Patents

Literature

620results about How to "Guaranteed working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fan framework machining machine

InactiveCN102689257AAvoid playingProtection securityGrinding machinesGrinding/polishing safety devicesAgricultural engineeringMechanical equipment

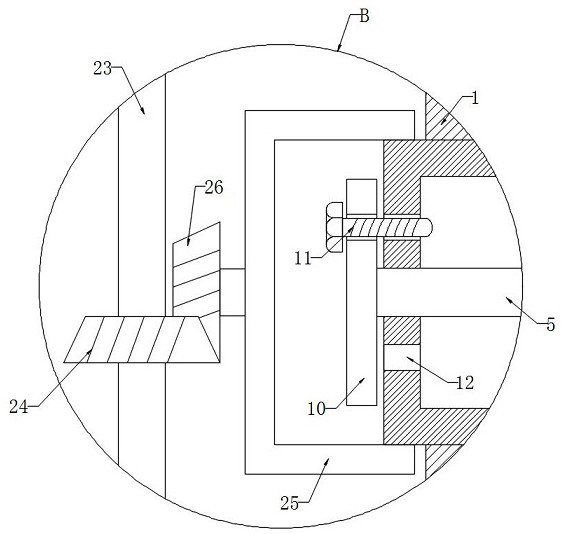

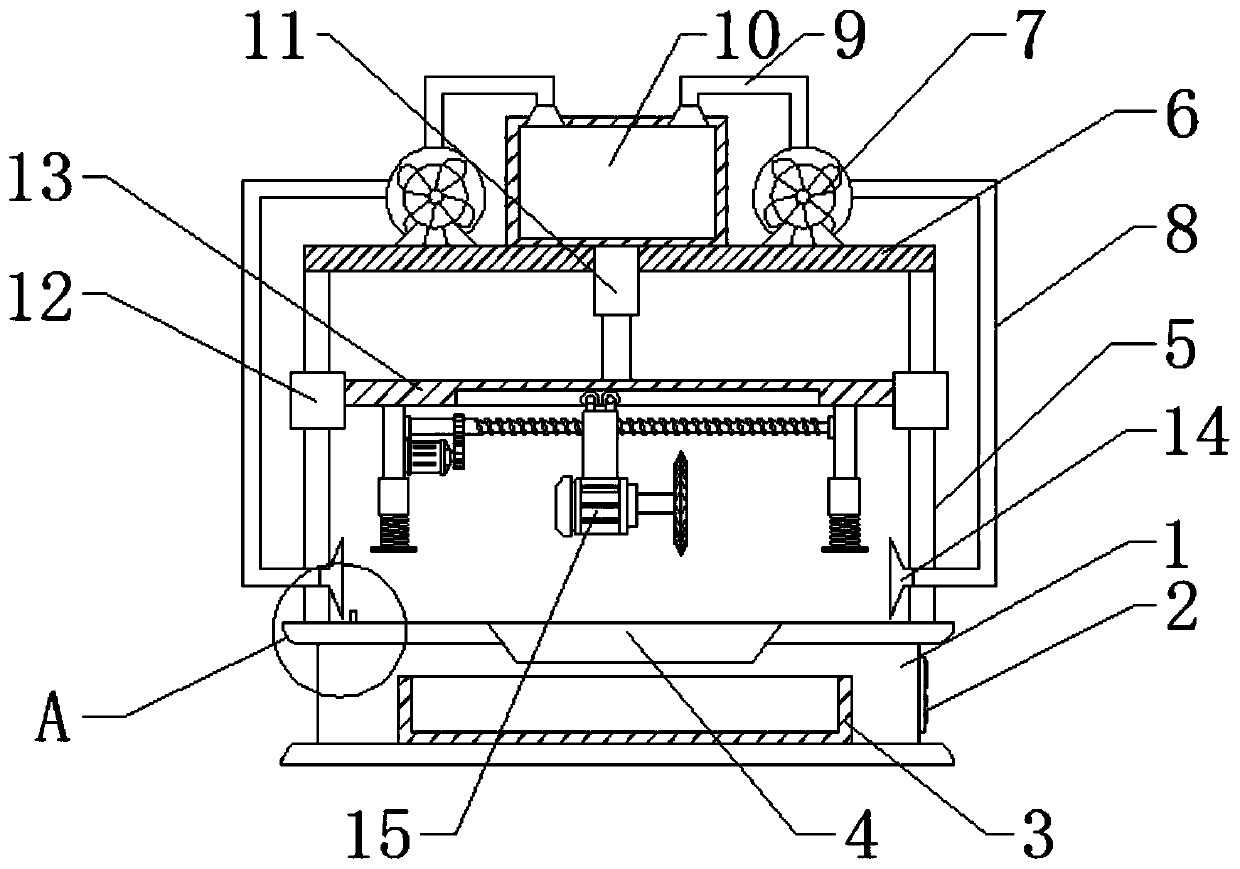

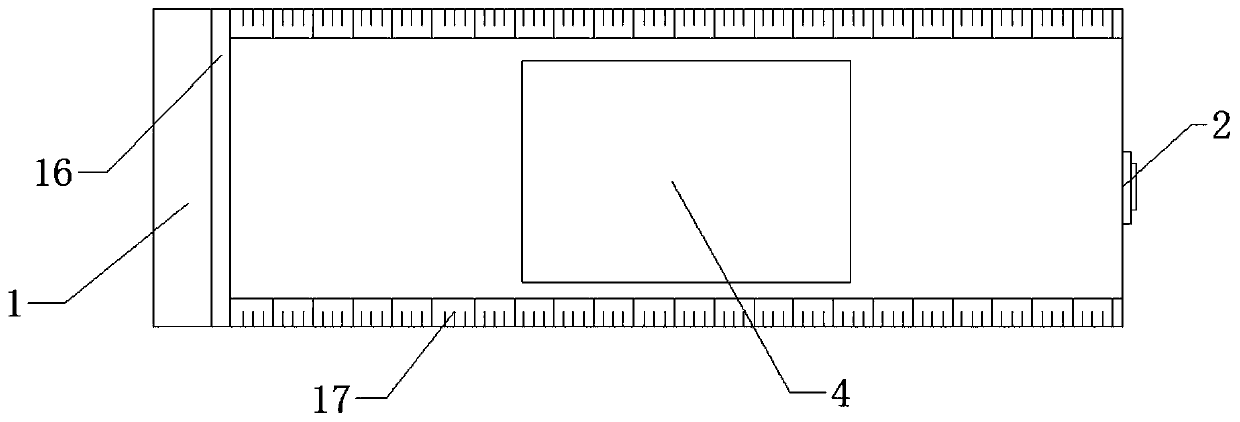

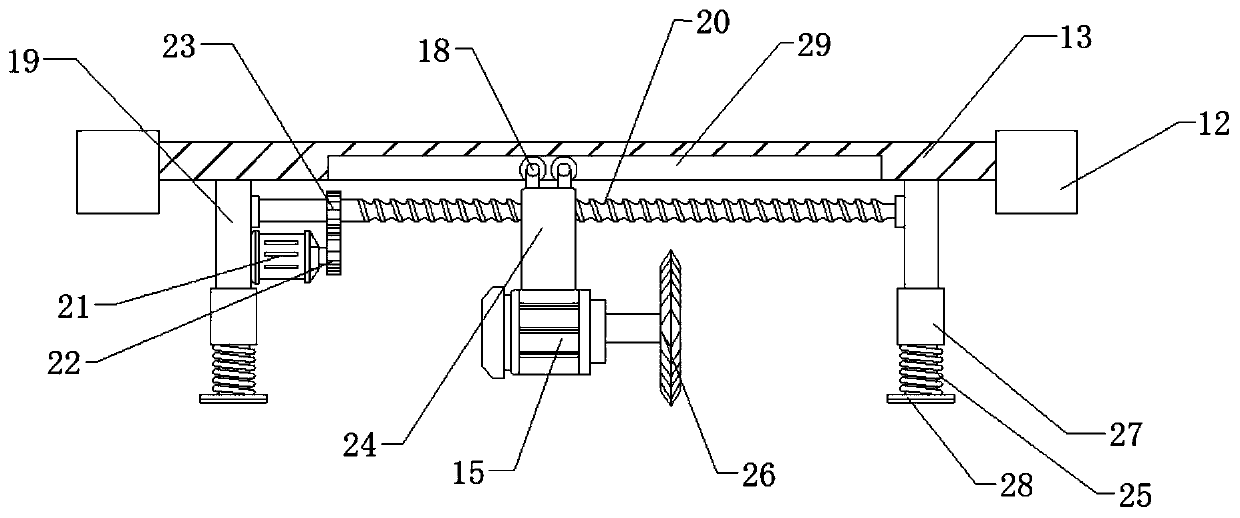

The utility model belongs to the technical field of fan manufacturing equipment tools, and particularly relates to a fan framework machining machine. The invention discloses the fan framework machining machine, which comprises a rack, wherein the rack is provided with a grinding wheel; the grinding wheel is connected with a motor; the rack is movably connected with a sliding plate; the sliding plate is provided with a clamp and a cylinder; the clamp comprises a fixed clamp and a movable clamp; the movable clamp is connected with the cylinder through a push rod; the clamp can approach the grinding wheel under the driving of the sliding plate until to the space below the grinding wheel; and a water spray pipe is arranged on the rack on one side of the grinding wheel. According to the fan framework machining machine, mechanical equipment is used for machining a fan framework, the step of grinding the fan framework is finished better and quickly, the efficiency is increased, the labor cost is saved, and meanwhile, large-scale production of fans can be realized, so that the conventional manual machining becomes mechanical production.

Owner:DEQING XINGYITAI ARTS & CRAFTS

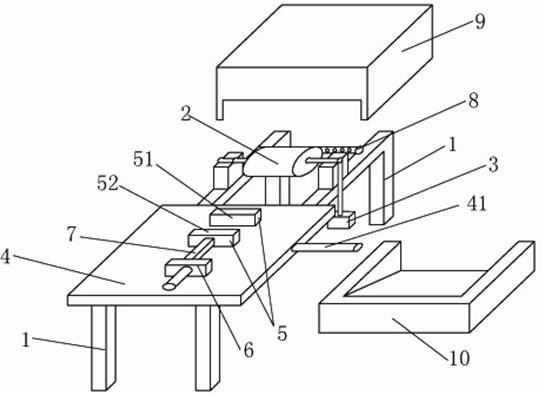

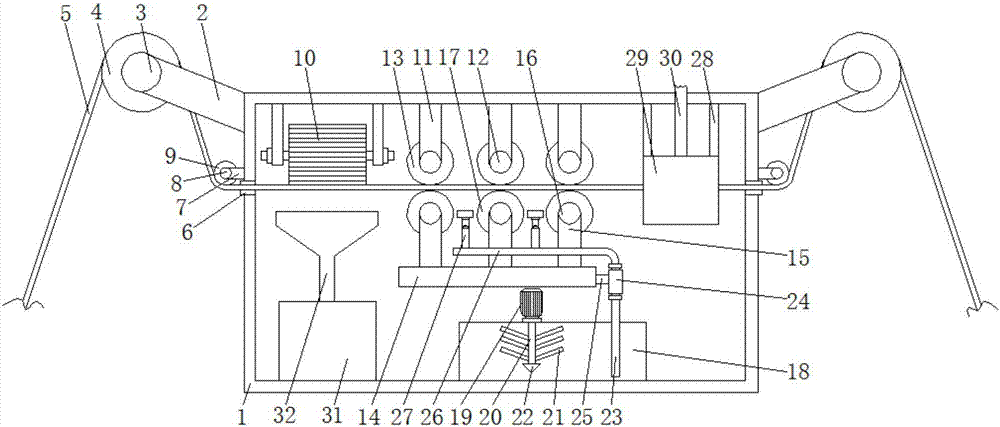

Lithium ion battery automatic dismantling device

ActiveCN106058357ANo deviationTimely recyclingWaste accumulators reclaimingBattery recyclingElectrical batteryEngineering

The invention provides a lithium ion battery automatic dismantling device comprising a frame and a circulation carrier for transferring a waste battery; the frame bottom located at one side of the circulation carrier is successively fixedly provided with a cover plate recycling box, an electric core recycling box, and an outer shell recycling box; the bottom of the frame is successively fixedly provided with a cutting manipulator for annular cutting of a waste battery shell body and two outer shell clamping mechanisms for clamping and fixing the waste battery shell body along the running direction of the circulation carrier; the top of the frame is successively erected with a cover plate recycling mechanism for clamping a waste battery cover plate, an electric core taking-out mechanism for clamping a waste battery electric core, and an outer shell transfer mechanism for clamping the waste battery shell body along the running direction of the circulation carrier; the cover plate recycling mechanism and the electric core taking-out mechanism are respectively located at the top ends of the two outer shell clamping mechanisms; an electrode ear cutting mechanism for cutting a waste battery electrode ear is arranged between the cover plate recycling mechanism and the outer shell clamping mechanism. The automation degree is improved, the work efficiency is increased, and the intensity of work is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

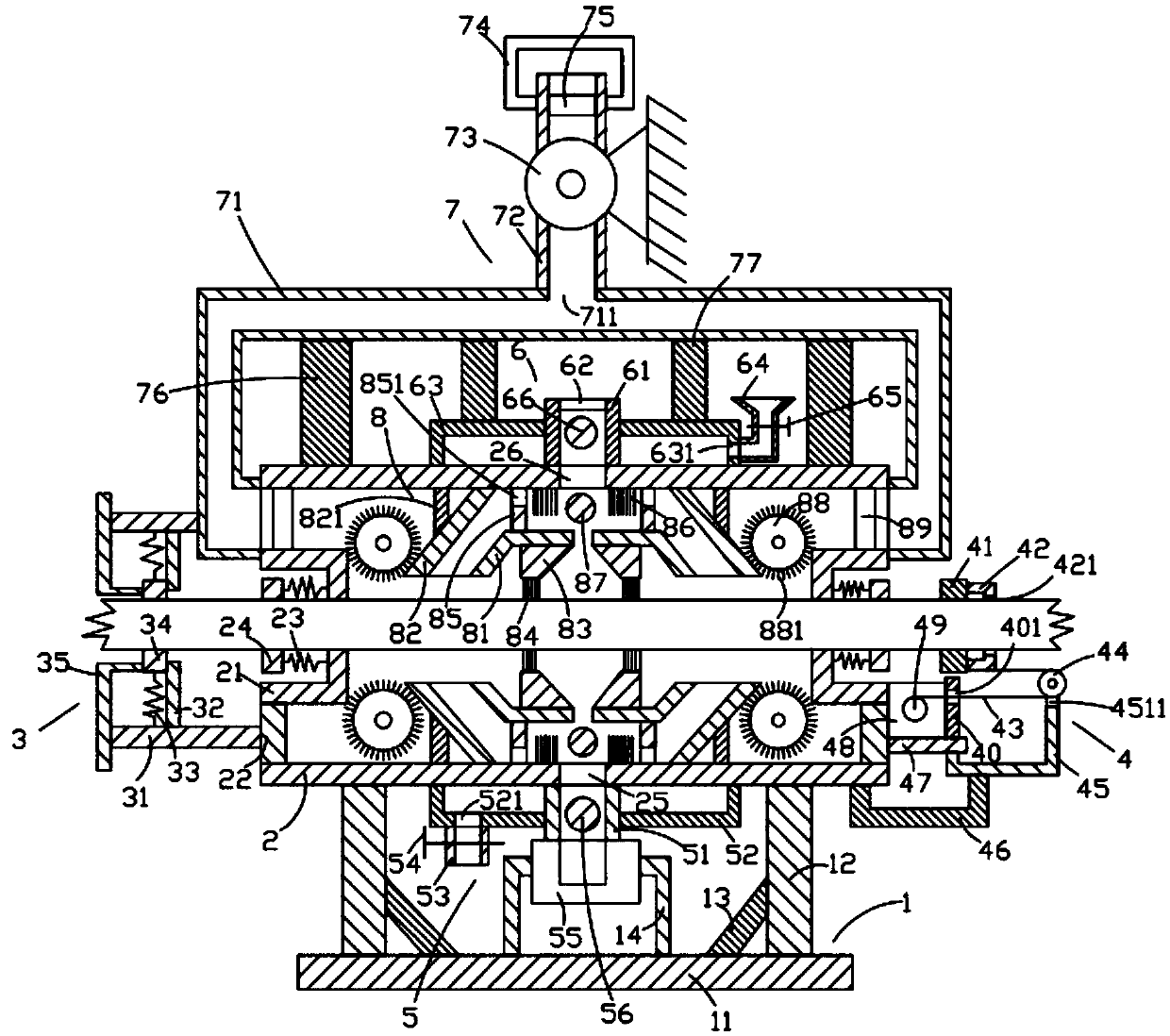

Equipment for processing plastic bottle cap by extrusion compression molding

ActiveCN102837412AQuality assuranceGuaranteed working environmentDomestic articlesCompression moldingEngineering

Equipment for processing a plastic bottle cap by extrusion compression molding is characterized by comprising a stand, wherein an extrusion mechanism, a scraping and feeding mechanism, a compression molding cap producing mechanism, a demolding mechanism, a cutting ring mechanism and a heat-insulating and dehumidifying mechanism are arranged on the stand; the extrusion mechanism comprises a feeding hopper, a charging barrel and an extrusion port; a reinforced feeding screw is arranged in the feeding hopper; a scraping and capping mechanism comprises a scraping shaft; a scraping disk and a cap toggling disk are arranged on the scraping shaft; a scraping knife is arranged in the scraping disk and is matched with the extrusion port; a compression molding machine comprises a main shaft; a lower mold plate is arranged on the main shaft; an upper mold plate and an upper fixing plate are arranged on the lower mold plate; a lower mold is arranged in the lower mold plate; an upper mold and a push rod are arranged in the upper fixing plate; one side of the cap toggling disk is connected with a cap conveying slideaway; the other end of the cap conveying slideaway is connected with the cutting ring mechanism; a heat-insulating and dehumidifying system comprises an upper mold; a heat-insulating sleeve is arranged outside a cooling water pipe of the upper mold; an air cooler is arranged on the stand; and a blowing port of the air cooler is opposite to the compression molding cap producing mechanism.

