Patents

Literature

36results about How to "Adjust stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

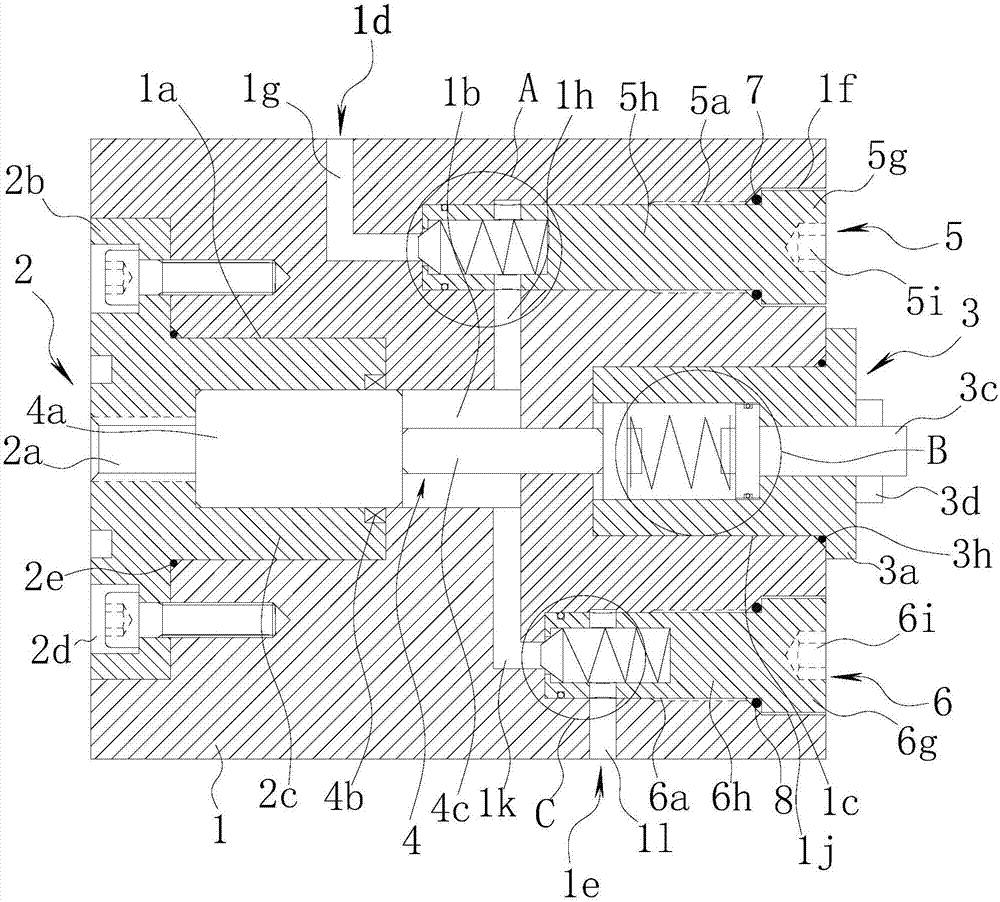

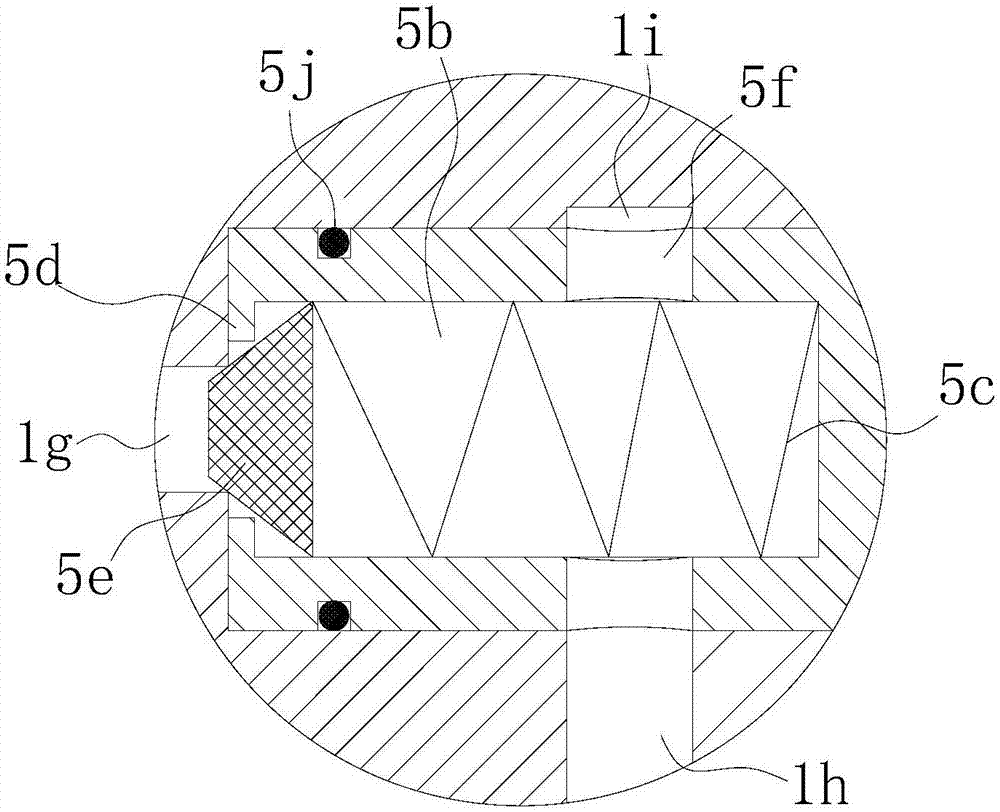

Automobile duel fuel guide rail multi-way valve

ActiveCN104696083AReduce resistanceAvoid mixingInternal combustion piston enginesFuel injection apparatusFuel tankEngineering

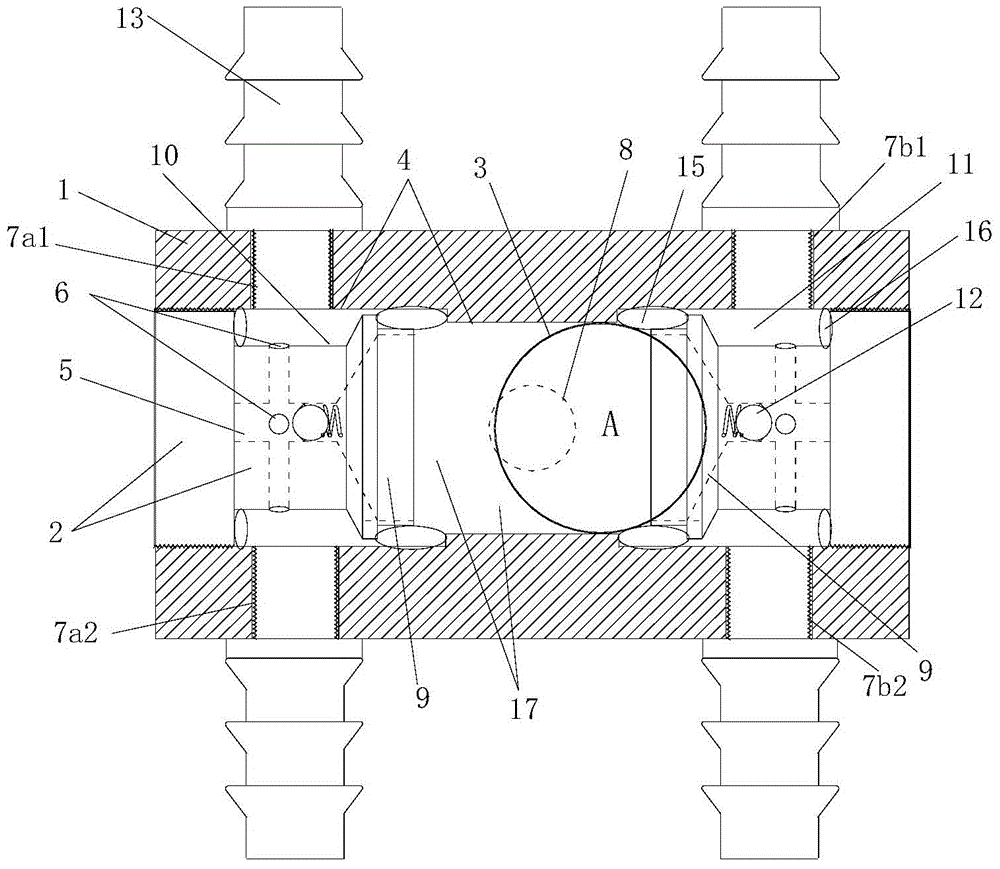

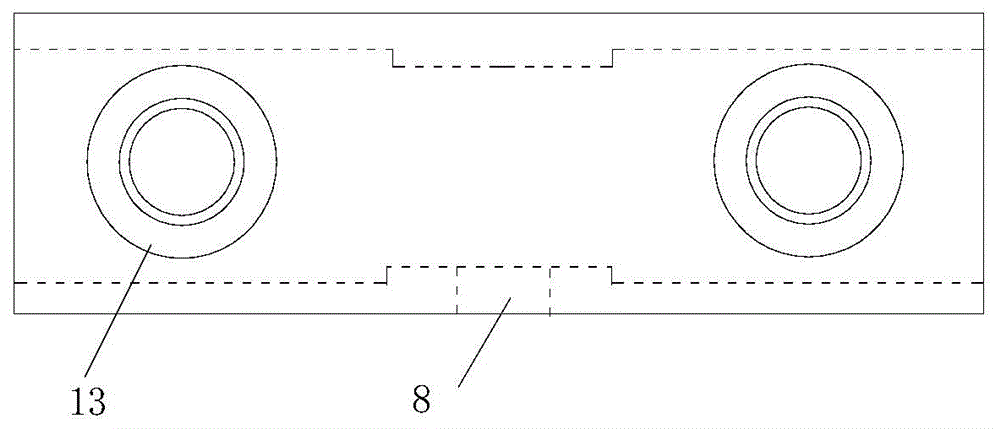

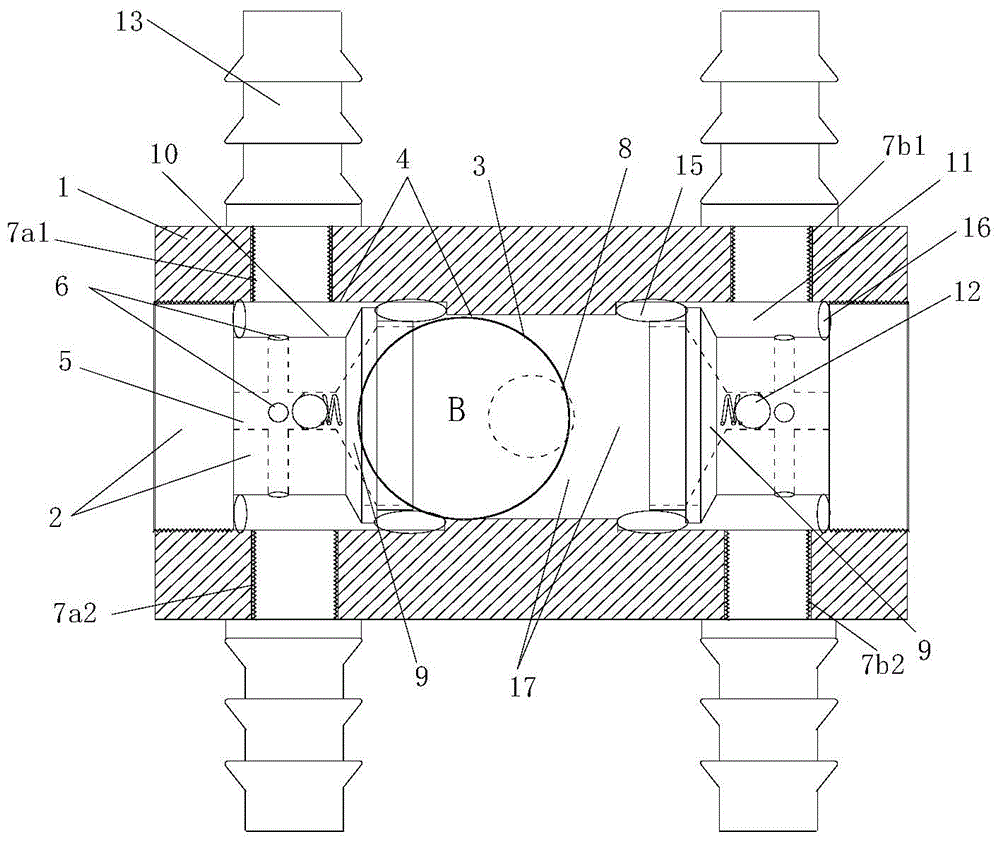

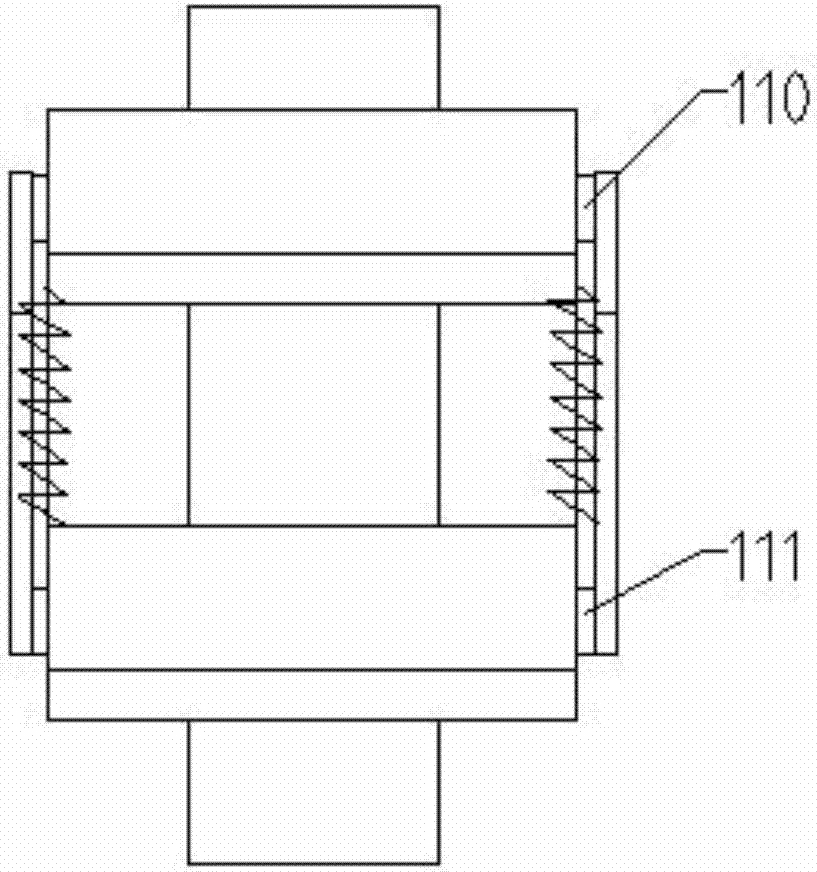

The invention belongs to the field of automobile dual fuel guide rail switching devices, and discloses an automobile duel fuel guide rail multi-way valve. The multi-way valve includes a casing, two end surface cylinder plugs, and a valve core piston, wherein a through hole is formed in the casing, the movable valve core piston is arranged in the through hole, the two end surface cylinder plugs are arranged at the two ends of the through hole, an internal passage is arranged in each end surface cylinder plug, and an oil inlet hole is formed in the surface of each end surface cylinder plug and communicated with the corresponding internal passage; guide rail mounting holes are respectively formed in the two ends of the casing, and are respectively communicated with the oil inlet holes in the two end surface cylinder plugs; an ejector mounting hole is formed in the casing and communicated with the center of the through hole. The device has the advantages that two automobile fuel guide rails can be reliably switched and share one ejector, the pipeline airtightness is good, drifting of the valve core piston is prevented, and the operation is stable; mixing of two fuels is avoided during switching, so that one fuel can be effectively prevented from entering a fuel tank for the other fuel during switching. The automobile duel fuel guide rail multi-way valve can be widely mounted in various types of automobiles.

Owner:青岛大洋技研工业有限公司

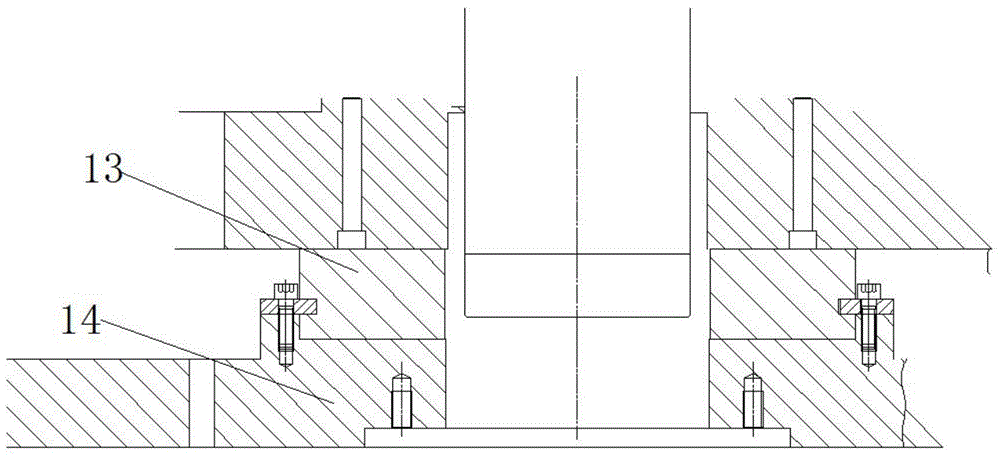

Oil cylinder with adjustable piston stroke

The invention discloses an oil cylinder with adjustable piston stroke, which comprises a cylinder body, the front and the rear ends of the cylinder body are respectively provided with a front end cover and a rear end cover; the cylinder body is internally provided with a piston and a piston rod; the rear end cover is provided with a rear limiting seat which is internally provided with a limiting cavity which passes through a mounting hole on the rear end cover and is communicated with a rear cavity; the limiting cavity and the mounting hole are internally and movably provided with rear limiting rods, the front ends of which are matched with the bottom of the piston, and the rear ends thereof are positioned inside the limiting cavity; the rear limiting seat is provided with a screwed hole communicated with the limiting cavity; and the screwed hole is internally provided with an adjusting screw rod matched with the screwed hole, and the adjusting screw rod is provided with a locking nut matched with the adjusting screw rod. The oil cylinder has the advantages that the oil cylinder with the adjustable piston stroke can be used for conveniently adjusting the stroke of the piston and the piston rod as well as the length of the piston rod, thus leading the oil cylinder to be more conveniently and flexibly used and have wider application scope.

Owner:张家港和升数控机床制造有限公司

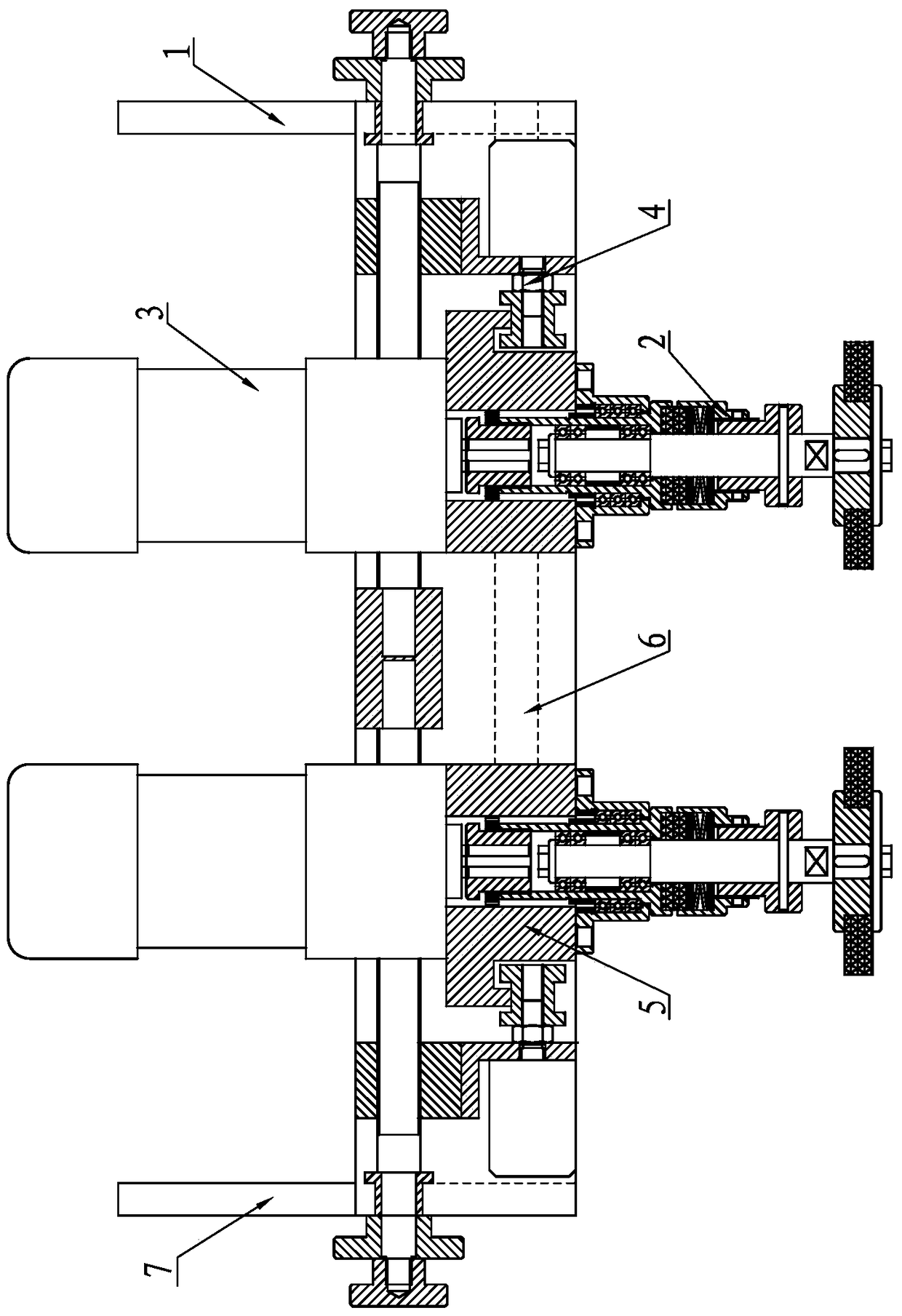

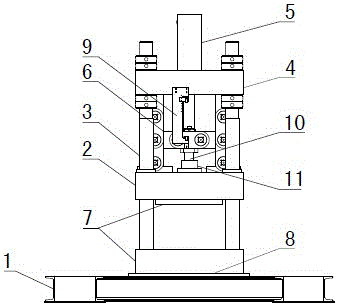

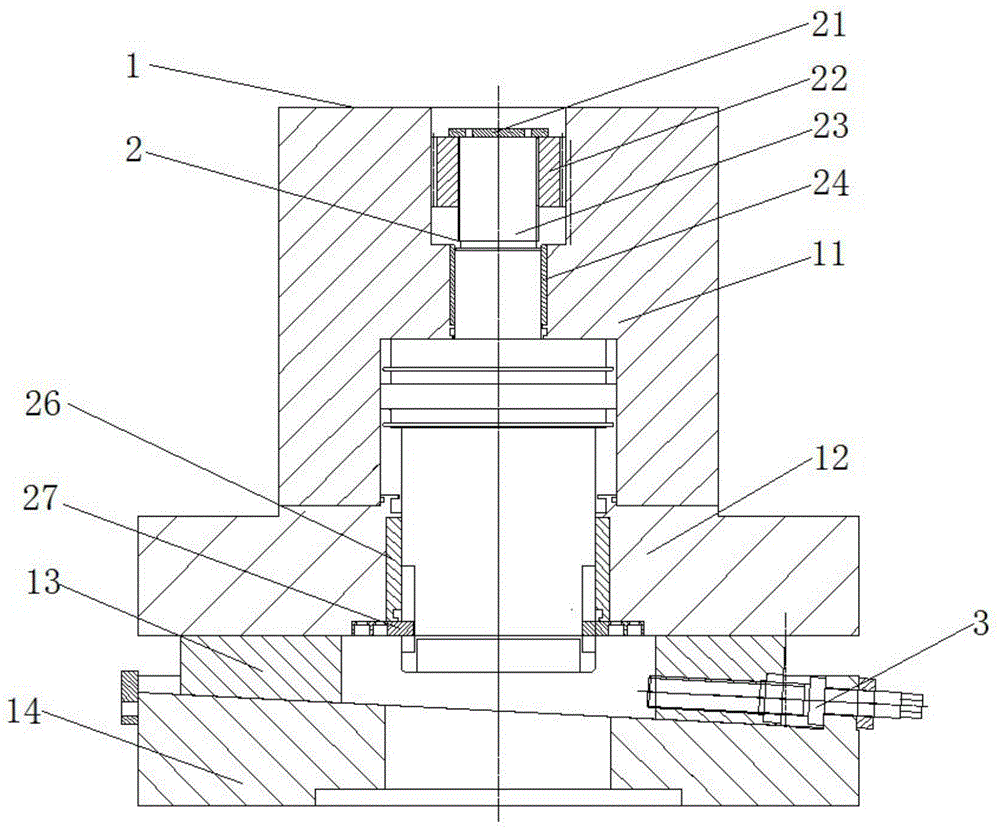

Press stroke and die setting height adjusting mechanism

ActiveCN106863875AChange the holding pressure range arbitrarilyEasy to adjustPress ramEngineeringFuselage

