Patents

Literature

93results about How to "Even sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

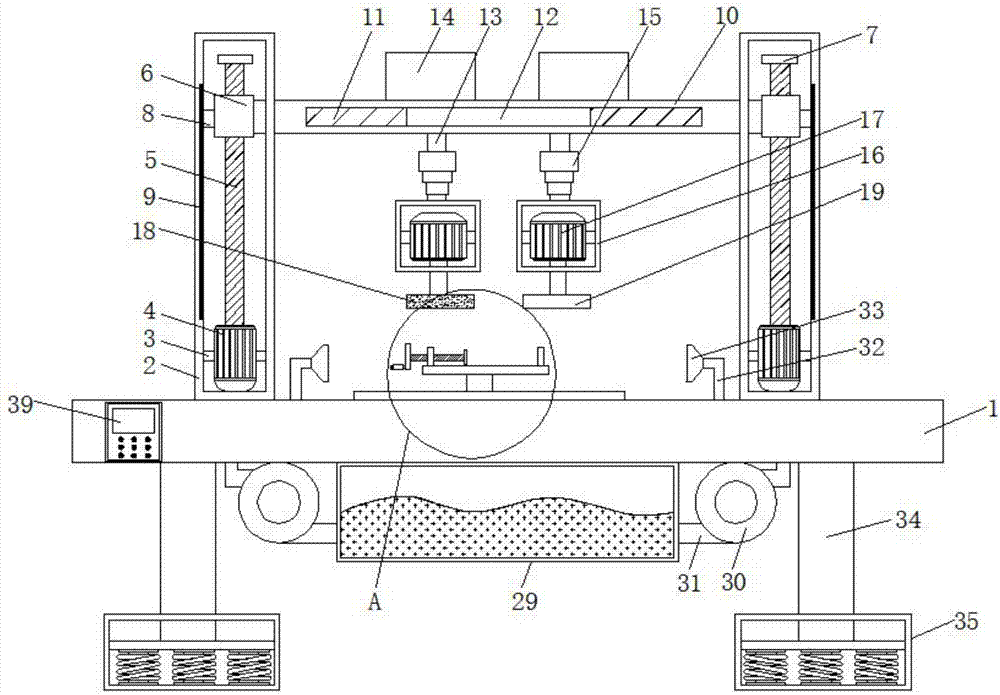

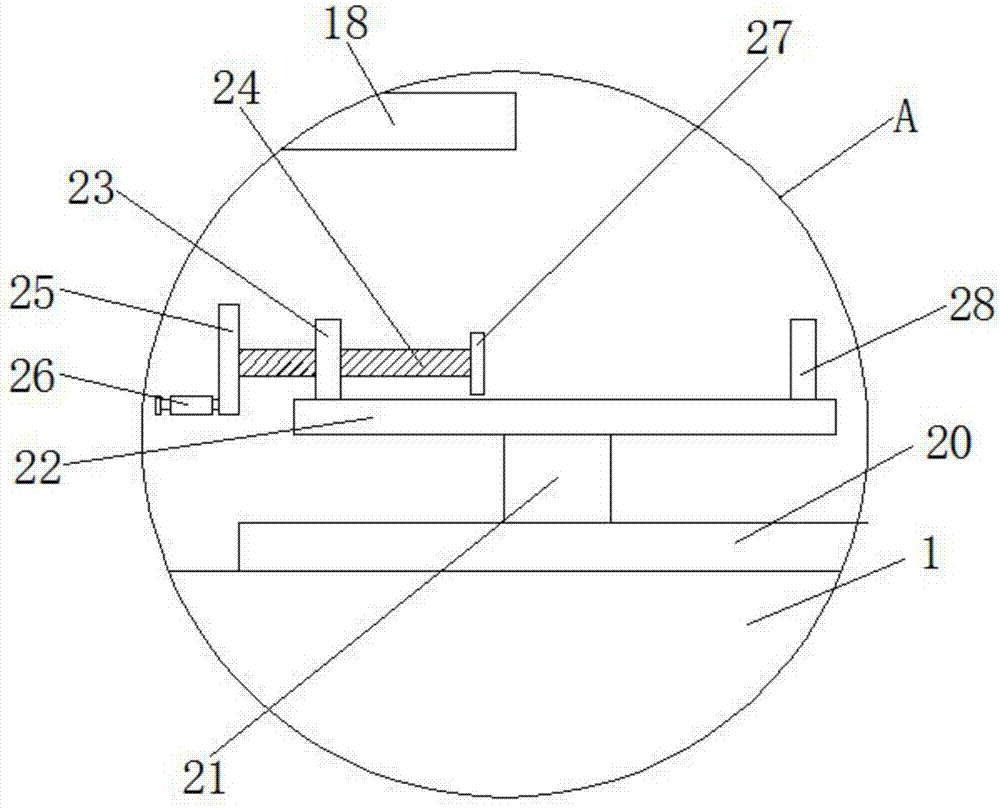

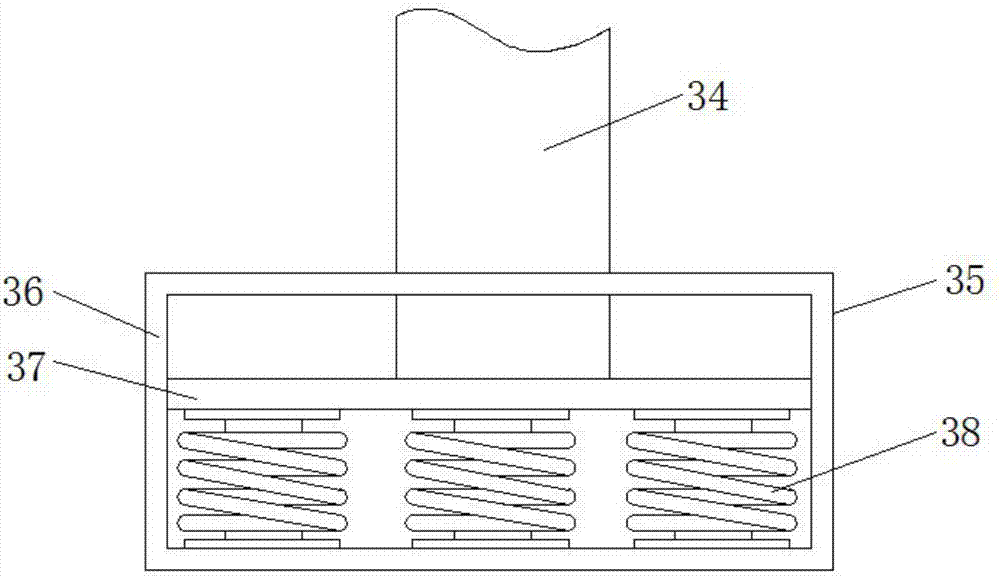

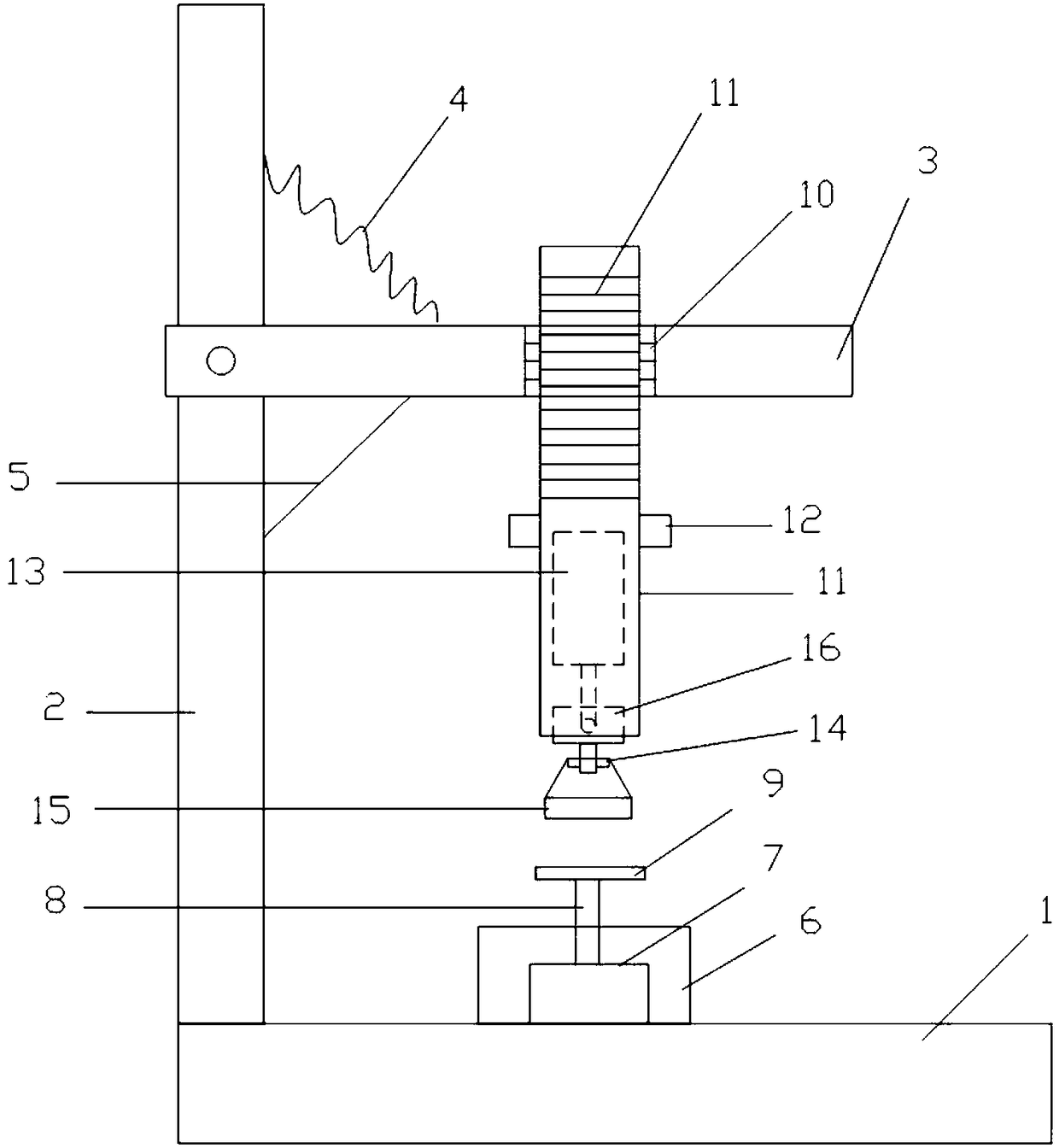

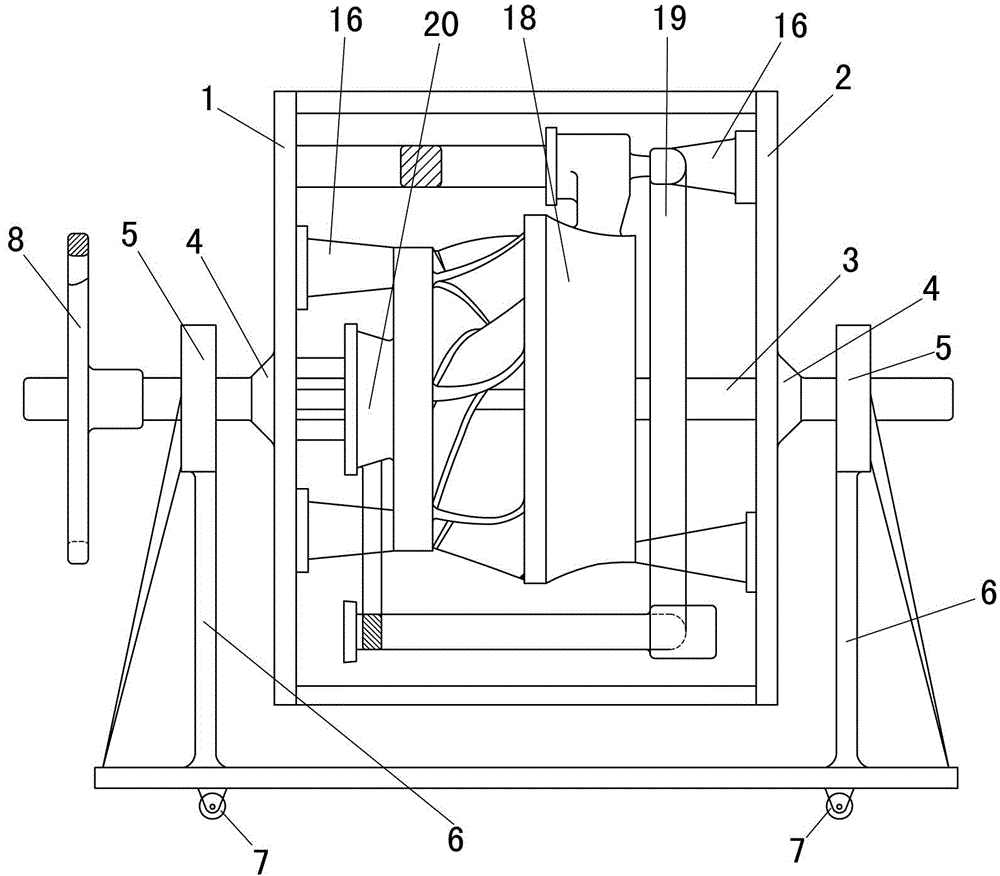

Automobile gear end surface polishing device

InactiveCN107336096AQuality improvementEasy to polishGrinding carriagesGrinding work supportsGear wheelEngineering

The invention provides an automobile gear end surface polishing device, and relates to the technical field of automobile gear polishing. The automobile gear end surface polishing device comprises a working table, standing columns are fixedly installed on both sides of the top of the working table, and motor mounting blocks are fixedly installed on both sides of the inner wall of each standing column. According to the automobile gear end surface polishing device, through arrangement of telescopic motors, threaded rods, telescopic blocks, sliding rods, a strip-shaped sliding groove and a cross plate, a polishing device body on the bottom of the cross plate can vertically move between the two standing columns under driving of the telescopic motors; through arrangement of the cross plate, the sliding groove and supports, the polishing device body on the bottom of the cross plate can transversely move on the bottom of the cross plate; through arrangement of a polishing table, a rotating rod and a clamping base, a gear to be polished which is fixed to the top of the clamping base in a clamped mode can conduct circular motion on the bottom of a polishing motor under driving of the rotating rod. In sum, by means of the automobile gear end surface polishing device, the effect that adjustment is convenient is achieved, it is convenient for people to polish the end surface of the gear from different angles, and the quality of the gear after polished is better.

Owner:姚飞

Preparing method of low-cost oxide ceramic shell for titanium alloy precision casting

A low-cost oxide ceramic mould for the precise casting of Ti-alloy is prepared through preparing paint and wax mould of casting, immersing the wax mould in paint for 10-20 min, leveling the paint, uniformly applying the white electro-corundum powder to the paint layer of wax mould, drying, and high-pressure dewaxing.

Owner:HARBIN INST OF TECH

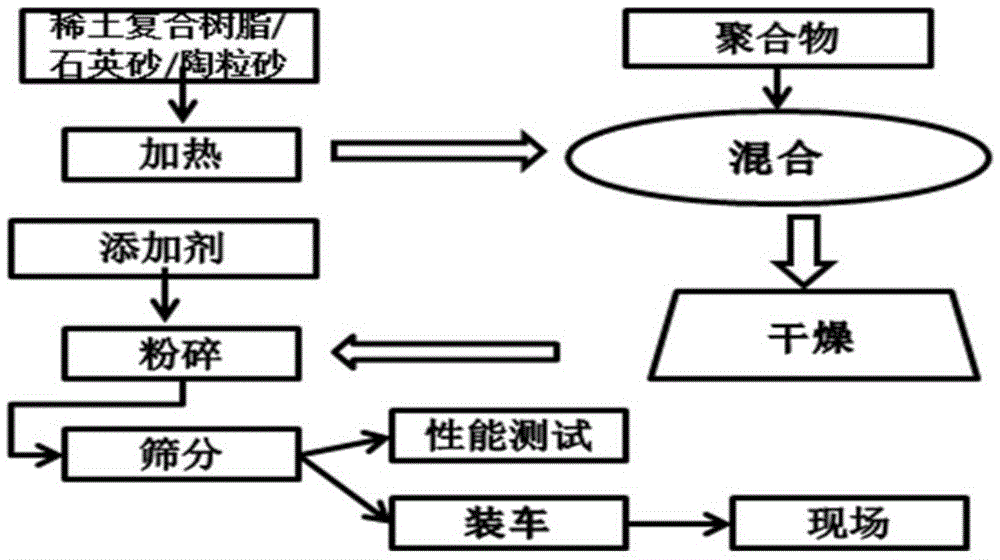

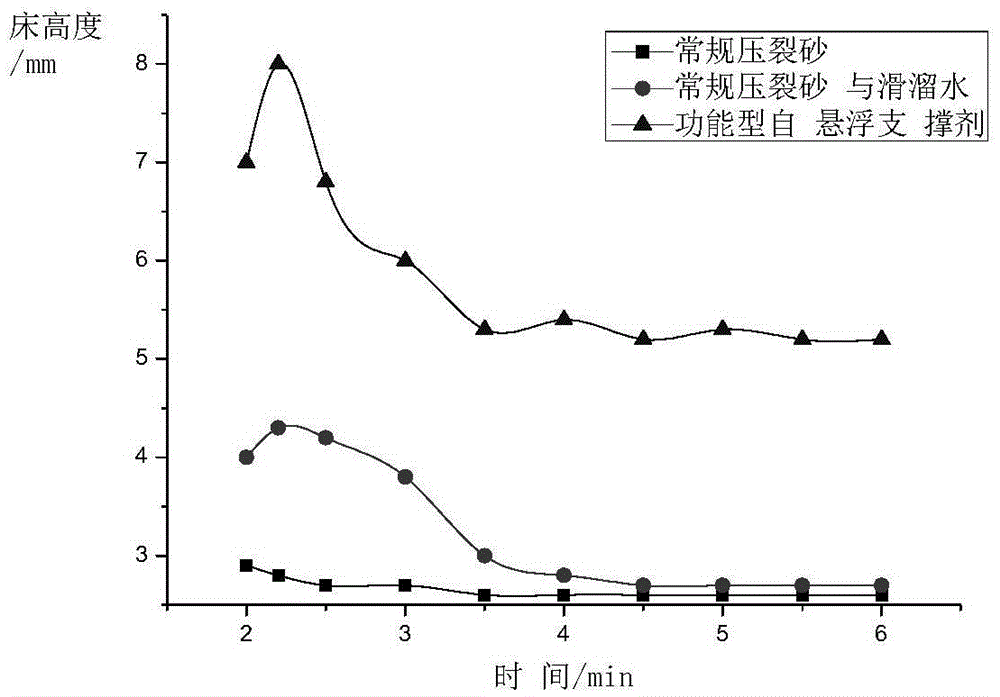

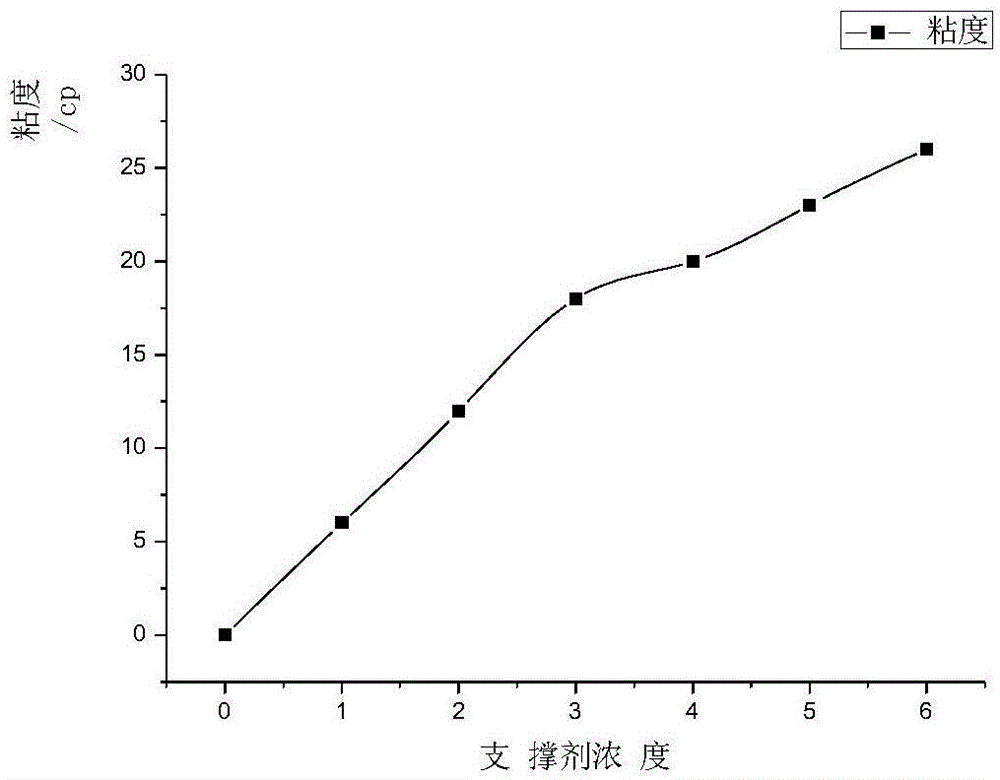

Water acid-sensitivity deformation magnetic tracer function self-suspension propping agent and preparation method thereof

InactiveCN105670600AReservoir damage is smallSave time and costFluid removalDrilling compositionMagnetic tracerSurface hydration

The invention belongs to the technical field of oil-gas field fracturing production-increase propping agent preparation, and relates to a water acid-sensitivity deformation magnetic tracer function self-suspension propping agent and a preparation method thereof. The propping agent comprises an aggregate and a surface hydration layer, wherein the aggregate is one of magnetic rare earth composite resin, quartz sand or ceramsite and like material; the surface hydration layer is composed of three layers, the innermost layer is a cationic macromolecule inner polymer layer or a modifier layer, the middle layer is an anionic macromolecule outer polymer layer, and the outer layer is anti-caking agent. The propping agent has the acid-sensitivity deformation self-suspension function of producing buoyant force while encountering water and breaking gel to precipitate while encountering the acid, and a tracer function of monitoring flow guiding position of the propping agent through electromagnetic imaging; in the process of exerting the fracturing engineering on shale, compact oil-gas or coal bed base and like argillaceous plasticity micronano hole reservoir, the fracturing liquid with the propping agent has excellent flow guiding characters of suspension sand-adding of non-floating to the roof and not sinking to the bottom; the permeation is improved, the hurt is avoided, the propping agent is efficient and capable of increasing production, the construction cost is lowered, and the application prospect is wide.