Owner:TAIZHOU HUANGYAN KAIPU MACHINERY

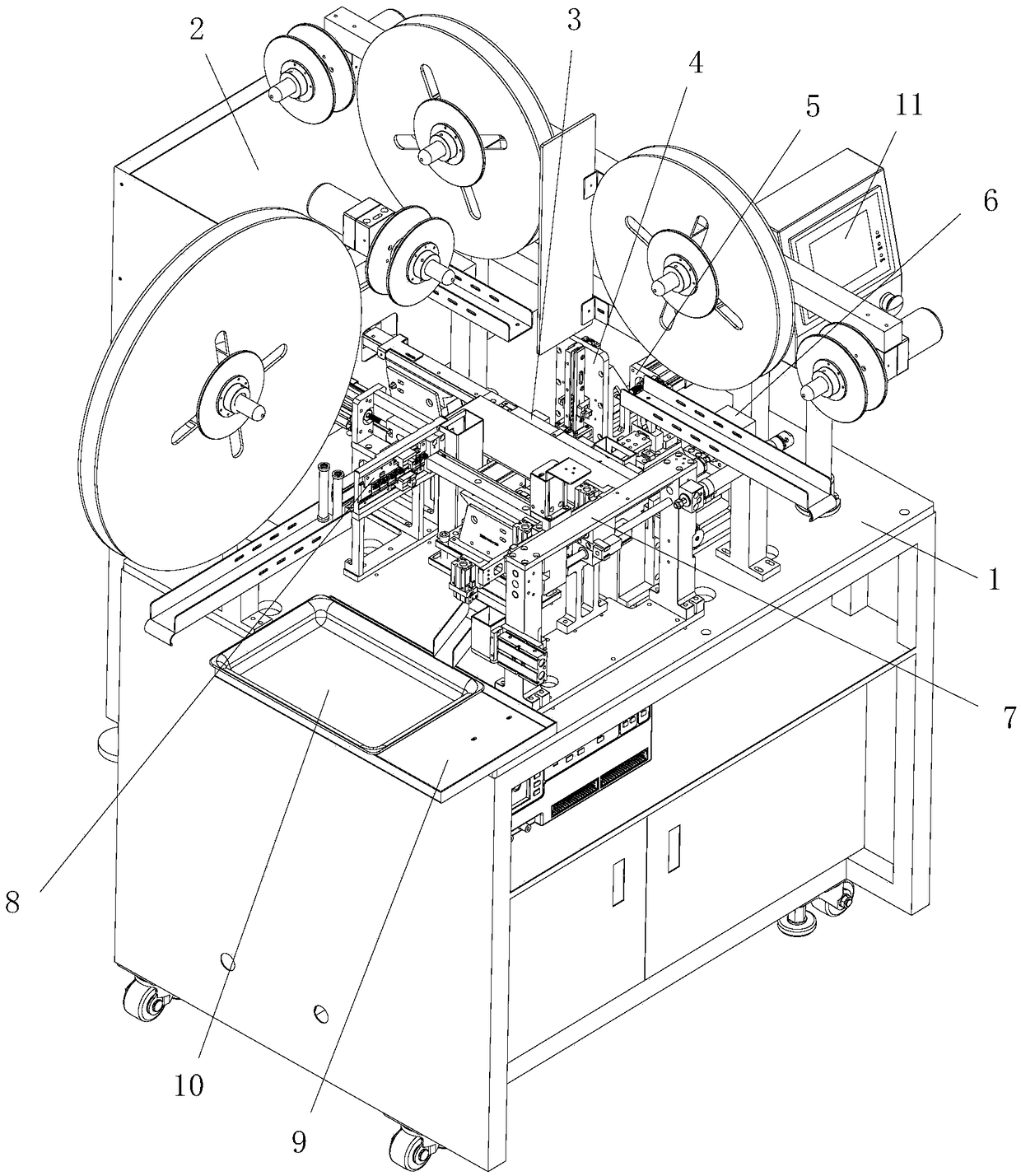

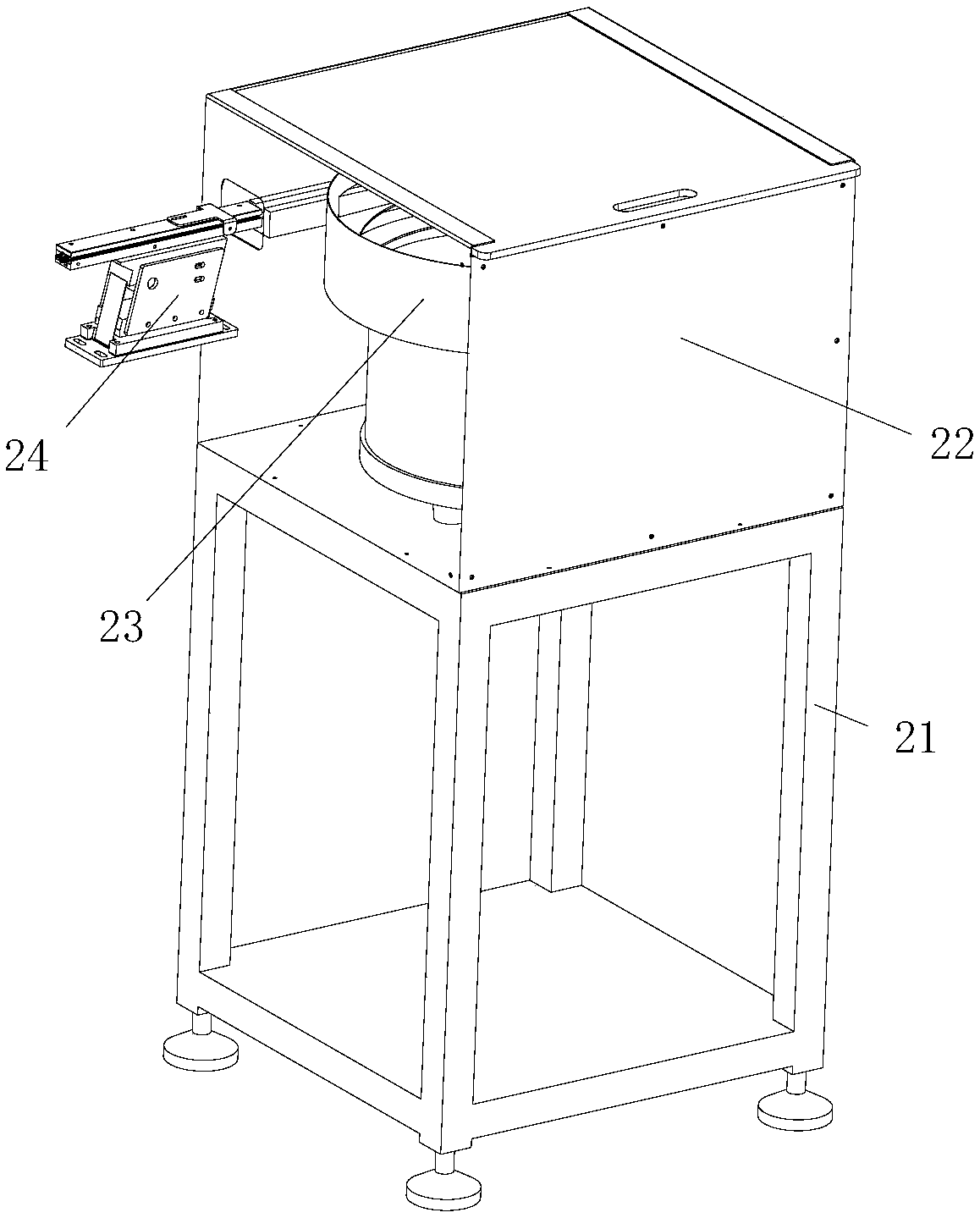

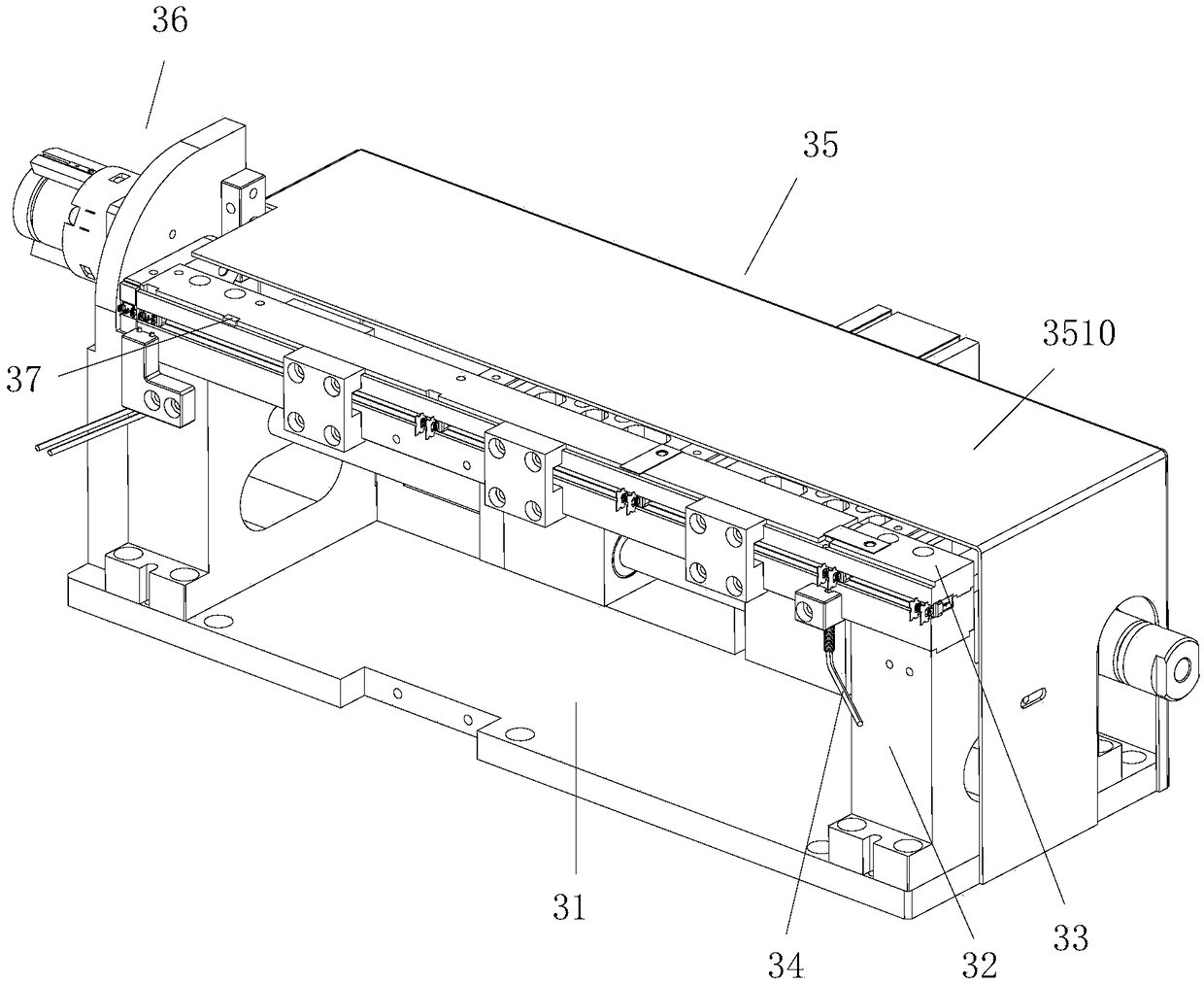

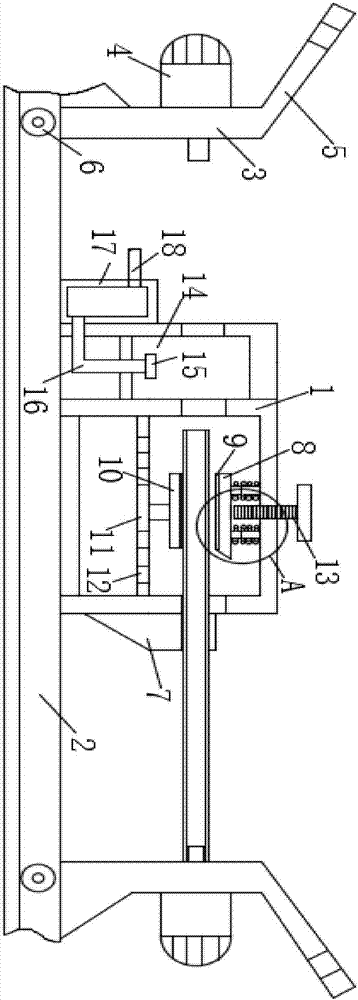

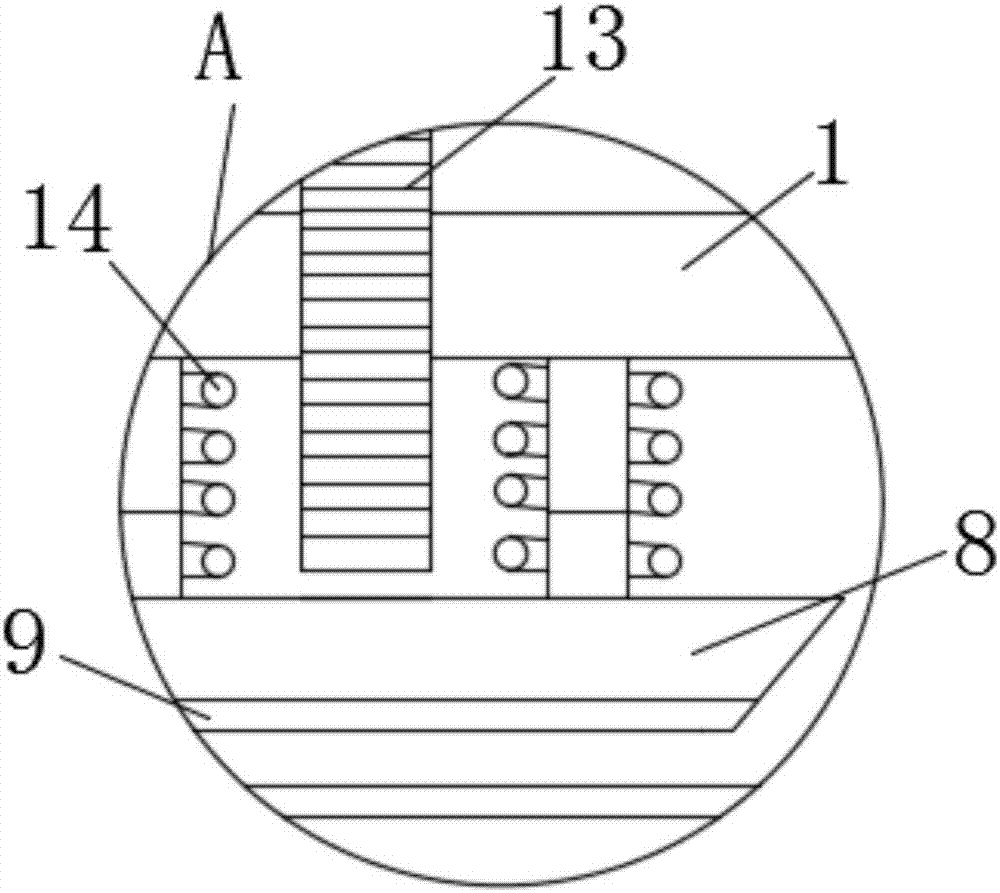

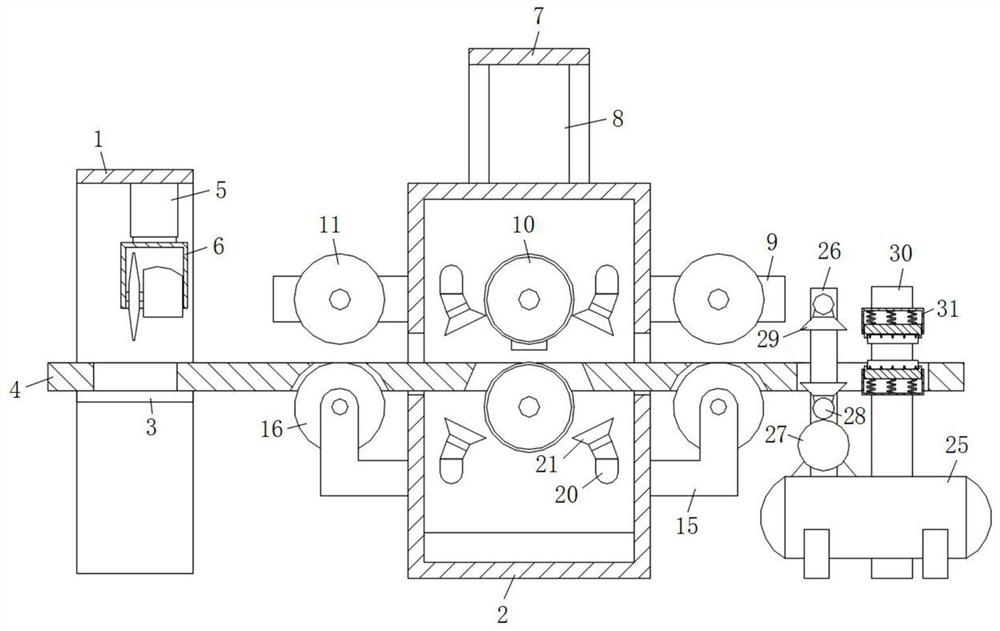

Connector automatic assembly and production device

PendingCN108832457AGuaranteed working environmentSimple structureContact member assembly/disassemblyEngineeringMechanical engineering

The invention discloses a connector automatic assembly and production device. The connector automatic assembly and production device comprises a rubber core feeding mechanism, a linear processing flowchannel, a double-terminal inserting mechanism, a sweeping belt mechanism, a riveting mechanism, an assembly mechanism, an iron shell cutting feeding mechanism, a material receiving tray, a materialtray and a control panel which are arranged on a frame. The rubber core feeding mechanism transports rubber cores to the linear processing flow channel on the right side of the rubber core feeding mechanism. The double-terminal inserting mechanism, the sweeping belt mechanism and the riveting mechanism are successively located at the rear side of the linear processing flow channel. The double-terminal inserting mechanism is inserted into the rubber core. The sweeping belt mechanism is configured to remove residual materials on a terminal. The riveting mechanism is configured to position and implant the terminal and the rubber core. The iron shell cutting feeding mechanism transports an iron shell to the assembly mechanism on the right side of the iron shell cutting feeding mechanism. The assembly mechanism transports assembled workpieces to the material receiving tray and the material tray. The connector automatic assembly and production device is simple in structure, can automaticallyassemble connectors in place of workers, has high assembly efficiency and saves cost.

Owner:SUZHOU E CONN TECH

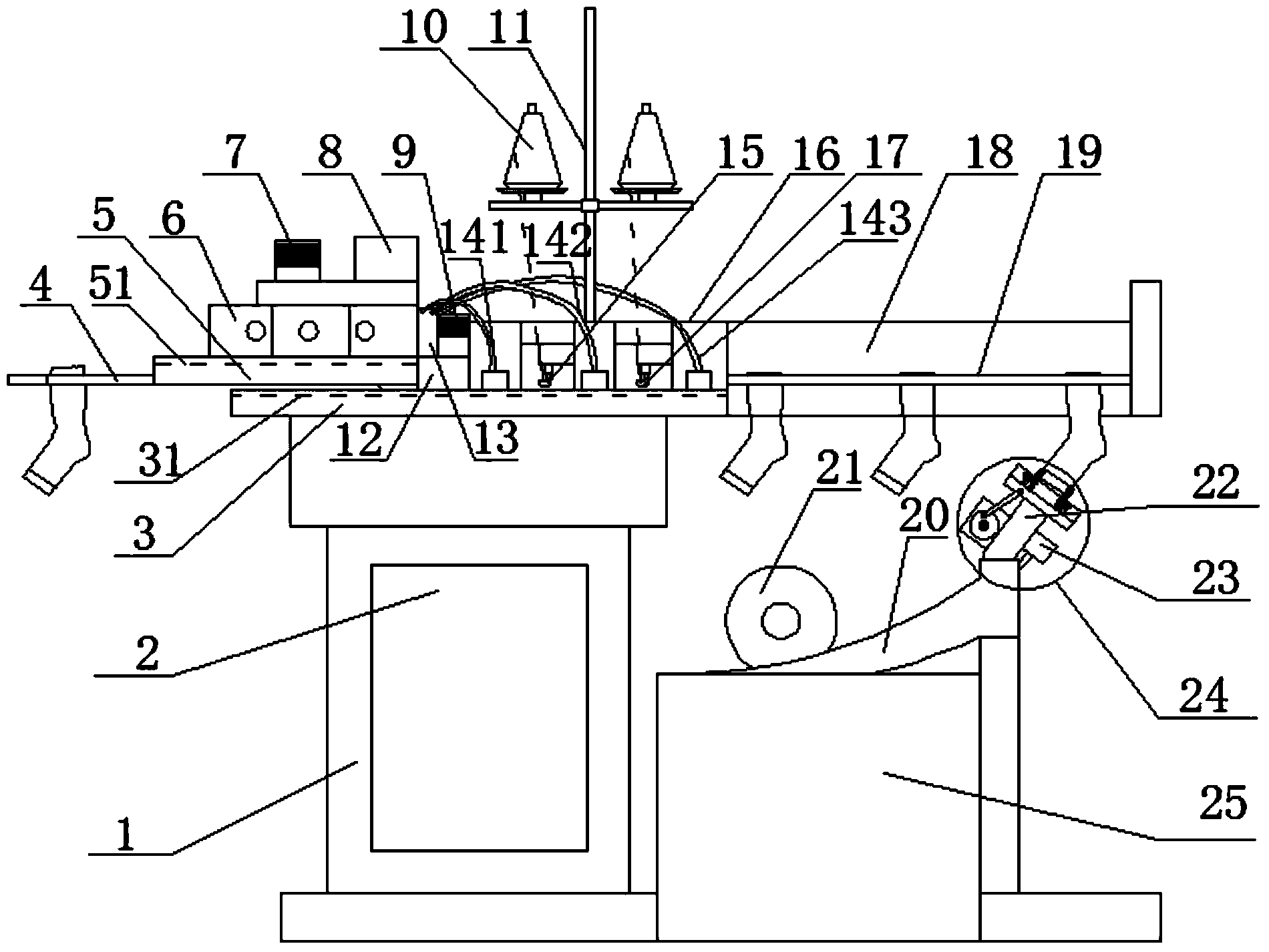

Sock production device

ActiveCN104233634ARealize automatic flippingBeautiful stitchesMechanical cleaningPressure cleaningSOCKSElectric machinery

The invention discloses a sock production device. The sock production device comprises a rack, a feeding device, a waste material recovery device, a sewing box, a discharging device and a sock turning device, wherein the feeding device comprises a guide rail, a guiding frame, a guiding box, a feeding box and a first electric motor component; the waste material recovery device comprises a negative air pressure pumping device and a pipeline, the negative air pressure pumping device is arranged on the rack, and one end of the pipeline is connected to the negative air pressure pumping device; the sewing box is fixedly arranged on the rack and is sequentially and fixedly provided with a first sewing head and a second sewing head from left to right; the right end of the rack is fixedly provided with the discharging device, the discharging device is provided with a discharging guide rail, the lower part of the discharging guide rail is provided with a sock guiding pipe, and the sock guiding pipe is provided with the sock turning device. According to the sock production device disclosed by the invention, socks can be automatically turned after the socks are sewed when a seam of a sock point is completely sewed, meanwhile, the situation that waster materials which are generated by the first sewing head, the second sewing head and a sock point cutting mechanism can be collected is realized, the automation degree is high, the working efficiency is increased, and the labor cost is reduced.

Owner:浙江圣邦化纤针织有限公司

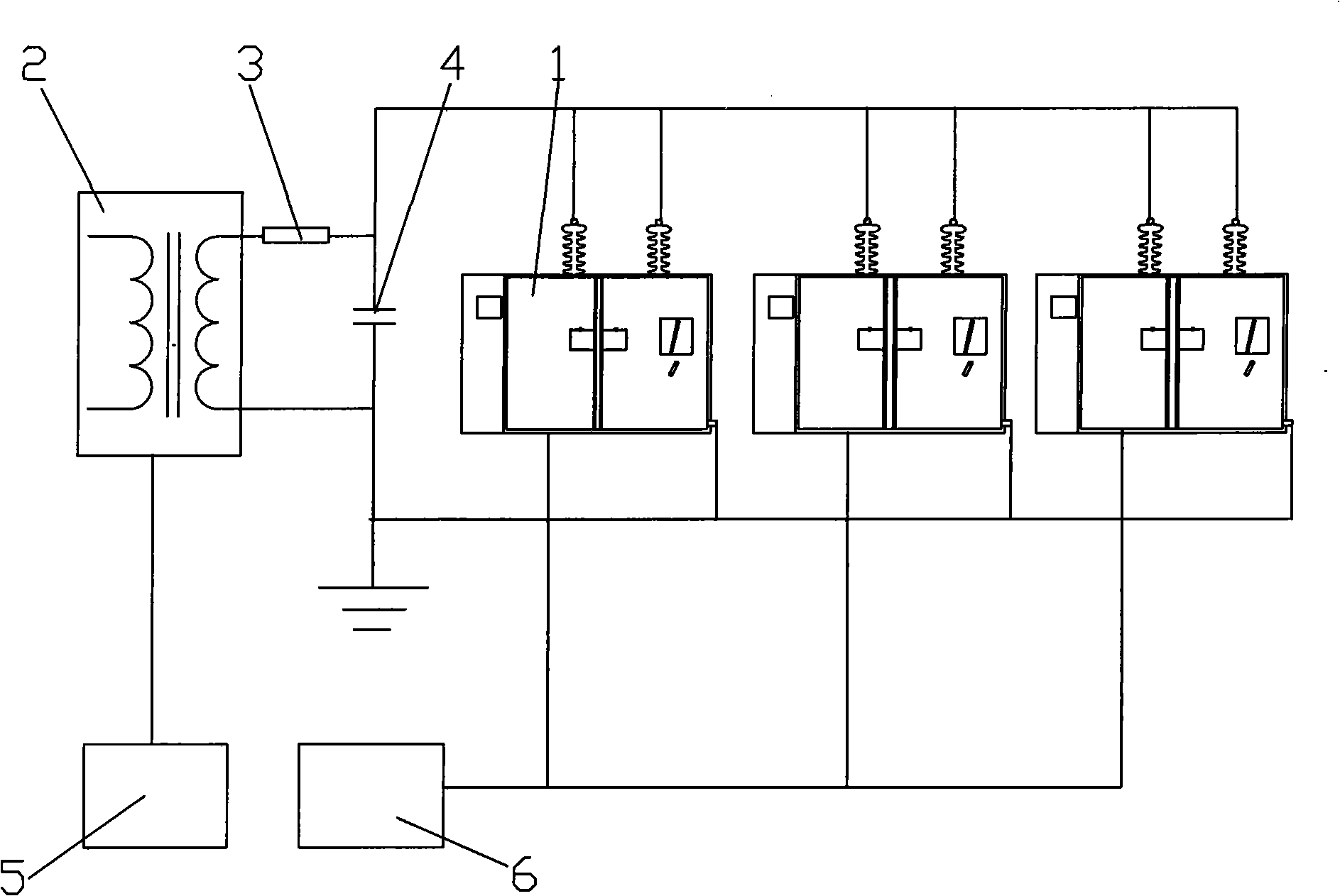

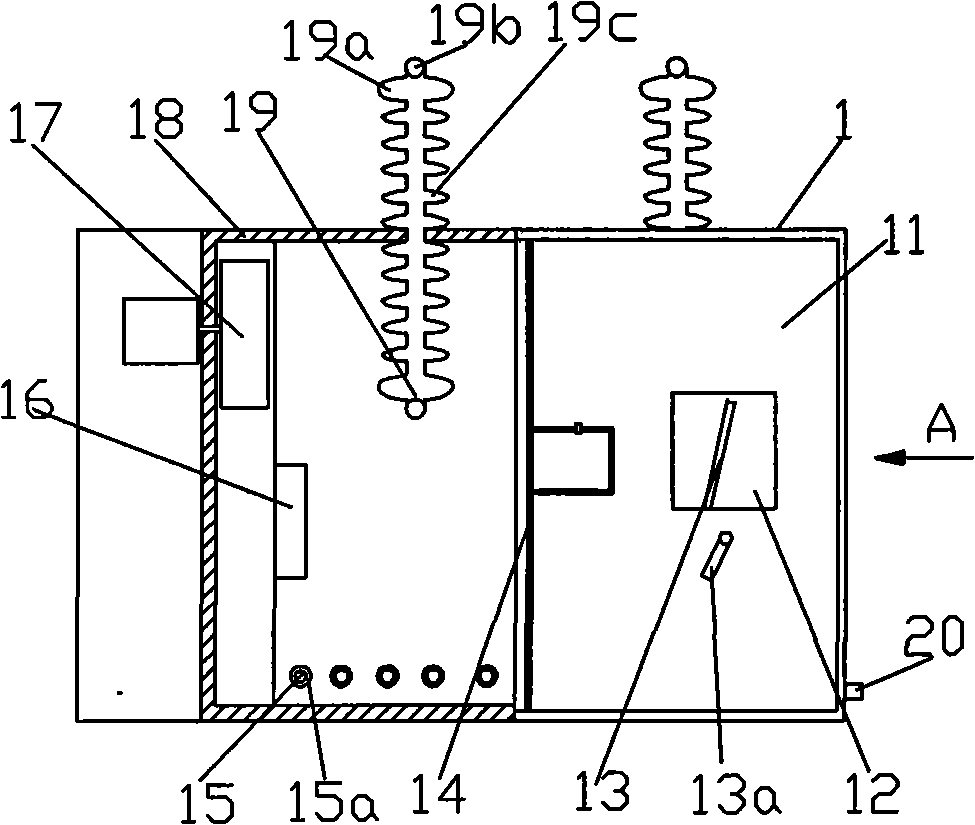

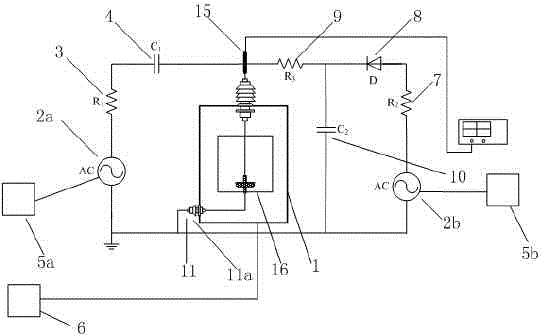

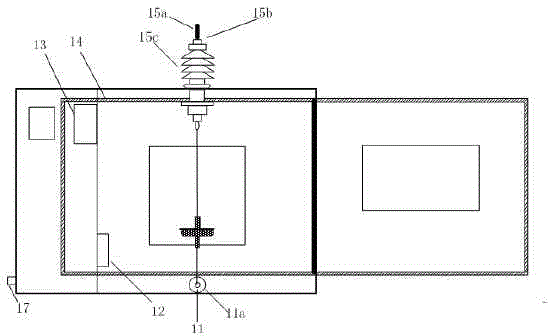

Electrical insulation electric heating ageing testing equipment

InactiveCN101285867AAvoid condensationAvoid thermal failureTesting dielectric strengthTransformerTest sample

The invention discloses electric insulation electric-heating aging test equipment, which comprises non-vignetting high-voltage testing transformer and at least one test box, wherein the box body of the test box is adiabatic; the inside of the test box is provided with a heating device; the top of the test box is provided with at least one high-voltage electrode connected with the high-voltage output end of the non-vignetting high-voltage testing transformer, while the lower part is provided with at least one detection terminal; and the high-voltage electrode and the detection terminal are respectively insulated from the box body of the test box. The electric insulation electric-heating aging test equipment can effectively simulate the electrical and thermal stress on electric equipment during operation, and carries out experiment on a plurality of test samples under different temperatures, voltage types and voltage grades; moreover, the test equipment obtains the data of current waveform and local discharging signal during the aging process of test samples.

