Patents

Literature

44results about How to "Prevents affecting cut quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

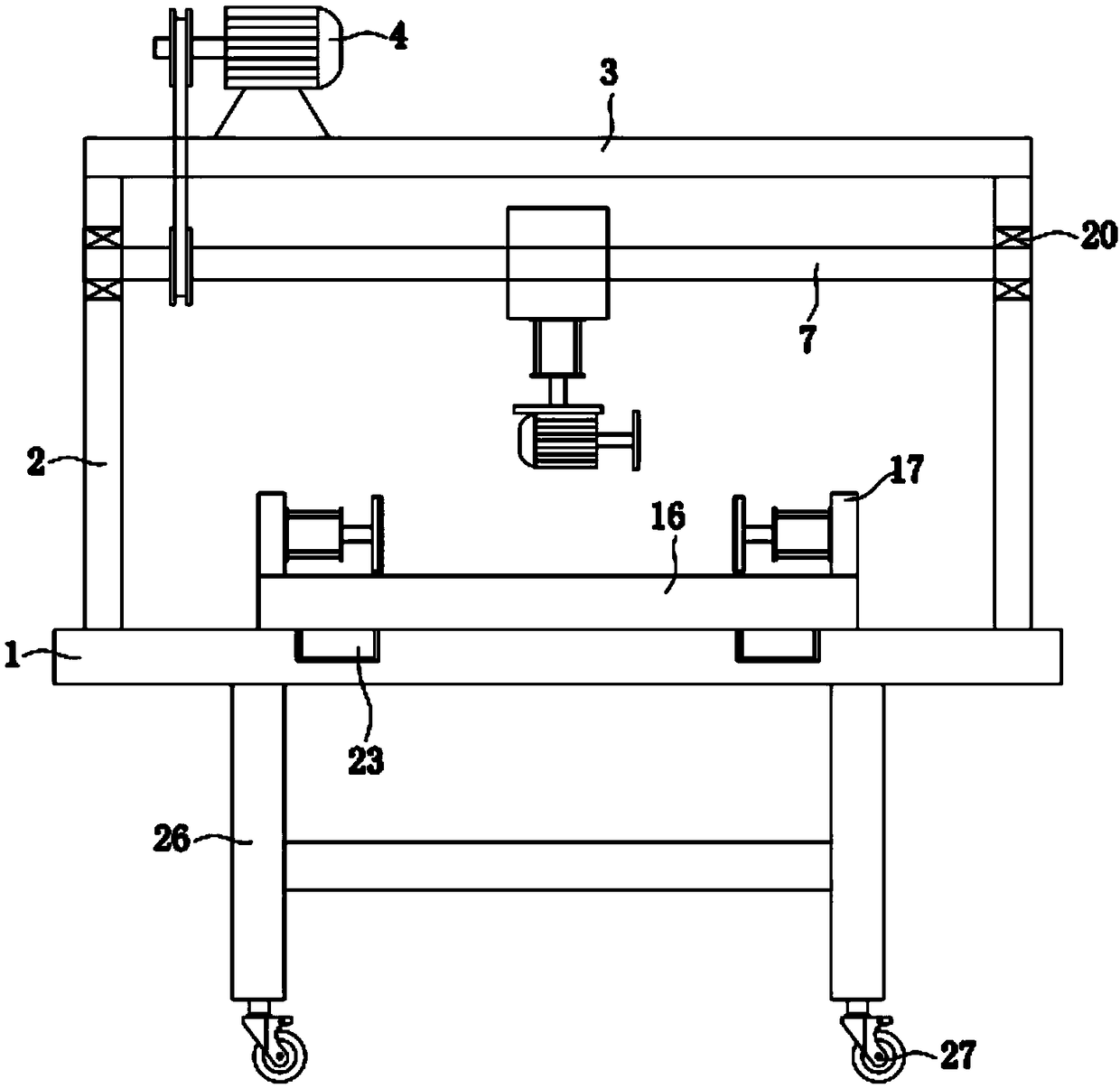

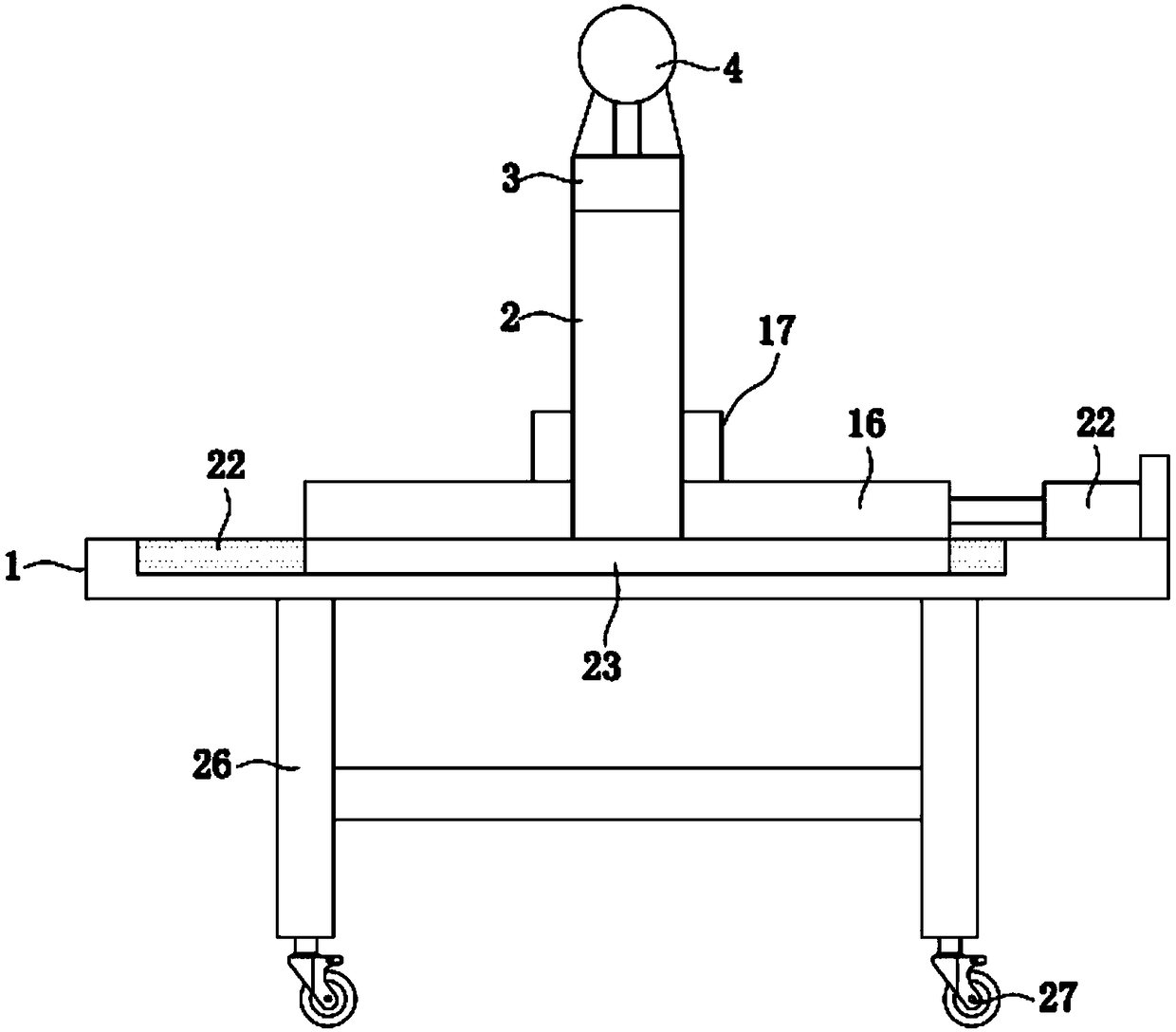

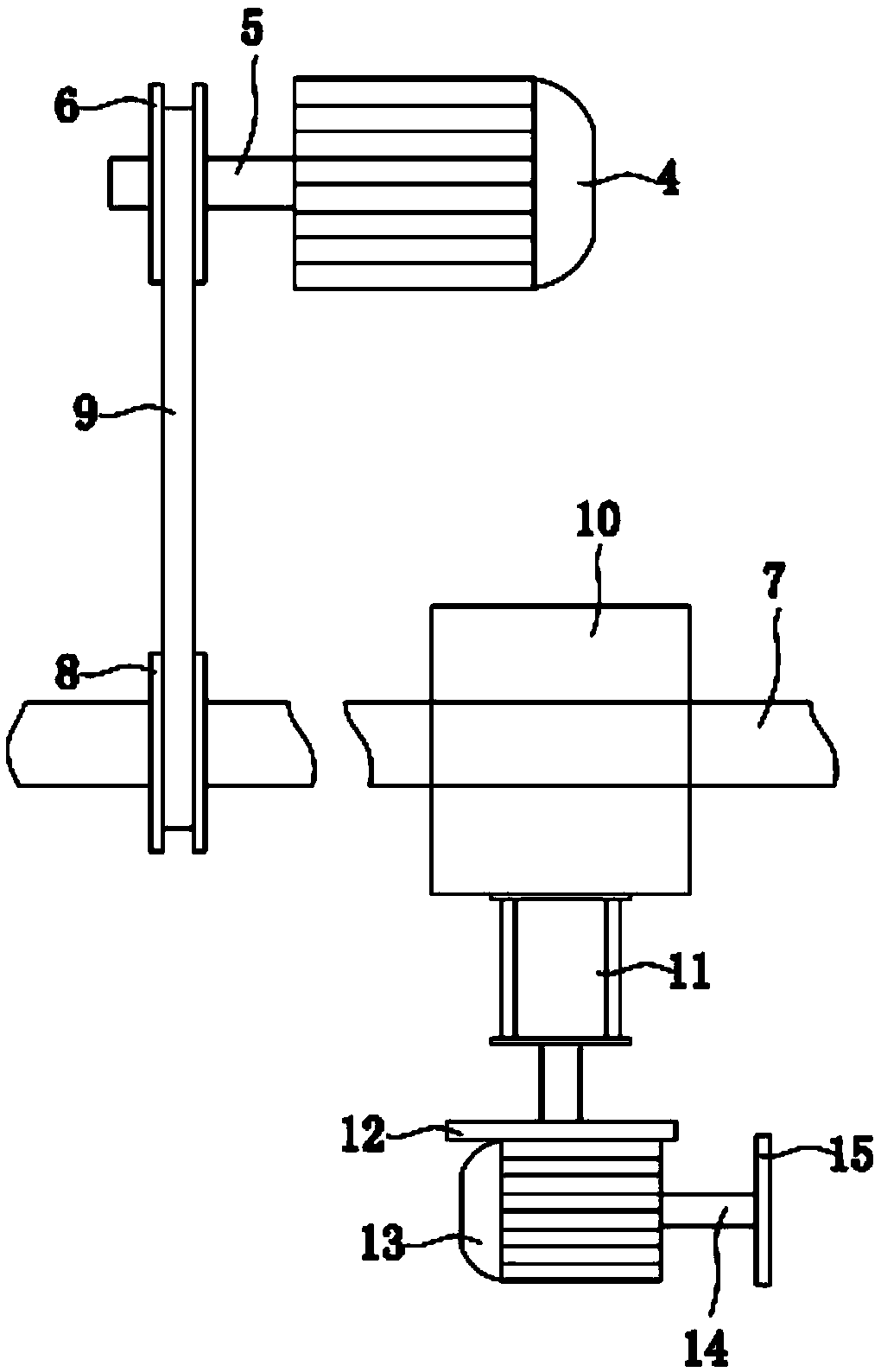

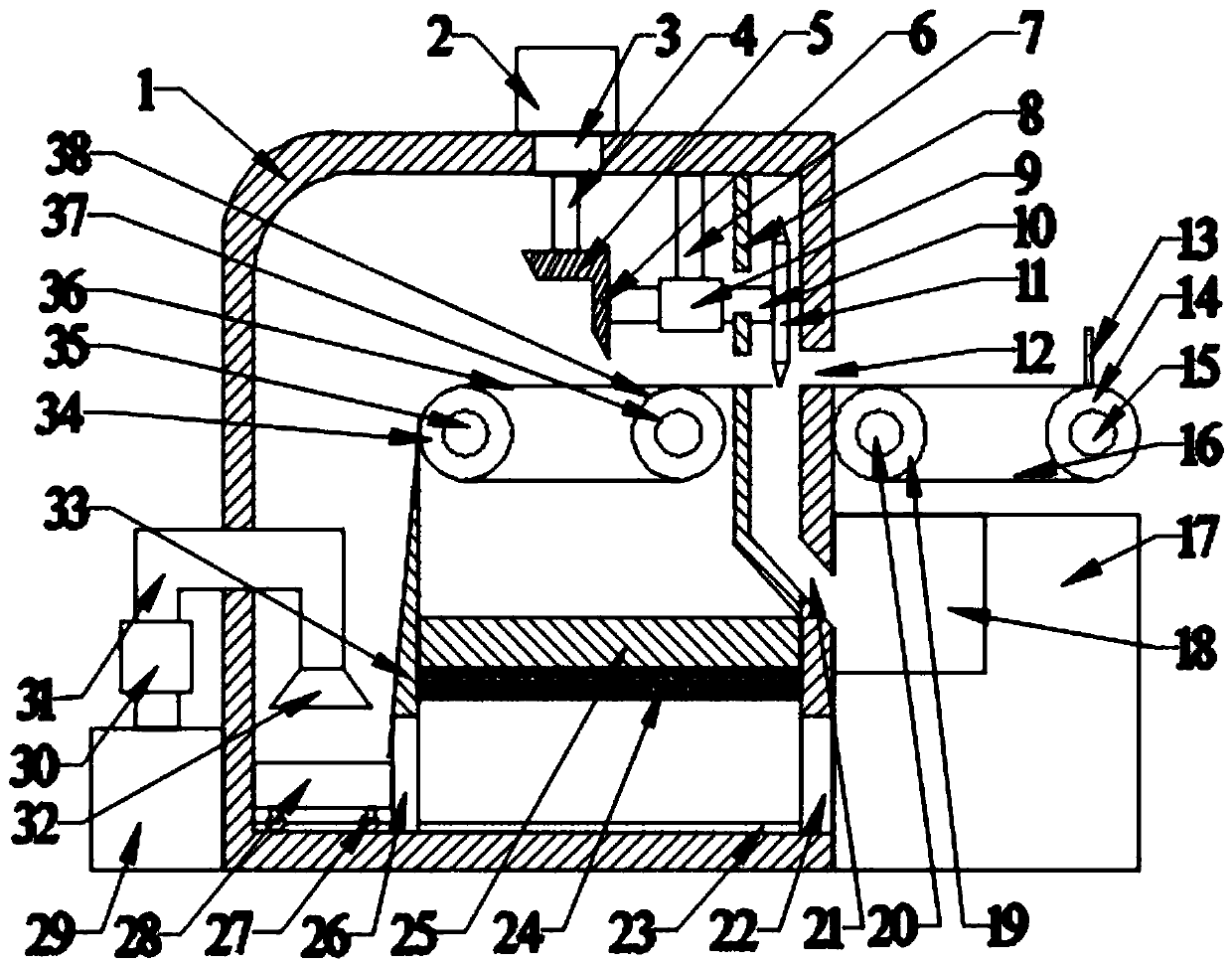

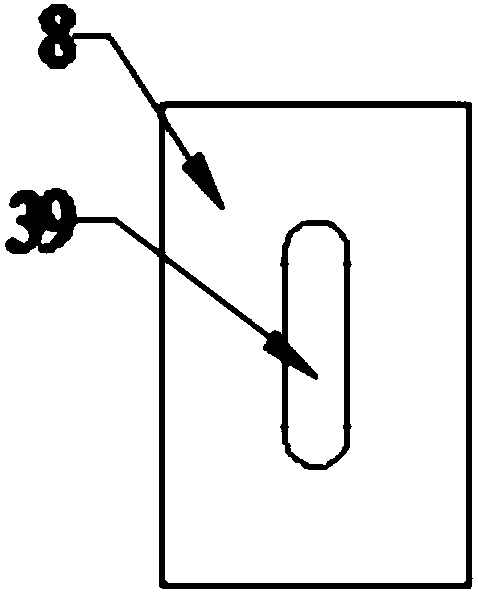

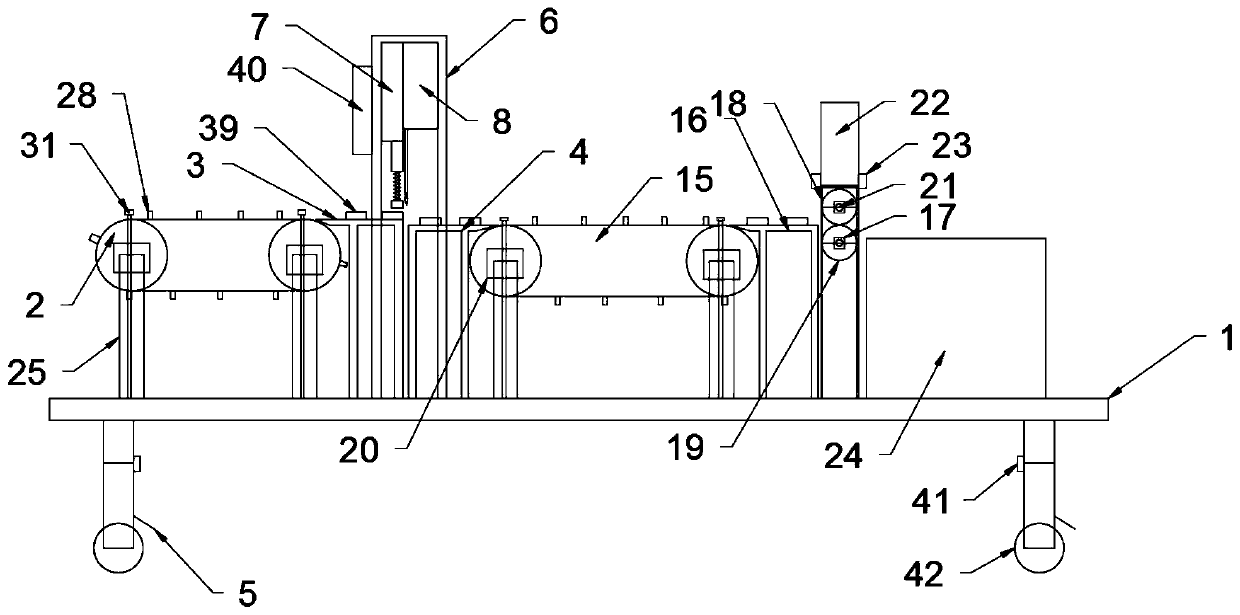

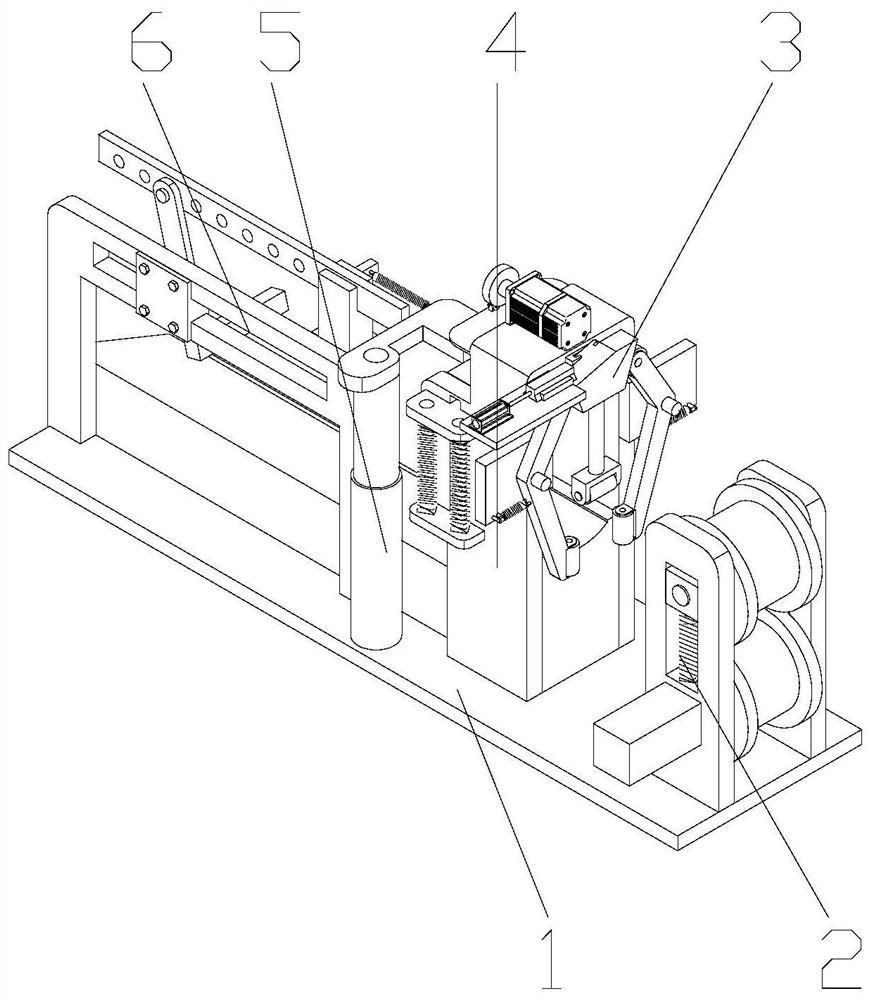

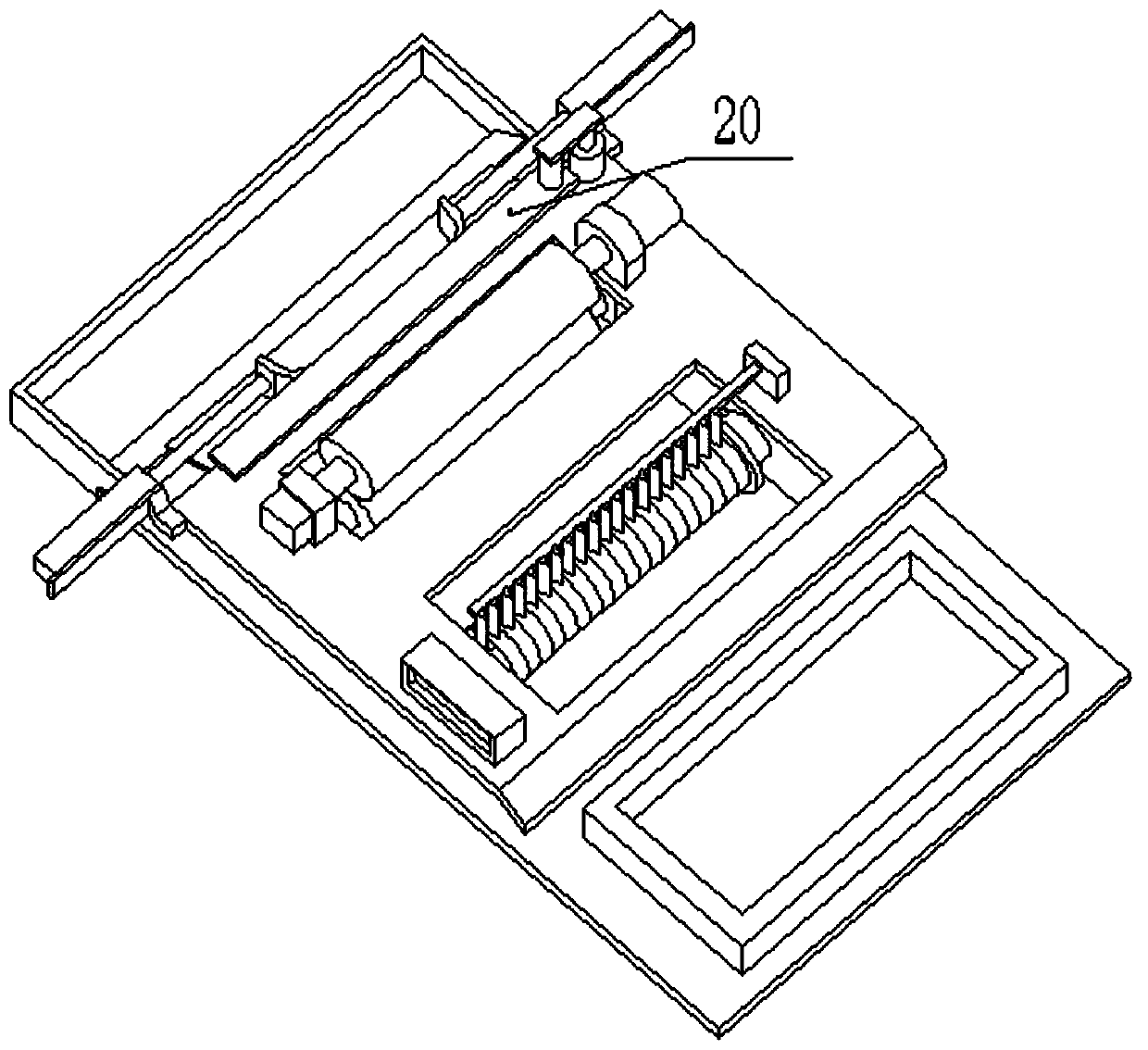

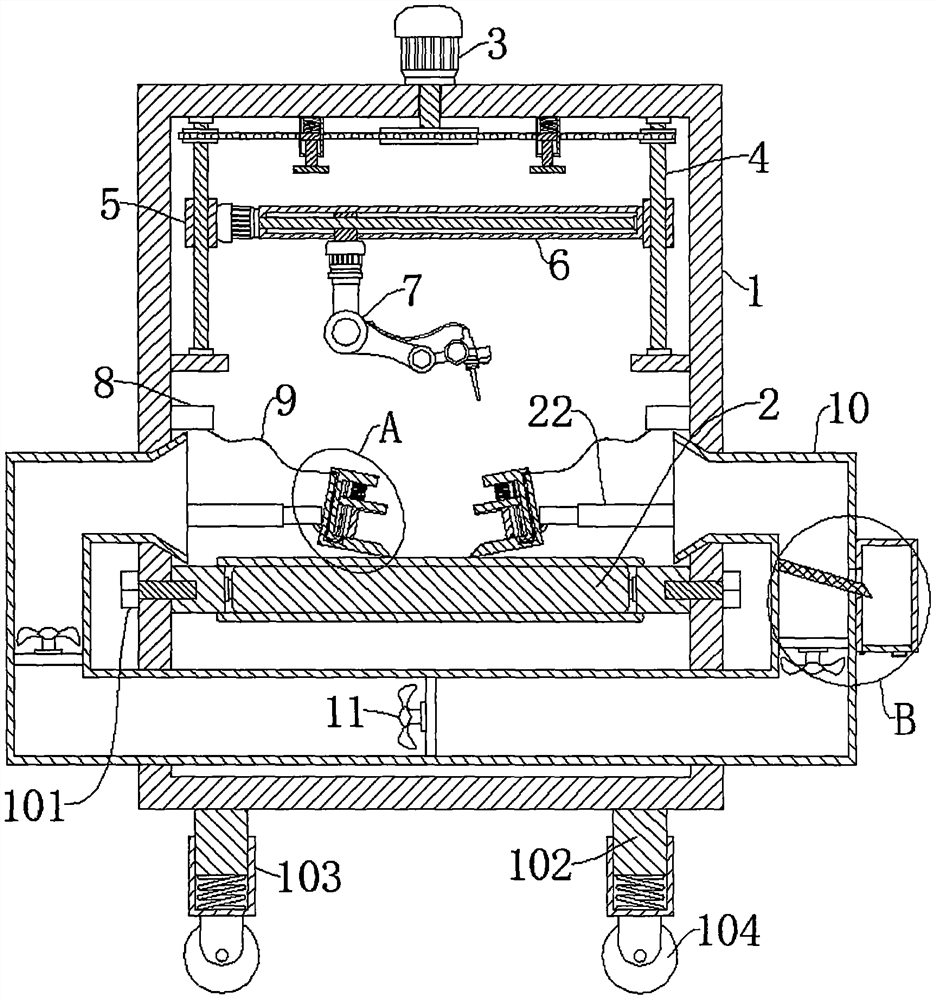

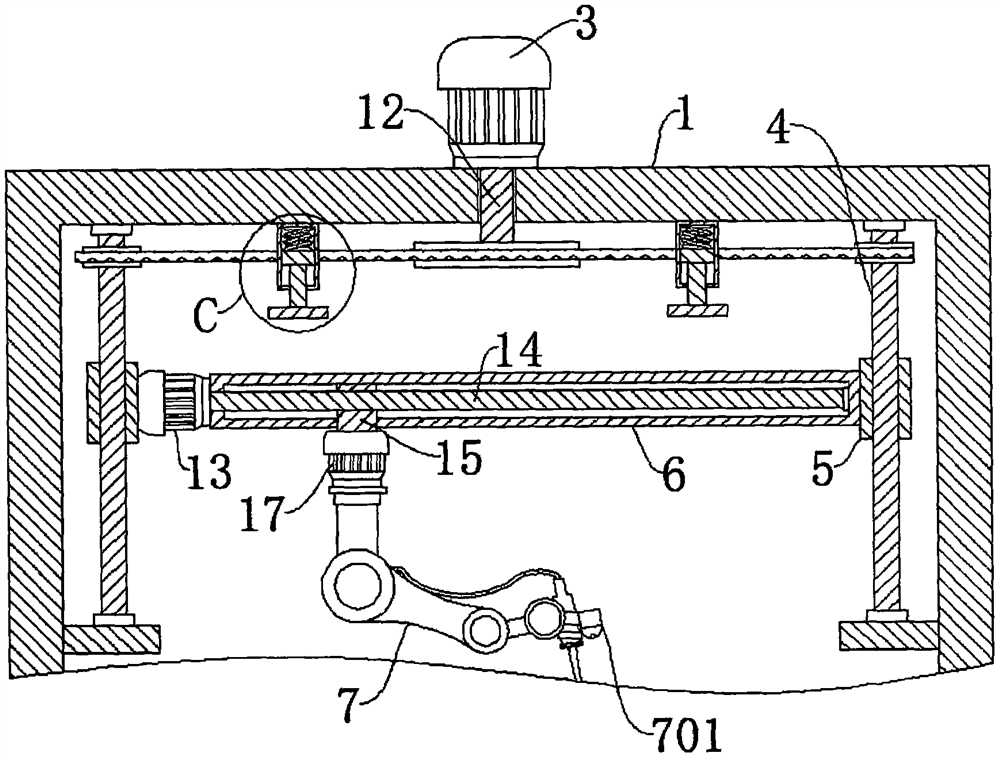

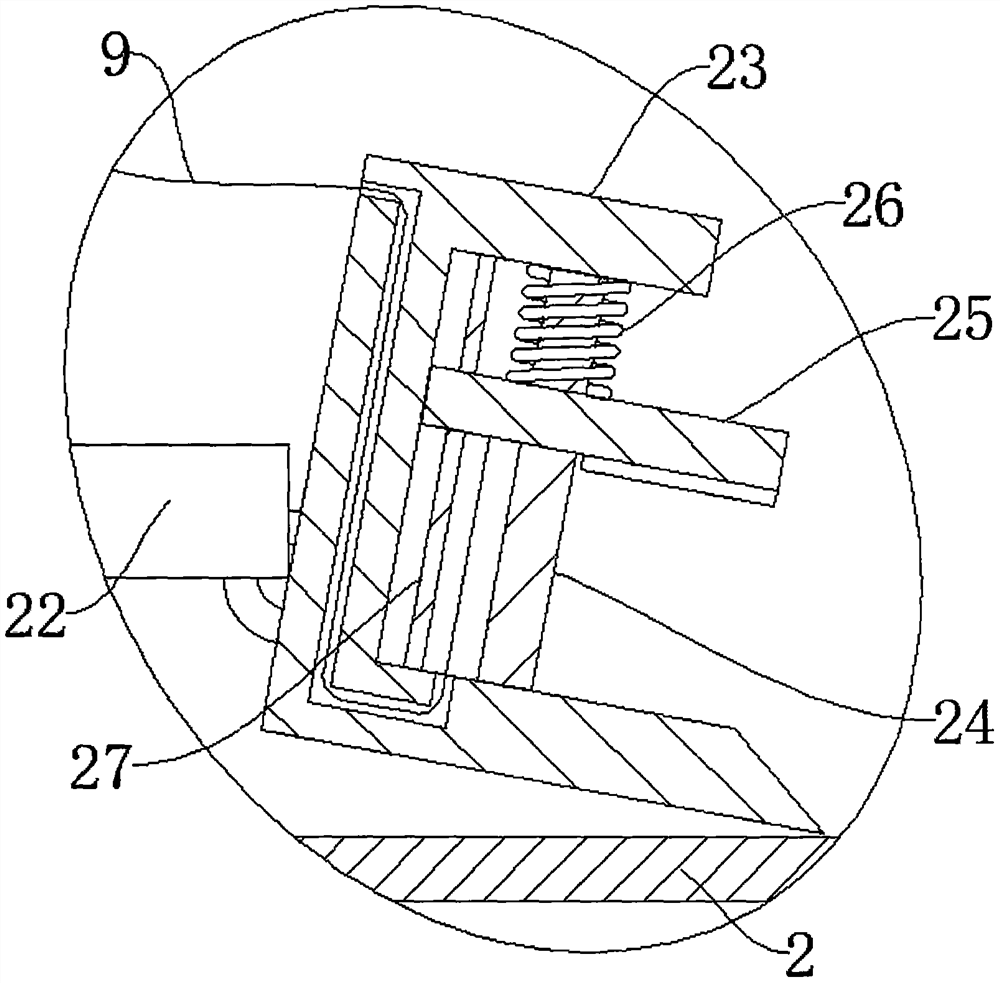

Building cutting device and using method thereof

InactiveCN109262069APrevents affecting cut qualityEasy to adjustWork clamping meansLarge fixed membersHydraulic cylinderEngineering

