Lithium ion battery automatic dismantling device

A lithium-ion battery and automatic technology, which is applied in the field of lithium-ion batteries, can solve the problems of low efficiency, unsmooth charging of the shell, and high heat generation of the cutting knife, so as to ensure the working environment and solve the problem of barbs and temperature rise on the cutting surface Higher, the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, in order to facilitate the understanding of the present invention, but the present invention is not limited to the listed embodiments.

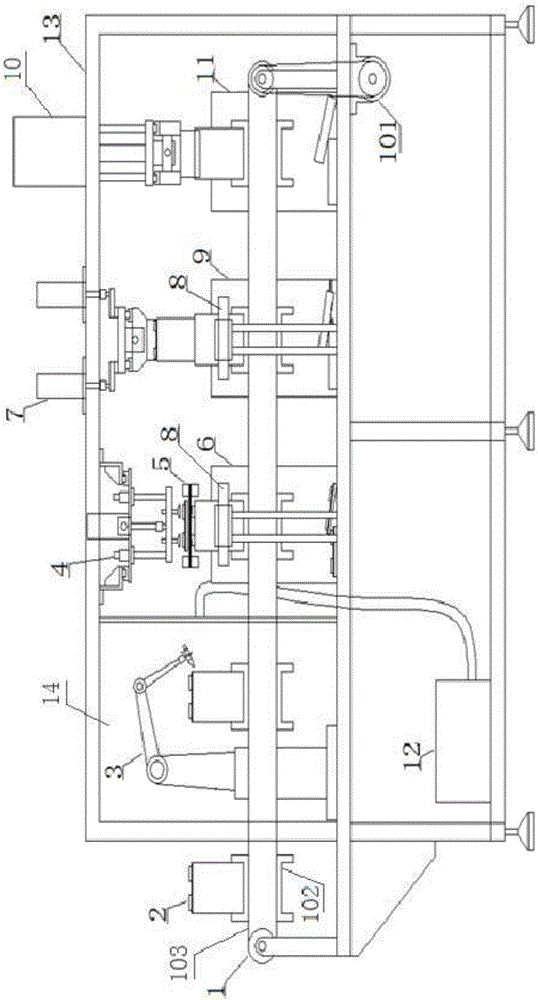

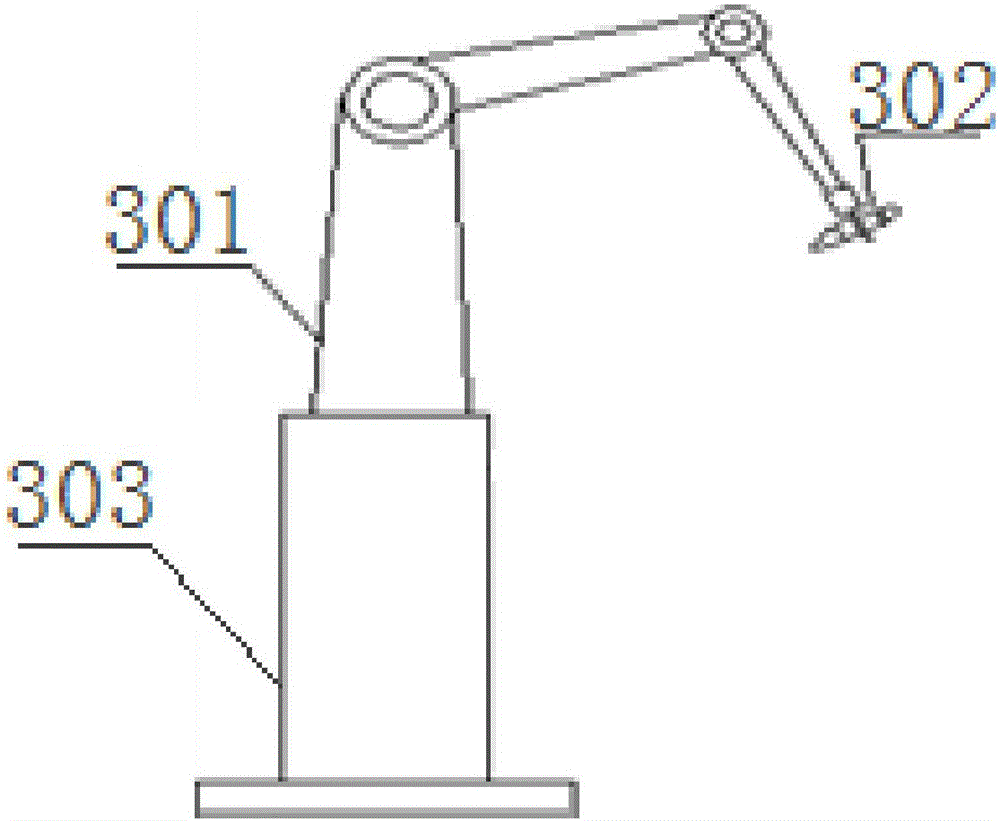

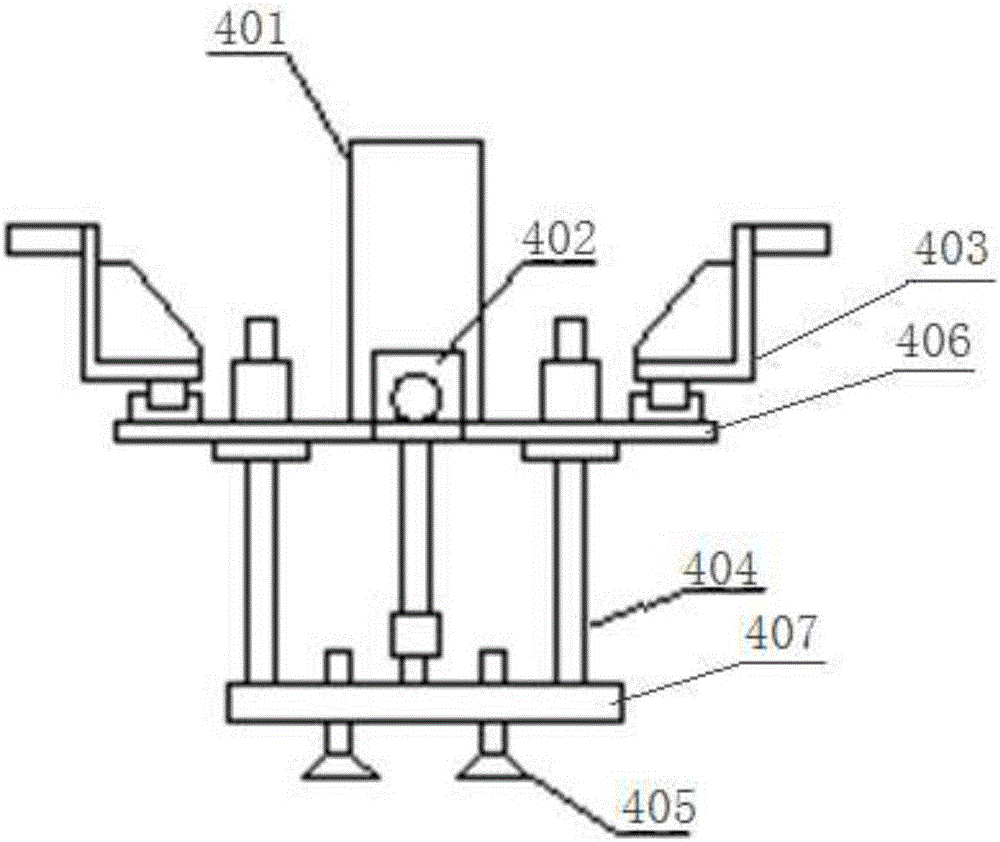

[0031] like figure 1 As shown, a lithium-ion battery automatic disassembly equipment includes a frame 13 and a recycling carrier 1 for transporting waste batteries 2, and the bottom of the frame 13 on one side of the recycling carrier 1 is sequentially fixed with a cover recovery box 6, Cell recovery box 9, shell recovery box 11; the bottom of the frame 13 is sequentially fixed with a cutting manipulator 3 for circularly cutting the shell of the waste battery 2 along the running direction of the circulation carrier 1 and two for recycling the waste battery. 2. The shell clamping mechanism 8 for clamping and fixing the shell; the top of the frame 13 is sequentially erected along the running direction of the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com