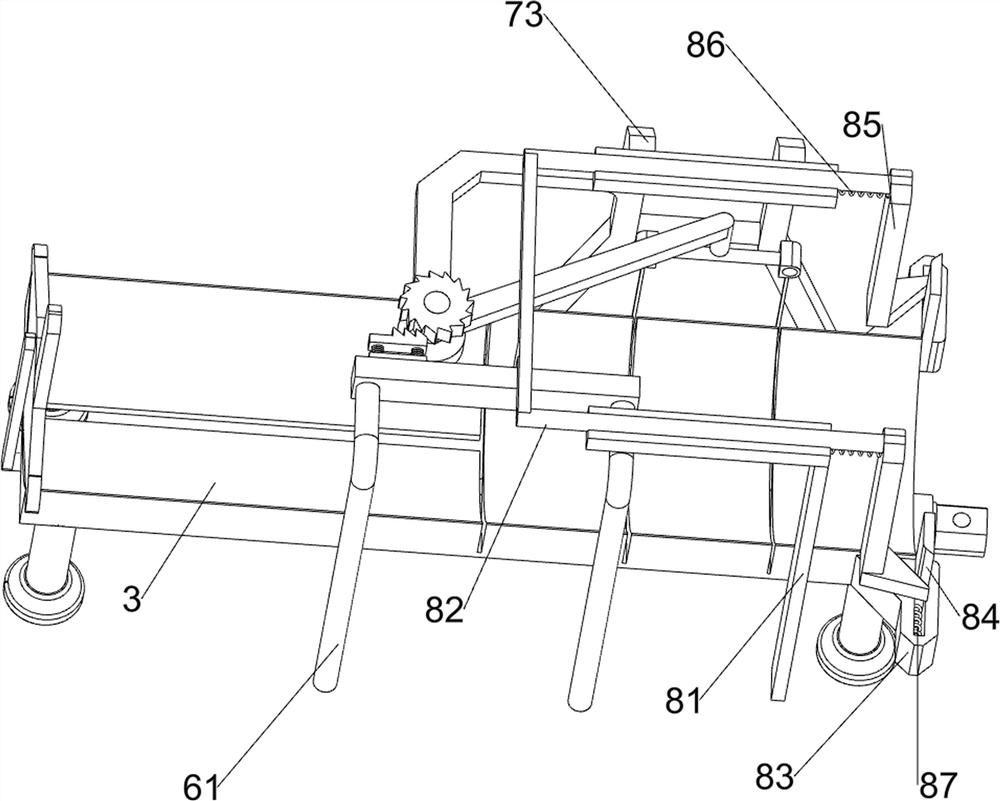

A large-batch cut device for agricultural garlic seedlings

The invention relates to a garlic seedling mass cutting device, in particular to a garlic seedling mass cutting device for agriculture. Therefore, the technical problem of the present invention is toprovide an agricultural garlic seedling cutting device capable of automatically cutting garlic seedlings and automatically collecting the cut garlic seedlings in large quantities. The technical embodiment of the invention is as follows: a bulk cutting device of garlic seedlings for agriculture comprises a bottom plate, a wheel, an auxiliary wheel, a guide sleeve, a plug rod, an annular sheet, a compression spring, a deep groove ball bearing, a pressure rod, a slider, a connecting rod, a fixing block, a first tension spring, etc.; The front and rear sides of the bottom plate are provided with wheels, the left side of the bottom plate is provided with auxiliary wheels, the left part of the bottom plate is embedded with a guide sleeve, the guide sleeve is slidably connected with a plug rod, and the plug rod is connected with an annular piece. As that swing rod, the arc frame, the semi-cylindrical frame, the rotary electric machine and the circular cutting knife are arrange, the rotary electric machine is continuously rotated, and garlic seedlings can be automatically cut.

Owner:赣州丰锦园生态农业发展有限公司

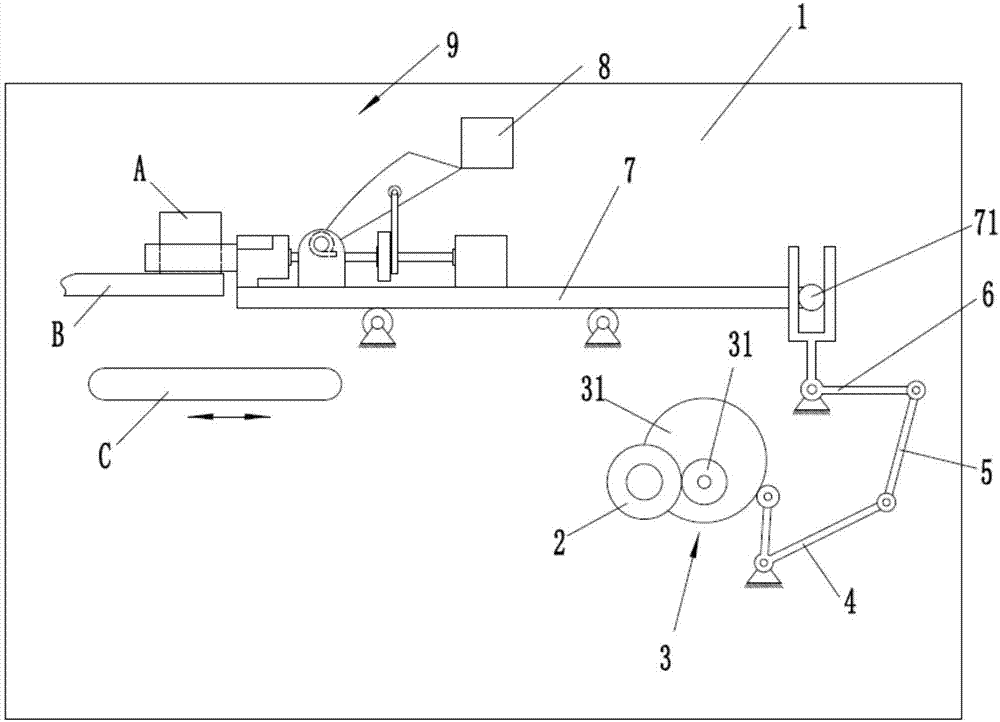

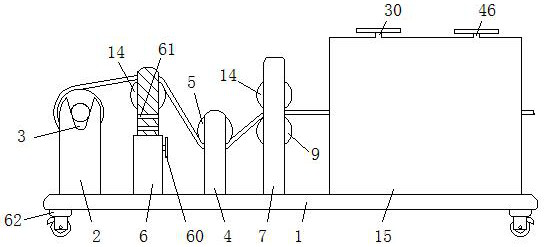

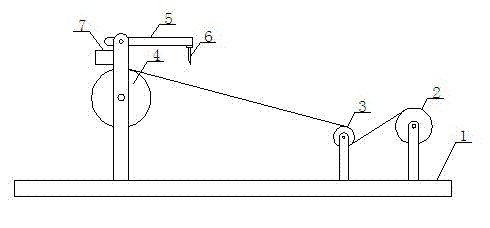

Winder with shift-sensing cutting function

The invention relates to the technical field of winding equipment, in particular to a winder with a shift-sensing cutting function. The winder comprises a support, an unwinding wheel, a guiding wheel and a winding wheel, wherein the unwinding wheel, the guiding wheel and the winding wheel are sequentially arranged and mounted on the support, a cutter rod is arranged above the winding wheel, and a cutter and a sense controller are arranged on the cutter rod. Since the cutter rod is arranged above the winding wheel, the cutter is arranged at the front end of the cutter rod, the tail end of the cutter rod is in rotating connection with the support, rotation of the cutter rod is controlled by the sense controller, wires can be automatically cut, and the winder is simple, high-efficient and time and labor saving.

Owner:周建江

Traditional Chinese medicine cutting device

InactiveCN106042025AAutomatic cuttingImprove work efficiencyMetal working apparatusMedicinal herbsReciprocating motion

The invention relates to a cutting device for Chinese herbal medicines, which includes a support platform, a cutting board, an electric telescopic rod for driving the cutting board to perform horizontal linear reciprocating motion, a cutting knife, a driving cylinder for driving the cutting knife to perform up and down linear reciprocating motion, and a For the controller that controls the electric telescopic rod and the driving cylinder, the top surface of the support platform is fixed with a horizontal slide rail, the cutting plate is horizontally slidably connected to the slide rail, and one end of the cutting plate is fixedly connected to the electric telescopic rod; A vertically distributed support beam is fixed on the support platform, the drive cylinder is fixed on the support beam, the cutting tool is located above the cutting board and detachably connected to the bottom of the drive cylinder; the electric telescopic rod and the drive cylinder are respectively Electrically connected to the controller. The invention utilizes the cooperation of the driving cylinder and the electric telescopic rod to automatically and quickly cut the medicinal material, the size of the cut medicinal material is uniform and standardized, the operation is automatic, the work efficiency is high, and time and effort are saved.

Owner:徐秀

Cooling circulation mechanism for drilling machining of forged workpieces

PendingCN113579283AReduce filter effectImprove filtering effectLarge fixed membersPositioning apparatusElectric machineryEngineering

The invention relates to the technical field of forging machining, and discloses a cooling circulation mechanism for drilling machining of forged workpieces. The cooling circulation mechanism comprises a fixing seat, a collecting box and a moving frame, the upper surface of the fixing seat is fixedly connected with a water tank, the outer wall of one side of the water tank is fixedly connected with a first motor, one end of an output shaft of the first motor penetrates through the water tank and is fixedly connected with a connecting rod, a first sliding groove is formed in the moving frame, the connecting rod is glidingly connected with the first sliding groove, a positioning frame is fixedly connected to the inner wall of one side of the water tank, and the positioning frame is glidingly connected with the moving frame. Metal scraps on a filter screen plate can be fully cleaned through a scraping plate, so that the filtering effect of the filter screen plate is improved; meanwhile, through cooperative use of a top frame and a wedge-shaped block, the device can achieve automatic discharging, and the convenience of the device is improved; the workpieces can be stably clamped through a clamping seat, so that a drill bit can conveniently and stably machine the workpieces subsequently, and the using effect of the device is improved.