Owner:王展旭

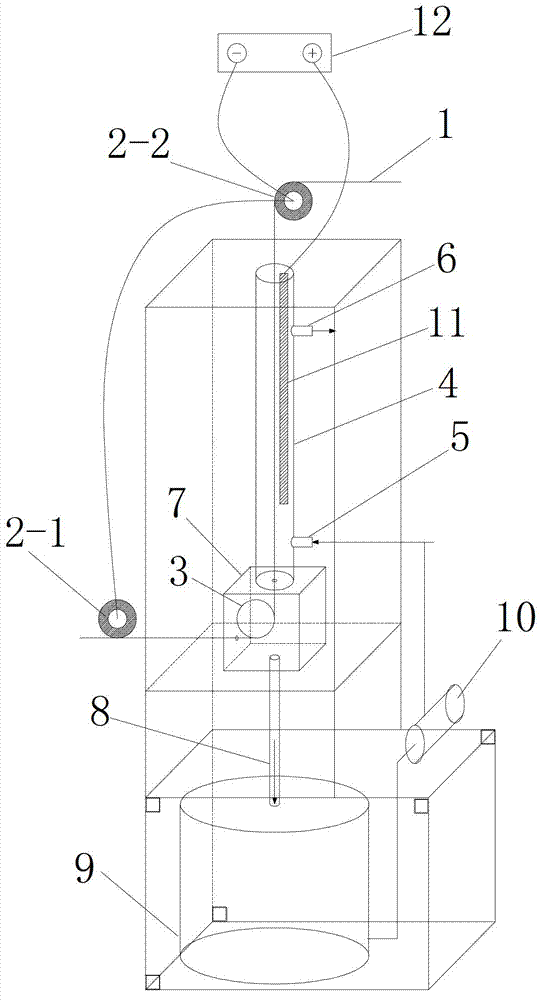

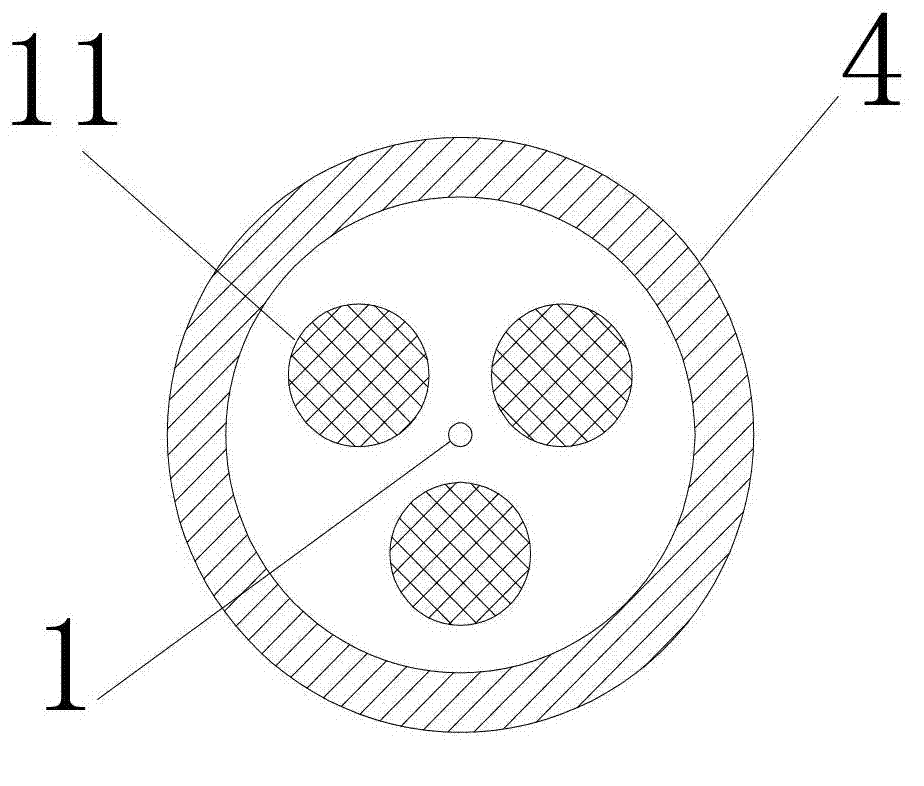

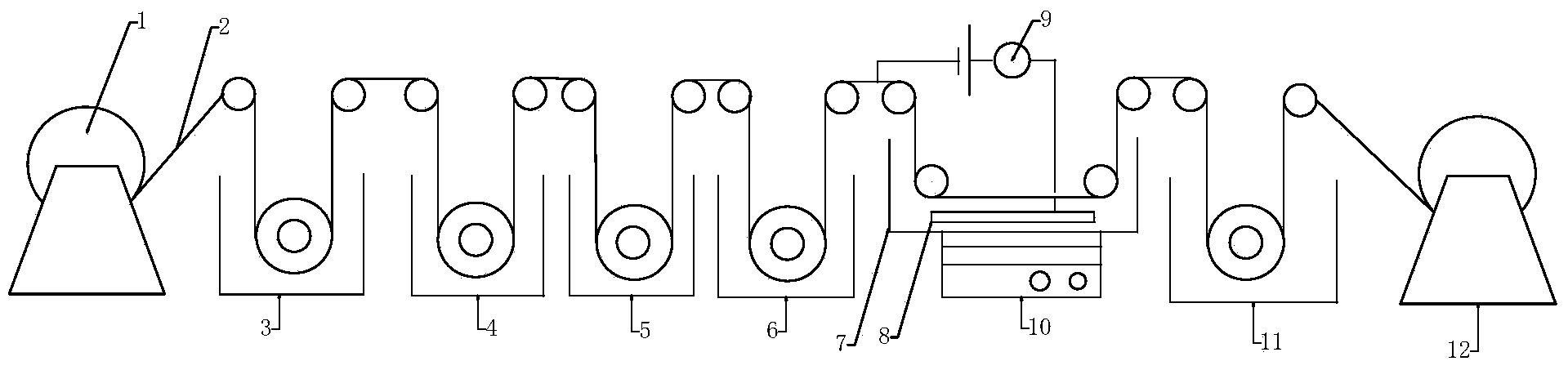

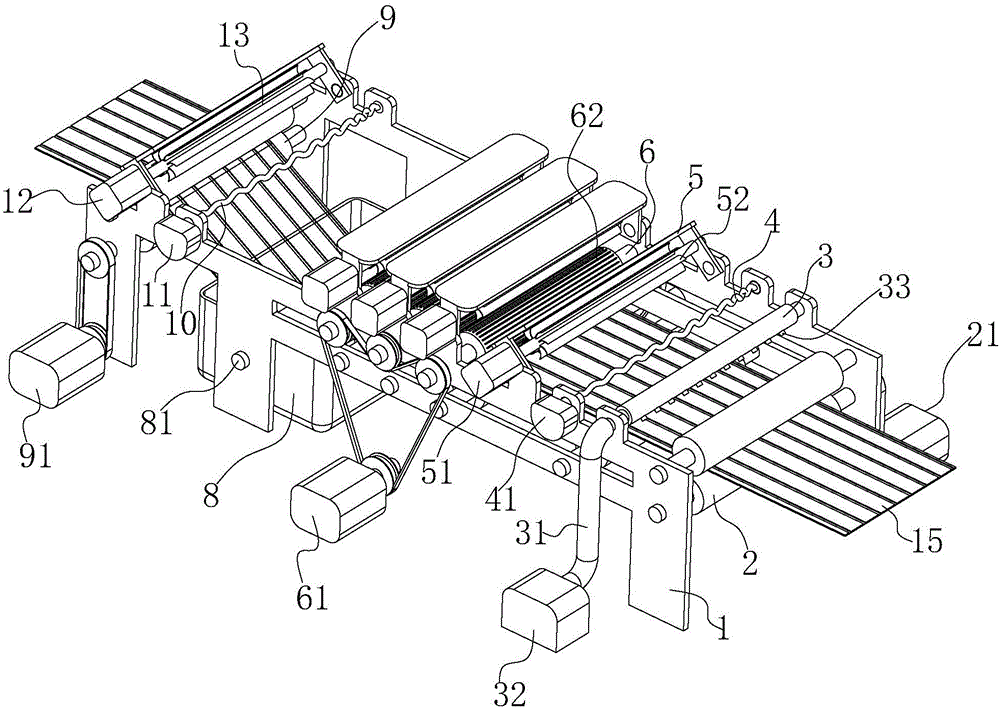

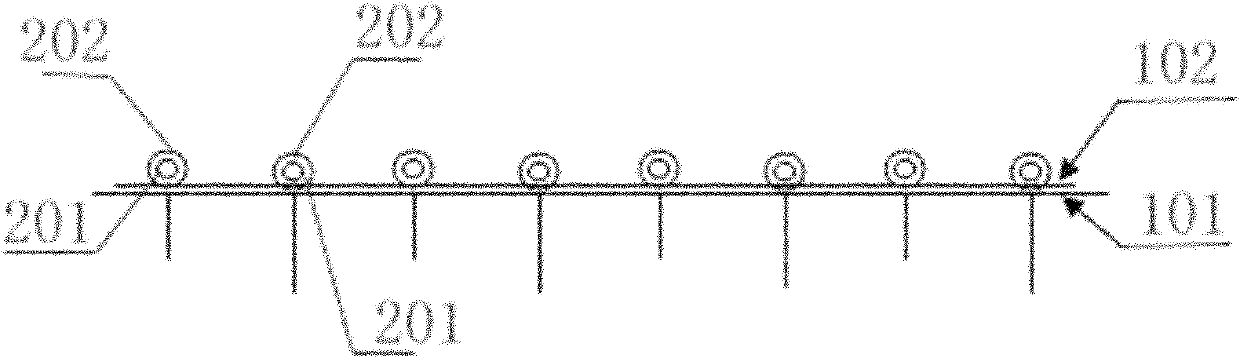

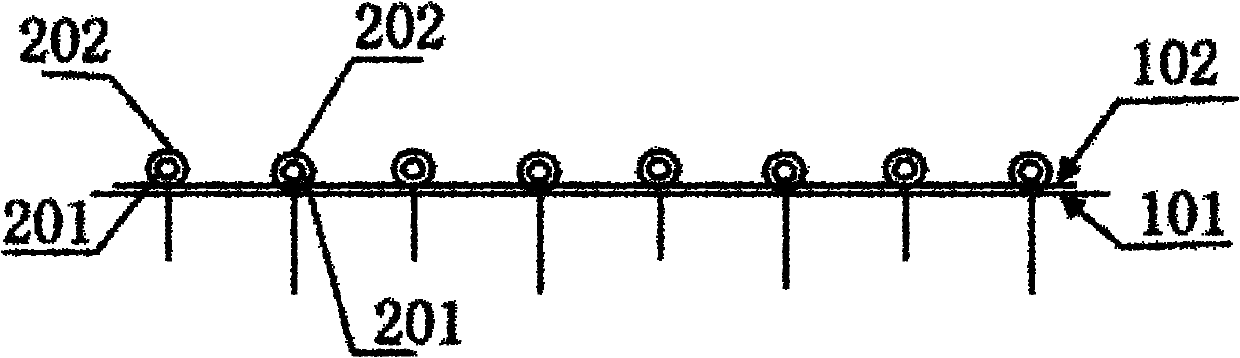

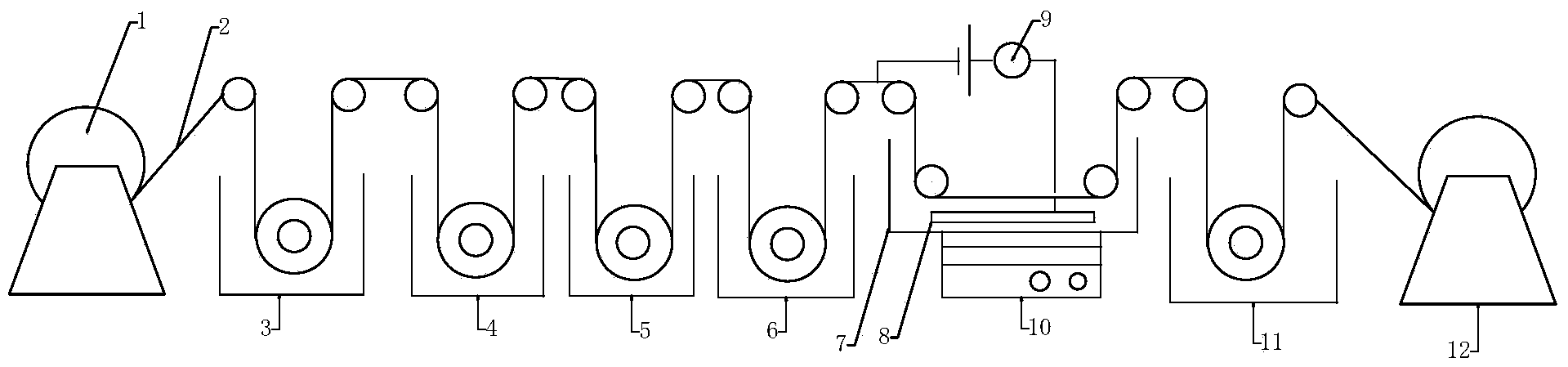

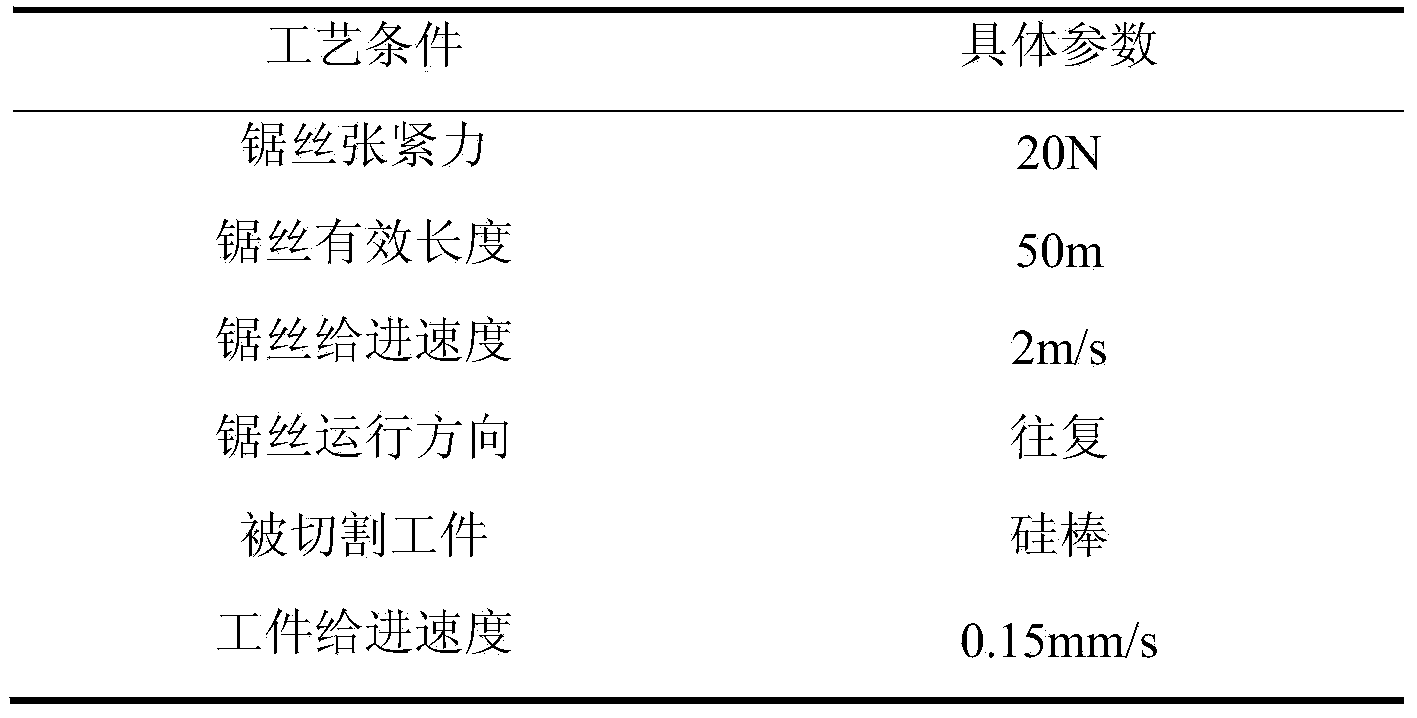

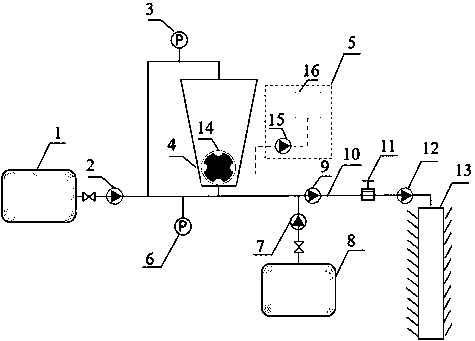

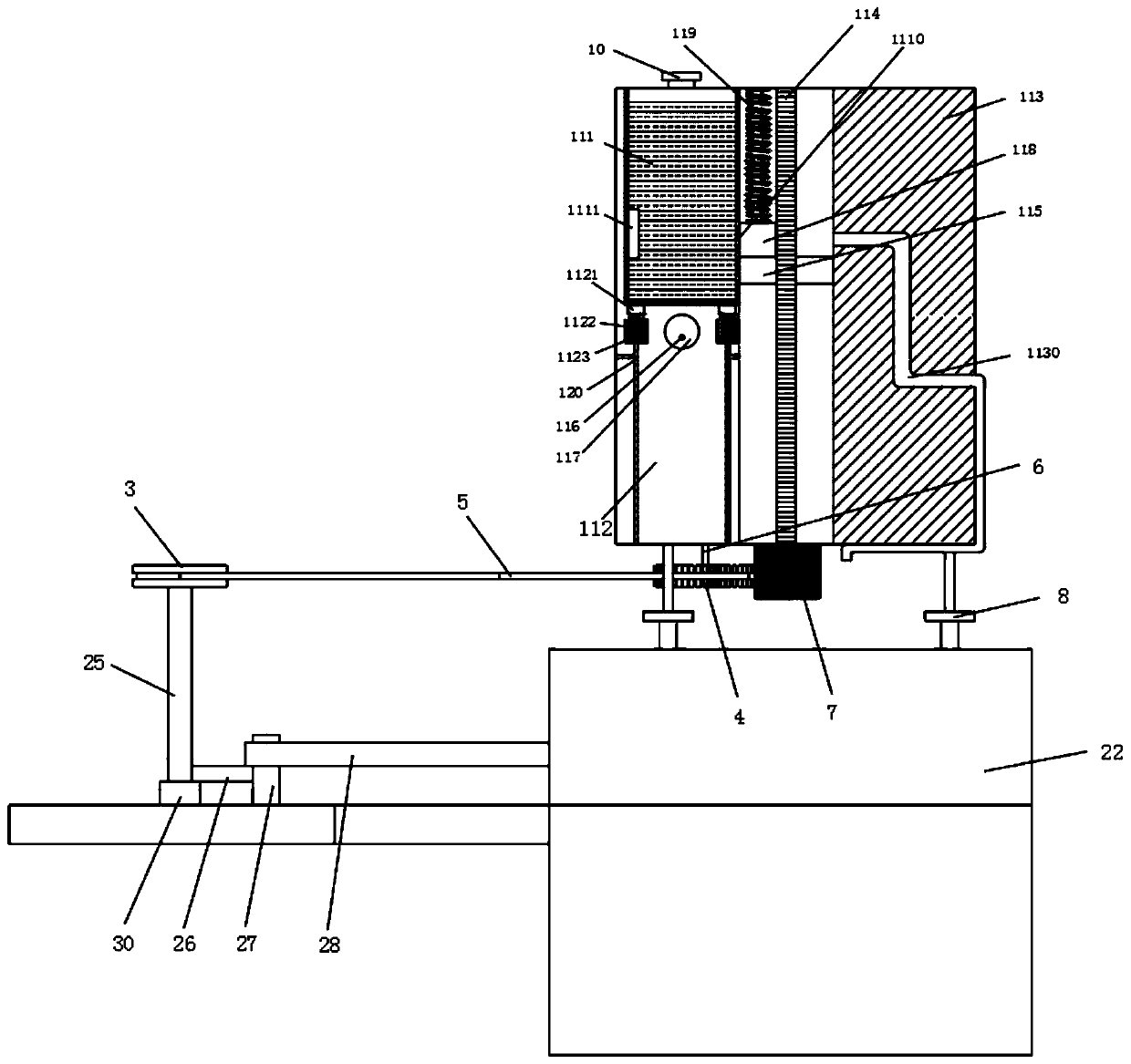

Electroplated diamond wire saw sand-applying device

The invention discloses an electroplated diamond wire saw sand-applying device. The device sequentially comprises the components, from top to bottom: a vertical tubular sand-applying sub tank, a liquid-returning box, and a plating solution master tank. A guide wheel is fixed in the liquid-returning box. A core wire is sequentially wound on a wire-feeding conductive wheel on the bottom of the vertical tubular sand-applying sub tank and the guide wheel. The core wire then penetrates the vertical tubular sand-applying sub tank, and is finally wound on a wire-discharging conductive wheel on the top of the vertical tubular sand-applying sub tank. The wire-feeding conductive wheel and the wire-discharging conductive wheel are connected in parallel, and are then connected to the negative electrode of an electroplating power supply. Metal anodes are arranged around the core wire in the vertical tubular sand-applying sub tank. The metal anodes are connected with positive electrodes of the electroplating power supply. Through a water pump above the plating solution, the plating solution is lifted from the plating solution master tank into the vertical tubular sand-applying sub tank. With the device provided by the invention, sand-application of produced diamond wire is uniform and good. During the production process, current density is high, efficiency is high, internal stresses of the plating and the substrate are small, plating solution application amount is low, and wire breakage probability is low.