The invention discloses a press stroke and die setting height adjusting mechanism in the field of presses. The press stroke and die setting height adjusting mechanism comprises a machine body cross beam. A rotatable crankshaft is horizontally arranged on the machine body cross beam. A connecting rod is arranged on the connecting rod journal of the crankshaft. An upper toggle rod and a lower toggle rod are hinged to the ends of the connecting rod correspondingly. A guide column which can vertically move is hinged to the lower end of the lower toggle rod. A sliding block is arranged at the lower end of the guide column. A rotatable eccentric shaft is arranged in the position, corresponding to the upper toggle rod, of the machine body cross beam and is parallel to the rotation axis of the crankshaft. The upper end of the upper toggle rod is fixedly connected with the eccentric section of the eccentric shaft. The main shaft section of the eccentric shaft is sleeved with a worm gear. The machine body cross beam is provided with a rotatable worm. The axis of the worm is perpendicular to the rotation axis of the eccentric shaft. The worm gear and the worm are engaged with each other. One end of the worm is in transmission connection with a rotary driving mechanism. The press stroke and die setting height adjusting mechanism can randomly adjust the press sliding block stroke and the die setting height, can automatically adapt to dies with different specifications and workpieces with different sizes, and is convenient to adjust and savable in time and effort.

Owner:YANGLI GRP CORP LTD

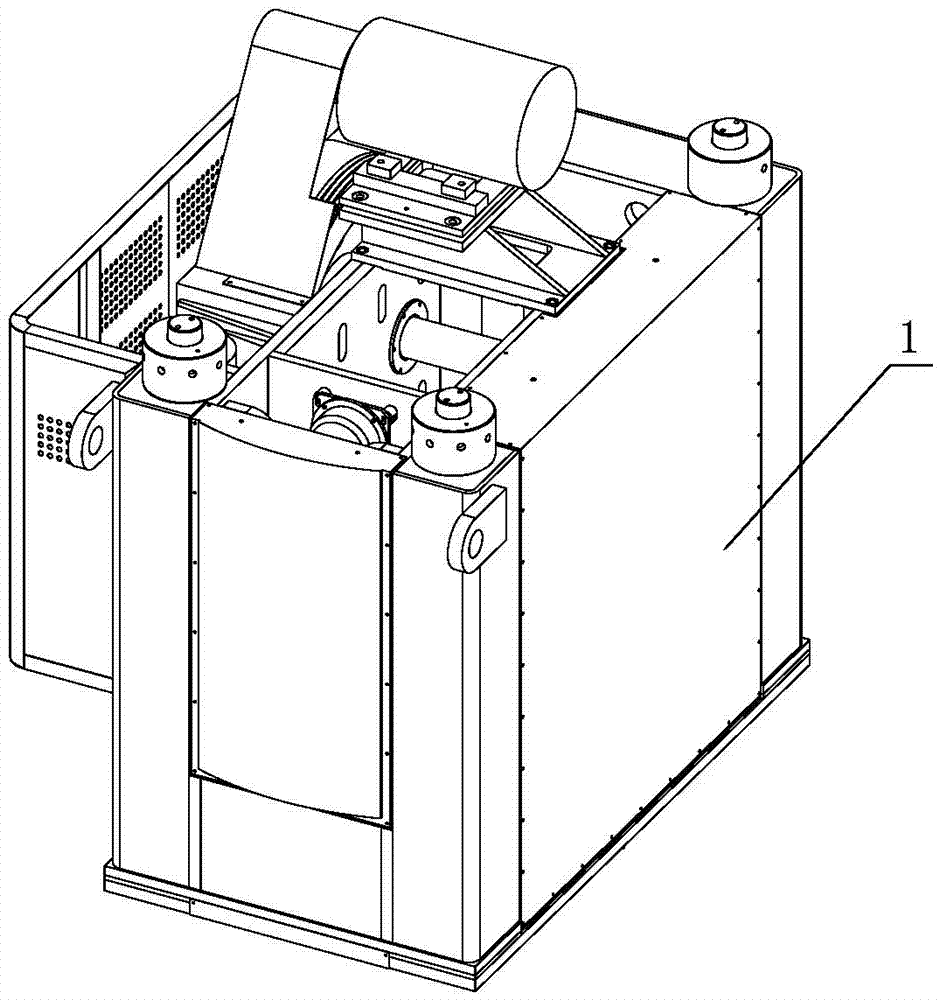

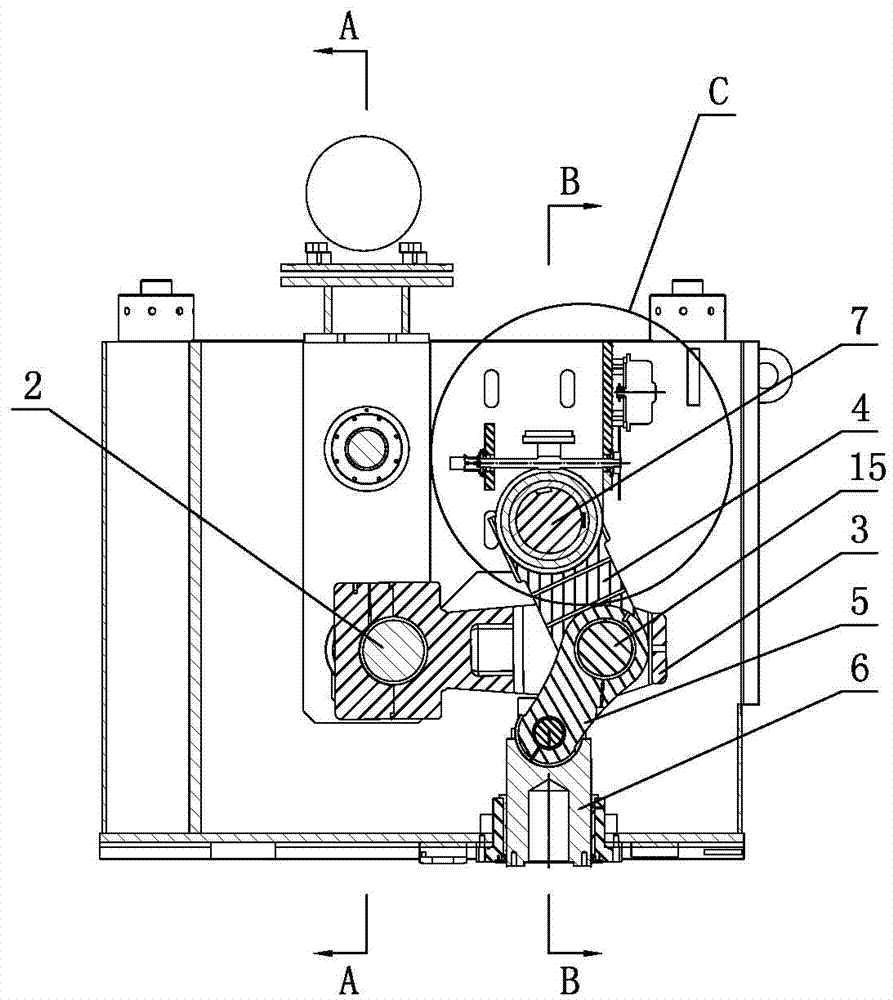

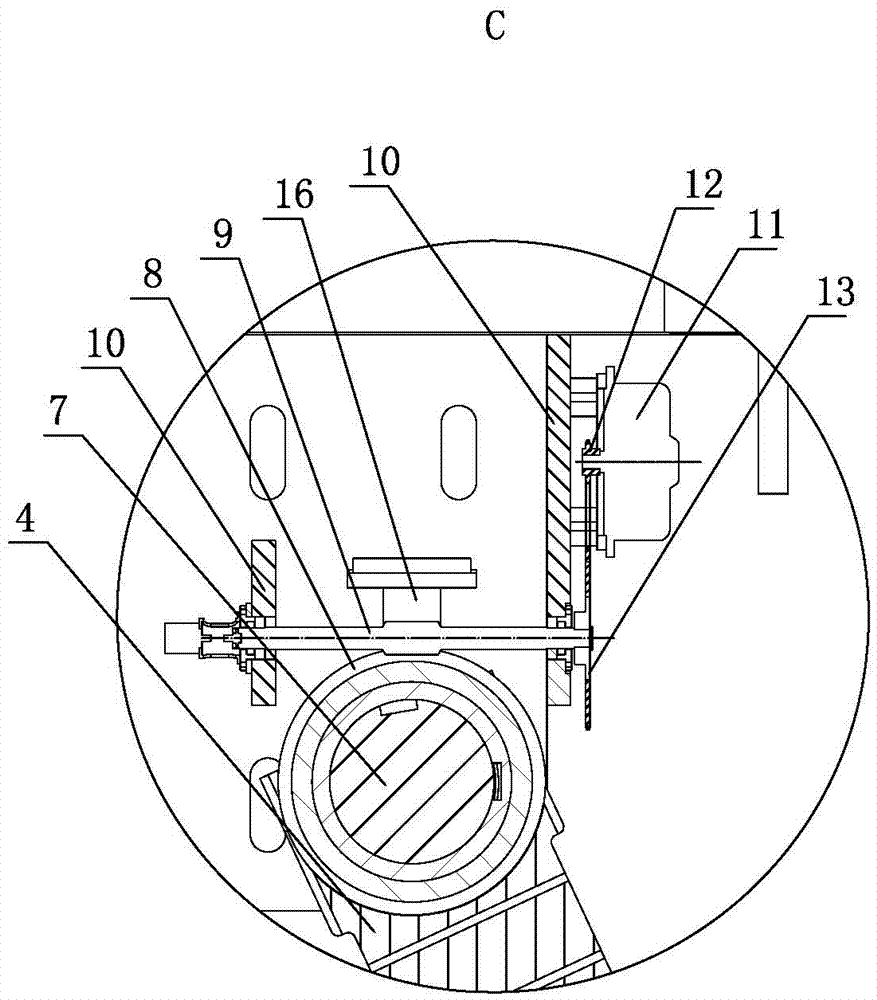

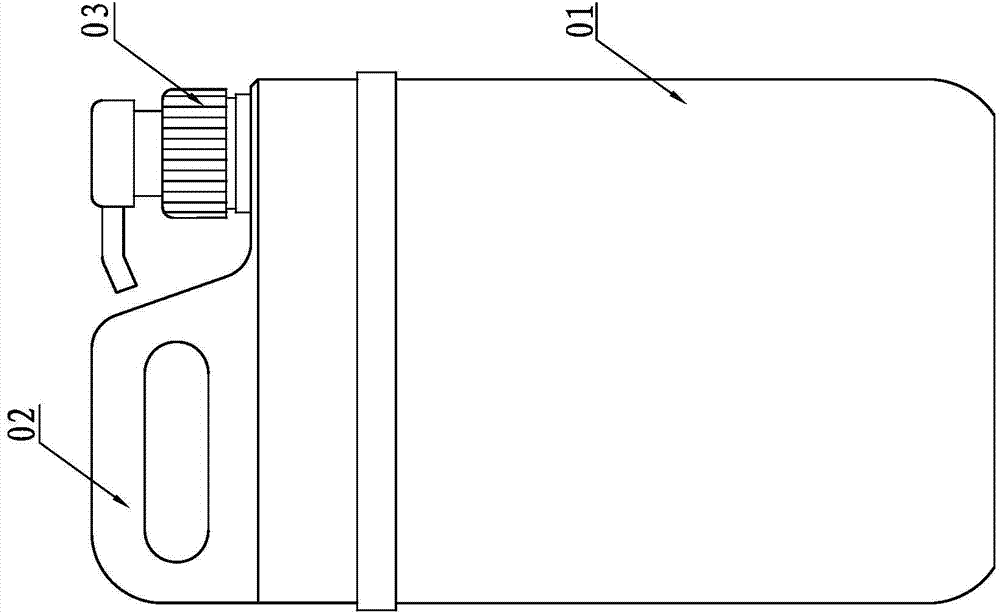

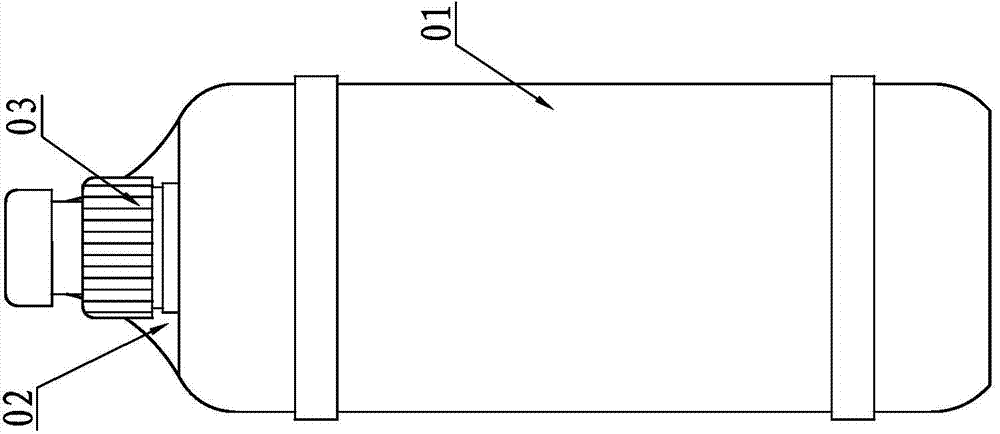

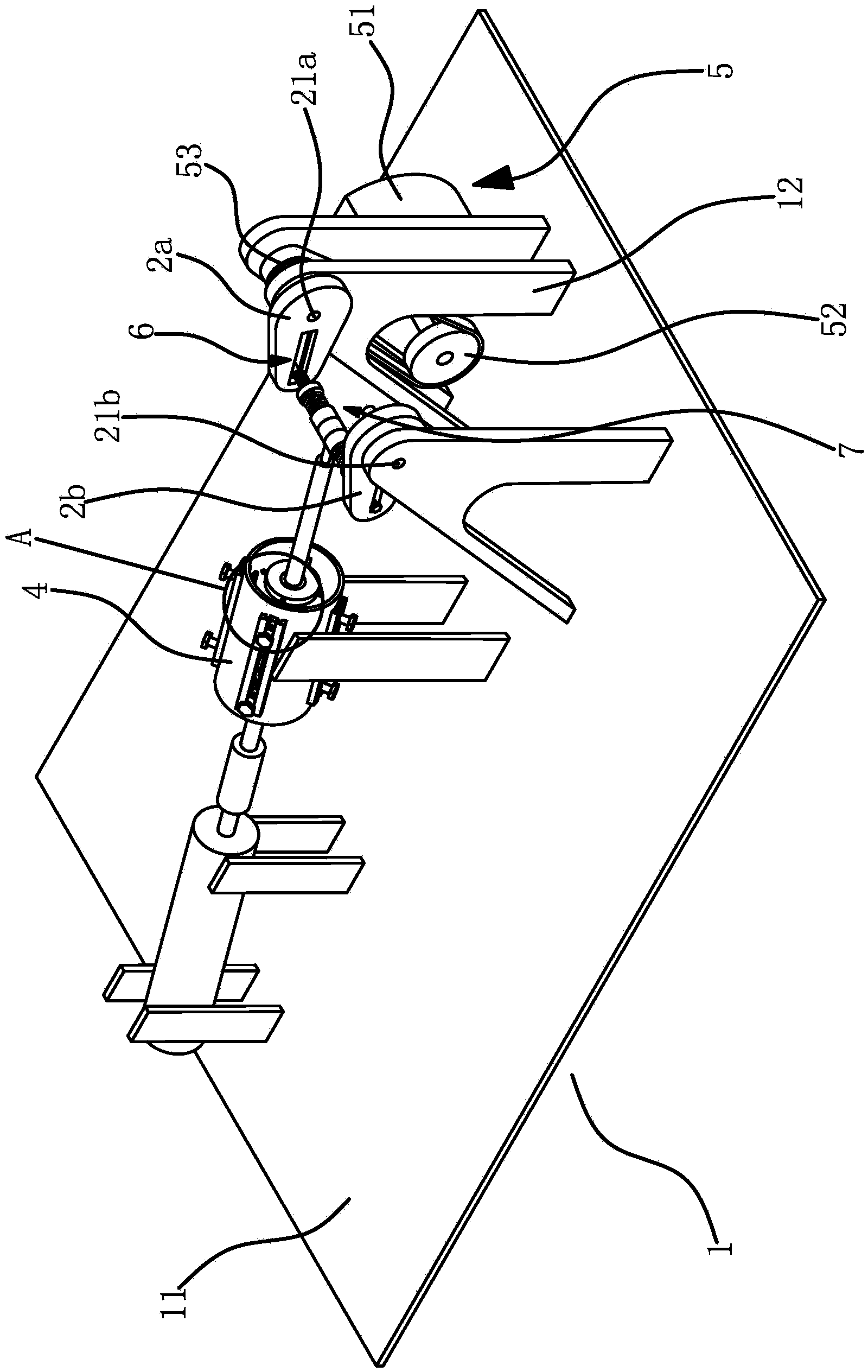

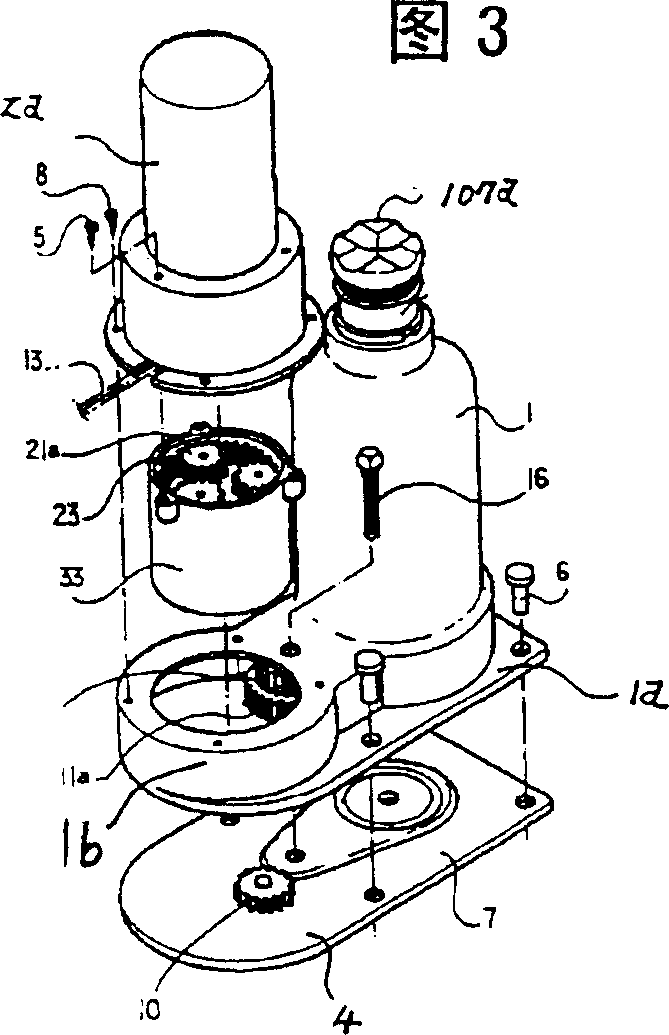

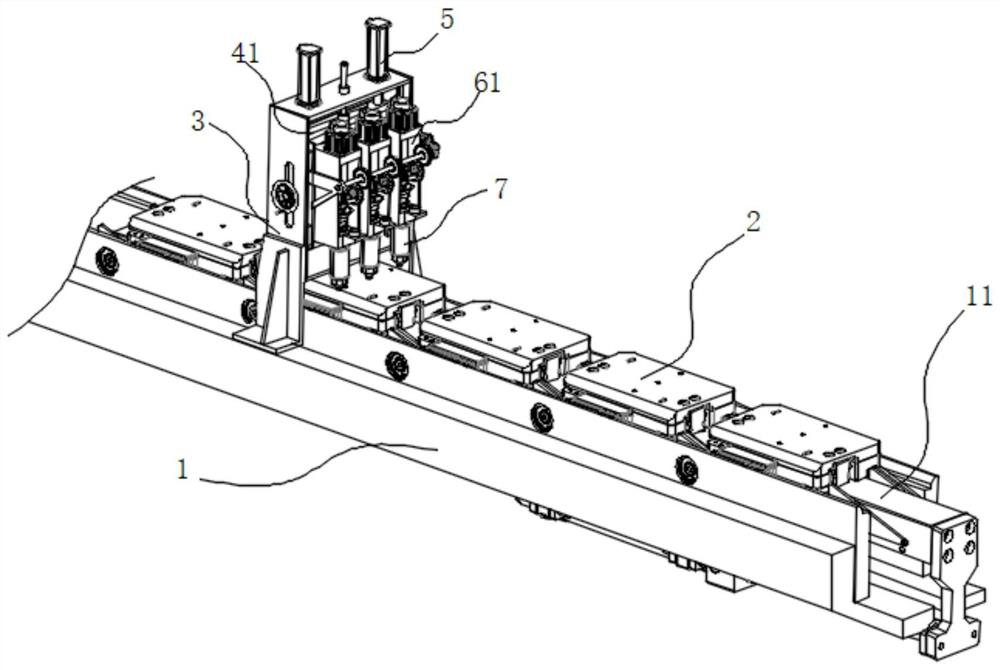

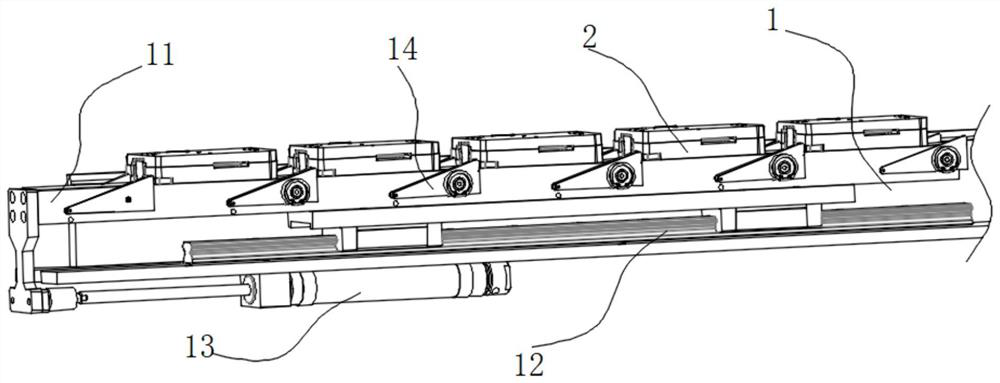

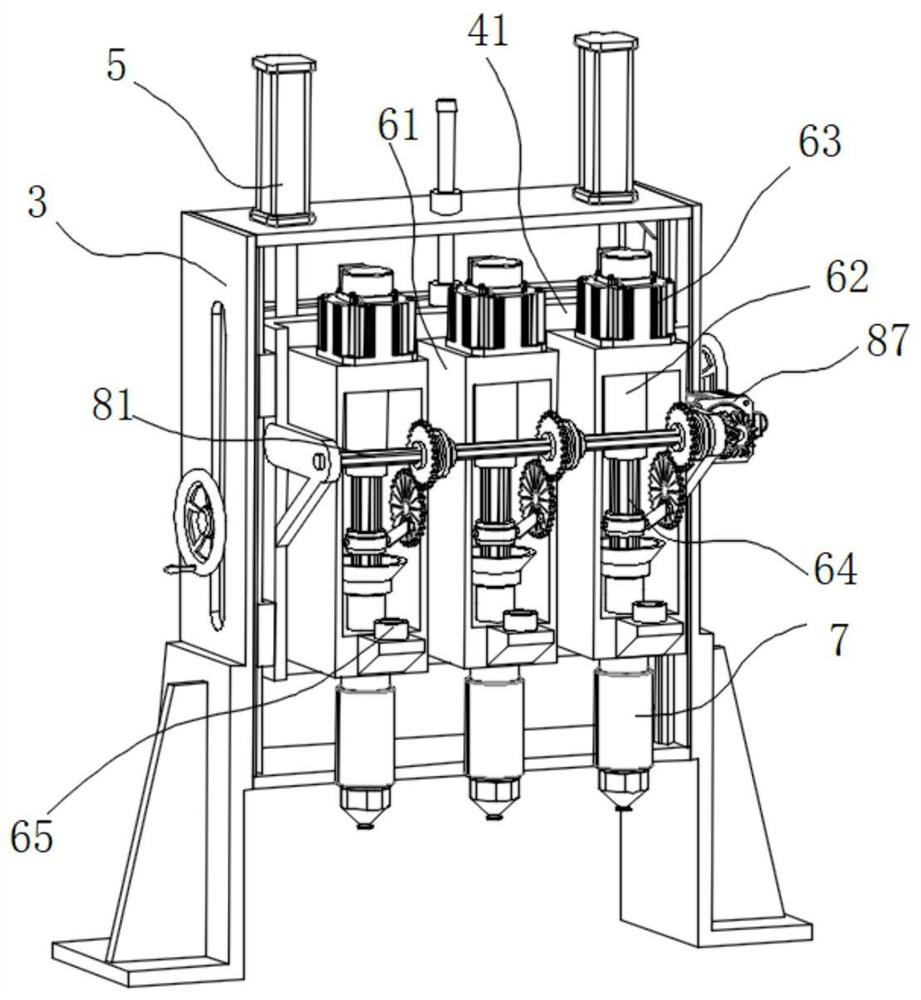

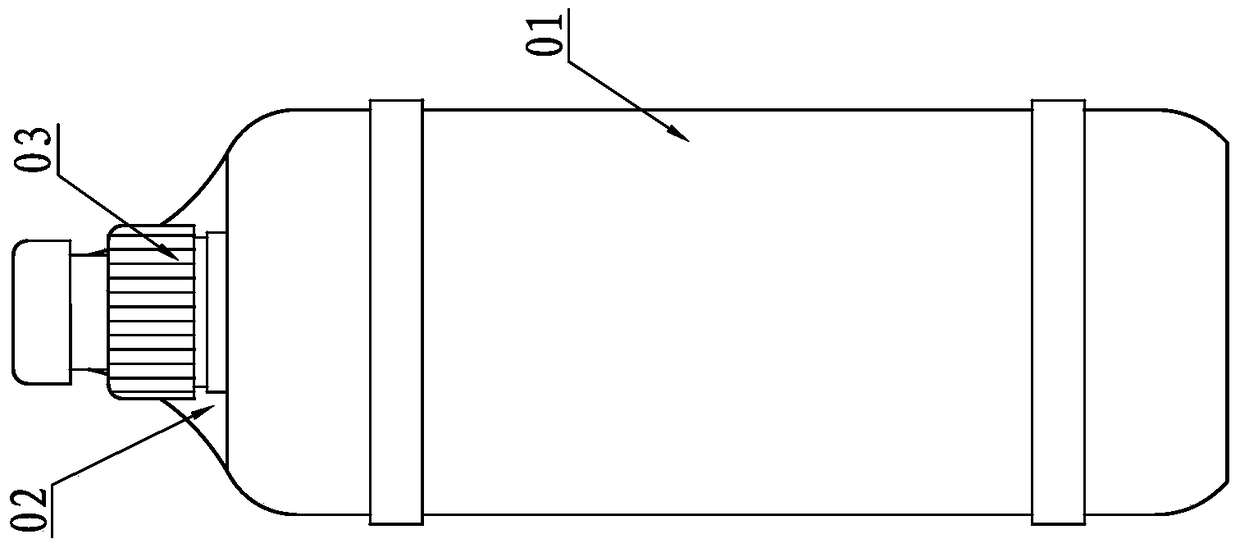

Clutch cap screwing device of linear pump cap screwing machine

A clutch cap screwing device of a linear pump cap screwing machine comprises a rack front side plate, torque cap screwing components, rotating driving components, a centering linear driving adjusting mechanism, sliding seats, sliding guide rails and a rack rear side plate. The two sliding guide rails are horizontally and fixedly mounted on the rack front side plate and the rack rear side plate in parallel, the two sliding seats are mounted on the two sliding guide rails in a sleeved mode, the torque cap screwing components are mounted on the lower end faces of the sliding seats, the rotating driving components are mounted on the upper end faces of the sliding seats, the rotating driving components drive the torque cap screwing components, the centering linear driving adjusting mechanism is arranged between the rack front side plate and the rack rear side plate, and a driving motor of the centering linear driving adjusting mechanism is connected with the sliding seats. The clutch cap screwing device of the linear pump cap screwing machine solves the problem of manual cap screwing, a flow process of continuous linear cap screwing can be achieved, a great amount of man power is saved, cap screwing efficiency is high and is 100 times that of manual cap screwing, and the aesthetic standards of people for diversified bottle bodies are met.