Owner:无锡市麒啸机械有限公司

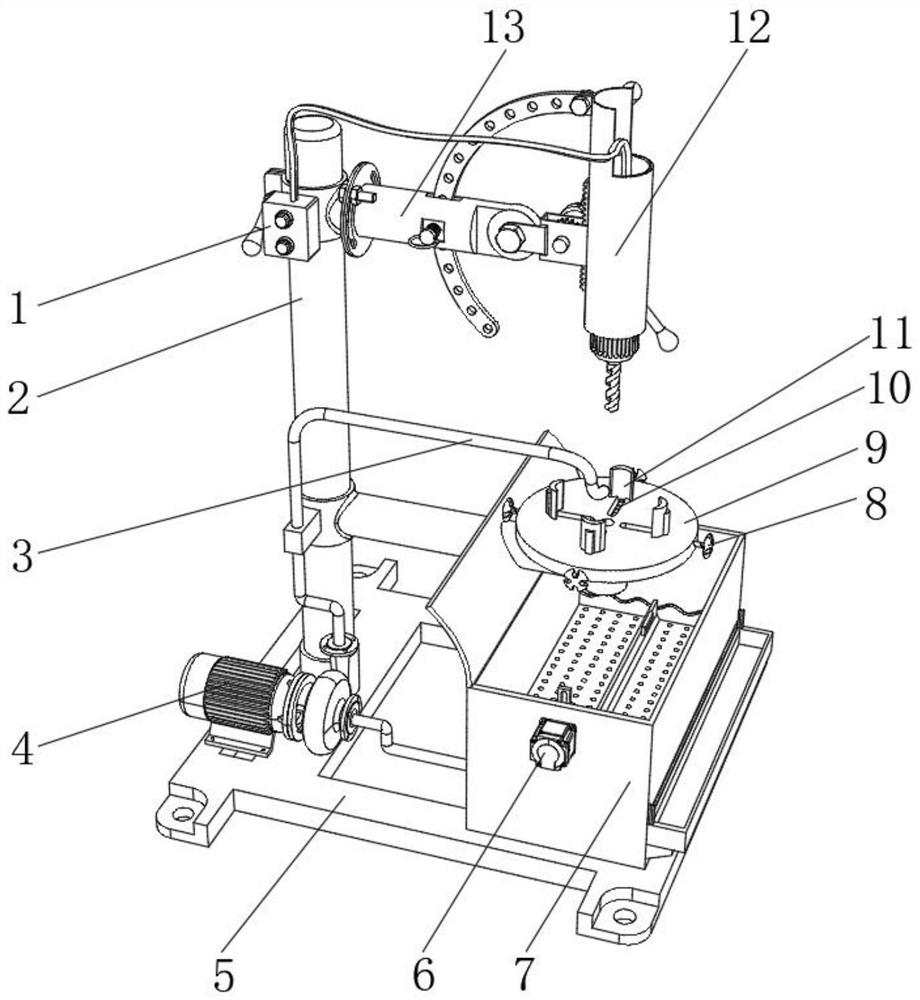

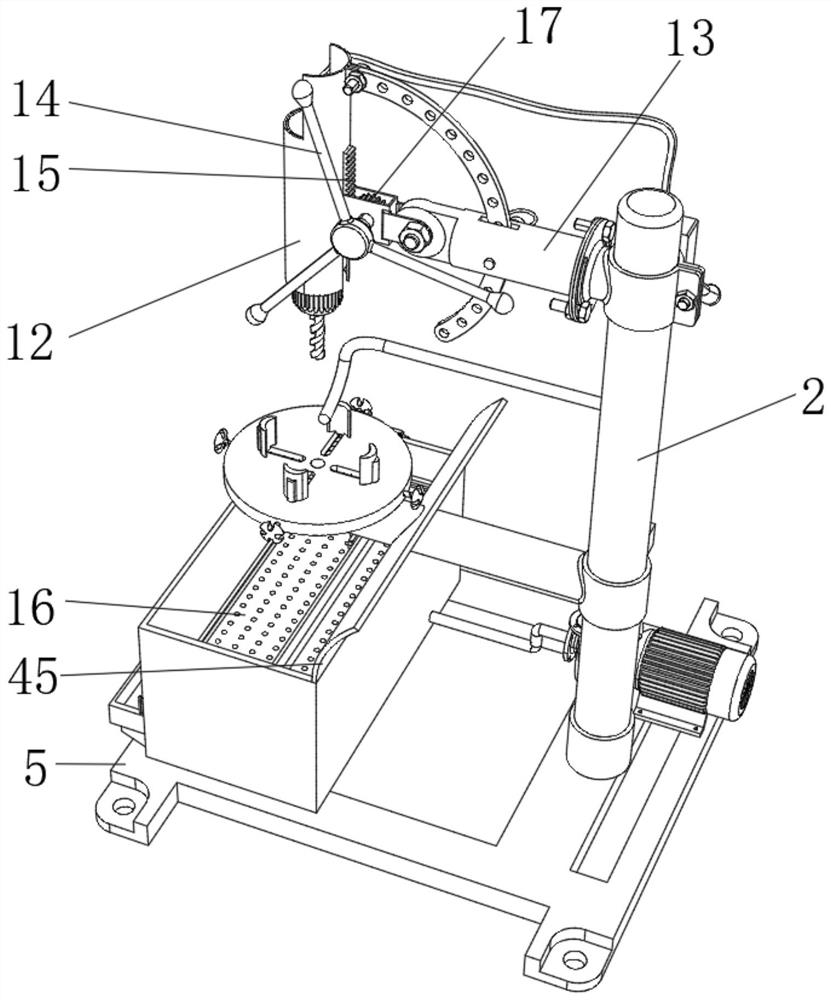

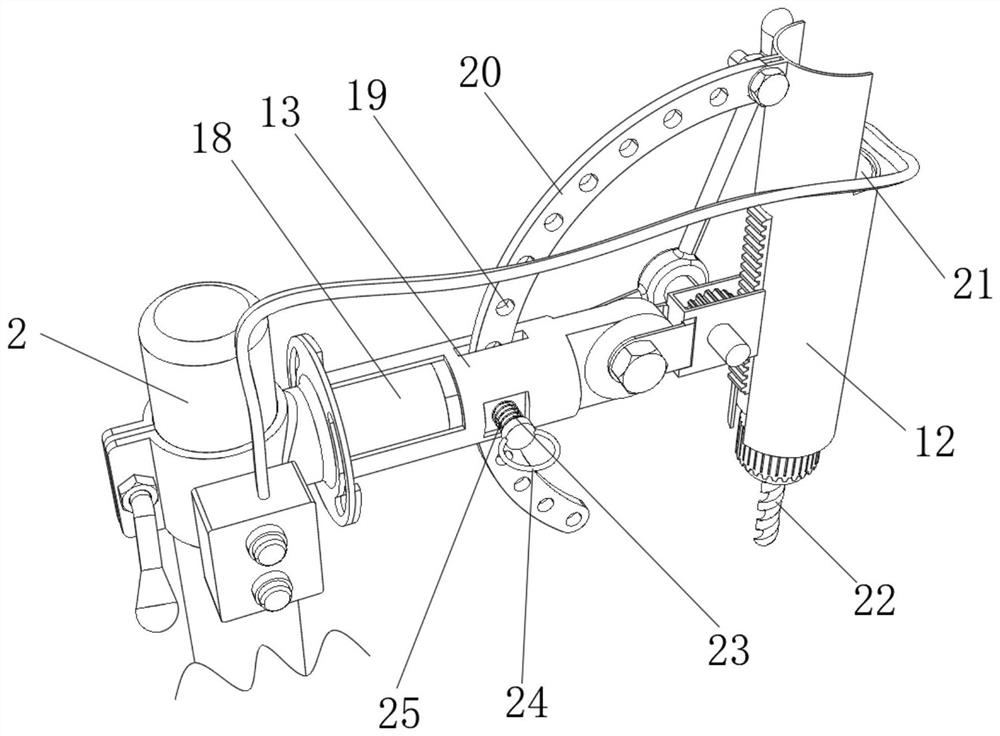

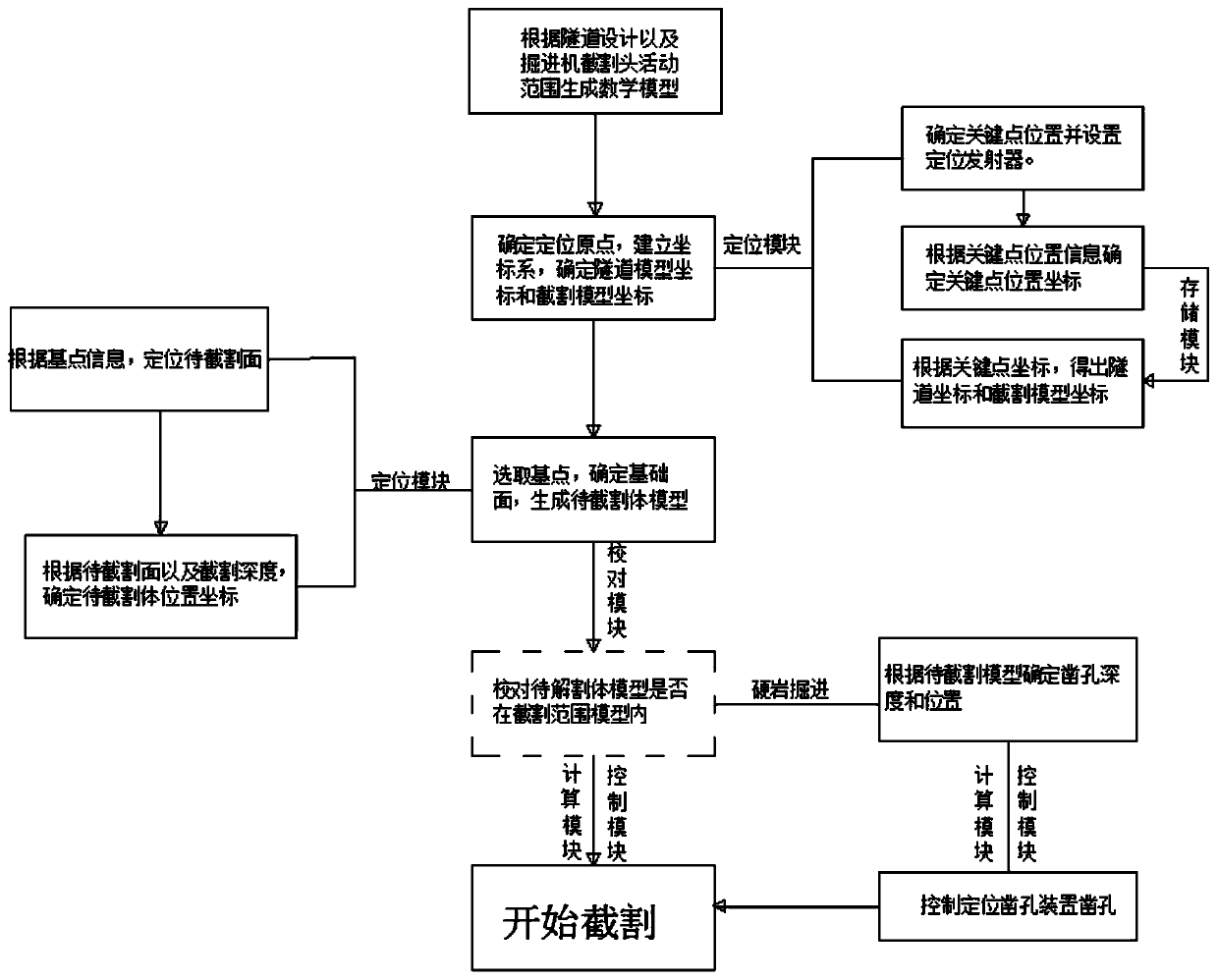

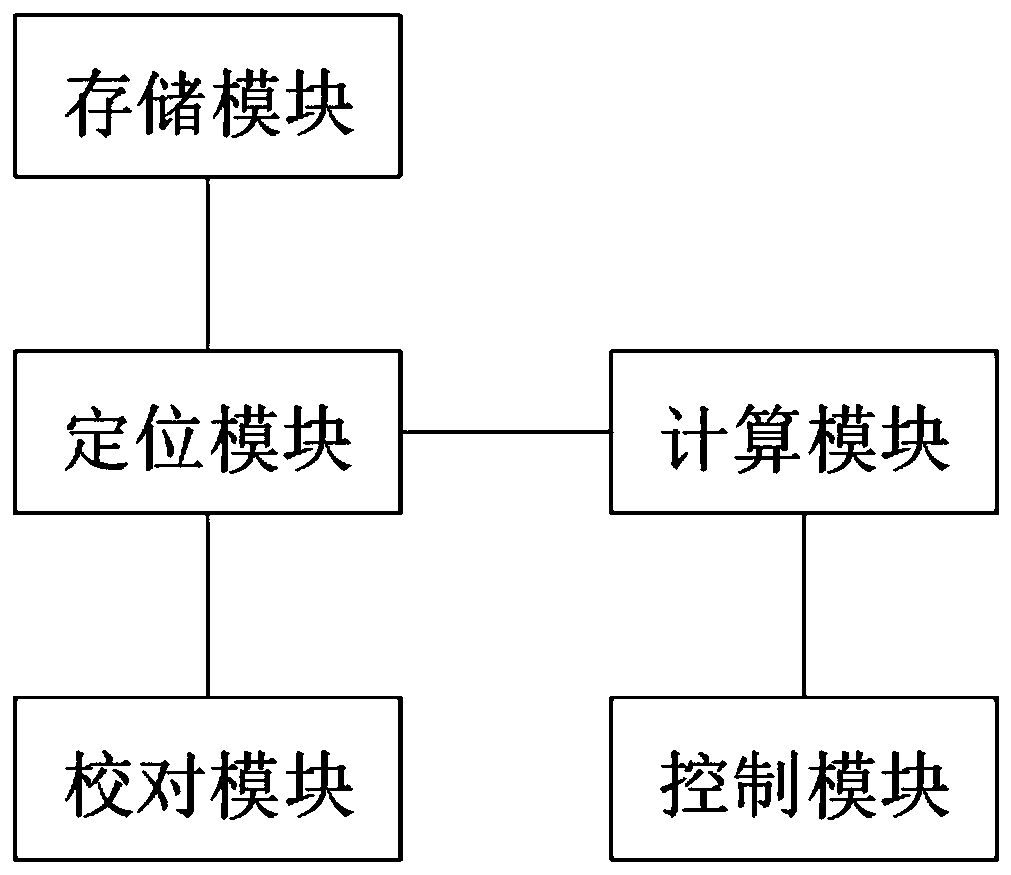

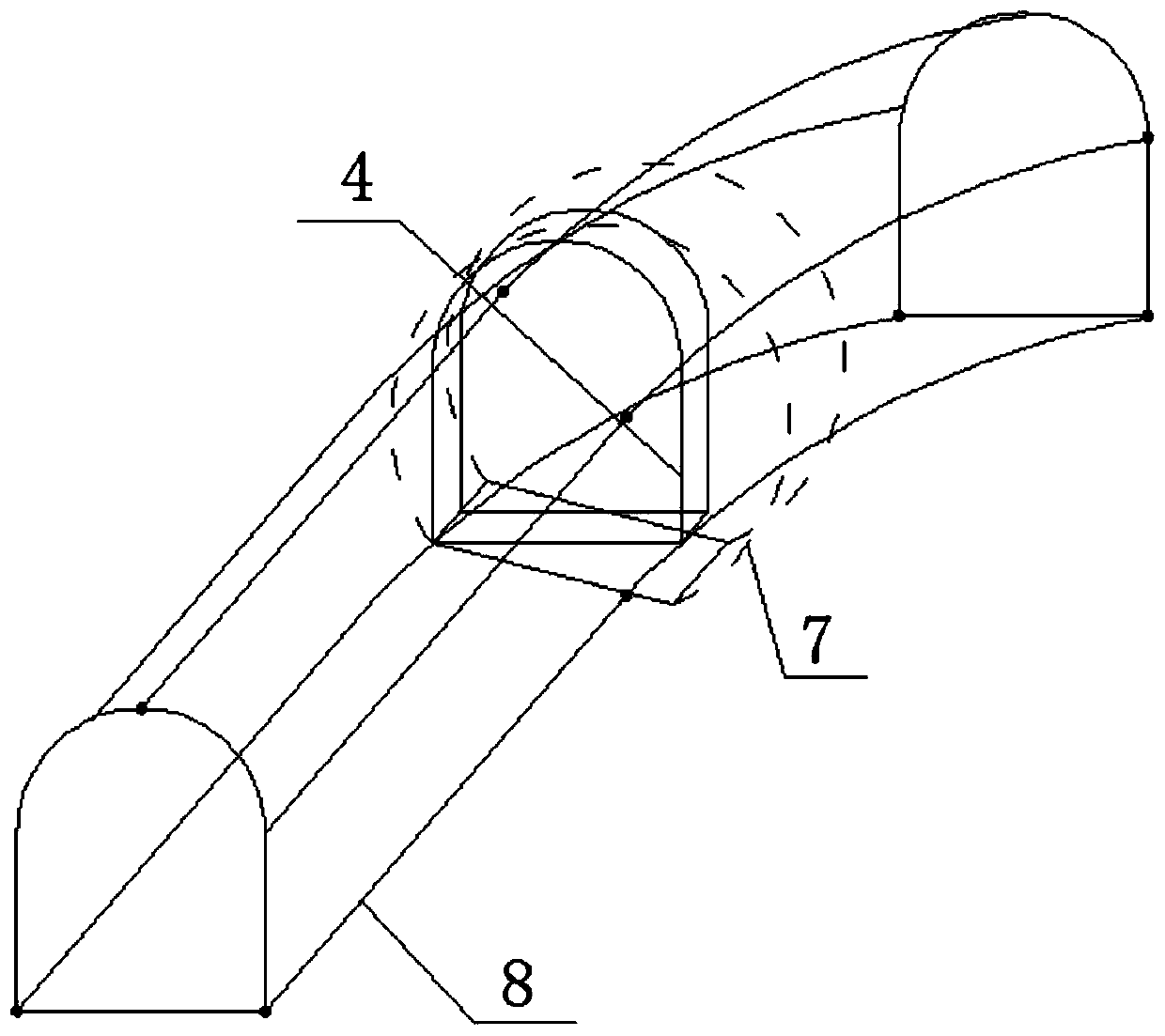

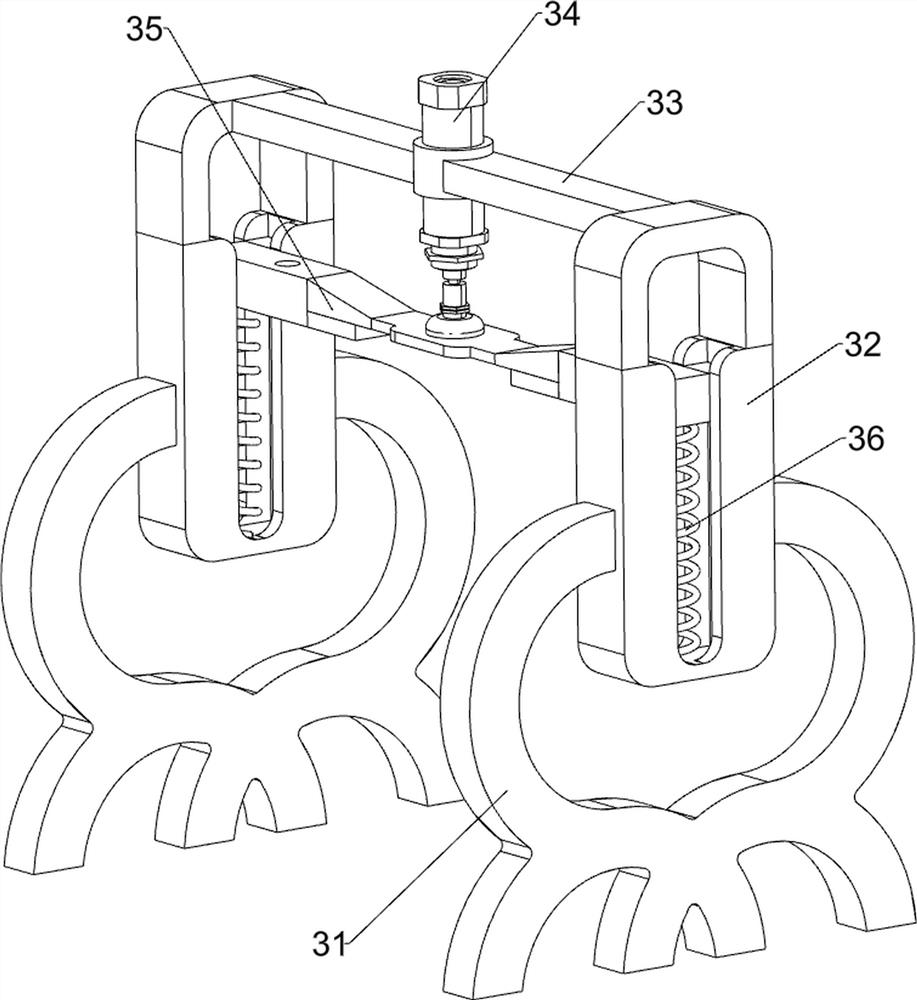

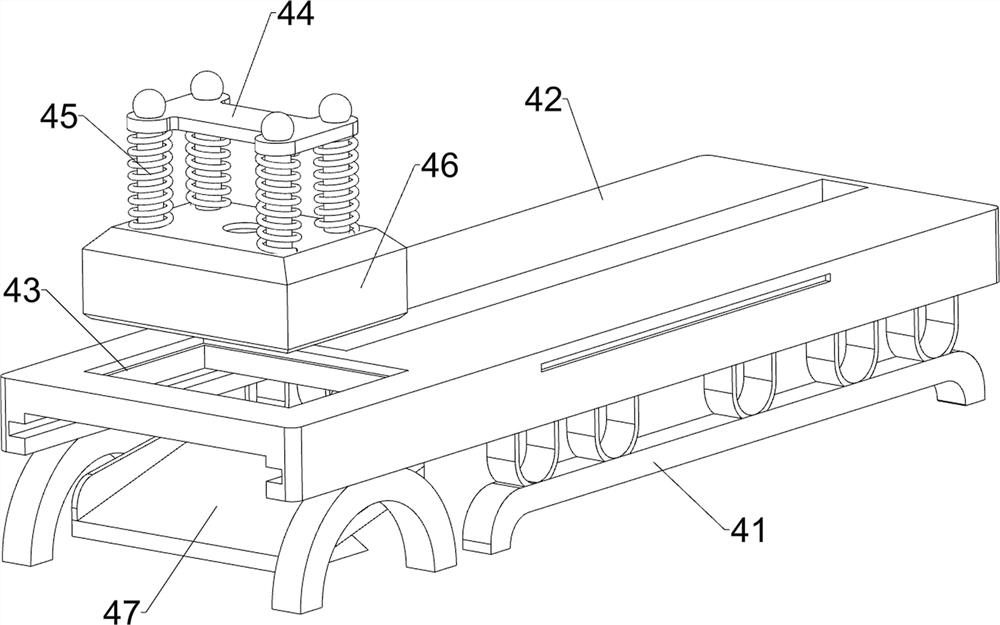

Tunneling machine positioning-tunneling method and system

The invention discloses a tunneling machine positioning-tunneling method and system, and belongs to the field of building method and equipment. A positioning punching device for a hard rock layer based on the tunneling machine positioning-tunneling method and the new system is included. The tunneling machine positioning-tunneling method comprises the following steps that S1, a tunnel model is generated according to tunnel design, and a model is generated according to the moving range of a cutting head; S2, a positioning original point is determined, a coordinate system is established, and tunnel model coordinates and cutting range model coordinates are generated; S3, a tunneling machine is positioned preliminarily, and cutting model coordinates of the tunneling machine are determined; S4,a base point is selected, and a datum plane is determined; S5, coordinates of a to-be-cut body are determined according to the datum plane and the cutting depth of each time; and S6, tunneling operation is started. By adopting small-section type cutting and matching automatic positioning control, the problem that under the situation that a cutting machine is manually controlled, the tunnel position error and the accumulative error are prone to being generated is solved.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

Copper sheet stamping equipment for electrical switch base production

ActiveCN112605216AAutomatic cuttingReduce labor intensityMetal-working feeding devicesPositioning devicesMetallurgyEngineering

The invention relates to stamping equipment, in particular to copper sheet stamping equipment for electrical switch base production. The copper sheet stamping equipment for electrical switch base production can automatically cut a copper plate into copper sheets and can reduce labor intensity and improve cutting efficiency. The copper sheet punching equipment for electrical switch base production comprises: a bottom plate, wherein the two sides of the bottom of the bottom plate are each connected with foot stands; and a driving mechanism, wherein the driving mechanism is installed at the top of the bottom plate, and a stamping mechanism is installed on the driving mechanism. The stamping mechanism can be driven to work through the driving mechanism, and the copper plate can be stamped into the copper sheets through the stamping mechanism; and therefore, the effects that the copper plate can be automatically cut into the copper sheets, the labor intensity can be reduced, and the cutting efficiency can be improved are achieved.

