Patents

Literature

325results about How to "No deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

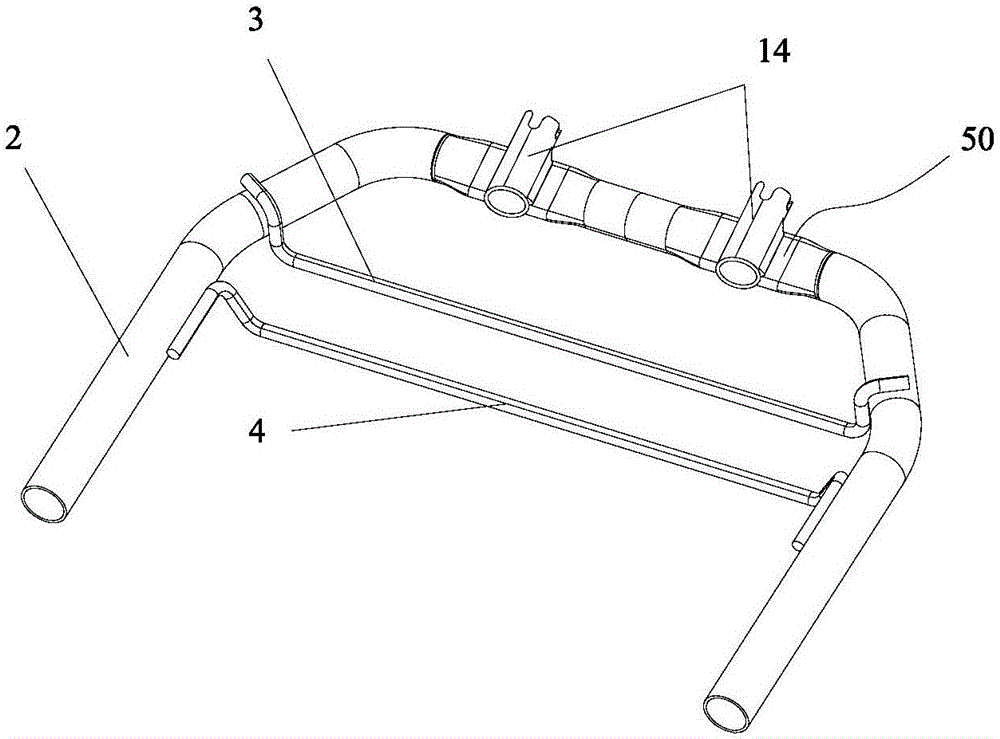

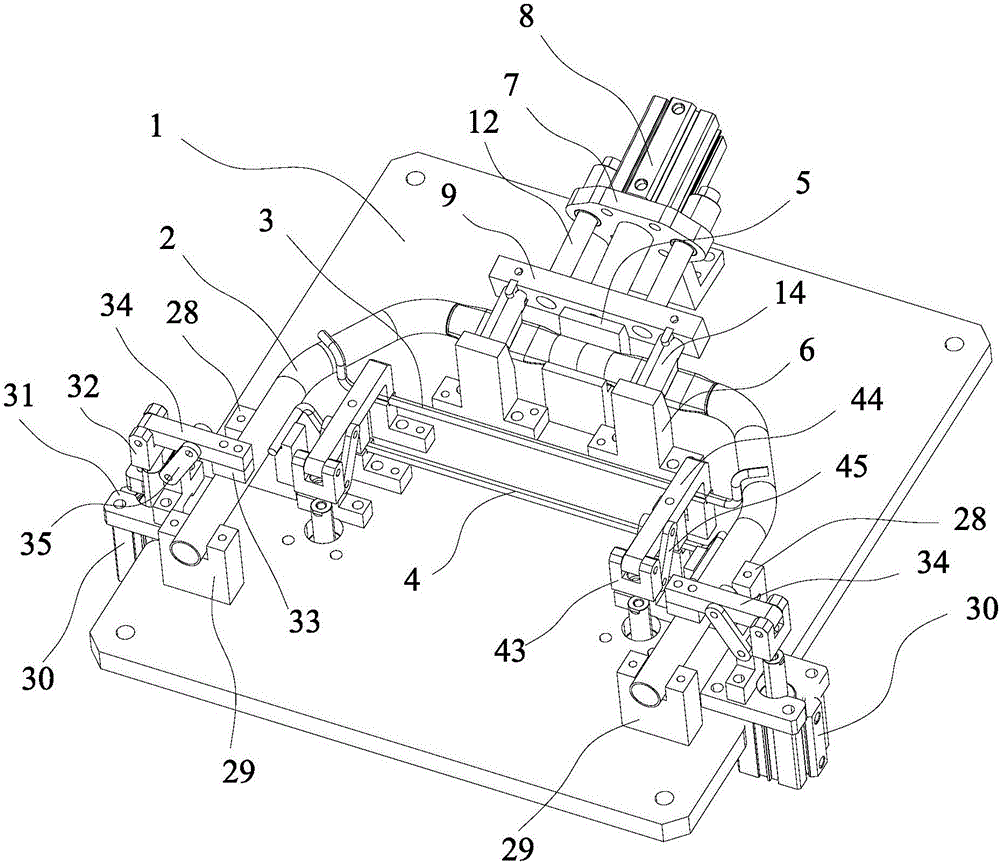

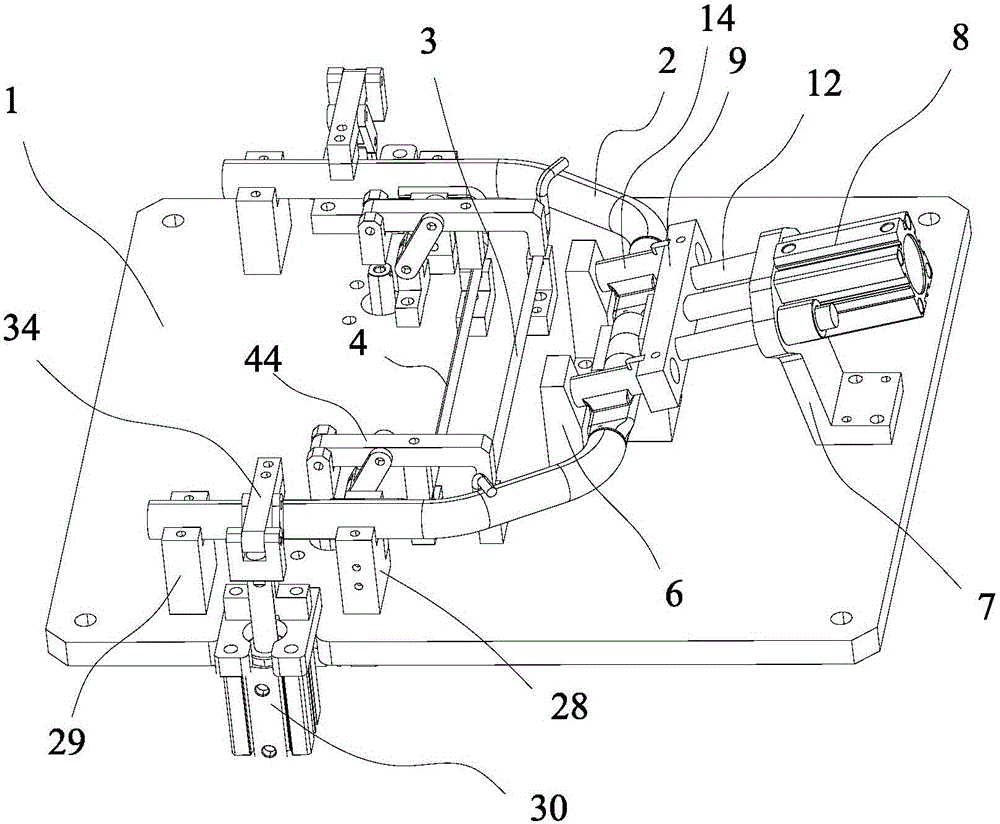

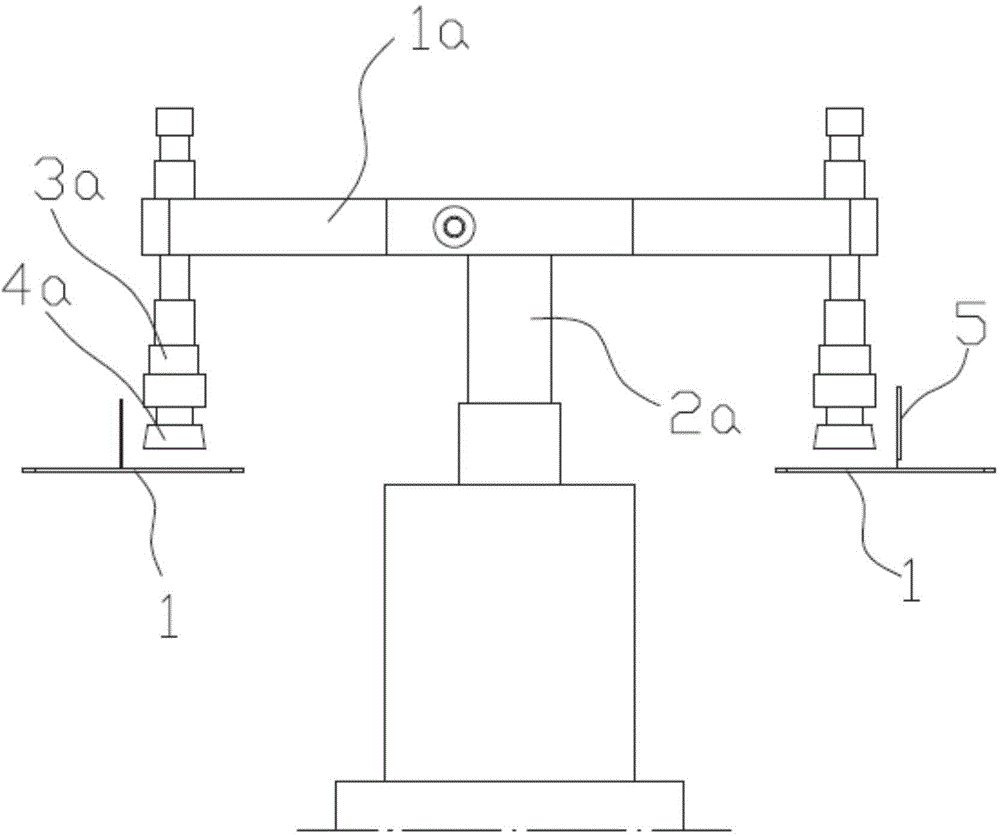

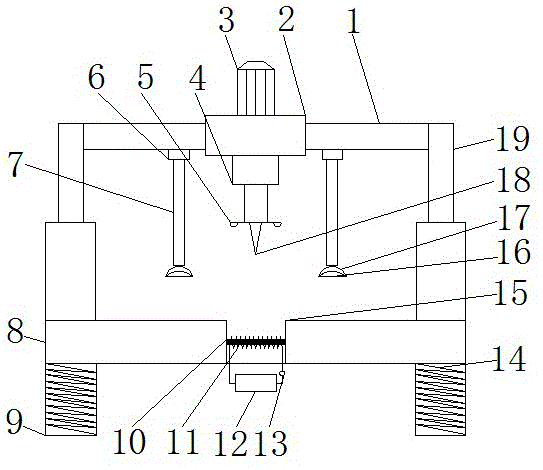

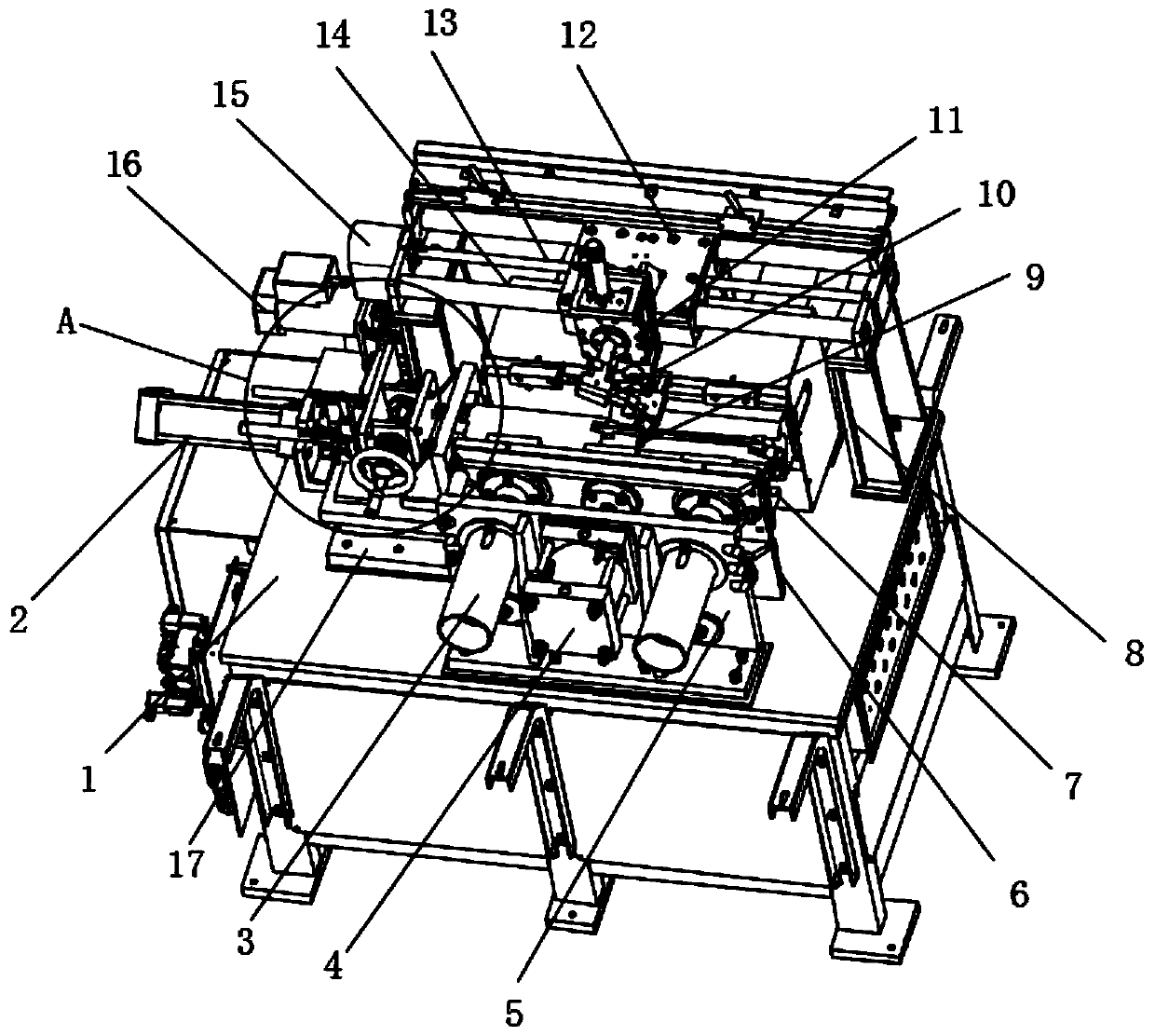

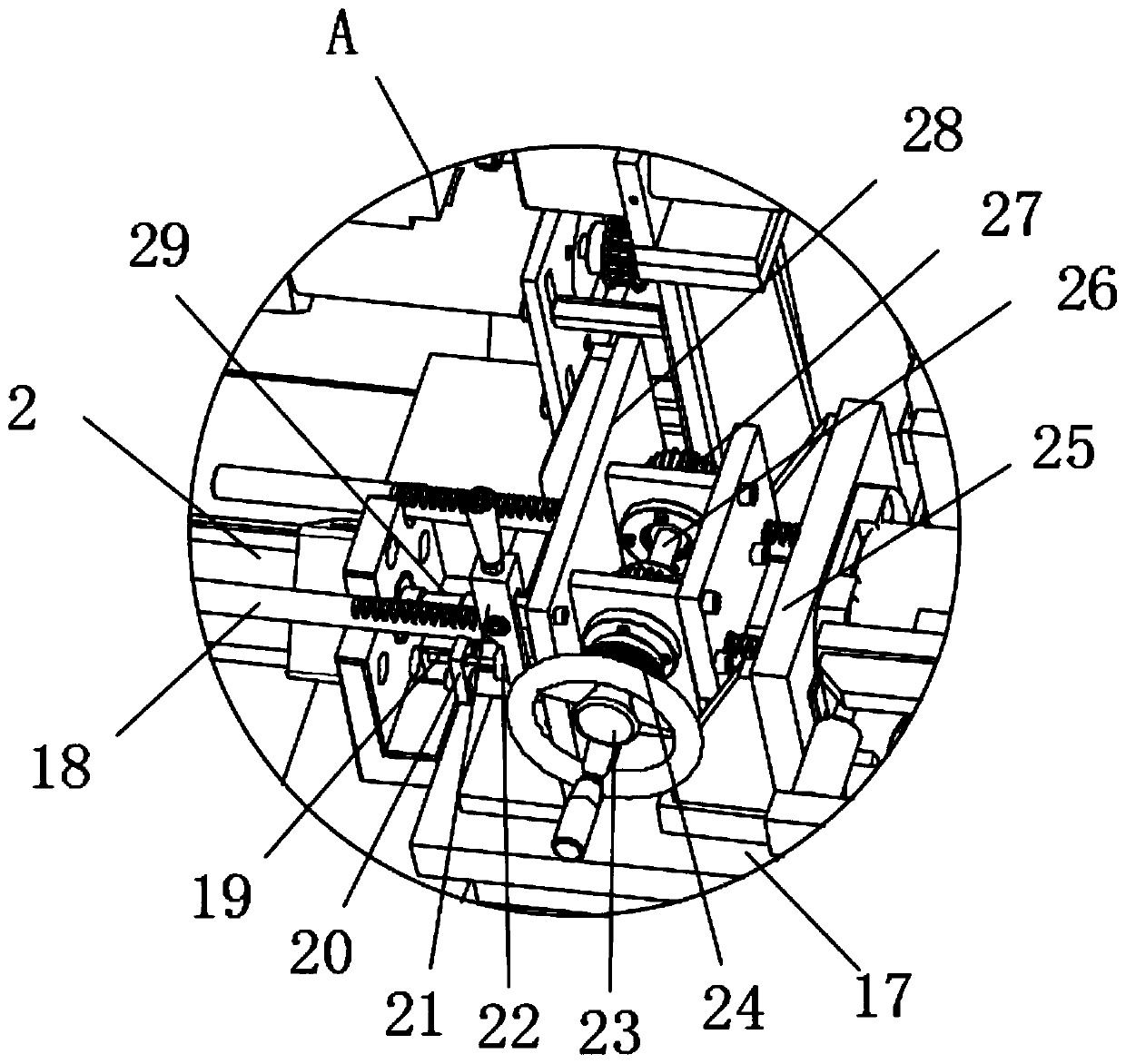

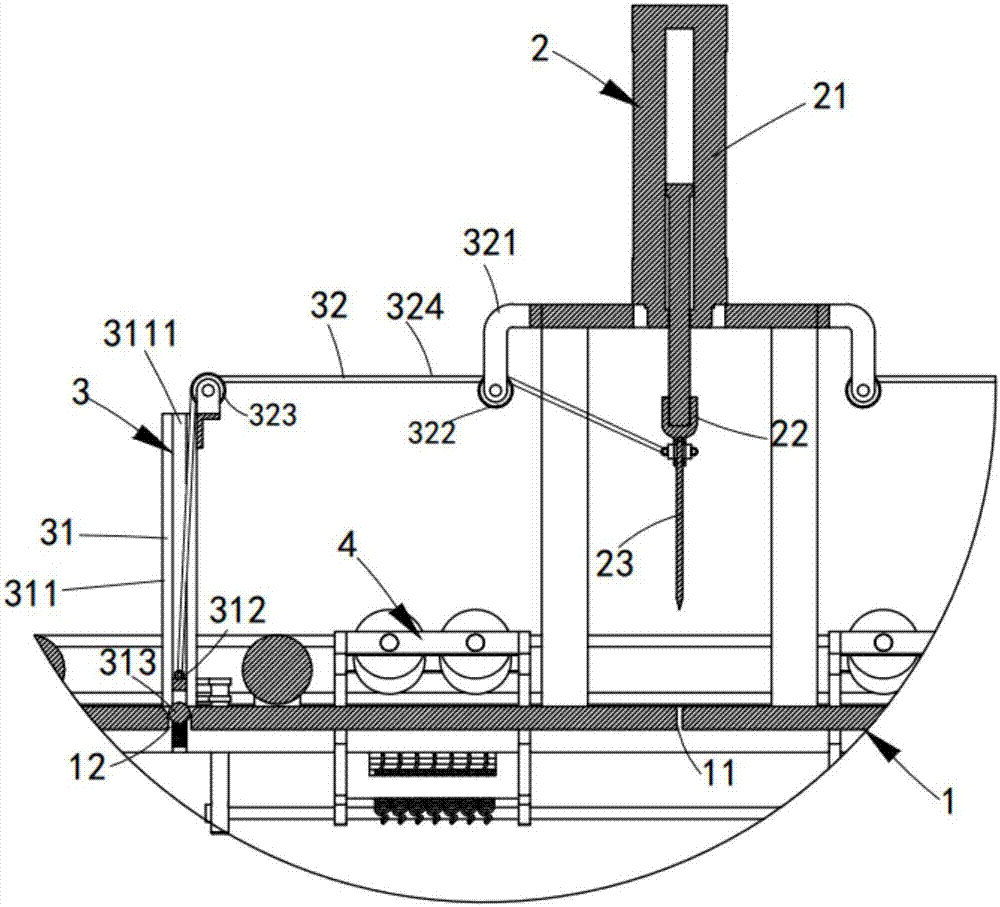

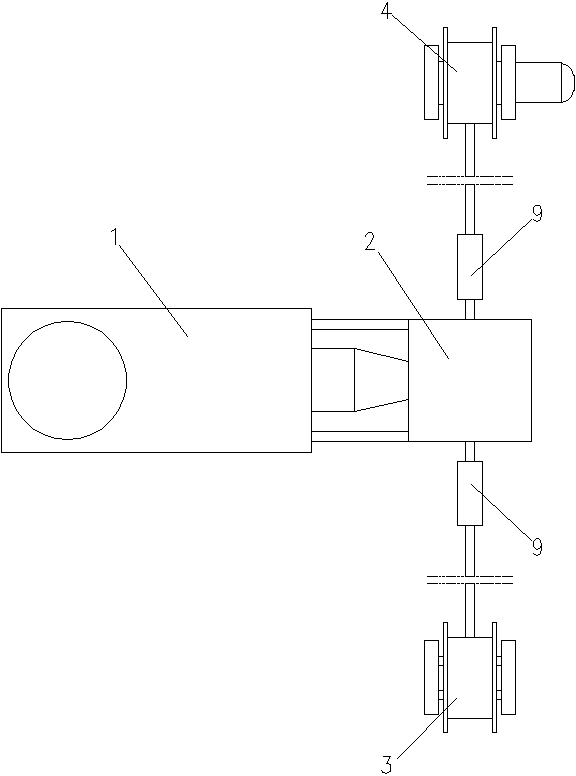

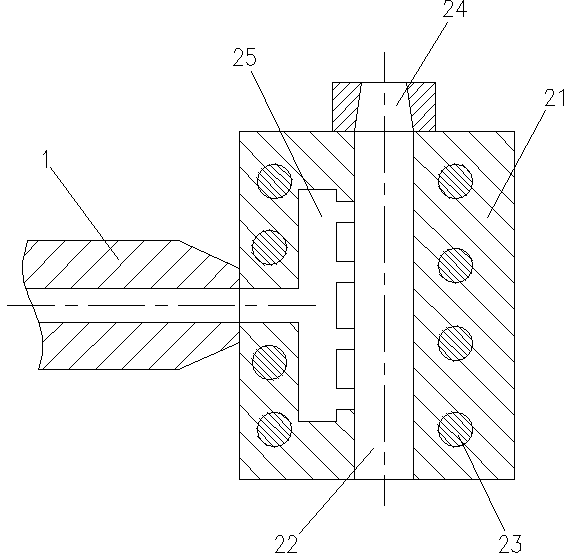

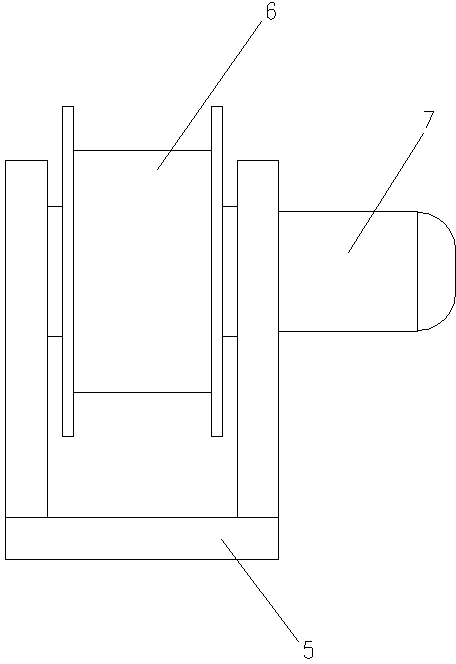

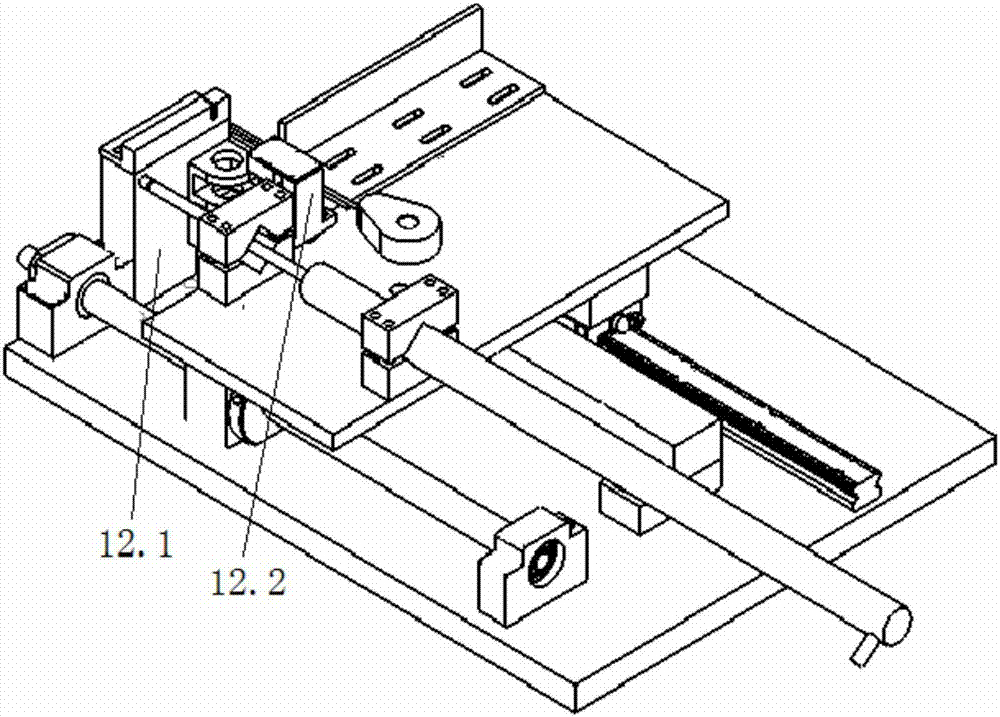

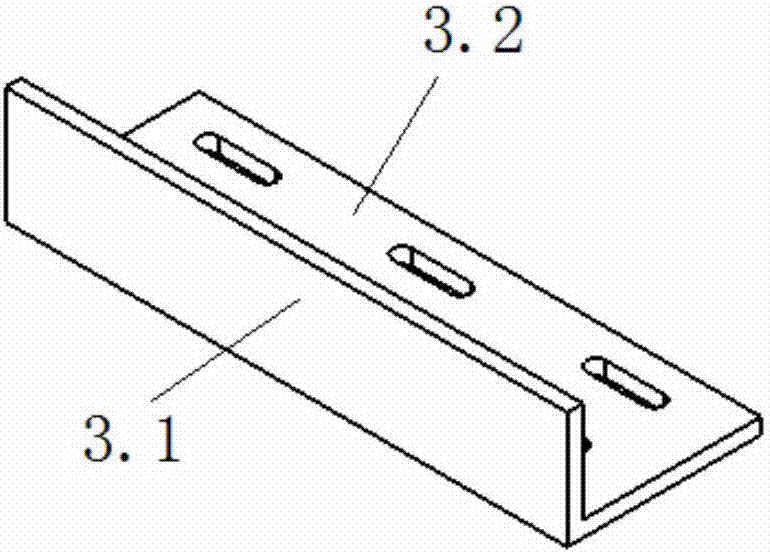

Welding tool for production of automobile seat framework

ActiveCN106112371AEnsure consistencyGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

The invention discloses a welding tool for production of an automobile seat framework. The welding tool for production of the automobile seat framework comprises a base (1), a feed clamping device, two side section clamping devices and a supporting bar clamping device, wherein the feed clamping device is provided with a sleeve (14) in advance and pushes the sleeve to the position above a slope (50) of the bottom section of a U-shaped bent pipe (2) in the automobile seat framework, the two side section clamping devices are used for fixedly clamping two side sections of the U-shaped bent pipe (2), and the supporting bar clamping device is used for fixedly clamping a first supporting bar (3) and a second supporting bar (4) so that the two ends of the first supporting bar (3) and the two ends of the second supporting bar (4) can be in fixed lap joint to the two side sections of the U-shaped bent pipe (2) correspondingly. By the adoption of the structure, the U-shaped bent pipe, the first supporting bar and the second supporting bar can be fixedly clamped, and therefore the welding tool for production of the automobile seat framework can guarantee fixed clamping of the U-shaped bent pipe and the welding precision and the product consistency of the first supporting bar and the second supporting bar during automatic welding.