Owner:常州市金坛晨光轻工机械有限公司

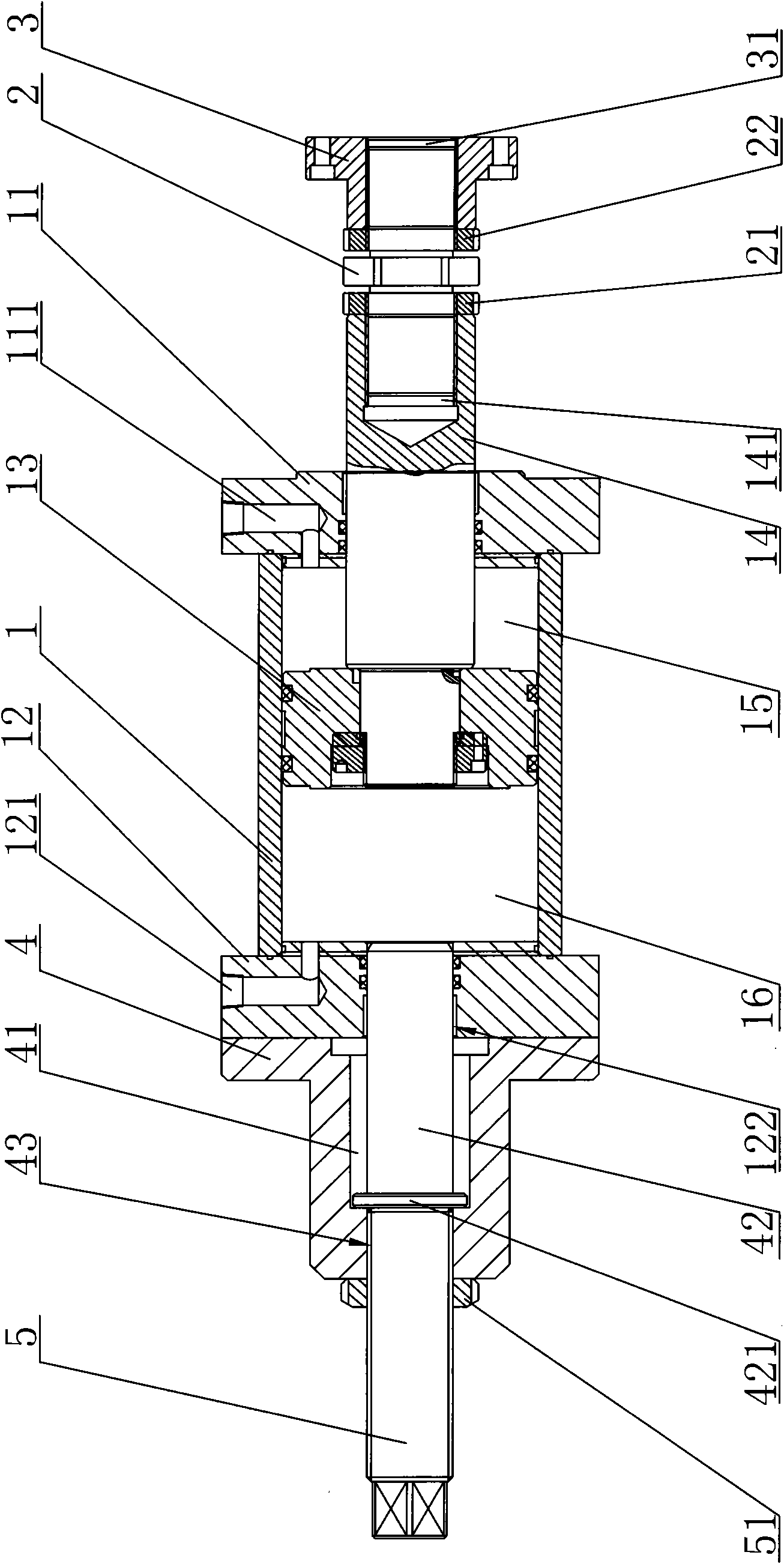

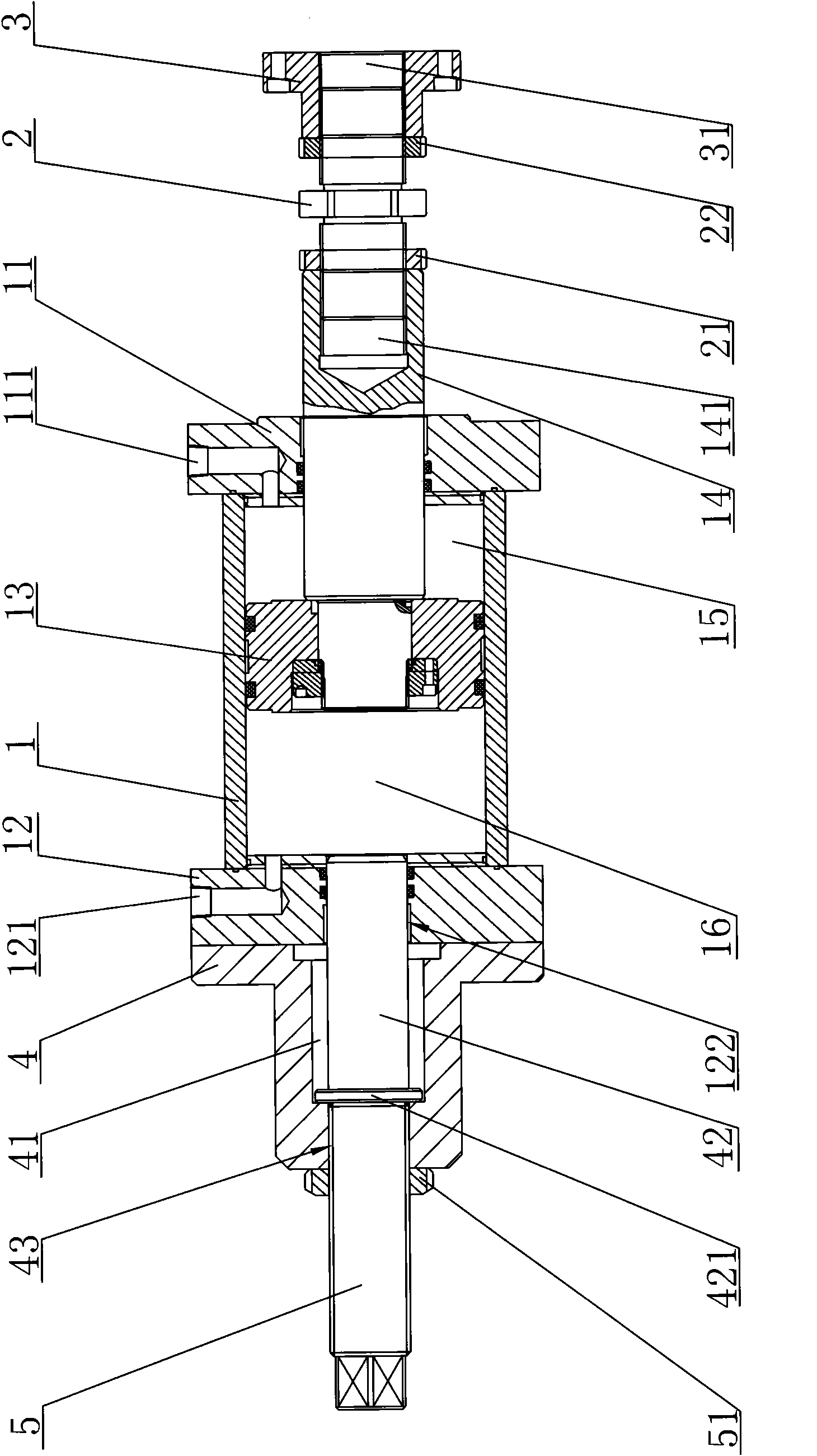

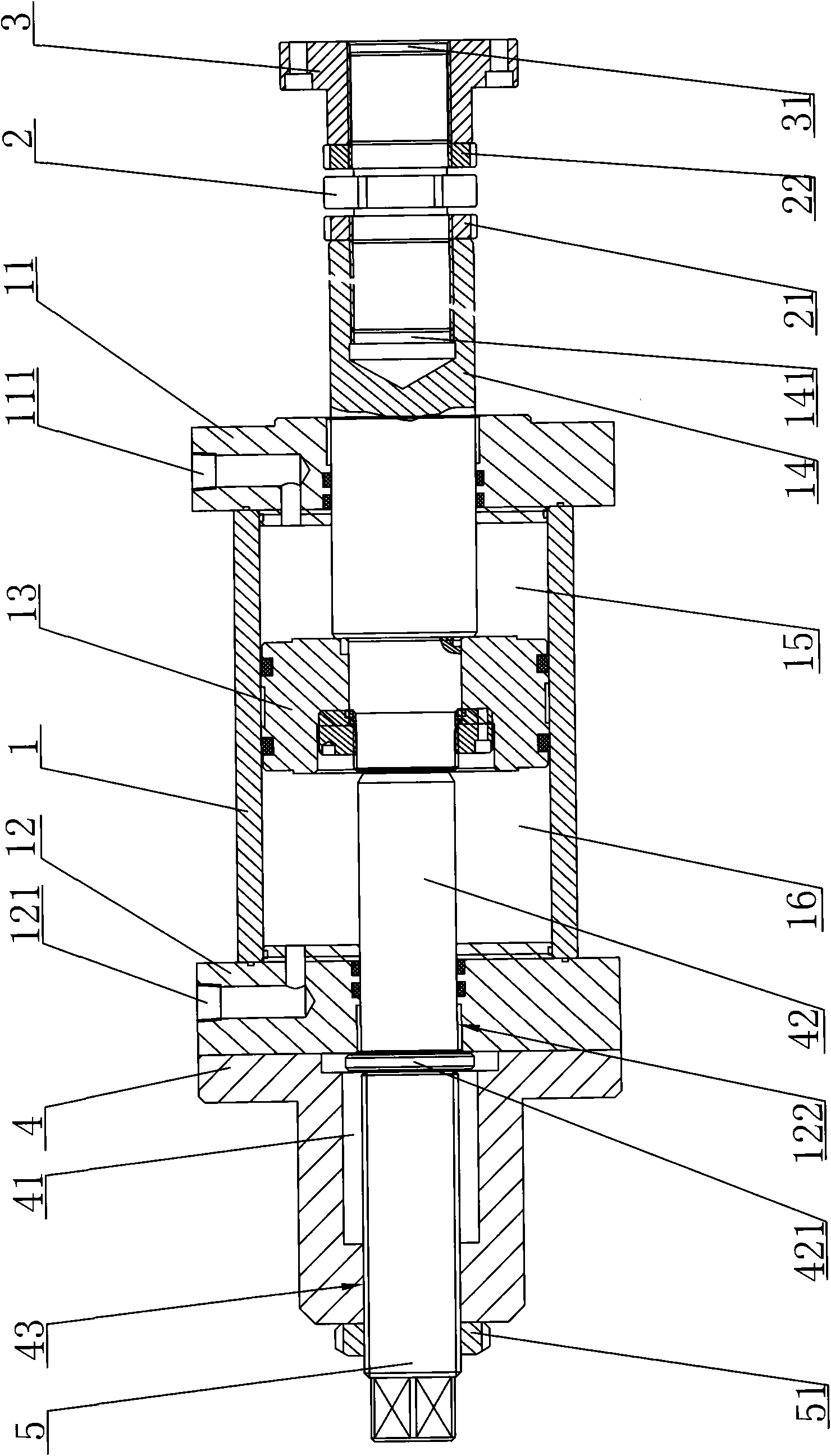

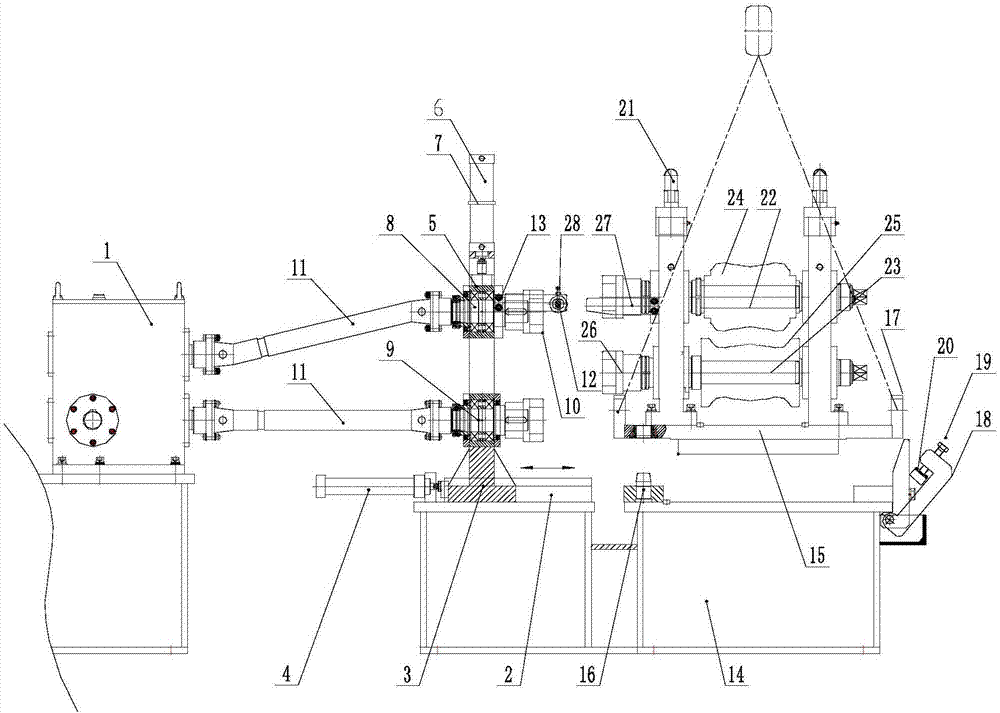

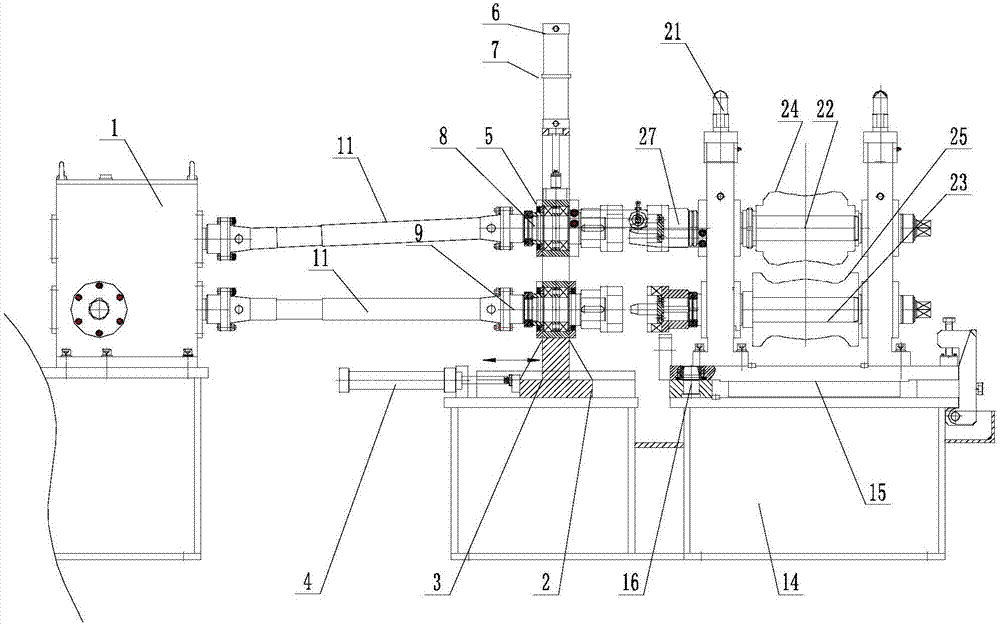

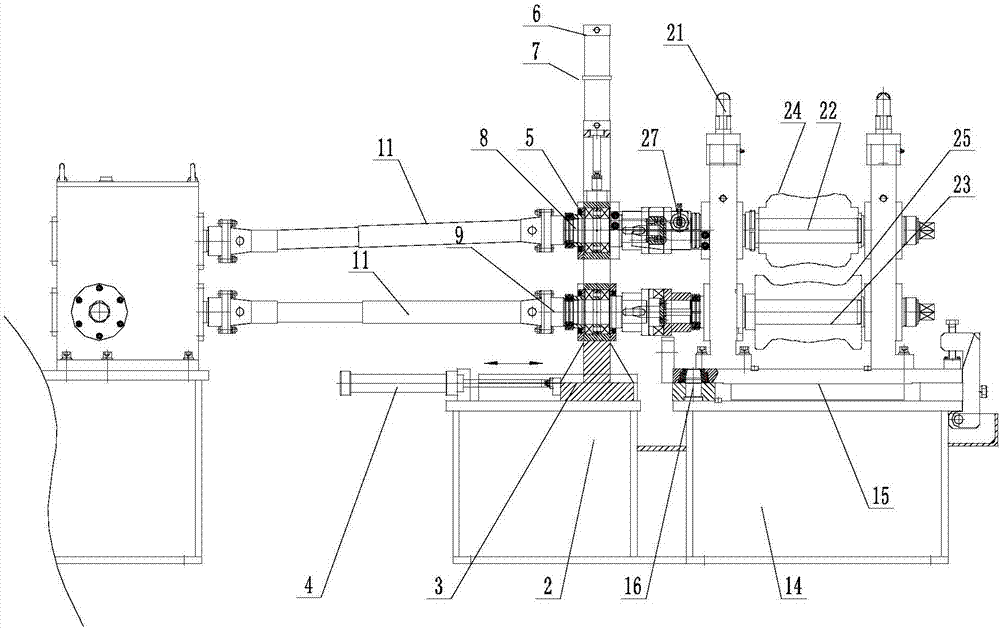

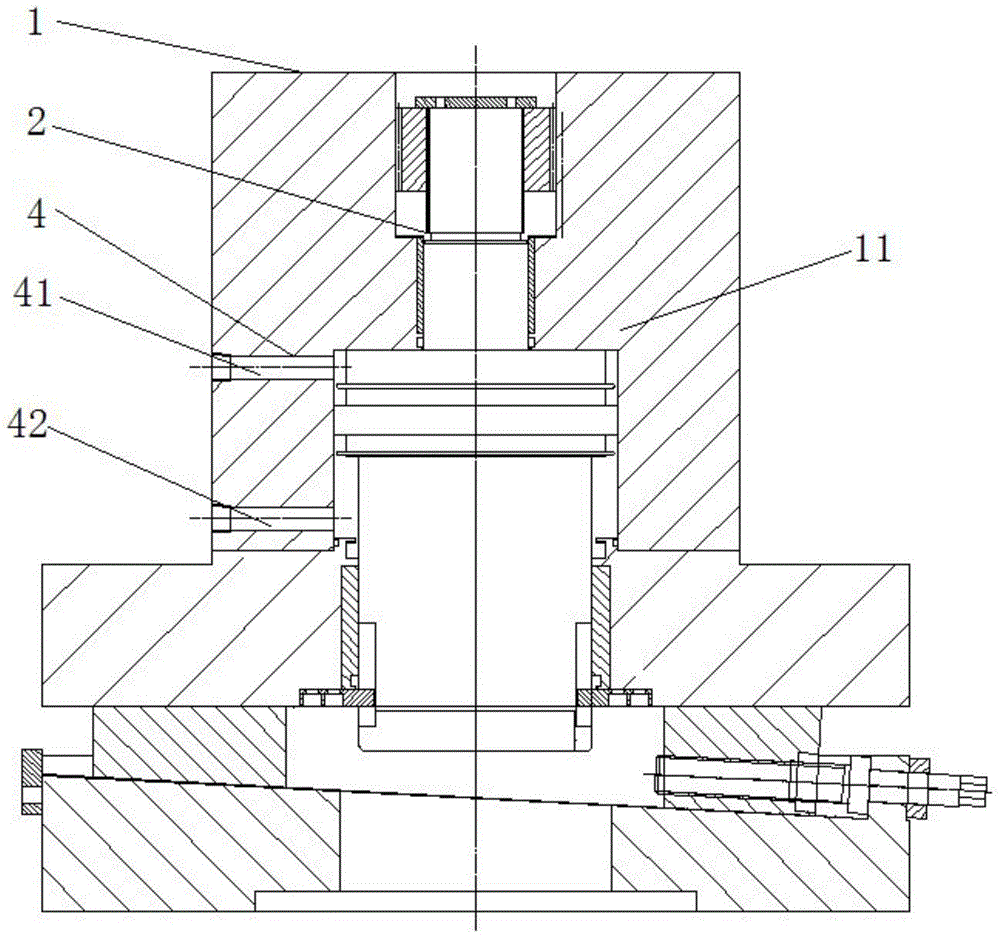

Fatigue test device for VVT (Variable Valve Timing) engine piston

ActiveCN103868684AGuaranteed coaxialityImprove applicabilityMachine part testingVariable valve timingCam

The invention provides a fatigue test device for a VVT (Variable Valve Timing) engine piston and belongs to the technical field of engine test equipment. The problem that the test data of the present fatigue test device is not accurate enough is solved. The fatigue test device for the VVT engine piston comprises a frame, wherein a first cam is in rotating connection with the frame through a rotating shaft; a connecting shaft is vertically connected with a side face of the first cam; a distance-adjusting structure is arranged between the connecting shaft and the cam; a sleeve is fixedly connected with the frame; the rotating shaft is connected with a driving structure; a detecting structure for detecting the coaxiality of a cylinder sleeve and the piston is also arranged on the frame; an adjusting structure for adjusting the coaxiality of the cylinder sleeve and the piston is arranged on the sleeve and the connecting shaft. The fatigue test device for the VVT engine piston can be used for performing a fatigue test under the condition that the coaxiality of the cylinder sleeve and the piston is ensured. The accuracy of the test data is increased.

