Equipment for polishing car accessory

A technology for auto parts and equipment, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding workpiece support, etc., which can solve the problems of reduced grinding efficiency, achieve replacement time, improve work efficiency, and improve market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

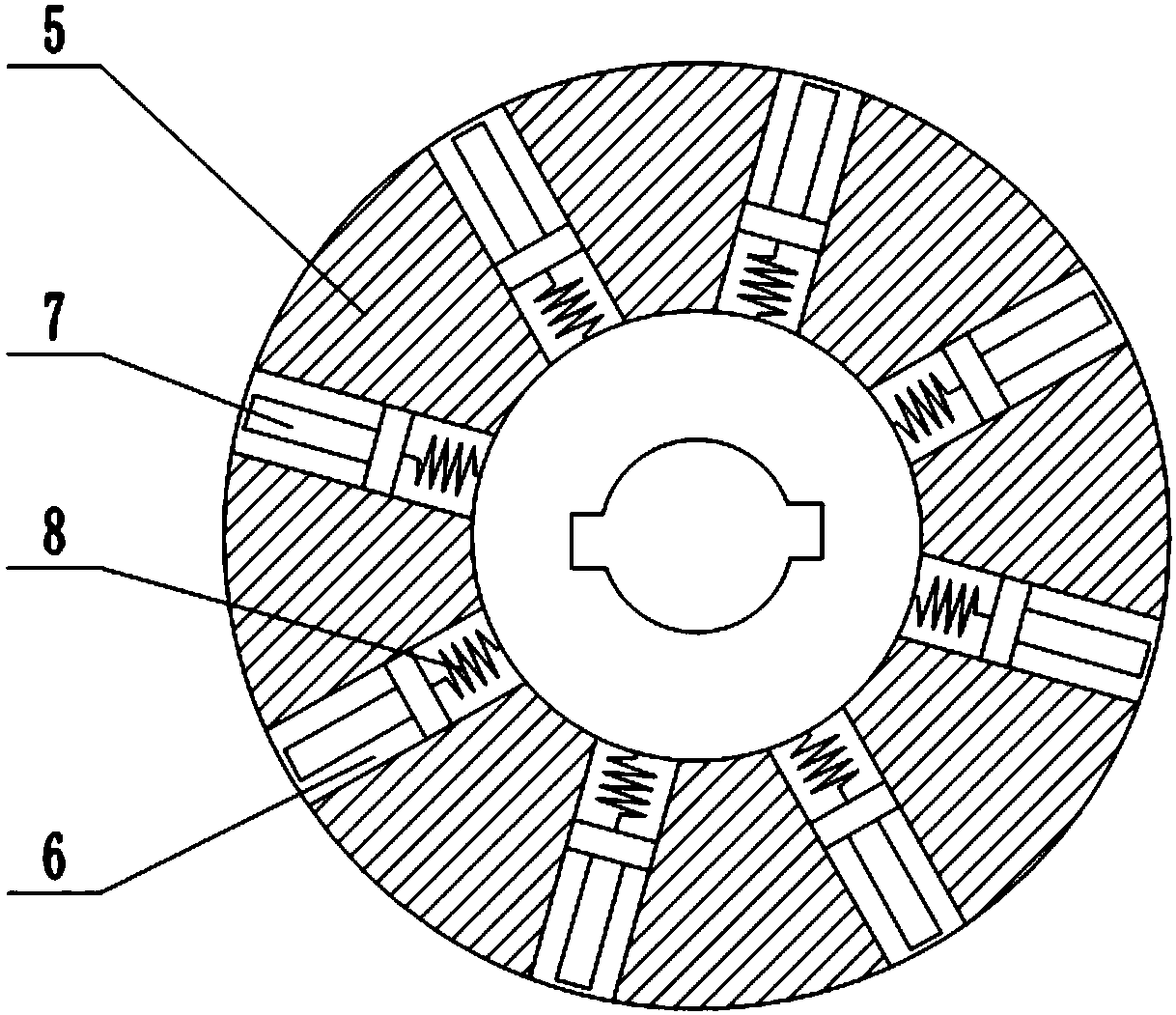

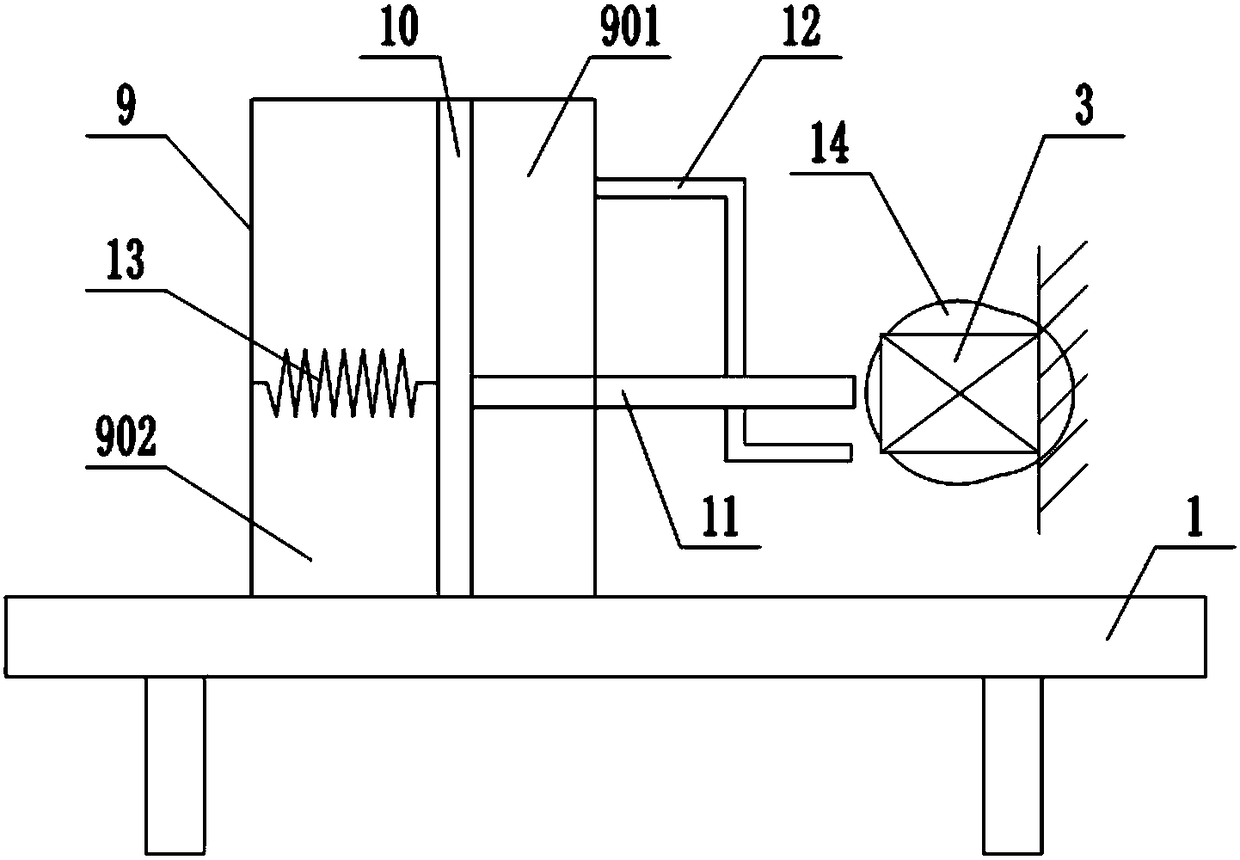

[0019] The reference signs in the drawings of the description include: workbench 1, clamping mechanism 2, stepper motor 3, rotating shaft 4, grinding wheel mandrel 5, chute 6, latch 7, first spring 8, cylinder body 9, second A chamber 901, a second chamber 902, a piston 10, a piston rod 11, an intake pipe 12, a second spring 13, a cam 14, a telescopic rod 15, a spare wheel 16, sandpaper 17, and an intermediate layer 18.

