Patents

Literature

45results about How to "Achieve the effect of automatic clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

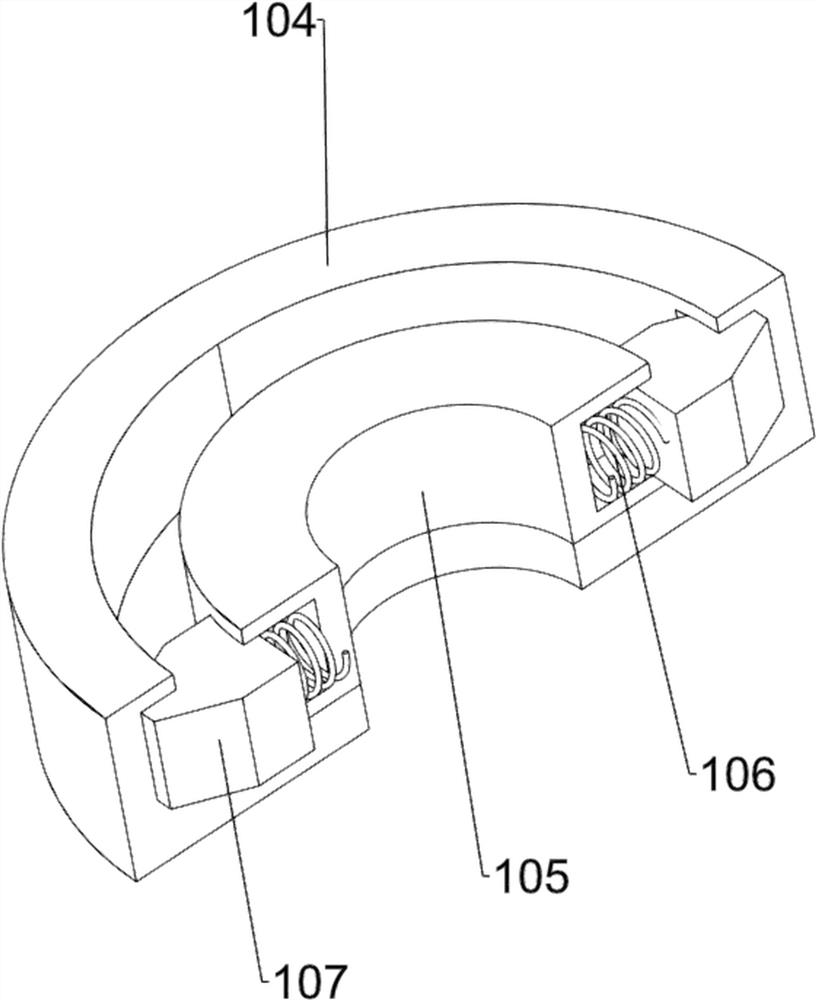

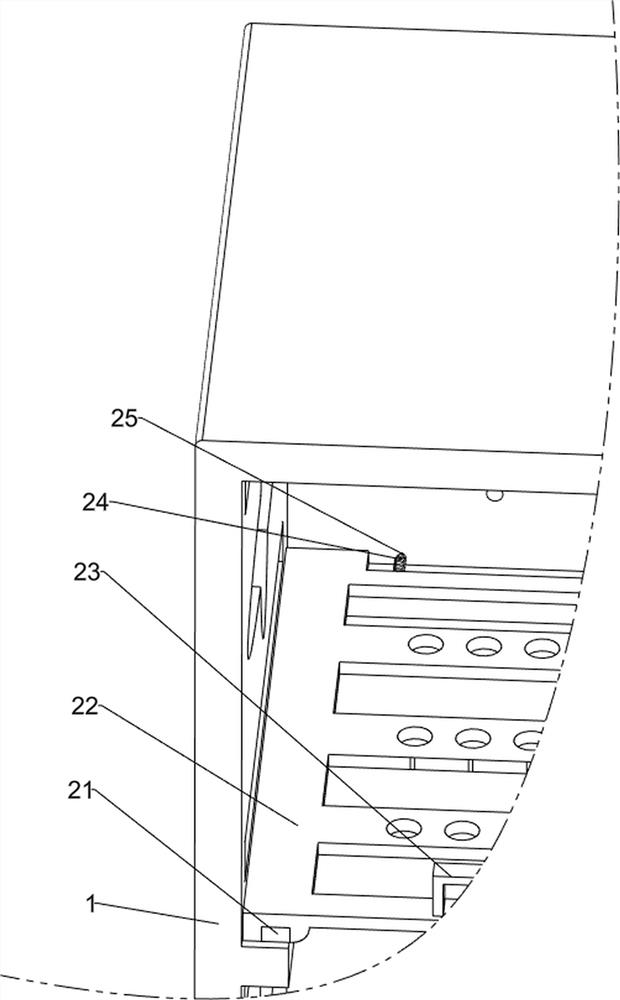

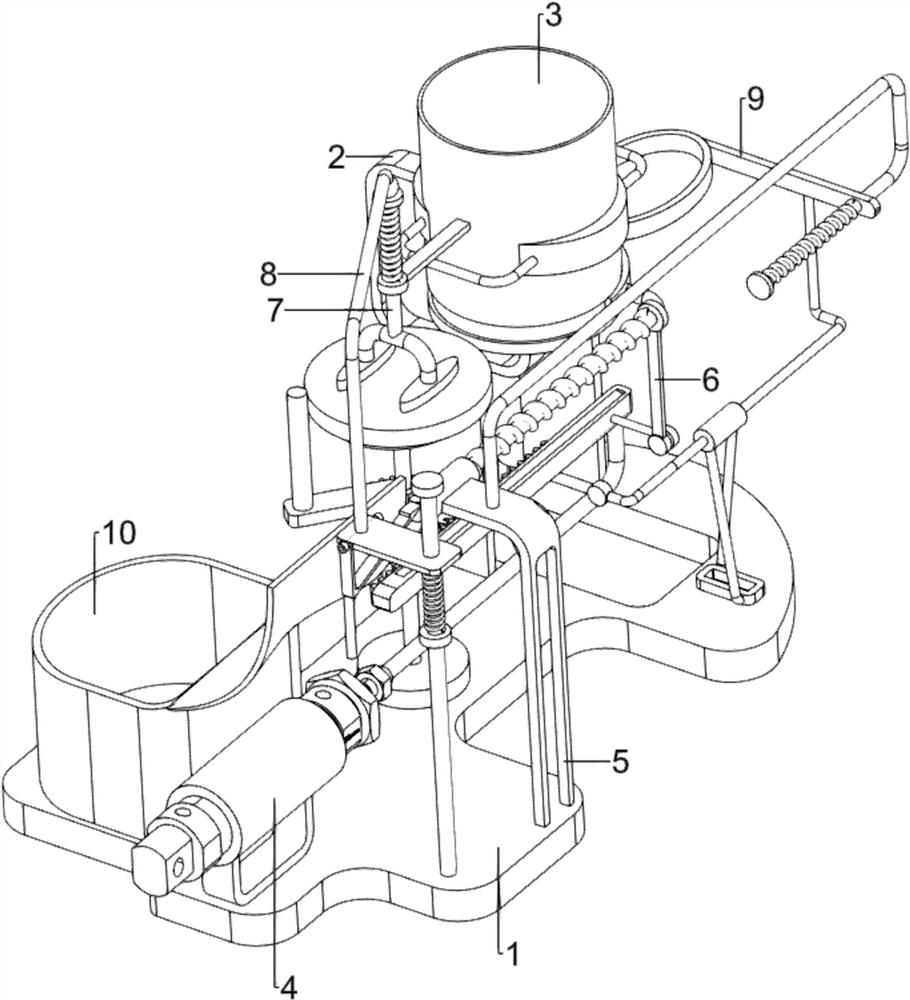

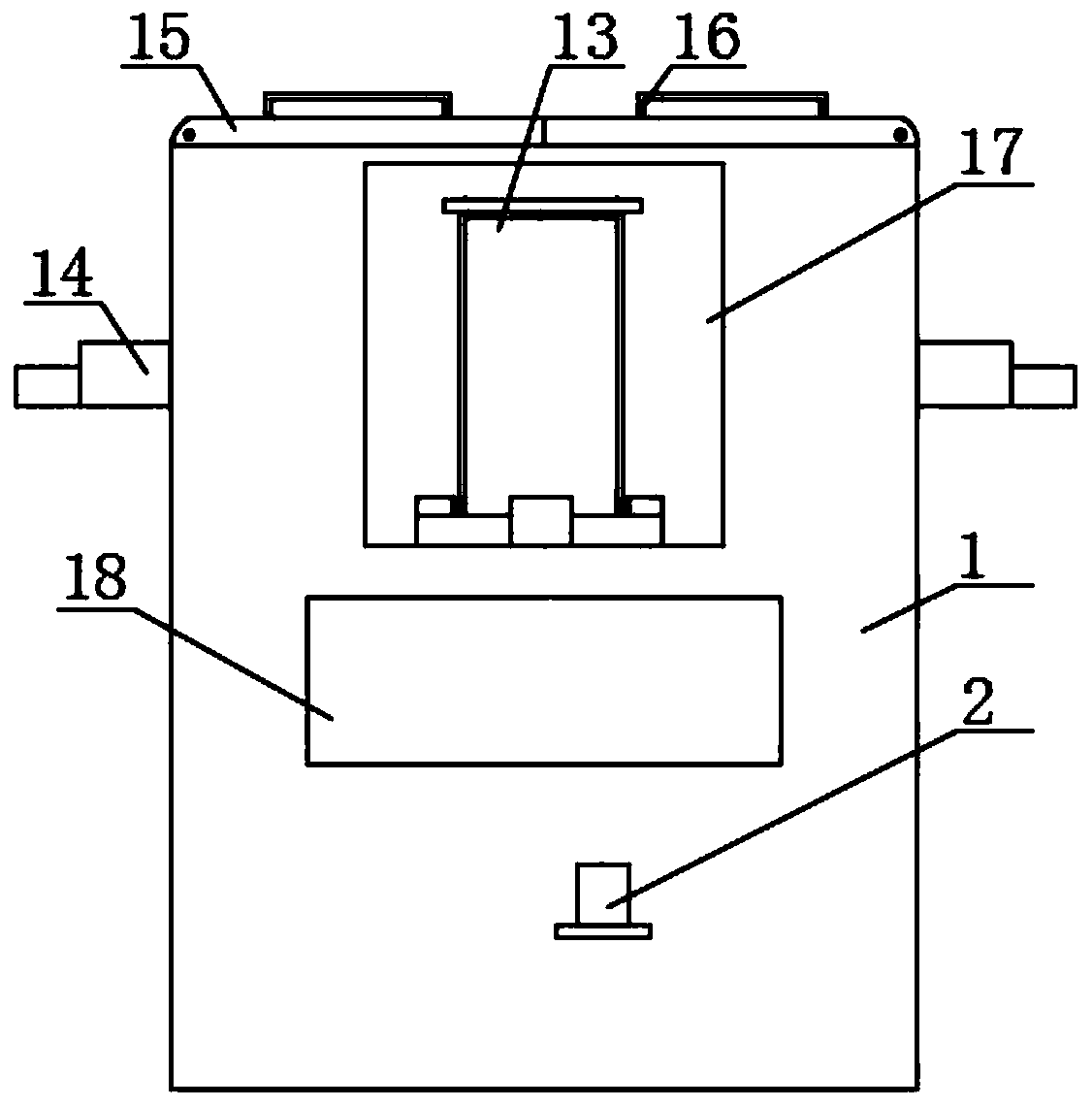

Household stainless steel inner wall polishing device

PendingCN112518445APlay a guiding roleEven sandingEdge grinding machinesGrinding carriagesPolishingStructural engineering

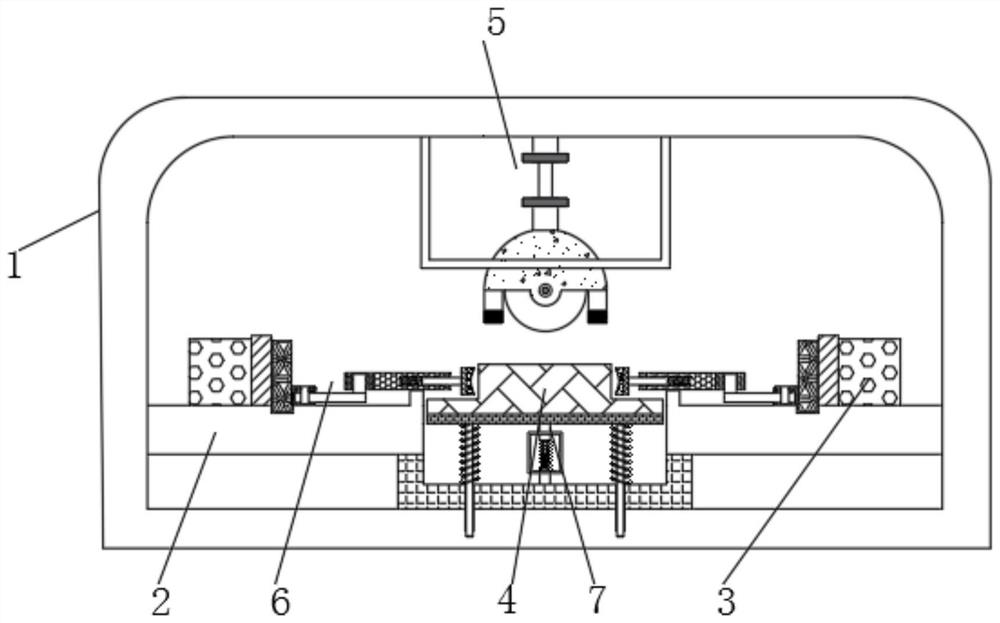

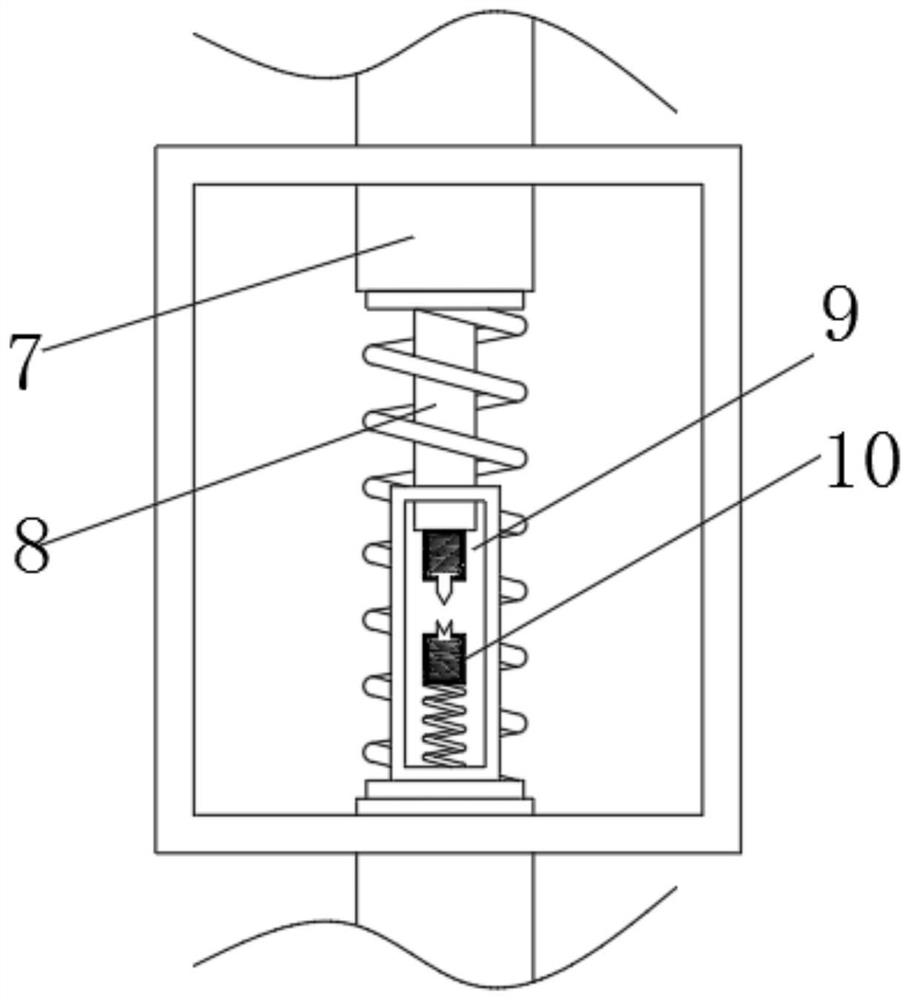

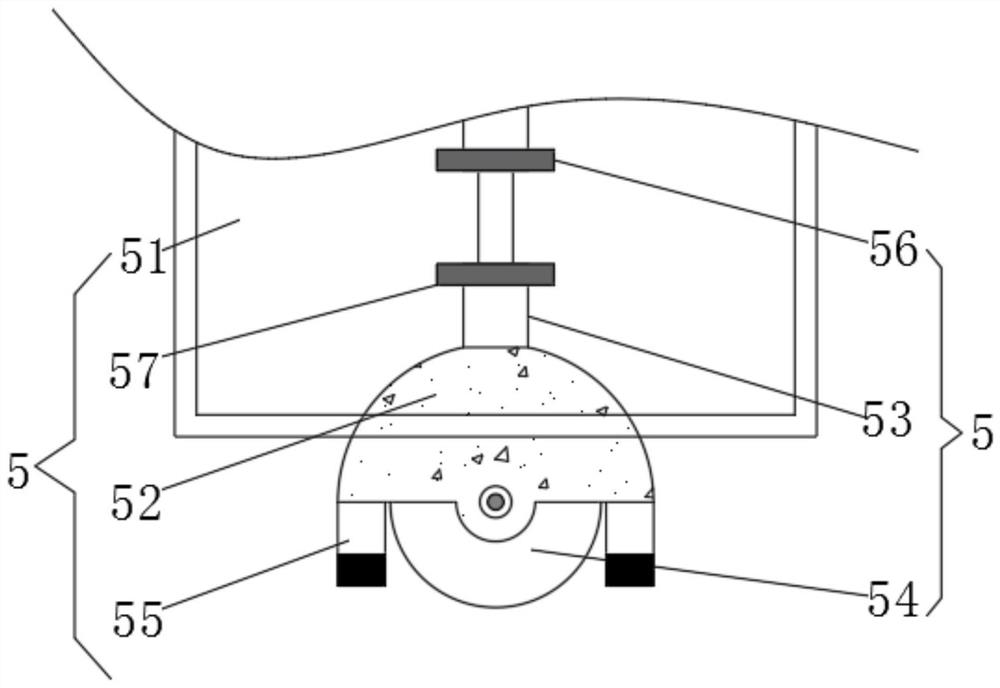

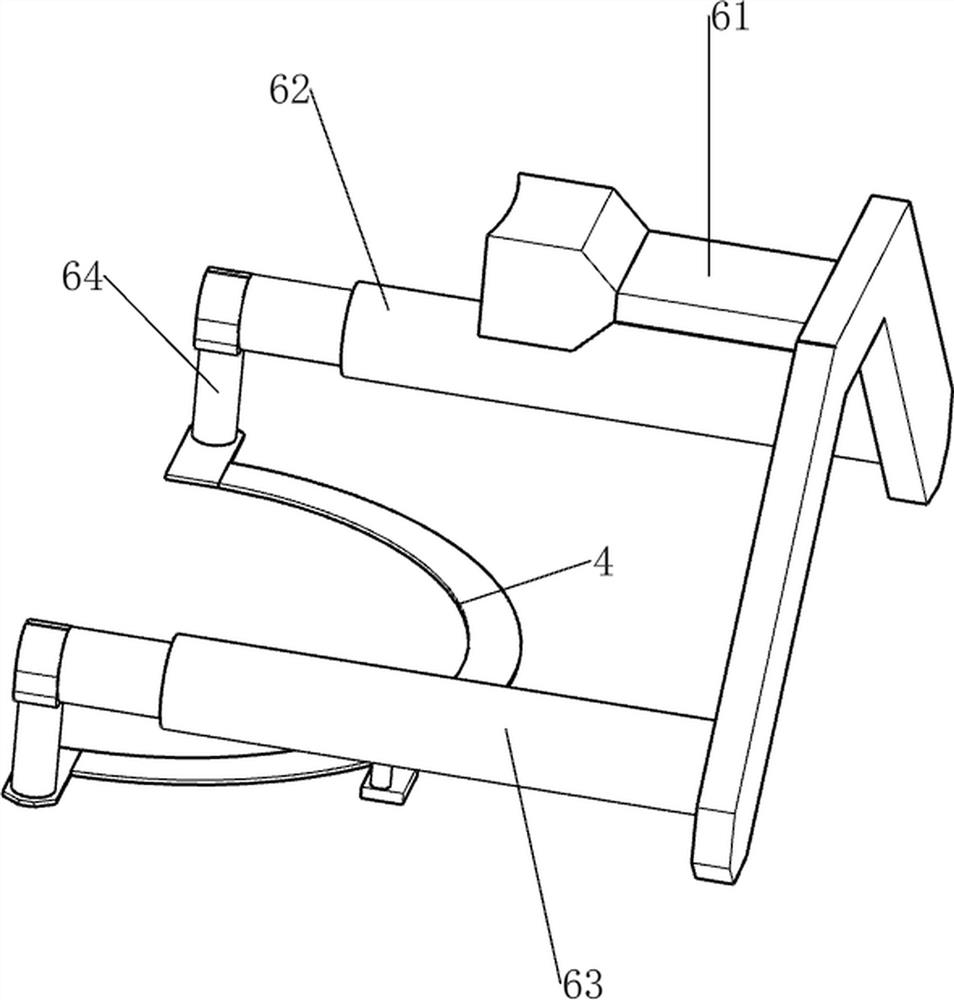

The invention relates to a polishing device, in particular to a domestic stainless steel inner wall polishing device. The domestic stainless steel inner wall polishing device saves time and labor, andis high in efficiency and polishing quality. The household stainless steel inner wall polishing device comprises a base, two supports, a workbench, guiding mechanisms and a polishing mechanism. The two supports are arranged on the base. The workbench is connected between the upper parts of the two supports. The guiding mechanisms are arranged at the tops of the supports. The polishing mechanism is arranged on the guiding mechanisms. According to the household stainless steel inner wall polishing device, wedge-shaped rods are matched with second connecting rods, the wedge-shaped rods move to enable the second connecting rods to slide towards the inner sides in first connecting rods, fourth springs are changed into a compressed state from an initial state, and the second connecting rods move to enable arc-shaped pressing plates to move towards the inner side, so that stainless steel is clamped, the automatic clamping effect is achieved, the stainless steel can be prevented from shakingin the polishing process, and the polishing quality is improved.

Owner:莫英文

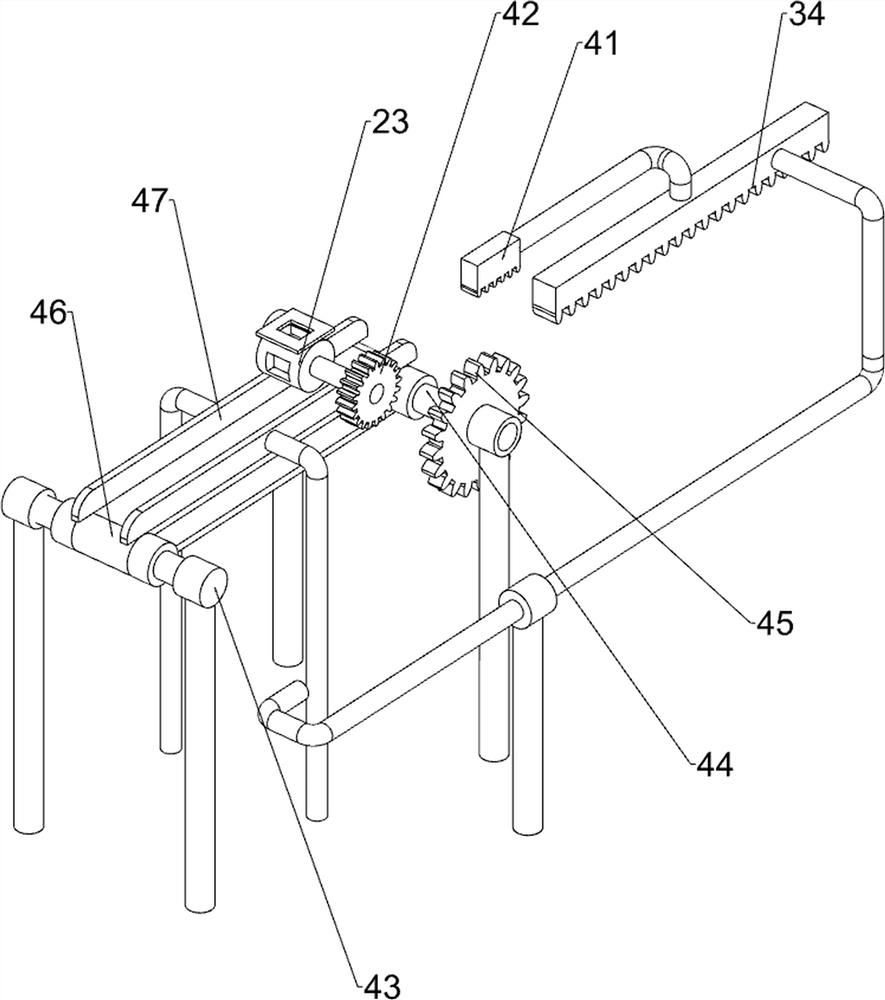

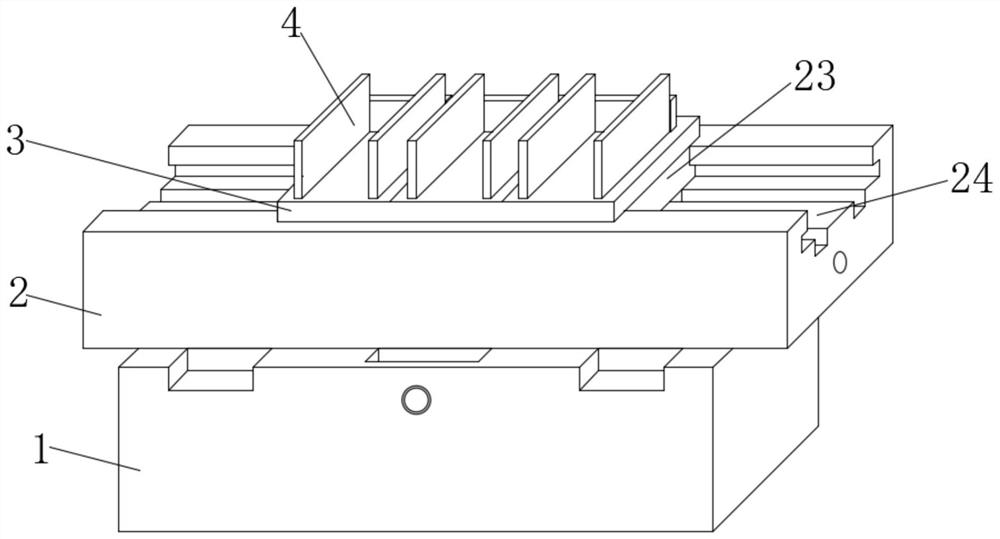

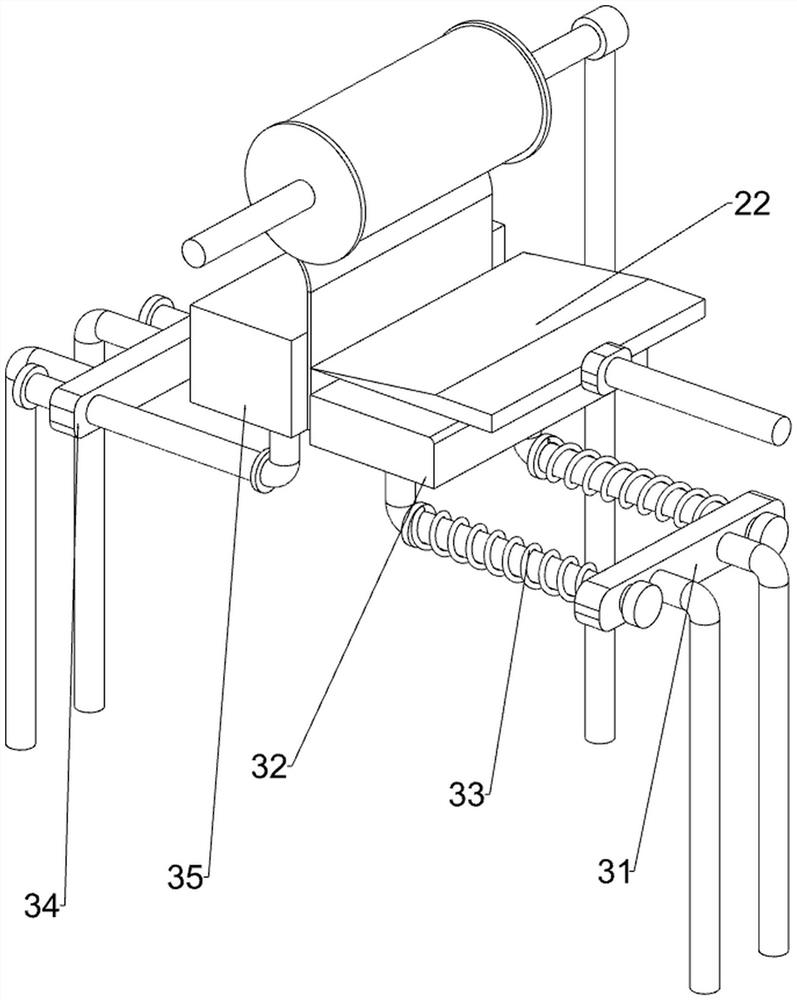

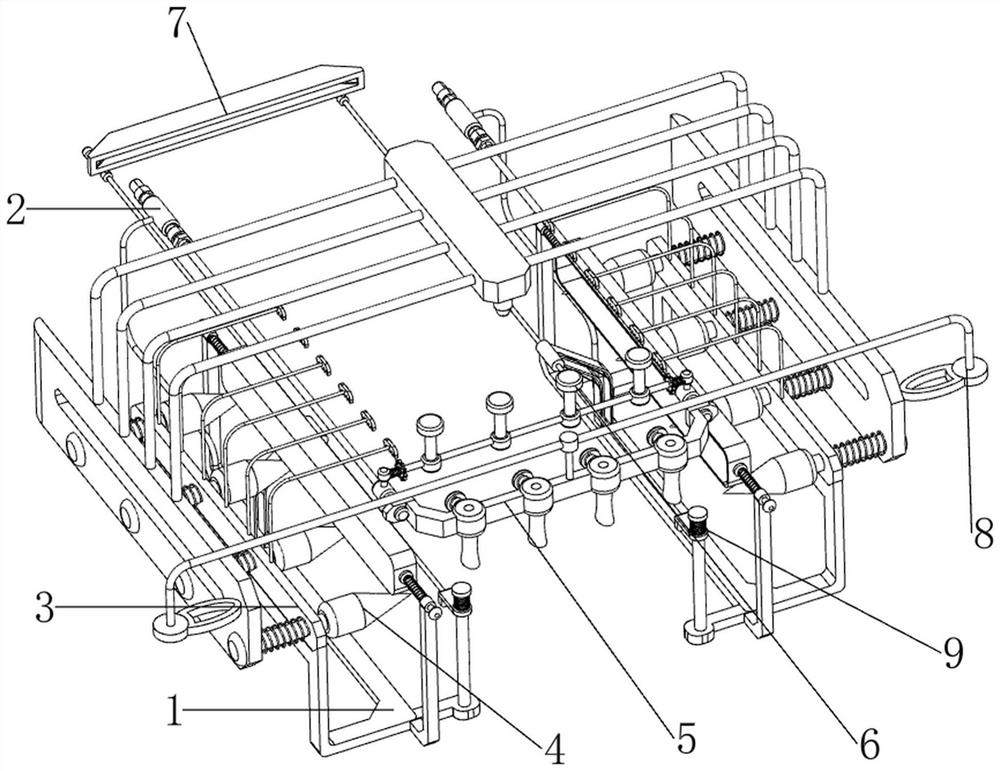

Slotting device for manufacturing wood tooth comb

ActiveCN112589931AAchieve the effect of automatic feedingAchieve the effect of automatic clampingWood mortising machinesWood slotting machinesWood plankWorkbench

The invention relates to a slotting device, in particular to a slotting device for manufacturing a wood tooth comb. The invention provides the slotting device for manufacturing the wood tooth comb with the advantages of high tooth forming precision, time and labor saving and low cost. The slotting device for manufacturing the wood tooth comb comprises supporting legs, workbenches, a first supporting frame, a fixing mechanism and a cutting mechanism, wherein two workbenches are connected onto the two supporting legs; the first supporting frame is arranged on one supporting leg; the fixing mechanism is arranged on the workbenches; the cutting mechanism is arranged at the upper part of the first supporting frame; and the cutting mechanism cooperates with the fixing mechanism. The slotting device for manufacturing the wood tooth comb has the advantages that through cooperation of first wedge blocks and second wedge blocks, the second wedge blocks apply pressure to the first wedge blocks, so that the first wedge blocks moves downwards, and first connecting rods moves downwards, and finally a cutting device moves downwards; the cutting device cuts a wood plate, and an automatic cutting effect is achieved; and the tooth forming precision is high, and time and labor are saved.

