Automatic capping machine

A capping machine and capping technology, applied in packaging and other fields, can solve problems such as low production efficiency, low degree of automation, and complex structure, and achieve the effects of improving efficiency, high degree of automation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

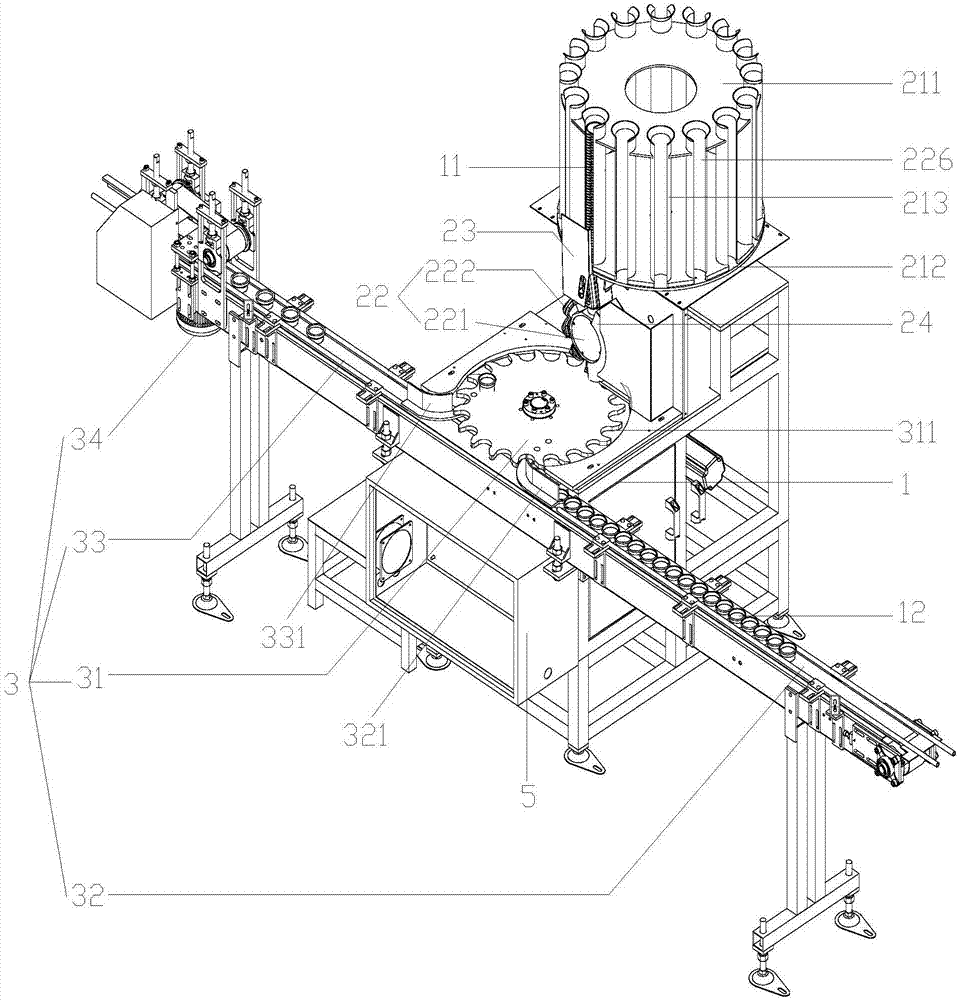

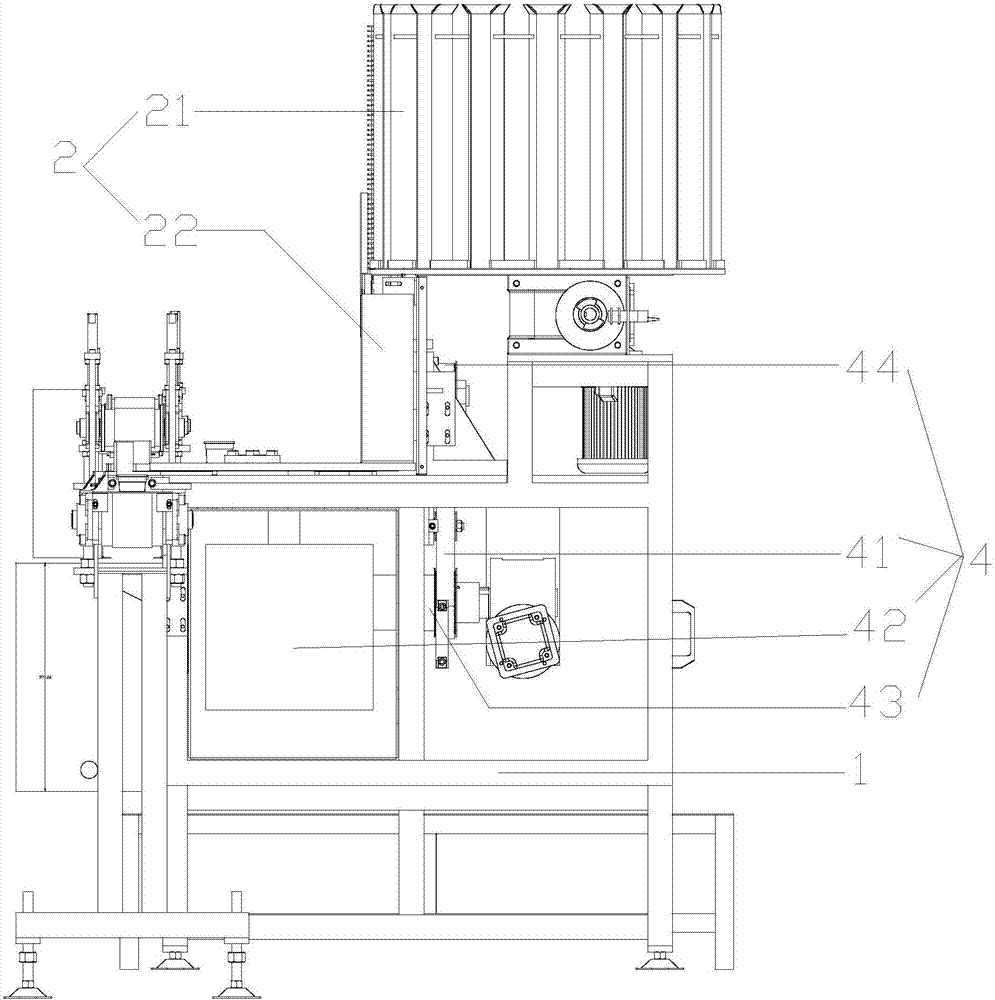

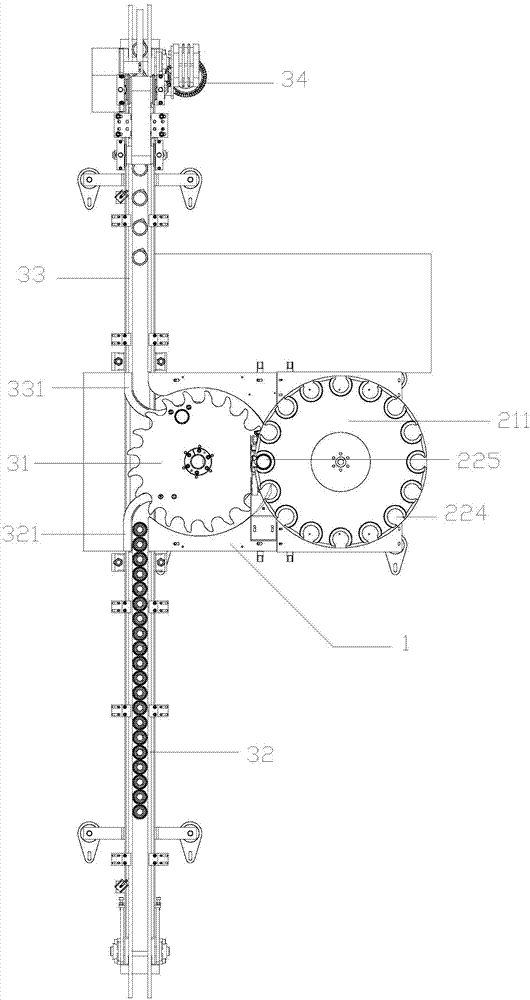

[0059] Such as Figure 1-5 As shown, an automatic capping machine includes: a workbench 1 on which a cap placing module 2 and a transmission module 3 for transporting a cup body 23 are arranged;

[0060] The cover-putting module 2 includes: a cover storage device 21, which rotates around a horizontal axis and is used to capture the cup cover 11 in the cover storage device 21 and press-fit the cup cover 11 on the cup body 12 device 22;

[0061] The capping device 22 is arranged below the cap storage device 21;

[0062] The transmission module 3 includes: a cup transport tray 31 rotating around a vertical axis, used to transport the uncapped cup body 12 to the first transmission track 32 of the cup transport tray 31, for receiving the transport cup The second transmission track 33 of the capped cup body 12 on the disc 31 is used to drive the transmission motor 34 of the first transmission track 32 and the second transmission track 33;

[0063] The capping device 22 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com