Owner:宁波明望汽车饰件有限公司

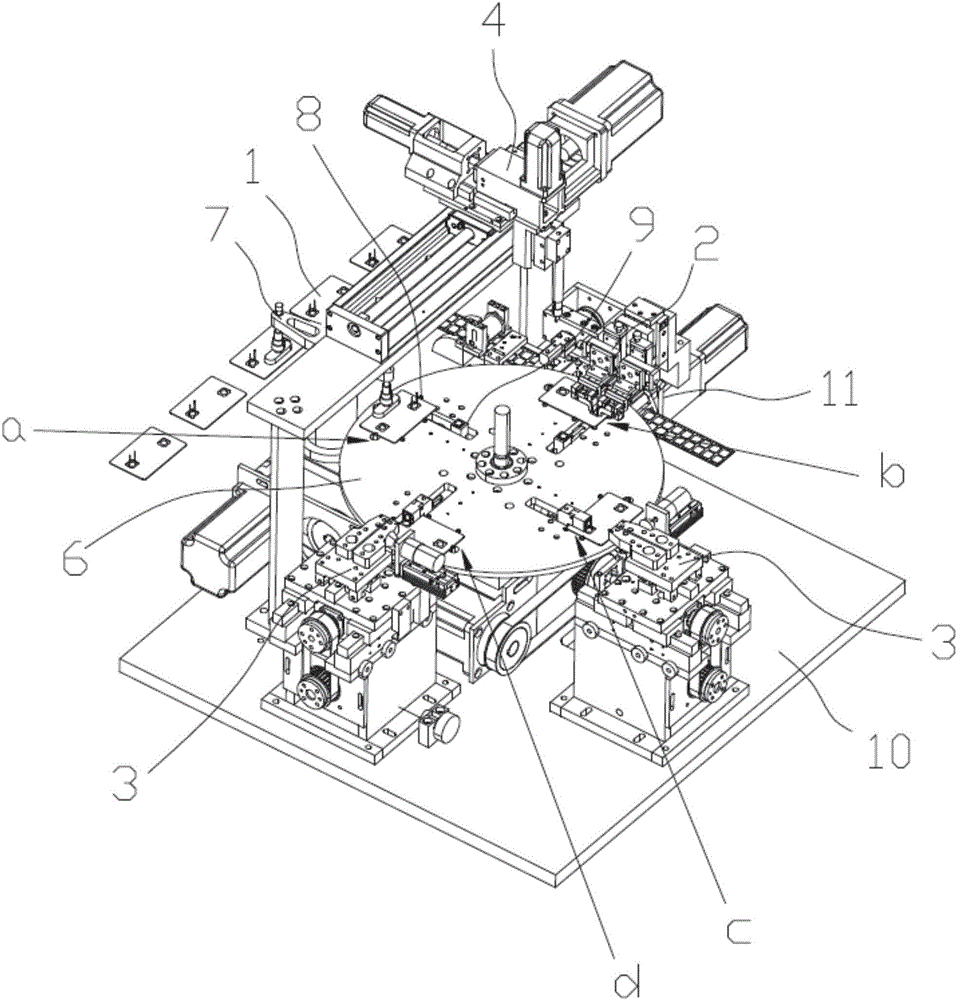

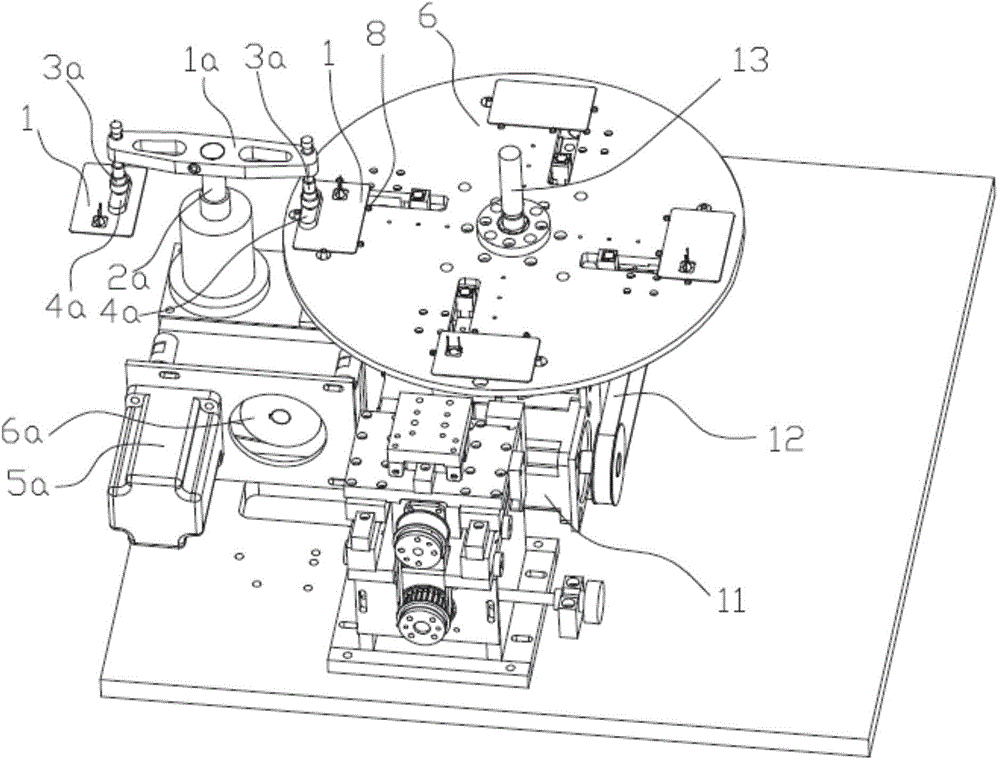

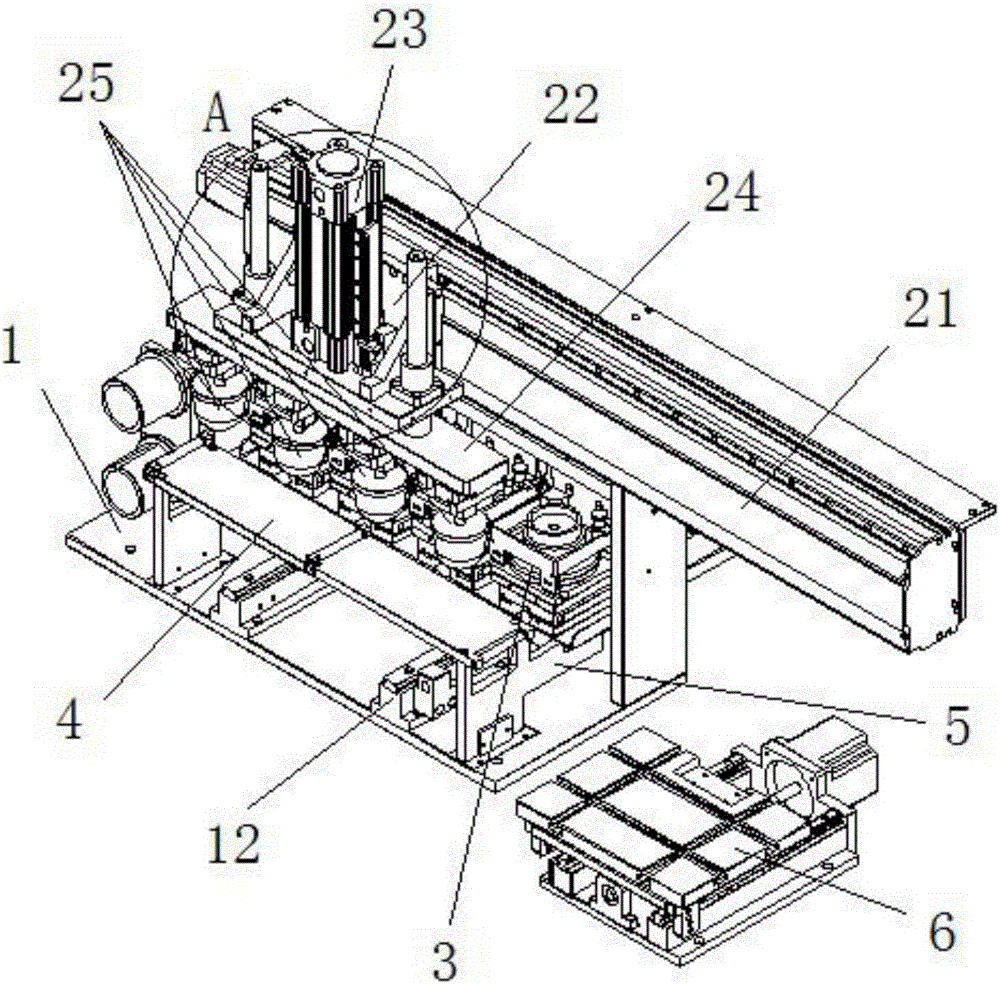

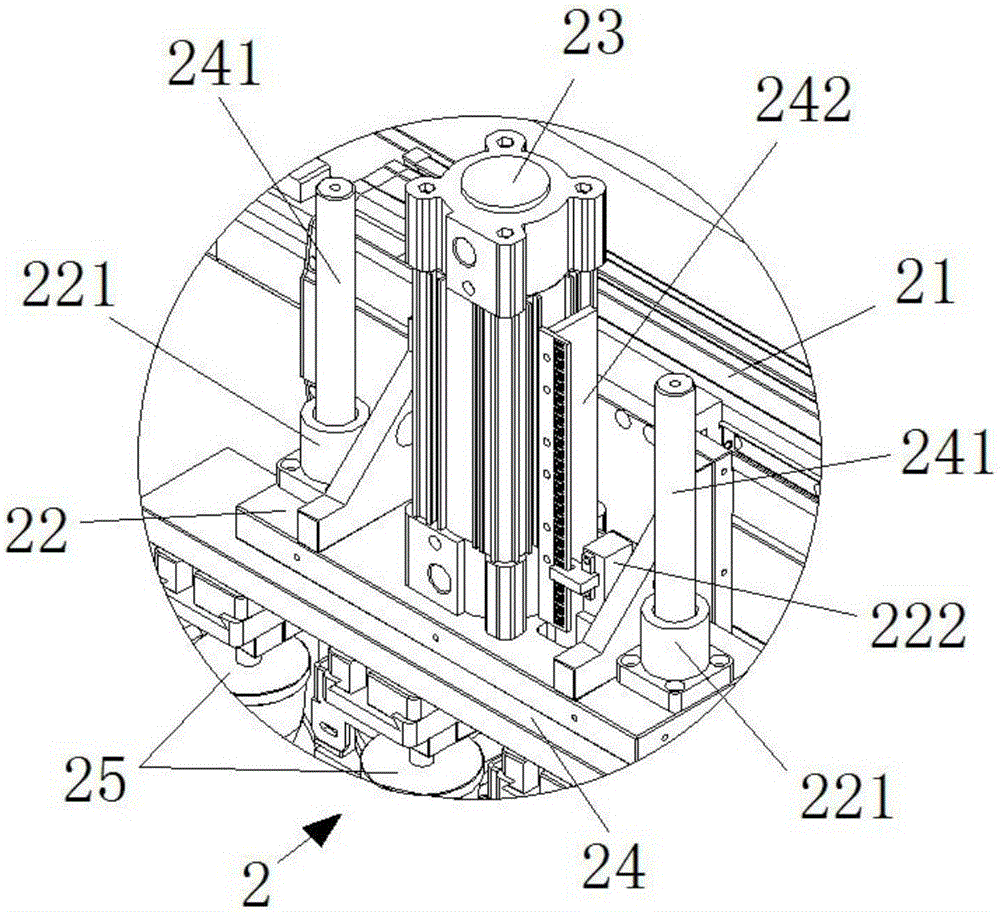

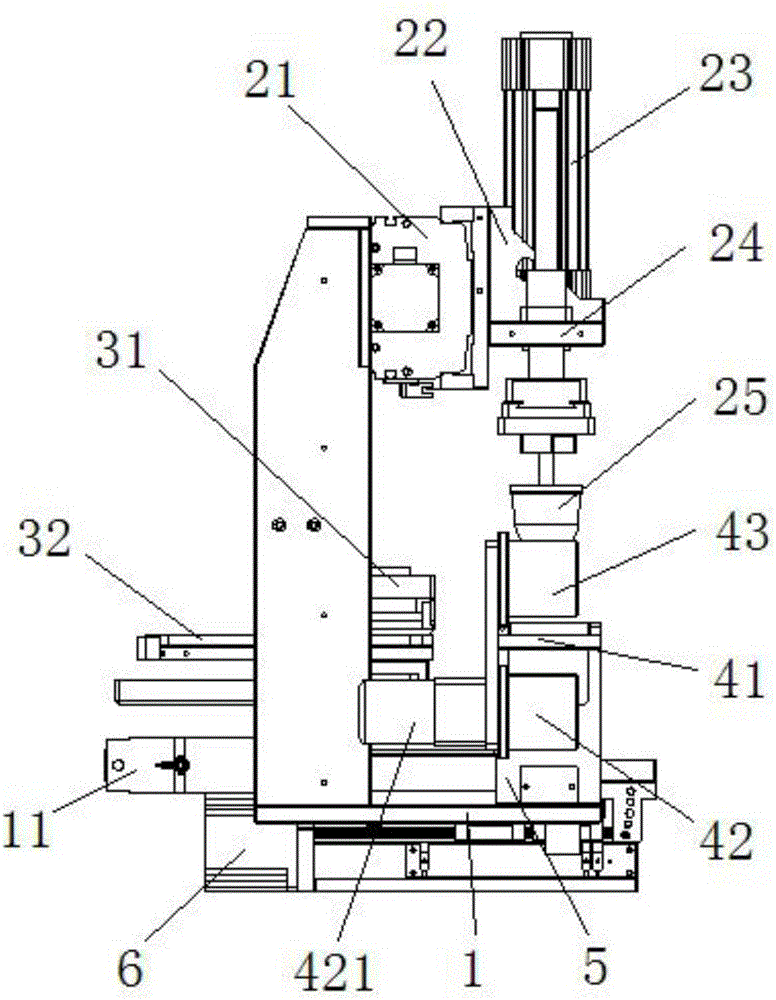

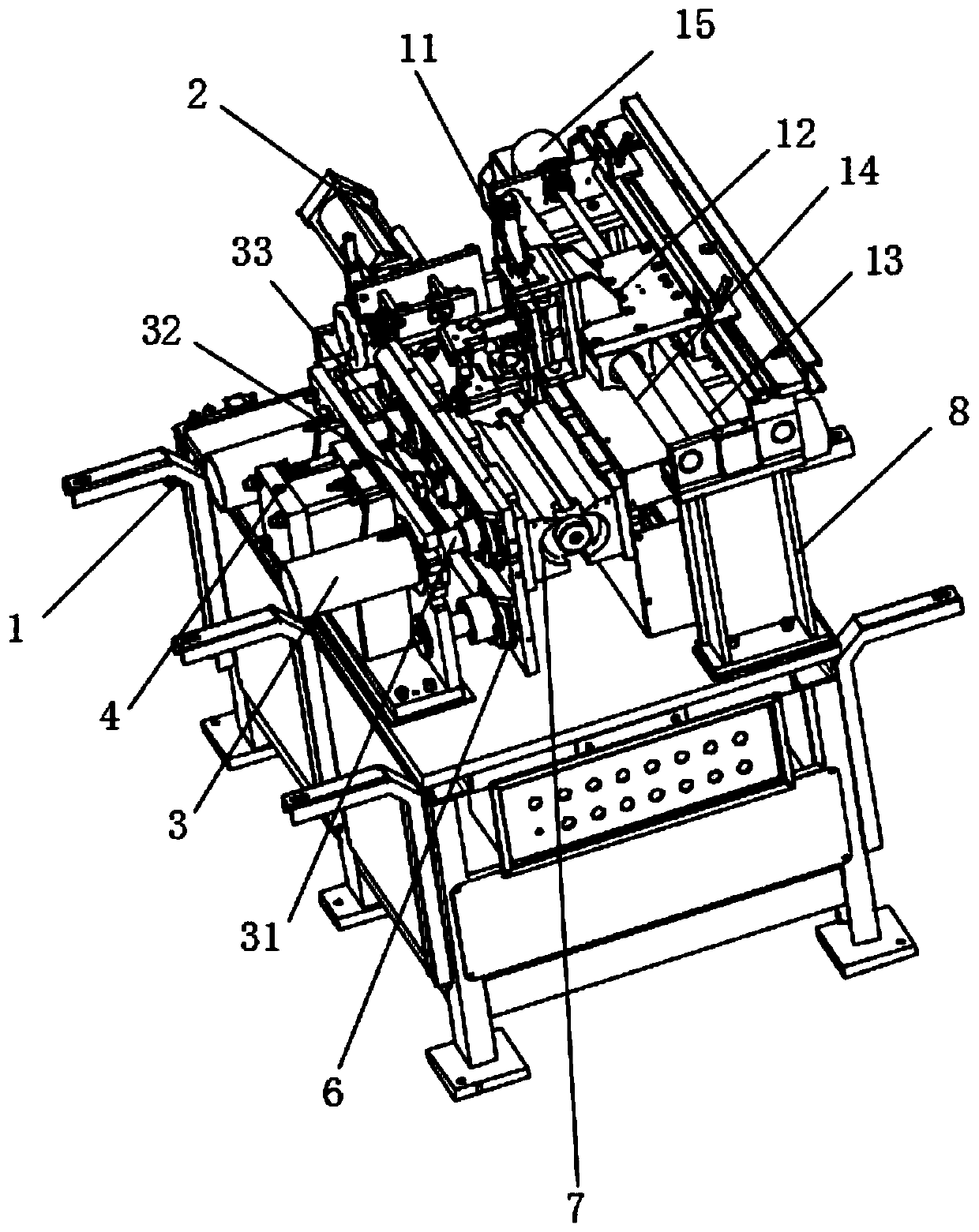

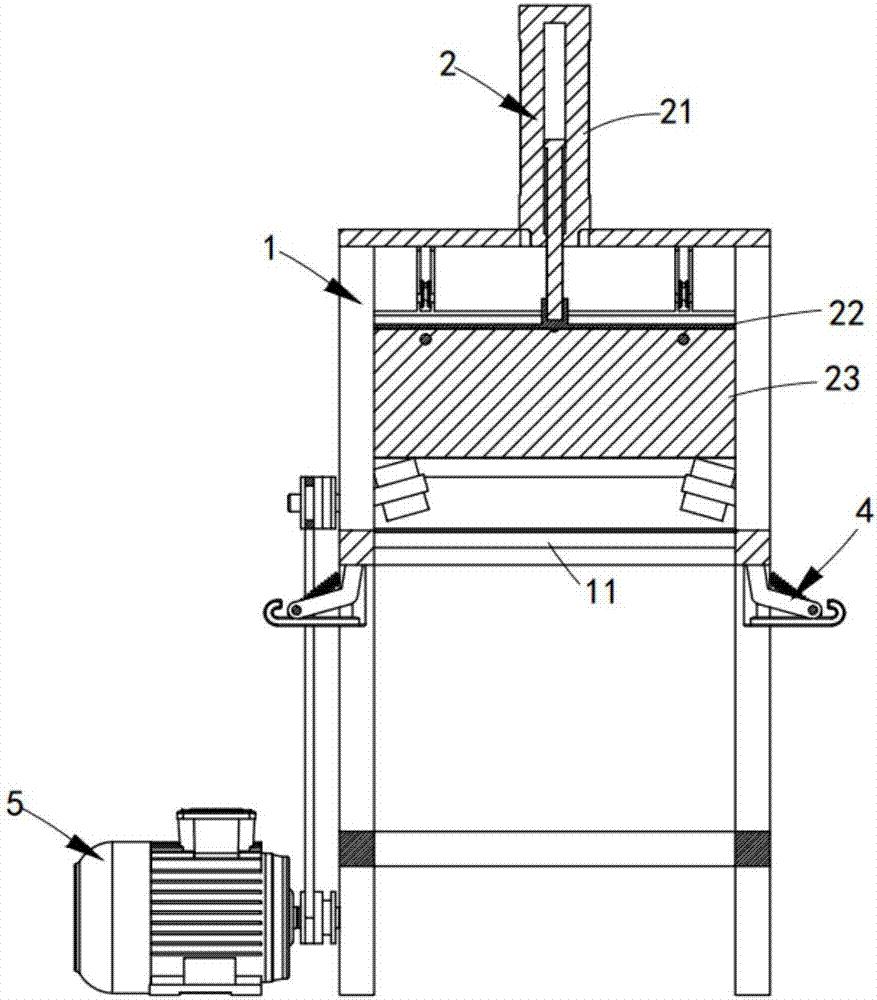

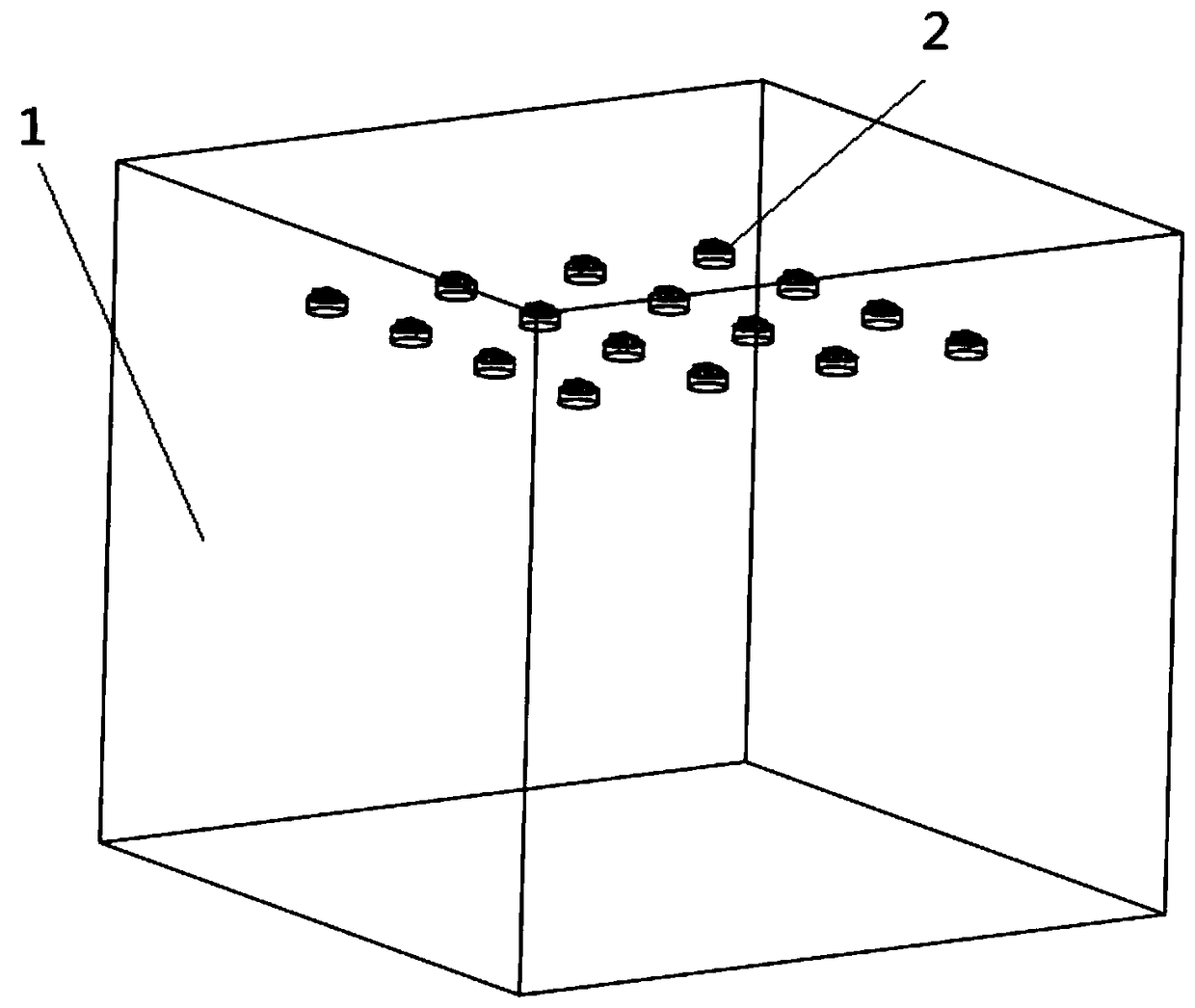

Equipment and method for efficiently welding chips of double-interface intelligent cards

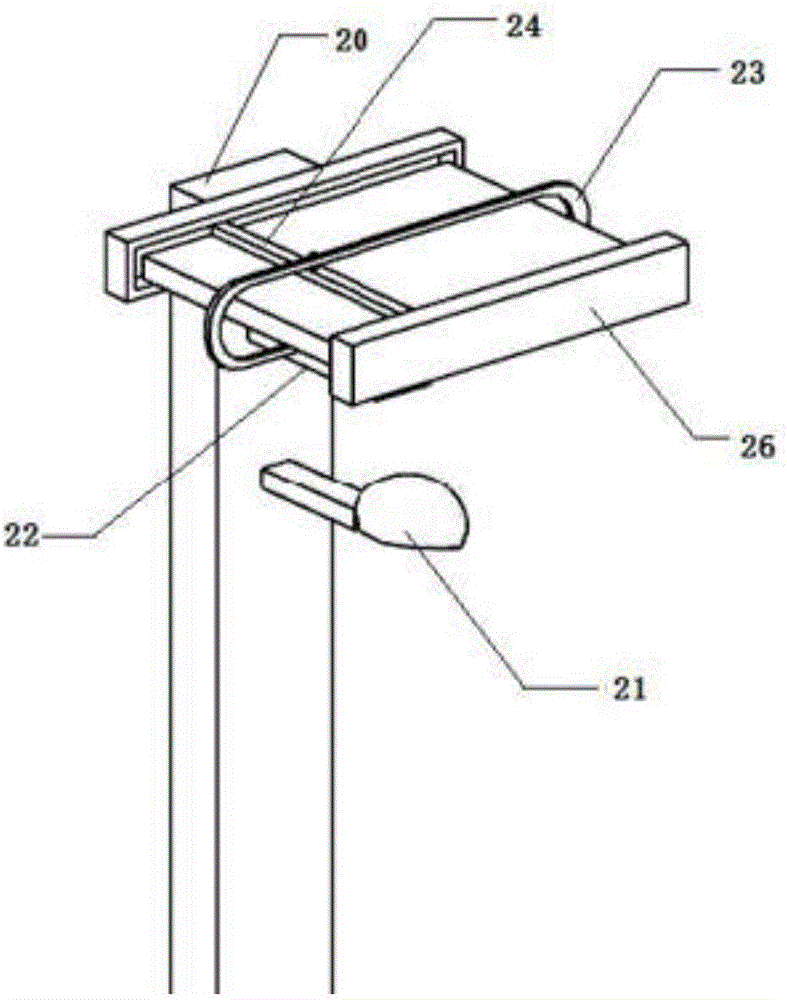

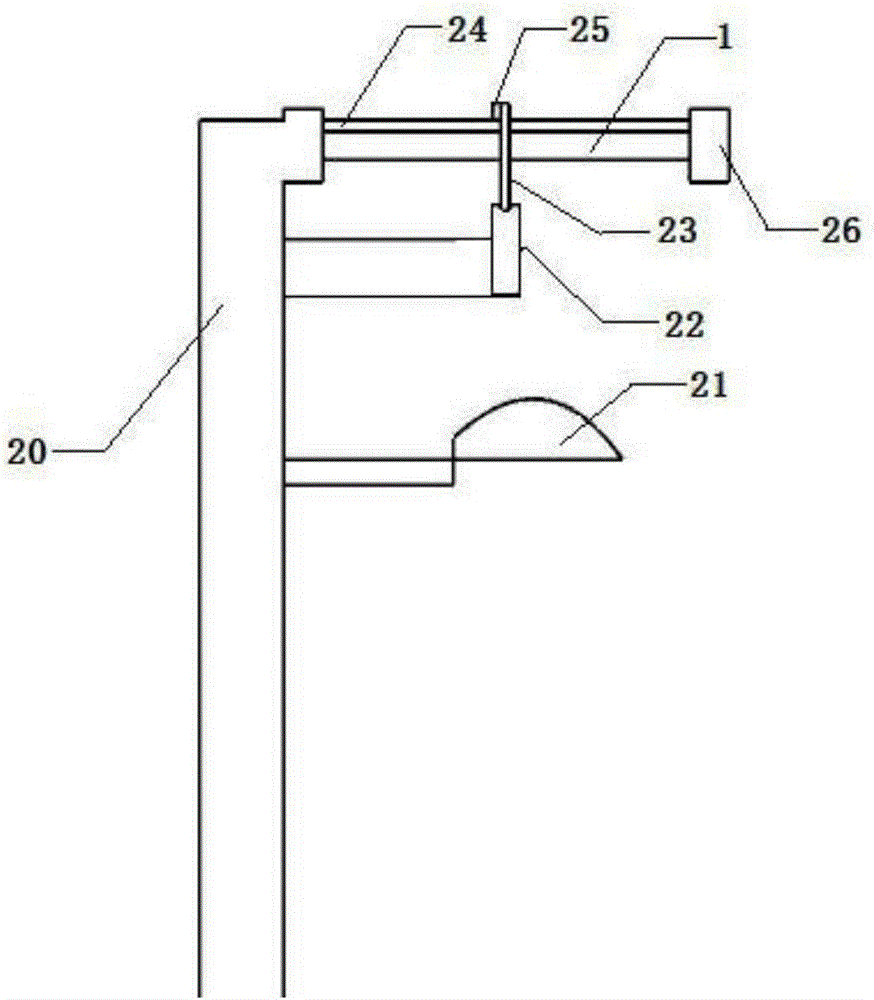

ActiveCN104148834AImprove efficiencyIncrease productivityPrinted circuit assemblingWelding/cutting auxillary devicesSmart cardWork unit