Owner:谢凤香

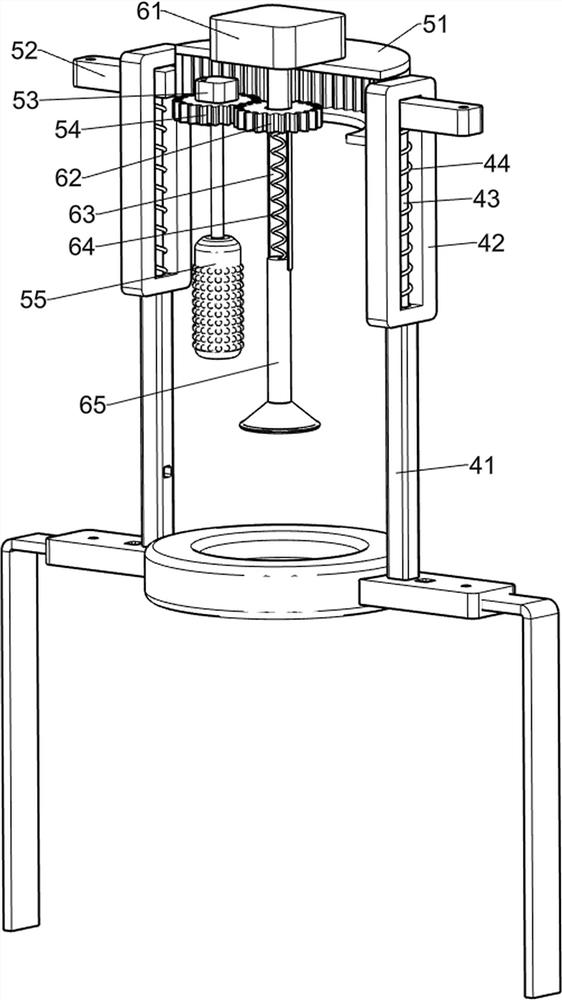

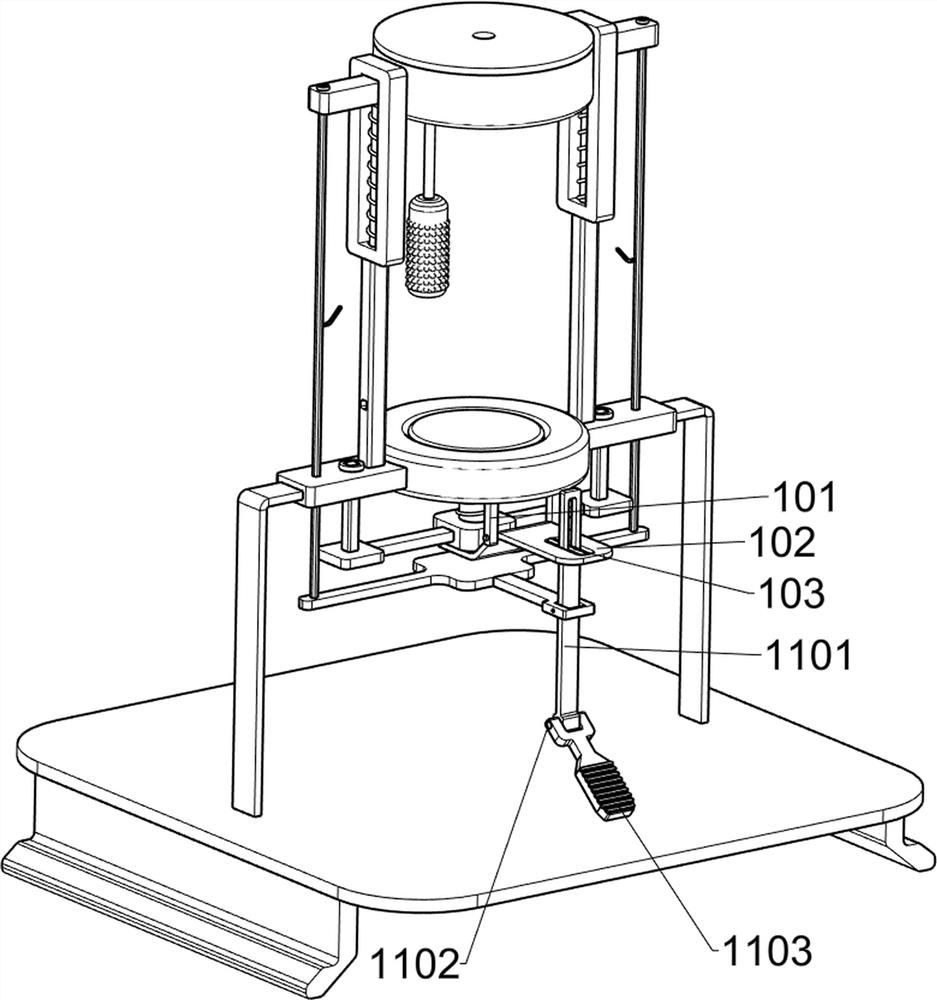

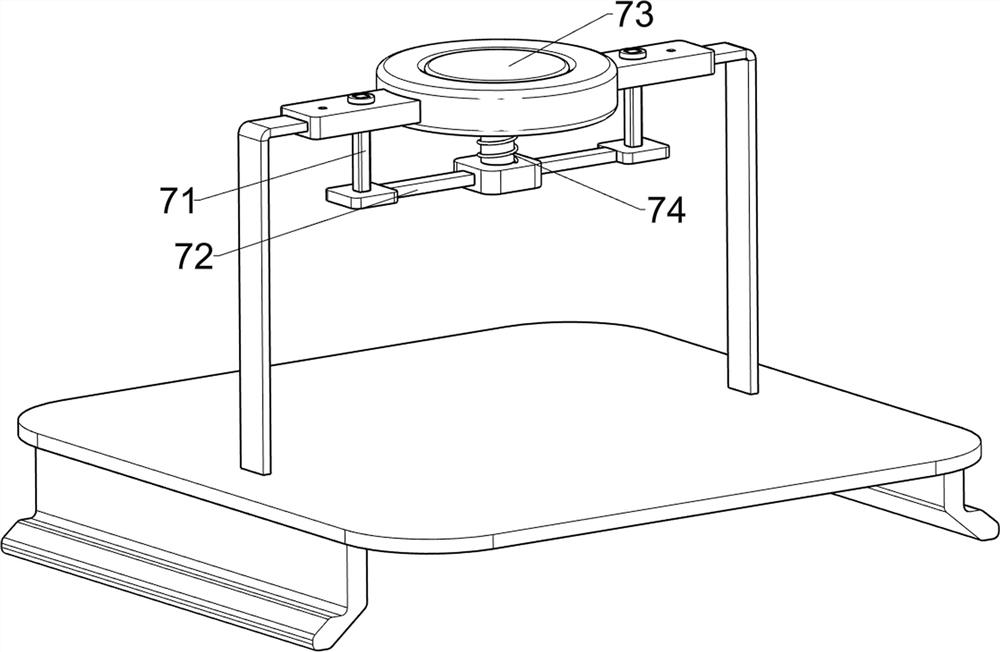

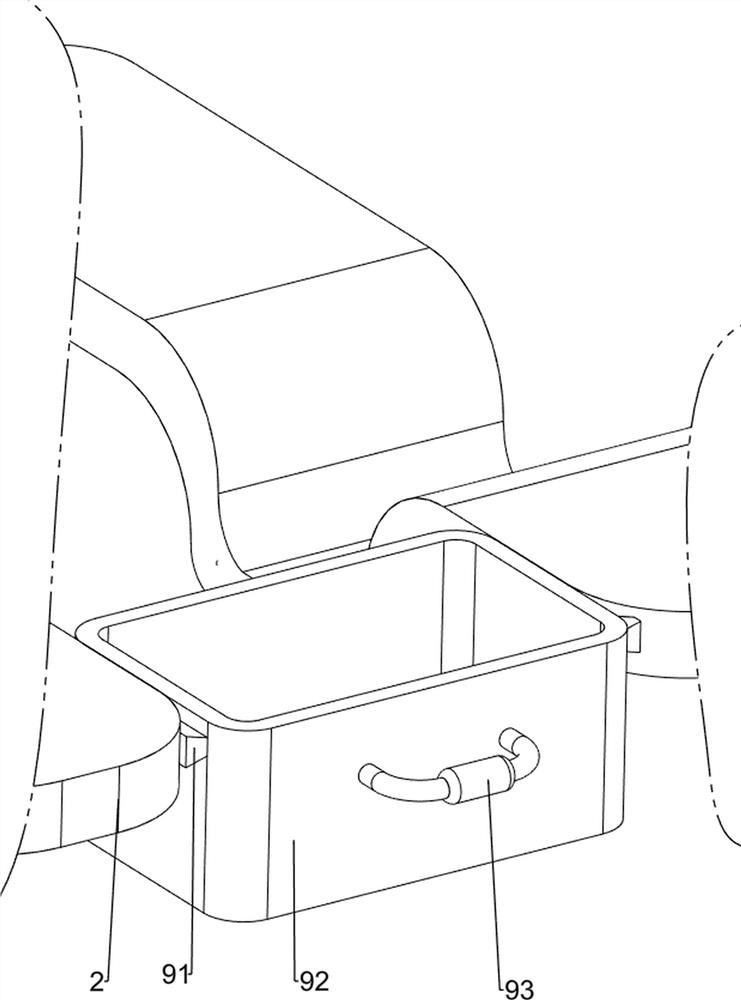

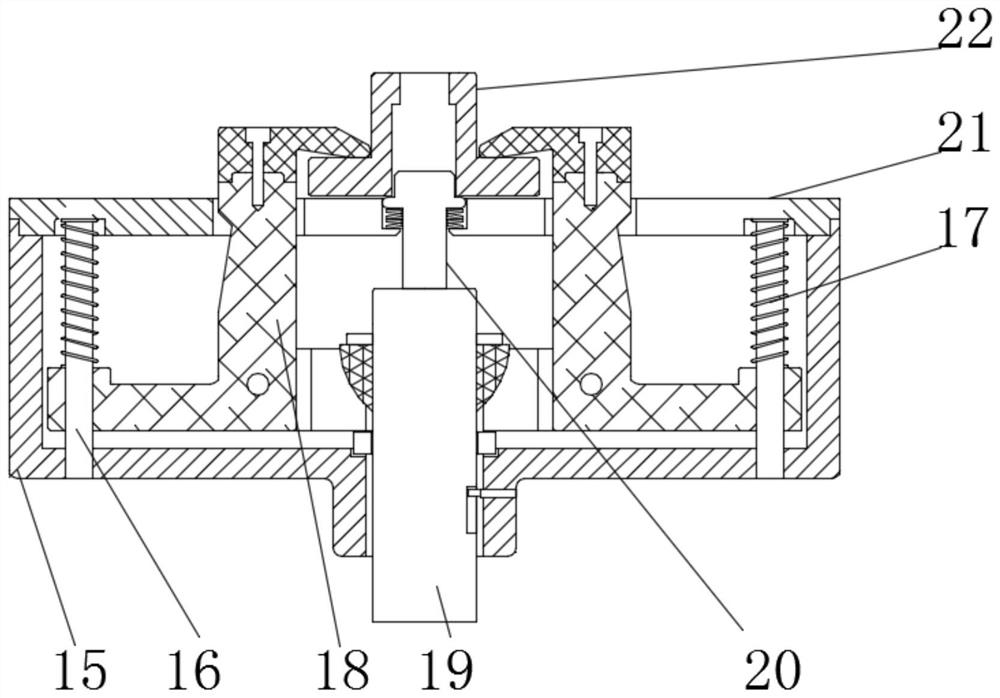

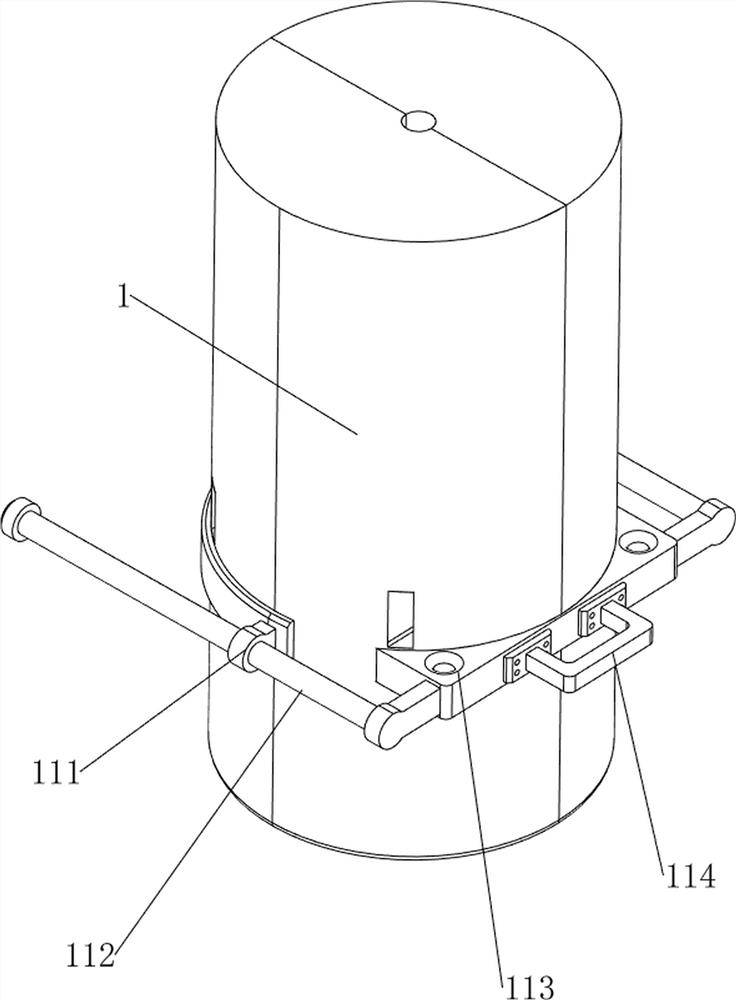

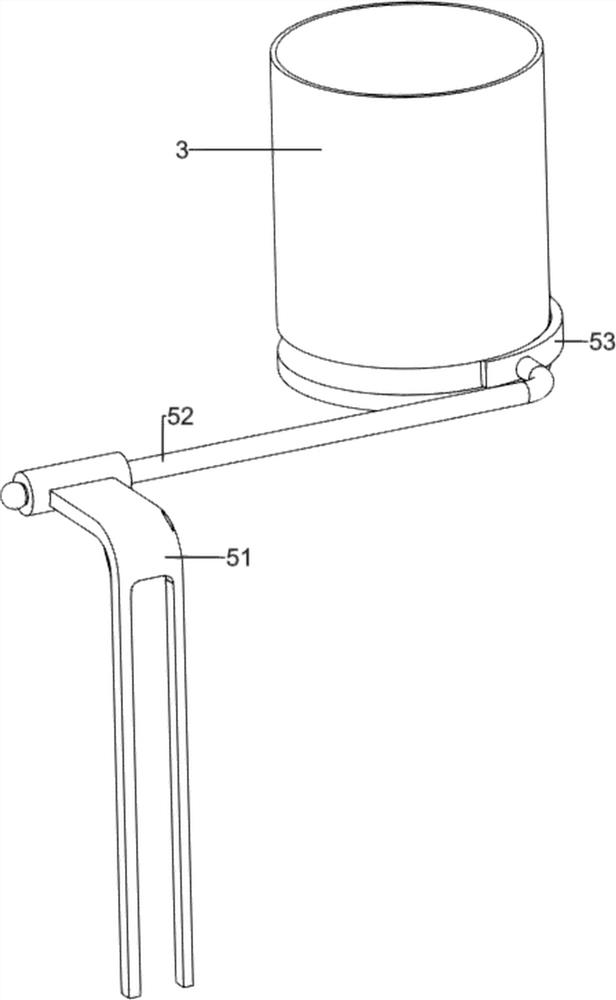

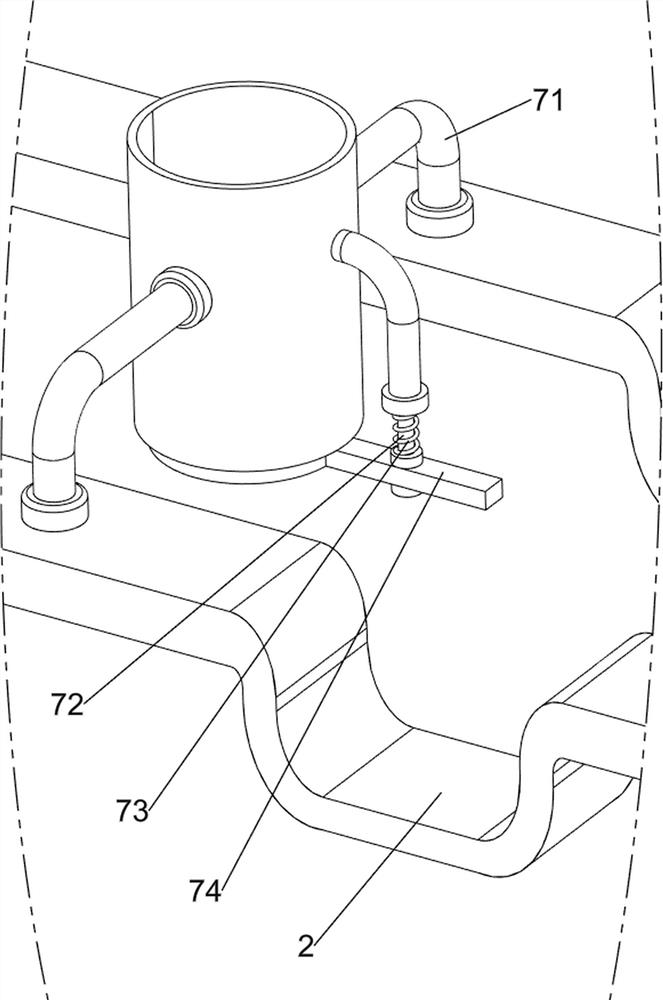

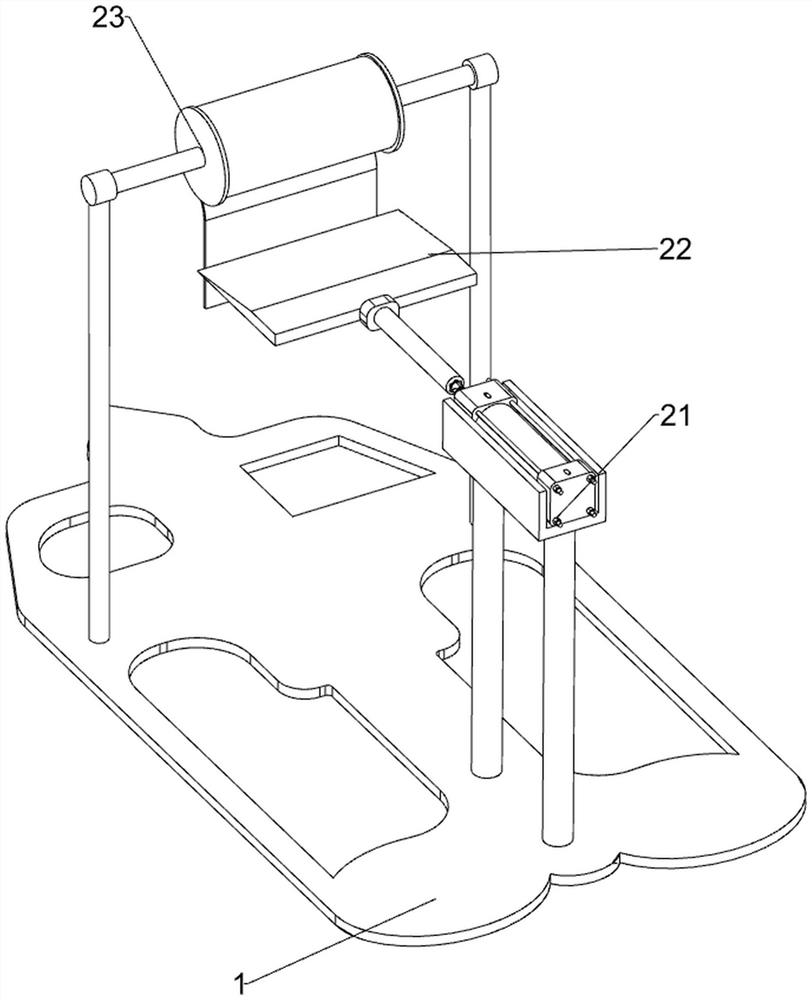

Medicine barrel sealing equipment used for pharmacy department

InactiveCN112810861ATo achieve the sealing effectAchieve the effect of automatic clampingWrapper twisting/gatheringPharmacyTransfer mechanism

The invention relates to sealing equipment, in particular to medicine barrel sealing equipment used for the pharmacy department. The medicine barrel sealing equipment, capable of automatic feeding, automatic sealing and automatic film replacing, used for the pharmacy department is provided. The medicine barrel sealing equipment used for the pharmacy department comprises a baseboard, stopping blocks and oblique blocks, wherein the two stopping blocks are arranged on the baseboard, the two oblique blocks are arranged on the baseboard, a film-laminating sealing mechanism is arranged on the baseboard, and a manual downward-pressing mechanism is arranged on the film-laminating sealing mechanism. According to the medicine barrel sealing equipment used for the pharmacy department, by arranging a transfer mechanism, the transfer mechanism runs to drive a pushing mechanism and a clamping mechanism to run, the pushing mechanism runs to make the manual downward-pressing mechanism run, the clamping mechanism drives medicine barrels to move rearwards, the medicine barrels are sealed by the manual downward-pressing mechanism, thus effects of automatic feeding and automatic sealing are achieved, by arranging an automatic take-up mechanism, an automatic downward-pressing mechanism runs to drive the automatic take-up mechanism to run, and thus sealing films are updated, so that an effect of automatically updating the sealing films is achieved.