Owner:台州市焱迪企业有限公司

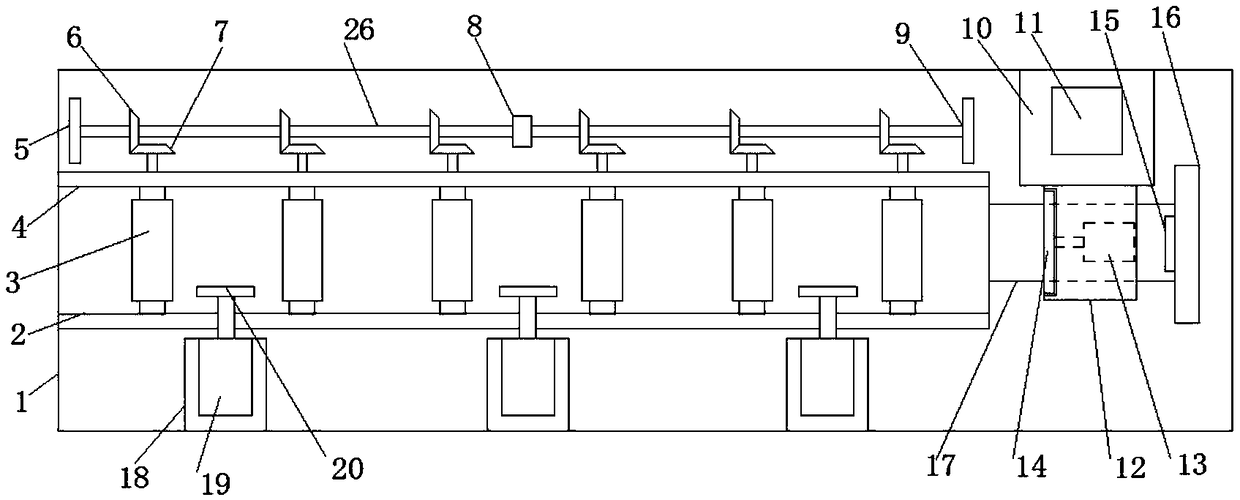

Stainless steel plate cutting system

InactiveCN107775417AAutomatic cuttingEasy to cutFeeding apparatusLarge fixed membersEngineeringMechanical engineering

The invention discloses a stainless steel plate cutting system. The system comprises a clamping table and a cutting machine, wherein a cutting machine moving chute is formed in the clamping table, anda cutting machine glides in the cutting machine moving chute through a cutting machine support frame; the cutting machine support frame comprises a vertical support, a horizontal support, a cutting machine suspension bar and a cutting machine horizontal support rod, the lower end of the vertical support is mounted in the cutting machine moving sliding chute through a cutting machine slider, one end of the horizontal support is connected with the upper end of the vertical support, the other end of the horizontal support is a vertically arranged cutting machine suspension bar and a horizontallyarranged cutting machine horizontal support rod, the cutting machine is connected with the outer end of the cutting machine horizontal support rod through a connecting rod, a horizontal adjusting shaft is arranged on the cutting machine, an arc-shaped sliding chute with the outer end of the cutting machine horizontal support rod as a circle center is formed in the cutting machine suspension bar,and the cutting machine is arranged in the arc-shaped sliding chute through the horizontal adjusting shaft for height adjustment.

Owner:巴中市新越不锈钢有限公司

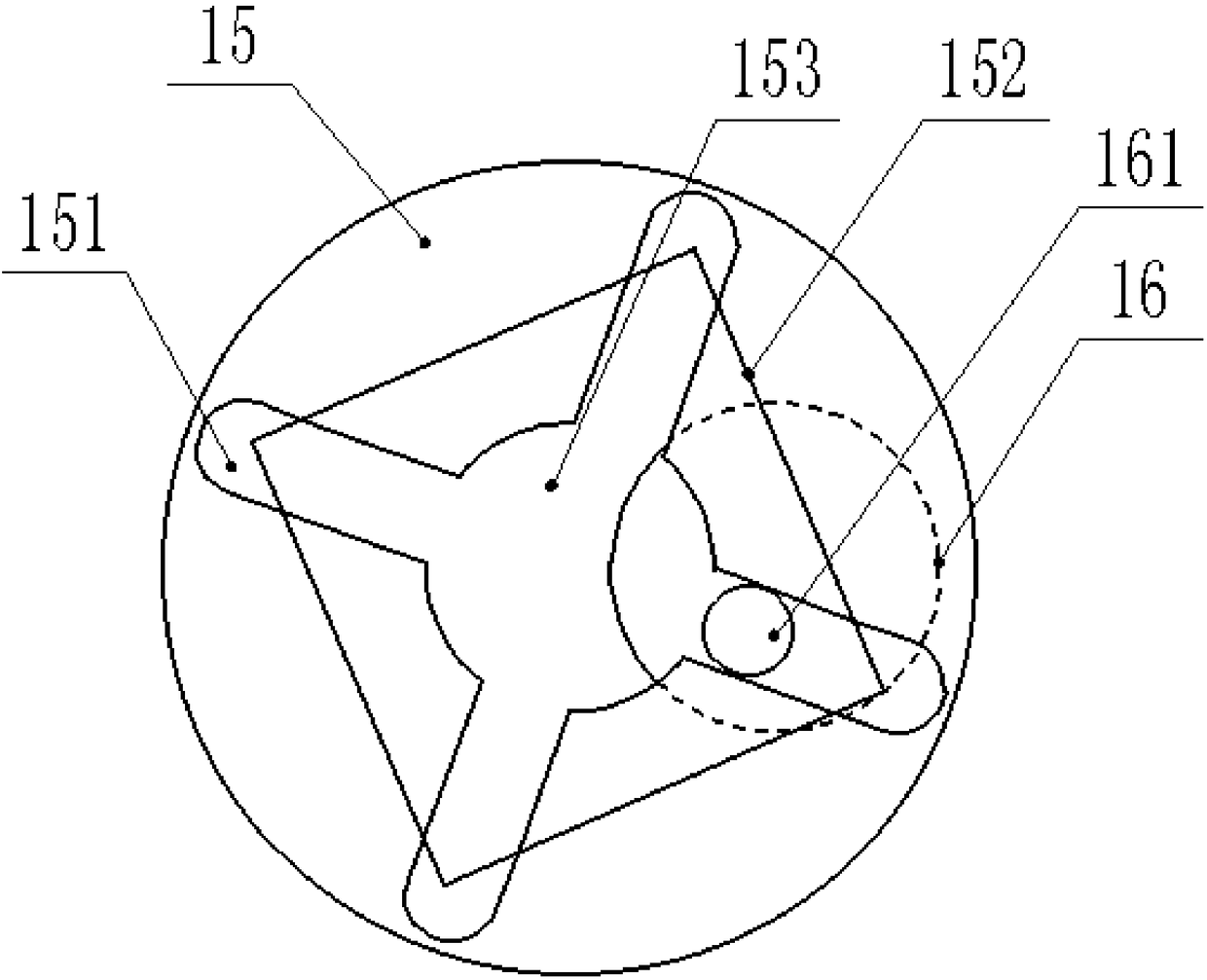

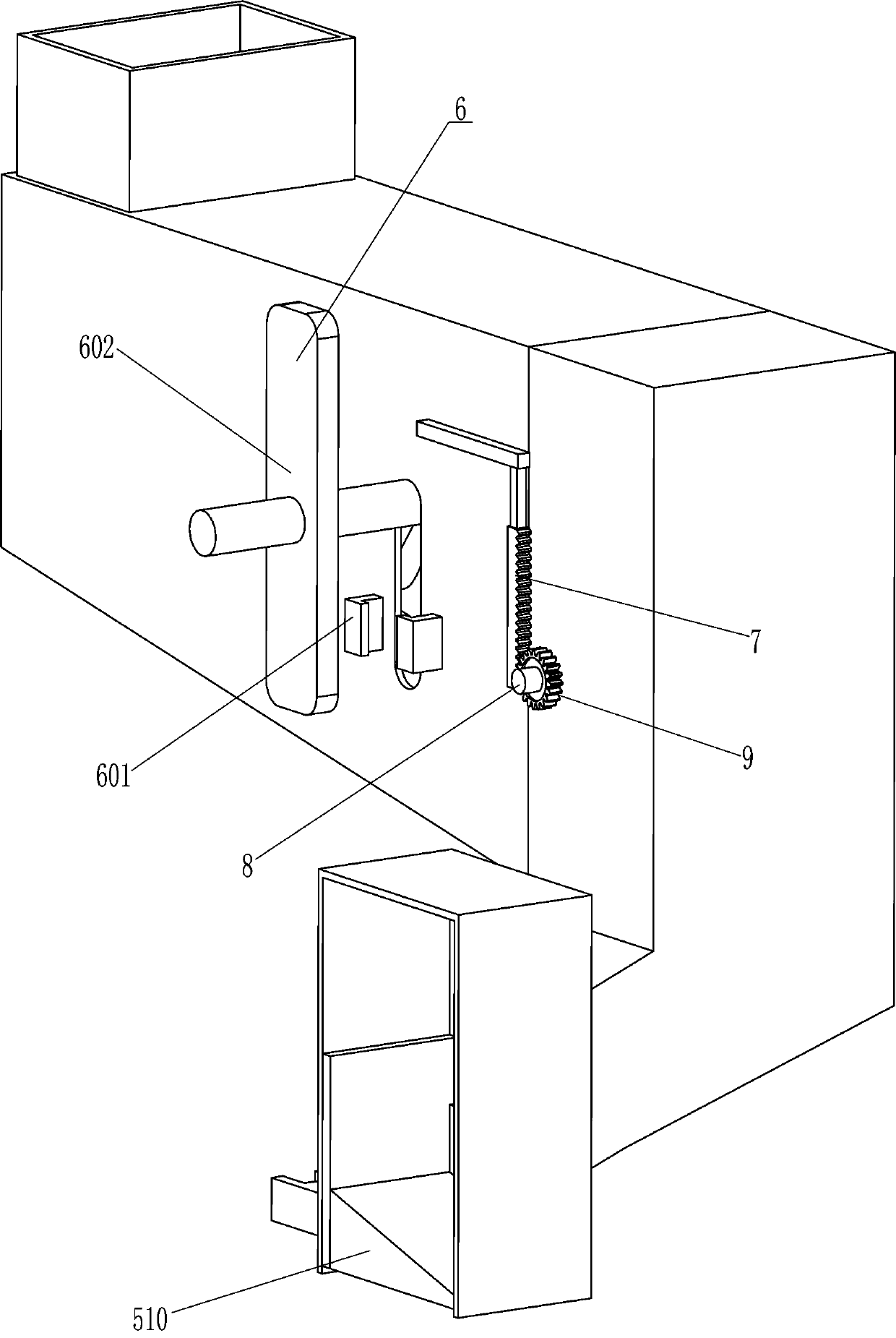

Rotating conveying device

PendingCN107564182ANo need to deliberately adjust the placement angleNo need to deliberately adjust the placementCoin-freed apparatus detailsApparatus for dispensing discrete articlesMotor driveElectric machinery

Owner:山东显柜网络科技有限公司

Square steel cutting device

InactiveCN108637345AQuick cutting jobImprove cutting efficiencyShearing machinesShearing control devicesEngineeringMachining

The invention discloses a square steel cutting device and relates to the technical field of square steel machining. The square steel cutting device comprises a workbench, and a conveying device, a pressing device, a cutting mechanism and a control device are arranged on the top of the workbench; the conveying device is used for conveying square steel to the position below the cutting mechanism; the pressing device is located on the side face of the conveying device and used for pressing the square steel on the conveying device; the cutting mechanism is used for cutting the square steel; and the control device controls the work state of the conveying device, the pressing device and the cutting mechanism. According to the square steel cutting device, due to the design of the conveying device, the pressing device, the cutting mechanism and the control device, fast cutting operation on the square steel is achieved, and the cutting efficiency is greatly improved; and meanwhile, automation is higher in the cutting process, and the safety of the device in the cutting work is improved.