Owner:CHONGQING UNIV

Continuous building wall grinding device

InactiveCN107263234AEasy to polishPromote absorptionGrinding carriagesGrinding drivesArchitectural engineeringElectrical control

The invention discloses a continuous building wall grinding device. The continuous building wall grinding device comprises a base, wherein drive wheels are arranged on four corners at the lower side of the base; an electrical control box is arranged at the left end of the upper side of the base; slide slots are formed in the left end and the right end of the upper side of the base; first motors are arranged at the lower ends inside the slide slots; first lead screws are arranged at the upper sides of the first motors; first slide blocks are arranged on the first lead screws; first connecting rods are arranged inside the first slide blocks; right sides of the first connecting rods are equipped with motor boxes; second motors are arranged inside the motor boxes; right sides of the second motors are equipped with second lead screws; second slide blocks are arranged on the second lead screws; telescopic poles are arranged at the rear sides of the second slide blocks; the rear sides of the telescopic poles are connected with connecting covers; grinding devices are arranged inside the connecting covers; the lower sides of the connecting covers are equipped with a first connecting tube; the front side of the first connecting tube is equipped with a connecting hose; the front side of the connecting hose is equipped with a second connecting tube; and a dust collecting box is arranged at the front side of the second connecting tube. According to the continuous building wall grinding device disclosed by the invention, a lifting device, a dust absorbing device and telescopic poles are arranged, so that grinding of equipment can be convenient, and working efficiency is improved.

Owner:张峰

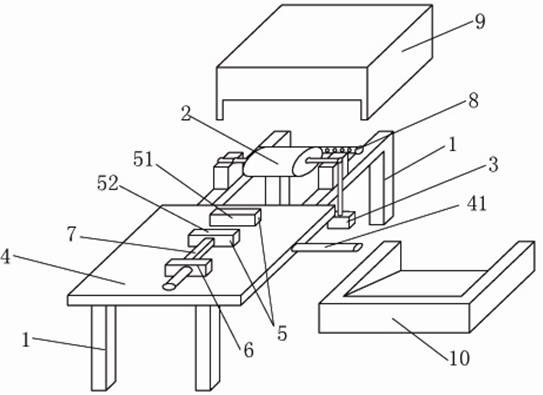

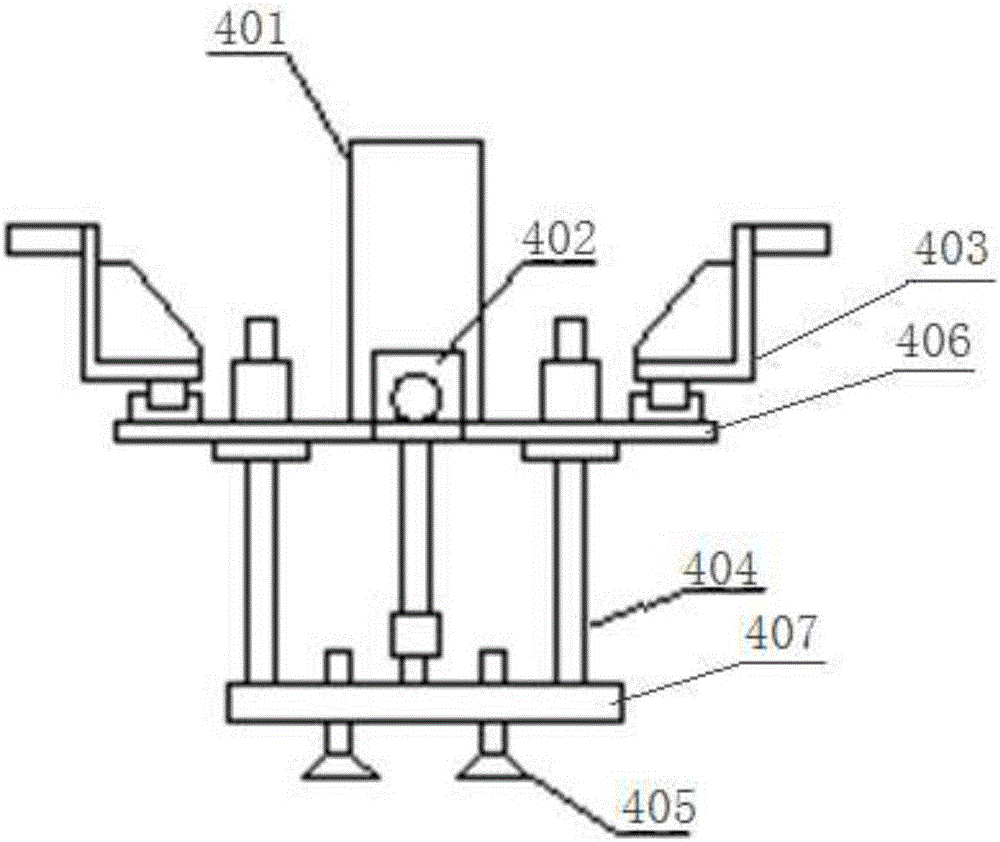

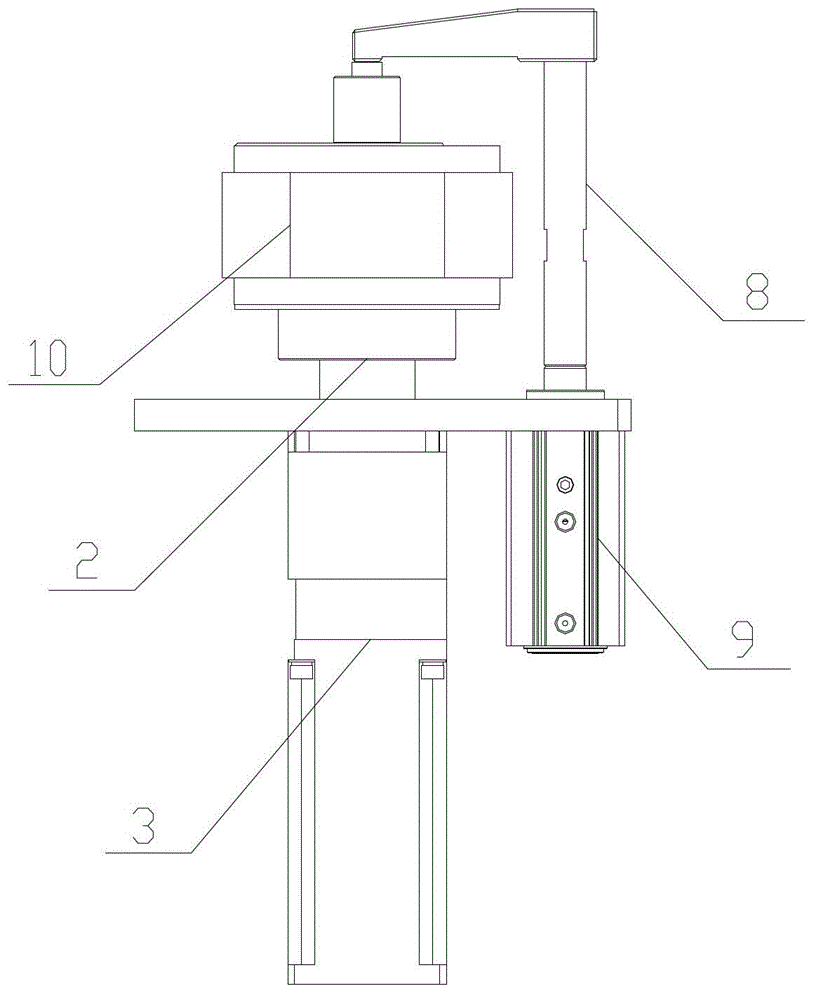

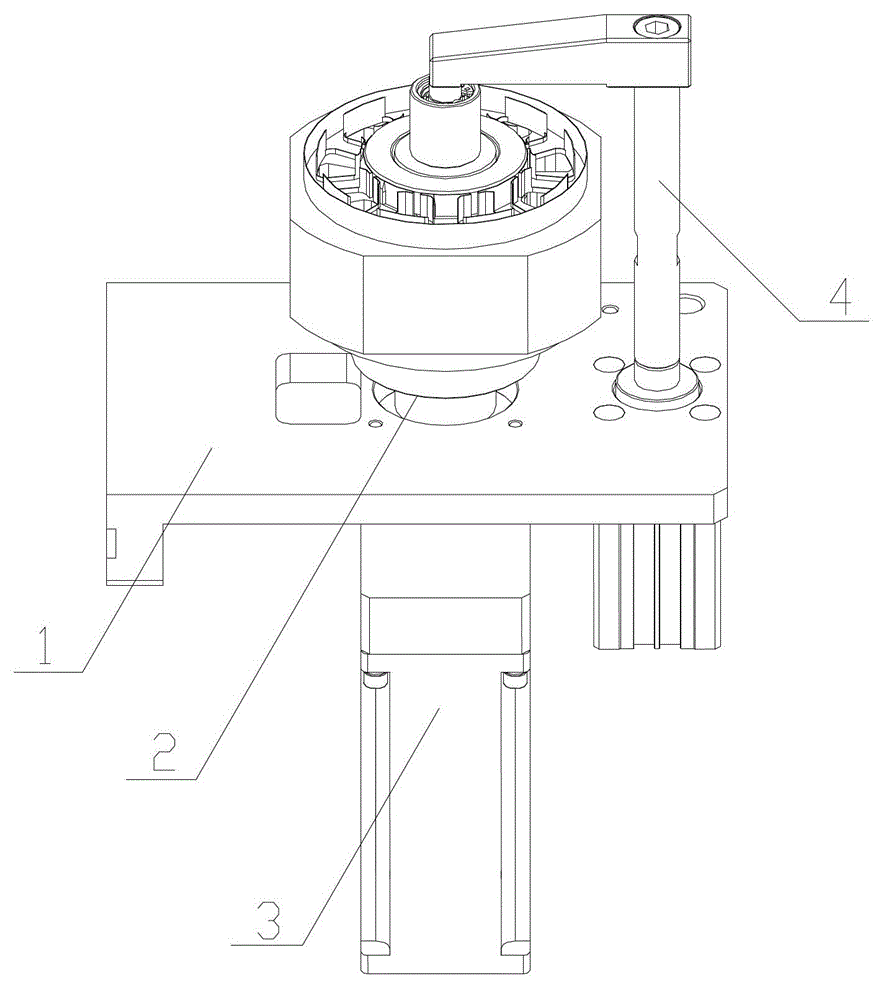

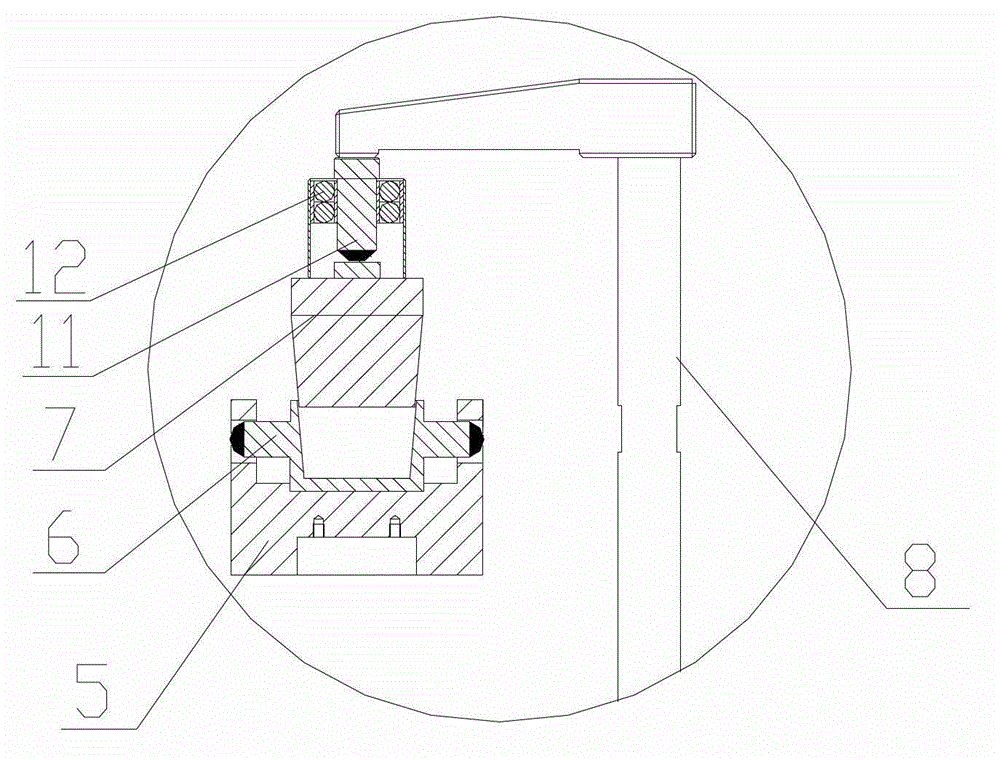

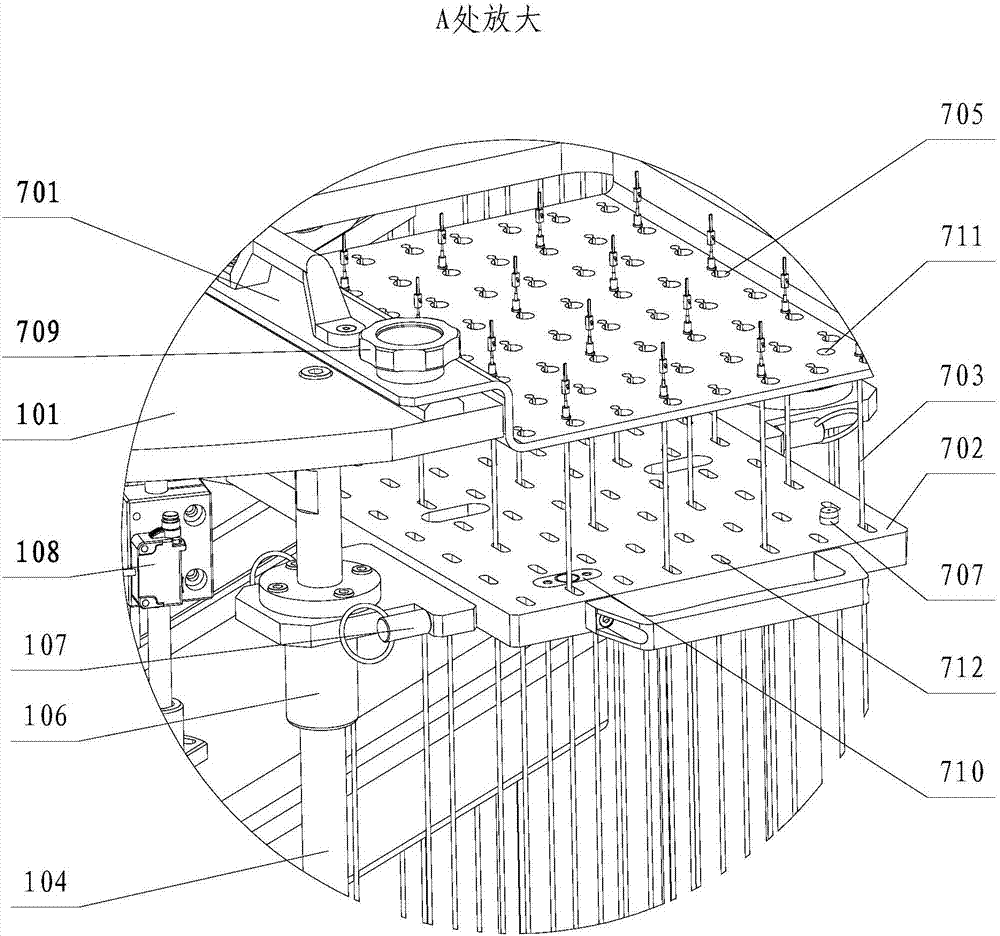

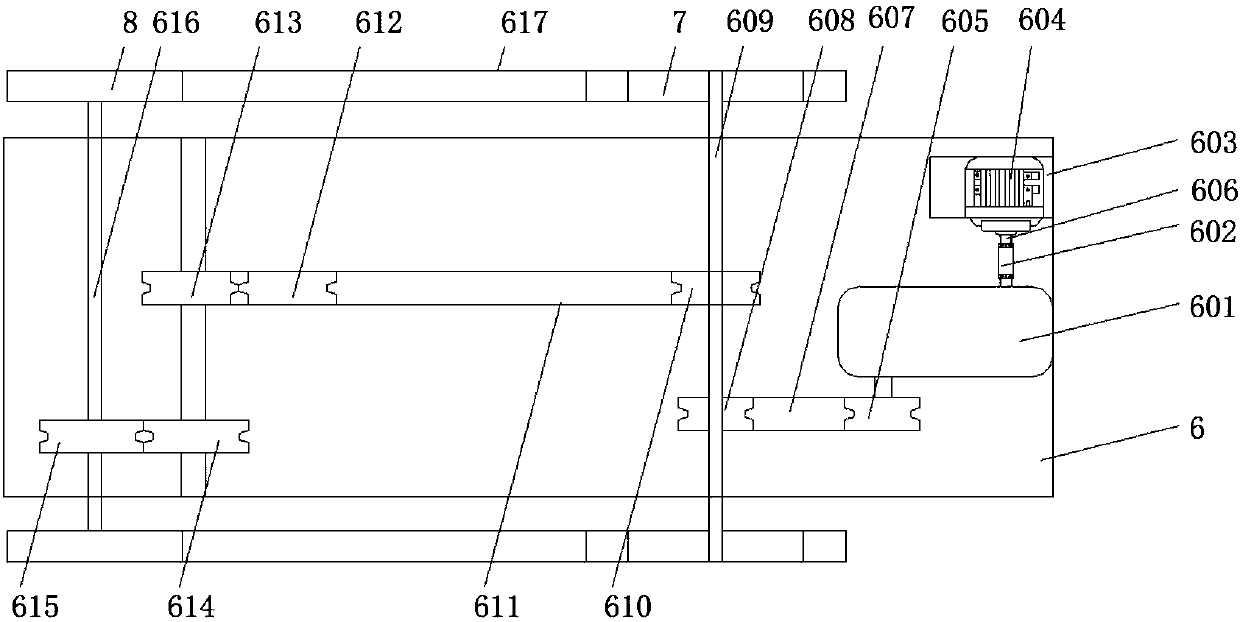

Stator clamping workbench used for pushing in insulation paper in stator

ActiveCN103337936ASafe working environmentSmooth switchingWindings insulation shape/form/constructionApplying solid insulationProcess engineeringWorkbench

The invention discloses a stator clamping workbench used for pushing in insulation paper in a stator, which mainly comprises a working platen, wherein a central hole is formed in the working platen; a rotary device is assembled in the central hole in the vertical direction; the rotary device is driven by a stator transposition motor; the stator transposition motor is fixed on the reverse side of the working platen; the working platen is further provided with a stator compressing device; the stator compressing device is vertical to the working platen and matched with the rotary device to compress a to-be-processed stator. Through the manner, the stator clamping workbench used for pushing in insulation paper in the stator is provided, and smooth switching of processing stations during the manufacturing process can be guaranteed through the power of the stator transposition motor; at the same time, an air cylinder is adopted for pushing a grasping rod to grasp a motor stator, convenience and high efficiency are ensured, and the work environment is guaranteed; a mechanical manner is utilized to position and hold out against the stator from the internal part of the stator, so external process is not affected.

Owner:圣玛特智能设备制造(浙江)有限公司

Dedusting and drying integrated printing-and-dyeing drying equipment

InactiveCN107339871AGuaranteed smoothImprove cleanlinessDrying gas arrangementsDrying machines with progressive movementsWorking environmentEngineering

The invention discloses a printing and dyeing drying equipment integrating dust removal and drying. A rotating shaft, the outer surface of the first rotating shaft is sleeved with unwinding rollers. The printing and dyeing drying equipment integrating dust removal and drying can effectively ensure the cleanliness of the fabric, effectively maintain the working environment of the equipment, avoid dust falling into the fabric again, and cause the fabric to be polluted again, effectively making the fabric quality better. Effectively spray the dye evenly onto the second electric printing and dyeing roller, which ensures the automation of the equipment, ensures the stable flow of the dye liquid, and avoids the excessive impact of the dye during stirring, which causes the equipment to shake, effectively It ensures the drying of the fabric, solves the problem of the fabrics sticking together, improves the quality of the fabric, and saves the drying time.

Owner:姚飞

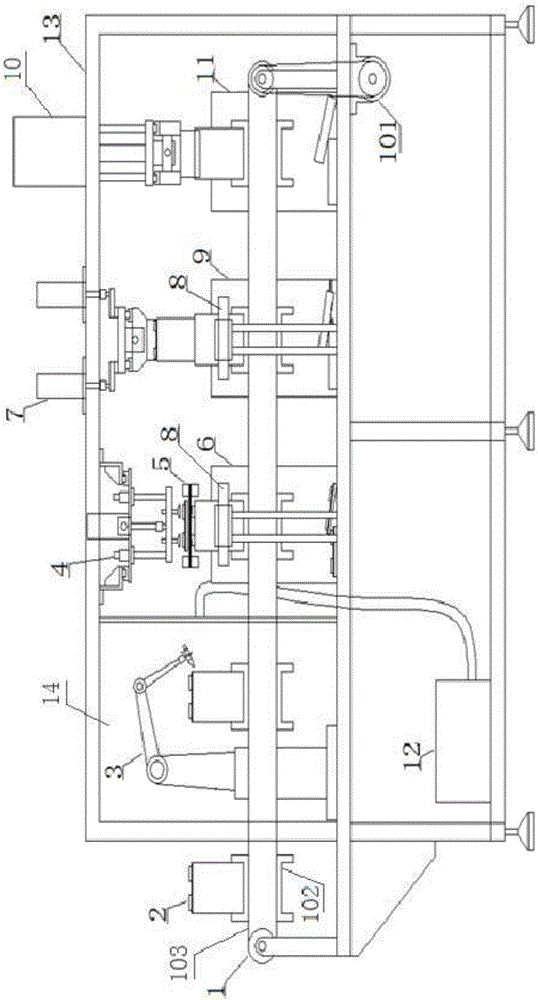

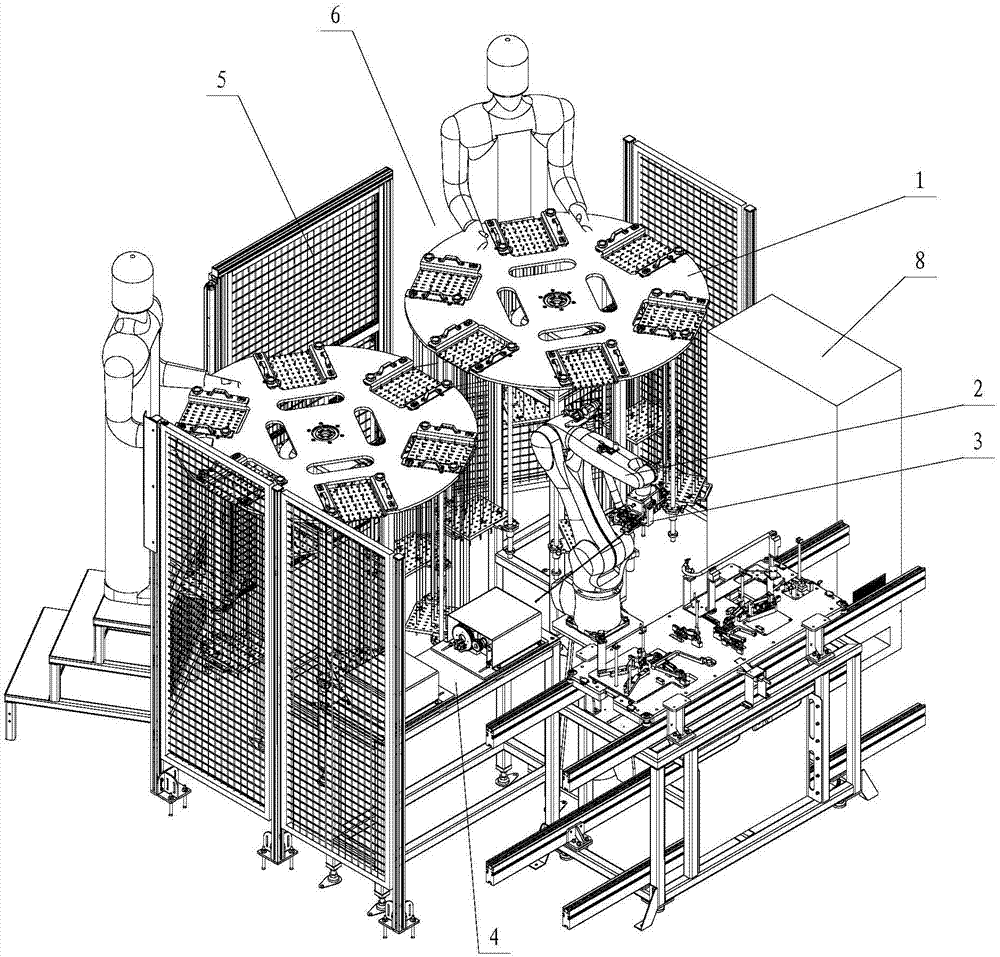

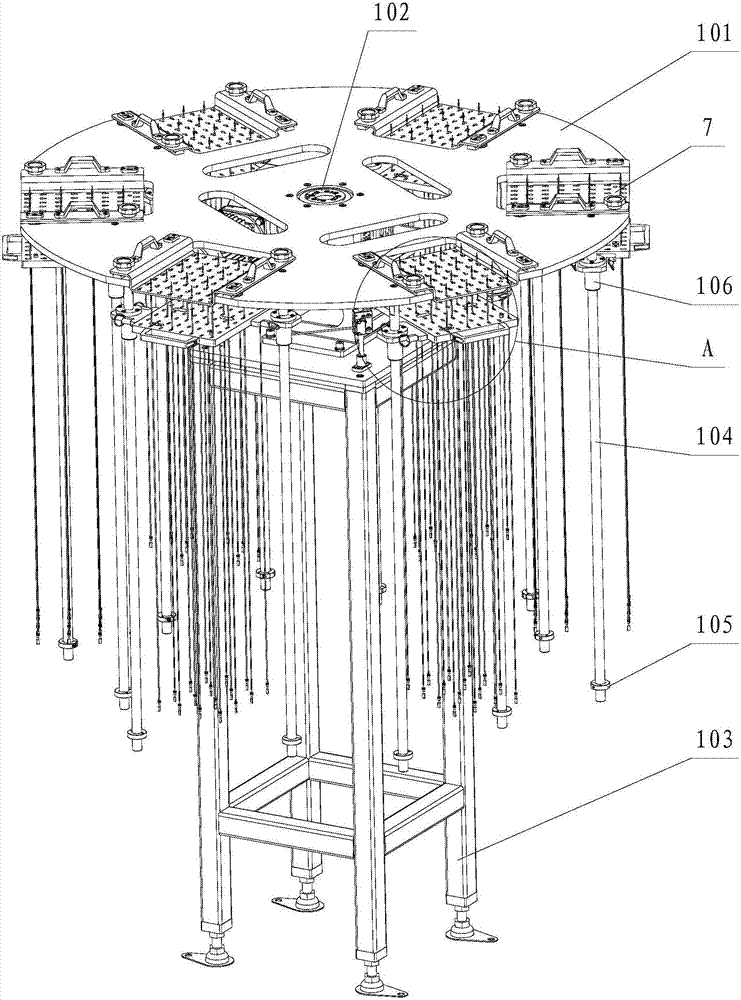

Robot-based wiring harness terminal automatic plugging device and wiring harness terminal plugging method thereof

ActiveCN107346857AImprove work efficiencyHigh precisionVehicle connectorsContact member assembly/disassemblyDiffuse reflectionEngineering

The invention belongs to the automotive wire harness assembling field and relates to a robot-based wiring harness terminal automatic plugging device and a wiring harness terminal plugging method thereof. The device comprises a material loading rotary mechanism, a multi-axis linkage robot, a wire plugging and collection clamping jaw and a visual verification work table; according to the material loading rotary mechanism, a splitter drives a rotary platform provided with tray assemblies; manual material loading is performed at a work station, the robot takes materials at a work station opposite the material loading work station; and material loading and unloading work and the wire plugging work of the robot can be performed simultaneously, and therefore, the work safety of a material loading worker can be ensured. With the robot-based wiring harness terminal automatic plugging device and the wiring harness terminal plugging method thereof of the invention adopted, fully-automatic material feeding, wiring harness terminal plugging and detection can be realized, work efficiency, precision and reliability are greatly improved, and human resource costs can be saved. According to the robot-based wiring harness terminal automatic plugging device and the wiring harness terminal plugging method thereof of the invention, a visual detection system, a tension and pressure sensor detection system and a laser diffuse reflection sensor detection system are integrated, so that the accuracy and reliability of terminal plugging can be ensured.