Owner:李伟杭

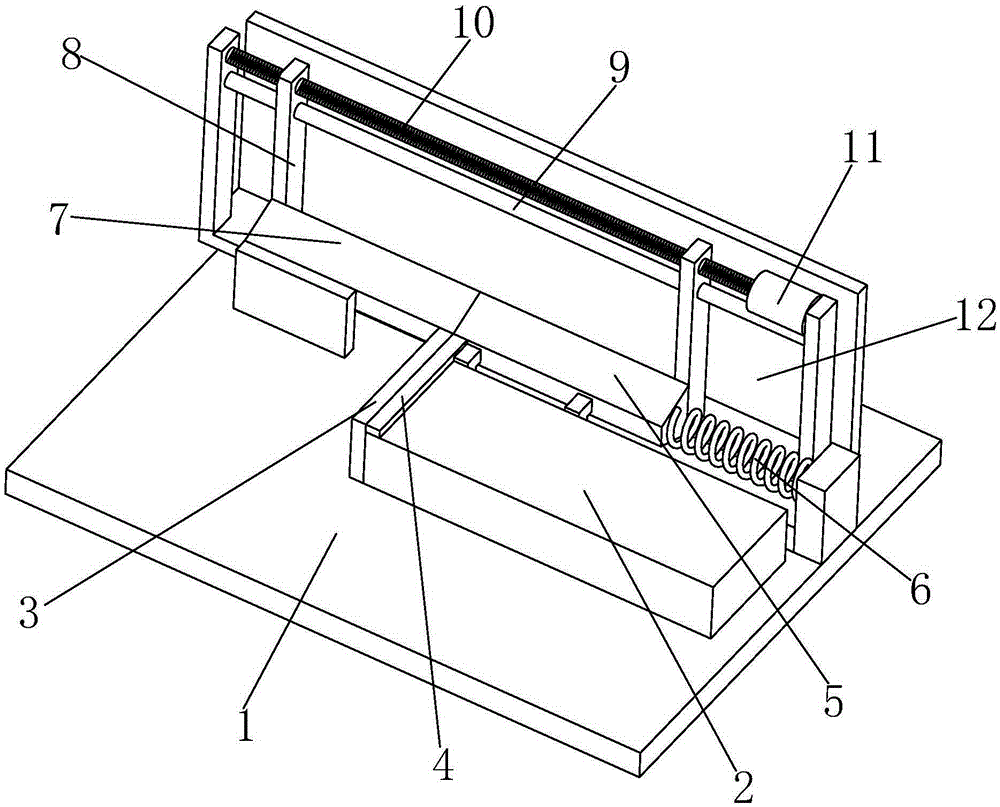

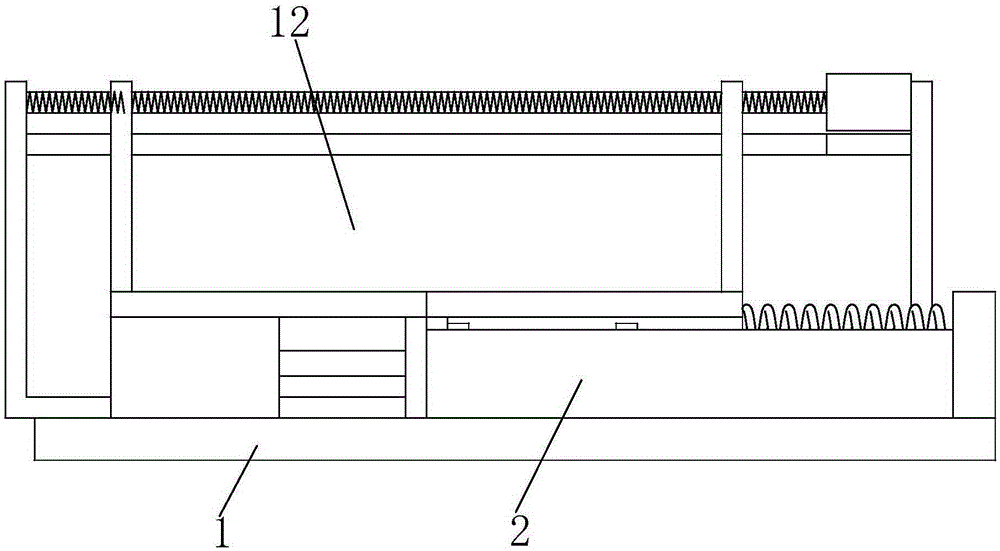

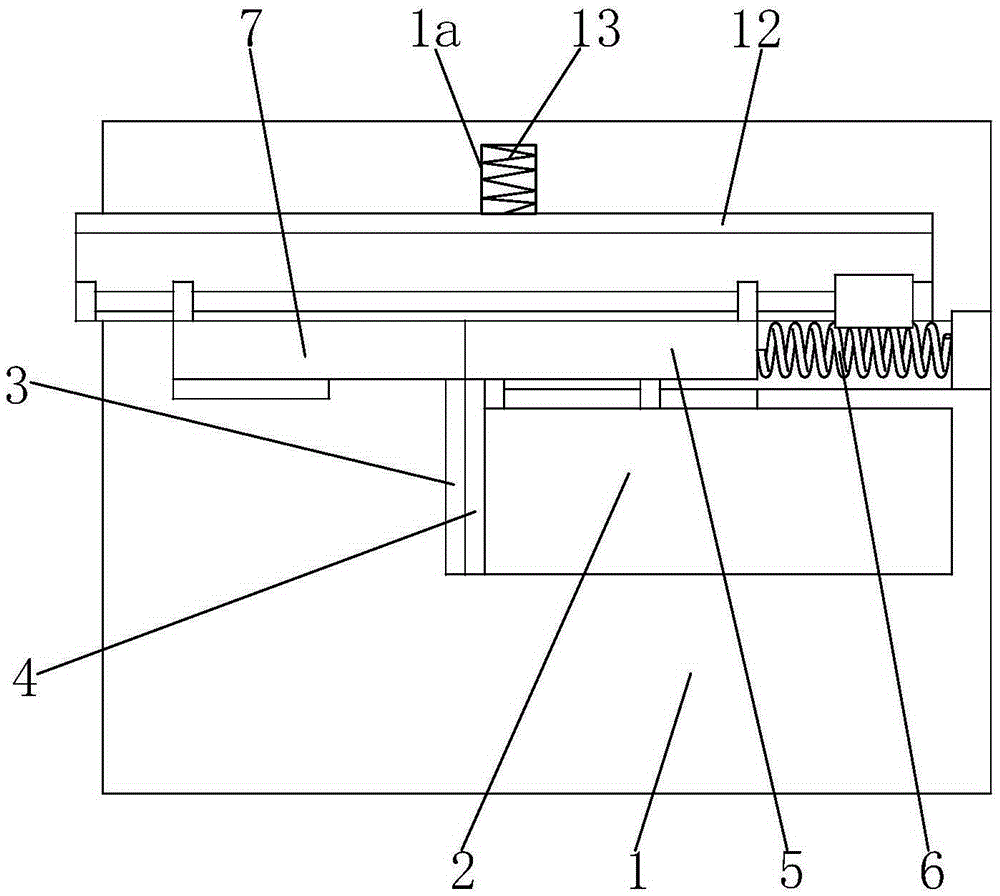

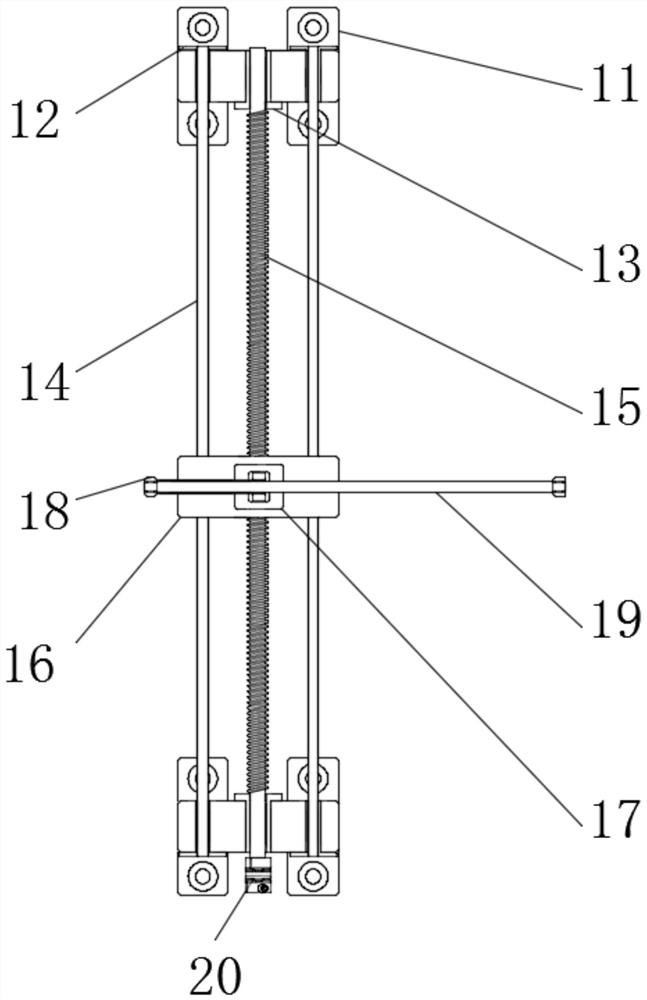

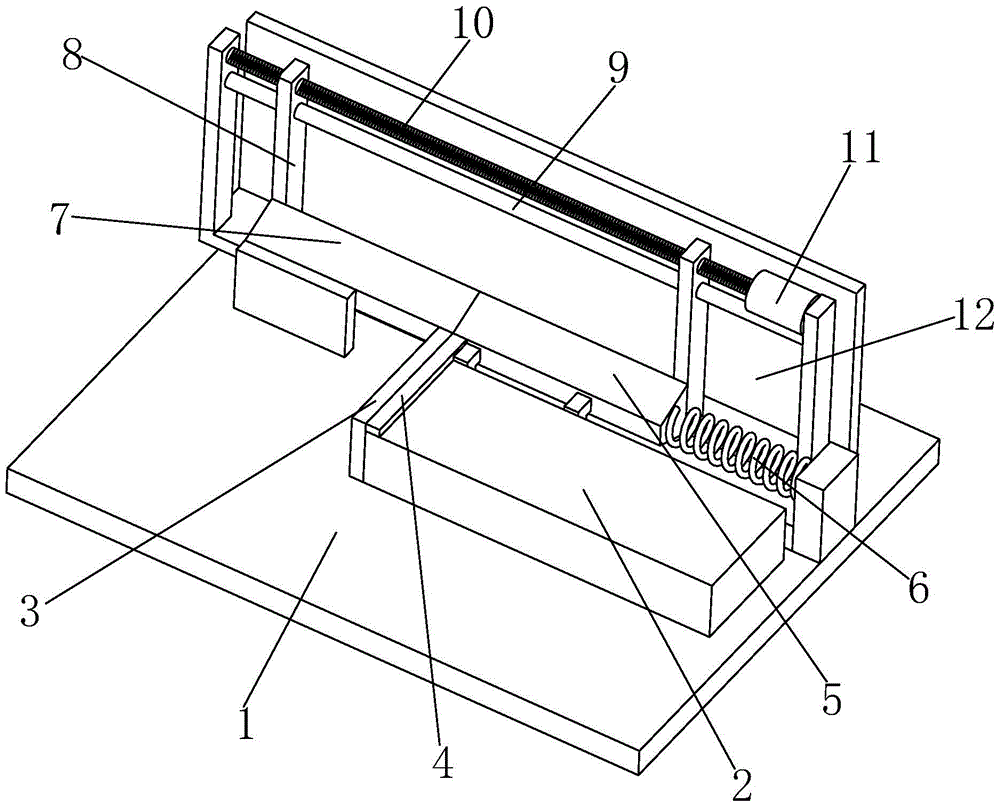

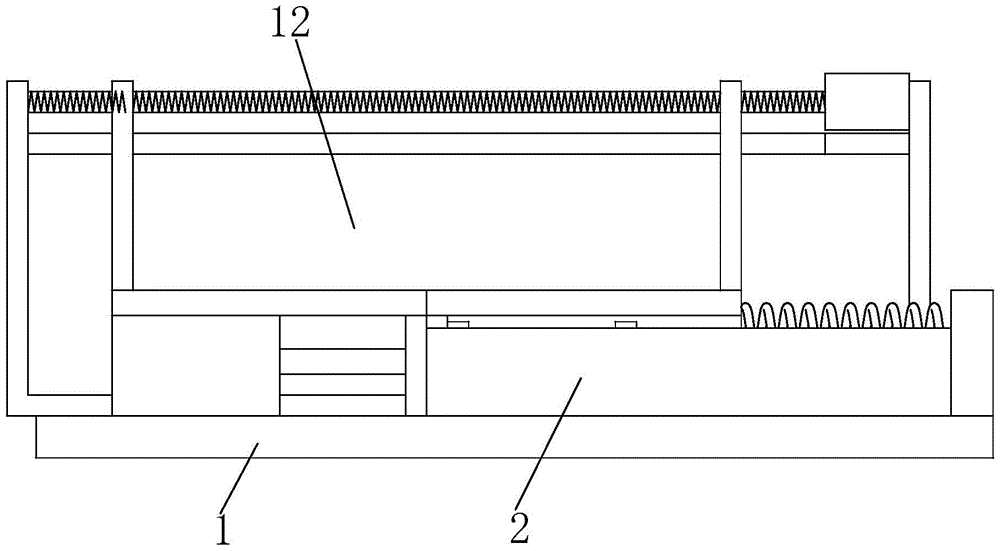

Simple clamping equipment

InactiveCN105291632AAchieve the effect of automatic clampingThe fixing method is simple and convenientSheet bindingArchitectural engineeringElectric machinery

The invention relates to simple clamping equipment. The simple clamping equipment mainly comprises a base board; a placement table is arranged on the base board and provided with a left positioning board; the right end of the left positioning board abuts against a clamping board in a combined mode; a right table column is welded to the rear end of the clamping board; the right end of the right table column is connected with a spring; the left end of the right table column abuts against a left table column in a combined mode; the rear end of the left table column and the rear end of the right table column abut against drive rods in a combined mode respectively; the upper portions of the drive rods are provided with a polish rod and a composite lead screw; the composite lead screw is connected with a motor. An adjusting groove is formed in the rear end of the base board and is internally provided with a main installation base in a sliding mode; a reset spring is arranged between the main installation base and the rear end of the adjusting groove. The two drive rods are driven in a lead screw driving mode to drive a clamp for centering movement, and the effect of automatically clamping bills is achieved. The simple clamping equipment further has the characteristics that the clamp filling mode is simple and operation is simple and has the advantages that the bill fixing mode is simple and applicability is wide.

Owner:东莞市拓尔玛特自动化科技有限公司

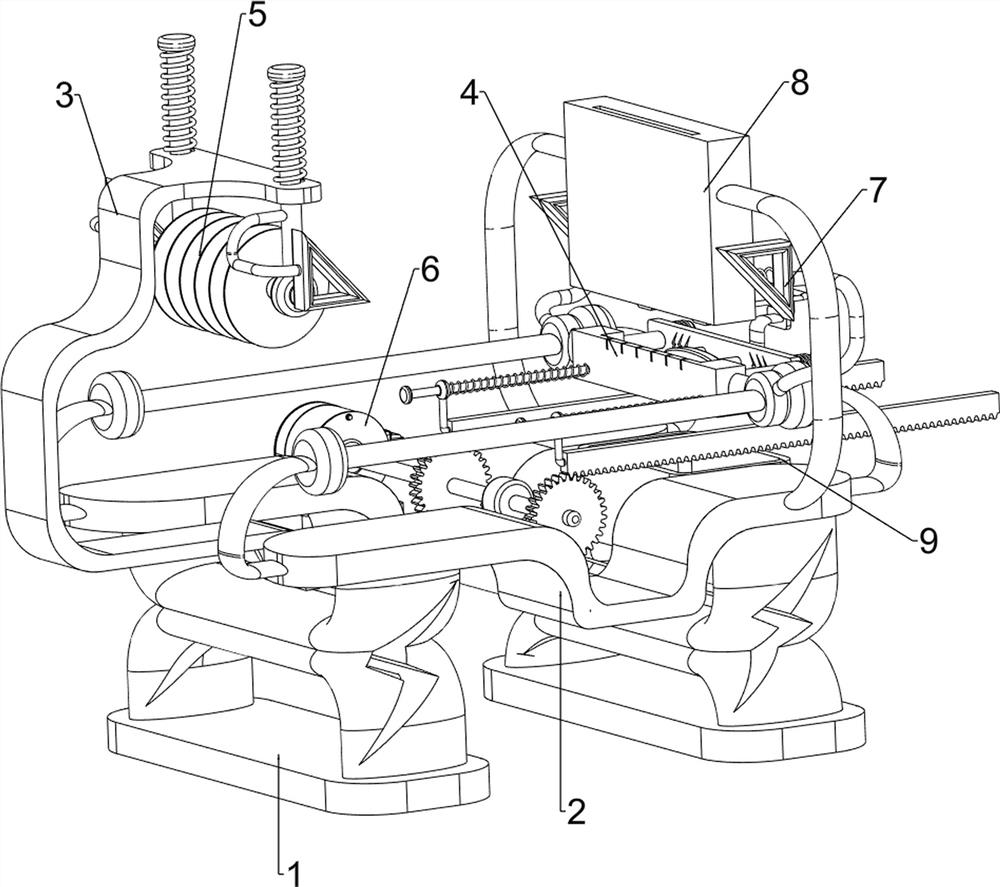

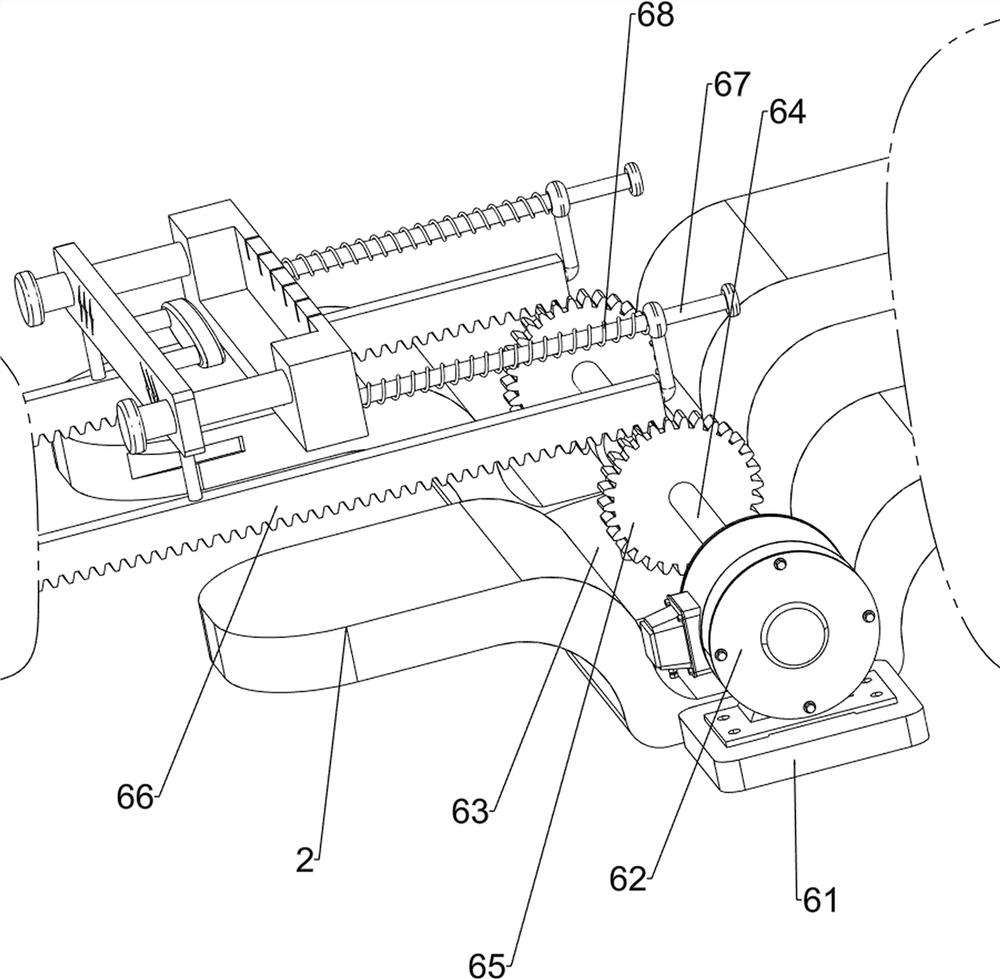

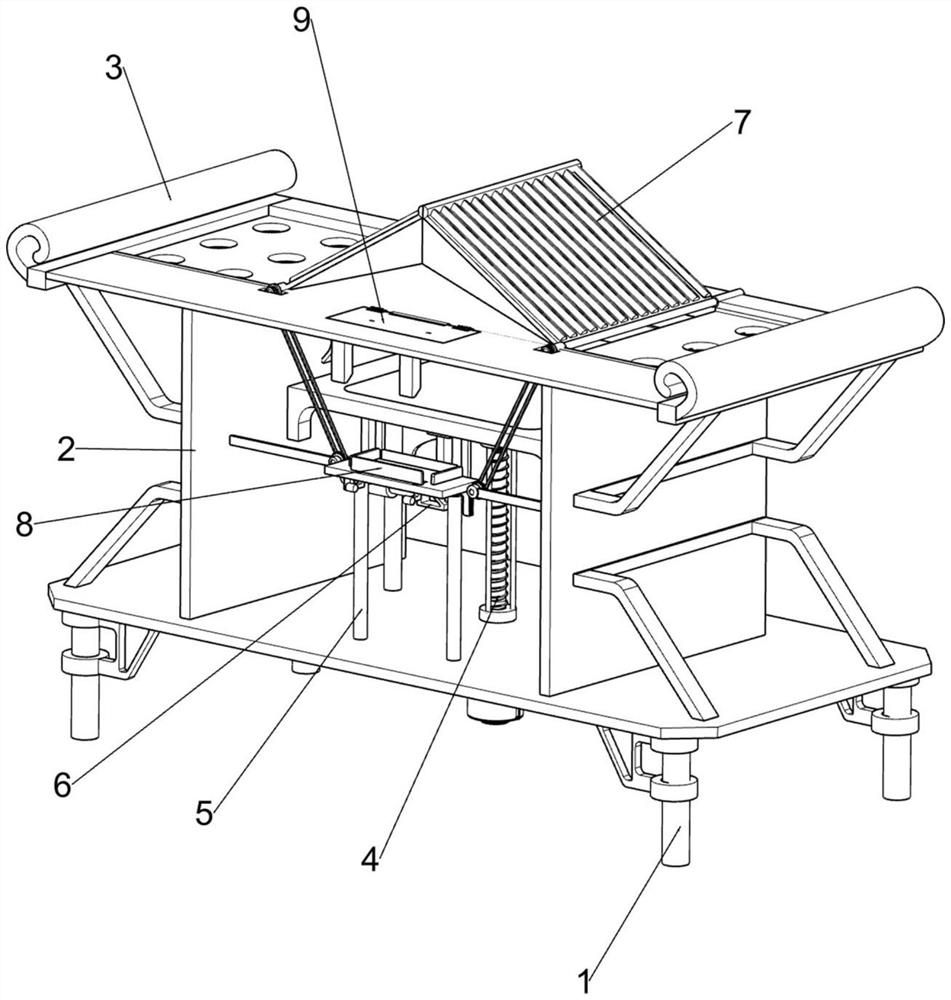

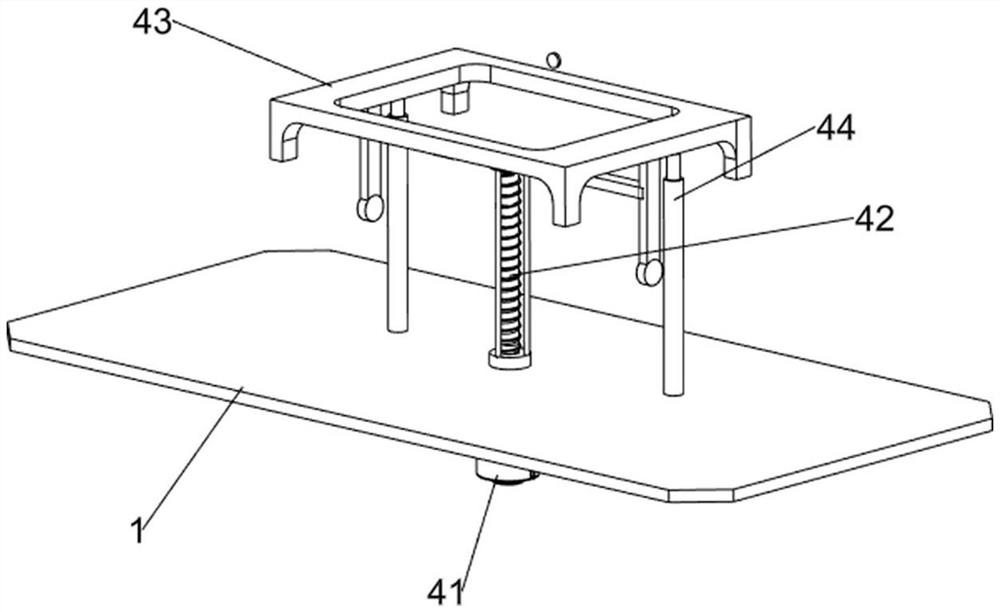

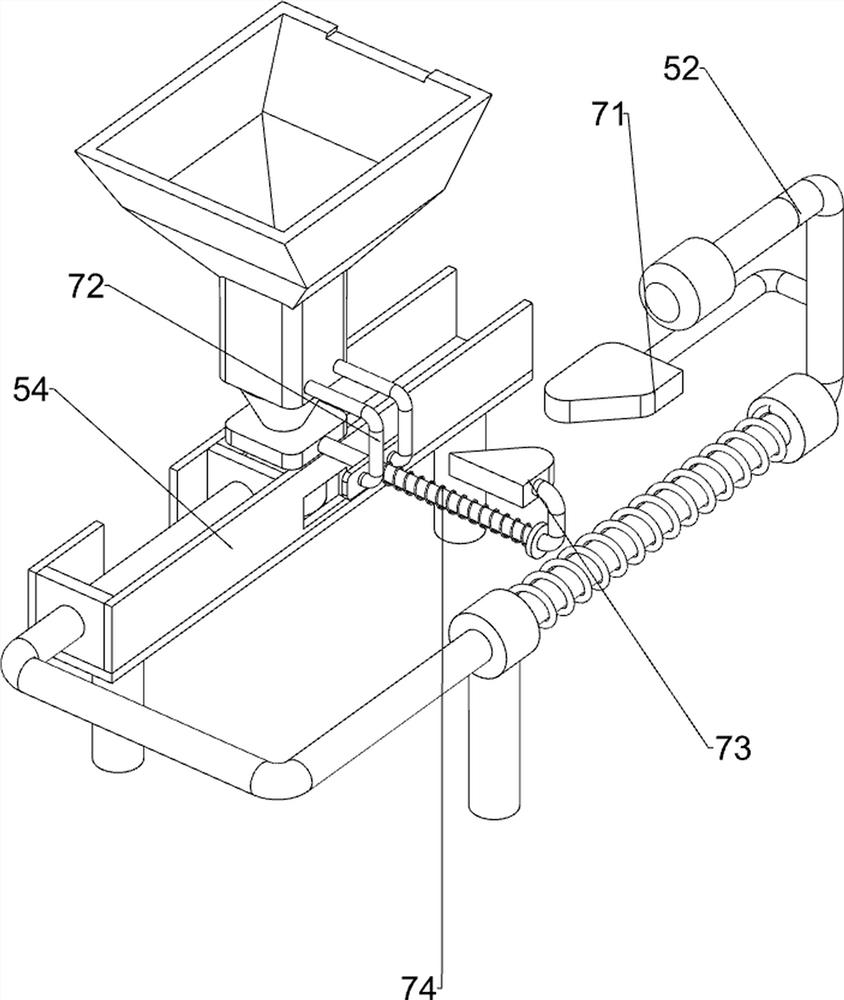

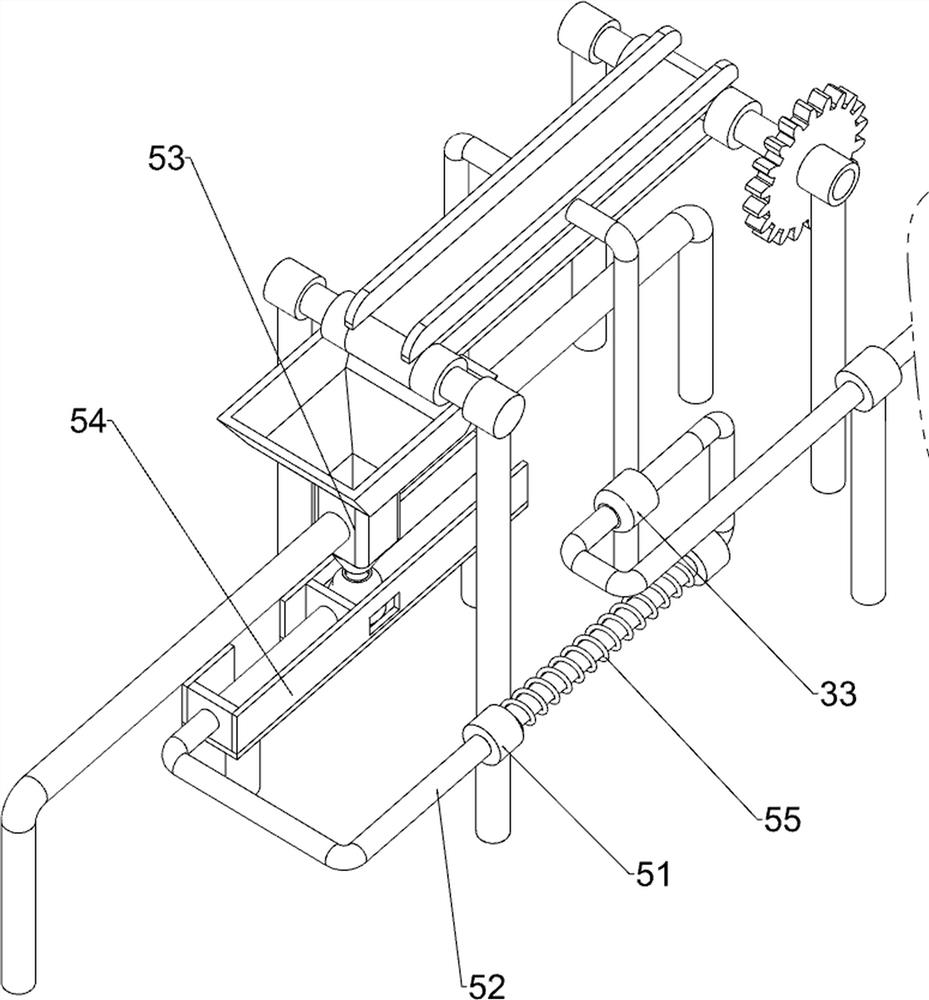

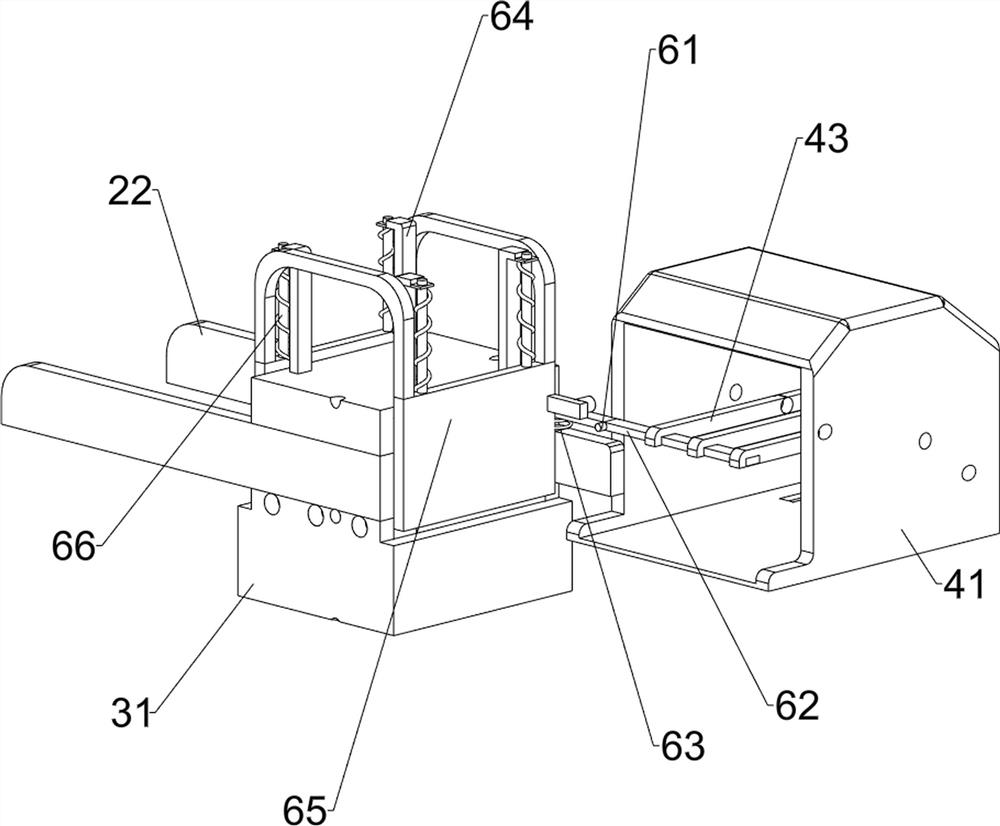

Wood corner cutting equipment for furniture

ActiveCN112621897AAchieve automatic feedingRealize the purpose of automatic feedingFeeding devicesGripping devicesElectric machineryAgricultural engineering

The invention relates to cutting equipment, in particular to wood corner cutting equipment for furniture. According to the wood corner cutting equipment for the furniture, automatic feeding is conducted before wood corner cutting, automatic clamping is conducted during wood corner cutting, and automatic pushing-out is conducted after wood corner cutting. The wood corner cutting equipment for the furniture comprises a base and a saw blade, and the saw blade is arranged on one side of the top of the base; a placing assembly, arranged at the top of the base; a motor, arranged on the placing assembly; and a pushing assembly, arranged on the side, close to the placing assembly, of the top of the base, wherein components of the pushing assembly are connected with components of the placing assembly. The effects of automatic feeding before wood corner cutting, automatic clamping during wood corner cutting and automatic pushing-out after wood corner cutting are achieved.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

Multifunctional bone ash storage rack for display

ActiveCN112814466AAchieve the purpose of automatic riseEasy to displayBurial vaultsMonumentsClassical mechanicsEngineering

The invention relates to a storage rack, in particular to a multifunctional bone ash storage rack for display. The invention provides the multifunctional bone ash storage rack for display. The multifunctional bone ash storage rack for display can be automatically lifted, is dustproof and can be automatically opened and closed. The multifunctional bone ash storage rack for display comprises a bottom base, a supporting plate and a supporting table, wherein the supporting plate is arranged at the top of the bottom base, the supporting table is arranged at the top of the supporting plate, a lifting mechanism is arranged on the bottom base, a driving mechanism is arranged on the bottom base, and the driving mechanism is connected with the lifting mechanism. According to the multifunctional bone ash storage rack for display, through the arrangement of the lifting mechanism, the lifting mechanism operates to enable a cinerary casket to move upwards, so that the purpose of automatic lifting is achieved; through the arrangement of an opening and closing mechanism, the driving mechanism operates to drive the opening and closing mechanism to operate, so that the purpose of automatic opening and closing is achieved; through the arrangement of a closing mechanism, a memorial tablet moves to operate the closing mechanism, so that the automatic closing effect is achieved, and meanwhile the situation that the memorial tablet is contaminated by dust in the outside air can be prevented.