Owner:芜湖立普德机械科技有限公司

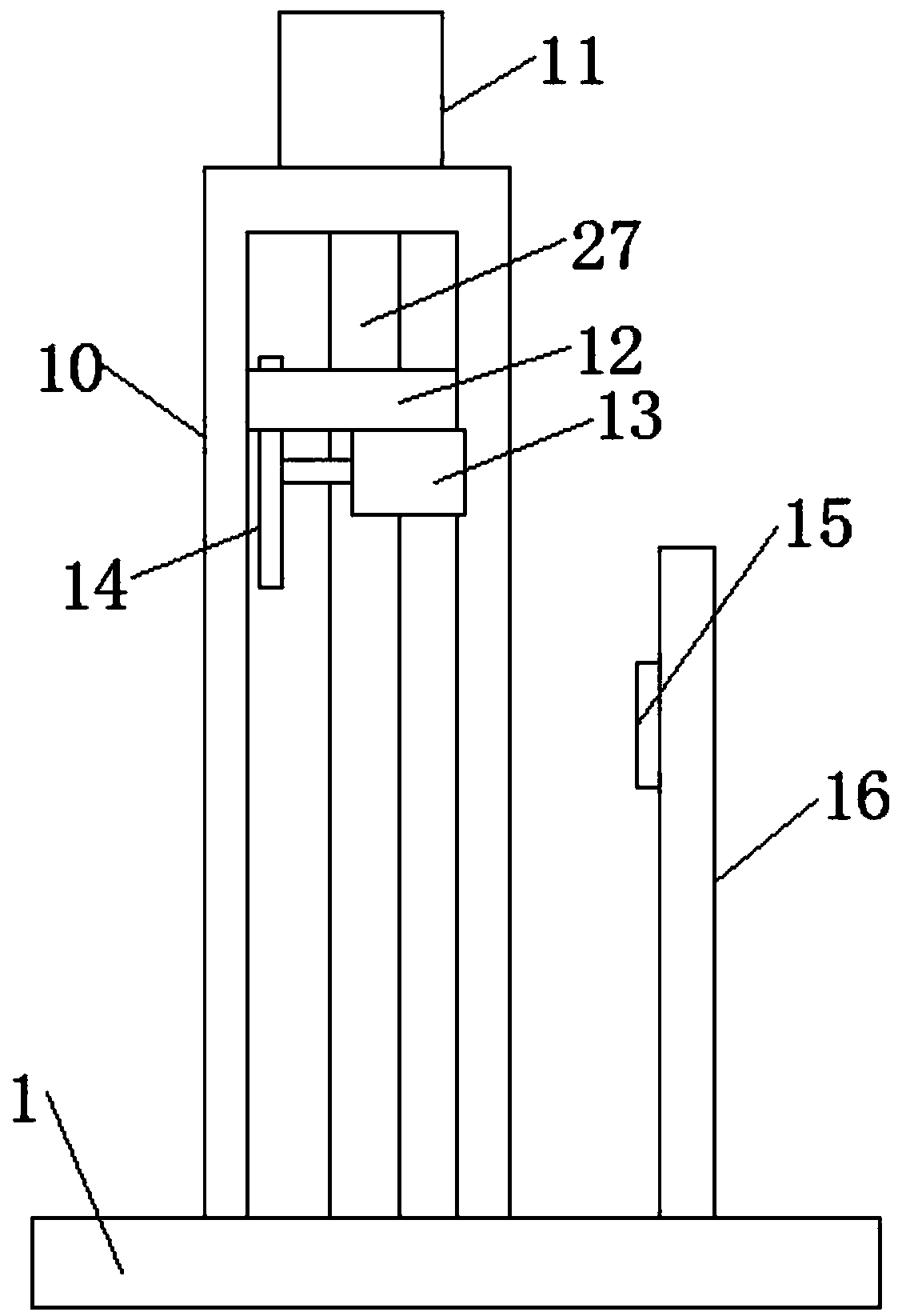

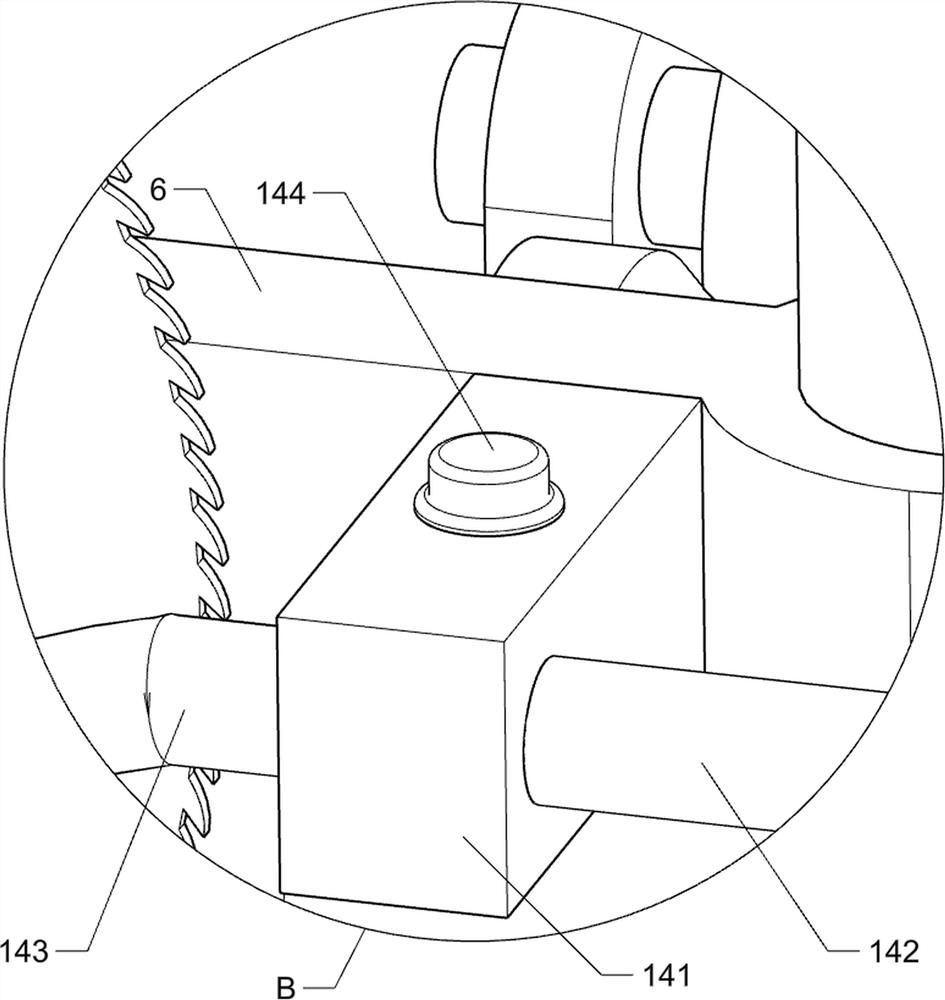

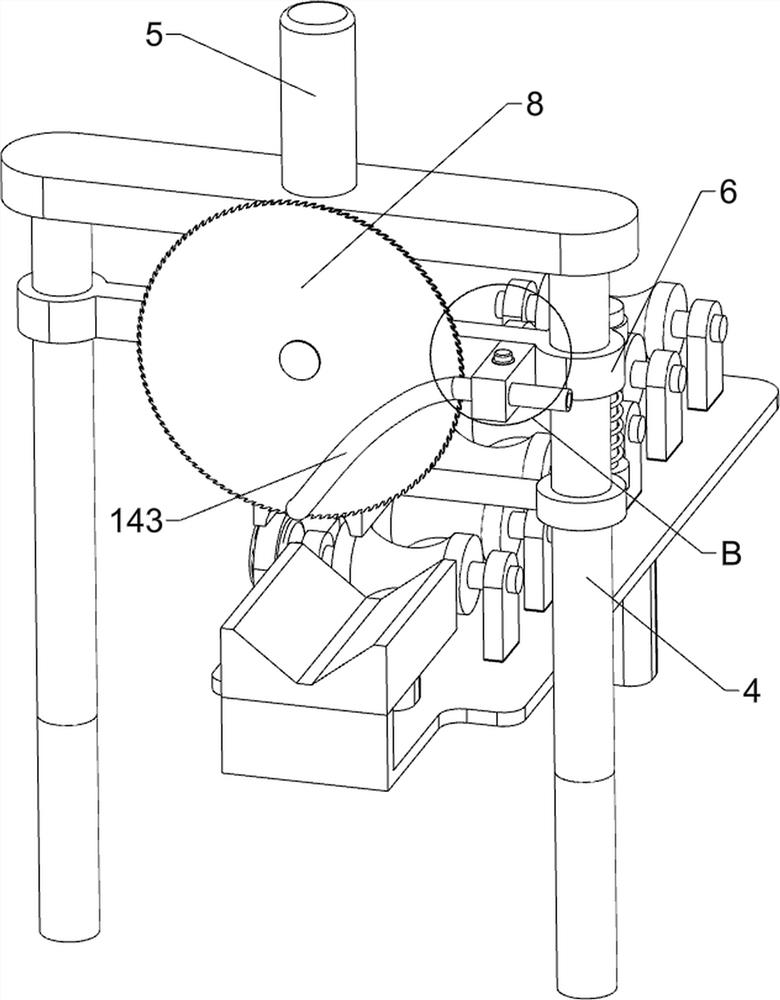

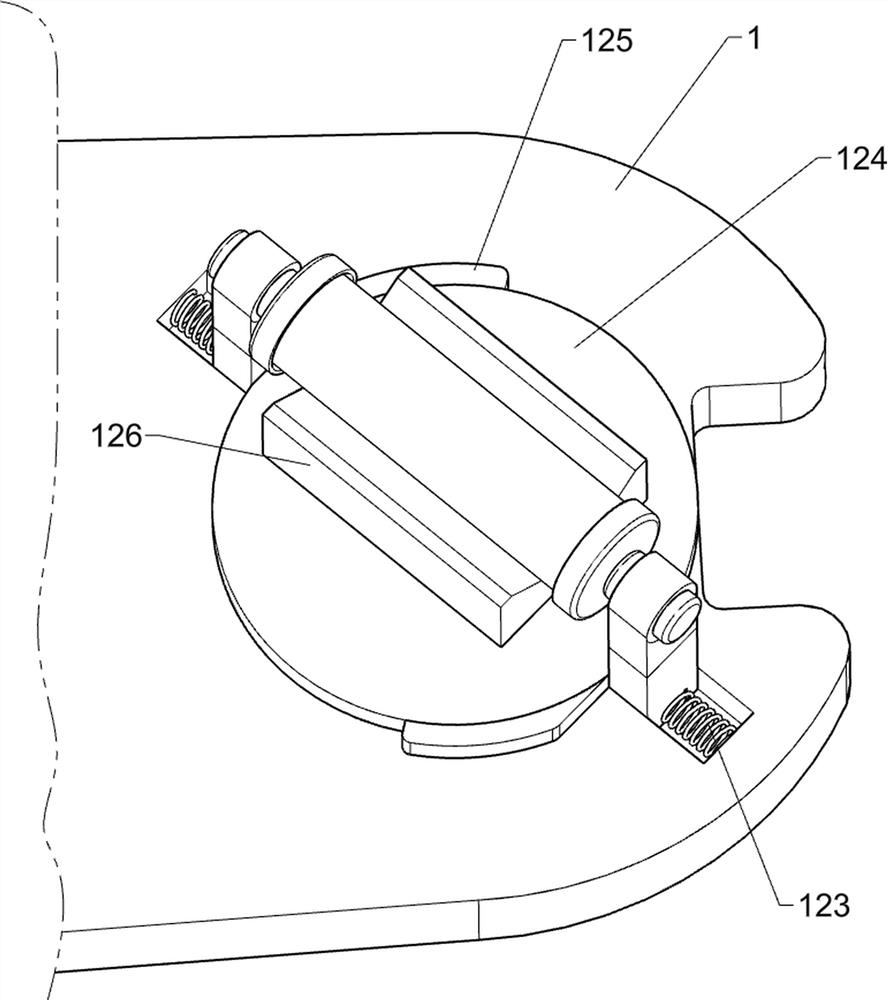

Equipment for automatically deburring two ends of cut hollow steel pipe

ActiveCN114055178AAutomatic cuttingReduce manual operationsOther manufacturing equipments/toolsPositioning apparatusElectric machineryMachine

The invention relates to equipment for automatically deburring two ends of a cut hollow steel pipe. The equipment comprises a bottom plate, one side of which is connected with a connecting base, wherein the connecting base is connected with a middle platform on which the hollow steel pipe can be placed; a fixed machine frame, whereinthe middle of the bottom plate is connected with the fixed machine frame, and the top of the fixed machine frame is provided with an air cylinder capable of providing power; a sliding machine frame which is connected to the fixed machine frame in a sliding mode, wherein the sliding machine frame is connected with a telescopic rod of the air cylinder; a large motor which is capable of providing power and is installed in the sliding machine frame, wherein a saw blade capable of cutting the hollow steel pipe is connected to the large motor; and a deburring mechanism which is capable of polishing and deburring the hollow steel pipe and is arranged at the top of the bottom plate. The large motor can drive the saw blade to rotate, the air cylinder can enable the saw blade to move downwards and upwards, the saw blade moves downwards and rotates to cut the hollow steel pipe, and the end parts of the two sides of the hollow steel pipe can be polished and deburred through the deburring mechanism.

Owner:浙江友霓钢业有限公司

Intelligent cable receiving device

PendingCN114014090AAct as a supportImprove stabilityFilament handlingStructural engineeringMechanical engineering

The invention belongs to the technical field of cable receiving, in particular to an intelligent cable receiving device, and aims to solve the problems that existing operations such as cable winding, cutting and weighing need to be manually operated by workers, and time is wasted, the following scheme is provided, the intelligent cable receiving device comprises a bottom plate, and a cable disc placing mechanism is arranged at the top of the bottom plate; a cable disc is placed on the top of the cable disc placing mechanism, a cable is wound on the cable disc, a vertical plate and a weighing device are installed on the top of the bottom plate, a cable hole is formed in the vertical plate, a containing groove is formed in the inner wall of the top of the cable hole, a cutting mechanism is arranged in the containing groove, the cable is movably connected with the cable hole, and the cutting mechanism is matched with the cable. A transverse plate is installed at the top of the vertical plate, a lifting mechanism is installed at the bottom of the transverse plate, and a circular plate is installed on the lifting mechanism. The cable receiving device is convenient to operate, cables can be automatically wound, cut, weighed and the like, manual operation of workers is not needed, and time is saved.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