The invention discloses equipment and a method for efficiently welding chips of double-interface intelligent cards. The equipment for efficiently welding the chips comprises a card transfer mechanism, a chip transportation mechanism, chip turnover mechanisms, an antenna correcting device, welding devices and a turntable. The card transfer mechanism is used for transferring each to-be-welded card to a card access station and fetching each welded card from the card access station, the chip transportation mechanism is used for transporting each chip to the card access station, the chip turnover mechanisms are used for turning the chips in horizontal states so that the chips can be in vertical states, the antenna correcting device is used for correcting the perpendicularity of the ends of each antenna, the welding devices are used for welding the ends of the antennas at corresponding welding spots of the chips, the turntable has an intermittent precision stopping function, a plurality of working units which are circumferentially and uniformly distributed are arranged on the turntable, and a card positioning mechanism and the corresponding chip turnover mechanism which can intermittently rotate along with the turntable are arranged in each working unit; working stations which are circumferentially and uniformly distributed are fixedly arranged at the outer periphery of the turntable, and the quantity of the working stations is identical to that of the working units. The equipment and the method have the advantages of high welding efficiency, good welding quality, convenience in use and maintenance and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

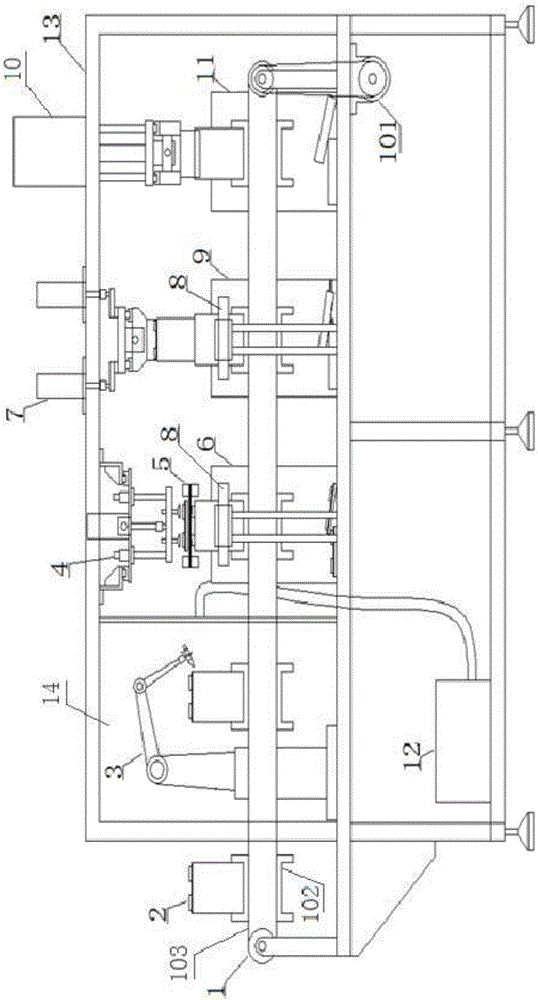

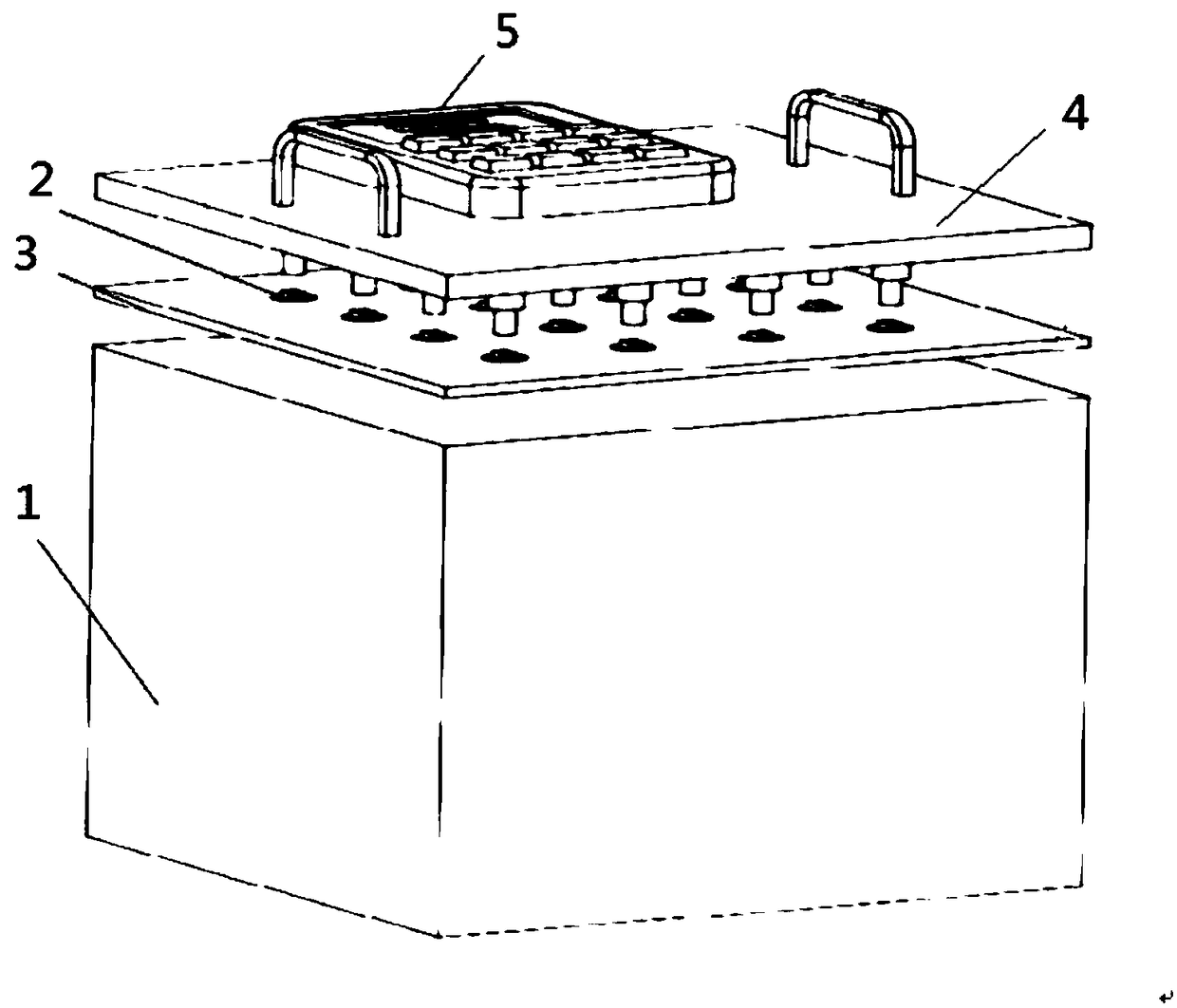

Lithium ion battery automatic dismantling device

ActiveCN106058357ANo deviationTimely recyclingWaste accumulators reclaimingBattery recyclingElectrical batteryEngineering

The invention provides a lithium ion battery automatic dismantling device comprising a frame and a circulation carrier for transferring a waste battery; the frame bottom located at one side of the circulation carrier is successively fixedly provided with a cover plate recycling box, an electric core recycling box, and an outer shell recycling box; the bottom of the frame is successively fixedly provided with a cutting manipulator for annular cutting of a waste battery shell body and two outer shell clamping mechanisms for clamping and fixing the waste battery shell body along the running direction of the circulation carrier; the top of the frame is successively erected with a cover plate recycling mechanism for clamping a waste battery cover plate, an electric core taking-out mechanism for clamping a waste battery electric core, and an outer shell transfer mechanism for clamping the waste battery shell body along the running direction of the circulation carrier; the cover plate recycling mechanism and the electric core taking-out mechanism are respectively located at the top ends of the two outer shell clamping mechanisms; an electrode ear cutting mechanism for cutting a waste battery electrode ear is arranged between the cover plate recycling mechanism and the outer shell clamping mechanism. The automation degree is improved, the work efficiency is increased, and the intensity of work is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

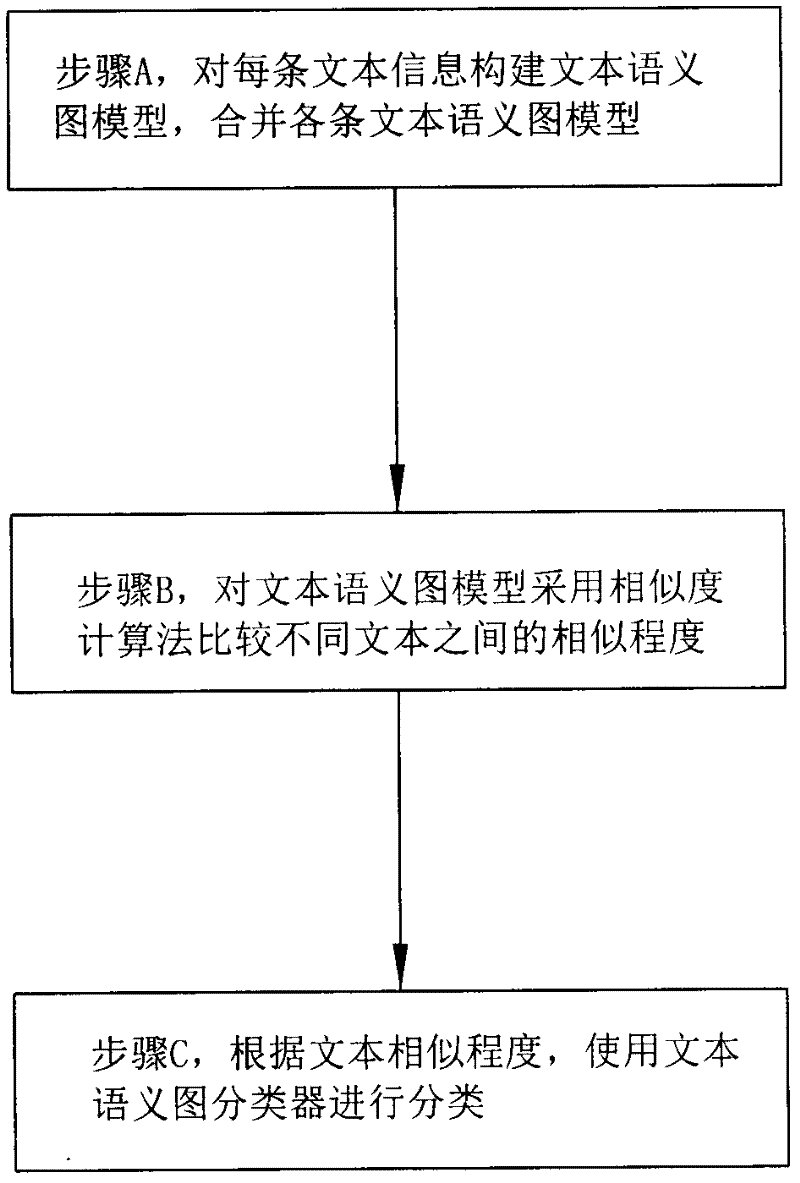

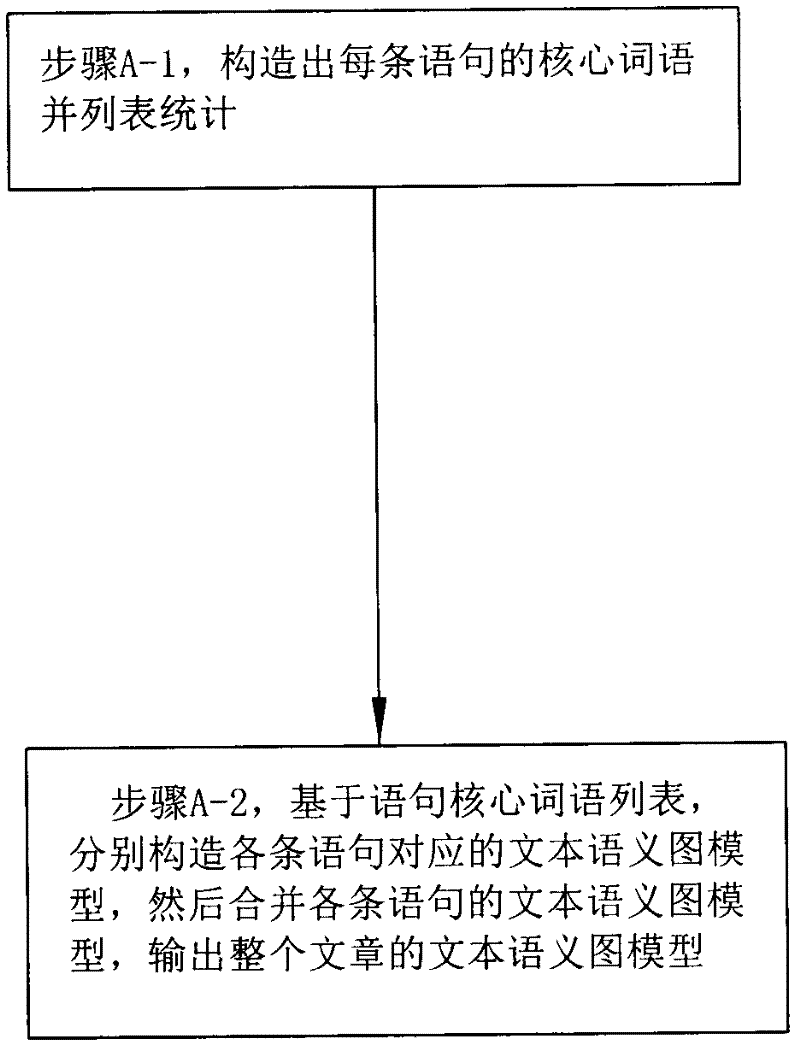

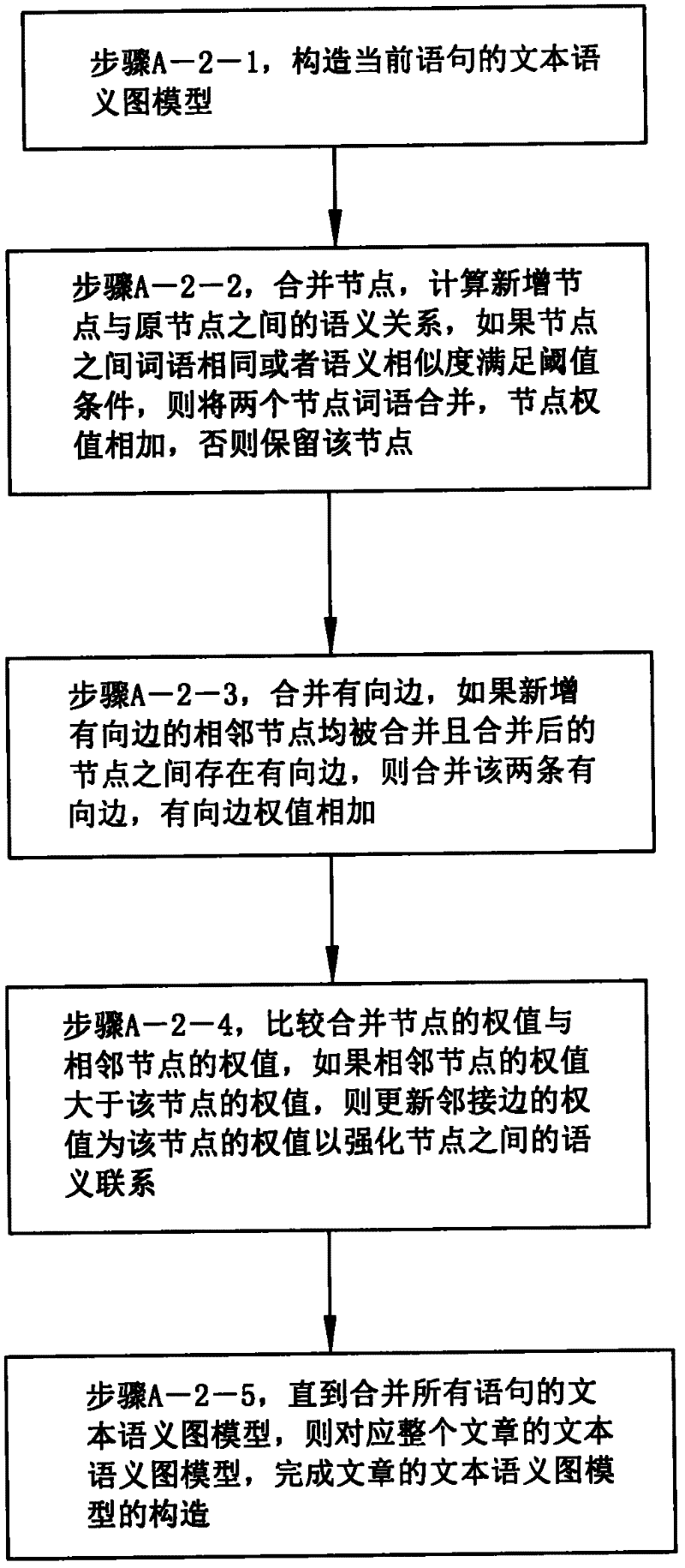

Short text classification method based on semantic graphs

InactiveCN102591988AAvoid manual finishingReduce labor overheadSpecial data processing applicationsClassification methodsGraph model

The invention discloses a short text classification method based on semantic graphs, which is characterized by including the steps: A, constructing a semantic graph model for each piece of text information, and combining all semantic graph models; B, comparing similarity level among different texts according to the semantic graph models and by means of a similarity computing method; and C, according to the text similarity level, classifying the texts by the aid of a text semantic graph classifier. The short text classification method based on the semantic graphs has the advantages that semantic connotations of documents can be highlighted to a maximum degree by using the graph models to represent the texts, latent semantic information and theme features in the texts can be accurately described to a great extent by the aid of the TSG (text semantic graph) models constructed by the method, and the TSG classification method can be more reliable and efficient in use as compared with other classification methods by means of the feature, so that human cost is greatly reduced, artificial arrangement of the text information is avoided to a great extent, and the text information is automatically organized by a computer.

Owner:XIDIAN UNIV

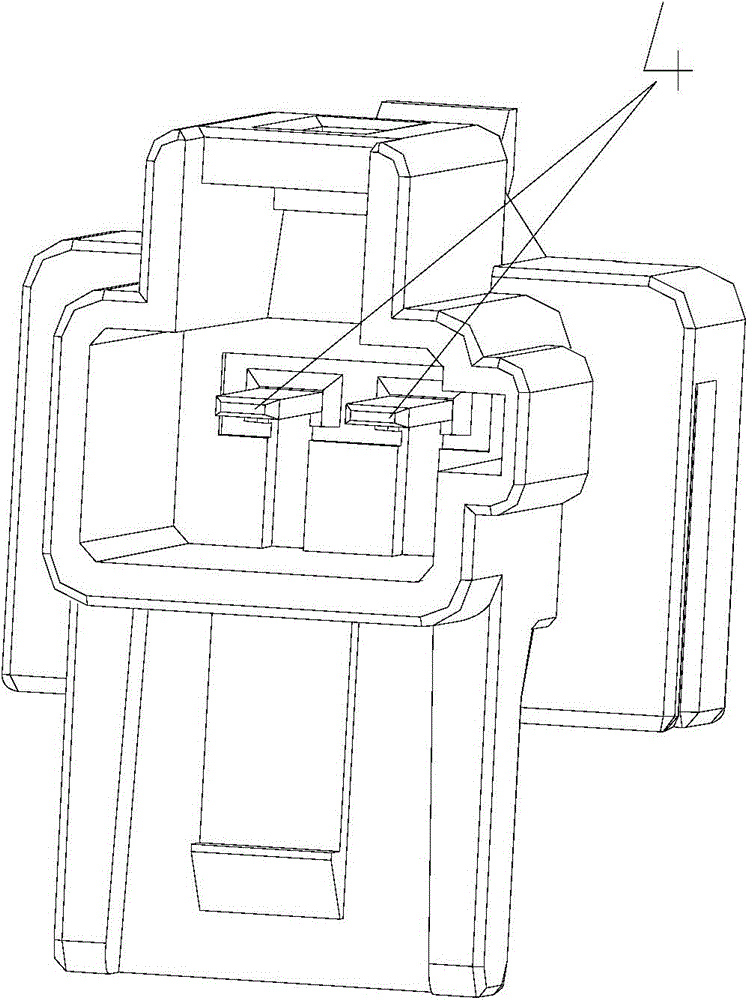

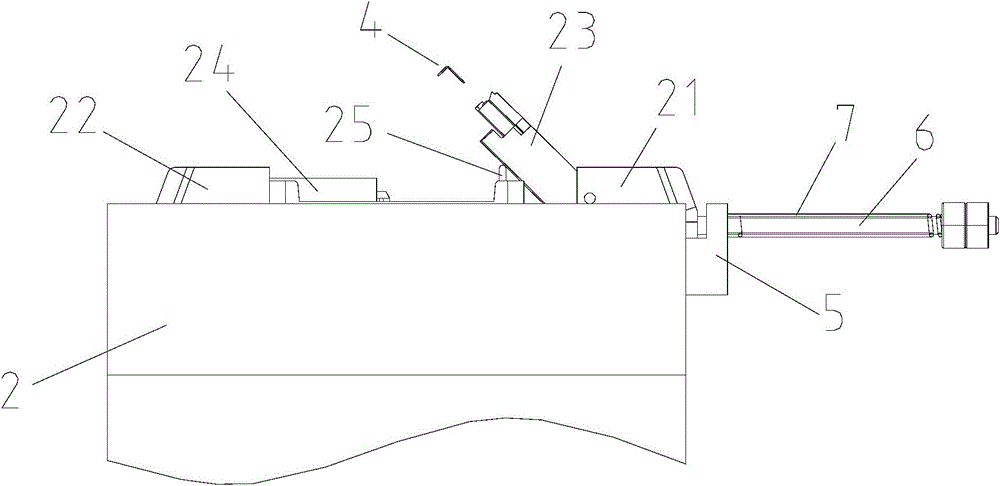

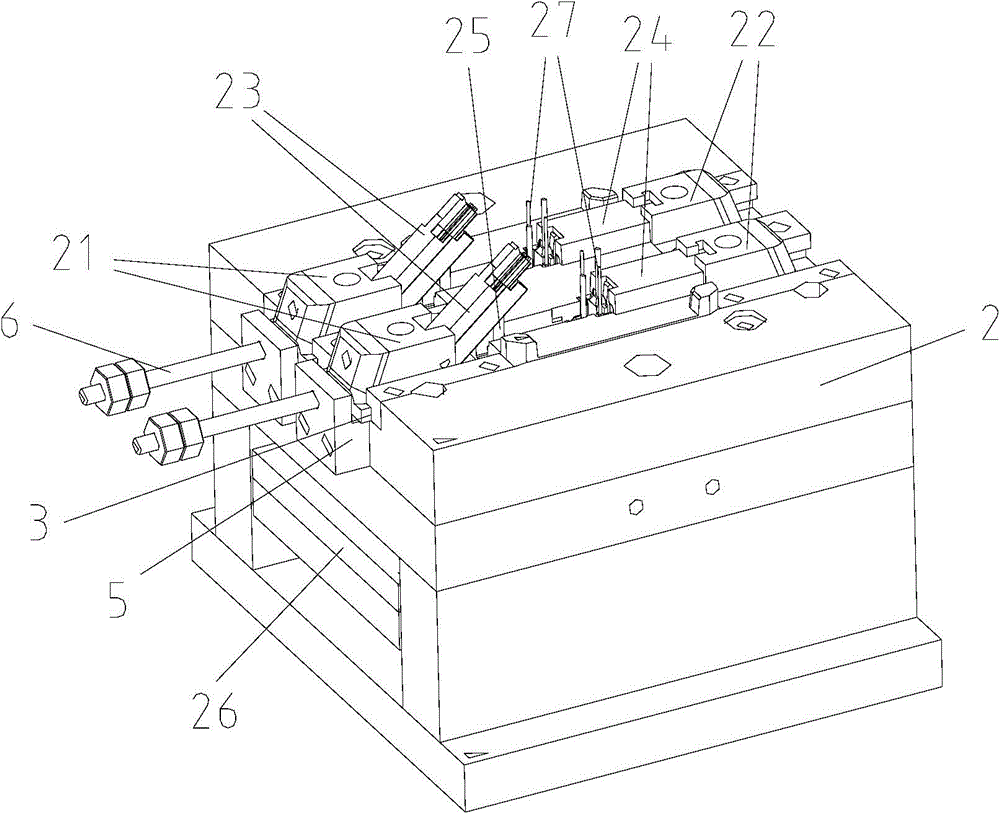

Injection mold with insert assembling structure

Owner:昌辉汽车电器(黄山)股份公司

Dispensing machine and method for correcting position of dispensing needle

The invention provides a dispensing machine, comprising a mobile assembly, a sensing assembly and a dispensing assembly, wherein the sensing assembly comprises a positioning seat, and a first raster and a second raster which are arranged on the positioning seat. The first raster and the second raster transmit light beams, the dispensing assembly is arranged on the mobile assembly, and the dispensing assembly comprises an electric control unit, a drive mechanism and a dispensing needle, wherein the electrical control unit is electrically connected with the drive mechanism, the drive mechanism is used for driving the dispensing needle to move, the mobile assembly drives the dispensing needle close to the positioning seat in order to shield the light beams from the first raster and the second raster, and the electrical control unit is used for recording a coordinate point position of the dispensing needle when he dispensing needle simultaneously shields light beams form the first raster and the second raster, calculates variable between the recorded coordinate point position and a preset initial coordinate point position, and furthermore controls the drive mechanism based on the variable in order to regulate the position of the dispensing needle. The invention further provides a method for correcting the position of the dispensing needle, and the dispensing machine can accurately correct the position of the dispensing needle.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