Owner:无锡超亚环保设备有限公司

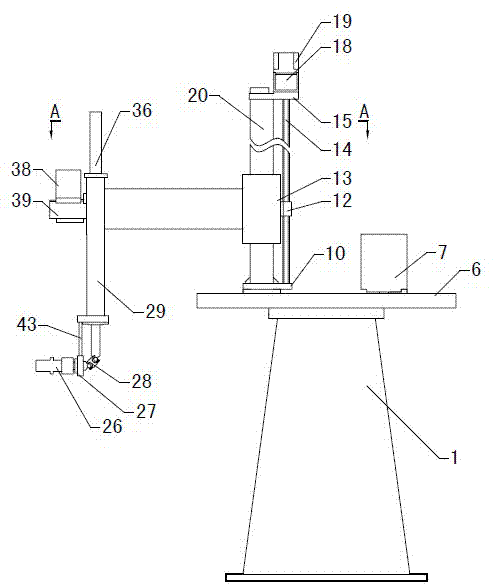

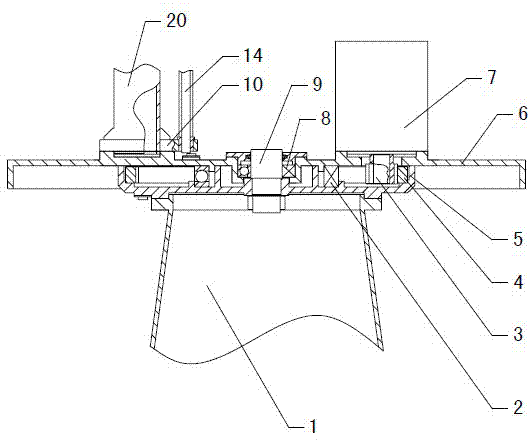

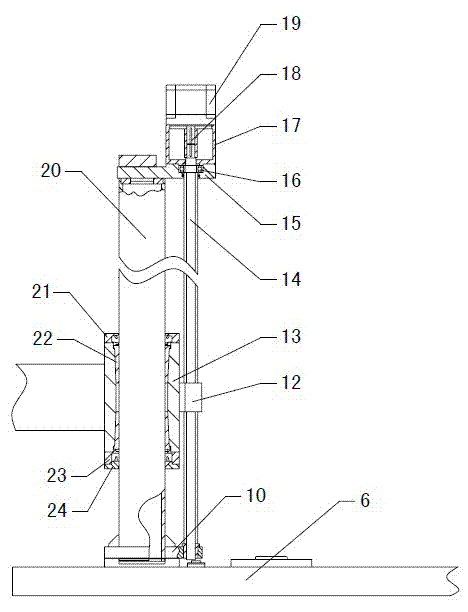

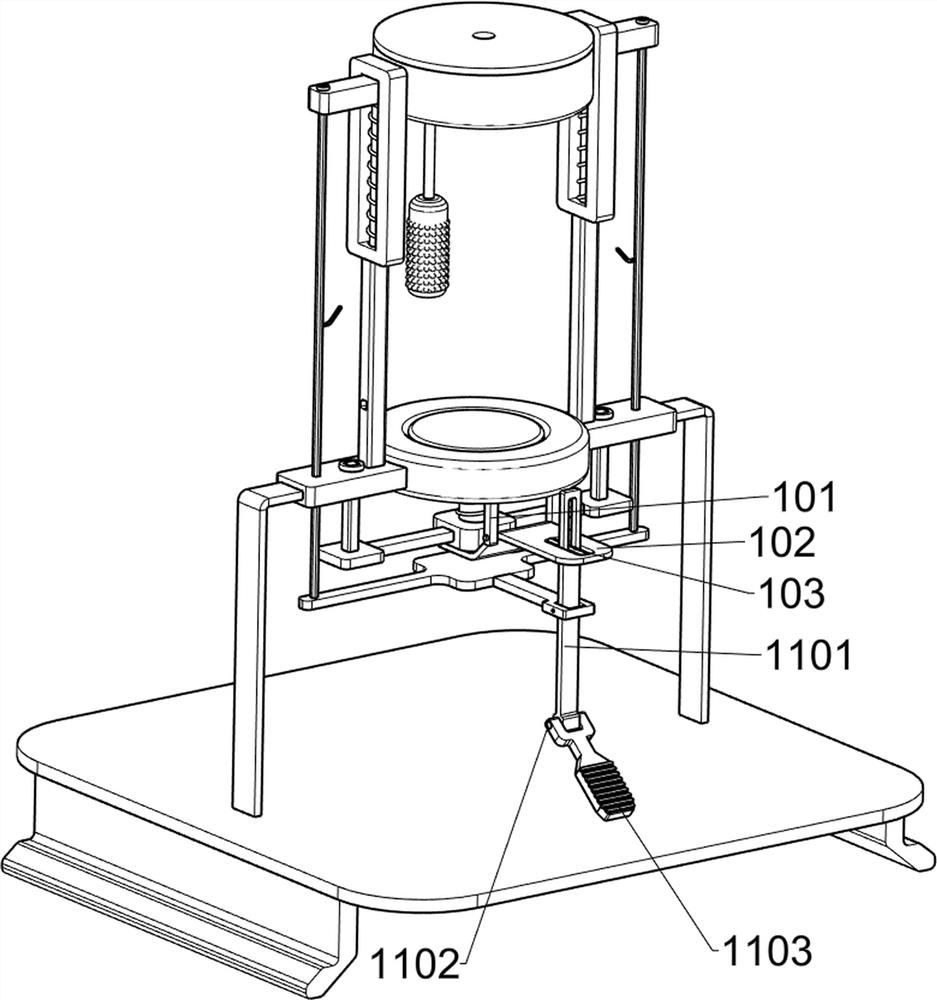

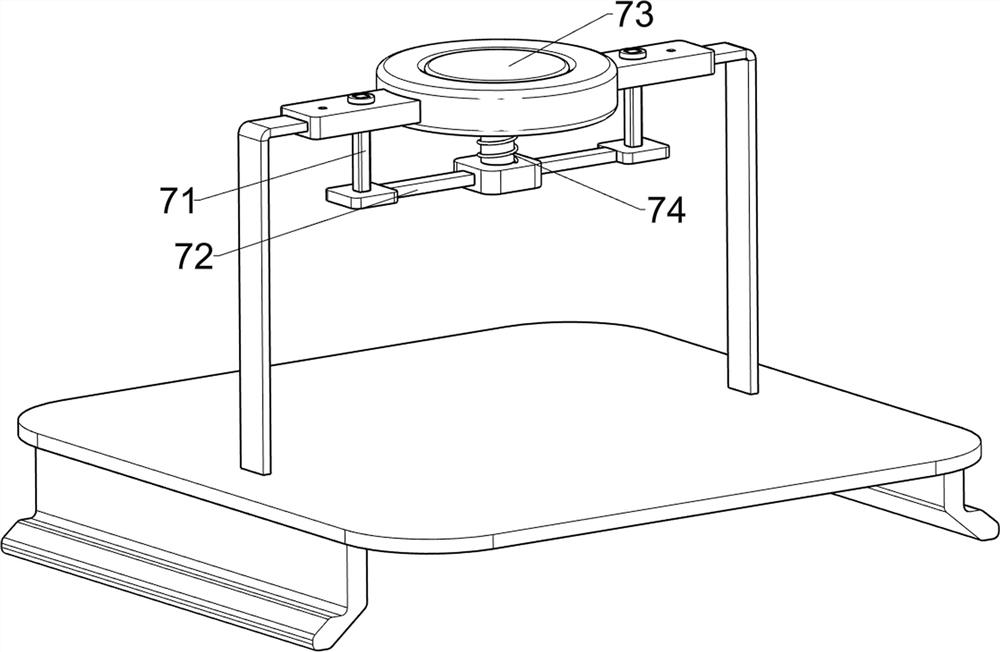

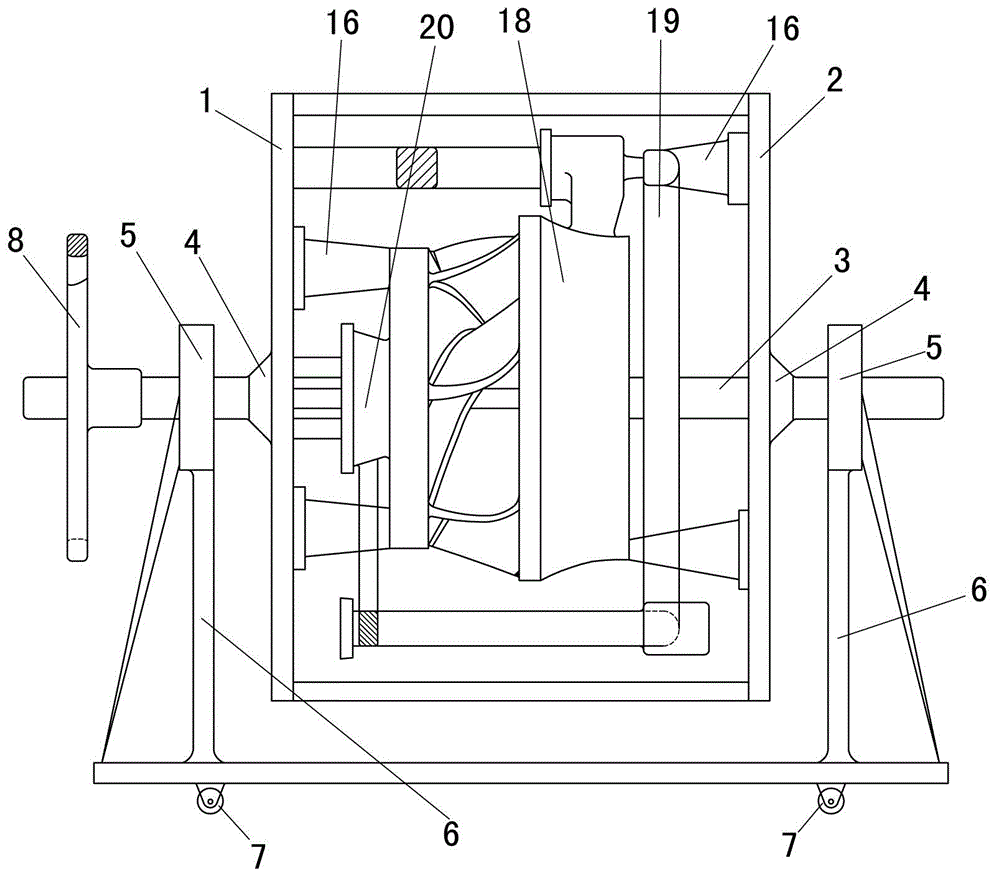

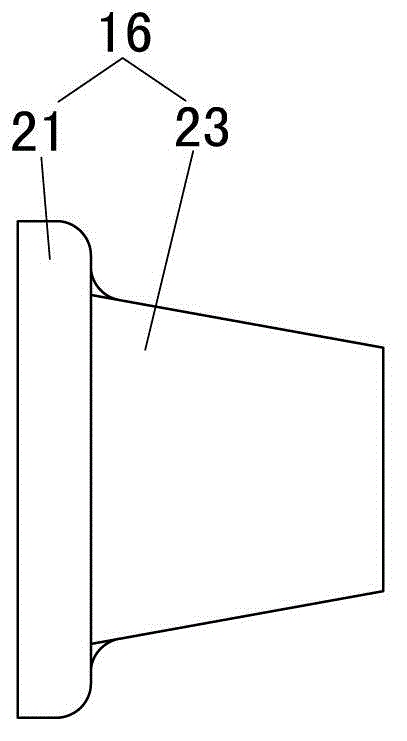

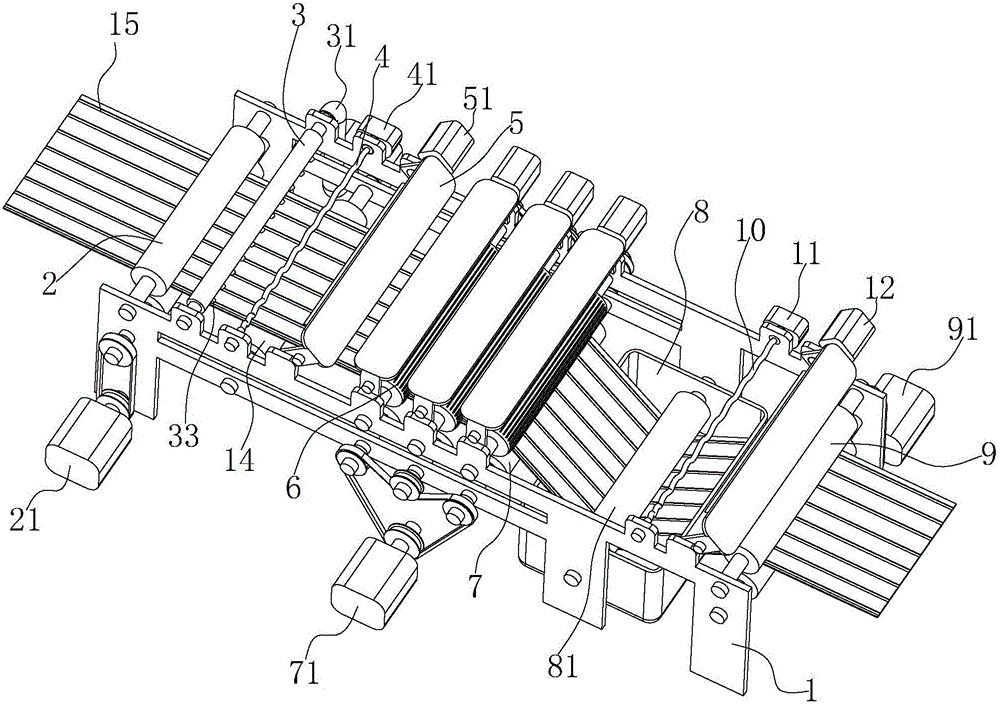

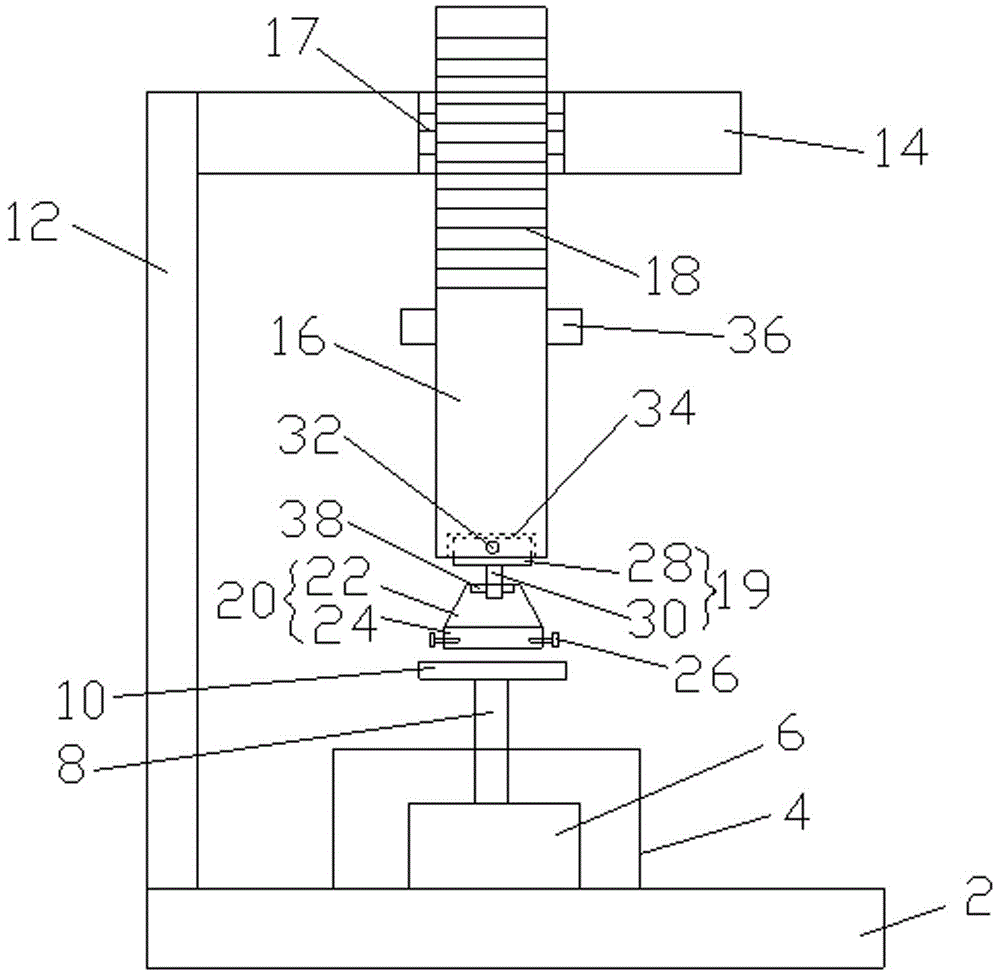

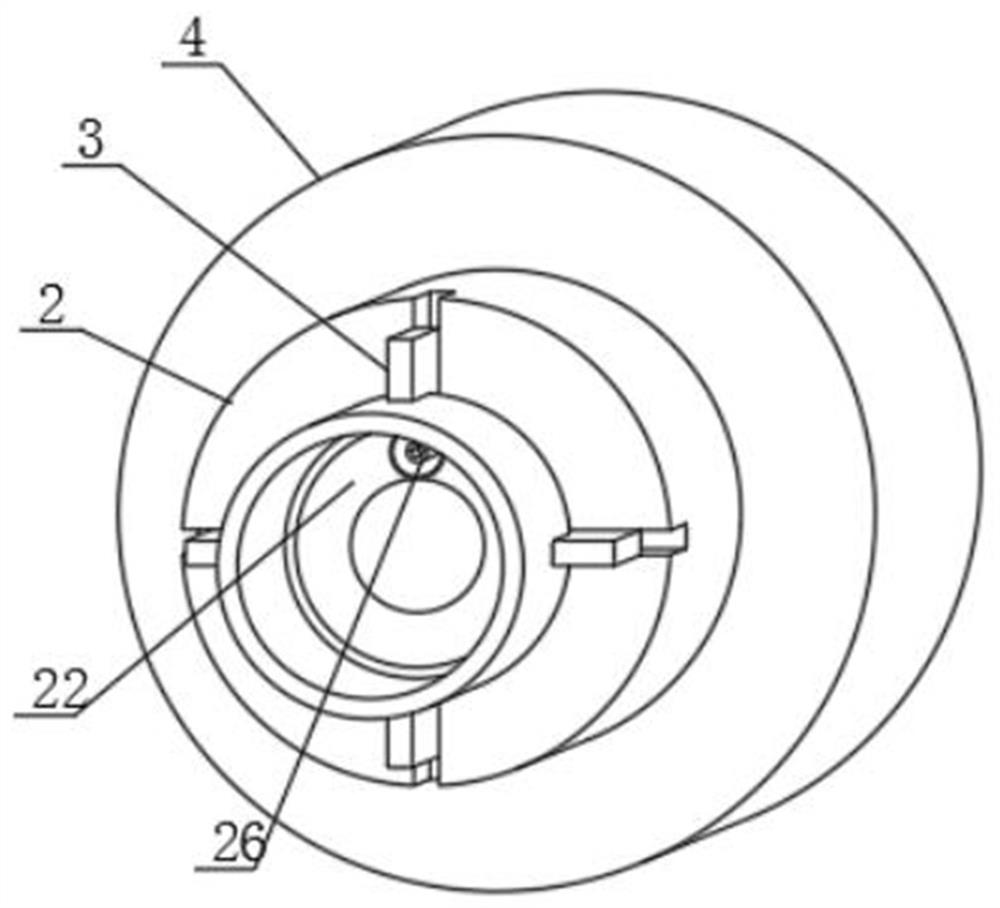

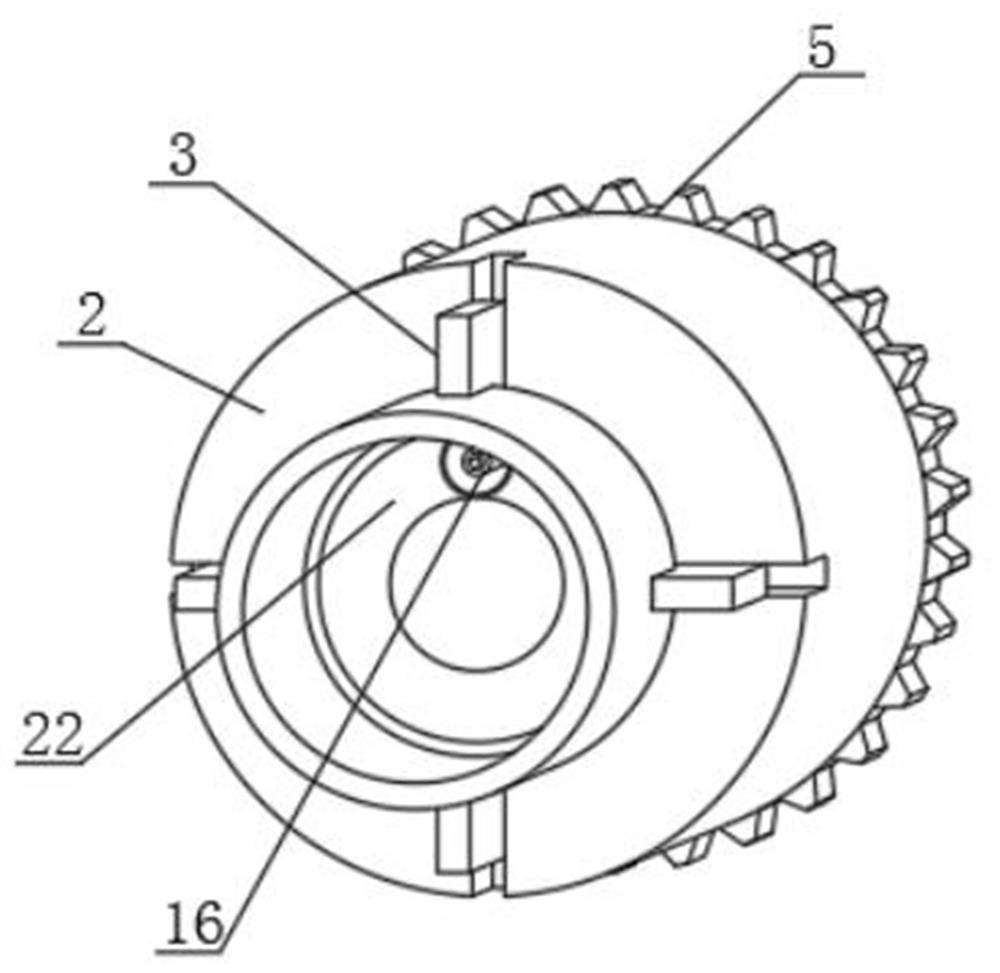

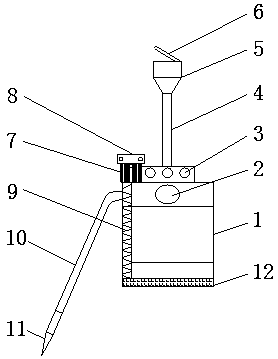

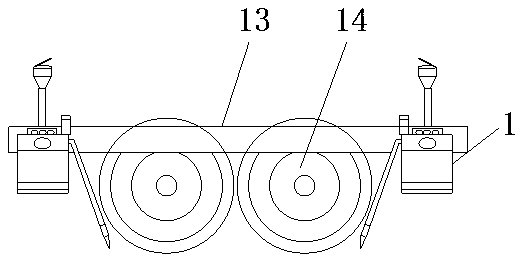

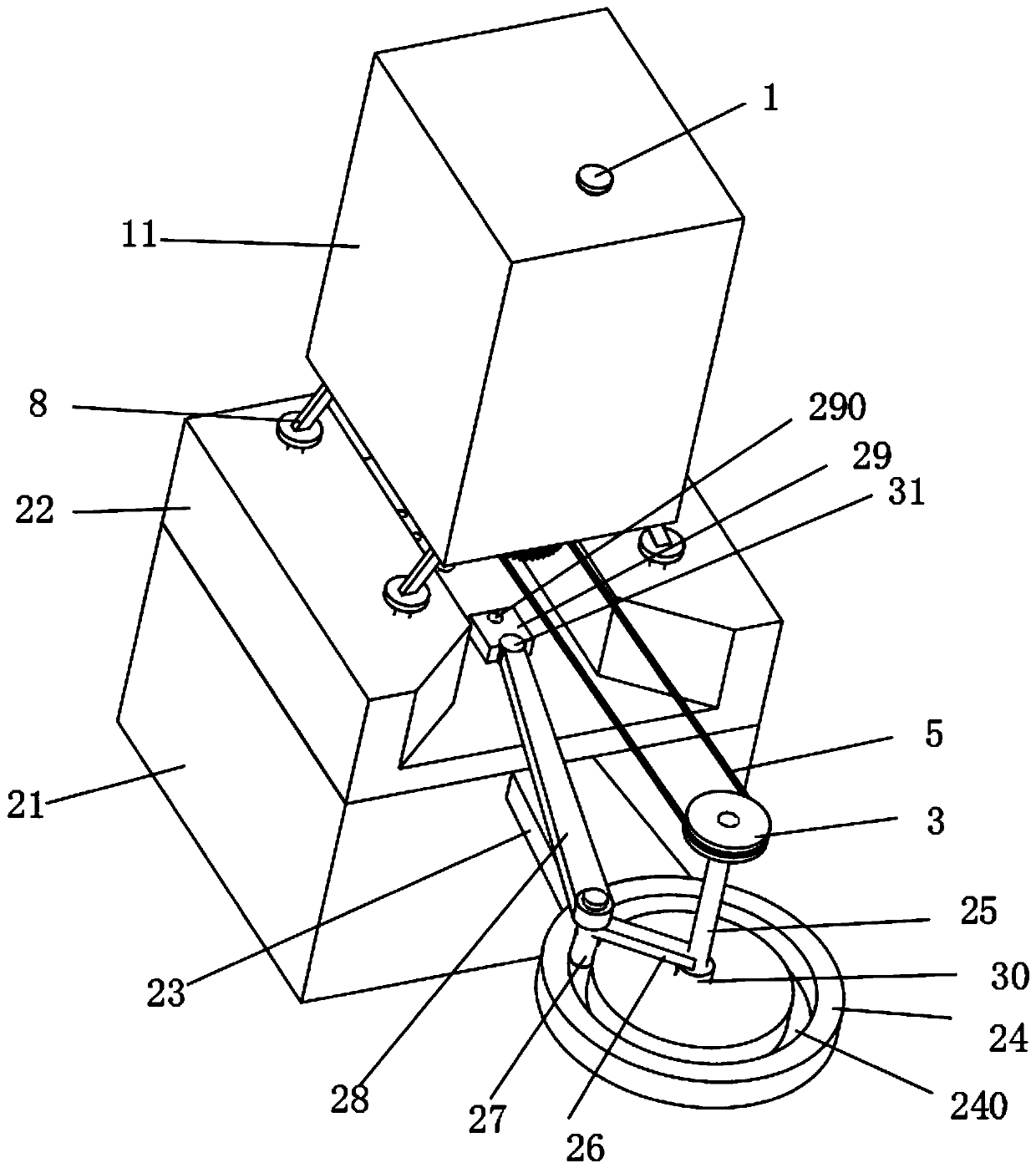

Mold-melting shell maker

ActiveCN103495706AUniform thicknessOvercome uniformity issuesFoundry mouldsMoulding machinesWaxUniversal joint

The invention relates to a mold-melting shell maker, and belongs to the field of shell maker equipment. The mold-melting shell maker comprises a base (1), a rotary workbench (6) arranged on the base (1) rotationally, a linear lifting mechanism arranged above the rotary workbench (6) vertically and a horizontal connecting arm. The inner end of the horizontal connecting arm is fitted on the linear lifting mechanism, and the horizontal connecting arm can slide along the linear lifting mechanism vertically; the outer end of the connecting arm is fixed with a vertical rotary lifting mechanism, the lower end of the rotary lifting mechanism is fixedly connected to a breaker (26) through a universal joint (28), the upper portion of the breaker (26) is provided with a breaker bearing seat (27) provided with a bearing inside, the corresponding distance between the breaker bearing seat (27) and the rotary lifting mechanism is fixed through a pull rod (43), and the lower end of the pull rod (43) is hinged with the breaker bearing seat (27). The mold-melting shell maker has the advantages that slurry sticking and sand sticking can be performed automatically, operating efficiency is improved, the thickness of a wax mold shell is uniform, and quality is stable.

Owner:山东先河悦新机电股份有限公司

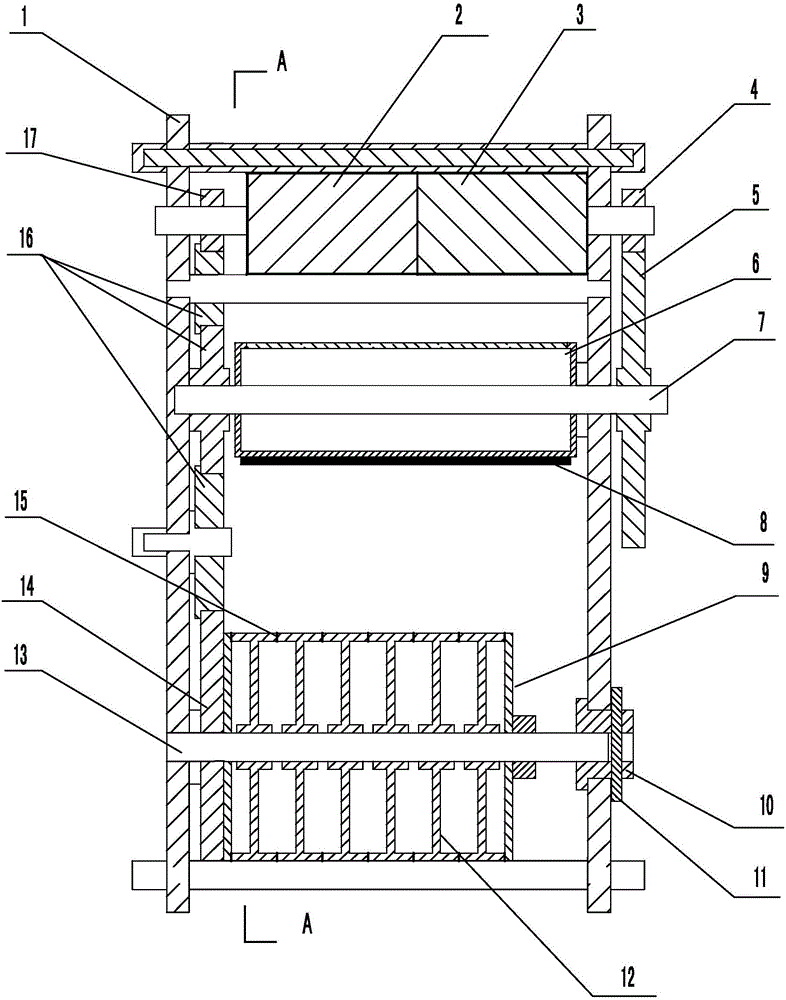

False twister spindle grinding device

InactiveCN107971846AEasy to adjustImprove efficiencyGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

The invention provides a false twister spindle grinding device and relates to the technical field of false twister production. The false twister spindle grinding device comprises a bottom plate; the two sides of the top of the bottom plate are fixedly provided with machine boxes; and motor mounting blocks are fixedly installed on the two sides of the inner walls of the machine boxes. According tothe false twister spindle grinding device, lifting motors, first rotating rods, sliding rings, bearings, a machine frame, a hydraulic telescopic device, a motor box and a grinding motor cooperate withone another; when