Square wet tissue edge cutting equipment for wet tissue production

A wet tissue and square technology, applied in the field of square wet tissue trimming equipment for wet tissue production, can solve the problems of uneven, unsafe, time-consuming and laborious trimming, etc., and achieve the effect of consistent shape and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

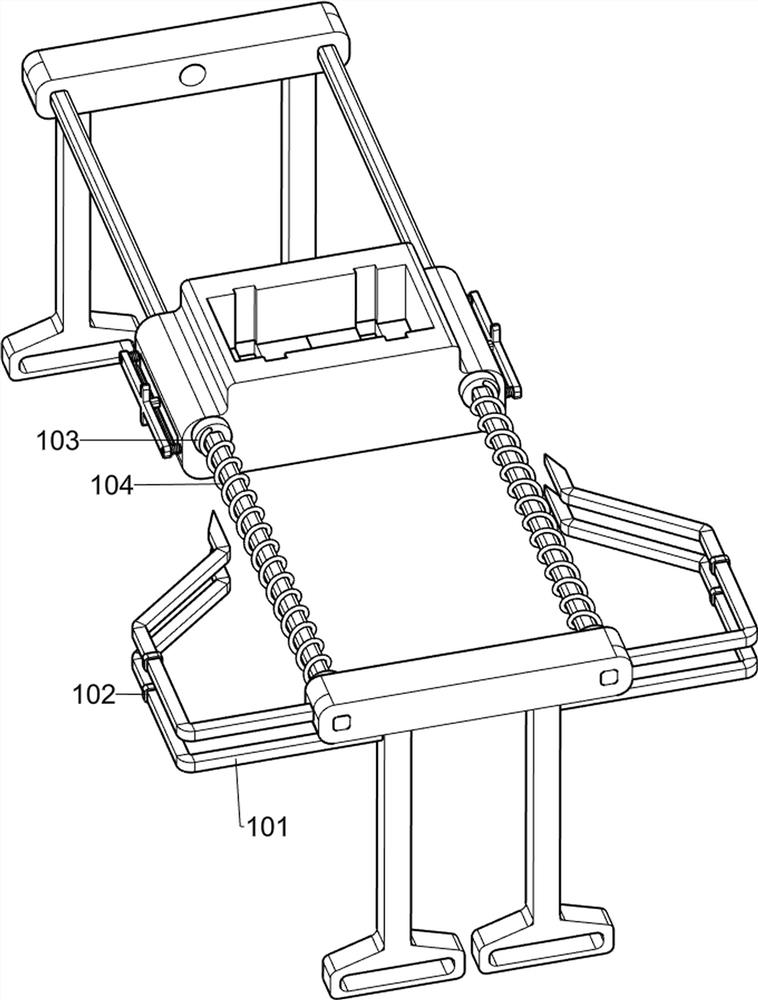

[0084] A square wet wipe trimming equipment for wet wipe production, such as figure 1 and figure 2 As shown, it includes a base 1, a bracket 2, a slide bar 3, a feeding mechanism 4 and a manual cutting mechanism 5. The left and right sides of the base 1 are provided with brackets 2, and two sliding rods are connected between the brackets 2 on the left and right sides. Bar 3, the sliding bar 3 on the front and rear sides is slidably connected with a discharge mechanism 4, and the upper middle part of the base 1 is provided with a manual cutting mechanism 5, and the manual cutting mechanism 5 cooperates with the discharge mechanism 4.

[0085] Manual operation is unsafe, time-consuming and labor-intensive, and the trimming is uneven. This equipment can automatically trim the edges, which is safe, time-saving and labor-saving, and the trimming is neat. First, people put paper towels in the discharging mechanism 4, and then the discharging mechanism 4 Slide to the right on the s...