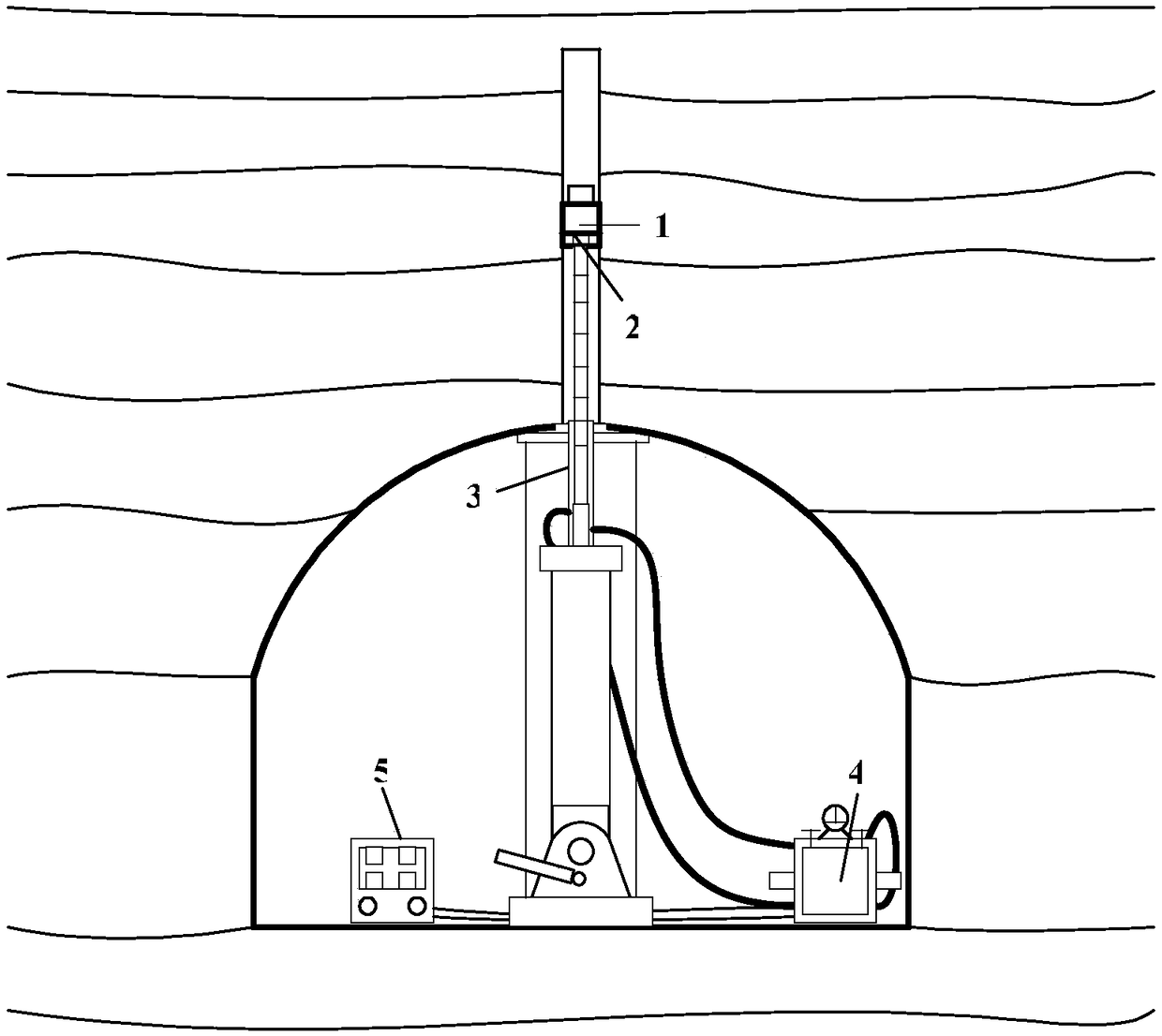

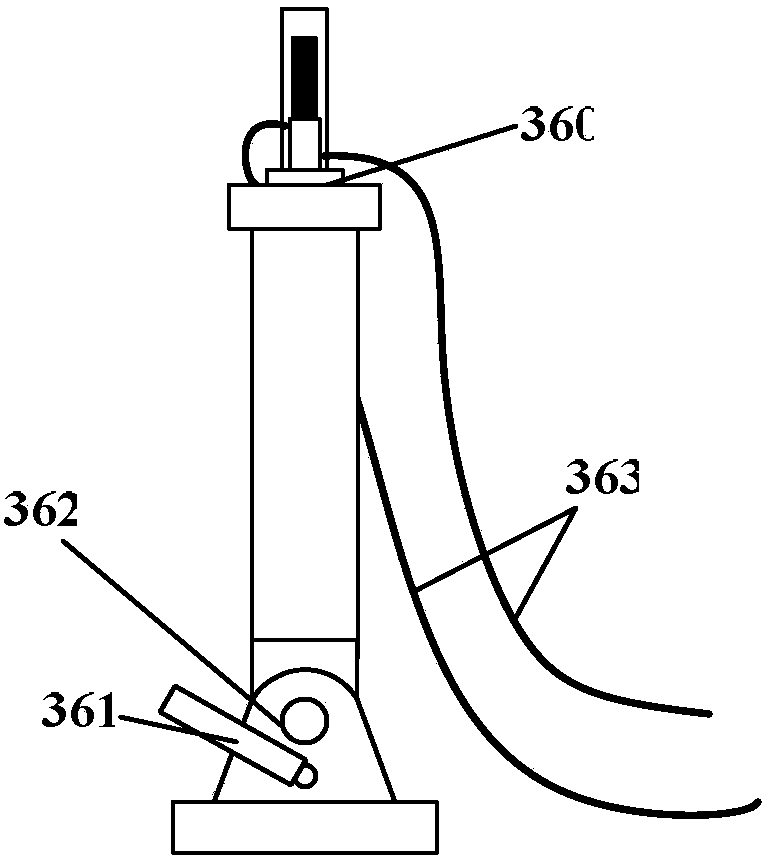

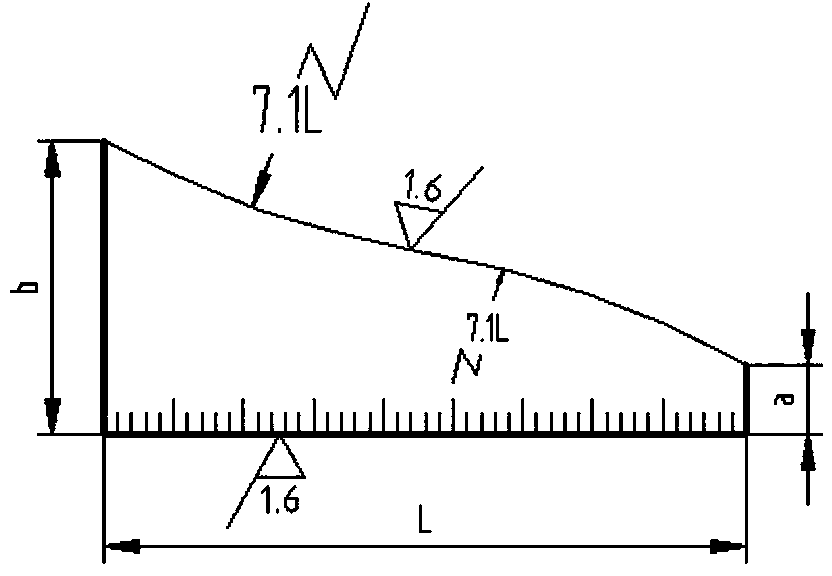

Drilling in-situ testing device for testing mechanical parameters of engineering rock mass and use method of drilling in-situ testing device

The invention discloses a drilling in-situ testing device for testing the mechanical parameters of an engineering rock mass and a use method of the drilling in-situ testing device. The device comprises a penetration sounding loading system, a multi-point testing rotational positioning system, a propelling support system, a hydraulic loading system and a control system. The penetration sounding loading system and the multi-point testing rotational positioning system are connected together through a bearing and can move along with a propelling lever of the propelling support system, and finally,the whole device is regulated and controlled through the hydraulic loading system and the control system. The device and the method drill and load and test the engineering rock mass in situ, the deformation and fracture characteristics of the rock mass having different lithological characters and different drilling depths and the load-displacement curve and data of a surrounding rock in the loading process are acquired, the relevant technical indexes and parameters are obtained through conversion, the device and the method are favorable for accurately simulating the numerical value and effectively designing the supporting scheme in the construction process, the supporting strength and the engineering strength are guaranteed, and the guarantee is provided for the safety construction of theengineering like rock and soil, water resources and hydropower, and mines.

Owner:SHANDONG UNIV OF SCI & TECH

Multi-color and multi-position pad printing machine

The invention belongs to the technical field of pad printing and discloses a multi-color and multi-position pad printing machine. The multi-color and multi-position pad printing machine comprises a base, a pad printing assembly arranged on the base in a straddling manner, a plurality of ink feeding assemblies located below the pad printing assembly, a cleaning assembly located in front of the ink feeding assemblies and a material supporting assembly located beside the ink feeding assemblies; the pad printing assembly comprises a horizontally-arranged servo module which is provided with an X movement module capable of moving in the X direction; the X movement module is provided with a first cylinder which drives an adhesive head assembly to move up and down in the Z direction; the adhesive head assembly is provided with pad printing adhesive heads side by side in the X direction, and the number of the pad printing adhesive heads corresponds to that of the ink feeding assemblies; and the material supporting assembly comprises a base, a carrying table located above the base and a third cylinder fixed to the base and driving the carrying table to move in the X direction. The multi-color and multi-position pad printing machine can print colorful patterns formed by combining different color blocks on products, cost is saved compared with a common multi-color pad printing machine, and besides, debugging is easy and fast.

Owner:YINGTUO ELECTRONICS APP KUSN

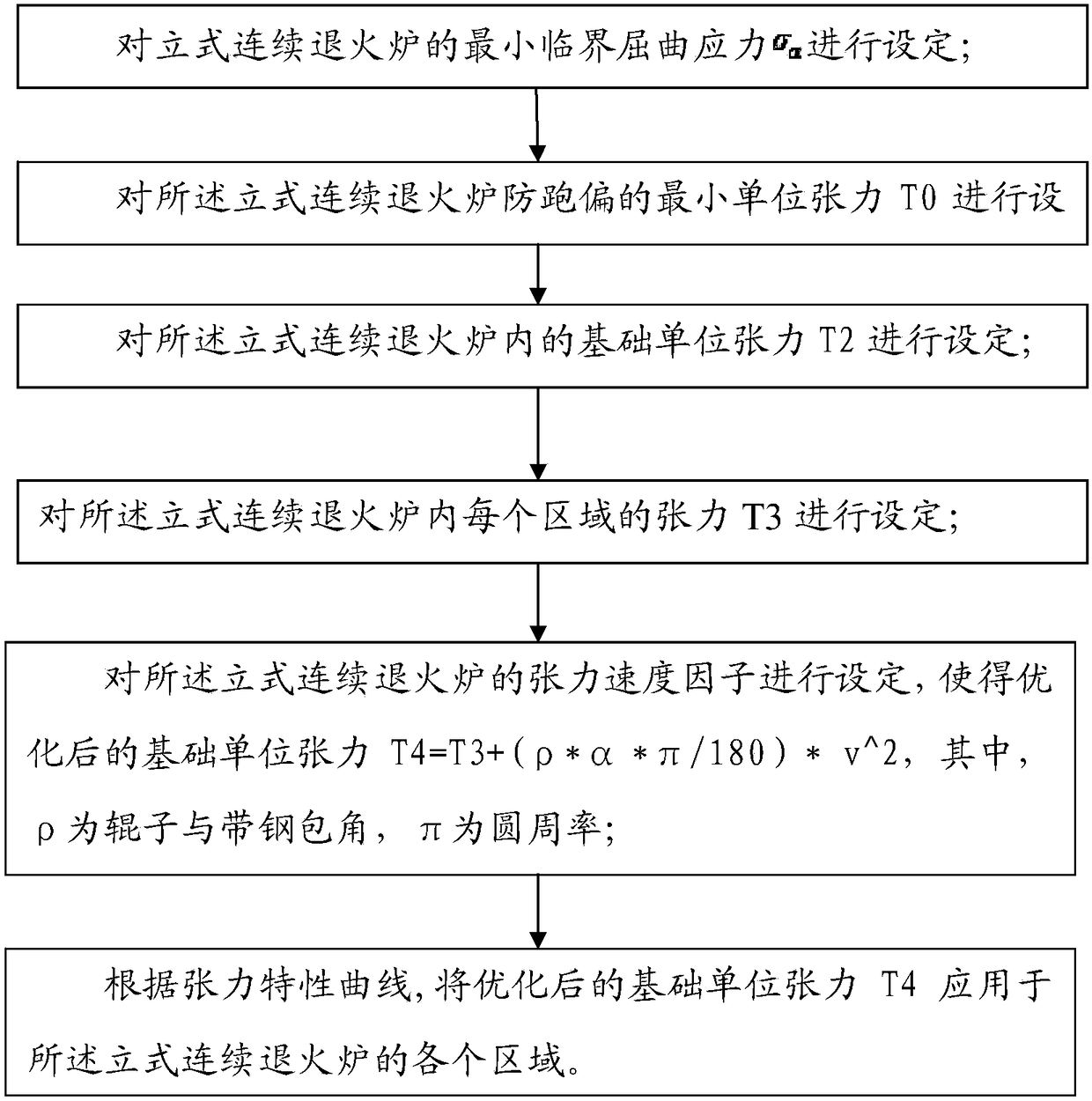

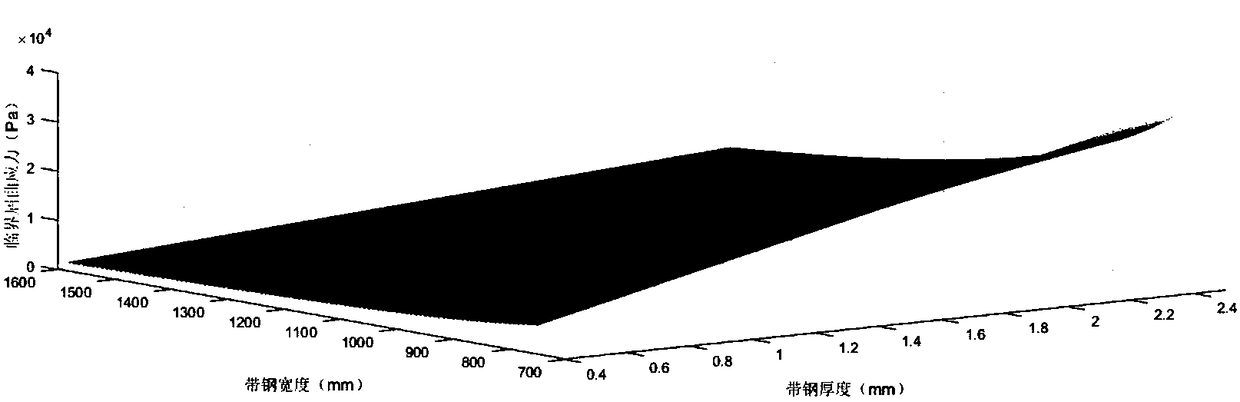

Tension setting method for vertical continuous annealing furnace

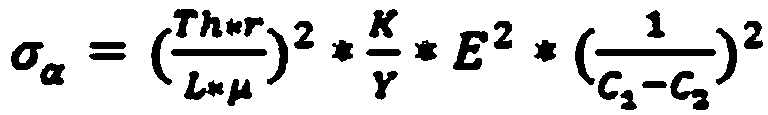

ActiveCN108359775AAvoid technical problems with deviationGuaranteed uptimeFurnace typesHeat treatment process controlSpeed factorGreek letter sigma

The invention discloses a tension setting method for a vertical continuous annealing furnace. The tension setting method comprises the following steps of: setting the minimum critical buckling stressSigma Alpha of the vertical continuous annealing furnace; setting the minimum unit tension T0 for preventing running deflection of the vertical continuous annealing furnace; setting the basic unit tension T2 inside the vertical continuous annealing furnace; setting the tension T3 of each region inside the vertical continuous annealing furnace; setting the tension speed factor of the vertical continuous annealing furnace to make sure that the optimized basic unit tension T4=T3+(sigma*alpha*pi / 180)*v^2; and applying the optimized basic unit tension T4 to each region of the vertical continuous annealing furnace according to a tension characteristic curve. The tension setting method for the vertical continuous annealing furnace disclosed by the invention solves the technical problem that running deflection of band steel inside the vertical continuous annealing furnace is easily caused in the prior art, and thus the band steel can stably run inside the vertical continuous annealing furnace.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

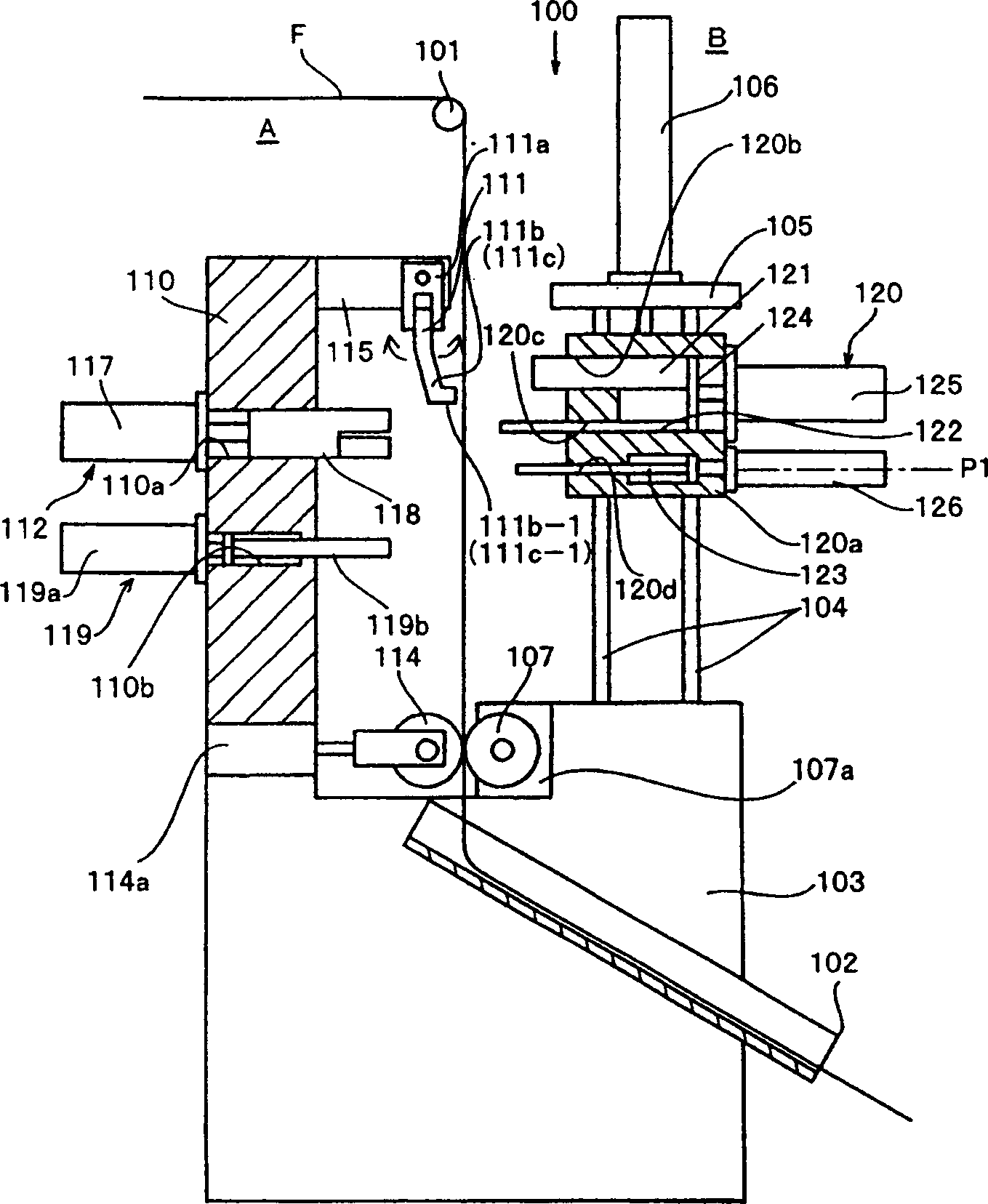

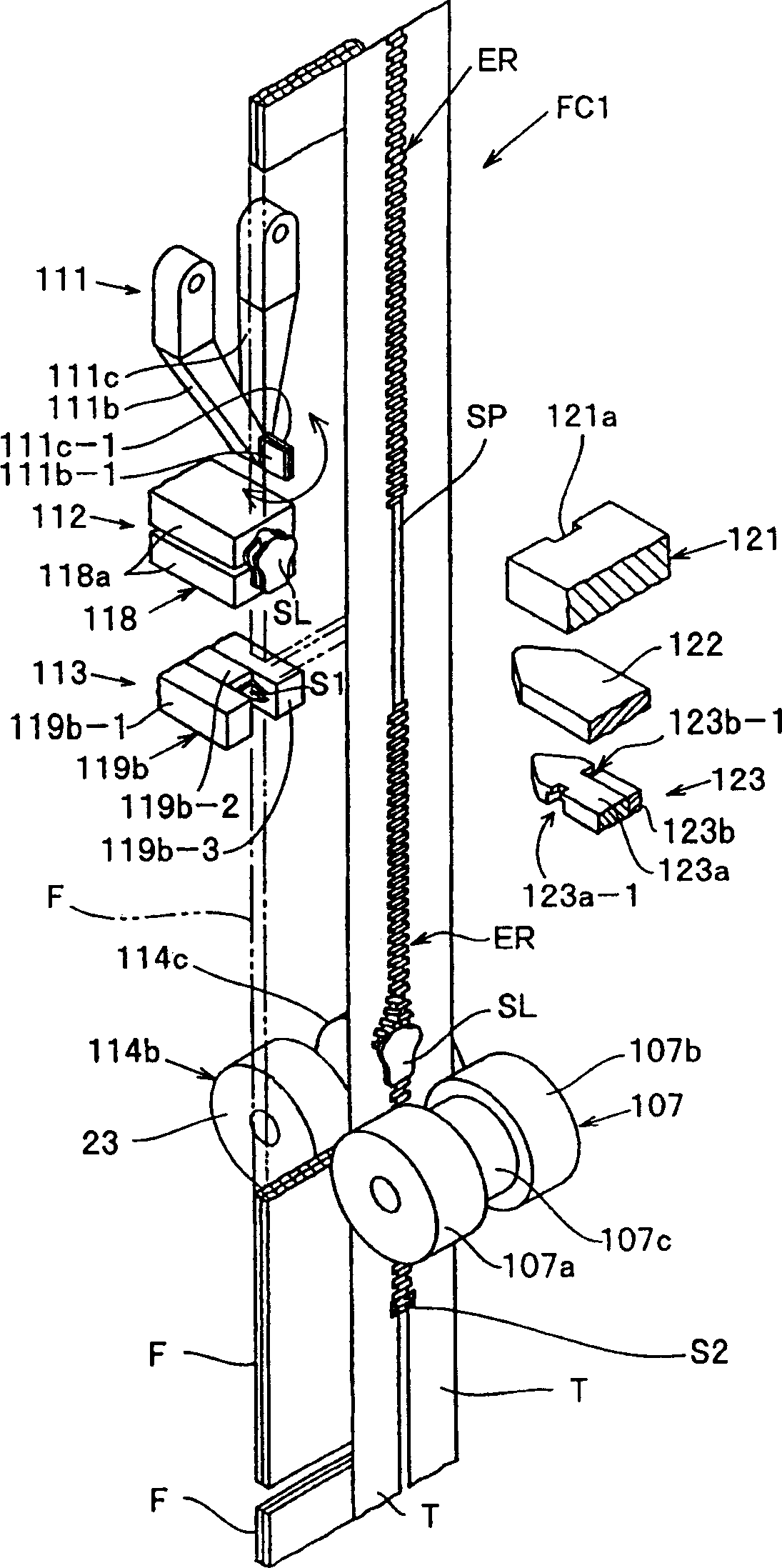

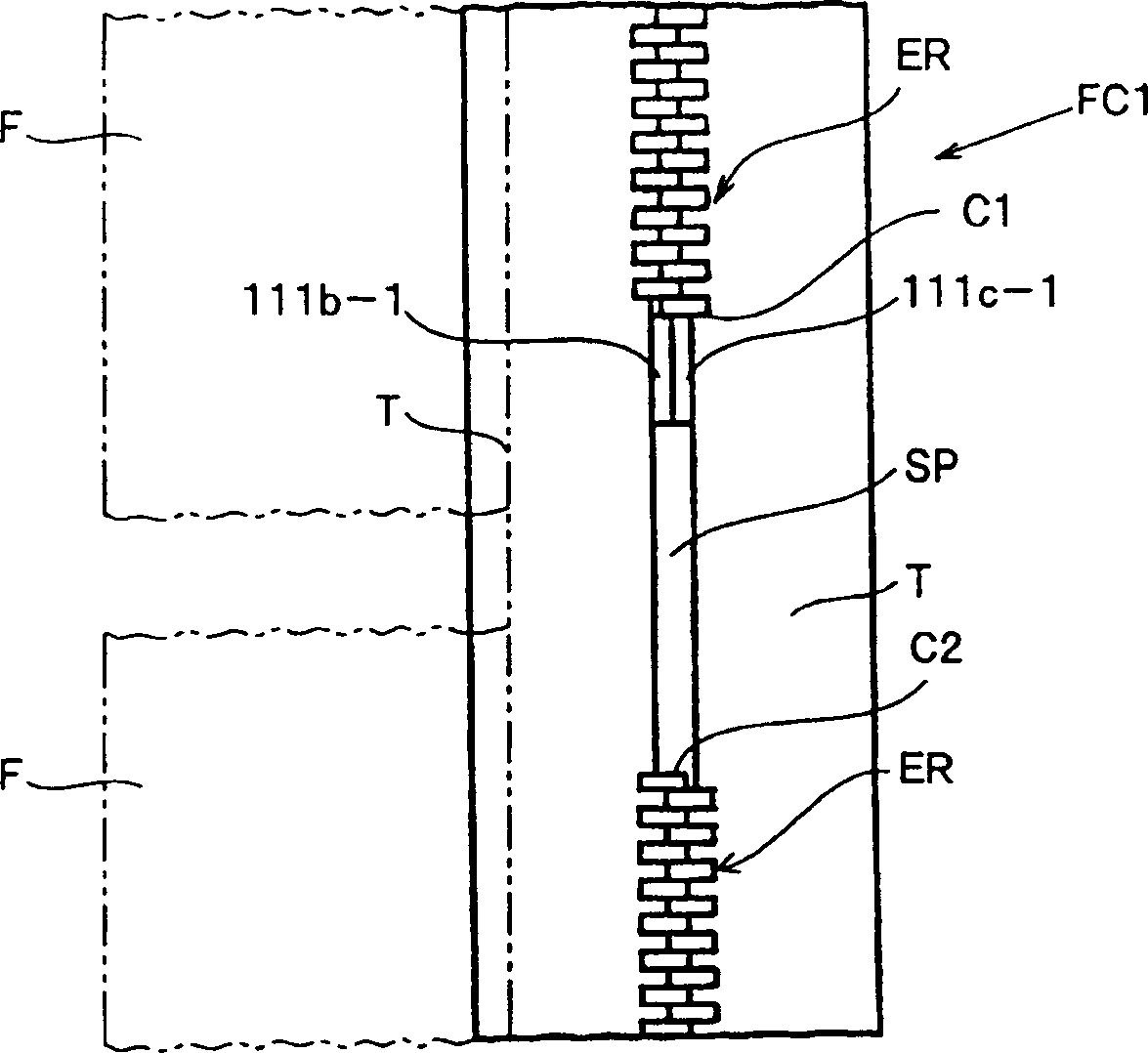

Continuous finishing apparatus for slide fastener

ActiveCN1820676ATemporarily release tensionWith positioning functionSlide fastenersClassical mechanicsFastener

The invention is a continuous finishing apparatus for a slide fastener having a slider introduction portion for successively introducing a slider by intermittently running a slide fastener chain, wherein, a slider introduction member thrusts into the space portion when the slider held by a slider holding member is brought into a space portion and set therein, moves downstream of the slide fastener chain within the space portion, holds an engaging element disposed at a downstream end portion of the space portion, and then, continues to move to the downstream for carrying the slide fastener chain, and wherein the slider is introduced and set along the same chain upon this carriage. Because the slider introduction member carries the slide fastener by holding the engaging elements on an edge of the fastener tape, which is least elongated, no disagreement occurs in position of corresponding right and left engaging elements.