Owner:ZHEJIANG FUJIEDE AUTOMOTIVE SYST CO LTD

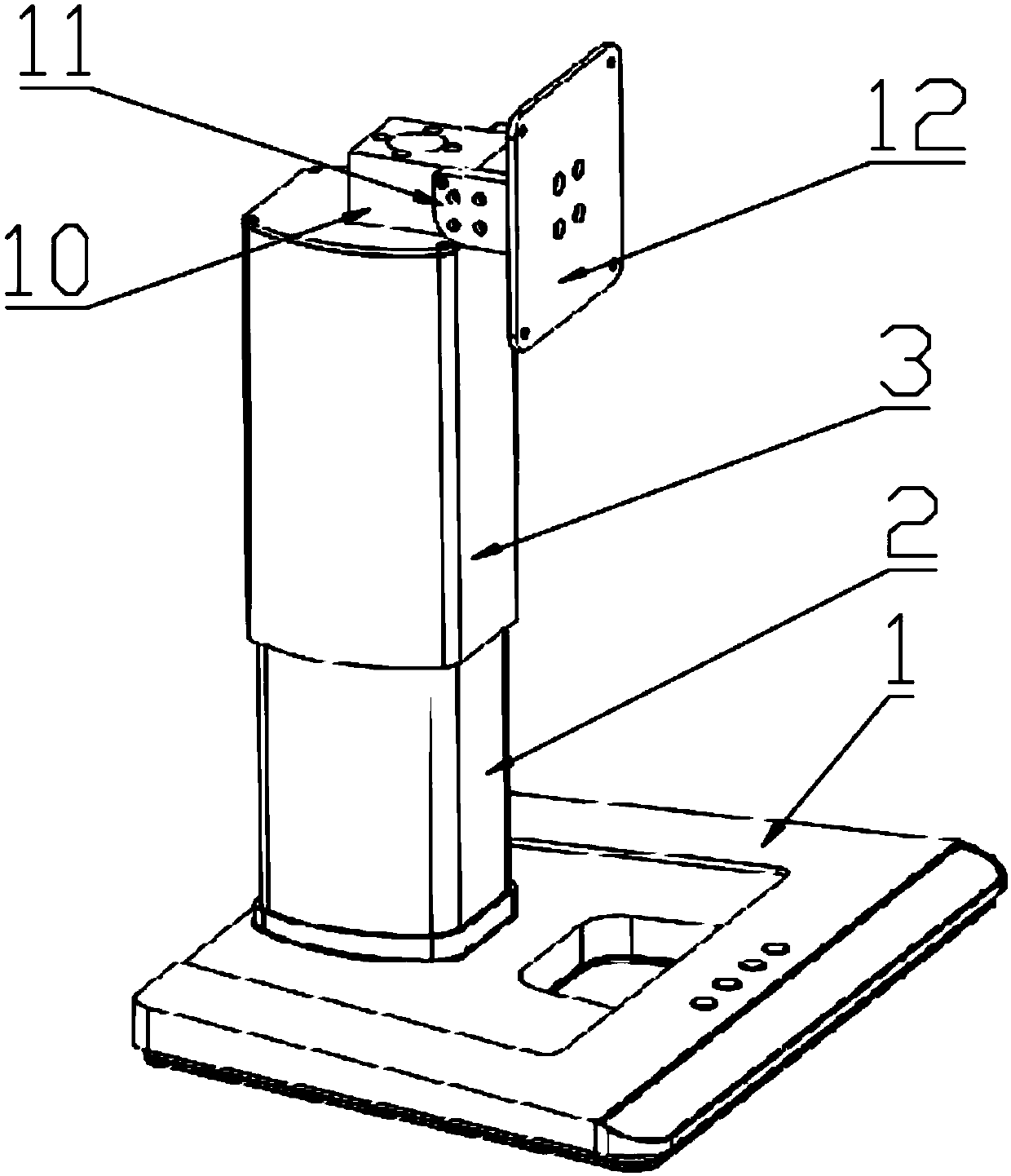

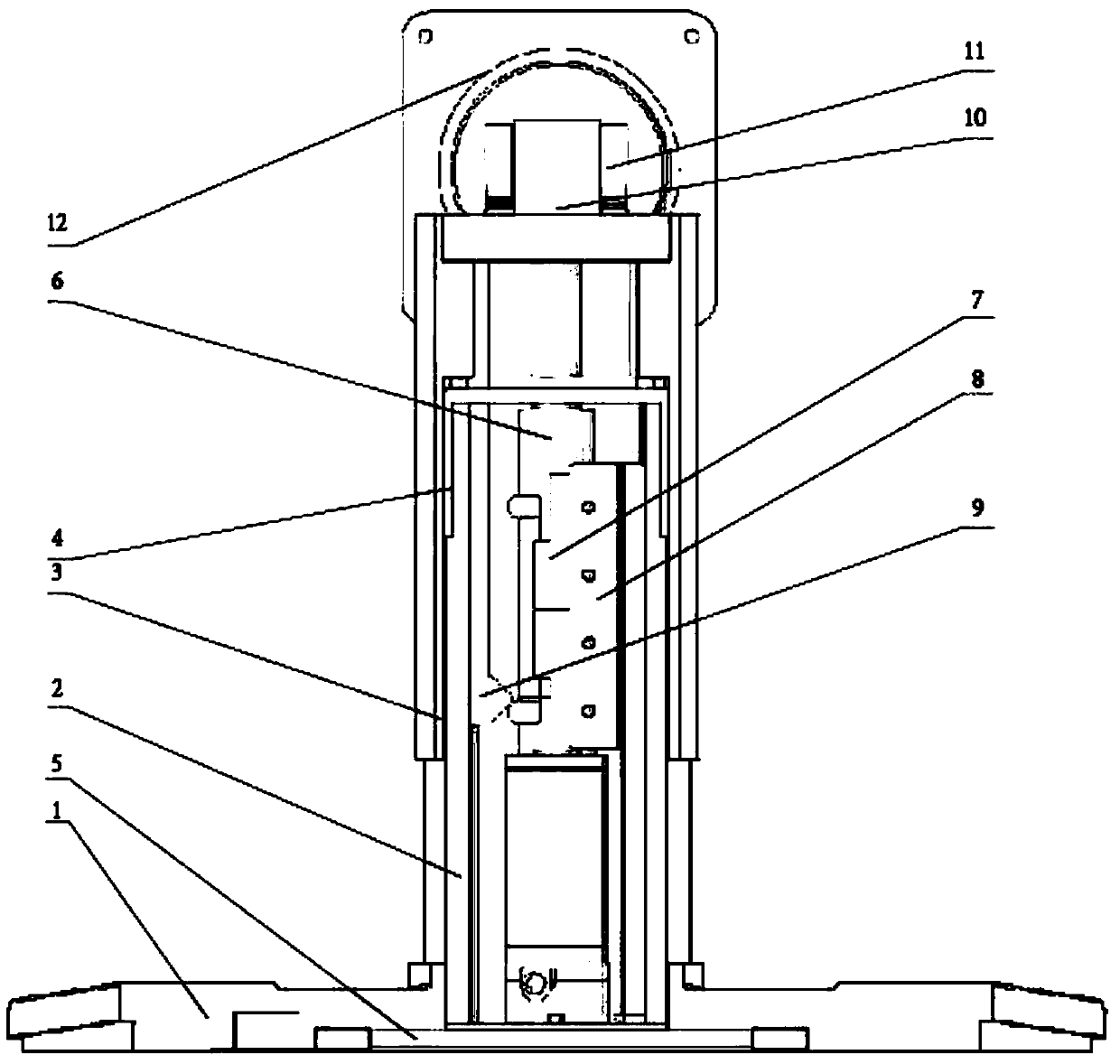

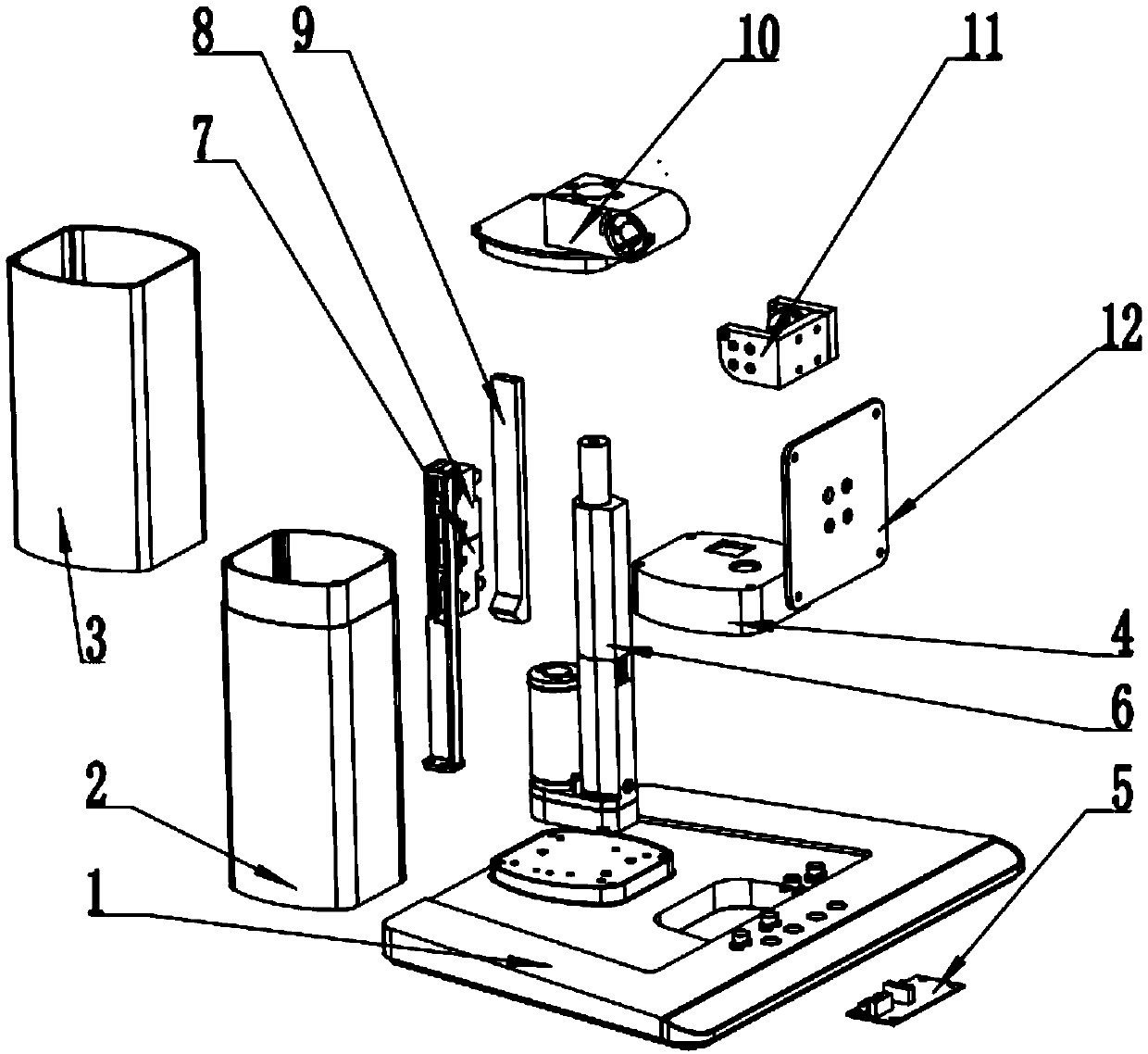

Desktop electric lifting base for hanging display

InactiveCN109681728AEliminate spondylosis and other diseasesSimple and fast operationOffice tablesStands/trestlesDisplay deviceComputer module

The invention provides a desktop electric lifting base for hanging a display, which comprises a chassis, a lower column, an upper column, a plastic sleeve, a control module, an electric lifting push rod, a limit switch and a bracket, a limit rod, a rotary hinge mechanism, a pitch hinge mechanism and a display fixing plate. When the desktop electric lifting base is used, the display is fixed on thedisplay fixing plate. Electric lifting of the display in height and adjusting of the angles of rotation and pitch can be realized according to personal needs and different scenes by controlling the buttons of the circuit by a user. The desktop electric lifting base is suitable for different scenes and the display of different weights, effectively eliminating the diseases such as vertebral diseasecaused by inappropriate display height, solving the defects of poor controllability, poor stability, poor operability and large noise of traditional manual adjusting base, and providing users with good operation experience. This device can be widely used in most display fields to meet the different needs of individual and scene differences, and has high application value.