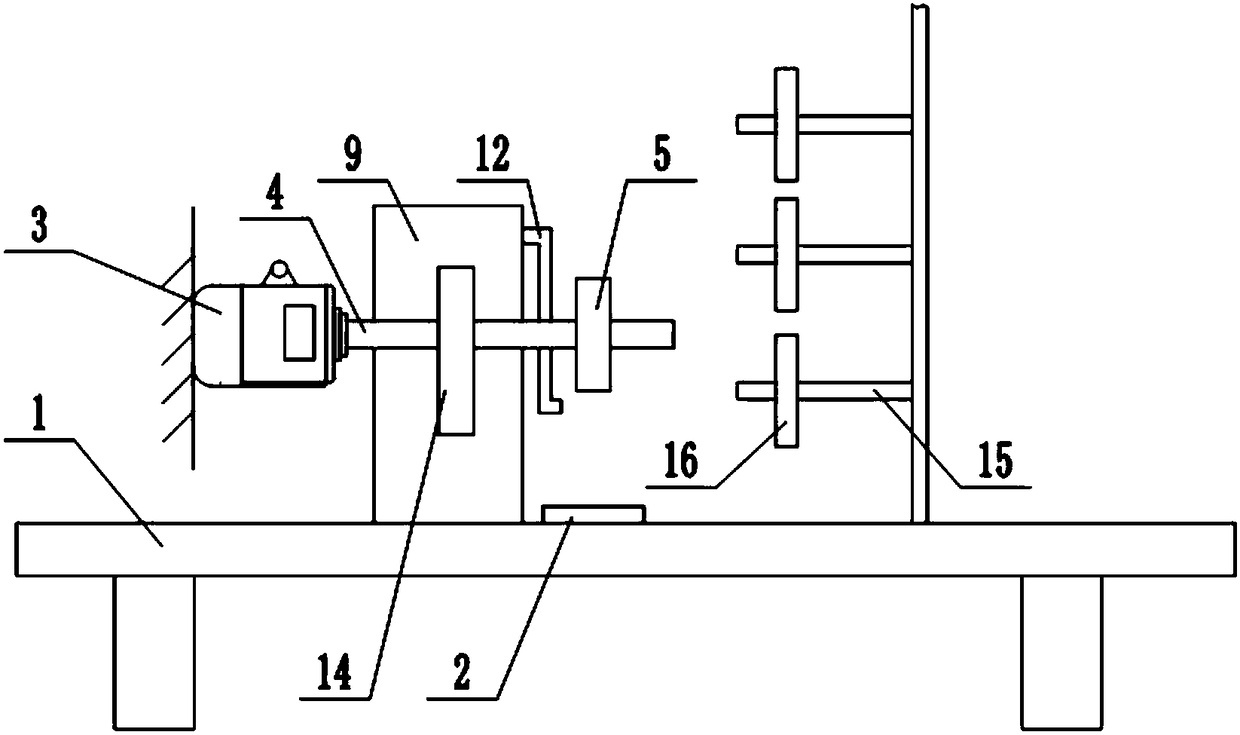

[0020] In this example, if figure 1 As shown, the equipment for grinding auto parts includes a workbench 1 and a frame. A clamping mechanism 2 for clamping auto parts is installed on the workbench 1. A stepping motor 3 is fixedly connected to the frame. The stepping motor The output end of 3 is fixedly connected with rotating shaft 4, and rotating shaft 4 is fixedly connected with grinding wheel mandrel 5, offers groove on the inner wall of grinding wheel mandrel 5, and rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com