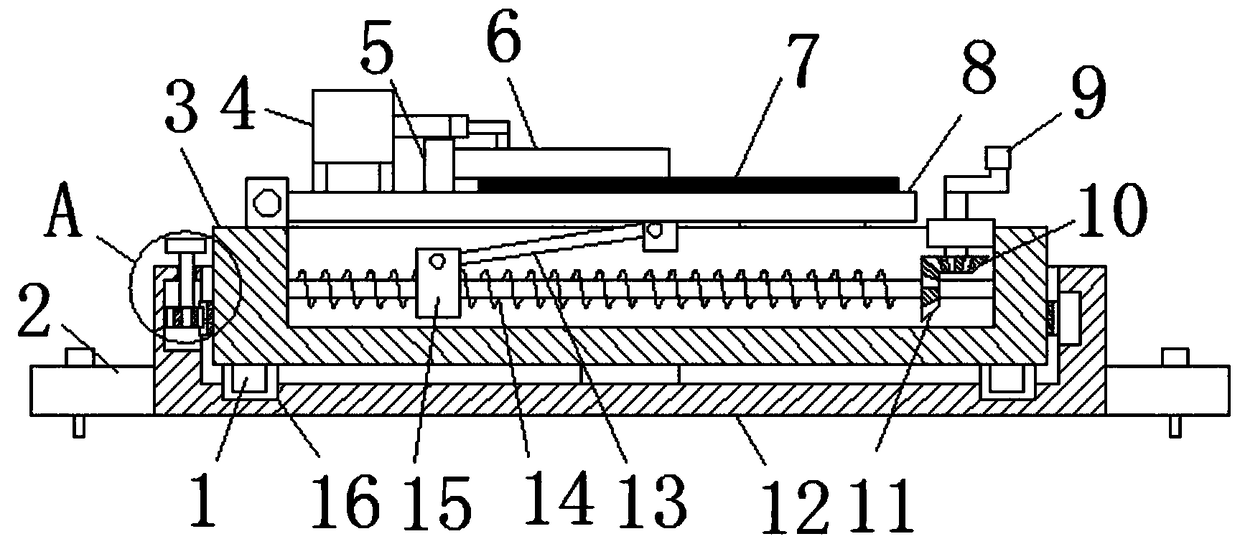

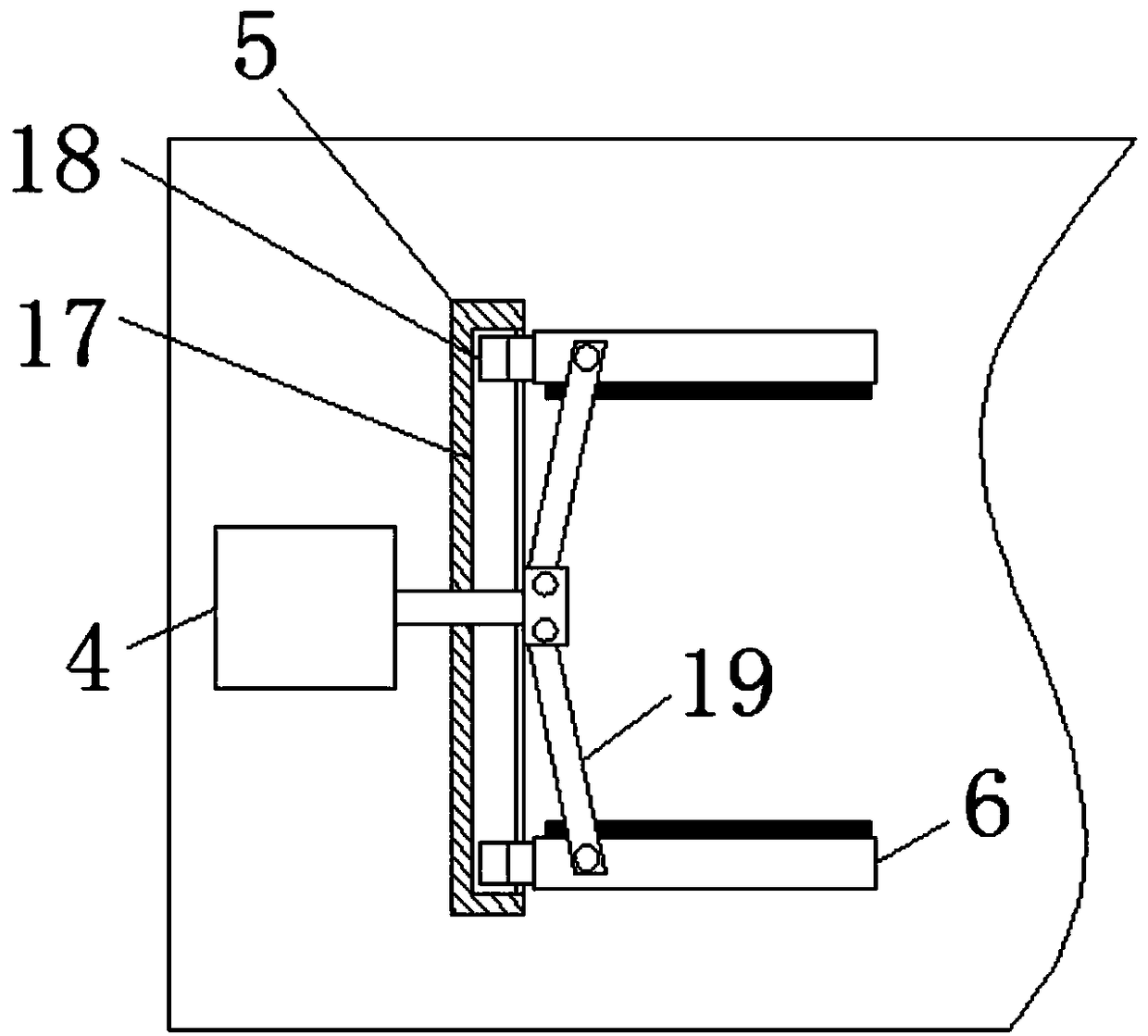

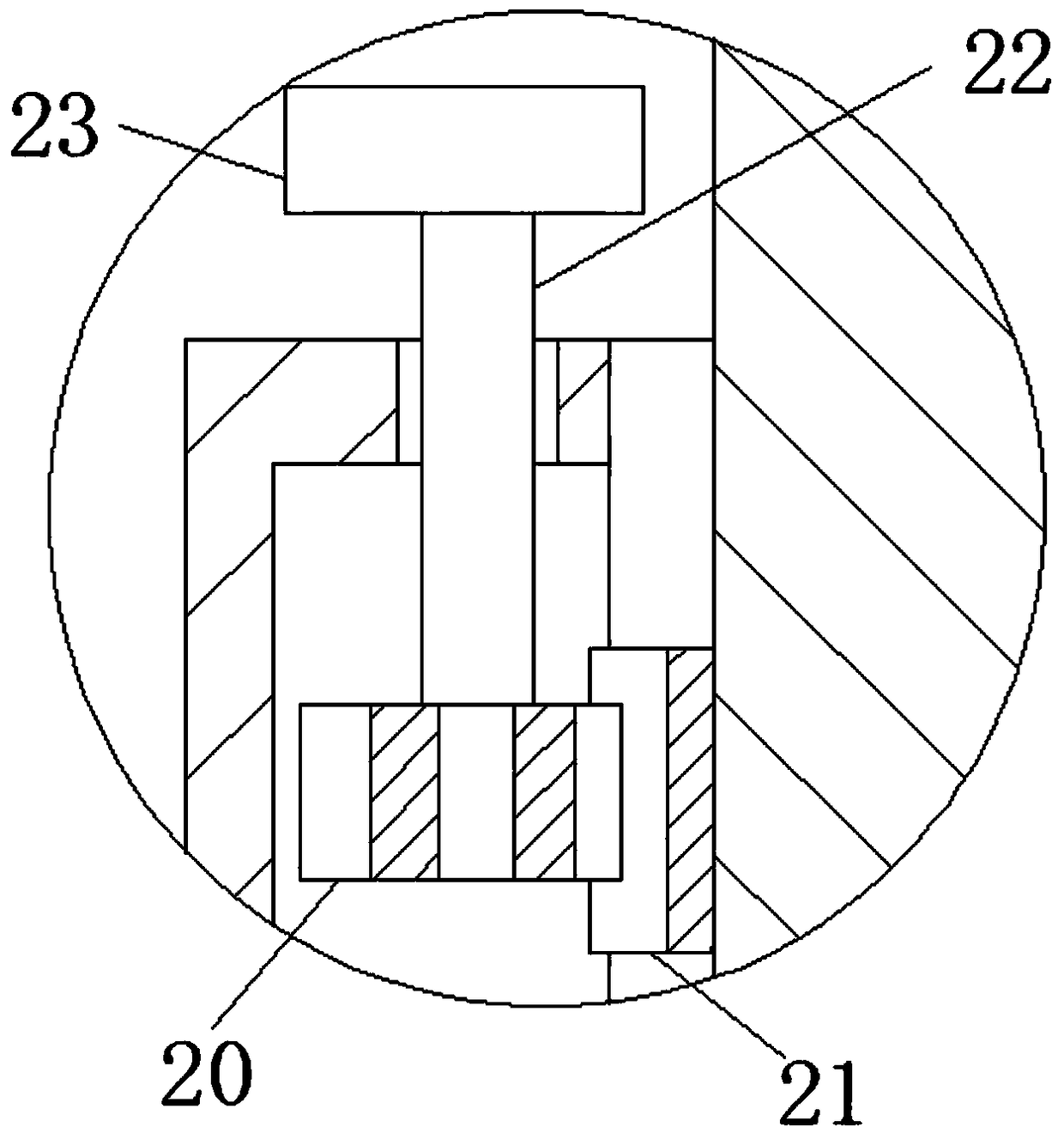

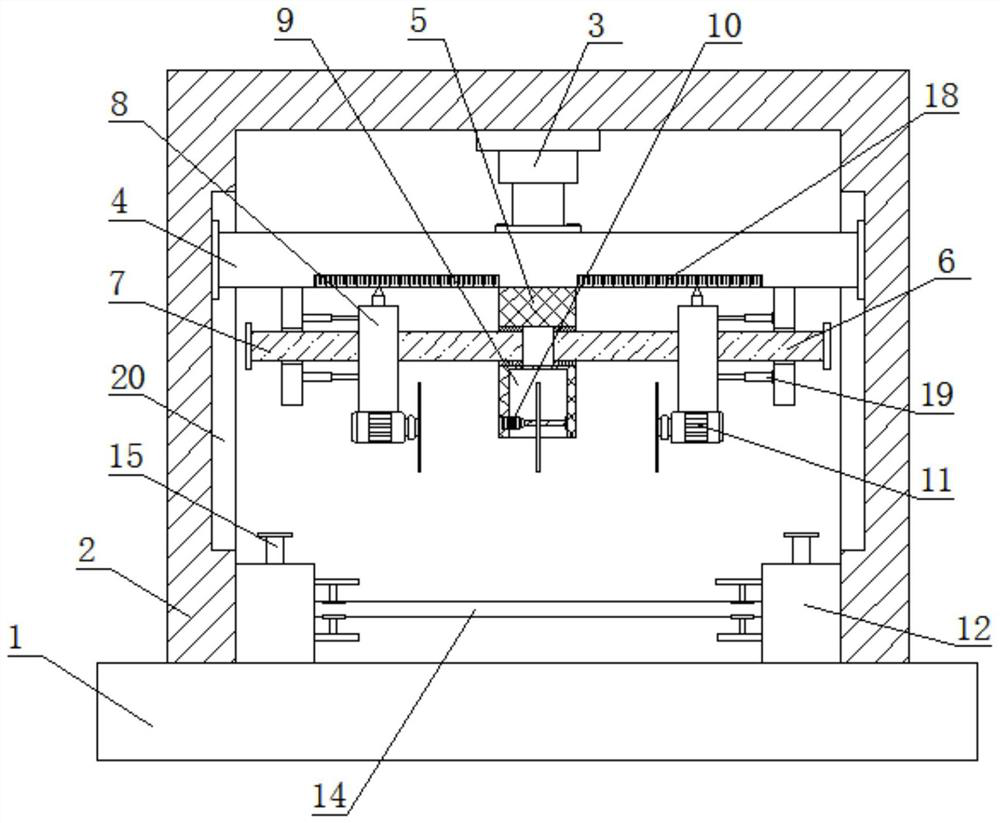

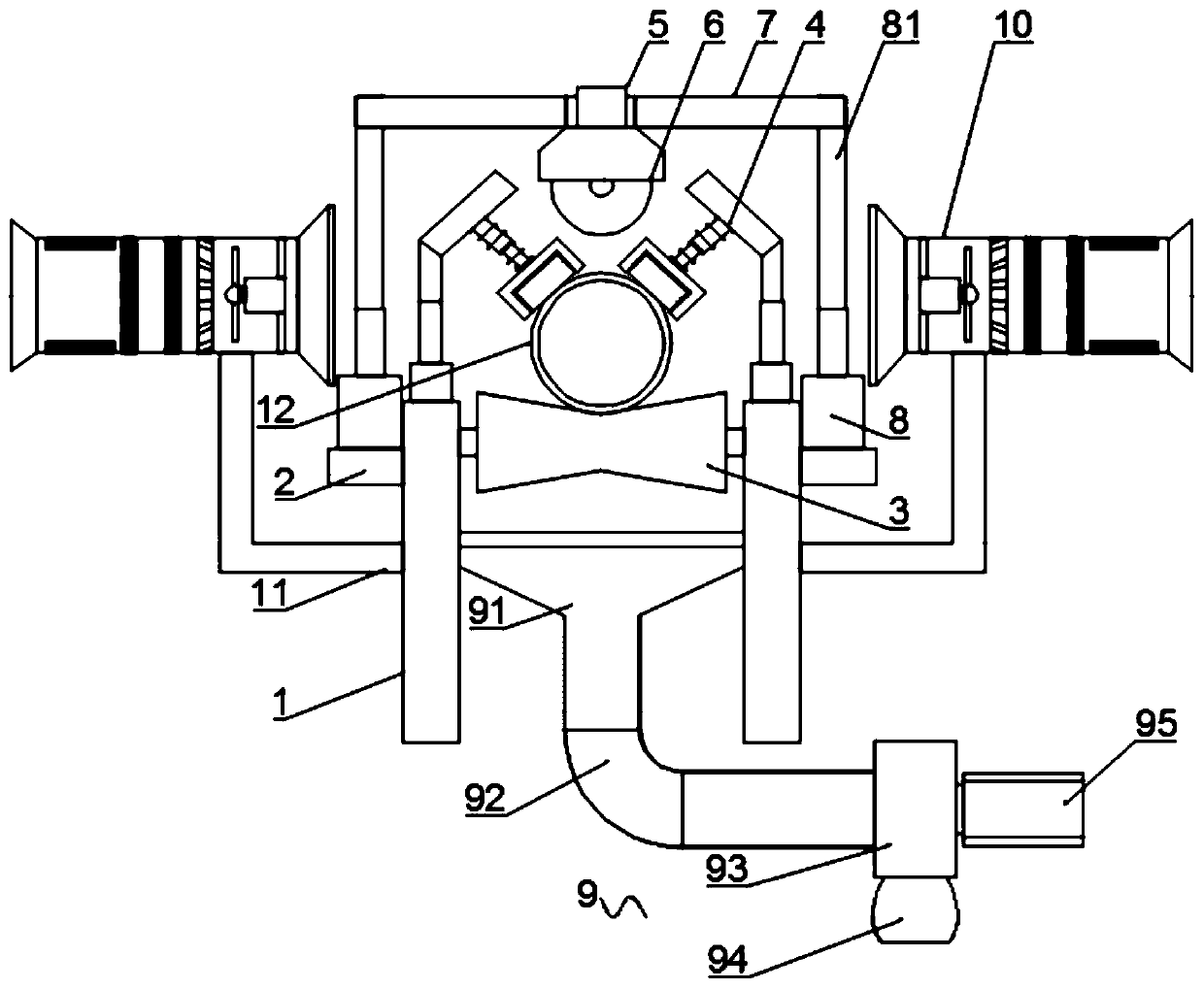

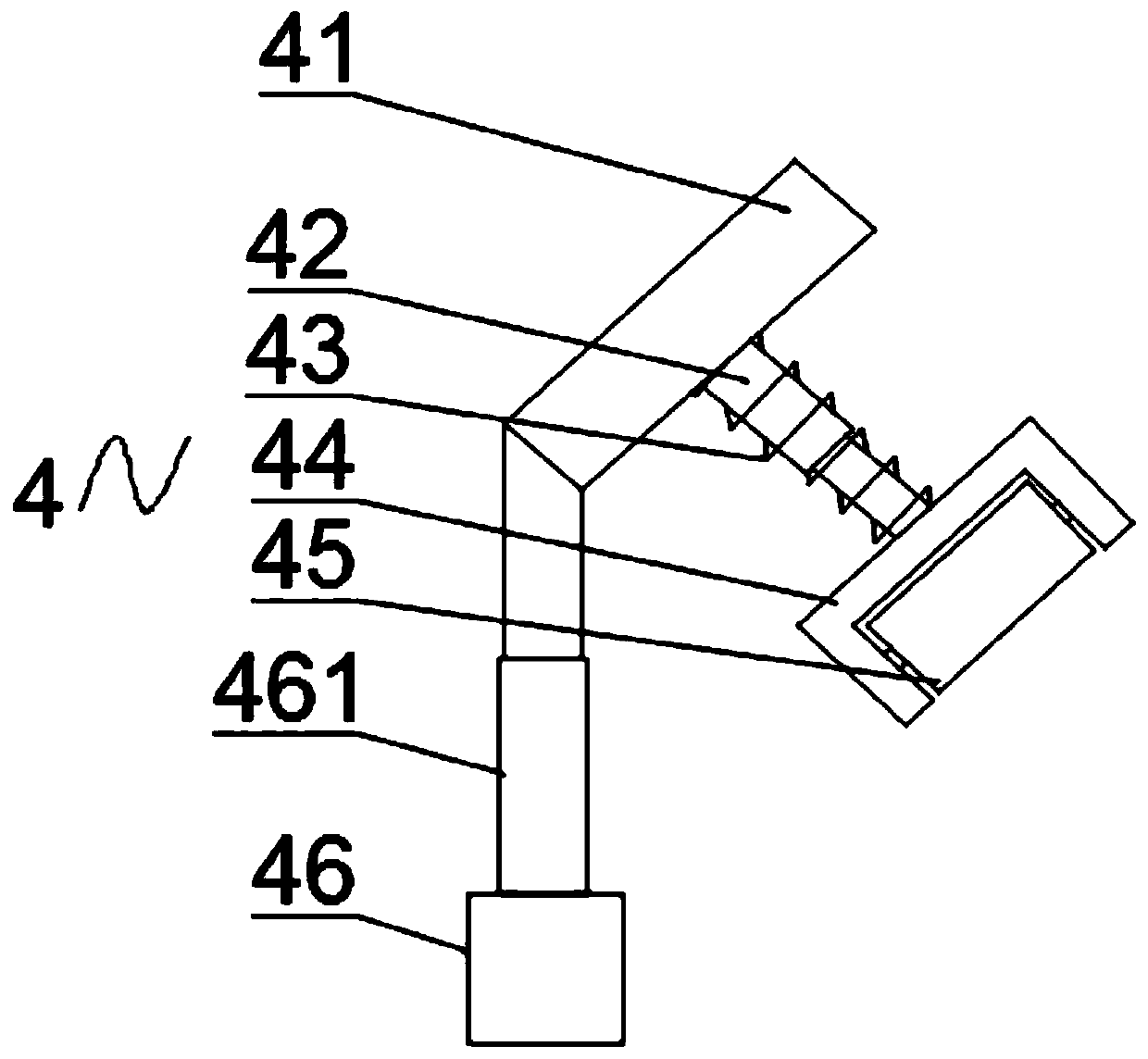

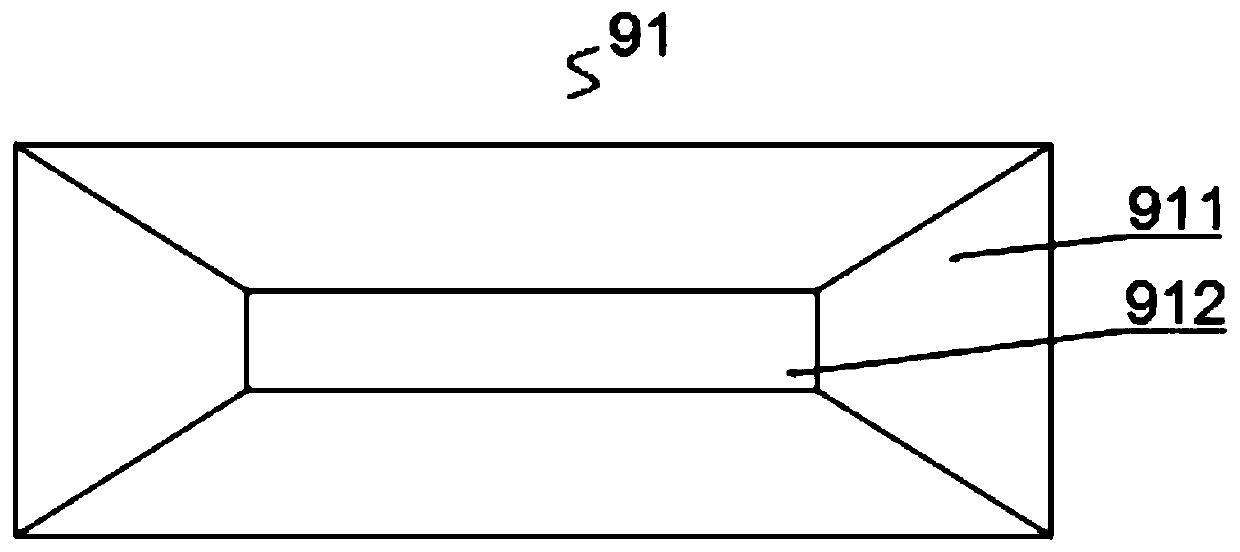

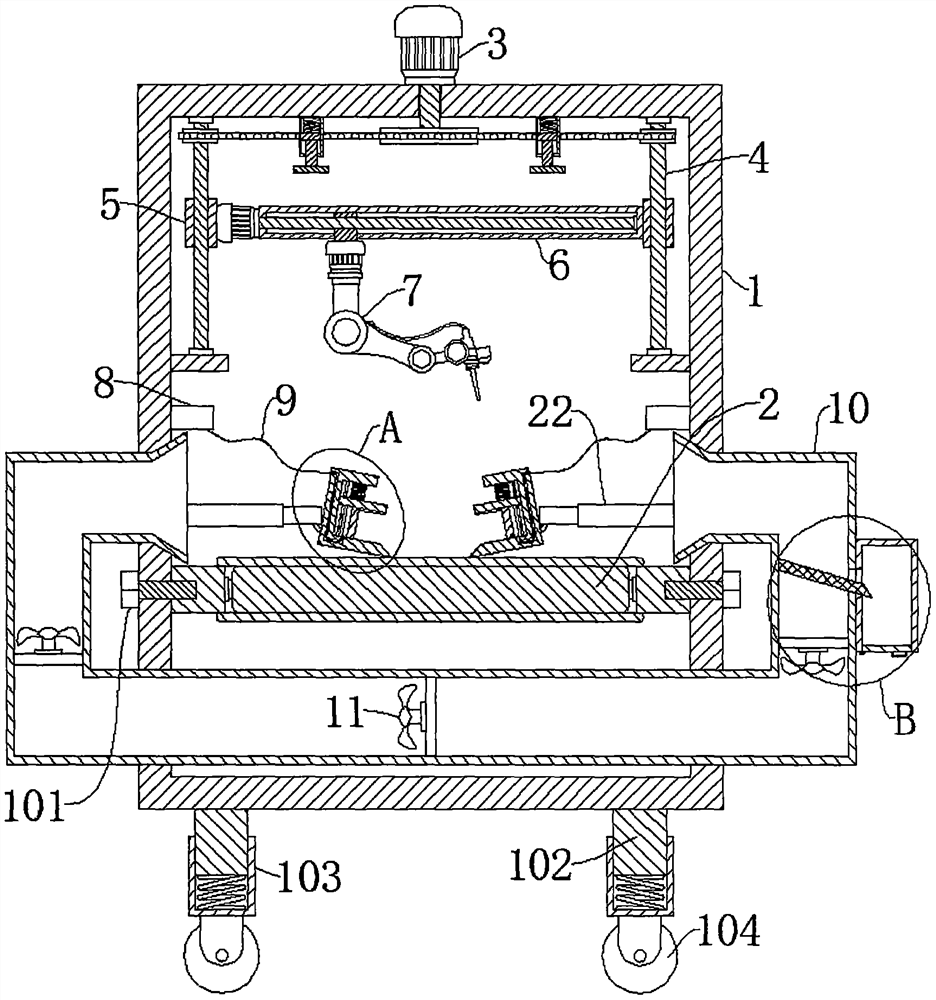

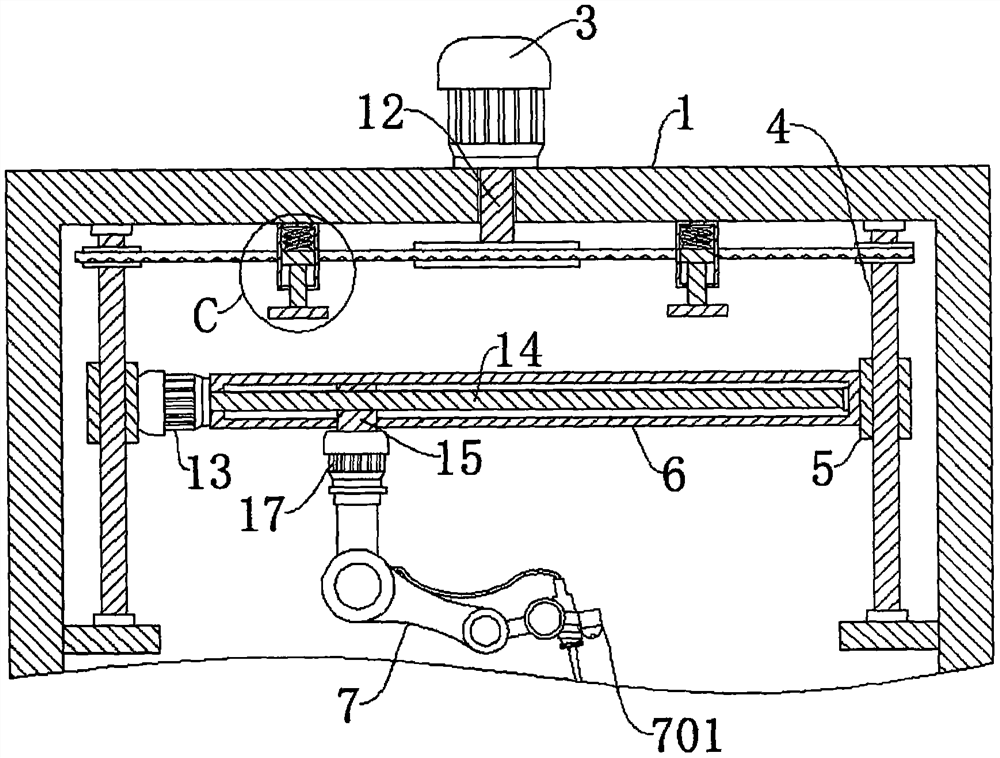

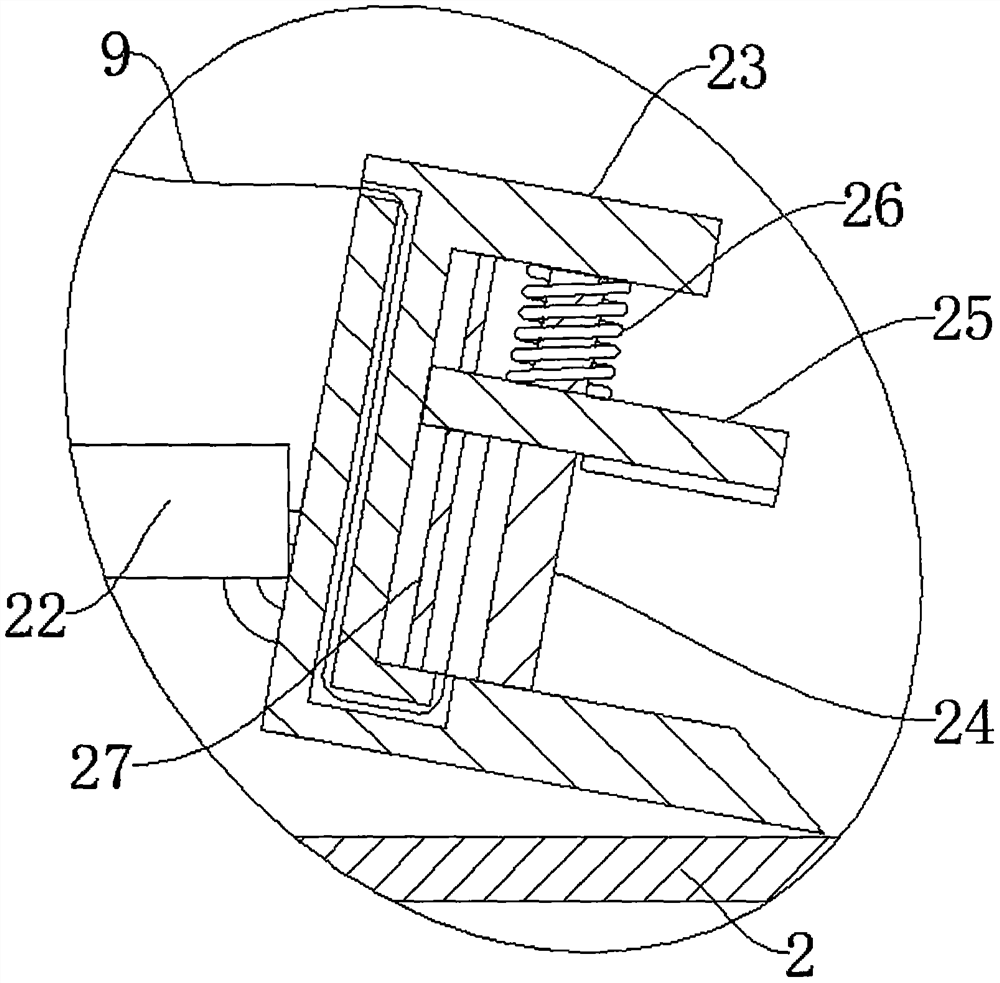

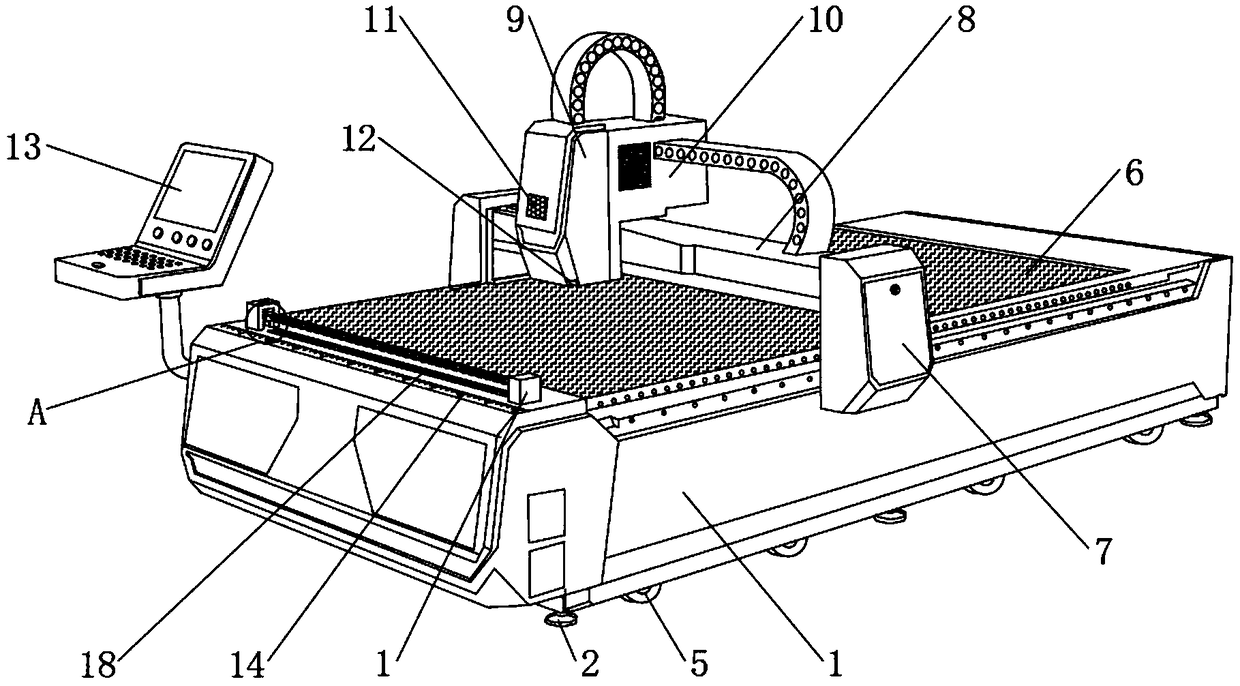

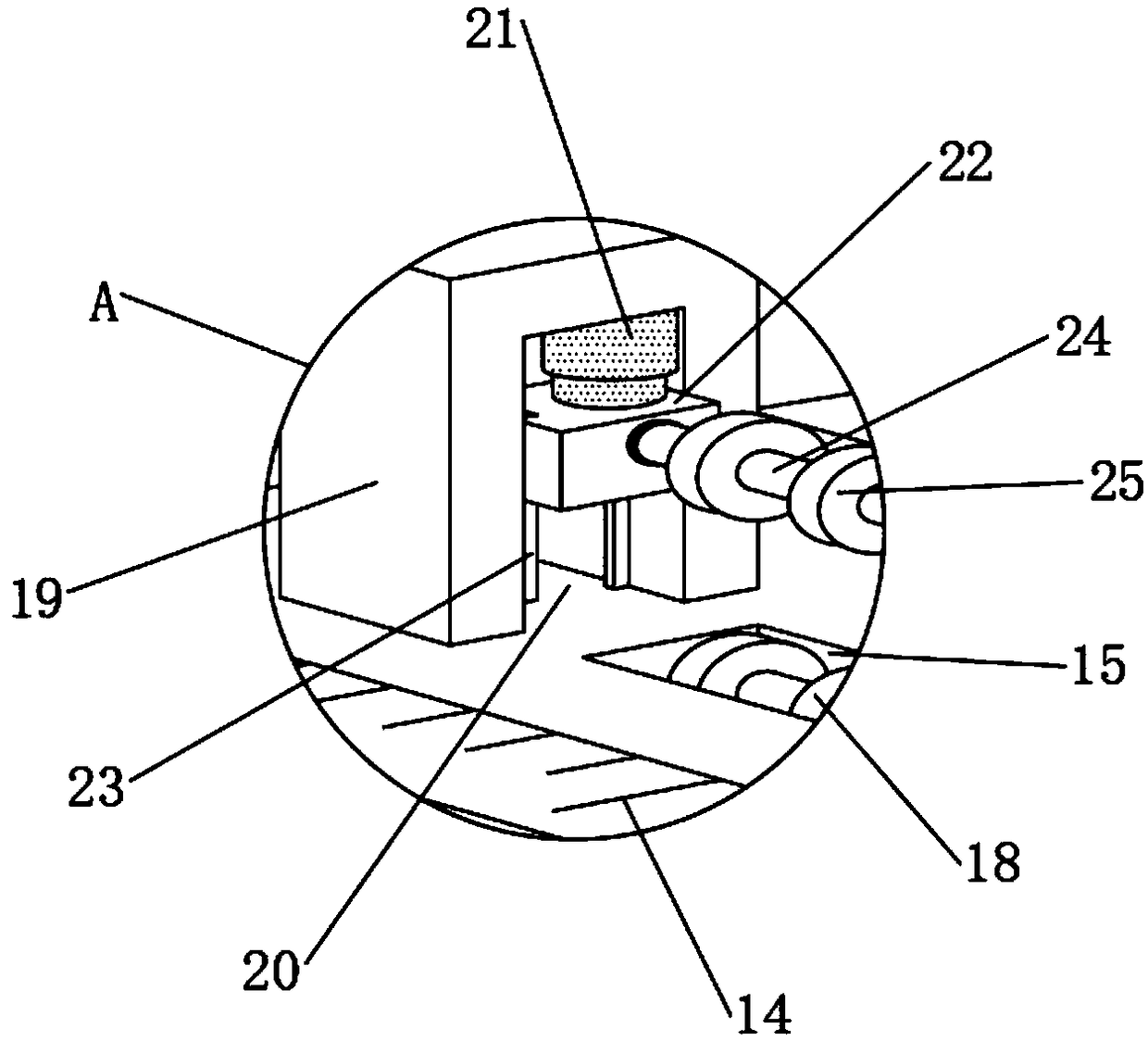

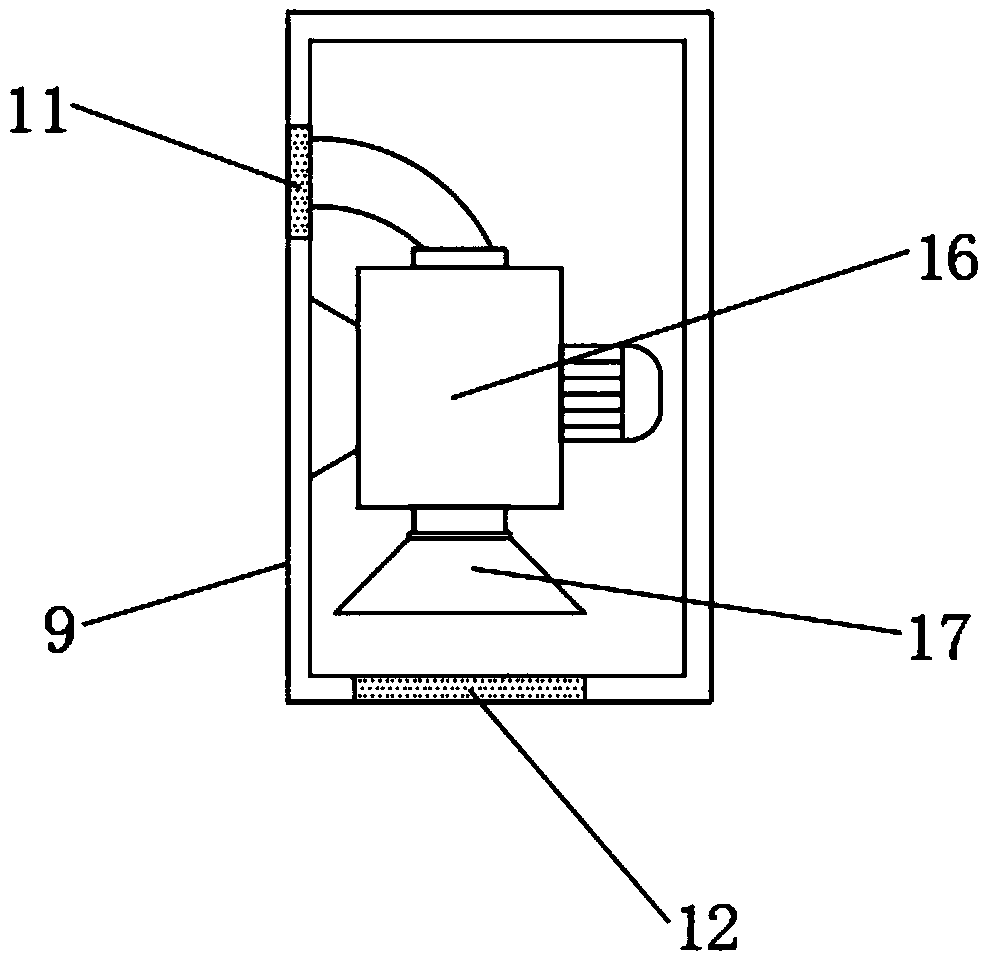

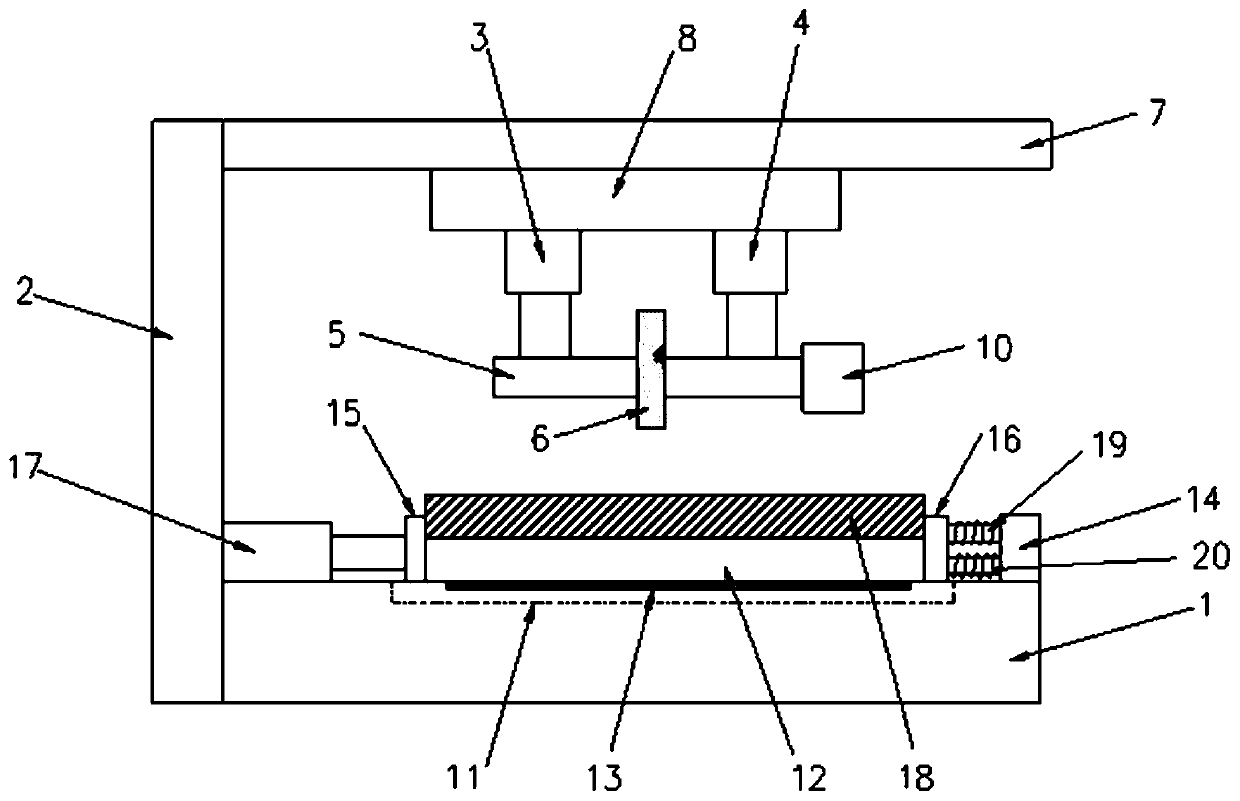

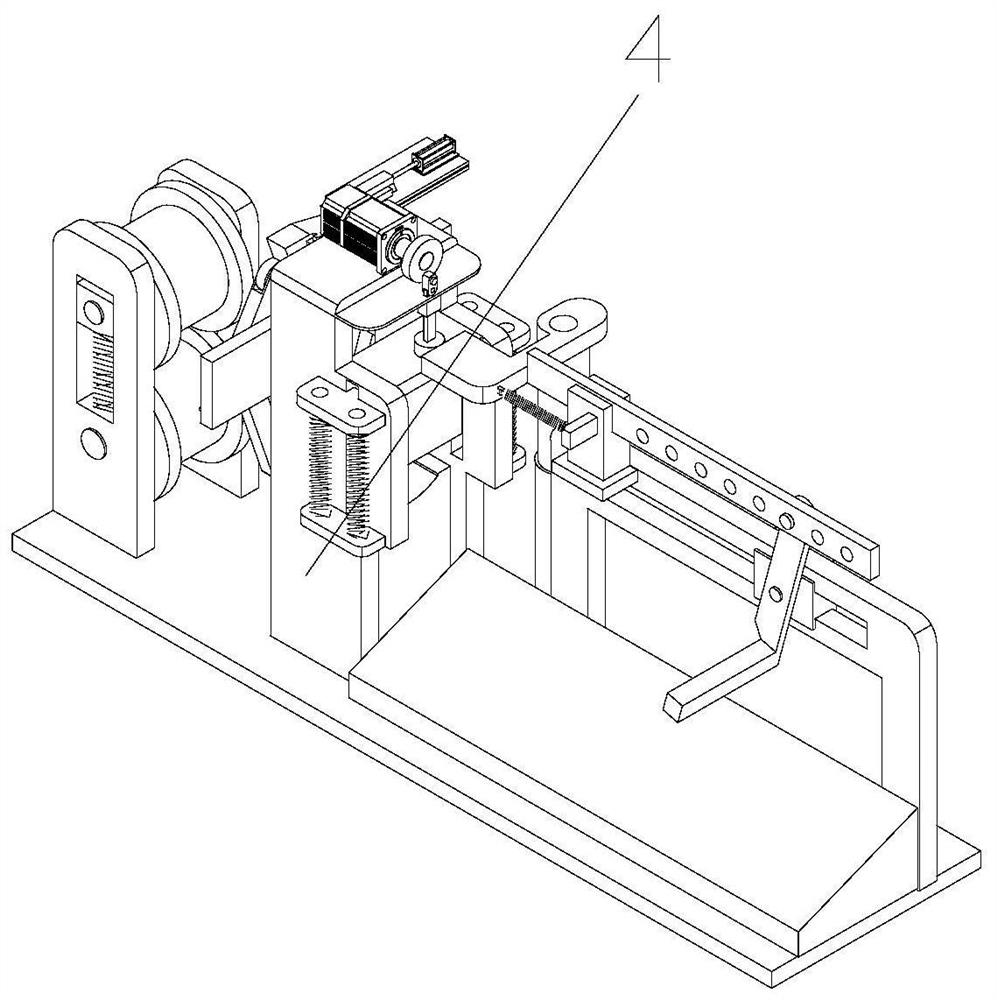

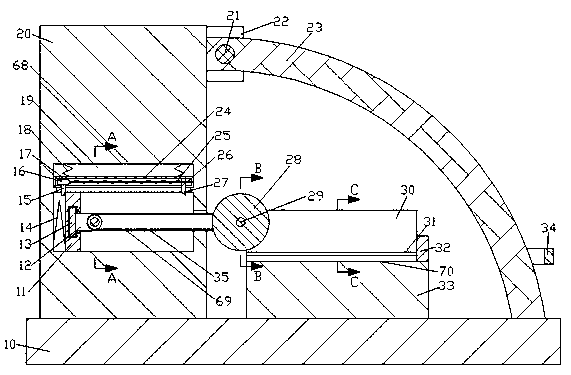

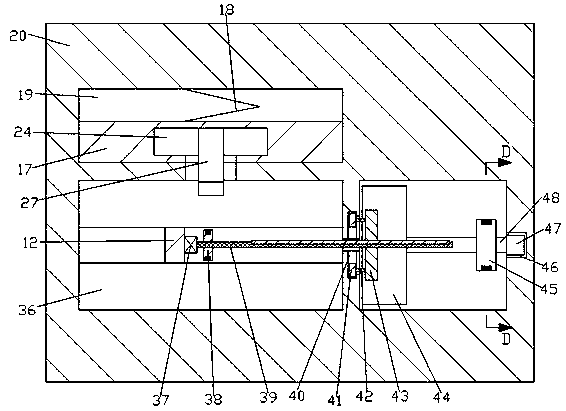

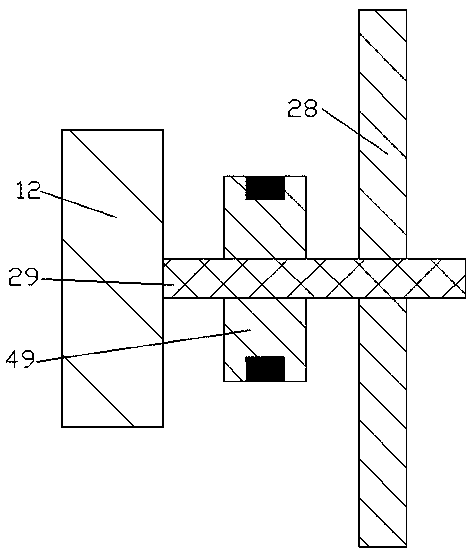

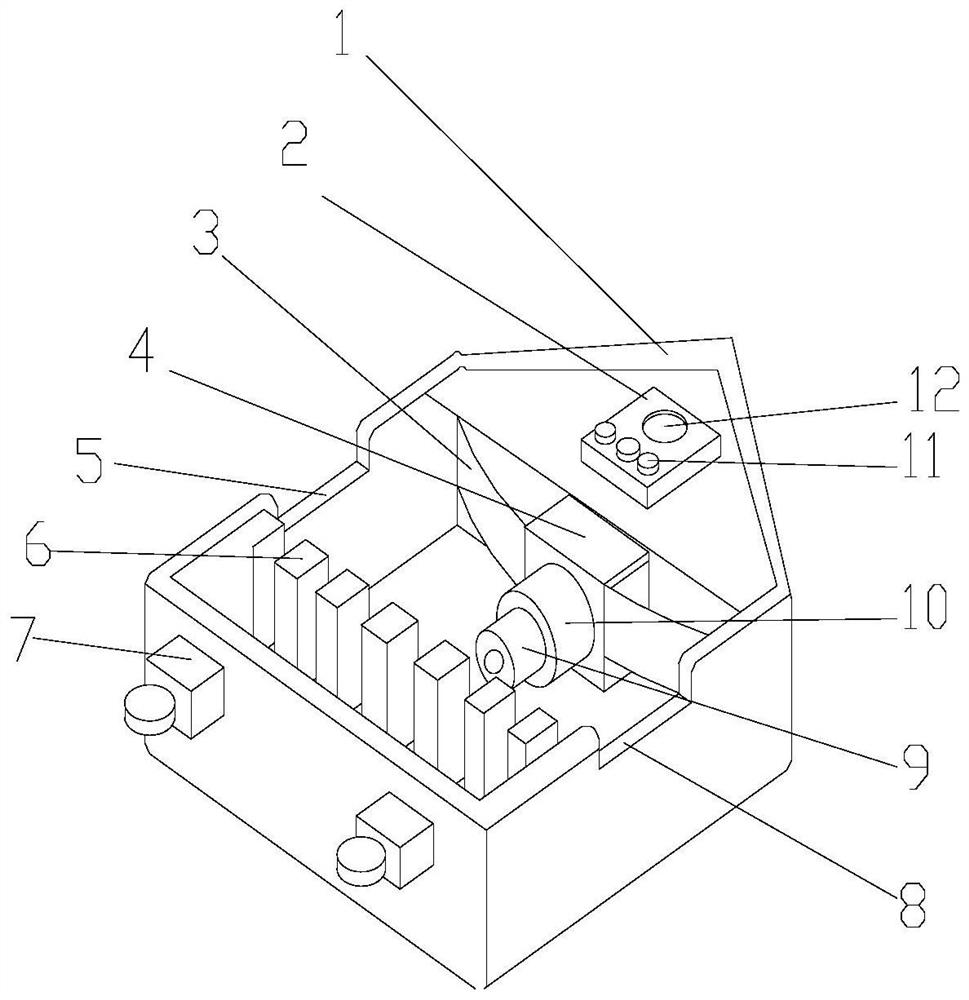

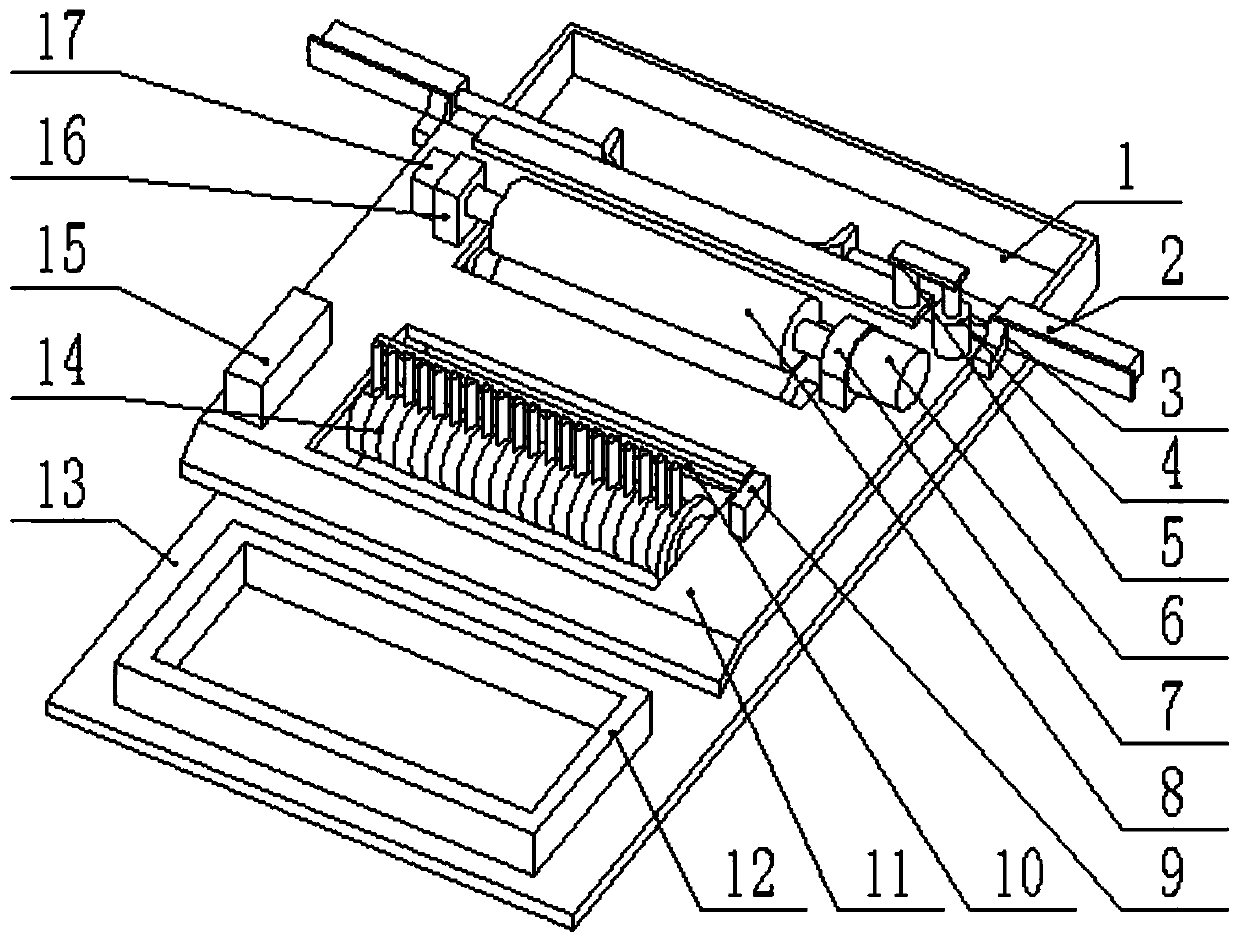

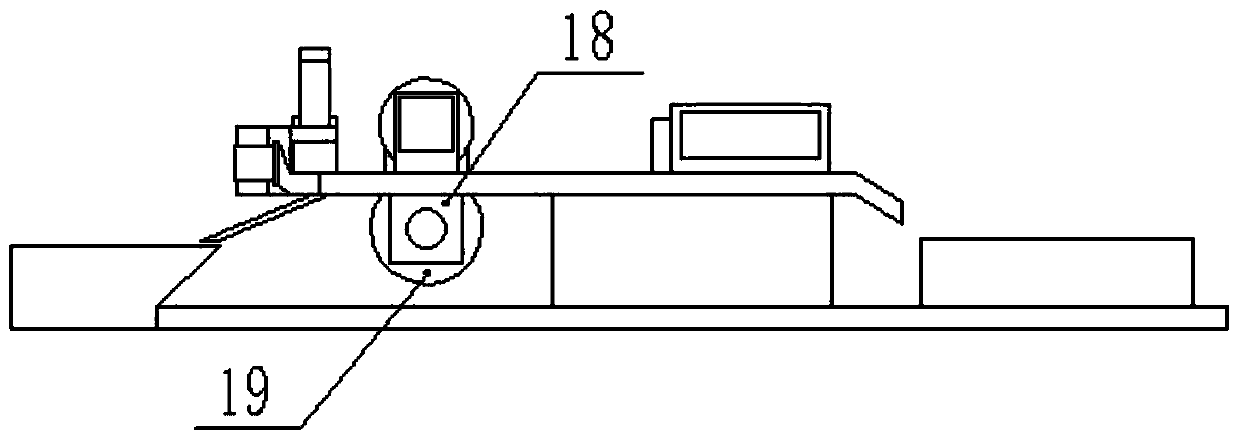

The invention discloses a building cutting device. The building cutting device comprises a workbench, supporting plates are arranged at the left and right sides of the upper end of the workbench, a top plate is arranged at the upper ends of the supporting plates, a through hole is formed in the top plate, and a first motor is arranged at the left side of the upper end of the top plate; a first rotary shaft is arranged at the output end of the first motor, a driving belt pulley is arranged on the first rotary shaft, a lead screw is arranged at the lower end of the top plate, and a driven belt pulley is arranged on the lead screw; through outstretching and back-drawing of the output end of an air cylinder, an abutting plate is driven to move left and right, and thus materials are clamped toprevent the situation that the materials move in the cutting process and the cutting quality is influenced; through the arrangement of an antiskid rubber pad, the antiskid effect can be achieved; through