the lifting motors are started, due to the fact that the sliding rings are in threaded connection with the first rotating rods, in the rotating process of the first rotating rods, the sliding rings can move up and down on the surfaces of the first rotating rods; meanwhile, the two sliding rings can drive the machine frame to move up and down between the two machine boxes; meanwhile, the hydraulic telescopic device drives the grinding motor and a grinding wheel at the bottom of the hydraulic telescopic device to move up and down on the top of a grinding table; and in conclusion, the false twister spindle grinding device can be conveniently adjusted, and improving of the grinding efficiency of a false twister spindle can be facilitated.

Owner:新昌县城关宾立机械厂

Red stoneware product and firing method thereof

The invention discloses a red stoneware product, which is calcined by the following raw materials in percentage by weight: 75-85% huanglong mountain red mud and 15-25% of huanglong mountain yellow buff-colored clay. According to the red stoneware product provided by the invention, a pot body is filled with sand inside and outside, sand is even to move, and the color and luster are full and mellow.

Owner:任静波

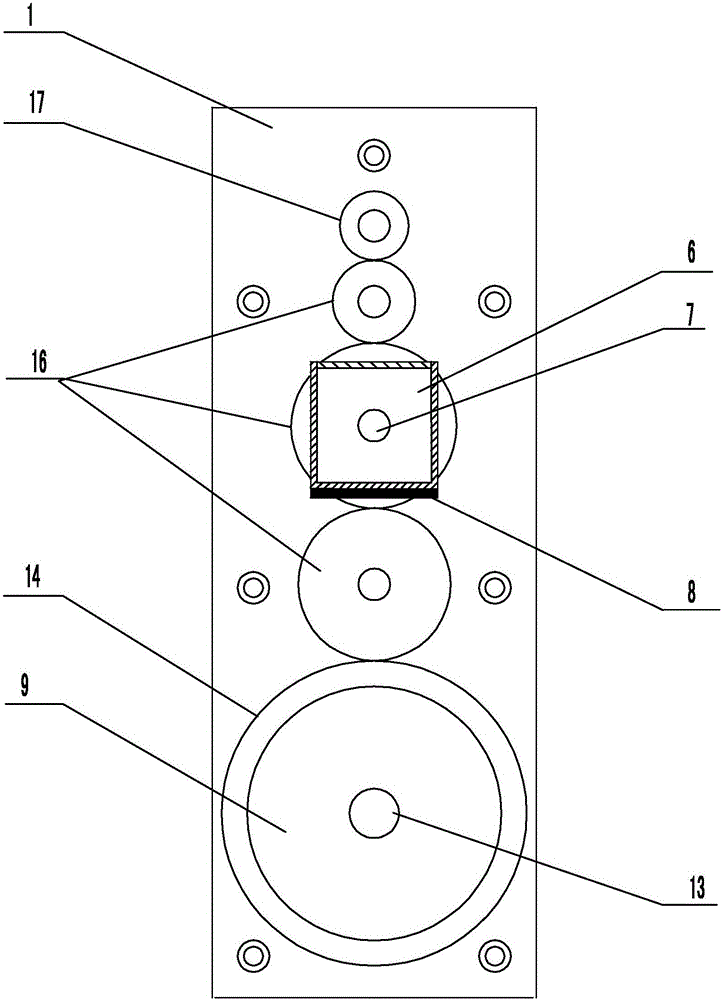

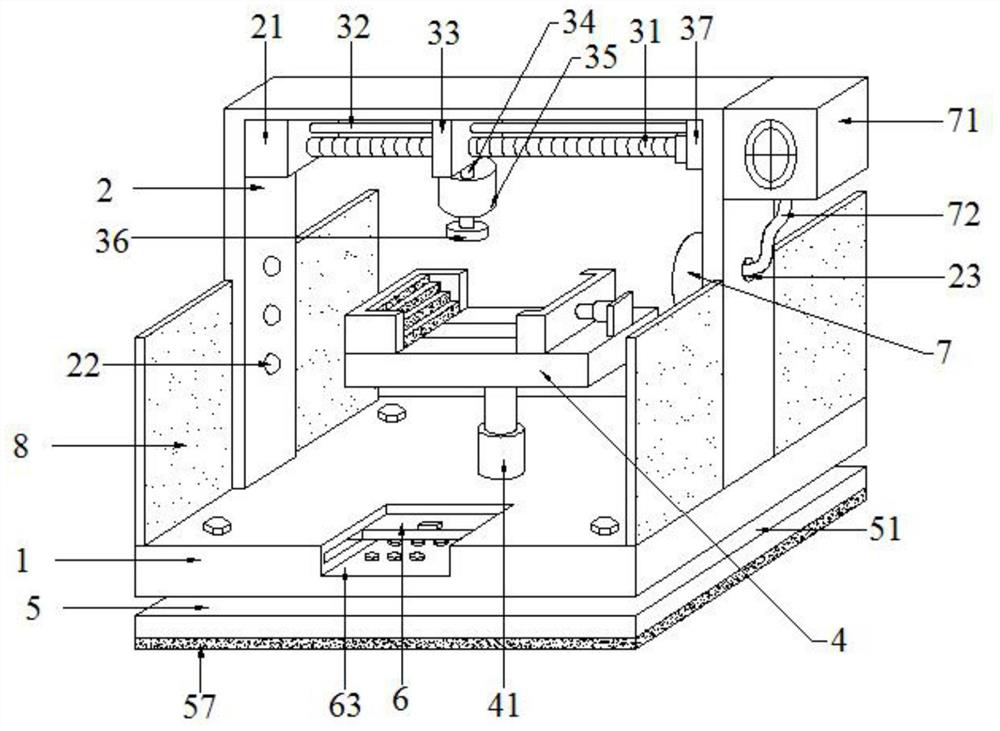

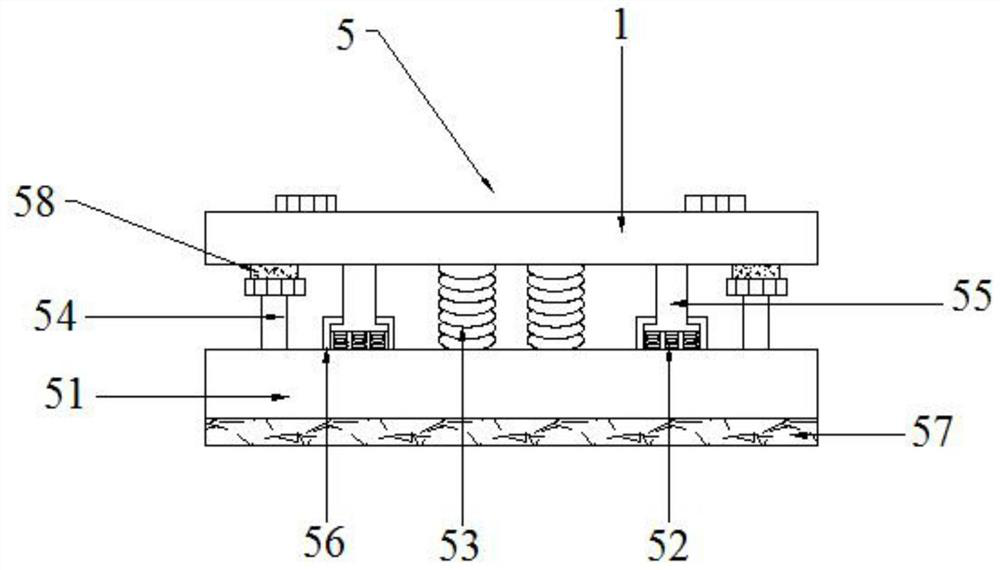

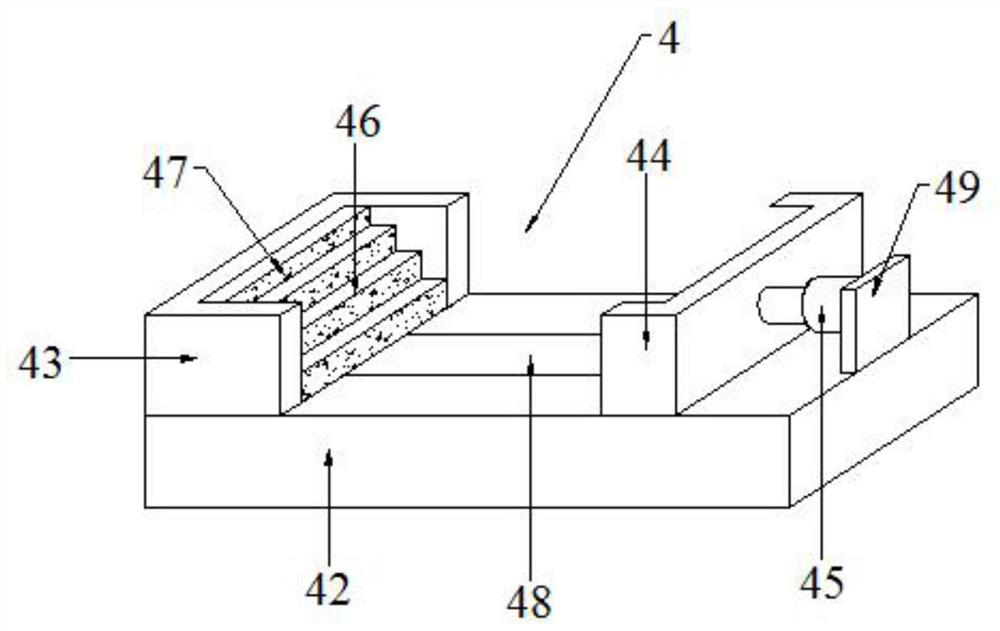

Household stainless steel inner wall polishing device

PendingCN112518445APlay a guiding roleEven sandingEdge grinding machinesGrinding carriagesPolishingStructural engineering

The invention relates to a polishing device, in particular to a domestic stainless steel inner wall polishing device. The domestic stainless steel inner wall polishing device saves time and labor, andis high in efficiency and polishing quality. The household stainless steel inner wall polishing device comprises a base, two supports, a workbench, guiding mechanisms and a polishing mechanism. The two supports are arranged on the base. The workbench is connected between the upper parts of the two supports. The guiding mechanisms are arranged at the tops of the supports. The polishing mechanism is arranged on the guiding mechanisms. According to the household stainless steel inner wall polishing device, wedge-shaped rods are matched with second connecting rods, the wedge-shaped rods move to enable the second connecting rods to slide towards the inner sides in first connecting rods, fourth springs are changed into a compressed state from an initial state, and the second connecting rods move to enable arc-shaped pressing plates to move towards the inner side, so that stainless steel is clamped, the automatic clamping effect is achieved, the stainless steel can be prevented from shakingin the polishing process, and the polishing quality is improved.

