Pharmacy department granular medicine crushing and mixing equipment

A technology of mixing equipment and granules, applied in the fields of mixers, grain processing, chemical/physical processes, etc., can solve the problems of low production efficiency of mixed powder, inability to automatically unload and discharge materials, etc., so as to improve production efficiency and shorten work. The effect of time-consuming and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

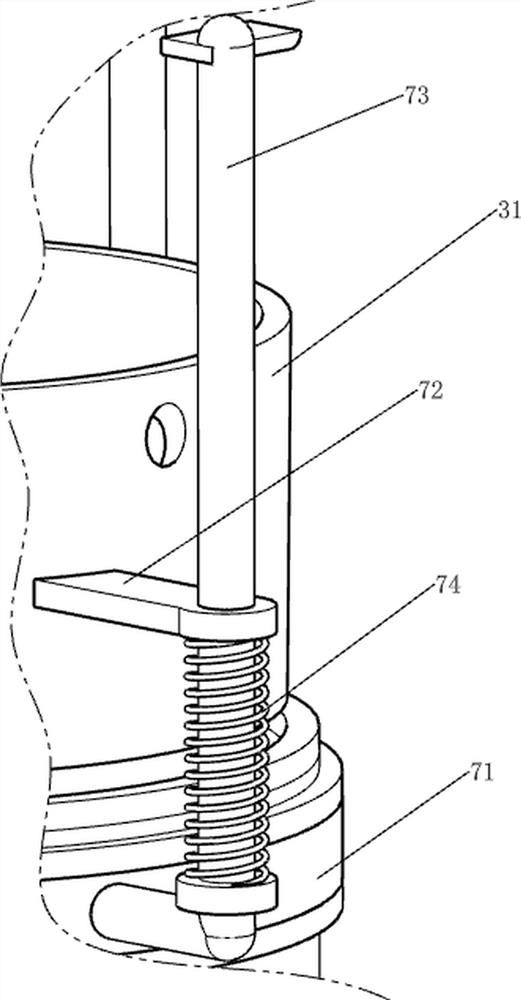

[0071] A granule drug crushing and mixing equipment used in pharmacy, such as figure 1As shown, it includes a fixed plate 1, a fixed frame 2, a stirring mechanism 3 and a crushing mechanism 4. The top of the fixed plate 1 is provided with three fixed frames 2, and the inner side of the top of the three fixed frames 2 is provided with a stirring mechanism 3, and the upper part of the stirring mechanism 3 is provided with There is a crushing mechanism4.

[0072] When people make mixed medicine powder, the work efficiency is low. The present invention helps people to increase the speed of making and mixing medicine powder. First, the tablet is placed in the crushing mechanism 4, and after the stirring mechanism 3 is started, the stirring mechanism 3 drives the crushing mechanism 4 to run. The mechanism 4 pulverizes the tablet into medicine powder, and the medicine powder falls into the mixing mechanism 3 due to gravity, and then the different drug powders are mixed evenly through...

