Patents

Literature

88results about How to "Improve capping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

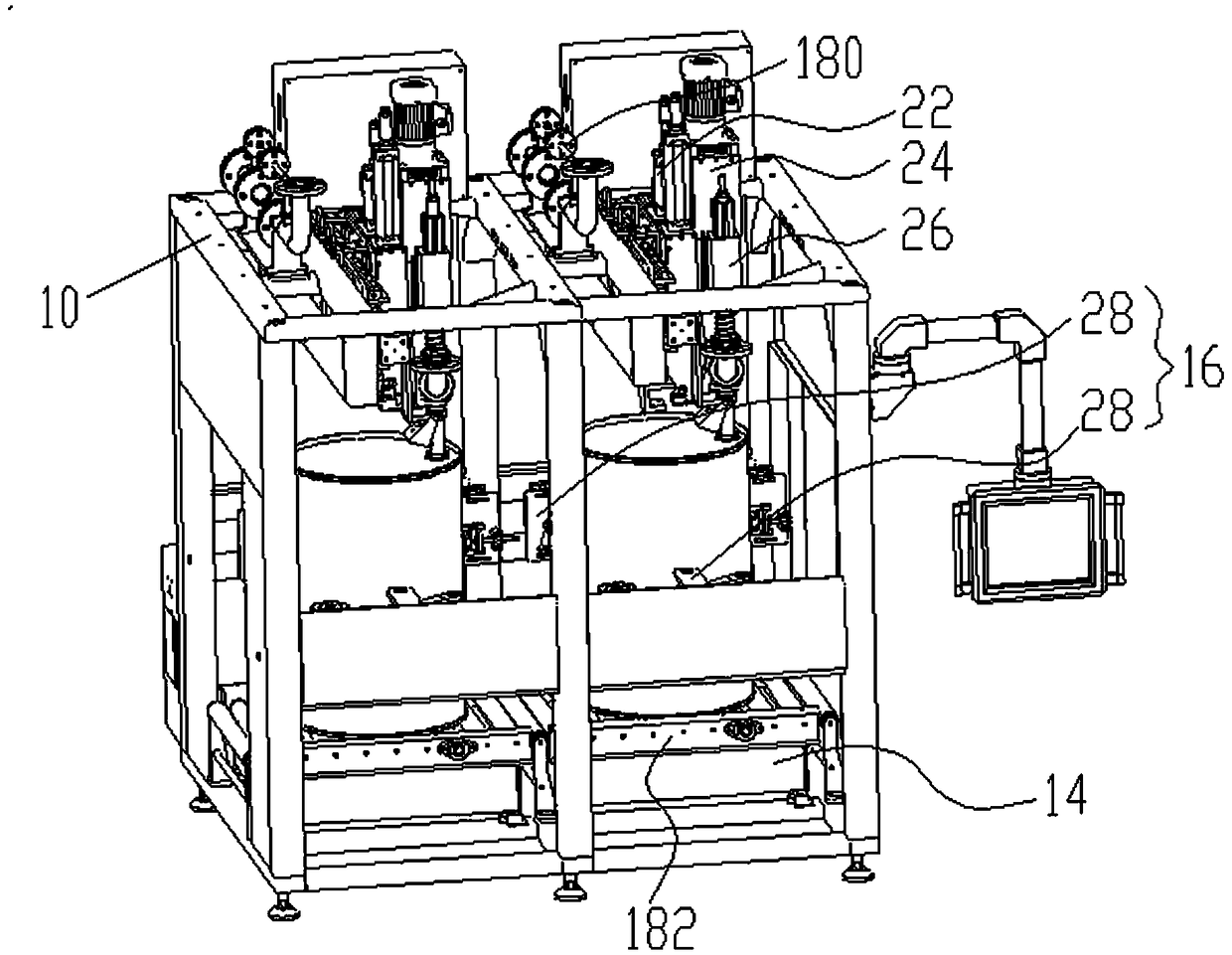

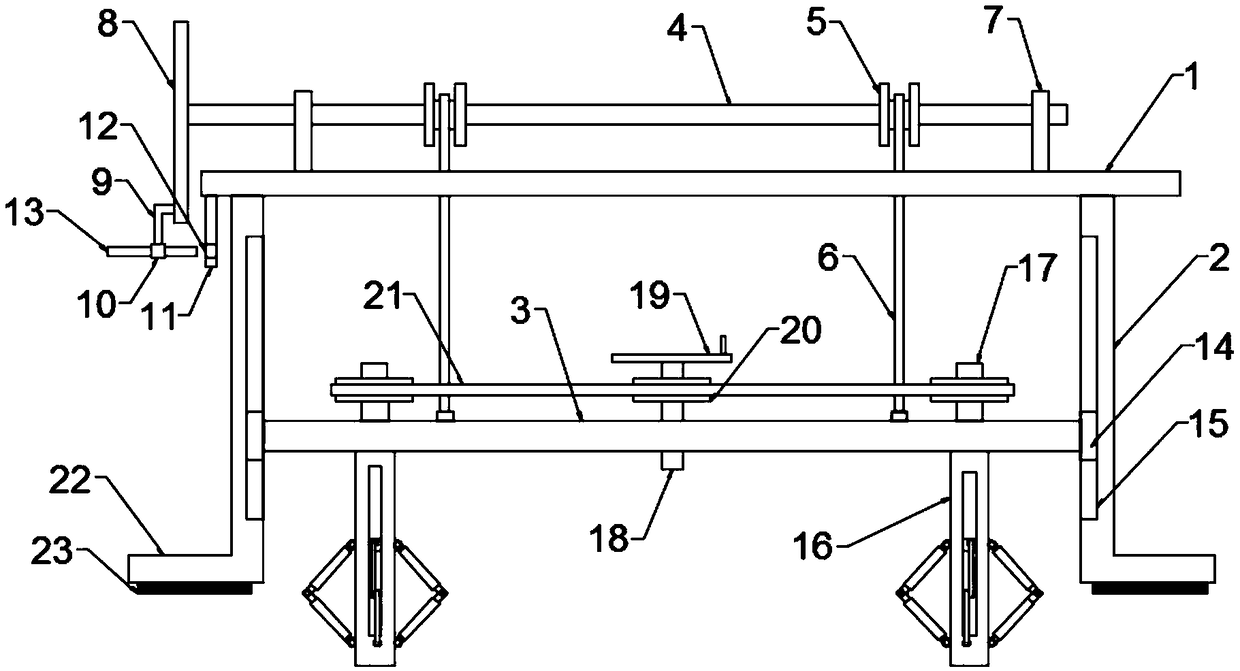

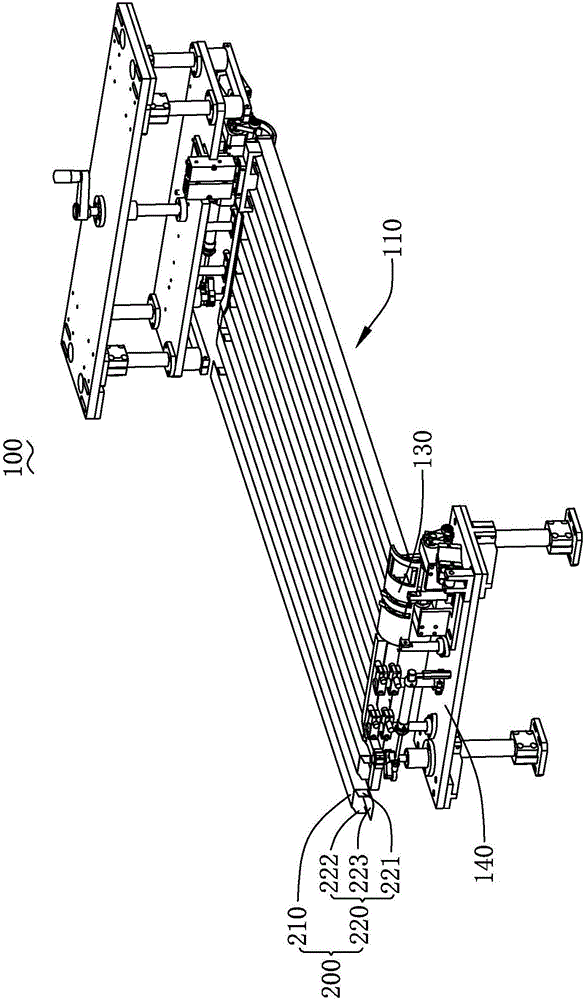

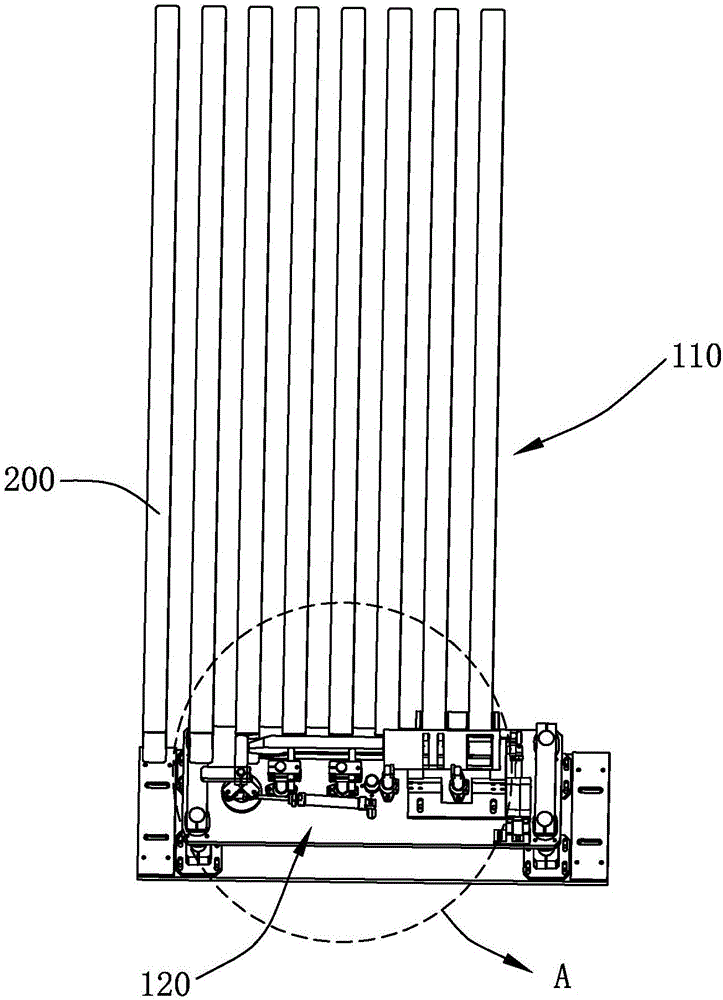

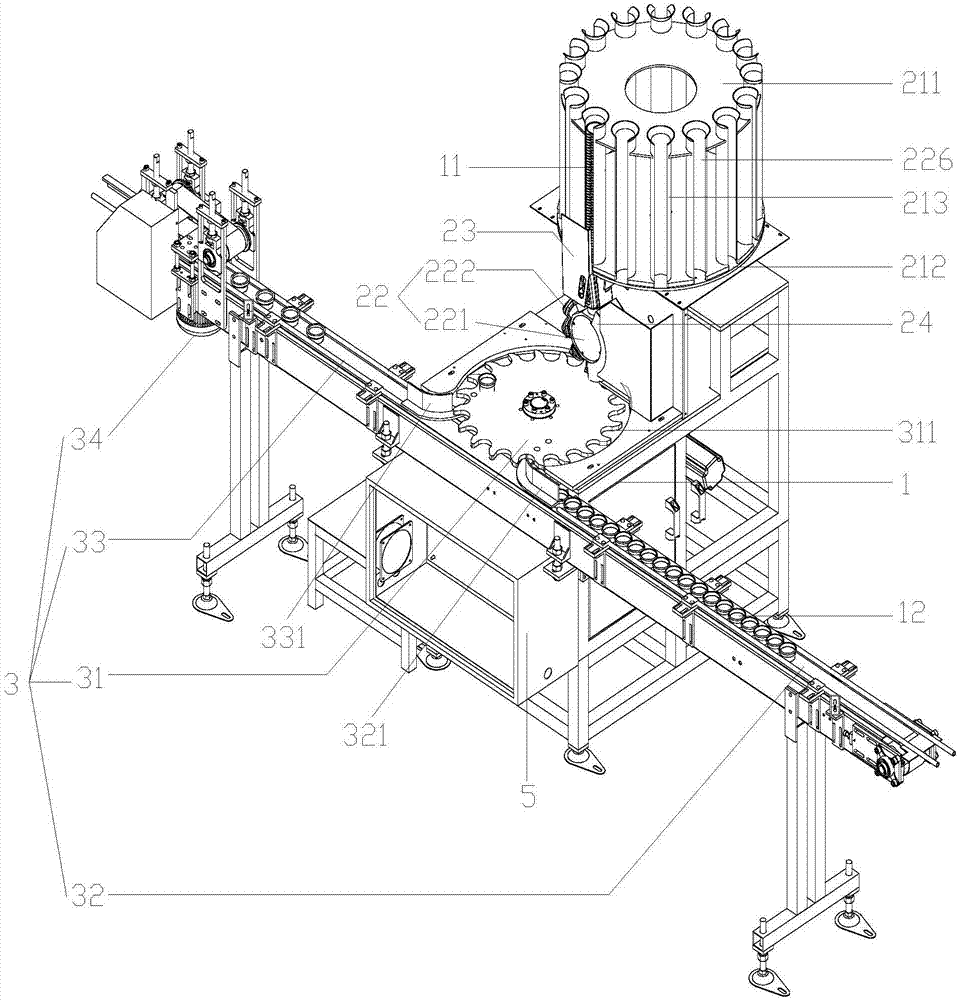

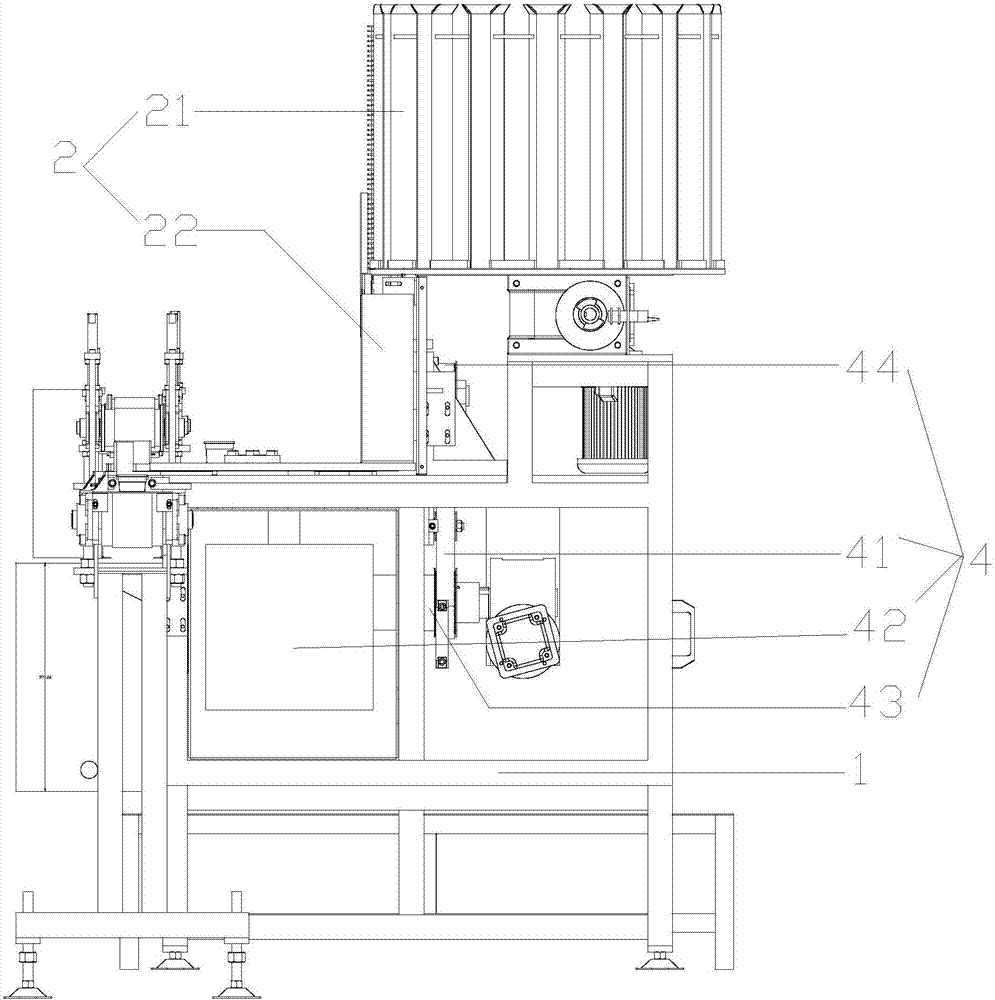

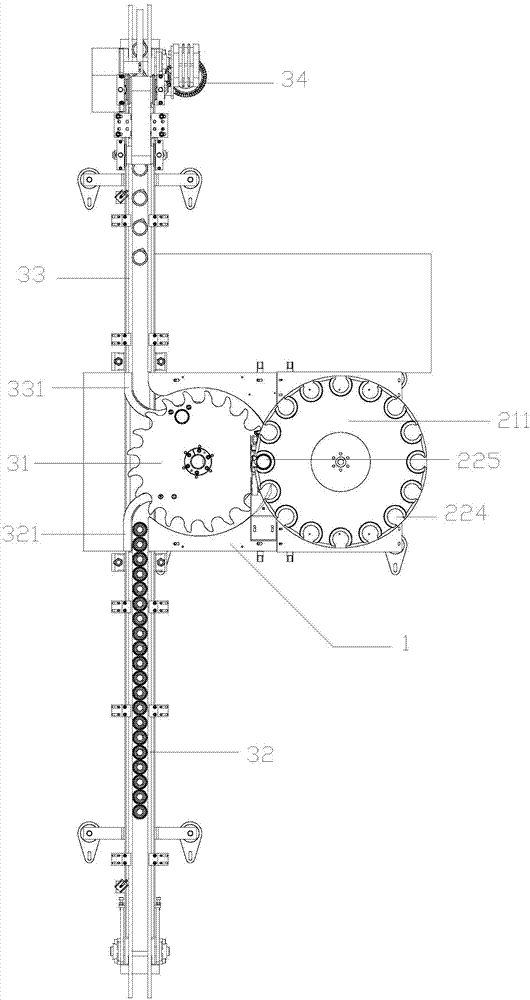

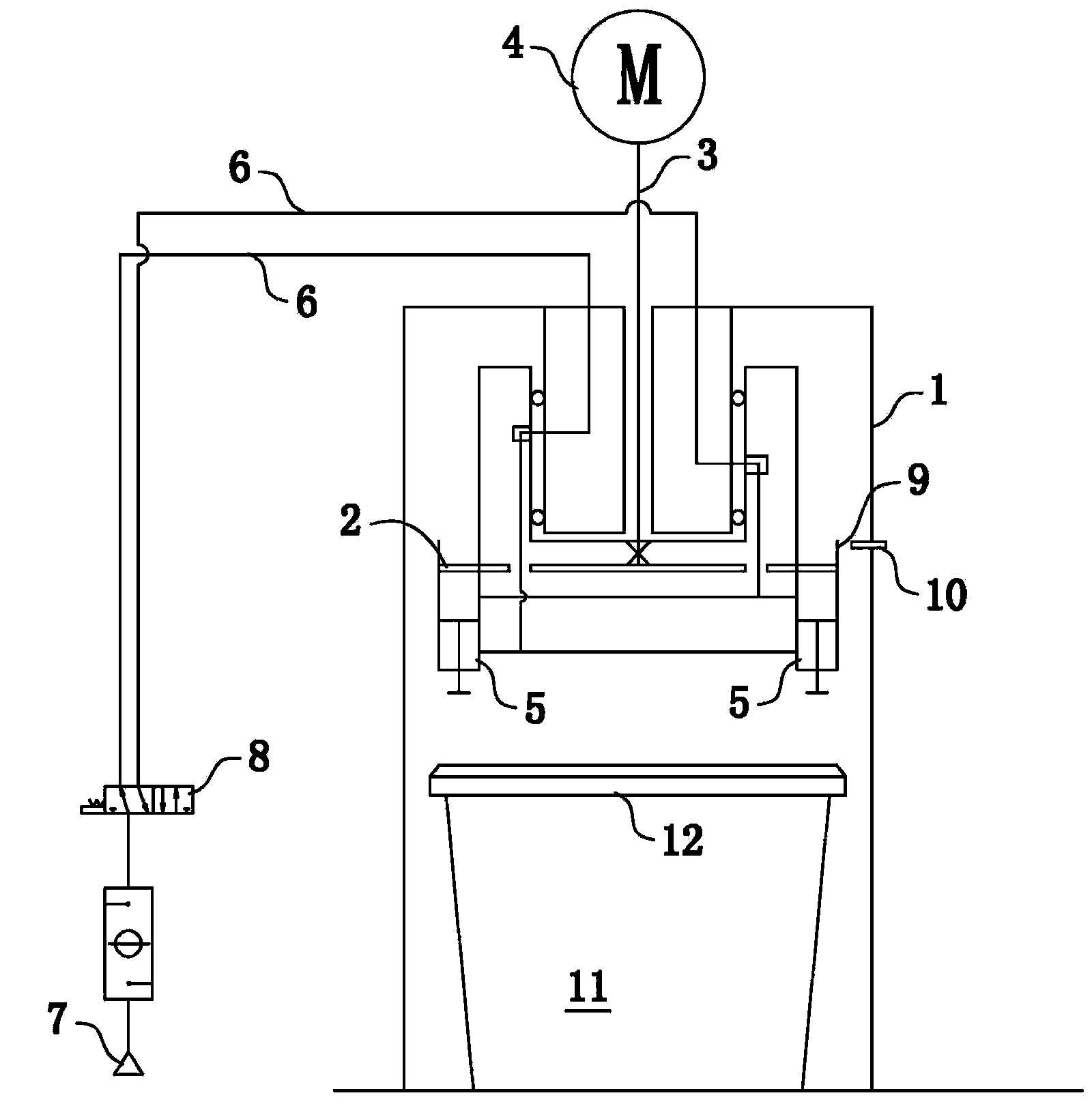

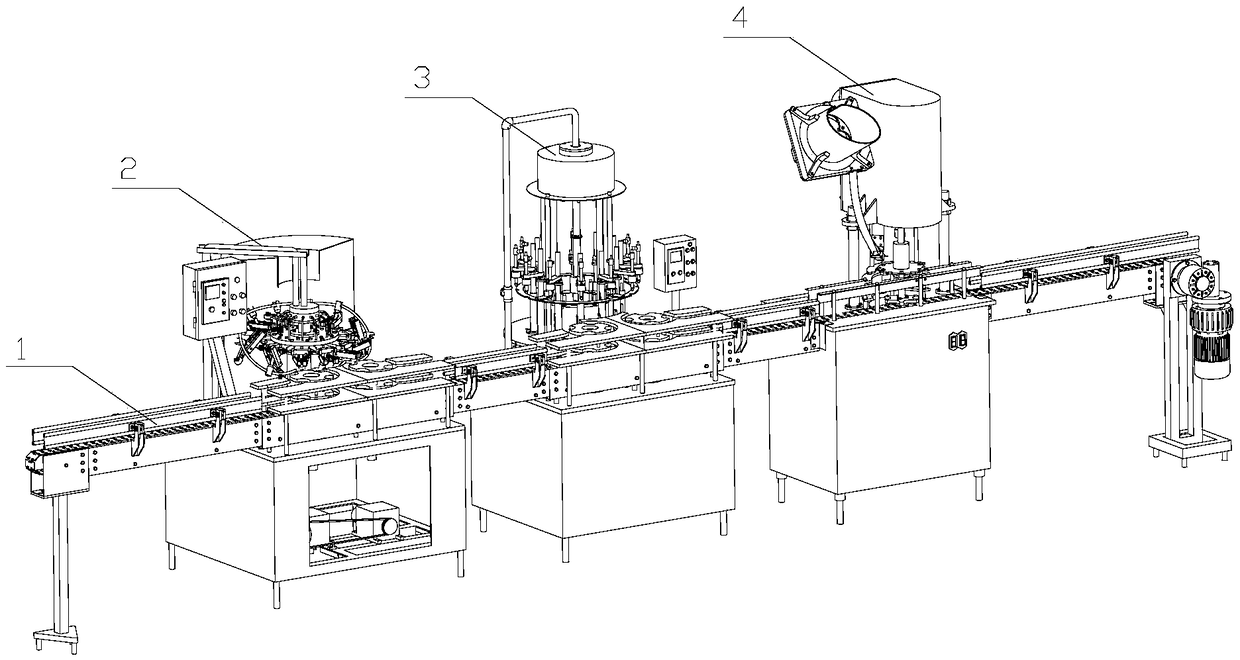

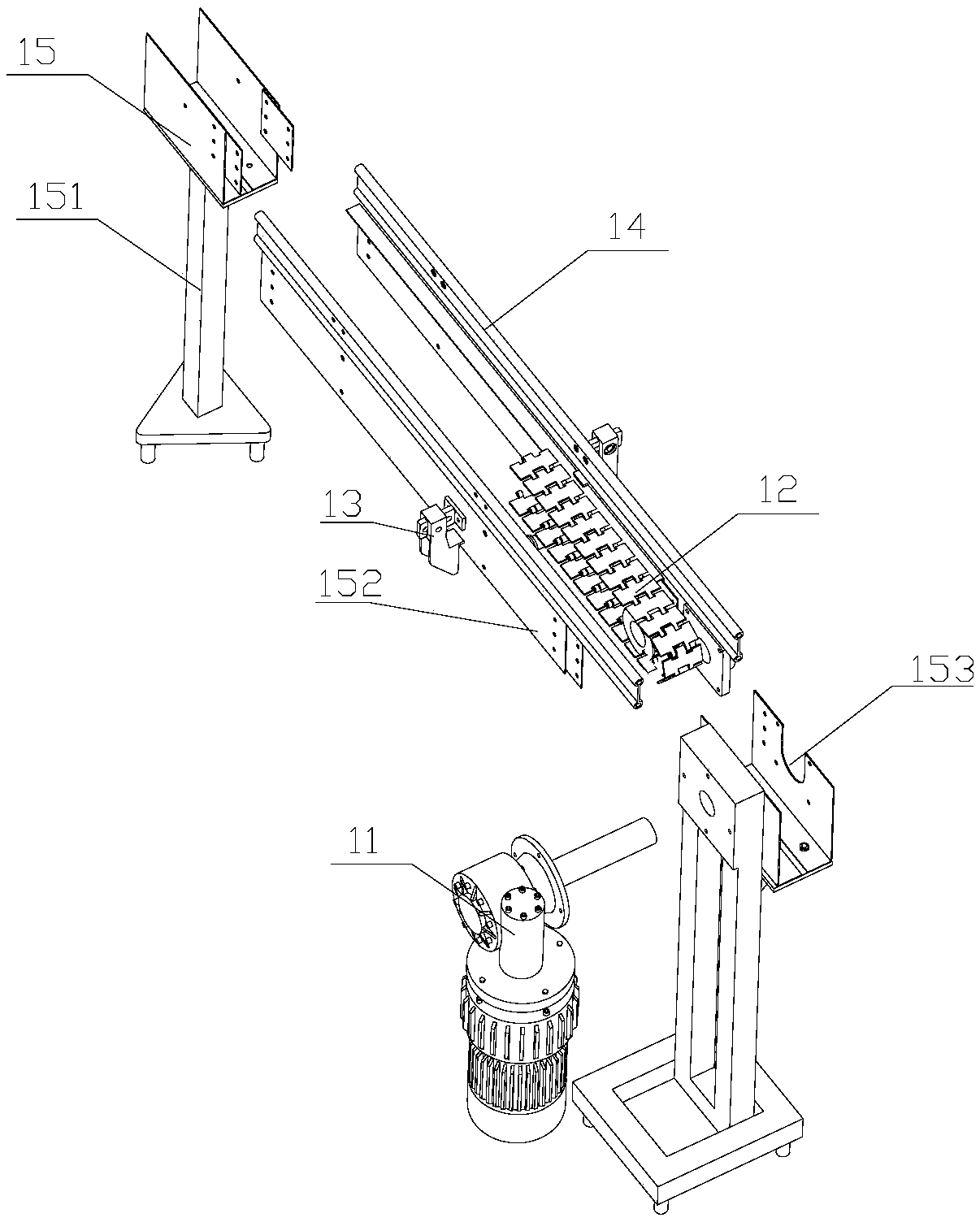

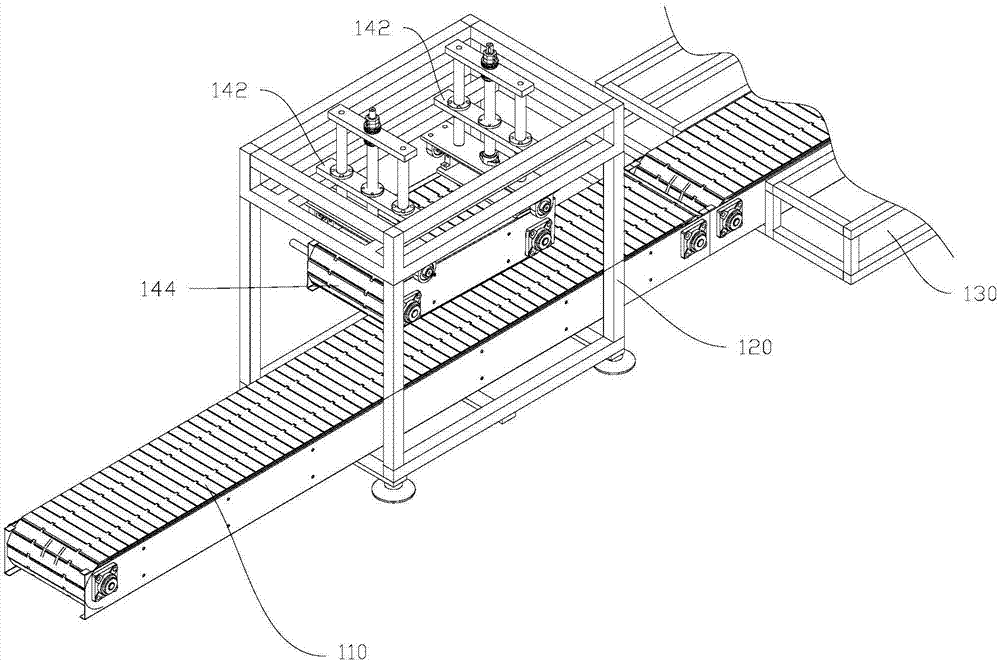

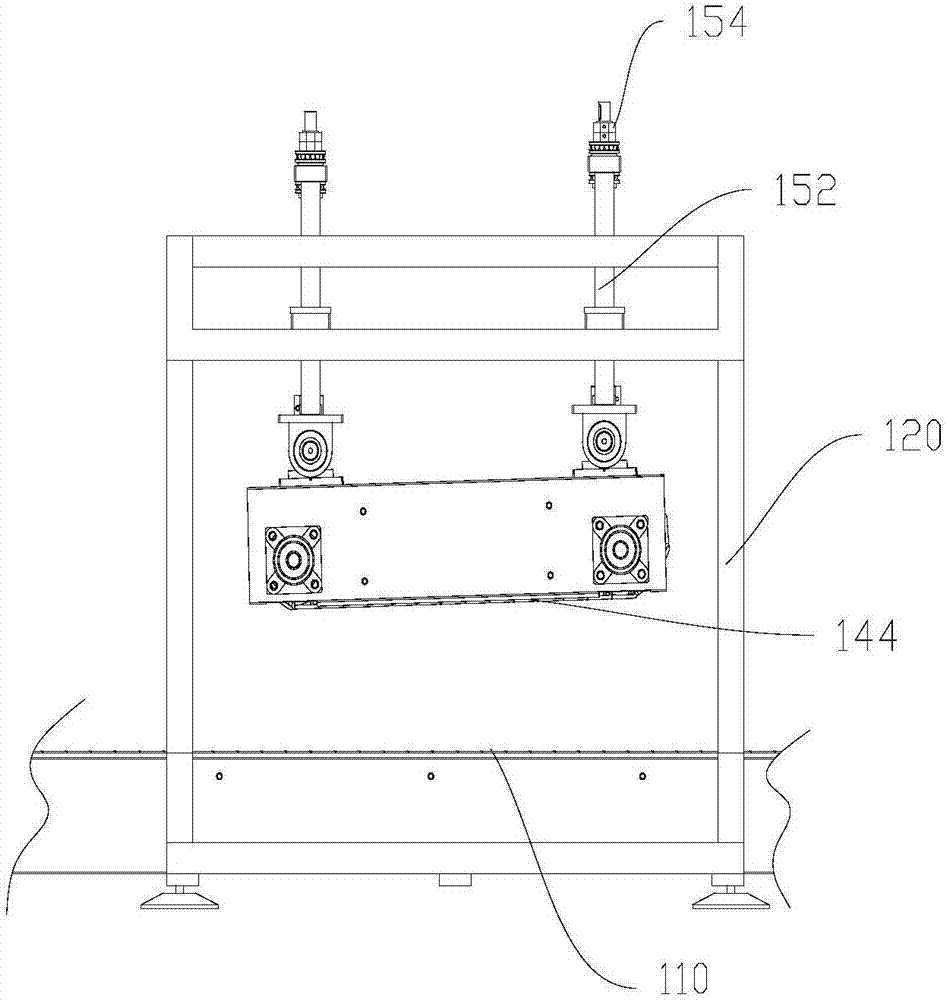

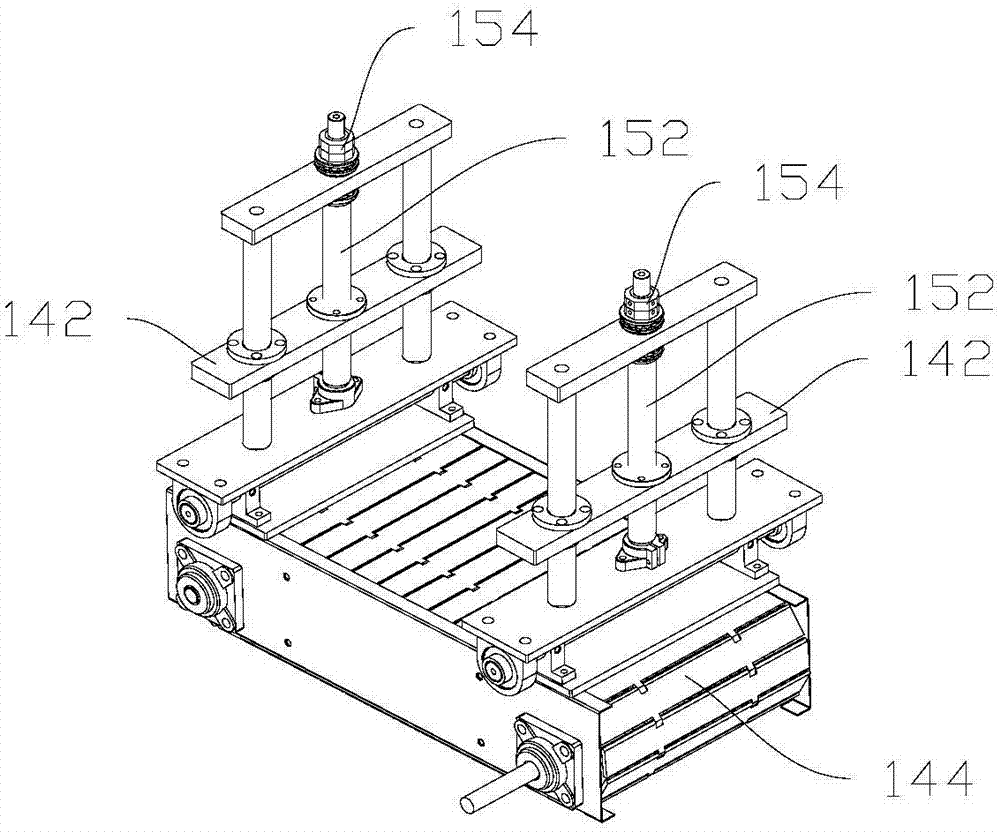

Automatic capping machine

InactiveCN103318820ANo human intervention requiredImprove capping efficiencyFlanged caps applicationConveyor partsControl systemMan machine

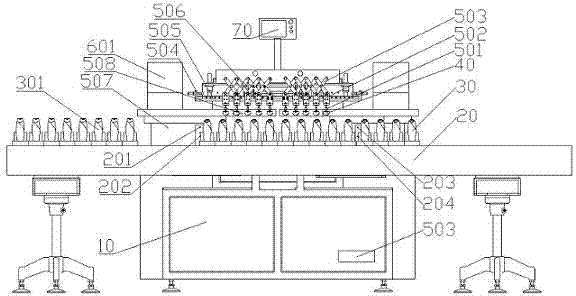

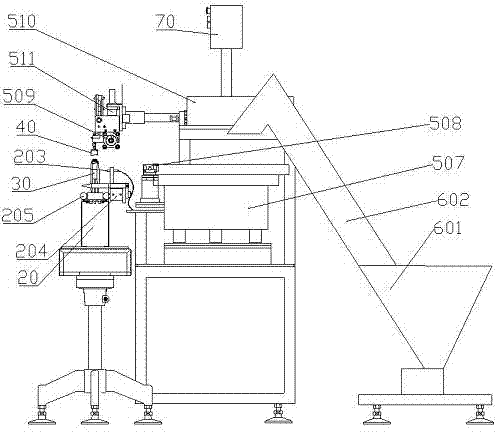

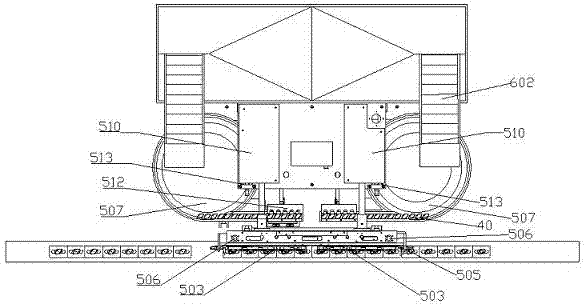

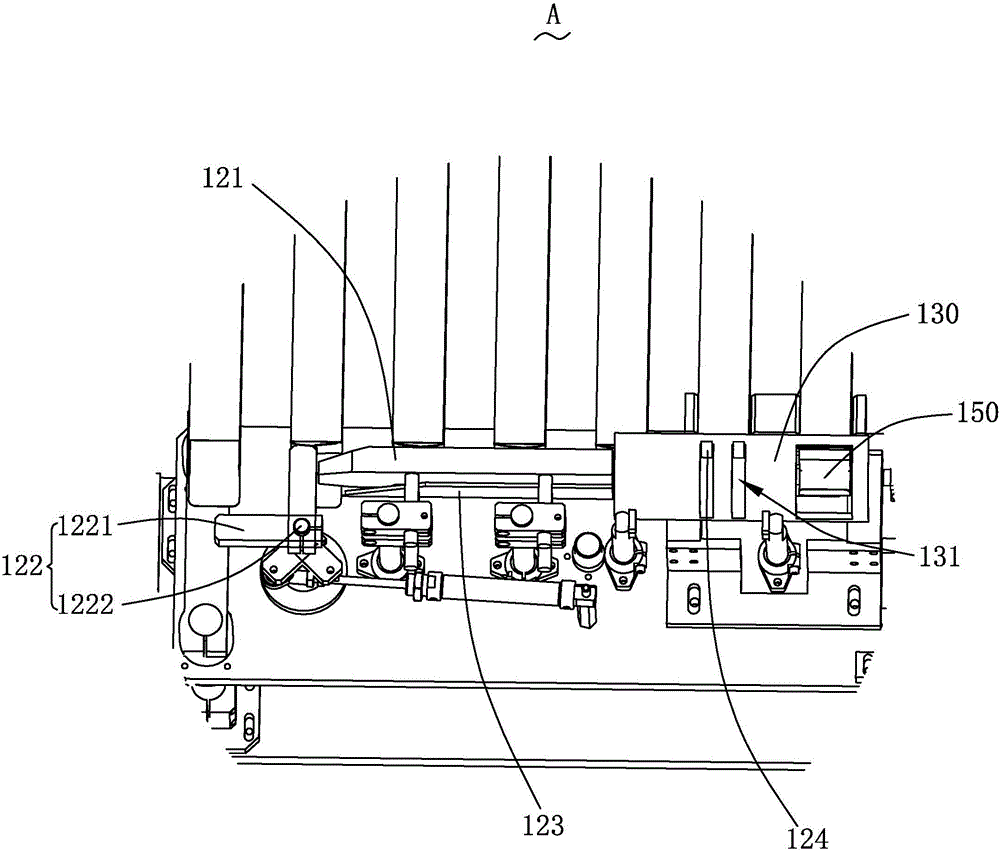

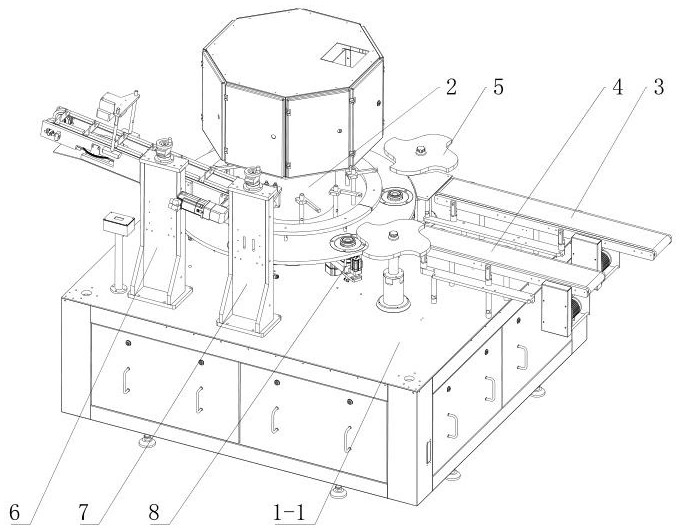

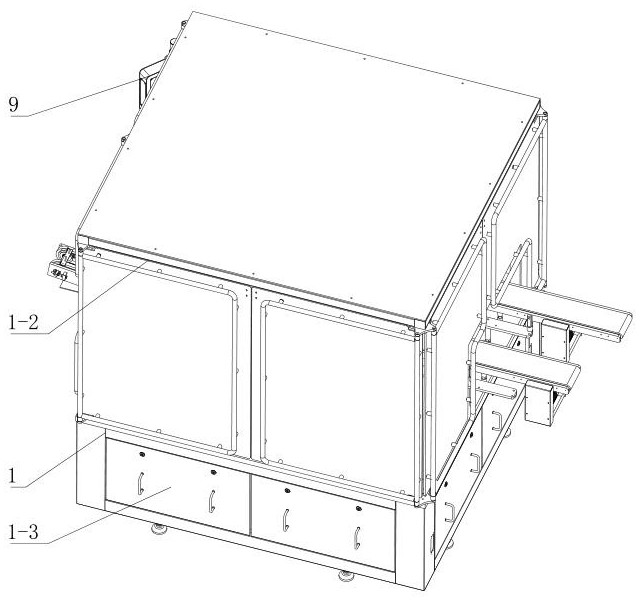

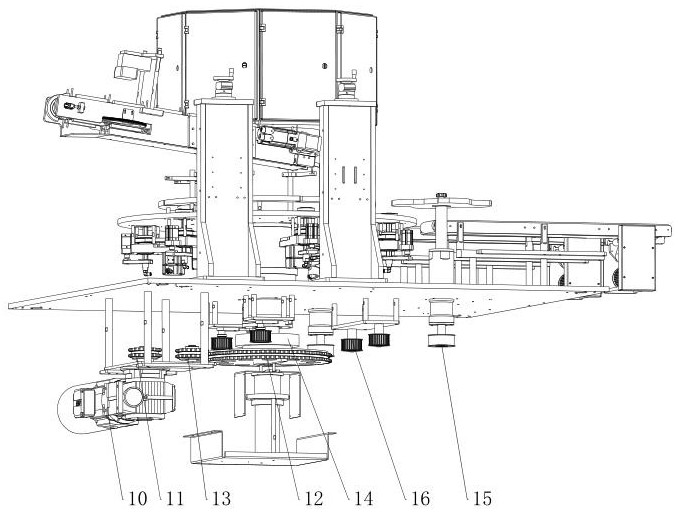

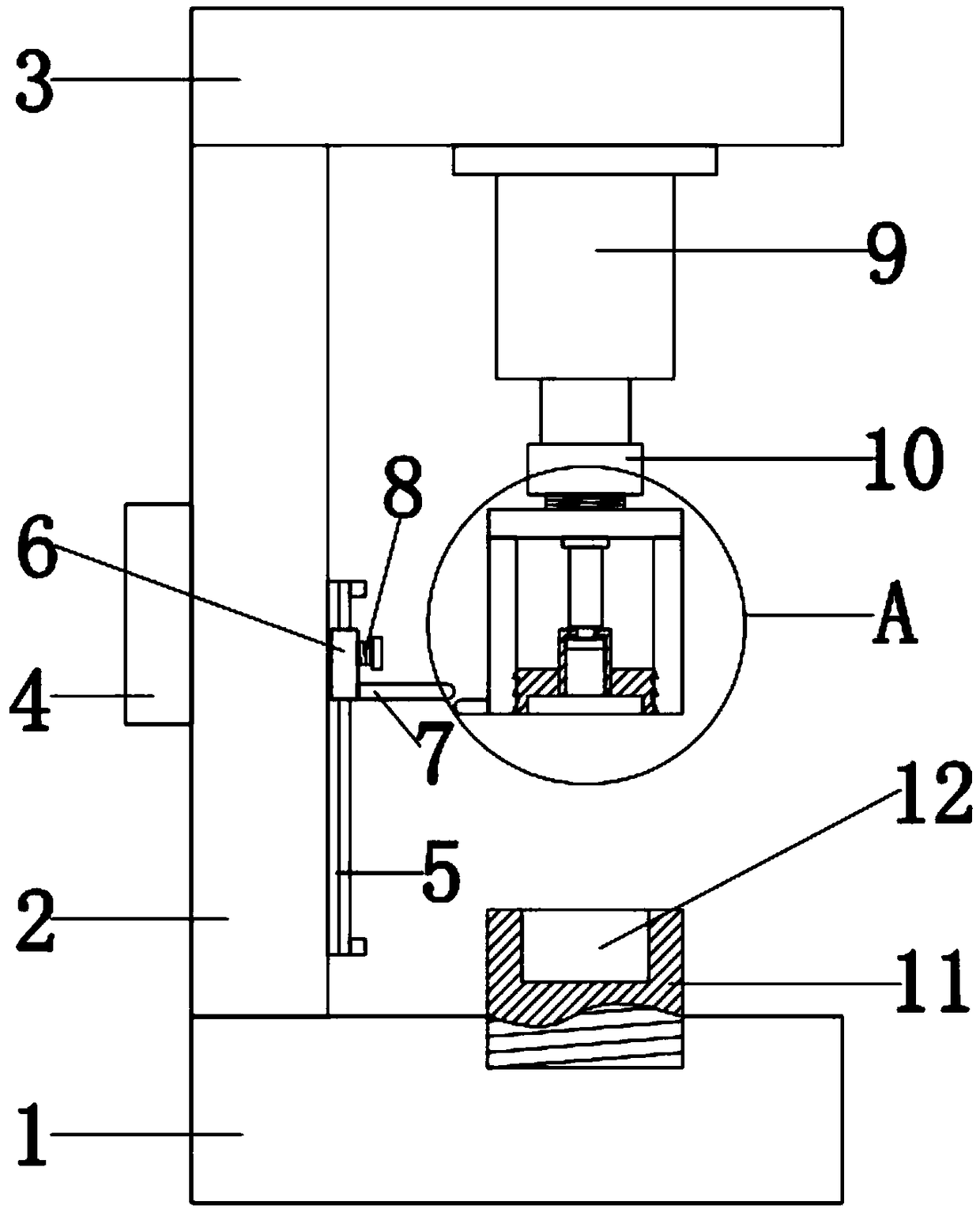

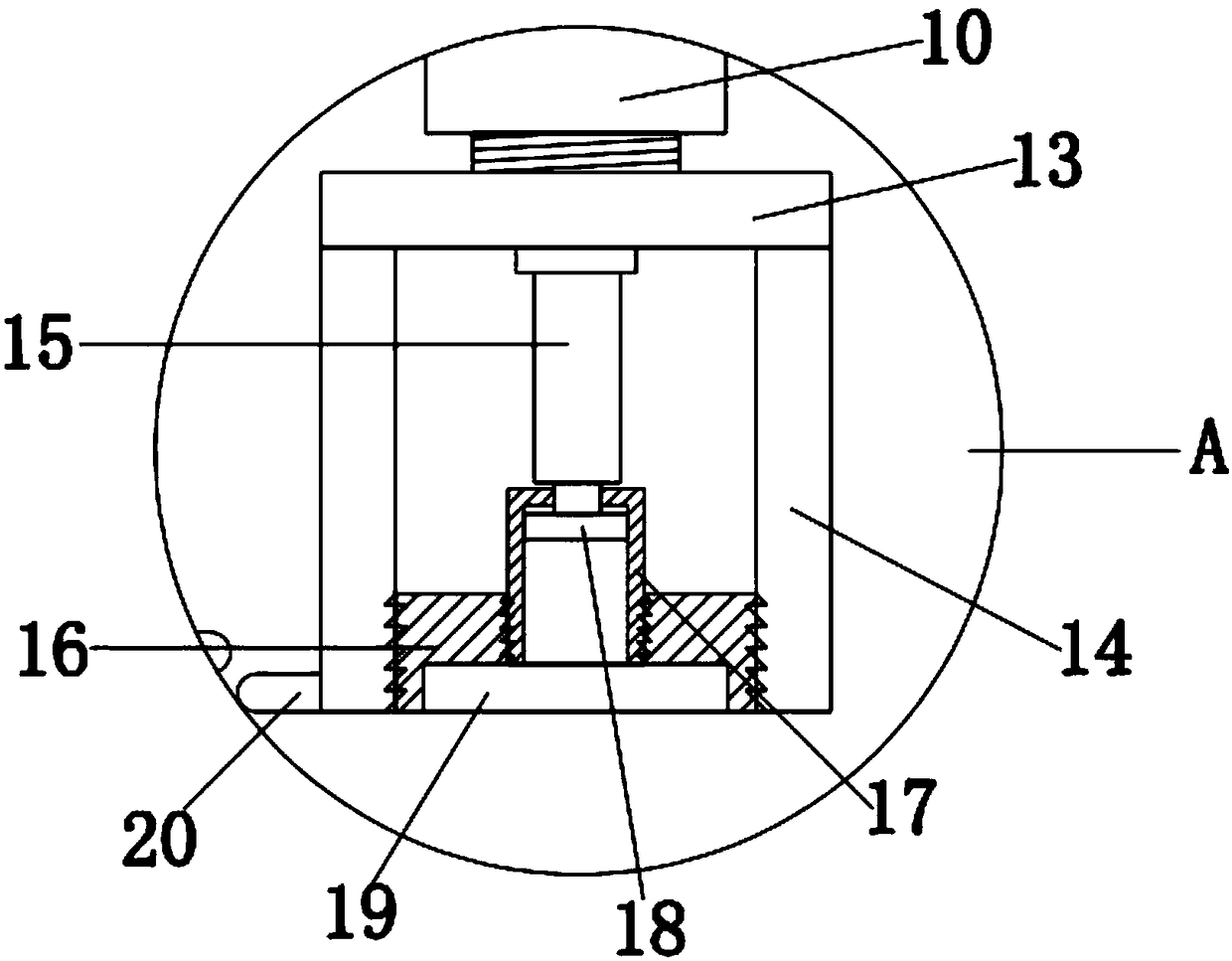

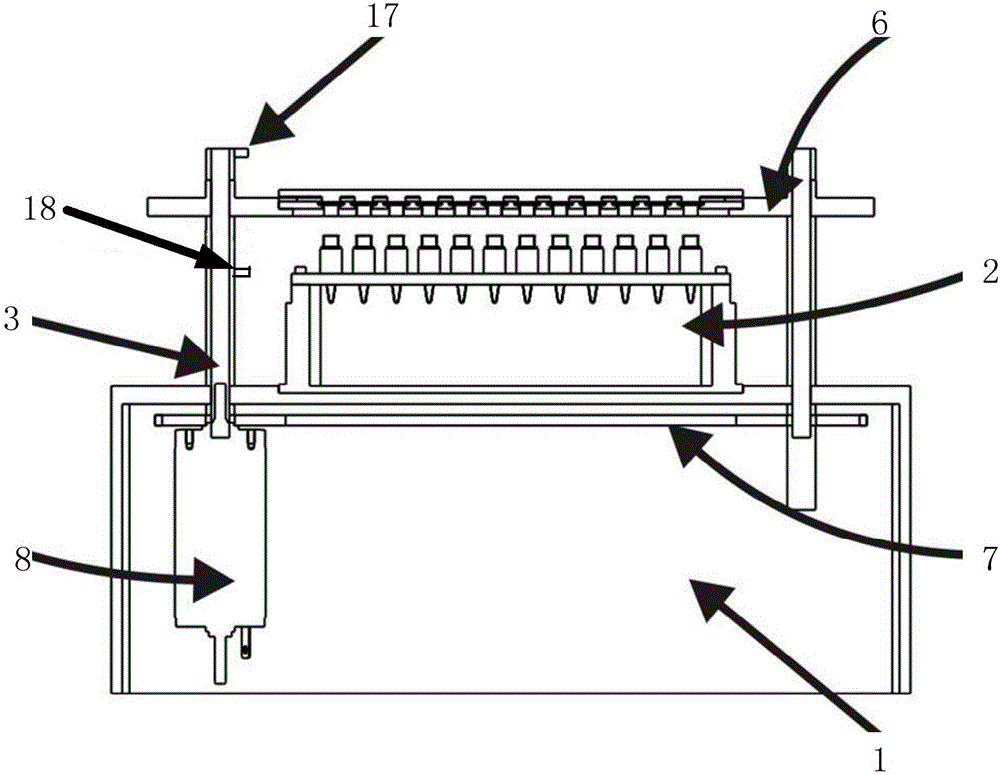

The invention provides an automatic capping machine. The automatic capping machine is used for capping a cap, especially an irregular-shaped cap, onto a bottle and substantially comprises a capping device, a feeding device and a control system. The capping device comprises a cap gripping mechanism which is used for absorbing caps and capping products to be capped on a product conveyer belt, a lifting mechanism which controls the lifting of the cap gripping mechanism, and a transversely-moving mechanism which control the cap gripping mechanism and the lifting mechanism to move forward and backward. The lifting mechanism is arranged at the front end of the transversely-moving mechanism, the front end of the transversely-moving mechanism is provided with guide rails, the cap gripping mechanism is mounted on the guide rails and comprises sucker mounting blocks and suckers, and the sucker mounting blocks are mounted on the guide rails and can move along the guide rails. The feeding device comprises a feed supplement mechanism which is used for supplementing the caps and a feed tidying mechanism which is used for tidying the caps provided by the feed supplement mechanism. The control system is a man-machine control system controlling the action of every mechanism. The automatic capping machine can automatically cap caps onto bottles and solve the problem of low efficiency and large labor intensity of manual operation.