outstretching and back-drawing of the output end of a second hydraulic cylinder, a placement plate can be driven to slide in a slide groove through a slide block, thus the placement plate moves front and back, and the positions of the materials and a cutting blade are convenient to adjust, so that the cutting process is more automatic; the cutting position is convenient to adjust, the labor ofworkers is reduced, and the working efficiency is improved.

Owner:淮北辰威科技有限公司

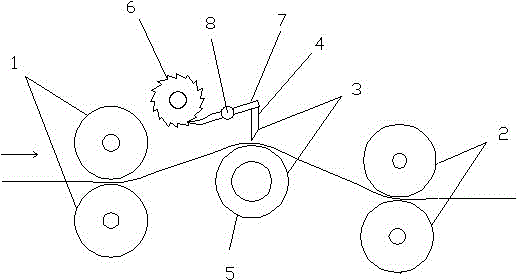

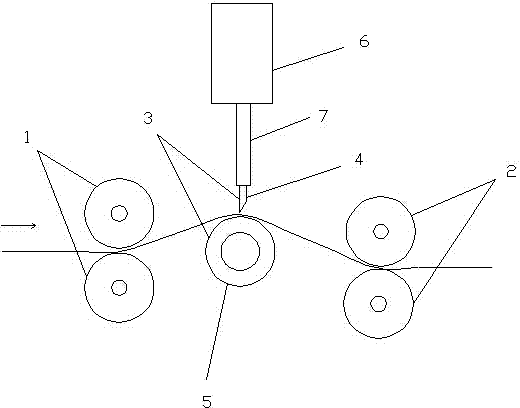

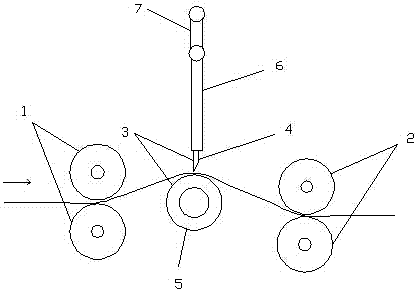

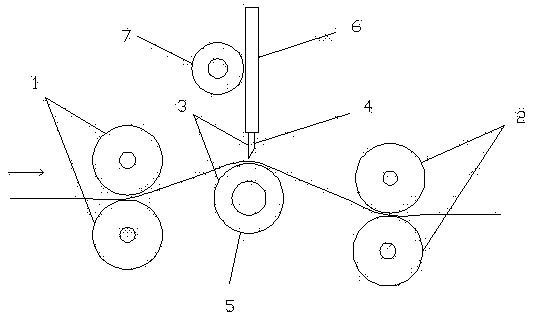

Ratchet wheel paper cutting device

ActiveCN104552380AReduce impactImprove cutting effectMetal working apparatusPulp and paper industryPaper cut

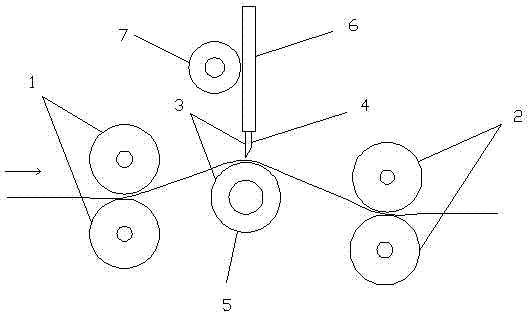

The invention discloses a ratchet wheel paper cutting device, which comprises two paper feeding rollers which are mutually cooperated, and two paper discharging rollers which are mutually cooperated, wherein a paper cutting mechanism is arranged between the paper feeding rollers and the paper discharging rollers; the paper cutting mechanism comprises a cutter and a rubber roller just below the cutter; the cutter vertically moves by being driven by a ratchet wheel and a pawl rod; the cutter is vertically arranged on one end of the pawl rod; the other end of the pawl rod is cooperated with the ratchet wheel; the middle of the pawl rod is provided with a positioning structure; the ratchet wheel is driven by a motor. Compared with the prior art, the ratchet wheel paper cutting device has the beneficial effects of precise paper cutting position, small noise and high working efficiency.

Owner:王霞

Cutting mold for polymer material product of oblique structure

InactiveCN108818750AAdjust tilt angleQuality improvementMetal working apparatusEngineeringOblique angle