Owner:江西渡海科技有限公司

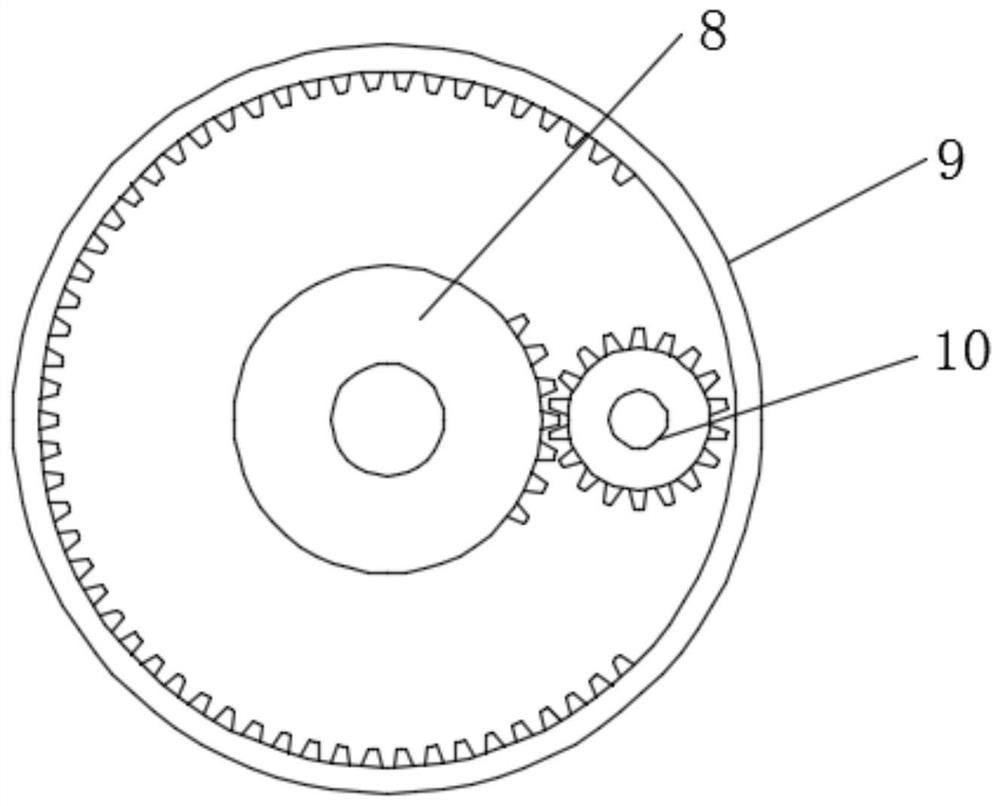

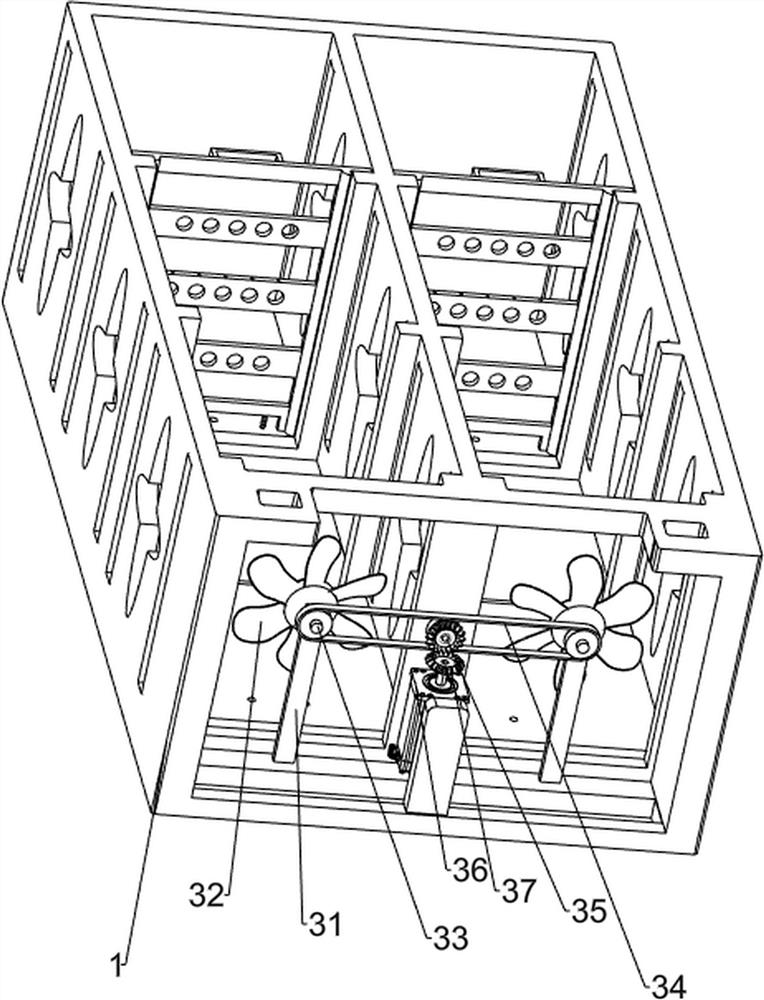

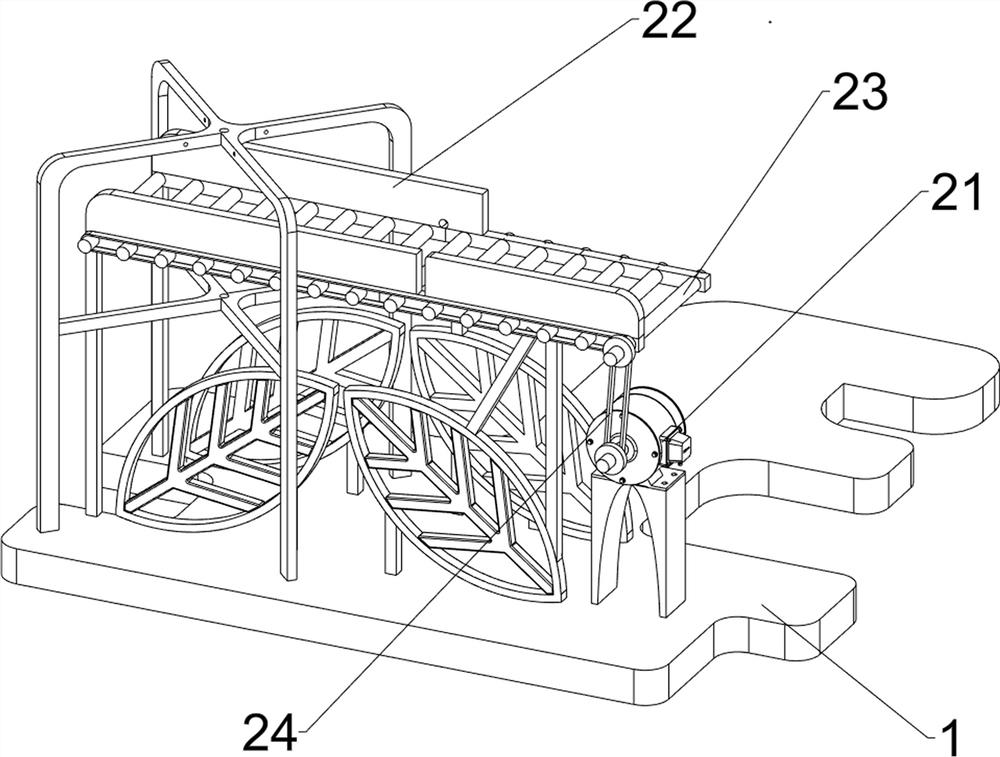

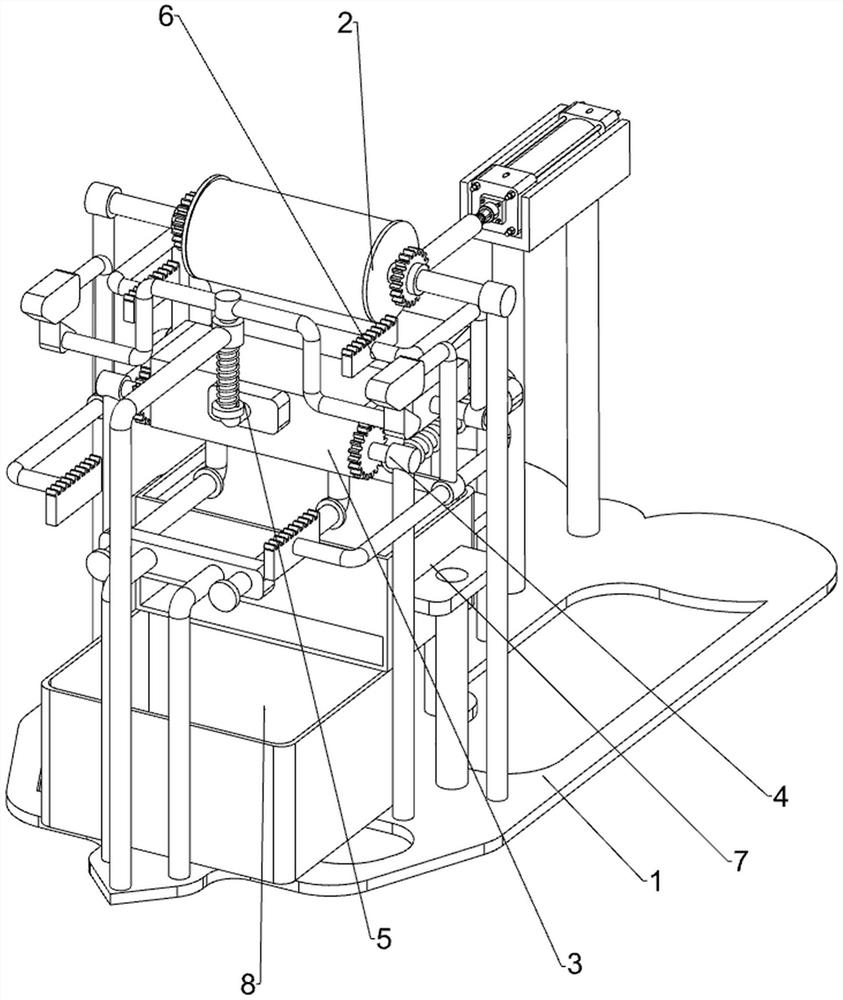

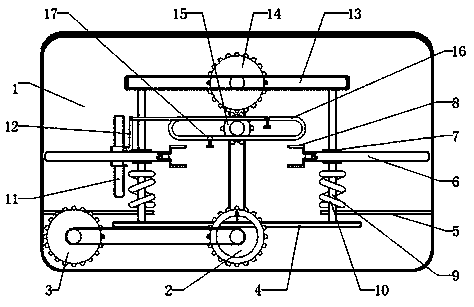

Automatic and uniform boxing machine for biological capsules

InactiveCN112520123AAchieve the effect of automatic feedingSave energySolid materialGear wheelEngineering

The invention relates to a boxing machine, in particular to an automatic and uniform boxing machine for biological capsules, and provides the automatic and uniform boxing machine which is used for thebiological capsules and is easy to operate, relatively low in cost and capable of saving energy. The automatic and uniform boxing machine for the biological capsules comprises a bottom plate, an intermittent discharging mechanism and an automatic vibration mechanism; the intermittent discharging mechanism is arranged in the middle of the bottom plate; the automatic vibration mechanism is arrangedon the bottom plate; and the intermittent discharging mechanism is matched with the automatic vibration mechanism. A second rack is engaged with a first straight gear, and the second rack moves to enable the first straight gear to rotate, so that an intermittent discharging rotating wheel rotates, the biological capsules in the intermittent discharging rotating wheel fall onto a conveying assembly, the automatic discharging effect is achieved, and operation is easy and convenient; automatic and uniform boxing is achieved through air cylinder operation, in this way, traditional electric boxingby the aid of a motor can be replaced, and thus the energy can be saved.

Owner:陈伙生

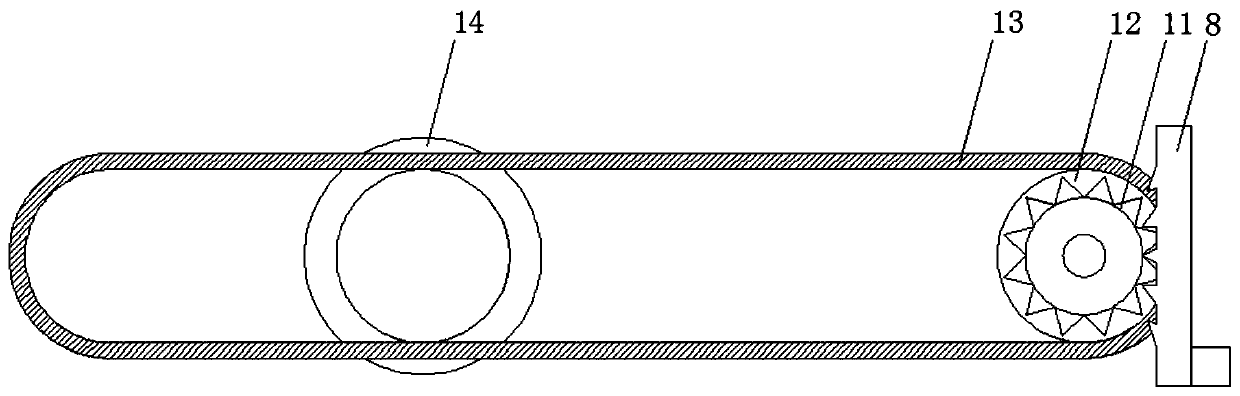

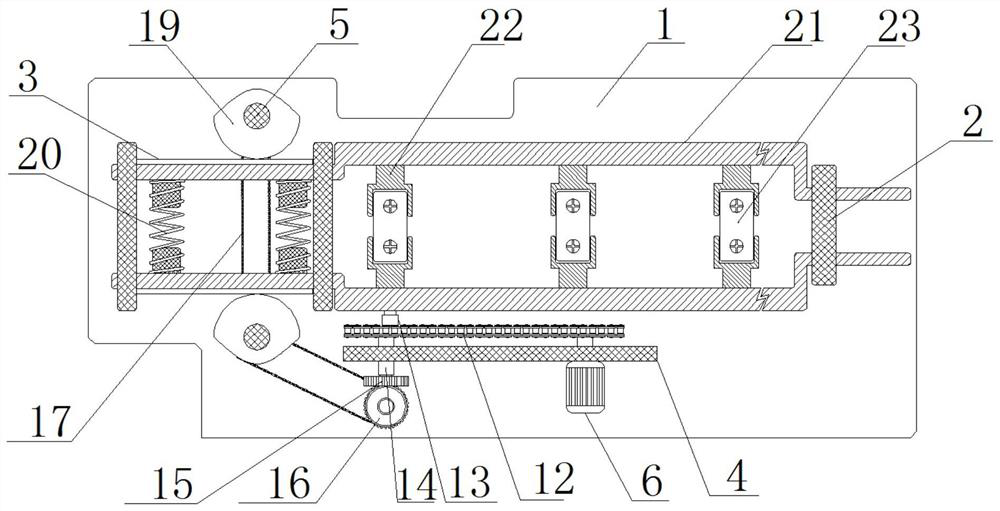

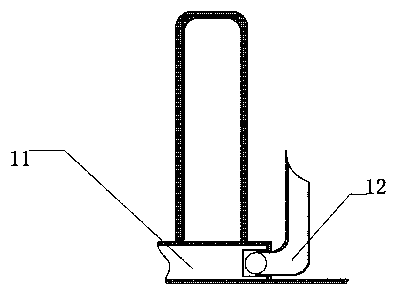

Auxiliary winding device for glass fiber yarns

ActiveCN112897253ARealize the clamping effectAchieve the effect of cuttingFilament handlingSevering textilesYarnEngineering

The invention relates to a winding device, in particular to an auxiliary winding device for glass fiber yarns. The invention provides the auxiliary winding device for glass fiber yarns, which is provided with automatic cutting, rotating and clamping mechanisms. The auxiliary winding device for the glass fiber yarns comprises a base and two first supporting frames as well a first slide rail, a clamping mechanism and a cutting mechanism, wherein the two first supporting frames are symmetrically arranged at the two sides of the base; the first slide rail is connected between the two first supporting frames on the same horizontal line; the clamping mechanism is arranged between the base and the first slide rails; and the cutting mechanism is arranged on the base. A pressure block is loosened, and a first spring drives the pressure block to return for clamping ends of the glass fiber yarns, so that the clamping effect is achieved.

Owner:元源新材料有限公司

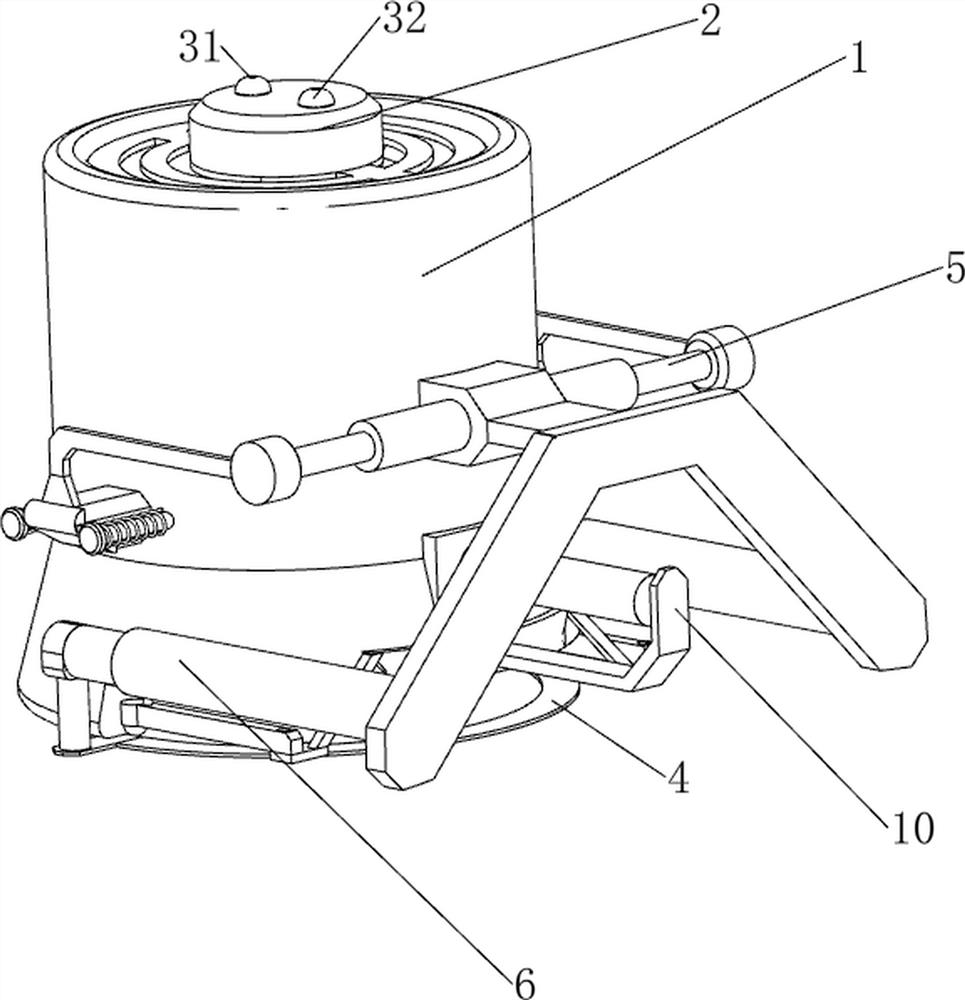

Mechanical hand for mechanical die casting

InactiveCN110000357AAchieve the effect of automatic drivingAchieve the effect of automatic steering controlProgramme-controlled manipulatorArmsControl engineeringDie casting

The invention belongs to the technical field of mechanical die castings, and particularly relates to a mechanical hand for a mechanical die casting. The mechanical hand comprises a control box, a guide rail moving device is arranged on the lower surface of the control box, a steering shaft is fixedly mounted on the inner wall of the control box through a bearing, a circumferential steering deviceis arranged on the surface, located inside the control box, of the steering shaft, a first hinged rod is fixedly mounted on the top of the steering shaft, a second hinged rod is hinged to one end of the first hinged rod through a pin shaft, and one end of the second hinged rod is fixedly provided with a material taking mechanical hand. According to the mechanical hand for the mechanical die casting, the effect of automatically driving the control box is achieved, the circumferential steering device is arranged on the surface, located inside the control box, of the steering shaft, therefore, the effect of automatically steering and controlling the structure of the top surface of the steering shaft is achieved, and the material taking mechanical hand is fixedly arranged at one end of the second hinged rod, so that the effect of automatically clamping the die casting is achieved.

Owner:安徽宝裕金属科技有限公司

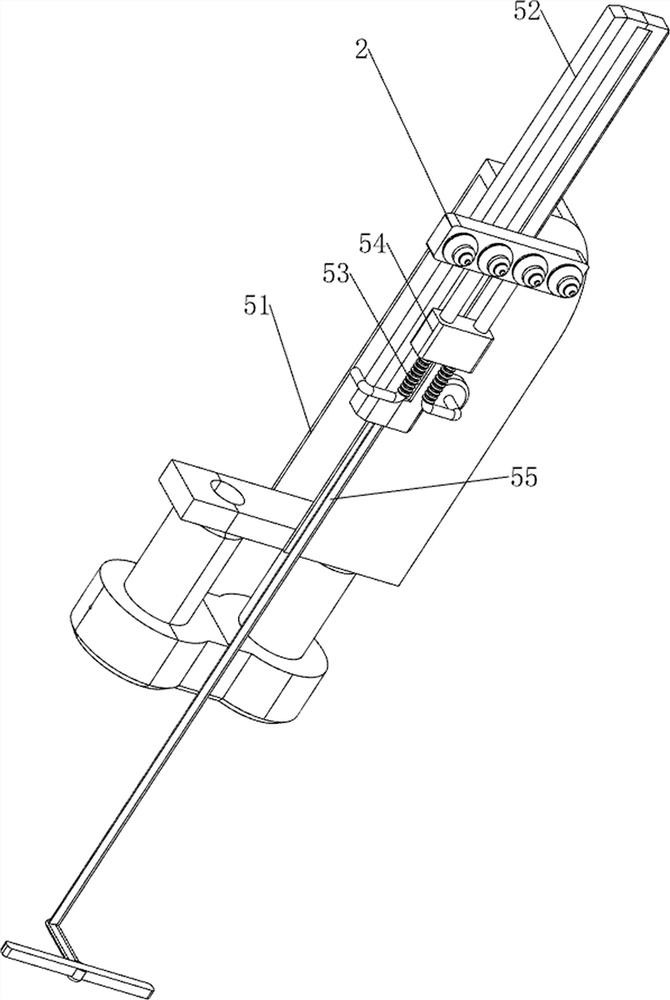

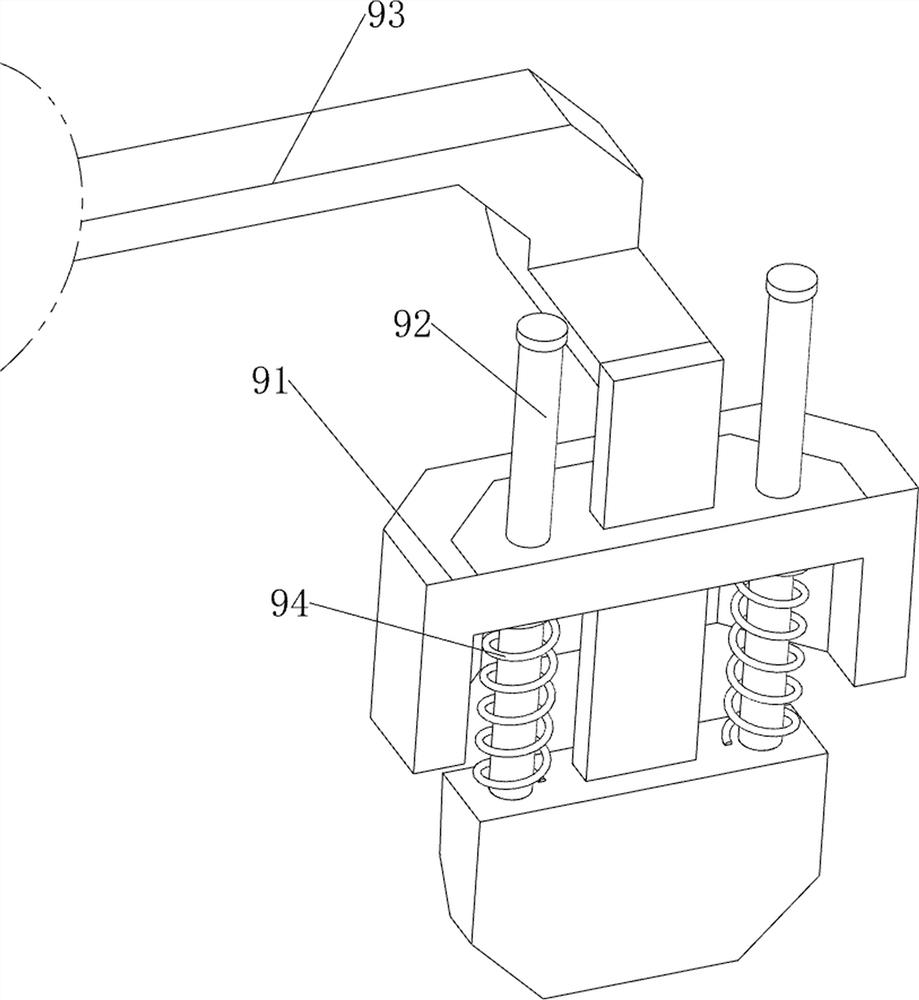

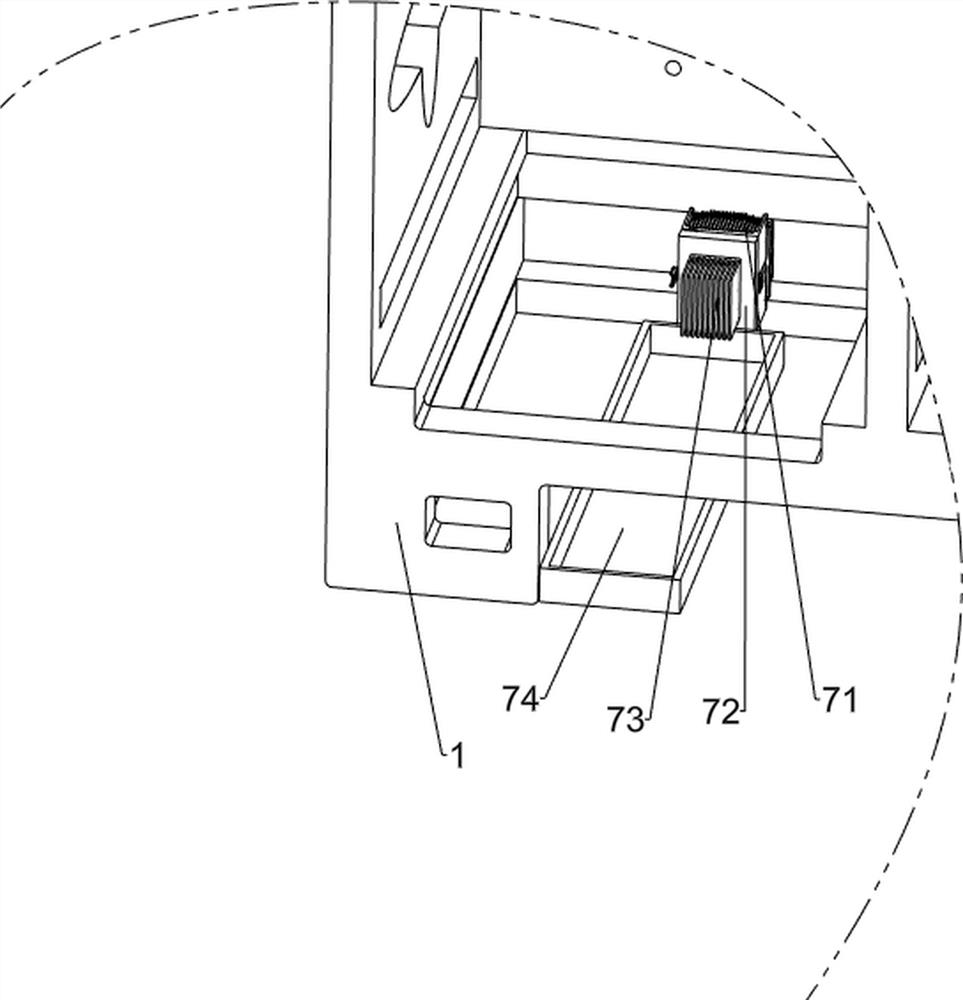

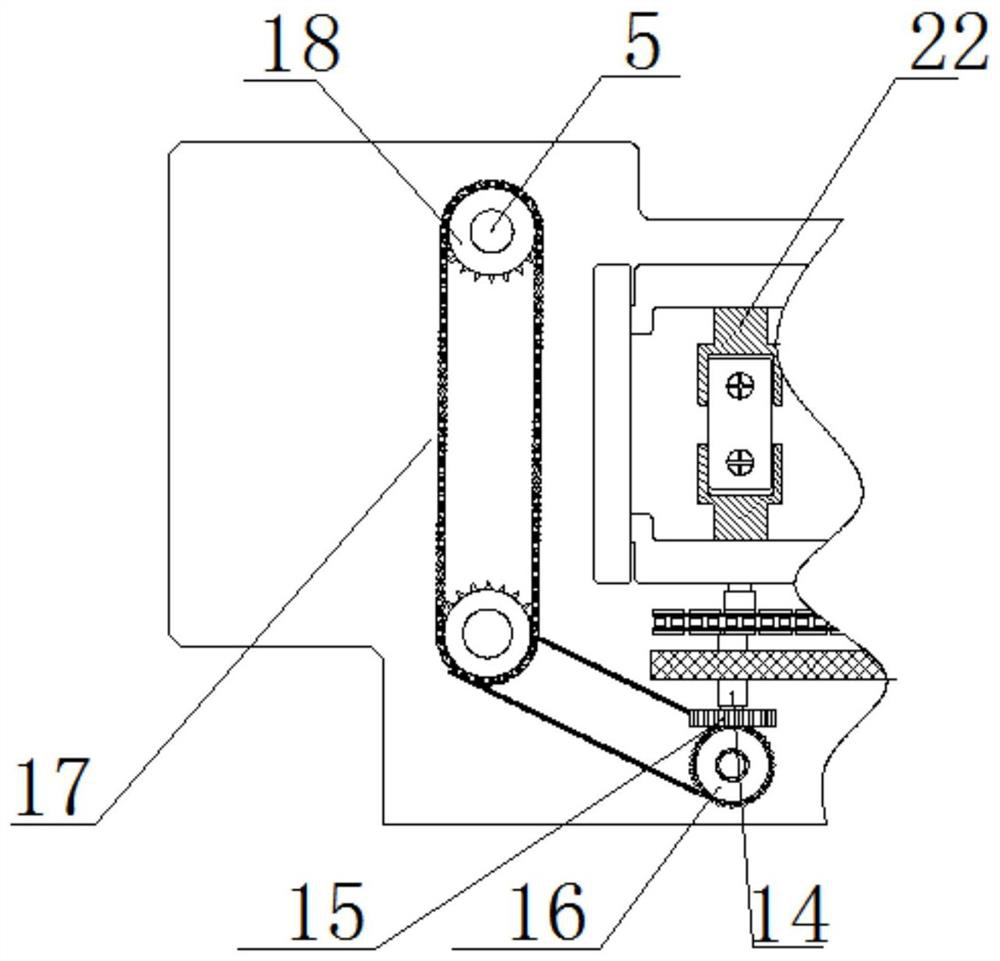

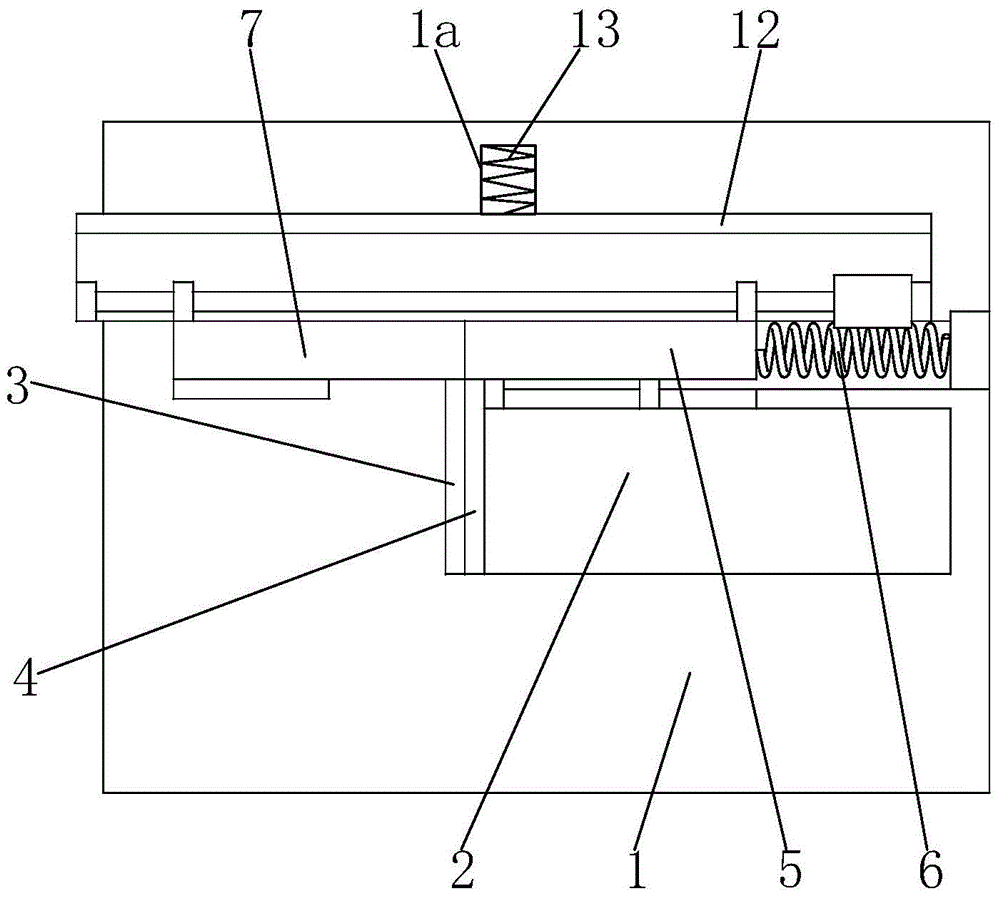

Automatic precise tapping mechanism for automobile sleeve accessory

InactiveCN111922456AAchieve the effect of automatic clampingThread cutting feeding devicesThread cutting machinesElectric machineryControl theory

The invention relates to the technical field of automobile accessories, and discloses an automatic precise tapping mechanism for an automobile sleeve accessory. The automatic precise tapping mechanismcomprises a frame, wherein the top of the frame is fixedly connected with mounting plates; slide rails are fixedly connected between the mounting plates; the outer sides of the slide rails are in slip connection with slide blocks; and a tapping frame is fixedly connected between the slide blocks. According to the automatic precise tapping mechanism for the automobile sleeve accessory, an alignment mold is driven to move downwards through a T-shaped sleeve assembly and drives a feeding wheel to move downwards, the feeding wheel drives clamping rods to move downwards, and clamping slide bars, reset springs and other mechanisms are used cooperatively, so that the automatic clamping effect is achieved. A tapping motor is used for driving the feeding wheel and a retracting wheel to rotate, thefeeding wheel and the retracting wheel are used for driving a rotating wheel to rotate, the rotating wheel is used for driving a tapping cone to rotate, a manual flange is used for driving a liftingroller train to rotate, the lifting roller train is used for driving a lifting rack to move downwards, and the slide rails and other mechanisms are used cooperatively, so that the effects of automatictapping and retracting are achieved.