Owner:莫英文

Manufacturing method of thin shell

The invention discloses a manufacturing method of a thin shell. With water glass as a paint binder, the method employs a manual shell making operation of hardening with crystal aluminum chloride and filters paint into a paint bucket after stirring it well. In the method, the processes of coating, sand lining, hardening, and air drying go repeatedly, with 3.5 shell layers manufactured and 40-60min of air drying for each layer. For technologies before changing, a small shell is usually made into 6 layers and a large shell is made into 7 layers. Thus, the method of the invention not only reduces the capital investment of raw materials, but also enhances the work efficiency.

Owner:淅川县华新铸造有限公司

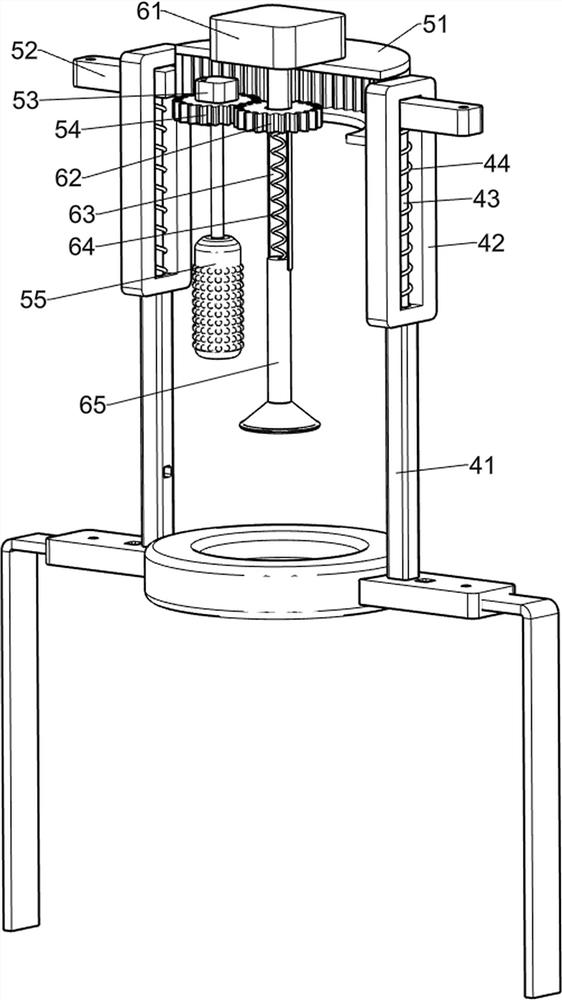

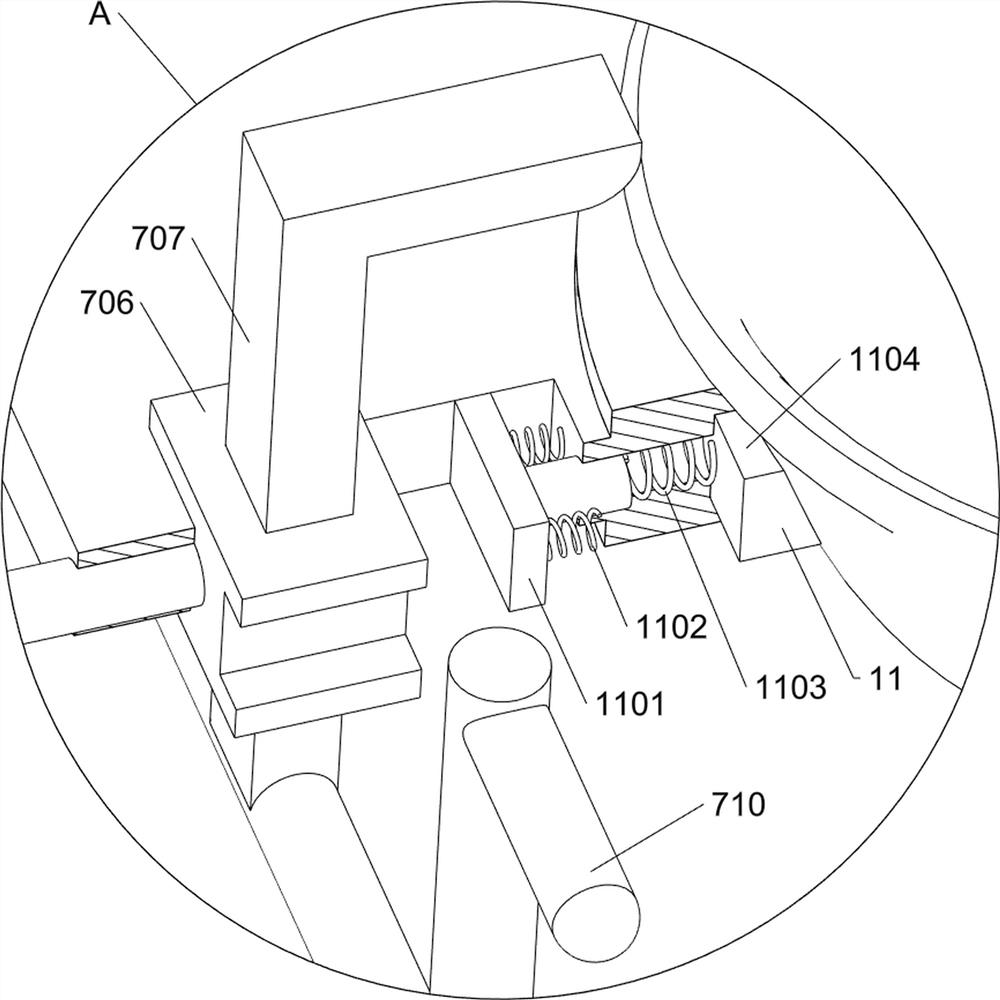

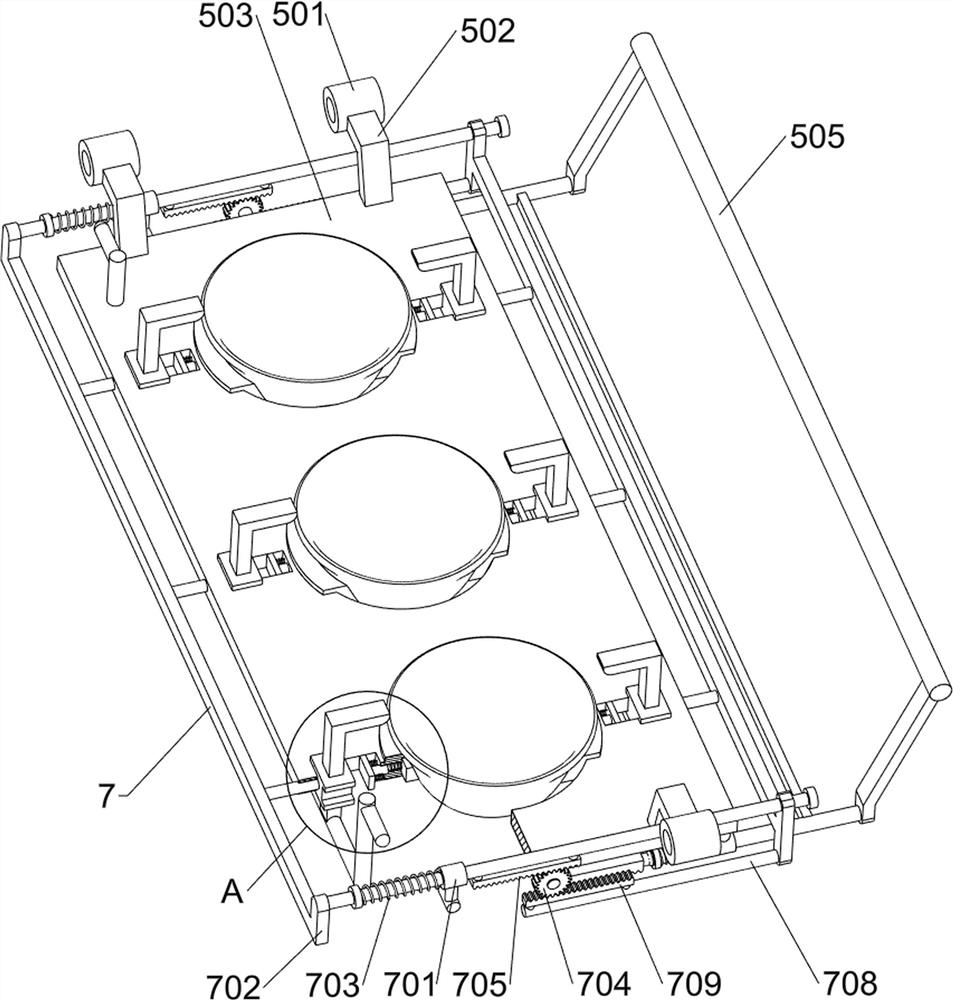

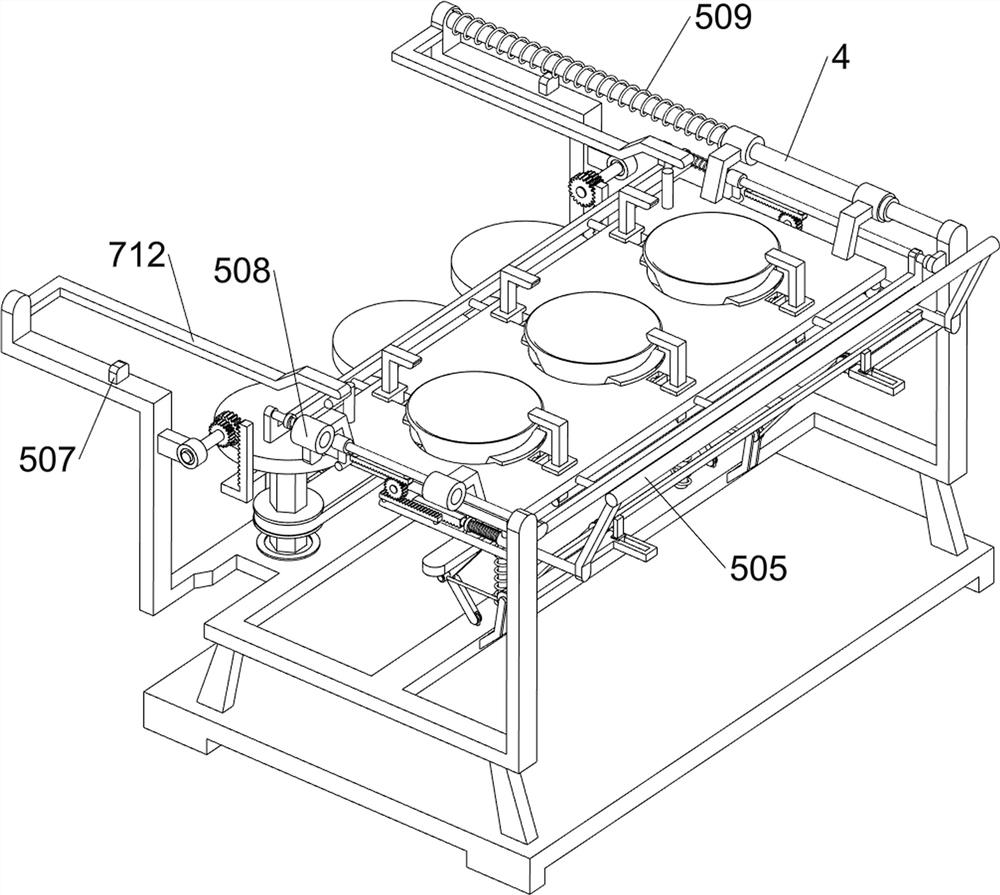

Plastic bowl bottom burr polishing equipment

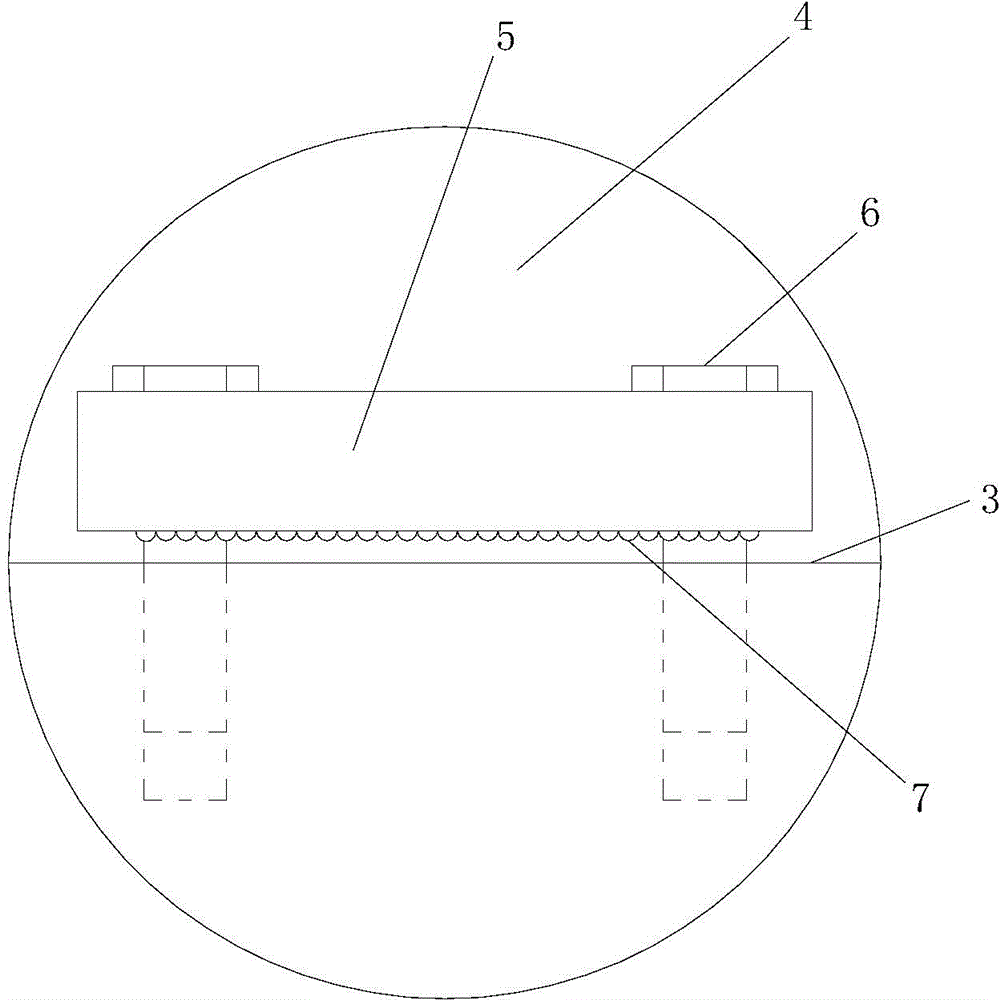

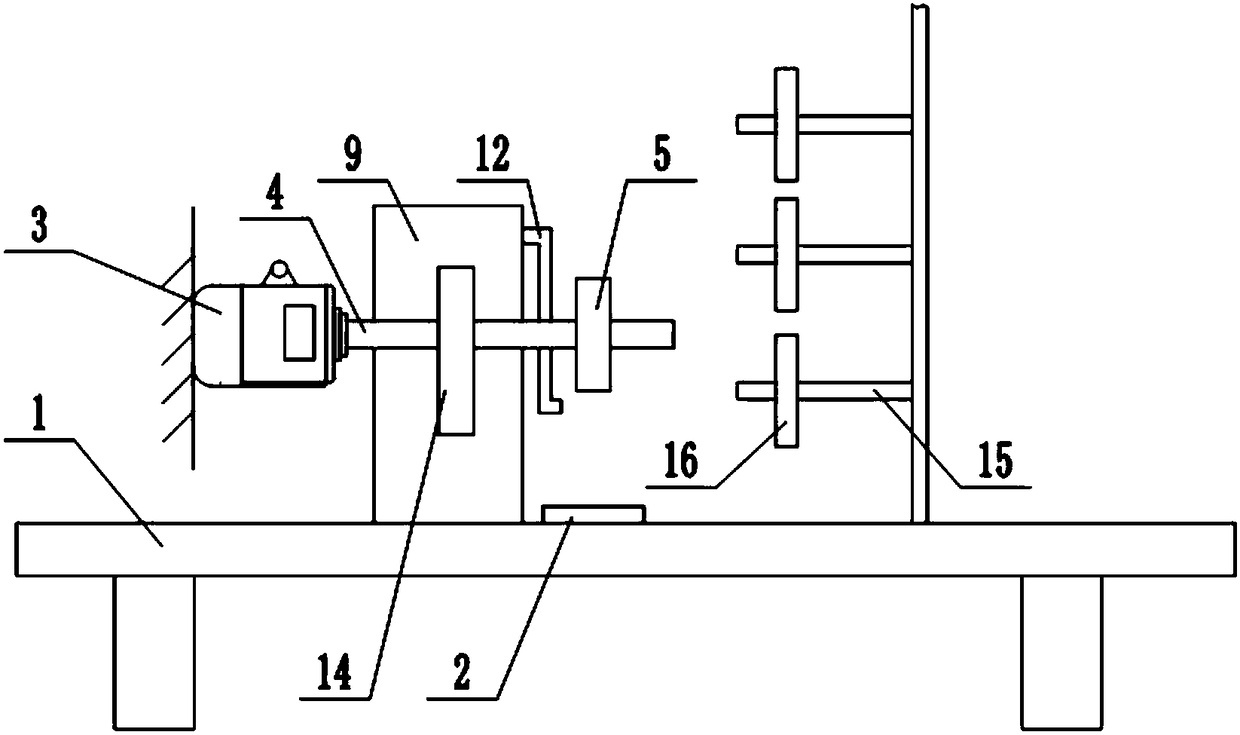

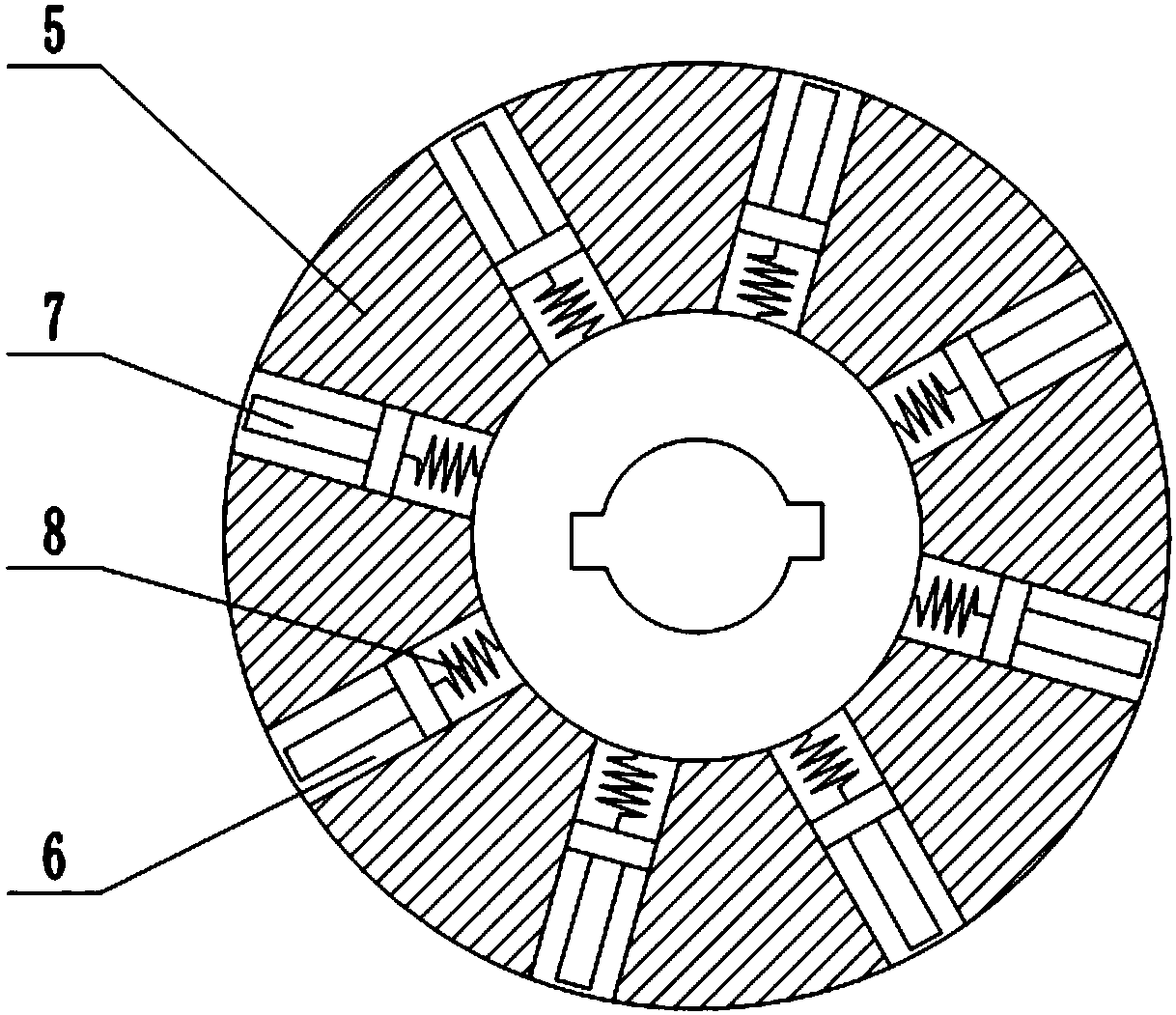

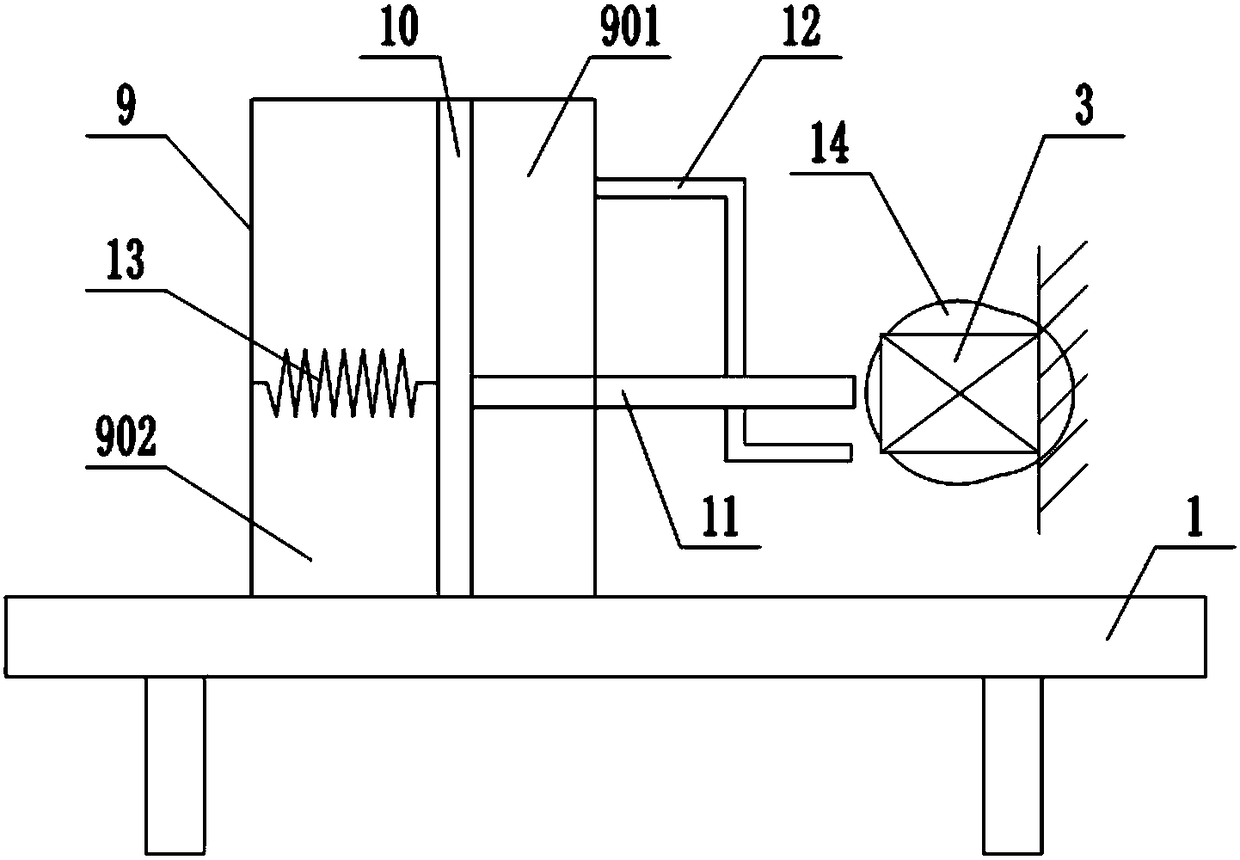

ActiveCN112605782AClamping is achievedHigh speed rotationEdge grinding machinesGrinding drivesPolishingEngineering

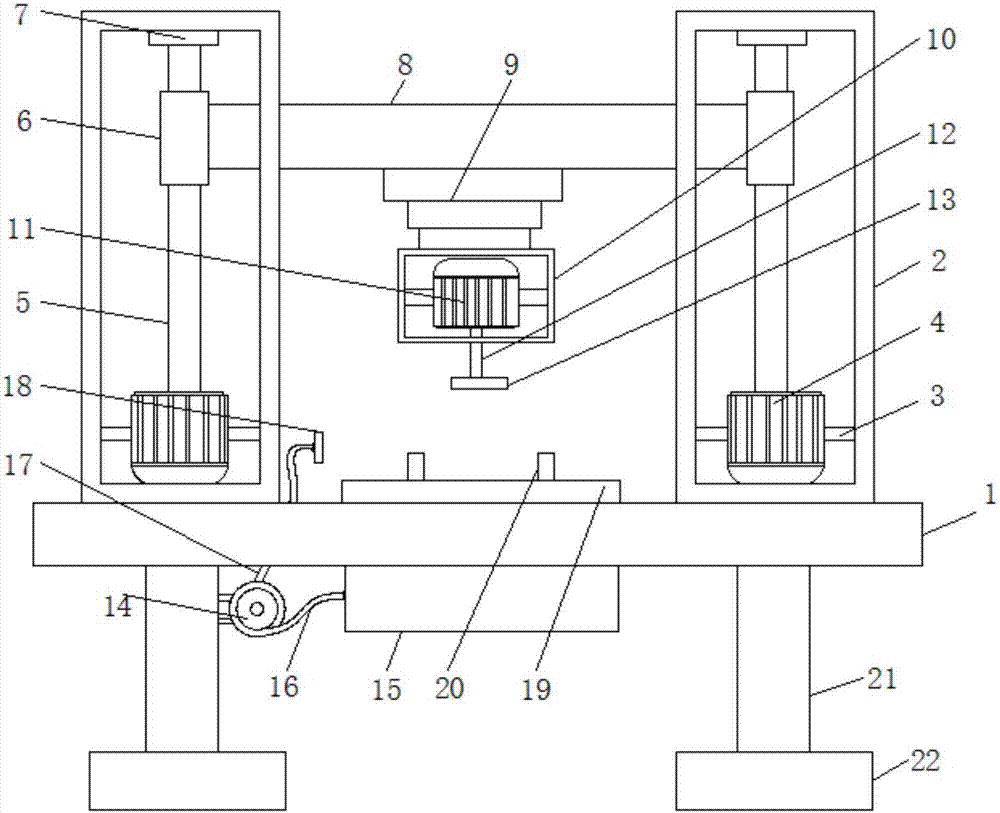

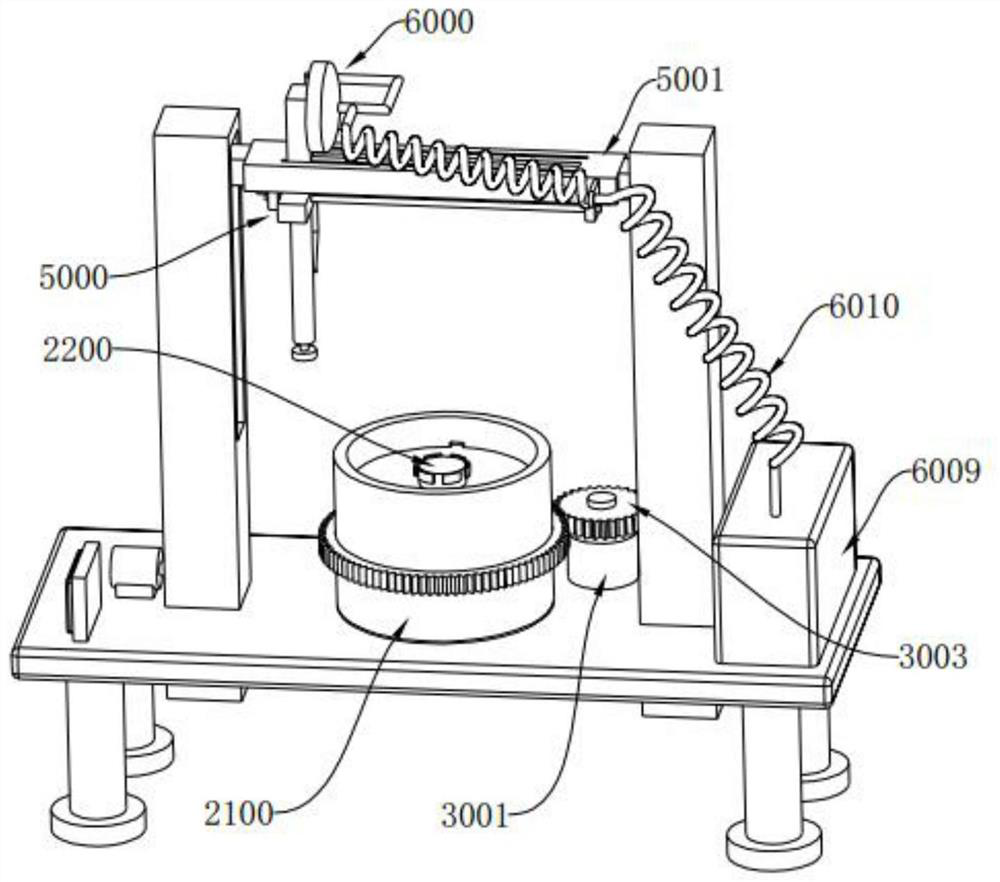

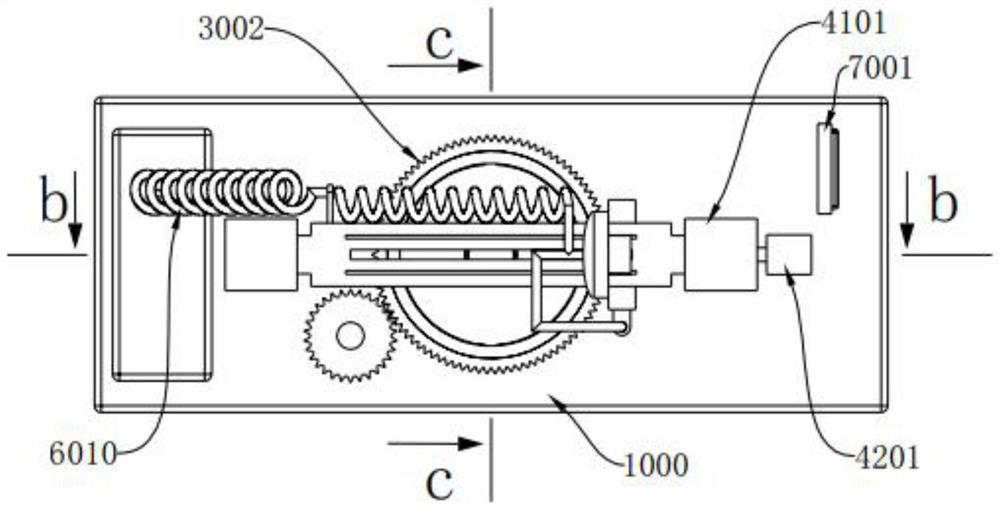

The invention relates to polishing equipment, in particular to plastic bowl bottom burr polishing equipment. The plastic bowl bottom burr polishing equipment is automatic, efficient, easy and convenient to operate and capable of achieving batch polishing. The plastic bowl bottom burr polishing equipment comprises a bottom plate of which the upper portion is provided with a machine frame, a servo motor mounted on one side of the upper portion of the bottom plate, first guide rods connected to the two sides of the upper portion of the machine frame, a moving assembly arranged between the upper portion of the machine frame and the first guide rods, a polishing assembly arranged on one side of the upper portion of the machine frame, a driving assembly arranged between the polishing assembly and an output shaft of the servo motor, and a clamping assembly arranged on the moving assembly. According to the plastic bowl bottom burr polishing equipment, by starting the servo motor, six-edge shafts are driven to rotate under a series of rotating and meshing actions, finally rotary discs are driven to rotate, high-speed rotation of the rotary discs is realized, and the effect of automatically polishing burrs at the bottoms of plastic bowls is achieved.