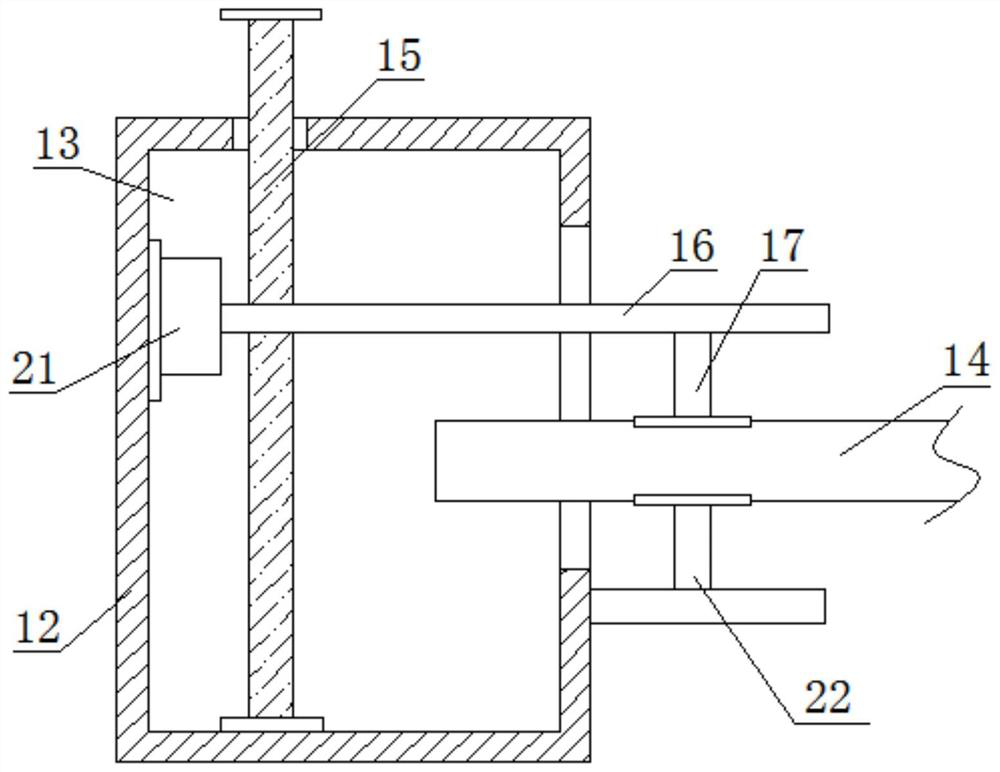

The invention discloses a cutting mold for a polymer material product of an oblique structure. The cutting mold comprises a mounting plate, a supporting plate is rotatably connected to the center of the upper end of the mounting plate, a cutting template is rotatably connected to the left side of the upper end of the supporting plate through a rotating shaft, a clamping mechanism is arranged at the upper end of the cutting template, a strip-shaped groove is formed in the upper end of the supporting plate, a lead screw is arranged in the strip-shaped groove, and the two ends of the lead screw are rotatably connected to the left and right sides of the strip-shaped groove respectively; a threaded sleeve is in threaded connection with the rod wall of the lead screw, a first transmission rod isrotatably connected to the upper end of the threaded sleeve, the end, away from the threaded sleeve, of the first transmission rod is rotatably connected to the lower end of the cutting template, anda first bevel gear is fixedly connected to the rod wall of the right end of the lead screw. According to the cutting mold, workers can adjust the oblique angle of a polymer material conveniently during cutting, and the polymer material can be clamped during cutting, so that the quality of the polymer material product is improved, and the labor intensity of the workers is reduced.

Owner:马鞍山久特新材料科技有限公司

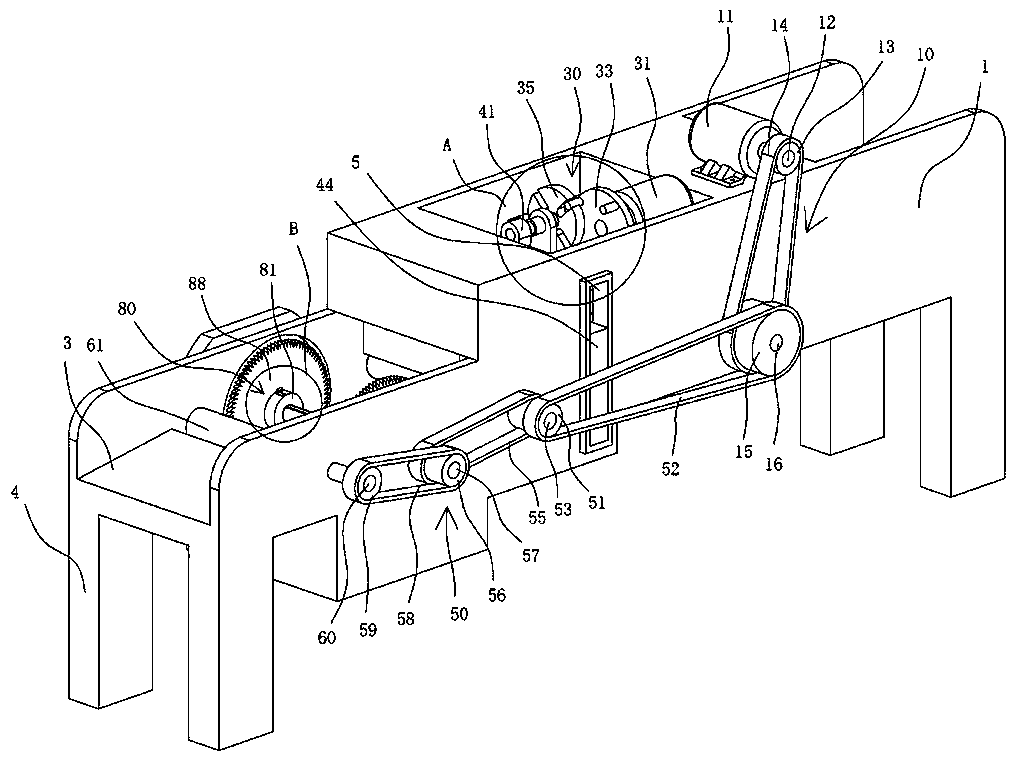

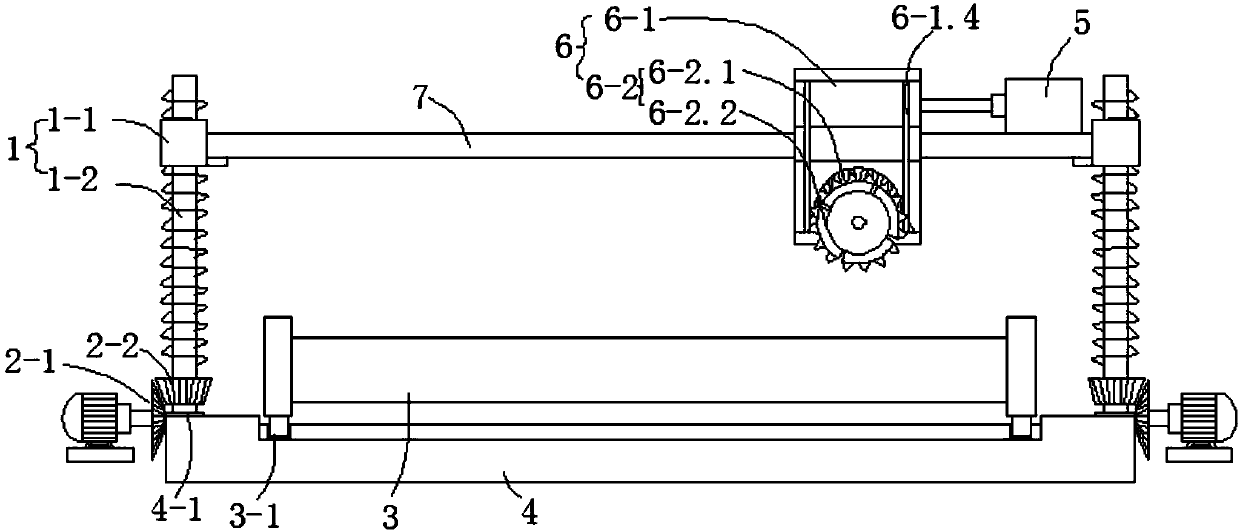

Board edge cutting device with automatic alignment function

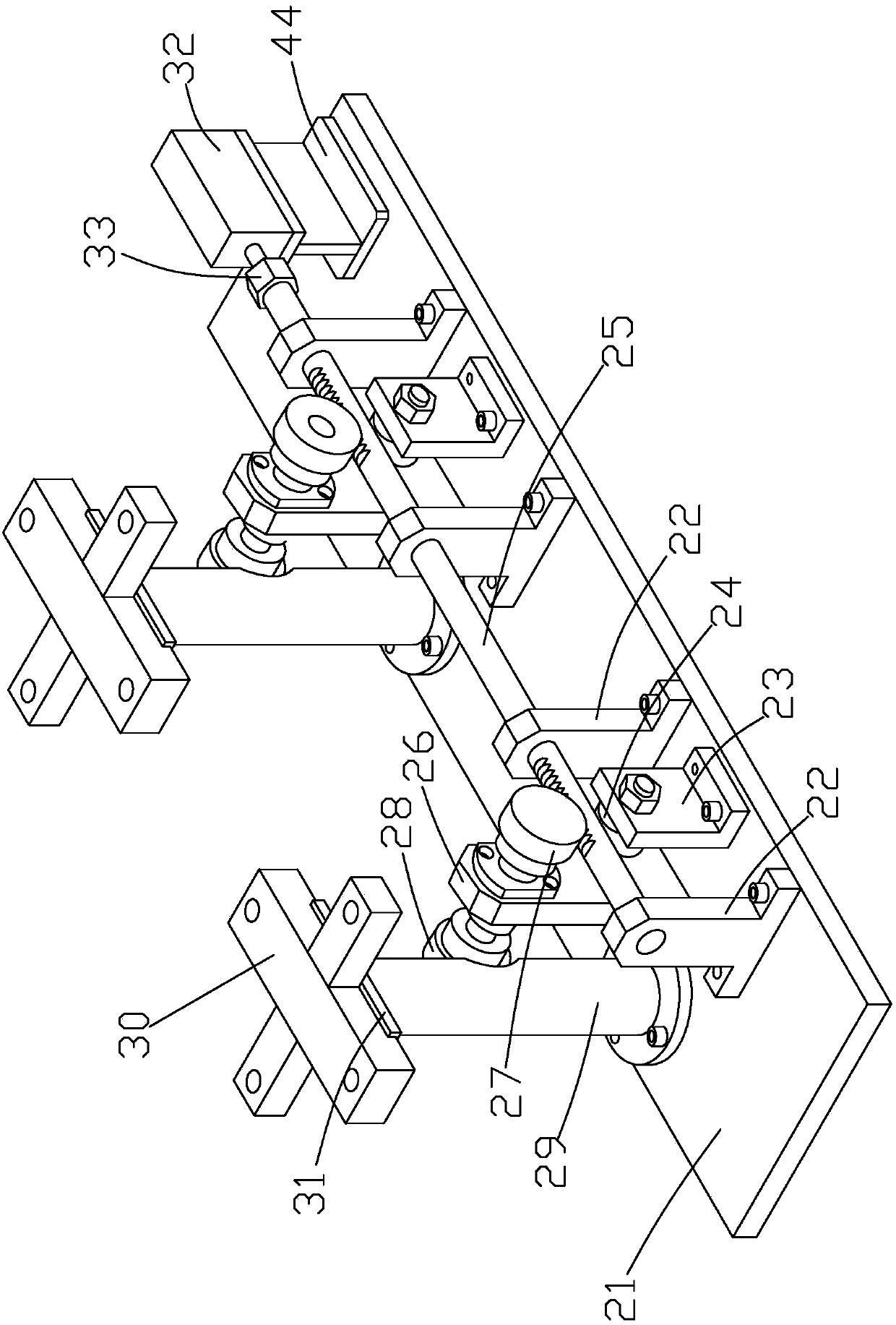

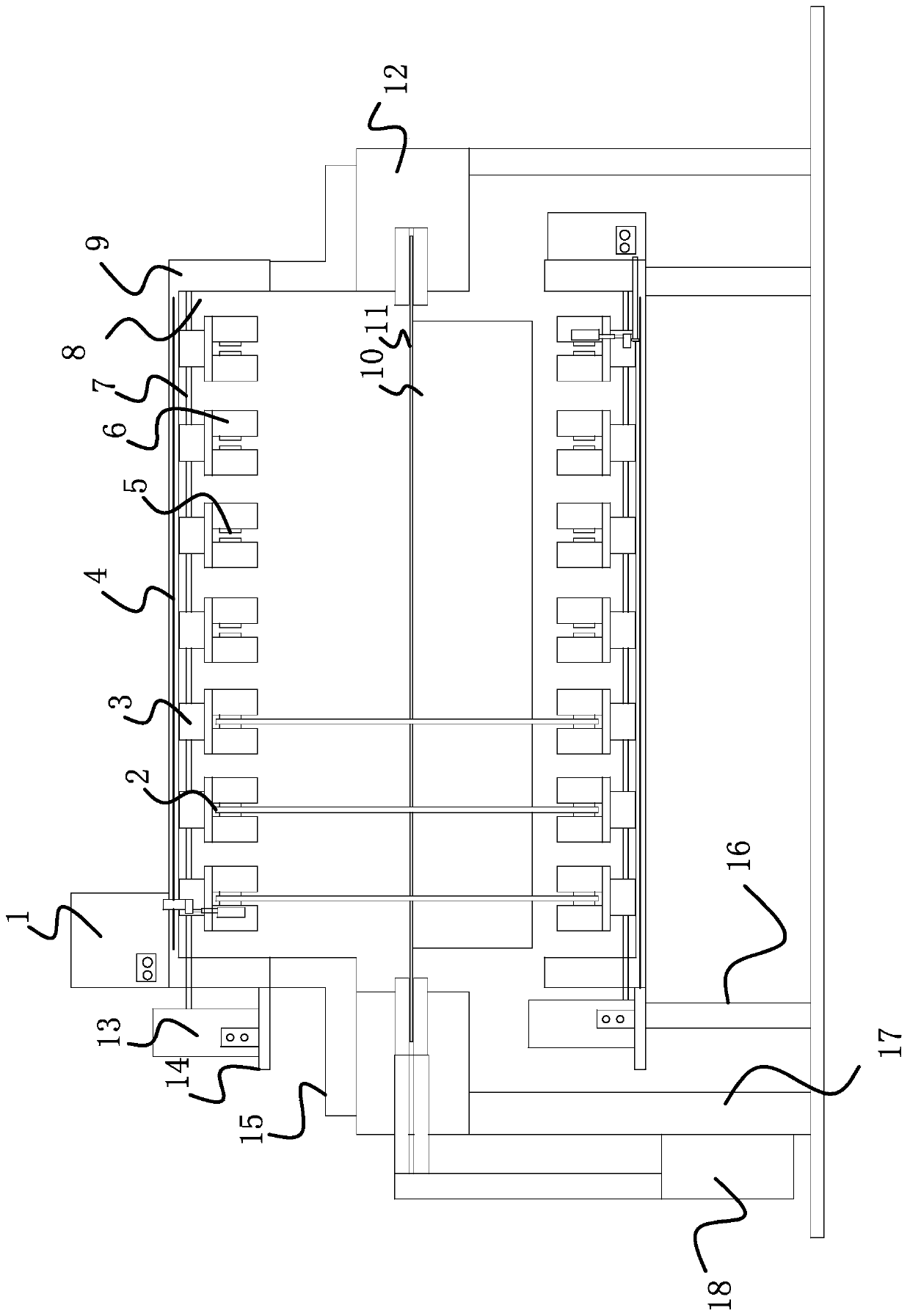

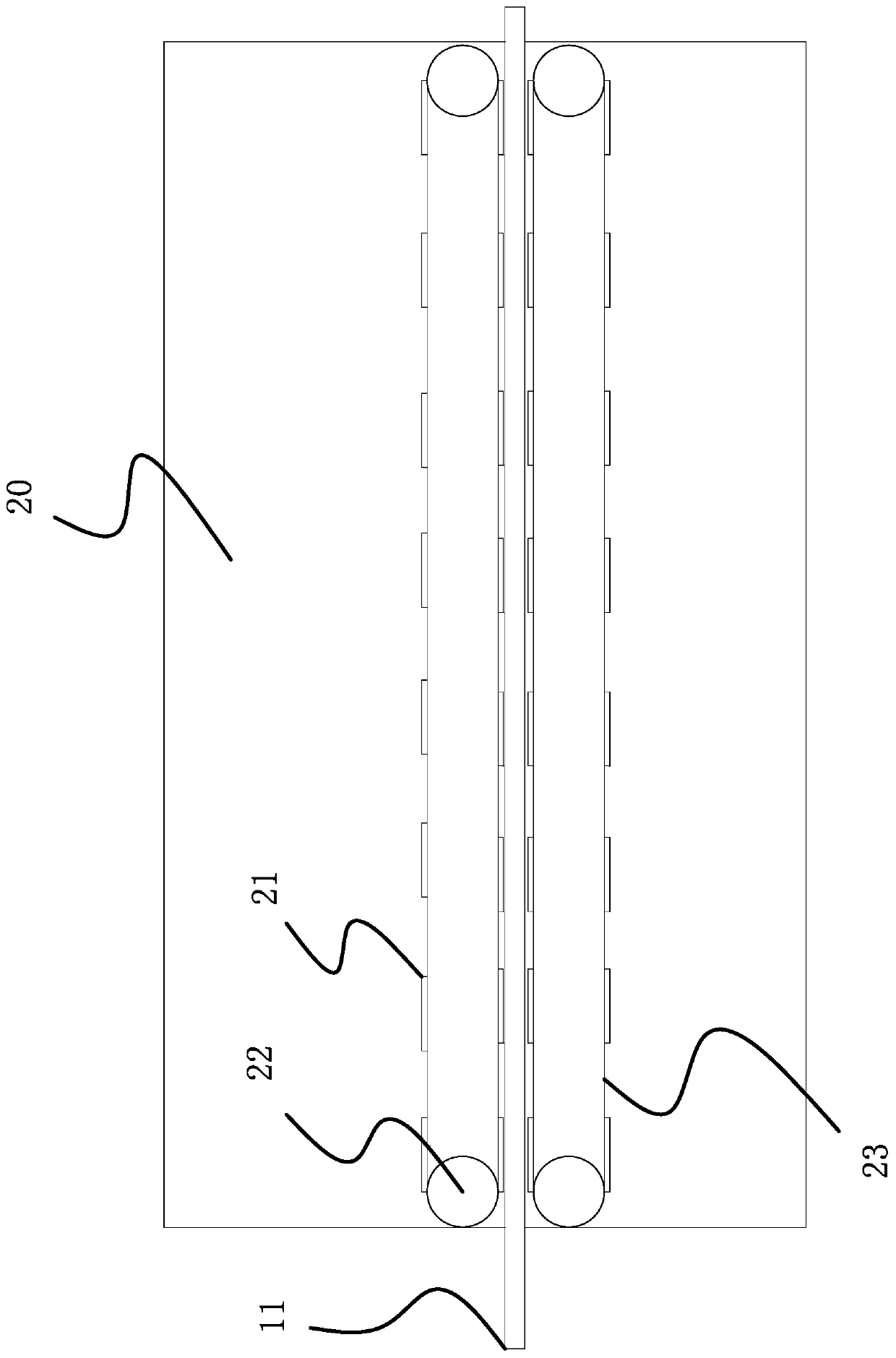

ActiveCN110788934AReduce labor intensityEliminate manual alignment stepsFeeding devicesCircular sawsMechanical engineeringWood plank