Owner:YKK CORP

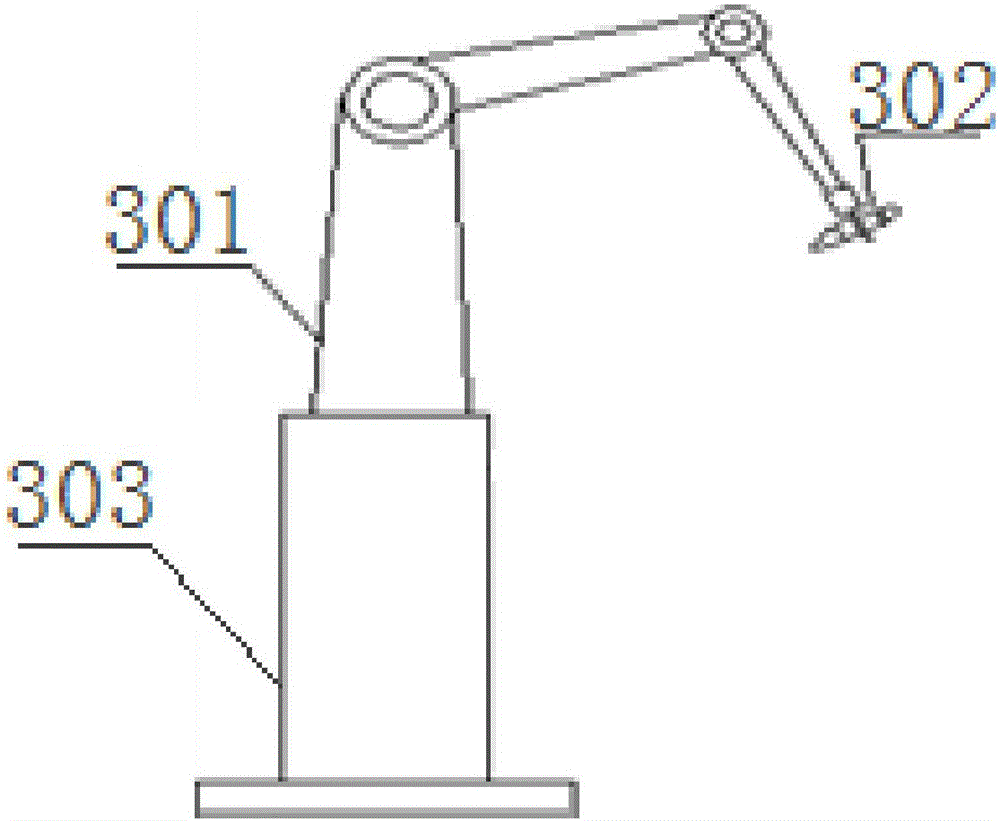

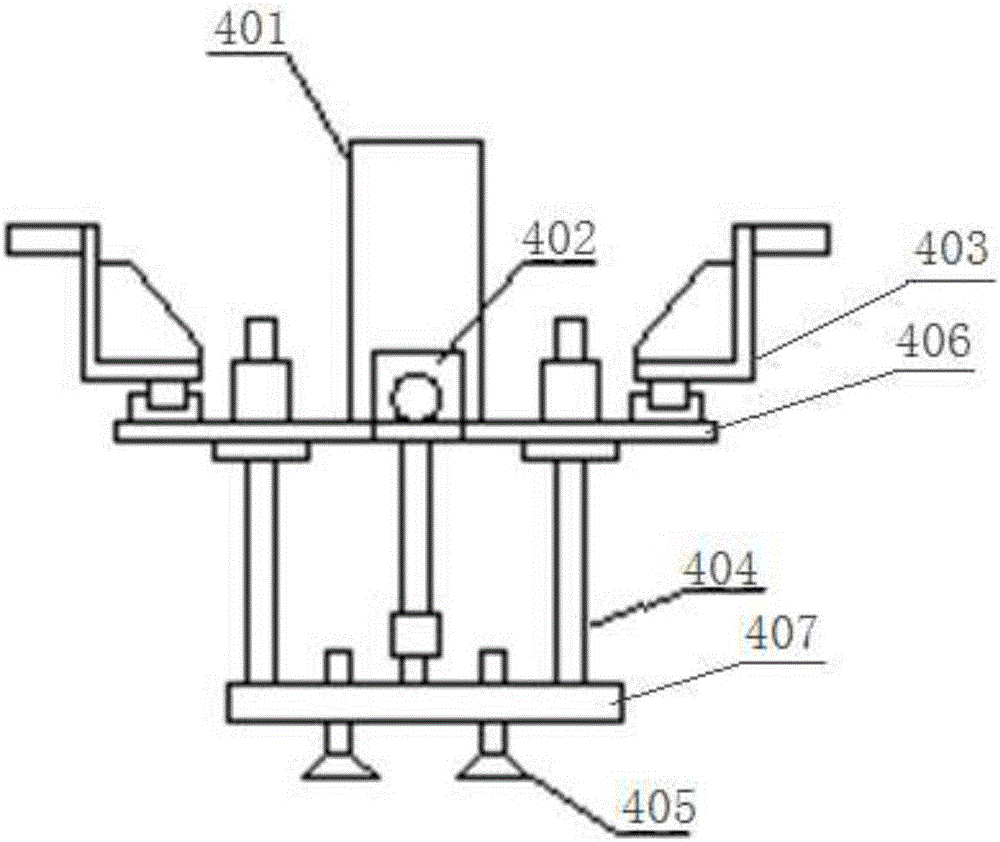

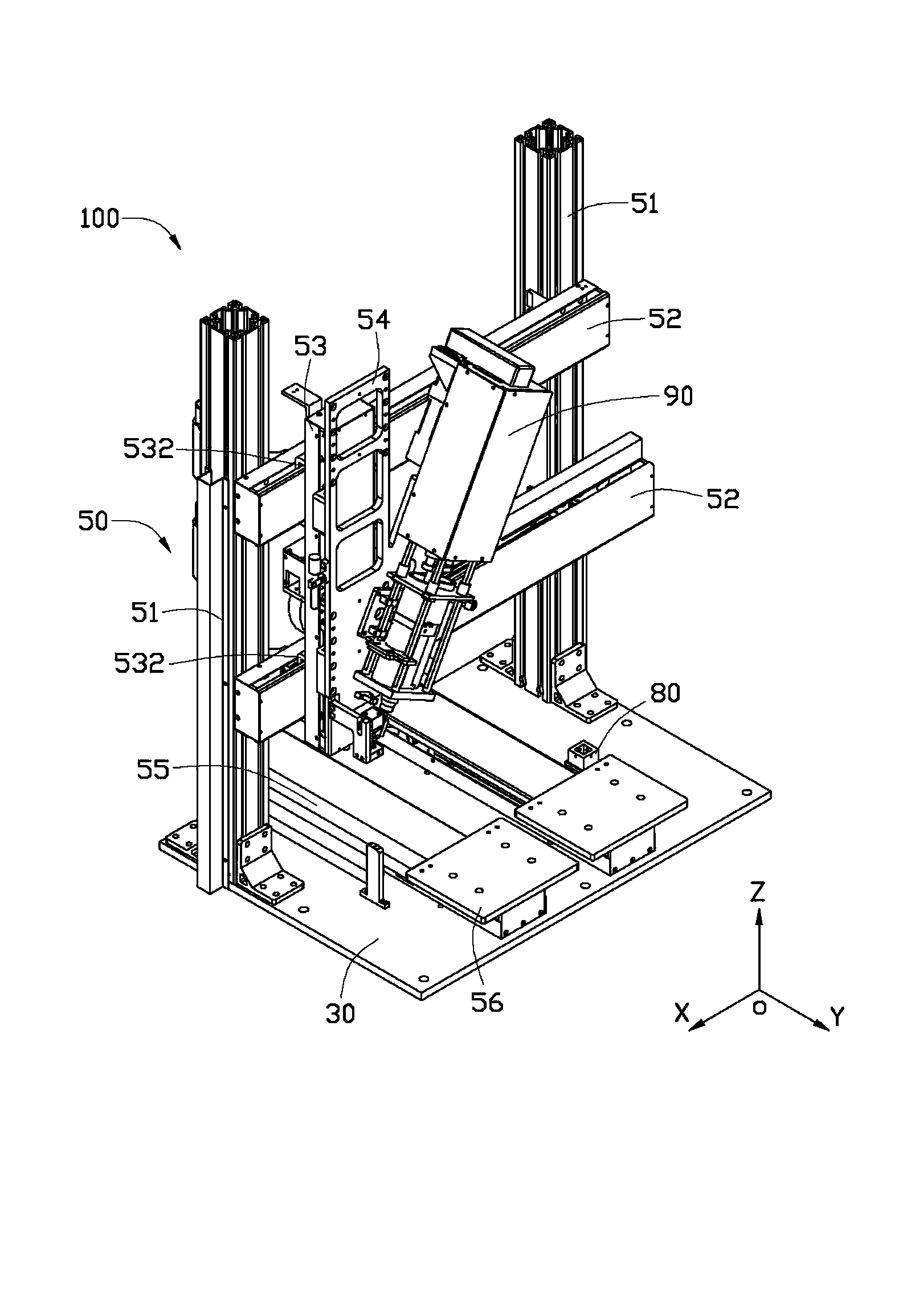

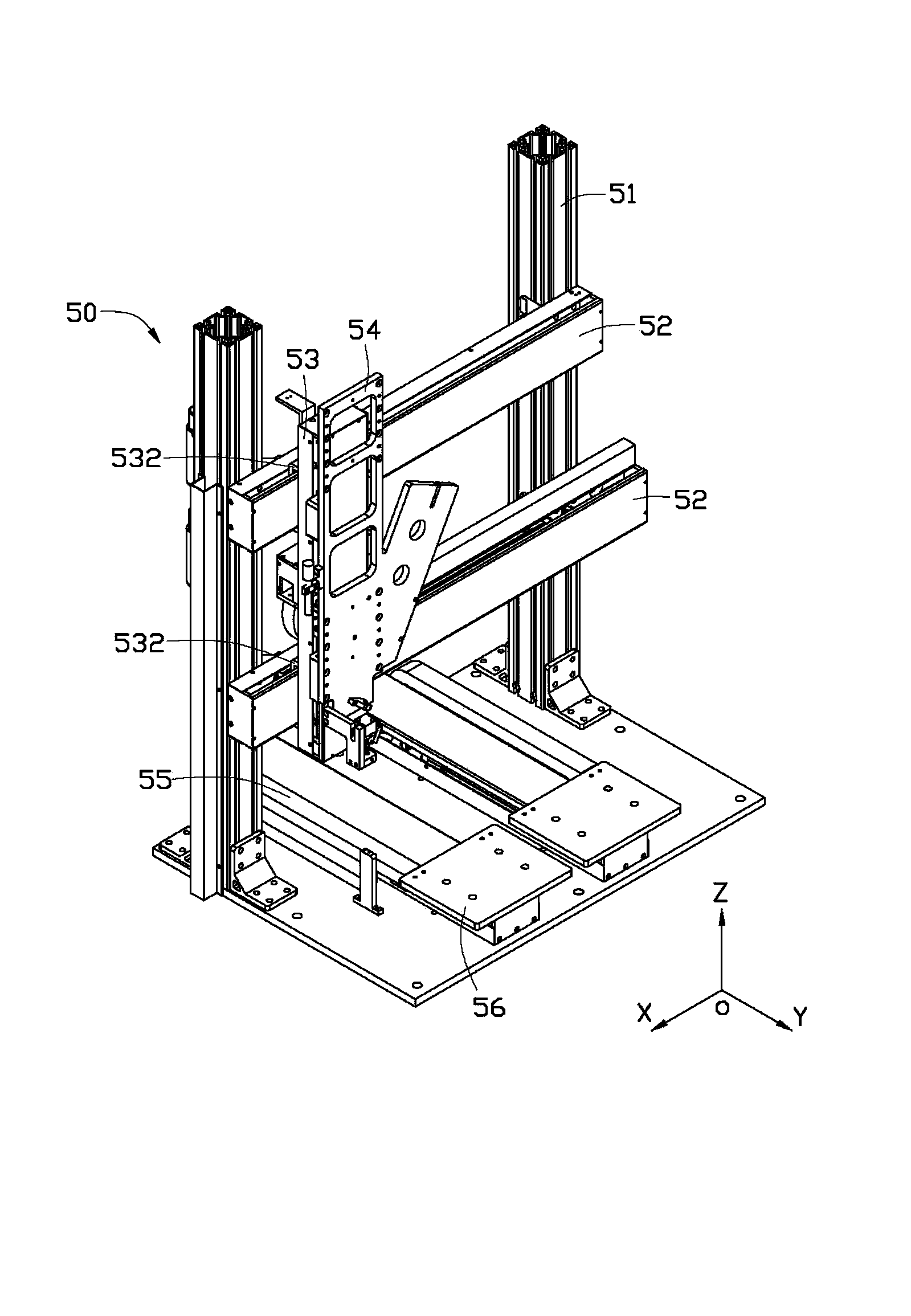

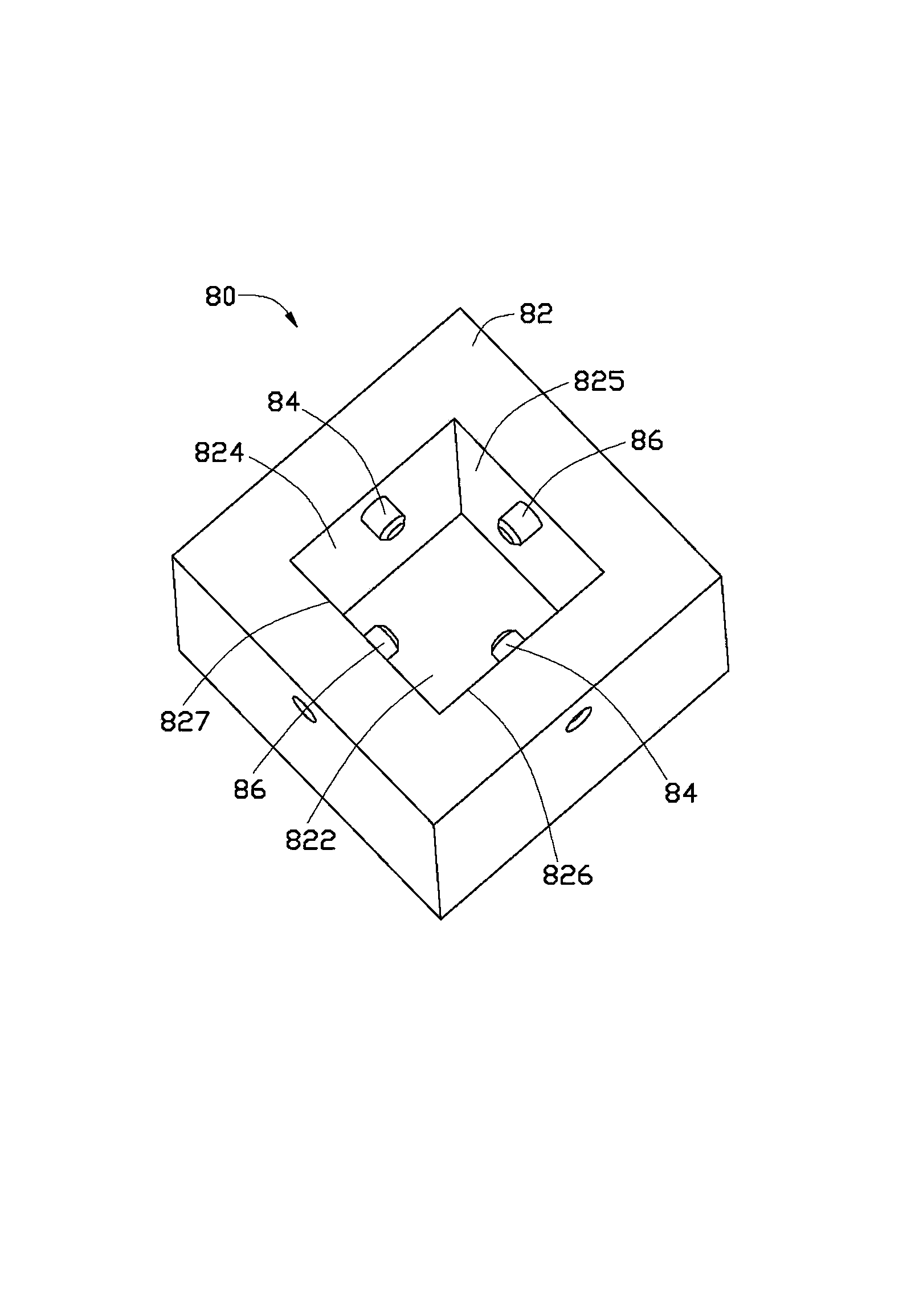

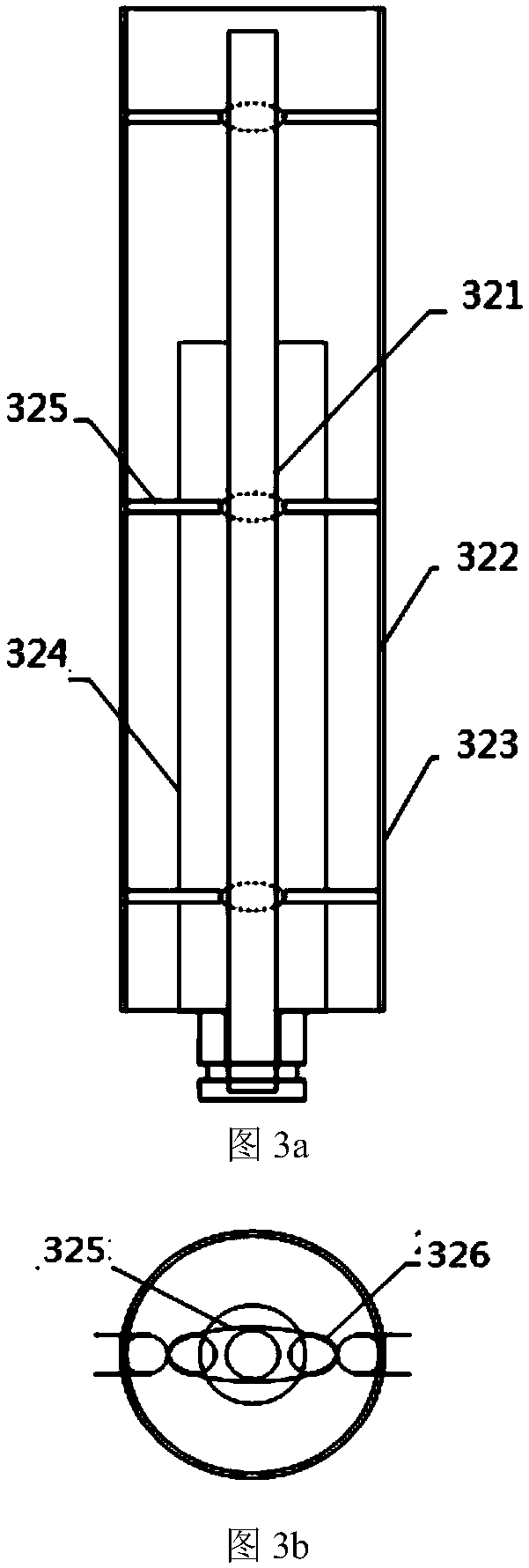

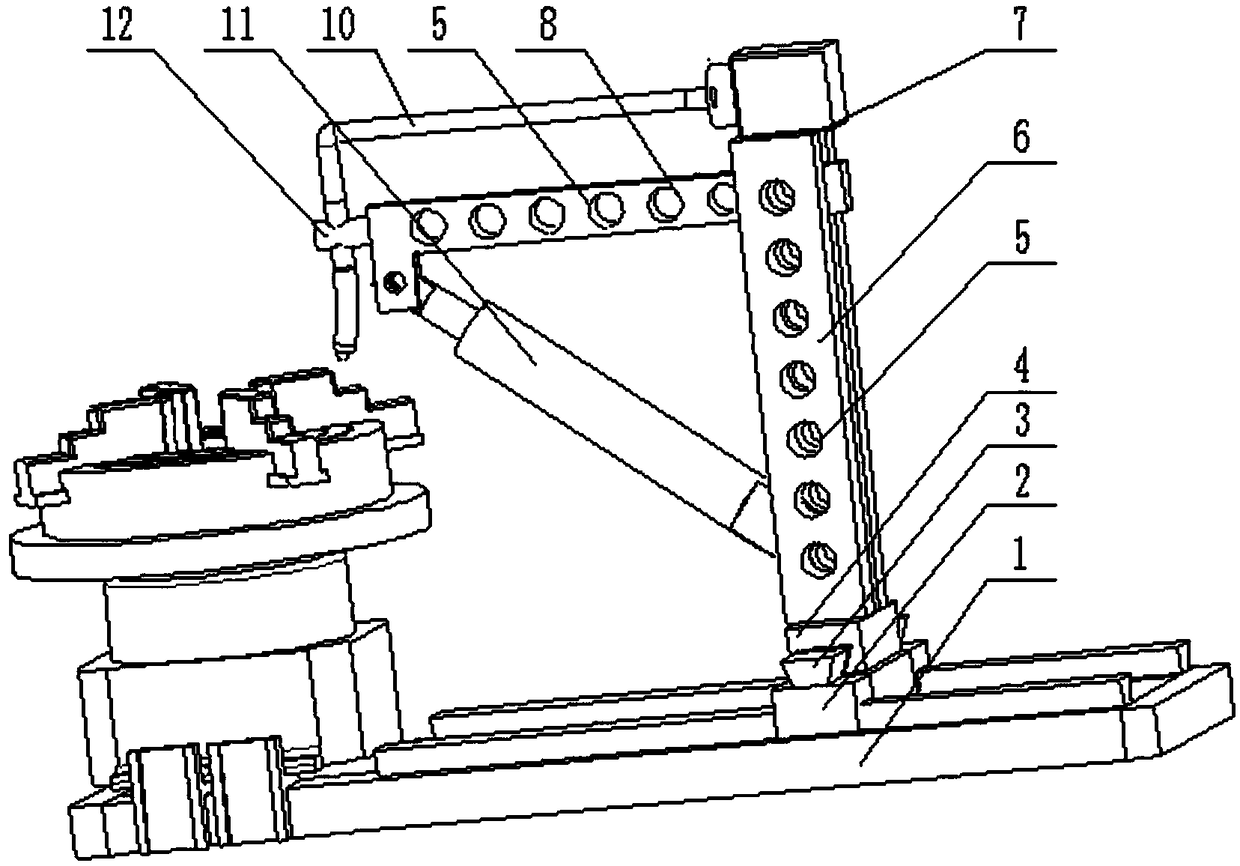

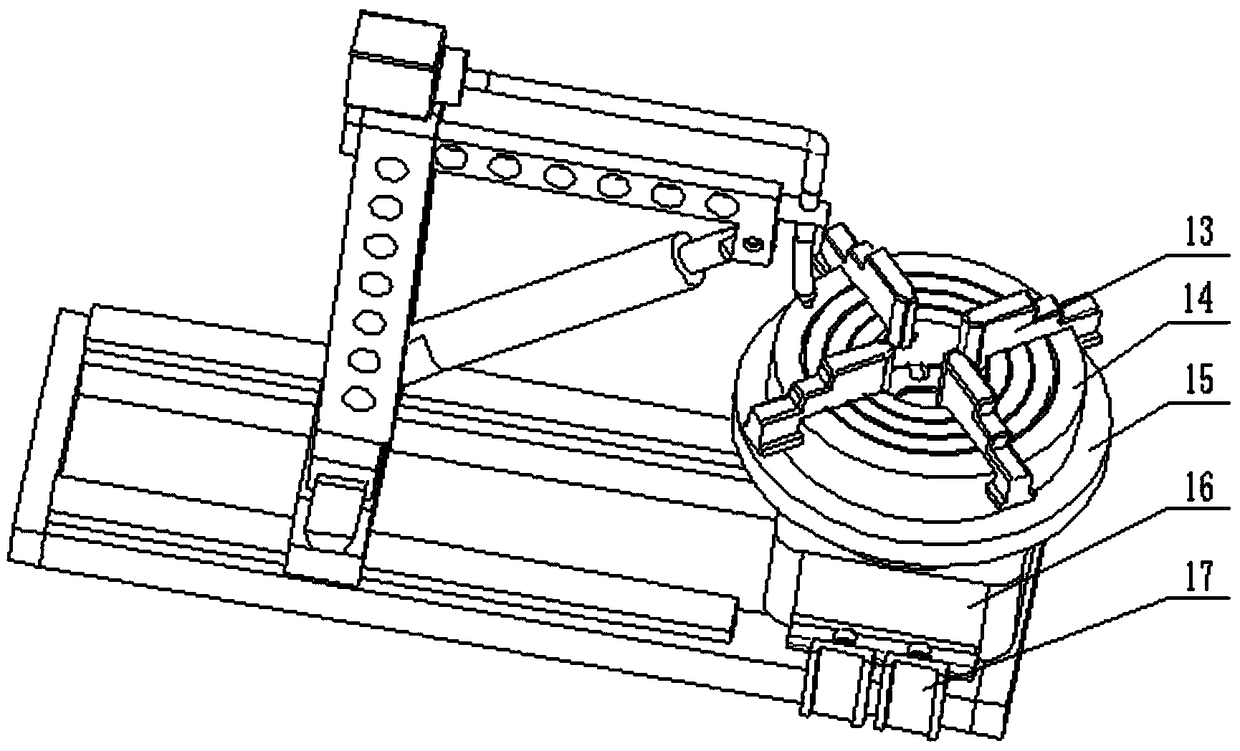

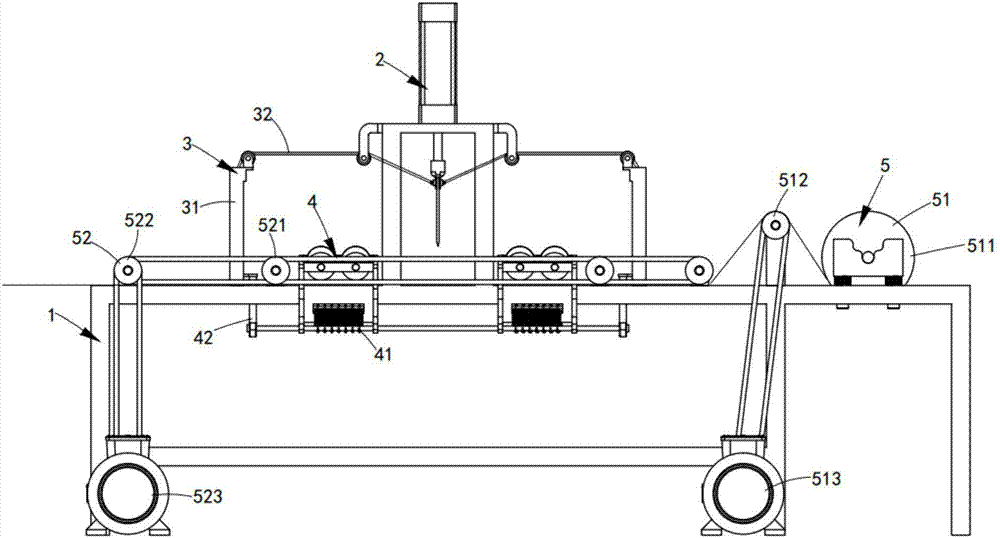

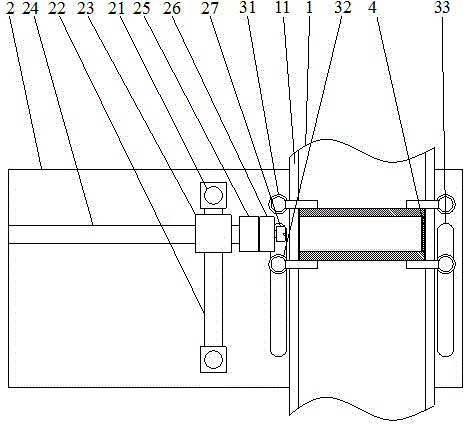

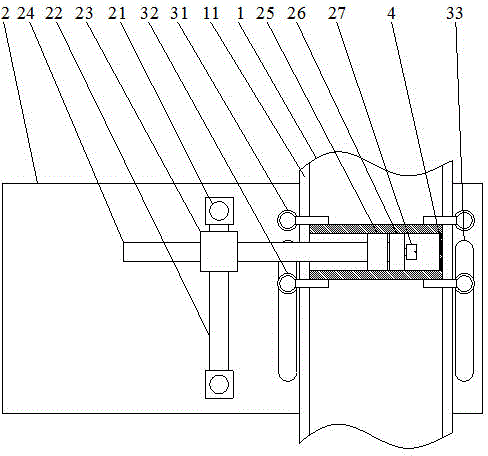

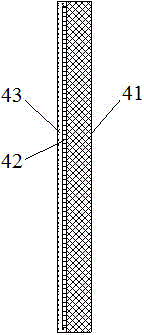

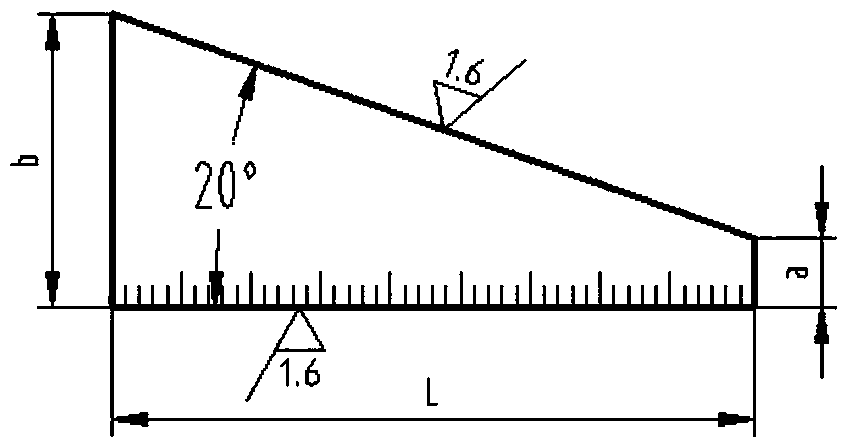

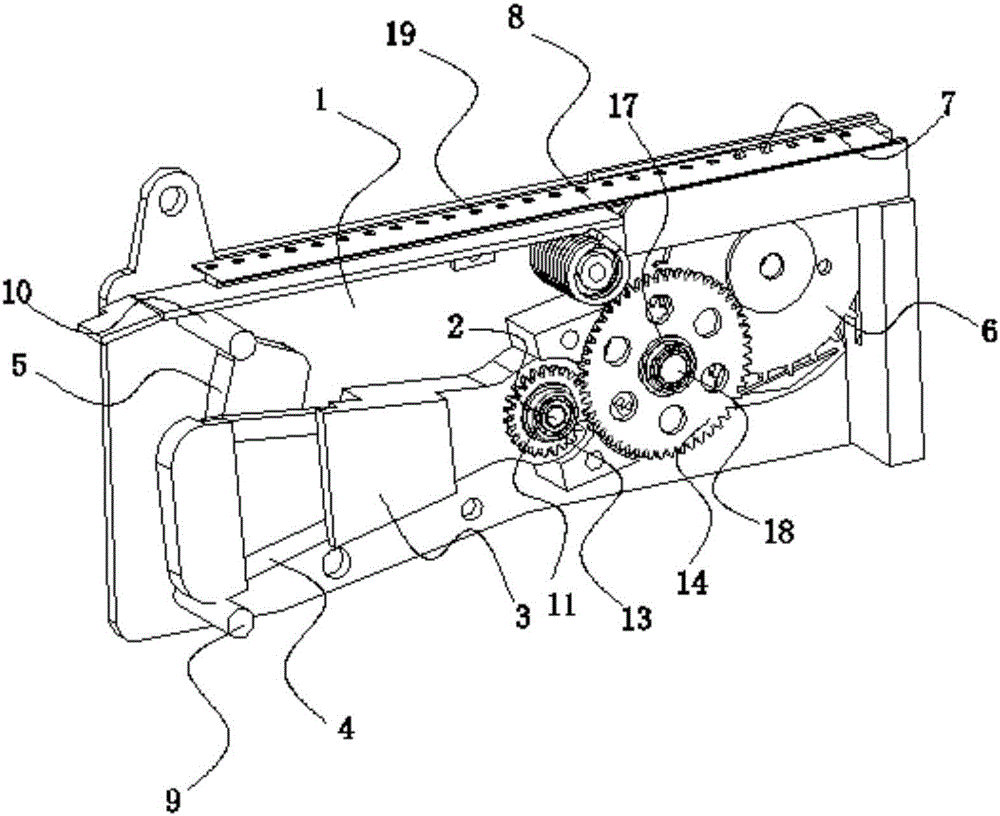

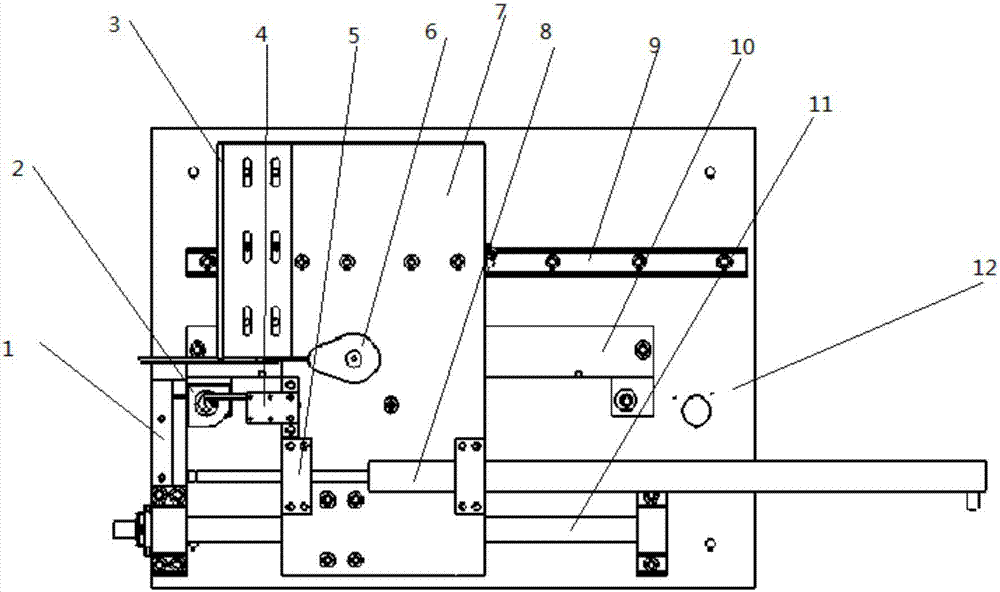

Precise positioning and welding system for cutting teeth of cutting head of heading machine and welding method thereof

ActiveCN109048147AChange angle of liftGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderControl system

The invention discloses a precise positioning and welding system for cutting teeth of a cutting head of a heading machine and a welding method thereof. The system comprises a first guide rail; one endof the first guide rail is fixedly connected with a support device for supporting and fixing the cutting head of the heading machine; an adjustable bracket capable of sliding in the length directionof the first guide rail is arranged at the other end of the first guide rail; and a welding gun for welding the cutting teeth of the cutting head of the heading machine is mounted on the adjustable bracket. The system controls a rotating motor connecting chuck to drive the cutting head to rotate; through sliding of a slide block on the corresponding guide rail, the distance from the welding gun toa cutting tooth base is controlled; a control system controls the oil inlet quantity and the oil outlet quantity of a hydraulic cylinder to guarantee extension of an extension rod, so that a liftingangle of the welding gun is changed, and the welding of the cutting teeth with different angles is realized; the connection between each cutting tooth and the cutting tooth base is controlled by the control system; and through movement and rotation of corresponding parts, no deviation is generated in any angle direction, so that the precise positioning is guaranteed, and the errors are reduced tothe greatest extent.

Owner:SHANDONG UNIV OF SCI & TECH

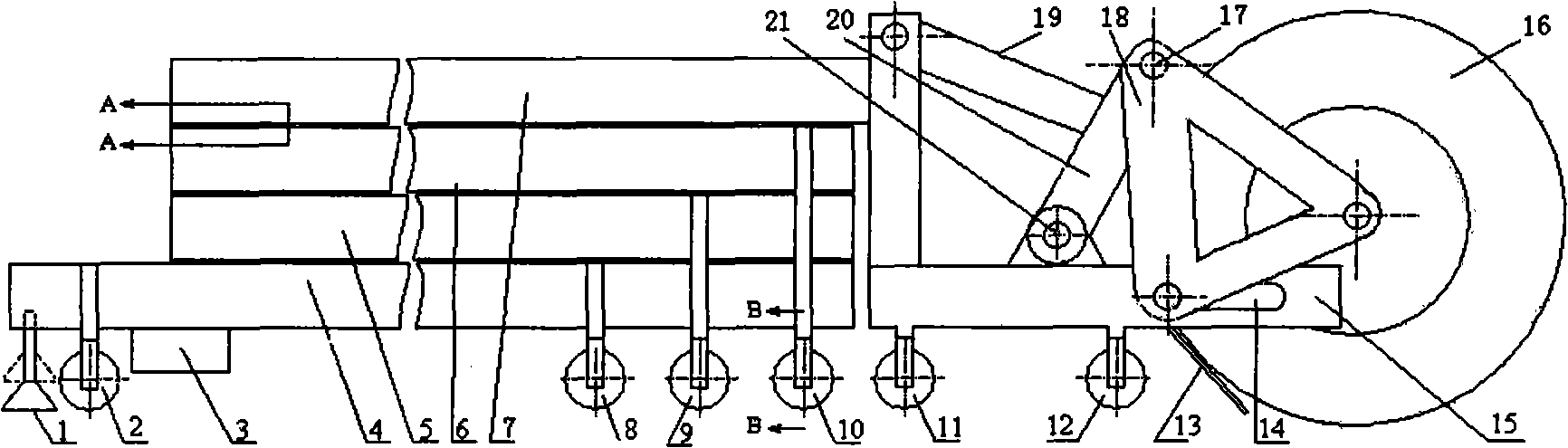

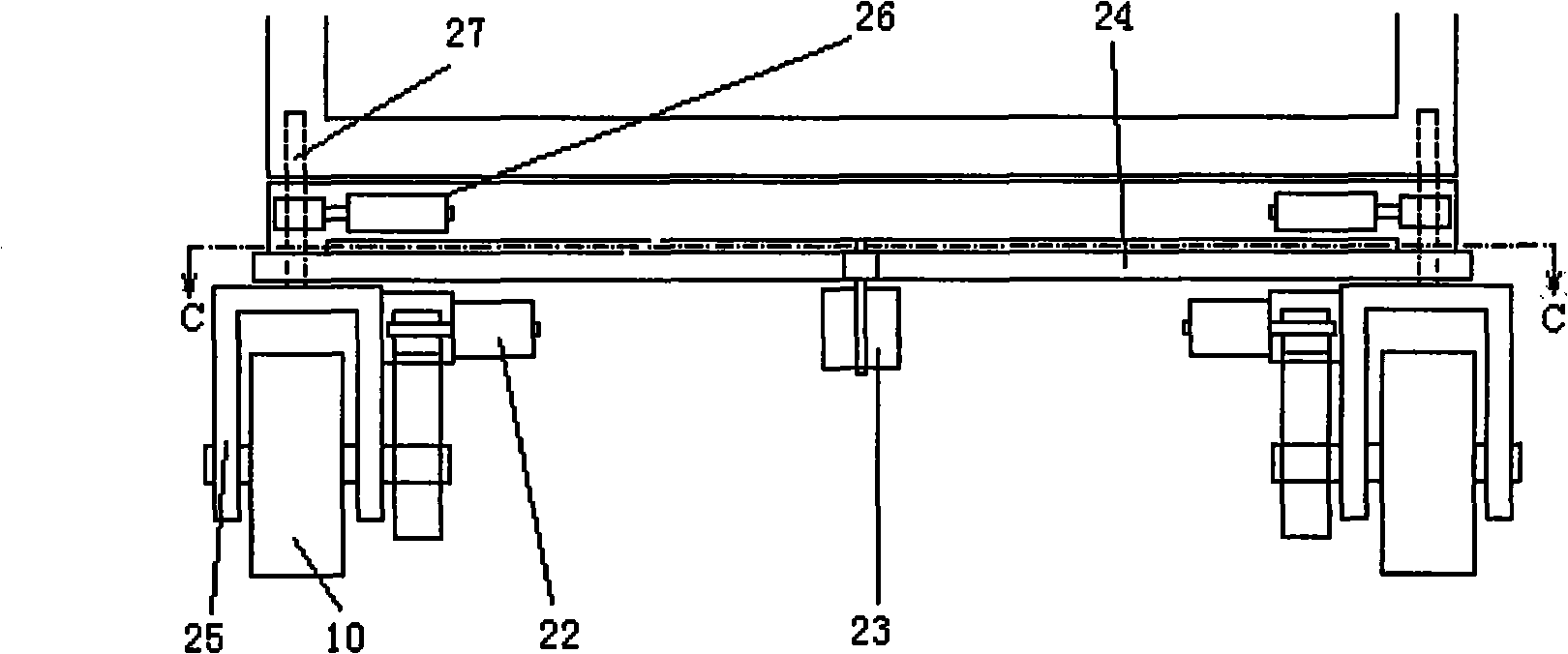

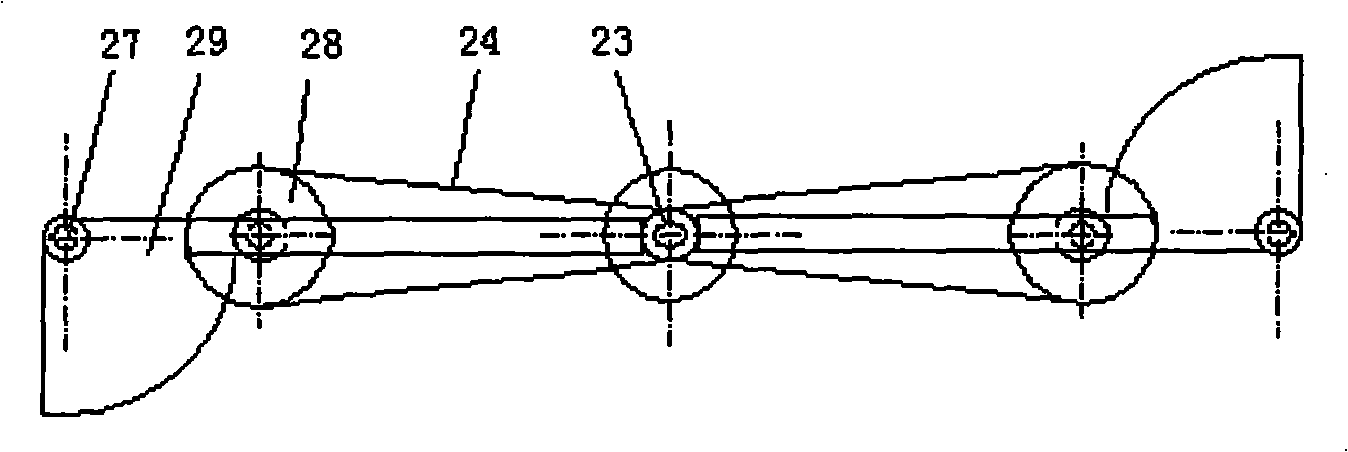

Belt conveyer

InactiveCN101306764ASimple organizationEasy maintenanceConveyorsSupporting framesEngineeringLeather belt

The invention discloses a belt conveyer, which comprises a material shoveling device, a conveyer belt, and a conveyer belt bracket. The conveyer belt is arranged on the surface of the conveyer belt bracket, the conveyer belt bracket is connected with the material shoveling device via a conveyer belt (19), and a running mechanism allowing the conveyer belt to move is arranged on the conveyer belt bracket; materials are shoveled on the conveyer belt (19) by the material shoveling device and delivered on the conveyer belt on the conveyer belt bracket through the conveyer belt (19); the conveyer belt bracket and the material shoveling device are fixed on a pedestal (15), and supporting wheels (11, 12) capable of running in a turnable way are arranged on the pedestal (15). The belt conveyer can adjust the conveying length via telescopic arm mechanisms of multistage conveyer belt devices and can move the operating position and adjust the working face flare angle thereof via the turnable running mechanism, so as to remarkably broaden the working range and improve the use flexibility of the belt conveyer.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Iron plate punching equipment

InactiveCN106734532ANo deviationImprove punch qualityMetal-working feeding devicesDirt cleaningPunchingPhysical health