Owner:无锡新松机器人自动化有限公司

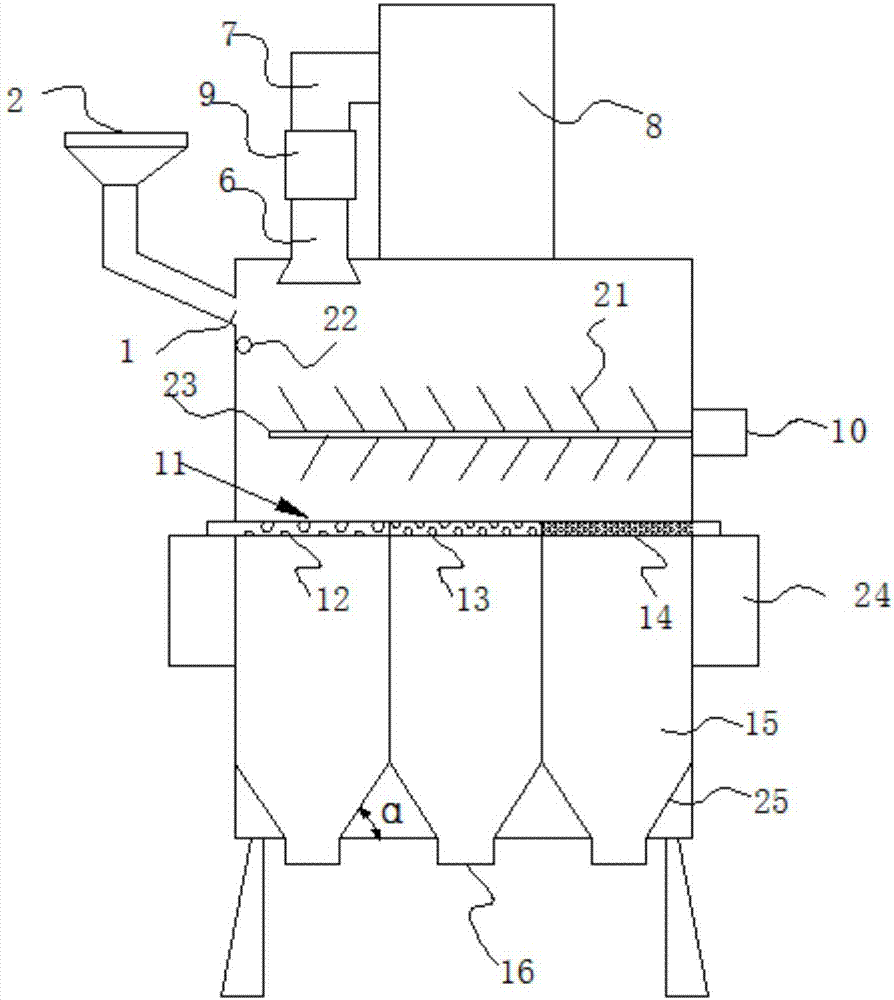

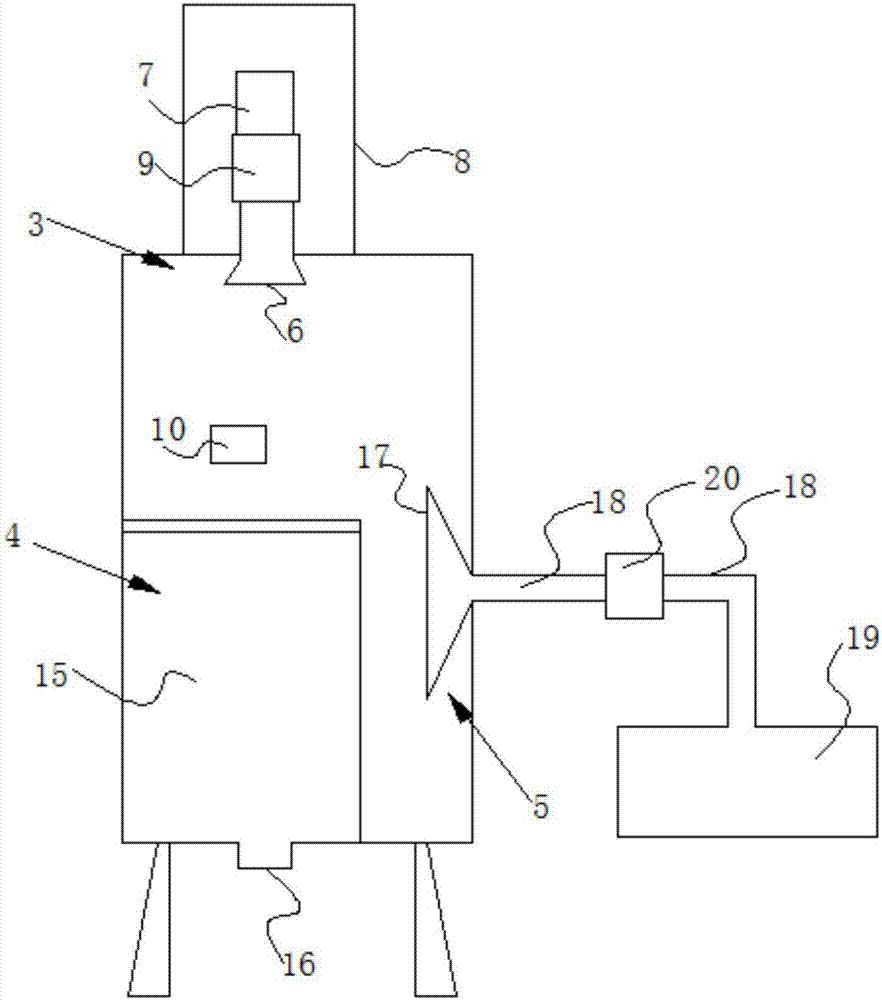

Multi-level dust removal rice screening device

InactiveCN107442420AImprove cleanlinessImprove dust removal effectSievingGas current separationImpellerWorking environment

The invention discloses a rice screening device with multi-stage dust removal. The feeding port of the screening box is connected to the feeding hopper through a pipeline. The dust pipe is connected to the dust collection box; the screening area includes an agitator and a screening plate, the screening plate is located below the agitator, and the agitator includes a stirring shaft with an impeller; the screening plate is provided with a coarse screening area, a medium screening area and a fine screening area in turn , and the corresponding collection chambers are set directly below; the bottom surface of each collection chamber is provided with a discharge port; the second dust suction hood in the side dust removal area is connected to the water tank through the second dust suction pipe. The present invention is equipped with two-stage dust removal, which has good dust removal effect, can not only ensure the working environment but also improve the cleanliness of rice; its screening structure is ingenious, and dust can be collected while screening in the screening box, so that the working environment is good; the structure design is reasonable, and once It can distinguish rice grains of different sizes without going through multi-layer screens, and the discharge is convenient and fast.

Owner:新沂市湖滨米业有限公司

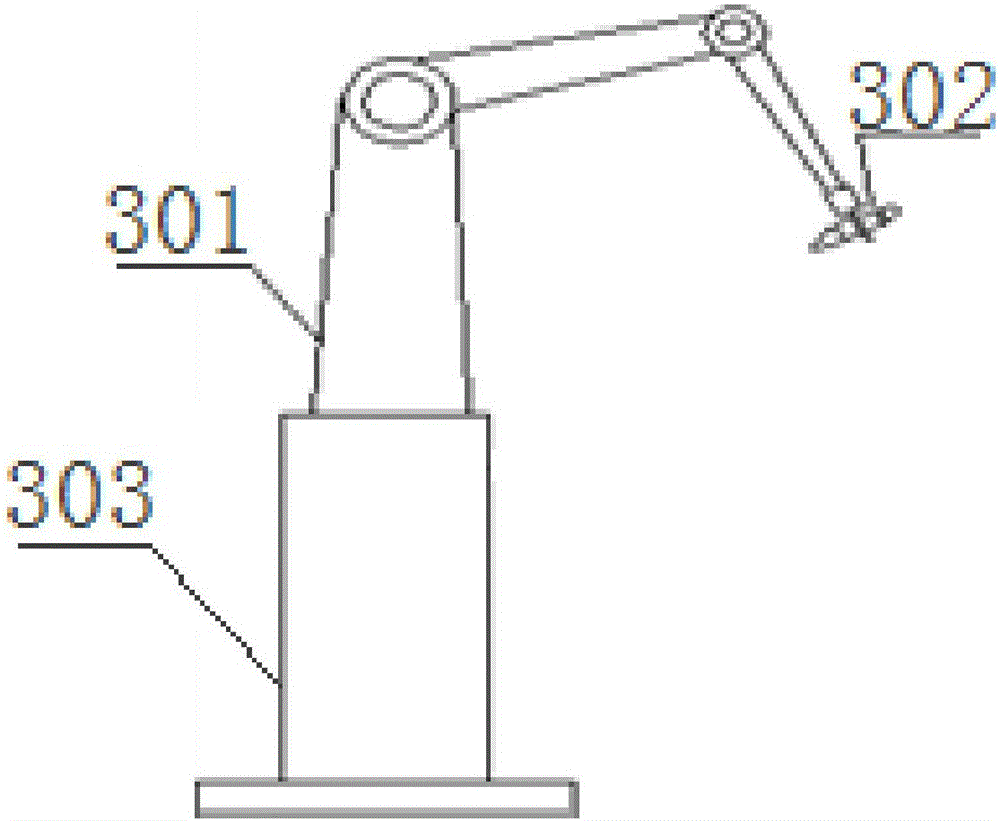

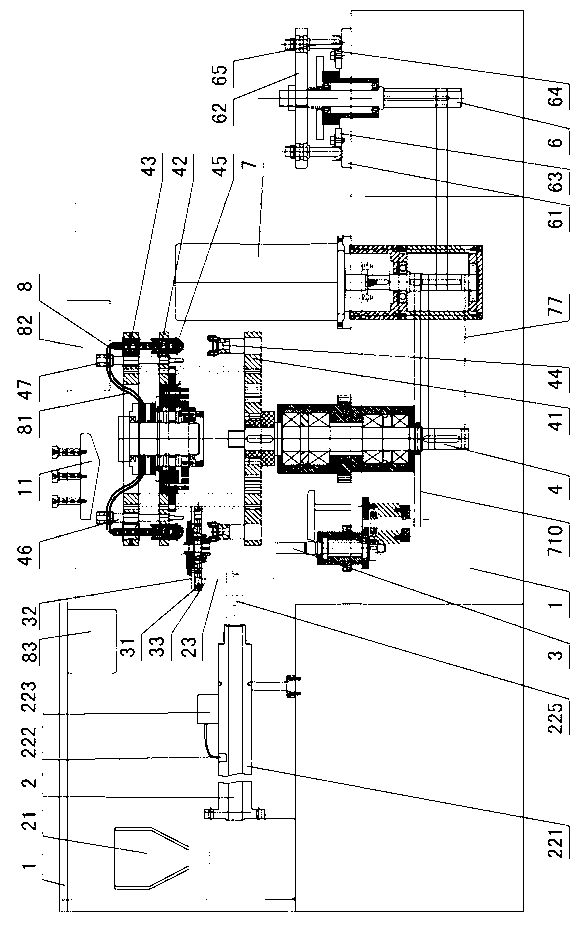

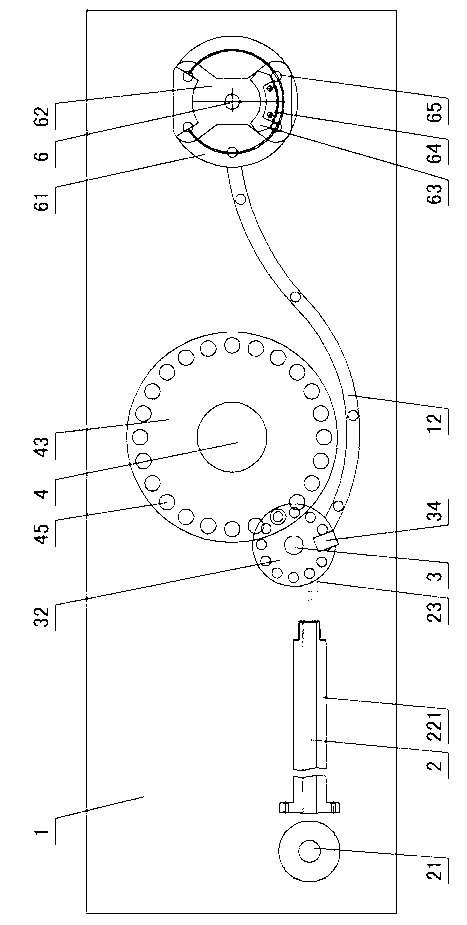

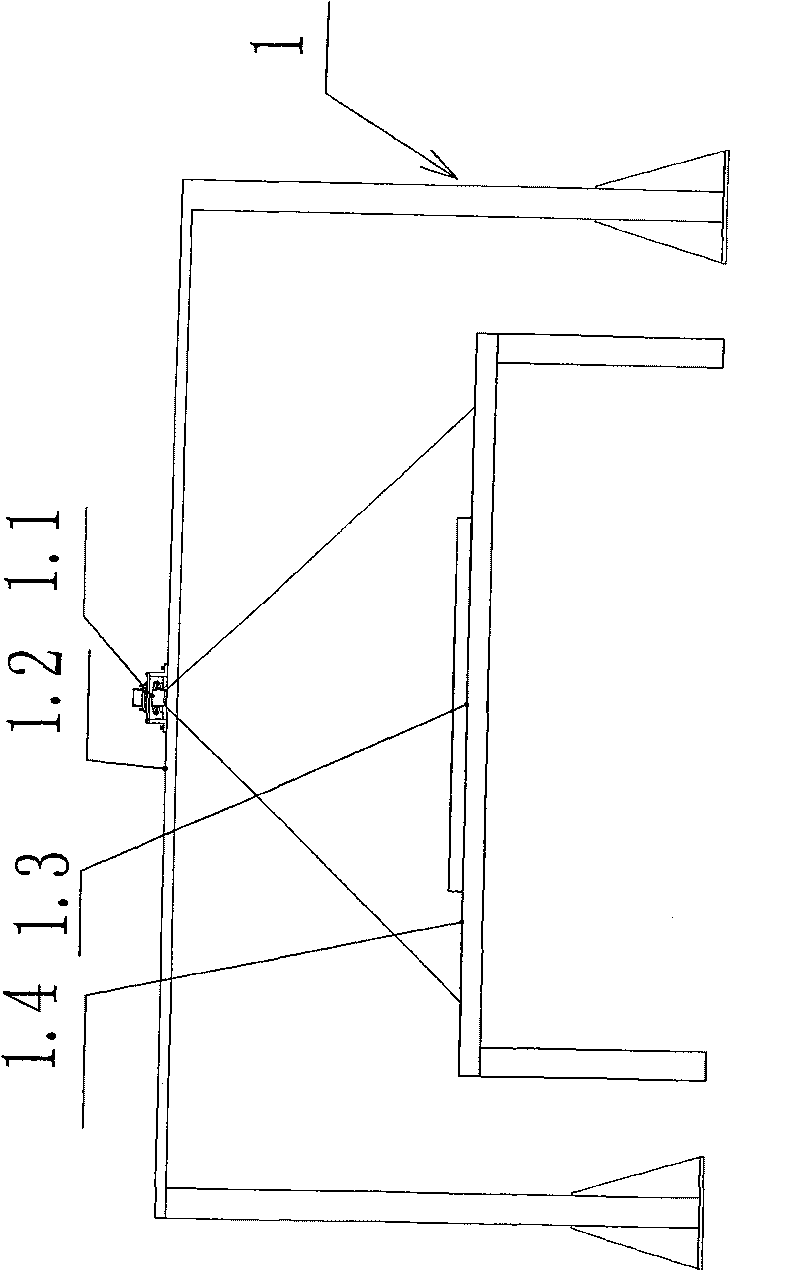

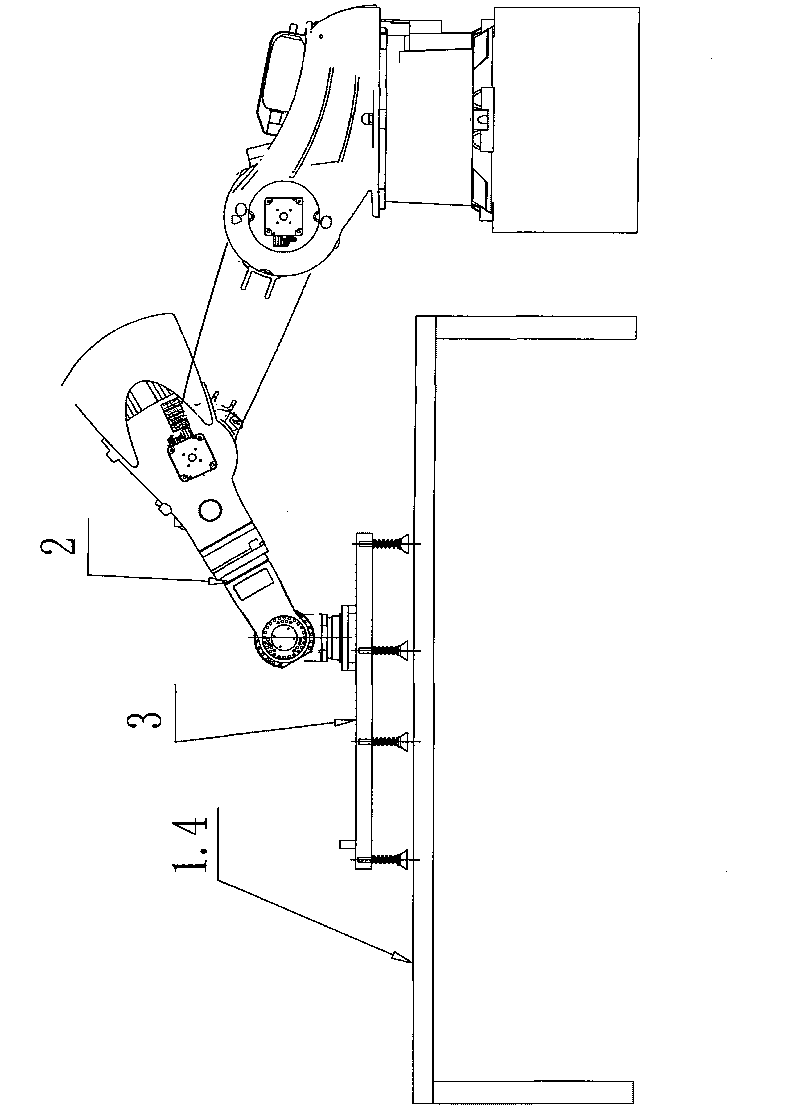

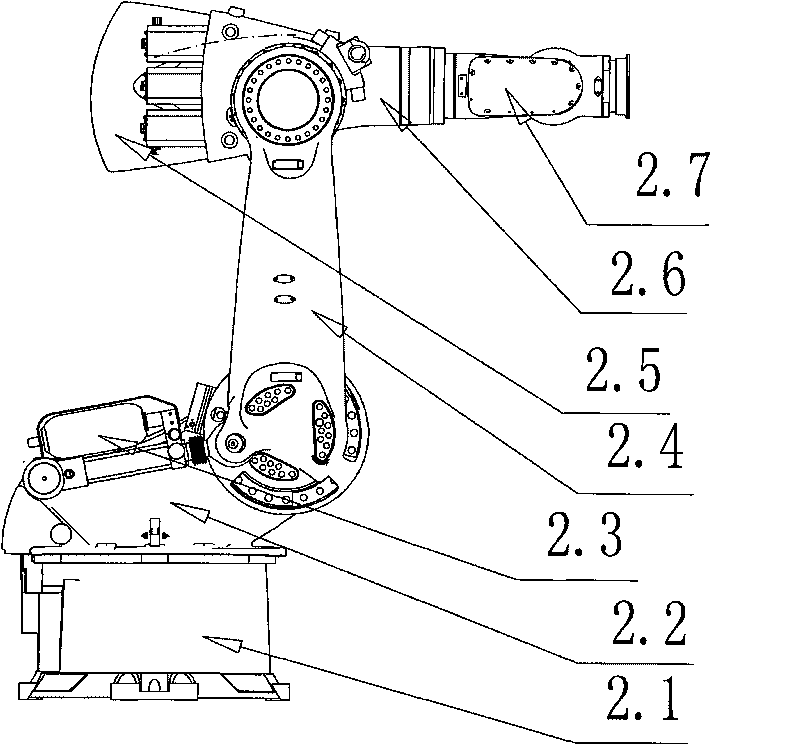

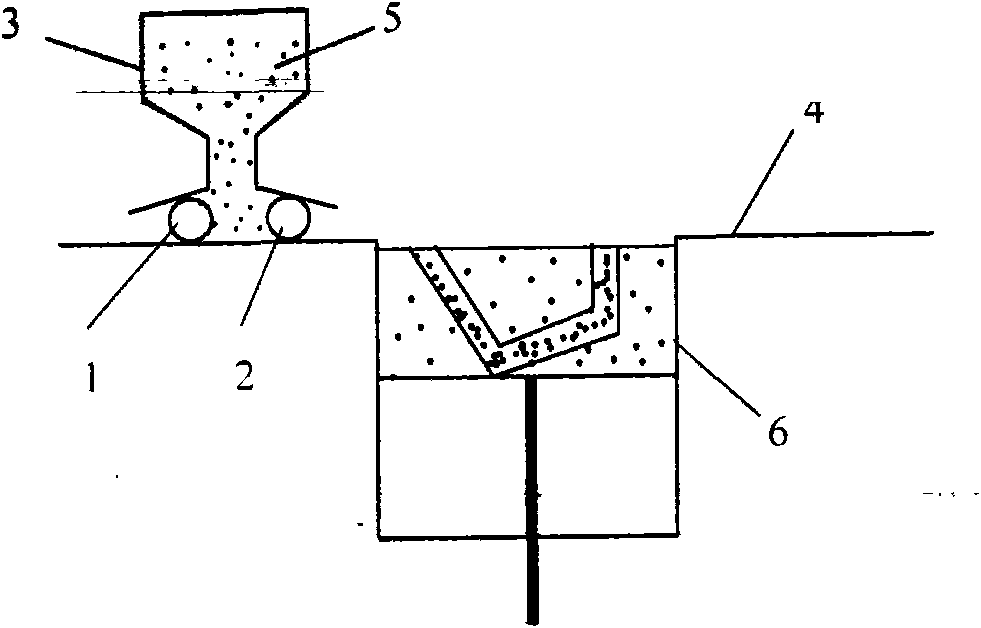

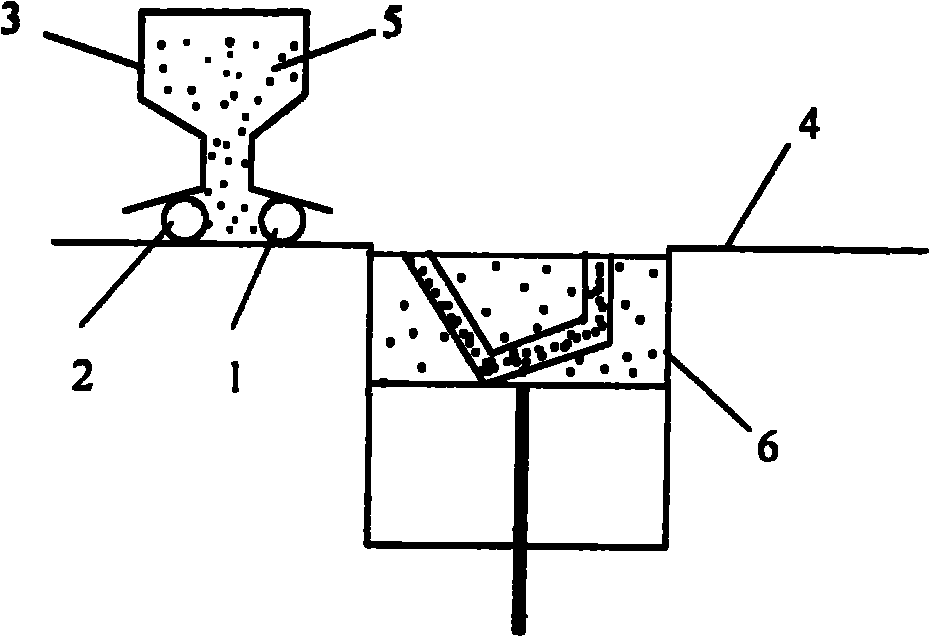

Stacking robot system of cold-end glass on floatation glass production line

ActiveCN101704454ASave manufacturing costReduce land costProgramme-controlled manipulatorStacking articlesProduction lineRobotic systems