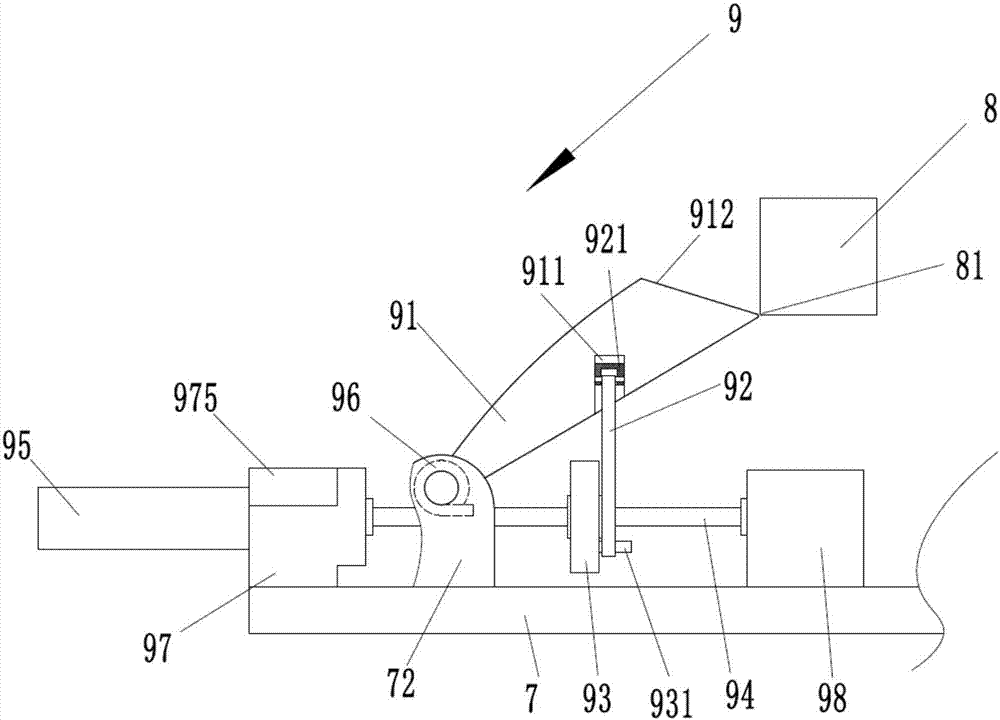

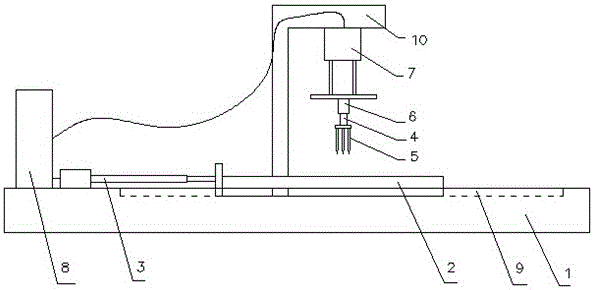

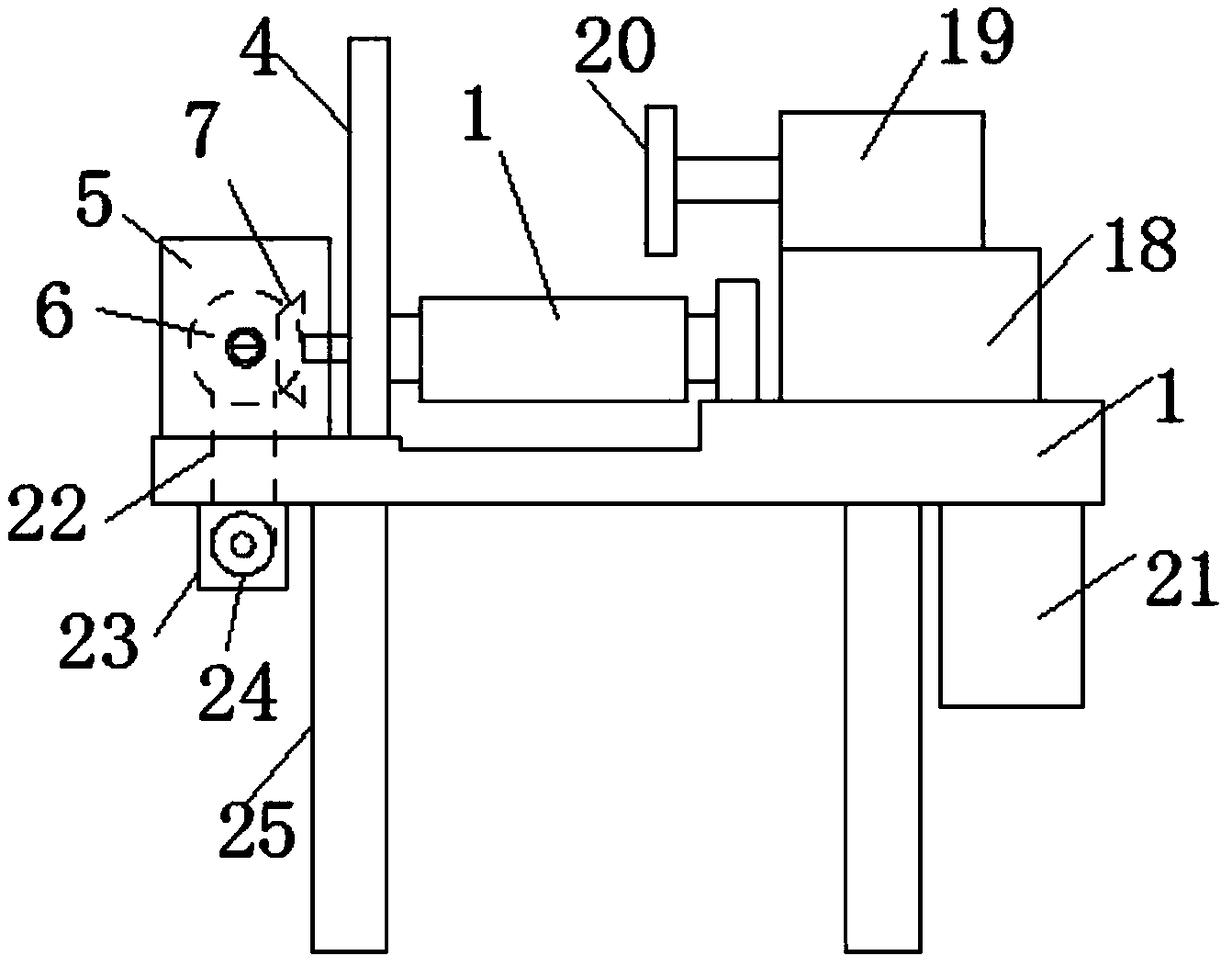

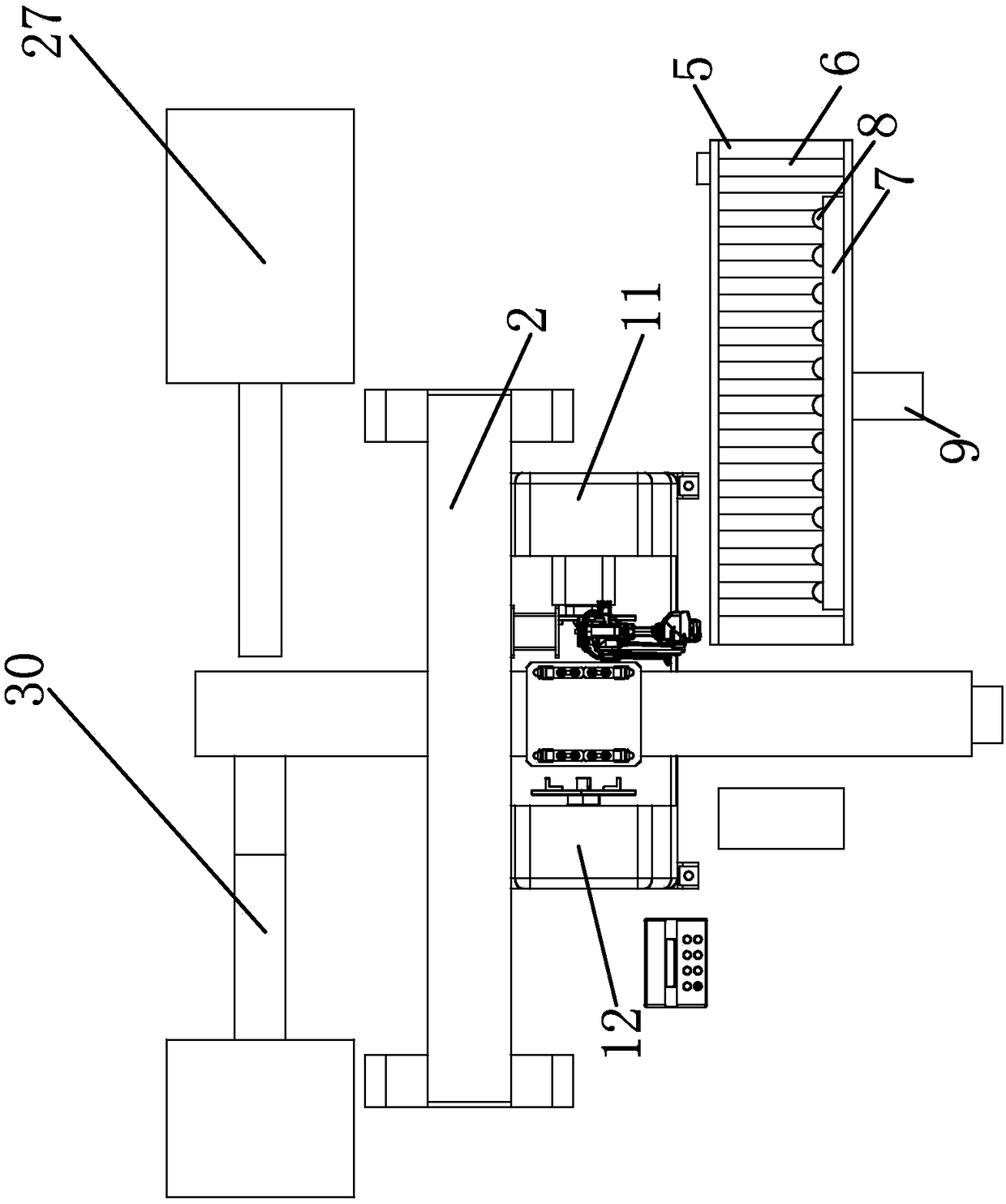

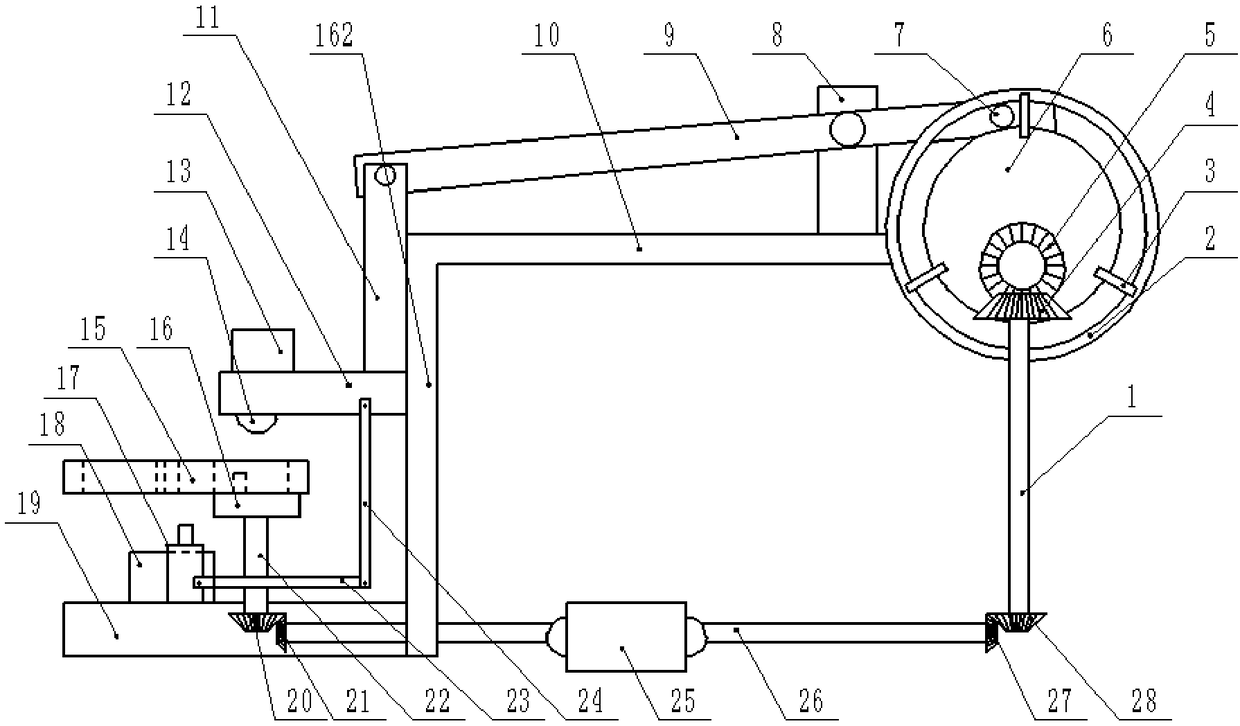

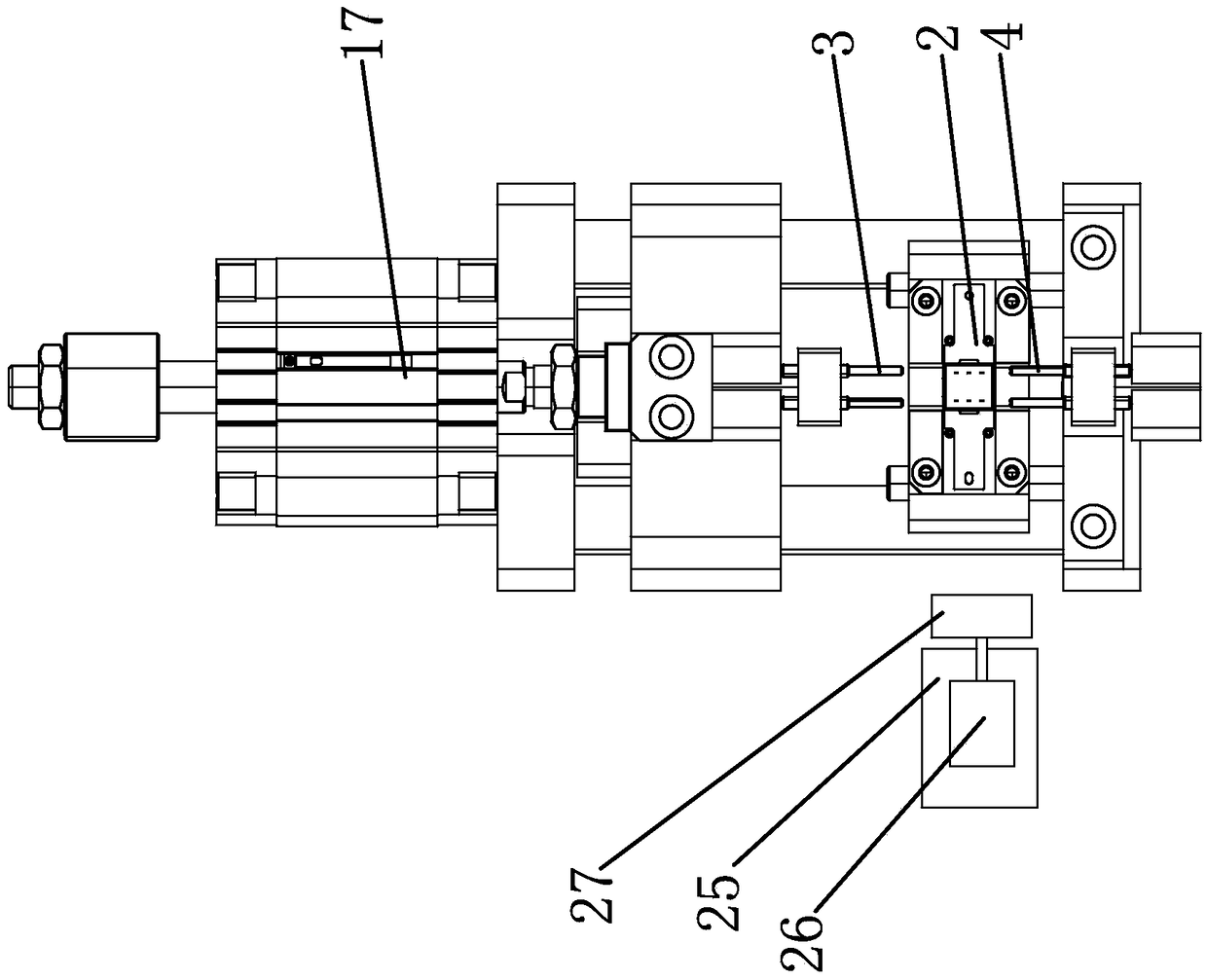

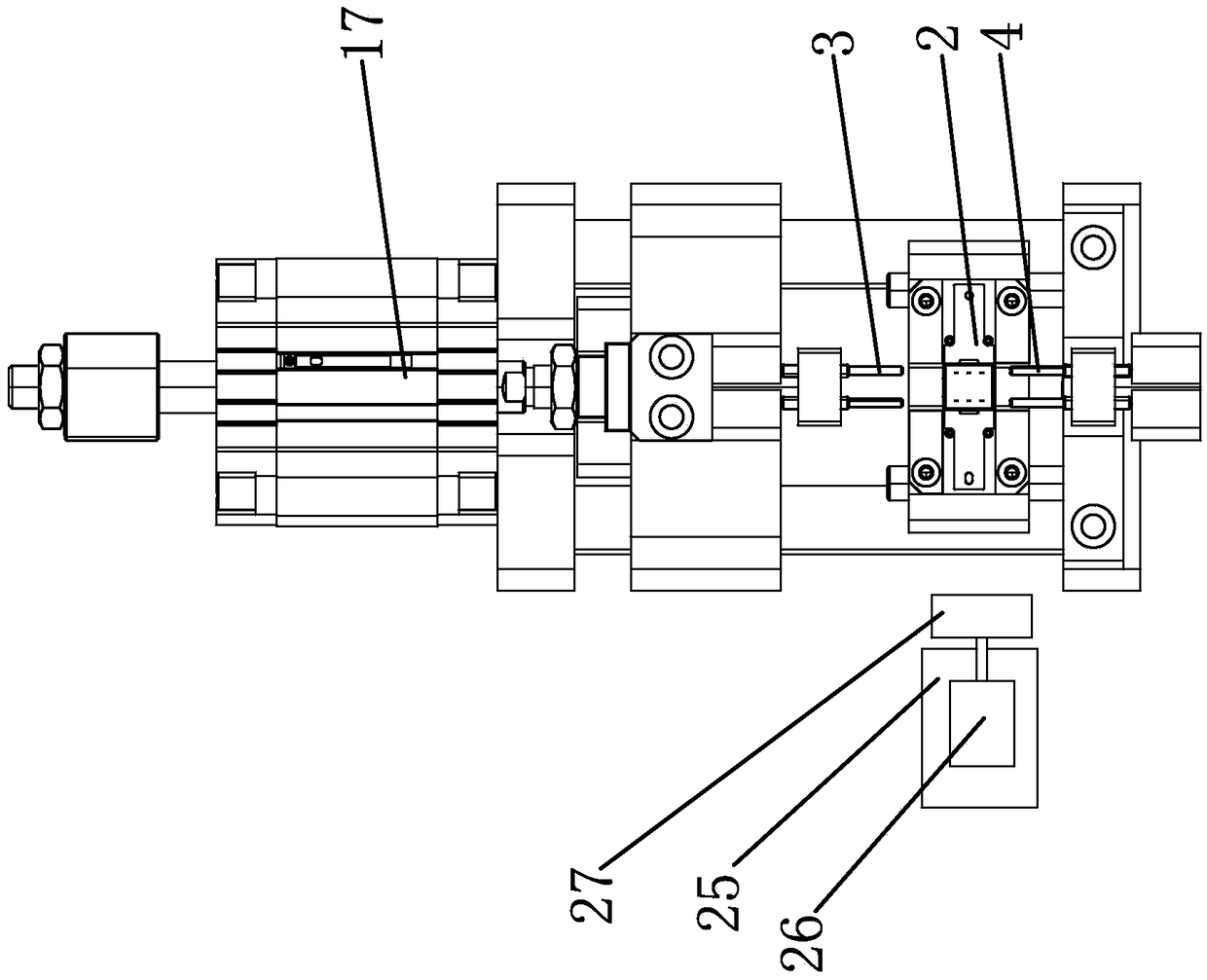

Welding machine

PendingCN108480889AWith precise feedingQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides a welding machine, and belongs to the technical field of welding machines. The welding machine solves the problem that in the prior art, the welding quality is low. The weldingmachine comprises a fixed seat and a machine frame, wherein objects to be welded by the welding machine are a pipe body and a base used for sealing the pipe body, a welding table is arranged on the fixed seat, a feeding mechanism capable of conveying the pipe body to the welding table is arranged on one side of the fixed seat, a displacement mechanism capable of moving the welding table back and forth is arranged on the fixed seat, clamping mechanisms capable of clamping the pipe body and the base are arranged at the two ends of the welding table, a welding head used for welding is arranged above the welding table, an adjusting mechanism capable of adjusting the space position of the welding head is arranged on the machine frame, and the other side of the fixed seat is provided with a discharging mechanism capable of discharging a finished product from the welding table. The welding machine has the advantage of improving the welding quality.

