Bidirectional air exhaust cable cooling device

A technology of cooling device and air extraction cable, applied in the direction of electrical components, etc., can solve the problems of low operational reliability, unfavorable cooling, power consumption, etc., and achieve the effect of remarkable cooling effect, preventing cooling effect, and saving cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

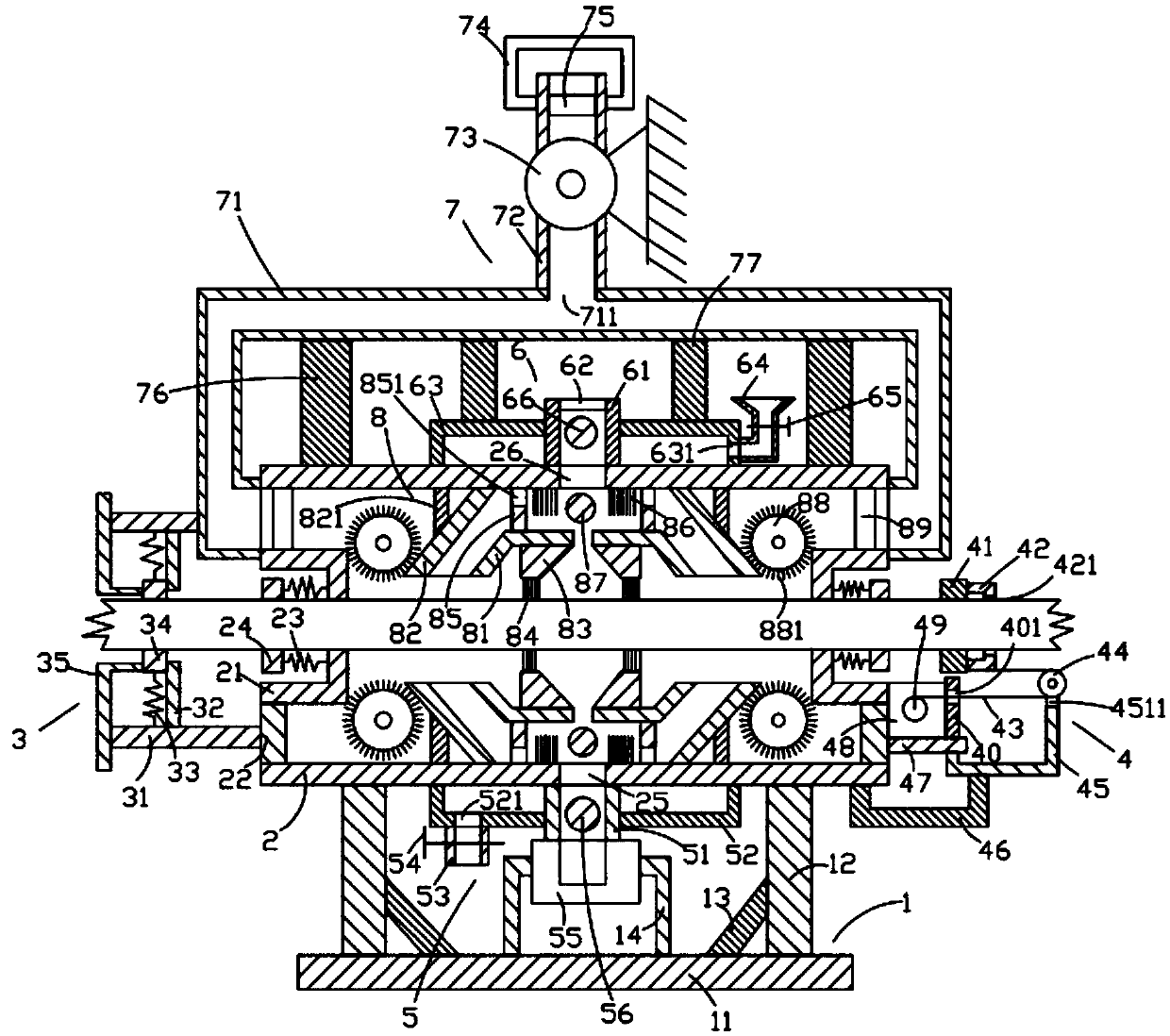

[0018] The following will make a clear and complete description of the two-way suction cable cooling device of the present invention in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the two-way suction cable cooling device of the present invention includes a base plate device 1, a frame body 2 located above the base plate device 1, a fixing device 3 located at the left end of the frame body 2, and a puller located on the right side of the frame body 2. Straight device 4, the first air intake device 5 located below the frame body 2, the second air intake device 6 located above the frame body 2, the suction device 7 located above the frame body 2 and the air intake device located above the frame body 2 The filtering device 8 inside the frame body 2 .

[0020] Such as figure 1 As shown, the base plate device 1 includes a base plate 11, a first support bar 12 located above the base plate 11, a first inclined bar 13 located on one side of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com