The invention discloses a board edge cutting device with an automatic alignment function. The board edge cutting device with the automatic alignment function comprises a device body. A feed inlet is formed in one end of the device body, and a discharge outlet is formed in the other end of the device body. The board edge cutting device with the automatic alignment function is characterized in thata first transport mechanism is arranged at one end of the device body, a power mechanism used for providing intermittent rotational force is arranged at one end of the device body, a stop mechanism which can rise and fall is arranged at one end of the power mechanism and is located on one side of the first transport mechanism, a second transport mechanism is arranged at one end of the first transport mechanism, a stabilizing mechanism used for preventing board from jumping is arranged on one side of the second transport mechanism, a plurality of movable edge cutting mechanisms are arranged inthe middle of the second transport mechanism, and a pressing mechanism used for board alignment is arranged on the other side of the first transport mechanism. The board edge cutting device has the beneficial effects automatic alignment and fixation of to-be-cut boards can be achieved, the working efficiency is effectively improved, and the labor intensity of users is relieved.

Owner:江西奥瑞森新材料科技有限公司

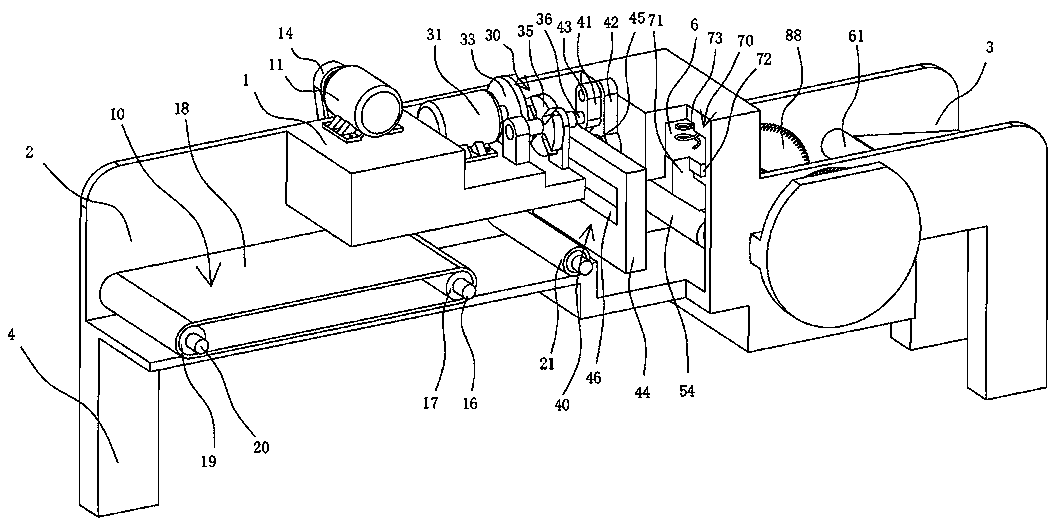

Stainless steel band production device with wide-range adjusting function and production method

ActiveCN107671347AHigh precisionHigh movement accuracyShearing machinesShearing machine accessoriesAssembly lineRejection rate

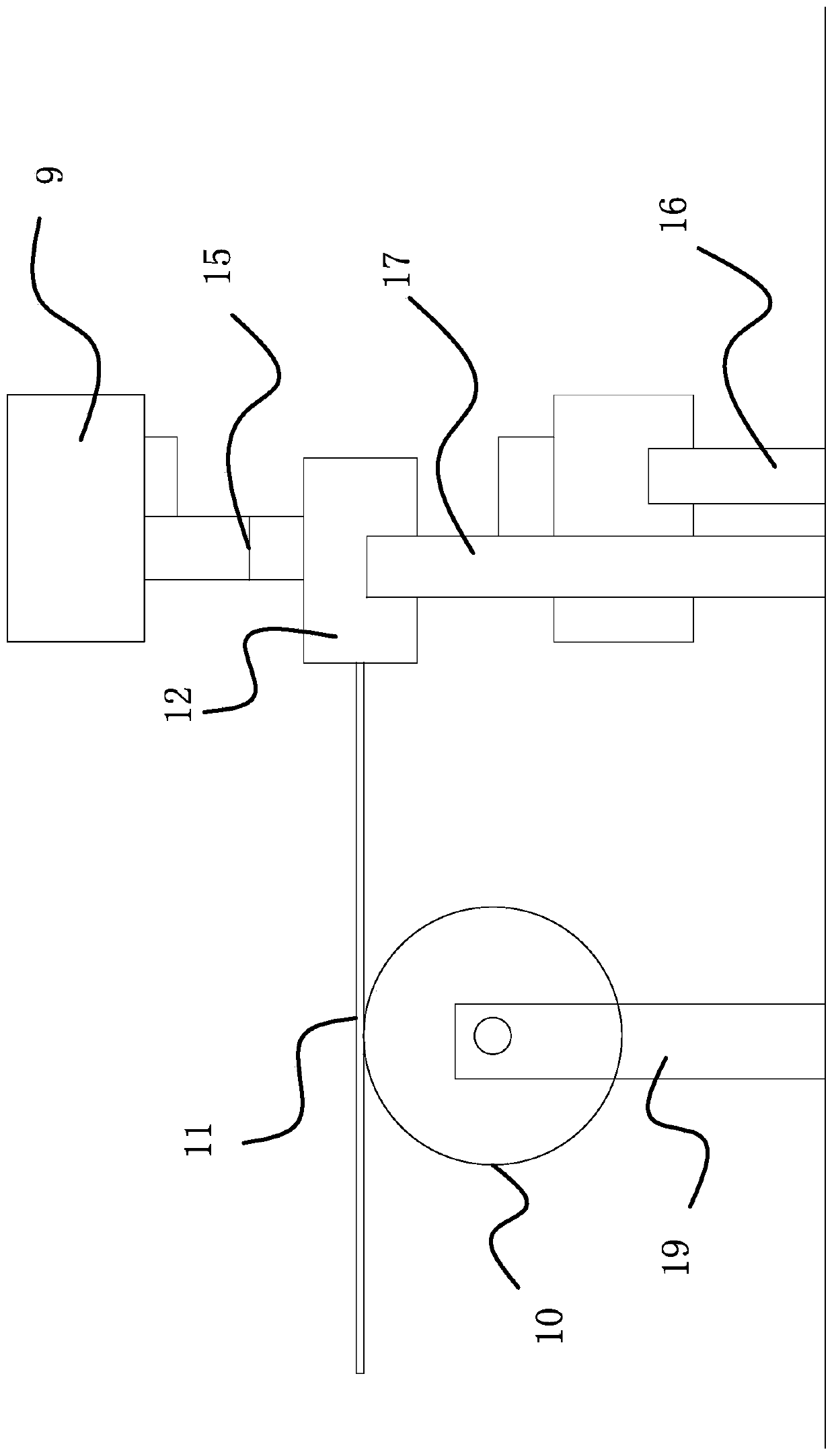

The invention discloses a stainless steel band production device with the wide-range adjusting function. The stainless steel band production device comprises a box body, a tensioning mechanism, a machining platform, a cutting mechanism and a height adjusting mechanism. The tensioning mechanism and the machining platform are both located above the box body. The tensioning mechanism is located at the left side of the machining platform. The machining platform is connected with the box body through a hydraulic lifting rod. The cutting mechanism is located above the machining platform and is further connected with the box body through the height adjusting mechanism. A driving roller and a driven roller are further arranged on the top face of the box body and are both located at the right sideof the machining platform. The driving roller and the driven roller are both connected with the box body through a supporting rod. Stainless steel bands penetrate in from the tensioning mechanism andfurther wind across the driven roller and the driving roller to be output after passing through the machining platform. By means of the stainless steel band production device with the wide-range adjusting function, the cutting machining requirements of the stainless steel bands of different widths can be met; and moreover, machining precision of the stainless steel bands is improved, and the rejection rate is lowered. The machining method is simple in technological step, the production demand of an assembly line can be met, manufacturing cost is reduced and the machining period is shortened.

Owner:ZHEJIANG JIANHENG IND

Paper cutting unit

The invention discloses a paper cutting unit comprising two feed rollers and two discharge rollers. The feed rollers fit each other; the discharge rollers fit each other. A cutting device is disposed between the feed rollers and the discharge rollers and comprises an upper blade and a rubber roller disposed right under the upper blade. The upper blade is disposed at the lower end of a rack vertically arranged. The rack is driven by a gear to move up and down. The gear is disposed on an output shaft of a motor through a coupling. Compared with the prior art, the paper cutting unit has the advantages that cutting position of paper is accurate, noise is low, and operating efficiency is high.

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

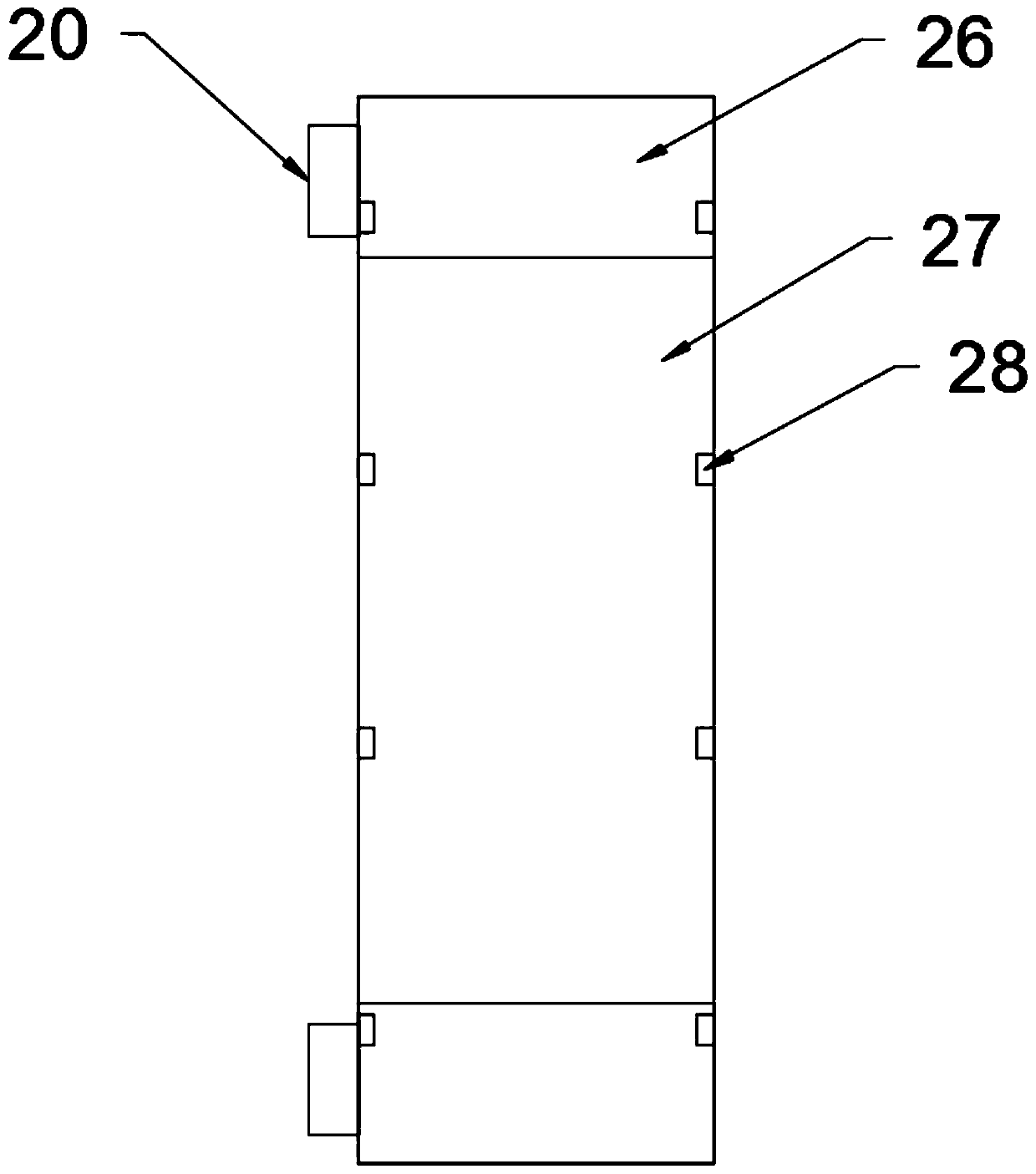

Synchronous multi-cutter fixed-distance cutting device for steel pipe

PendingCN111774642AReasonable structureEasy to operateTube shearing machinesShearing machine accessoriesSteel tubeElectric machinery

The invention discloses a synchronous multi-cutter fixed-distance cutting device for a steel pipe. According to the cutting device, an output shaft of a top air cylinder is fixedly connected with a sliding plate, wherein the bottom of the sliding plate is fixedly connected with a fixed plate, the bottom of the sliding plate is symmetrically and fixedly connected with two vertical plates, threadedholes are formed in the centers of the vertical plates, a screw rod penetrates through each threaded hole, the other end of each screw rod penetrates through the corresponding vertical plate, a mounting groove is formed in the bottom of the fixed plate, a first cutting motor is fixedly connected to the inner wall of one side of the mounting groove, an output shaft of the first cutting motor is fixedly sleeved with a first cutter, second cutting motors are fixedly connected to the bottoms of the two movable plates, and output shafts of the two second cutting motors are in driving connection with second cutters. According to the device, a steel pipe body can be cut into three sections at a time, and the working efficiency is improved.

Owner:YANGZHOU STRVALUE INFORMATION TECH CO LTD

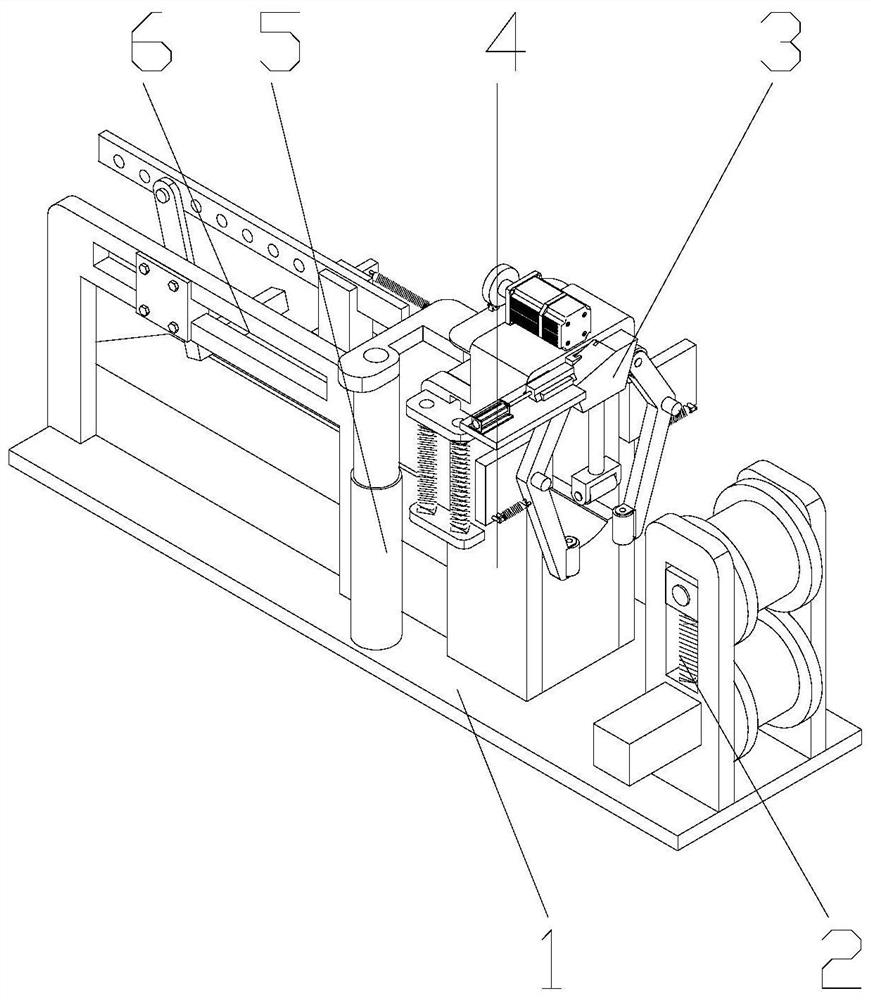

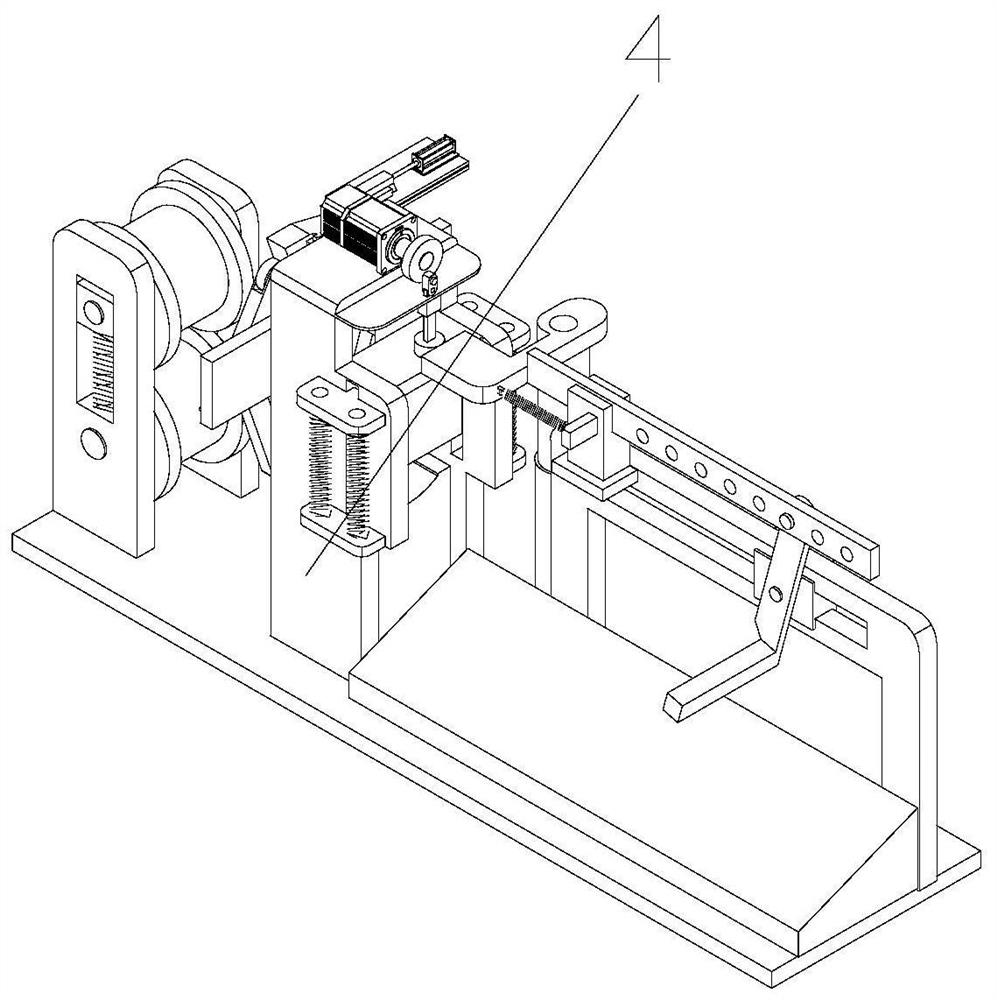

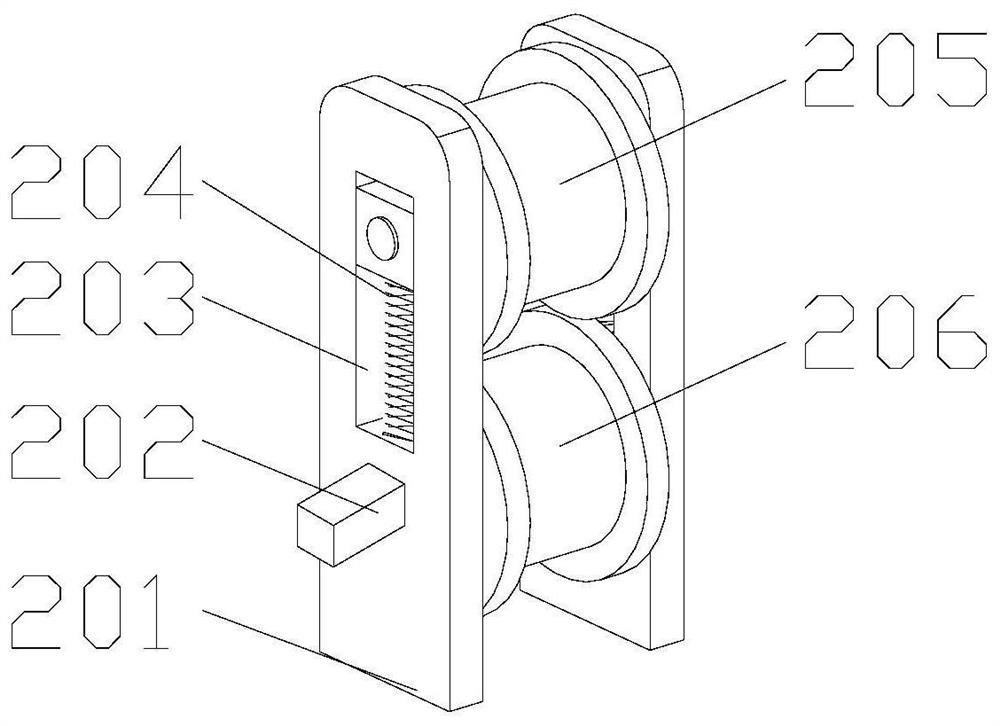

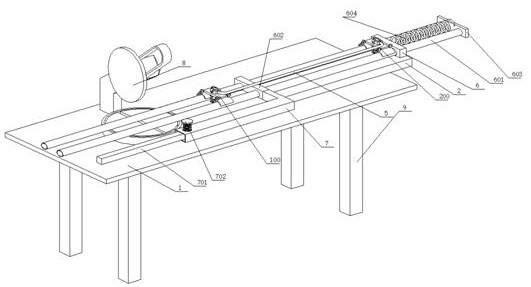

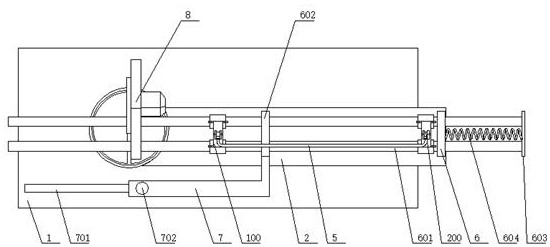

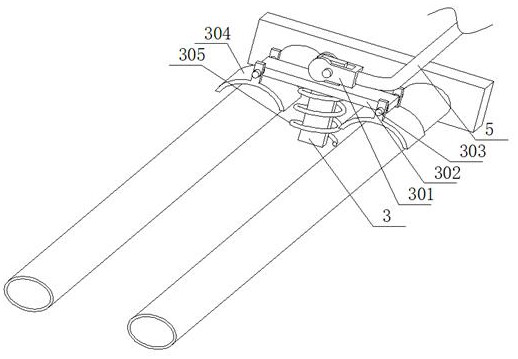

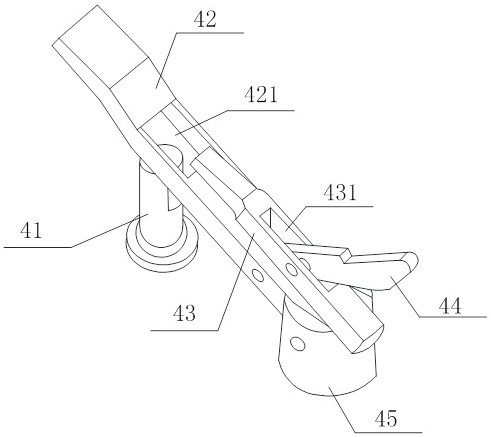

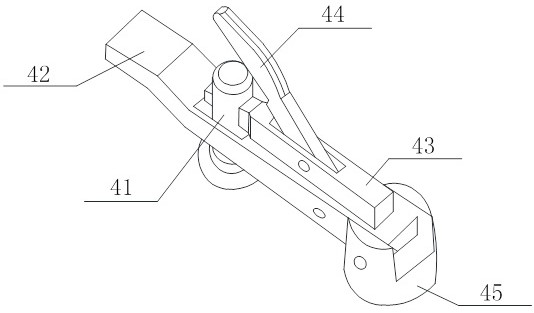

Power tube cutting device for power construction

ActiveCN112476014AGuaranteed smoothQuality assuranceMetal working apparatusPositioning apparatusStructural engineeringMechanical engineering