Embodiment 2

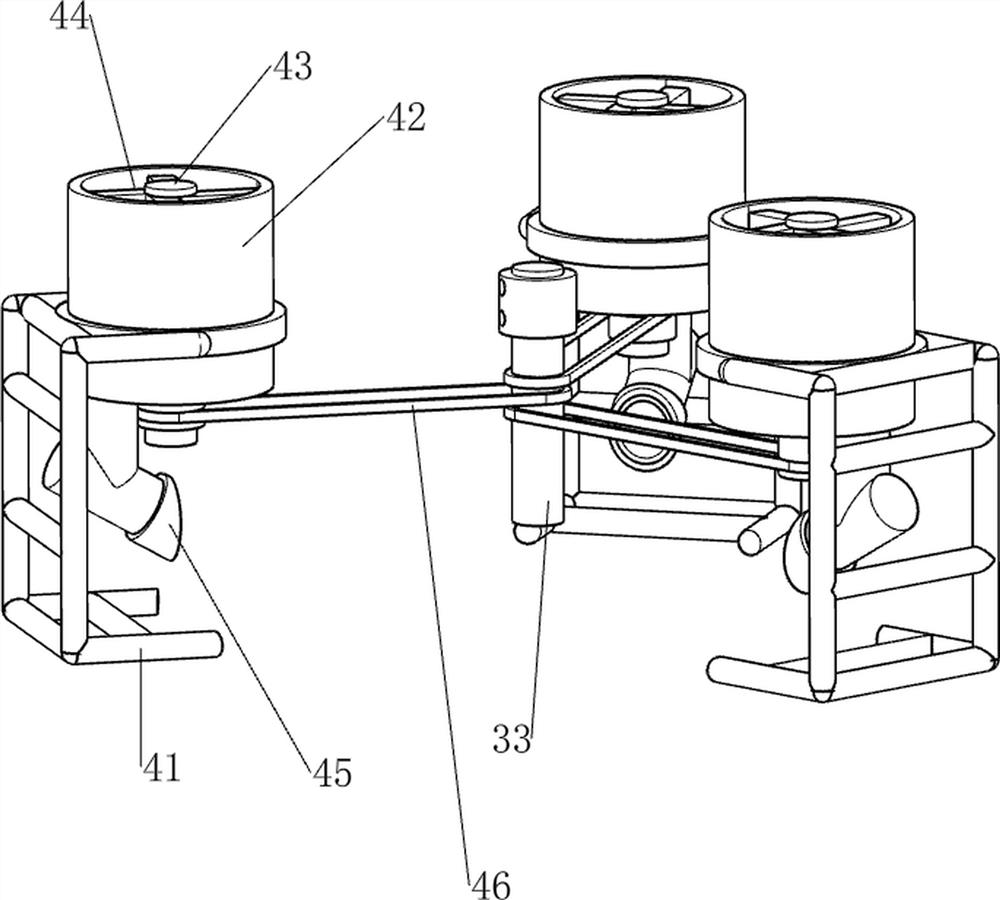

[0074] On the basis of Example 1, such as figure 2 , image 3 with Figure 4 As shown, the stirring mechanism 3 includes a material holding cylinder 31, a motor 32, a first transmission shaft 33, a first pulley assembly 34, a stirring plate 35, a swinging small plate 36, a first torsion spring 37, connecting stubs 38 and hard Rope 39, the inner side of three fixed mounts 2 tops is provided with material-filling cylinder 31, and the left part of material-filling cylinder 31 is equipped with motor 32, and the material-filling cylinder 31 is connected with the output shaft of motor 32 rotationally, and the middle part of material-filling cylinder 31 The rotary type is provided with a first transmission shaft 33, a first pulley assembly 34 is connected between the first transmission shaft 33 and the output shaft of the motor 32, and two stirring plates 35 are arranged in the middle of the first transmission shaft 33, and the stirring plates 35 are located In the cylinder 31, fo...

Embodiment 3

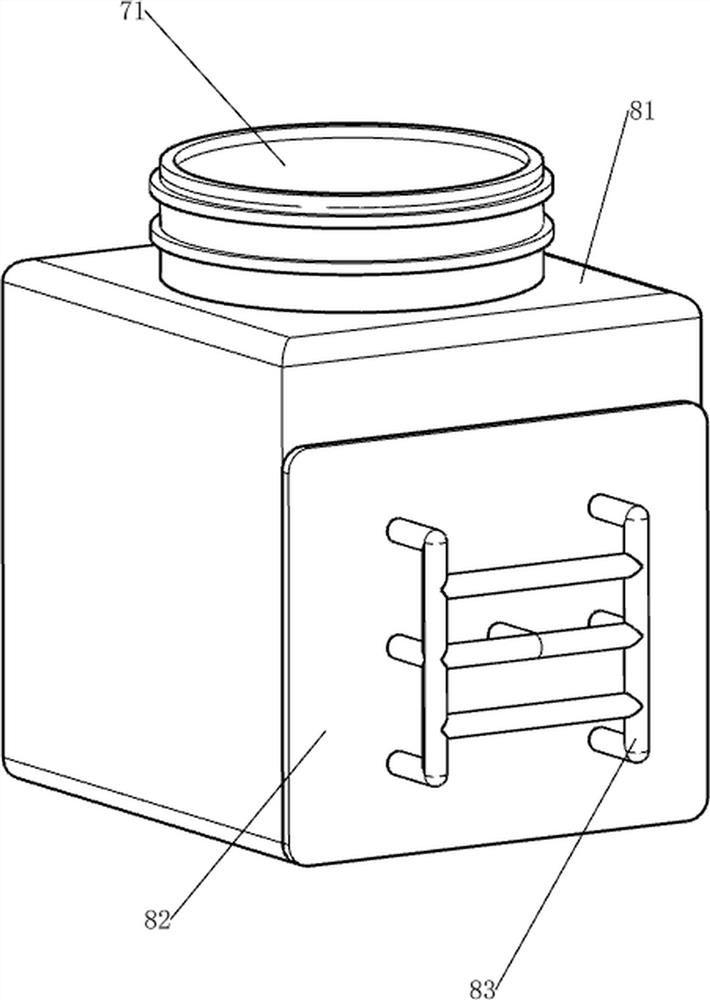

[0079] On the basis of Example 2, such as figure 1 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a primary feeding mechanism 5 is also included. The top of the mixing mechanism 3 is provided with a primary feeding mechanism 5. The primary feeding mechanism 5 is connected with the crushing mechanism 4. The primary feeding mechanism 5 includes a thick connecting column 51, a vat 52, Coarse discharge port 53 and cover 54, three coarse connection columns 51 are arranged on the upper part of the material storage cylinder 31, and a vat 52 is connected to the inner side of the upper part of the three coarse connection columns 51, and three coarse discharge ports 53 are evenly arranged on the bottom of the vat 52, and the coarse The discharge port 53 is connected with the small cylinder 42, and a lid 54 is placed on the top of the vat 52.

[0080] Three spaces for placing tablets are isolated in the vat 52. People can open the cover 54 before turning on the motor 32,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com