The invention discloses iron plate punching equipment which comprises a bracket. The middle of the bracket is provided with a motor base. The top of the motor base is connected with a motor. The bottom of the motor base is connected with a telescopic cylinder. The bottom of the telescopic cylinder is connected with a punching plunger chip. A fixing block is connected with each of the two sides of the bottom of the bracket. The bottoms of the fixing blocks are connected with supporting columns. The bottoms of the supporting columns are connected with suction discs. The two sides of the bracket are each provided with a telescopic stand column. The bottoms of the telescopic stand columns are provide with a worktable. The middle of the worktable is provided with a dust collection trough. An inner cavity of the dust collection trough is provided with an iron core. The surface of the iron core is connected with a coil in a winding mode. The bottom of the coil is connected with a power supply. The right side of the coil is provided with a switch. By adoption of the iron plate punching equipment, metal dust in the air is reduced and prevented from affecting physical health conditions, deviation cannot occur when the punching plunger chip punches an iron plate, and the punching quality of the iron plate is improved.

Owner:WUXI CAIYUN MACHINERY & EQUIP

Argon arc welding machine with heat dissipation function and working method thereof

ActiveCN110405325APrecise positioningProtectiveWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingSlide plate

The invention discloses an argon arc welding machine with a heat dissipation function and a working method thereof. The argon arc welding machine comprises an operating platform, a fixing plate, a support and a welding gun, wherein a second cylinder is fixedly arranged at the center of one side of the fixing plate, and an ejector rod is fixedly arranged on a piston rod of the second cylinder. Theejector rod is driven by the second cylinder to push two movable plates to move towards the middle, a pipe fitting is fixed by two clamps, the pipe fitting can be loosened instead, the pipe fitting isconvenient to fix and loosen, manual fixing is avoided, loosening is easy, labor intensity can be reduced, and working efficiency is improved; a first cylinder drives an air cylinder telescopic rod to push a sliding plate to move rightwards, so that the pipe fitting is pushed to slide rightwards, and the pipe fitting can be roughly adjusted in a large range; the sliding plate is driven by a second lead screw to push the pipe fitting to slide rightwards, accurate adjustment in a small range can be carried out, the pipe fitting can be positioned more accurately, deviation in positioning cannotoccur, welding is easy, and operation is convenient.

Owner:SHENZHEN SOLGOO TECH

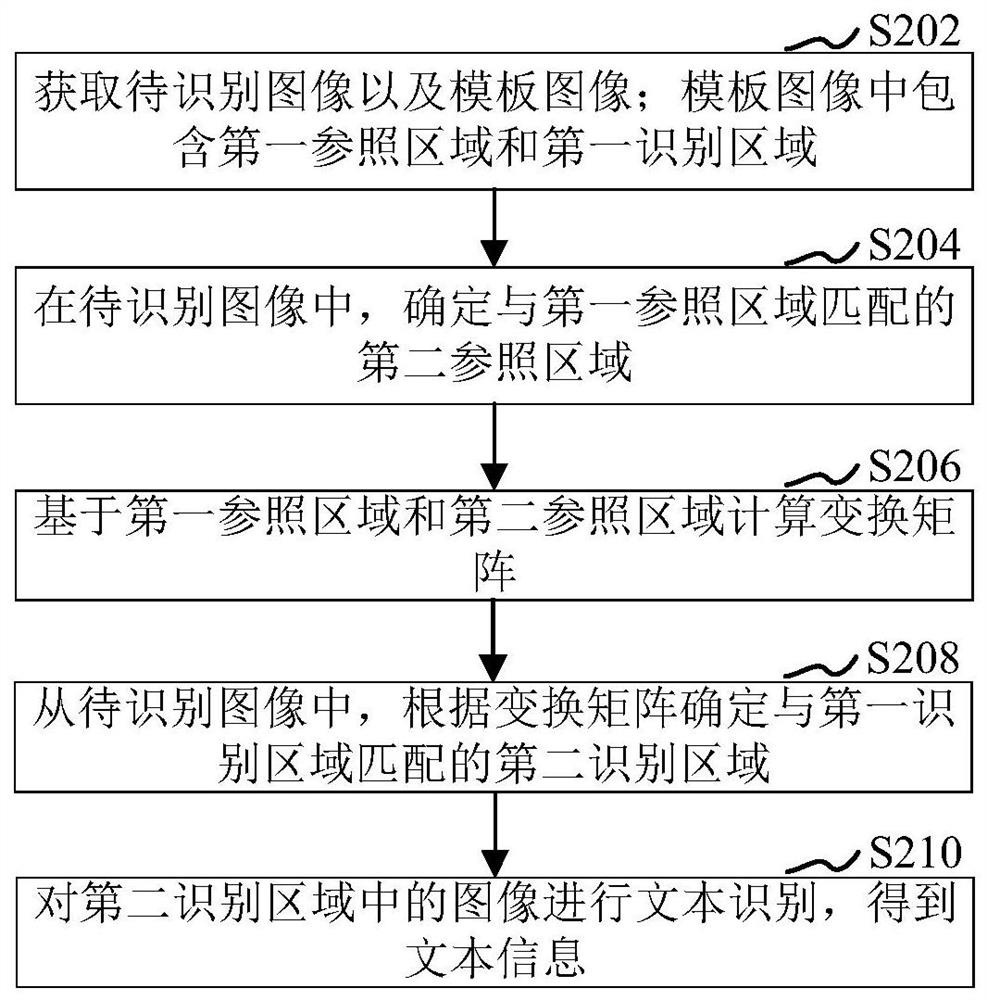

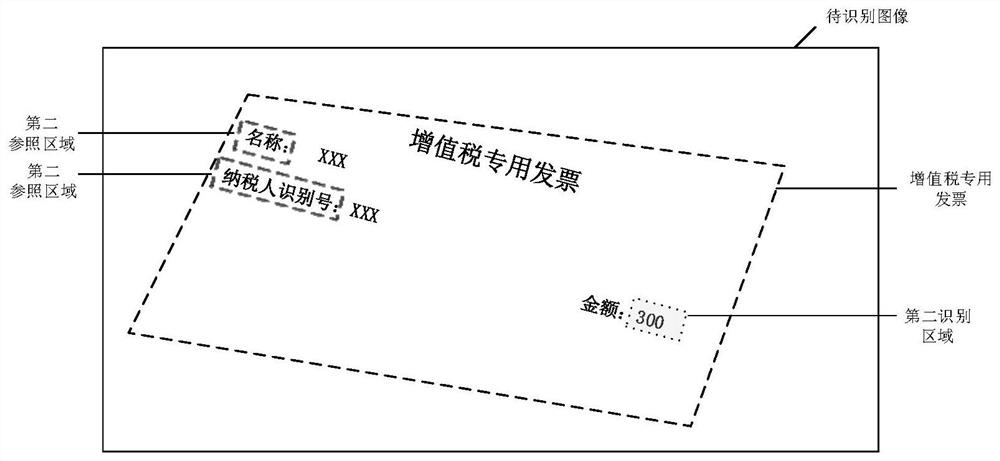

Text recognition method and device in image, computer equipment and storage medium

The invention relates to a text recognition method and device in an image, computer equipment and a storage medium. The method comprises the steps of obtaining a to-be-identified image and a template image, wherein the template image comprises a first reference area and a first identification area; determining a second reference area matched with the first reference area in the to-be-identified image; calculating a transformation matrix based on the first reference area and the second reference area; determining a second identification area matched with the first identification area from the to-be-identified image according to the transformation matrix; and performing text recognition on the image in the second recognition area to obtain text information. By adopting the method, complete text information can be identified.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

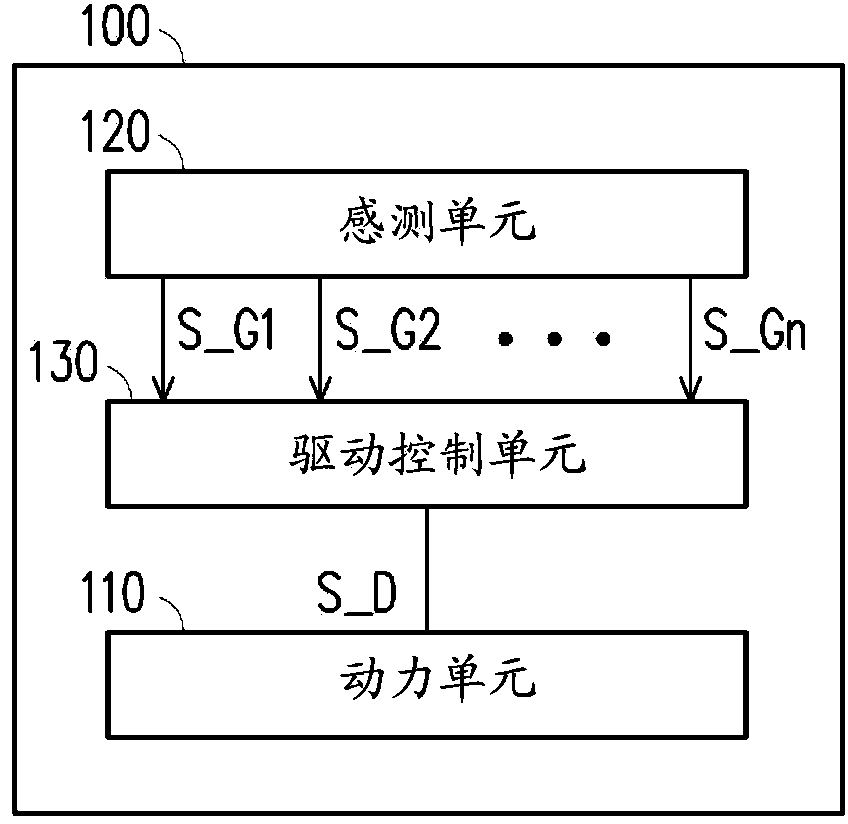

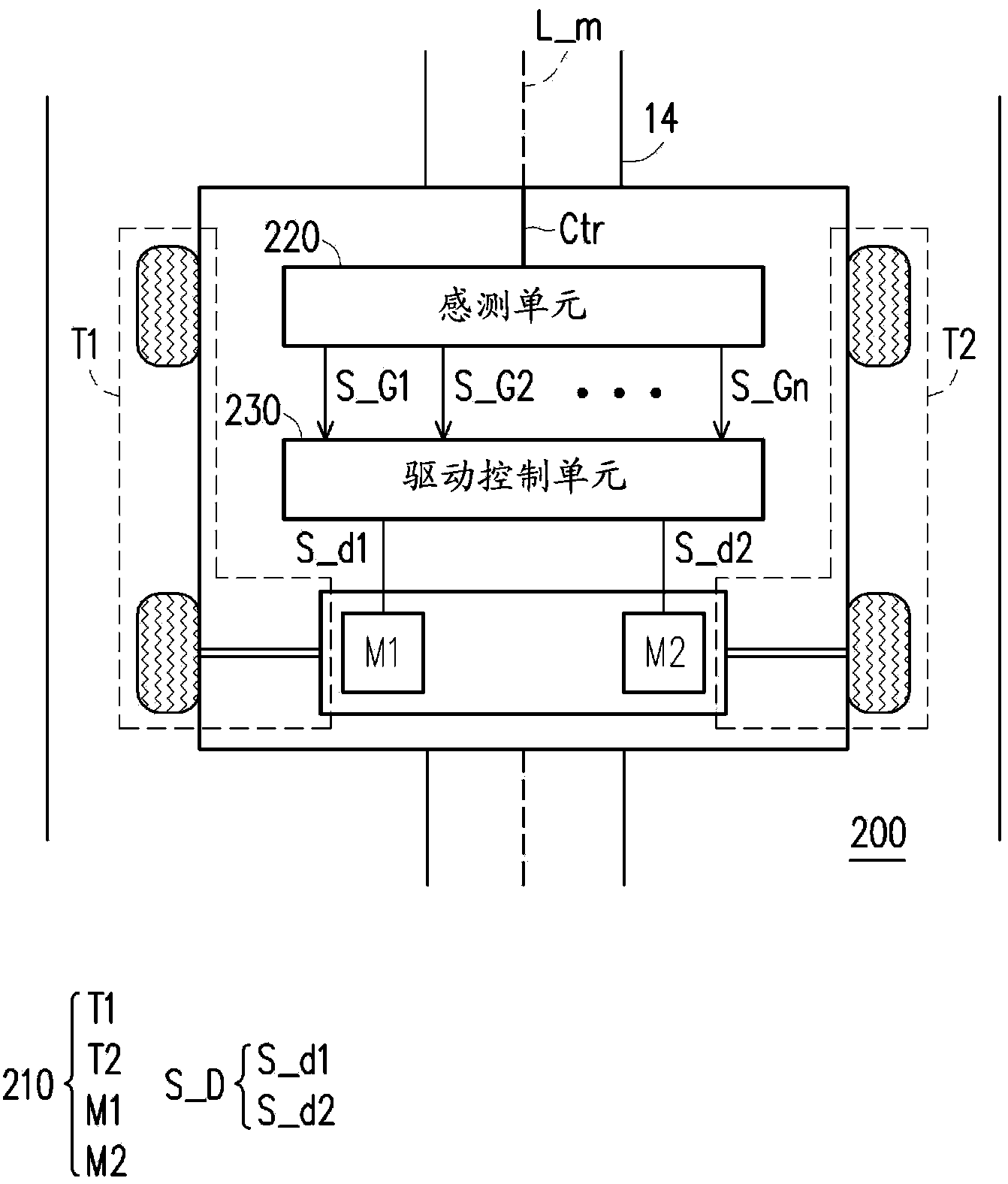

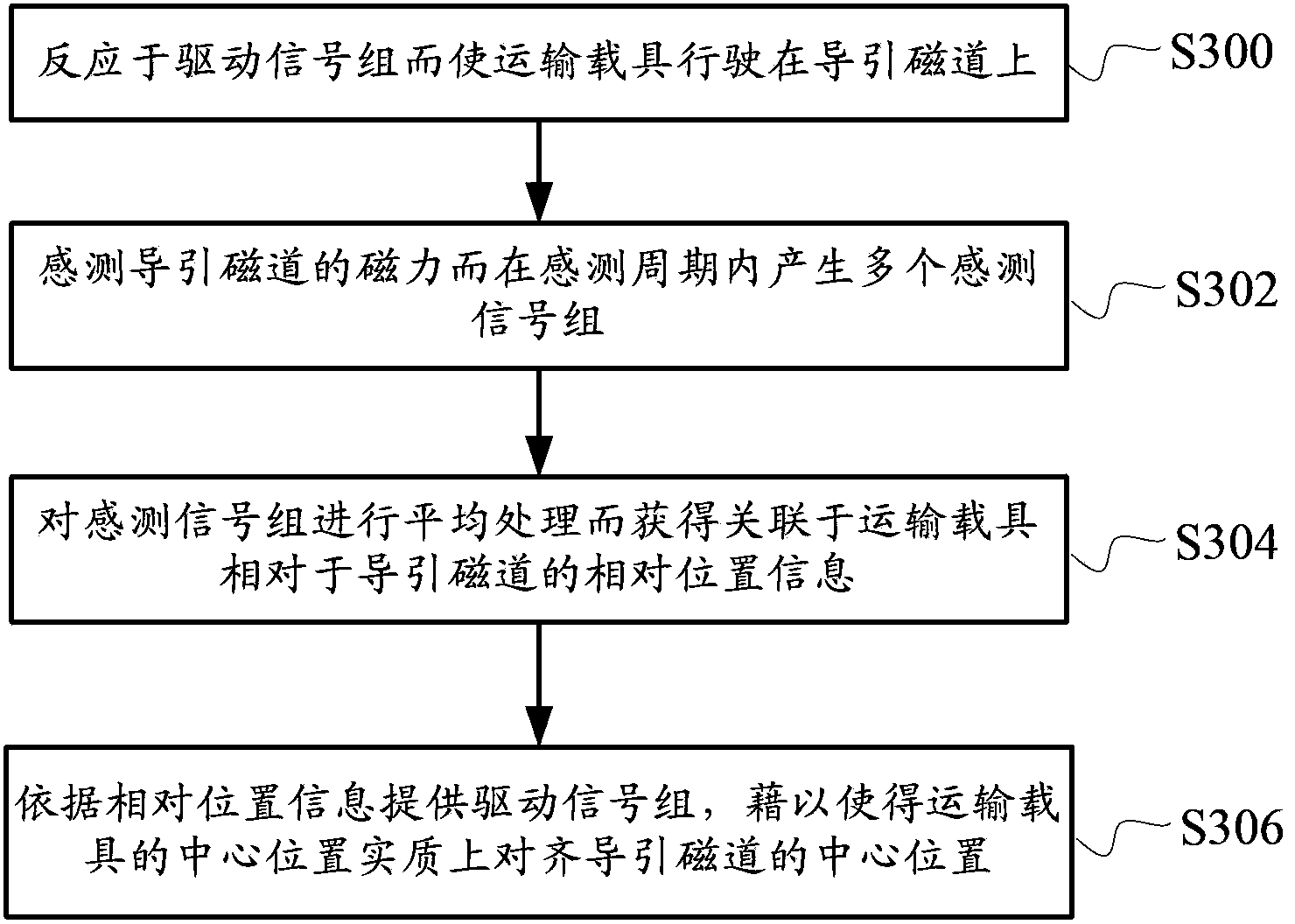

Transport vehicle and control method thereof

InactiveCN103631260ANo deviationImprove stabilityPosition/course control in two dimensionsMagnetic tension forcePower unit

The invention provides a transport vehicle and a control method thereof. The transport vehicle includes a power unit, a sensing unit and a drive control unit. The power unit is configured to respond to a drive signal group so that the transport vehicle can travel on a guide magnetic track. The sensing unit is configured to sense a magnetic force on the guide magnetic track, and generate a plurality of sensing signal groups in a sensing period. The drive control unit is coupled between the power unit and the sensing unit. The drive control unit is configured to receive the sensing signal groups; conduct averaging process of the sensing signal groups to obtain relative position information of the transport vehicle to the guide magnetic track; and provide the drive signal group to the power unit based on the relative position information, so that the central position of the transport vehicle is substantially aligned to the central position of the guide magnetic track.