The invention relates to a stacking robot system of cold-end glass on a floatation glass production line, comprising a vision system, a roller way (1) and a plurality of stacking mechanical hands, wherein the vision system and the roller way (1) comprise a roller way (1.4), an installation rack (1.2) and a photographic system (1.1); each stacking mechanical hand comprises a mechanical hand (2), a sucking disc combination rack (3) and two double-station rotary tables (4), wherein the sucking disc combination rack (3) comprises a sucking disc rack (3.1), a plurality of sucking disc mechanisms (3.2), a set of two-point detection assembly (3.6), a set of one-point detection assembly (3.5) and four sets of anti-collision detection assemblies (3.10, 3.11, 3.12); the two-point detection assembly (3.6) is transversely arranged on the bottom of the sucking disc rack (3.1), the one-point detection assembly (3.5) is longitudinally arranged on the bottom of the sucking disc rack (3.1), and the four anti-collision detection assemblies (3.10, 3.11, 3.12) are arranged on the sucking disc rack (3.1) in a rectangle shape. The stacking robot system of the cold-end glass on the floatation glass production line can automatically realize the grading stacking casing.

Owner:JIANGSU JINMING IND ROBOT AUTOMATION

Palladium-103 and io-125 compound sealed seed source, source core and source core preparation method

ActiveCN101797392AEvenly distributedCompact distributionRadioactive preparation carriersAntineoplastic agentsChemical platingSodium iodide

The invention belongs to the technical field of medical preparations containing radioactive substances, in particular to a palladium-103 and io-125 compound sealed seed source, a source core and a source core preparation method. A palladium-103 and io-125 compound film covers on a carrier to form the source core, and the palladium-103 and io-125 compound sealed seed source is prepared in a way that the source core is welded and sealed in a titanium pipe or titanium alloy pipe. The source core preparation method of the palladium-103 and io-125 compound sealed seed source comprises the steps of: 1, inoculating a nano palladium seed crystal: dipping a carrier bar into a chloroform solution of palladium diacetate, and then dipping into an alkaline ammonia solution of hydrazine; 2, carrying out chemical plating on palladium-103 and silver: putting the carrier bar into a mixed solution of palladium chloride, silver nitrate, ethylene diamine tetraacetic acid, ammonium hydroxide and hydrazine to enable the surface of a carrier to be uniformly coated with a layer of palladium-103 and silver; and 3, carrying out chemical absorption of iodine-125: putting the carrier bar into a mixed solution of sodium bromide or potassium bromide, sodium iodide or potassium iodide, sodium hydroxide or potassium hydroxide, and potassium ferricyanide.

Owner:HTA CO LTD

SLS (selective laser sintering) double-roller powder spreading device

InactiveCN102078963ASave spaceNo pollutionIncreasing energy efficiencyClosed systemWorking environment

The invention provides an SLS (selective laser sintering) double-roller powder spreading device which comprises a worktable and a powder spreading device, wherein the powder spreading device is arranged on the worktable; the SLS double-roller powder spreading device is characterized in that the powder spreading device comprises a powder storage cylinder and two parallel powder spreading rollers, namely, a left powder spreading roller and a right powder spreading roller; and the powder spreading device and the worktable form a closed system. The double-roller powder spreading device is of a simple structure and convenient to control, and can effectively save the space of SLS equipment, reduce the size, complexity and cost of the equipment, improve the equipment reliability and ensure a clean working environment in the equipment.

Owner:湖南美纳科技有限公司

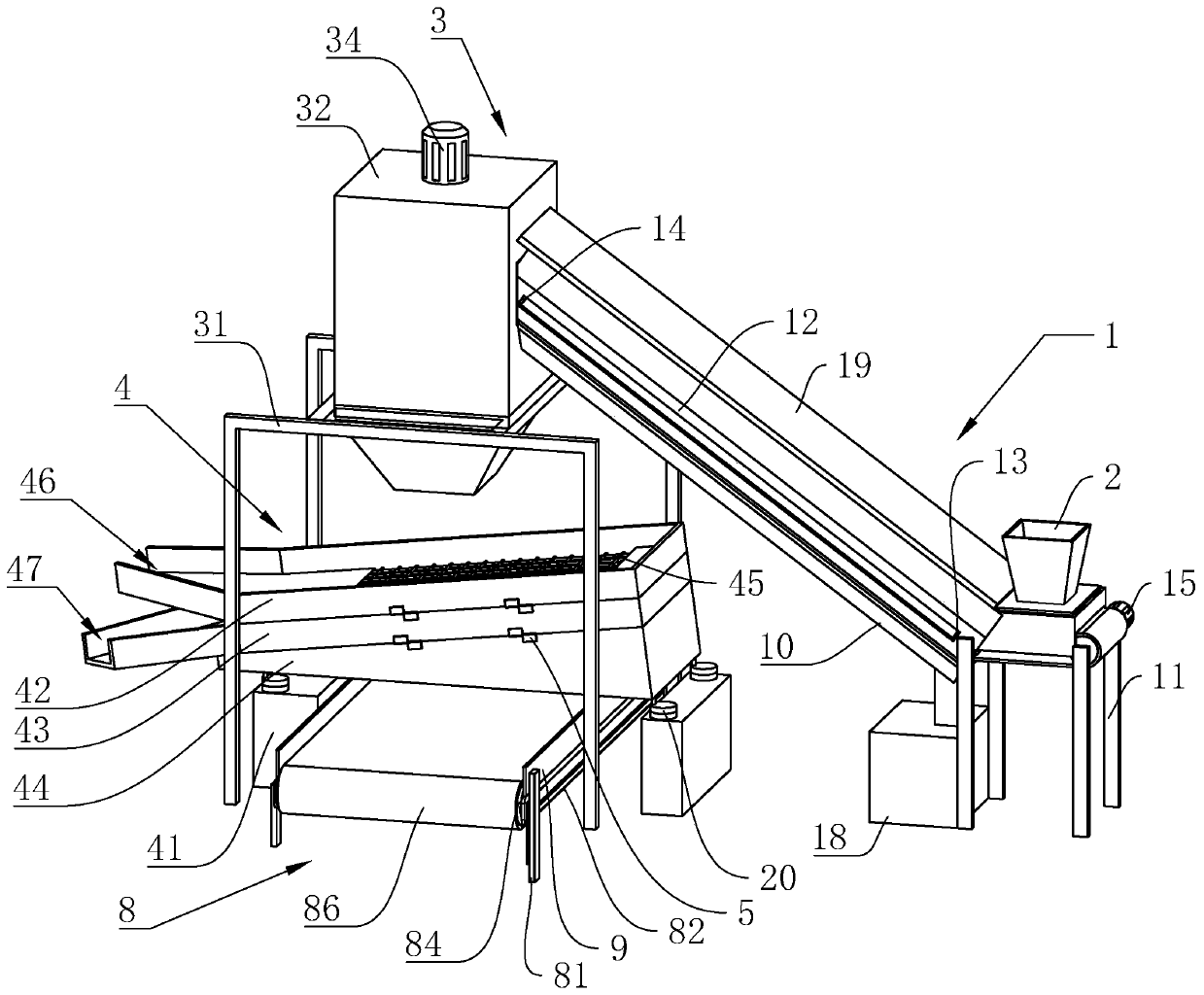

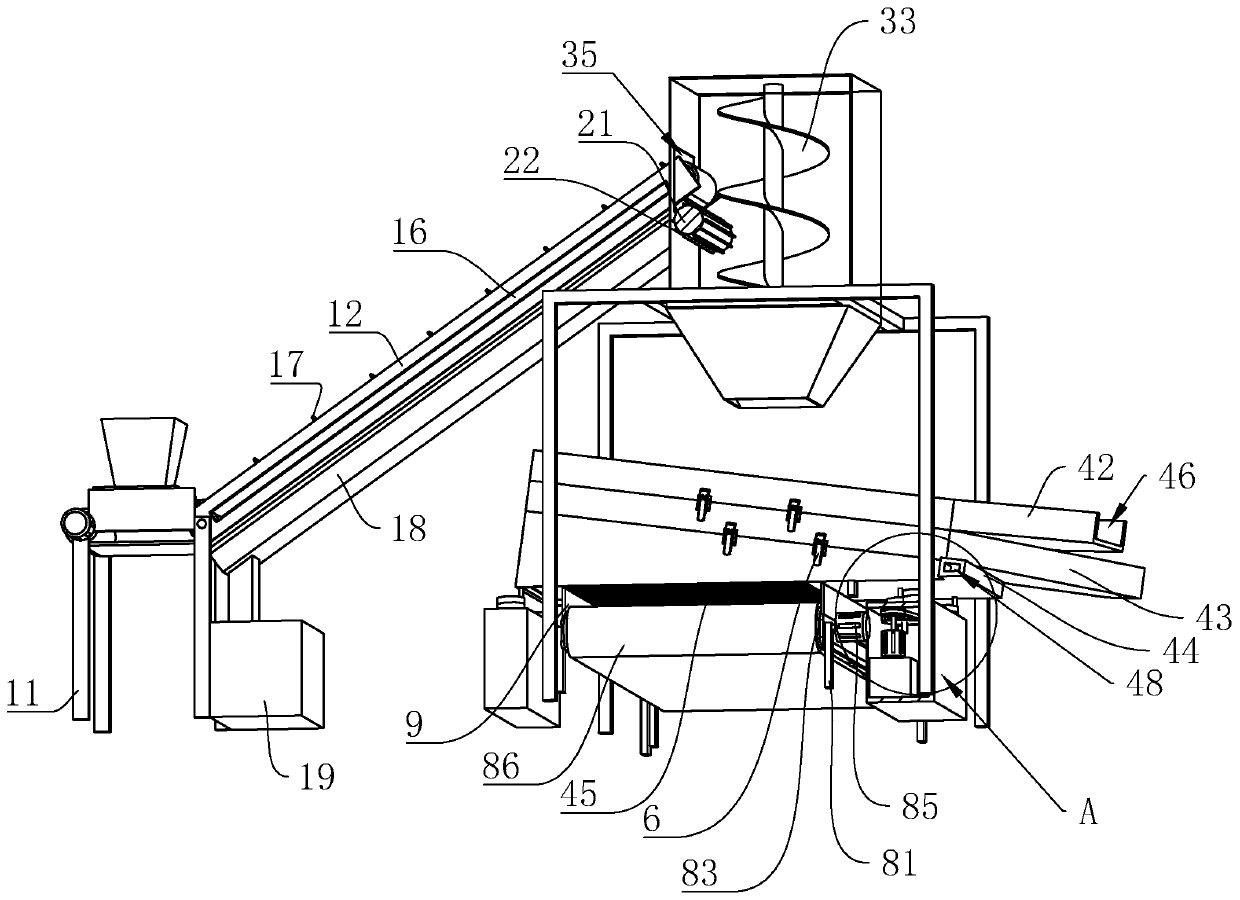

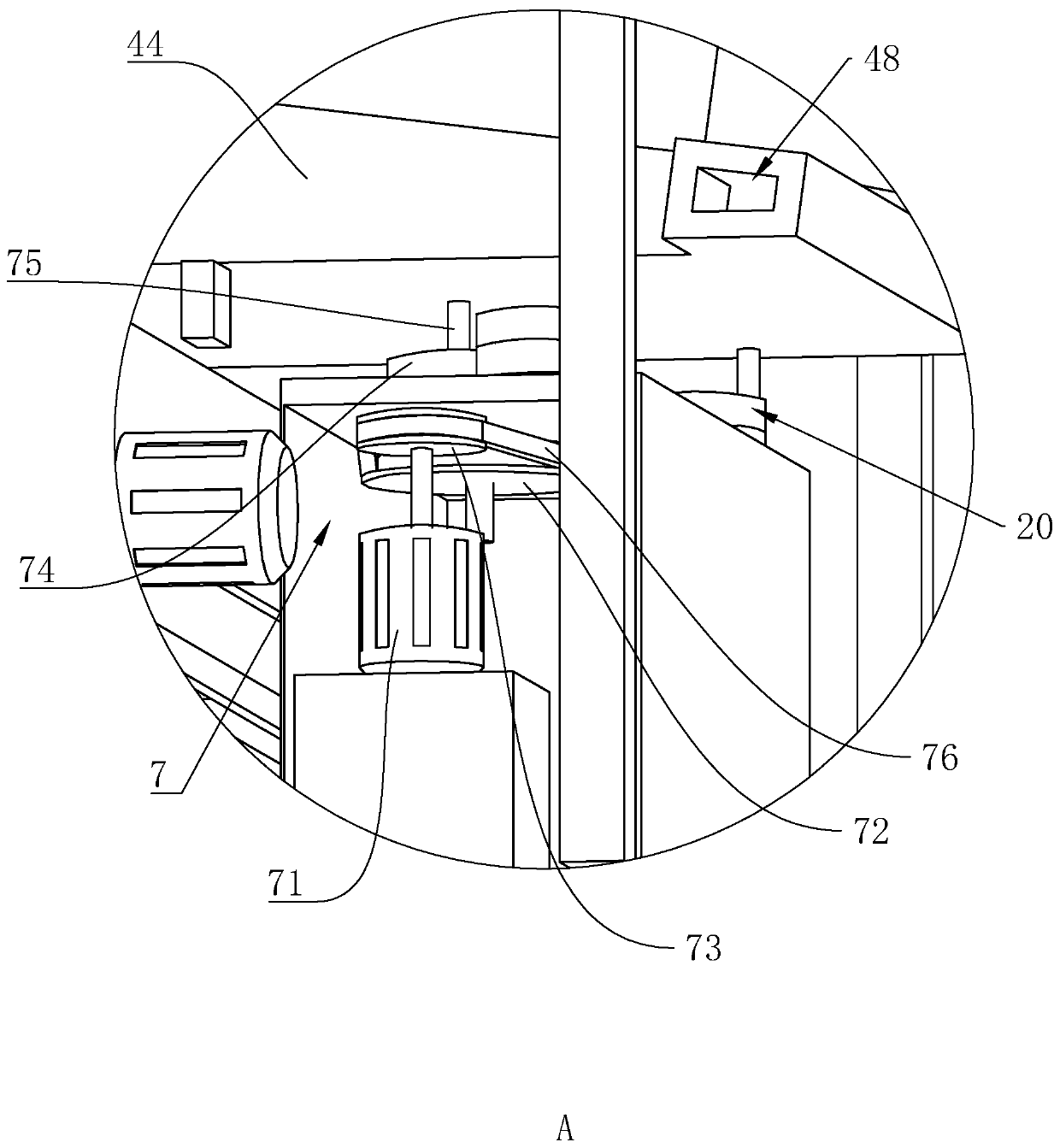

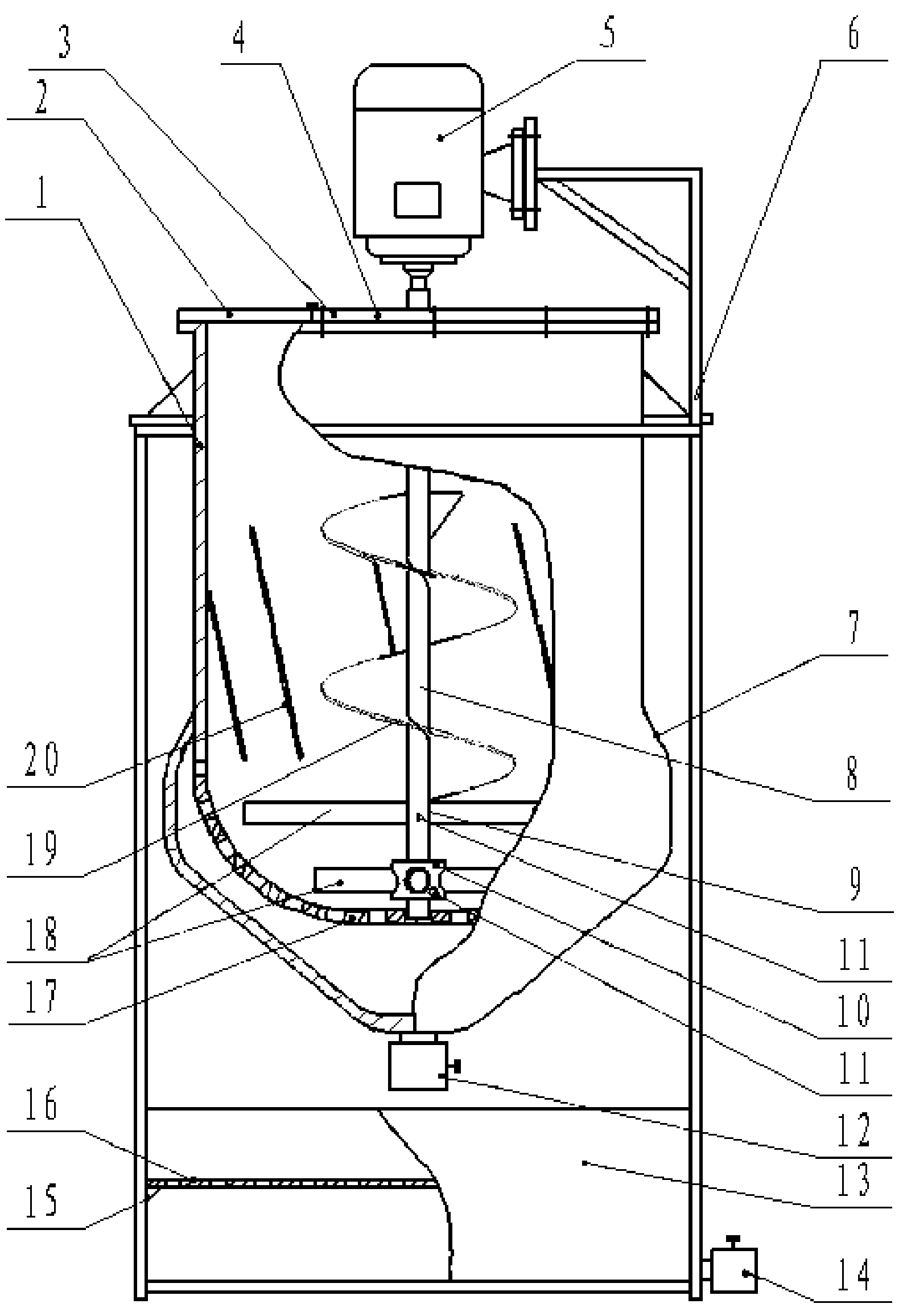

Pretreatment device and soil remediation method using same

The invention relates to a pretreatment device and a soil remediation method using the same. The pretreatment device comprises a slope feeding mechanism used for feeding, a smashing mechanism used forsmashing soil, a screening mechanism used for screening the soil and a discharging mechanism used for discharging the screened soil, wherein the screening mechanism comprises a screening support, a first screening plate, a second screening plate and a third screening plate are sequentially installed on the screening support, screen meshes with different hole diameters are installed on plate bodies of the first screening plate, the second screening plate and the third screening plate respectively, and an eccentric structure for driving the first screening plate, the second screening plate andthe third screening plate to achieve eccentric motion is installed on the screening support. The soil remediation method comprises the following steps: soil is collected, sprayed, wetted and dried, then treated through the pretreatment device, flushed through a metal remediation agent and an organic matter remediation agent and finally dried and backfilled. The eccentric structure drives the screening mechanism to screen soil, noise in the screening process is reduced, and soil screening is more thorough through multi-stage screening.

Owner:顺茂环境服务(上海)有限公司

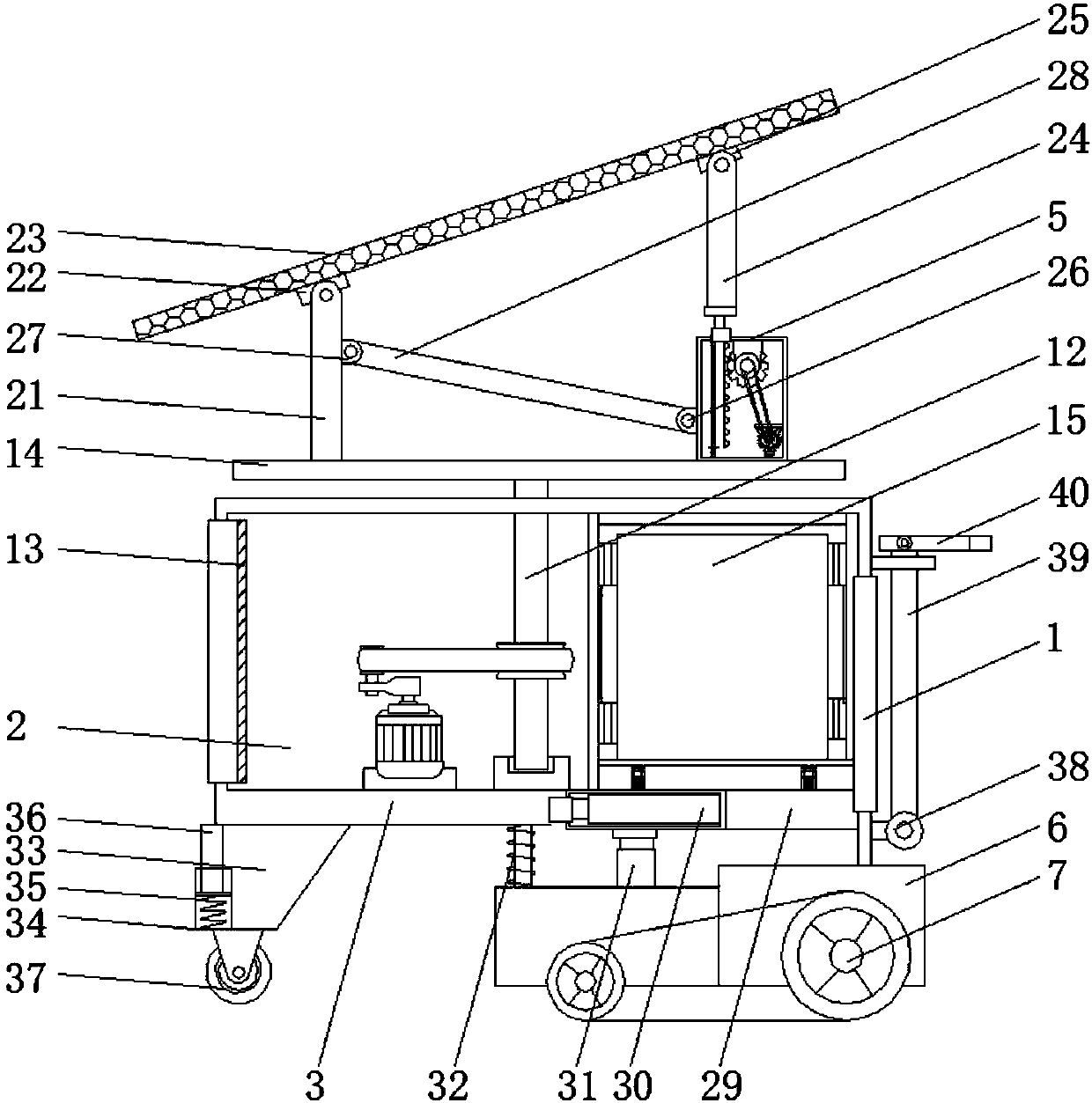

Mobile solar photovoltaic power generation storage device

ActiveCN107645270AGuaranteed working environmentStable collectionPhotovoltaic supportsPV power plantsEngineeringTopography

The invention discloses a mobile solar photovoltaic power generation storage device which comprises a work chassis. A rotary chassis is fixedly connected with one side of the bottom of the inner wallof the work chassis. A mounting bracket is fixedly connected with the bottom of the outer wall of the rotary chassis. The bottom of the inner wall of the rotary chassis is fixedly connected with a rotary motor. The rotary motor is rotatably connected with a deceleration connector through an output shaft. A first pulley is fixedly connected with the output shaft of the deceleration connector through a flat key. A second pulley is rotatably connected with the first pulley through a belt. The invention relates to the technical field of solar photovoltaic power generation. According to the mobilesolar photovoltaic power generation storage device, angle adjustment and direction conversion of a solar panel are realized, and the stability of a battery box is ensured; stable and the most efficient solar energy collection is ensured; the electric energy collection amount is improved, and the overall device can control different work topographies; and the utilization and penetration rate of machinery can be greatly improved.