Owner:GUANGZHOU BEAUTY STAR CO LTD

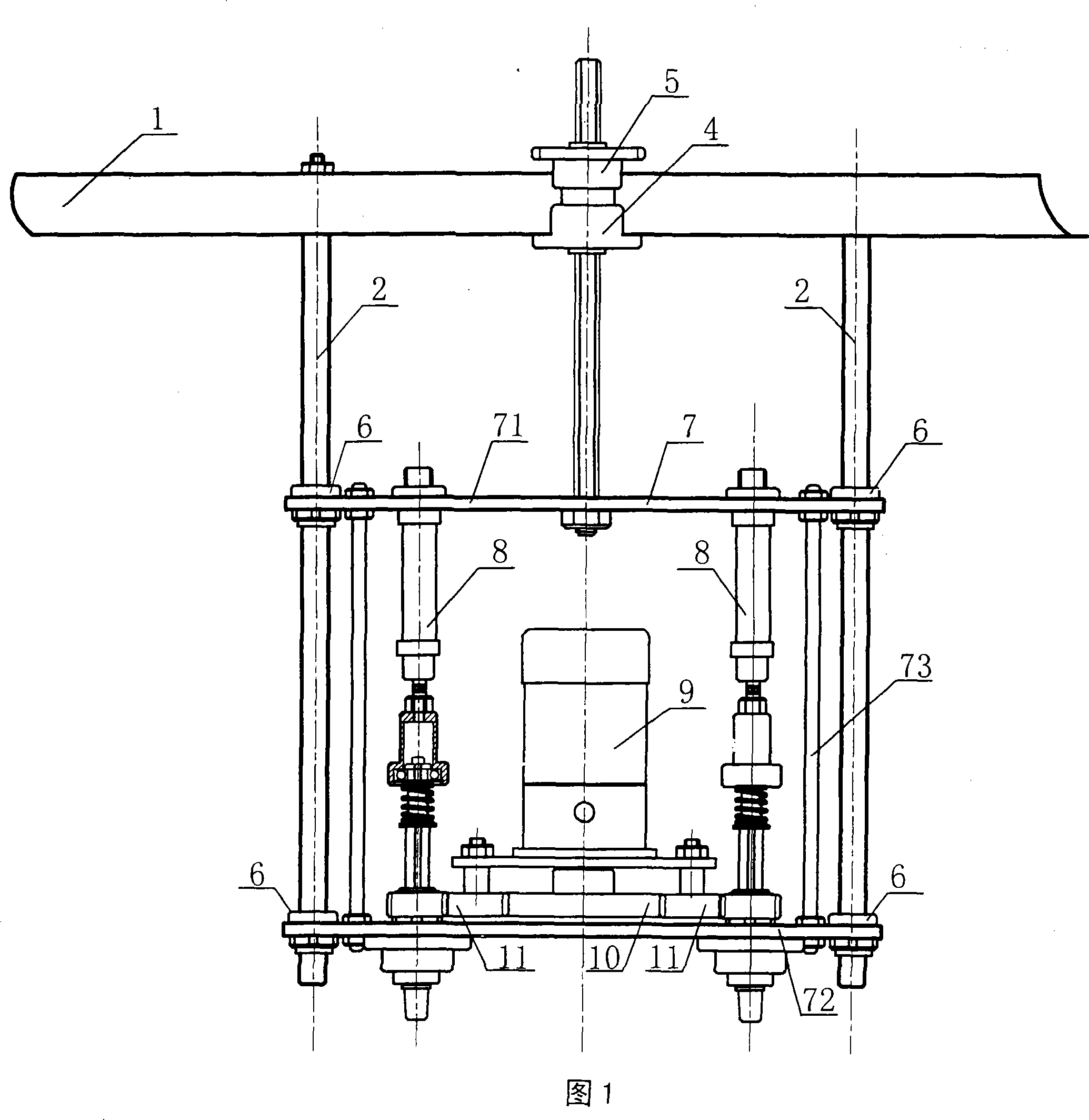

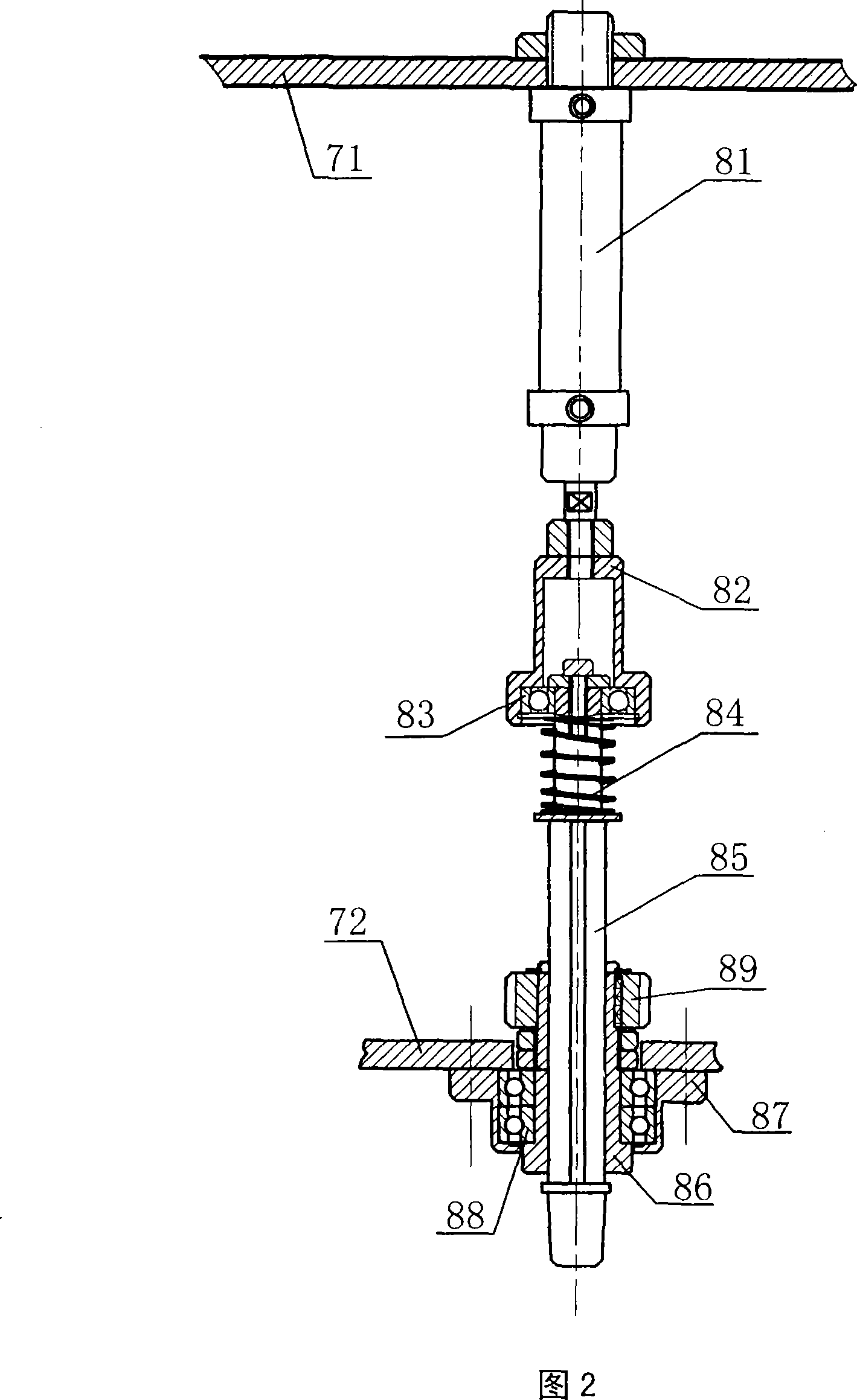

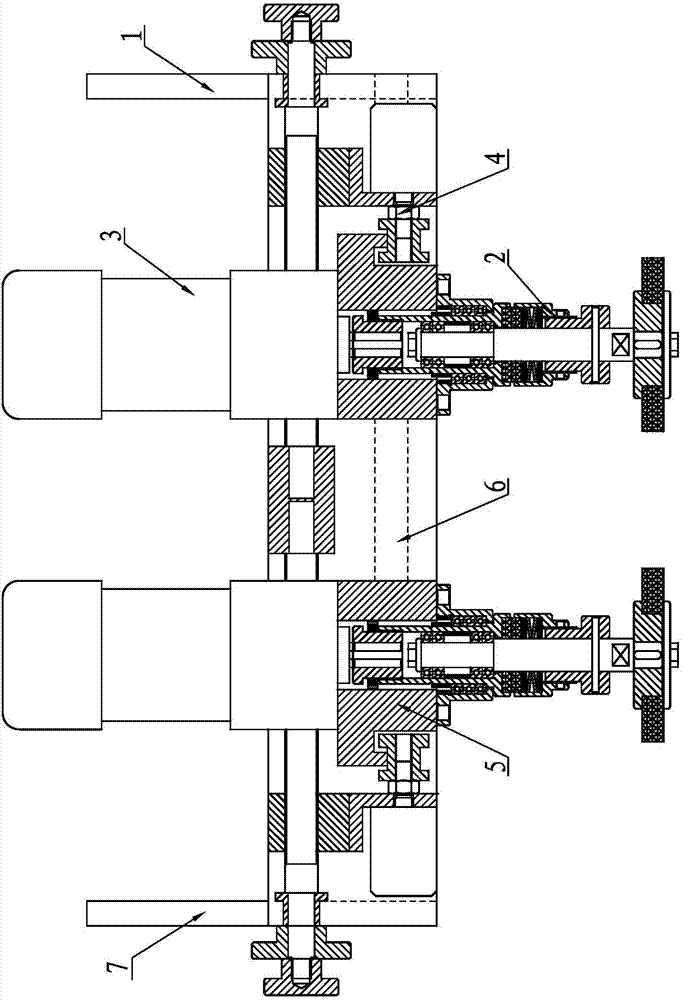

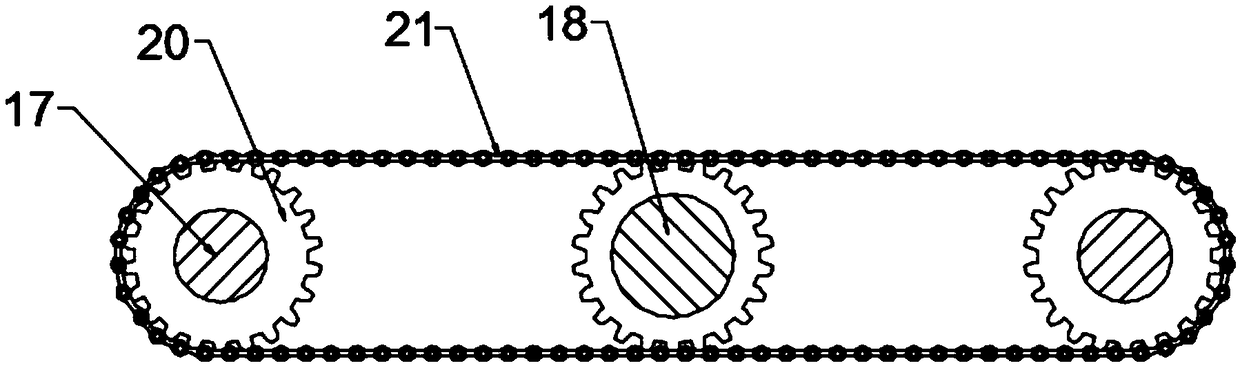

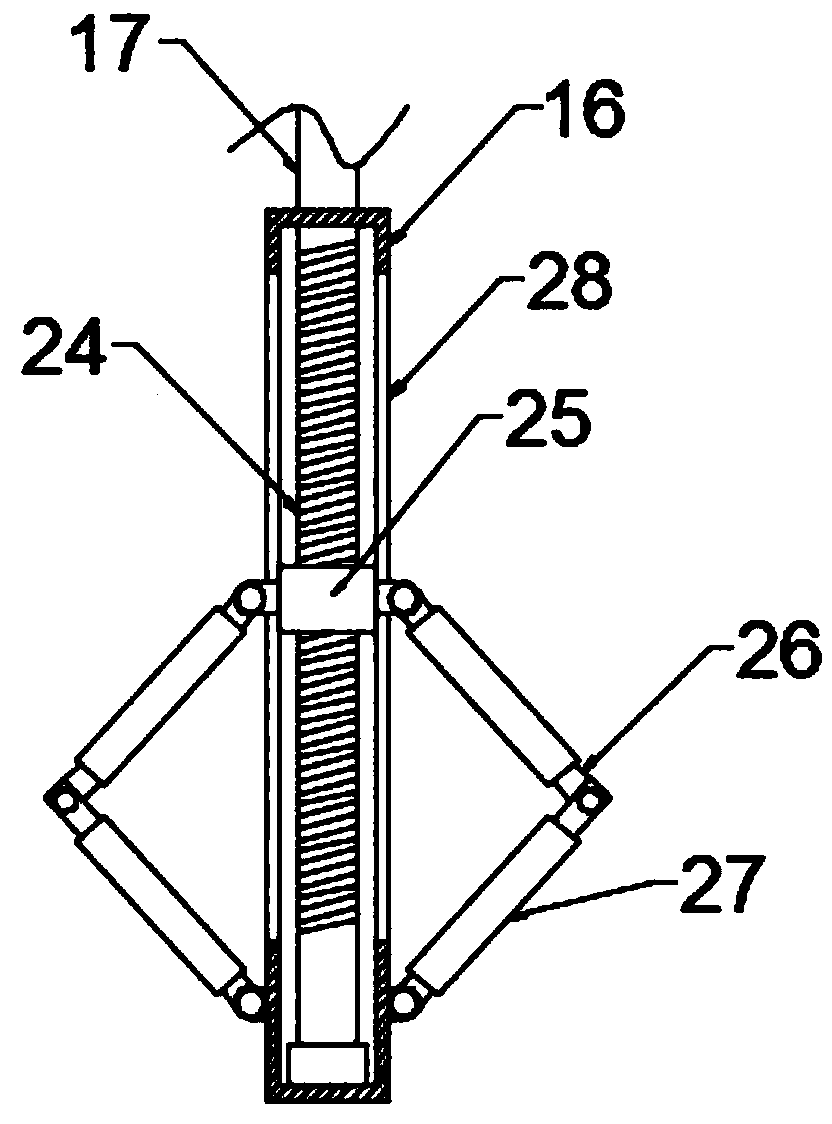

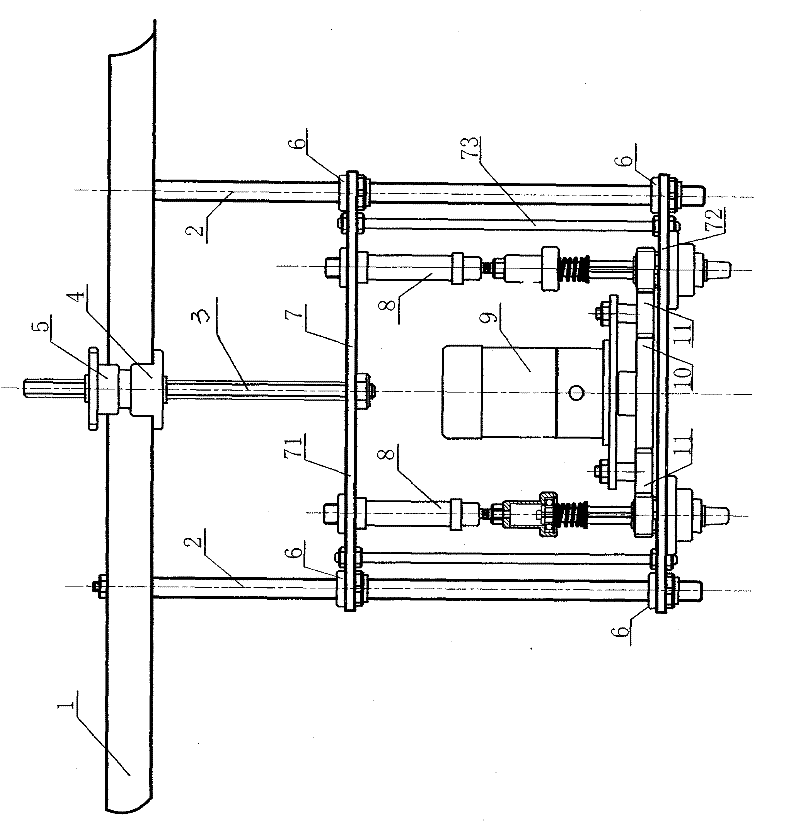

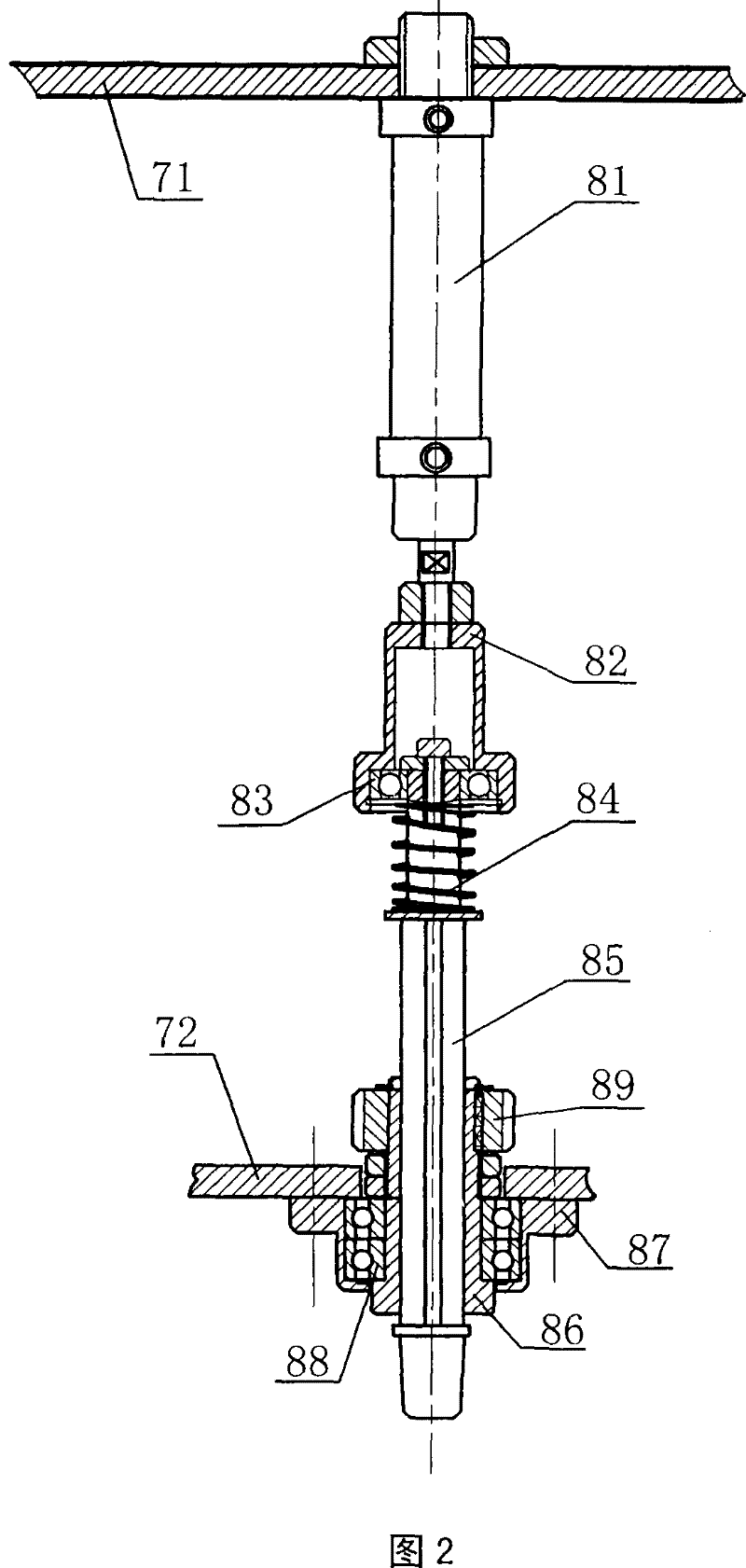

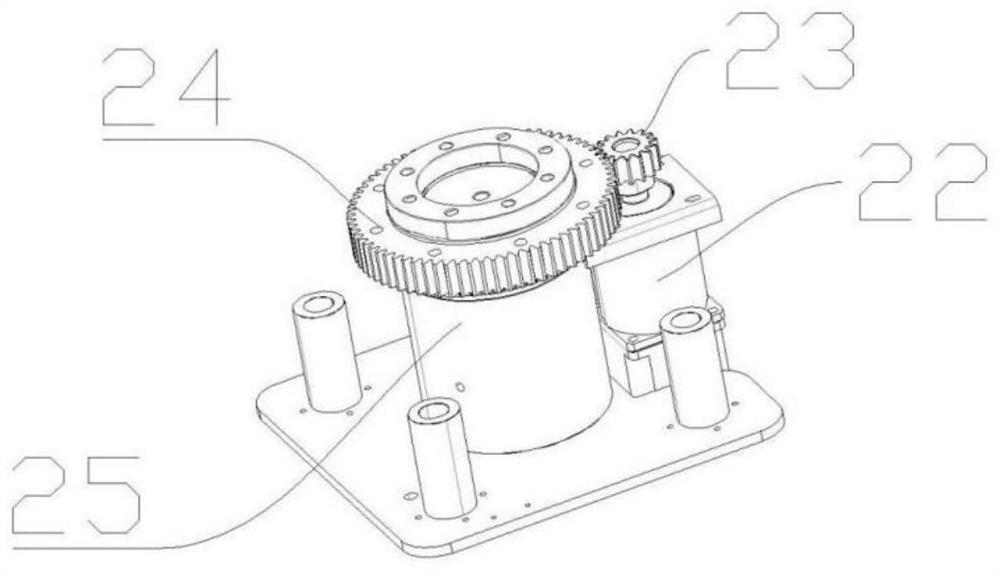

Lifting gear of cap whirling machine

InactiveCN101157433AAutomatic adjustment of tightening torqueFast flexible preload approachCapsThreaded caps applicationMotor driveGear wheel

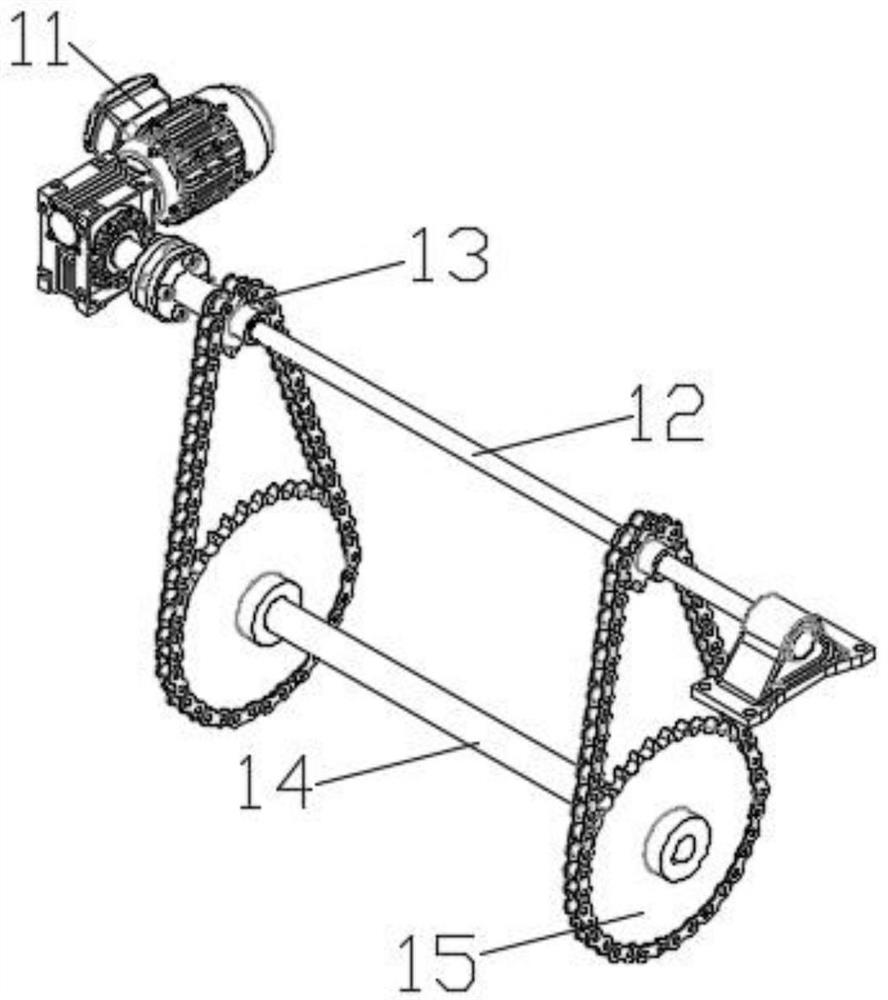

A screw cover retractor device of a screw cover machine comprises a supporting frame, two screw retractor components, a motor, a motor gear and a gear idle. The screw retractor components are arranged at the supporting frame. The motor drives the screw retractor components turning by the gear idle. The flexing of screw cover tie-ins is drove by a cylinder. The cylinder is communicated with pressure air source and controlled by a control circuit. Adopting the device, a motor can synchronously drive two screw retractor components and can synchronously and tightly screw two covers once, screwing cover efficiency can be increased by one time by comparing with the prior technology. By adopting quick disappearing end bumper of the cylinder driving disappearing end bumper axis of rotation, the rapid flexible prepressing approach of the screw cover tie-ins and the covers is implemented. A reset spring can ensure the bottle covers and the bottle mouths are in a compressing condition all the time and can also automatically adjust bottle cover winding moment to ensure the screw cover tie-ins wind up the moments of the bottle covers, etc, automatically avoid screwing loosely or in a fractured state due to dimension errors of the bottle covers and the bottle height.

Owner:常州市金坛中正包装机械科技有限公司

Automatic capping machine

The invention discloses an automatic capping machine. At least one placement channel is fixedly reserved above a rack; the initial states of a first chunk plate and a second chunk plate are respectively an open state and a retraction state; the first chunk plate and the second chunk plate are placed under the placement channel at an upper position and a lower position in the axial direction; the first chunk plate and the second chunk plate are radially positioned on the rack in a retractable way and an openable way respectively; the inner wall of the first chunk plate is provided with at least one circle of annular groove; when the first chunk plate and the second chunk plate are in the open state, the inside diameters of the first chunk plate and the second chunk plate are both greater than the maximal outside diameter of a cup cover; when the first chunk plate is in the retraction state, the edge at the upper end of the cup cover is clamped in the annular groove inside the edge; when the second chunk plate is in the retraction state, the inside diameter of the second chunk plate is less than the outside diameter of the lower end of the cup cover; a suction cup frame is fixedly positioned on the rack in a radial direction rotatably and axially; suction cups in the same number of the placement channels are vertically positioned on the radial outside wall of the suction cup frame telescopically; and when the suction cups are positioned at the upper end of the suction cup frame, the suction cups are exactly positioned on the lower side of the inside diameter of the second chunk plate completely. The automatic capping machine has a simple structure, high work efficiency and low encapsulation defective rate, and is convenient to operate and reliable in use.

Owner:苏州澳昆智能机器人技术有限公司

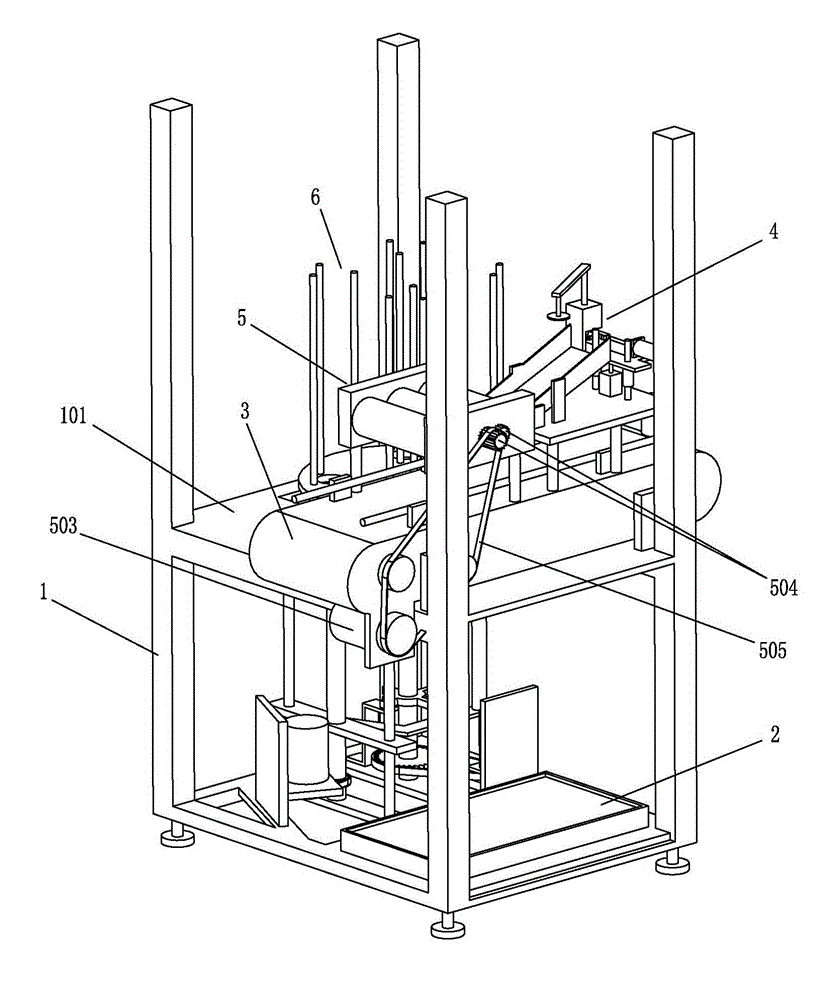

Automatic capping packaging machine

ActiveCN102718175ASimple working principleSimple mechanical structureCapsClosure using capsEngineeringBottle

The invention relates to an automatic capping packaging machine which comprises a stand and an electronic control device, wherein a working platform is arranged on the stand; a conveying track is fixedly arranged on the working platform; a cover taking device and a capping device are respectively arranged above the conveying track along the direction of forward motion of the conveying track; and a cover storage device is arranged at one side (close to the cover taking device) of the conveying track. The automatic capping packaging machine is simple in working principle, simple and reasonable in mechanical structure and short in capping time, thus effectively improving the capping efficiency of bottle cans and reducing the production cost.

Owner:广州市利悦食品包装技术有限公司

Automatic film covering machine for barreled printing ink

PendingCN107298417AReduce exposureProtect your healthDecorative coversClosure decorative/protective coversEngineeringPrinting ink

The invention relates to an automatic film covering machine for barreled printing ink. The automatic film covering machine is characterized in that a movable film release mechanism is arranged on the upper portion of a framework, and a middle positioning mechanism and a plastic film automatic jacking mechanism are arranged in the middle of the framework; a movable arm support of the movable film release mechanism is connected with a rodless cylinder, and a film suction device and a film release device are arranged on the movable arm support; vacuum suckers of the film suction device and the film release device are connected with electromagnetic valves by vacuum generators, a spiral elevator is connected with a plastic film tray, plastic film auxiliary positioning rods are mounted on a lifting platform, a plastic film location photoelectric detection head and a plastic film tray location photoelectric detection head are mounted on a platform of the framework, an alignment positioning seat and two alignment cylinders are arranged on an alignment platform of the middle positioning mechanism, and plastic films can be pushed towards the alignment positioning seat by the two alignment cylinders, so that each plastic film can be aligned and positioned. The automatic film covering machine has the advantages that extraction, positioning, film conveying and film pressing covering can be carried out on each single plastic film for the barreled printing ink, the automatic film covering machine is high in work efficiency, the barreled printing ink can be safely and reliably packaged by the automatic film covering machine, and the like.