Owner:浙江豪精机电有限公司

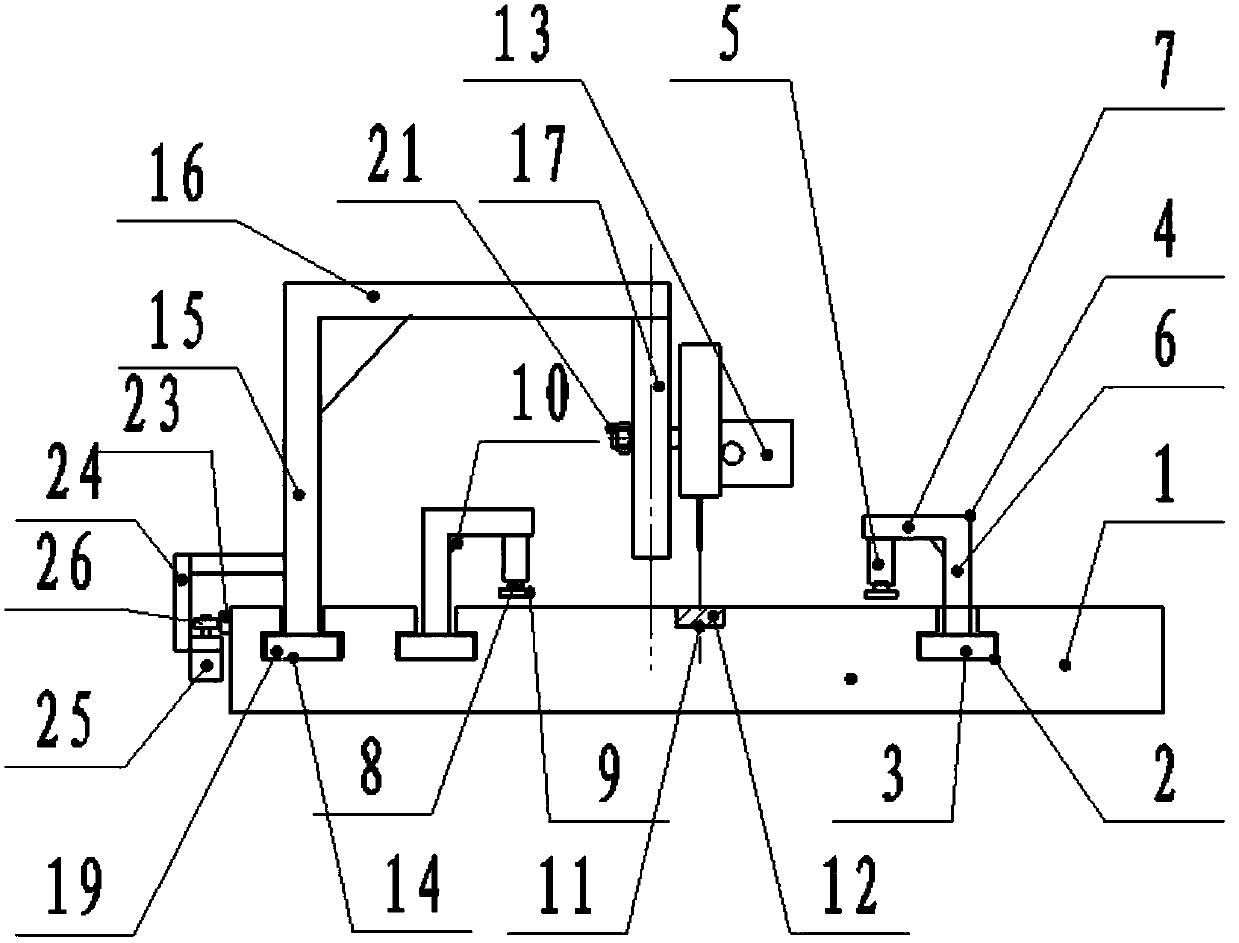

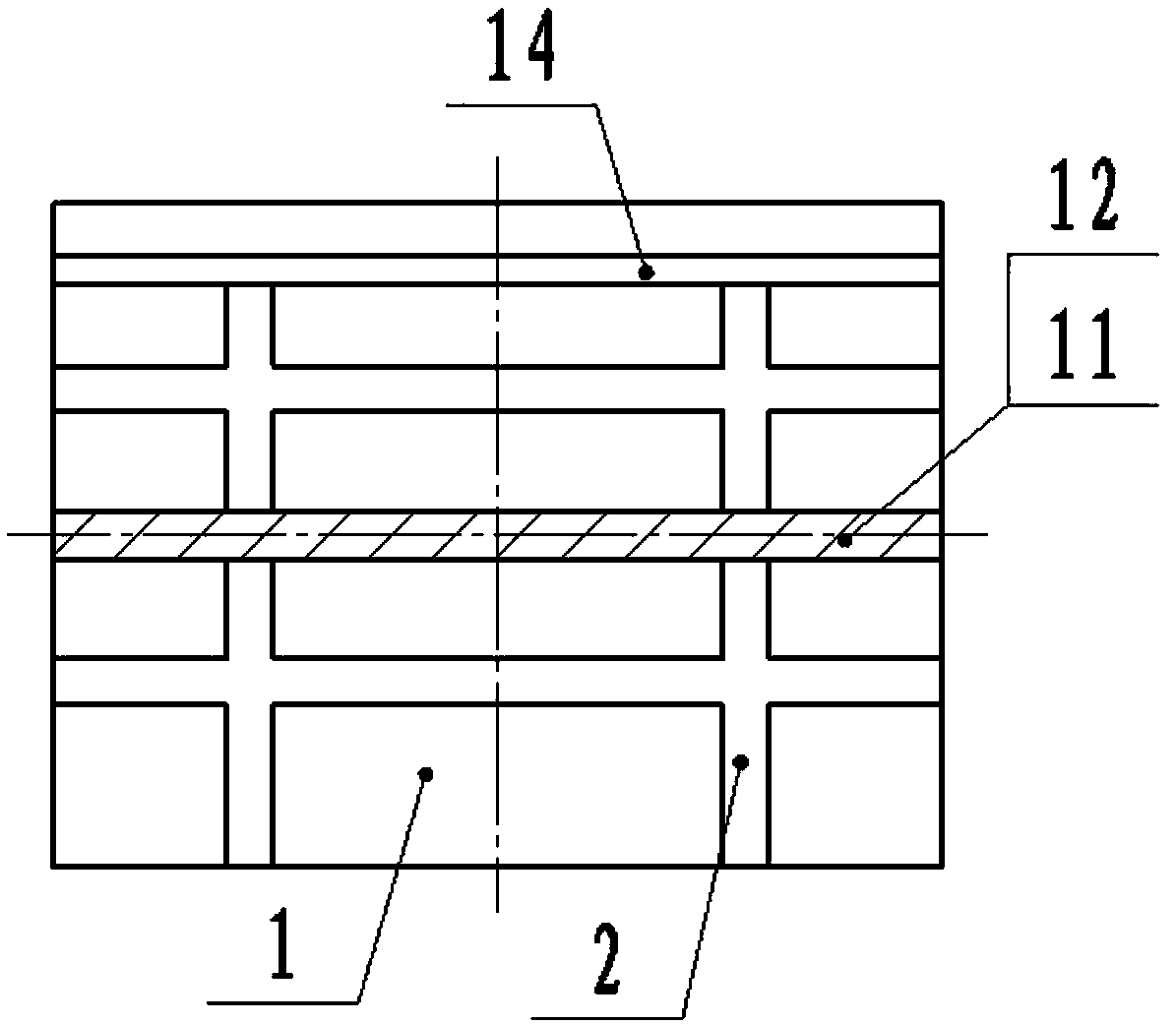

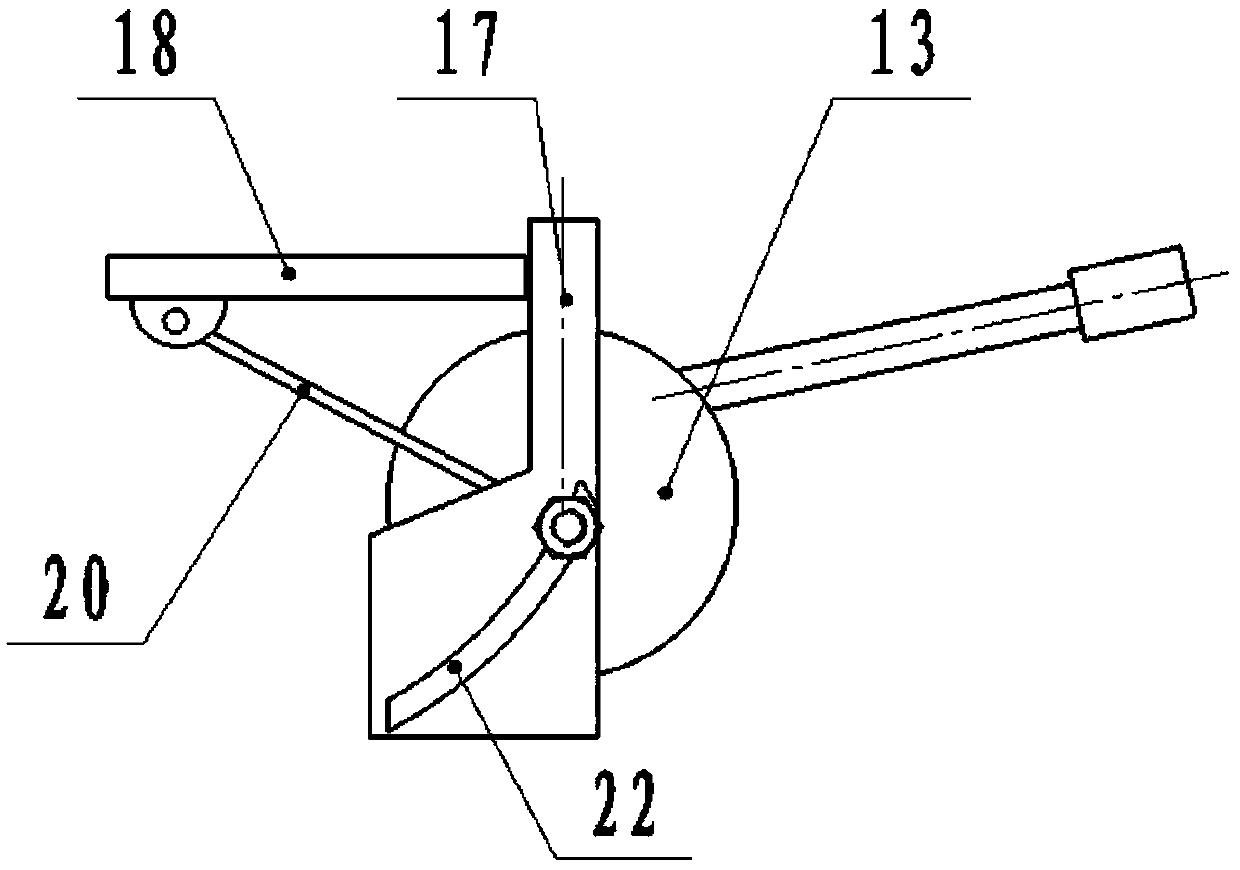

Circuit board processing device

The invention relates to a circuit board processing device, which comprises a rack. The rack comprises a base, a cross plate and a slide rail. A lever is rotatably connected onto the cross plate; a cutting plate is slidably connected onto the slide rail; a cutting tool is arranged on the cutting plate; a rotary plate is arranged under the cutting plate; a through hole is formed in the middle of the rotary plate; four long-strip holes communicating with the through hole are formed in the rotary plate; a square placement groove is formed in the top part of the rotary plate; a driving plate is arranged on the bottom part of the rotary plate; a driving lever is fixedly connected onto the driving plate; a motor and a circular disc are arranged on the outer side of the rack; a first output shaftand a second output shaft for driving the driving plate to rotate are arranged on the motor; the first output shaft is meshed through a bevel gear so as to drive the circular disc to rotate; a connecting part of a cross shaft and the circular disc is located at an eccentric part of the circular disc; a circular ring sleeves the outer side of the circular disc; an annular sliding chute is formed between the circular disc and the circular ring; one end of the lever is rotatably connected with the cutting plate; and a pin shaft slidably connected into the sliding chute is rotatably connected onto the lever. According to the scheme, a circuit board can be rotated automatically.