Owner:KINPO ELECTRONICS +1

High-precision film cutting device for film production

ActiveCN106945090AAvoid stretchingSolve the pull effectMetal working apparatusEngineeringMechanical engineering

The invention discloses a high-precision film cutting device for film production. The device comprises a cutting mechanism, a buffer mechanism and an edge pressing mechanism; when the cutting mechanism is used for cutting films in an up-down reciprocating manner, the cutting mechanism drives the buffer mechanism to downwards press the films to form buffer sections; when the cutting mechanism cuts the films, the buffer mechanism can be quickly ascended along with descending of the cutting mechanism without needing the films to bear the weight thereof; and meanwhile, the edge pressing mechanism can press two side edges of the films for fixation, so that the cutting mechanism can accurately and quickly cut the films, the technical problem of pull deformation of the films in the cutting process due to punching force and tension is solved, and the functions of film buffering and automatic cutting positioning are realized.

Owner:浙江班萘特复合材料股份有限公司

Grinding machine with automatic positioning and fine adjusting functions

ActiveCN104889837AHigh precisionQuality improvementRevolution surface grinding machinesGrinding feed controlGrinding wheelMechanical engineering

The invention discloses a grinding machine with automatic positioning and fine adjusting functions, and relates to the field of grinding machines. By the grinding machine, the problems of inaccurate positioning, proneness to deviation, irreversible damage to parts, inaccurate part size and even scrapping which are caused when inner walls of parts are grinded by existing grinding devices are solved. The grinding machine comprises an operating platform and a grinding wheel platform. Limiting plates are arranged on the operating platform. Numerically-controlled sliding rails and a numerically-controlled slider are arranged on the grinding wheel platform. An X-axis sliding rod penetrates the numerically-controlled slider. A fine grinding wheel, a coarse grinding wheel and an infrared beam emitter are connected to the right side of the X-axis sliding rod sequentially. Two sides of the operating platform are provided with fixed rotatable stop rods, movable rotatable stop rods and sliding grooves. A positioning cover is arranged at the right end of a workpiece. An infrared ray receiving plate is arranged in the positioning cover. The grinding machine has the advantages that an infrared ray positioning mode is adopted by the grinding machine, the central position of an inner hole of a part is judged automatically, high accuracy is kept during part grinding, deviations are avoided, and accordingly, part grinding quality is improved.

Owner:SUZHOU RUIQI ELECTRONICS

Cable extrusion test run technology

InactiveCN104167260AImprove electrical performanceImprove mechanical propertiesInsulating conductors/cablesElectricityMaterials science

The invention discloses a cable extrusion test run technology. The technology comprises the steps that (1) a mold core and a mold sleeve are selected according to the cable extrusion thickness, a wedge-shaped ruler is inserted into the gap between the mold core and the mold sleeve for measurement after the mold core and the mold sleeve are installed, and meanwhile the coaxiality of the mold core and the mold sleeve are precisely adjusted; (2) technology traction and extension are achieved for the cable extrusion technology, concretely, optimal technological parameters are set for the cable type, cable materials and indoor temperature, in other words, glue output amount, the traction speed and indoor temperature are set as fixed values, the plastifying temperature which is a variable is adjusted, five kinds of finished products plastified at different temperatures are manufactured in a trial mode, insulation voltage, tensile strength, elongation at break and hot extending tests are carried out, test results are compared, the plastifying temperature value with the best electric performance and mechanical performance is taken as the optical parameter value for the processing technology of the cable type, and the standard technological process is formed. According to the cable extrusion test run technology, a mold is precisely adjusted before cable extrusion, the structural precision is ensured, using is easy and convenient, the maneuverability is high, and the rate of rejected products produced in the cable manufacturing process can be effectively lowered.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

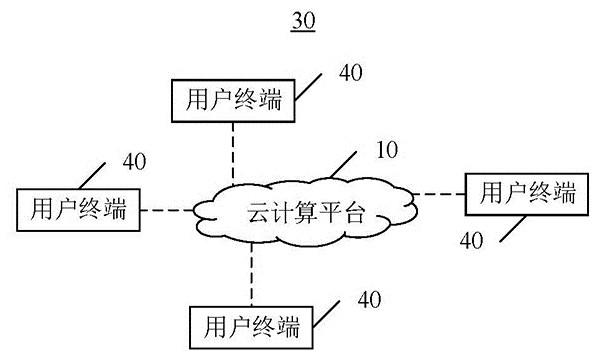

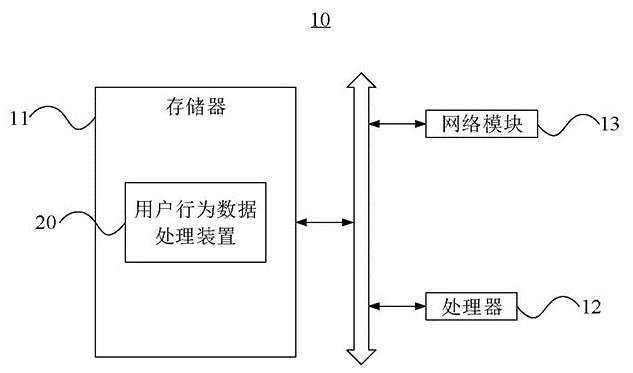

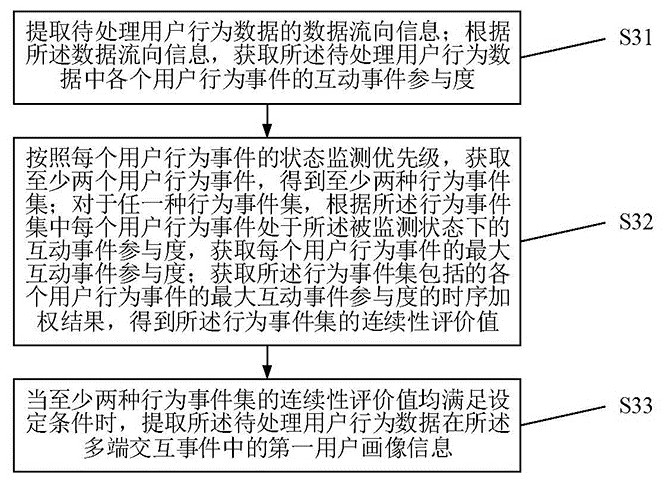

User behavior data processing method based on big data analysis and cloud computing platform

ActiveCN112163008ANo deviationAvoid deviating from actual user behaviorDigital data information retrievalSpecial data processing applicationsCloud computingEngineering

According to the user behavior data processing method based on big data analysis and the cloud computing platform, data flow direction level analysis can be performed on the to-be-processed user behavior data so as to extract the data flow direction information, then the interaction event participation degree of each user behavior event in the to-be-processed user behavior data can be acquired, and in this way, the interaction event corresponding to the user behavior and the participation degree can be considered. In addition, a corresponding time sequence weighting result can be determined incombination with the state monitoring priority and the interaction event participation degree, so that a continuity evaluation value of the behavior event set is obtained. Thus, the participation degree of the interaction event is considered, and the continuity of the user behavior on the behavior event set can be considered, thereby ensuring that the analysis of the to-be-processed user behaviordata is global and continuous rather than fragment-type local analysis, preventing the obtained user portrait information from breaking away from the actual behavior of the user, and thus, it is ensured that the obtained user portrait information does not deviate.

Owner:SHENZHEN AIYIRUI TECH CO LTD

Automatic wrapping device of insulation layer of wire and cable

InactiveCN104282398ANo uneven thicknessMeet the requirementsInsulating conductors/cablesInsulation layerEngineering

The invention discloses an automatic wrapping device of an insulation layer of a wire and cable. The automatic wrapping device of the insulation layer of the wire and cable comprises a screw extruder, and is characterized in that a rubber wrapping device is arranged at a rubber outlet of the screw extruder, the rubber wrapping device is fixedly connected with the screw extruder through a support, a paying off device and a taking up device are arranged on the front side and the rear side of the rubber wrapping device respectively, and a cable copper core is wound between the paying off device and the taking up device and penetrates through the rubber wrapping device. Pressure of liquid rubber is ensured by the adoption of the screw extruder, porous liquid rubber permeates and fills a cable passing channel, a front cable guide pipe and a rear cable guide pipe position the position of the copper core, a rubber scraper amends the insulation layer outside the wire and cable and controls the diameter of the insulation layer outside the wire and cable, the mode that the paying off device takes up the wire and cable in a damping mode is adopted so that the copper core can be located in the core portion of the wire and cable when wrapping the insulation layer, and it is ensured that the insulation wrapping of the wire and cable meets the use requirement. The insulation layer of the wire and cable is bright and clean in appearance, wire diameters are uniform, and the phenomena that a wire core deflects and insulation layers are not uniform in thickness are avoided.

Owner:FOSHAN YUEJIAXIN WIRE & CABLE

Solar street lamp with cleaning device

InactiveCN106838797ASolve the problem that it is easy to be exposed to wind, sun and rain.Troubleshoot prone to failureMechanical apparatusPhotovoltaicsSolar street lightEngineering

The invention provides a solar street lamp with a cleaning device. The solar street lamp comprises a lamp pole, a street lamp body, a solar battery panel, a power device, a power device frame, a stirring type power device for providing power, a shell, an installation shaft and a stirring wheel, wherein the solar battery panel covers the top of the street lamp body; the power device is fixed on the lamp pole, the street lamp body or the solar battery panel; the power device frame surrounds the solar battery panel; two sides of the solar battery panel are provided with guide rails; the shell and the installation shaft are fixed on the position of the power device; the stirring wheel is driven by the power device for a traction belt to proceed; the stirring wheel is provided with stirring wheel teeth matched with traction belt holes. By use of the solar street lamp, the volume and the cost of a power device are reduced while the cleaning problem of a high altitude solar panel is solved, and therefore, the solar battery panel also can perform a function of a top cover and a lampshade so as to block the lamp body and the power device.

Owner:浙江比弦物联科技有限公司

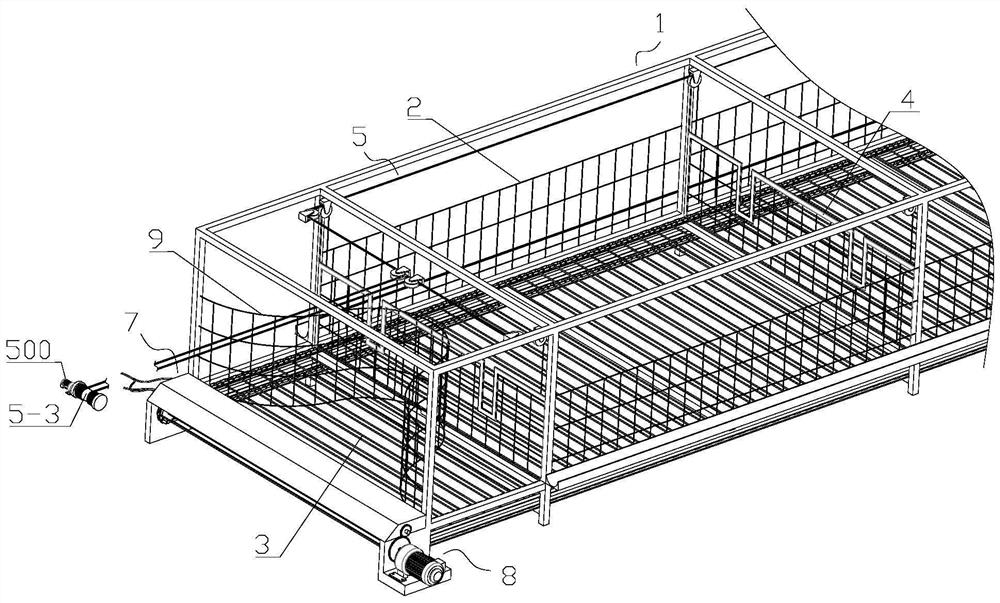

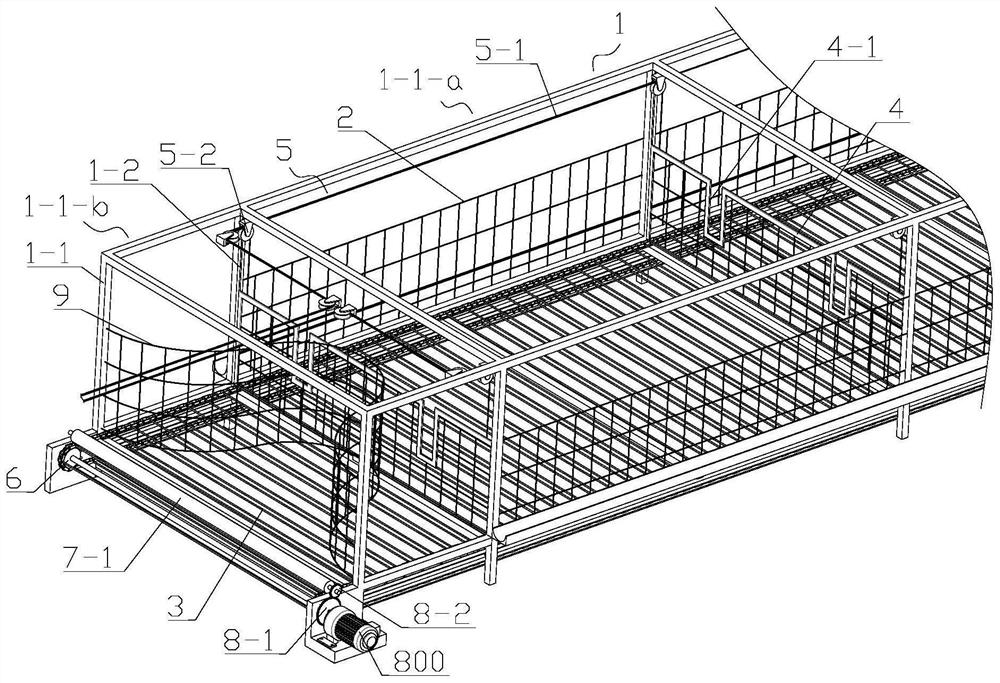

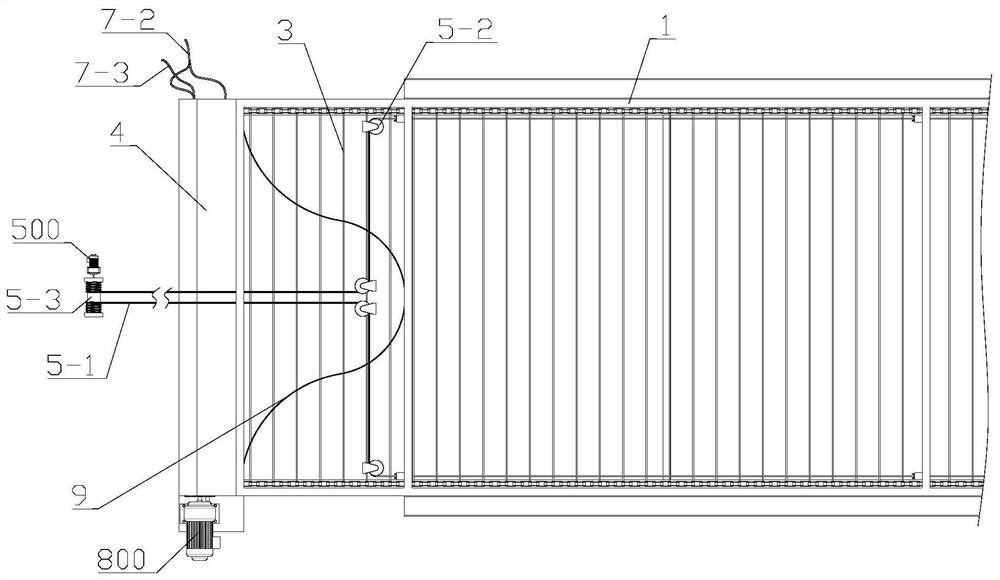

Poultry breeding cage with longitudinally movable bottom net

ActiveCN111771758AImprove poultry removal efficiencyImprove cleaning and disinfection efficiencyCleaning using toolsCleaning using liquidsAnimal scienceDomestic bird

The invention discloses a poultry breeding cage with a longitudinally movable bottom net, and belongs to the technical field of poultry breeding equipment. According to the technical scheme, the poultry breeding cage with the longitudinally movable bottom net comprises a cage frame, two side nets correspondingly arranged on the two sides of the cage frame, the bottom net rotationally arranged between the head end and the tail end of the cage frame, a bottom net driving part for controlling the bottom net to do rotational motion, a plurality of n transverse separation nets which are positionedbetween the two side nets and are uniformly arranged in the longitudinal direction of the cage frame, and a lifting part for controlling the n-1 transverse separation nets, wherein the transverse separation net positioned at the head end is fixedly connected with the cage frame, and the n-1 transverse separation nets positioned in the middle and at the tail end are fixedly connected with the lifting part. The poultry breeding cage with the longitudinally movable bottom net has the beneficial effects that the poultry discharging efficiency after breeding is improved, the manual use and grabbingcost is saved, the defective loss is reduced, the cleaning and disinfection efficiency is improved, and the service life is long.

Owner:SHANDONG NEW HOPE LIUHE GROUP +4

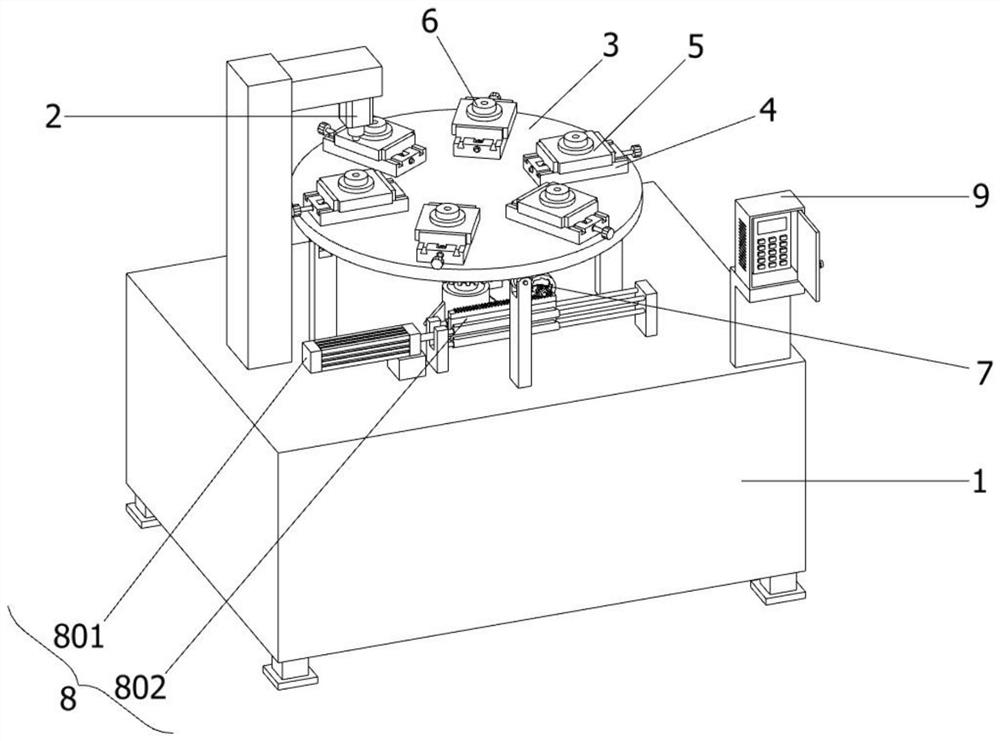

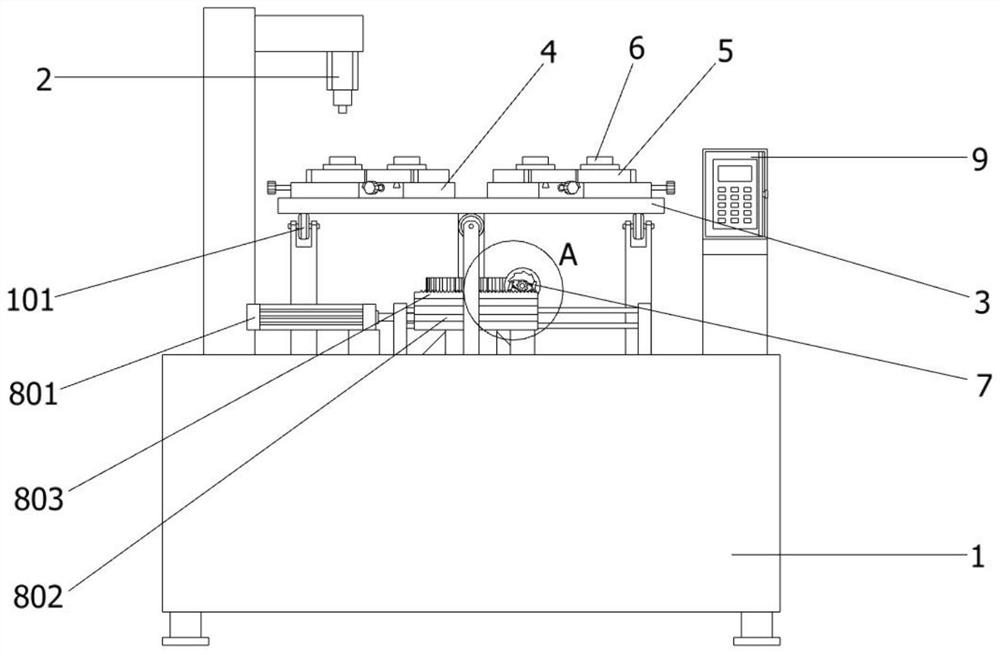

Multi-station detection device based on automatic control

InactiveCN112857426AEasy to fixImprove detection accuracyElectrical testingMeasurement instrument housingAutomatic controlGear drive

The invention provides a multi-station detection device based on automatic control, belongs to the technical field of detection devices, and aims to solve the problem that errors are easy to generate after a servo motor or other angle motors rotate in one direction for a long time when a multi-station turntable in the existing multi-station detection device rotates. The device comprises a workbench. The upper part of the left side of the workbench is provided with a detection member through a pillar, and the middle side of the upper part of the workbench is provided with a multi-station turntable. The multi-station rotating disc comprises a supporting shaft sleeve and a worm wheel, and a rotating shaft is arranged in the center of the bottom end face of the multi-station rotating disc. After the worm rotates three circles anticlockwise, because the transmission ratio between the worm and the worm gear is 18: 1, the worm gear drives the multi-station turntable to rotate one sixth circle, namely 60 degrees, so that the rotation angle of the multi-station turntable does not generate errors, the detection precision of a detection piece on the multi-station detection device is not influenced, and the reliability of the multi-station detection device in use is greatly improved.