Owner:SHANGHAI HENGTUO IND DEV

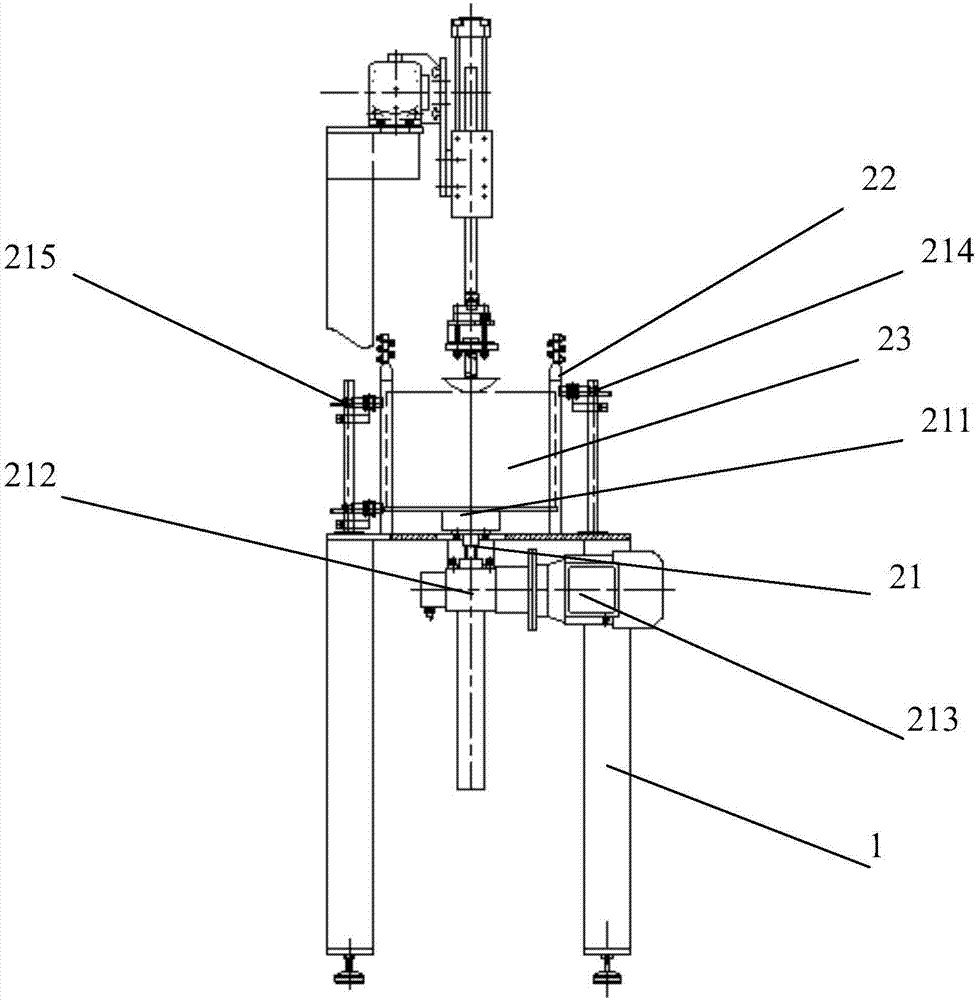

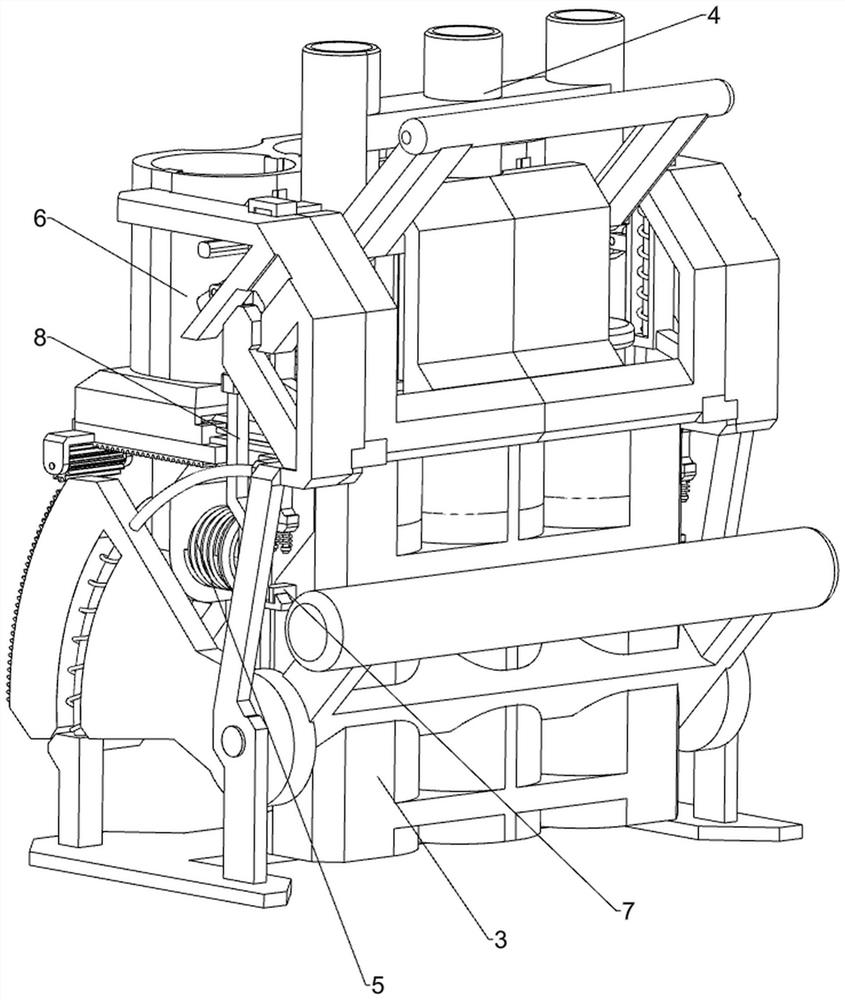

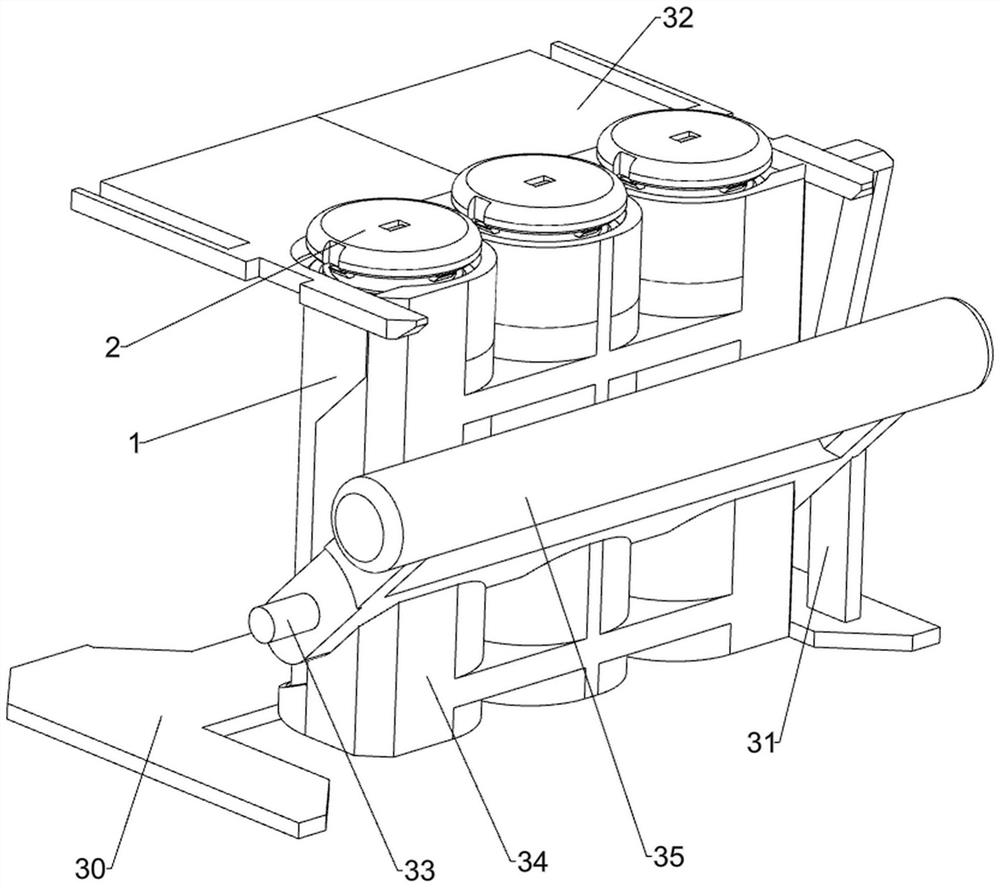

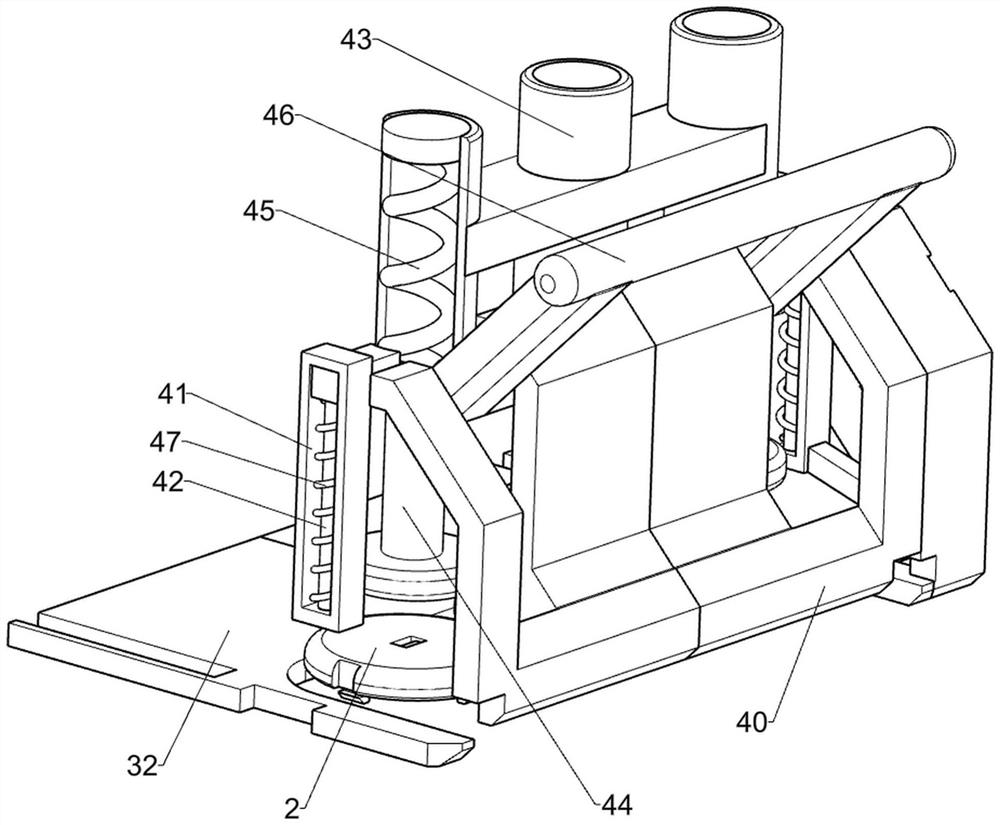

Full-automatic filling and spinning all-in-one machine

PendingCN109052294AEnsure safetyReduce manufacturing costBottle-handling machinesProduction lineAutomation

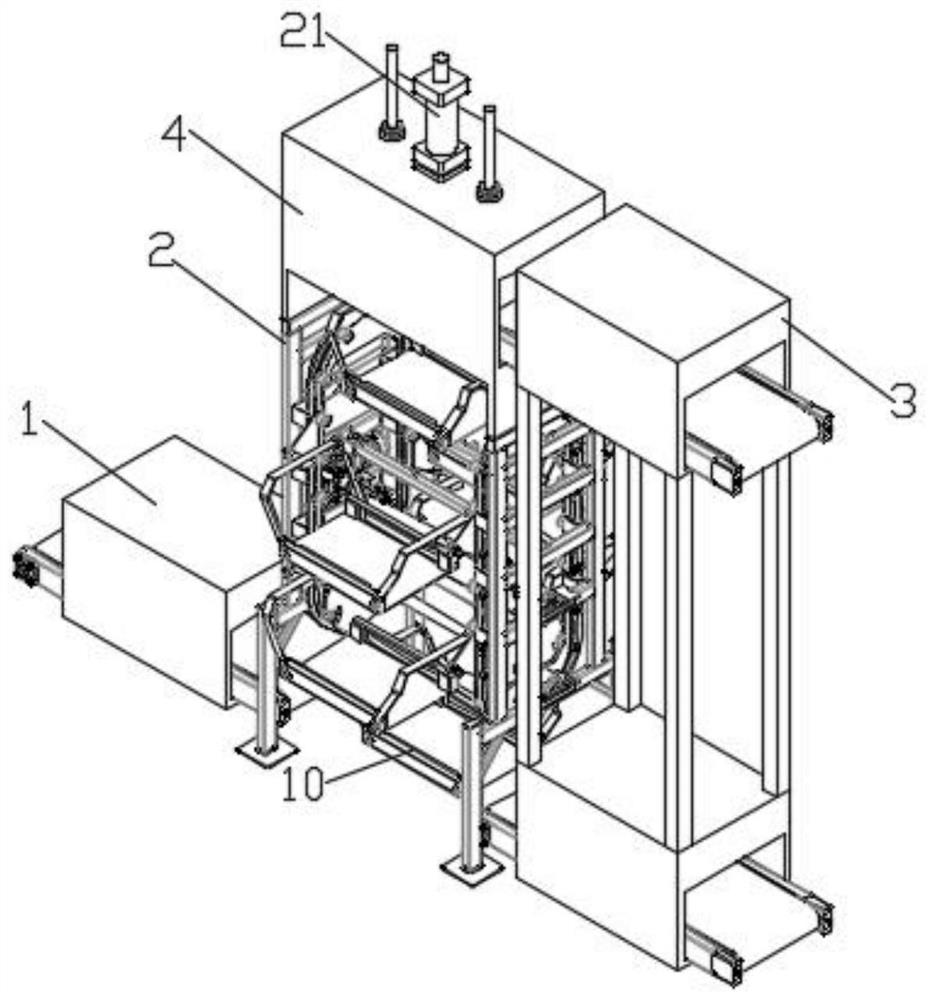

The invention discloses a full-automatic filling and spinning all-in-one machine. The full-automatic filling and spinning all-in-one machine comprises a frame, at least one filling and spinning devicewhich is installed on the frame, wherein each filling and spinning device comprises a weighing platform, a barrel port aligning device and a filling cap screwing assembly, wherein the barrel port aligning device is arranged above the weighing platform, and the filling cap screwing assembly is arranged above the barrel port aligning device; each filling cap screwing assembly comprises a positioning and translation device, a barrel port positioning device, a cap screwing device and a filling device, wherein the barrel port positioning devices, the cap screwing devices and the filling devices are sequentially installed on the positioning and translation devices. According to the machine, the functions of barrel feeding, cover opening, filling and cap screwing are integrated in one body, so that production cost is low, labor intensity is low, the barrel port is automatically aligned, a cap screwing pass percent is high, the cap screwing efficiency is high, the filling metering precision is high, the automation degree is high, the operation is simple, the adjustment is convenient, the safety of operators is ensured, the production efficiency is high, and high speed and high efficiencyare achieved; and a solution is provided for automatic filling and cap screwing of a large-specification barrel production line.

Owner:米多智能包装(昆山)有限公司

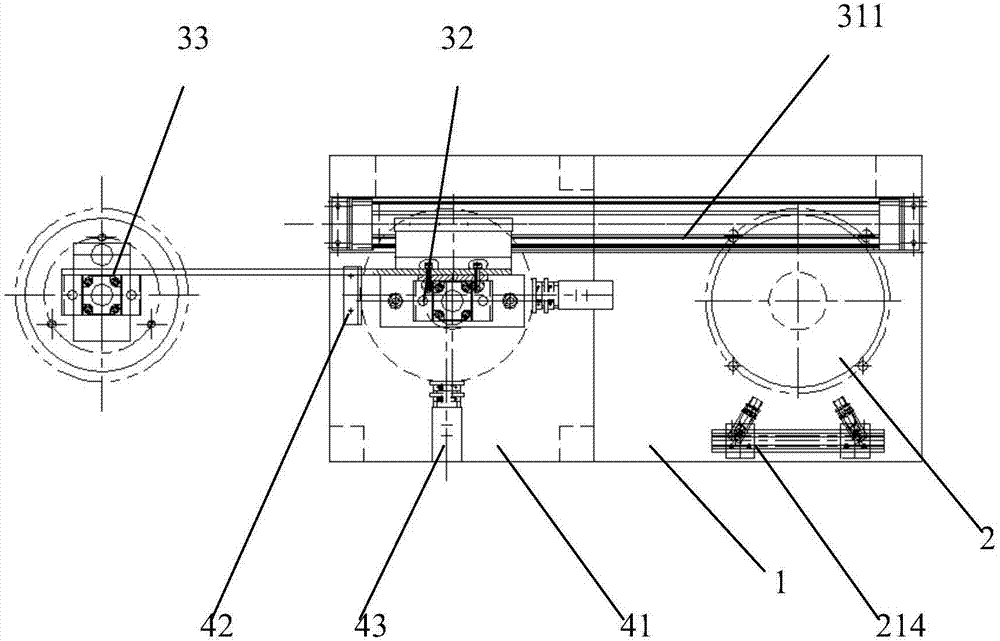

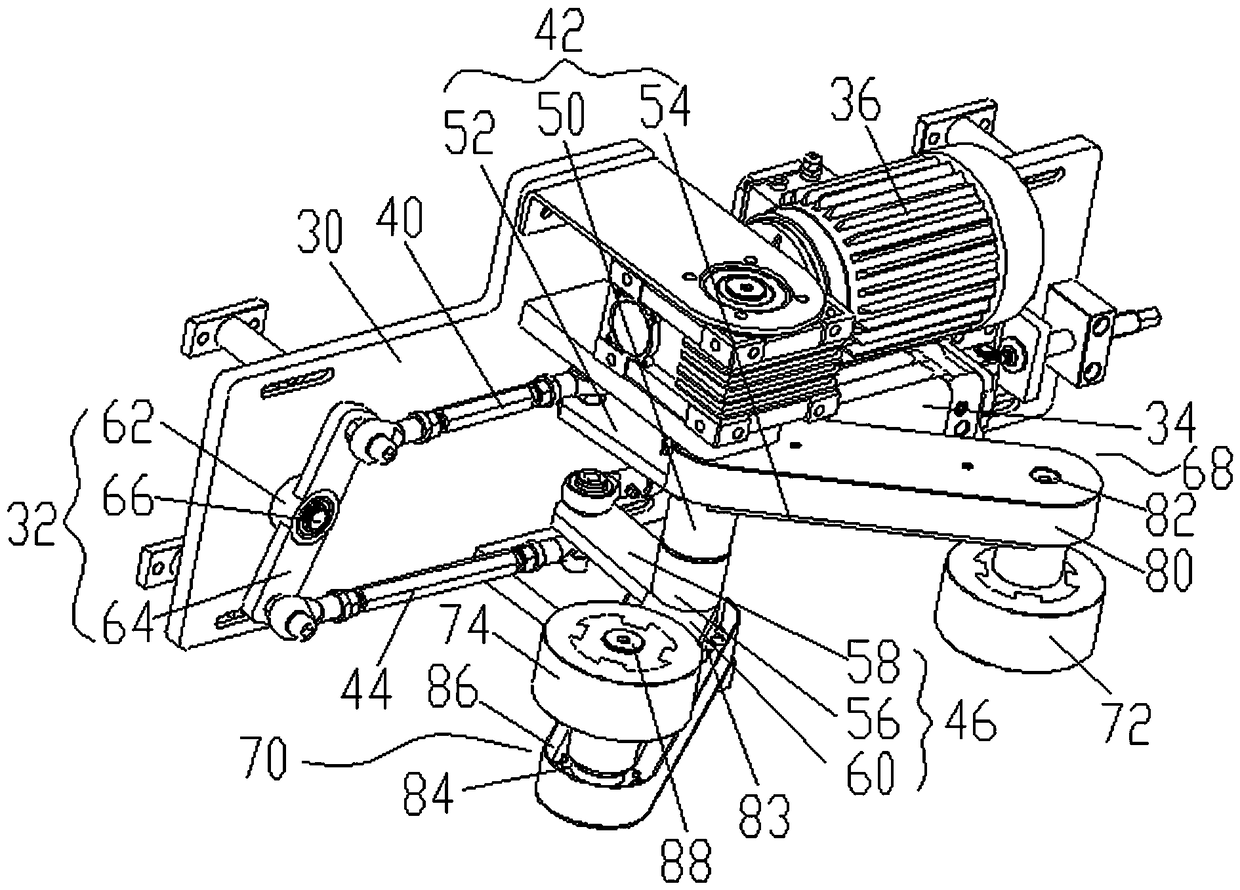

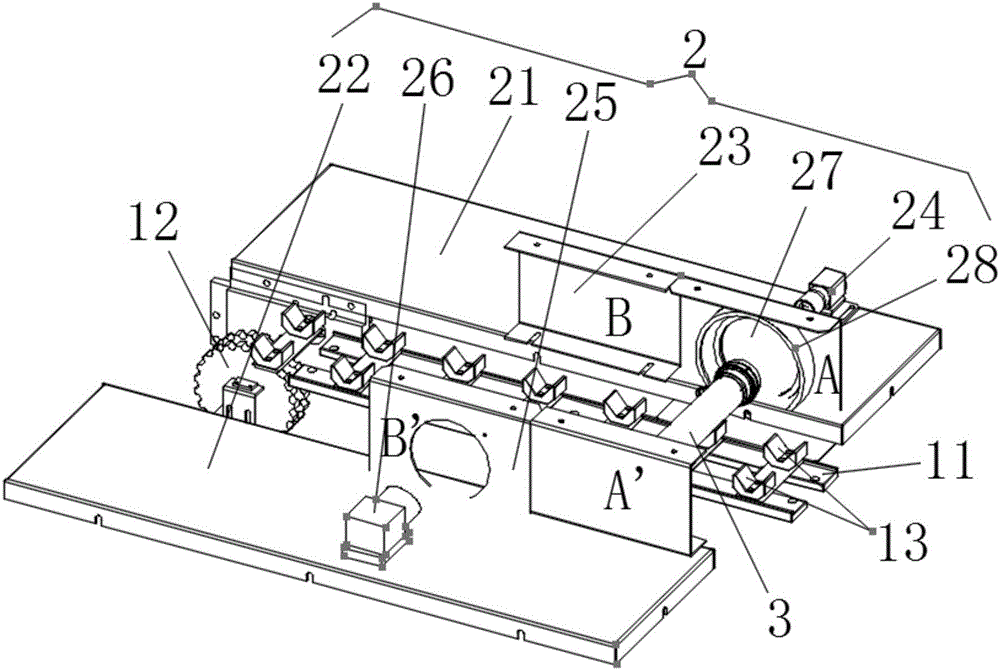

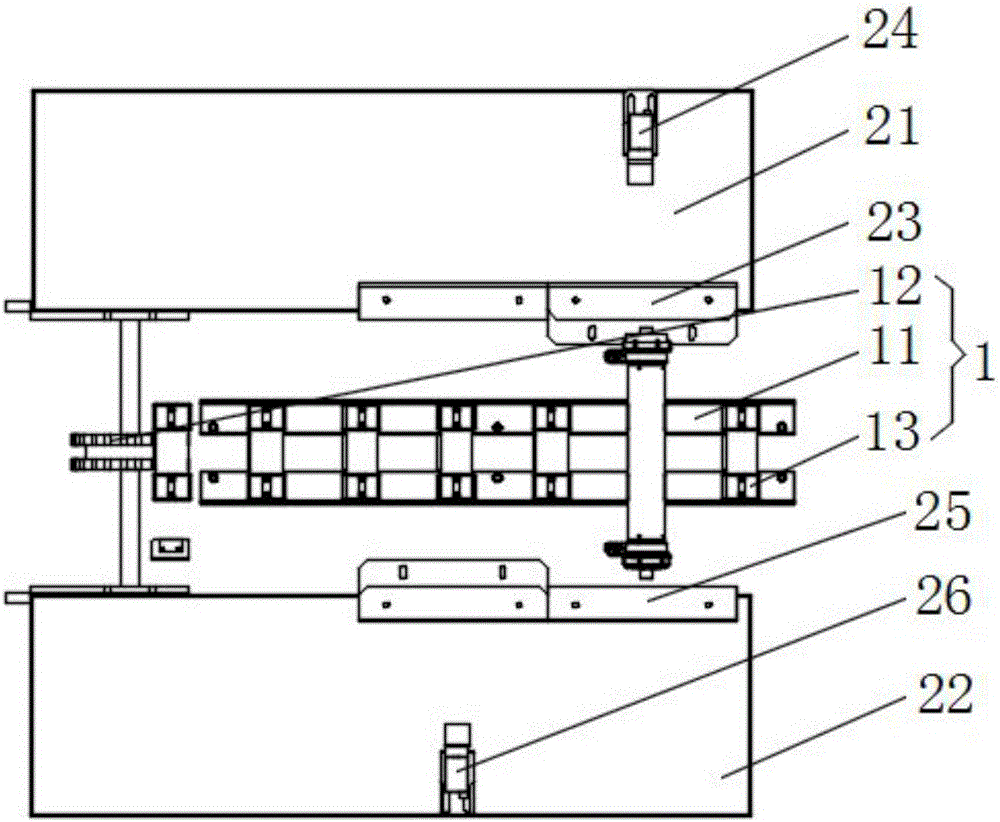

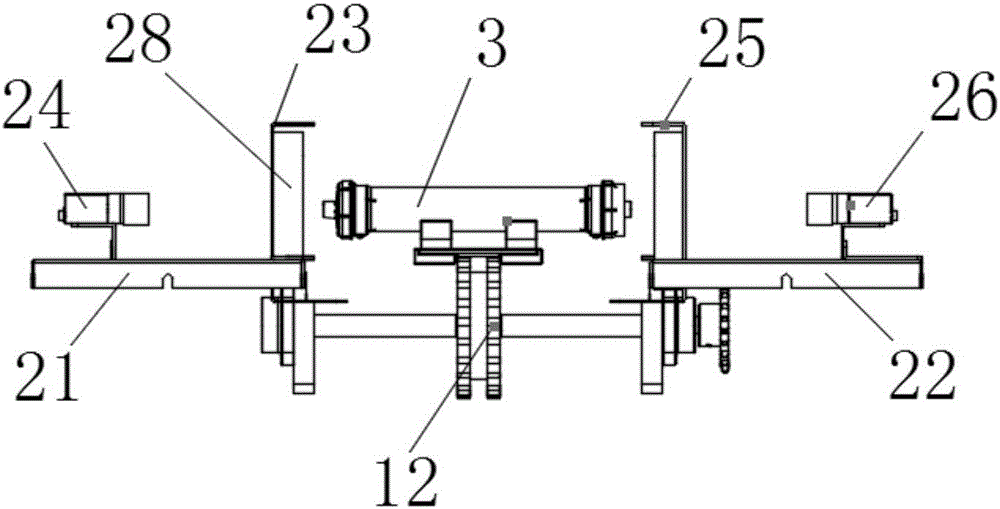

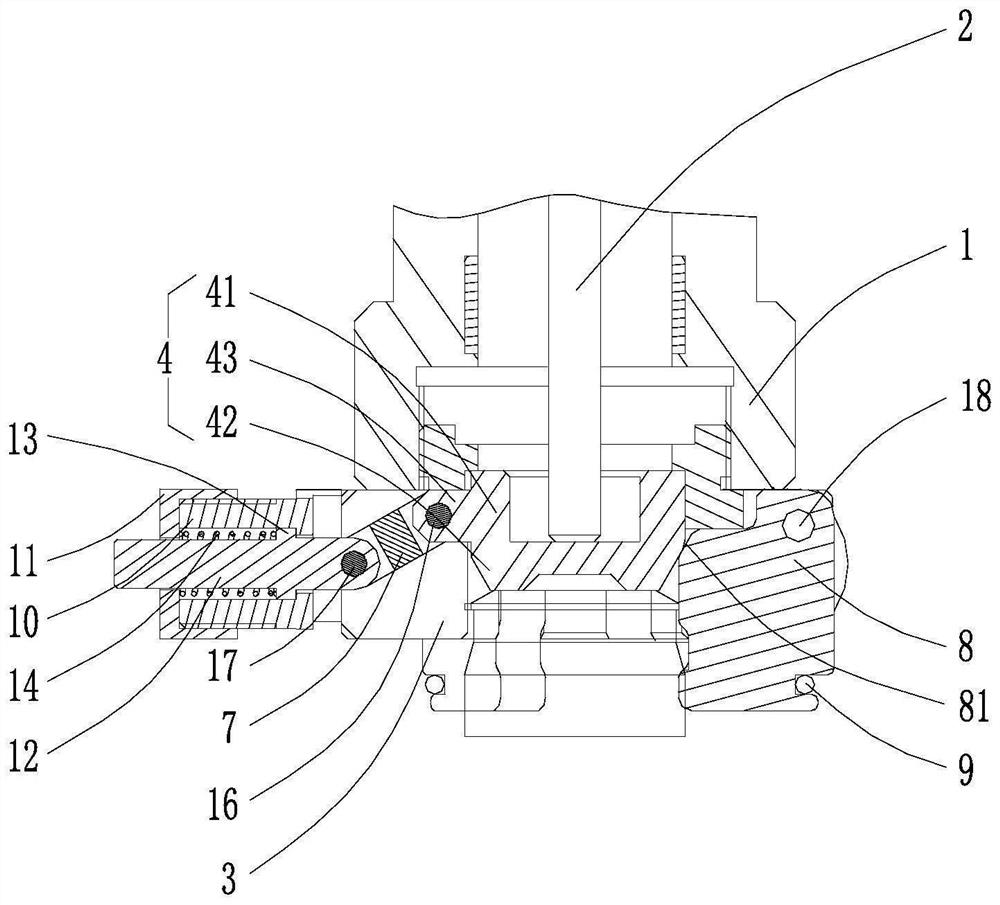

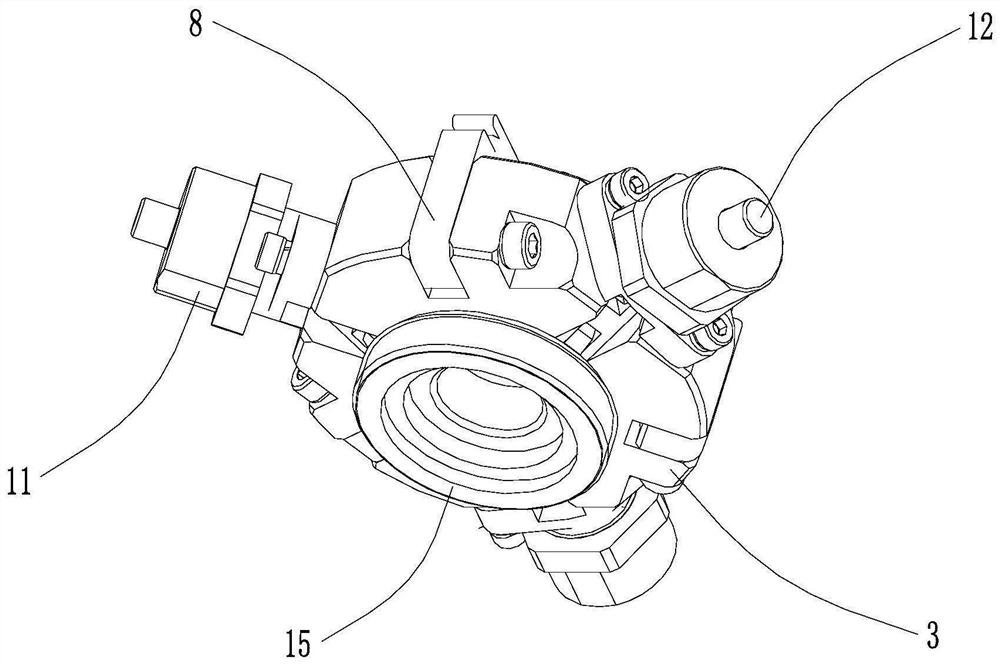

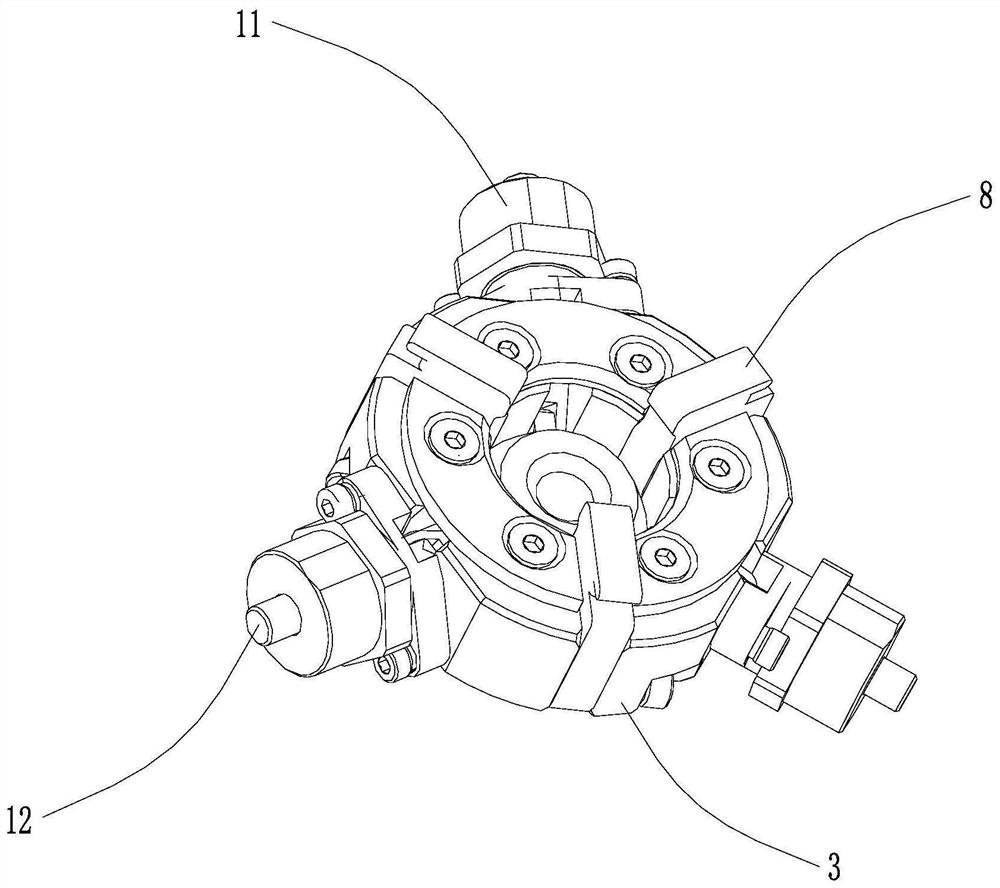

Clutch cap screwing device of linear pump cap screwing machine

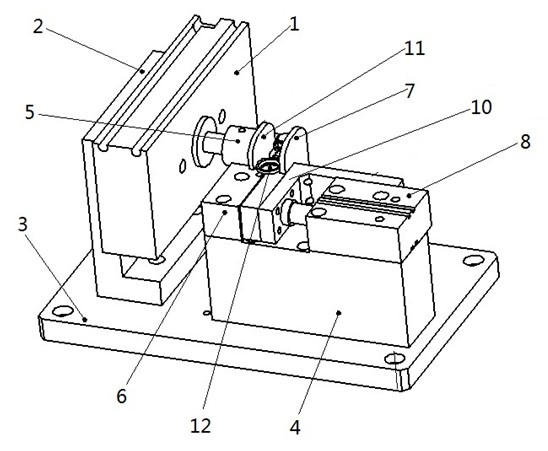

A clutch cap screwing device of a linear pump cap screwing machine comprises a rack front side plate, torque cap screwing components, rotating driving components, a centering linear driving adjusting mechanism, sliding seats, sliding guide rails and a rack rear side plate. The two sliding guide rails are horizontally and fixedly mounted on the rack front side plate and the rack rear side plate in parallel, the two sliding seats are mounted on the two sliding guide rails in a sleeved mode, the torque cap screwing components are mounted on the lower end faces of the sliding seats, the rotating driving components are mounted on the upper end faces of the sliding seats, the rotating driving components drive the torque cap screwing components, the centering linear driving adjusting mechanism is arranged between the rack front side plate and the rack rear side plate, and a driving motor of the centering linear driving adjusting mechanism is connected with the sliding seats. The clutch cap screwing device of the linear pump cap screwing machine solves the problem of manual cap screwing, a flow process of continuous linear cap screwing can be achieved, a great amount of man power is saved, cap screwing efficiency is high and is 100 times that of manual cap screwing, and the aesthetic standards of people for diversified bottle bodies are met.