Owner:深圳市合利环保科技开发有限公司

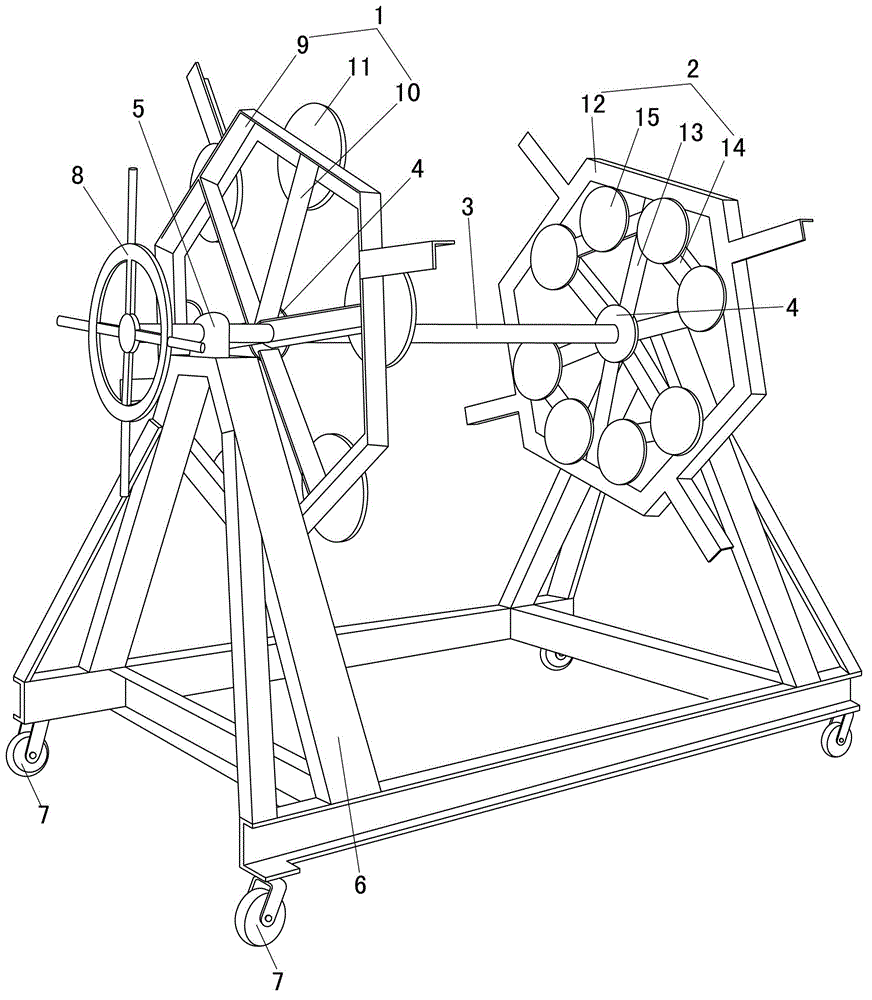

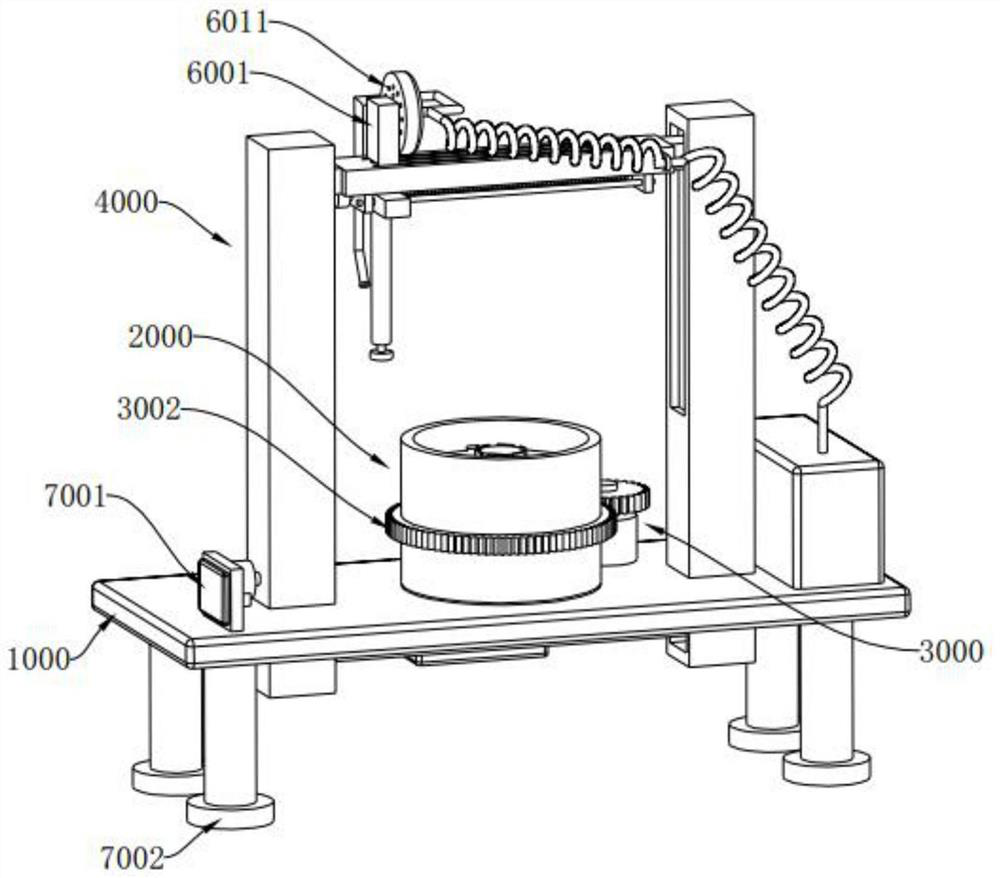

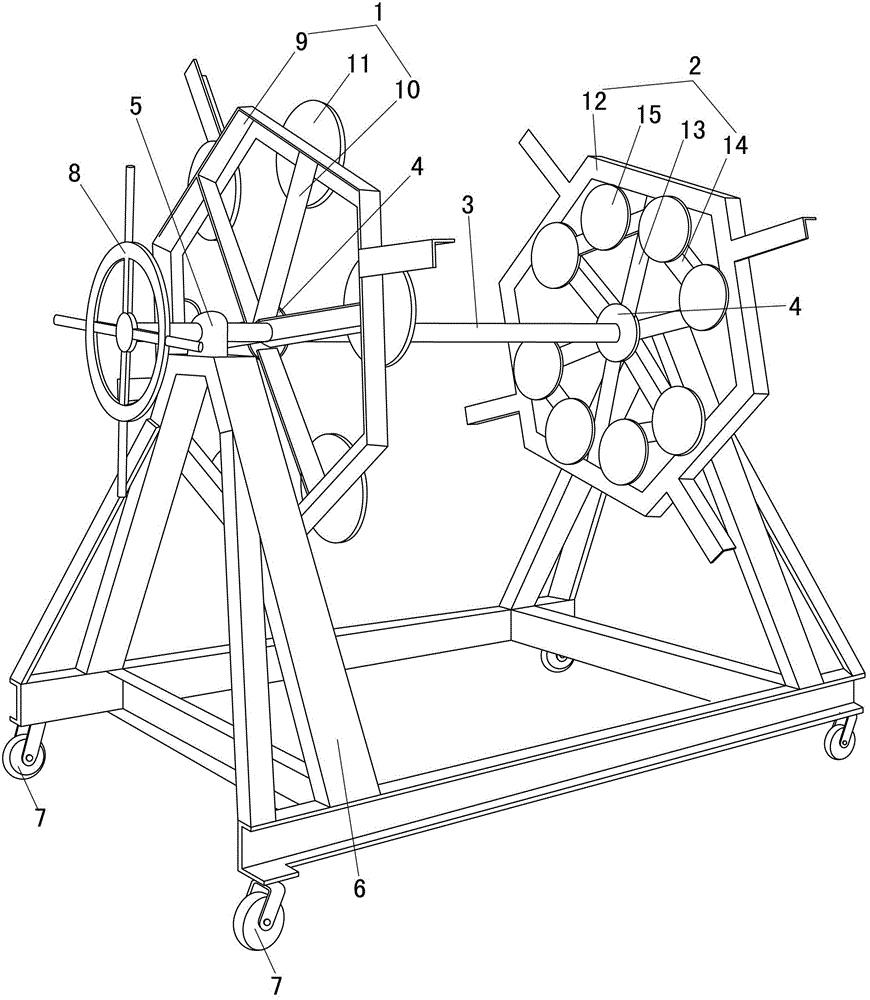

Ultra-large type evanescent mould precision-casting shell manufacturing tool and shell manufacturing process thereof

ActiveCN102744369AIncrease buoyancySave human effortFoundry mouldsFoundry coresInvestment castingAgricultural engineering

The invention relates to an ultra-large type evanescent mould precision-casting shell manufacturing tool and a shell manufacturing process thereof, belonging to the technical field of investment casting. The ultra-large type evanescent mould precision-casting shell manufacturing tool comprises a first wheel spoke structure and a second wheel spoke structure which are arranged on a main shaft, one end of the main shaft is connected with a power mechanism, the main shaft is provided with bearings between the power mechanism and the first wheel spoke structure and on the right end part of the second wheel spoke structure, the two bearings are arranged on two bearing seats, and the two bearing seats are fixed on a chassis. The shell manufacturing process comprises the following steps of: when a shell is manufactured, installing an evanescent mould on the main shaft, adhering the small ends of a plurality of connected lug bosses on a pouring channel and a feed head of the evanescent mould and an evanescent mould body, and adhering the large ends to the inner sides of the first wheel spoke structure and the second wheel spoke structure; rotating the main shaft, spraying paint on the surface of the evanescent mould by adopting flow coating mode, and then scattering sand; after the evanescent mould is dried, spraying the paint and scattering the sand again till the number of mould shell layers is reached, and then cutting off the connected lug bosses; taking down the evanescent mould and the shell from the ultra-large type evanescent mould precision-casting shell manufacturing tool, and then roasting to obtain the mould shell. The mould shell has the advantages of difficult deformation, smooth paint immersion process, stable quality of a produced product, labor conservation and work efficiency increase.

