Automatic and uniform boxing machine for biological capsules

A bio-capsule and cartoning machine technology, applied in packaging, transportation and packaging, packaging item types, etc., can solve the problems of large power consumption, complicated operation, high cost, etc., and achieve the effect of energy saving and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

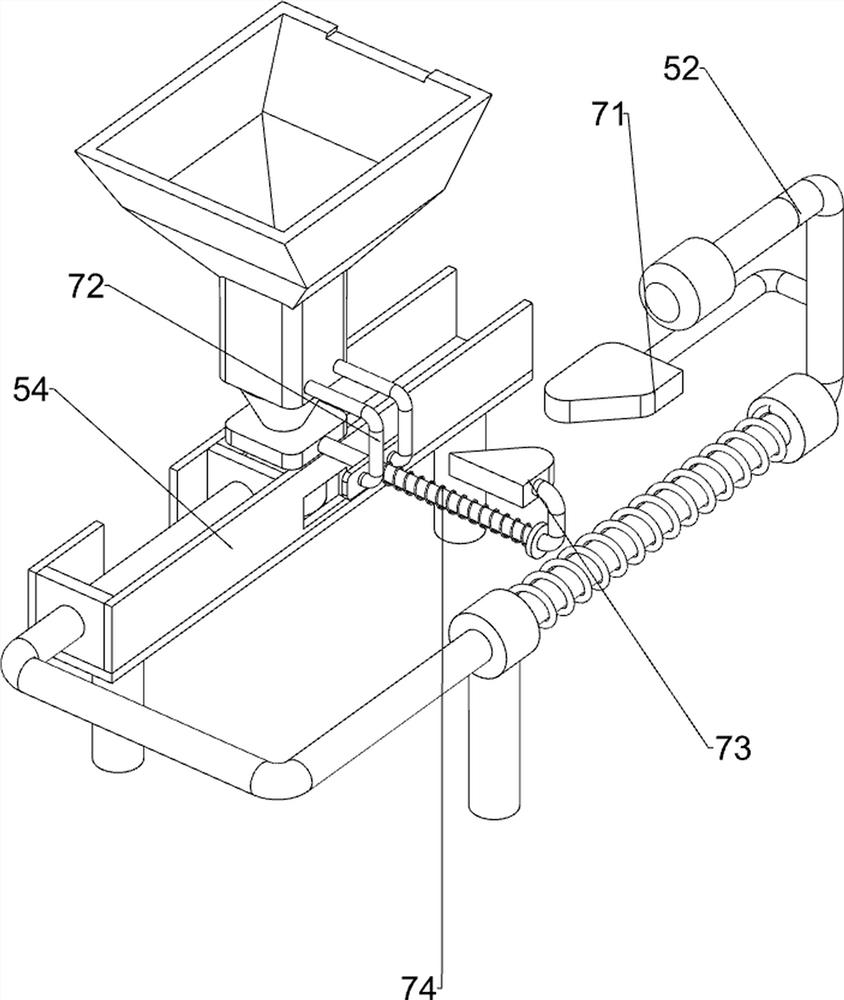

[0072] A kind of automatic uniform cartoning machine for biological capsules, such as figure 1 As shown, it includes a base plate 1, an intermittent feeding mechanism 2 and an automatic vibration mechanism 3. The upper middle of the base plate 1 is provided with an intermittent feeding mechanism 2, and the base plate 1 is provided with an automatic vibration mechanism 3. The intermittent feeding mechanism 2 and the automatic vibration mechanism 3 fit.

[0073] The traditional cartoning machine is complex in operation, high in cost and high in power consumption. This equipment can automatically pack the biological capsules evenly, with simple operation, low cost and energy saving. First, people pour the biological capsules into the intermittent feeding mechanism 2, Then make the automatic vibrating mechanism 3 run, so that the biocapsules in the intermittent feeding mechanism 2 vibrate. , people make it into the packaging bottle, so as to achieve the purpose of uniform boxing,...