Embodiment 2

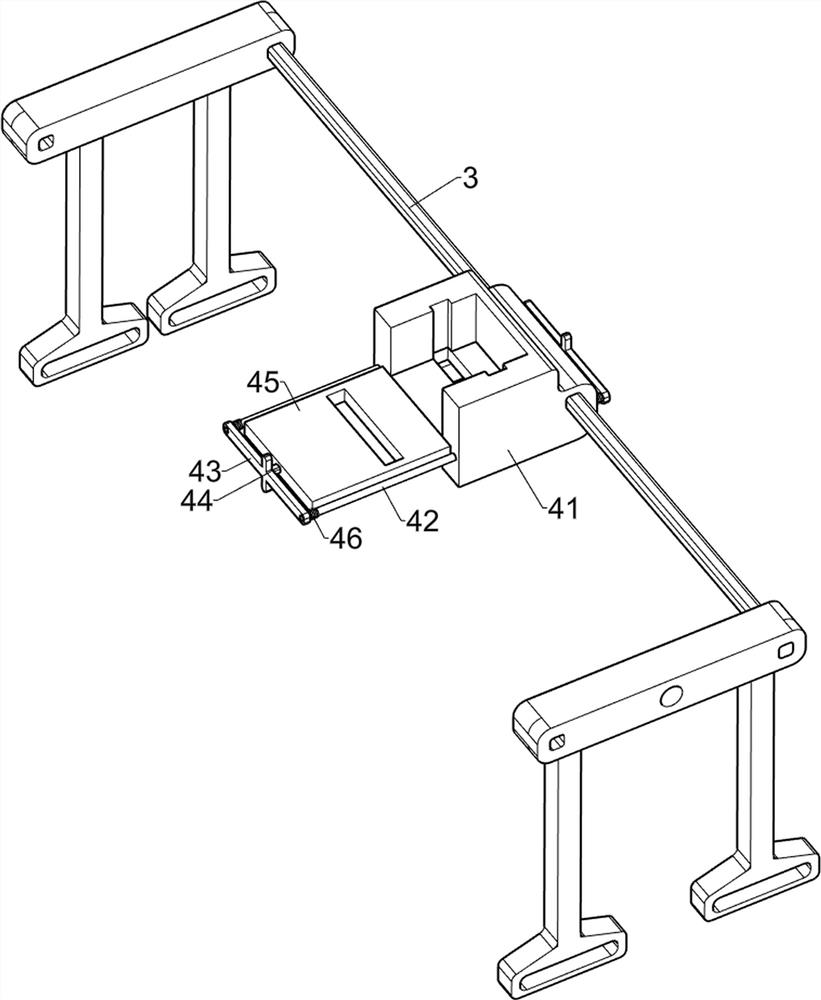

[0087] On the basis of Example 1, such as figure 2 and image 3 As shown, the feeding mechanism 4 includes a mechanism outer frame 41, a first guide rod 42, a cross connecting rod 43, a first connecting block 44, a placement plate 45 and a first spring 46, and the slide bars 3 on the front and rear sides are of sliding type. Connected with the mechanism outer frame 41, the front and rear sides of the lower side of the mechanism outer frame 41 are slidingly provided with a placement plate 45, and the placement plates 45 on the front and rear sides cooperate with each other, and the left and right sides of the lower side of the mechanism outer frame 41 are slidingly arranged. There are two first guide rods 42, the first guide rods 42 on the front and rear sides cooperate with each other, and the front middle part of the placement plate 45 on the front side and the rear side middle part of the placement plate 45 on the rear side are all provided with a first connecting block 44....

Embodiment 3

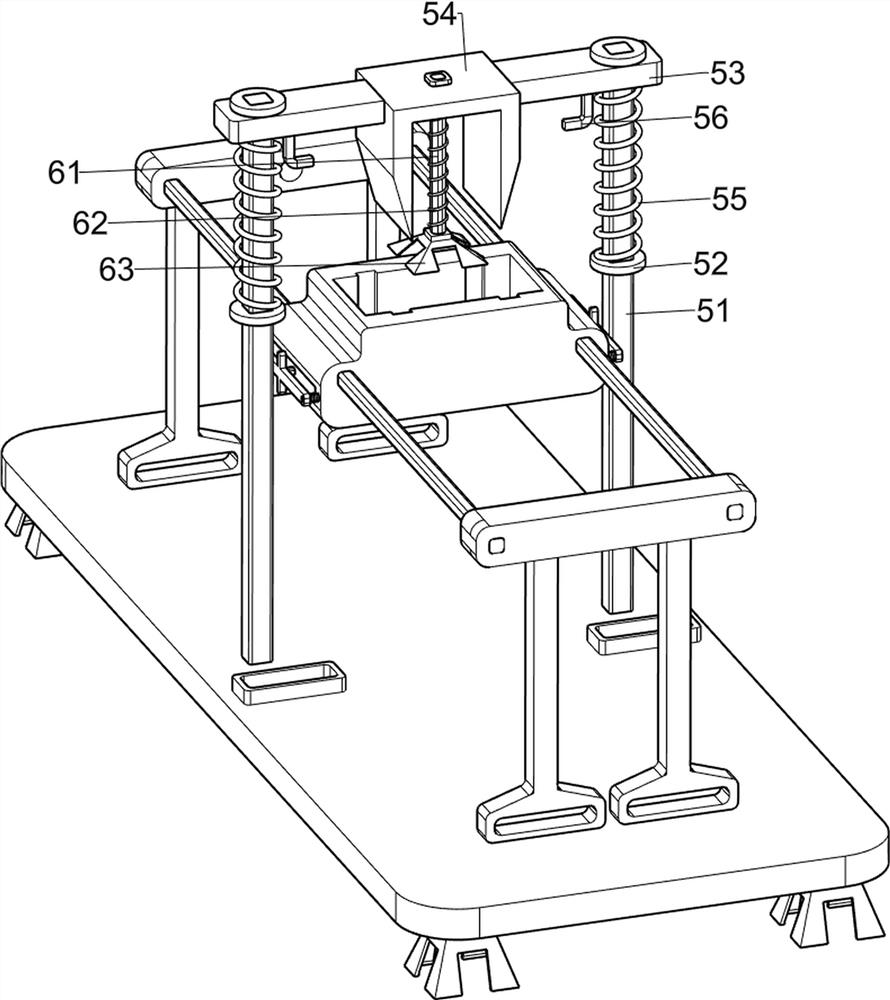

[0092] On the basis of Example 2, such as image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a pressing mechanism 6 is also included. The bottom of the cutter 54 is provided with a pressing mechanism 6. The pressing mechanism 6 cooperates with the placement plate 45. The pressing mechanism 6 includes a first connecting rod 61, a third spring 62 and a pressing mechanism. Block 63, cutter 54 bottom side middle part sliding type is provided with first connecting rod 61, and the bottom of first connecting rod 61 is provided with pressing block 63, is wound with the 3rd spring 62 on the first connecting rod 61, the 3rd spring 62 bottom and The pressing block 63 is connected, and the top of the third spring 62 is connected with the cutter 54 .

[0093]When the cutter 54 moves downward, the cutter 54 drives the first connecting rod 61 to move downward, thereby driving the third spring 62 and the pressing block 63 to move downward, and the cutter 54 gradually mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com