Owner:苏州南师大科技园投资管理有限公司

Electrical insulation electric heating aging test device under composite voltage

InactiveCN102749543AGuaranteed working environmentAvoid temperature driftElectrical testingElectric heatingTest sample

The invention discloses an electrical insulation electric heating aging test device under composite voltage, which comprises two corona-free high-voltage test transformers and at least one test box, wherein a box body of the test box insulates heat; the test box is internally provided with a heating device; at least one high-voltage electrode which is connected with high-voltage output ends of the corona-free high-voltage test transformers is introduced to the top of the test box; the lower part of the test box is provided with at least one detection terminal; and the high-voltage electrodes and the detection terminals are respectively insulated with the box body of the test box. The electrical insulation electric heating aging test device under composite voltage provided by the invention can effectively simulate the composite electricity and heat stress borne by an electrical device in operation, also can test sample products under different temperatures, voltage types and voltage grades at the same time, and can obtain the breakdown voltage and breakdown time of the sample products in the aging process.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

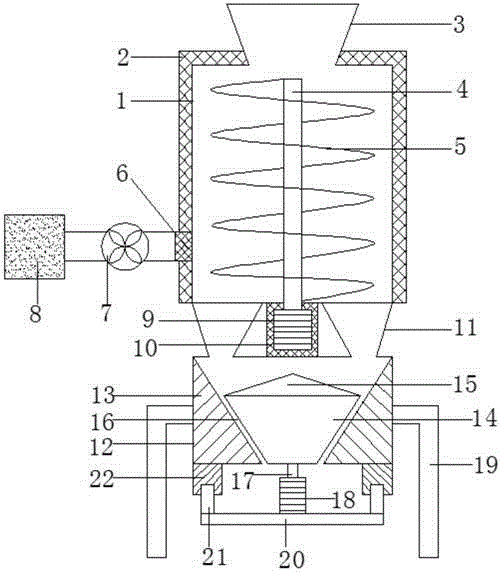

Efficient pulverizer for ceramic production

The invention discloses an efficient pulverizer for ceramic production. The efficient pulverizer for ceramic production comprises a first pulverizing cavity, a pulverizing roller and a hydraulic cylinder, wherein the outer wall of the first pulverizing cavity is covered with an electric heating layer, the upper side of the first pulverizing cavity is connected with a feeding funnel, a first rotary shaft is vertically arranged at the axis position of the inside of the first pulverizing cavity, screw blades are evenly arranged on the outer wall of the first rotary shaft, an air outlet pipe is horizontally arranged at the left end of the outer wall of the lower side of the first pulverizing cavity, and the left end of the air outlet pipe is connected with an exhaust fan. The efficient pulverizer for ceramic production integrates material pulverizing and drying functions, ensures the quality of processed finished products and fully pulverizes materials through two pulverizing mechanisms, an oblique pulverizing gap enables pulverizing time to be long and enables pulverizing to be sufficient, the material pulverizing effect is ensured, the size of pulverized material particles can be controlled, practicability is high, dehumidification is performed in the drying process through a drying device, drying efficiency is improved, noise in the working process of the efficient pulverizer is small, and a working environment of an operator is improved.

Owner:陆丽曼

Rust removing and paint spraying device for outer wall of steel pipe

InactiveCN107185748AEasy to operateImprove rust removal efficiencyPretreated surfacesLiquid spraying apparatusSteel tubeEngineering

The invention discloses a rust removal and painting device for the outer wall of a steel pipe. The center of the upper surface of the main body is connected with a knob bolt through a threaded hole. A movable pressure plate is arranged above the main body of the derusting device, a fixed plate is arranged under the main body of the derusting device, and a spray booth is provided on the left surface of the main body of the derusting device. The invention pushes the steel pipe into the body of the derusting device, the steel pipe is closely attached to the movable plate between the fixed plates, the rotation of the steel pipe enables the derusting frosted sheet to derust the steel pipe, and when the left end of the steel pipe moves into the paint spraying room, the compressed gas will The paint in the paint tube is sprayed onto the surface of the steel pipe through the nozzle to complete the steel pipe painting work, which improves the rust removal efficiency of the steel pipe, and can also spray the steel pipe to prevent the steel pipe from rusting again.

Owner:桐乡市锦格家纺有限公司

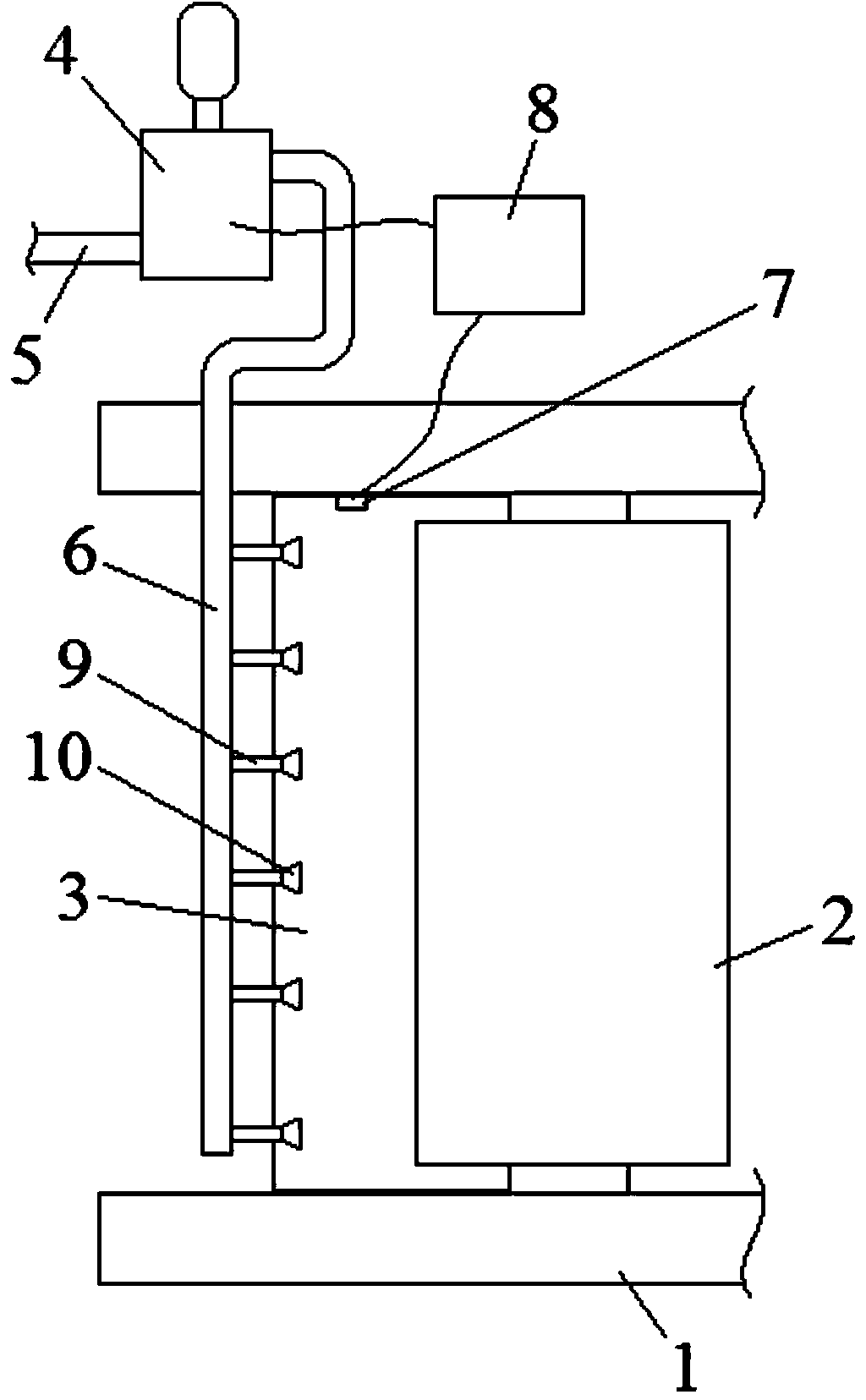

Automatic ink supply system for printing machine

InactiveCN104275929AAvoid volatilityReasonable structurePrinting press partsElectricityWorking environment

The invention discloses an automatic ink supply system for a printing machine. The automatic ink supply system comprises a printing roll set, an ink box and an ink supply pump, wherein an ink inlet pipe and an ink outlet pipe are respectively connected to the ink supply pump; a liquid level sensor is mounted in the ink box and is electrically connected with the ink supply pump through a controller; a plurality of openings are respectively formed in the front side of the ink box, a plurality of branch pipes are respectively connected to one side of the front end of the ink outlet pipe, front ends of the branch pipes respectively penetrate through the openings and extend into the ink box, and spray heads facing to the surfaces of roll bodies of the printing roll set are respectively connected to the front ends of the branch pipes. The automatic ink supply system is reasonable in structure; the ink supply pump is controlled by the liquid level sensor and the controller to automatically supply ink, and ink supplied into the ink box is sprayed to the surfaces of the roll bodies of the printing roll set by virtue of the spray heads, so that the fluctuation of the ink caused by the rotational inertia of the roll bodies of the printing roll set is avoided, resources are saved, the clean working environment is guaranteed, and the influence caused by the splashing of the ink to the printing quality is avoided.

Owner:HEFEI DAAN PRINTING

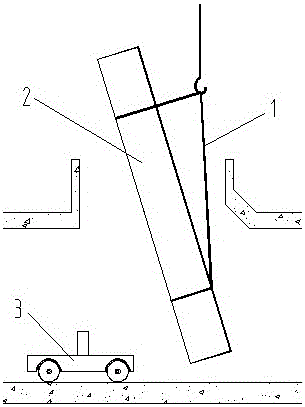

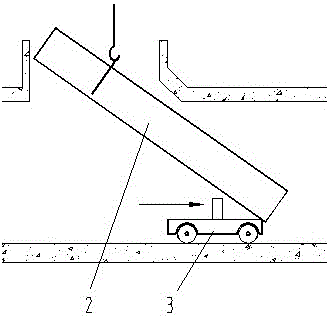

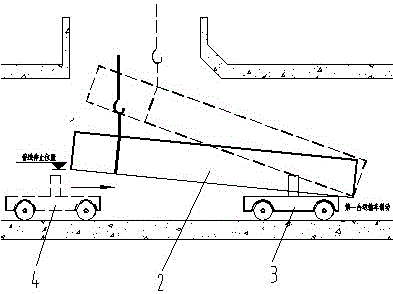

Pipe gallery pipeline transporting and installing method

ActiveCN106352158AReduce investmentReduce consumptionPipe laying and repairLifting devicesPipeline transportWorking environment

The invention relates to a pipe gallery pipeline transporting and installing method, which comprises the following steps of selecting a feeding opening; preparing dual vehicle groups; starting a first transporting vehicle for completing the material collecting work; starting a second transporting vehicle for completing the material collecting work; after pipelines fall onto the transporting vehicles, performing temporary pipeline fixation; starting the transporting vehicles for performing horizontal transportation of the pipelines; performing vertical transportation work of the pipelines; performing fine turning pairing. The pipe gallery pipeline transporting and installing method has the advantages that machinery replaces manual work for completing the horizontal transportation of the pipelines, so that the investment of manpower resources is reduced; the construction mechanization degree is improved; the work efficiency is improved; the work is performed in a relative sealed underground space; good ventilation safety measures are needed; an electric towing vehicle is used for completing the horizontal transportation of the pipelines; the work environment inside a pipe gallery is ensured; the consumption of oil type resources is reduced; meanwhile, the environment pollution is reduced.