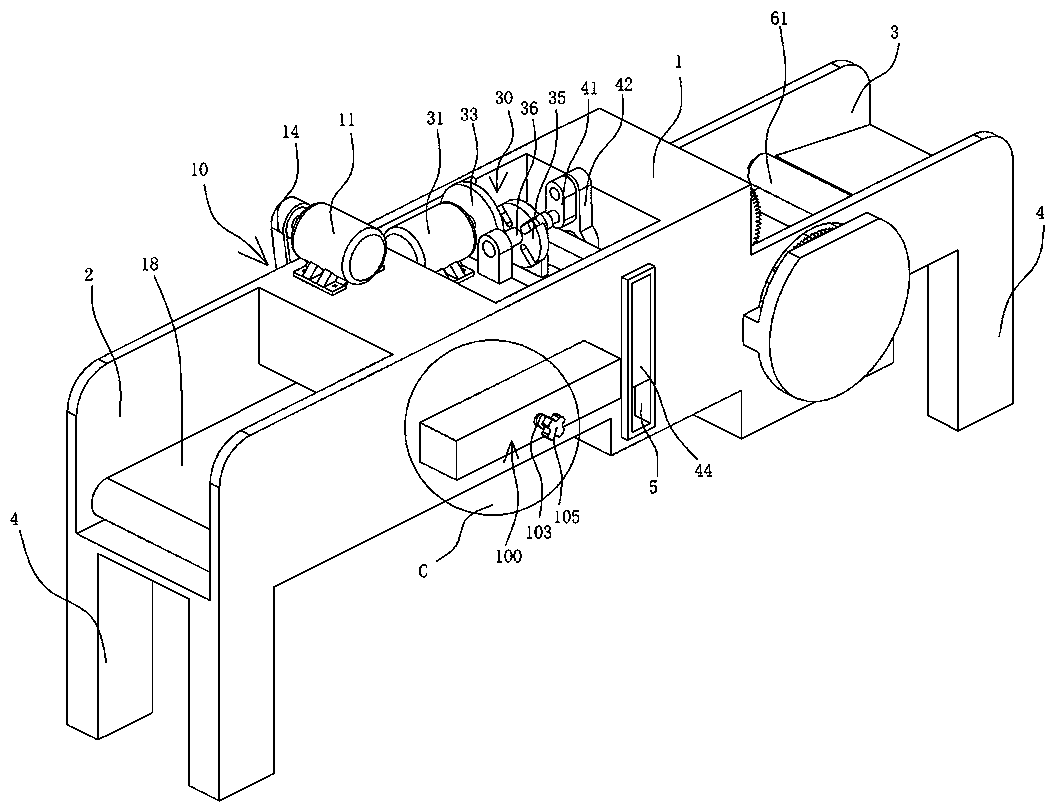

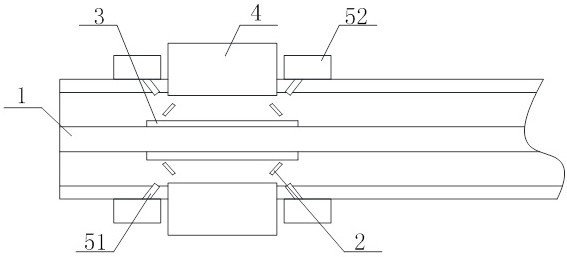

The invention discloses a power tube cutting device for power construction. The power tube cutting device comprises a bottom plate, wherein a conveying mechanism, a cutting mechanism, a limiting mechanism and an adjusting mechanism are mounted on the bottom plate; the conveying mechanism is mounted at one end of the bottom plate; the cutting mechanism is mounted on the bottom plate and on one sideof the conveying mechanism; a fixing mechanism is mounted on the cutting mechanism; the adjusting mechanism is mounted at the other end of the bottom plate and matched with the limiting mechanism; and the limiting mechanism is mounted on the bottom plate and between the adjusting mechanism and the cutting mechanism and matched with the cutting mechanism. The power tube cutting device can guarantee the flatness of a notch of a power tube and the quality of the power tube, can guarantee the cutting of the power tube with the same length, can adjust the length of the power tube as required, guarantees the cutting quality of the power tube, guarantees the normal use of the power tube, reduces the production cost and improves the working efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO TAOXIAN POWER SUPPLY CO

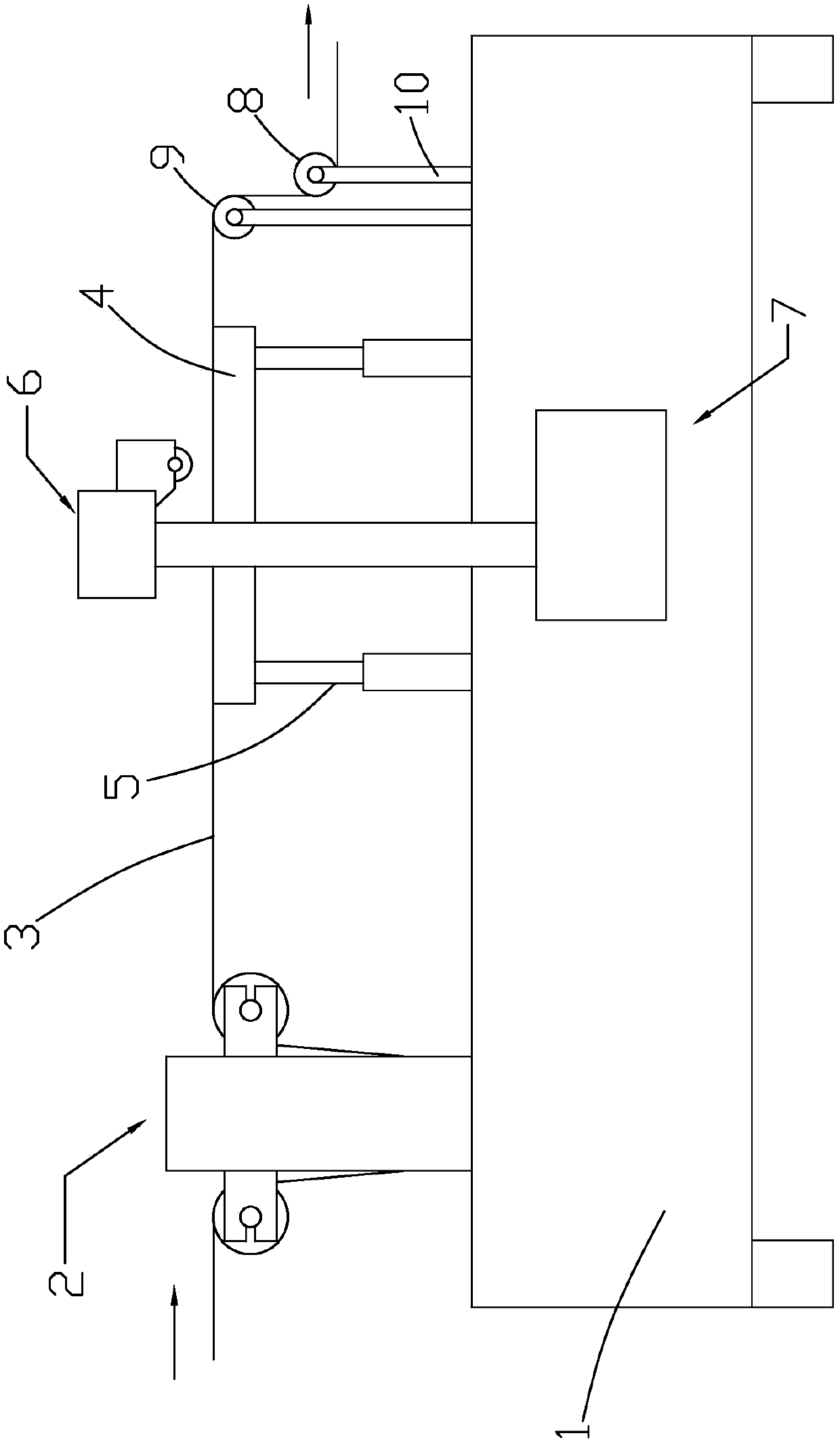

Spiral pipe cutting device with waste gas and waste residue treatment function

PendingCN111283261ADisadvantages that affect cut qualityAffect healthDispersed particle separationTube shearing machinesElectric machineryWorking environment

The invention relates to a spiral pipe cutting device with a waste gas and waste residue treatment function, in particular to the technical field of spiral pipe production equipment. The spiral pipe cutting device with the waste gas and waste residue treatment function comprises supports, fixing plates, a roller, anti-deviation devices, a cutting motor, a cutting knife, a connecting rod, first aircylinders, a waste residue treatment mechanism, waste gas treatment mechanisms and a mounting frame, wherein the fixing plates are arranged on one sides, far away from the roller, of the two supports; the first air cylinders are fixed to the fixing plates; the connecting rod is arranged over the roller; the anti-deviation devices are arranged on the two supports; the waste residue treatment mechanism is arranged under the roller; and the waste gas treatment mechanisms are arranged on one sides, far away from the roller, of the two supports. The treatment of waste gas and waste residues in thespiral pipe cutting process is realized, and the working environment and the health of workers are guaranteed.

Owner:福建冠宇钢管制造有限公司

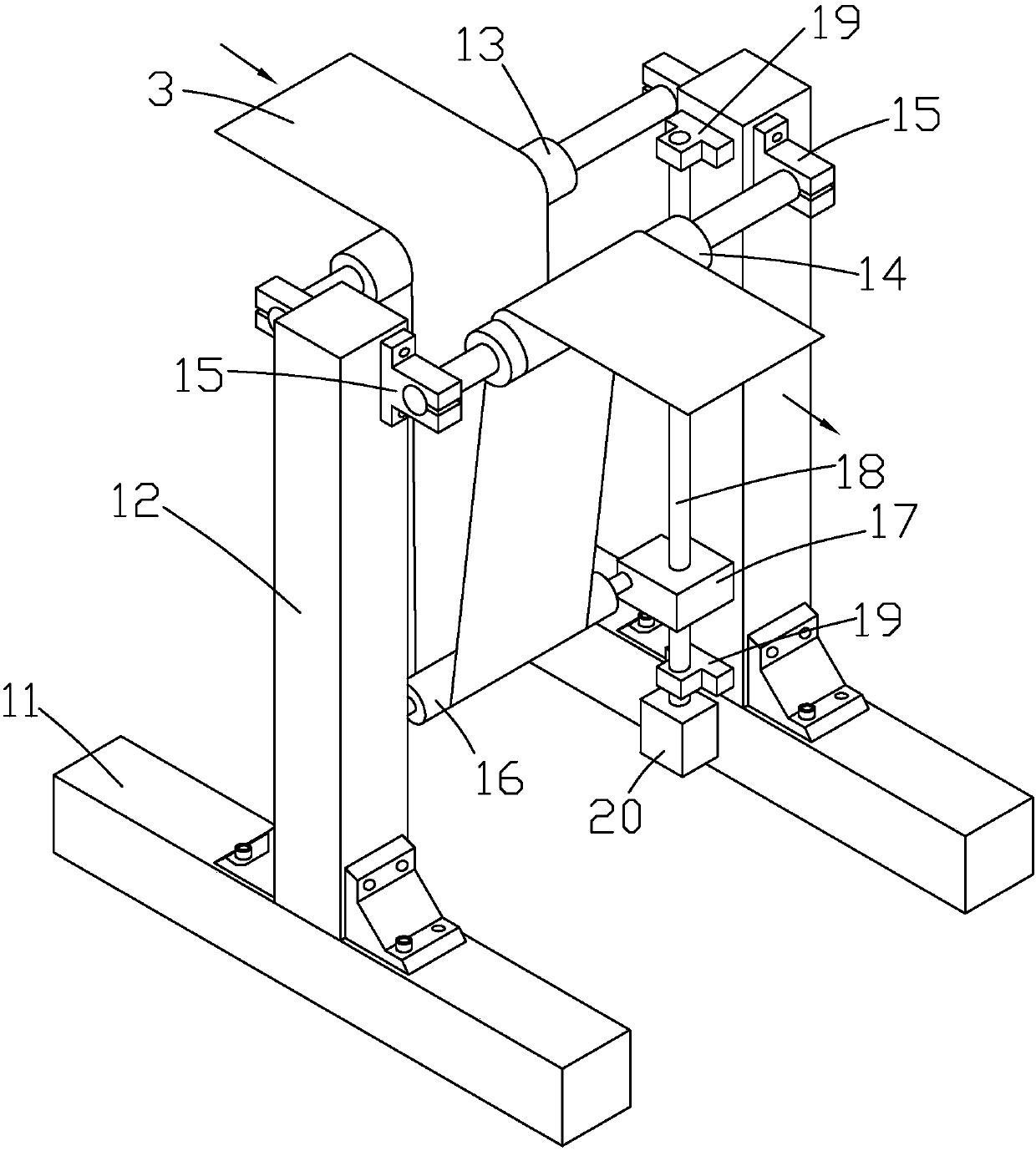

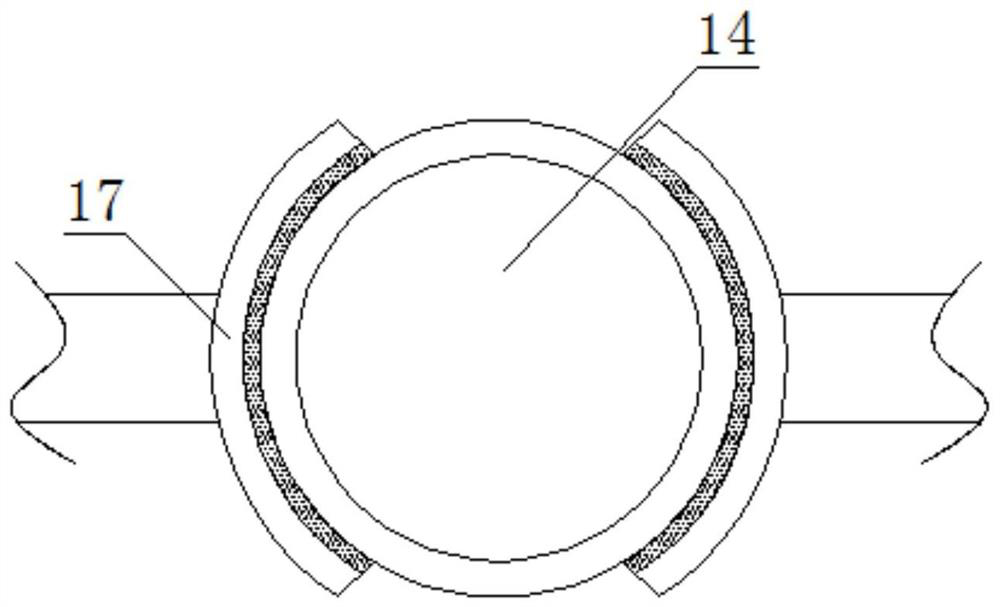

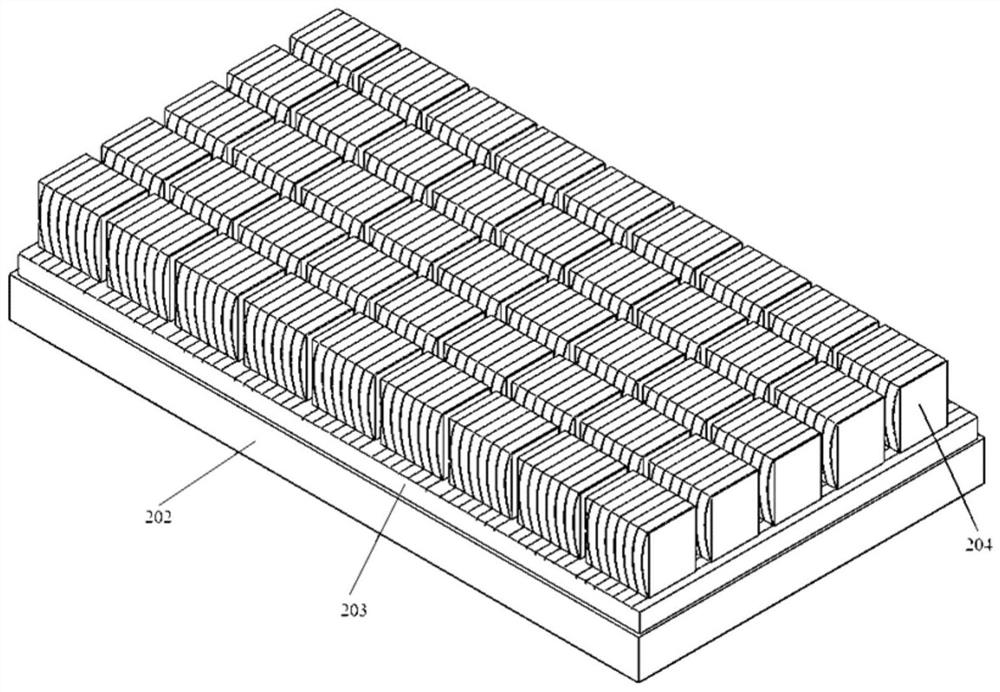

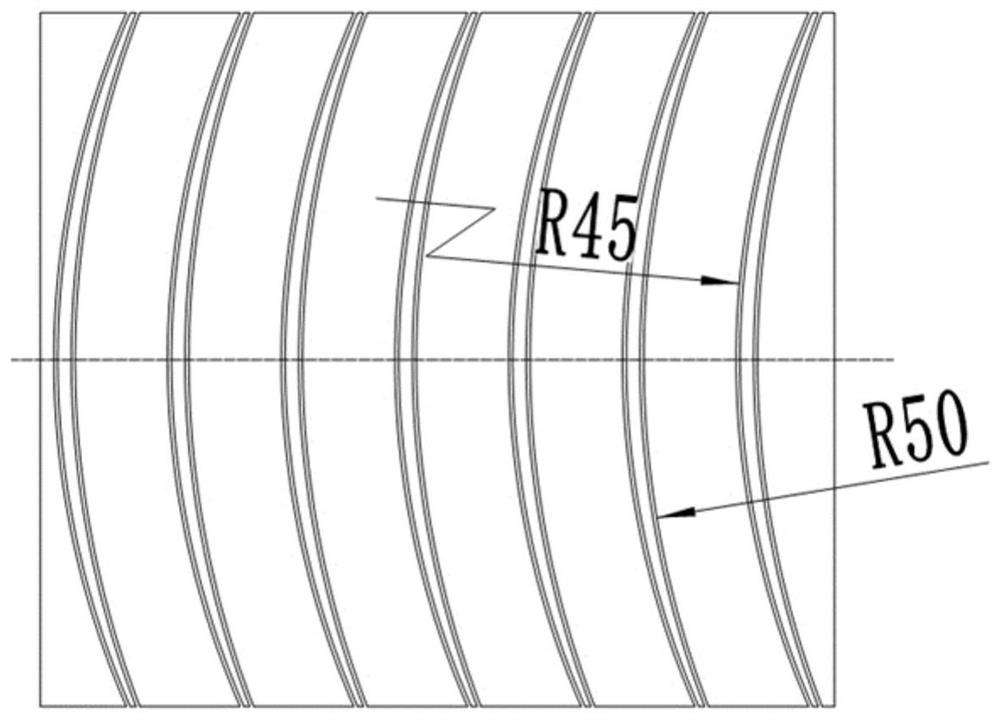

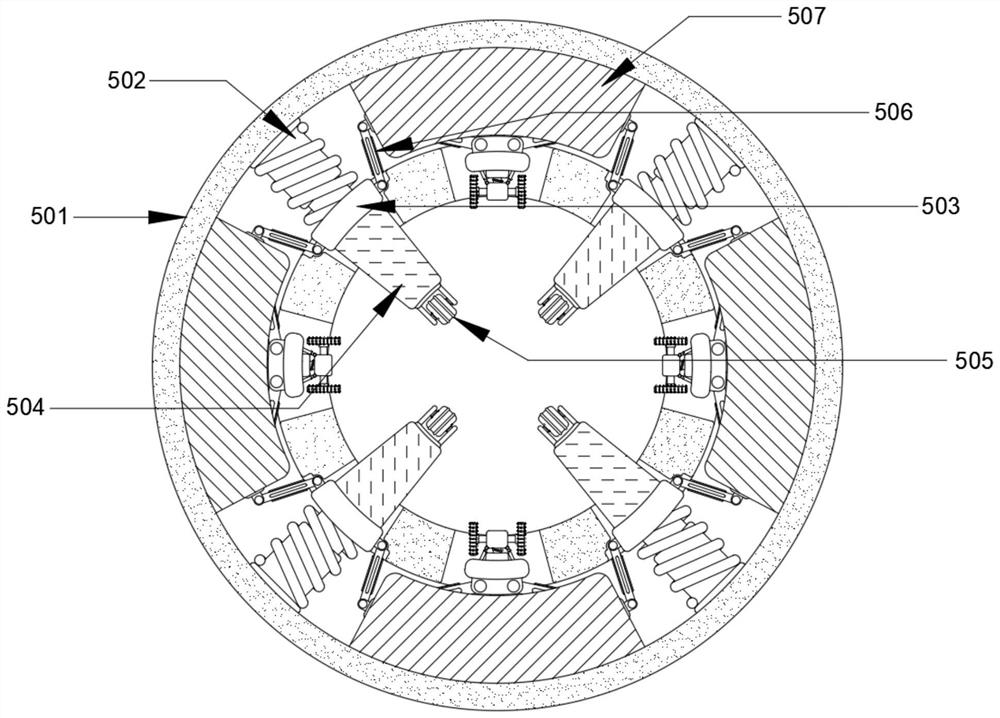

Material bonding device and machining method of neodymium iron boron tile-shaped magnet

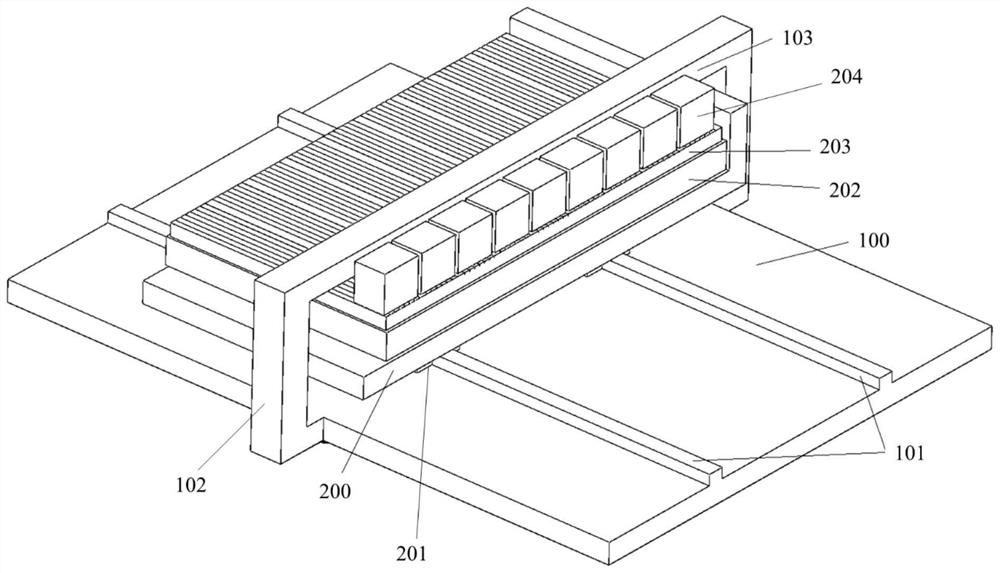

ActiveCN112809534APrevents affecting cut qualityPrecise BondingGrinding machinesGrinding work supportsWire cuttingEngineering

The invention discloses a material bonding device and a machining method of a neodymium iron boron tile-shaped magnet. The material bonding device comprises a material bonding tool which is in a flat plate shape, wherein two parallel convex edge sliding rails are arranged on the upper surface of the material bonding tool, two vertical rods which are perpendicular to the material bonding tool and extend upwards are arranged on the two side walls of the material bonding tool, and the top ends of the two vertical rods are fixedly connected with a material bonding tool stop lever; and a material plate platform, wherein the longitudinal section of the material plate platform is in an L shape, grooves matched with the convex edge sliding rails are formed in the lower surface of the material plate platform, the grooves and the convex edge sliding rails are connected in an inserted mode, a material plate is detachably installed on the material plate platform, and the material bonding tool stop lever is higher than the material plate. According to the machining method of the neodymium-iron-boron tile-shaped magnet based on the material bonding device, secondary cutting is conducted on a neodymium-iron-boron magnet blank by means of a tile-shaped multi-wire cutting machine, and finally the neodymium-iron-boron tile-shaped magnet with the inner arc radius and the outer arc radius being different are obtained. According to the method, the machining qualification rate can be increased, and the machining efficiency can be improved.

Owner:廊坊京磁精密材料有限公司

Adjustable wood cutting and deworming device for construction

InactiveCN107599076AImprove securityQuickly put into useMulti-purpose machinesBark-zones/chip/dust/waste removalHydraulic cylinderPulp and paper industry

The invention provides an adjustable wood cutting and deworming device for construction, which belongs to the technical field of construction machinery. The adjustable wood cutting and deworming device comprises a box body, a collecting table and a liquid storage box, wherein a motor is fixedly connected to the upper part of the box body; a hydraulic cylinder is arranged below the motor; the hydraulic cylinder passes through the box body, and a hydraulic telescopic rod is fixedly connected to the lower part of the hydraulic cylinder; a driving helical gear is fixedly connected to the lower part of the hydraulic telescopic rod; and the driving helical gear is engaged with a driven helical gear. According to the adjustable wood cutting and deworming device, wood with different lengths can becut by adjusting the telescopic rod; a stop block is arranged, so that feeding can be quickly performed; a vertical baffle is arranged, so that wood chips generated during cutting can be effectivelycollected, and the wood chips are prevented from entering the cutting device so as not to influence the cutting quality and the service life of the device; pesticides are sprayed to wood, so that thepurpose of killing larvae on the wood is achieved, and the safety factor is increased when the wood is used; and the pesticides can be quickly dried by a drying device, so that the wood can be quicklyput into use.