Owner:郑国筱

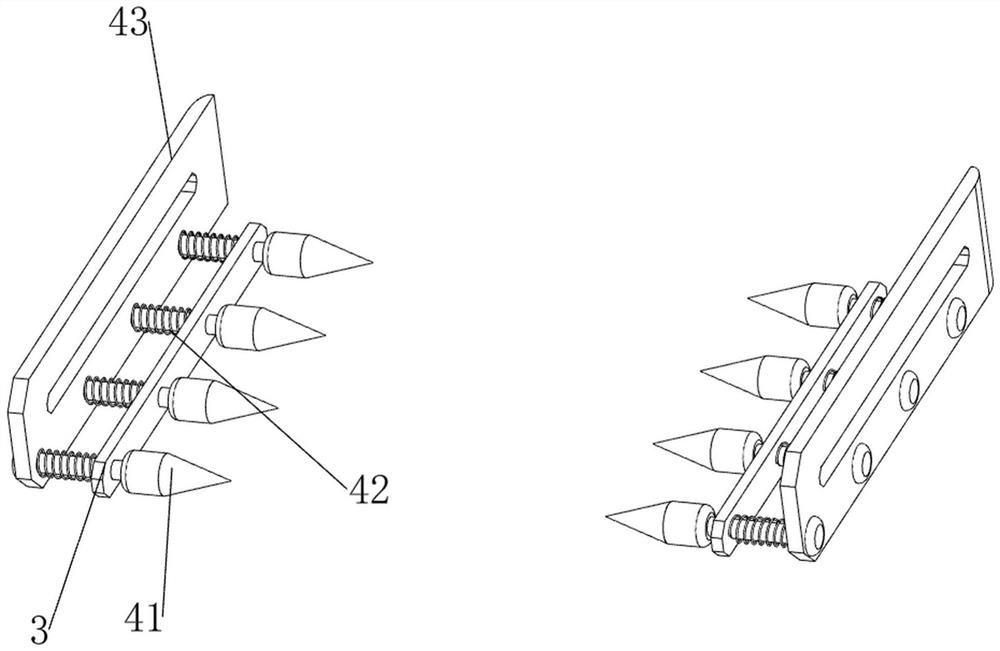

Clinical wart removing device for dermatology department

PendingCN113303880AConvenient collectionEasy to cutIncision instrumentsExcision instrumentsMedical staffEngineering

The invention relates to a removing device, and concretely relates to a clinical wart removing device for the dermatology department. The invention provides the clinical wart removing device for the dermatology department, which is capable of automatically cutting, automatically clamping materials and conveniently collecting the materials. The clinical wart removing device for the dermatology department comprises a mounting base, first sliding rods, first springs, first sliding sleeves, a blade, a contact block, a clamping mechanism and a pushing mechanism, the four first sliding rods are arranged on the mounting base, the first sliding sleeves are connected between every two adjacent first sliding rods in a sliding mode, the first springs are wound on the first sliding rods, the first springs are connected between the first sliding sleeves and the mounting base, a blade is arranged on the inner side of each first sliding sleeve and matched with the mounting base, a contact block is arranged on the lower portion of the mounting base, and a clamping mechanism is arranged on the lower portion of the mounting base. By arranging a material collecting mechanism, warts falling from the material clamping mechanism can fall into the material collecting mechanism, and medical staff take out the warts, so the medical staff can conveniently collect materials.

Owner:戴发辉

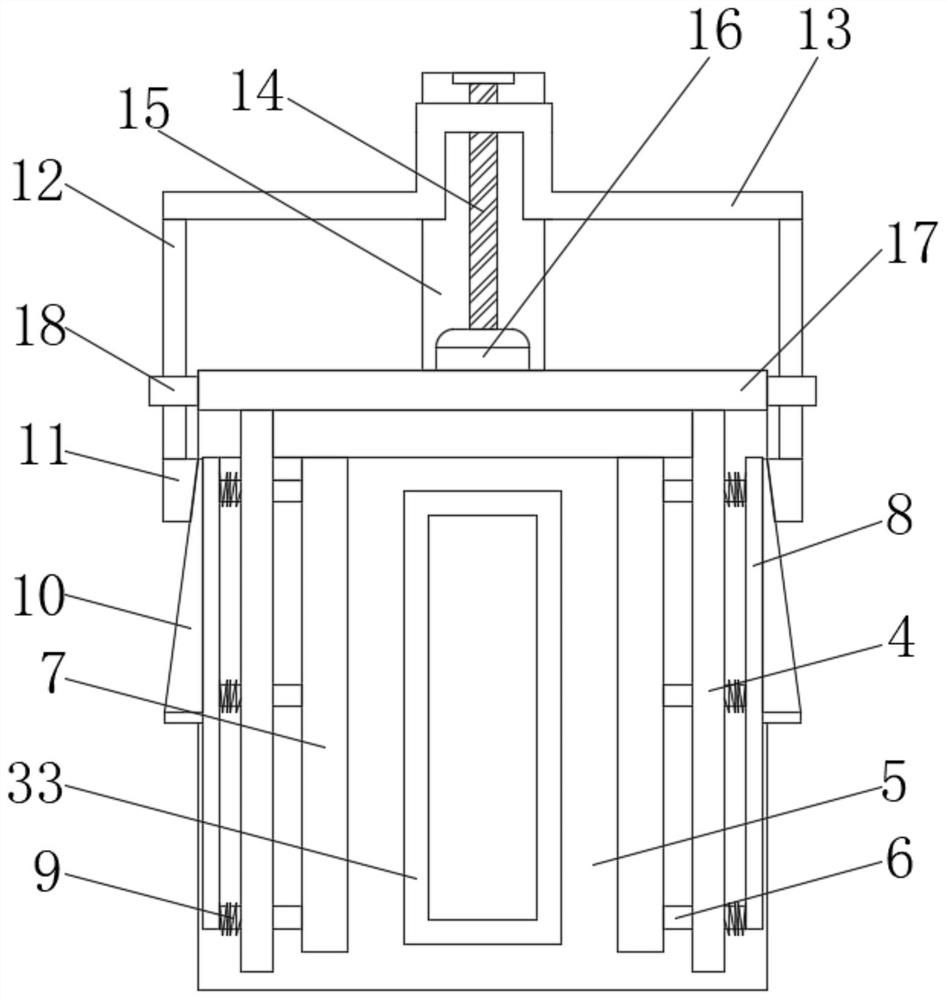

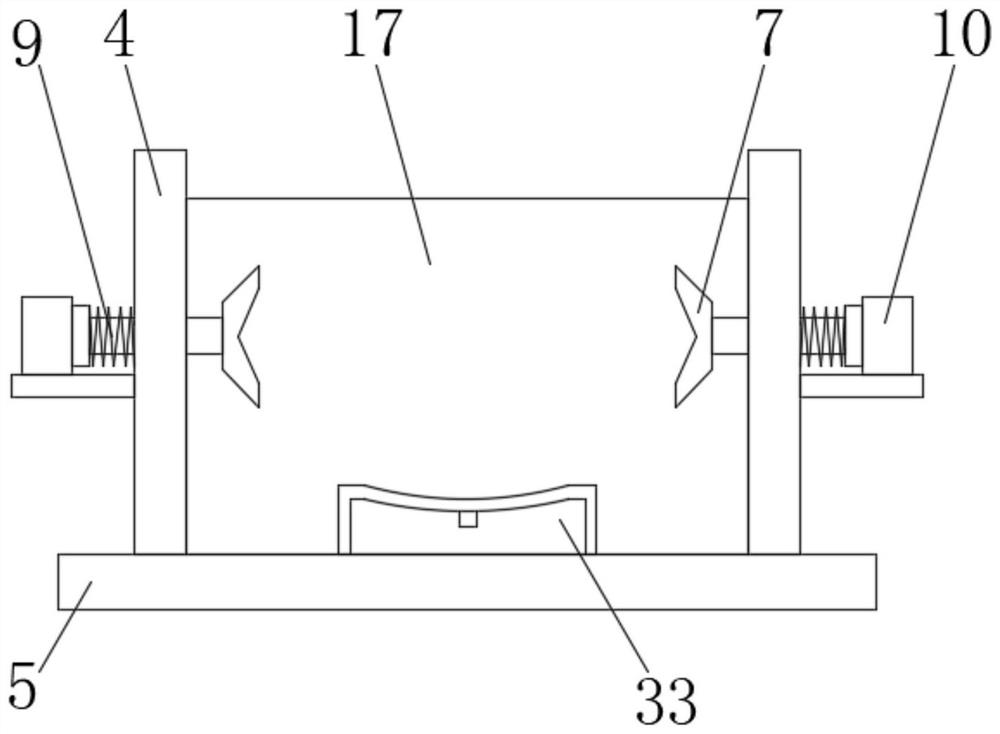

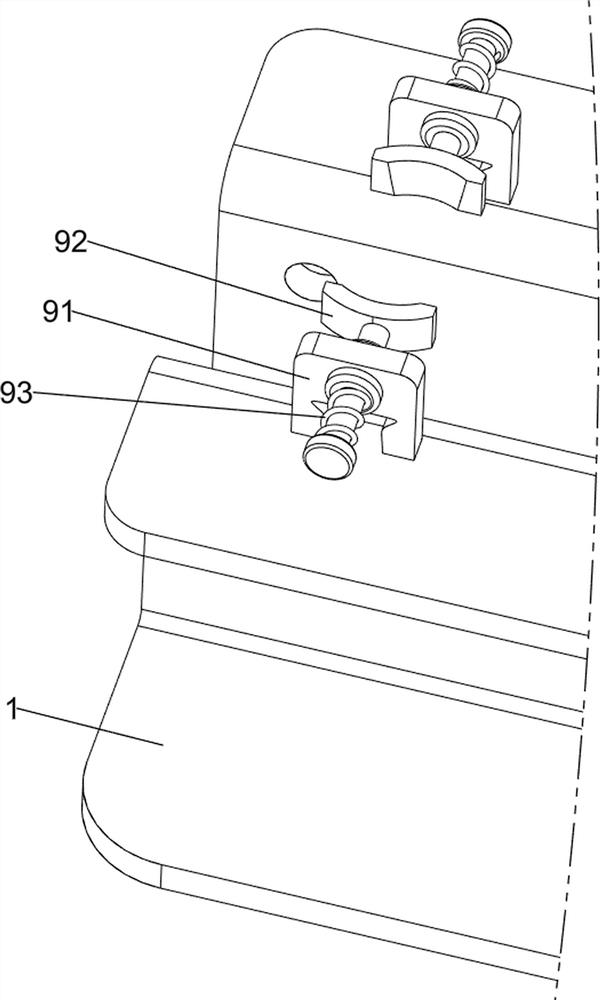

Clamping table with alarm function for machining

PendingCN112705973AAchieve the effect of automatic clampingTo achieve the alarm effectPositioning apparatusMaintainance and safety accessoriesStructural engineeringMachine tool

The invention discloses a clamping table with an alarm function for machining. The clamping table comprises a base and a supporting table, wherein the supporting table is slidably connected to the top end of the base. By arranging a motor, the motor drives a screw to rotate, then the screw drives a support at the outer side of the screw to move, when the support gets close to a limiting boss, the two ends of the support push push rods to slide at the inner sides of spacing rings, and then the push rods push pressing blocks to slide at the outer sides of trapezoidal blocks, the trapezoidal blocks and connecting plates push sliding rods to slide at the inner sides of the clamping plate sets, the ends, located at the opposite inner sides of the clamping plate sets, of the sliding rods are fixedly connected to the clamping blocks, then the clamping blocks clamp the two sides of a workpiece, and then the automatic clamping effect is achieved; and by arranging a pressing plate and a proximity switch, when the pressing plate slides to the bottom end, the other end of a supporting rod just reaches the induction distance of the proximity switch, it shows that the pressing plate is extruded in place, at the moment, the motor stops clamping, a machine tool gives a buzzing alarm, and the effect of giving an alarm during clamping is achieved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

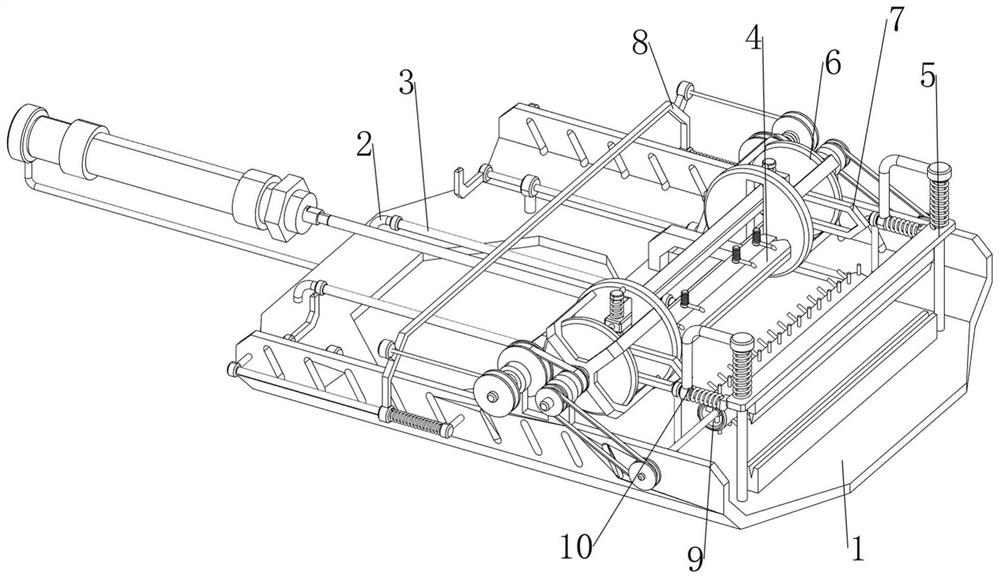

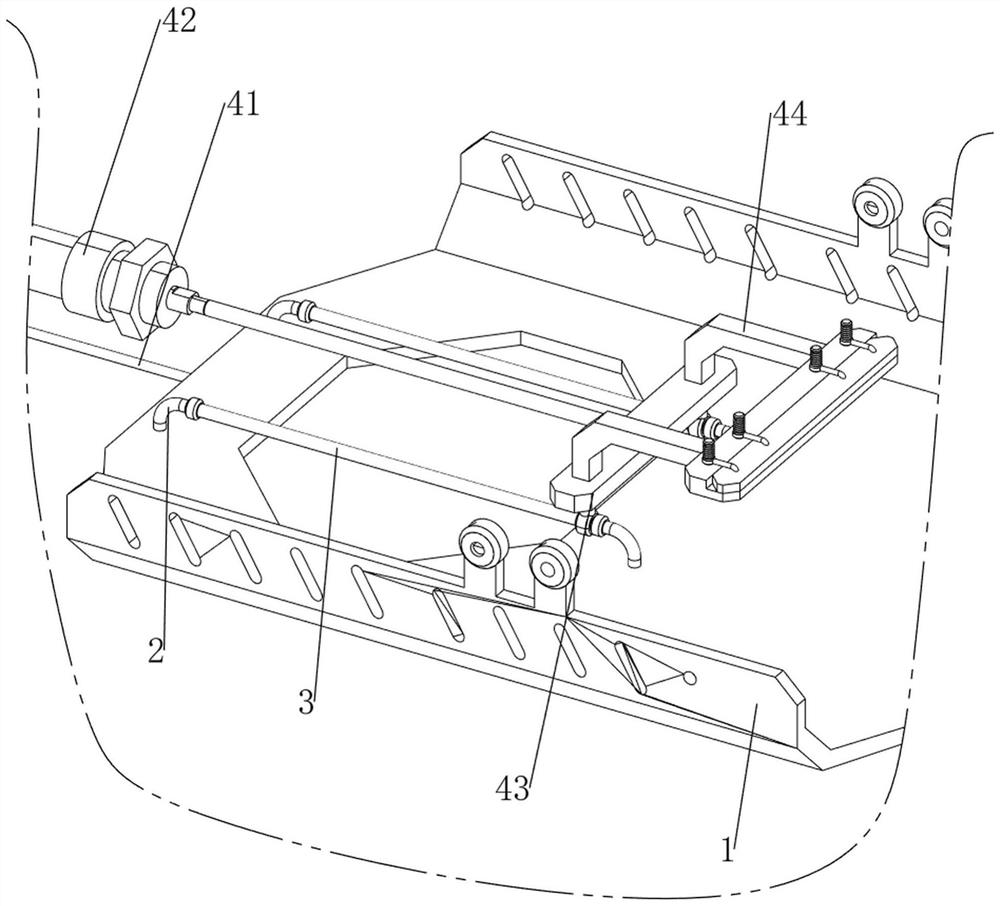

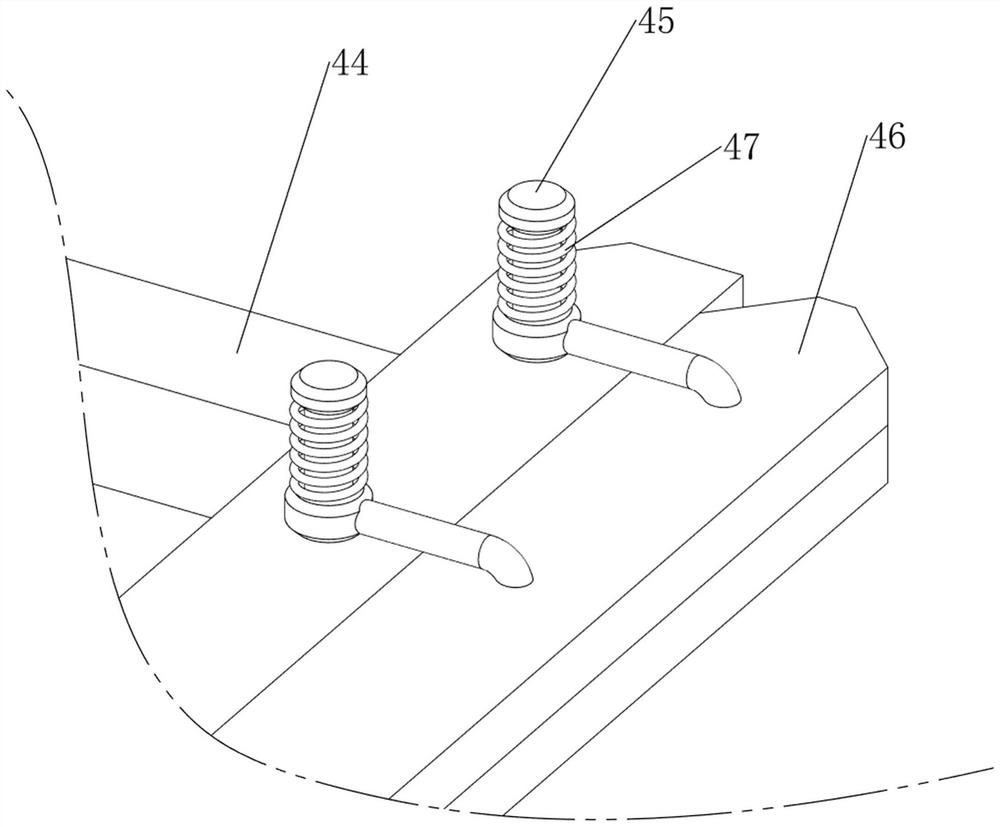

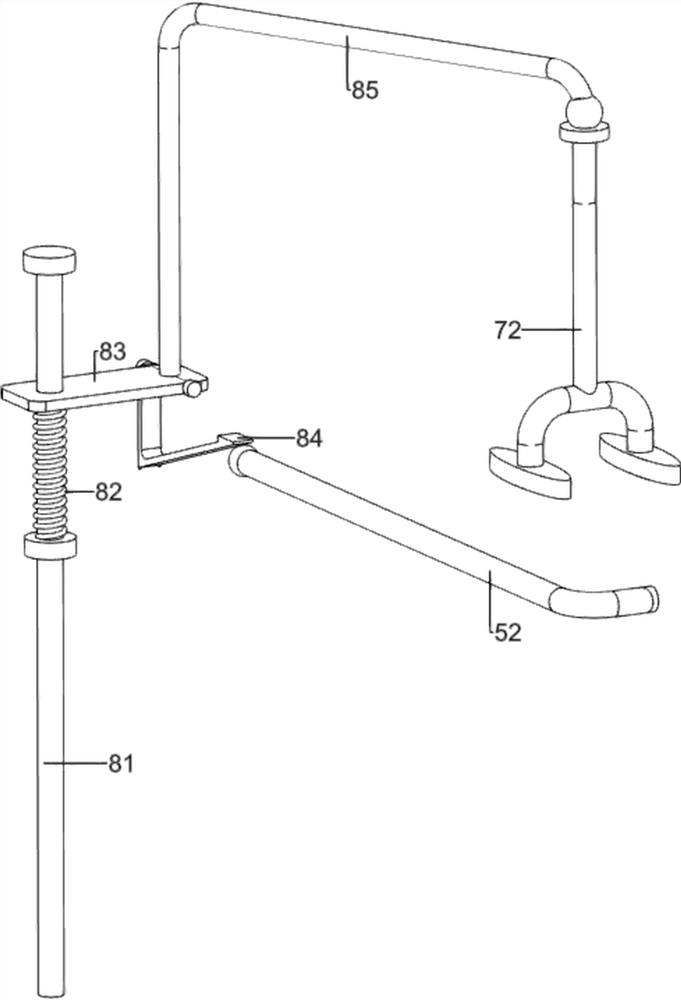

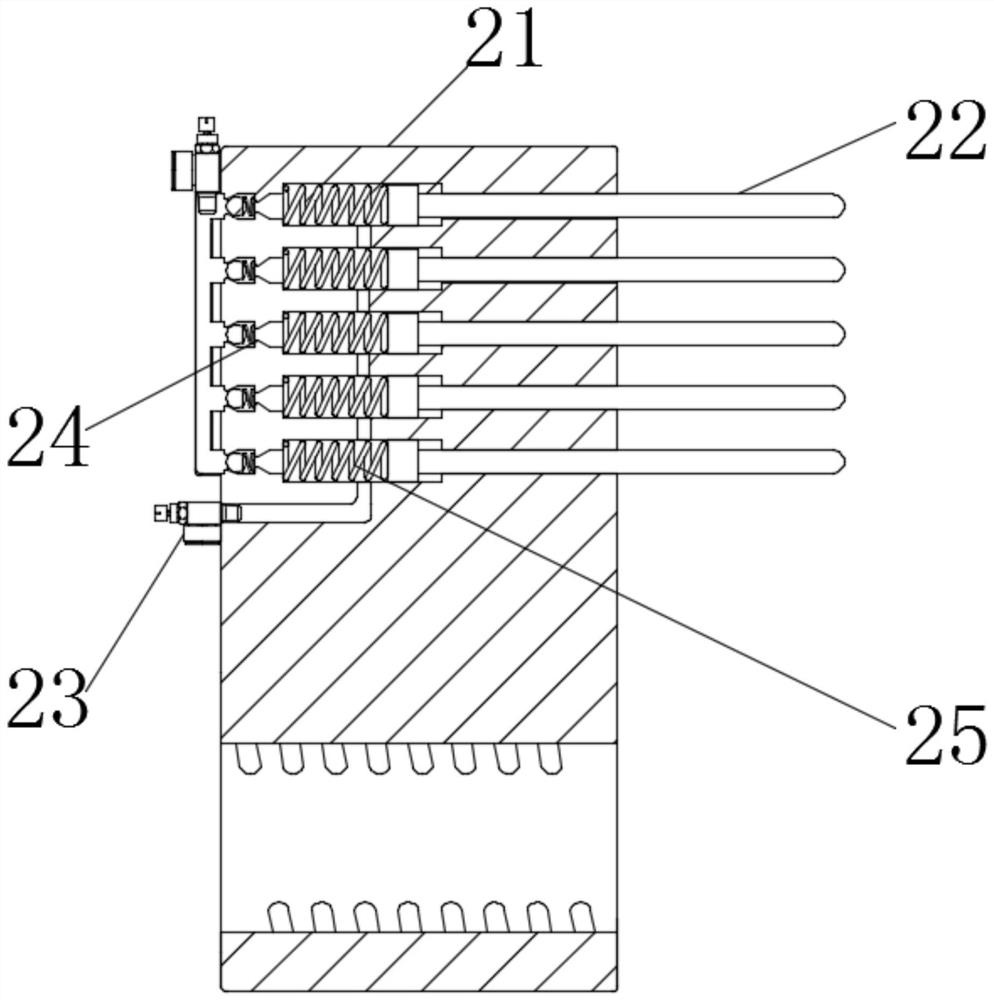

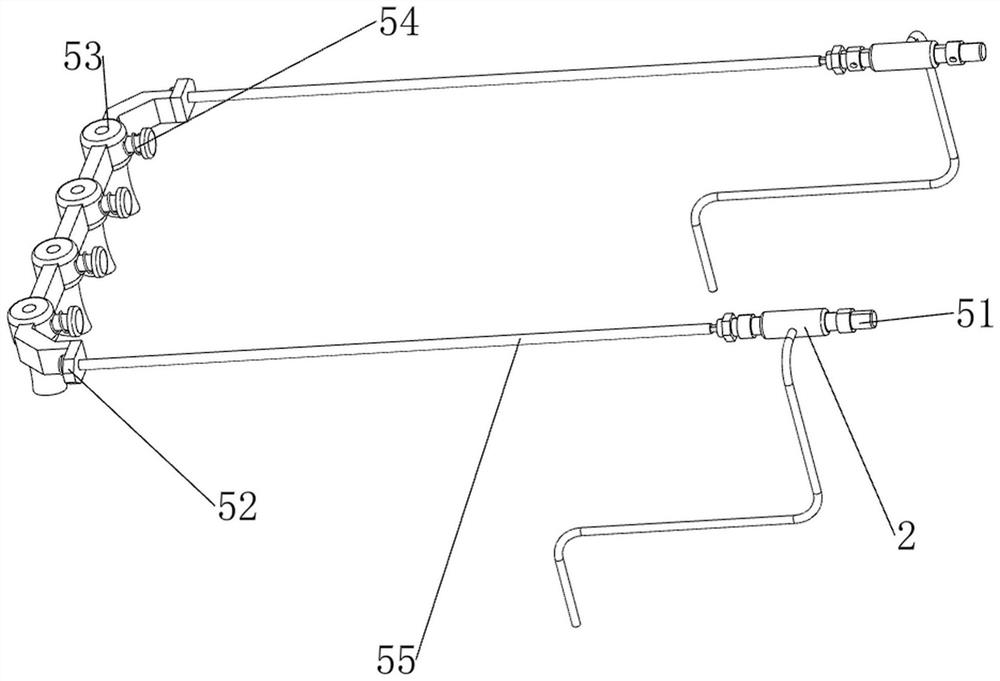

Nutrient solution injection device for biological in-vitro culture

PendingCN114317199ATo achieve the effect of pushingPrevent movementBioreactor/fermenter combinationsBiological substance pretreatmentsNutrient solutionBiochemistry

The invention relates to an injection device, in particular to a nutrient solution injection device for biological in-vitro culture. The invention provides the nutrient solution injection device for biological in-vitro culture, which has the advantages of automatic liquid feeding, automatic clamping and automatic pushing. A nutrient solution injection device for biological in-vitro culture comprises a frame and a placing mechanism, and the placing mechanism is arranged on the frame; the clamping mechanism is arranged in the frame; the pushing mechanism is arranged on the upper side in the frame; and the nozzle is arranged on the pushing mechanism. According to the device, a pull handle is moved backwards, so that a bearing disc moves backwards, then a first spring is compressed, and the pushing effect is achieved; a first connecting frame is moved towards the inner side, so that a rubber block moves towards the inner side, then a first telescopic rod and a second spring are stretched, the clamping effect is achieved, and the test tube is prevented from moving.

Owner:杨崇勇

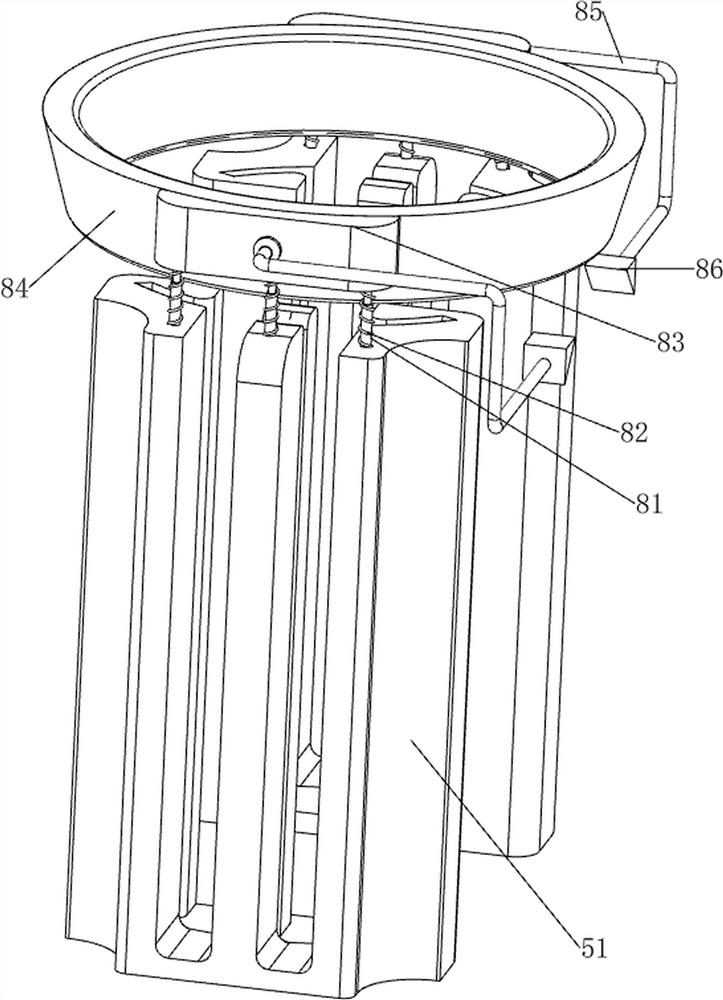

Battery efficient storage device for new energy automobile production

InactiveCN112830061ATo achieve the purpose of storing batteriesTo achieve the purpose of automatic coolingContainers preventing decayContainers to prevent mechanical damageThermodynamicsNew energy

The invention relates to a storage device, in particular to a battery efficient storage device for new energy automobile production. The battery efficient storage device for new energy automobile production can automatically dissipate heat, automatically remove dust and automatically achieve dehumidification. The battery efficient storage device for new energy automobile production comprises a supporting frame, a containing mechanism, a heat dissipation mechanism and the like; and the containing mechanism is arranged in the supporting frame, and the heat dissipation mechanism is arranged in the lower side of the supporting frame. By arranging the heat dissipation mechanism, after people store a battery, the heat dissipation mechanism operates to dissipate heat of the battery, and therefore the aim of automatic heat dissipation is achieved; and by arranging a dehumidification mechanism and the heat dissipation mechanism, air in the supporting frame quickly flows downwards, when the air passes through the dehumidification mechanism, the dehumidification mechanism enables water vapor in the air to be condensed into water drops and collects the water drops, and therefore the aim of automatic dehumidification is achieved.