Owner:常州市金坛晨光轻工机械有限公司

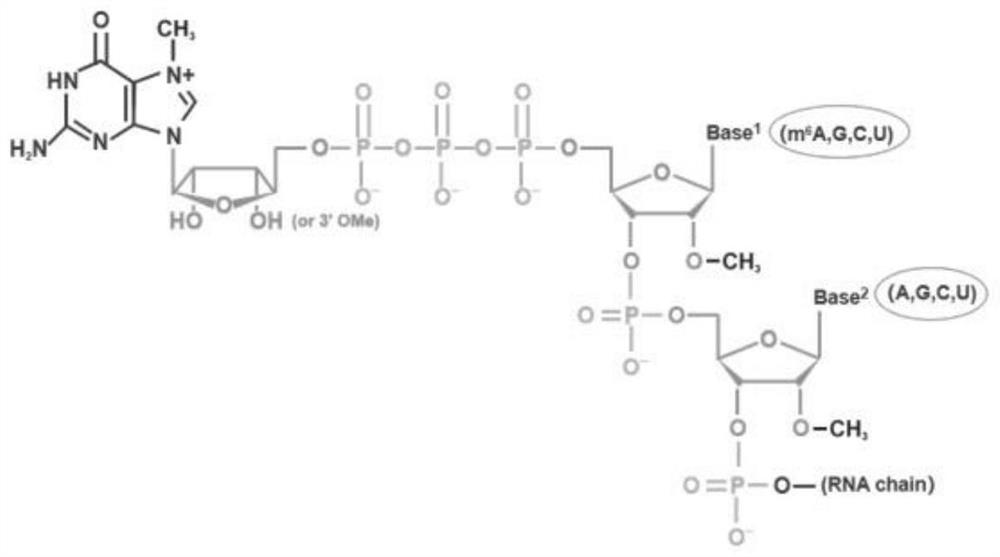

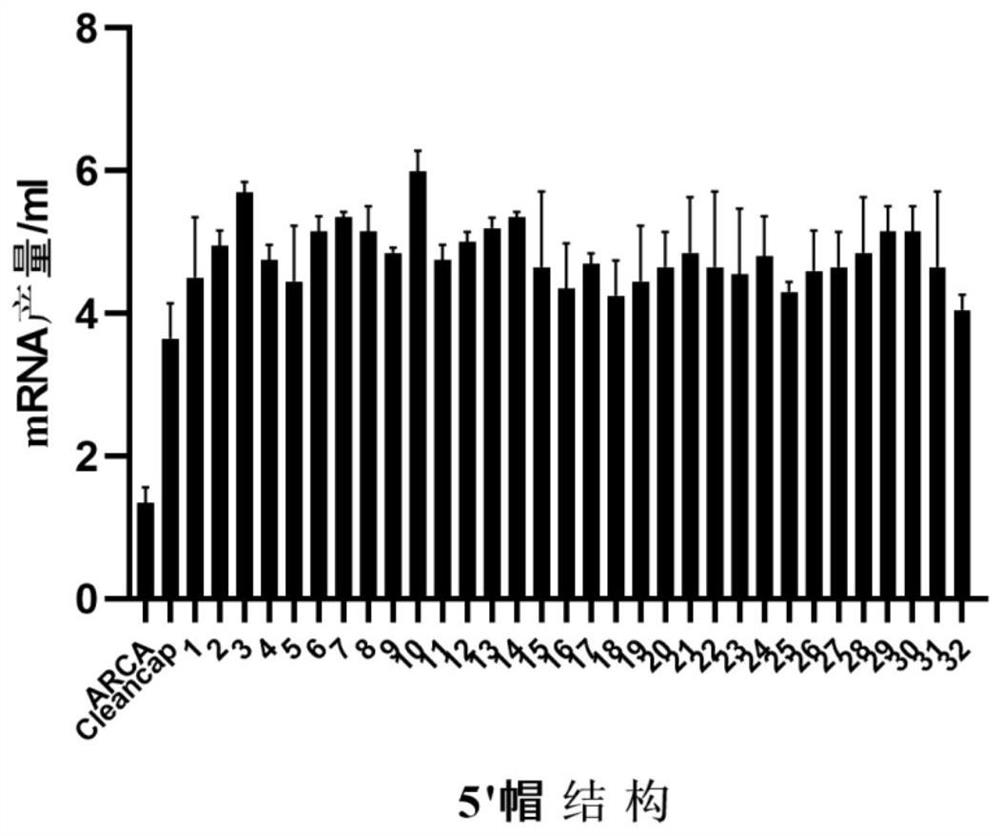

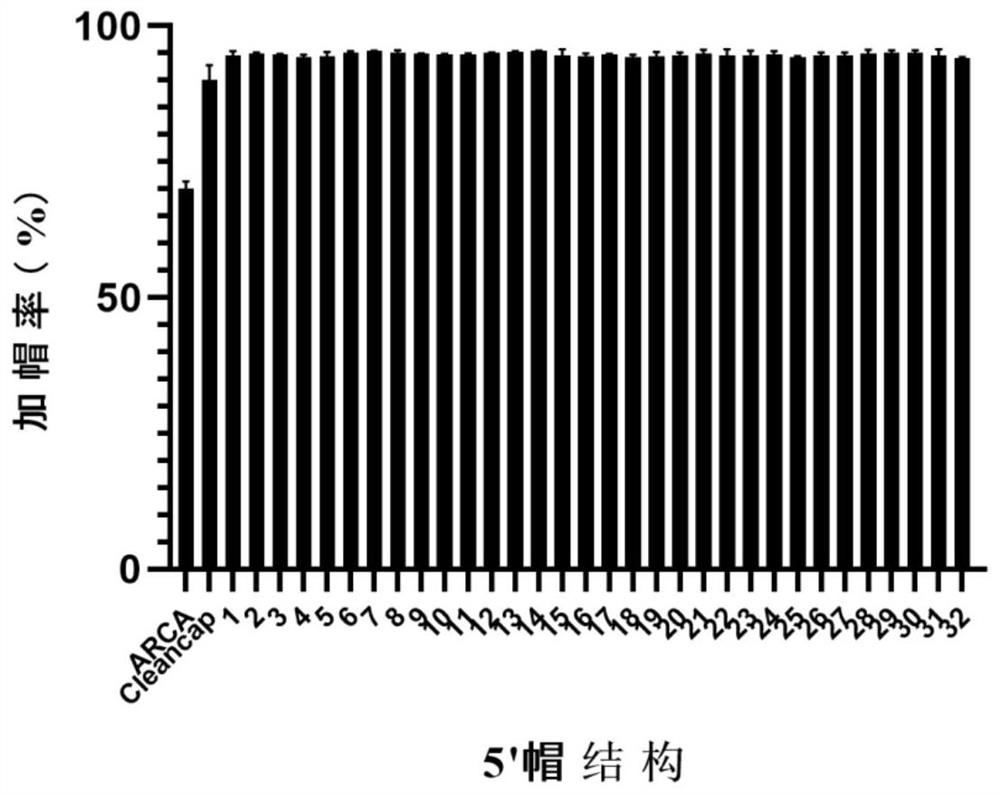

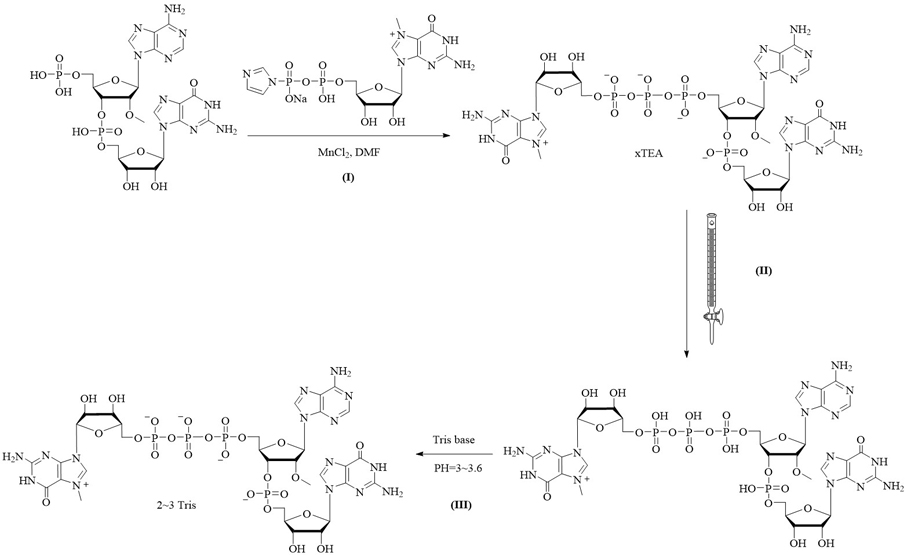

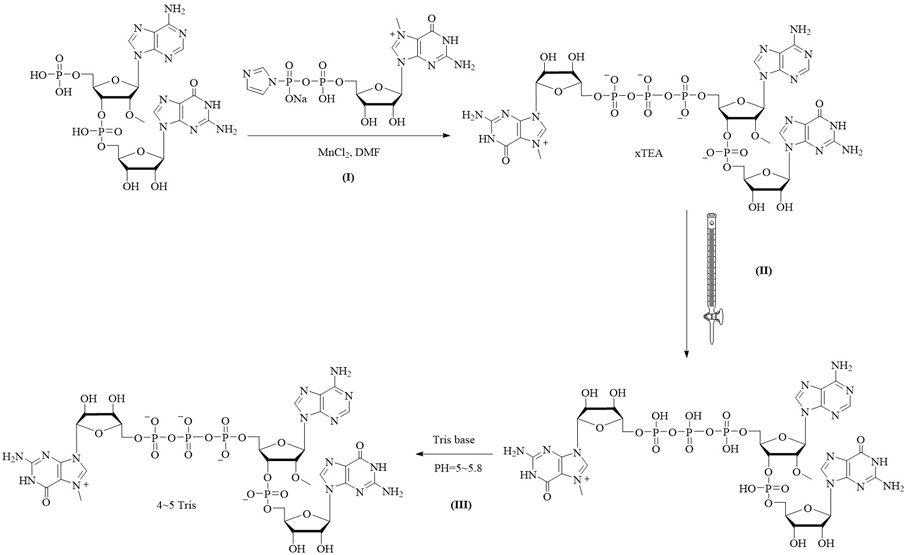

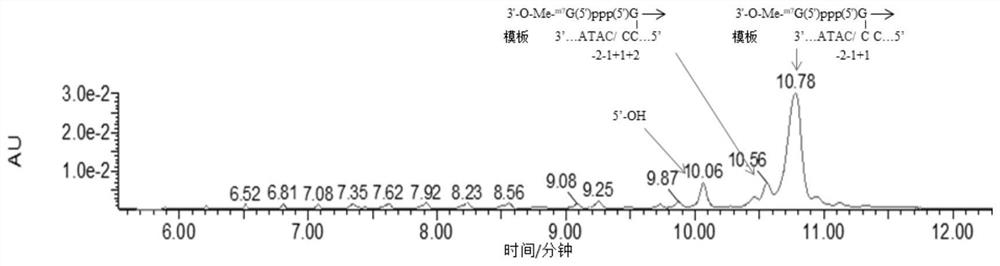

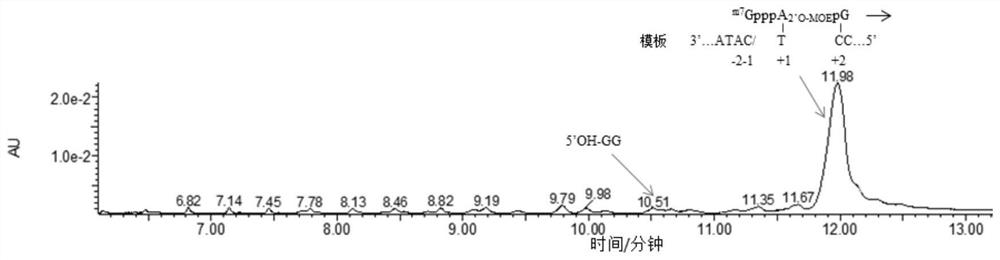

Novel Cap2 structure 5' cap analogue and preparation method thereof

ActiveCN111944864AHigh synthesis efficiencyImprove capping efficiencySugar derivativesFermentationBiochemistryGene engineering

The invention provides a novel Cap2 structure 5' cap analogue and a preparation method thereof, and belongs to the technical field of gene engineering. The molecular formula of the novel Cap2 structure 5' cap analogue is selected from any of m7G (5') ppp (5 ') (2' OMeA) p (2 'OMeG), m7G (5') ppp (5') (2 'OMeG) p (2' OMeG) and the like. The novel Cap2 structure 5' cap analogue provided by the invention has higher synthesis efficiency, higher capping efficiency, lower immunogenicity and higher protein translation efficiency.

Owner:SHENZHEN RHEGEN BIOTECHNOLOGY CO LTD

Hand-operated type simple lid lifting device of well lid

InactiveCN108706484APrevent slippingSimple structureWinding mechanismsLoad-engaging elementsDuctorEngineering

The invention discloses a hand-operated type simple lid lifting device of a well lid. The hand-operated type simple lid lifting device comprises a supporting transverse plate, wherein the two sides ofthe lower end surface of the supporting transverse plate are equipped with supporting vertical plates; a lid lifting transverse shaft which is parallel to the supporting transverse plate is arrangedabove the supporting transverse plate; the two ends of the lid lifting transverse shaft are mounted on the supporting transverse plate through rotary bases; two rolling-up wheels are arranged on the lid lifting transverse shaft; steel wire lifting ropes are wound on the rolling-up wheels; the lower ends of the two steel wire lifting ropes pass through the supporting transverse plate, and are connected with the upper end surface of a lifting plate; one end of the lid lifting transverse shaft is fixedly connected with a pulling circular disc; the position, on the outer side wall of the inner part of a square guide tube, of a rotary vertical shaft is equipped with a spiral section; a regulating drive sleeve which is matched with the spiral section is in sleeve connection on the outer side ofthe rotary vertical shaft; the regulating drive sleeve is in up-down sliding connection with the inner wall of the square guide tube; and four pairs of connecting rods are arranged at the outer side of the square guide tube. The device is simple in structure, is labor-saving in lid lifting, is simple and convenient to operate, is relatively high in well lifting efficiency, is relatively low in cost, and is relatively high in practicability.

Owner:湖北鑫盛宏峰建设有限公司

Carton capping device

The invention discloses a carton capping device. The carton capping device comprises a delivery mechanism for driving a carton to move perpendicular to a length direction of a carton body, and cover closing assemblies arranged at two ends of a carton body. The cover closing assembly comprises a block piece, a first shifting mechanism located at the same horizontal height as the stop piece, a right-angled part matching the stop piece to form a gap, and a second shifting mechanism. A stop surface of the stop piece abuts against the first cover in the movement process of the carton with the first cover stressed to close up inwards. The first shifting mechanism shifts the second cover to close up inwards after the first cover closes up. The third cover enters the gap and forms a bent section. The second shifting mechanism shifts the third cover to close up inwards, and the bent section is inserted in the carton body. The carton capping device solves the problem of low capping efficiency due to dependency on manual labor in existing carton capping.

Owner:广东大唐永恒智能科技有限公司

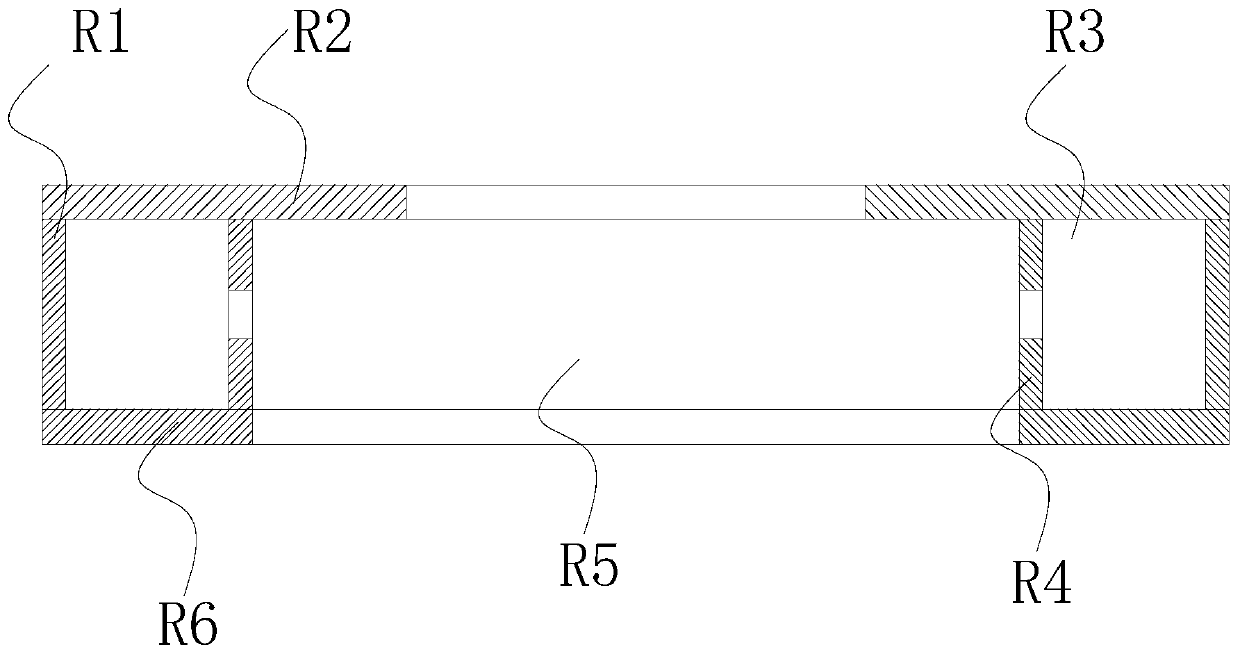

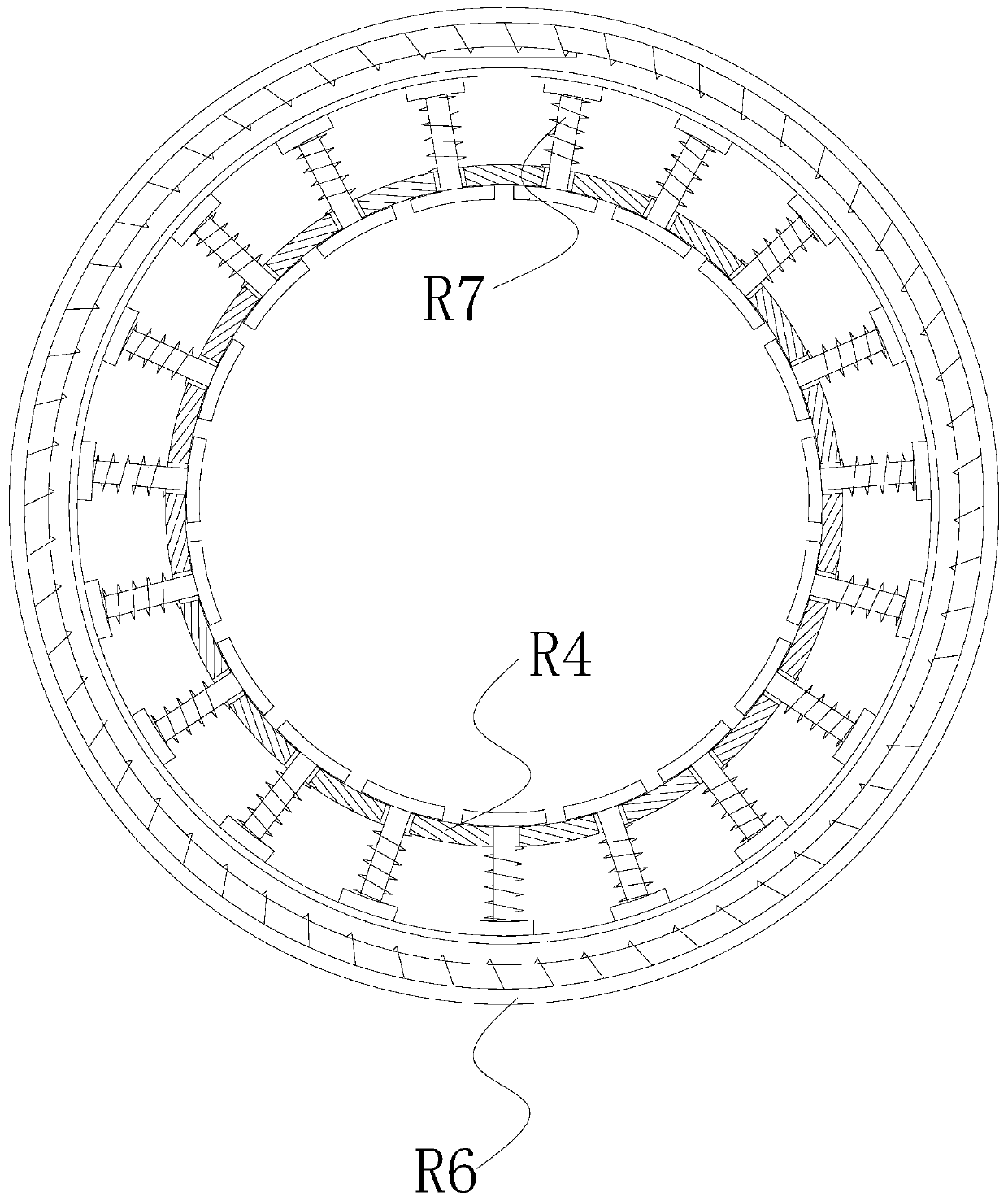

Sealing device for processing of new-energy batteries and working method of sealing device

ActiveCN111977300AImprove capping efficiencySmall footprintCell component detailsConveyor partsNew energyEngineering

The invention discloses a sealing device for processing of new-energy batteries and a working method of the sealing device. The sealing device comprises a sealing cover chamber; the sealing cover chamber is mounted on a circulating frame; two lower conveying chambers are arranged on the two sides of the circulating frame; two circulating tracks are arranged on the circulating frame; circulating chains are arranged on the inner circles of the circulating tracks; a plurality of connecting disks are arranged on the circulating chains; and connecting arms are arranged on the connecting disks. According to the sealing device, the new-energy batteries and battery cover plates can be conveyed, and meanwhile, position adjustment can be performed on the new-energy batteries on trays and battery sealing covers in the sealing cover chambers, so that the battery sealing covers can be efficiently aligned to the new-energy batteries, circulation of the trays can be realized, and then the sealing efficiency of the new-energy batteries is high; meanwhile, the whole sealing device occupies the small space through arrangement of the circulating frame, so that use of the sealing device in a workshopis facilitated; and welding of the four sides of the new-energy batteries can be realized by the aid of two welding heads, the whole structure is ingenious, and sealing of the new-energy batteries indifferent sizes can be realized while efficient welding is guaranteed.

Owner:WUHU HONGJING ELECTRONICS

High-speed capping machine for high caps

ActiveCN113548614AImprove capping efficiencyMeet the needs of modern productionClosing machinesFlanged caps applicationMachineIndustrial engineering

The invention relates to the technical field of canning equipment, in particular to a high-speed capping machine for high caps. The high-speed capping machine is provided with a rack, a rotating part, an inlet net chain part, an outlet net chain part, a star wheel part, a cap feeding part, a cap pressing part, a tank body positioning part and a control part, and the control part is arranged on the rack and electrically connected with the rotating part, the inlet net chain part, the outlet net chain part, the star wheel part, the cap feeding part, the cap pressing part and the tank body positioning part, so that an integral control effect is achieved. The cap pressing efficiency is improved, the cap pressing speed reaches 100 pieces or above per minute, and the requirement of modern production is met. Cap feeding operation can be conducted on tank bodies with different heights through the cap feeding lifting part, the efficiency is high, and full automation is achieved. A visual camera can monitor whether the cap feeding work is normally carried out or not in real time, cap neglected loading is prevented, and it is ensured that the positions of the caps are correct when the caps are conveyed to the next procedure.