Owner:NANJING JUSHA DISPLAY TECH +1

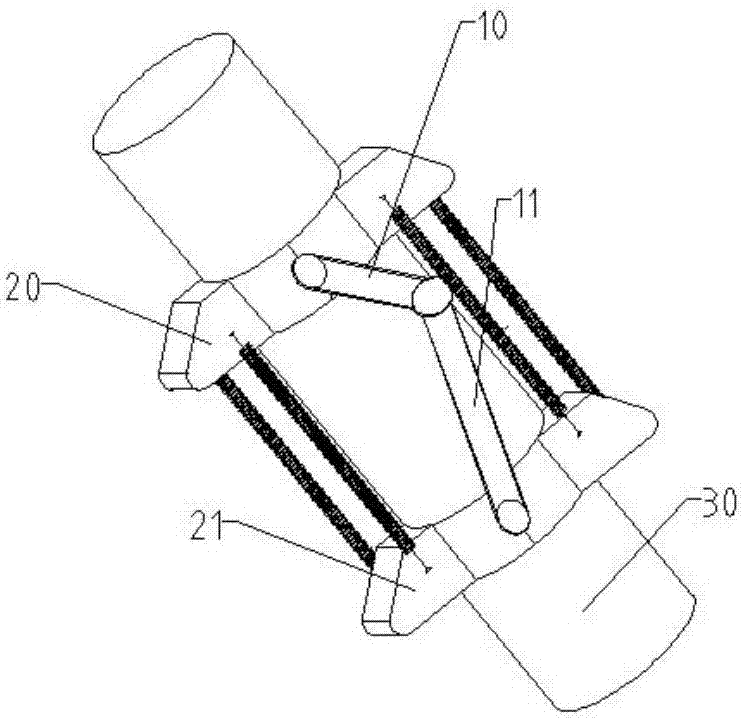

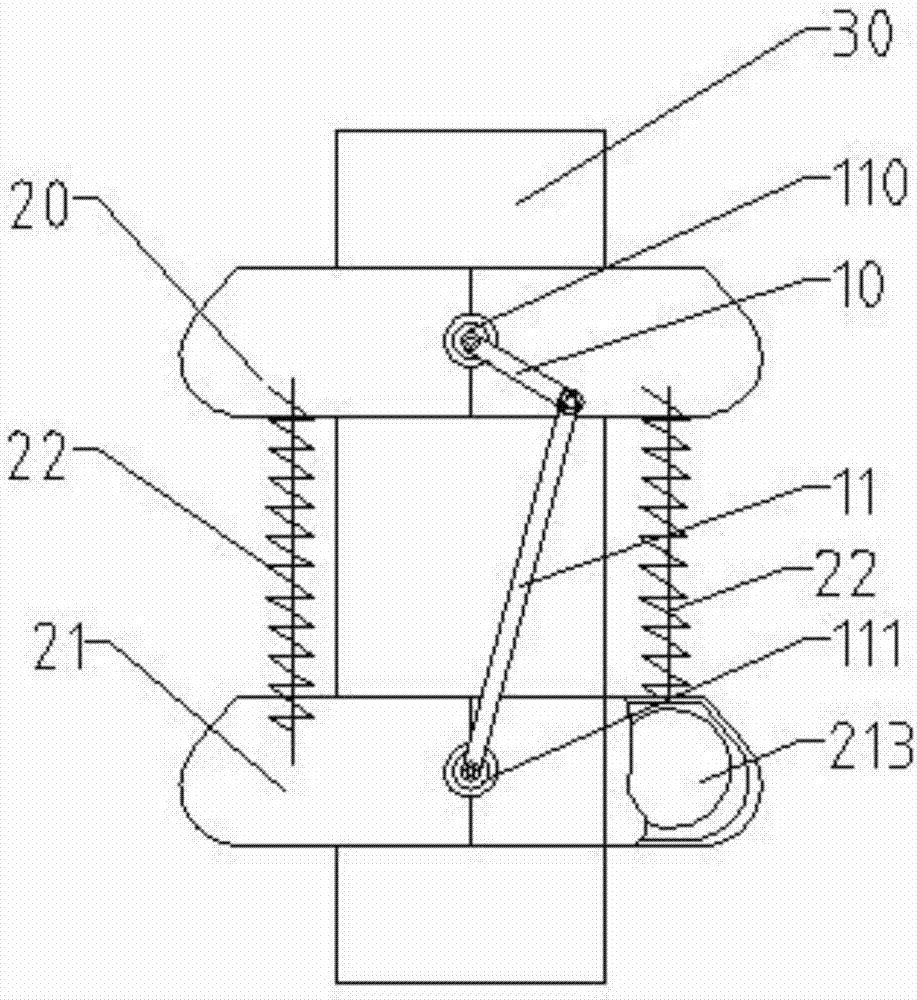

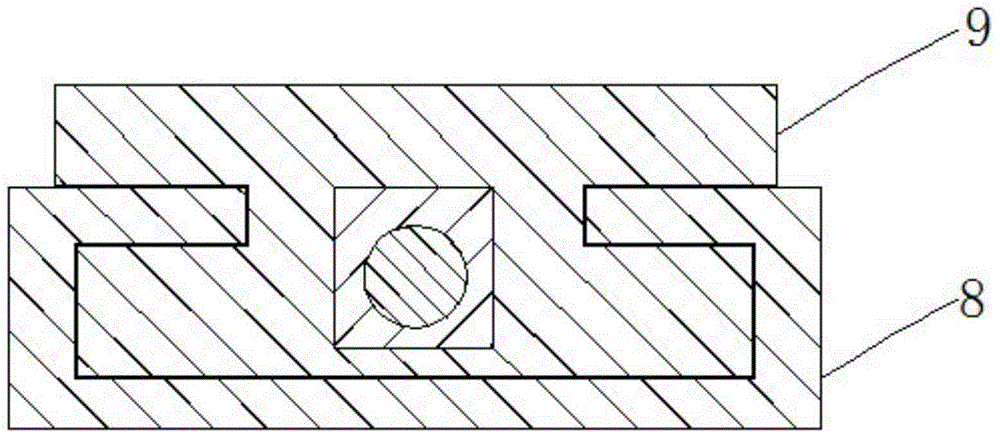

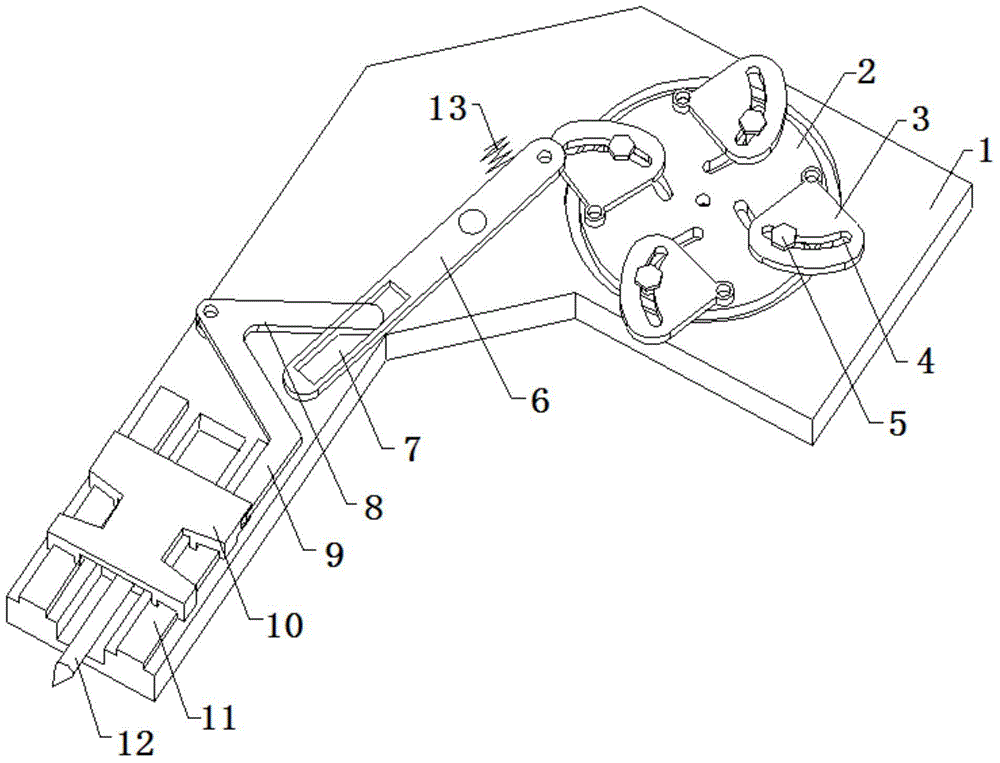

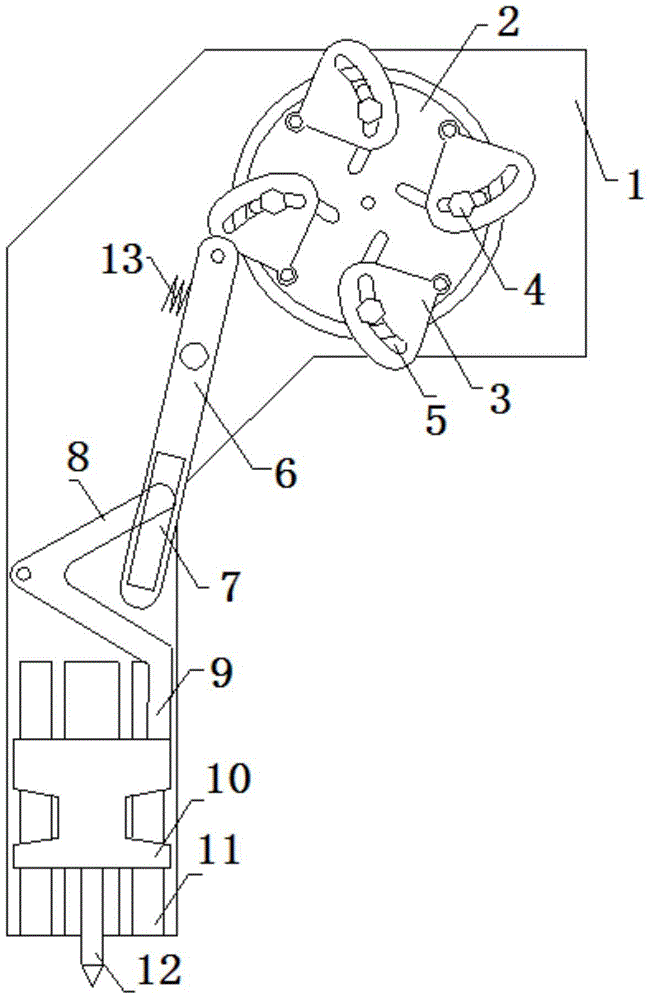

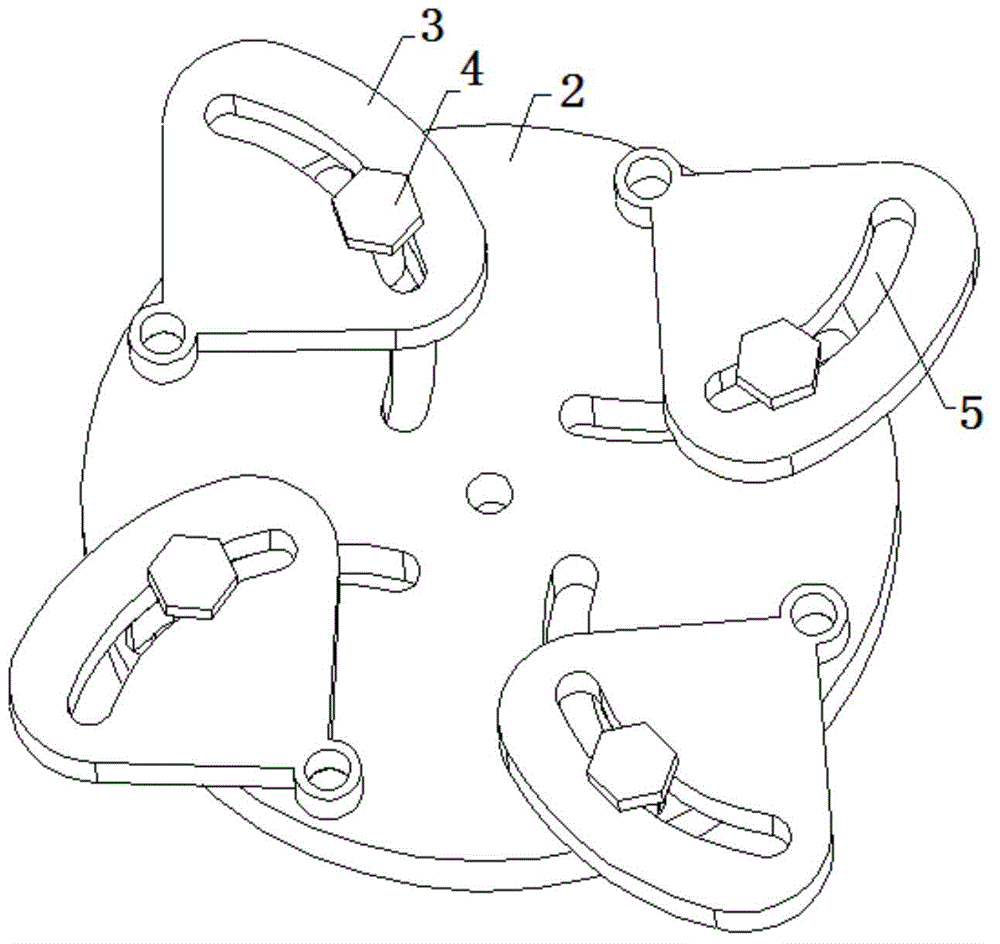

Worm type robot

The invention discloses a worm type robot. The robot comprises self-locking sleeve pair, self-locking balls, and a crank linkage mechanism, wherein the self-locking sleeve pair comprise an upper self-locking sleeve and a lower self-locking sleeve, the upper self-locking sleeve and the lower self-locking sleeve are both provided with through holes for crawling on a cylindrical object, and both ends of the upper self-locking sleeve and the lower self-locking sleeve are provided with a trapezoidal arc structure; the self-locking balls are arranged in both the trapezoidal arc structures and a cavity formed by the upper self-locking sleeve and the lower self-locking sleeve, the diameter of each self-locking ball is greater than the top edge length of each trapezoidal arc structure, and the diameter of the self-locking sphere is less than the bottom length of each trapezoidal arc structure, and the self-locking balls have large enough friction coefficient to provide adequate friction to achieve the self-locking; one end of the crank linkage mechanism is connected in a rotary mode with the upper self-locking sleeve, and the other end is connected in a rotary mode with the lower self-locking sleeve. The worm type robot can achieve the crawling on a complex cylindrical object.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

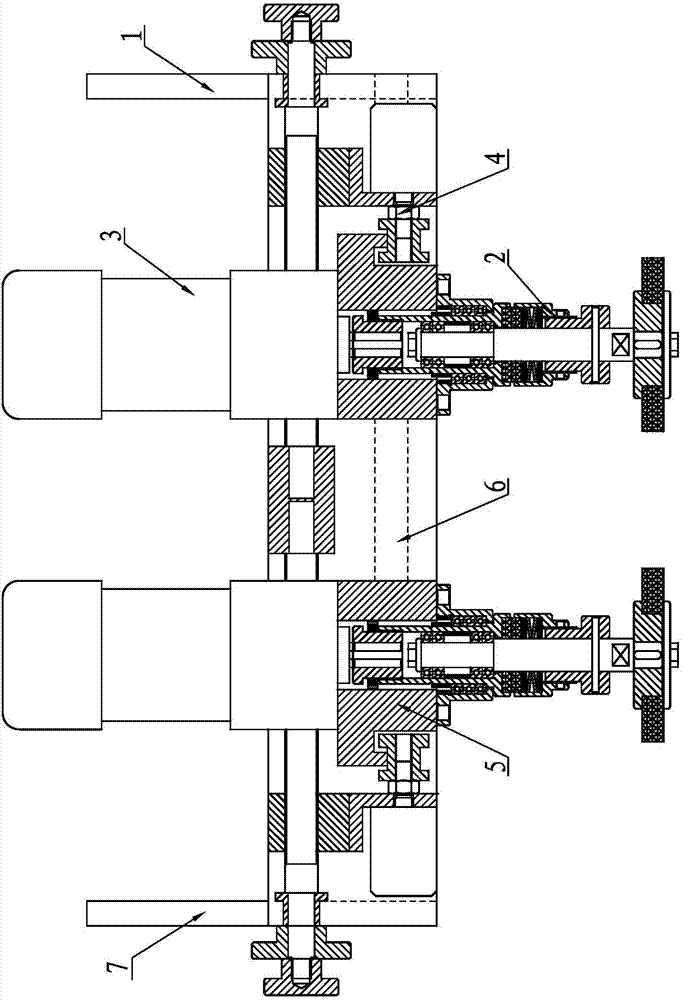

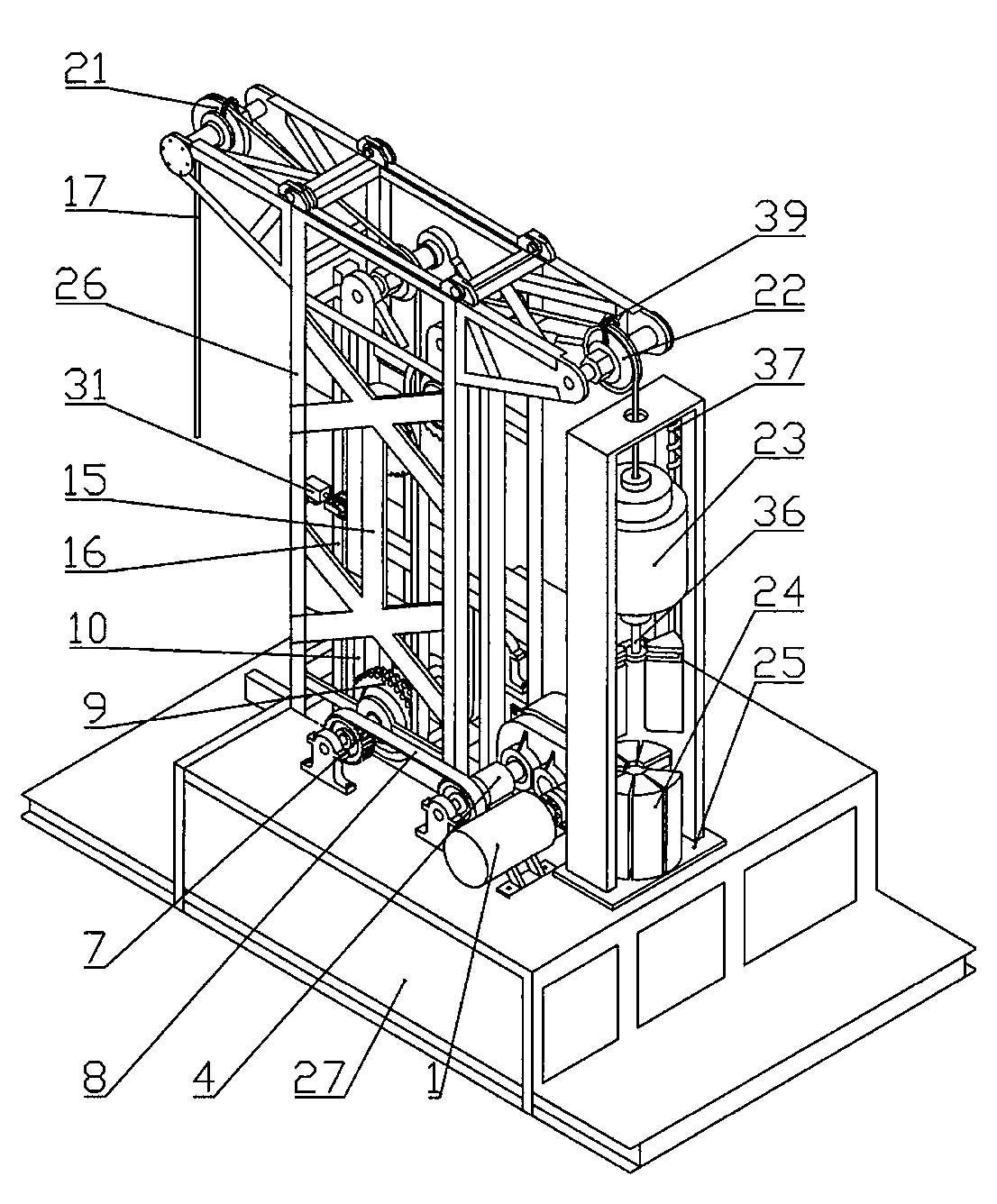

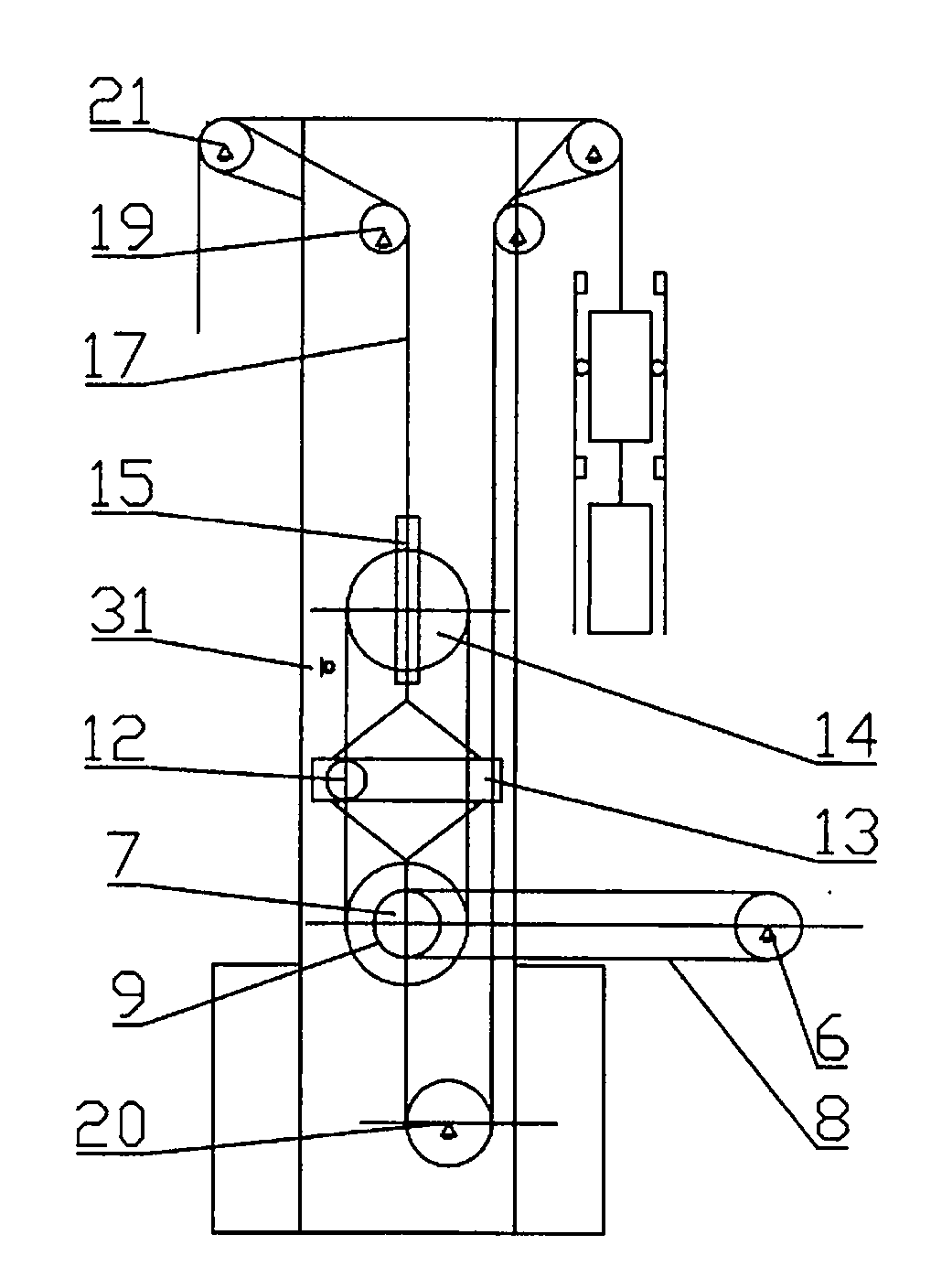

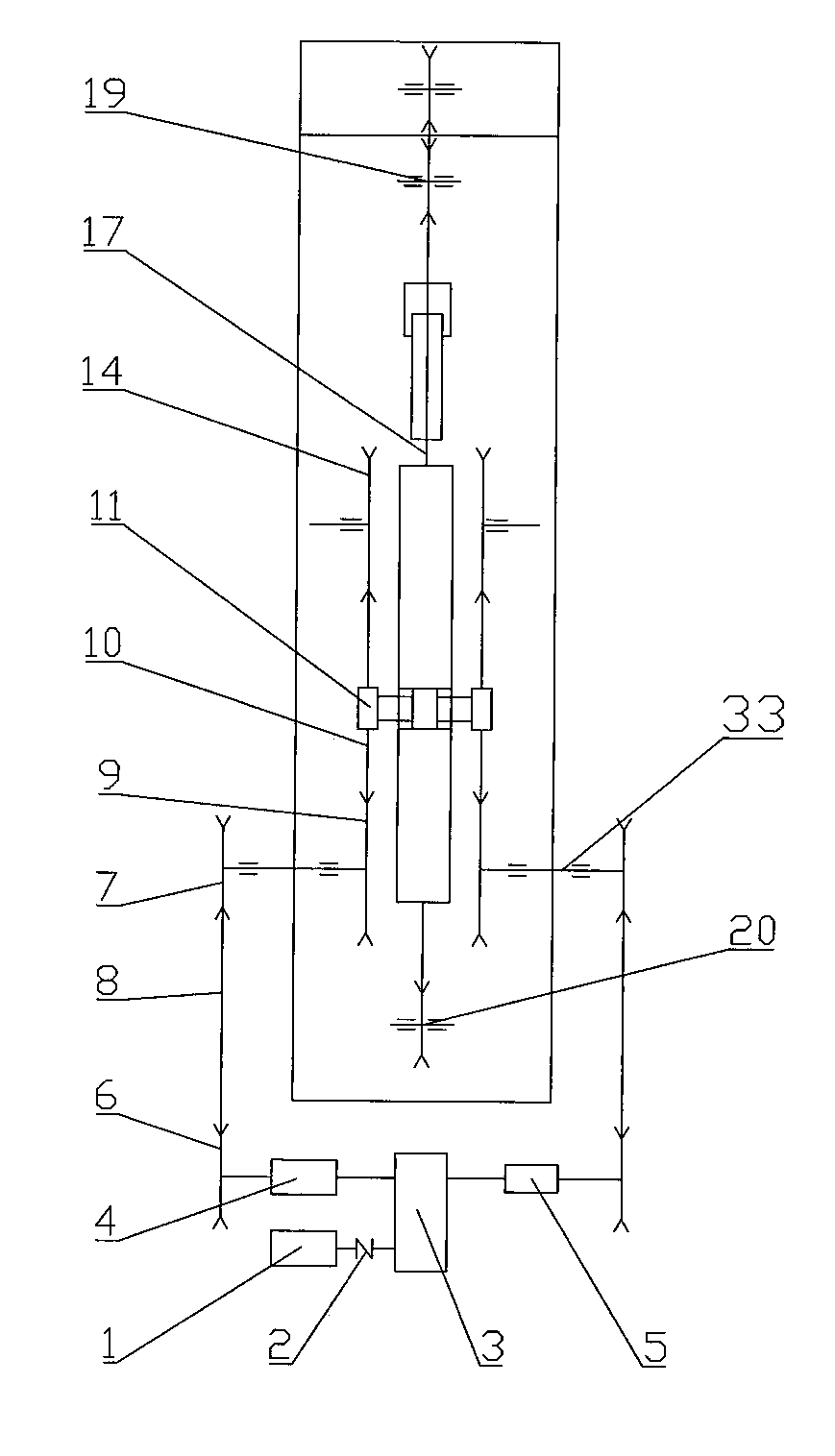

Single-motor bilateral-drive energy-saving chain type pumping unit

The invention discloses a single-motor bilateral-drive energy-saving chain type pumping unit. The pumping unit is composed of a support portion, a transmission portion and a counter weight adjusting portion. According to the pumping unit, two chains are driven by a single motor, tensioning degrees of the chains are adjusted in real time, the stroke is variable, the time of strokes is adjustable, and dynamic counter weight is achieved.