Owner:二十二冶集团天津建设有限公司

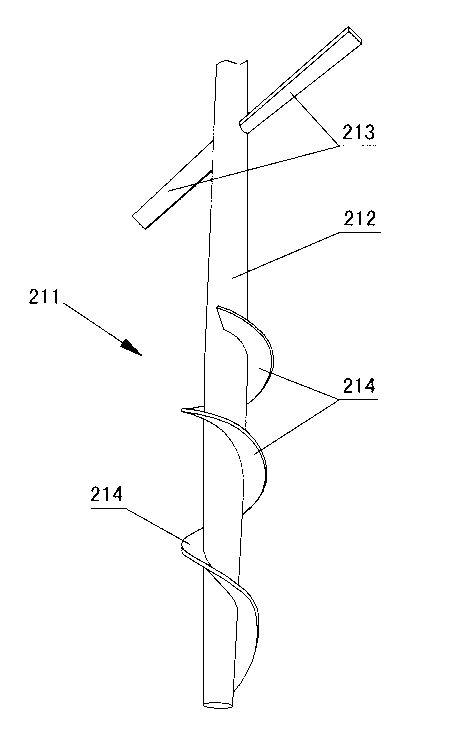

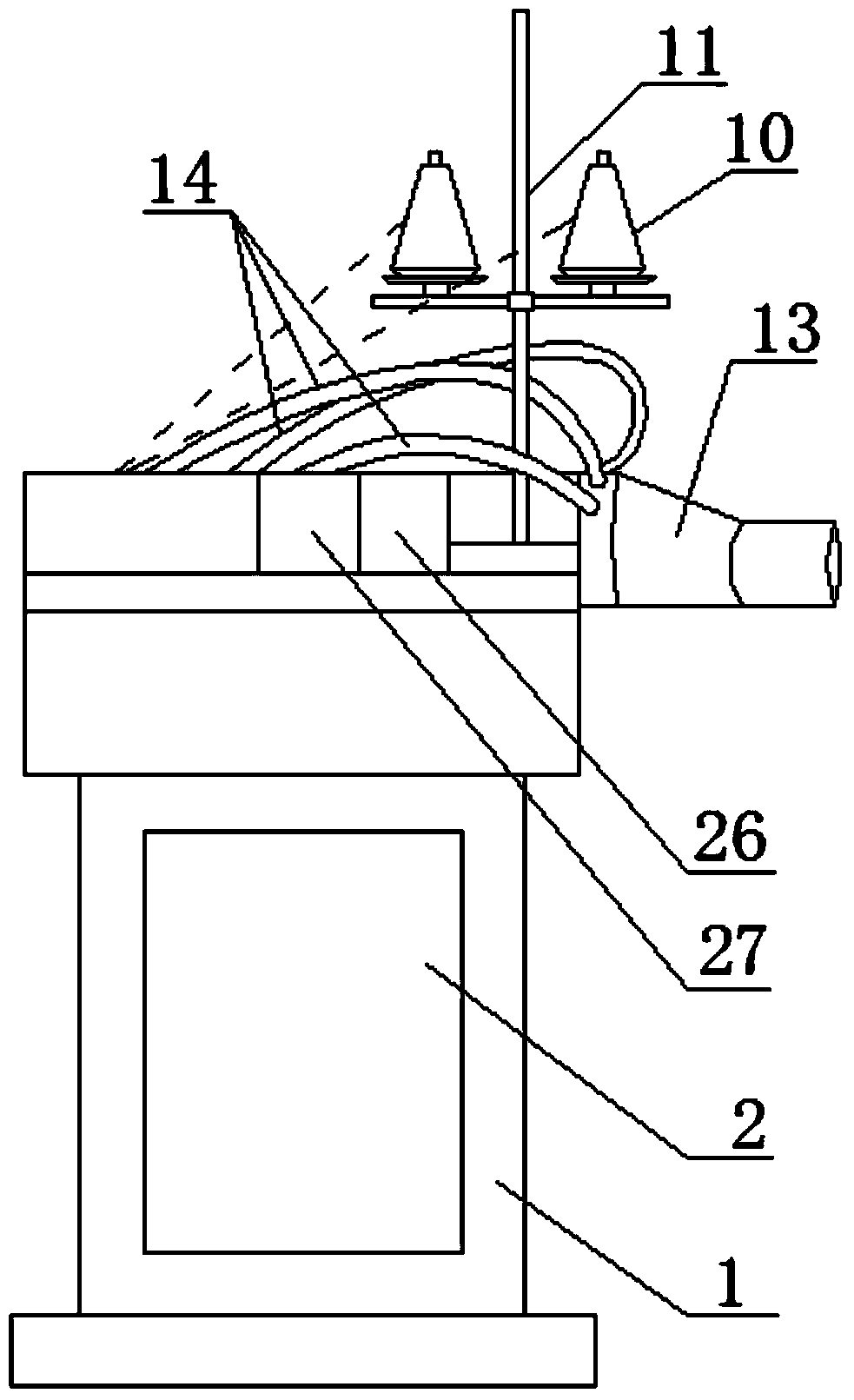

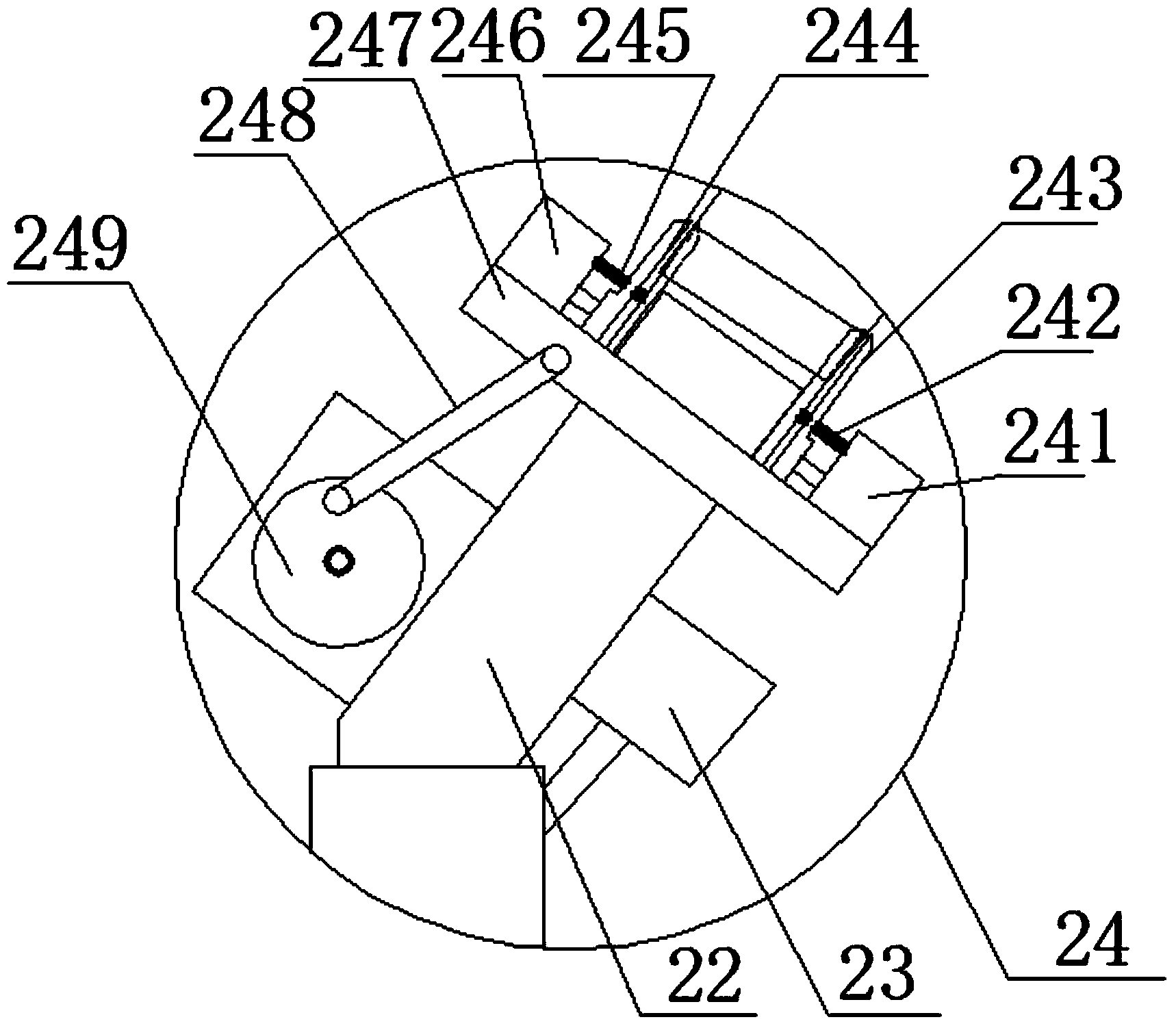

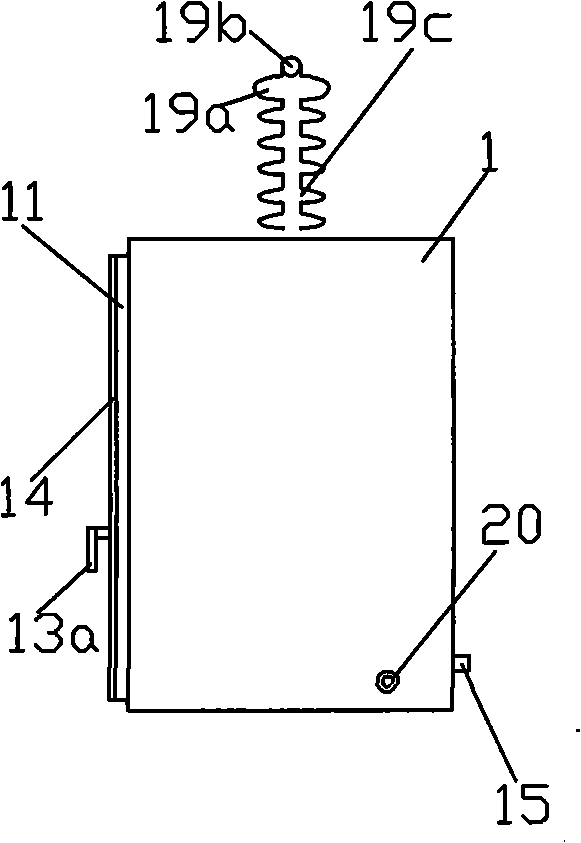

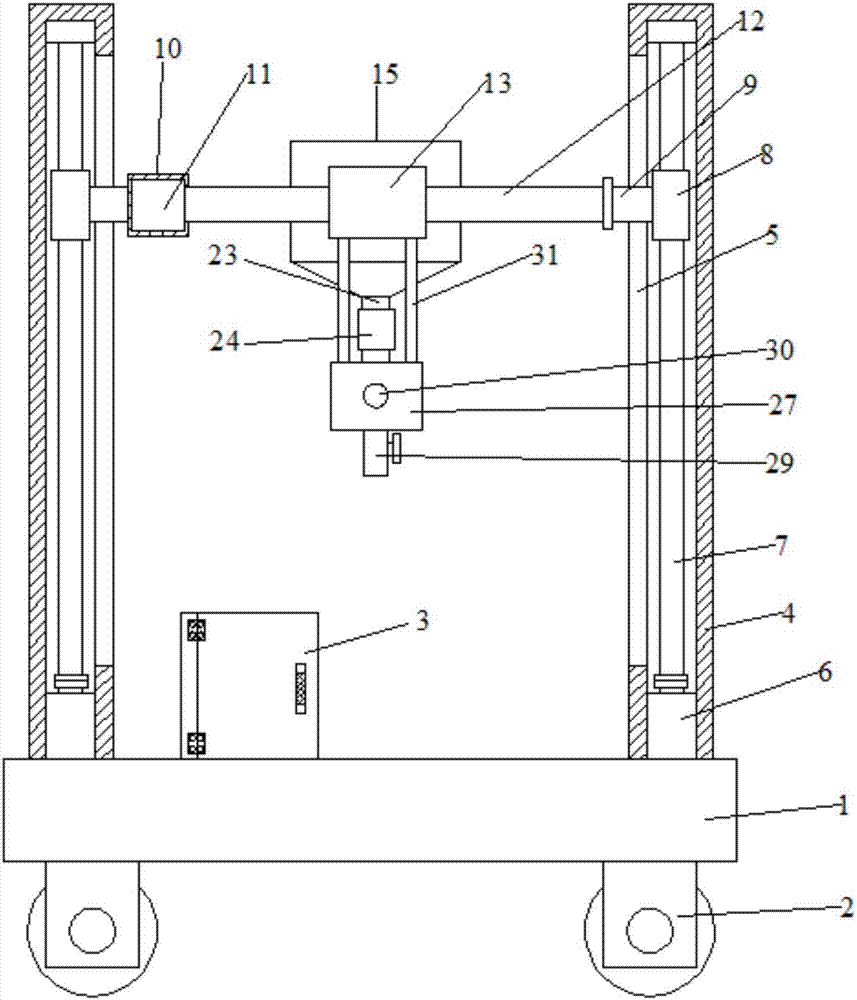

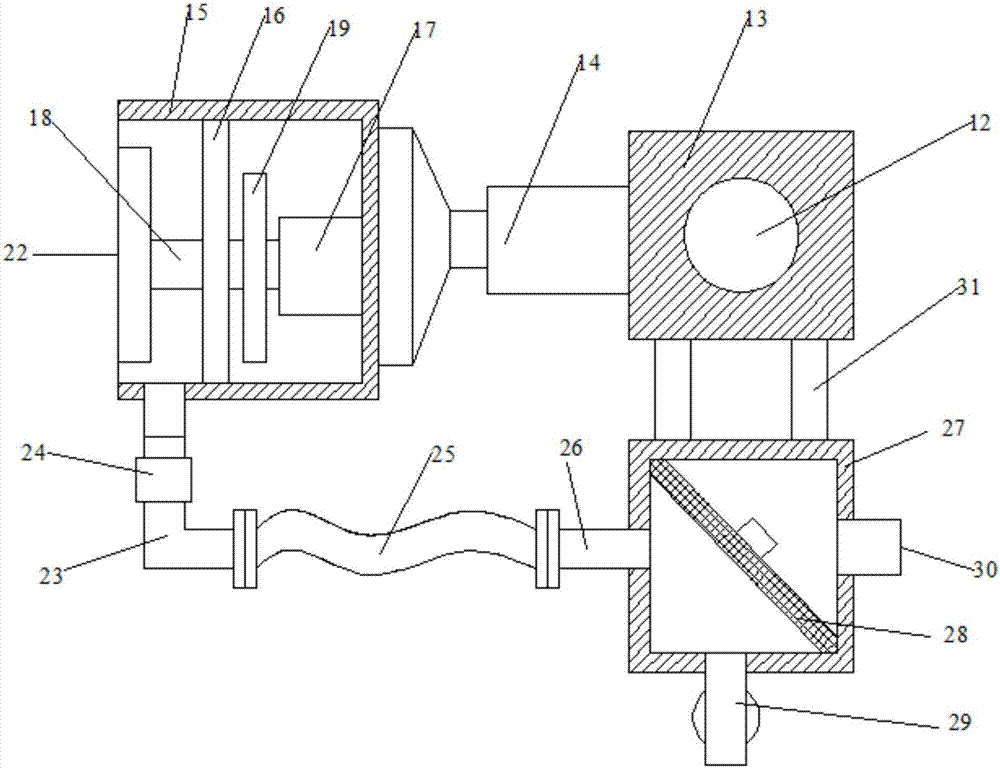

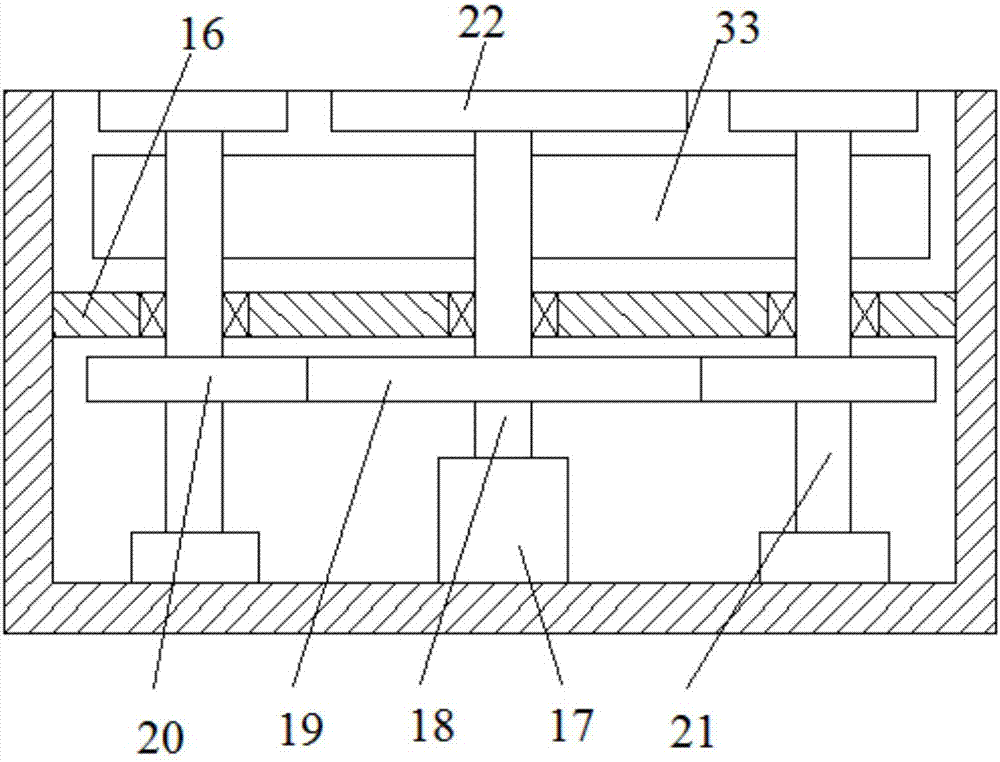

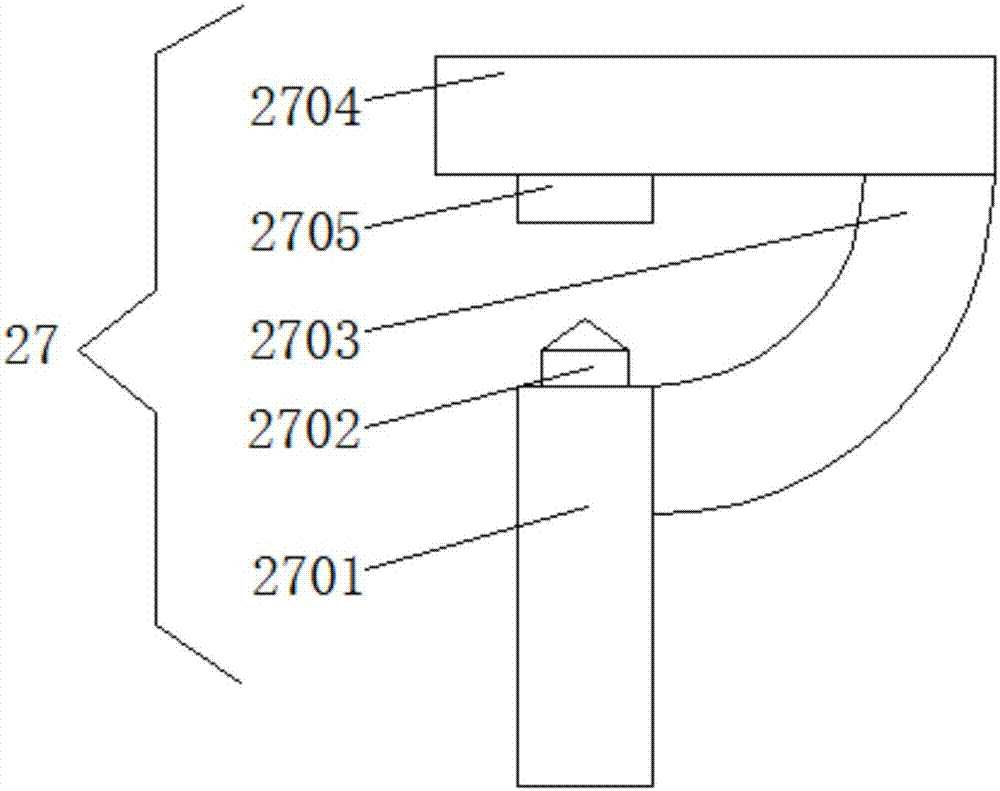

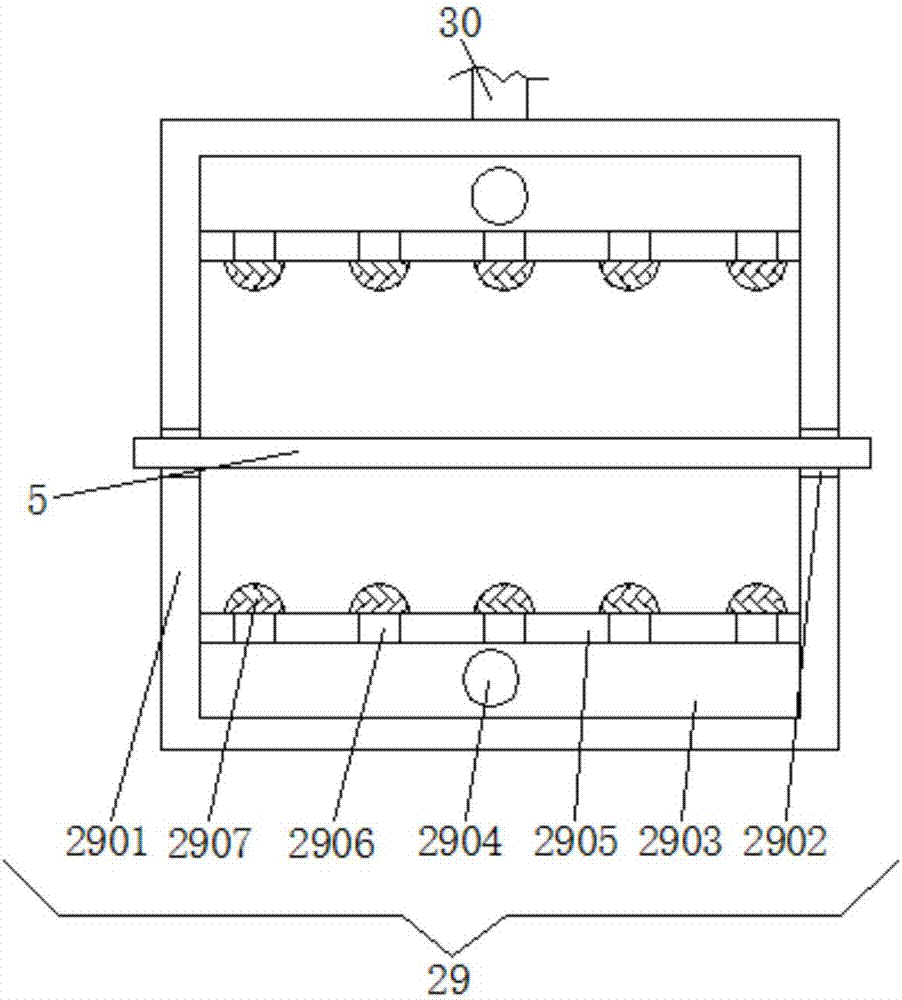

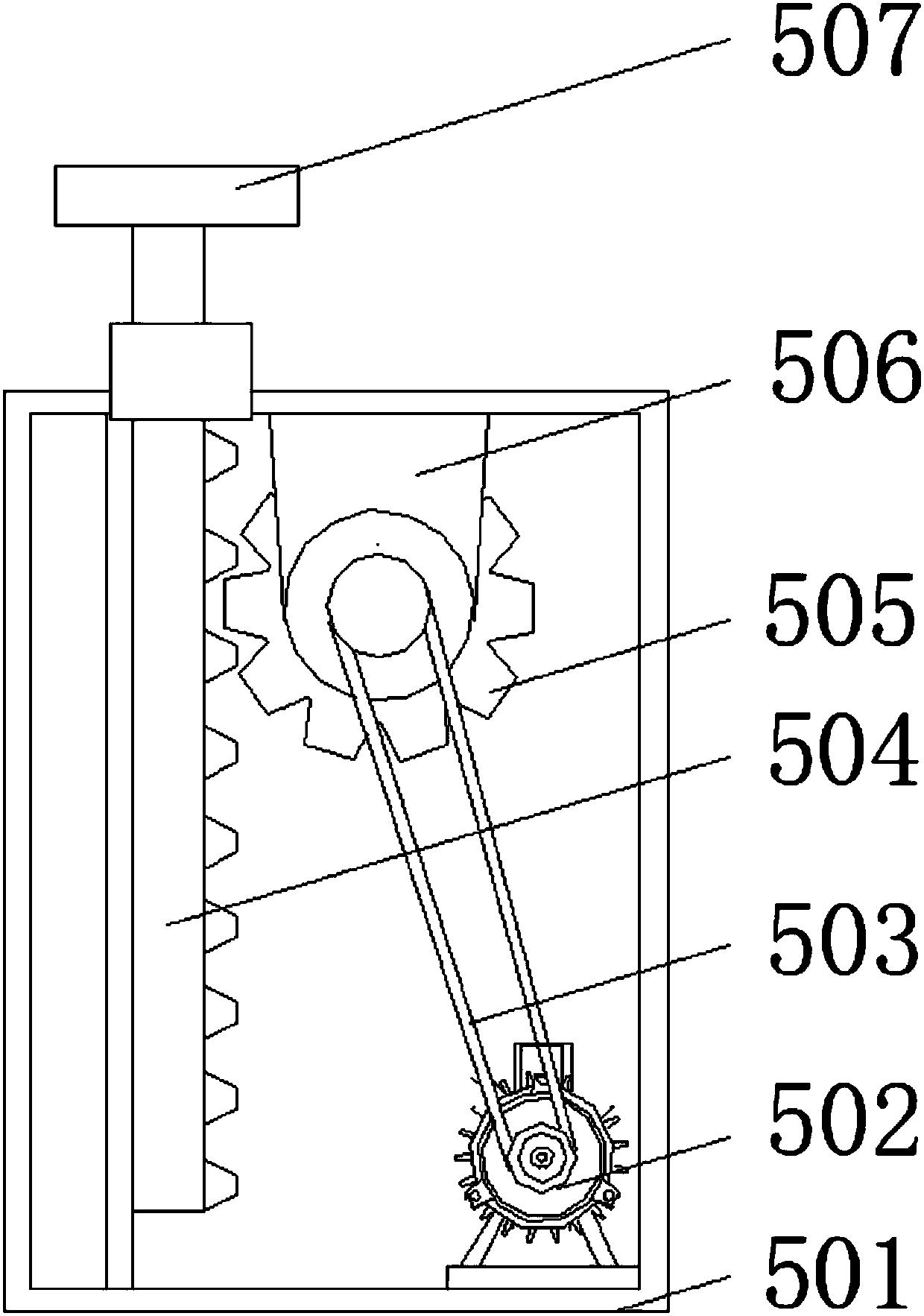

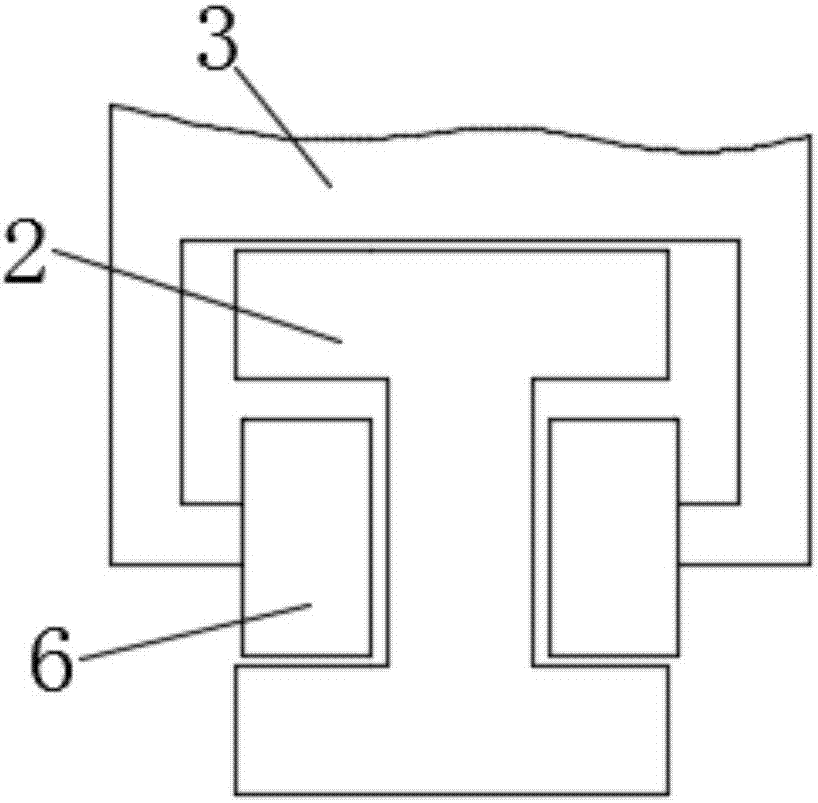

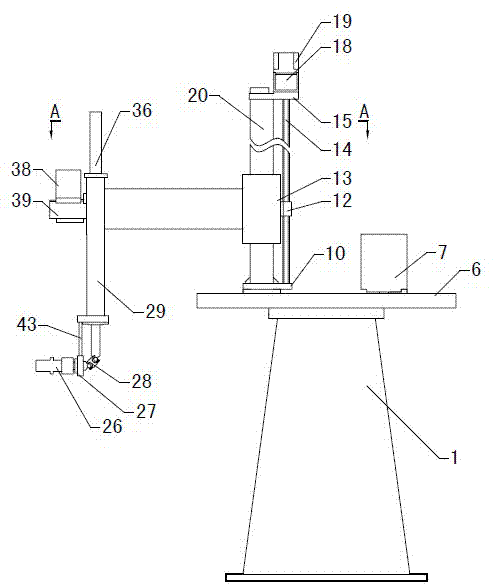

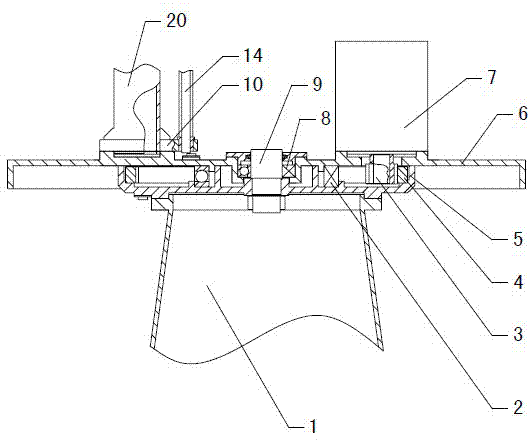

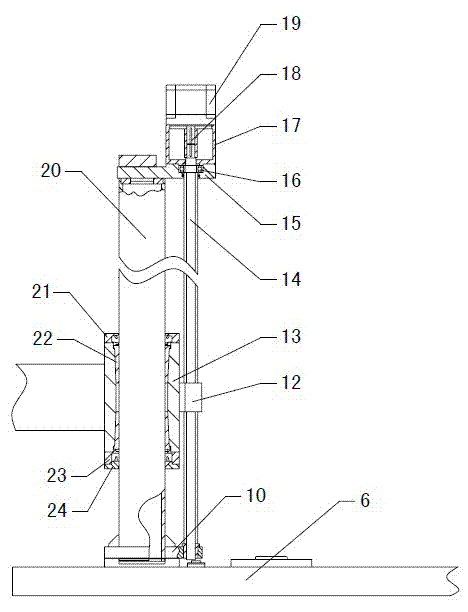

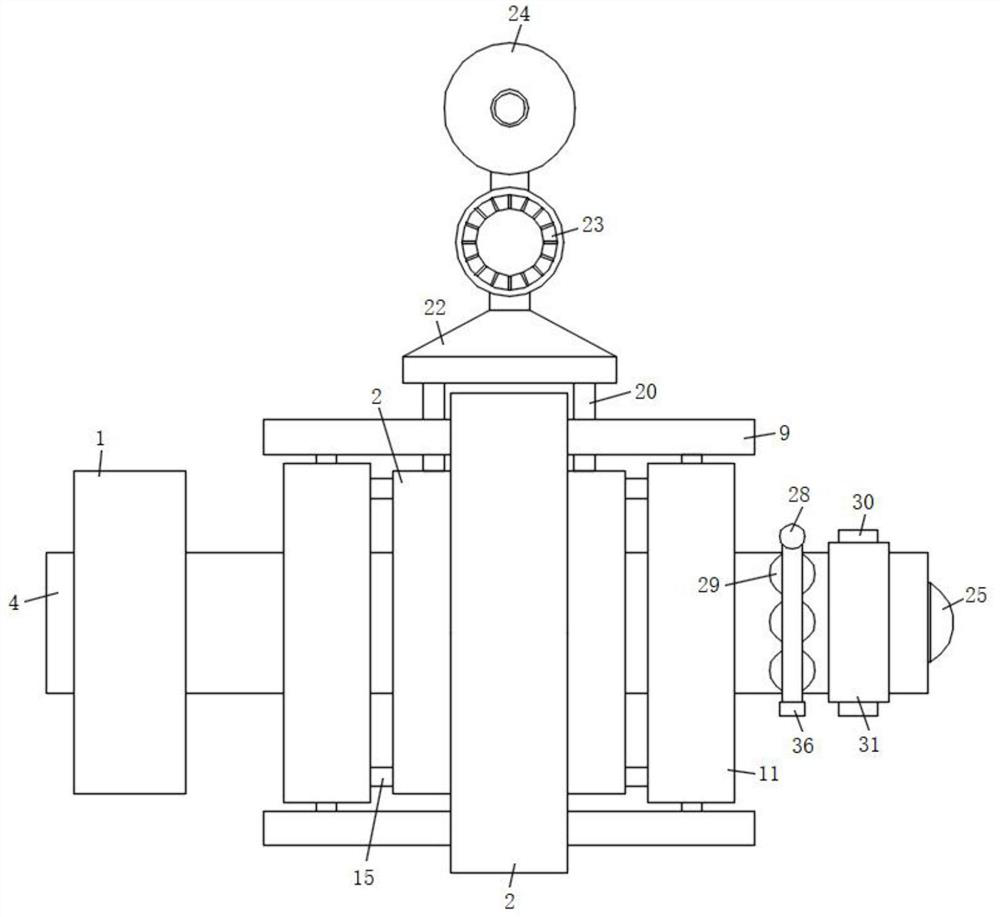

Mold-melting shell maker

ActiveCN103495706AUniform thicknessOvercome uniformity issuesFoundry mouldsMoulding machinesWaxUniversal joint

The invention relates to a mold-melting shell maker, and belongs to the field of shell maker equipment. The mold-melting shell maker comprises a base (1), a rotary workbench (6) arranged on the base (1) rotationally, a linear lifting mechanism arranged above the rotary workbench (6) vertically and a horizontal connecting arm. The inner end of the horizontal connecting arm is fitted on the linear lifting mechanism, and the horizontal connecting arm can slide along the linear lifting mechanism vertically; the outer end of the connecting arm is fixed with a vertical rotary lifting mechanism, the lower end of the rotary lifting mechanism is fixedly connected to a breaker (26) through a universal joint (28), the upper portion of the breaker (26) is provided with a breaker bearing seat (27) provided with a bearing inside, the corresponding distance between the breaker bearing seat (27) and the rotary lifting mechanism is fixed through a pull rod (43), and the lower end of the pull rod (43) is hinged with the breaker bearing seat (27). The mold-melting shell maker has the advantages that slurry sticking and sand sticking can be performed automatically, operating efficiency is improved, the thickness of a wax mold shell is uniform, and quality is stable.