Owner:CHANGZHOU JOYO AUTOMATION EQUIP CO LTD

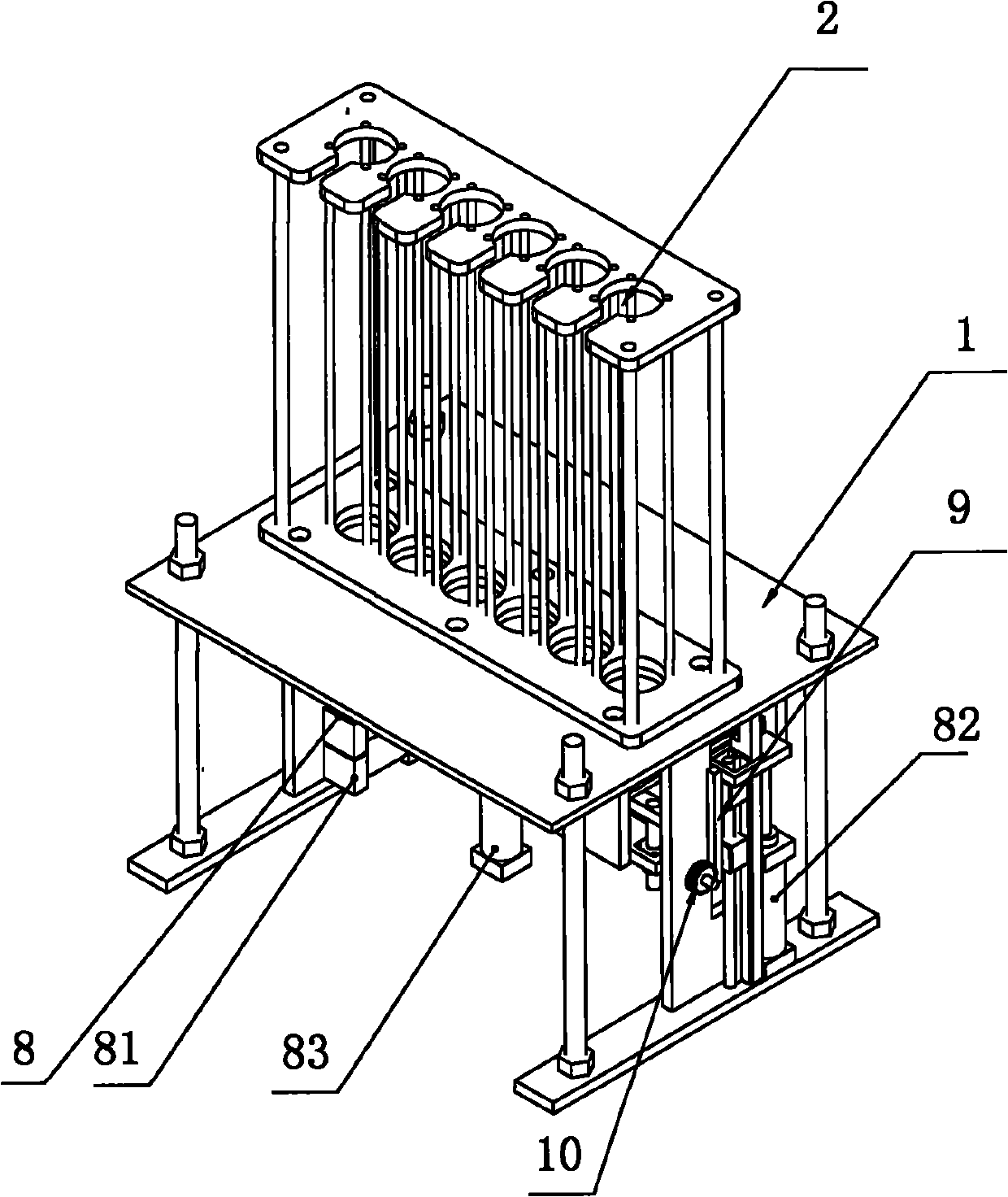

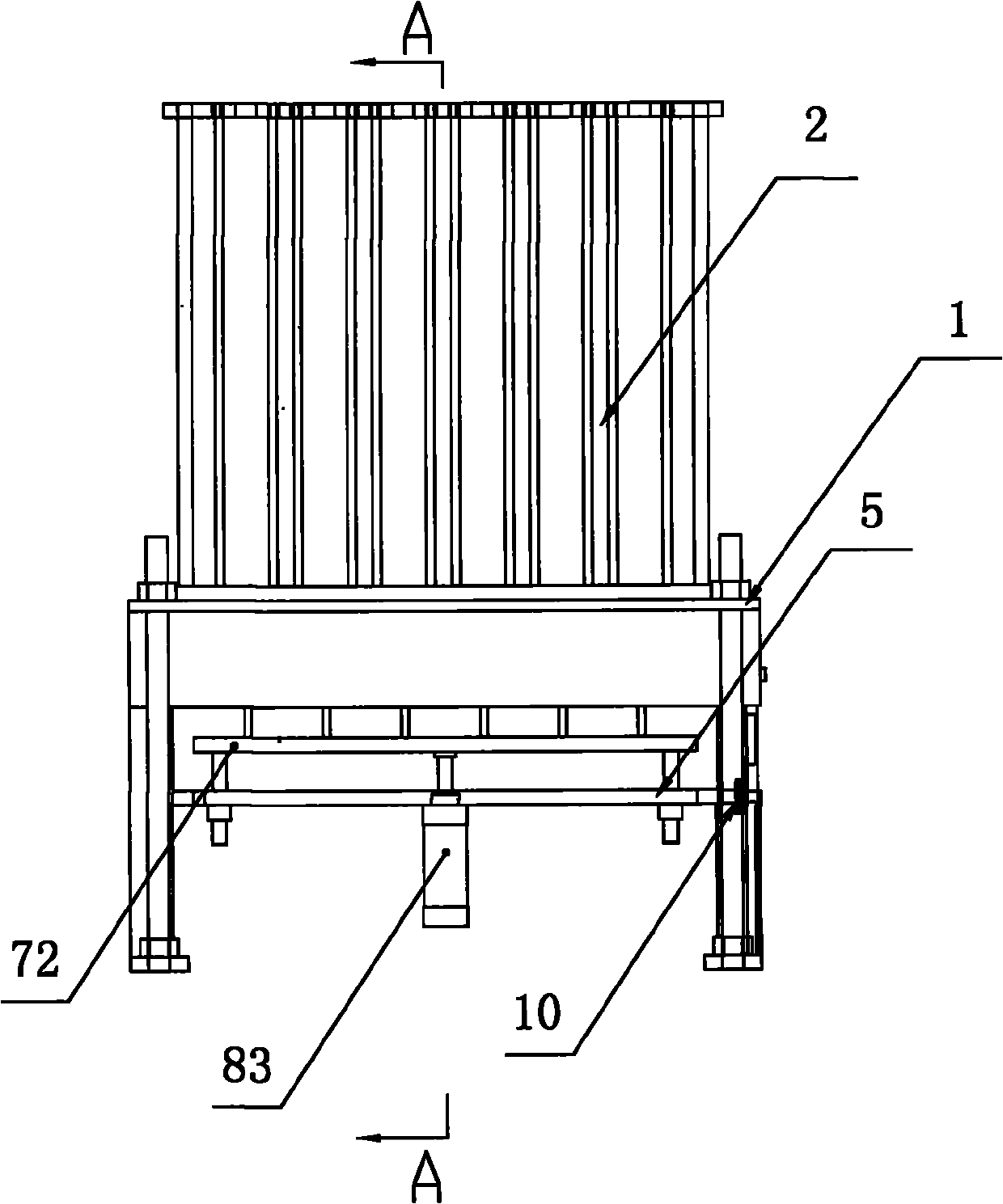

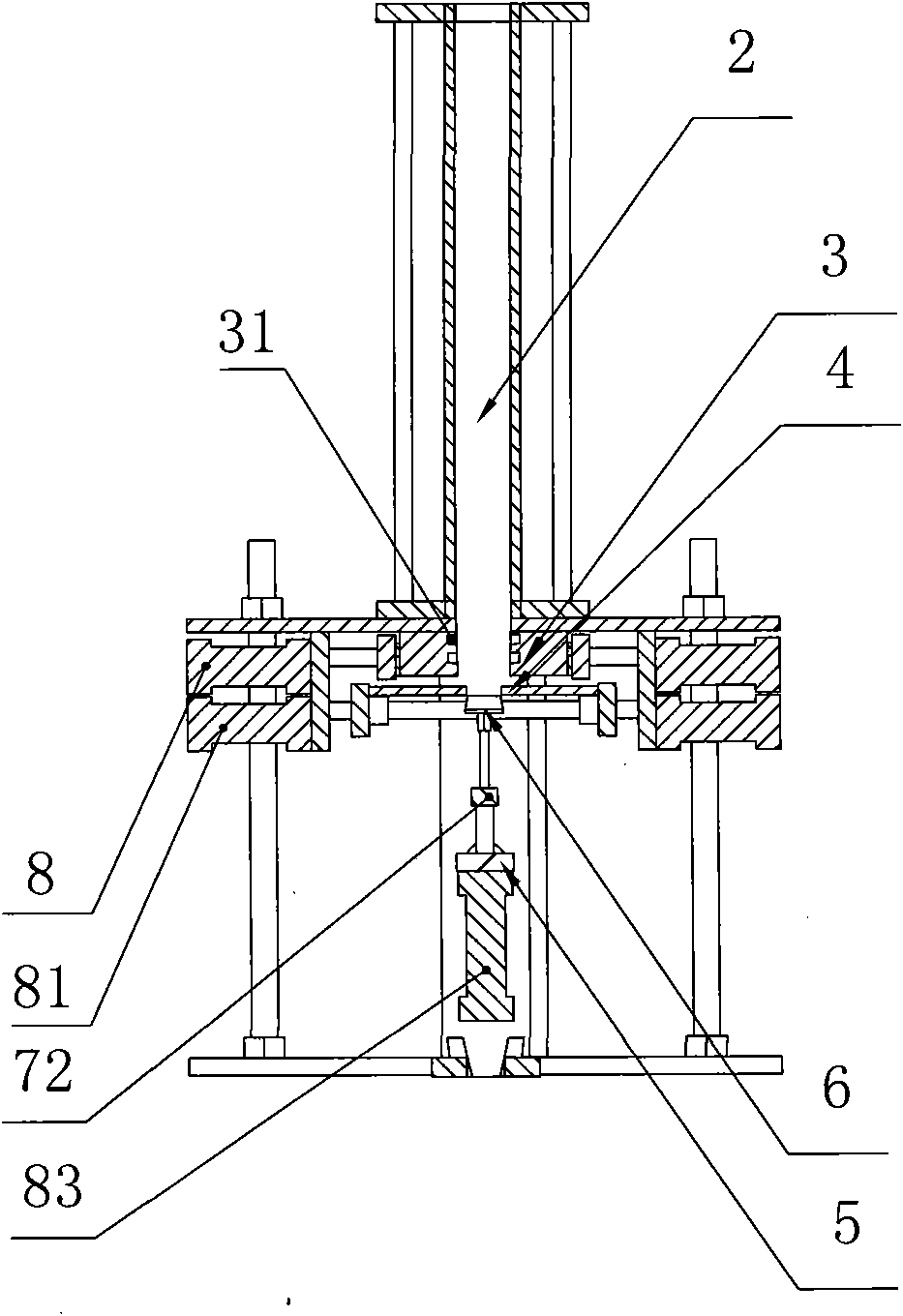

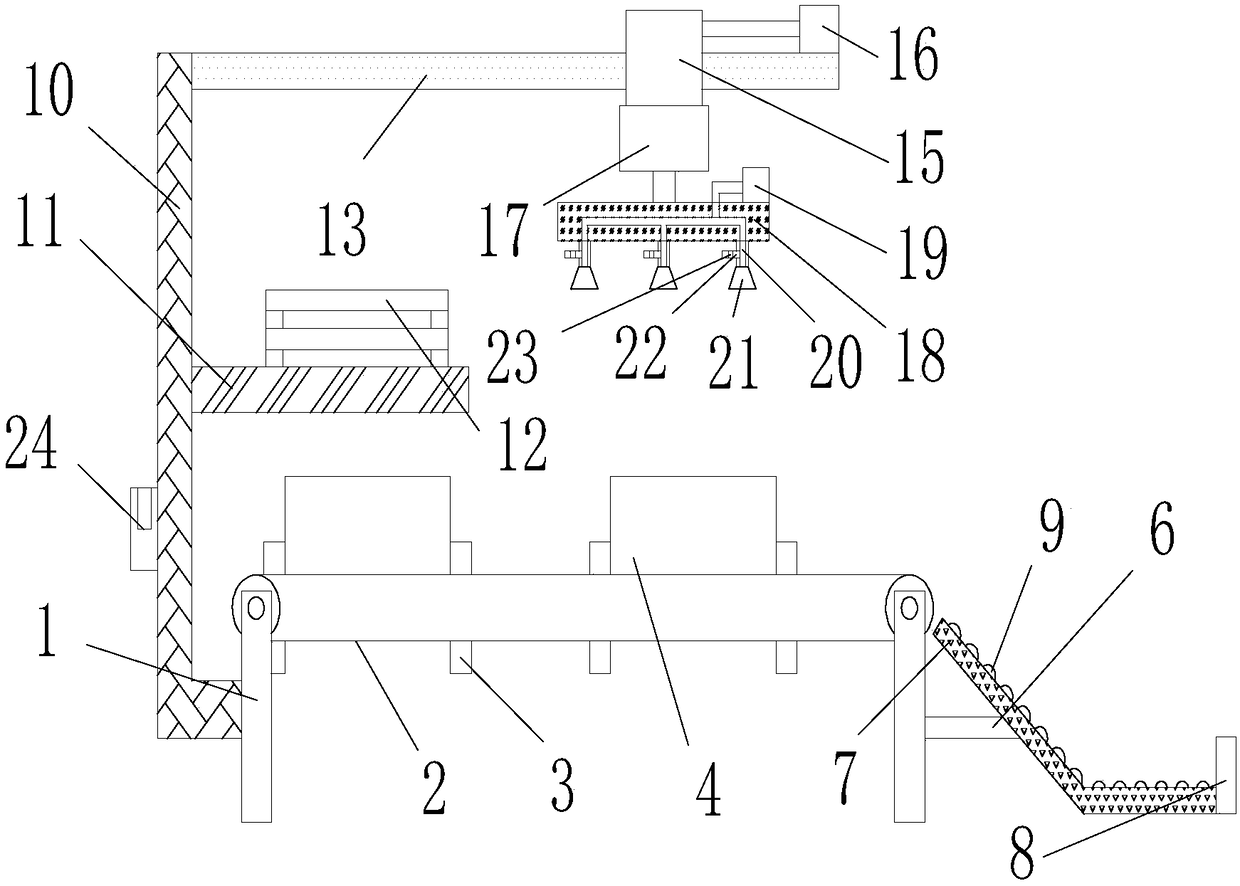

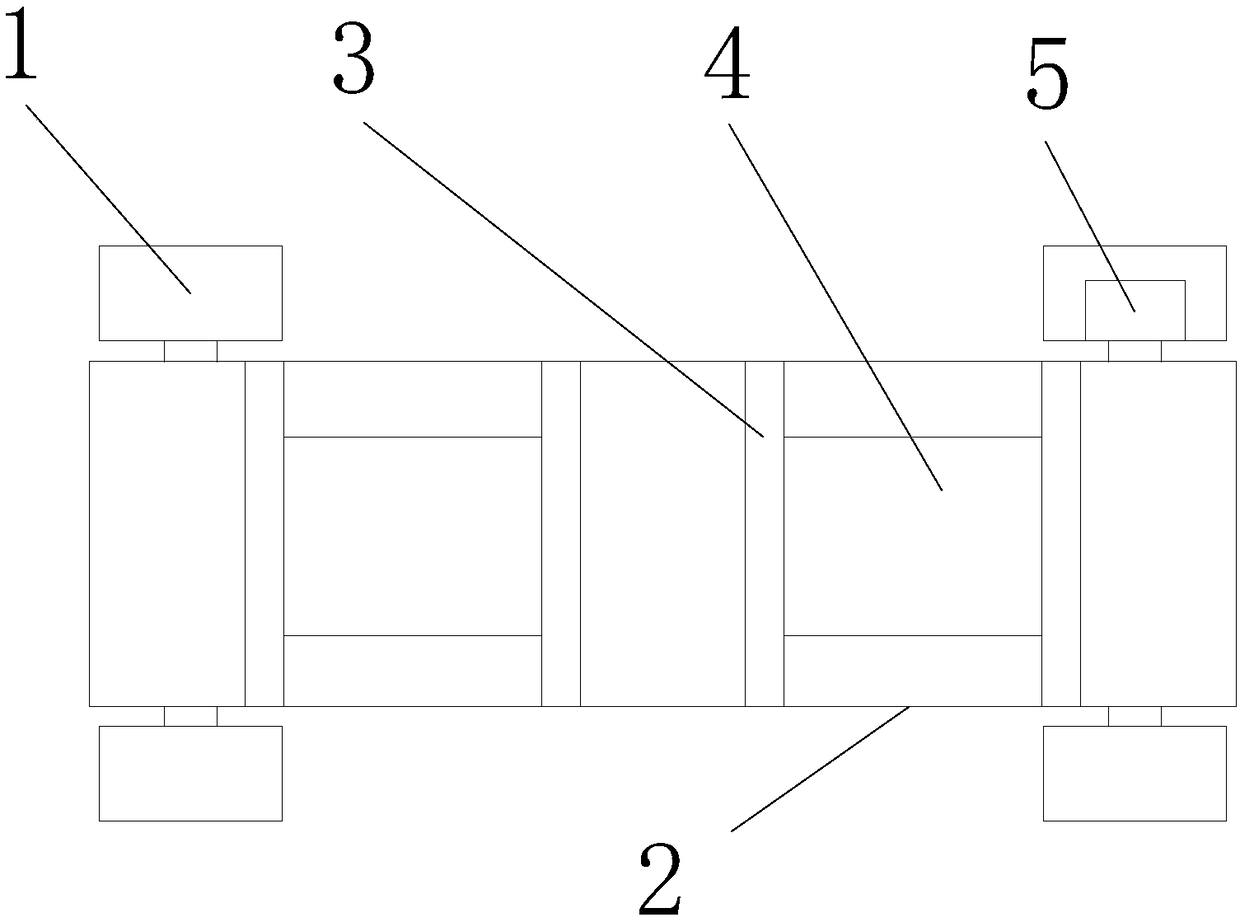

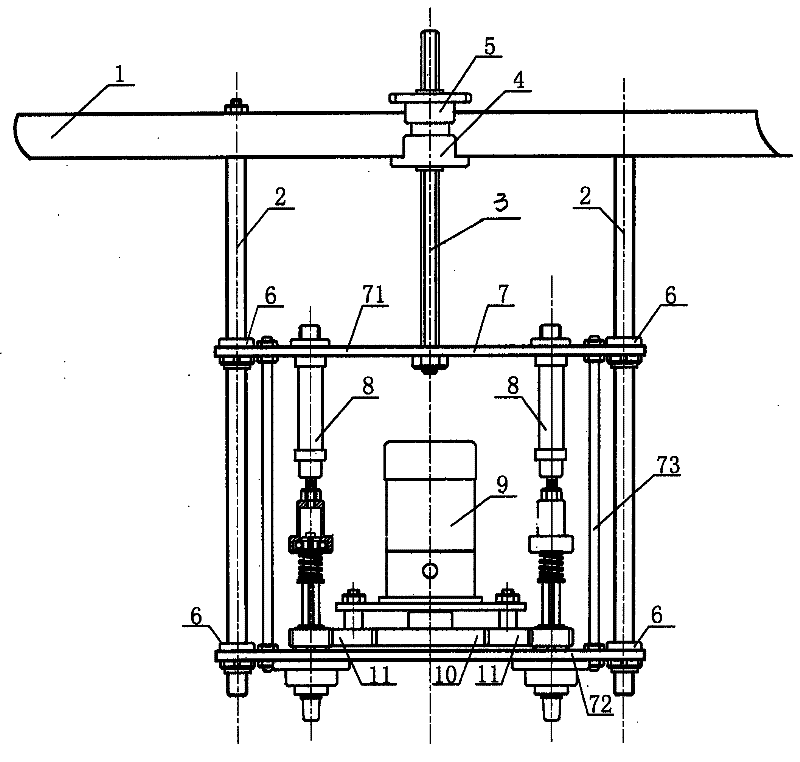

Medical centrifugal tube capping device

ActiveCN102001607AImprove capping efficiencyLow biological riskCapsClosure using capsControl systemEngineering

The invention provides a medical centrifugal tube capping device for capping and sealing medical centrifugal tubes. The medical centrifugal tube capping device is composed of a bottom board, a clamping mechanism, a capping mechanism and a control system, wherein the clamping mechanism is arranged on the bottom board, and is composed of a fixed seat with a fixed clamping part, a pushing mechanism and a sliding seat with a movable clamping part, wherein the pushing mechanism can drive the sliding seat to move. The capping mechanism is arranged on the bottom board, and comprises a rotating mechanism and a capping head which is driven to rotate by the rotating mechanism, and the control system can control the clamping mechanism to perform clamping and the rotating mechanism respectively to rotate. By the automatic clamping and capping of the mechanisms, the capping efficiency of the medical centrifugal tubes is greatly improved, and the biological risks of workers are reduced. The medical centrifugal tube capping device has low cost and simple structure and is convenient for maintenance.

Owner:SHENZHEN GOLDSITE DIAGNOSTICS

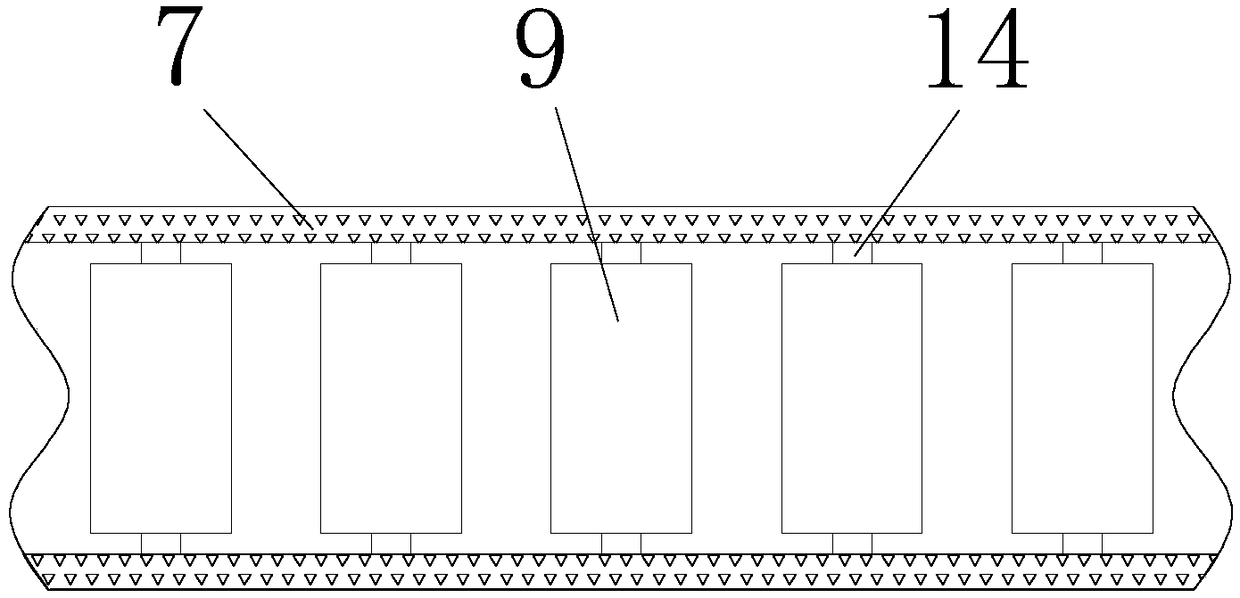

Cover sealing device for storage battery

InactiveCN108520973AGood sealingRealize automatic cappingAssembling battery machinesFinal product manufactureFixed frameSolenoid valve

The invention discloses a cover sealing device for a storage battery. The device comprises a support column, a conveyor belt, a clamping block, the storage battery, a motor, a fixing plate, a discharging frame, a rubber buffer plate, a rubber roller, a fixing frame, a placing plate, a storage battery top cover, a top plate, a fixing shaft, a sliding block, a first linear actuator, a second linearactuator, a connecting plate, an air pump, an air suction pipe, a vacuum sucker, an exhaust pipe, a solenoid valve and a solenoid valve controller. The cover sealing device for the storage battery issimple in structure and novel in design, automatic cover sealing of the storage battery is achieved, the storage battery cover sealing efficiency is improved, the labor intensity of workers is lowered, the time is shortened, cover sealing can be conveniently conducted on the storage battery continuously, the cover sealing efficiency of the storage battery is improved, and the workers can use the device conveniently; when the device is used, by means of interaction of the air pump, the air suction pipe, the exhaust pipe, the vacuum sucker and the connecting plate, stable fixing of the storage battery top cover is achieved, it is guaranteed that the storage battery is stable in the adjusting process, and use is facilitated.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

Portable glass tank capping machine

ActiveCN111285307AFast and secure insertionShrinking is good forThreadless stopper insertionClosure stoppersHydraulic cylinderMechanical engineering

The invention discloses a portable glass tank capping machine. The structure of the portable glass tank capping machine comprises a wooden plug clamping and shrinking device, a hydraulic cylinder, ananti-skid handle, a supporting barrel, an inner connecting rod, an outer connecting rod and a glass tank clamping device, the outer top center of the supporting barrel is perpendicularly connected tothe anti-skid handle, the inner bottom of the supporting barrel is perpendicularly connected with the hydraulic cylinder, and the hydraulic cylinder is located over the wooden plug clamping and shrinking device. Compared with prior art, the portable glass tank capping machine has the beneficial effects that the novel portable glass tank capping machine is formed by combining the wooden plug clamping and shrinking device, the hydraulic cylinder, the anti-skid handle, the supporting barrel, the inner connecting rod, the outer connecting rod and the glass tank clamping device, the size is small,carrying is convenient, a glass tank is fixed through the suction cups, the wooden plug is clamped and shrunk in the mode that the wooden plug is clamped and shrunk, so that the diameter of the woodenplug is reduced, the wooden plug is pushed downwards through the hydraulic cylinder, the wooden plug can be conveniently, rapidly and stably plugged into a glass tank opening, the capping and plugging efficiency is greatly improved, capping and plugging are stable, and damage to the glass tank capping and plugging is effectively avoided.

Owner:平邑经济开发区投资发展有限公司

Automatic capping machine

The invention discloses an automatic capping machine. The automatic capping machine comprises a worktable; the worktable is provided with a lid placing module and a transmission module used for conveying cup bodies; the lid placing module comprises a lid storing device and a capping device, wherein the capping device rotates around a horizontal axis and is used for obtaining cup lids in a sleeving mode and pressing the cup lids on the cup bodies; the capping device is arranged below the lid storing device; the transmission module comprises a cup conveying disc, a first transmission track and a second transmission track, wherein the cup conveying disc rotates around a vertical axis, the first transmission track is used for conveying the cup bodies to the cup conveying disc, and the second transmission track is used for receiving the capped cup bodies on the cup conveying disc; the capping device is arranged above the cup conveying disc; a driving module which is used for driving the capping device and the cup conveying disc to rotate is further arranged in the worktable; and the worktable is further provided with a controlling module. The automatic capping machine is simple in structure, high in capping efficiency and high in automation degree, and production cost is reduced.

Owner:FOSHAN UNIVERSITY

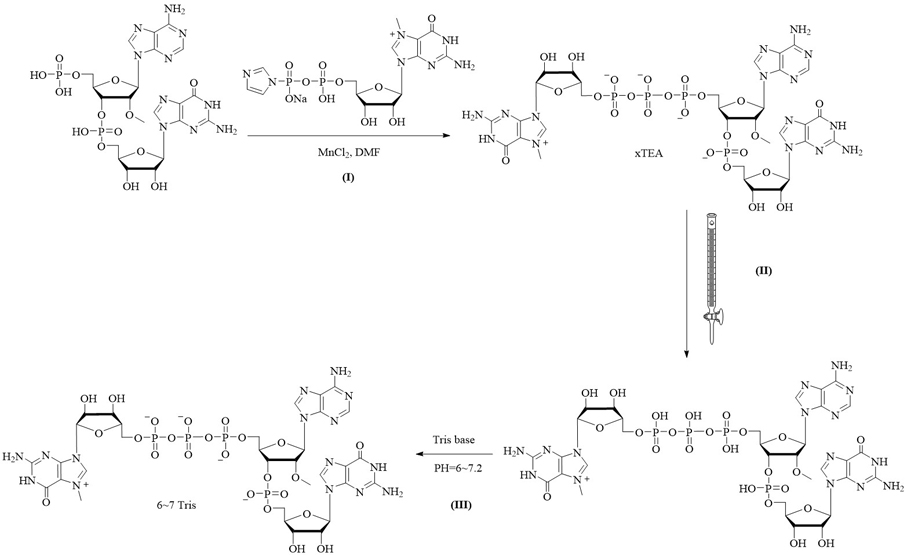

Capped composition as well as preparation method and in-vitro transcription reaction system thereof

ActiveCN114540444AIncrease productionImprove capping efficiencyFermentationEnzyme catalysisBio engineering

The invention discloses a capping composition as well as a preparation method and an in-vitro transcription reaction system thereof, and belongs to chemical and biological engineering, the inventor of the application applies TRIS to a biological enzyme catalysis system, the composition is mainly composed of a salt solution compounded by a capping analogue and TRIS according to a molar ratio of 1: (3-7), and the TRIS has relatively good biocompatibility, so that the TRIS can be applied to a biological enzyme catalysis system. When some special mRNA sequences are transcribed, the biocompatibility of the TRIS and the mRNA is more excellent, the in-vitro transcription efficiency of the mRNA can be improved, and the capping efficiency of the mRNA can be obviously improved.

