Household stainless steel inner wall polishing device

A stainless steel, home-use technology, which is applied in the direction of grinding drive devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of low grinding quality, time-consuming and labor-intensive, low efficiency, etc., to improve grinding quality, prevent shaking, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

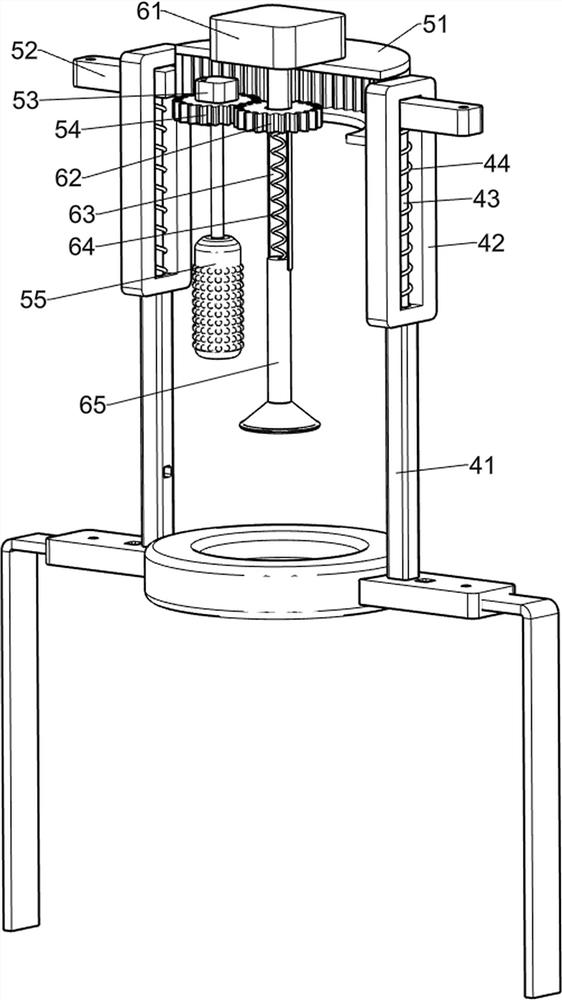

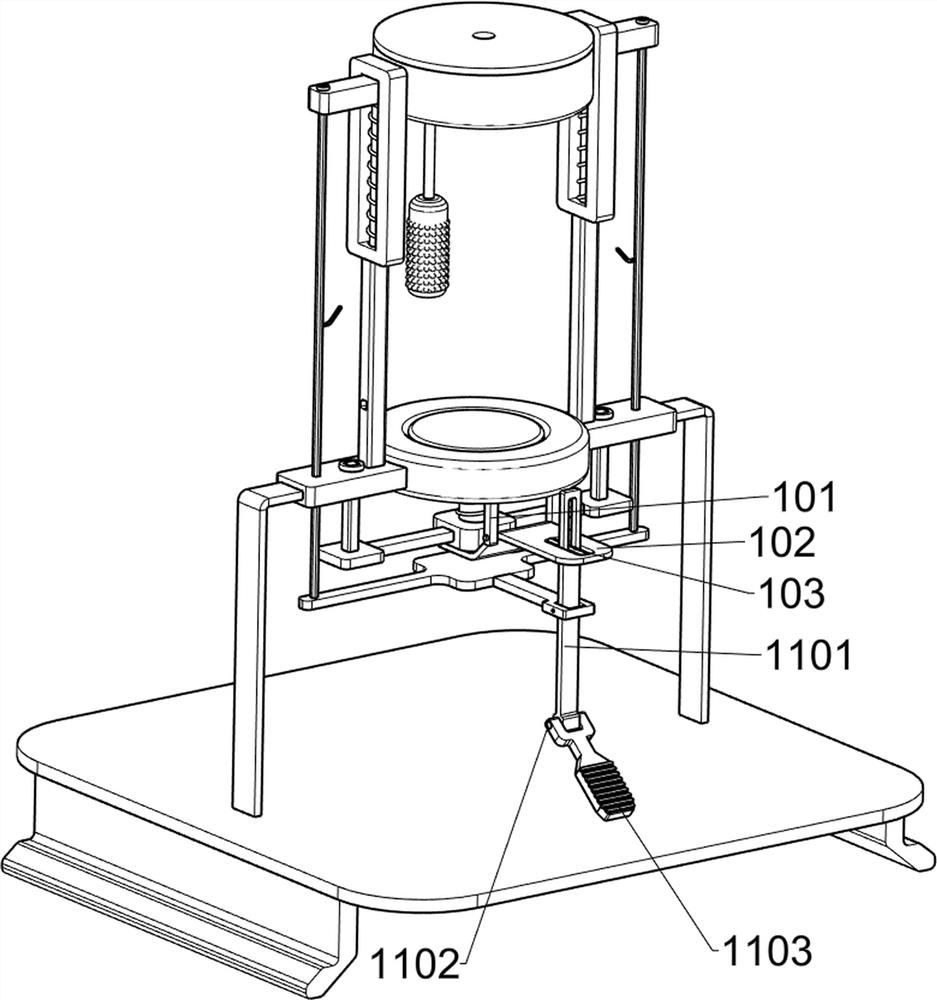

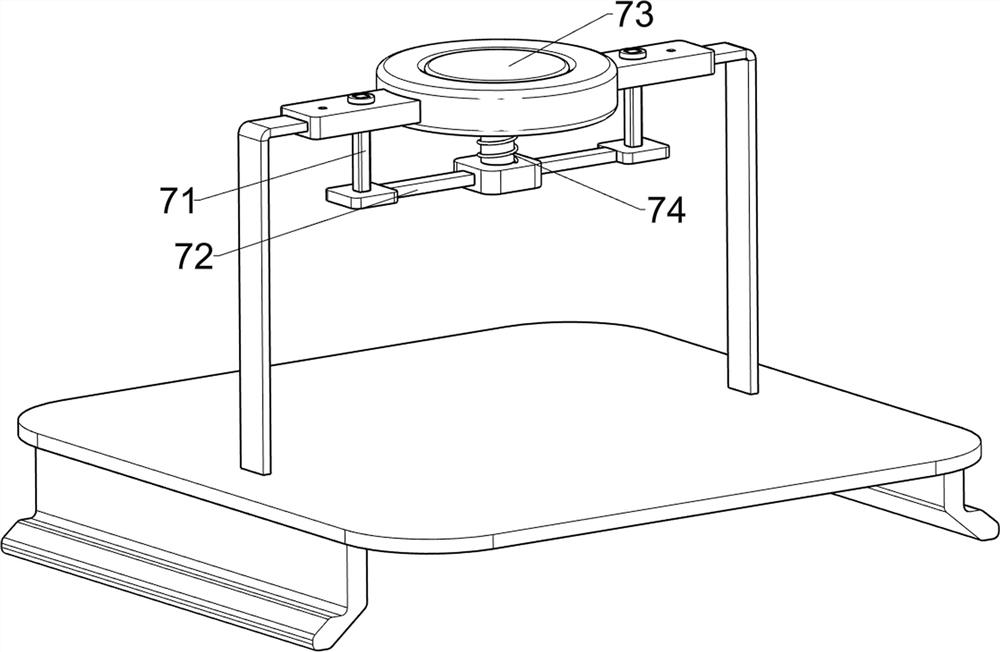

[0076] A kind of household stainless steel inner wall grinding device, such as figure 1 As shown, it includes a base 1, a support 2, a workbench 3, a guide mechanism 4 and a grinding mechanism 5. The middle parts of the left and right sides of the base 1 are provided with supports 2, and the upper parts of the supports 2 on the left and right sides are connected with a workbench 3. , The top of the bracket 2 is provided with a guide mechanism 4, and the guide mechanism 4 is provided with a grinding mechanism 5.

[0077] Manual grinding is time-consuming, labor-intensive, low in efficiency and low in grinding quality. This equipment can automatically grind stainless steel, saving time and effort, high in efficiency and high in grinding quality. First, people put stainless steel household tools on the top of the workbench 3, and Make it fixed, then make the grinding mechanism 5 run, the running of the grinding mechanism 5 drives the guide mechanism 4 to run, the guide mechanism ...

Embodiment 2