Owner:南京杏胜餐饮管理有限公司

Pore plate edge grinding device

InactiveCN112428059AAchieve the effect of automatic grindingSimple operation saves time and effortEdge grinding machinesGrinding carriagesSupport planeManufacturing engineering

The invention relates to an edge grinding device, in particular to a pore plate edge grinding device. The pore plate edge grinding device shortens time and saves labor, and is high in efficiency and easy to operate. The pore plate edge grinding device comprises a bottom plate, a first supporting frame, a material placing box and a grinding mechanism, and the first supporting frame is arranged on the bottom plate. The material placing box is arranged on the inner side of the upper portion of the first supporting frame. The grinding mechanism is arranged on the bottom plate, and the grinding mechanism is matched with the material placing box. According to the pore plate edge grinding device, a small circular block is matched with a third circular block support, the small circular block movesto enable the third circular block support to slide forwards on the inner side of the upper portion of a support stabilizing base, then a material blocking frame slides forwards on a fourth fixed support, the material blocking frame prevents remaining pore plates in the material placing box from moving downwards, so that an arc-shaped frame pushes the remaining pore plates in the material placingbox conveniently; and the automatic material blocking effect is achieved, operation is easy, and time is shortened and labor is saved.

Owner:华传锦

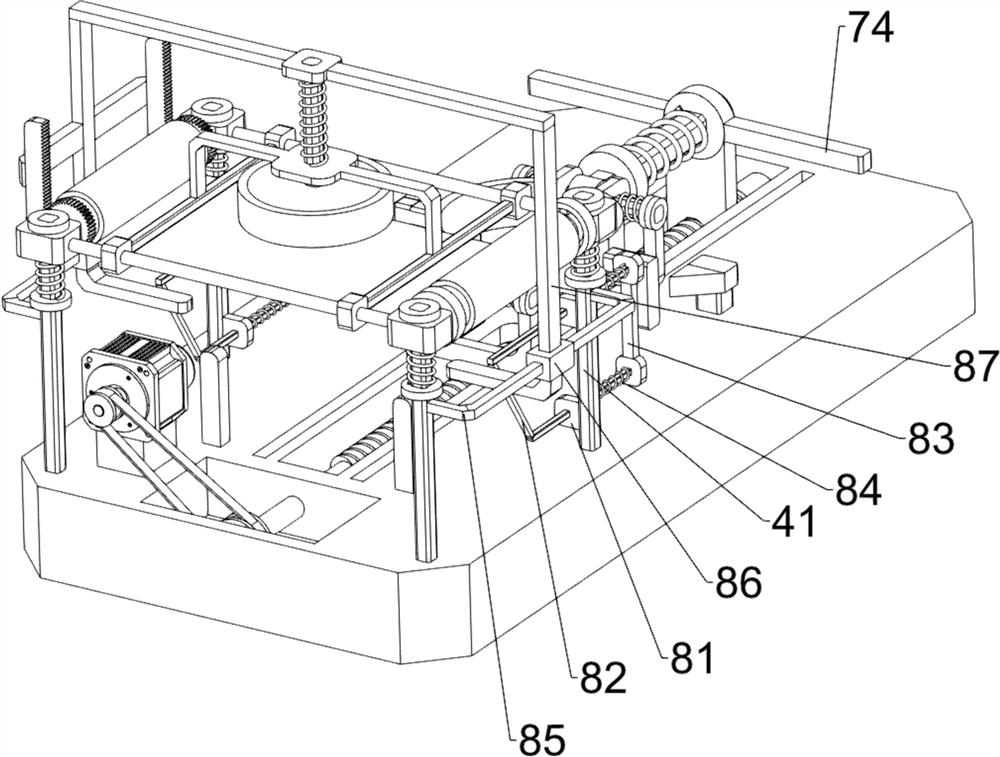

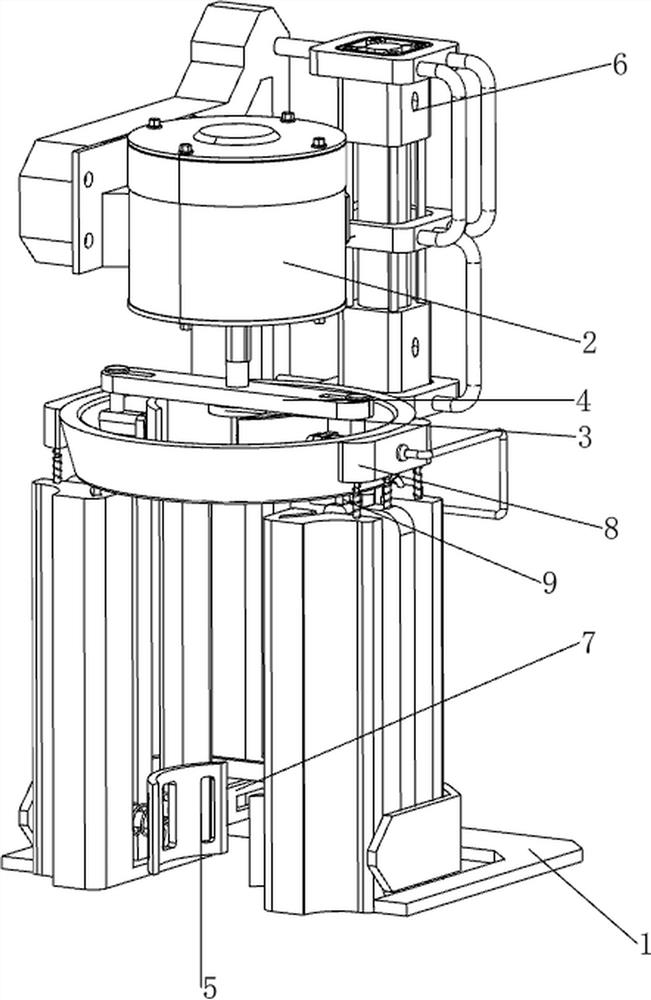

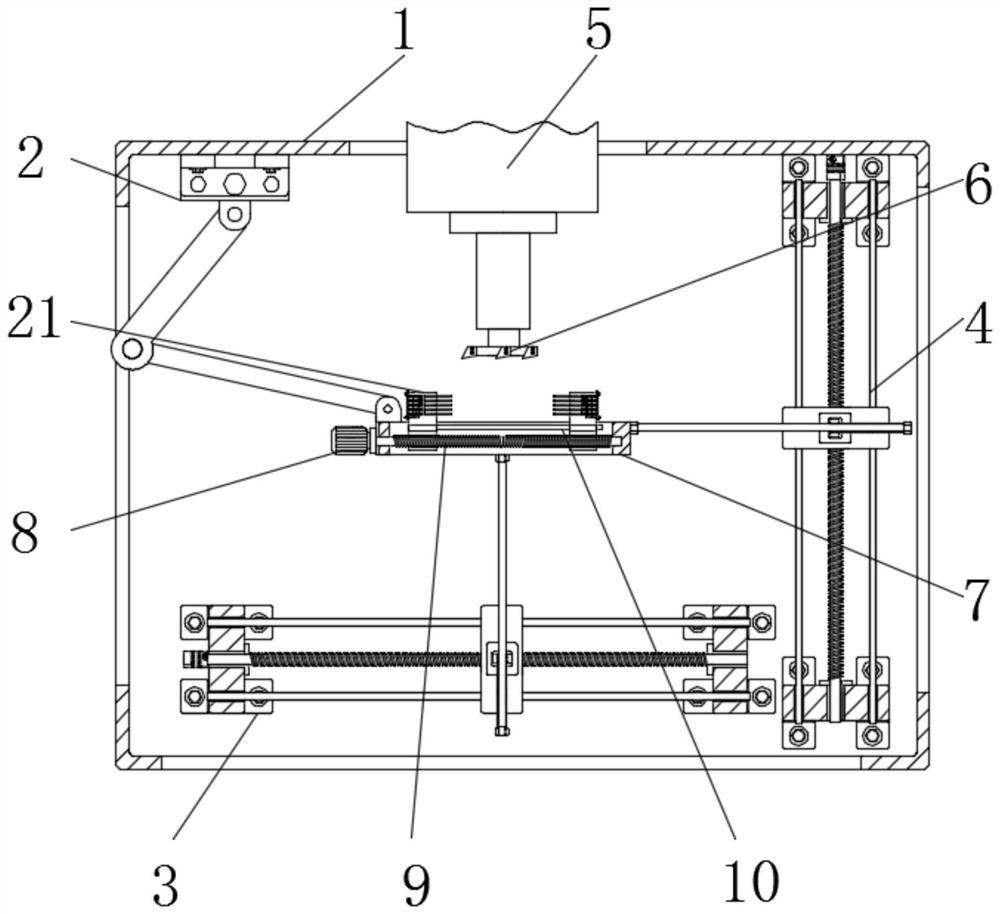

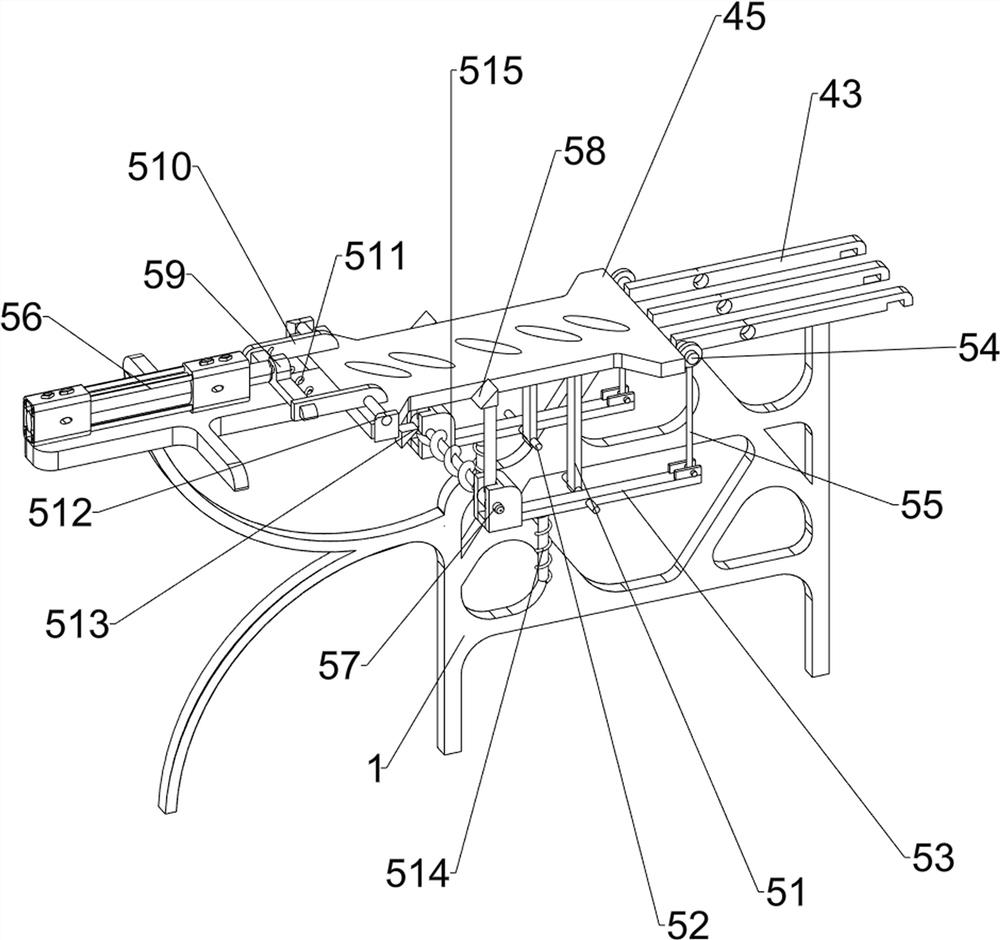

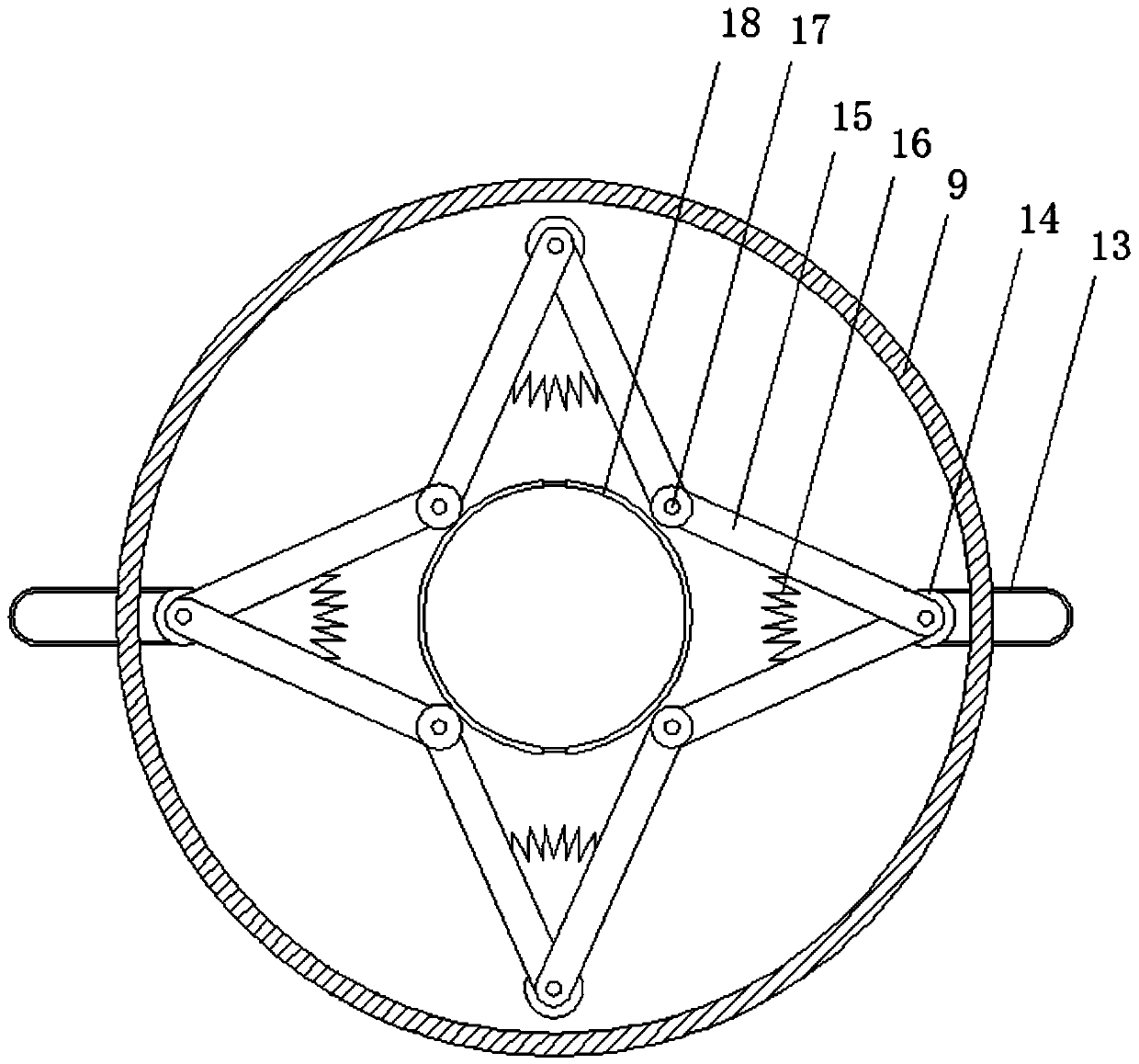

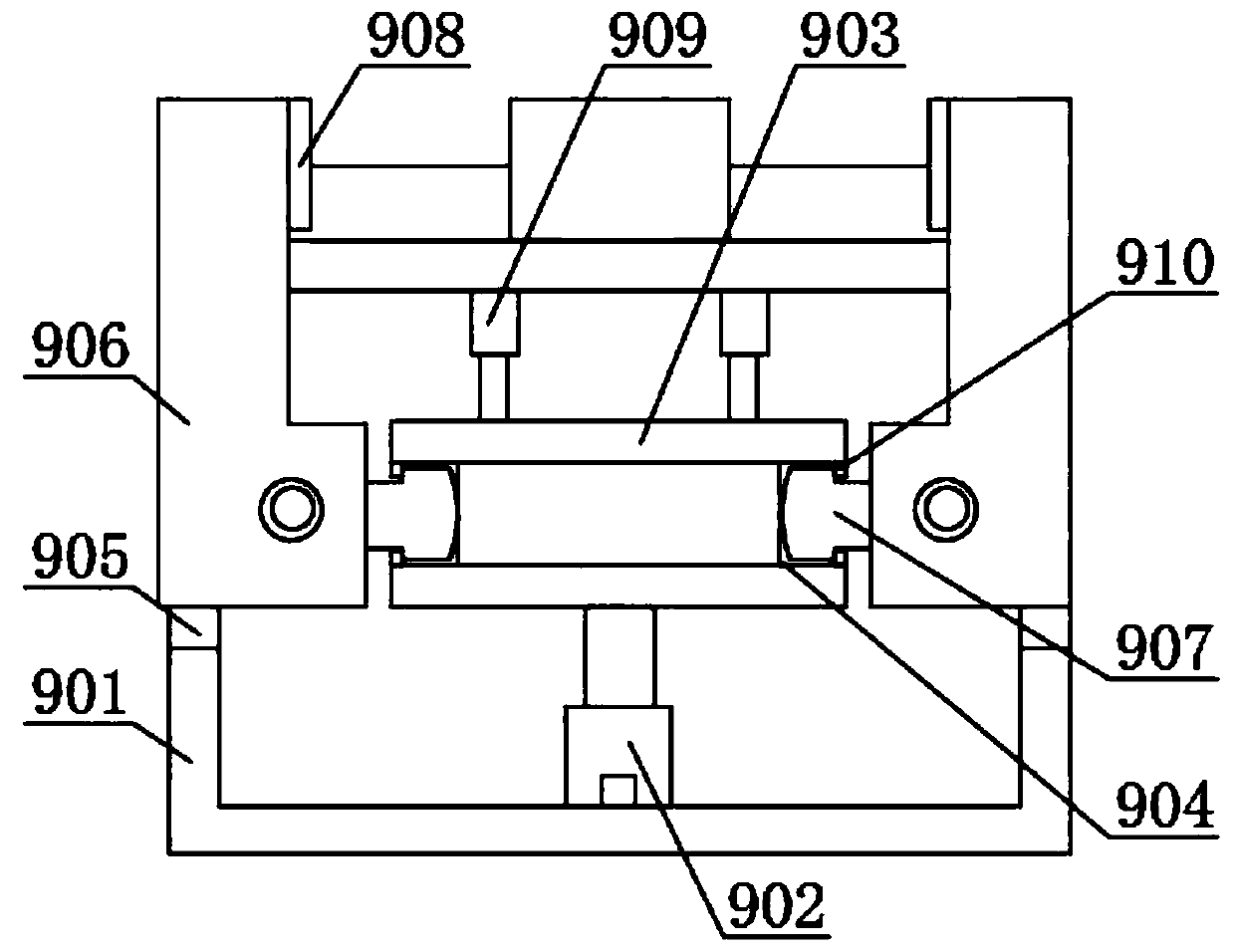

Torsion resistance performance testing device for transmission shaft of new energy automobile

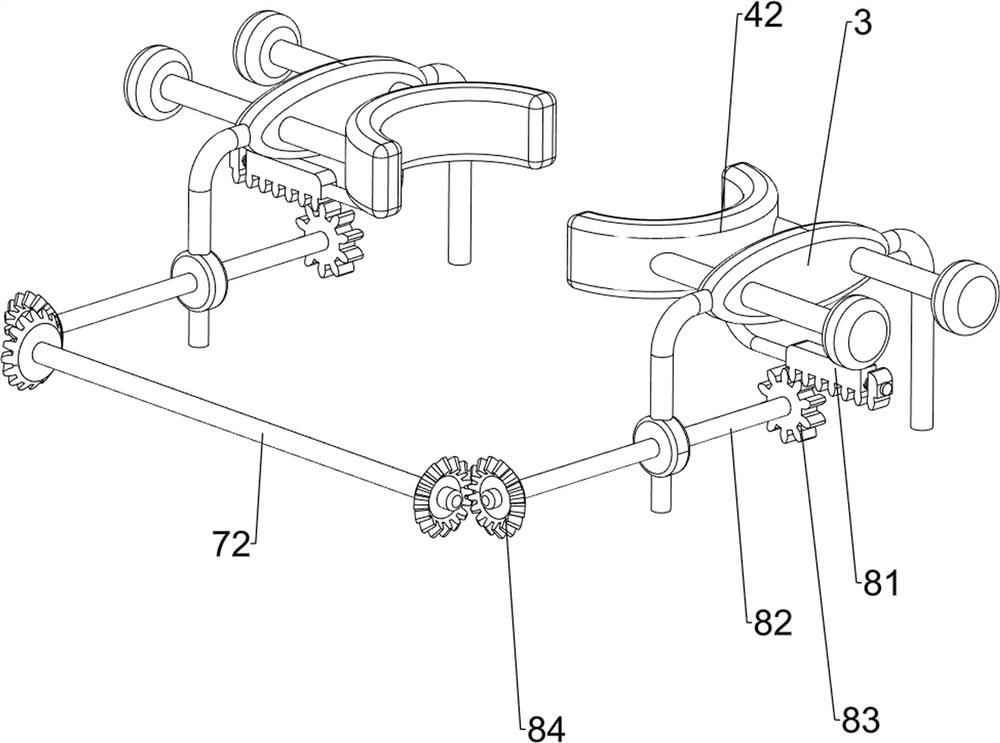

PendingCN113740178AAvoid rotational imbalanceTo achieve the detection effectMaterial strength using steady torsional forcesTorque sensorServo

The invention relates to a testing device, in particular to a torsion resistance performance testing device for a transmission shaft of a new energy automobile. The invention provides the torsion resistance performance testing device for the transmission shaft of the new energy automobile, which is accurate in measurement, improves the working efficiency and improves the existing mode. The torsion resistance performance testing device comprises a bottom plate and a detection mechanism, wherein the detection mechanism is arranged on the bottom plate; a servo motor mounted on the detection mechanism; a torsion torque sensor, wherein an output shaft of the servo motor is connected with the torsion torque sensor; a lifting mechanism arranged on the detection mechanism; and a feeding mechanism arranged between the bottom plate and the lifting mechanism. The output shaft of the servo motor rotates to drive the rotating rod and the torsion torque sensor to rotate, so that the first connecting rod and the first clamping block are driven to rotate, the transmission shaft rotates, the torsion torque sensor detects the transmission shaft, and the detection effect is achieved.

Owner:瑞金鸿多美商贸有限公司

Medical alcohol boxing and packaging device

PendingCN112919395AImprove packaging efficiencyAchieve the effect of automatic cuttingCapsFlanged caps applicationBiomedical engineeringWorkbench

The invention relates to a boxing and packaging device, in particular to a medical alcohol boxing and packaging device. According to the medical alcohol boxing and packaging device provided by the invention, when alcohol is packaged, an alcohol box is tightly covered, and alcohol volatilization is reduced. The medical alcohol boxing and packaging device comprises workbenches, mounting frames, a feeding hole, a feeding mechanism and a first discharging mechanism; the two workbenches are placed on the ground, the mounting frames are arranged on the two workbenches respectively; the feeding hole is formed between the upper sides of the two mounting frames; the feeding mechanism is arranged between the middle parts of the two workbenches; and the first discharging mechanism is arranged between the workbench on one side and the mounting frame on one side. According to the medical alcohol boxing and packaging device, through mutual cooperation of the feeding mechanism and the first discharging mechanism, the alcohol box is conveyed through a belt assembly, the alcohol is discharged into the alcohol box through a material conveying pipe, and therefore the packaging is carried out on the alcohol, and the alcohol packaging efficiency of people is relatively improved.