Owner:山东先河悦新机电股份有限公司

Fruit unshelling device

InactiveCN102835715ARealize unpackingAvoid destructionHuskingHullingSocial benefitsEconomic benefits

The invention discloses a fruit unshelling device, which comprises a tube body, a cover plate, a driving device and a machine frame and is characterized in that the unshelling device is also provided with a stirrer, a jacket and a sieving groove, the jacket is arranged at the bottom of the tube body, a propeller and a stirring rod are arranged on a stirring shaft of the stirrer, the bottom of the tube body is provided with a tube body bottom hole plate, the inner wall of the tube body is provided with a baffle strip, the lowest end of the jacket is provided with a ball valve A, the sieving groove is arranged under the jacket, the middle of the sieving groove is provided with a movable hole plate, the bottom end of the sieving groove is provided with a ball valve B. In the work process, the fruit generates kneading movement through mutual extrusion under the effects of the baffle strip and the stirrer in the tube body, so the fruit unshelling is reached. The fruit unshelling device is applicable to the dry type and wet type unshelling of the fruit, the structure is reasonable, the operation is simple and convenient, the fruit extraction rate, the efficiency and the quality are improved, the fruit unshelling device is particularly suitable for the fruit unshelling, the beneficial conditions are created for the propagation acceleration of precious tree species, and good economic benefits and social benefits are realized.

Owner:GUANGXI FORESTRY RES INST

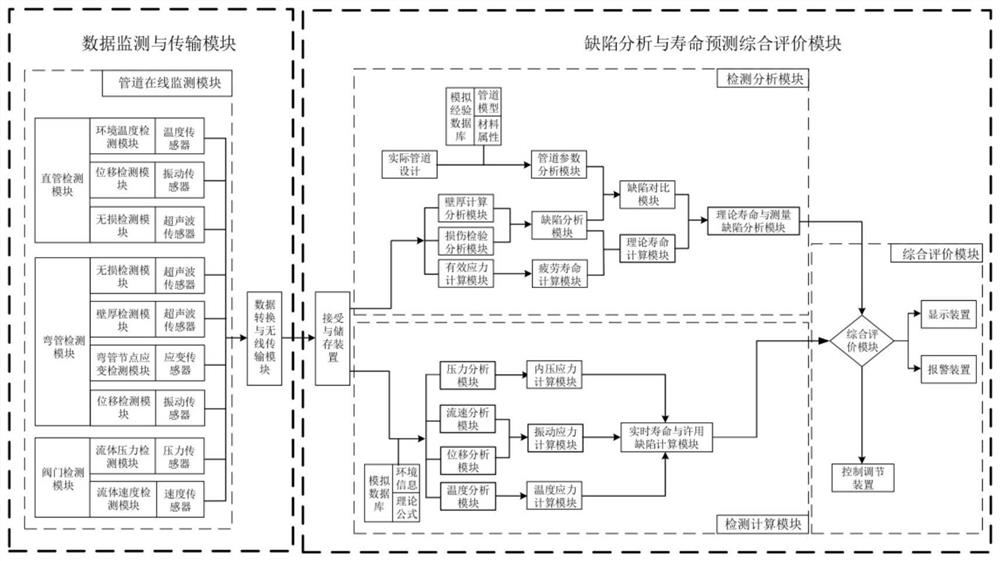

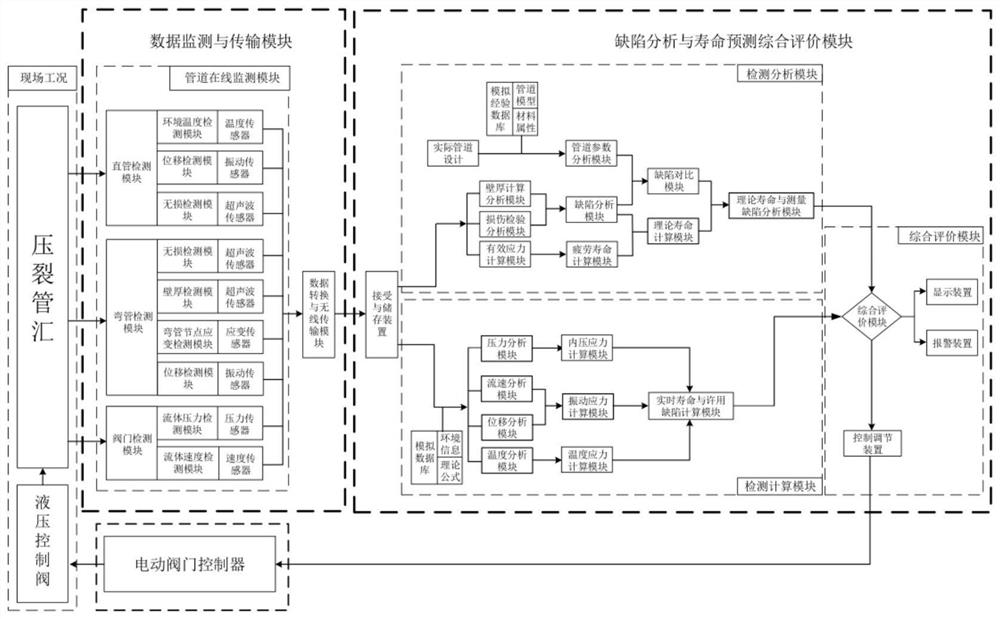

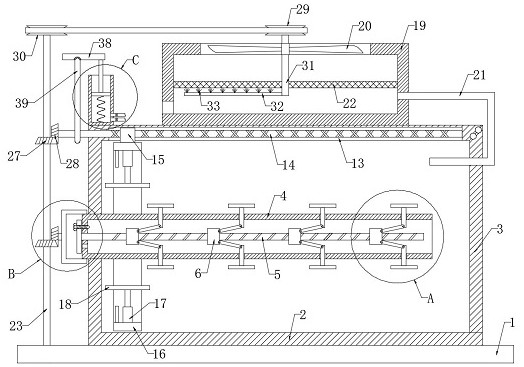

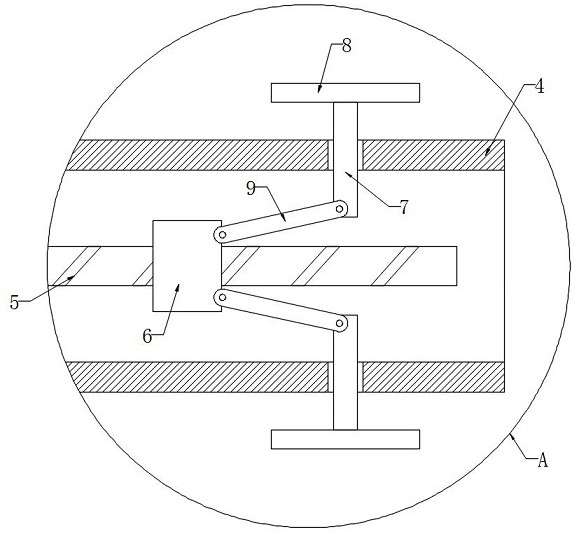

Fracturing manifold working condition monitoring and life prediction and feedback regulation and control system

InactiveCN111609890AReal-time analysisTimely feedback adjustmentAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansData transformationDisplay device

The invention relates to a fracturing manifold working condition monitoring and life prediction and feedback regulation and control system, which belongs to the technical field of pipeline monitoringand mainly comprises a data monitoring and transmission module and a defect analysis and life prediction comprehensive evaluation module. The data monitoring and transmission module comprises a pipeline online monitoring module and a data conversion and wireless transmission module; the pipeline online monitoring module monitors data and transmits the data to the data conversion and wireless transmission module in a wireless transmission mode; the data are transmitted to a defect analysis and life prediction comprehensive evaluation module provided with a storage and collection device, a detection and analysis module, a detection and calculation module and a comprehensive evaluation module; and the comprehensive evaluation module is input by the detection and analysis module and the detection and calculation module and output to a control and adjustment device, a display device and an alarm device. The damage degree of a fracturing manifold is monitored in real time; the service life of the pipeline is judged, and control and early warning decisions are made in time; and the safety of the pipeline and fracturing construction operation is enhanced.

Owner:SOUTHWEST PETROLEUM UNIV

Stainless steel pipe machining device

InactiveCN112296777AEasy to operatePracticalRevolution surface grinding machinesDispersed particle filtrationMetallurgyEngineering

The invention discloses a stainless steel pipe machining device which comprises a base. A grinding box is fixedly connected to the upper end of the base, a box cover is hinged to the side wall of thegrinding box, a cylinder is rotatably connected to the inner wall of the grinding box, a lead screw is rotatably connected to the inner wall of the cylinder, multiple lead screw nuts are in threaded connection with the side wall of the lead screw, multiple sliding rods are symmetrically and slidably connected to the side wall of the cylinder, and clamping plates are fixedly connected to the ends,away from the lead screw, of the sliding rods. According to the stainless steel pipe machining device, the lead screw nuts slide on the side wall of the lead screw by rotating the lead screw, then thelead screw nuts drive the sliding rods to slide on the side wall of the cylinder through connecting rods, then the clamping plates are driven to slide on the side wall of the cylinder, stainless steel pipes with different pipe diameters can be clamped, and operation is easy; and when grinding plates slide on the side walls of stainless steel back and forth, the cylinder drives the clamped stainless steel pipes to rotate, then the stainless steel pipes can be comprehensively and quickly ground, and the grinding efficiency to the stainless steel pipes is improved.

Owner:刘丹丹

Wood cutting device with measuring function

InactiveCN109940709AShorten the timeImprove working environmentProfiling/shaping machinesBark-zones/chip/dust/waste removalWorking environmentEngineering

The invention discloses a wood cutting device with a measuring function. The wood cutting device with the measuring function comprises a workbench, a collecting groove, fans and a dust collection box,wherein a collecting groove is arranged in the workbench; a waste port is formed in the top of the workbench; a baffle is fixedly arranged on one side of the top of the workbench; vertical rods are fixedly arranged on two sides of the top of the workbench; a cross beam is fixedly arranged on the top of the vertical rods; the dust collection box is arranged on the top of the cross beam; and the fans are arranged on two sides of the top of the cross beam. According to the wood cutting device with the measuring function, when debris dust is generated during cutting, the debris can fall into thecollecting groove from the waste port, and some small dust is pumped into the dust collection box by the fans, so that the working environment of workers is guaranteed, and the dust cleaning frequencyof the workers is reduced.

Owner:扬州一平米高科有限公司

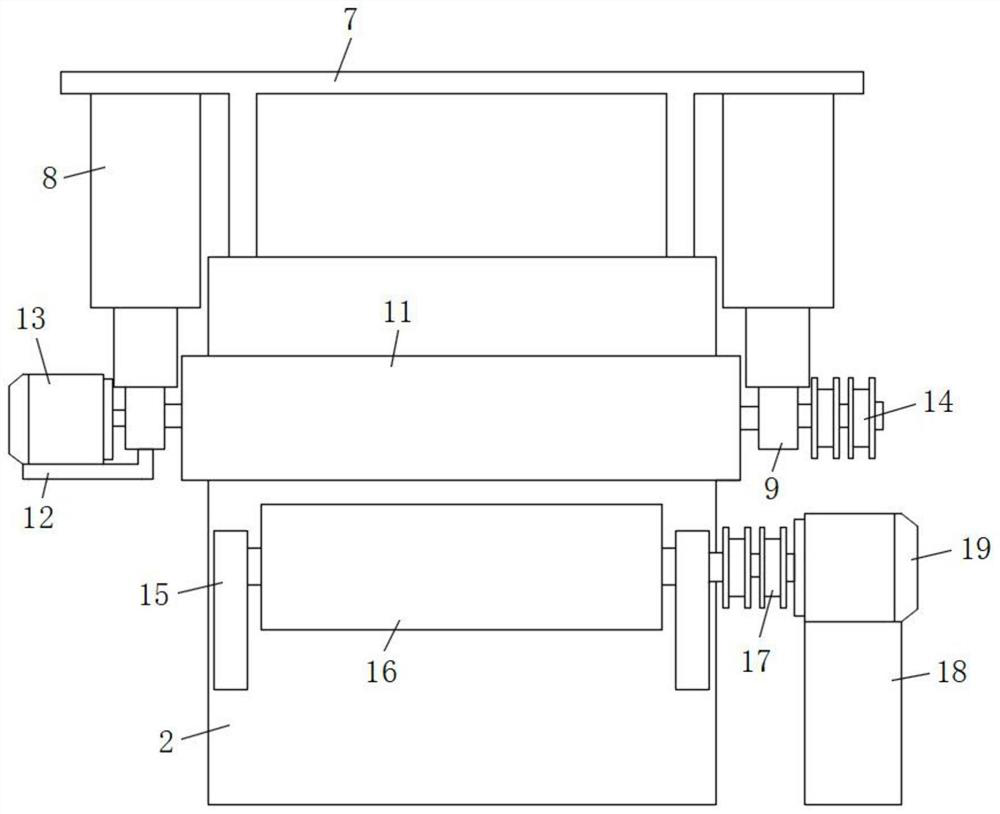

Wood board surface machining treatment device

InactiveCN112496909AContinuous processing is easy to operateAchieve double-sided grindingGrinding drivesProfiling/shaping machinesPolishingWood plank

The invention discloses a wood board surface machining treatment device which comprises a cutting frame and a polishing chamber; a supporting plate is further fixedly connected to the middle of the inner wall of the front end and the middle of the inner wall of the rear end of the cutting frame, rectangular holes are formed in the two sides of a polishing chamber in a penetrating mode, and a working plate is further fixedly connected between the bottom faces of the interiors of the rectangular holes and the top face of the supporting plate; a first air cylinder is fixedly connected to the inner top face of the cutting frame through screws, a cutting machine is fixedly connected to the output end of the first air cylinder through screws, a mounting frame is fixedly connected to the outer top face of the polishing chamber, second air cylinders are fixedly connected to the front side and the rear side of the bottom face of the mounting frame through screws, and mounting strips are fixedlyconnected to the output ends of the second air cylinders through screws; and polishing rollers are rotatably connected to the middles of the two mounting strips and the lower sides of the inner wallsof the front end and the rear end of the polishing chamber correspondingly, and first pushing rollers are further rotatably connected to the two sides of the two mounting strips. The wood board surface machining treatment device is reasonable in design and stable, continuous machining operation of wood boards is easy and convenient, double-face polishing and waxing operation of the wood boards can be achieved at the same time, and the working efficiency of wood board machining is greatly improved.

Owner:怀宁县三兴木业有限公司

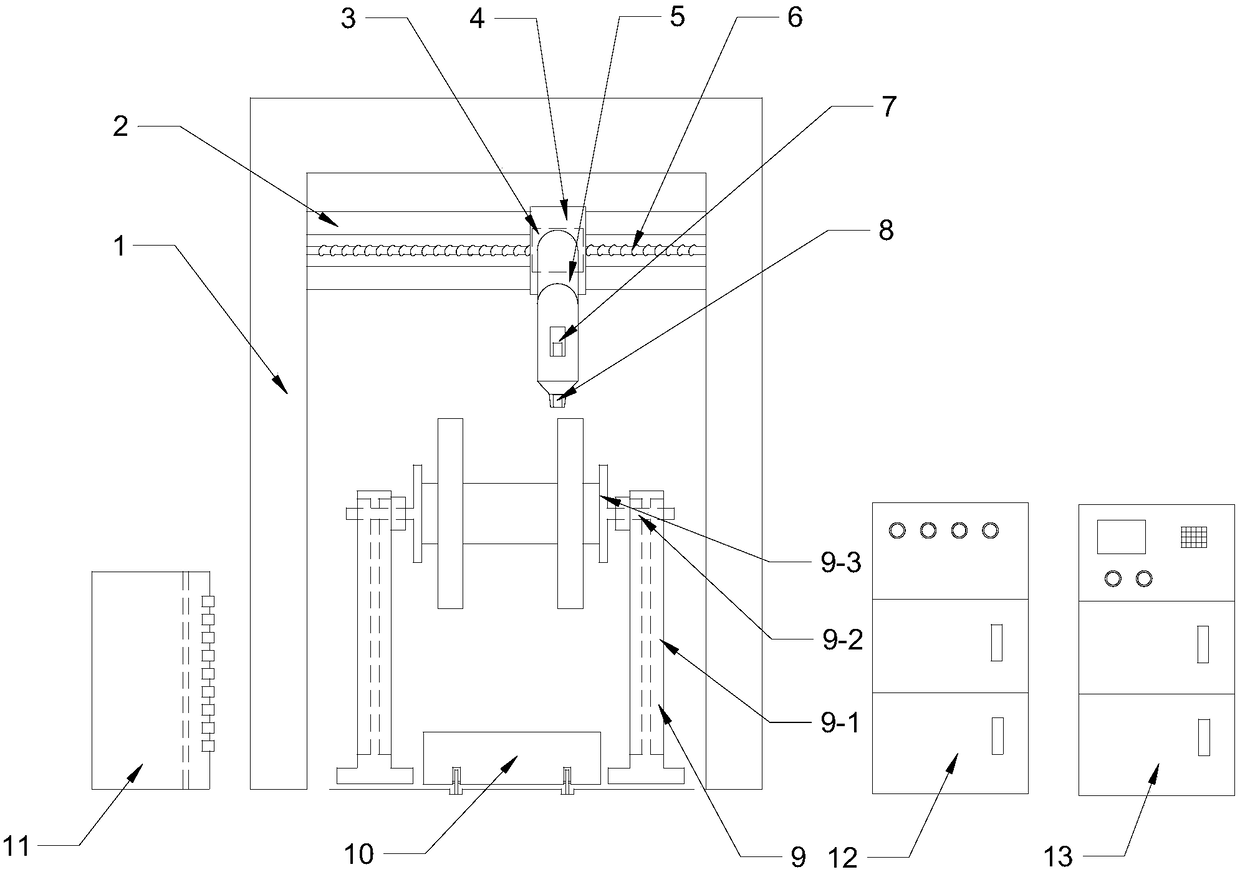

Intelligent laser washing system for wheel sets and bogies

PendingCN108435710AHigh degree of automationReduce work intensityCleaning processes and apparatusTruckRail traffic

The invention relates to the field of rail traffic washing equipment, in particular to an intelligent laser washing system which is used for washing metal components such as wheels sets and bogies oftrucks, passenger cars, metros, bullet trains and locomotive inspection and repair bases. The intelligent laser washing system comprises a portal frame. A linear rolling guide rail pair and a horizontal ball screw pair are installed on the portal frame. A fixing box is fixed on a moving part of the rolling guide rail pair. A ball screw nut is installed on the ball screw pair. The ball screw nut isfixedly connected with a back plate of a robot through the fixing box. A machine vision system is installed on an arm of the robot. A laser head is installed on the portion under the wrist joints ofthe robot. According to the system, the automation degree is improved, working intensity of workers is reduced, operation efficiency is improved, a sewage treatment system is not needed, consumable items are not needed during operation, return on investment can be obtained fast, the operation and maintenance cost is reduced, long-distance operation is achieved, the parts which cannot be reached easily through the traditional washing method can be washed, and the system is suitable for being popularized in the field of the rail traffic washing equipment.

Owner:德阳瑞方智能交通设备科技有限公司

Bidirectional air exhaust cable cooling device

InactiveCN105514883AReduce labor intensityGuaranteed working environmentElectrical apparatusCooling effectEngineering

The invention discloses a bidirectional air exhaust cable cooling device, and the device comprises a bottom plate apparatus, a frame body, a fixing apparatus, a straightening apparatus, a first air incoming apparatus, a second air incoming apparatus, an aspiration apparatus, and a filtering apparatus. The bottom plate apparatus comprises a bottom plate, a first supporting rod, a first inclined rod, and a first support. The frame body is provided with a first fixed support, a first baffle plate, a first spring, a first fixed ring, a first through hole, and a second through hole. The fixing apparatus comprises a first cross bar, a first vertical rod, a second fixed ring, a second spring, and a first holding rod. The straightening apparatus comprises a third fixed ring, an elastic piece, a connection line, a first fixed pulley, a second support, a third support, a second cross bar, a first motor, an output shaft, and a second baffle plate. The first air incoming apparatus comprises a first air inlet pipe, a first water tank, a first pipeline, a first valve, a filtering frame, and a first blocking column. The second air incoming apparatus comprises a second air inlet pipe, a first filter screen, a second water tank, a second pipeline, and a second valve. The device can be used for bidirectional air exhaust of a cable, and is remarkable in cooling effect.

Owner:张萍

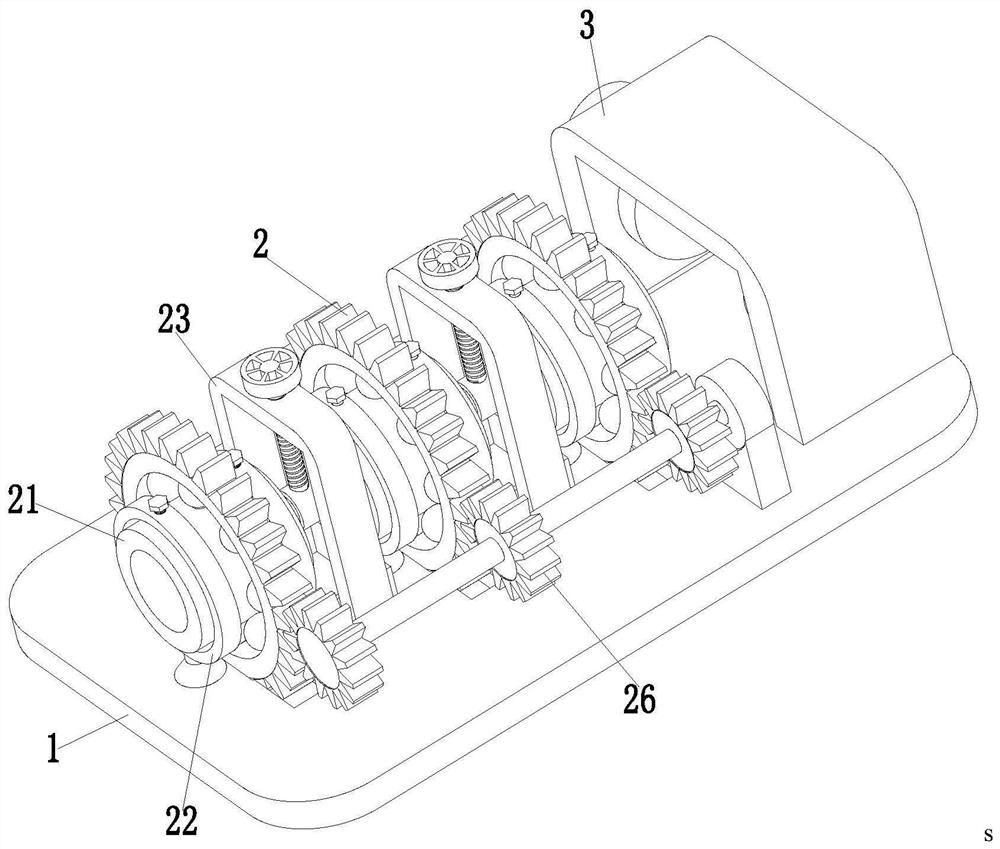

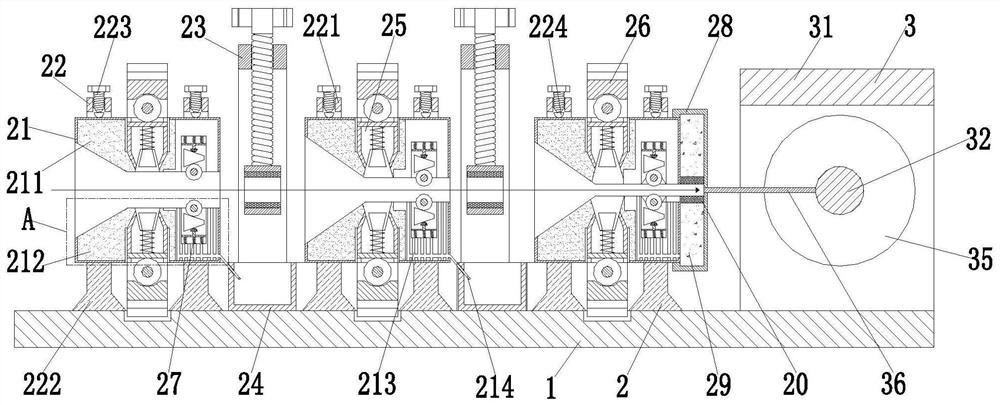

Stainless steel wire manufacturing process

InactiveCN112427470AAffect mechanical propertiesAvoid breakageExtrusion cleaning devicesWire rodMetallurgy

The invention relates to a stainless steel wire manufacturing process, in particular to a stainless steel wire manufacturing device. The stainless steel wire manufacturing device comprises a bottom plate, a stretching mechanism and a traction mechanism, the stretching mechanism is installed in the middle of the upper end face of the bottom plate, and the traction mechanism is arranged on the rightside of the stretching mechanism and fixedly installed on the right side of the upper end face of the bottom plate. The problems that most existing stainless steel wire manufacturing devices adopt aone-time wire stretching mode, stainless steel wires cannot be stretched step by step, consequently, the wires become thinner suddenly, drawing force changes suddenly, the stainless steel wires are prone to being snapped, and the quality and the mechanical property of the formed stainless steel wires are affected are solved; and the problems that an existing stainless steel wire manufacturing device cannot evenly coat the surface of a stainless steel wire with a lubricating agent, so that the lubricating degree is insufficient when the wire is stretched, and burrs are likely to appear on the surface of the stretched wire are solved.

Owner:刘静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com