[0079] On the basis of Example 1, such as figure 2 As shown, the guide mechanism 4 includes a first connecting rod 41, a guide groove 42, a first guiding rod 43 and a first spring 44, and the tops of the brackets 2 on the left and right sides are provided with a first connecting rod 41, two first connecting rods The top of the rod 41 is provided with a guide groove 42, the first guide rod 43 is connected between the upper and lower sides of the guide groove 42, the first guide rod 43 is slidably connected with the grinding mechanism 5, and the first guide rod 43 is wound with a first guide rod 43. The top of the first spring 44 is connected to the grinding mechanism 5 , and the bottom of the first spring 44 is connected to the guide groove 42 .

[0080] After people put stainless steel on the top of the workbench 3, the grinding mechanism 5 is operated, and the grinding mechanism 5 is slid downward on the first guide rod 43, and the first spring 44 is changed from the initial...

Embodiment 3

[0084] On the basis of Example 2, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, an automatic winding mechanism 6 is also included, and the mechanism casing 51 is provided with an automatic winding mechanism 6, and the automatic winding mechanism 6 includes a second motor 61, a second gear 62, a sleeve rod 63, a second spring 64 and a pressing rod 65 A second motor 61 is installed in the middle part of the top side of the mechanism housing 51, and the output shaft of the second motor 61 is provided with a second gear 62. The second gear 62 meshes with the first gear 54. Sleeve rod 63 is provided, and the inner side of the bottom of sleeve rod 63 slides to be provided with depression bar 65, and depression rod 65 is positioned at the top of workbench 3, and second spring 64 is connected between depression rod 65 and sleeve rod 63, and second spring 64 is positioned at sleeve. Rod 63 inside.

[0085] When the mechanism casing 51 moves downward, the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com