Owner:HUIAN WEIKE ELECTRONICS TECH CO LTD

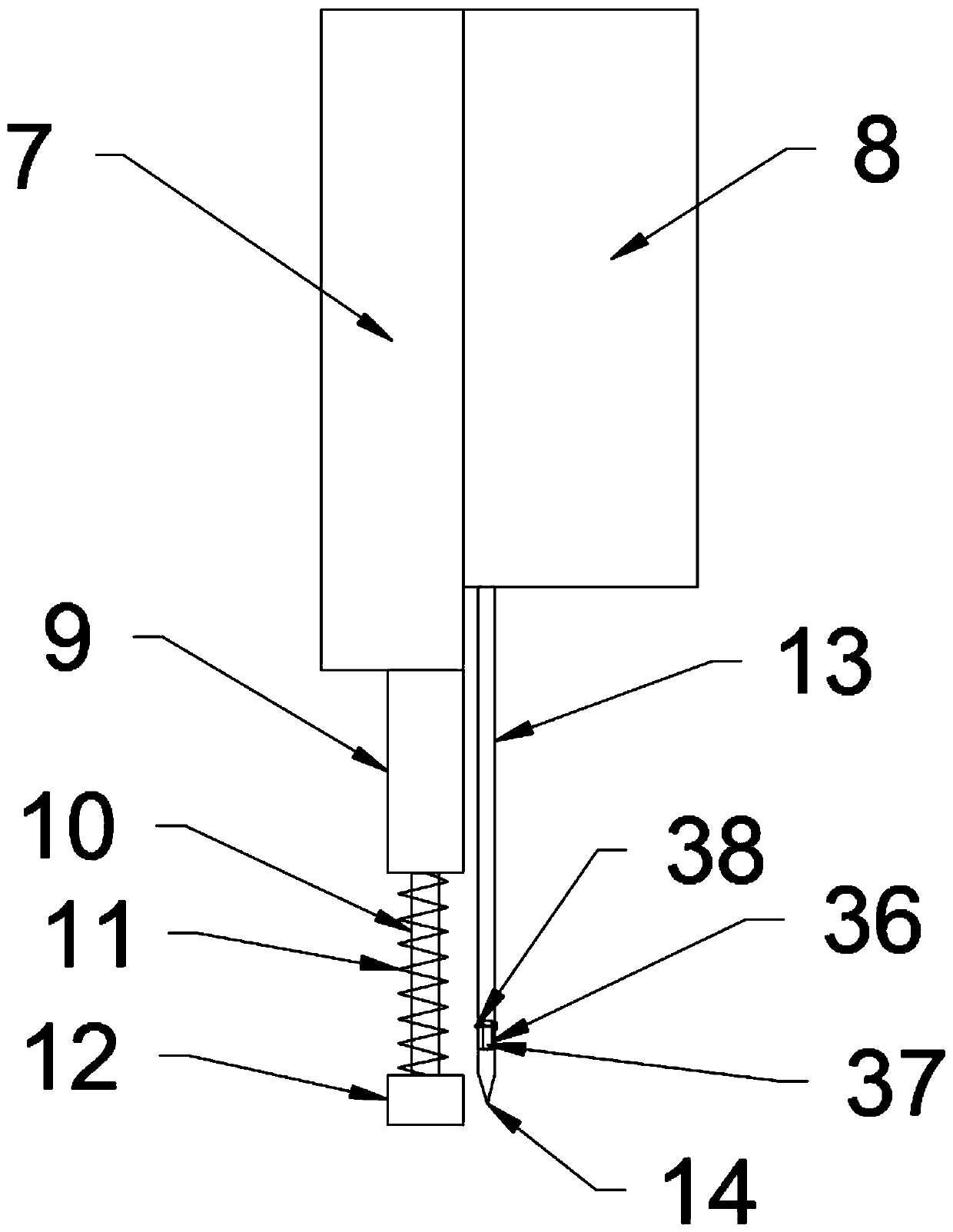

Laser cutting tool and laser cutting production line for soft package battery tab

ActiveCN113182702AImprove stabilityPrevents affecting cut qualityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineElectrical battery

The invention discloses a laser cutting tool and a laser cutting production line for a soft package battery tab, and belongs to the technical field of battery production. The laser cutting tool for the soft package battery tab includes a fixing frame and a conveying belt body, wherein the fixing frame is detachably connected to the conveying belt body by using bolt. The laser cutting tool further includes an arm-type laser cutting machine arranged in the fixing frame; and a driving mechanism connected to the fixing frame. According to the invention, by arranging an electric push rod, a connecting rope and a clamping mechanism, a battery can be fixed, so that the stability of the battery during cutting is effectively improved; by arranging the driving mechanism and the arm-type laser cutting machine, a tab can be cut according to various cutting tracks, so that the practicability of the cutting tool in actual use is effectively improved; and by arranging a waste collecting assembly, the tool can automatically collect tab waste, and manual cleaning of the tab waste is not needed, so that the workload of a user is effectively reduced.

Owner:JINAN G WEIKE SCI & TECH

A cooling water spray component for laser cutting, a spray device and a laser cutting machine

ActiveCN111230343BDoes not change the structureWill not affect normal workLaser beam welding apparatusEngineeringLaser cutting

Owner:株洲特装智能装备有限公司

Paper cutting and grinding integrated device

InactiveCN110509317AAvoid flyingPrevents affecting cut qualityGrinding machinesMetal working apparatusBiochemical engineeringKnife blades

The invention discloses a paper cutting and grinding integrated device. The device comprises a workbench. A first conveying device is arranged on the workbench. A first limit support is arranged on the right side of the first conveying device. A second limit support is arranged on the right side of the first limit support. A first supporting frame is arranged between the first limit support and the second limit support. A lifting motor and a cutting motor are arranged on the first supporting frame. A first connecting rod is mounted on the lifting motor. A telescopic rod is arranged on the first connecting rod. A buffer protection pad is arranged at the bottom end of the telescopic rod. A second connecting rod is arranged on the cutting motor. A cutting blade is arranged on the second connecting rod. A second conveying device is arranged on the right side of the second limit support. A third limit support is arranged on the right side of the second conveying device. A grinding device isarranged on the right side of the third limit support. A dust collector is arranged on the grinding device. According to the paper cutting and grinding integrated device, paper cutting and grinding are integrated, and the paper processing efficiency and quality are improved.

Owner:安徽文博纸品印刷有限公司

Hydraulic paper cutting device

InactiveCN104493862AReduce impactNo deviationMetal working apparatusHydraulic cylinderHydraulic pump

The invention discloses a hydraulic paper cutting device comprising two paper feed rollers matched with each other and two paper delivery rollers matched with each other. A paper cutting mechanism is arranged between the paper feeding rollers and the paper delivery rollers and comprises a cutter and a rubber roller arranged under the cutter, the cutter is arranged at the free end of a piston rod of a hydraulic cylinder, and the cutter is driven by the hydraulic cylinder to move up and down. Compared with the prior art, the hydraulic paper cutting device has the advantages of accurate paper cutting position, small noise and high working efficiency.

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

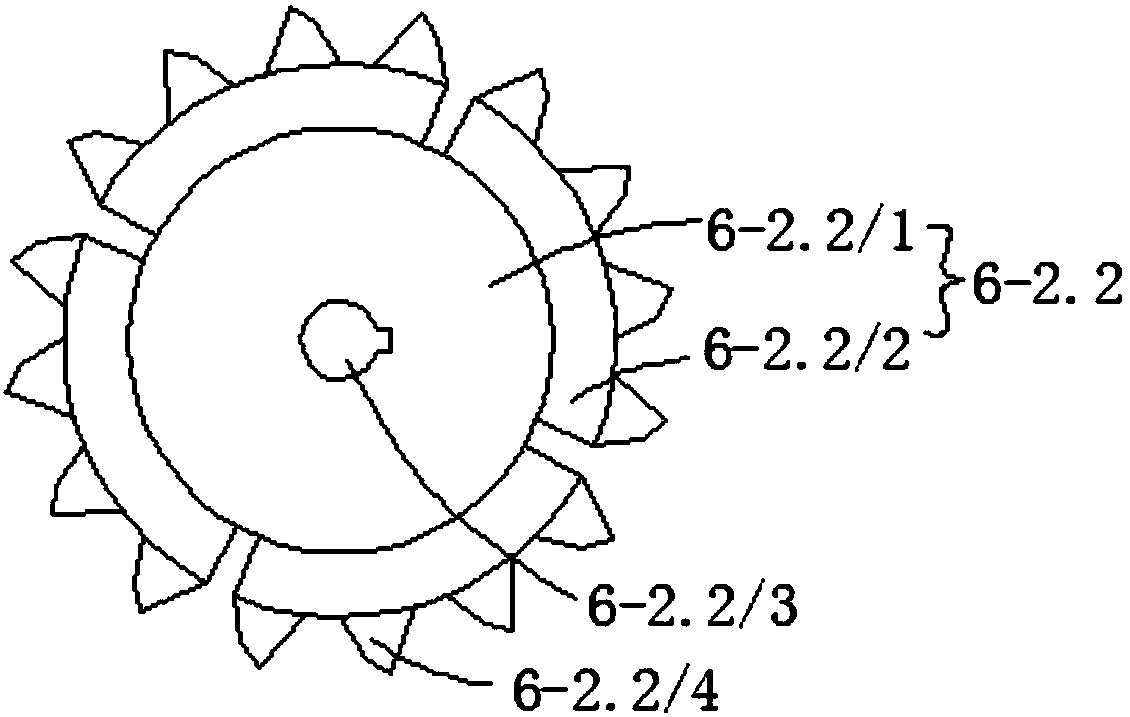

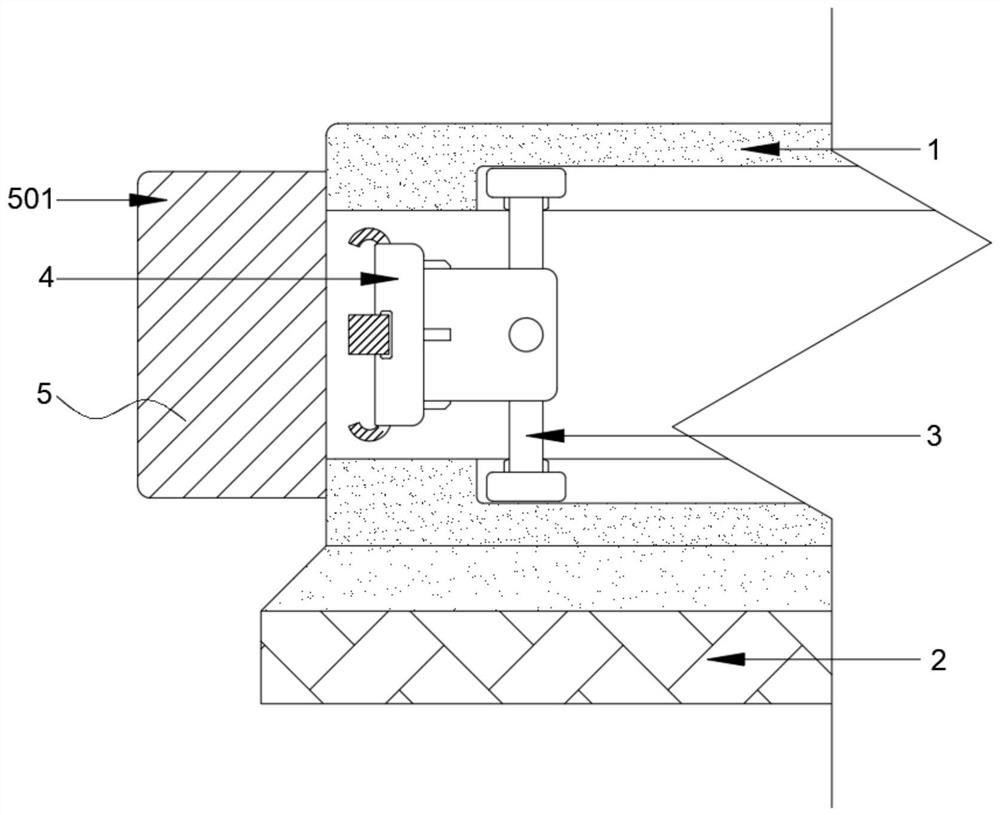

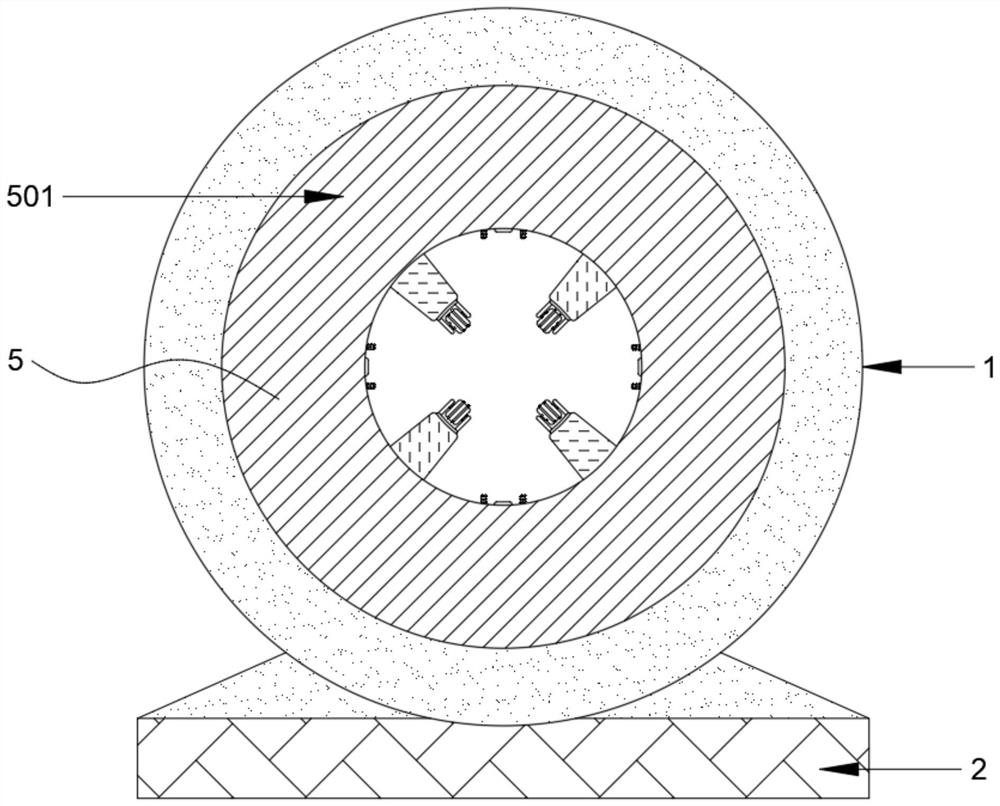

Optical glass lifting type cutting equipment

InactiveCN107856205APrevents affecting cut qualitySimple structureWorking accessoriesGlass severing apparatusCircular discEngineering

The invention discloses a lift-type cutting device for optical glass, and relates to the technical field of optical glass processing equipment. The invention includes a base and a cutting mechanism. A horizontal support plate is connected between them, and one end of the horizontal support plate is provided with a telescopic cylinder. The cutting mechanism includes a mounting frame and a cutting assembly. The cutting assembly includes a cutting motor and a disc-shaped cutting blade. The inner disc and the outer disc have a through hole in the center of the inner disc that fits the output shaft of the cutting motor, a square slot is provided on the inner wall of the through hole, and a number of cutting teeth are evenly distributed on the circumference of the outer disc. , the cutting teeth are fixed on the outer disk by rivets, the cutting teeth of the present invention are fixed on the outer disk by rivets, when a certain cutting tooth is damaged, the damaged cutting tooth can be replaced separately, which reduces the cost.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Paper-cutting crankshaft unit

InactiveCN104493857AGuaranteed to be verticalEasy to cutMetal working apparatusElectric machineryEngineering

The invention discloses a paper-cutting crankshaft unit comprises two feed rollers and two discharge rollers. The feed rollers fit each other; the discharge rollers fit each other. A cutting mechanism is disposed between the feed rollers and the discharge rollers and comprises a cutting blade and a rubber roller disposed right under the cutting blade. The cutting blade is disposed at the lower end of a connecting bar; the connecting bar is in sleeving connection with a crankshaft through a bearing; the crankshaft is driven by a motor; the cutting blade is driven by the crankshaft and the connecting bar to move up and down. Compared with the prior art, the paper-cutting crankshaft unit has the advantages that cutting position of paper is accurate, noise is low, and work efficiency is high.

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

Paper cutting device

InactiveCN108247697AEasy to cutGuaranteed to be verticalMetal working apparatusWebs handlingPaper cutPulp and paper industry

The invention relates to a paper cutting device. The paper cutting device comprises two paper feeding rollers cooperating with each other, and two paper discharge rollers cooperating with each other;and paper cutting devices are arranged between the paper feeding rollers and the paper discharge rollers. The paper cutting device overcomes the problems of completion of paper cutting through cooperation of the an upper cutter and a lower cutter in paper cutting and unsuccessful paper cutting caused by such conditions as halfway rotation of the upper cutter, halfway adjustment of the lower cutterand halfway engagement of edges of the upper cutter and the lower cutter in the prior art.

Owner:HENAN XINZHIXIANG EDUCATION TECH CO LTD

Laser cutting machine for alloy steel machining

The invention discloses a laser cutting machine for alloy steel machining. A machining lathe body is included, and a fixed suction cup is installed at the bottom end of the machining lathe body; the position, located on the inner side of the fixed suction cup, of the bottom of the machining lathe body is provided with a first fixed groove; a first hydraulic telescopic rod is installed in the firstfixed groove; and the position, located on the inner side of the first fixed groove, of the bottom of the first hydraulic telescopic rod is connected with universal wheels. According to the laser cutting machine for alloy steel machining, moving and stable placing of the laser cutting machine are facilitated, measuring on the width of an alloy steel plate needing to be cut is also facilitated, and therefore the transverse distance of laser cutting is conveniently adjusted, and the unnecessary time and electric quantity waste is reduced; stability and accuracy are improved when the alloy steelplate is placed on a workbench, and deviation happening to the alloy steel plate is prevented; and meanwhile, cooling and dust removing treatment can be conveniently performed at the cut position, and it is prevented that waste scraps generated during cutting adhere to a high-temperature cut position, and the cutting quality is affected.

Owner:浙江冯家桥机械有限公司

Cutting device for mattress formation

InactiveCN110843002ARealize multi-segment cuttingNovel structural designMetal working apparatusElectric machineryStructural engineering

The invention discloses a cutting device for mattress formation. The cutting device for mattress formation comprises a base and a cutting assembly. A stand column is fixedly installed on one side of the base. The cutting assembly comprises a first telescopic oil cylinder, a second telescopic oil cylinder, a cutter installation frame and a cutter. The end of the stand column is perpendicularly provided with a cross beam. An oil cylinder fixing seat is installed at the lower end of the cross beam. The upper ends of the first telescopic oil cylinder and the second telescopic oil cylinder are fixed to the oil cylinder fixing seat. The lower ends of the first telescopic oil cylinder and the second telescopic oil cylinder are fixedly connected with the two ends of a cutter installation frame. The middle portion of the cutter installation frame is fixedly provided with a cutter. One side of the cutter installation frame is provided with a cutting motor which is in transmission connection withthe cutter. A mattress holding platform is further installed on the base. The cutting device for mattress formation is novel in structural design, capable of achieving multi-section cutting of the formed mattress and high in cutting efficiency and effectively improves work efficiency.

Owner:湖南喜传天下家居有限公司

Efficient surface layer peeling machine for optical fiber recovery processing

ActiveCN112946818AEasy to cutPrevents affecting cut qualityCoupling light guidesEngineeringStructural engineering

Owner:北京佳诚速通网络科技有限公司

A laser blade aluminum bead cutting positioning device

ActiveCN111843551BEasy positioningSolve the inconveniencePositioning apparatusMetal working apparatusLaser KnivesLocked plate

The invention relates to the technical field of aluminum bead cutting, in particular to a laser blade aluminum bead cutting and positioning device. The technical problem to be solved by the invention is that the existing devices are inconvenient to use. In order to solve the above technical problems, the present invention provides a laser blade aluminum bead cutting and positioning device, including a working plate, the right side of the top of the working plate is fixedly connected with a slide plate, and the top of the left side of the slide plate is fixedly connected with a left latch structure, the left locking structure includes a left locking plate, the bottom of the left locking plate is fixedly connected to the top of the left side of the slide plate, the top of the left locking plate is movably connected with a left cam block through a pin shaft, and the left The outer side of the middle part of the lock plate is provided with a left lower pressure plate, and the front and back of the left lower pressure plate are movable and interspersed with a left shaft. The right top is fixedly connected with a right locking structure, and the right locking structure includes a right locking plate.

Owner:安庆创跃电器有限公司

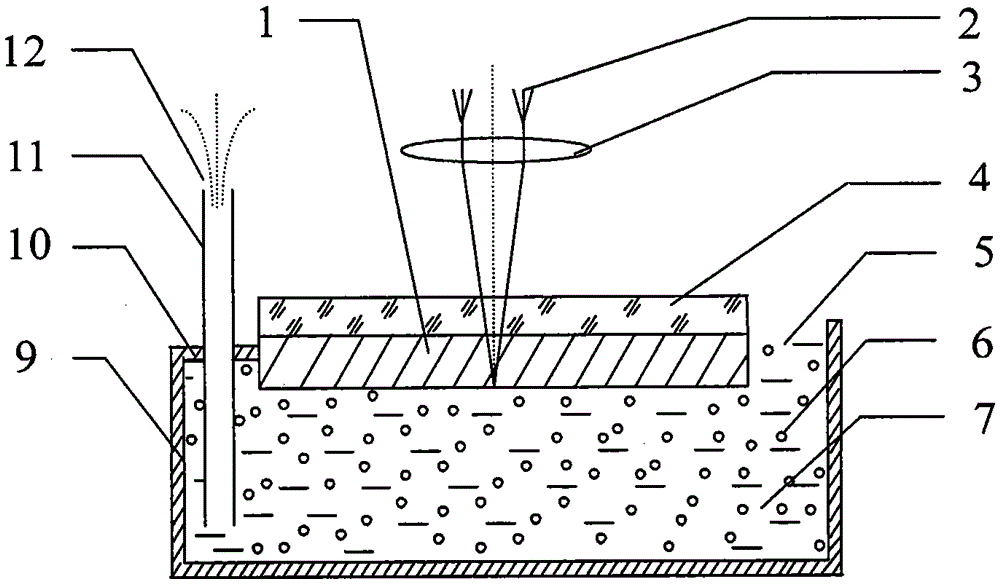

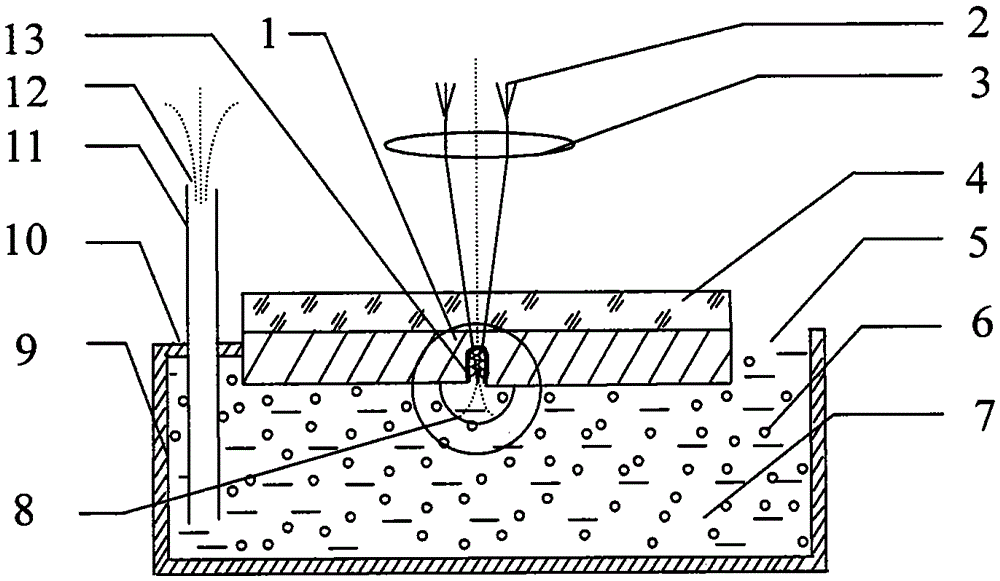

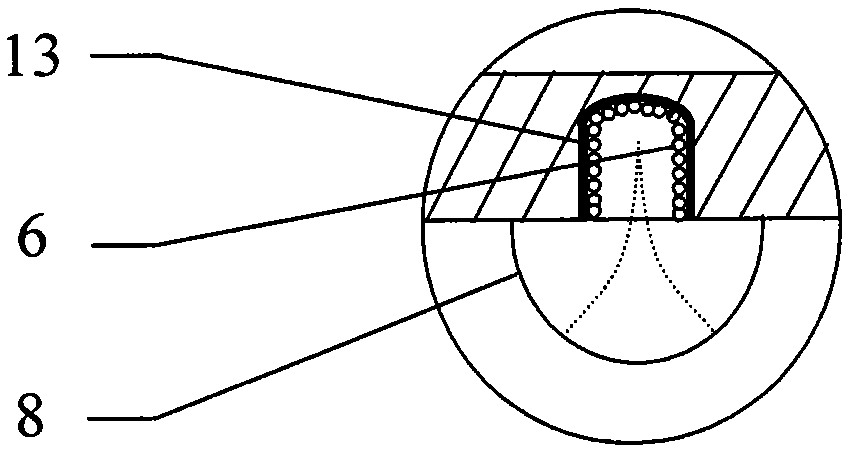

A processing method and device for laser forming and cutting sapphire substrate

ActiveCN104028898BDebris take awayEasy to take awayVacuum evaporation coatingSputtering coatingSuspended particlesRegelation

The invention discloses a machining method and device for laser forming cutting of a sapphire substrate. The machining device mainly comprises a protection device, a laser beam, a lens set, a container, a limiting layer, suspended particles and a gas inlet pipe. Working liquid is arranged in a cavity formed in the container, the working liquid generates a sedimentation layer on the lower surface of a base material through lasers, the suspended particles in the liquid at a solid-liquid contact face and the sedimentation layer are combined to enhance the absorption of laser energy so that the melting temperature and the vaporizing temperature of sapphire materials near a laser focus can be reached, in addition, under laser irradiation, a large amount of small bubbles are generated with the suspended particles as the centers, bubble detonation impact force is used for brushing cut grooves, discharging of chippings is facilitated, and therefore the materials can be removed under the combined action of the laser action and the laser irradiation. According to the machining method, the heat effect of the cut grooves is small, a regelation layer in a machined area is omitted, machining quality is high, and forming cutting can be achieved. The machining method is easy to operate, convenient to conduct, practical, high in machining rate and extremely-low in machining cost.