Owner:安徽应流铸业有限公司

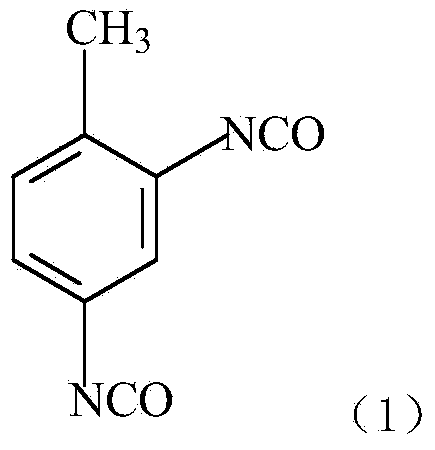

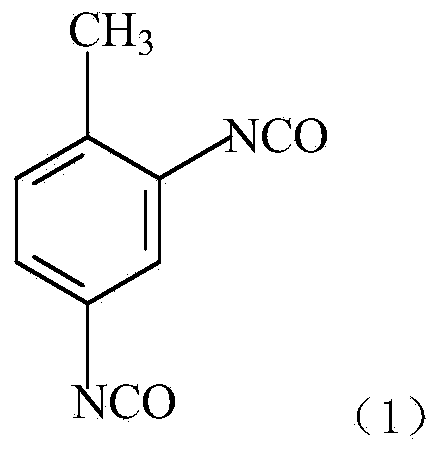

Preparation and superhigh-pressure processing method for cathode-electrophoresis-resin diamond scroll saw

ActiveCN104018207ALow unsealing temperatureHigh reactivityElectrolytic coatingsEmulsionPolymer science

The invention discloses preparation and a superhigh-pressure processing method for a cathode-electrophoresis-resin diamond scroll saw, and belongs to the field of preparation of diamond scroll saws. The diamond scroll saw is prepared by employing an electrophoresis method. The preparation method comprises: firstly preparing an emulsion of cathode electrophoresis resin, then adding diamond into the prepared emulsion, and employing an intermittent stirring manner to enable diamond to be uniformed suspended in the emulsion; and enabling a pretreated saw filament to pass through the diamond-containing emulsion in an electrophoresis way, and then performing pre-solidification, deep solidification, superhigh-pressure processing and the like, so as to finally prepare the diamond scroll saw. According to the prepared diamond scroll saw, the diamond usage amount is less, applied sand is uniform, the thickness of a resin layer is easily controllable, the resin layer is uniform, retention capability on wear debris, wear resistance and other aspects are better than those of diamond scroll saw coated with a resin binder.

Owner:SHANDONG UNIV OF SCI & TECH

Napping machine for producing flax yarn

InactiveCN105926233ASmooth sandingImprove washing effectHeating/cooling textile fabricsFloats removalYarnPulp and paper industry

The invention discloses a napping machine for producing flax yarns. According to the napping machine, a blowing device is mounted above a napping device, so that napping operation can be thoroughly completed at one time, meanwhile the cut villi can be blown off, and then the quality of a napped product can be ensured. According to the napping machine, the blowing device is mounted above the napping device, villi can be relatively easily napped on the surfaces of the flax yarns due to the wind blown by the blowing device, the cut villi on the napped flax yarns can be blown off by the wind of the blowing device, then no cut villi can be hidden in the flax yarns, a relatively good later washing effect can be achieved, and drying operation can be implemented after simple washing. As a heating device is added behind a humidifying device, another blowing device is also mounted to blow the heating device, the surfaces of the flax yarns can be rapidly heated by the heating device, and then later flax yarn napping operation can be implemented successfully.

Owner:芜湖金凯亚麻科技有限公司

Grinding device

InactiveCN106002615AImprove sanding qualitySimple structureGrinding carriagesGrinding work supportsEngineeringGrinding wheel

The invention relates to a grinding device. The grinding device comprises a base and a grinding body mounted on the base, wherein a motor is arranged inside the grinding body; an output shaft of the motor stretches out of the grinding body; a grinding wheel is fixed to the output shaft; a vertical rod is fixed to the base; the vertical rod is connected with a transverse rod through a first hinge pin; a spring and a pull rope are connected between the vertical rod and the transverse rod; the spring is positioned above the pull rope; the transverse rod is connected with a clamping assembly through a second hinge pin; the clamping assembly comprises a support and a clamping seat connected with the support; the clamping seat comprises a truncated cone-shaped seat and a cylinder-shaped seat which are arranged up and down and are integrally formed; and at least two adjusting bolts are arranged on the circumferential surface of the cylinder-shaped seat. According to the grinding device, the transverse rod is pressed or lifted upwards according to workpieces of different thicknesses, the pressure between the workpieces and the grinding wheel is adjusted to the required value, and the smooth implementation of grinding is guaranteed; and the outer diameter of a first cylindrical seat is larger than the outer diameter of a second cylindrical seat, the first cylindrical seat can be supported on a changing platform, supporting is stable, and shaking is avoided.

Owner:SUZHOU BOLAIXI ELECTRICAL APPLIANCE CO LTD

High-hardness wear-resisting polishing head material and efficient polishing device

InactiveCN108296994AHigh hardnessImprove wear resistanceAbrasion apparatusGrinding feed controlPolyesterFiber

The invention discloses a high-hardness wear-resisting polishing head material and an efficient polishing device. The polishing head material is prepared from, by weight, 32-42 parts of silicon carbide, 4-6 parts of polyester fiber, 1-3 parts of magnesium chloride, 3-5 parts of calcium carbonate, 5-8 parts of raw talc, 4-8 parts of copper powder, 2-5 parts of bismuth powder, 2-4 parts of magnesiumcarbide, 3-6 parts of aluminum oxide, 2-4 parts of aluminum borate, 1-3 parts of methylcellulose, 1-3 parts of boron nitride, 1-3 parts of vinyltriethoxysilane, 1-3 parts of antioxidant and 5-10 parts of heat stabilizer. The polishing device is flexible and convenient and fast to use, the position of a polishing head and pressure between workpieces and an abrasive wheel can be controlled by rotating a sleeve before polishing, and therefore it is ensured that polishing is smoothly carried out; and the pressure between the workpieces and the abrasive wheel can be adjusted to the required valueby pressing or lifting up a transverse rod according to the workpieces with different thicknesses during polishing, and therefore it is ensured that polishing is smoothly carried out.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Grinding machine

InactiveCN105945725AImprove sanding qualitySimple structureGrinding work supportsBarrel ShapedEngineering

The invention relates to a grinding machine which comprises a base and a grinding machine body installed on the base. A motor is arranged in the grinding machine body. An output shaft of the motor stretches out of the grinding machine body, and a grinding wheel is fixed to the output shaft of the motor. A support is fixed to the base and comprises a vertical rod and a horizontal rod. The horizontal rod is in threaded connection with a stand rod. The bottom end of the stand rod is detachably connected with a clamp assembly. The clamp assembly comprises a support seat and a clamp seat connected with the support seat. The clamp seat comprises a circular truncated cone shaped seat and a barrel-shaped seat which are integrally formed and arranged up and down. At least two adjusting bolts are arranged on the circumference of the barrel-shaped seat. According to the grinding machine, a workpiece is installed in the barrel-shaped seat, and the height of the stand rod can be adjusted by rotating the stand rod, so that pressure between the workpiece and the grinding wheel is adjusted to guarantee the smooth proceeding of grinding. The outer diameter of a first cylindrical seat is greater than that of a second cylindrical seat; when the workpiece in the barrel-shaped seat needs to be replaced, the first cylindrical seat is supported by a replacement platform by rotating the barrel-shaped seat, supporting is stable and firm, and shaking is avoided.

Owner:SUZHOU BOLAIXI ELECTRICAL APPLIANCE CO LTD

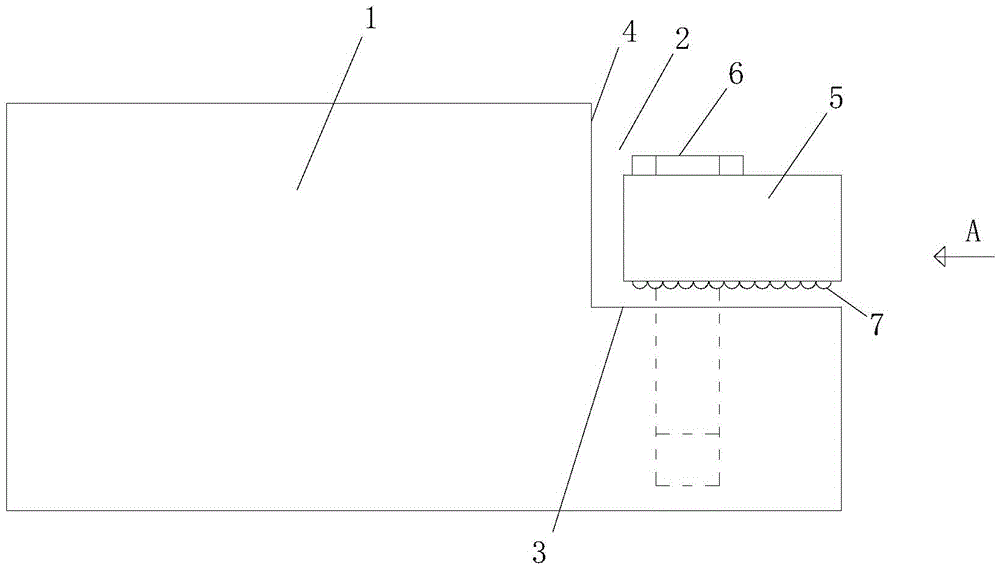

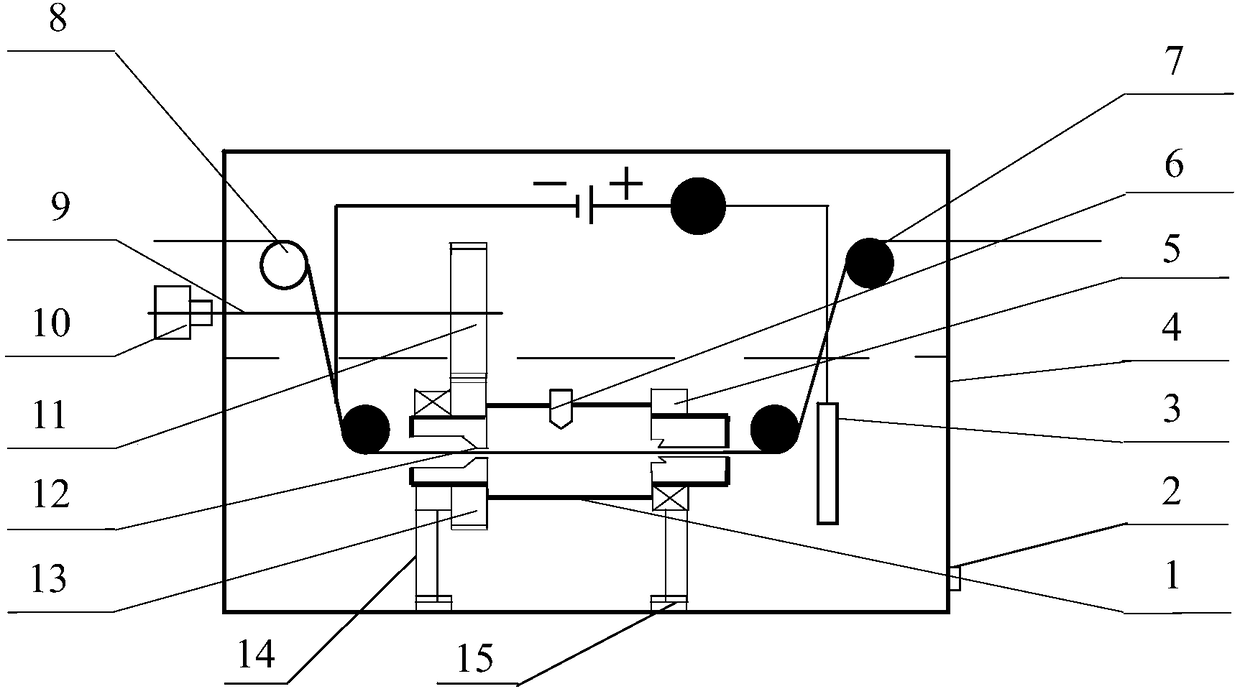

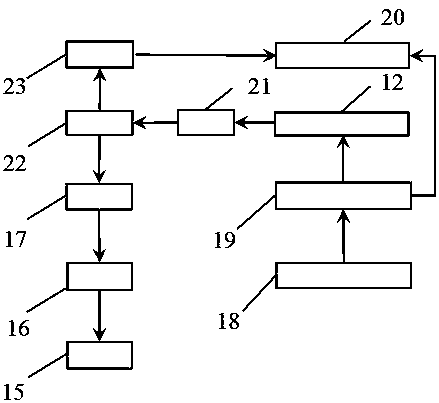

Automatic sand feeding and thickness increasing system for diamond abrasive wheel and use method

ActiveCN105803511AAchieve pre-platingRealize automated productionElectrolysis componentsElectrolytic coatingsPower flowTime control

The invention discloses an automatic sand feeding and thickness increasing system for a diamond abrasive wheel and a use method. A center controller of the system is connected with and controls a time control any waveform stabilized current supply, a motor A driving an abrasive wheel tire body, and a motor B driving a diamond box. The diamond box with the top face provided with a porous plate is located in the middle portion, and a tire body placemen pillar is sleeved with the abrasive wheel tire body and is located below the abrasive wheel tire body. The use method includes the steps that the abrasive wheel tire body is cleaned firstly and installed on the tire body placement pillar, an abrasive wheel part of the abrasive wheel tire body is subjected to acid pickling, the diamond box is sufficiently filled with sand, the system is lifted into a plating solution bath, and the diamond box is submersed in a plating solution; the abrasive wheel tire body rotates positively and negatively multiple times to be pre-plated; the diamond box is temporarily rotated reversely for slinging so as to be subjected to sand feeding; all parts of the abrasive wheel tire body are rotated to face upwards in turns to be subjected to sand feeding continuously; the abrasive wheel tire body rotates positively and negatively multiple times so that thickness increasing can be completed; the proper current density is controlled in the process; and machining of the abrasive wheel is completed. By means of the automatic sand feeding and thickness increasing system for the diamond abrasive wheel and the use method, the structure is simple, operation is convenient, sand feeding is uniform, automation of the whole process of pre-plating, sand feeding and thickness increasing of the diamond abrasive wheel is achieved; and the efficiency and the quality are obviously improved.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Structure of nylon polyurethane fiber sanding fabric and production method thereof

InactiveCN102560841AHigh color fastnessQuality improvementWeft knittingHeating/cooling textile fabricsFiberSurface layer

The invention discloses a structure of a nylon polyurethane fiber sanding fabric and a production method thereof. The structure comprises a nylon polyurethane contact surface and is characterized in that the nylon polyurethane contact surface is an upper and lower double-layer structure, wherein a plurality of a nylon polyurethane fiber sanding circles are distributed on an external surface layer and are internal and external double-layer circle structures; and the production method comprises the steps of weaving, seaming and post-processing. The double-layer contact surface and the sanding circle structures are manufactured through the transformation of different stitches so that the fabric has good color fastness, stable quality and low repairing rate, and therefore, the production efficiency is greatly improved.

Owner:SHANGHAI JIALE

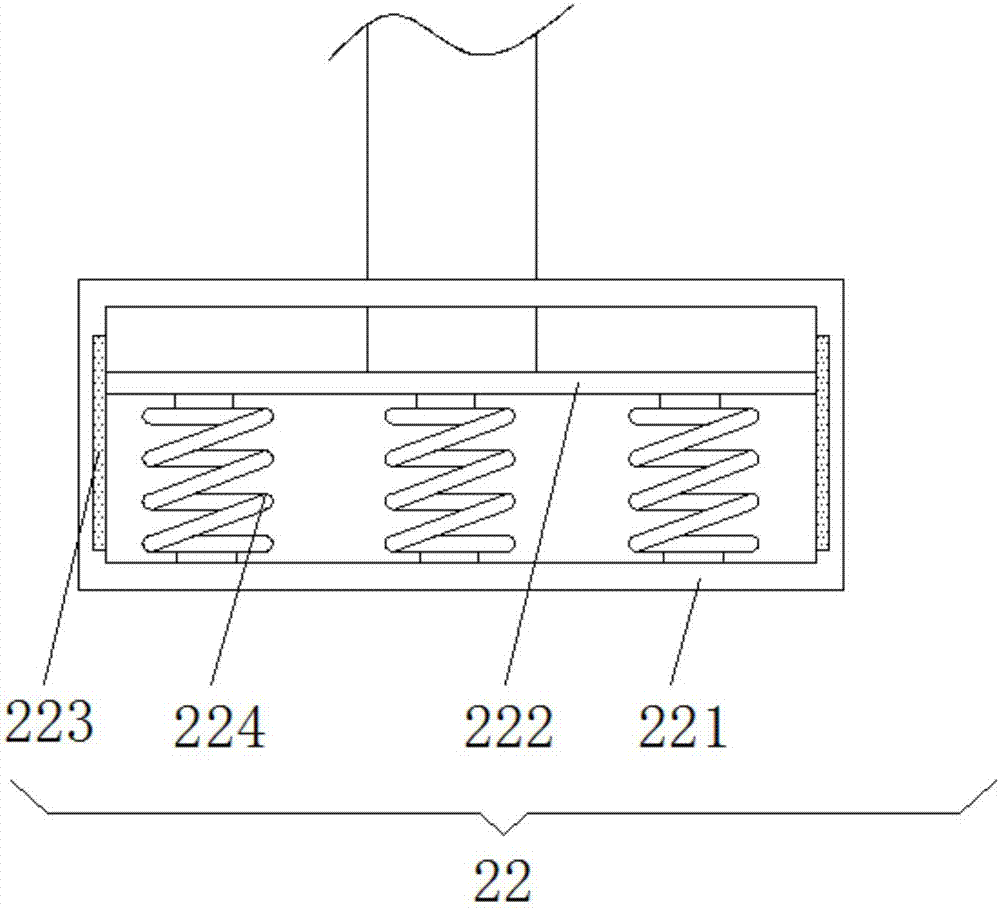

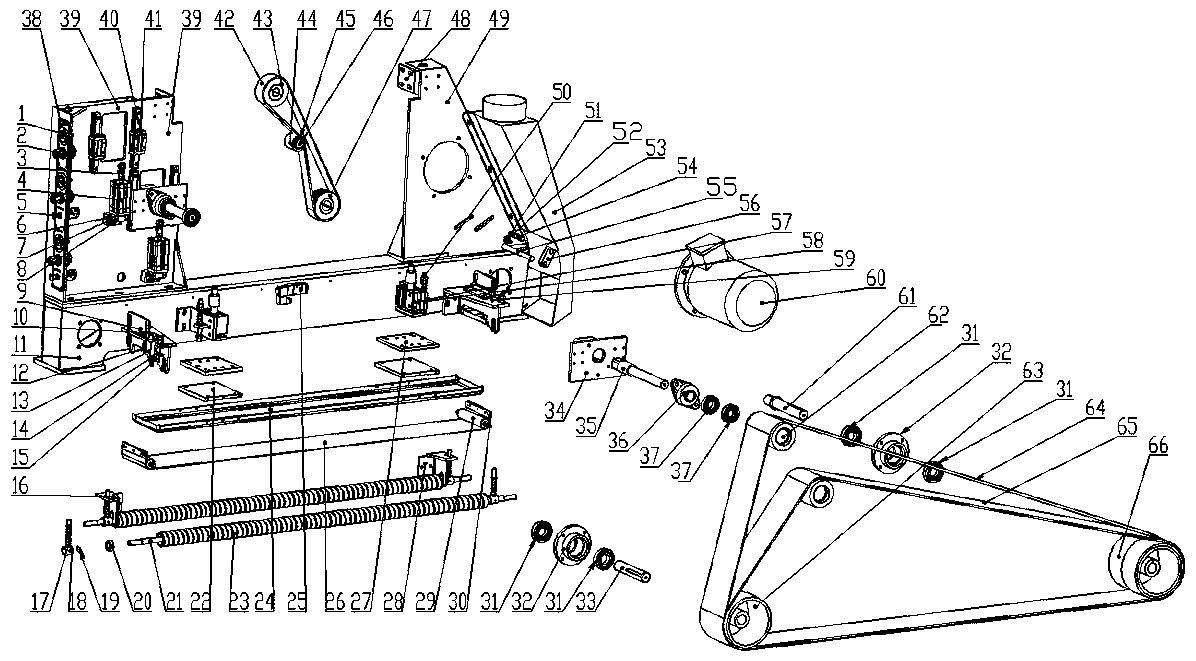

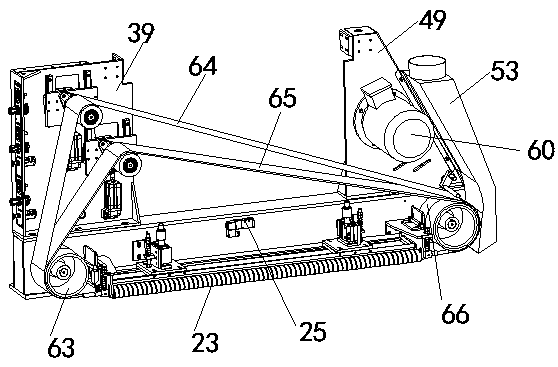

Transverse belt sanding mechanism

PendingCN110605640AExtended service lifeGuaranteed flatnessBelt grinding machinesGrinding/polishing safety devicesEngineeringGraphite

The invention discloses a transverse belt sanding mechanism. The sanding mechanism comprises a mounting base, a pressing grinding component, a power component, cutting grinding component, a tension wheel component, and a dust blowing component, the pressing grinding component, the power component, the cutting grinding component and the tension wheel component are arranged on the mounting base, anadjustable stroke guide rod air cylinder and a material pressing spring on the pressing grinding component are arranged on the mounting base, the adjustable stroke guide rod air cylinder is connectedwith a pressing mounting plate B, the pressing mounting plate B is connected with a pressing mounting plate A, the pressing mounting plate A is connected to a pressing plate, the pressing plate is connected with the material pressing spring, a high-elastic sponge is arranged below the pressing plate, graphite cloth is arranged below the high-elasticity sponge, the graphite cloth is connected witha graphite cloth spring seat and an adjusting block, the graphite cloth is connected with a high-precision wool felt lining band in a surrounding mode, and the high-precision wool felt lining band isconnected with a sand belt in a surrounding mode. The sanding mechanism has the beneficial effects that abrasive paper is long in service life, noise is small, sanding is uniform, installing and debugging is easy, and the sanding mechanism is mainly used for grinding articles.