Owner:重庆军航科技有限公司

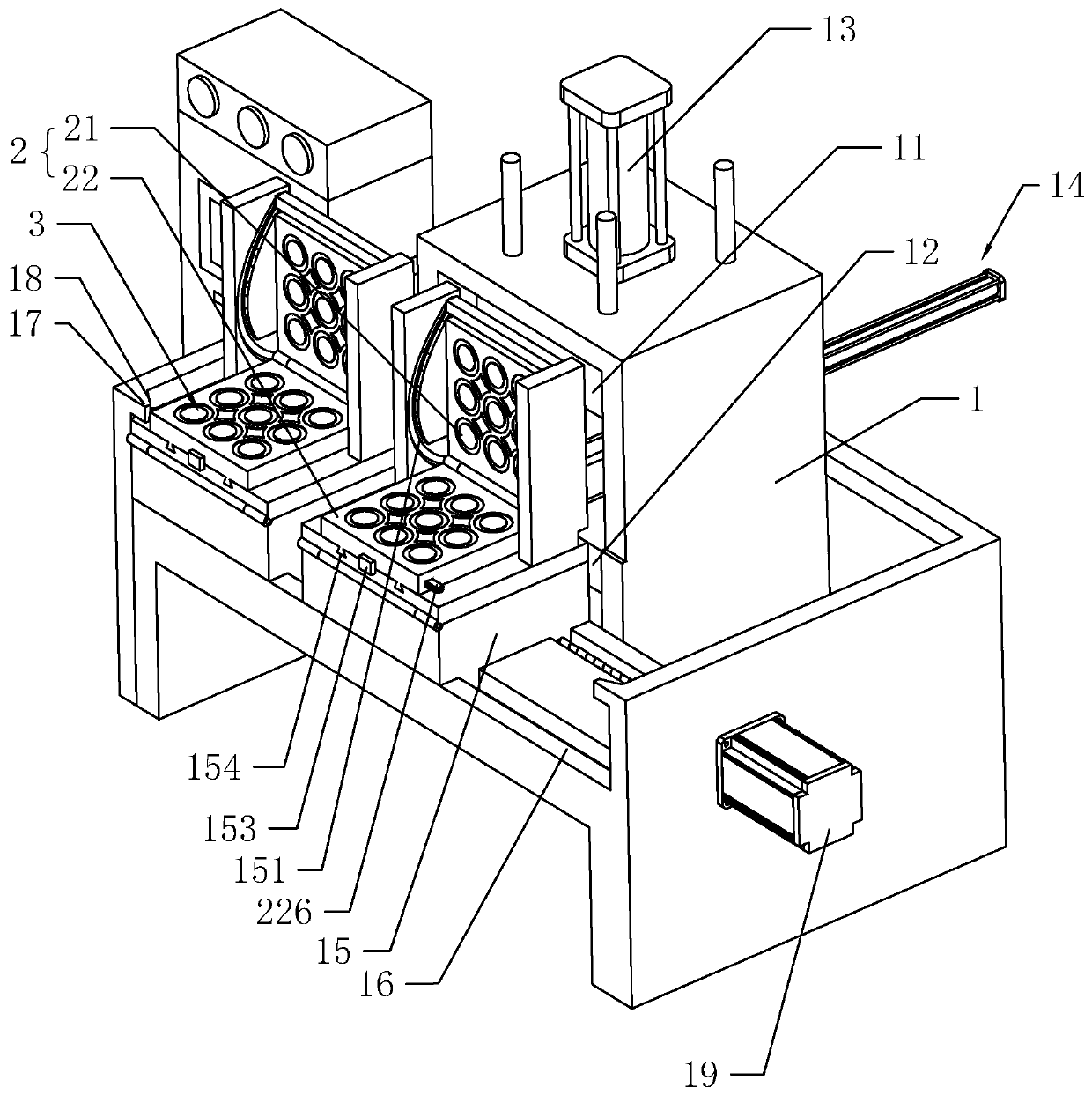

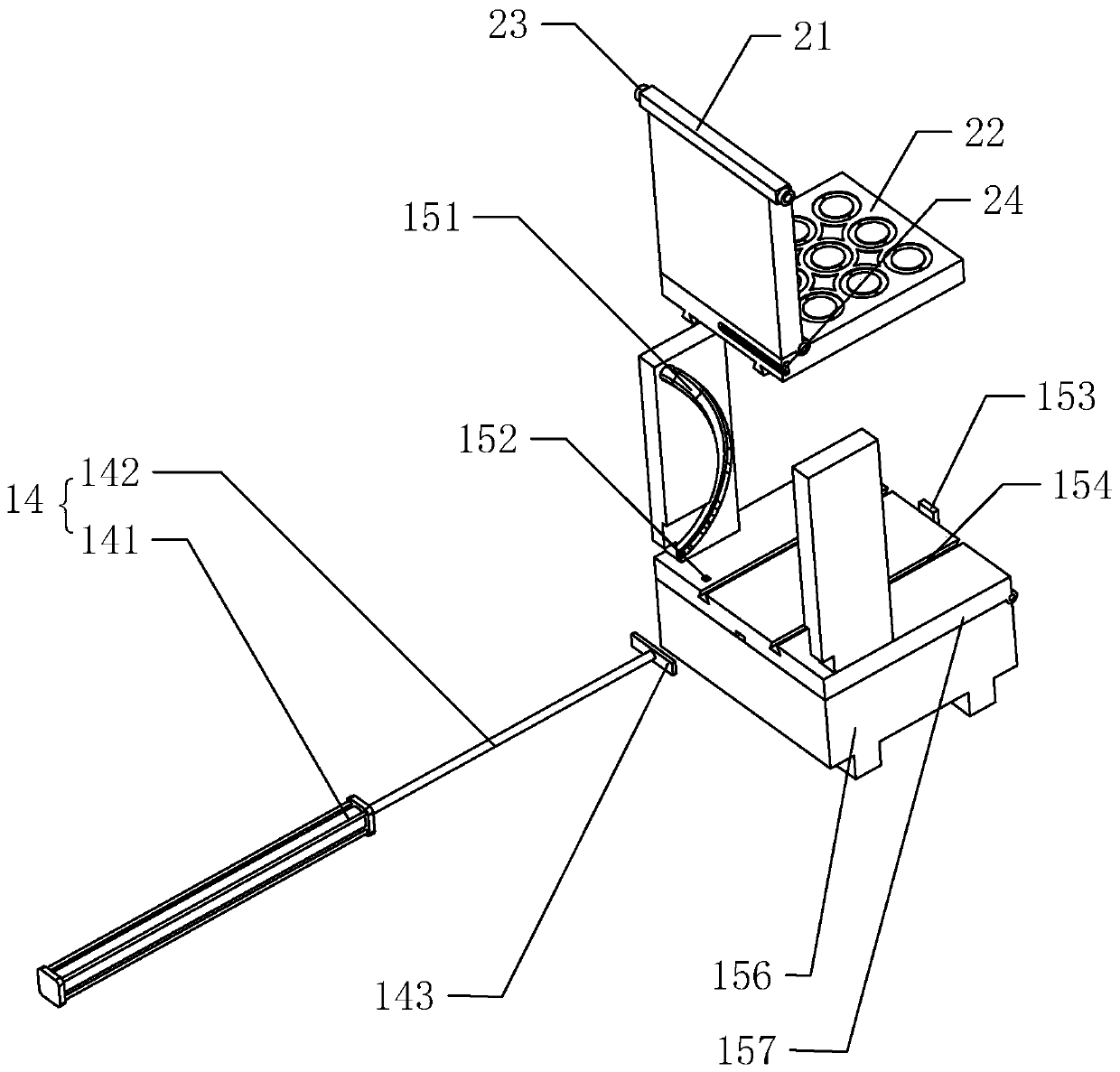

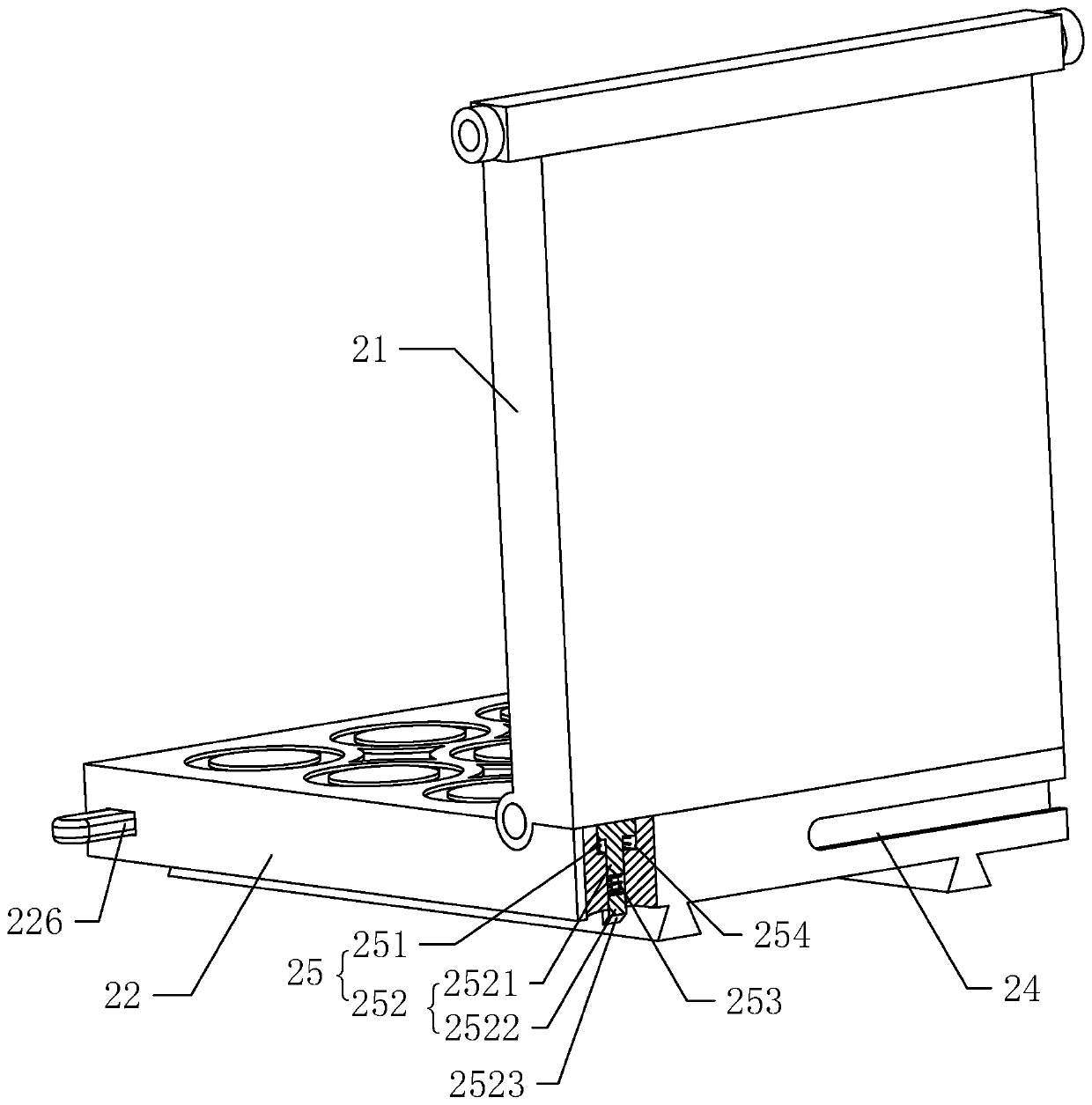

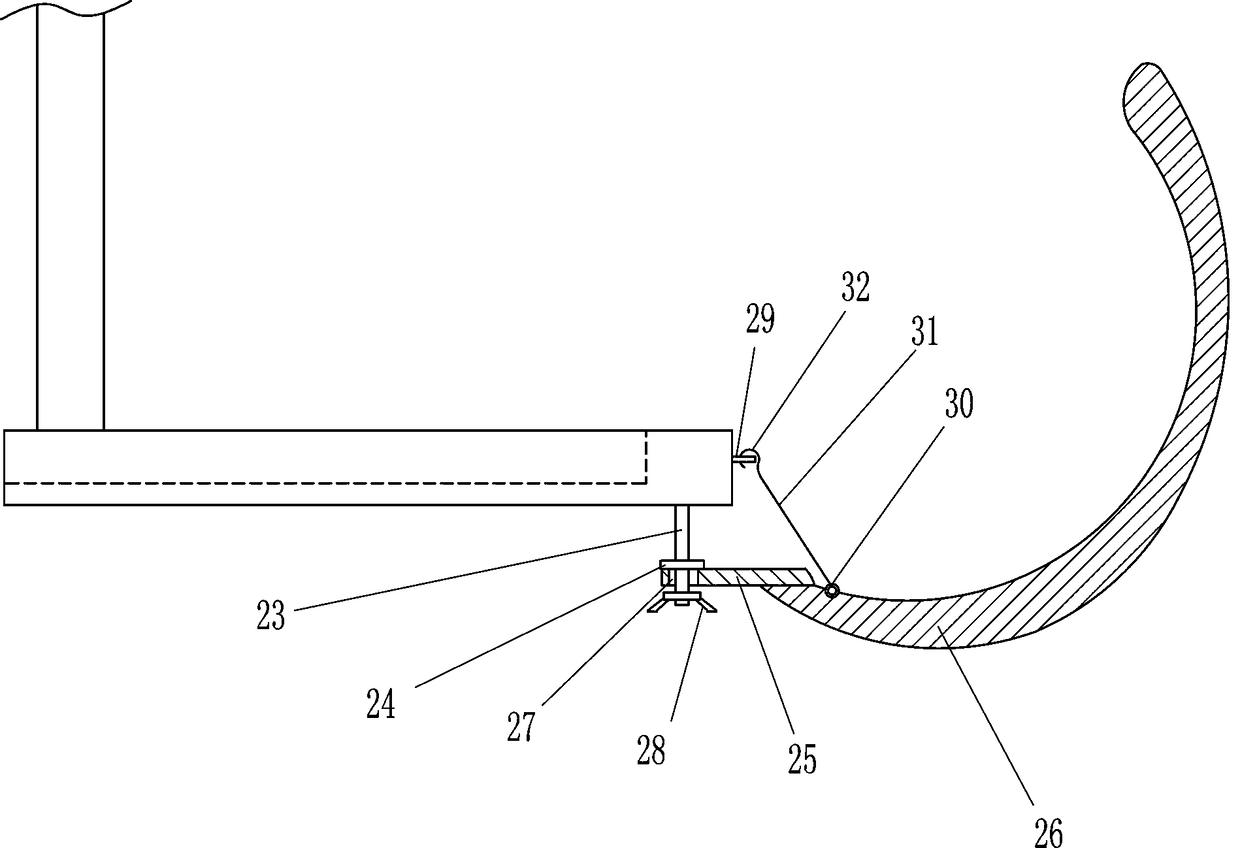

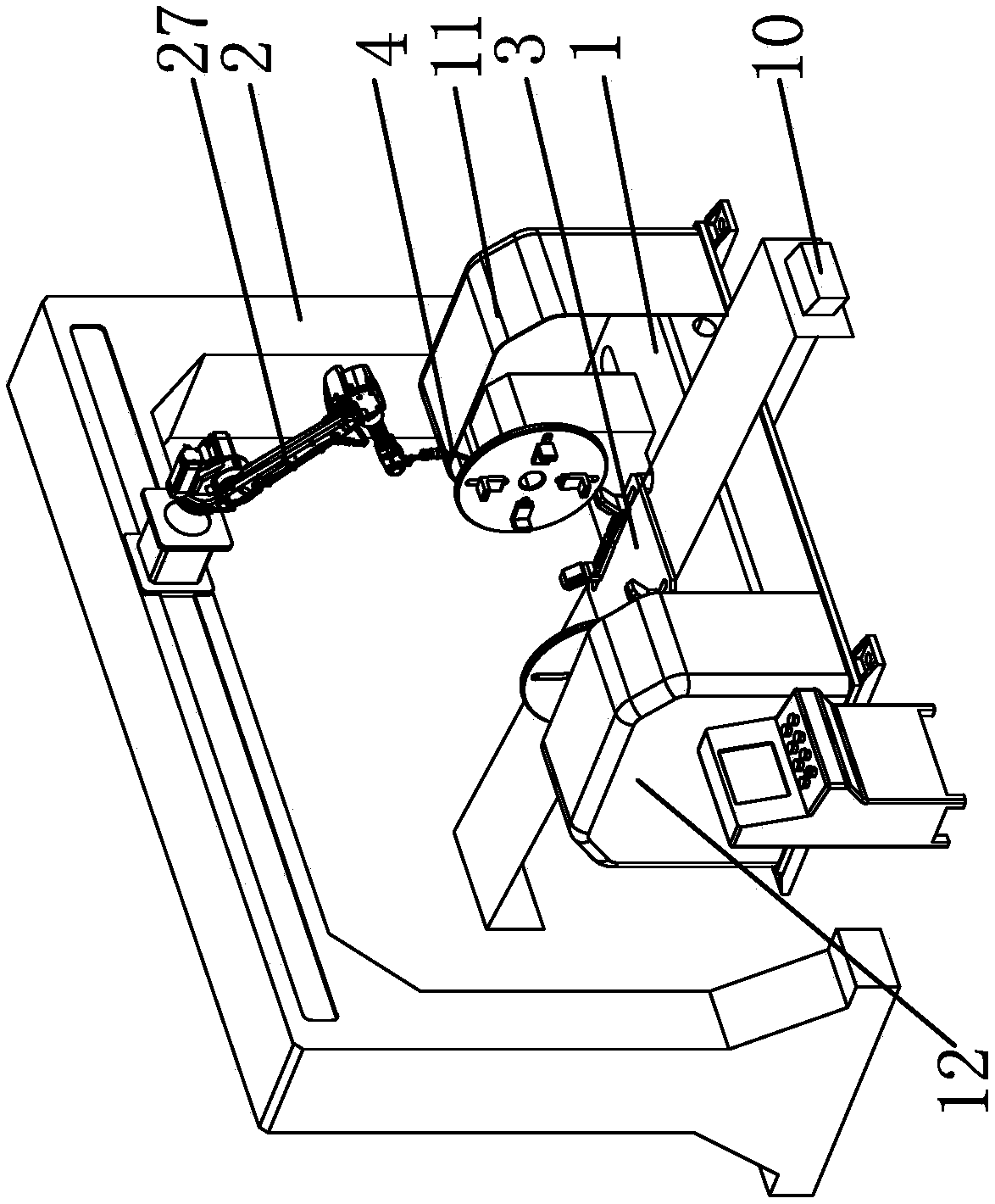

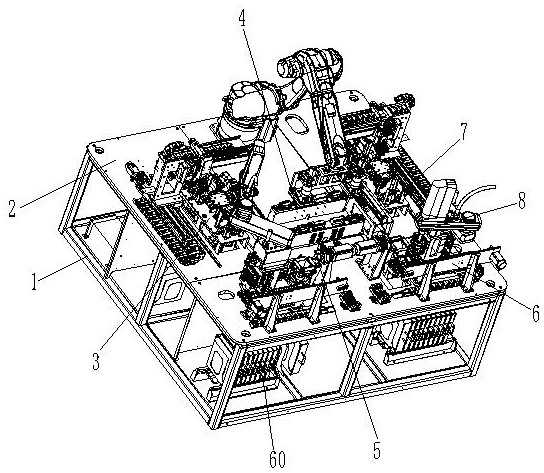

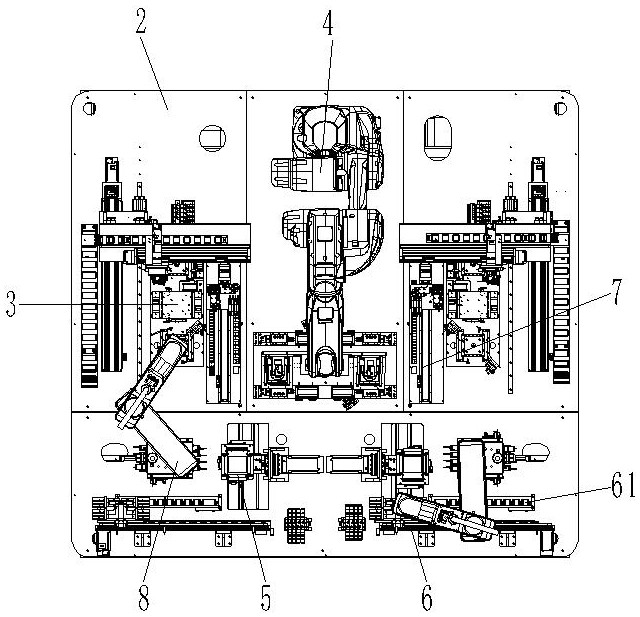

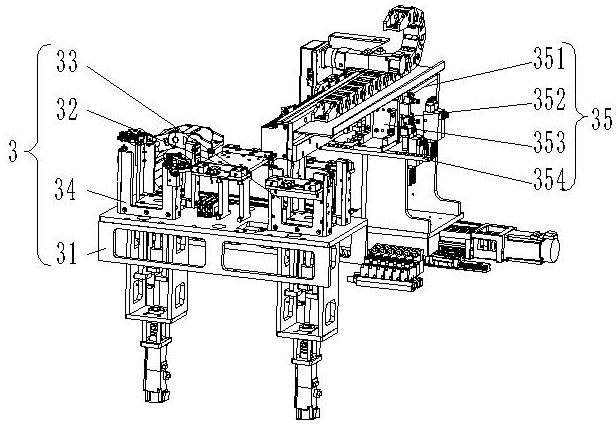

Mobile phone internal support plate appearance visual inspection device

ActiveCN113252696AComprehensive and precise shootingComprehensive and accurate detectionOptically investigating flaws/contaminationSortingVisual inspectionMechanical engineering

The invention relates to a mobile phone internal support plate appearance visual inspection device which is provided with a rack and a working platform, the working platform is provided with a feeding station, a detection station, a carrying station and a discharging station, the feeding station is provided with two feeding mechanisms which are oppositely arranged, the detection station is provided with a first detection mechanism and two oppositely-arranged second detection mechanisms, the carrying station is provided with two oppositely-arranged carrying mechanisms, the discharging station is provided with two oppositely-arranged discharging mechanisms, and the feeding mechanisms are in one-to-one correspondence with the carrying mechanisms and the discharging mechanisms; and the support plates on all the feeding mechanisms are transferred to the first detection mechanisms through the corresponding carrying mechanisms, the support plates are transferred to the corresponding second detection mechanisms through the corresponding carrying mechanisms to be detected after detection is completed, and the support plates are carried to the corresponding discharging mechanisms to be distributed and discharged after detection is completed. The device can realize comprehensive, rapid and accurate detection of the support plate, and is efficient and practical.