Owner:JILIN UNIV

Gas valve

ActiveCN102235270AAdjust strokeCompensation for axial playInternal combustion piston enginesFuel supply apparatusMagnet

The present invention relates to a dry running gas valve. In order to achieve high opening speeds in a dry running gas valve with electromagnetic actuation, it is provided to arrange the engagement point of the magnet armature (22) and the limit stop at the radially inner guide region (16) of the valve element (2). Due to the resulting reduced deflection, the valve element can be built more compact and lighter and the residual air gap can be reduced, which allows higher opening speeds.

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

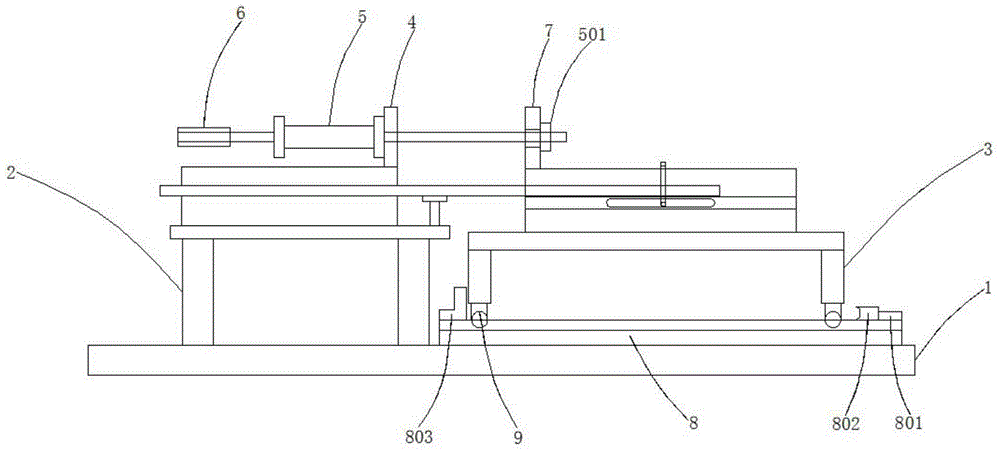

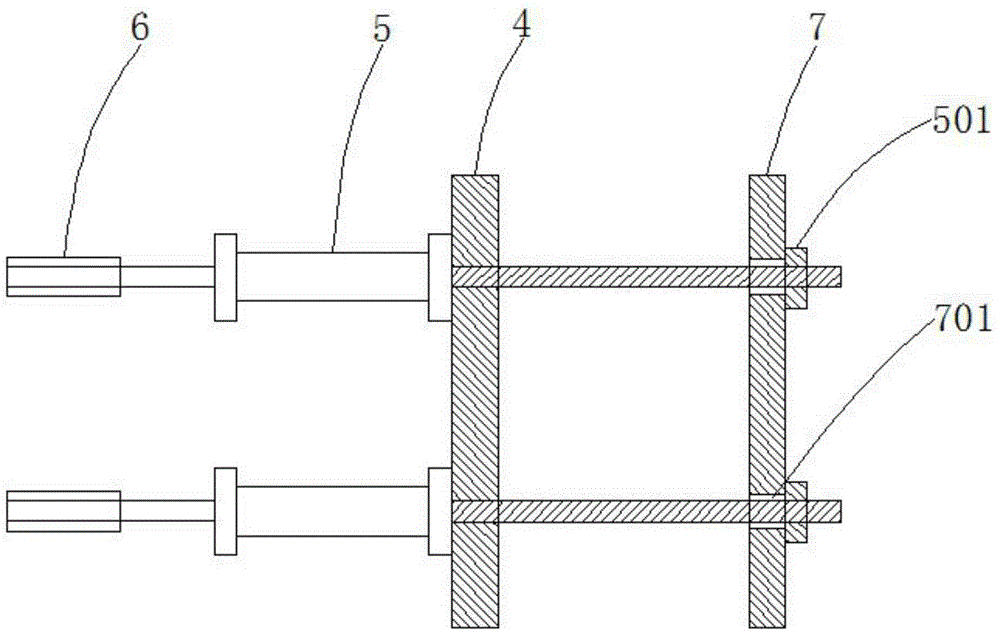

Automatic moving device

InactiveCN104526433AAdjust strokeSolve the distance problemLinear bearingsFluid-pressure actuatorsEngineeringScrew thread

The invention discloses an automatic moving device which comprises a working table, a cooling machine, a receiving machine, an air cylinder fixing plate, air cylinders, adjusting bolts, a push plate, a guide rail and slide blocks, wherein the air cylinder fixing plate is located on the left side of the top end of the cooling machine and is in threaded connection with the cooling machine; the air cylinders are located at the middle ends on the left side and the right side of the front surface of the air cylinder fixing plate and are in threaded connection with the air cylinder fixing plate; the adjusting bolts are located at the tail ends of the air cylinders and are in threaded connection with the air cylinders; the pushing plate is located on the right side of the top end of the receiving machine and is in threaded connection with the receiving machine; the guide rail is located at the bottom of the receiving machine and is in threaded connection with the working table; and the slide blocks are located at the periphery of the bottom of the receiving machine and are in threaded connection with the receiving machine. The automatic moving device effectively avoids the problems of deviation and distance difference and greatly increases the production efficiency.

Owner:安徽池州瑞强塑业有限公司

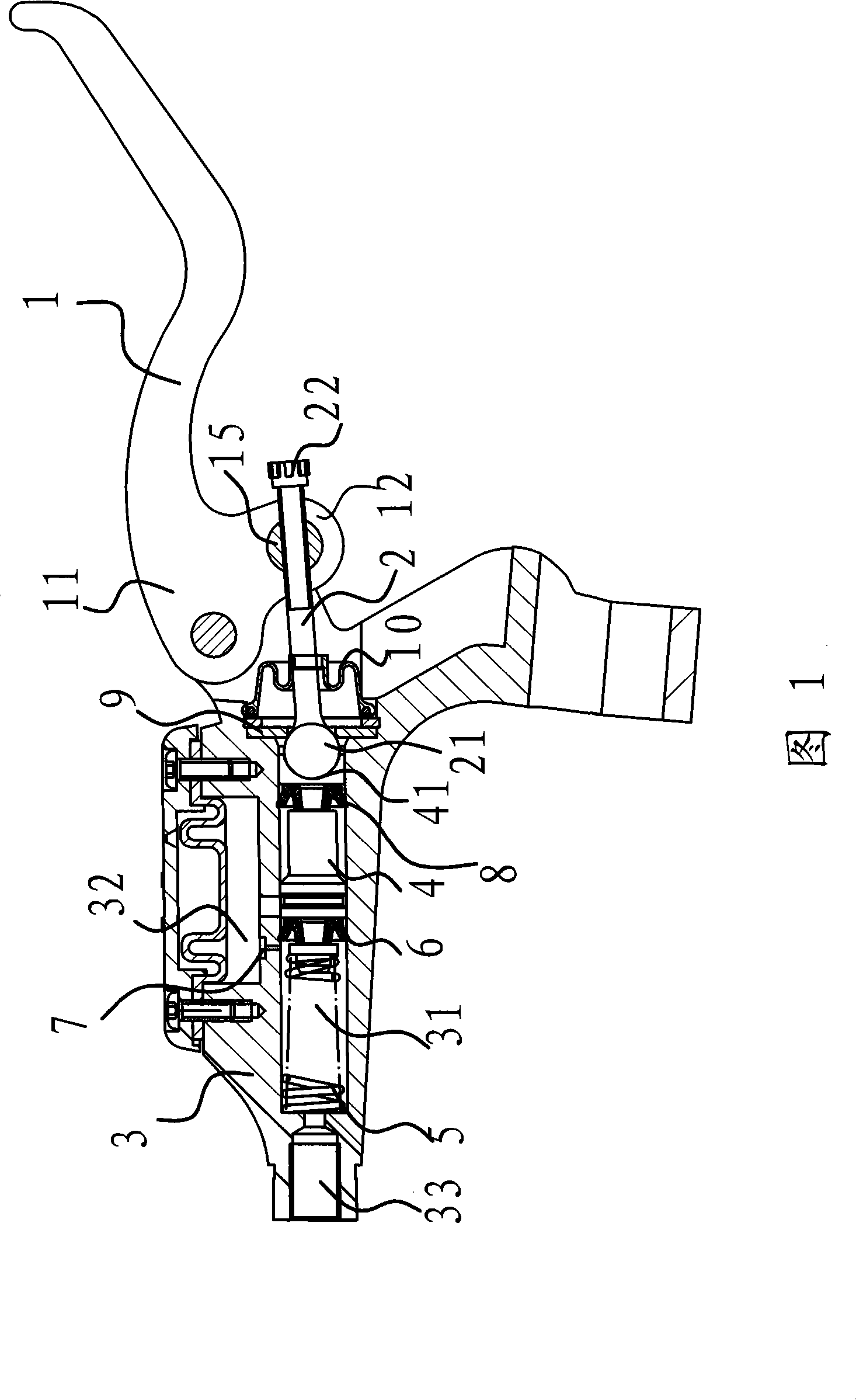

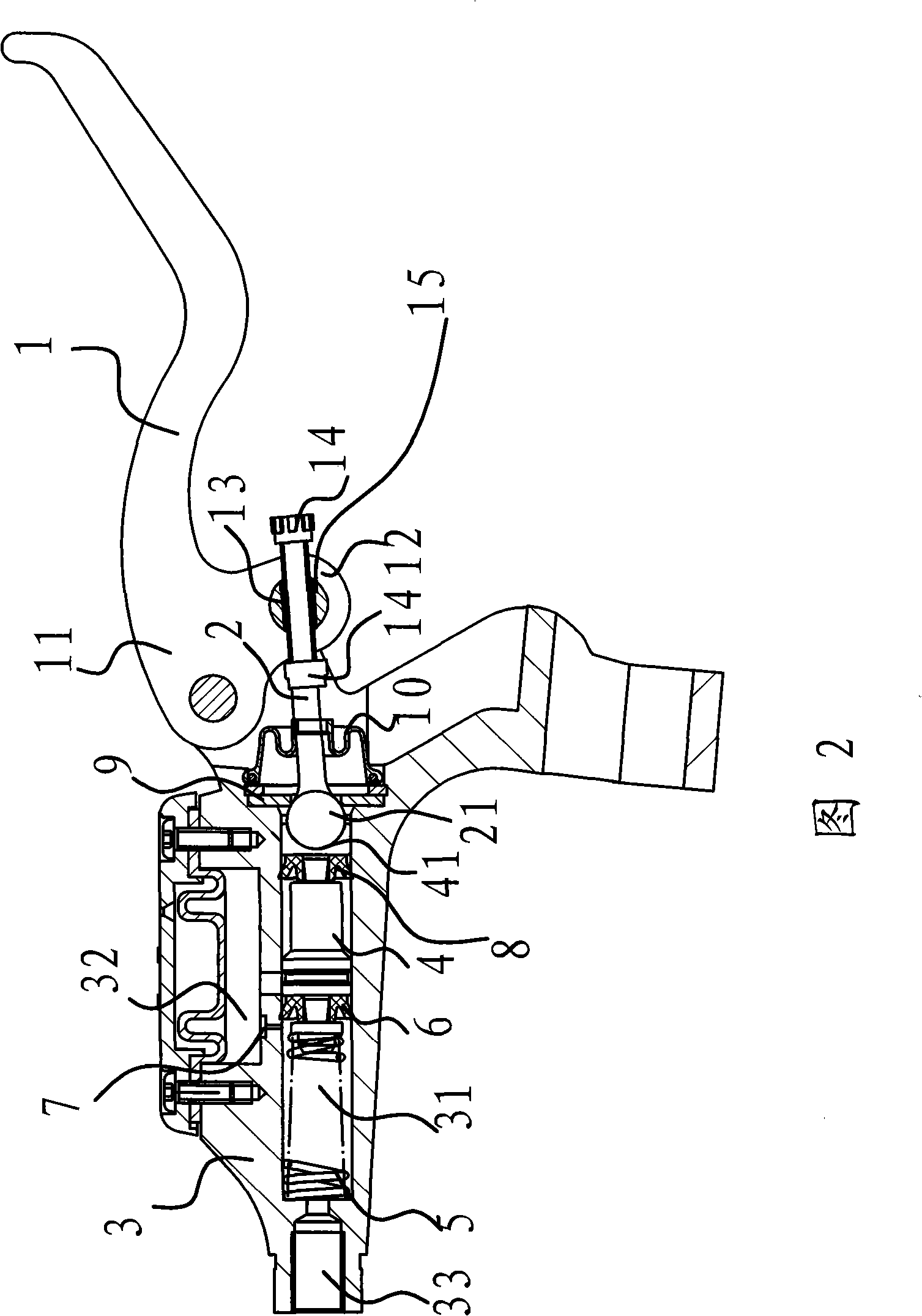

Adjusting mechanism for brake handle

InactiveCN101259867AIncrease the extension lengthLarge adjustment rangeCycle control systemsCycle brakesEngineeringMechanical engineering

The invention provides a regulating mechanism for brake handle, which belongs to the technical field of the machinery. The regulating mechanism solves the problem that the phenomenon of deadlocking occurs if the regulative distance between the rear part and front part of the handle of the regulating mechanism of the prior brake handle is too large. The regulating mechanism of the brake handle is arranged between a hydraulic brake pump and a brake handle and the hydraulic brake pump comprises a pump body and a piston arranged inside the pump body; the brake handle is hinged with the pump body and a connecting rod is arranged between the piston and the brake handle; one end of the connecting rod is connected with the external end of the piston in a rotary way and the other end of the connecting rod passes through the brake handle and can relatively move with the brake handle; a positioning structure which can regulate the position of the brake handle is arranged between the connecting rod and the brake handle. The regulating mechanism of the brake handle has simple structure, big regulative distance of the brake handle and has no effect on the idle stroke of the piston.

Owner:YUHUAN KAILING MASCH GRP CO LTD

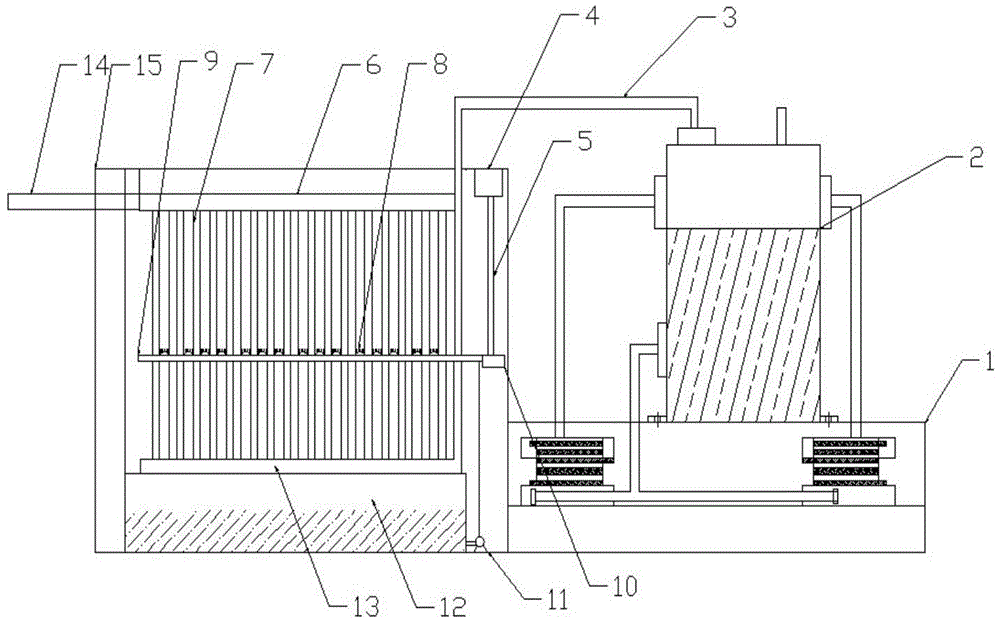

Car-mounted hydrogen generation system

InactiveCN104481746ARelieve stressChange lengthElectrolysis componentsNon-fuel substance addition to fuelElectrolysisAir filter

The invention discloses a car-mounted hydrogen generation system and relates to the field of car energy development. The system comprises solution storage chamber containing electrolysis solutions, an electrolysis machine for electrolyzing the electrolysis solutions in the solution storage chamber to generate hydrogen and a heat exchanger for cooling the generated hydrogen. The electrolysis machine is connected with a direct-current power supply. The heat exchanger is the all aluminum cooling-fin-free micro-channel heat exchanger. A water collection tank is arranged below the heat exchanger, and a water pump is arranged on one side of the water collection tank and is connected between the water collection tank and a spray water unit. Compared with the prior art, a few of electrolysis solutions are added in water in the solution storage chamber, electrolysis is performed through the electrolysis machine to generate hydrogen, the electrolyzed hydrogen is cooled through the water-film external heat exchanger, moisture mixed in hydrogen is reduced during cooling, and treatment pressure of later car air filters is reduced.

Owner:BEIJING UNIV OF TECH

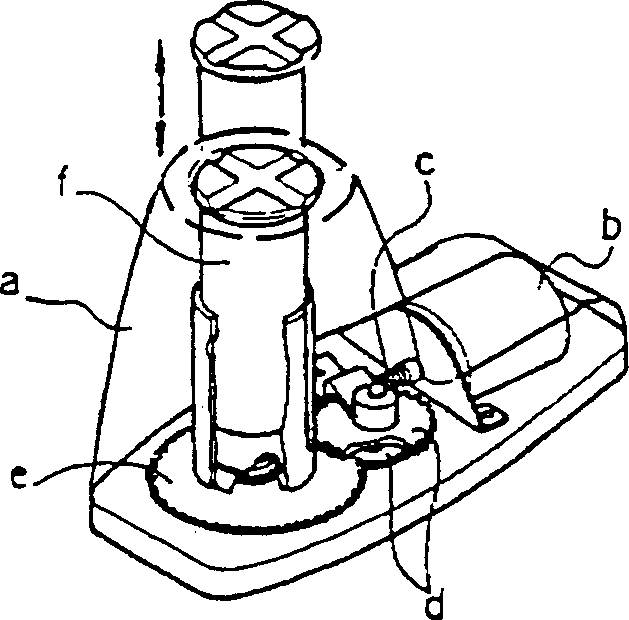

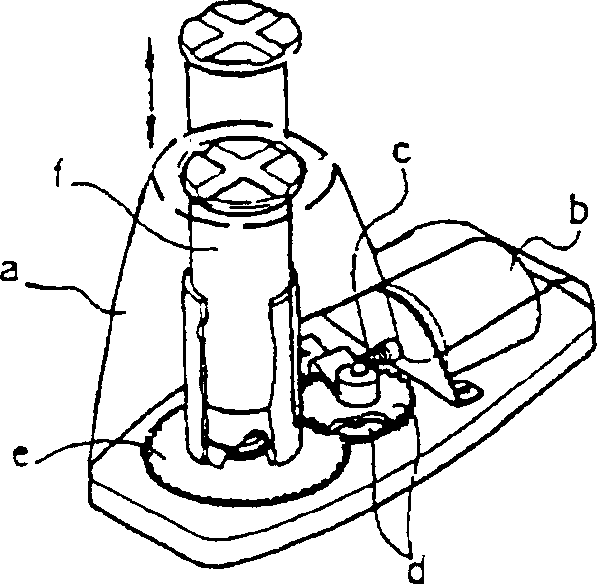

Electric jack for vehicle

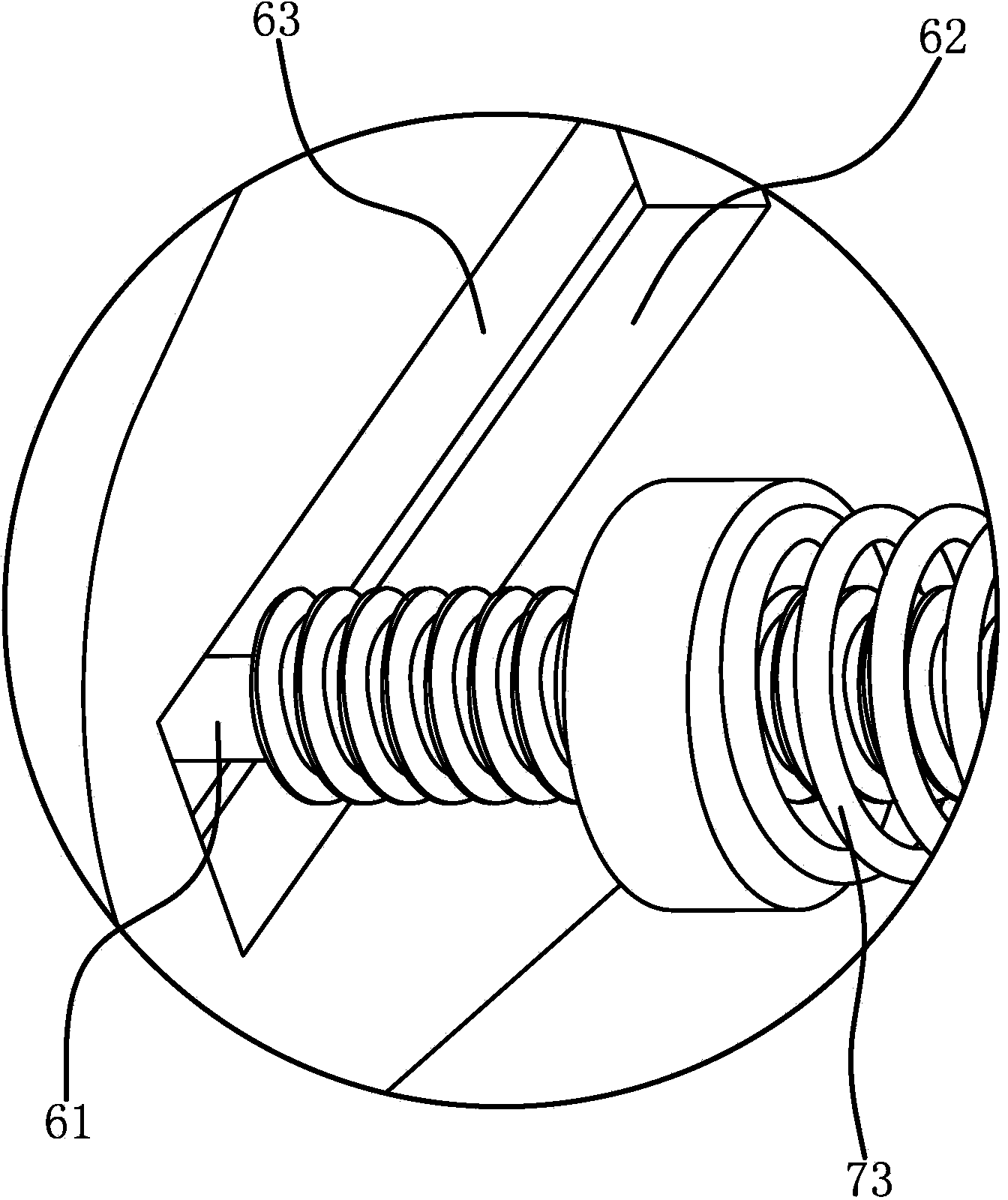

InactiveCN1386697AAvoid elevationReduce frictional resistanceGearingVehicle fittings for liftingCoil springEngineering

In the electric jack for vehicles of the present invention, the lifting unit comprises a helical lifting column, and the internal thread is only formed at the lower part of the helical lifting column, thereby reducing its frictional resistance. A pin is placed in a horizontal groove formed at the top of the primary helix, this pin protruding slightly into two longitudinal cavities symmetrically formed at the top of the secondary helix. A coil spring, spring cover and snap ring are placed sequentially over the pin with the snap ring seated in an annular groove formed on the inner surface of the top wall of the secondary helix, thereby allowing the coil spring to bias the pin. As a result, the secondary helix is prevented from rising together with the helical lifting column. A support post having a top support member and external threads capable of movably engaging the secondary helix and the gap between the helical lifting posts when the external threads are engaged with the internal threads of the helical lifting post, thereby allowing the user to follow the It is required to adjust the stroke of the lifting unit.