Owner:张雪梅

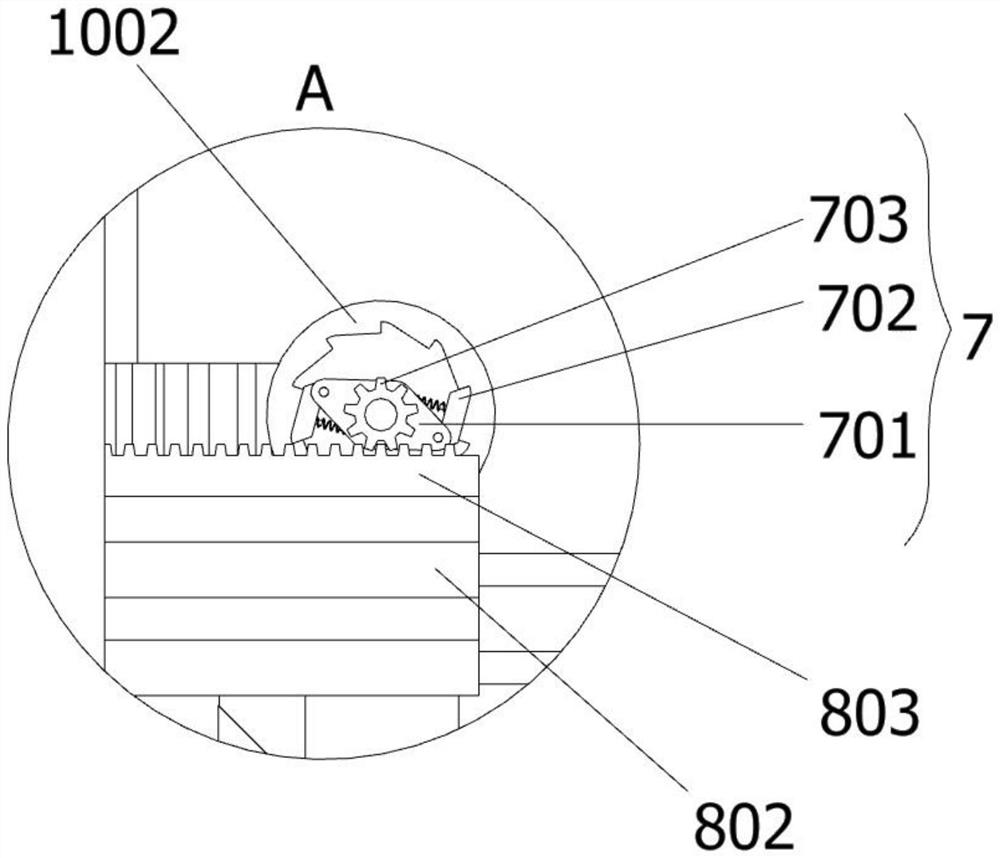

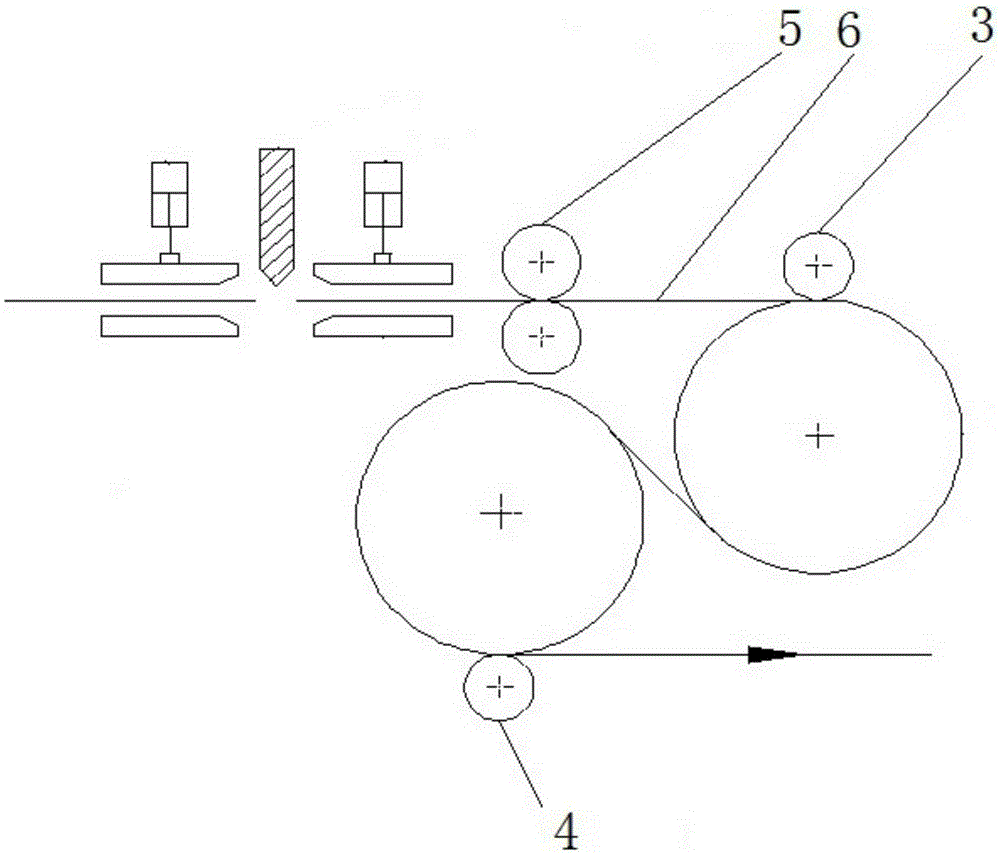

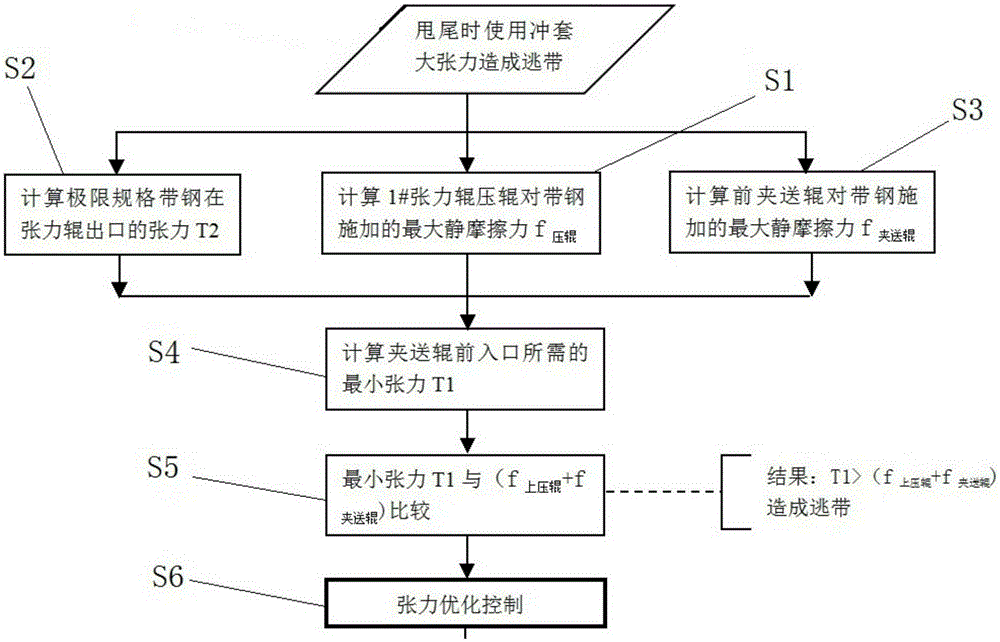

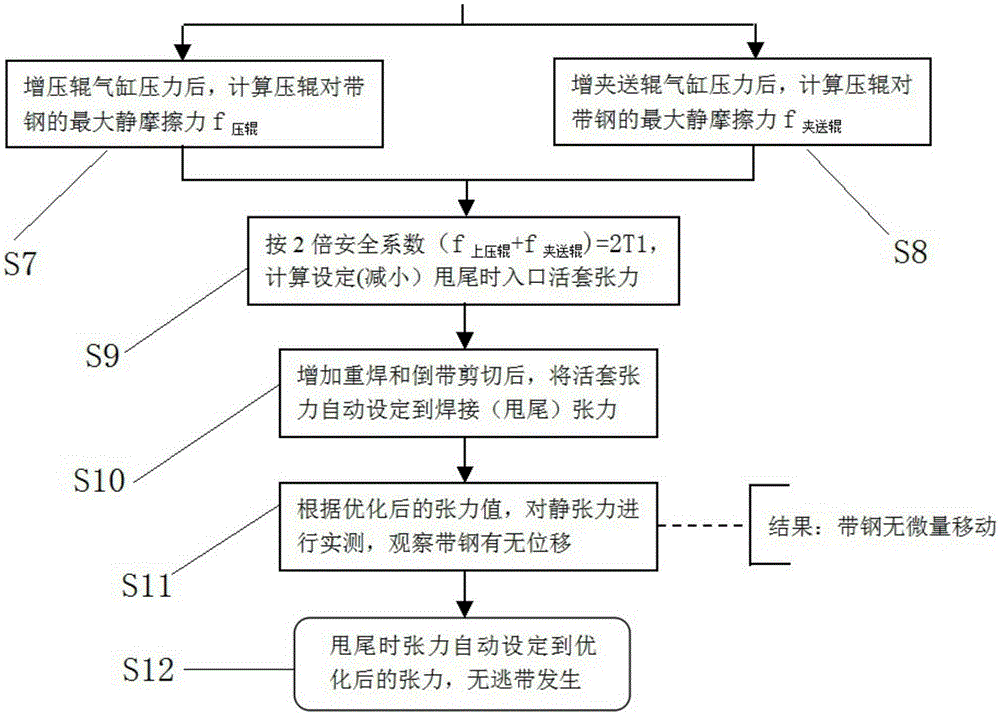

Tension control optimization method during welding tail swinging of cold-rolling strip steel

InactiveCN106807760ANo escape zoneNo deviationTension/compression control deviceStrip steelEngineering

The invention discloses a tension control optimization method during welding tail swinging of cold-rolling strip steel. The method includes the following steps that the required minimum tension of an inlet in front of pinch rolls is calculated; the minimum tension is compared with the total pressure of an upper pressuring roll and the pinch rolls; and optimization controlling is performed on tension. By means of the tension control optimization method during welding tail swinging of the cold-rolling strip steel, no abnormal deviation of the strip steel in a loop can be guaranteed, and the effects that no abnormal escape of a strip tail occurs and the welding quality is not affected are guaranteed.

Owner:BAOSHAN IRON & STEEL CO LTD

Testing device of compacted soil samples and sampling method thereof

ActiveCN107314926AImprove flatnessGuaranteed smoothPreparing sample for investigationControl systemElectric machinery

The invention belongs to the field of civil engineering, and relates to a testing device of compacted soil samples and a sampling method thereof. The testing device comprises a support, a compaction system, a sampling mould and a control system, wherein a support base is of a circular frame; support side plates are arranged on two sides of the support base; a support top plate is arranged on an upper top surface of the support; a motor and a pulley group are arranged above the middle of the support top plate; one end of a traction rope is connected with the motor while the other end of the traction rope passes by the pulley group and then penetrates through a traction hole formed in the middle of the support top plate and is connected with connecting holes formed in an upper part of a hammer; the compaction system comprises a guide rod, the hammer, a compaction bottom plate and limiting plates; an upper part of the sampling mould is of a hollow circular column and a lower part of the sampling mould is a hollow cylinder with a bottom part; a circular cutter is arranged between the upper part of the sampling mould and the lower part of the sampling mould; the control system comprises a pressure sensitive sensor, an infrared transmitting sensor, a motor and a controller. According to the testing device and the sampling method thereof disclosed by the invention, the technical problems that the guide rod is not vertical and the dry density are difficultly controlled in a process of manually manufacturing the compacted soil samples are solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

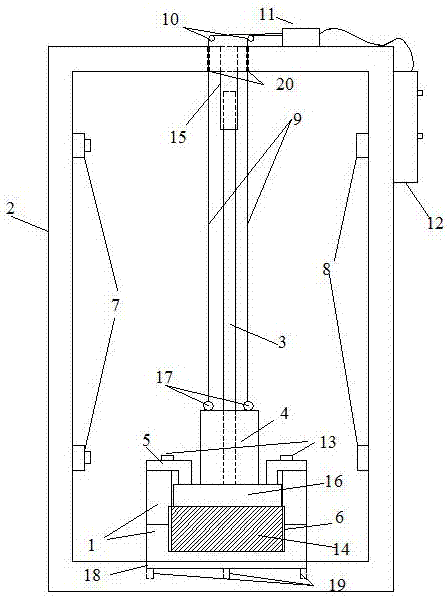

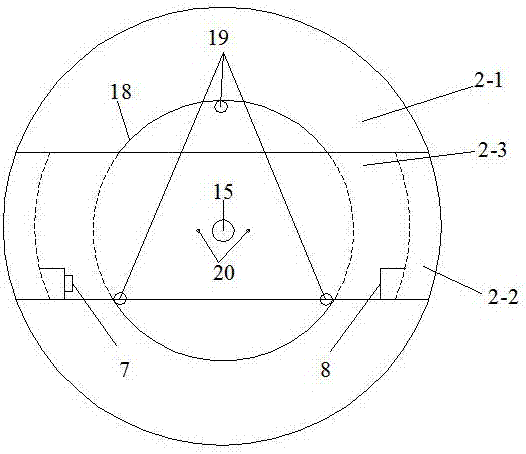

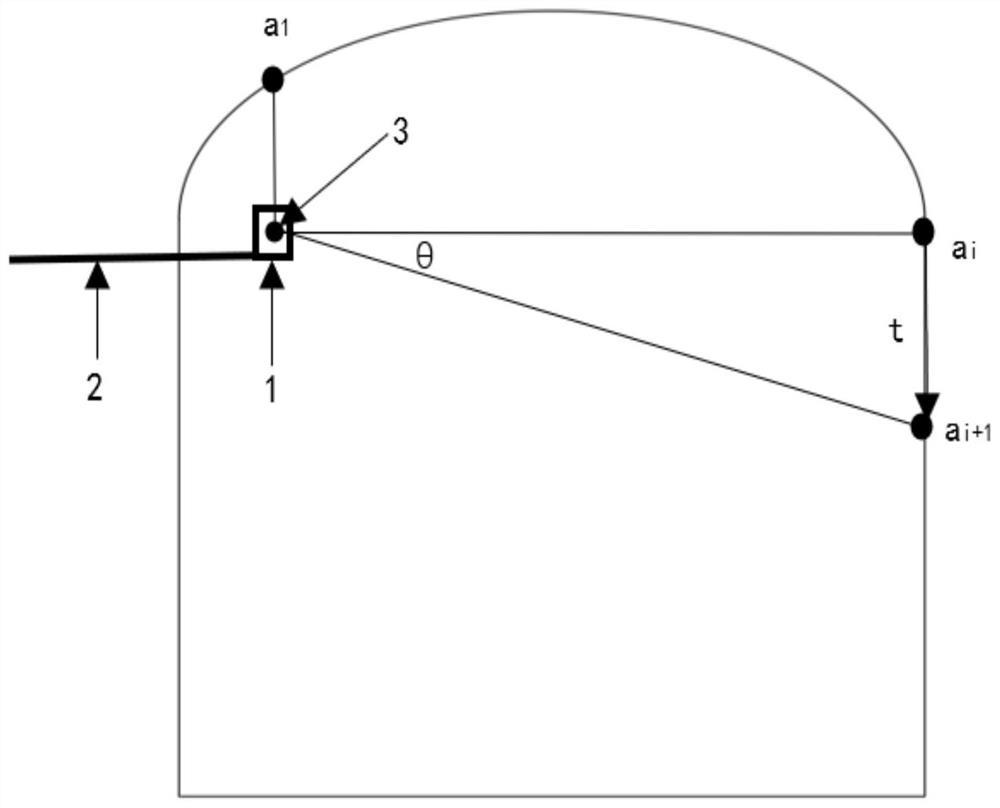

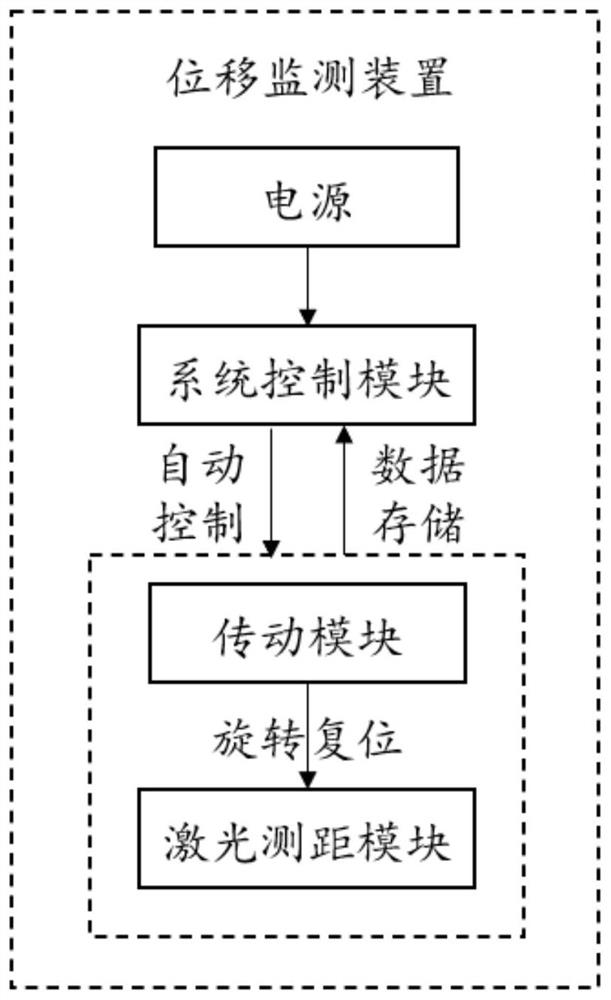

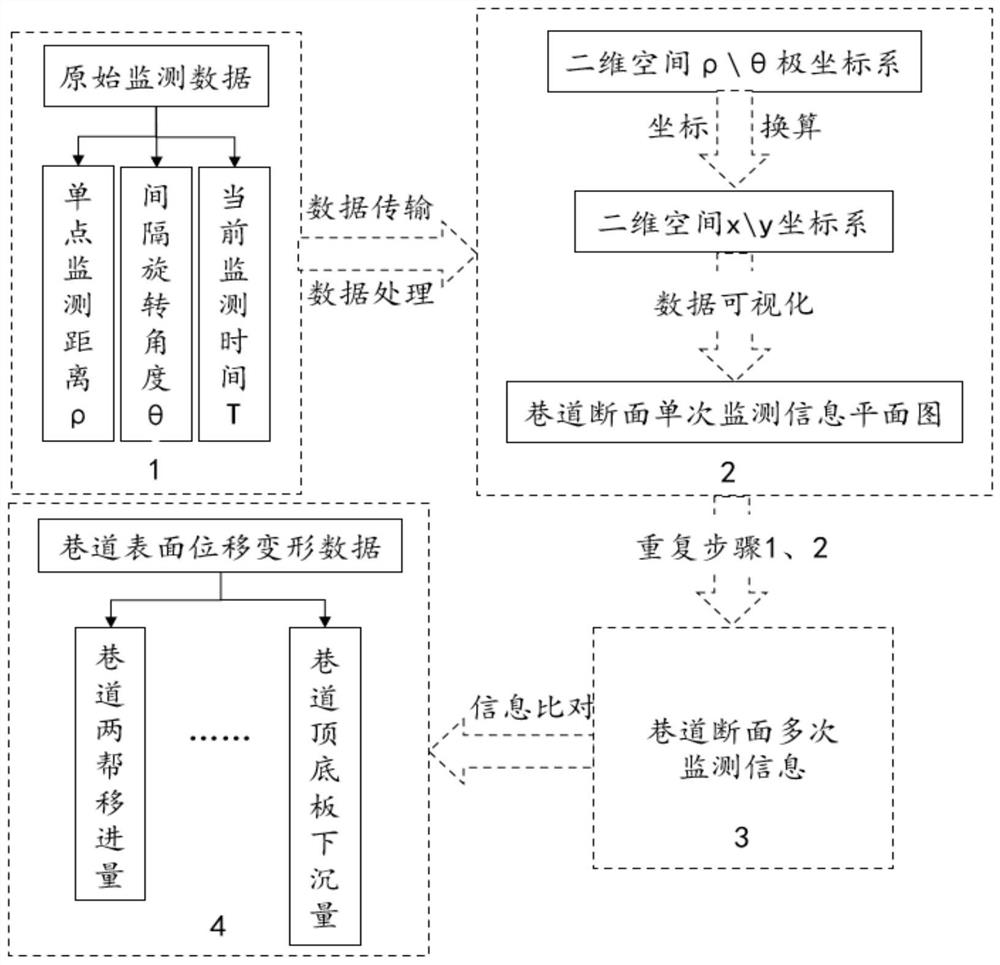

Roadway surface displacement deformation monitoring method based on laser ranging principle

InactiveCN111829441ANo deviationNo cumulative mechanical errorUsing optical meansDeformation monitoringEngineering

The invention provides a roadway surface displacement deformation monitoring method based on the laser ranging principle. The method comprises steps that a displacement monitoring device composed of alaser ranging module, a transmission module and a system control module is installed on a platform on an upper portion of a wall of a roadway, and a data receiving device is arranged at the bottom ofthe roadway; the laser ranging module performs 360-degree periodic rotation and resetting according to the set rotation angle theta and the rotation interval time t, emits a laser beam to a roadway section monitoring point every time the laser ranging module rotates by one angle theta to serve as a single-point distance measurement, and records and stores a distance between the laser ranging module and the monitoring point and the corresponding angle; repeated monitoring is carried out to obtain multiple monitoring data of the roadway section; a roadway section two-dimensional monitoring information plane graph is constructed and compared to obtain the displacement of two sides of the roadway and the displacement of a top plate and a bottom plate. The monitoring method is advantaged in that the laser ranging module rotates multiple times without generating accumulated mechanical errors to influence the measurement precision; data analysis is carried out from the overall perspective byutilizing a two-dimensional monitoring information plane graph, so monitoring precision can be further improved.

Owner:NORTHEASTERN UNIV

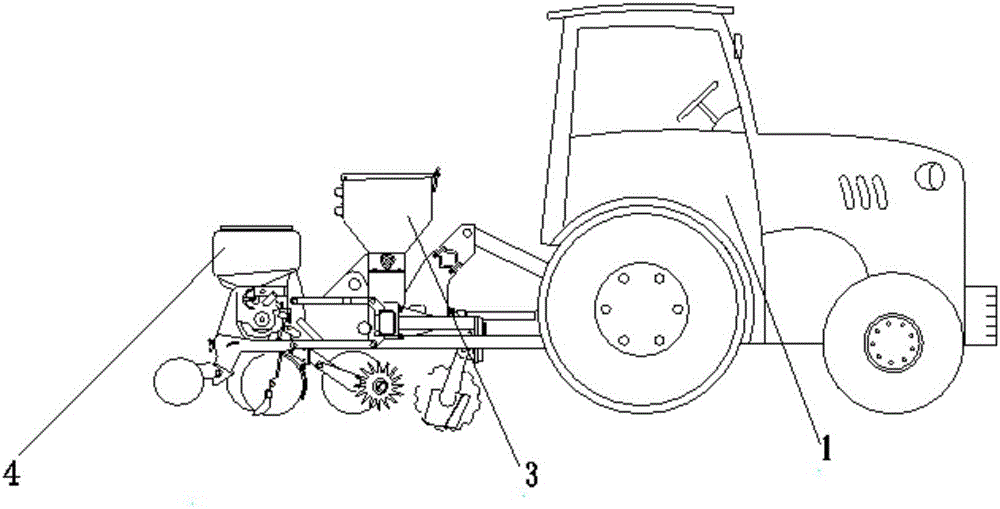

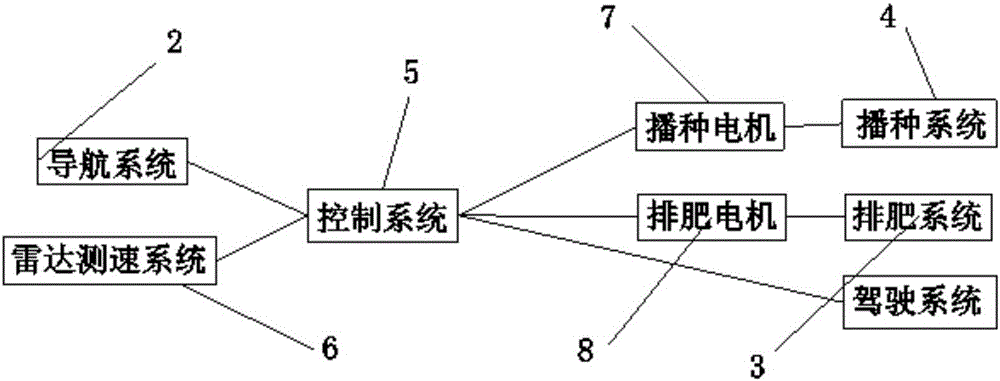

Unmanned intelligent precision seeder and control method thereof

InactiveCN105830595ANo deviationImplement variable seedingGuiding agricultural machinesSeed depositing seeder partsFertilizerEngineering

The invention discloses an unmanned intelligent precision seeder and its control method. system and a fertilizer discharge system, the seeder also includes a navigation system, a radar speed measurement system and a control system, and the navigation system and the radar speed measurement system are respectively connected to the input of the control system by communication, and the output of the control system The ends are respectively connected with the seeding system, the fertilizer discharge system and the driving system of the tractor. Beneficial effects of the present invention: variable sowing, variable fertilization, etc. can be realized under the condition of unmanned driving.

Owner:北京德邦大为科技股份有限公司

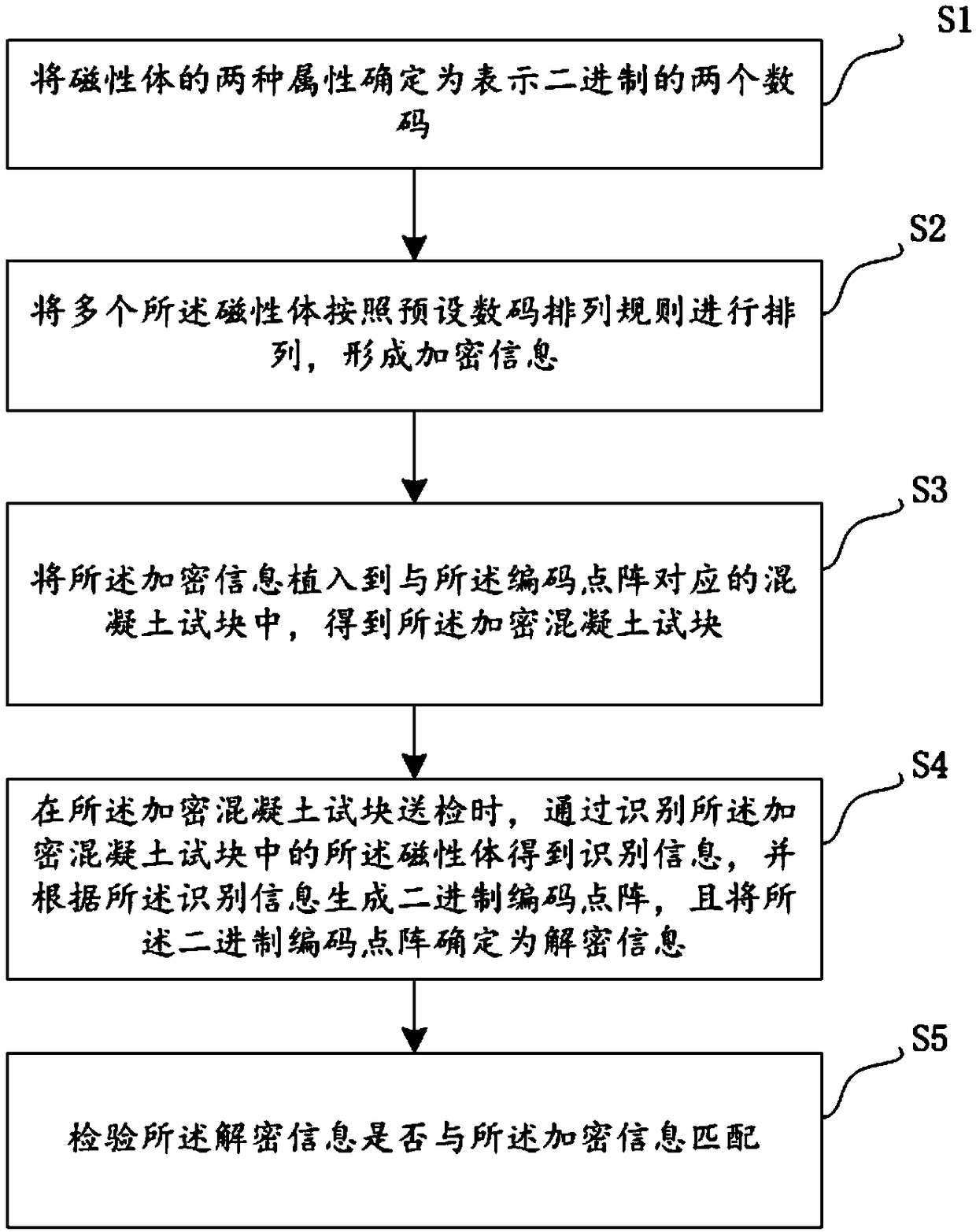

An intelligent management method and a system for a construction project concrete standard culture homoculture test block

InactiveCN109146712AImprove management efficiencyEnsure real qualityStampsData processing applicationsIntelligent managementComputer science

The invention relates to an intelligent management method and a system for a construction project concrete standard curing homoculture test block. The method comprises the following steps: S1, two attributes of a magnetic body being determined as two numbers representing binary; 2, arranging a plurality of magnetic bodies accord to a preset digital arrangement rule to form encrypted information; S3, embedding the encrypted information into the concrete test block corresponding to the encoded lattice to obtain the encrypted concrete test block; S4, when the encrypted concrete test block is sentfor inspection, identifying information obtained by identifying the magnetic body in the encrypted concrete test block, generating a binary encoded lattice according to the identifying information, and determining the binary encoded lattice as decryption information; 5, checking whether that decrypt information matches the encrypted information. Through the management method, the replacement of standard curing by the construction side and the submission of concrete test blocks under the same conditions are effectively prevented, and the concrete can not be tampered with after densification, thus ensuring the true quality of the construction project concrete.

Owner:四川广聚其力电子科技有限公司

Loading device for calibrating displacement sensor, and calibration method

ActiveCN107036517ANo deviationEasy to assemble and disassembleNuclear energy generationUsing electrical meansLine sensorBall screw

The invention discloses a loading device for calibrating a displacement sensor, and a calibration method. The loading device comprises a substrate, and the substrate is sequentially provided with a ball screw, a grating ruler and a linear guide rail in a parallel manner. A movable plate is disposed above the linear guide rail, the grating ruler and the ball screw. The movable plate is driven by the ball screw to move along the linear guide rail. The substrate or the movable plate is provided with fixing parts which are respectively used for fixing a stay wire sensor, an angular displacement sensor and a spring automatic telescoping displacement sensor, and enabling the stay wire sensor, the angular displacement sensor and the spring automatic telescoping displacement sensor to move with the movable plate to generate stay wire displacement, angular displacement and spring automatic telescoping displacement. The positions of the fixing parts of the three types of displacement sensors in the loading device are set compactly and reasonably. The device and method can complete the calibration of various types of displacement sensors with different ranges quickly and efficiently, and the disassembly of the sensors is convenient and simple. The data processing is quick and visual. The device is especially suitable for the calibration of a displacement sensor for an automobile impact test.

Owner:HANGZHOU JIPU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com