A manufacturing machine for industrial multi-sided fiberboard

A technology for fiberboard and industrial use, which is applied in the field of industrial multilateral fiberboard manufacturing machines, which can solve the problems of low safety performance and low efficiency, and achieve the effects of improving safety, reducing workload and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

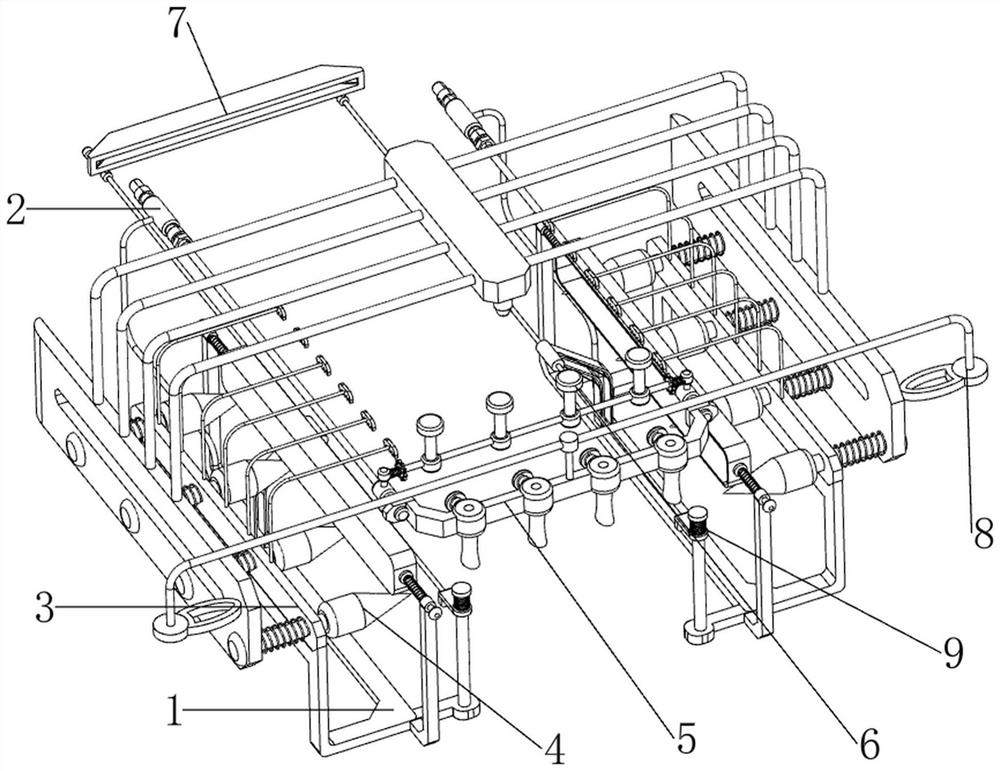

[0066] A machine for making multi-sided fiberboards for industrial use, such as figure 1 As shown, it includes a first fixing part 1, a second fixing part 2, a first plate 3, a fixing mechanism 4 and a dehairing mechanism 5, the number of the first fixing parts 1 is two, and the two first fixing parts 1 A second fixing part 2 is provided on the right side of the top, and a first plate 3 is provided on the outer top of the two first fixing parts 1. The first plate 3 is provided with a fixing mechanism 4, and the second fixing part 2 is provided with dehairing. Institution 5.

[0067]When it is necessary to remove the burrs from the fiberboard, people first pull the fixing mechanism 4 to both sides, put in the fiberboard, release the fixing mechanism 4 to clamp it, then start the dehairing mechanism 5, and the dehairing mechanism 5 moves left and right. Press or loosen the dehairing mechanism 5 to perform intermittent ignition dehairing operation. After the burrs are removed, c...

