Mold-melting shell maker

A shell machine and investment mold technology, applied in molding machines, manufacturing tools, casting and molding equipment, etc., can solve the problems of uneven thickness of wax mold shells, low efficiency of manual sanding, and unstable product quality, etc. The effect of low work efficiency, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

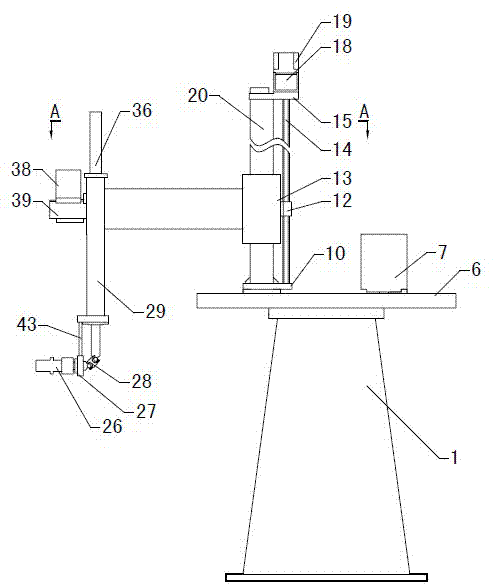

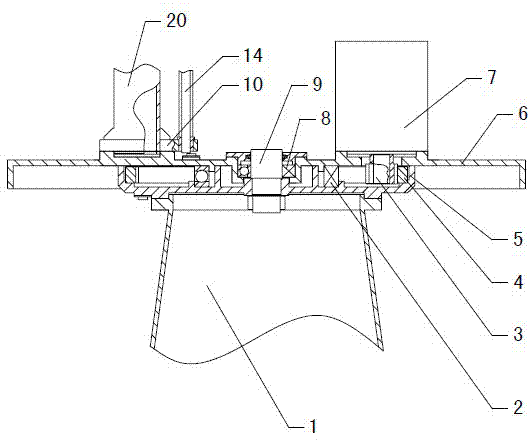

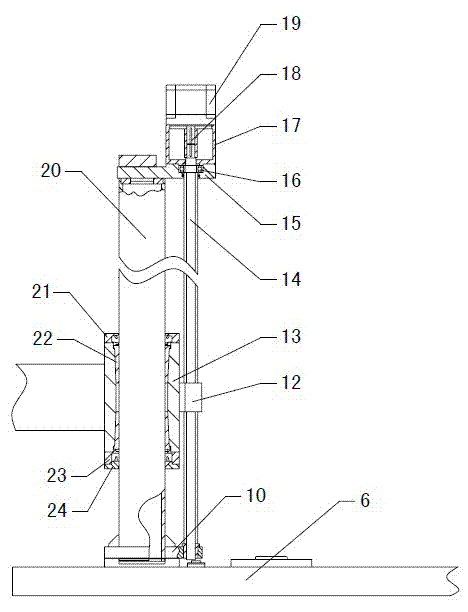

[0028] Figure 1~6 It is the best embodiment of investment shell making machine of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0029] Refer to attached figure 1: An investment shell making machine, including a base 1, a rotary table 6, a linear lifting mechanism, a connecting arm, a swing mechanism, a rotary lifting mechanism and a loader 26, the rotary table 6 is rotated and fixed on the upper end of the base 1, and multiple linear lifting mechanisms Vertically fixed on the upper side of the rotary table 6, the linear lifting mechanism is evenly distributed along the circumference of the rotary table 6, and each linear lifting mechanism is fixed with a group of connecting arms horizontally. The outer end of the connecting arm has a swing mechanism, and the swing mechanism The swing output end is fixedly connected with the rotary lifting mechanism, and the lower end of the rotary lifting mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com