Owner:郭华娇

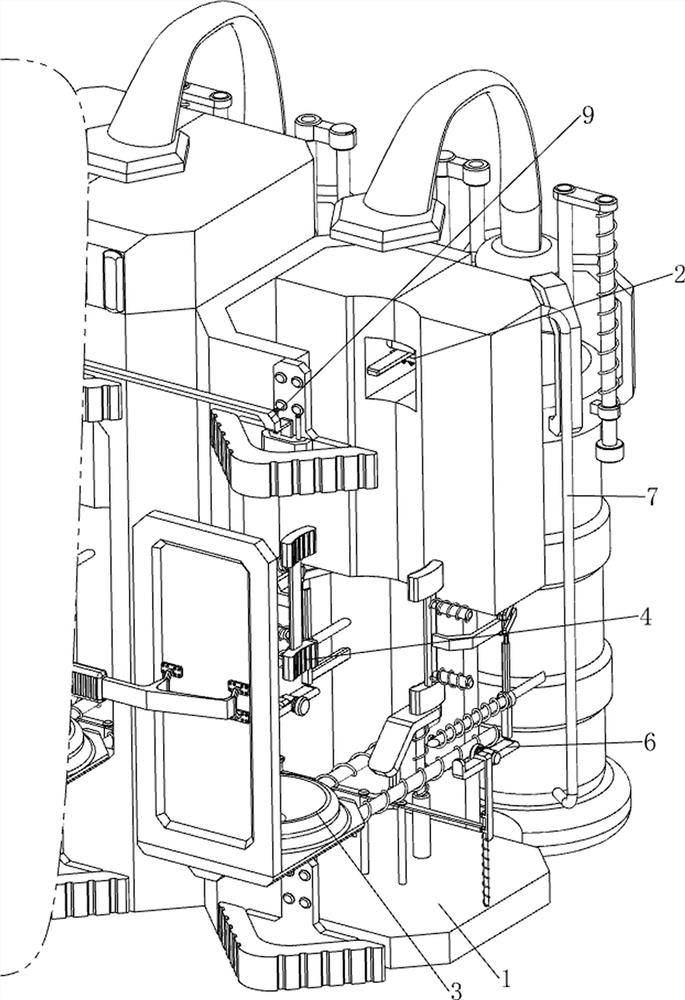

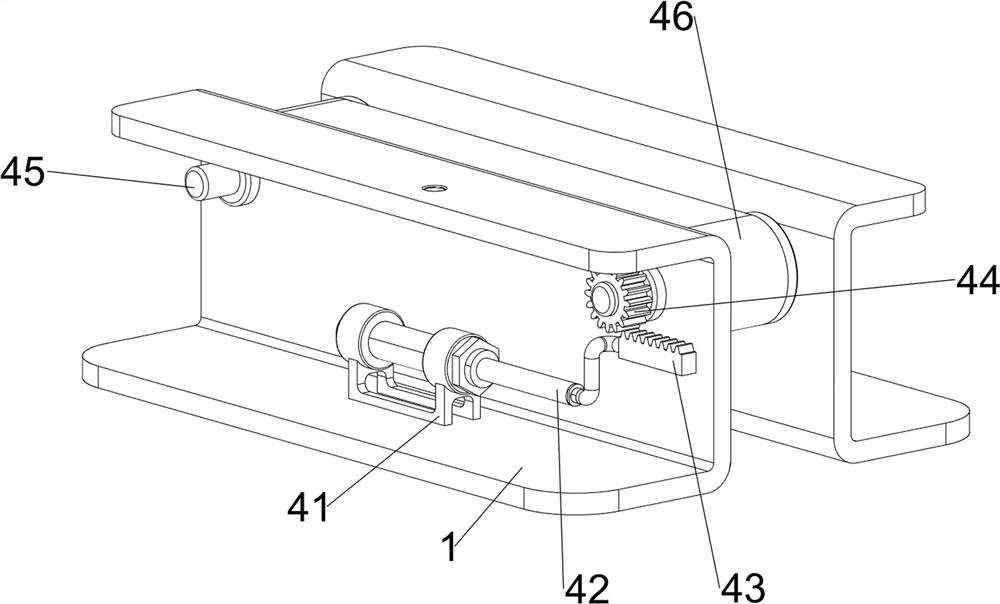

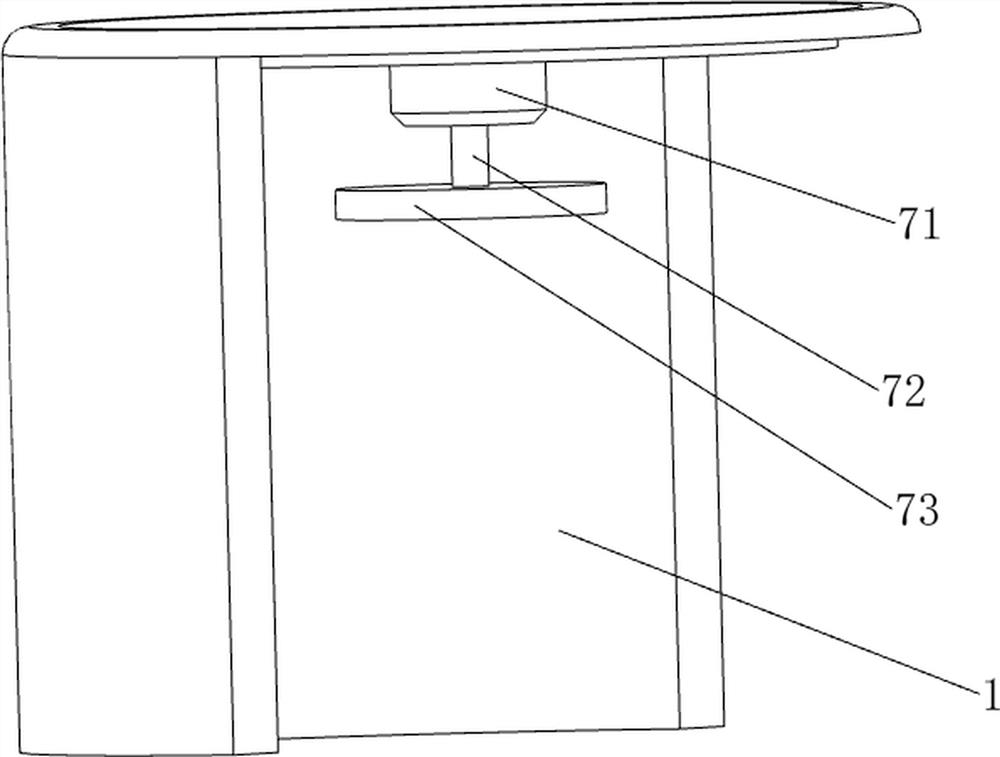

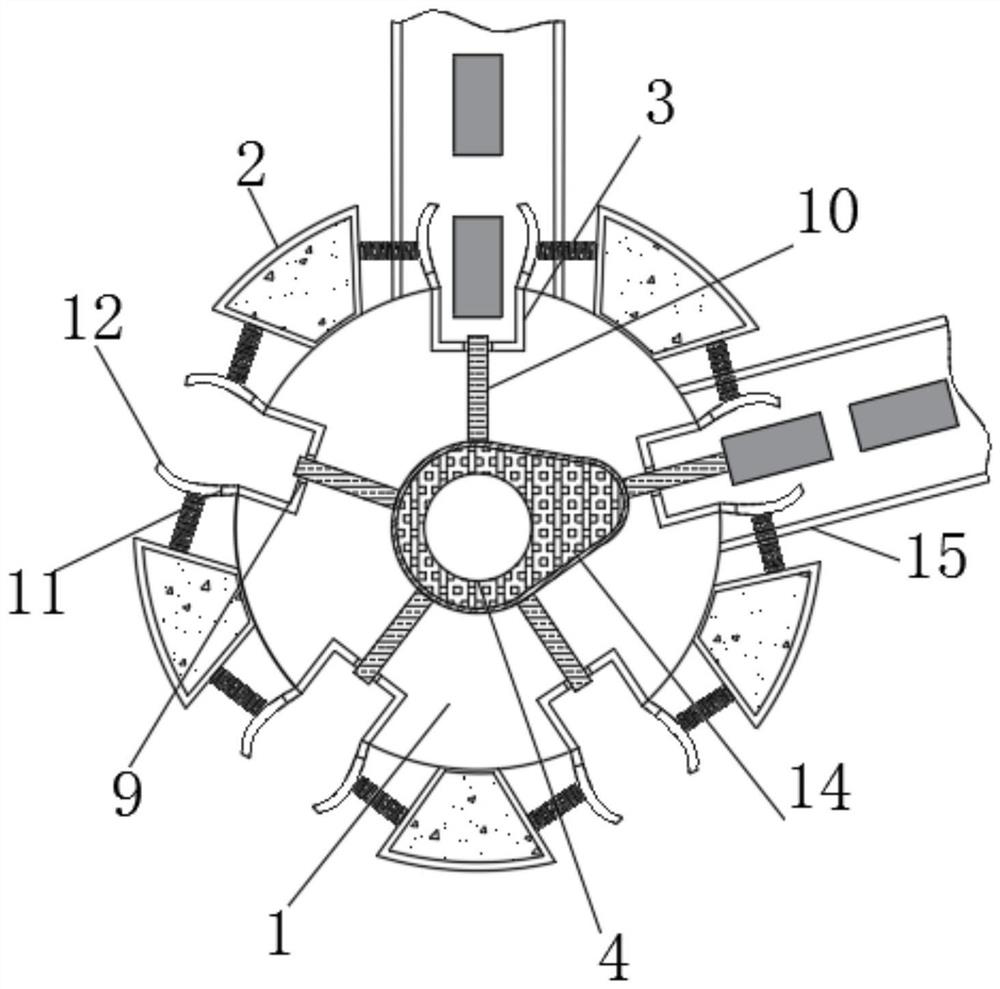

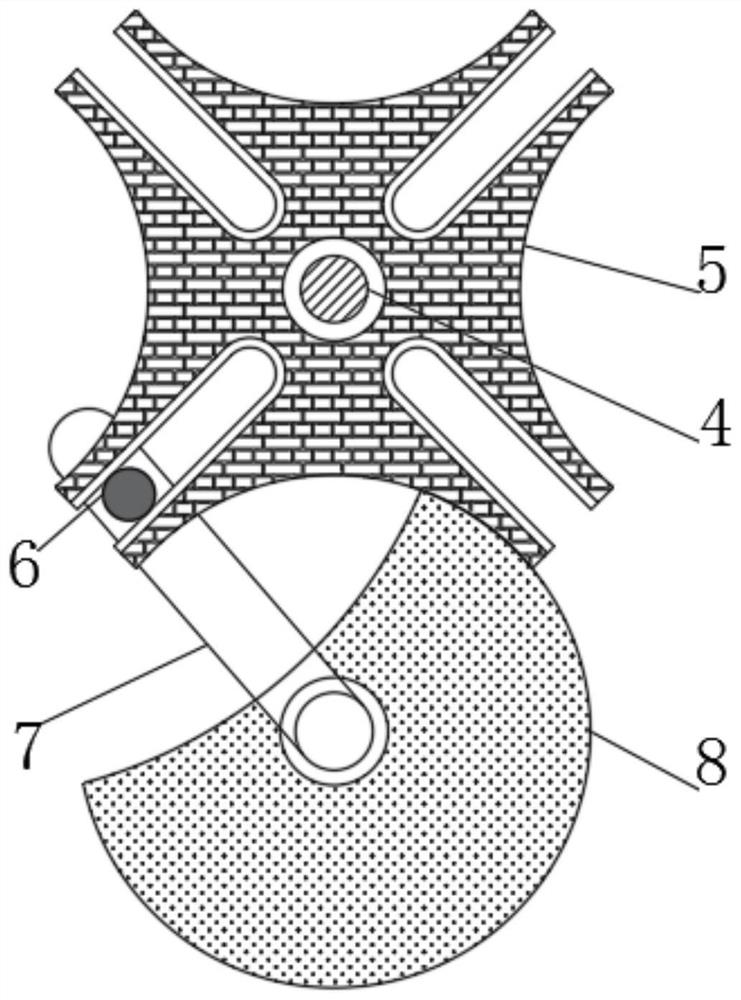

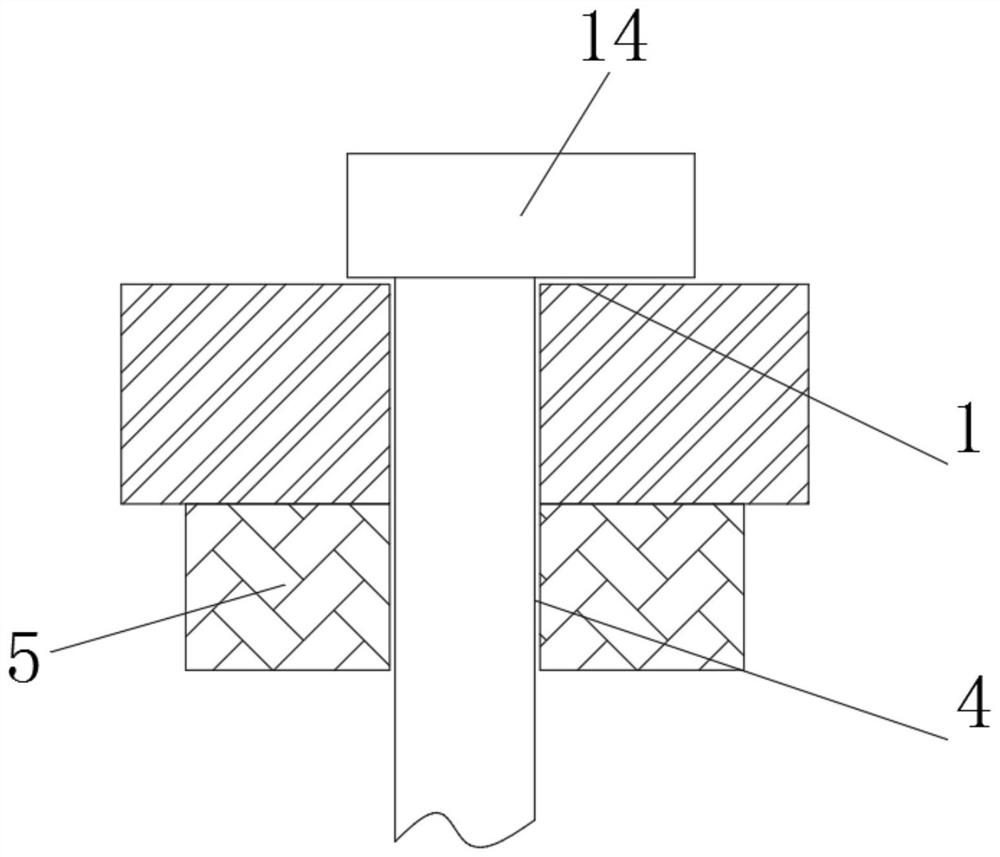

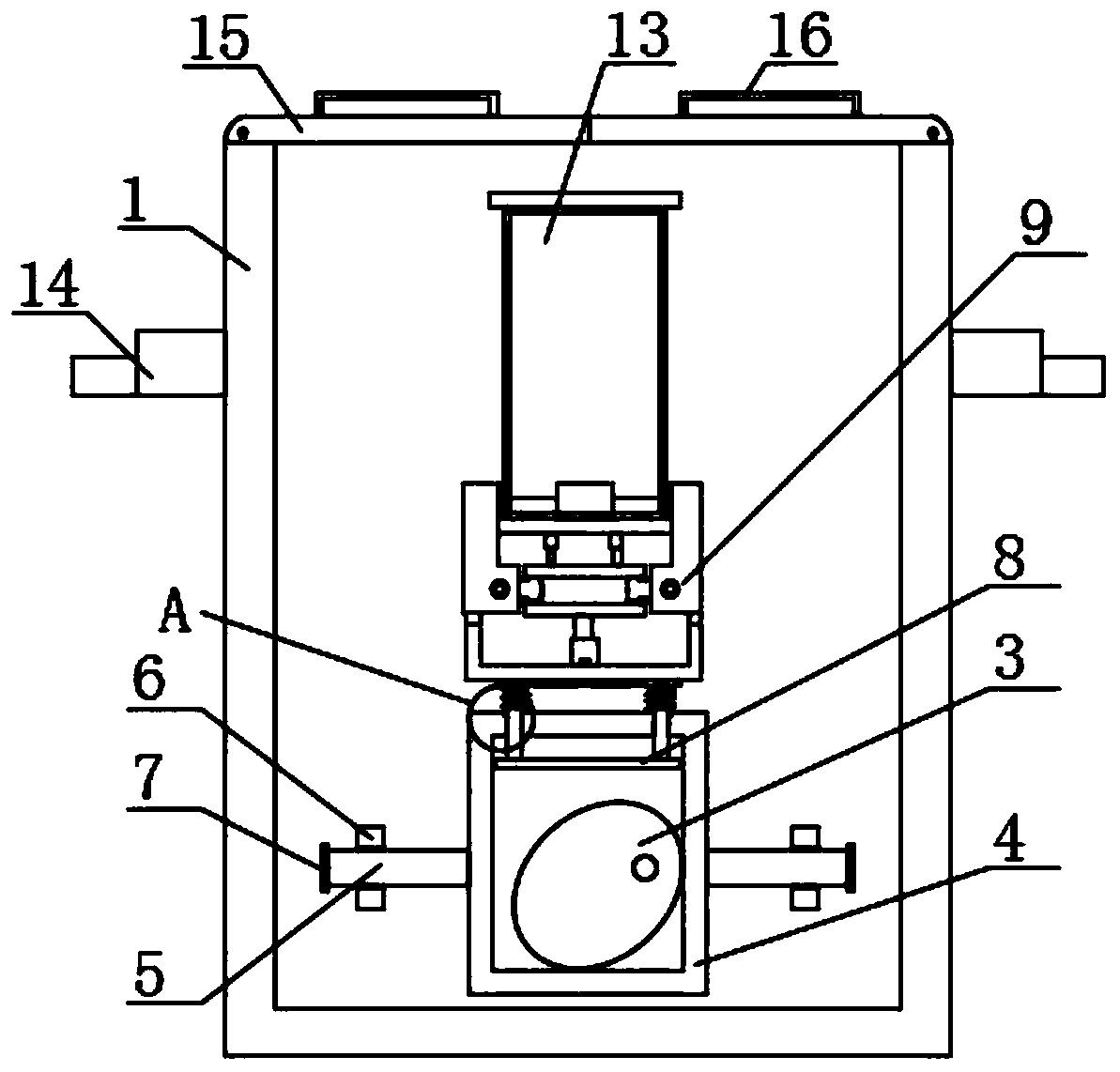

Multi-degree-of-freedom automatic adjusting and shaping numerical control machining platform

InactiveCN112139829AAchieve the effect of automatic clampingLarge fixed membersPositioning apparatusNumerical controlFixed bearing

The invention relates to the technical field of numerical control machining and discloses a multi-degree-of-freedom automatic adjusting and shaping numerical control machining platform which comprisesa machine body, a Z-axis control assembly is fixedly connected to the upper surface of the interior of the machine body, and an X-axis control assembly and a Y-axis control assembly are fixedly connected to the front face of the interior of the machine body. A machining shaft is fixedly connected to the top of the machine body, a machining tool is rotatably connected to the bottom of the machining shaft, a mounting seat is fixedly connected to the interior of the machine body, and a linear bearing and a fixed bearing are fixedly connected to the interior of the mounting seat. According to themulti-degree-of-freedom automatic adjusting and shaping numerical control machining platform, a coupler drives a movable lead screw to rotate, the movable lead screw drives a movable sliding table tomove, the movable sliding table drives a first rotating rod and a second rotating rod to move, the second rotating rod drives a movable platform to move, and then through cooperative use of mechanisms such as a mechanism tool, the effect of multi-degree-of-freedom precise control machining is achieved.

Owner:济南鑫军卓电子商务有限公司

Aluminum-titanium alloy material carbonization treatment equipment for aerospace satellite manufacturing

ActiveCN112746239AAchieve the effect of automatic clampingAchieve the effect of automatic feedingSolid state diffusion coatingSatelliteAerospace

The invention relates to carbonization treatment equipment, in particular to aluminum-titanium alloy material carbonization treatment equipment for aerospace satellite manufacturing, and provides the aluminum-titanium alloy material carbonization treatment equipment for aerospace satellite manufacturing. The aluminum-titanium alloy material carbonization treatment equipment can achieve automatic feeding, automatic heat insulation and automatic cooling. The aluminum-titanium alloy material carbonization treatment equipment for aerospace satellite manufacturing comprises a bottom plate, a conveying assembly, a carburizing mechanism, and an electromagnetic heating mechanism, wherein the conveying assembly is arranged on the bottom plate; the carburizing mechanism is arranged on the bottom plate, and the carburizing mechanism is connected with the conveying assembly; and the electromagnetic heating mechanism is arranged on the bottom plate, and the electromagnetic heating mechanism is matched with the conveying assembly. According to the aluminum-titanium alloy material carbonization treatment equipment, a water valve assembly is matched with a second liquid guide pipe, the water valve assembly moves to enable the bottom of the second liquid guide pipe to spray out a cooling liquid, and the cooling liquid falls onto the surface of an aluminum-titanium alloy material due to gravity, so that the aluminum-titanium alloy material is rapidly cooled, and the automatic cooling effect is achieved.

Owner:西安德蓝高科材料股份有限公司

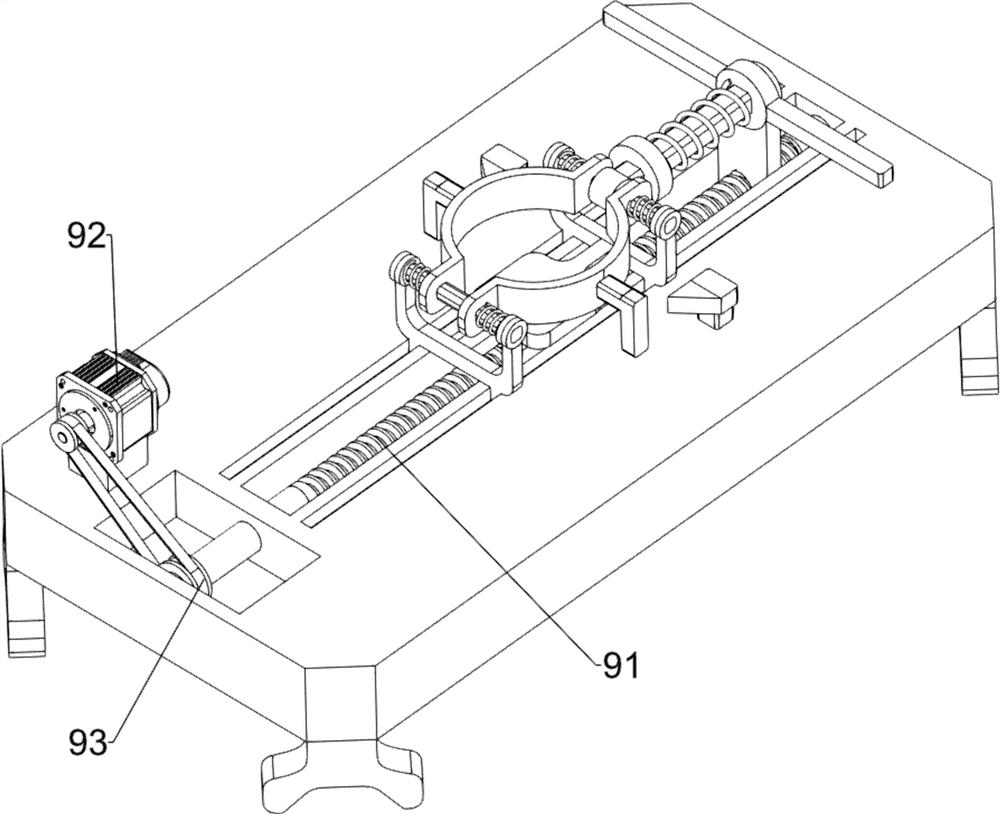

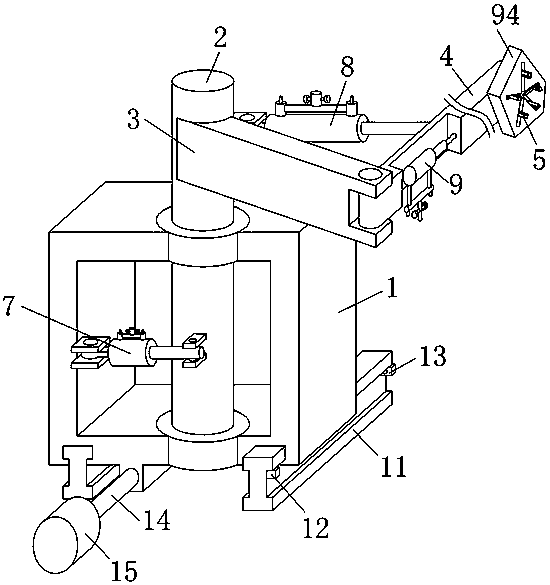

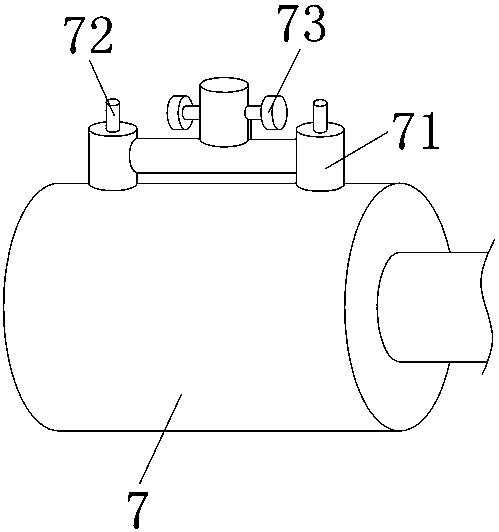

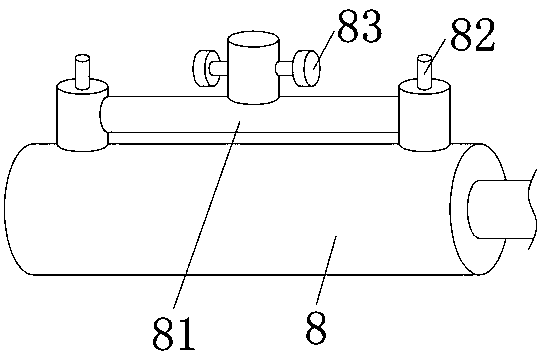

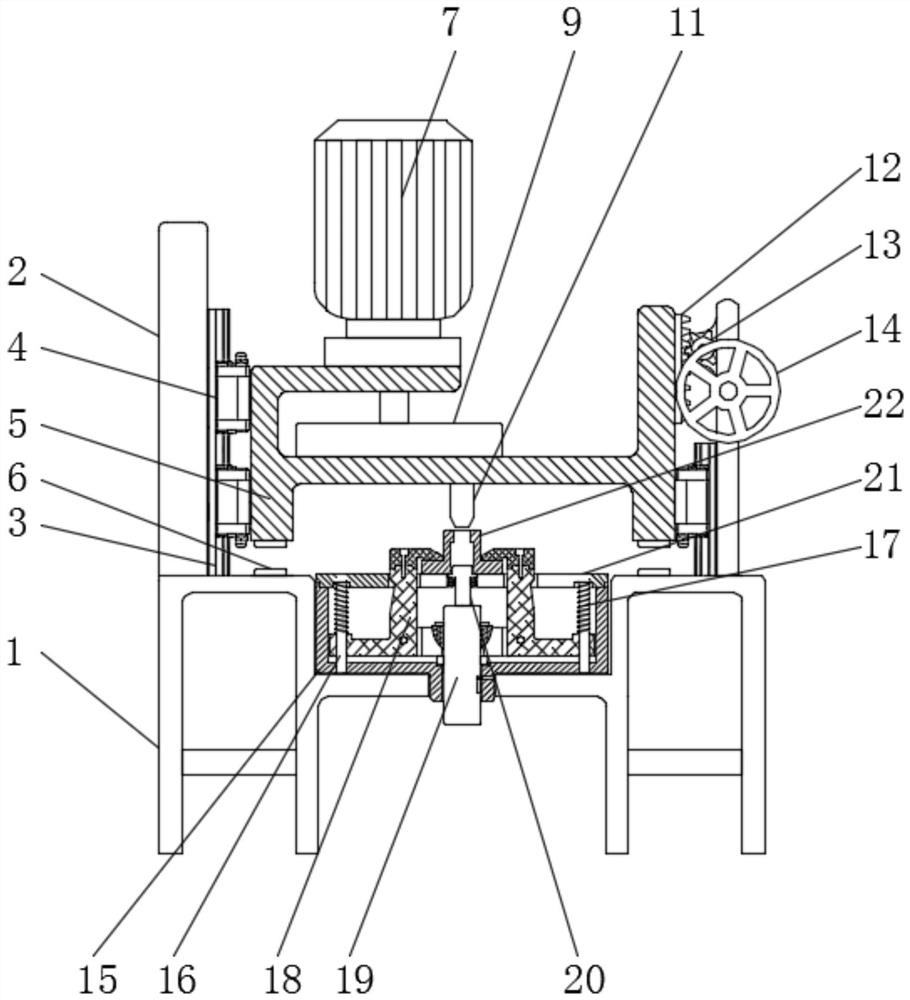

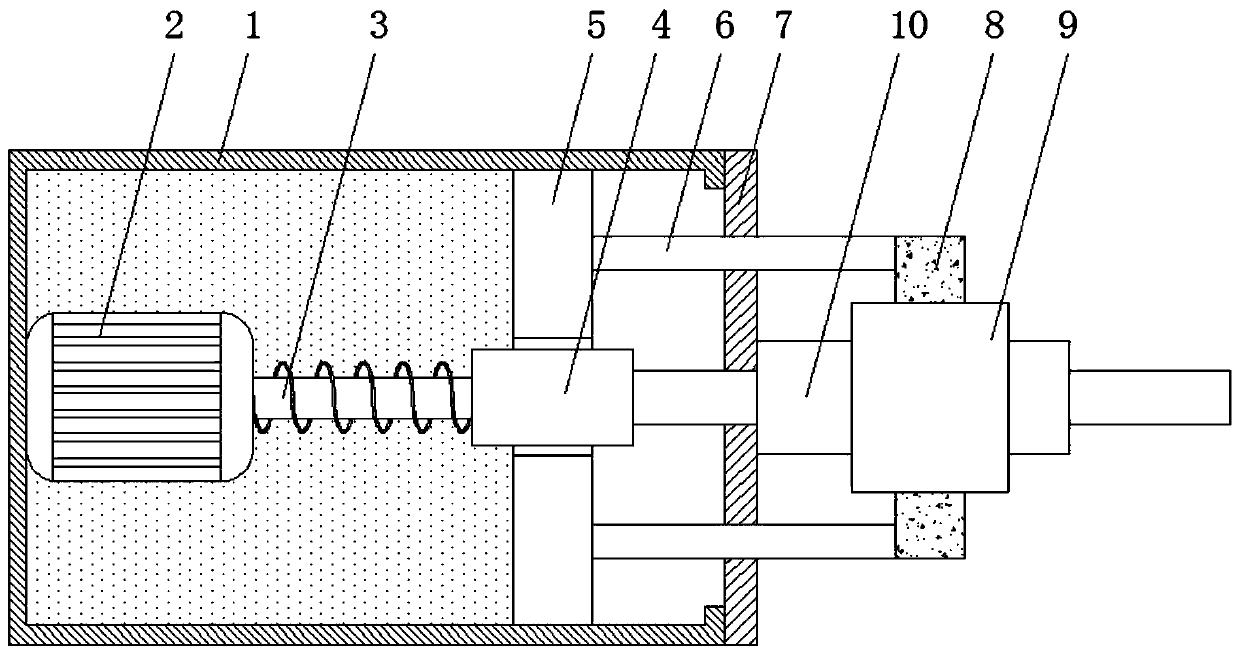

Hardware pipe surface rust removing equipment

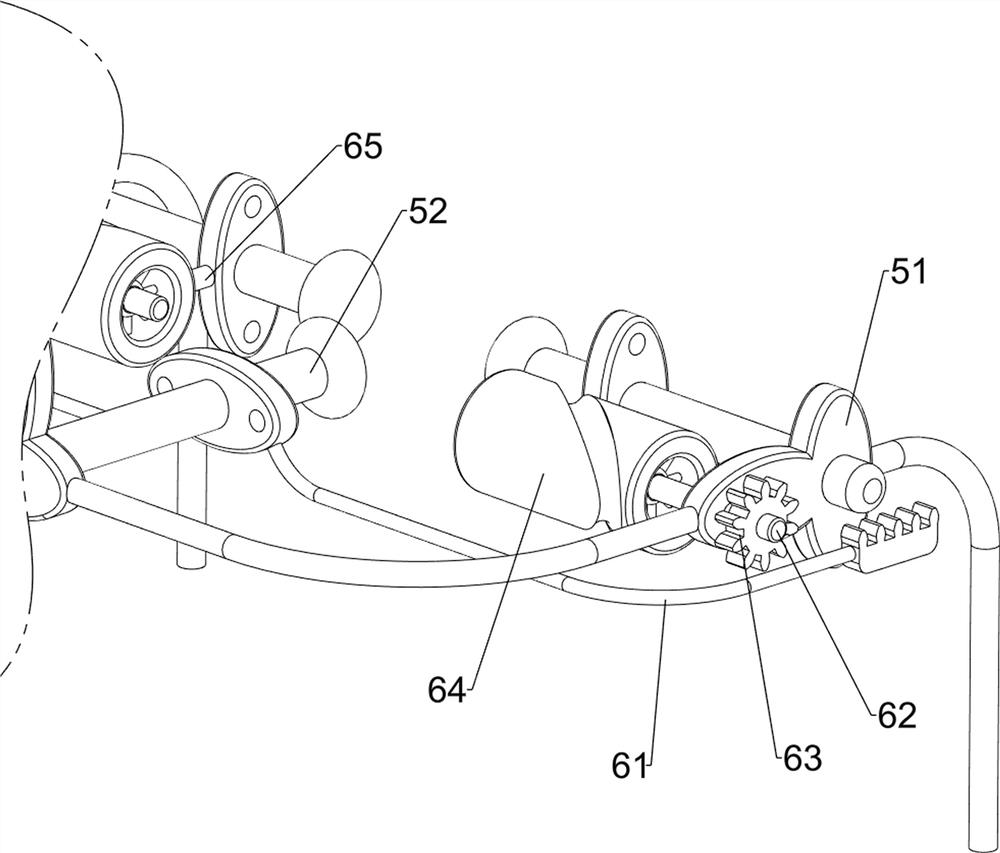

InactiveCN110465874AAchieve the effect of automatic clampingAchieve regulationGrinding drivesGrinding machinesArchitectural engineeringMetal

The invention relates to the technical field of hardware machinery, and discloses hardware pipe surface rust removing equipment. The hardware pipe surface rust removing equipment comprises a shell, amotor is movably connected to the right end of the inner wall of the left side of the shell, a rotation shaft is movably connected to the right end of the motor, a nut is movably connected to the outer surface of the middle of the rotation shaft, lifting plates are movably connected to the upper side and the lower side of the nut, pushing rods are movably connected to the right ends of the liftingplates, a top plate is movably connected to the right end of the shell, a bevel gear is movably connected to the ends, far away from the lifting plates, of the pushing rods, a rust removing device ismovably connected to the lower end of the bevel gear, and a metal column is movably connected to the outer surface, close to the right end of the top plate, of the rotation shaft. According to the hardware pipe surface rust removing equipment, through cooperative use of the structures such as the rotation shaft, the nut, the lifting plates and the pushing rods, the effect of automatically clamping pipes can be achieved; and through cooperative use of the structures such as pressing blocks, fixing plates, connecting rods and rust removing brushes, the effect of fully removing rust is achieved.