Owner:GUANGDONG MOOC TECH CO LTD

Preparation method of cathode electrophoresis resin diamond wire saw

The invention discloses a preparation method of a diamond wire saw, and belongs to the preparation field of the diamond wire saw. An electrophoresis method is adopted to prepare the diamond wire saw; firstly, cathode electrophoresis resin emulsion is prepared; then, diamond is added in the prepared emulsion; an intermittent mixing manner is adopted to evenly suspend the diamond in the emulsion; a pretreated saw wire passes through the diamond-contained emulsion through an electrophoresis manner; the steps, such as pre-curing and deep curing, are performed for the saw wire; and finally, the diamond wire saw is prepared. The diamond wire saw, prepared by the method, has the advantages of small diamond usage, uniform sand loading, easy control of resin layer thickness and even resin layer, and is superior to a resin binder diamond wire saw in such aspects as abrasive grain holding force and wear resistance.

Owner:SHANDONG UNIV OF SCI & TECH

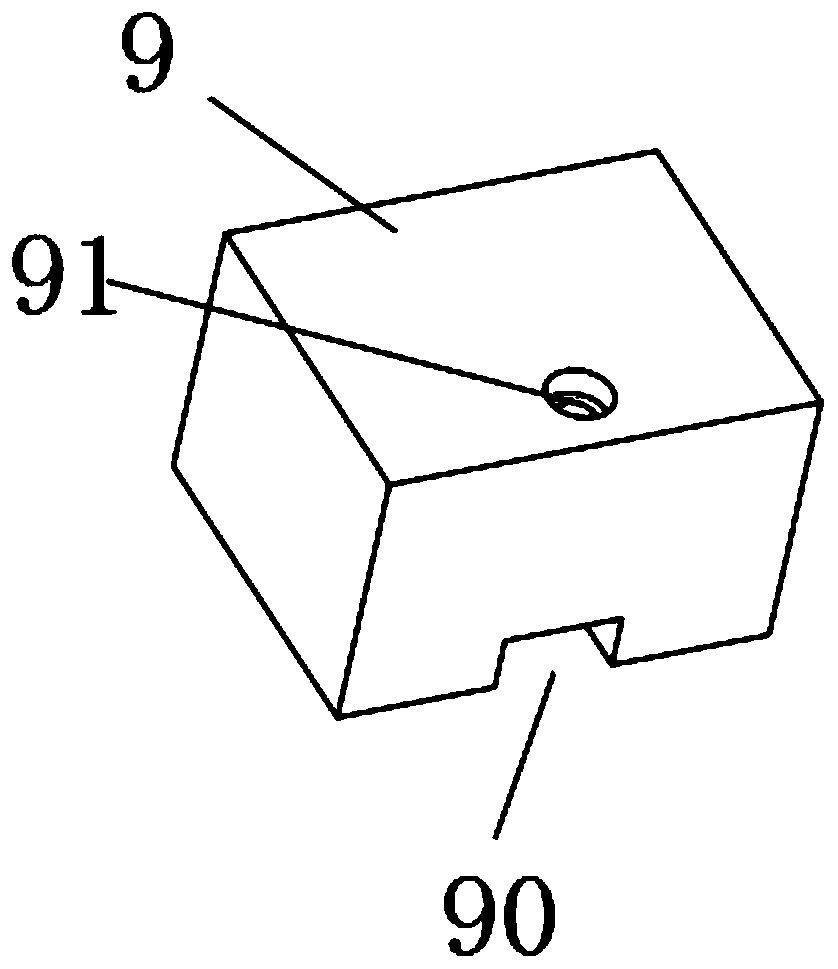

Abrasive paper clamping device

InactiveCN104416457AEven sandingImprove grinding efficiencyGrinding wheel securing apparatusPortable power-driven toolsEngineeringMechanical engineering

The invention relates to the technical field of abrasive paper and particularly relates to an abrasive paper clamping device. The device comprises a cylindrical clamping handle, and a semi-circular mounting notch is formed in one end face of the clamping handle and is formed by an axial face along the clamping handle axial direction and a radial face along the diameter direction. A compression block and locking bolts which penetrate the compression block to lock the compression block on the axial face are arranged on the axial face. The abrasive paper is arranged between the axial face and the compression block, the compression block is compressed towards the abrasive paper direction through the locking bolts, and the abrasive paper is compressed on the axial face by the compression block firmly, the abrasive paper cannot be thrown away even during high-speed rotation, smoothly sanding of work-pieces is guaranteed, and the sanding efficiency is improved.

Owner:CHANGZHOU KINGCATTLE ABRASIVES

Equipment for polishing car accessory

ActiveCN108188872AClever implementation of replacementImprove work efficiencyGrinding machinesGrinding work supportsEngineeringMachining

The invention relates to the technical field of car accessory machining equipment, and particularly discloses equipment for polishing a car accessory. The equipment comprises a workbench and a rack. Aclamping mechanism is mounted on the workbench, and the rack is fixedly connected with a stepping motor. The stepping motor is connected with a polishing wheel core shaft, and the polishing wheel core shaft is a circular electromagnet. A plurality of sliding grooves are evenly formed in the polishing wheel core shaft in the radial direction, and plugs are in sliding connection in the sliding grooves. The rack is in sliding connection with a plurality of telescopic rods, and each telescopic rod is rotationally connected with a standby wheel. The standby wheels are circular electromagnets, anda middle layer surrounds the outer edge of each standby wheel. Each middle layer comprises a chain and a chain plate fixedly connected to the chain, clearances allowing the plugs to be inserted are reserved between the adjacent chain plates, and the chain plates are made from materials capable of being magnetically adsorbed. Abrasive paper is arranged between the standby wheels and the middle layers and fixedly connected with the middle layers, and the abrasive paper on the standby wheels is different in roughness. According to the equipment, the abrasive paper can be replaced fast, polishingefficiency is improved, and equipment cost is reduced.

Owner:宁波隆锐机械制造有限公司

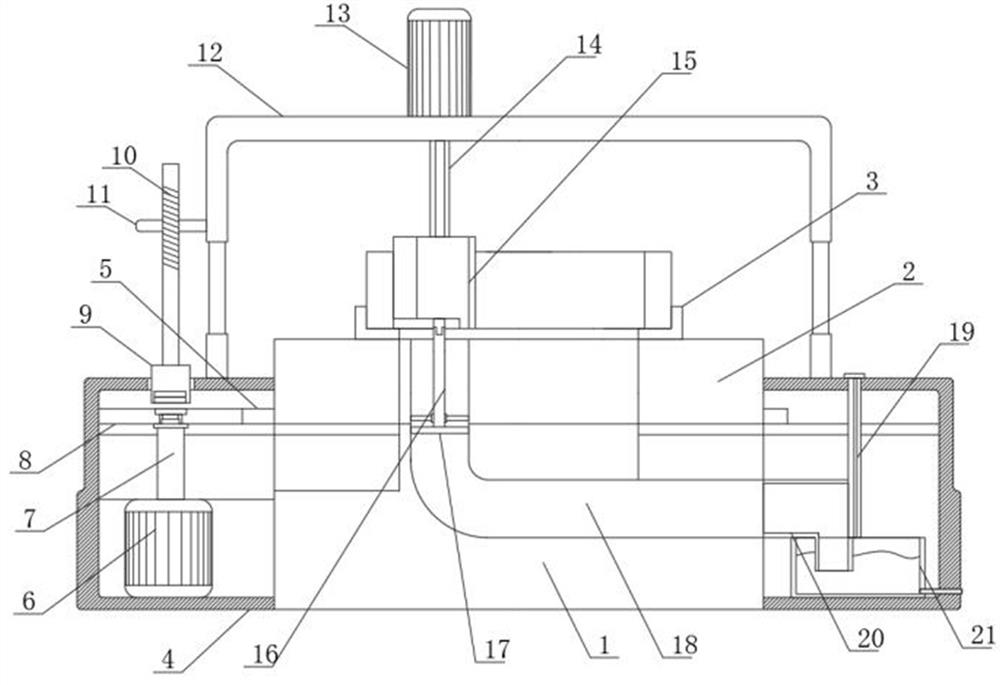

Polishing device for mechanical part machining

InactiveCN111975548AEven sandingEasy to operateGrinding drivesGrinding machinesPolishingElectric machinery

The invention relates to a polishing device for mechanical part machining. The polishing device for mechanical part machining comprises a base plate, U-shaped fixed plates, a servo motor, a fixing assembly and a shock absorbing assembly. The U-shaped fixed plates are welded and fixed to two sides of the upper surface of the base plate, the output end of the servo motor is welded and fixed to rotating bases on the U-shaped fixed plates, a polishing head is connected and fixed to the output end of the polishing motor in a clamping manner, the fixing assembly is arranged at the bottom end of thepolishing head on the upper surface of the base plate, and an operating assembly is arranged on the side of the fixing assembly on the base plate. The polishing device has the beneficial effects thatthe servo motor drives a movable block on a threaded rod to move on a fixed bar to drive the polishing head to adjust, so that the polishing device is smooth to polish and convenient to operate; a platy mechanical part is stably and safely by means of the fixing block and the U-shaped movable block under a second electrical push rod, so that the polishing device is safe to operate; and a first shock absorbing spring buffers vibration on the shock absorbing base, so that noises are reduced and the environment is protected.

Owner:卫浩

Tool equipment for repairing parts of engineering machinery

ActiveCN114603411AEasy to adjustEven sandingRevolution surface grinding machinesGrinding drivesSuction forceButt joint

The invention relates to the technical field of bearing repairing, and discloses tool equipment for repairing engineering mechanical parts, which comprises a base, a hydraulic chuck and a transmission motor, the hydraulic chuck is rotatably connected to the top of the base, an inner shaft is sleeved in the hydraulic chuck, a clamping jaw is arranged at the top of the hydraulic chuck, and a clamping groove is formed in the top of the clamping jaw. The inner shaft is rotationally connected to the inner wall of the hydraulic chuck and fixedly connected to the base, a connecting rod is arranged in the inner shaft, and a connecting shaft is arranged at the output end of the transmission motor; when the grinding wheel roller conducts grinding, the butt joint shaft can be synchronously driven to rotate, rotation of the butt joint shaft drives the fan blades on the butt joint shaft to rotate, suction force can be generated when the fan blades rotate, the outer plate is arranged on the outer wall of the grinding wheel roller in a sleeving mode, and therefore the suction force can be generated at the gap between the grinding wheel roller and the outer plate through rotation of the fan blades; and metal scraps and powder generated by polishing are sucked into the inner shaft through suction force, and the situation that subsequent use of the hydraulic chuck is affected by the metal scraps and the powder is avoided.

Owner:防城港瑞泰激光科技有限公司

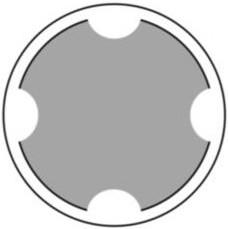

Horizontal sanding apparatus for electroplated diamond wire saw

InactiveCN108441929AHigh sand contentReduce usageCellsElectrolytic coatingsDiamond wire sawElectroplating

The invention provides a horizontal sanding apparatus for an electroplated diamond wire saw. The apparatus comprises an electroplating tank, the electroplating tank contains a plating solution, an anode is placed in the plating solution, a sand barrel is horizontally arranged at the bottom of the electroplating tank, the sand barrel is completely immersed in the plating solution, a metal wire is driven to be immersed in the plating solution in the plating tank by a pay-off wheel, goes through the sand barrel from the left to the right, and then departs from the electroplating tank through a take-up wheel, the sand barrel is connected with a driving device capable of driving the sand barrel to rotate with the metal wire as a rotating shaft, a sand inlet for adding diamond powder is arrangedin the top wall surface of the sand barrel, the left end, positioned at a metal wire inlet, of the sand barrel is provided with an impregnation solution opening to communicate with an external plating solution, and the right end, positioned at a metal wire outlet, of the sand barrel is provided with a sand blocking groove to prevent the diamond powder from flowing out with the metal wire. The sanding apparatus has the advantages of uniformity in sanding, high content of sands in the sand barrel, compactness in sanding, no shedding, and reduction of the use amount of the diamond powder.

Owner:泰州伟益新材料科技有限公司

Cylindrical metal accessory grinding machine for mechanical equipment research and development and use method of cylindrical metal accessory grinding machine

InactiveCN114833690AAchieve fixationEasy to operateGrinding drivesIncreasing energy efficiencyEngineeringMechanical equipment

The invention discloses a cylindrical metal accessory grinding machine for mechanical equipment research and development and a using method of the cylindrical metal accessory grinding machine for mechanical equipment research and development. The cylindrical metal accessory grinding machine comprises a supporting plate, a passive induction clamping mechanism, a rotating assembly, a height adjusting mechanism, a translation assembly and a cooling and dust suppression mechanism; the passive induction clamping mechanism is rotationally arranged on the annular rotating groove, the rotating assembly is arranged on the supporting plate, the rotating assembly is arranged on the passive induction clamping mechanism, the height adjusting mechanism is arranged on the supporting plate, the translation assembly is arranged on the height adjusting mechanism, and the cooling and dust suppression mechanism is arranged on the supporting plate. And the cooling dust suppression mechanism is arranged on the translation assembly. The device belongs to the technical field of mechanical equipment research and development, has the beneficial effects of automatically clamping, fixing and unfixing a cylindrical metal accessory without an external power source, not only saves time and labor, but also improves the grinding efficiency, and meanwhile, has the functions of high safety and good dust suppression effect.

Owner:吉水县秀敏信息技术有限公司

Locomotive sandbox

The invention discloses a locomotive sandbox comprising a sandbox, a sandbox end cover is arranged above the sandbox body, an upper surface of that sandbox end cover is provided with a threaded mounthole, a drive motor controller is mounted on the top end of the drive motor fixed to the left of the threaded mounting hole, at that tail end of the sandbox body, a sandbox pressure detection module is fix, and the sandbox body electronic module part comprises a driver display unit, an output unit, an MVB transmission module, a battery pack, a power conversion module, a sand spreading module, a gateway GW, a locomotive central control unit and a CAN transmission module. As that sand supply pipe of the machine room is arrange, sand supply pipe funnel, funnel end cap of sand supply pipe, drive motor, drive motor controller, the sand pumping screw and its casing, sand pipe, sand nozzle, sandbox pressure detection module, driver display unit, output unit, MVB transmission module and power conversion module solve the problems that the sand amount in the sandbox cannot be automatically detected, and the sand spreading devices in Gaza and sand spreading devices are affected by wind pressure during operation, especially when the sand is insufficient, so that the sand spreading is uneven and the sand is wasted.

Owner:HENAN NORMAL UNIV

Liquid CO2/N2 two-phase system dry fracturing fluid sand adding system and method

The invention relates to a liquid CO2 / N2 two-phase system dry fracturing fluid sand adding system under a high-pressure condition and an implementation method thereof, and belongs to the technical field of liquid CO2 / N2 two-phase system dry fracturing fluid performance testing. The sand adding system comprises a gas pressurizing system, a sand adding pump, a sand adding control system, a conveyingpipe, a conveying pump and a flow control valve; the gas pressurization system comprises a CO2 storage tank, a CO2 pump, a liquid nitrogen storage tank and a liquid nitrogen pump; the CO2 storage tank is connected with the CO2 pump, and the liquid nitrogen storage tank is connected with the liquid nitrogen pump; and the CO2 pump is sequentially connected with the bottom end of the sand adding pump, the liquid nitrogen pump, the flow control valve and the conveying pump through the conveying pipe, the CO2 pump is connected with the upper end of the sand adding pump through a branch conveying pipe, and the sand adding pump is connected with the sand adding control system. By means of the system, sand is evenly added into fracturing of a liquid CO2 / N2 two-phase system, the sand ratio is adjusted in real time, sand blocking is prevented, the fracturing construction effect is improved, and then the recovery efficiency and the development effect are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shaft cleaning and polishing device

InactiveCN111515780AEasy to useSimple structureShaking/oscillating/vibrating mixersGrinding drivesPolishingWater storage tank

The invention discloses a shaft cleaning and polishing device. The shaft cleaning and polishing device comprises a cleaning mechanism and a polishing mechanism; the cleaning mechanism comprises a water storage tank in a chassis, a bottom box with an upward opening, and a filling block; the bottom box is positioned below the water storage tank; a projection part and an elastic piece are arranged inthe bottom box; the projection part is positioned below the water storage tank; the elastic piece is positioned below the projection part; bearing pieces are arranged around the elastic piece; a slide rod is arranged in an annular groove; one end of the slide rod is fixedly connected with a rotating rod, and a swing rod is arranged at the other end of the slide rod; a second I-shaped wheel is arranged on the right side of a first I-shaped wheel; the first I-shaped wheel and the second I-shaped wheel are rotationally connected through a connecting belt; a connecting rod is arranged above the second I-shaped wheel; the lower end of the connecting rod is rotationally connected with the second I-shaped wheel, and the upper end of the connecting rod is fixedly connected with the lower surfaceof a base; and a gear piece is arranged in the center of the lower surface of the chassis. The shaft cleaning and polishing device is convenient to use and simple in structure, and realizes integratedoperation of polishing and water adding of shafts.

Owner:云和县达祥凯机械设计工作室

Ultra-large type evanescent mould precision-casting shell manufacturing tool and shell manufacturing process thereof

ActiveCN102744369BIncrease buoyancySave human effortFoundry mouldsFoundry coresInvestment castingAgricultural engineering

The invention relates to an ultra-large type evanescent mould precision-casting shell manufacturing tool and a shell manufacturing process thereof, belonging to the technical field of investment casting. The ultra-large type evanescent mould precision-casting shell manufacturing tool comprises a first wheel spoke structure and a second wheel spoke structure which are arranged on a main shaft, one end of the main shaft is connected with a power mechanism, the main shaft is provided with bearings between the power mechanism and the first wheel spoke structure and on the right end part of the second wheel spoke structure, the two bearings are arranged on two bearing seats, and the two bearing seats are fixed on a chassis. The shell manufacturing process comprises the following steps of: when a shell is manufactured, installing an evanescent mould on the main shaft, adhering the small ends of a plurality of connected lug bosses on a pouring channel and a feed head of the evanescent mould and an evanescent mould body, and adhering the large ends to the inner sides of the first wheel spoke structure and the second wheel spoke structure; rotating the main shaft, spraying paint on the surface of the evanescent mould by adopting flow coating mode, and then scattering sand; after the evanescent mould is dried, spraying the paint and scattering the sand again till the number of mould shell layers is reached, and then cutting off the connected lug bosses; taking down the evanescent mould and the shell from the ultra-large type evanescent mould precision-casting shell manufacturing tool, and then roasting to obtain the mould shell. The mould shell has the advantages of difficult deformation, smooth paint immersion process, stable quality of a produced product, labor conservation and work efficiency increase.

Owner:安徽应流铸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com