Embodiment 2

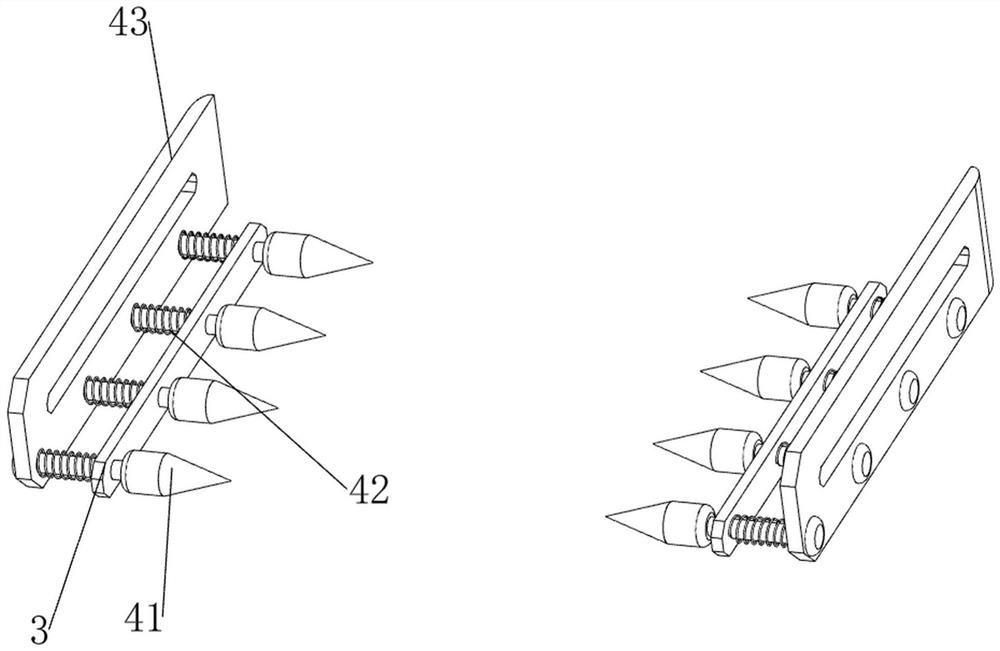

[0069] On the basis of Example 1, as figure 2 and image 3 As shown, the fixing mechanism 4 includes a clamping member 41, a first spring 42 and a second plate 43. The two first plates 3 are evenly provided with a clamping member 41 in a sliding manner. The front portion of the clamping member 41 on the front side is A second plate 43 is provided, another second plate 43 is arranged between the rear of the rear clamping member 41, and a first spring 42 is sleeved on each of the eight clamping members 41, and the first springs 42 are respectively connected to the same side. The second plate 43 is connected to the clamping part 41 .

[0070] In the process of fixing the fiberboard, people first pull the second plate 43 outward, and then drive the clamping member 41 to move outward. At this time, the first spring 42 is stretched, and after the fiberboard is put in, the second plate 43 is released, and the first The reset of the spring 42 drives the second plate 43 to move inwa...

Embodiment 3

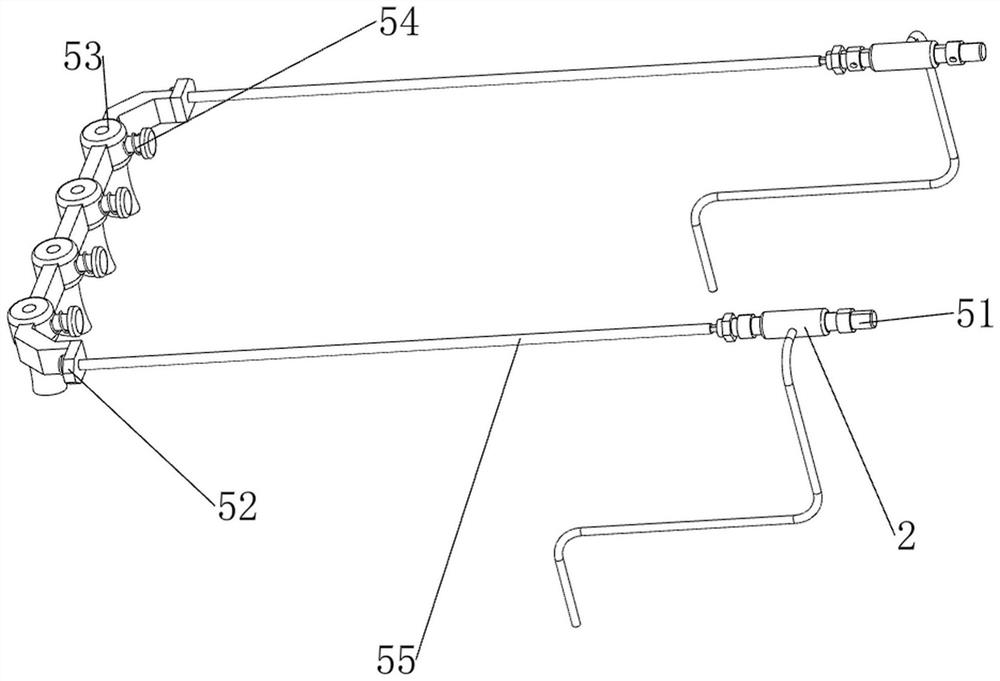

[0074] On the basis of Example 2, as figure 1 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, it also includes a switching mechanism 6, a discharging mechanism 7, an auxiliary mechanism 8 and a cleaning mechanism 9, a switching mechanism 6 is provided on the first plate 3 and the first connecting rod 55, and a discharging mechanism is provided on the first fixed part 1 Mechanism 7, an auxiliary mechanism 8 is arranged on the connecting plate 52, and a cleaning mechanism 9 is arranged on the first fixing part 1 and the second plate 43.

[0075] When deburring the fiberboard, people can push the discharging mechanism 7 to the left for automatic loading and unloading, and pull the discharging mechanism 7 to the right to place a new fiberboard. The left and right movement of the first connecting rod 55 drives the switching mechanism 6 to operate, thereby replacing manual Press and release the lighter 53 to realize automatic intermittent ignition operation. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com