Owner:JIANGSU SYNTHGENE BIOTECHNOLOGY CO LTD

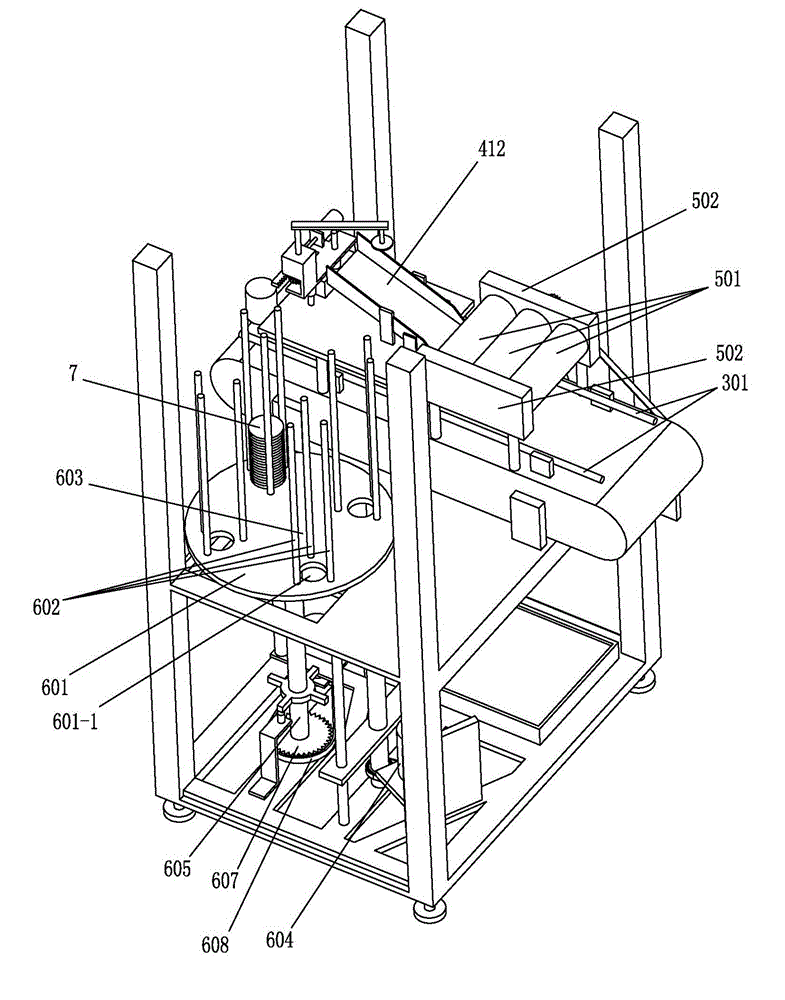

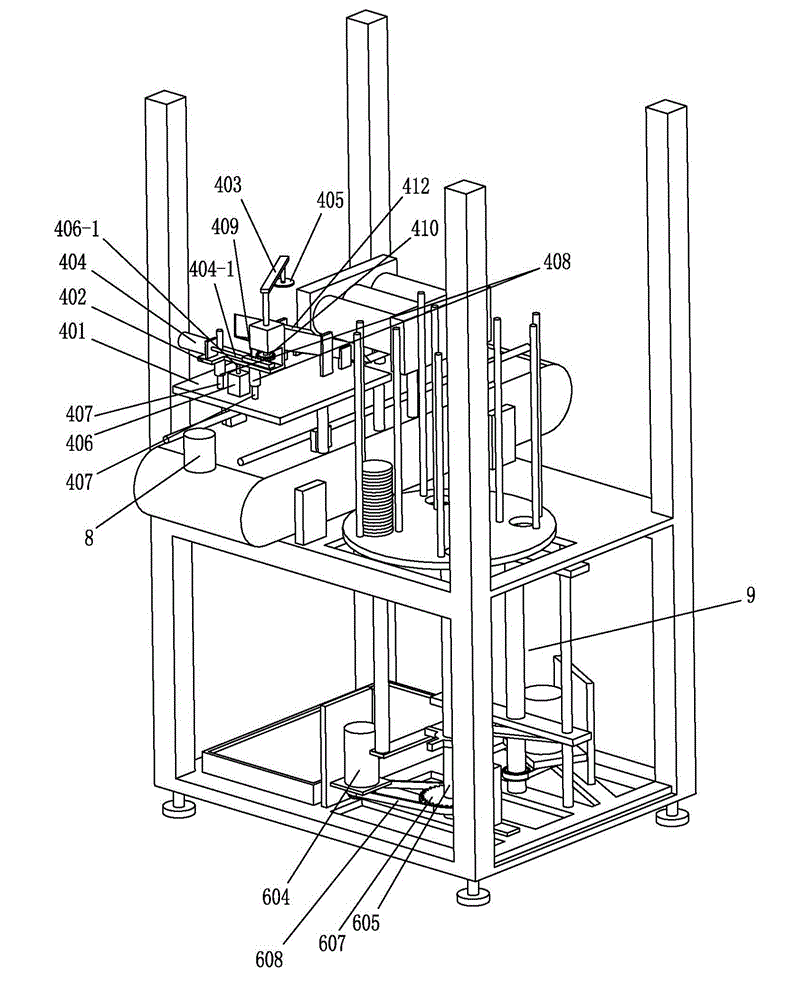

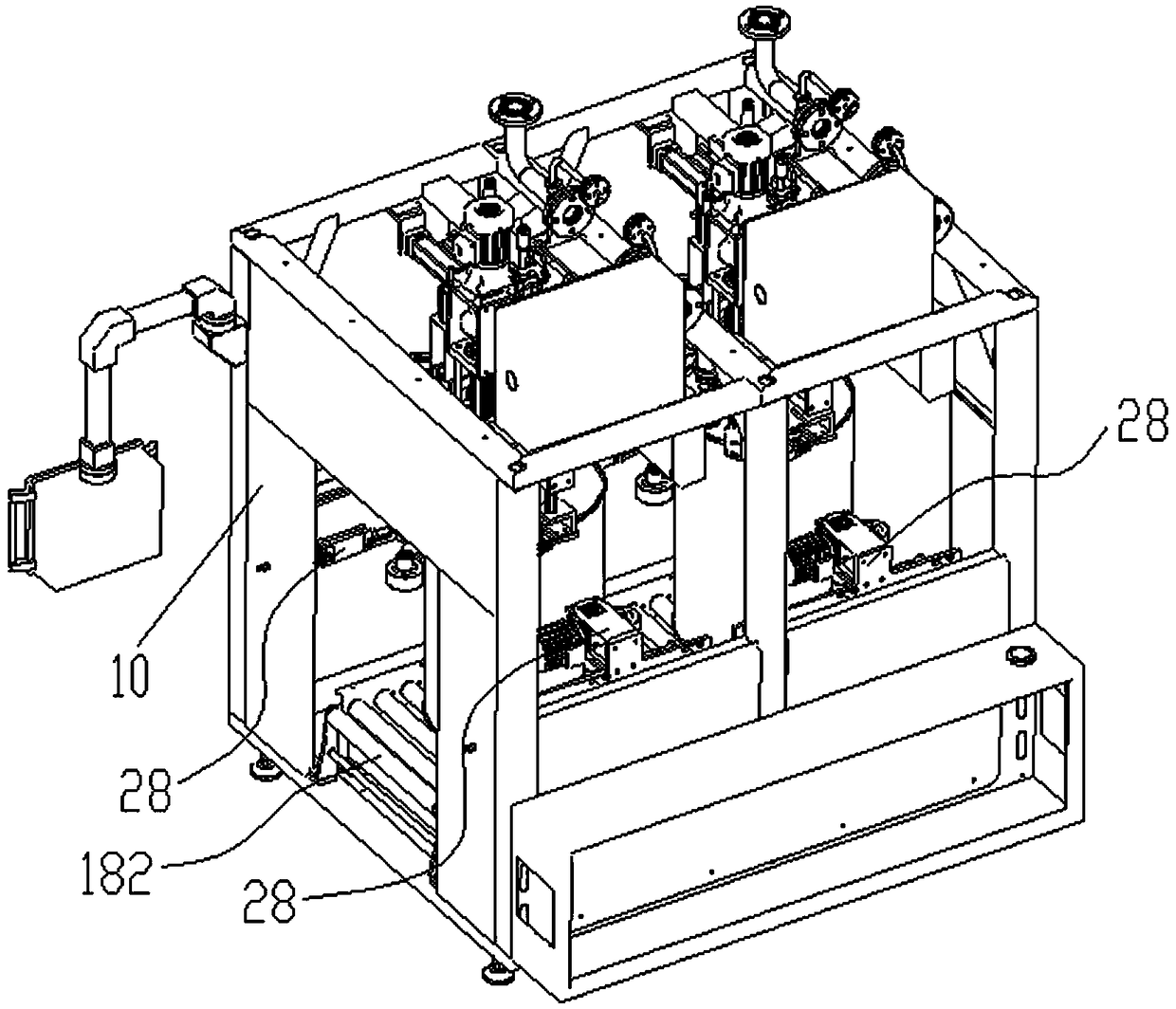

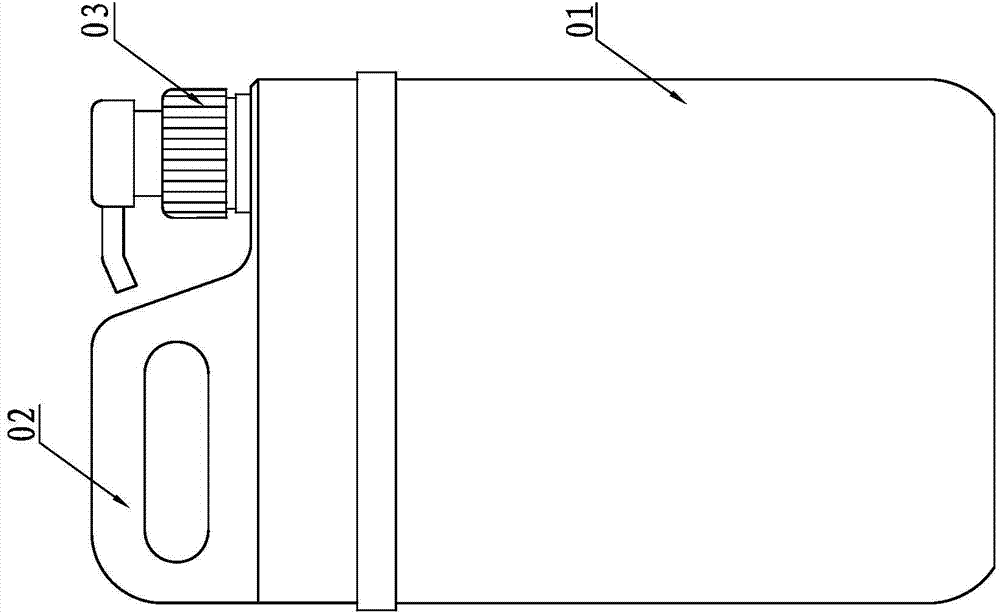

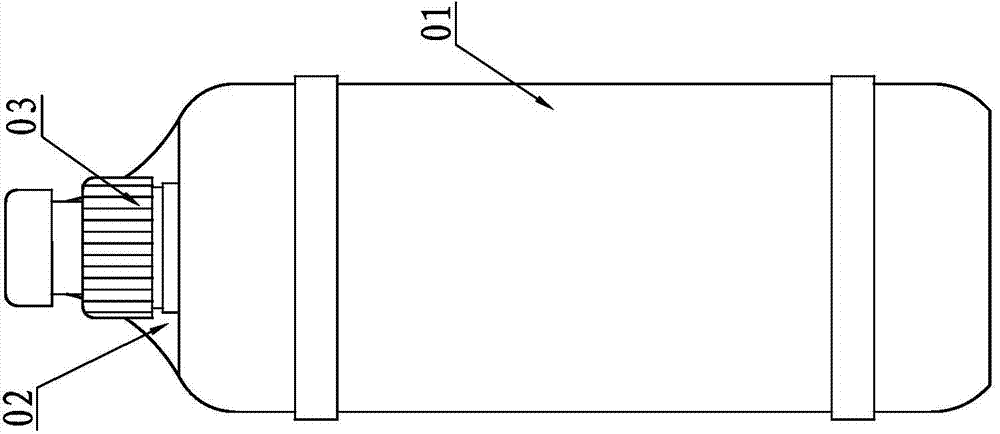

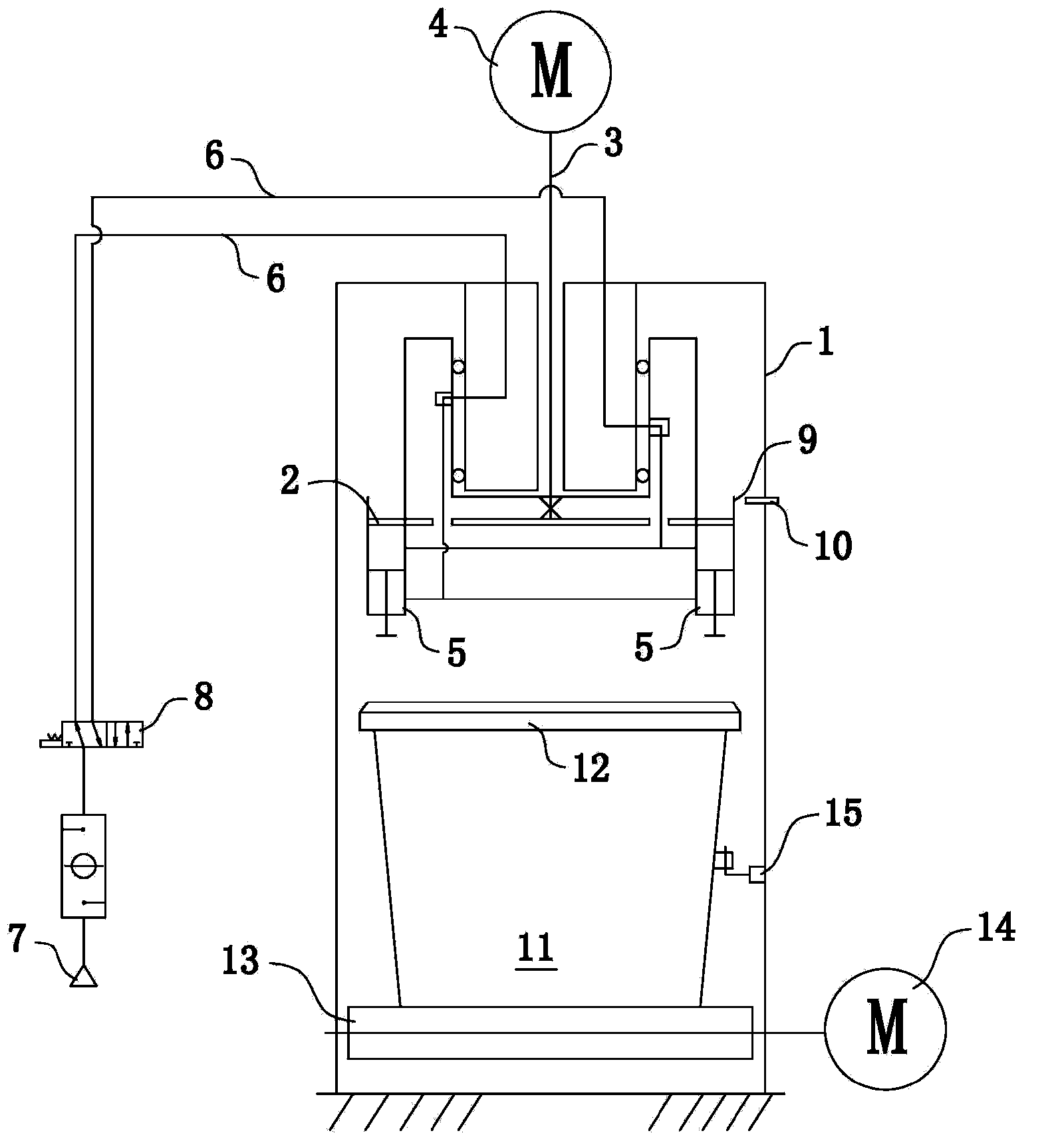

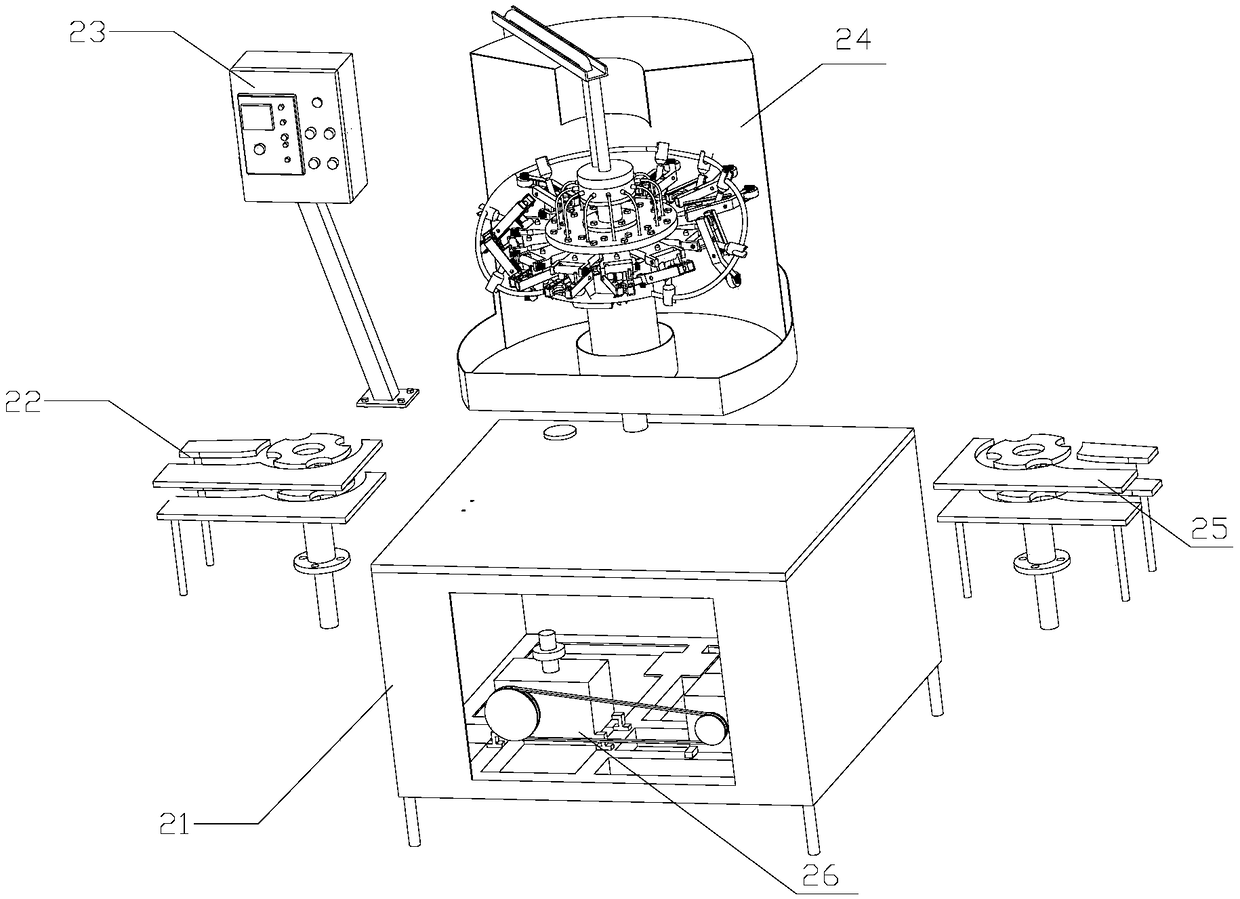

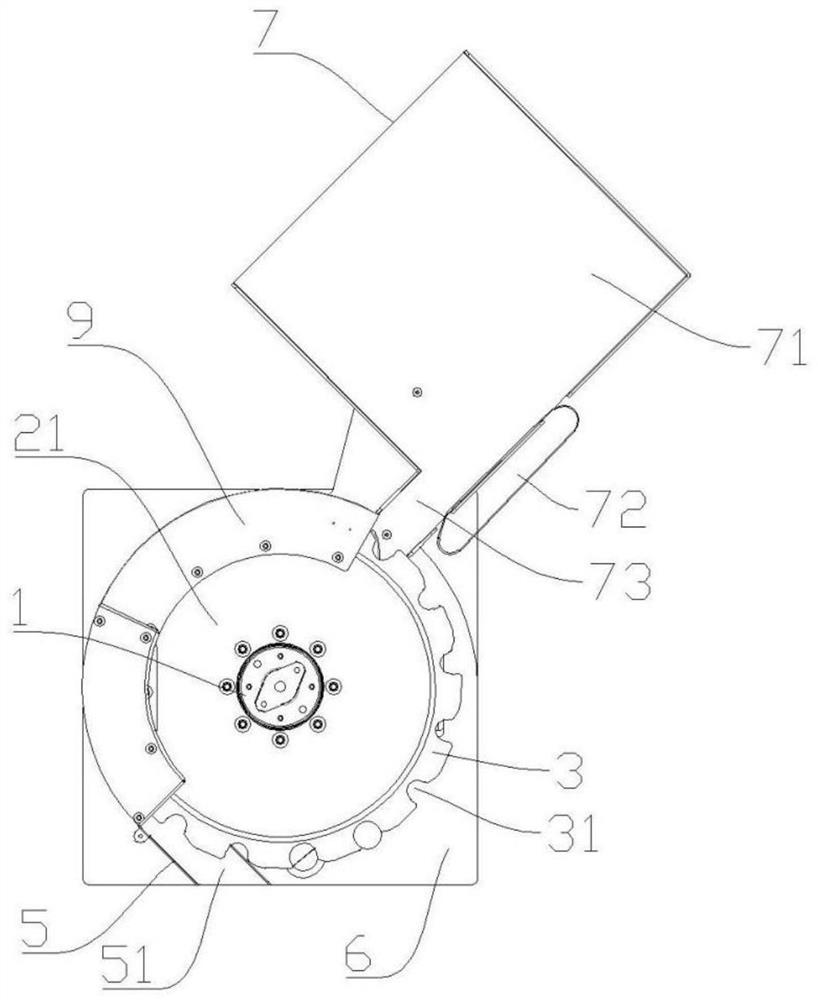

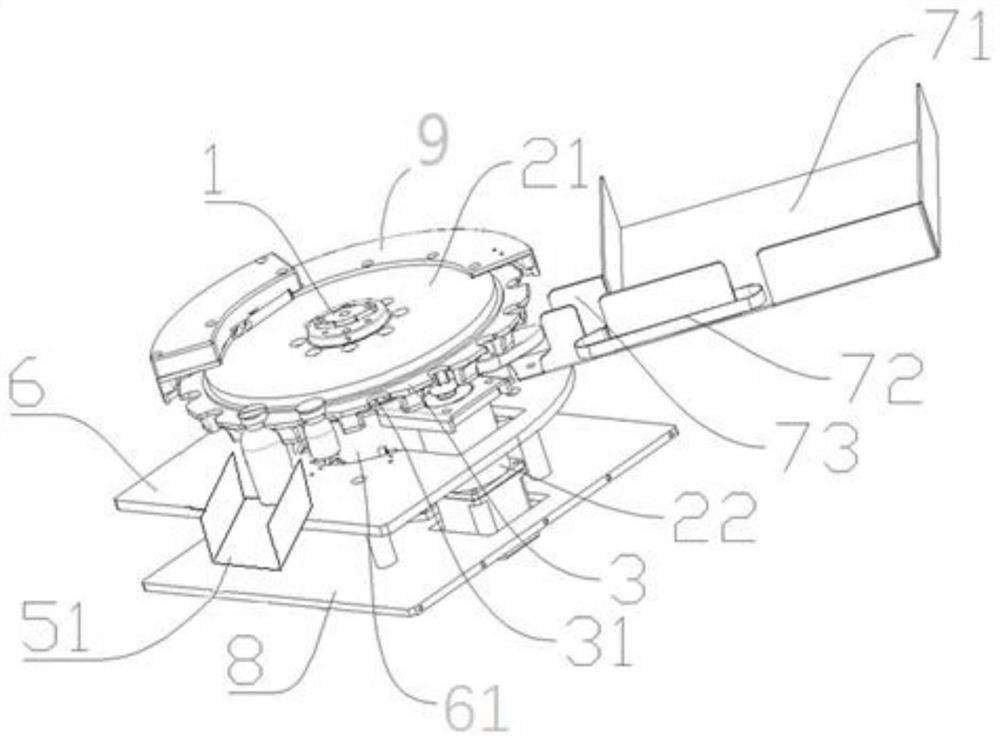

Automatic lid beating machine for sealing glue barrel

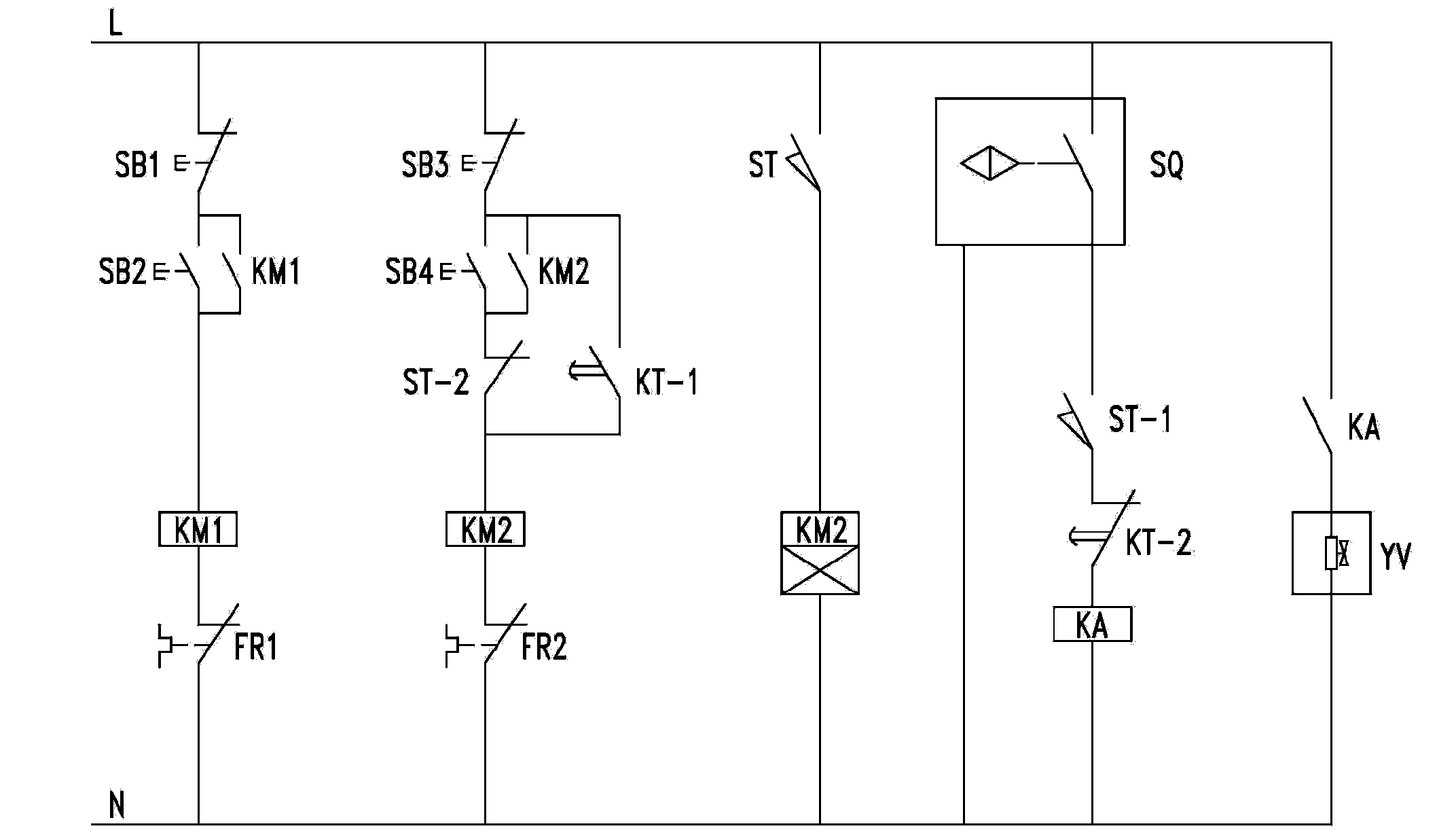

ActiveCN103449341AGuaranteed tightnessSimple structureCapsCapping machinery safety/controlEngineeringElectrical and Electronics engineering

The invention discloses an automatic lid beating machine for sealing a glue barrel and belongs to auxiliary packaging devices for glue barrels. The automatic lid beating machine comprises a frame, wherein a rotation disc is mounted on the frame, the rotation disc is in power connection with a first motor through a linkage rod and used for driving the rotation disc to rotate through the first motor, a cylinder is mounted on the rotation disc and communicated with an air feeding air source through a pipeline, and an electromagnetic directional valve is further arranged on the pipeline; the cylinder is driven to shift in the circular direction by the rotation disc, and during the process of shifting, the lid of the glue barrel is impacted downwards repeatedly, the lid of the barrel is enabled to receive equal impact each time, therefore, the leak tightness of the product packaging can be ensured, and the stability of the product quality is effectively improved; the functions of a travel switch and a proximity switch are combined, through the coordination with the input and the output of a power roll, the operation of capping the glue barrel can be automatically accomplished on the equipment completely, and the capping efficiency is remarkably improved when compared with the capping efficiency of traditional manual beating.

Owner:CHENGDU GUIBAO NEW MATERIAL

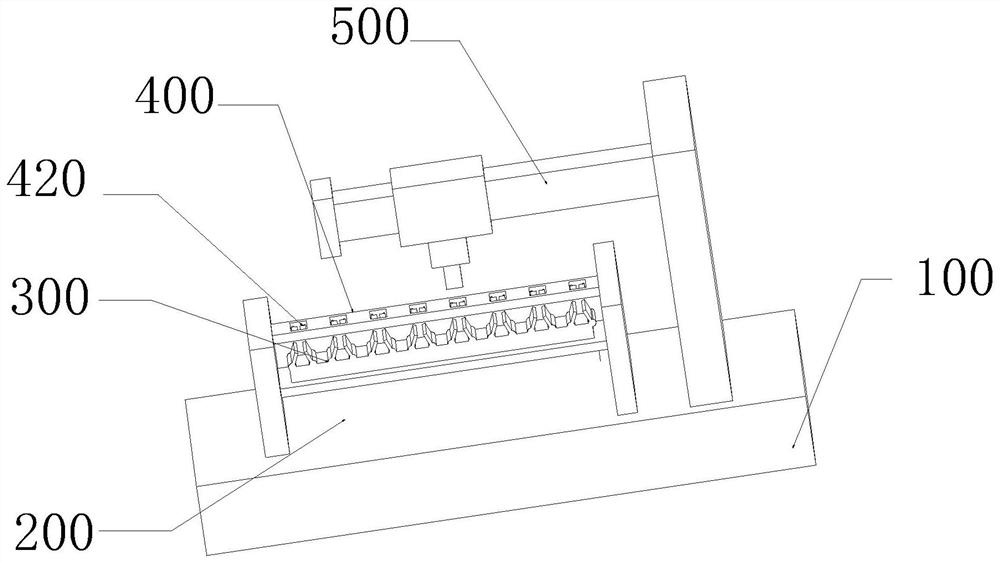

Bottom cover pressing equipment based on electronic cigarette battery production

InactiveCN113017145AStable gland workImprove capping efficiencyTobacco pipesGear driveElectrical battery

The invention relates to bottom cover pressing equipment, in particular to bottom cover pressing equipment based on electronic cigarette battery production. According to the technical aims, the bottom cover pressing equipment based on electronic cigarette battery production has an automatic feeding function and is good in clamping effect. The bottom cover pressing equipment based on electronic cigarette battery production comprises three electronic cigarette boxes; covers, which are arranged at the tops of the electronic cigarette boxes in a sliding manner; placing mechanisms, which are arranged between the electronic cigarette boxes; and capping mechanisms, which are arranged on the placing mechanisms. When a first rotating rod rotates anticlockwise, a sector gear is driven to rotate to be meshed with a first gear, a fourth spring is compressed, the first gear rotates clockwise, the first gear drives a rack and a sliding plate to move rightwards, the sliding plate conveys a bottom cover to a cover pressing rod, and the automatic feeding effect is achieved.

Owner:SHENZHEN AIRUISI ELECTRONICS CO LTD

Canning and cover pressing equipment after agricultural byproduct deep processing

InactiveCN108483372AReduce manual labor intensityImprove capping efficiencyCapsClosure using capsAgricultural engineeringDeep processing

The invention discloses canning and cover pressing equipment after agricultural byproduct deep processing and belongs to the technical field of canning and cover pressing equipment. A supporting column is arranged on the left side of the top of a base; a supporting rod is arranged on the top of the supporting column; a single chip microcomputer control box is installed on the left side of the supporting column; a sliding strip is installed on the right side of the supporting column; a sliding seat is connected to the right side of the sliding strip in a clamping manner; a limiting sensor is installed at the bottom of the right side of the sliding seat; a fixing bolt is connected to the right side of the sliding seat in an inserting manner; a large electric telescopic rod is arranged at thebottom of the supporting rod; a connection head is welded to the bottom of the large electric telescopic rod; a placement seat is in threaded connection to the top of the base; a placement groove isformed in the top of the placement seat; a supporting plate is in threaded connection to the bottom of the connection head; and fixed columns are welded to the left side and the right side of the bottom of the supporting plate respectively. Through arrangement of the canning and cover pressing equipment after agricultural byproduct deep processing, the canning and cover pressing equipment can replace manual cover pressing, lowers the manual labor intensity and is high in cover pressing efficiency.