Owner:新昌县云璟智能科技有限公司

Packaging equipment used after cutting of non-woven fabric for manufacturing mask

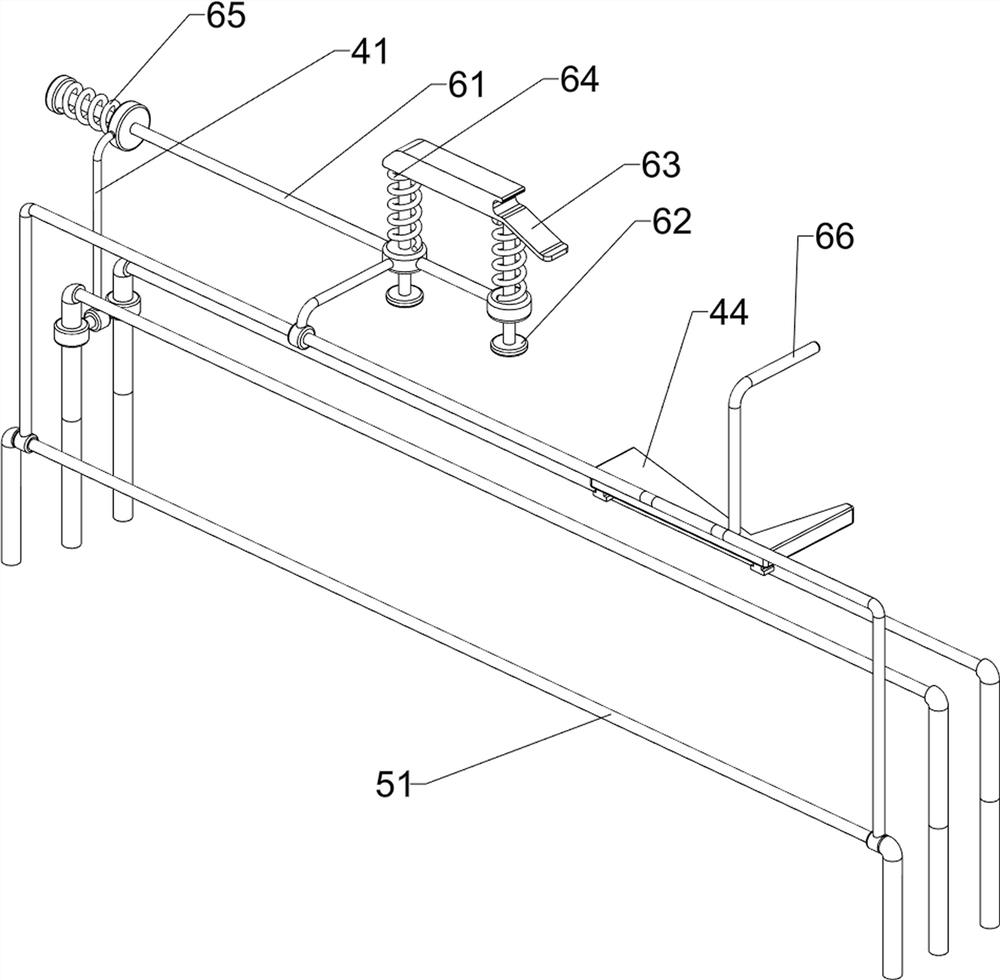

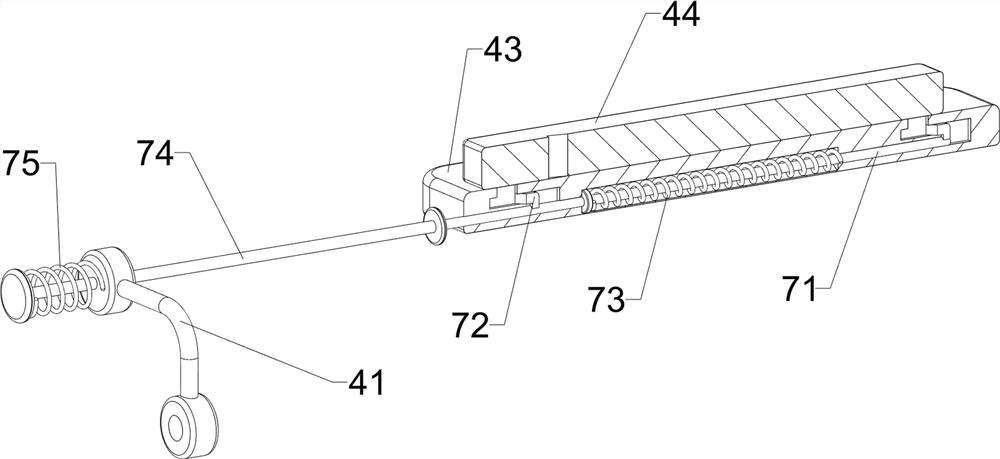

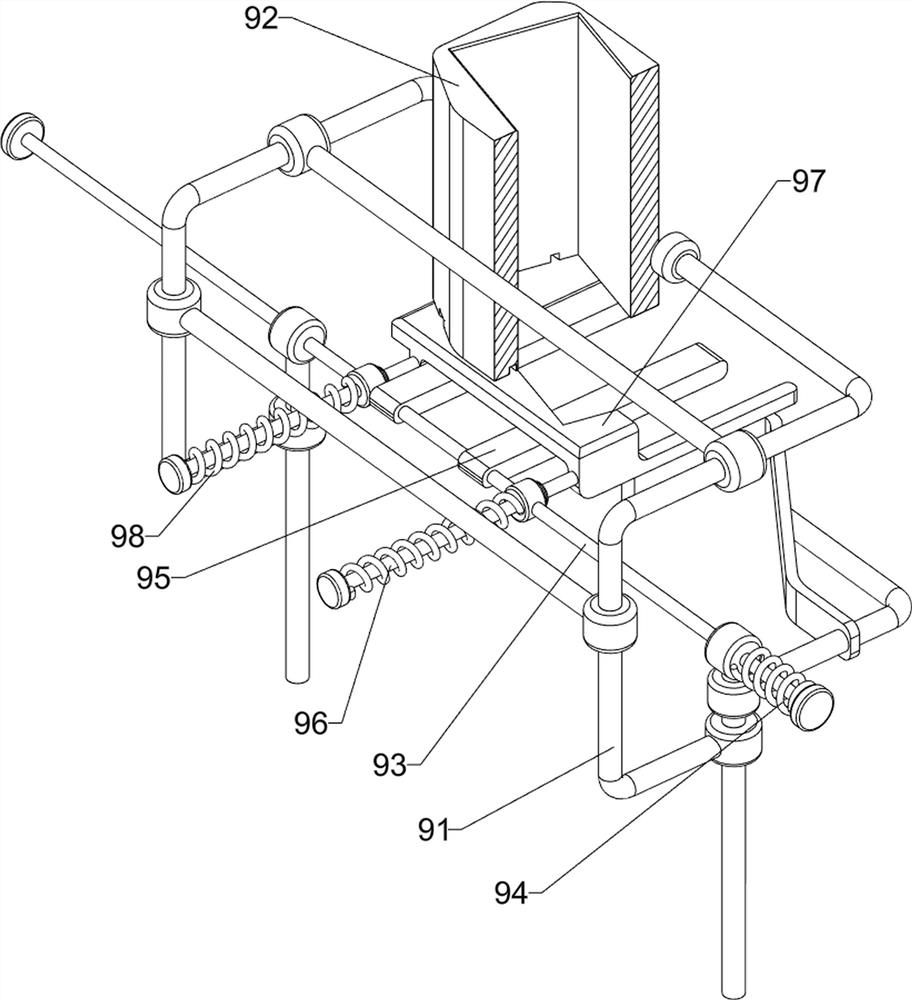

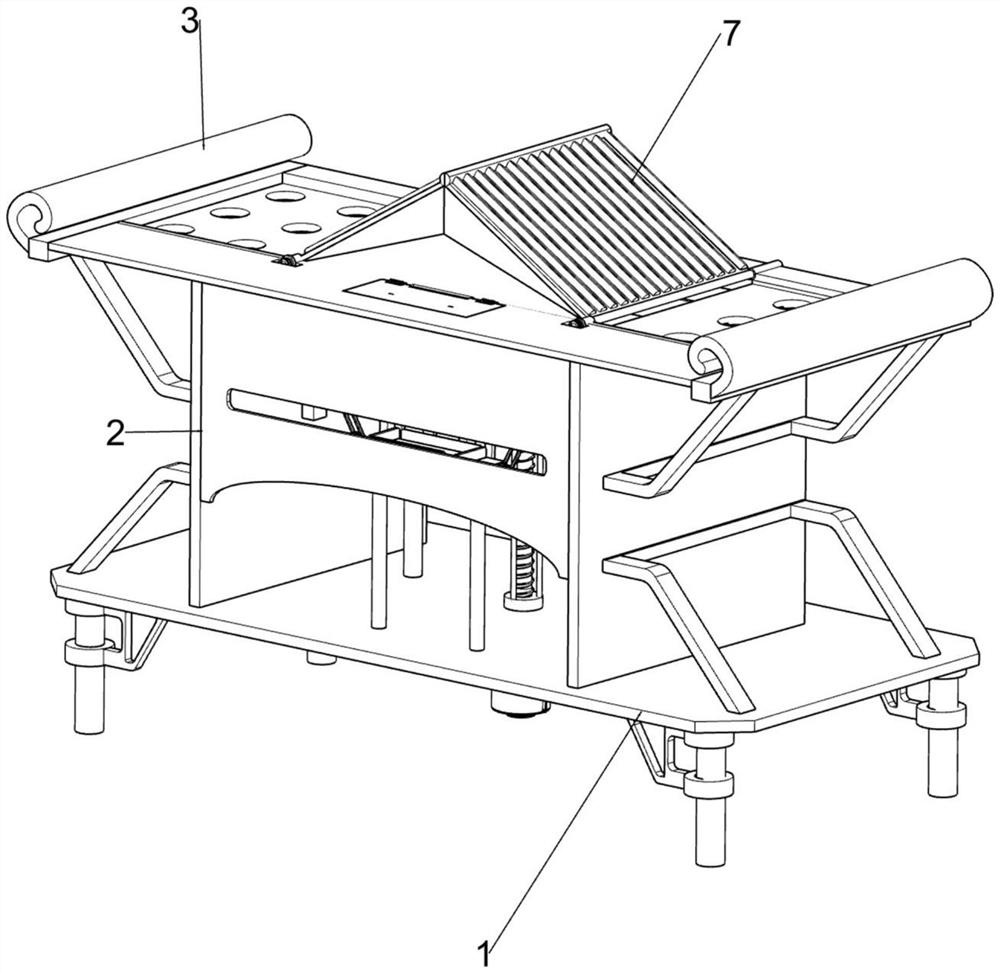

ActiveCN112693670ATo achieve the effect of automatic croppingAchieve the effect of automatic clampingSevering textilesPackagingStructural engineeringNonwoven fabric

The invention relates to packaging equipment used after cutting, in particular to packaging equipment used after cutting of non-woven fabric for manufacturing a mask. The packaging equipment used after the cutting of the non-woven fabric for manufacturing the mask is higher in efficiency, uniform in cutting, time-saving and labor-saving. The packaging equipment used after the cutting of the non-woven fabric for manufacturing the mask comprises a bottom plate, a cutting mechanism and a clamping mechanism, wherein the cutting mechanism is arranged on the bottom plate, and the clamping mechanism is arranged on the bottom plate, and the clamping mechanism matches with the cutting mechanism. According to the packaging equipment, an air cylinder operates to enable a cutter to move back and forth repeatedly, and when the cutter matches with the clamping mechanism, the cutter cuts part of drooping non-woven fabric, so that the automatic cutting effect is achieved, a third rack meshes with a second straight gear, the third rack moves to enable the second straight gear to rotate, and therefore a winding rotary column rotates and releases the non-woven fabric, the effect of automatic discharging is achieved, the lengths of the fabric discharged each time are the same, and therefore the cut non-woven fabric is uniform in shape and size.

Owner:广东捷标网信息科技有限公司

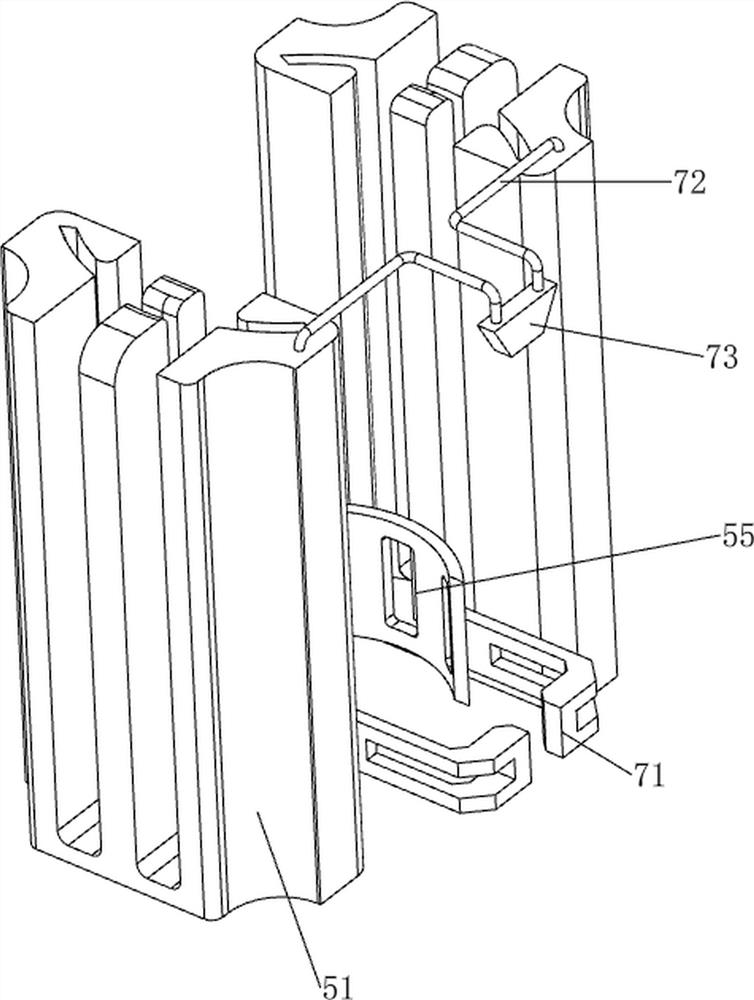

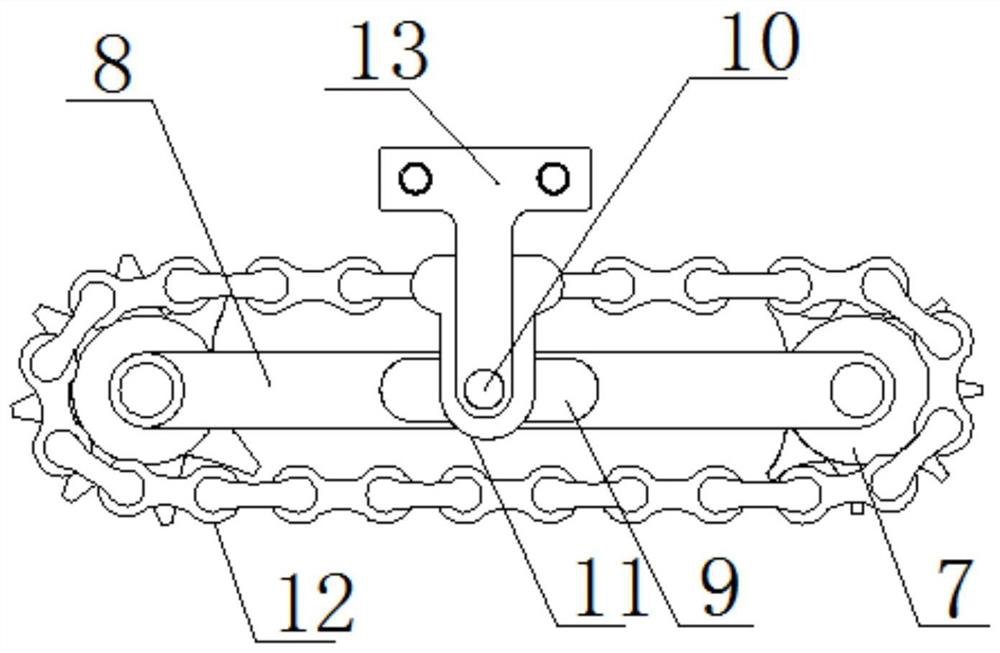

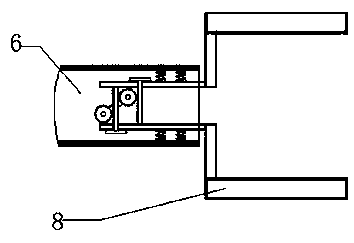

Water treatment electric water pump multi-station processing step-by-step advancing mechanism

InactiveCN111805282AAchieve the effect of automatic clampingAutomatic feedDriving apparatusPositioning apparatusRotational axisElectric machine

The invention relates to the technical field of water treatment auxiliary equipment, and discloses a water treatment electric water pump multi-station processing step-by-step advancing mechanism. Themechanism comprises a countertop; a fixed slide groove and an advancing bracket are connected with a front side steel rope of the countertop; a cam rotating shaft and a clamping driven pulley are rotatably connected with the front side of the countertop; clamping rods are slidably connected with the inside of the fixed slide groove; and a clamping mold and a resetting spring fixedly connect the clamping rods. According to the water treatment electric water pump multi-station processing step-by-step advancing mechanism, through the arrangement that an advancing motor drives a clamping power shaft to rotate, the clamping power shaft drives a clamping driving pulley to rotate, the clamping driving pulley drives the clamping driven pulley to rotate, the clamping driven pulley drives a transmission chain wheel to rotate, the transmission chain wheel drives the cam rotating shaft to rotate, the cam rotating shaft drives a clamping cam to rotate, and the clamping cam drives the clamping moldto displace, and through the application of the clamping rods and other mechanisms, the effect of automatic clamping is achieved.

Owner:洪卓锋

A manufacturing machine for industrial multi-sided fiberboard

ActiveCN113043416BEfficient removalAchieve automatic ignitionIrregularity removal devicesDomestic articlesProcess engineeringMachine

The present invention relates to a manufacturing machine, in particular to a manufacturing machine for industrial multi-sided fiberboard. The invention provides a manufacturing machine for industrial polygonal fiberboard, which can automatically and efficiently remove burrs, has high safety performance, and has good burr removal effect. A machine for manufacturing multi-sided fiberboards for industrial use, comprising a first fixing part, the number of the first fixing parts is two; a second fixing part, the second fixing parts are arranged on the two first fixing parts; the first fixing part is The plate, the two first fixing parts are provided with a first plate; the fixing mechanism, the fixing mechanism is arranged on the first plate; the dehairing mechanism, the second fixing part is provided with a dehairing mechanism. In the invention, the fiberboard is clamped by the fixing mechanism, and the ignition operation is performed by means of the dehairing mechanism, thereby realizing the purpose of effectively removing the burr from the fiberboard.

Owner:上犹耀兴复合材料有限公司

A simple clamping device

InactiveCN105291632BAchieve the effect of automatic clampingThe fixing method is simple and convenientSheet bindingSoftware engineeringDriving mode

The invention relates to simple clamping equipment. The simple clamping equipment mainly comprises a base board; a placement table is arranged on the base board and provided with a left positioning board; the right end of the left positioning board abuts against a clamping board in a combined mode; a right table column is welded to the rear end of the clamping board; the right end of the right table column is connected with a spring; the left end of the right table column abuts against a left table column in a combined mode; the rear end of the left table column and the rear end of the right table column abut against drive rods in a combined mode respectively; the upper portions of the drive rods are provided with a polish rod and a composite lead screw; the composite lead screw is connected with a motor. An adjusting groove is formed in the rear end of the base board and is internally provided with a main installation base in a sliding mode; a reset spring is arranged between the main installation base and the rear end of the adjusting groove. The two drive rods are driven in a lead screw driving mode to drive a clamp for centering movement, and the effect of automatically clamping bills is achieved. The simple clamping equipment further has the characteristics that the clamp filling mode is simple and operation is simple and has the advantages that the bill fixing mode is simple and applicability is wide.

Owner:东莞市拓尔玛特自动化科技有限公司

Electromechanical machining equipment with automatic clamping and automatic cutting stopping functions

InactiveCN114193182AReduce workloadImprove item qualityPositioning apparatusMetal-working holdersMagnetEngineering

The invention relates to the technical field of electromechanical machining, and discloses automatic clamping and automatic cutting stopping electromechanical machining equipment which comprises an equipment body, a supporting plate is fixedly connected to the interior of the equipment body, a fixing base is fixedly connected to the upper end of the supporting plate, and a machining table is movably connected to the interior of the equipment body. According to the electromechanical machining equipment with the automatic clamping and automatic cutting stopping functions, due to the fact that the wheel shell is rotationally connected with the cutting wheel, after cutting is completed, an object can be broken, at the moment, light rays received by a photoresistor are more, the resistance value of the photoresistor is decreased, and the cutting stopping function is achieved. And therefore, the repulsive force between the first magnet and the second magnet is reduced, the telescopic column can contract, the cutting wheel is driven to move upwards through the wheel shell, the automatic cutting stopping effect is achieved, and the workload of workers is reduced.

Owner:JIANGSU OUMEI STEEL STRUCTURE CURTAIN WALL

Automatic clamping and overturning deburring device using dead weight of sheet metal raw material plate

PendingCN110948322AReduce labor costsIncrease productivityEdge grinding machinesGrinding work supportsStructural engineeringManufacturing engineering

The invention relates to the technical field of sheet metal machining, and discloses an automatic clamping and overturning deburring device using the dead weight of a sheet metal raw material plate. The device includes a burr machine, wherein a power wheel is movably connected to the inner bottom of the burr machine; an overturning wheel is movably connected to the bottom of the inner left side ofthe burr machine; a movable plate is movably connected to the top of the power wheel; a positioning plate is fixedly connected between the top of the movable plate and the burr machine; a machining rod is movably connected to the top of the positioning plate; and a movable clip is disposed on the outer side of the machining rod. A deburring plate moves rightwards, a material rotating wheel separates from the overturning wheel, the machining rod remains stationary. Another deburring plate deburrs the overturned sheet metal raw material, so that an operation is achieved of automatically overturning the sheet metal material in the deburring process and deburring the two sides of the sheet metal material. Further, labor cost is reduced, and the production efficiency of sheet metal machining is improved.

Owner:HUNAN UNIV OF TECH

Wart resection equipment for dermatology department

PendingCN114176719AEasy to cutAchieve the effect of automatic clampingDiagnosticsMedical applicatorsEngineeringDermatology department

The invention relates to excision equipment, in particular to wart excision equipment for the dermatology department. The wart resection equipment for the dermatology department can automatically smear disinfection liquid medicine, can automatically clamp and can be used for cutting at present. The wart resection equipment for the dermatology department comprises a shell and a control box, and the control box is arranged at the top of the shell; the first contact switch is arranged on the control box, and the first contact switch is electrically connected with the control module; the second contact switch is arranged on the control box, and the second contact switch is electrically connected with the control module; the clamping mechanism is arranged on the shell; the cutting mechanism is arranged on the clamping mechanism; and the cutter is arranged on the cutting mechanism. According to the wart cutting device, by arranging the clamping mechanism, the clamping mechanism operates and clamps a wart body, so that the automatic clamping effect is achieved, and subsequent wart body cutting is facilitated.

Owner:李有新

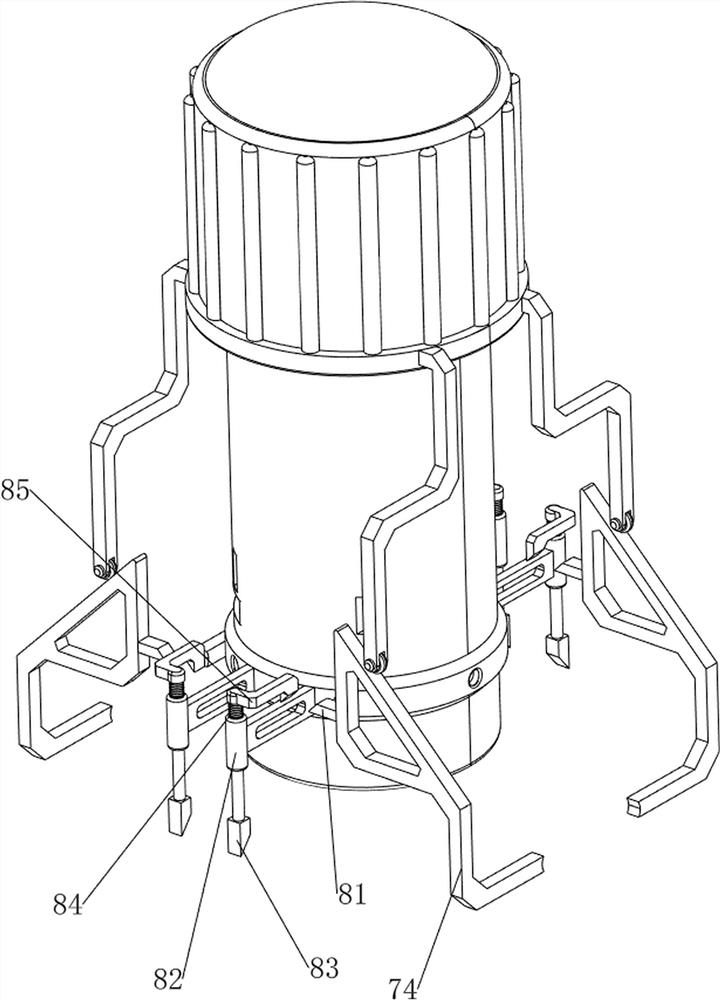

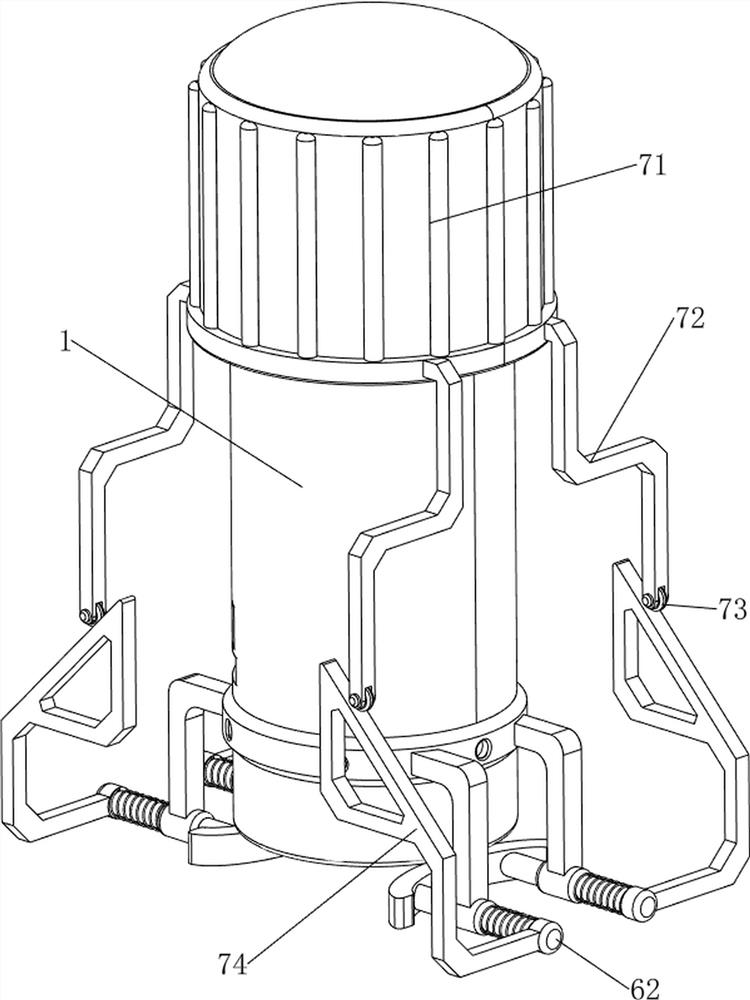

A device for removing snow from garden vegetation that is easy to move

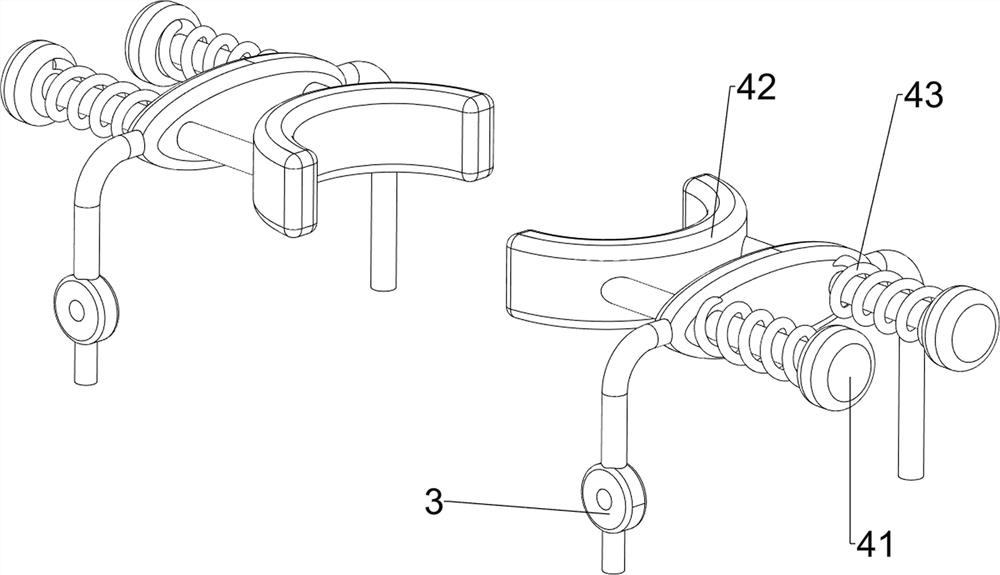

ActiveCN112449954BRemove snowTo achieve the effect of clamping treesPlant protectionSnowpackEnvironmental engineering

The invention relates to a device for eliminating snow, in particular to a device for eliminating snow on garden vegetation which is easy to move. The invention provides a device for removing snow on vegetation of different heights, which is convenient to move and removes snow on garden vegetation. A device for removing snow from garden vegetation, which is easy to move, comprises: a workbench and a handrail, the handrails are connected between the front sides of the two workbenches; a first support frame is provided on the two workbenches. ; Clamping mechanism, the first support frame is provided with a clamping mechanism; Knock mechanism, a percussion mechanism is arranged on the worktable, and the clamping mechanism cooperates with the percussion mechanism. In the present invention, the tooth-missing gear is meshed with the second gear, so that the three beating blocks move to the outside, and when the tooth-missing gear is not meshed with the second gear, the three beating blocks move inward, and then the trees are beaten to achieve automatic The knocking effect saves time and effort.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

Automatic clamping and transporting device for hardware equipment

InactiveCN114212538AAchieve the effect of automatic clampingReduce security risksConveyor partsComputer hardwareTransmission belt

The invention relates to the technical field of hardware machinery, and discloses an automatic hardware equipment clamping and transporting device which comprises a rotating disc, a sector plate is clamped outside the rotating disc, an object containing block is welded in the rotating disc, a rotating shaft is rotatably connected in the rotating disc, and a rotating block is rotatably connected outside the rotating shaft. The automatic clamping and transporting device for the hardware equipment comprises a rotating block, a sliding column is slidably connected to the interior of the rotating block, a transmission rod is movably connected to the exterior of the sliding column, a semicircular clamping block is rotatably connected to the exterior of the transmission rod, a sleeve is connected to the interior of an object containing block in a clamped mode, and a cylindrical rod is connected to the interior of the sleeve in a sleeved mode. When the hardware parts are conveyed into the clamp through the conveying belt, due to the fact that hardware equipment and the magnet block attract each other, the clamp tightly clamps the hardware parts, the automatic clamping effect is achieved, potential safety hazards can be greatly reduced, and the production efficiency can be improved.

Owner:NINGBO XIATAO PLASTIC PLANTING CO LTD

Portable food heavy metal detector

PendingCN111537683ATo achieve the effect of mixingWell mixedPreparing sample for investigationTesting foodElectric machineryStructural engineering

The invention provides a portable food heavy metal detector, and relates to the technical field of food detection. The portable food heavy metal detector comprises a shell and a test tube, a gear motor is fixedly installed on one side face of the shell, an oval block is fixedly connected to the output end of the gear motor, a mouth-shaped block is arranged on the outer surface of the oval block, supporting rods are fixedly connected to the two side faces of the mouth-shaped block, two fixing blocks matched with the supporting rods are fixedly connected to the interior of the shell, and a pushplate is arranged in the mouth-shaped block. The portable food heavy metal detector is provided with the gear motor, the oval block, the mouth-shaped block, the supporting rods, the fixing blocks, a sliding rod, a clamping mechanism, a supporting plate and a spring, so the detector has the advantages of high automation degree, uniform mixing and stirring and high detection efficiency, and solves the problems of low detection efficiency and inaccurate detection result due to the fact that most of traditional detection modes adopt manual test tube holding for mixing and stirring and are prone touneven mixing.

Owner:张亚琪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com