Owner:GUANGDONG UNIV OF TECH

Electric power pipe cutting device for electric power construction

ActiveCN112476014BGuaranteed smoothQuality assurancePositioning apparatusMetal working apparatusStructural engineeringControl theory

The invention discloses a power pipe cutting device for electric power construction, comprising a bottom plate, on which a transmission mechanism, a cutting mechanism, a limit mechanism and an adjustment mechanism are installed, the transmission mechanism is installed on one end of the bottom plate, and the cutting mechanism Installed on the bottom plate, one side of the transmission mechanism, a fixing mechanism is installed on the cutting mechanism, the adjustment mechanism is installed on the other end of the bottom plate, and cooperates with the limit mechanism, the limit mechanism is installed on the bottom plate , between the adjustment mechanism and the cutting mechanism, and cooperate with the cutting mechanism. The invention can not only ensure the smoothness of the cut of the power tube and the quality of the power tube, but also ensure the cutting of the same length of the power tube, and can adjust the length of the power tube according to the needs, thereby ensuring the cutting quality of the power tube and the normality of the power tube The use reduces production costs and improves work efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO TAOXIAN POWER SUPPLY CO

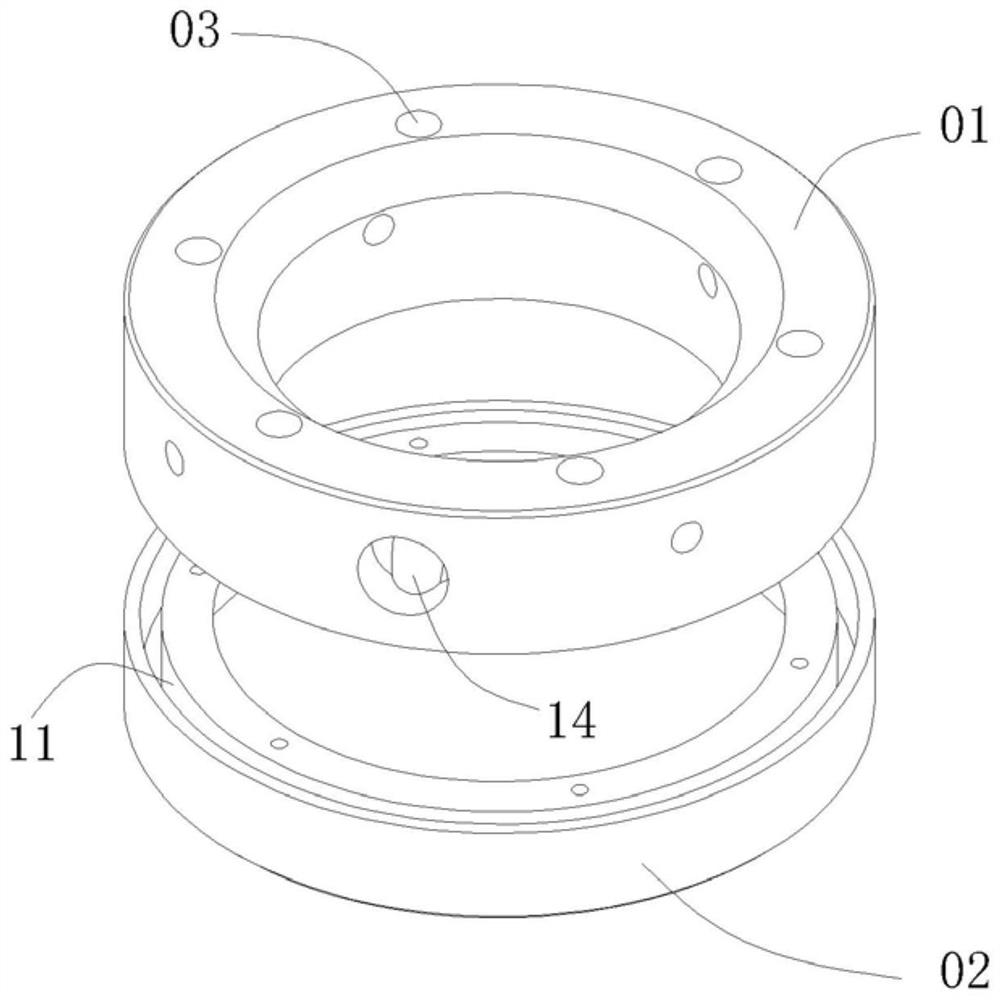

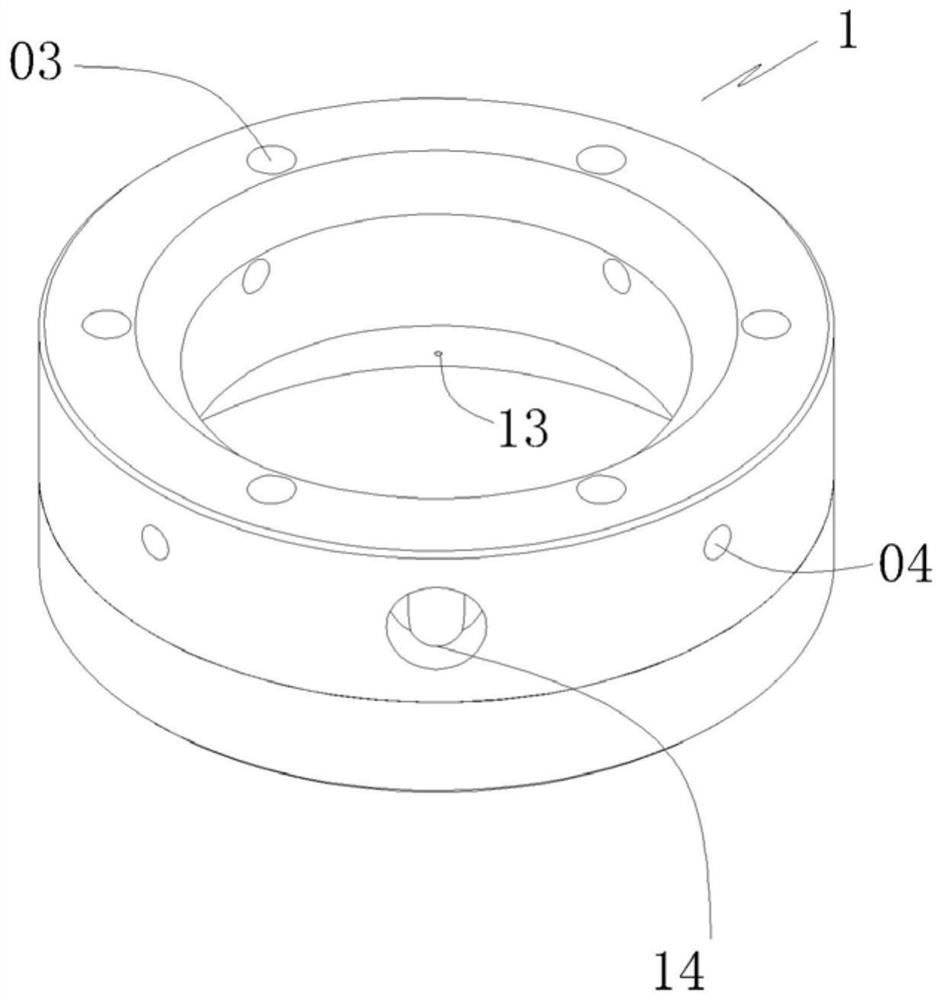

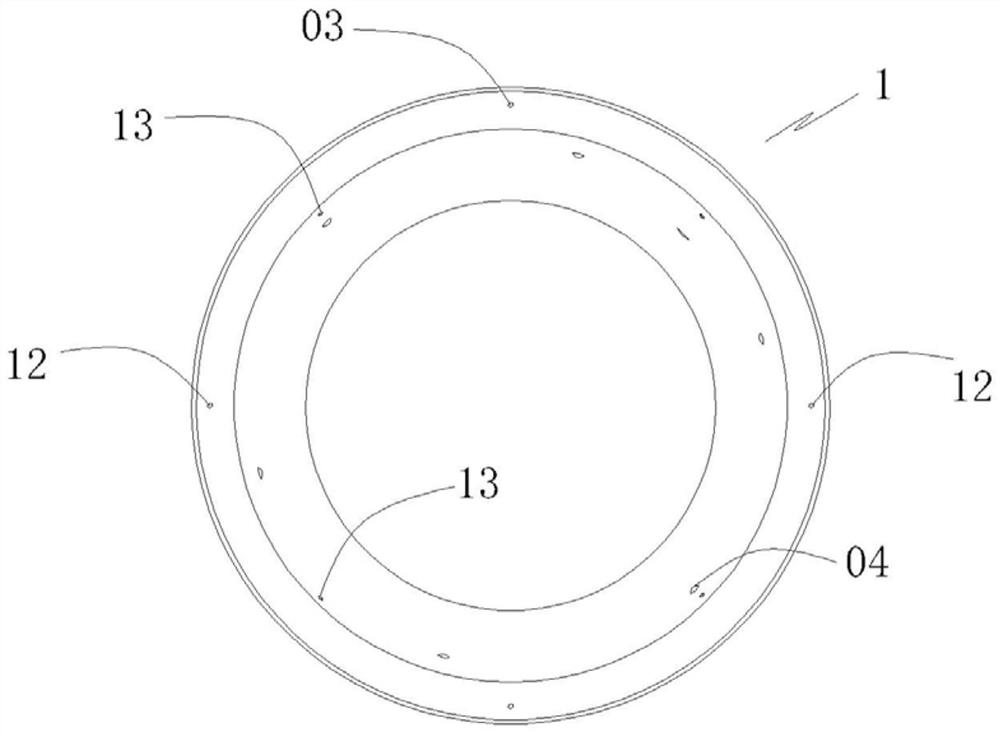

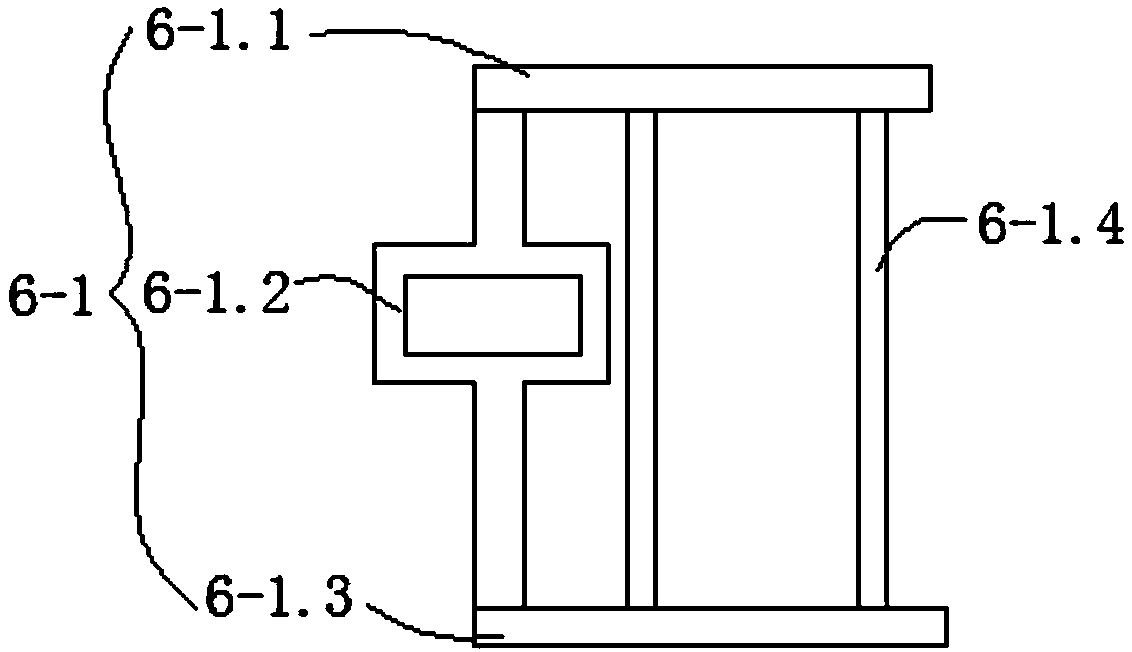

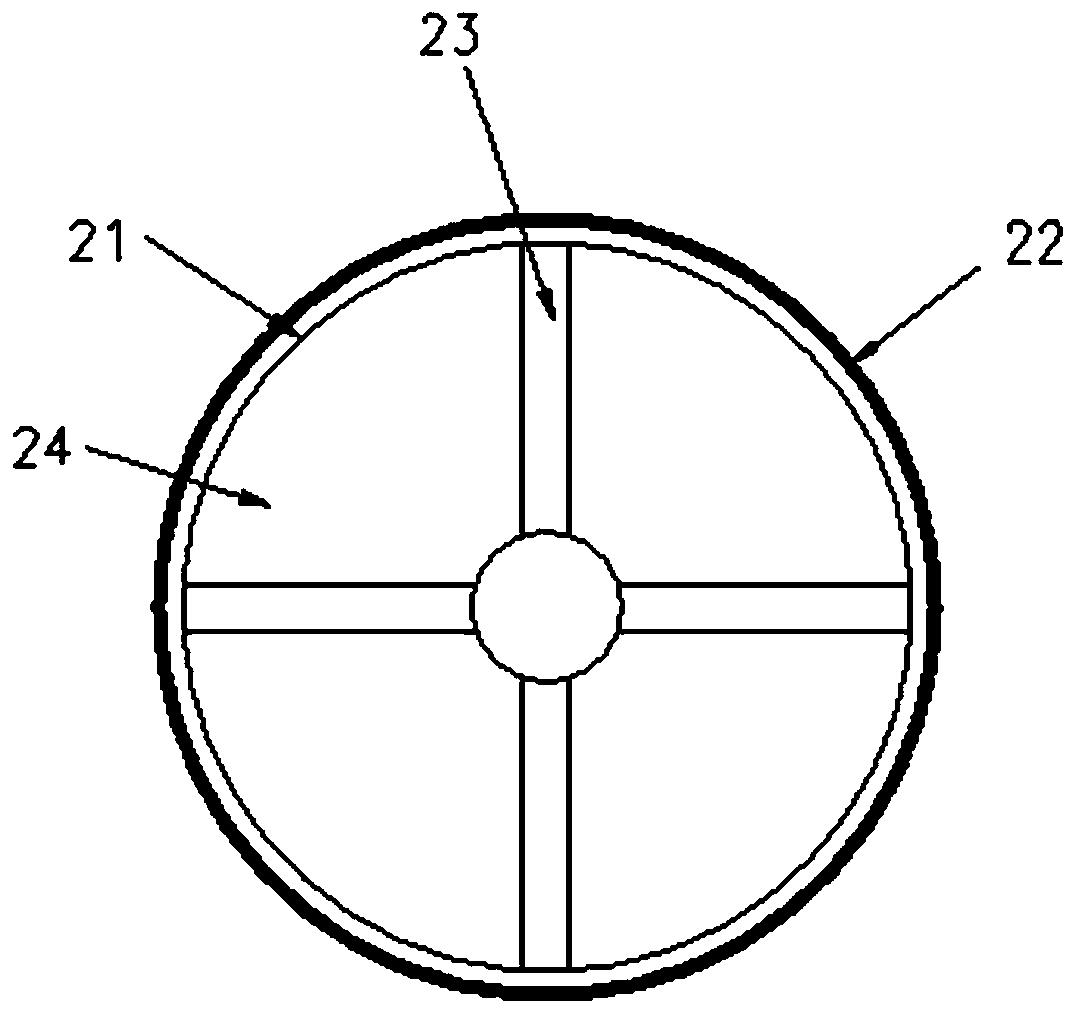

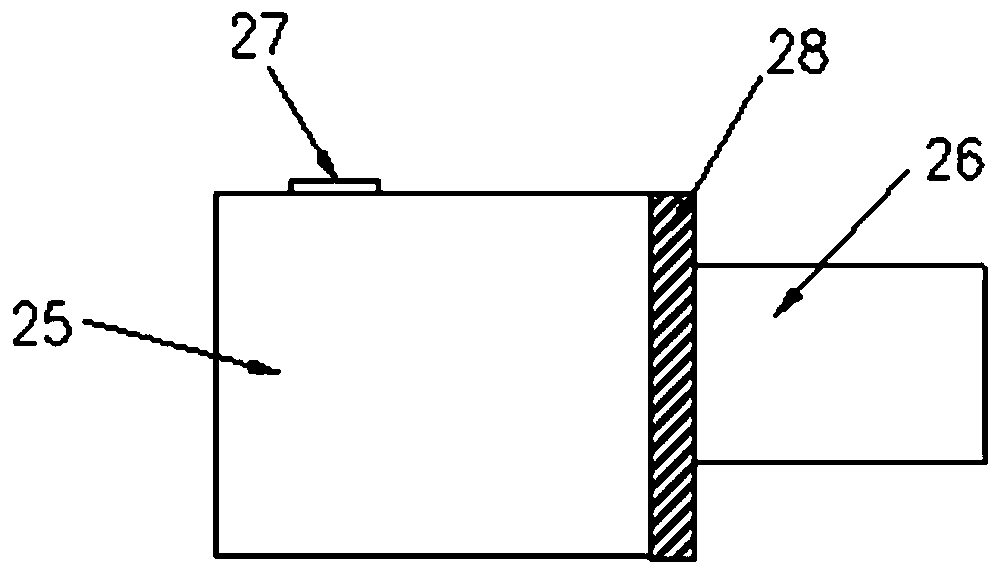

A splitting and shearing machine for processing the protective cover of the steel belt of the transmitting antenna

ActiveCN108581050BImprove cutting efficiencyFast cutting speedMetal sawing devicesMetal sawing accessoriesHydraulic pumpEngineering

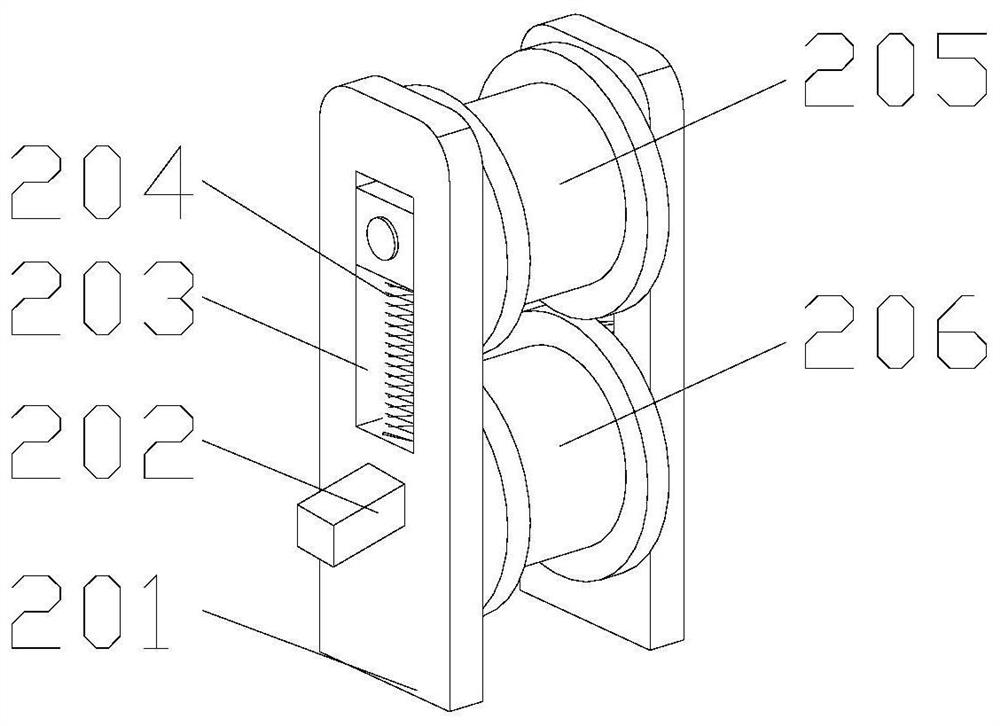

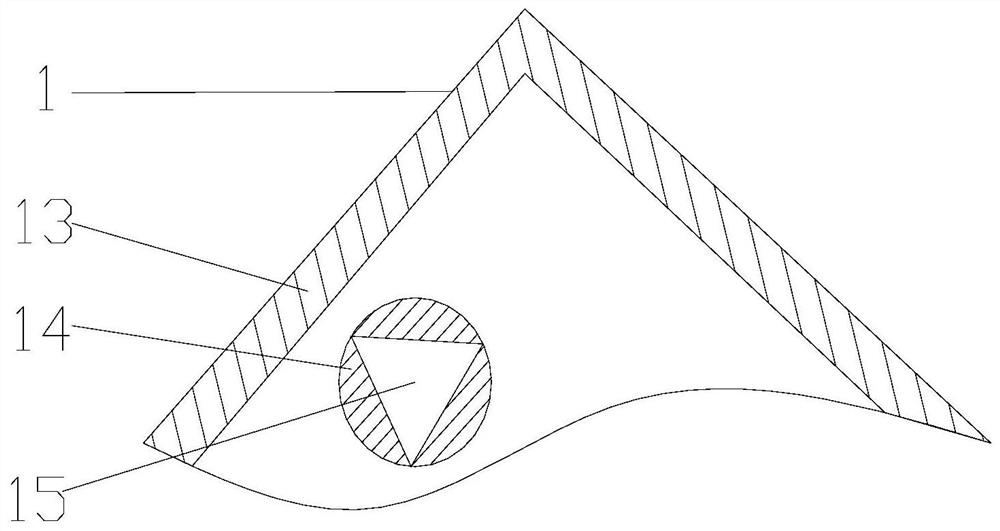

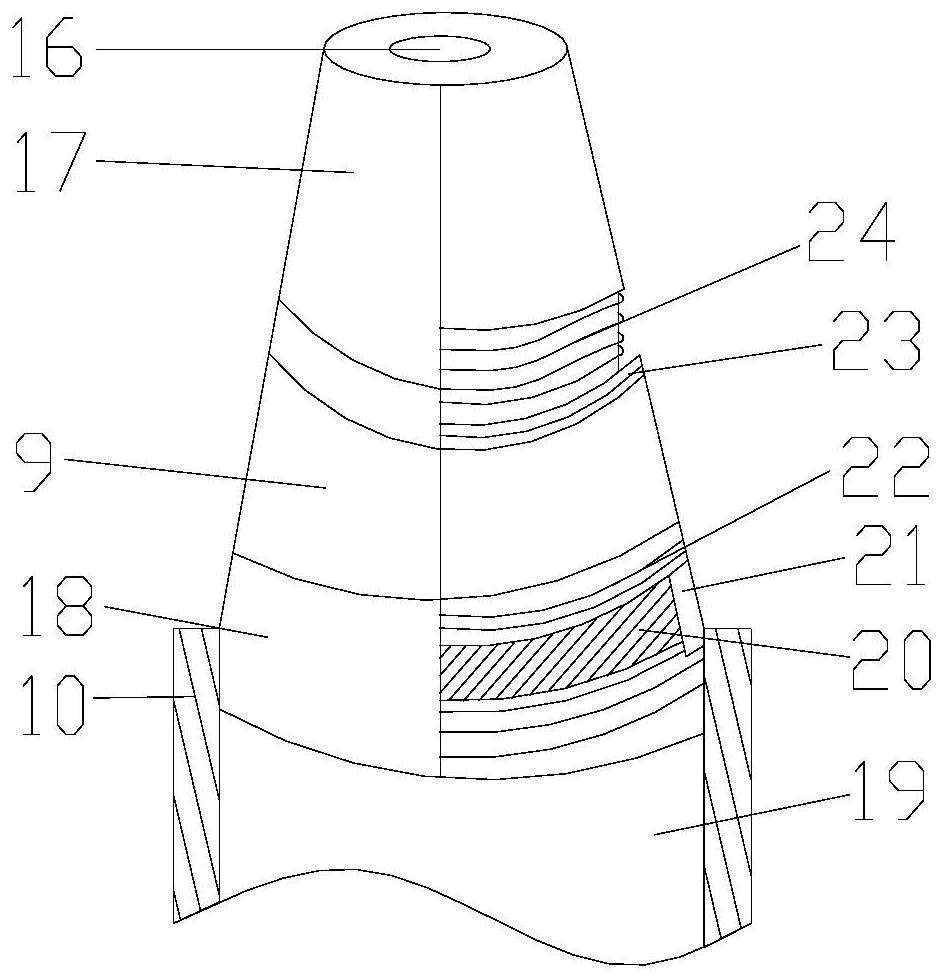

The invention provides a shearing machine for machining a protective sleeve of a steel strip of a transmitting antenna. The shearing machine is characterized in that a cutter group mechanism comprisesannular saw blades, a motor I, a hydraulic pump, a hydraulic fixed roller and two sets of cutter group seats, wherein the cutter group seats are arranged in an up-down mirror image mode, the cutter group seats are provided with a plurality of clamping parts and a plurality of sliding parts and are in a square shape, and strip-shaped grooves are formed in the bottoms of the cutter group seats; each clamping part is internally provided with two rotating wheels, the end portions of each of the annular saw blades are clamped between two corresponding rotating wheels, and the annular saw blades are driven by the rotating wheels to operate; the clamping parts are internally provided with concave shrapnels, and two ends of the concave shrapnels abut against the rotating wheels and apply the force to enable the rotating wheels to get close to each other; the clamping parts are provided with buttons, clamping blocks are connected to the inner ends of the buttons, the clamping blocks abut against the two end faces of the concave shrapnels, and the concave shrapnels are propped to open by the clamping blocks under pushing of the buttons; and the sliding parts are fixedly connected to the clamping parts. When the annular saw blades are installed, just the buttons on the clamping parts are pressed, the end portions of the annular saw blades are put at the rotating wheels after the rotatingwheels are released, and tool changing can be completed by releasing the buttons, so that tool changing is convenient.

Owner:浙江联品电子科技有限公司

A dust-proof and deviation-proof cutting device for insulation boards

ActiveCN110421623BAvoid flyingPrevents affecting cut qualityFouling preventionMetal working apparatusThermal insulationEngineering

The invention discloses a dustproof anti-deviation efficient cutting device for an insulation board. The dustproof anti-deviation efficient cutting device comprises a work platform. A supporting blockis fixed to the upper end face of the work platform. A fixed block is fixed to the right end of the supporting block. A rotary shaft is fixed to the front end face of the fixed block. The rotary shaft is rotationally connected with a dustproof cover. A handle is fixed to the right end of the dustproof cover. A clamping mechanism capable of supporting and clamping the insulation board is further arranged on the upper end face of the work platform. A movable cavity with the right end wall communicating the external space is formed in the supporting block. A driving mechanism for driving the device to move and cut the insulation board is arranged in the movable cavity. After the insulation board is placed in the device, the cutting position can be automatically locked by the device, then cutting is stably completed, and the cutting efficiency and the cutting stability are guaranteed through full-automatic cutting; it is avoided that during manual cutting, deviation is caused by the subjective factor of people, and the cutting quality is influenced; and dust generated during cutting is effectively prevented from flying all around through the dustproof cover.

Owner:南通中保节能科技有限公司

A sheet metal cutting box

ActiveCN112692375BAdjustable temperatureEasy to collectMaintainance and safety accessoriesEngineeringMechanical engineering

Owner:SHENZHEN HANXING PRECISION TECH

Plastic light panel base trimming device

ActiveCN111805608BPrevent splashPrevents affecting cut qualityMetal working apparatusEngineeringStructural engineering

The invention is applicable to the technical field of plastic lamp panel trimming, and provides a plastic lamp panel base trimming device, which includes a conveyor belt, a cutting device, a carrier frame and a fixing device. The cutting device includes a shell, a flexible cutting strip and a fixing piece. The bar is connected to the rotating part, and the rotating part is connected to the casing through the fixing part, and the casing is connected to the lifting cylinder; the fixing device includes a limit column, a pressure rod, a limit rod, a rotating rod and a fixed seat, and the limit post is provided with a through hole, and the pressure rod There is an accommodating space for the limit column on the top, the end of the pressure rod is movably connected to the fixed seat, the limit rod is connected to the rotating rod through the rotating shaft, and the distance between the rotating shaft and the bottom surface of the rotating rod is greater than the thickness of the pressing rod; the outside of the fixing device A protective cover is installed. Thereby, the present invention can effectively realize the right-angle cutting of the base of the lamp panel, thereby facilitating subsequent combined installation and improving installation efficiency.

Owner:山东三晶照明科技有限公司

Nylon rope separating device for constructional engineering

InactiveCN111283767ASo as not to damagePrevents affecting cut qualityMetal working apparatusHydraulic cylinderDrive wheel

The invention discloses a nylon rope separating device for constructional engineering, and belongs to the field of construction equipment. The nylon rope separating device is characterized in that a hydraulic cylinder is fixed to the right rear corner of a workbench, a motor is fixed to the right side of a motor base, a driving wheel is fixed between the motor base and a third support, a limitingsupport is installed on a second support, a cutting device is fixed to the upper portion of the base, a controller is fixed to the lower left corner of the workbench, an encoder is fixed to the left side of the third support, a pressing support is installed below a first support, and a cutting tool is fixed to a main shaft of an electromagnet. According to the nylon rope separating device, nylon ropes with different numbers of thin wires are separated out through the cutting device, the motor drives the driving wheel to rotate to drag the nylon ropes to move forwards, the cutting tool cuts thenylon ropes into designated lengths through the action of the electromagnet, the process of manually tearing the nylon ropes is replaced, efficiency is improved, and manpower is saved.

Owner:荆门宁杰机电技术服务有限公司

Laser cutting tooling and laser cutting production line for soft-pack battery tabs

ActiveCN113182702BImprove stabilityPrevents affecting cut qualityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineElectrical battery

The invention discloses a laser cutting tool and a laser cutting production line for tabs of soft-pack batteries, belonging to the technical field of battery production. A laser cutting tool for the tab of a soft-pack battery, including a fixing frame and a transmission belt body, the fixing frame is detachably connected to the transmission belt body through bolts, and also includes: an arm-type laser cutting machine set on the fixing frame Inside; the driving mechanism is connected on the fixed frame. The present invention can fix the battery through the setting of the electric push rod, the connecting rope and the clamping mechanism, which effectively improves the stability of the battery during cutting. Through the driving mechanism, The setting of the arm-type laser cutting machine can cut various cutting tracks on the tabs, which effectively improves the practicability of the cutting tool in actual use. Through the setting of the waste collection component, the tooling can automatically align the tabs The waste is collected without manual cleaning, which effectively reduces the workload of the user.

Owner:JINAN G WEIKE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com