Owner:李柱子

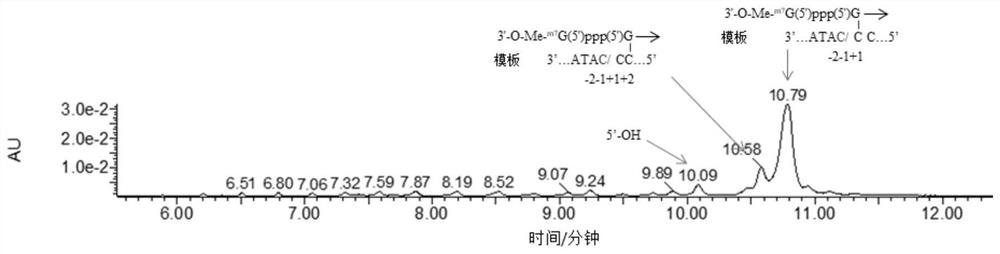

Synthesis method of capping RNA and capping RNA transcription reaction solution

The invention relates to the technical field of gene engineering, in particular to a synthesis method of capping RNA and a capping RNA transcription reaction solution. The synthesis method of the capping RNA comprises the following steps: mixing raw materials and performing incubating, wherein the raw materials comprise a DNA template, capping polynucleotide, NTPs, RNA polymerase and a solution containing magnesium ions, the DNA template comprises an RNA promoter, a basic group at the -1 site of a template chain of a RNA promoter is cytosine, and The basic groups from the +1 site to the +n site of a template strand of the RNA promoter are respectively complementarily paired with B1 to Bn in capping polynucleotide. According to the application, the basic group at the site 1 of the template strand of the RNA promoter is regulated to be the cytosine, and besides, the basic groups at the site + 1 to the site + n of the template strand of the RNA promoter are respectively regulated to be complementarily paired with the B1 to the Bn in the capping polynucleotide, so that the RNA capping efficiency is remarkably improved, and the stability of the RNA after transcription synthesis is favorably improved.

Owner:SHANGHAI ZHAOWEI TECH DEV +1

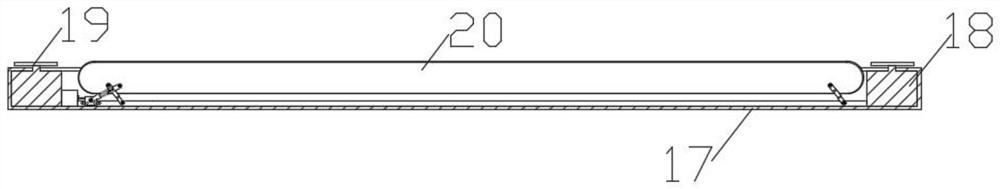

Bottle cleaning mechanism and beverage loading equipment

InactiveCN108821217AImprove cleaning efficiencyReasonable structureSynchronising machinesFlanged caps applicationLiquid storage tankEngineering

The invention relates to the field of food automation production. A bottle cleaning mechanism comprises a sleeve, a slide track, a rotating disk, a liquid storage tank, a clamp assembly, a fluid baffle, a waste liquid barrel, a rotation shaft and a rinse-solution material pipe; the bottom of the fluid baffle is fixed at a rear side of the waste liquid barrel, and a cross section of the fluid baffle presents an arced baffle plate. The bottle cleaning mechanism has the advantages of reasonable structure and high bottle cleaning efficiency.

Owner:杨立撒

Online detection device and method for dialyzer O-shaped ring

PendingCN106841220AIncrease productivityImprove efficiencyOptically investigating flaws/contaminationProduction lineHuman power

The invention relates to an online detection device for a dialyzer O-shaped ring. The online detection device comprises a conveying mechanism and shooting components, wherein a dialyzer is loaded on the conveying mechanism; the shooting components are arranged on the two sides of the conveying mechanism; and the shooting components are used for shooting the O-shaped ring on a side wall of the dialyzer. According to the invention, in the production process, a camera is adopted for shooting the O-shaped ring, and then a worker can observe from a high-definition picture, so that the manpower resource is reduced while the production efficiency is increased, and the detection is more careful; and a multi-station rotating cover device is used for producing, so that the manpower is greatly reduced, the efficiency of the rotating cover is greatly increased, and the whole production line is more intelligent, efficient and stable.

Owner:贝恩医疗设备(广州)有限公司

Capping machine

The invention relates to a capping machine, comprising a conveyor belt arranged in a longitudinal direction and a capping assembly, the capping assembly includes a first pulley, a second pulley, and a pressing machine mounted on the first pulley and the second pulley. Capping conveyor belt, the capping conveyor belt is arranged along the longitudinal direction, the capping conveyor belt is located above the conveyor belt, the capping assembly can move up and down under the drive of the driving device to cap the product, and the transmission of the capping conveyor belt and the conveyor belt Same speed. When the product needs to be capped and sealed, the product is continuously conveyed by the conveyor belt. When the product reaches the bottom of the capping assembly, the driving mechanism drives the capping assembly to cap the product. While the capping assembly is performing the capping action, The product still moves with the conveyor belt, the whole capping process has no intermittent, and the capping efficiency is high.

Owner:江苏首达机械有限公司

Lifting gear of cap whirling machine

InactiveCN101157433BAutomatic adjustment of tightening torqueFast flexible preload approachCapsThreaded caps applicationMotor driveEngineering

A screw cover retractor device of a screw cover machine comprises a supporting frame, two screw retractor components, a motor, a motor gear and a gear idle. The screw retractor components are arranged at the supporting frame. The motor drives the screw retractor components turning by the gear idle. The flexing of screw cover tie-ins is drove by a cylinder. The cylinder is communicated with pressure air source and controlled by a control circuit. Adopting the device, a motor can synchronously drive two screw retractor components and can synchronously and tightly screw two covers once, screwingcover efficiency can be increased by one time by comparing with the prior technology. By adopting quick disappearing end bumper of the cylinder driving disappearing end bumper axis of rotation, the rapid flexible prepressing approach of the screw cover tie-ins and the covers is implemented. A reset spring can ensure the bottle covers and the bottle mouths are in a compressing condition all the time and can also automatically adjust bottle cover winding moment to ensure the screw cover tie-ins wind up the moments of the bottle covers, etc, automatically avoid screwing loosely or in a fracturedstate due to dimension errors of the bottle covers and the bottle height.

Owner:常州市金坛中正包装机械科技有限公司

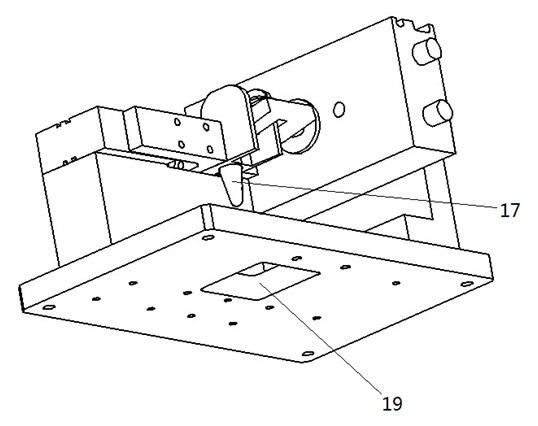

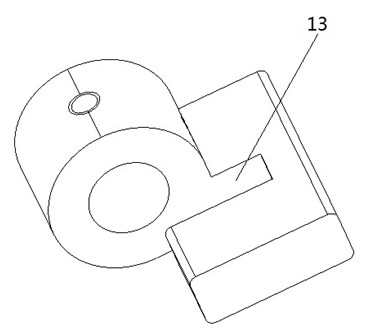

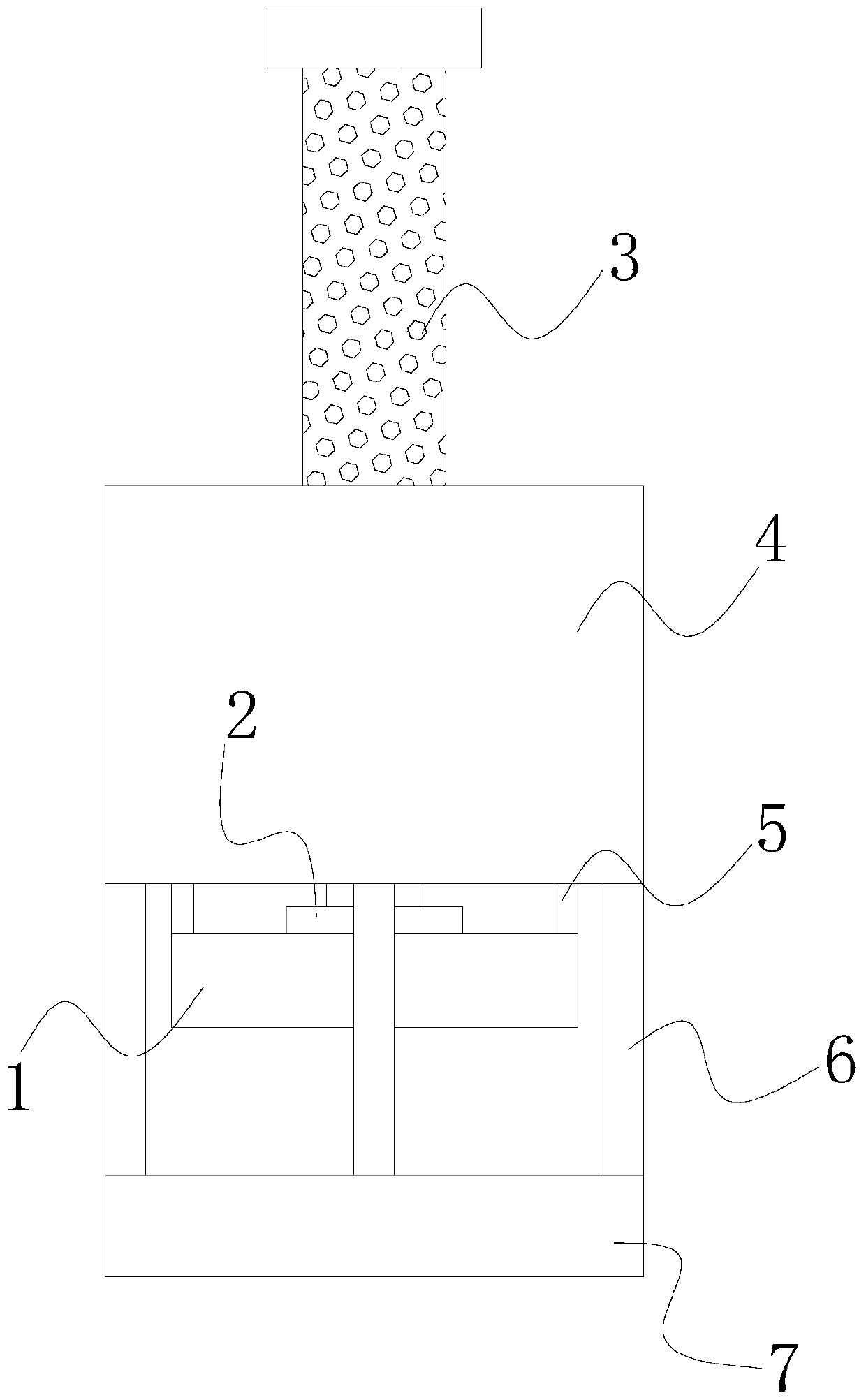

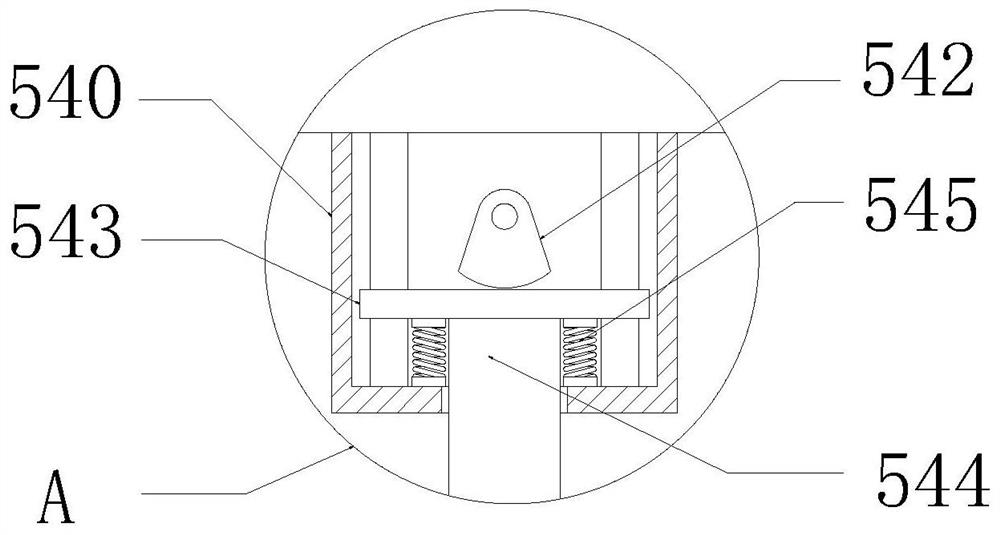

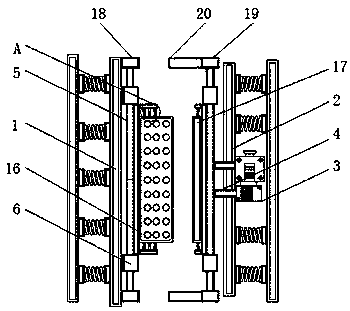

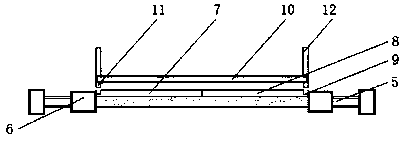

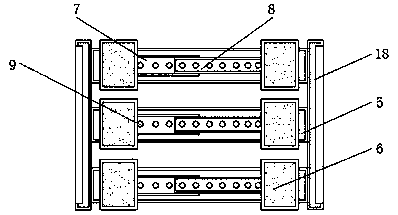

Capping mechanism for relay processing

PendingCN111900038ARealize the function of automatic cappingImprove capping efficiencyRelaysStructural engineeringCap device

The invention relates to the technical field of relay processing, and further discloses a capping mechanism for relay machining. The capping mechanism comprises a bottom plate, and a machining plate is fixedly mounted at the top end of the bottom plate. A seat placing device is arranged above the machining plate; a cover placing device is arranged above the seat placing device; a capping device isarranged above the cap placing device; the seat placing device comprises a seat placing belt arranged above the machining plate, an installation seat is fixedly installed at the top end of the seat placing belt, the cover placing device comprises a cover placing belt arranged over the seat placing device, a cover placing groove is formed in the top end of the cover placing belt, and cover placingplates are hinged to the two sides of the cover placing groove. According to the capping mechanism for relay processing, through the arrangement of the seat placing device, the cap placing device andthe structures of the seat placing device and the cap placing device, under the cooperation of the capping device, the automatic capping function can be achieved, the capping mechanism has the advantages of being high in capping efficiency and the like, and the above-mentioned technical problems are solved.

Owner:南通梓晟照明科技有限公司

A proofreading-oriented capping device for the production of a new energy battery module

InactiveCN109037744AReduce labor intensityAvoid low stabilityMaterial gluingSecondary cell detailsEngineeringCap device

The invention discloses a proofreading-oriented capping device for producing a new energy battery module, include a first support arm, moving sleeve, connecting sleeve, a first guide cap and a secondguide cap, a second support arm is mounted on the right side of the first support arm, The connecting sleeve is fixedly welded to the inner wall of the side baffle plate, and a connecting rod is arranged on the right side of the inner end of the connecting sleeve, the first guide cap and the second guide cap are fixedly bonded to the ends of the fixing plate, a second guide cap is arranged on theright side of the first guide cap, and the inner wall of the second guide cap is fixedly bonded to the guide bar. In a proofreading-oriented cover device for producing the new energy battery module, During the process of fixing the cover between the battery module and the cover plate, the central axis between the battery module and the cover plate is in the same position, so that the battery module cover plate can be first calibrated, and the hydraulic cylinder can provide mechanical power for the lifting and lowering of the cover plate, which is beneficial to reducing the labor intensity of the laborer.

Owner:潍坊华高信息科技有限公司

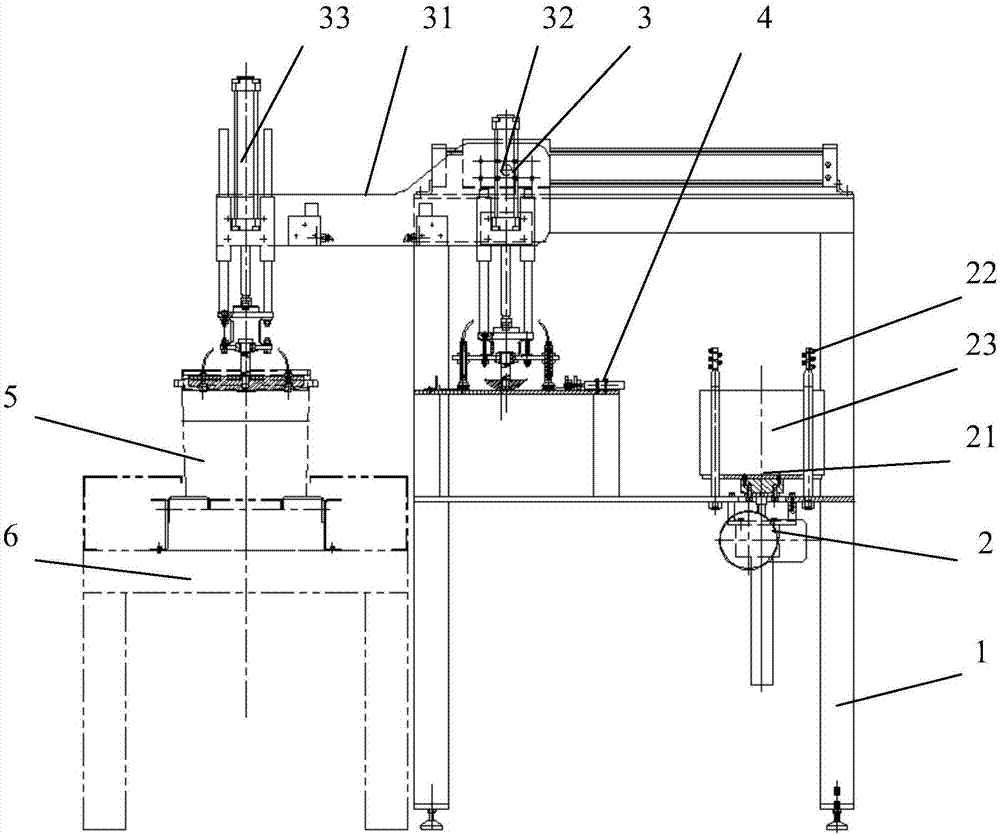

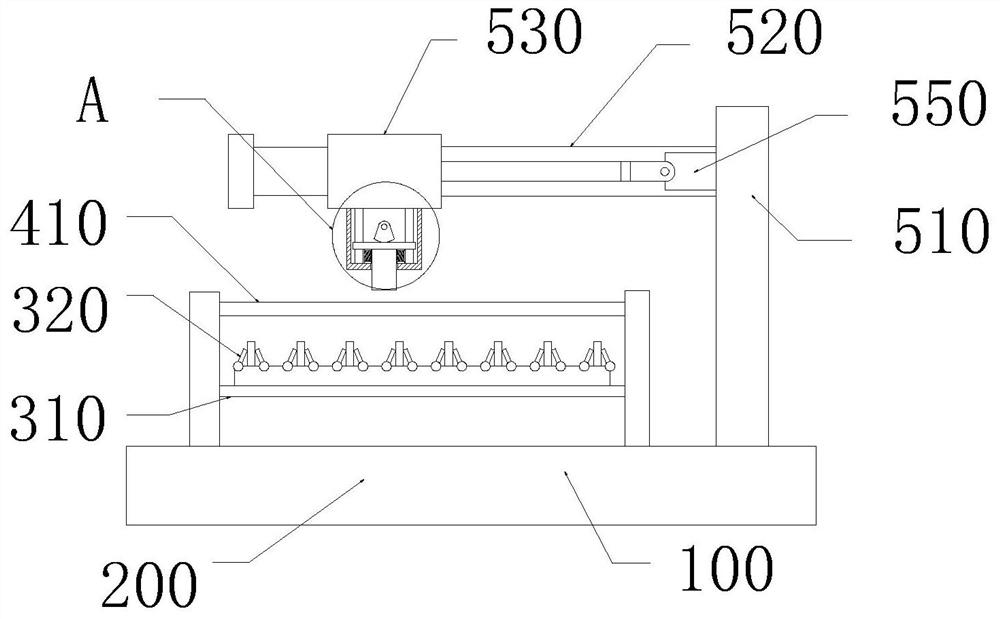

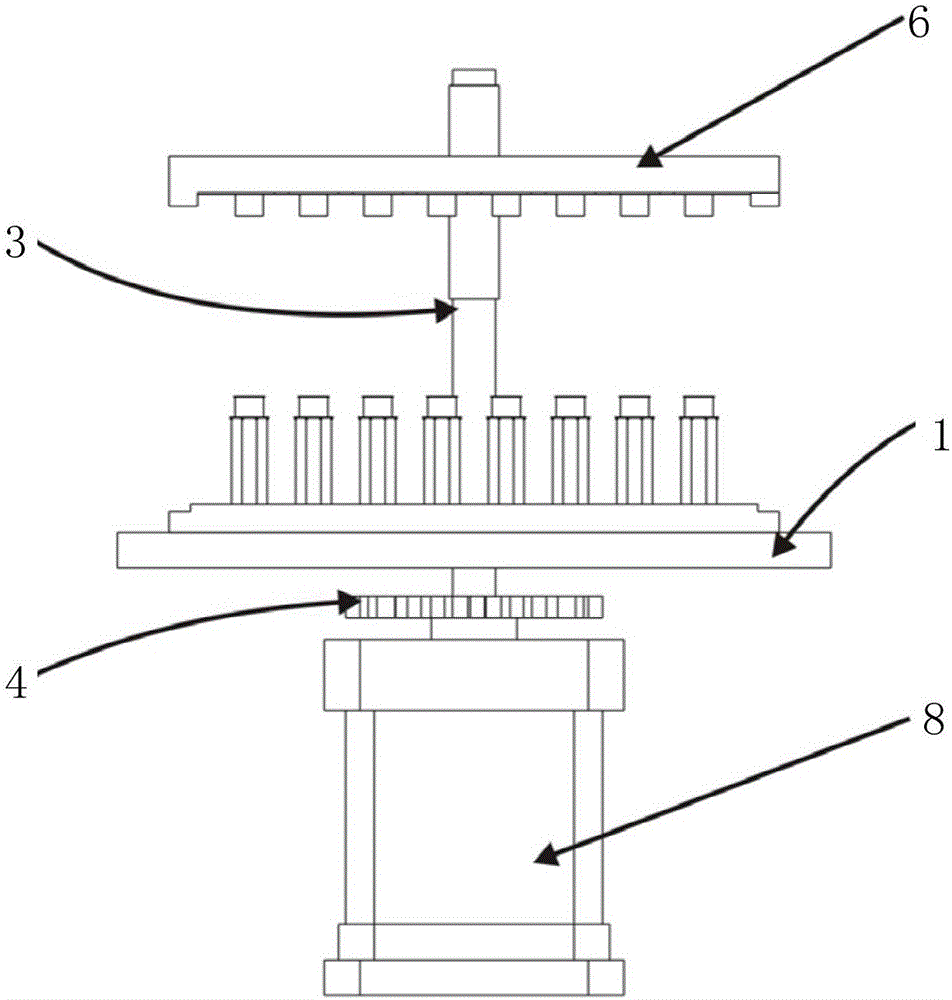

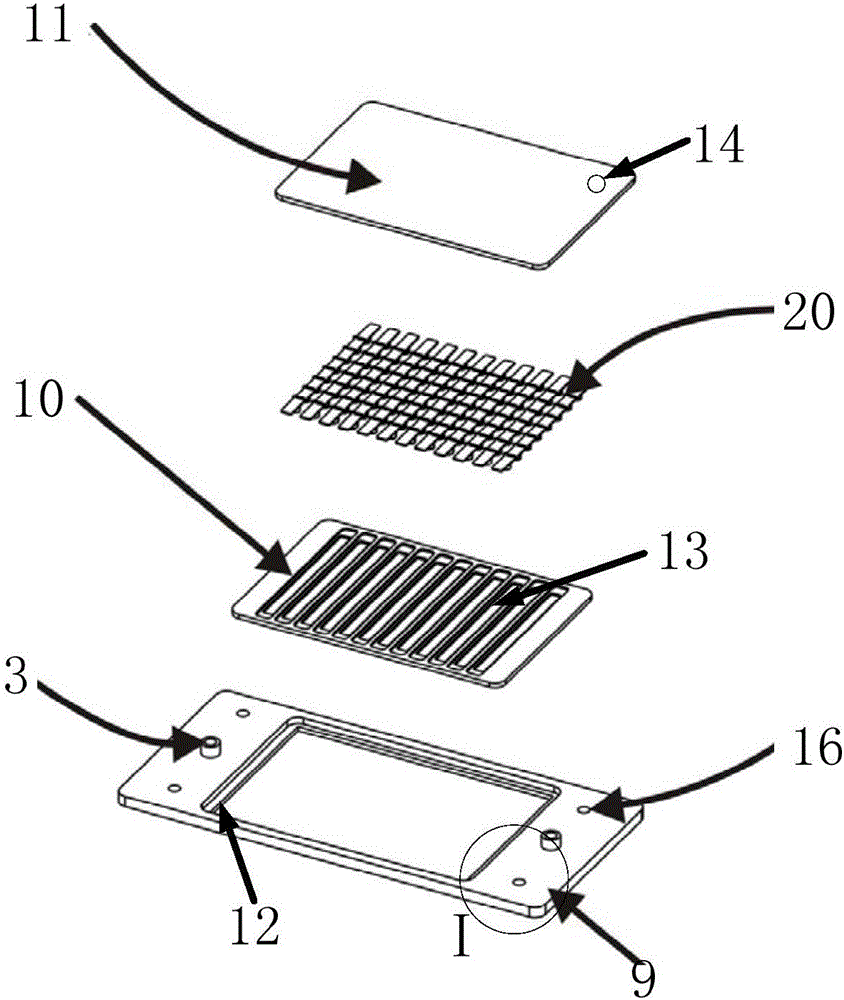

Cap pressing system of PCR reaction tubes and utilization method thereof

The invention provides a cap pressing system of PCR reaction tubes and a utilization method thereof. The system achieves up-and-down motion of a cap pressing device through ball screws, a driving wheel, a driven wheel, a connecting piece and a driving motor. According to the system, PCR reaction tubes are placed on a reaction tube carrying rack, PCR reaction tube caps are placed in the cap pressing device, and the cap pressing device is positioned above a carrying base, so that when the cap pressing device moves downwards, the PCR reaction tube caps can steadily cover the PCR reaction tubes tightly under the driving of the cap pressing device, the PCR reaction tube caps do not need to be pressed manually row by row, the operation is convenient, and the cap pressing is uniform; and the caps of the plurality of PCR reaction tubes can be pressed during one-time PCR reaction tube cap pressing process, so that the cap pressing efficiency can be effectively improved, and the manpower is saved.

Owner:SANSURE BIOTECH INC

Clamping device used for bottle caps

The invention discloses a clamping device used for bottle caps. The clamping device comprises a mounting seat with a columnar inner cavity, a sliding seat slidably arranged in the columnar inner cavity in a penetrating manner, first grooves, second grooves and an elastic abutting mechanism arranged on the mounting seat, wherein the first grooves and the second grooves are arranged in the mountingseat and communicate with the columnar inner cavity. The elastic abutting mechanism comprises a connecting rod arranged in the first grooves, wherein one end of the connecting rod is rotationally connected to the sliding seat. The elastic abutting mechanism is used for applying radial elastic abutting force to the sliding seat through the connecting rod. The device further comprises at least two clamping jaws and elastic hoops, wherein the clamping jaws are rotationally arranged in the second grooves and used for rotating in and out of the columnar inner cavity, and the elastic hoops are arranged on the outer sides of the clamping jaws in a hooped manner. The clamping jaws are used for being connected with the sliding seat in an abutting manner through the inner sides of the clamping jaws.When the sliding seat is driven by an ejector rod to move downwards and enter the clamping jaws, the sliding seat drives the clamping jaws to open. When the sliding seat is driven by bottle caps to move upwards and retreat from the clamping jaws, the clamping jaws are driven by the elastic hoops to be tightened. The clamping device is suitable for clamping of bottle caps in different shapes, andclamping is rapid and stable.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Automatic feeding cap stripping machine

PendingCN112875613AImprove capping efficiencyFlanged caps removalConveyor partsPenicillinEngineering

The invention relates to an automatic feeding cap stripping machine. The automatic feeding cap stripping machine comprises a support, a bottom plate and a base connected with the support, a connecting column sleeving a guide supporting rod, a connecting disc fixedly connected with the connecting column, a penicillin bottle chuck capable of rotating or lifting relative to the support, a chuck rotating mechanism for driving the penicillin bottle chuck to rotate, a lifting mechanism for driving the connecting column to move up and down along the guide supporting rod and a cap opening piece arranged on the movement track of the penicillin bottle chuck, wherein the front end and the bottom of the cap opening piece are in an open gantry shape, and the two sides of the open gantry-shaped cap opening piece ascend in a gradient mode from front to back; the bottle neck of a penicillin bottle is clamped with the penicillin bottle chuck, and the chuck rotating mechanism drives the penicillin bottle chuck to rotate, so that the penicillin bottle is clamped with the cap opening piece and slides along the open gantry-shaped cap opening piece until the bottle cap and the bottle body of the penicillin bottle are separated. The automatic feeding cap stripping machine can separate the bottle cap from the bottle body of the penicillin bottle, manual operation is not needed, and efficiency is improved.

Owner:苏州荣耀安捷医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com