Owner:CHANGZHOU MICROINTELLIGENCE CO LTD

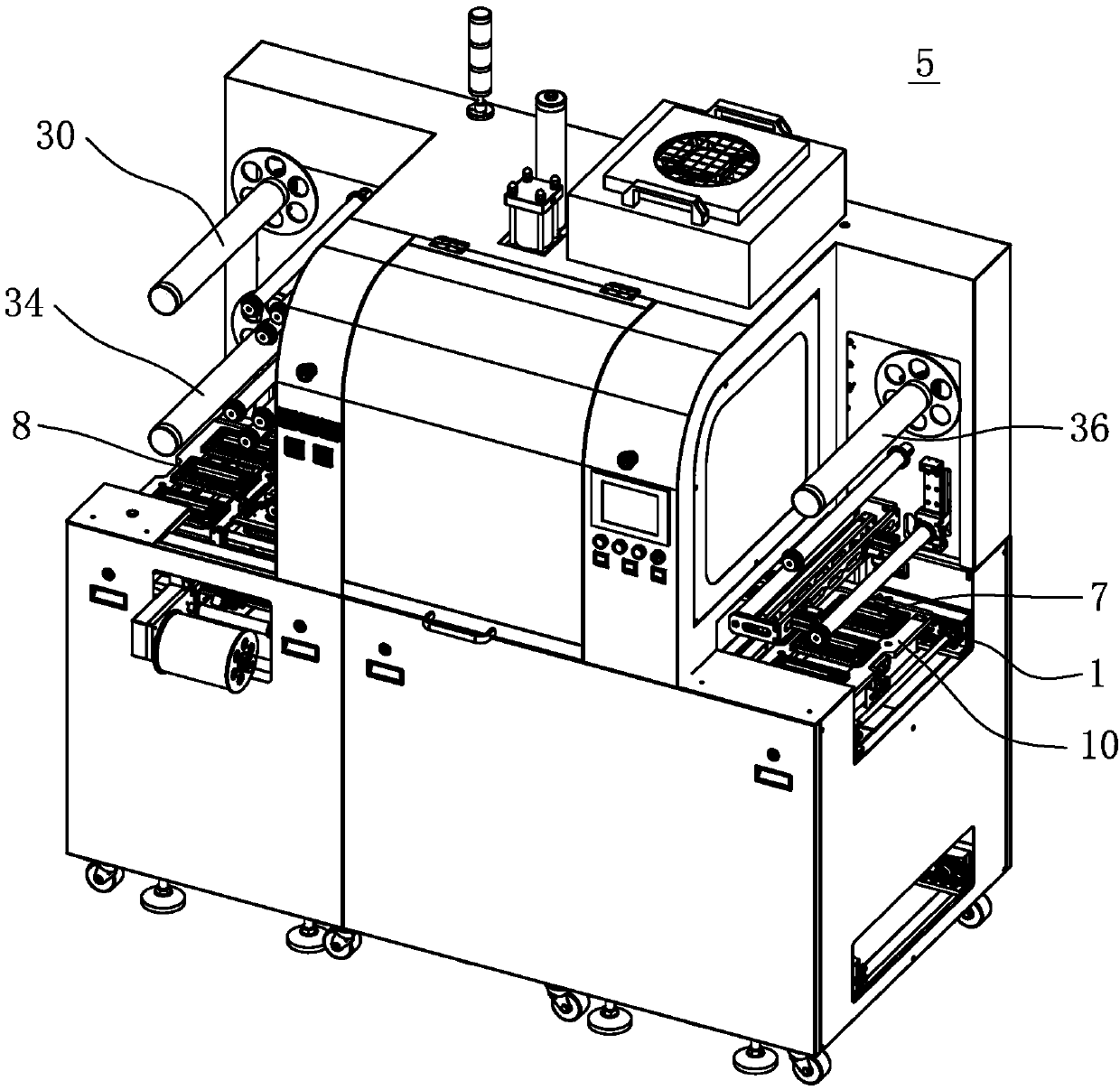

3D film pasting equipment and method

The invention provides 3D film pasting equipment and method. The 3D film pasting equipment comprises a fixture conveying device, a film pasting device, a film material supplying device, a driving mechanism, a temperature adjusting mechanism and a film cutting mechanism. The film pasting device is arranged above the fixture conveying device, and comprises an upper mold and a lower mold, an upper mold cavity and a lower mold cavity are formed in the upper mold and the lower mold correspondingly, an air channel communicating with the upper mold cavity and connected with an outer air source is formed in the upper mold, and the lower mold cavity penetrates through the lower mold up and down. The film materials supplied by the film material supplying device are arranged between the upper mold and the lower mold, the upper mold cavity is aligned with the lower mold cavity to form a film pasting cavity when the upper mold is assembled with the lower mold, and the film materials seal the uppermold cavity. The driving mechanism drives the upper mold to lift relative to the lower mold. The temperature adjusting mechanism jacks a workpiece which needs to be subjected to film pasting and is conveyed by the fixture conveying device to a jacking mechanism which is attached to the film materials in the film pasting cavity. According to the 3D film pasting equipment and method, the upper moldcavity is sealed by the film materials, after preheating is conducted, the jacking mechanism jacks the workpiece needing to be subjected to film pasting into the film pasting cavity to be attached tothe film materials in high precision, and the automation degree is high.

Owner:SHENZHEN HANJIANG AUTOMATION SCI & TECH CO LTD

Feed put-in equipment for pig breeding

ActiveCN111492993AStir wellAutomatic cuttingRotary stirring mixersTransportation and packagingAnimal sciencePig breeding

The invention relates to put-in equipment, and especially relates to feed put-in equipment for pig breeding. The technical problems to be solved are to provide the feed put-in equipment for pig breeding which can automatically and intermittently put in feed and fully stir the feed. The put-in equipment includes an installation platform, four universal wheels, a push rod and a material storage box;the installation platform is used for supporting the whole equipment; the universal wheels are symmetrically arranged at the bottom of the installation platform; the push rod is arranged on the top of the installation platform and used for pushing the equipment; and the material storage box is arranged on the top of the installation platform and in opposite arrangement with the push rod. The put-in equipment can achieve the effects of automatically and intermittently putting in the feed and fully stirring the feed; and a first rotating shaft drives a stirring rod to continuously rotate, so that the feed can be continuously stirred and fully mixed.

Owner:李启福

Equal-distance cutting device for grey tiles

PendingCN112917709AAutomatic cuttingEasy to collectWorking accessoriesStone-like material working toolsRatchetGear wheel

The invention relates to an equal-distance cutting device, in particular to an equal-distance cutting device for grey tiles. The technical aim to be achieved is to provide the equal-distance cutting device for the grey tiles. The device can automatically carry out cutting and facilitates collection. The equal-distance cutting device for the grey tiles comprises a base, two supporting columns, a guide rail, a pulling mechanism, a cutting knife and a pushing mechanism. The two supporting columns are symmetrically arranged at the top of the base. The guide rail is arranged between the supporting columns; the pulling mechanism is arranged in the middle of the top of the base; the cutting knife is arranged on the pulling mechanism; and the pushing mechanism is arranged at one side of the guide rail in a sliding manner. A piston rod of an air cylinder can drive a push plate to move rightwards, the push plate can push the grey tiles rightwards, after the grey tiles are pushed to the right side of the guide rail, a ratchet wheel can drive a rotating rod to rotate clockwise, the rotating rod can drive a groove rod and the cutting knife to move forwards to cut the grey tiles at equal intervals, and the effect of automatic cutting is achieved.

Owner:马佳炫

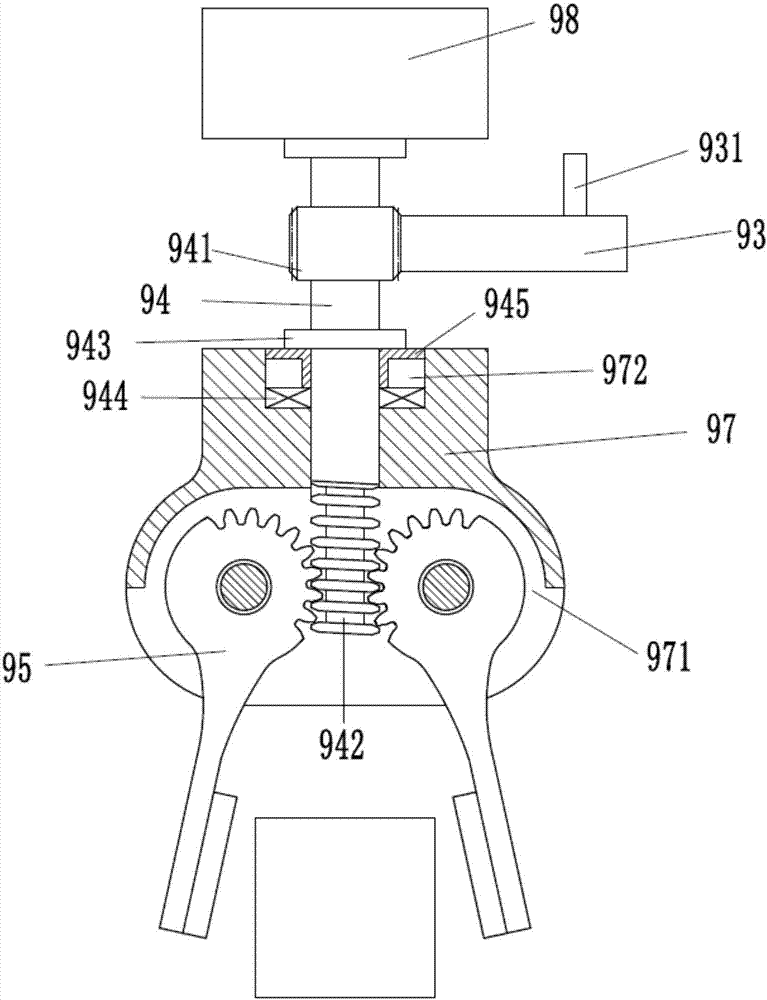

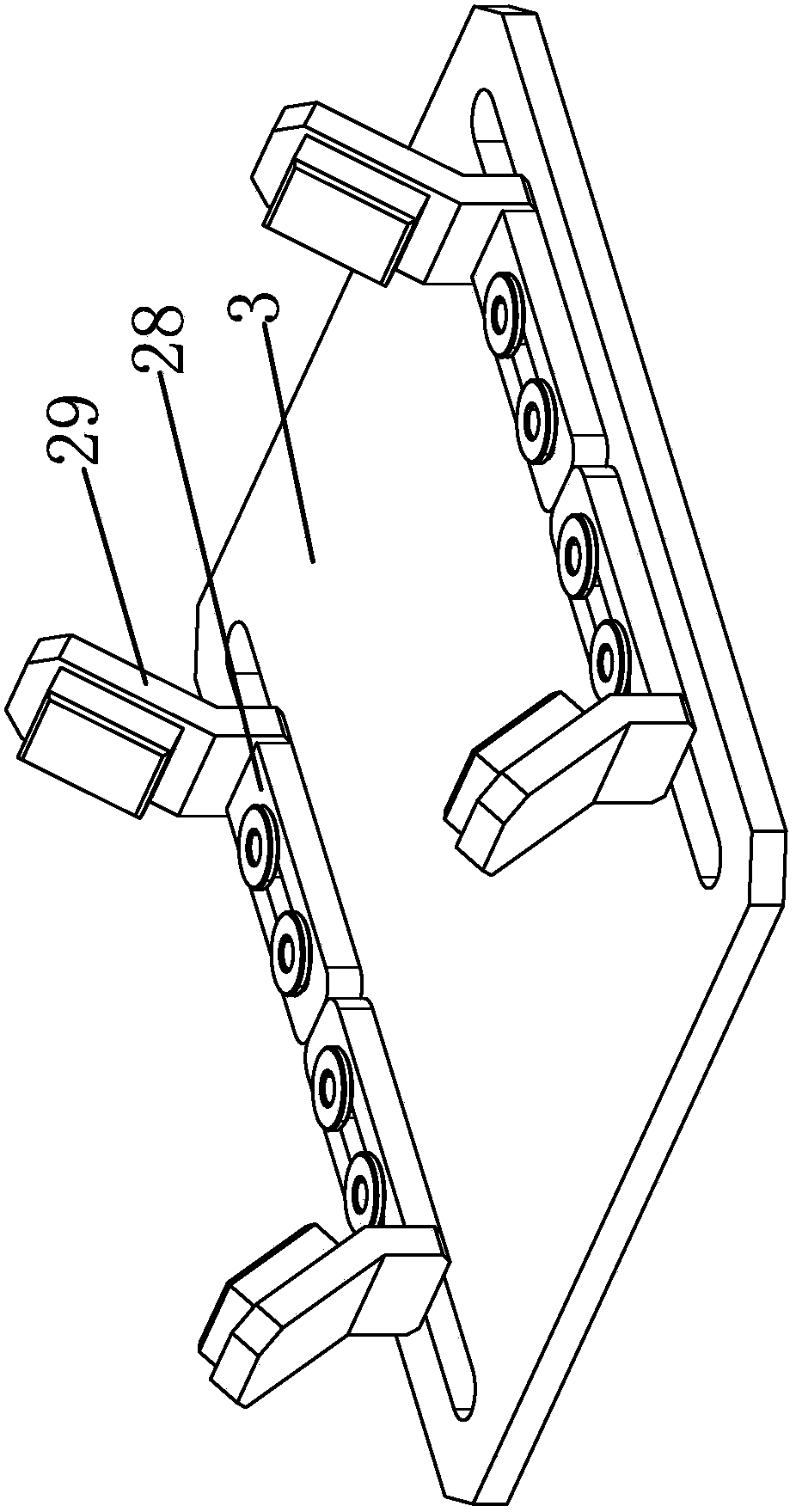

Grab mechanism of high-precision spot welding machine

InactiveCN108788421AImprove work efficiencyAccurate captureResistance welding apparatusSpot weldingIndustrial engineering

The invention provides a grab mechanism of a high-precision spot welding machine, and belongs to the technical field of spot welding machines. The problem of low welding quality in the prior art is solved. According to the grab mechanism of the high-precision spot welding machine, the high-precision spot welding machine comprises a work box which is provided with a welding bench, and one end of the welding bench is provided with an electrode I; and the other end of the welding bench is provide with an electrode II, and a weldment comprises a part seat and a part block welded with the part seat. The grab mechanism is characterized in that the grab mechanism is arranged above the welding bench, and comprises a base fixed to the work box, and the base is rotatably provided with a fourth screwrod as well as an erection column in parallel with the fourth screw rod; one end of the fourth screw rod is connected to a working motor which enables the fourth screw rod to rotate, and the fourth screw rod is in threaded connection with a nut III which is fixedly provided with a sliding seat II; the sliding seat II is provided with a sliding hole II, and the sliding seat II and the erection column are slidably arranged. The grab mechanism has the advantage that the welding quality is improved.

Owner:浙江豪精机电有限公司

High-precision spot welding machine

PendingCN108714736AImprove work efficiencyAccurate captureResistance welding apparatusEngineeringSpot welding

The invention provides a high-precision spot welding machine, and belongs to the technical field of welding machines. The high-precision spot welding machine solves the problem that in the prior art,the welding quality is low. The high-precision spot welding machine comprises a working box, a welding object of the high-precision spot welding machine comprises a part seat and a part block, the part block is welded on the part seat, a welding table is arranged on the working box, a first electrode is arranged at one end of the welding table, a second electrode is arranged at the other end of the welding table, a feeding mechanism capable of feeding the part seat is arranged on one side of a welding machine table, a placing frame is arranged at one end of the welding machine table, a conveying mechanism capable of conveying the part block is arranged on one side of the placing frame, and a grabbing mechanism capable of grabbing the part seat, the part block and a finished welded productis arranged above the welding table. The high-precision spot welding machine has the advantage of improving the welding efficiency.

Owner:浙江豪精机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com