Bottom cover pressing equipment based on electronic cigarette battery production

A technology of pressing equipment and electronic cigarettes, which is applied in the directions of tobacco, pipe, and application, can solve the problems of easy increase of people's labor and low work efficiency, and achieve the effects of reducing labor intensity, improving efficiency and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

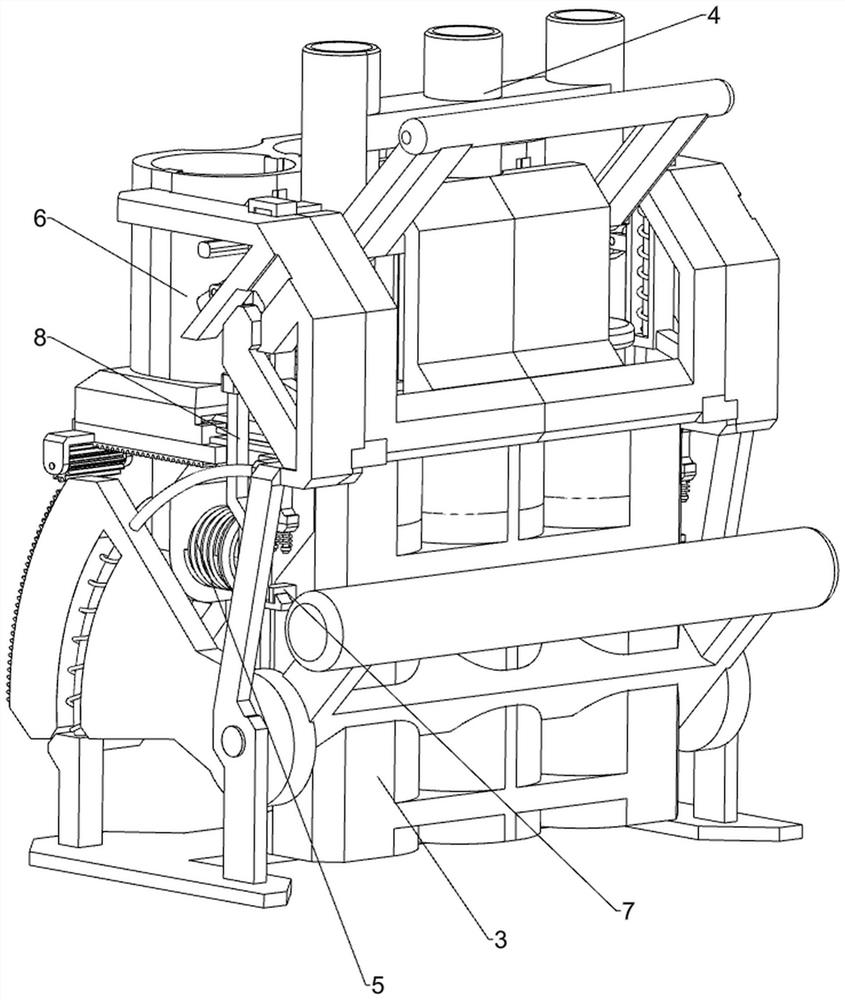

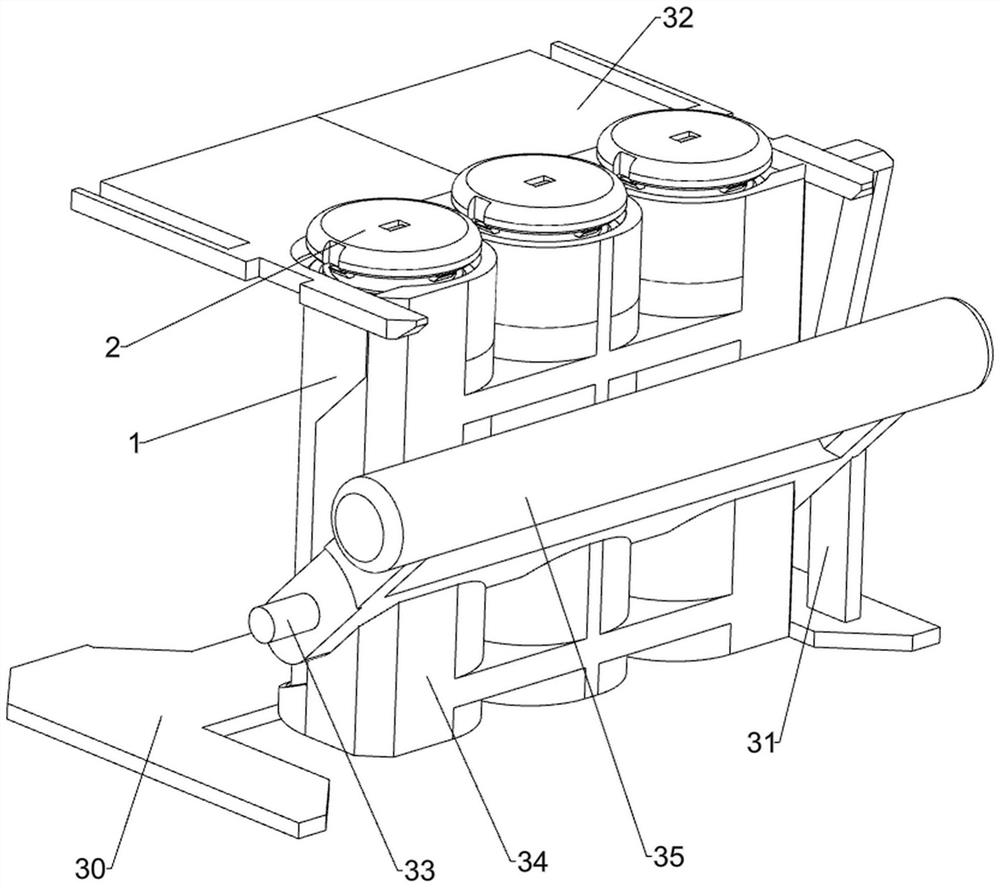

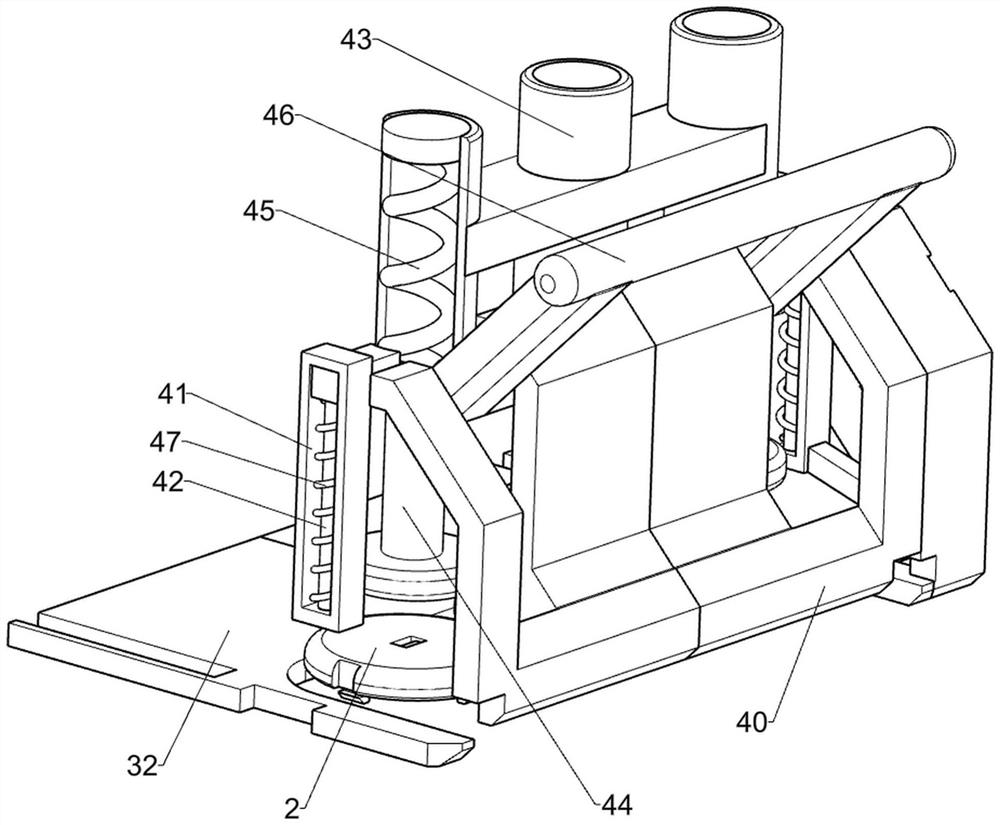

[0028] A pressing device for bottom cover production based on e-cigarette batteries, such as figure 1 , figure 2 and image 3 As shown, it includes an electronic cigarette case 1, a cover 2, a placement mechanism 3 and a capping mechanism 4. There are three electronic cigarette cases 1, and the top of the electronic cigarette case 1 is provided with a sliding cover 2, and between the electronic cigarette cases 1 there are The placing mechanism 3 is provided with a capping mechanism 4 on the placing mechanism 3 .

[0029] The placing mechanism 3 includes a bottom plate 30, a first support block 31, a placing plate 32, a first rotating rod 33, a placing block 34 and a handle 35. There is a placing block 34 between the right side of the bottom of the electronic cigarette case 1, and the bottom of the placing block 34 A base plate 30 is placed, and the top right side of the base plate 30 is symmetrically provided with a first support block 31 front and back, and a placement pla...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a clamping assembly 5 is also included, and the clamping assembly 5 includes a third support block 50, a second guide rod 51, a clamping block 52, a second rotating rod 53, a first torsion spring 54 and a third spring 55 , the left side of the bottom of the placement plate 32 is provided with a third support block 50, and the inner side of the third support block 50 is provided with a second guide rod 51 which slides forward and backward symmetrically, and the right side of the second guide rod 51 is provided with a second rotating rod 53 , a clamping block 52 is arranged between the second rotating rod 53, a first torsion spring 54 is arranged symmetrically between the clamping block 52 and the second guide rod 51, and the first torsion spring 54 is set on the second rotating rod 53 Above, a third spring 55 is provided between the third support block 50 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com