Owner:沈钟煜

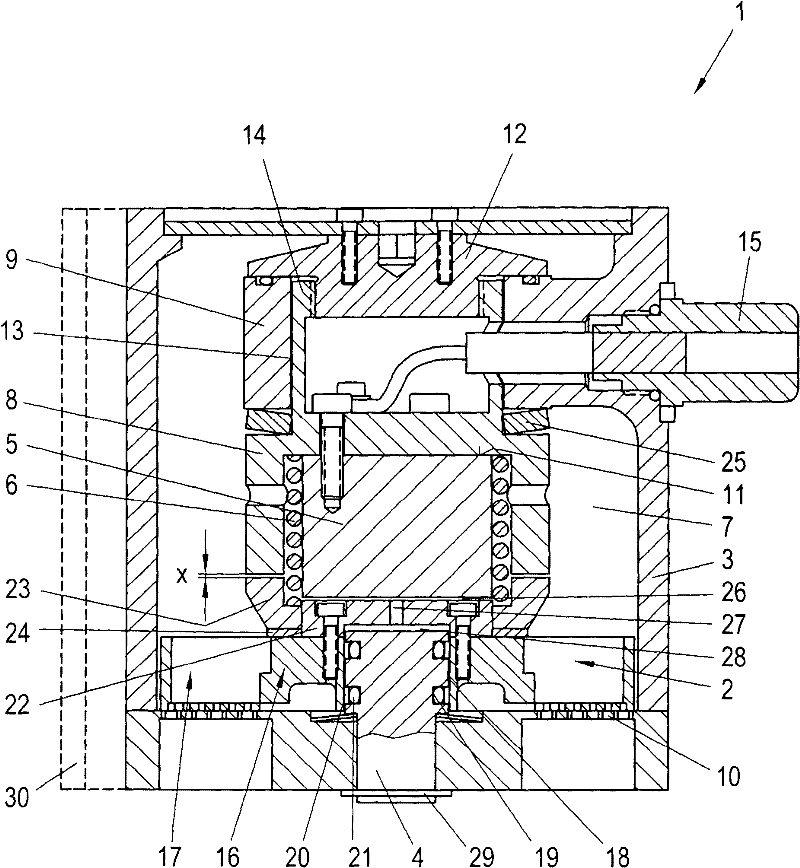

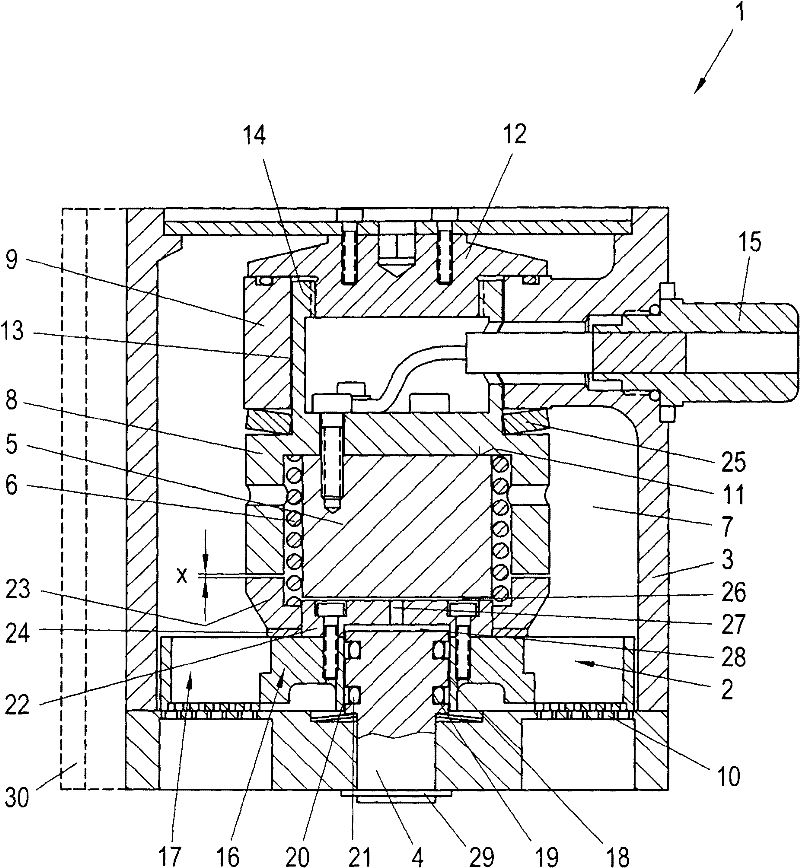

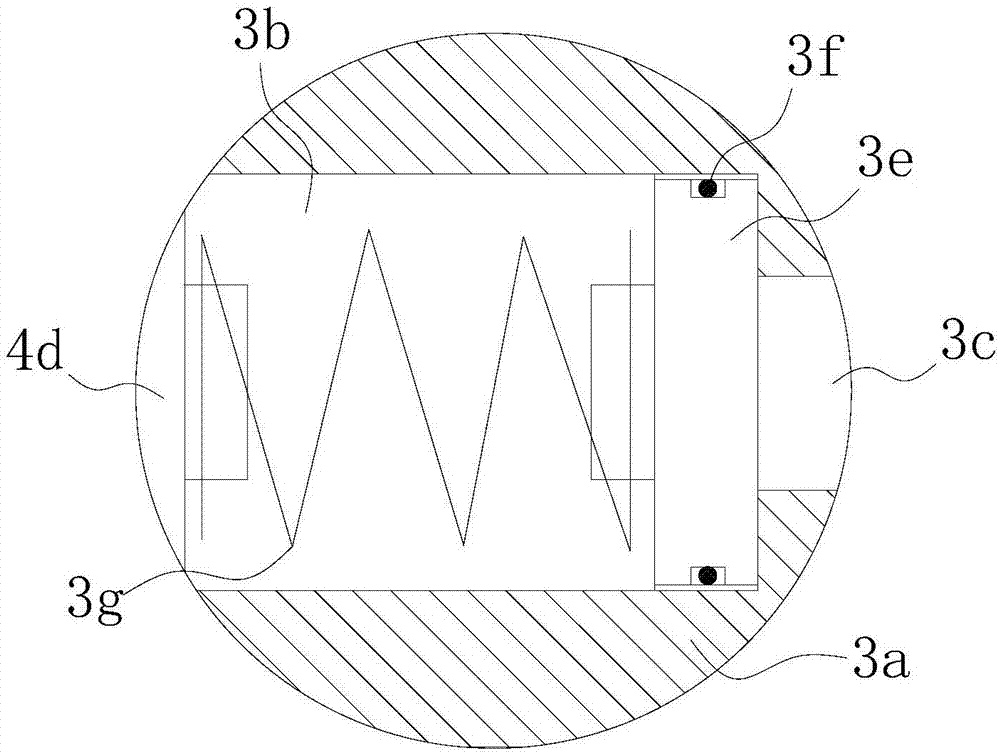

Automatic lubricant pump for hydraulic equipment

The invention discloses an automatic lubricant pump for hydraulic equipment, belonging to the technical field of lubricant pumps. The automatic lubricant pump is characterized by comprising a pump body, a first installing groove is formed in one end face of the pump body, a working chamber is arranged at the bottom in the first installing groove, and a cylinder body is arranged in the first installing groove; a second installing groove, opposite to the first installing groove, is arranged in the other end face, opposite to the first installing groove, of the pump body, a pressure regulating mechanism is arranged in the second installing groove, a pressure conducting mechanism connected with the pressure regulating mechanism is arranged in the cylinder body, and an external pressure oil inlet communicated with the pressure conducting mechanism is arranged in the outer end face of the cylinder body; an oil inlet passage and an oil outlet passage are respectively arranged on the side walls of the working chamber, the oil inlet passage is connected with an automatic oil inlet valve, and the oil outlet passage is connected with an automatic oil outlet valve; the invention aims at providing the automatic lubricant pump for the hydraulic equipment, which is compact in structure and small and exquisite in size, can automatically adapt to the load conditions and has a good effect; the automatic lubricant pump is used for the lubrication for moving parts of the hydraulic equipment.

Owner:广东鸿荣重工股份有限公司

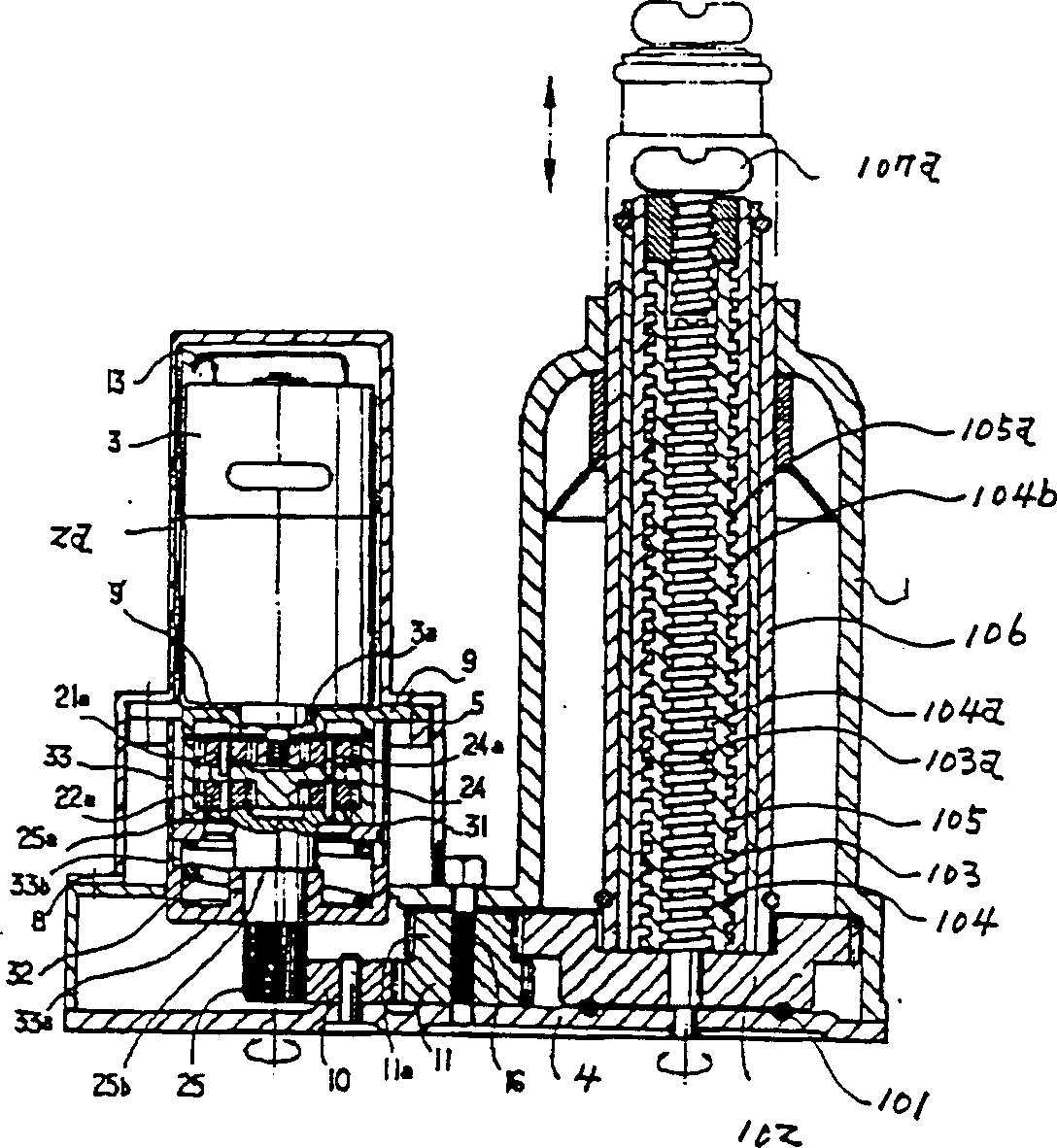

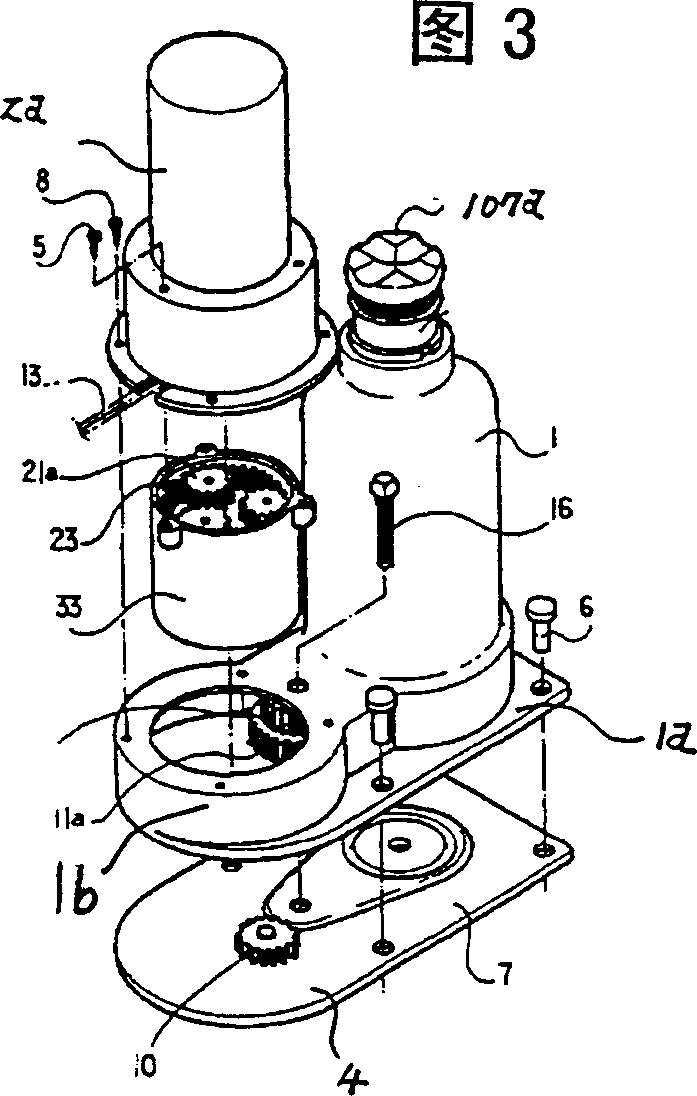

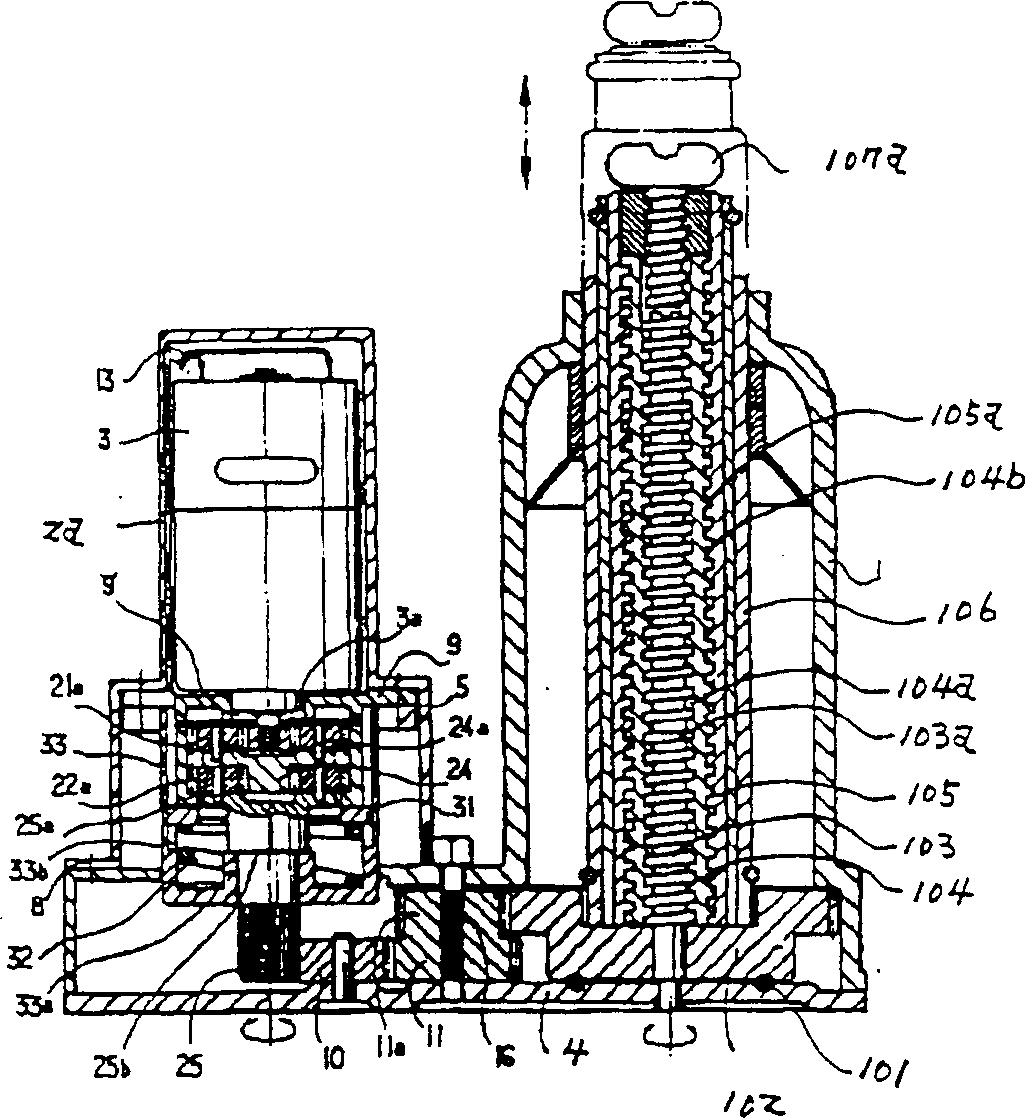

Electric jack for vehicle

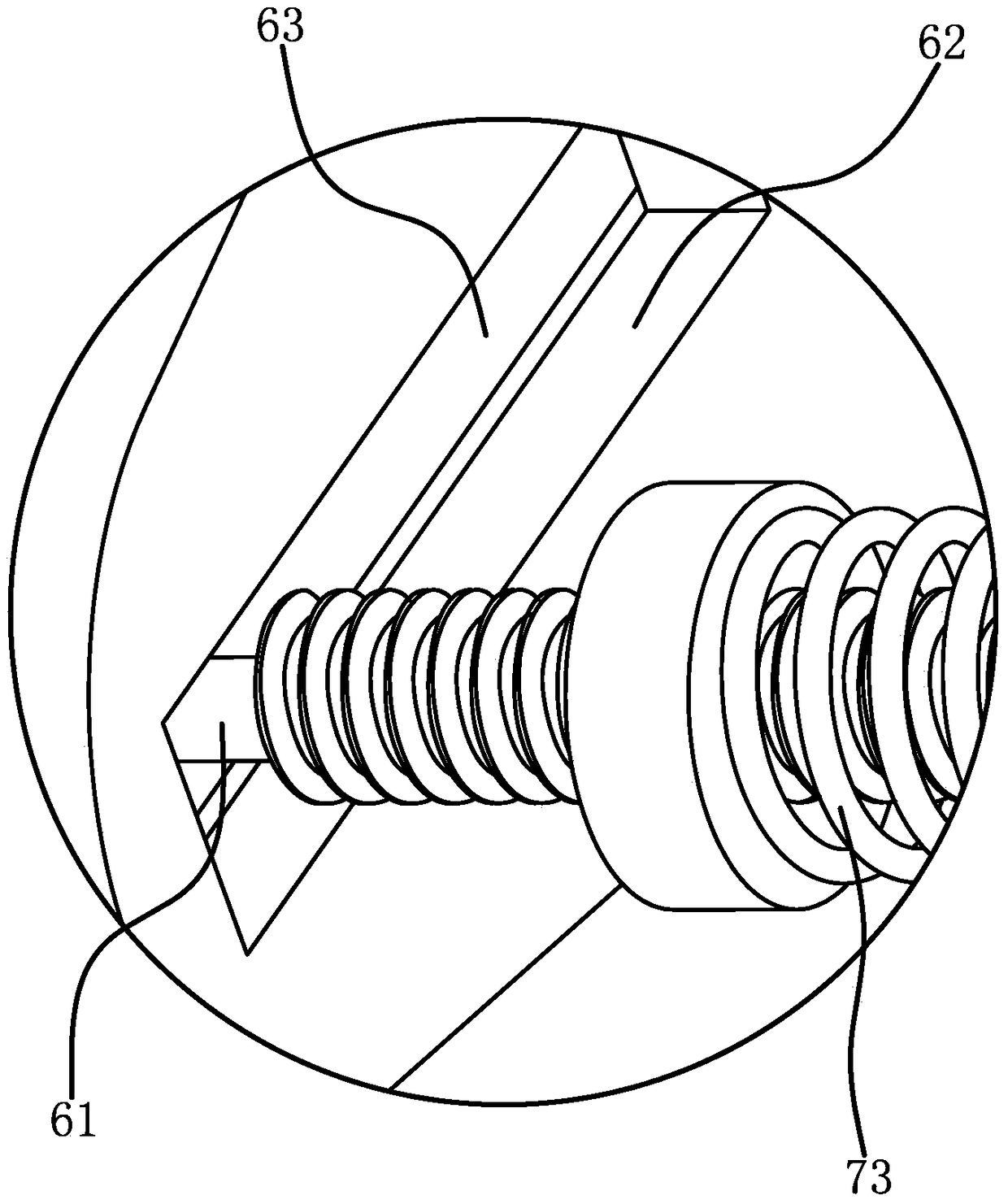

InactiveCN1140445CAvoid elevationReduce frictional resistanceGearingVehicle fittings for liftingCoil springFrictional resistance

A motor-operated jack for vehicles is disclosed. In the motor-operated jack of this invention, a lifting unit consists of a spiral lifting ram (105) having an internal thread (105a) limitedly formed at a lower portion of the spiral lifting ram (105), thus reducing its frictional resistance. A pin (103c) is held in a horizontal groove (103b) formed at the top end of a primary screw (103). This pin (103c) is slightly projected into two longitudinal holes (104c) symmetrically formed at the top portion of a secondary screw (104). A coil spring (103d), a spring cover (103e) and a snap ring (103f) are sequentially laid on the top of the pin (103c) such that the snap ring (103f) is seated in an annular groove (104d) formed on the inner surface of the top wall of the secondary screw (104), thus allowing the coil spring (103d) to bias the (103c) pin. This second screw (104) is thus prevented from being raised along with the spiral lifting ram (105). A support ram (107), having a top support (107a) and an external thread (107b), is movably fitted in a gap between the secondary screw (104) and the spiral lifting ram (105) while engaging with an internal thread (105c) of the spiral lifting ram (105) at the external thread (107b), thus allowing a user to control the moving stroke of the lifting unit as desired.