Embodiment 2

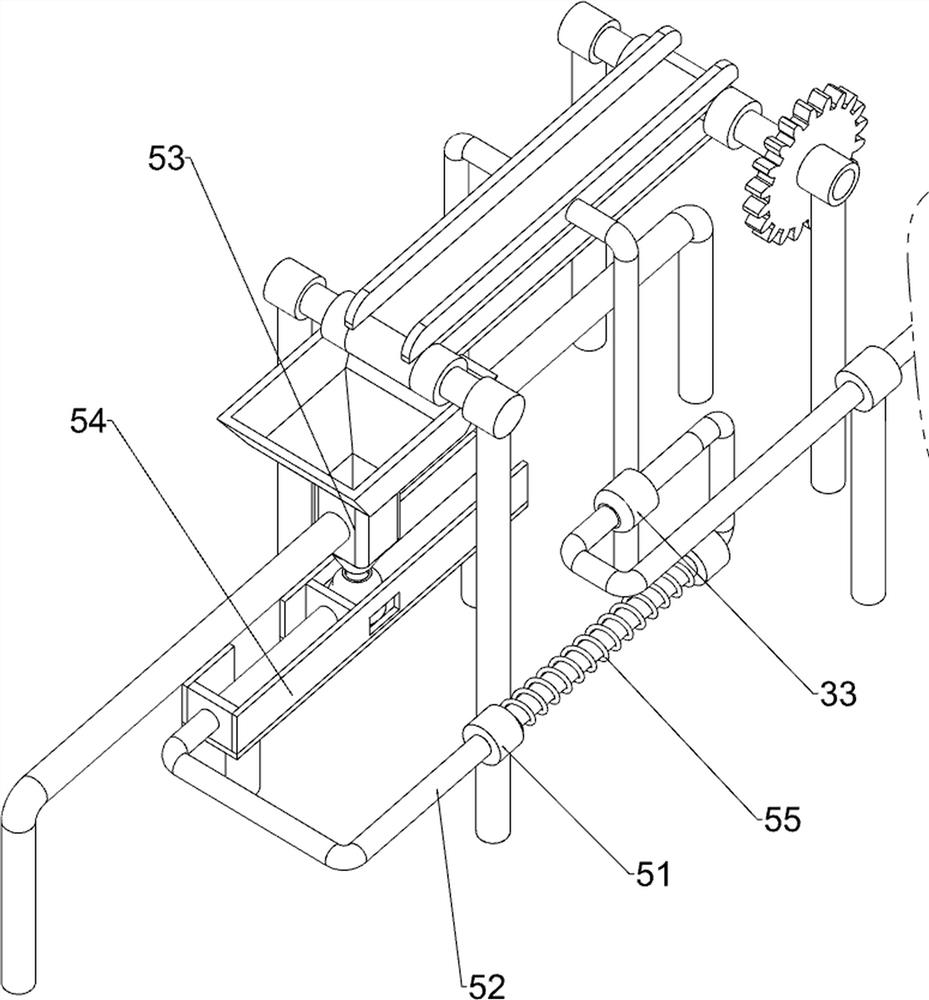

[0075] On the basis of Example 1, such as figure 2 with image 3 As shown, the intermittent blanking mechanism 2 includes a first support rod 21, a storage frame 22 and an intermittent blanking rotating wheel 23, the bottom plate 1 is provided with a first support rod 21 in the middle of the left and right sides, and the first support rods 21 in the left and right sides A storage frame 22 is connected between the tops of the support rods 21, and the right side of the bottom of the storage frame 22 is rotatably provided with an intermittent blanking rotating wheel 23.

[0076] People pour biocapsules into the storage frame 22, and some biocapsules fall into the intermittent feeding rotating wheel 23 due to gravity, and then people manually rotate the intermittent feeding rotating wheel 23, and the intermittent feeding rotating wheel 23 rotates 90% each time. At the same time, the biocapsules in the intermittent feeding rotating wheel 23 fall due to gravity, and people then ma...

Embodiment 3

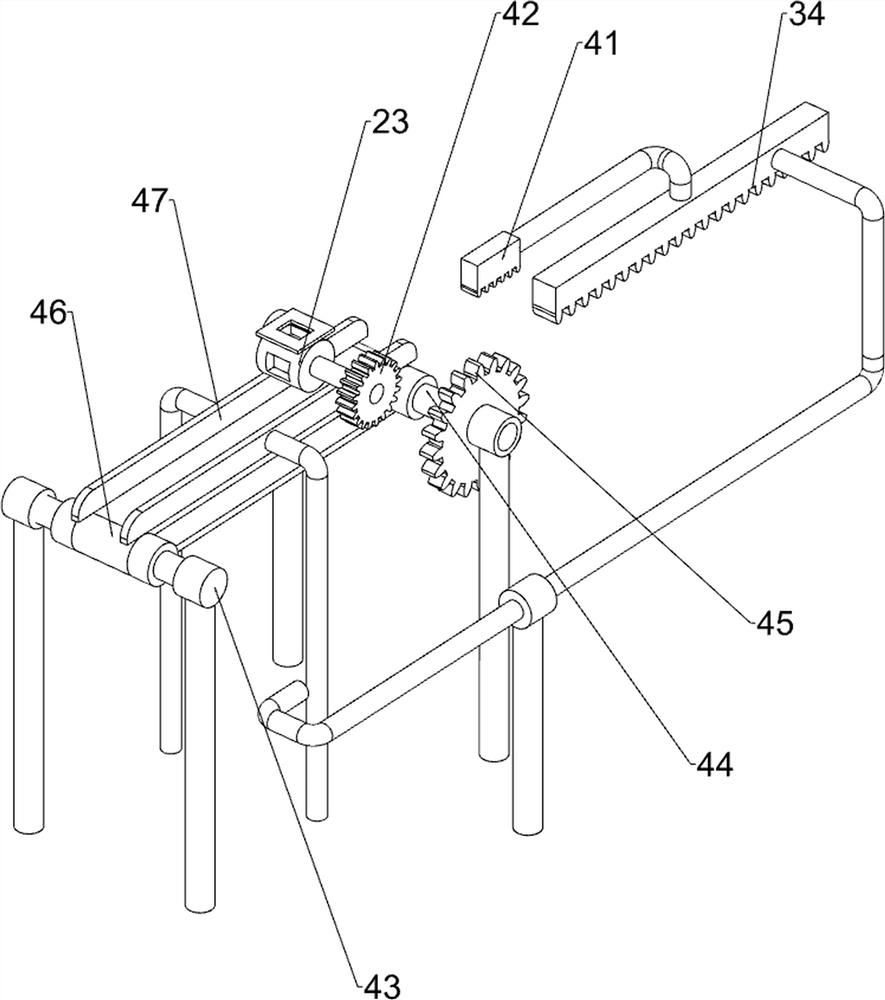

[0080] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, an automatic intermittent discharge transmission mechanism 4 is also included, and the automatic intermittent discharge transmission mechanism 4 includes a second rack 41, a first spur gear 42, a second support rod 43, a rotating shaft 44, a second spur gear 45, Transmission assembly 46 and baffle plate 47, first rack 34 top side middle part is provided with second rack 41, and the right side of intermittent blanking rotating wheel 23 is provided with first spur gear 42, and first spur gear 42 and second rack 41 meshing, the bottom plate 1 is provided with two second support rods 43 on the front and the middle, and a rotating shaft 44 is connected to the top of the second supporting rods 43 on the left and right sides, and the right part of the rotating shaft 44 on the rear side is provided with a second support rod 43. Two spur gears 45, the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com