Owner:沈钟煜

Cold-bending welding pipe main machine

The invention discloses a cold-bending welding pipe main machine with molding compression rollers conveniently and rapidly replaced. The cold-bending welding pipe main machine comprises a power device, a transmission device and a machine head device. The transmission device comprises an installation frame. Multiple sliding seats sliding in the direction perpendicular to the machine head device and multiple sliding oil cylinders driving the sliding seats are arranged on the installation frame in parallel. The sliding seats are provided with upper movable seats which can move vertically, and upper connecting shafts are rotationally arranged in the upper movable seats. Lower connecting shafts are arranged in the sliding seats. The ends, close to the machine head device, of the upper connecting shafts and the lower connecting shafts are provided with jaw clutch driving parts, and the other ends of the lower connecting shafts are connected with the power device through telescopic universal couplers. The ends, close to the machine head device, of the upper connecting shafts are also provided with jaw clutch driving parts. The machine head device comprises a rack, an installation platform is detachably arranged on the rack, two vertical seats are arranged on the installation platform in parallel, and the vertical seats are rotationally provided with multiple pairs of upper compression rollers and lower compression rollers corresponding to the sliding seats.

Owner:江苏薪泽奇机械股份有限公司

Mechanical and electrical integrated injection molding device for workpiece production and processing

The invention discloses a mechanical and electrical integrated injection molding device for workpiece production and machining, which comprises a conveying groove, wherein a plurality of molds are evenly placed in the conveying groove, a pushing sliding rod capable of conveying the molds in a stepping mode is arranged at the bottom of the conveying groove, and a portal frame is fixed to the conveying groove; a lifting table is arranged in the portal frame in an up-down sliding mode, a plurality of connecting bases are distributed in the lifting table in a sliding mode in the direction perpendicular to the advancing direction of the conveying groove, and an injection molding assembly is arranged in each connecting base; an injection molding motor is fixed above the connecting base, and an output shaft of the injection molding motor is connected with a hollow rotating shaft; and a spline piston rod is connected below the hollow rotating shaft in a torque transmission manner. Compared with the prior art, the mechanical and electrical integrated injection molding device has the advantages that a piston connecting rod is connected to the different positions of the sliding groove gear, the initial position and stroke of each spline piston rod can be adjusted, and the spline piston rods can operate according to the preset period so as to be suitable for the injection amount and injection time of plastic liquid of the molds.

Owner:CHONGQING CITY MANAGEMENT COLLEGE

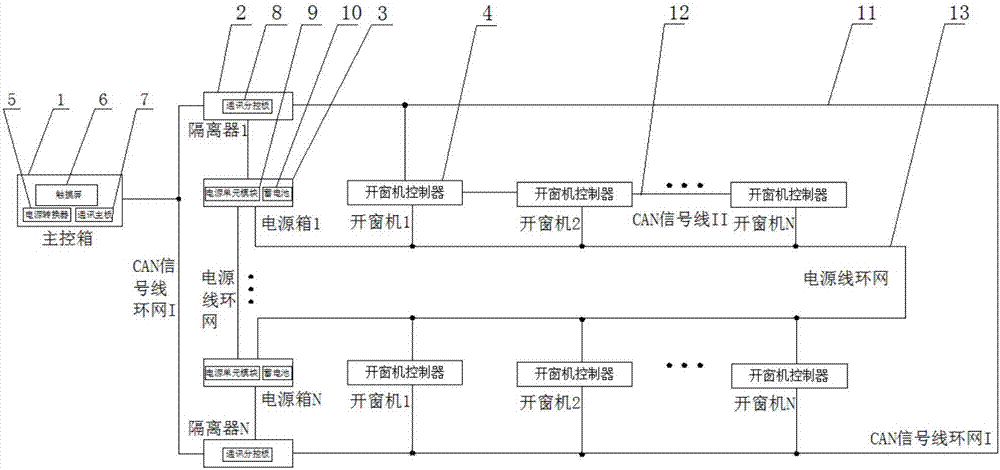

Dual CAN bus fire-fighting linkage intelligent control system

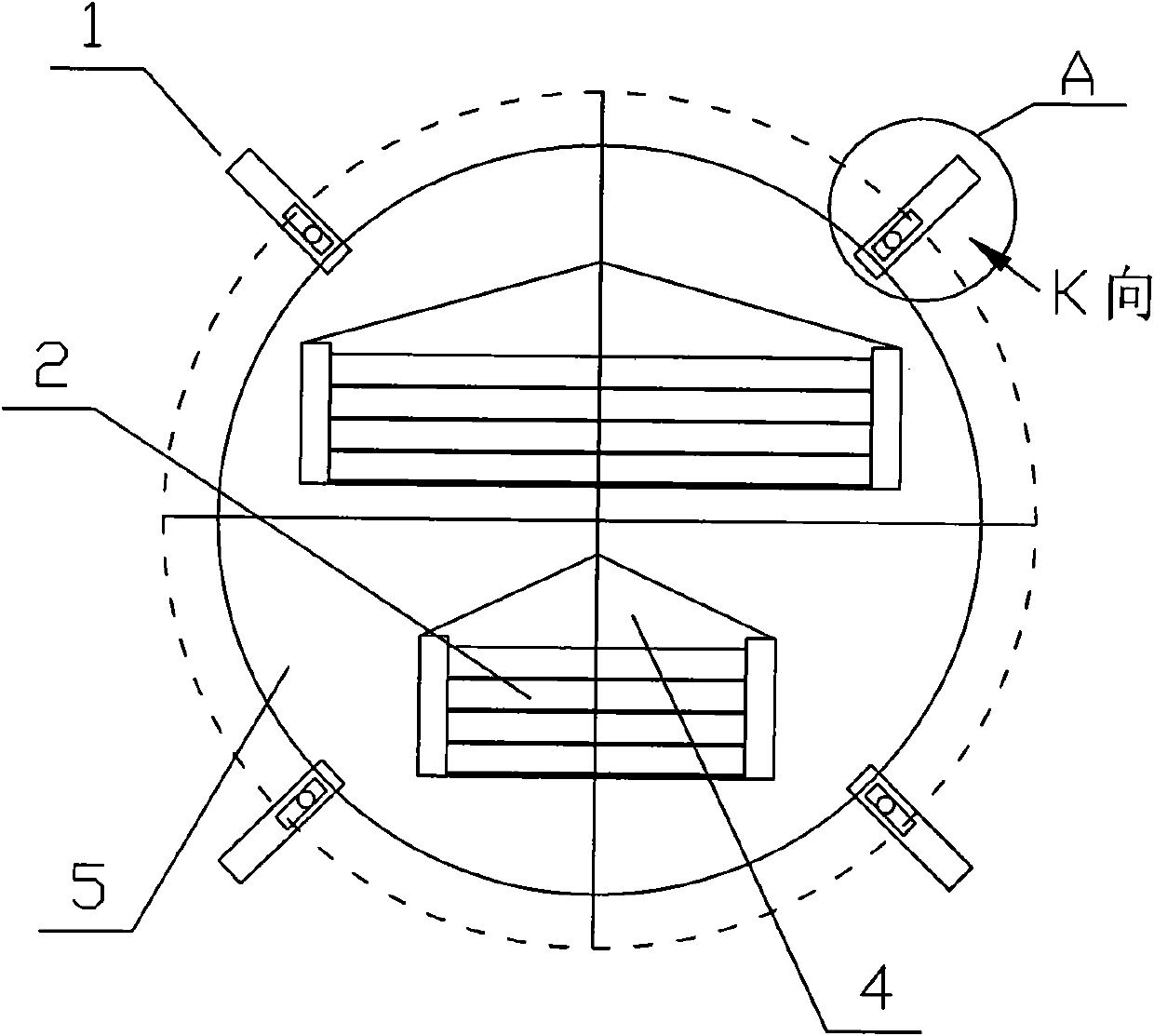

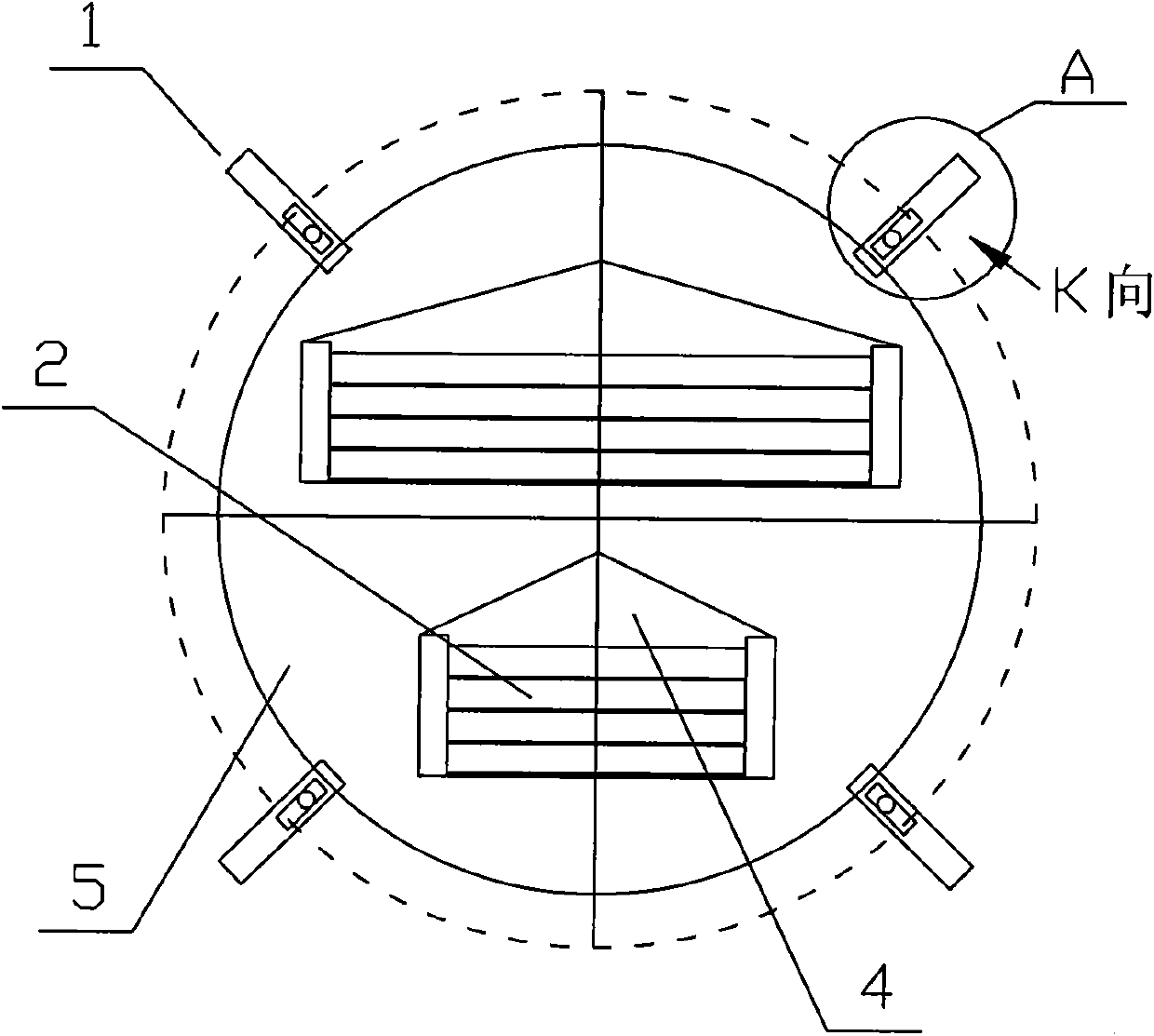

PendingCN107300899AStable and reliable power supplyIncrease risk resistanceProgramme total factory controlEmbedded systemIntelligent control system

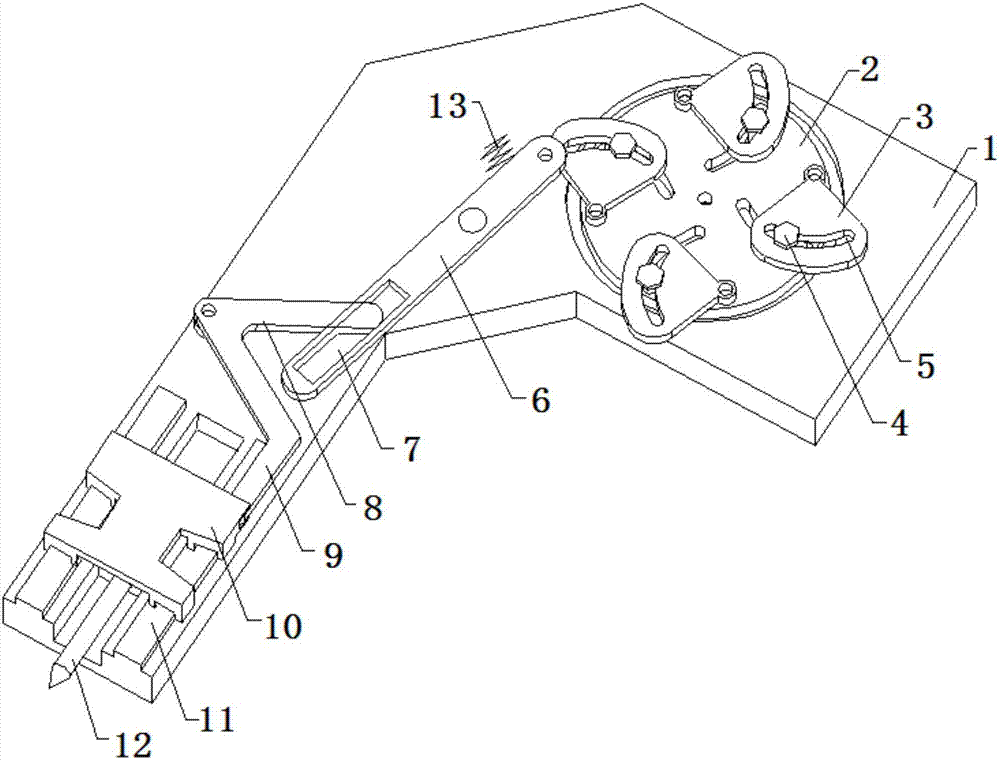

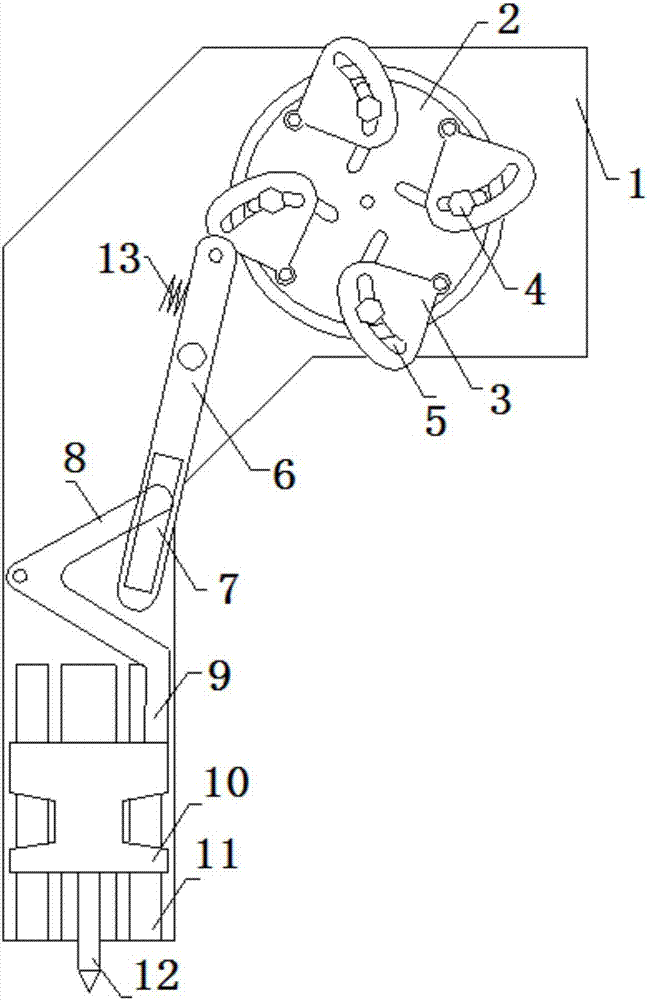

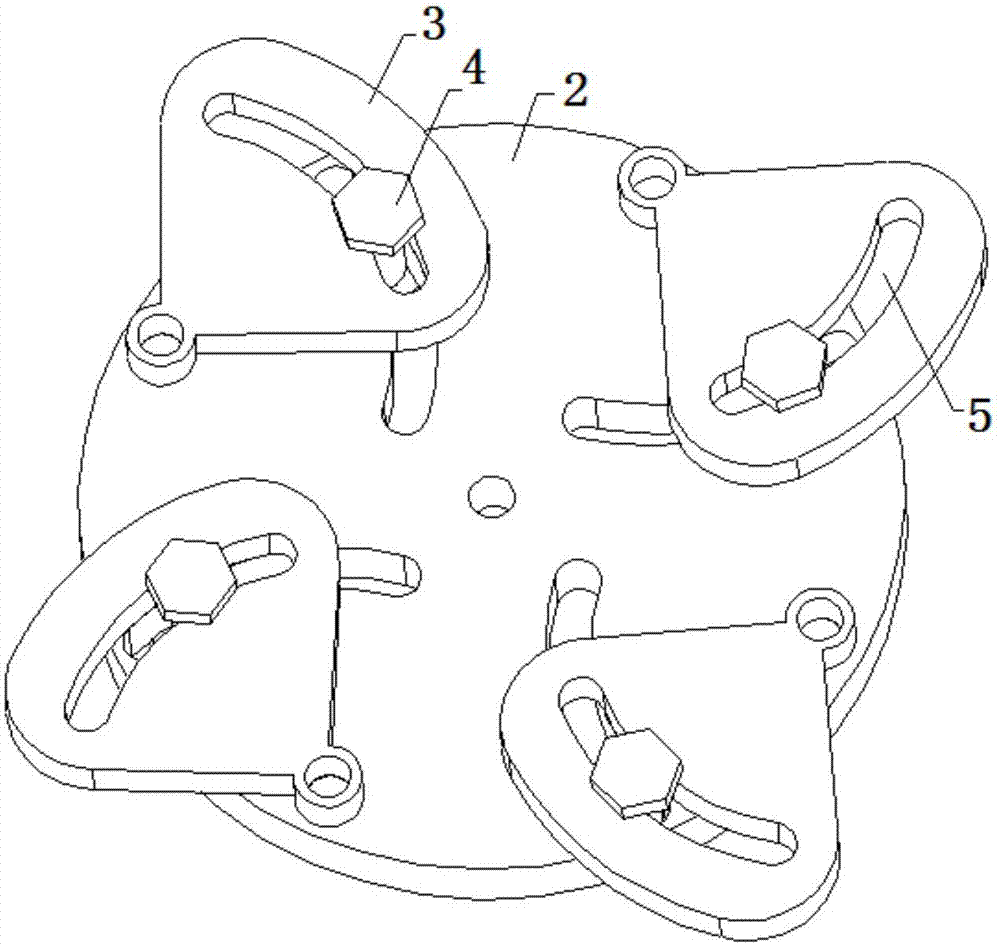

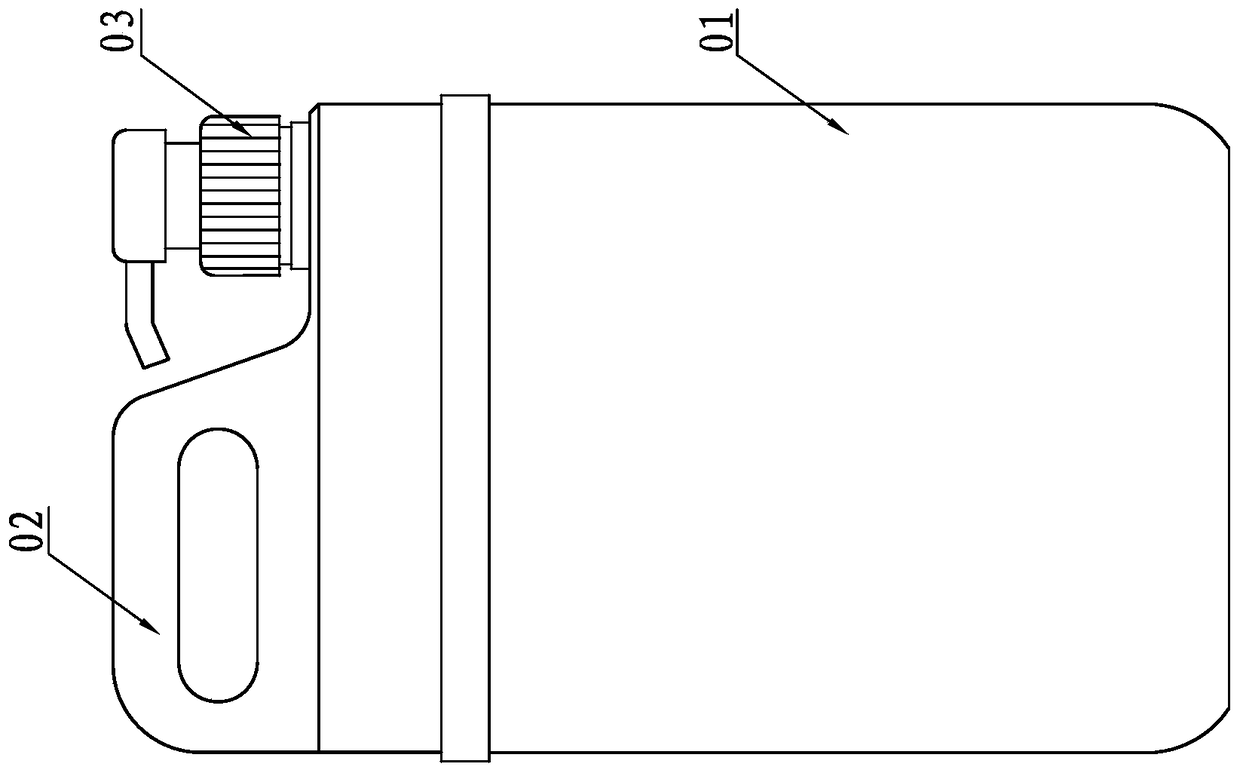

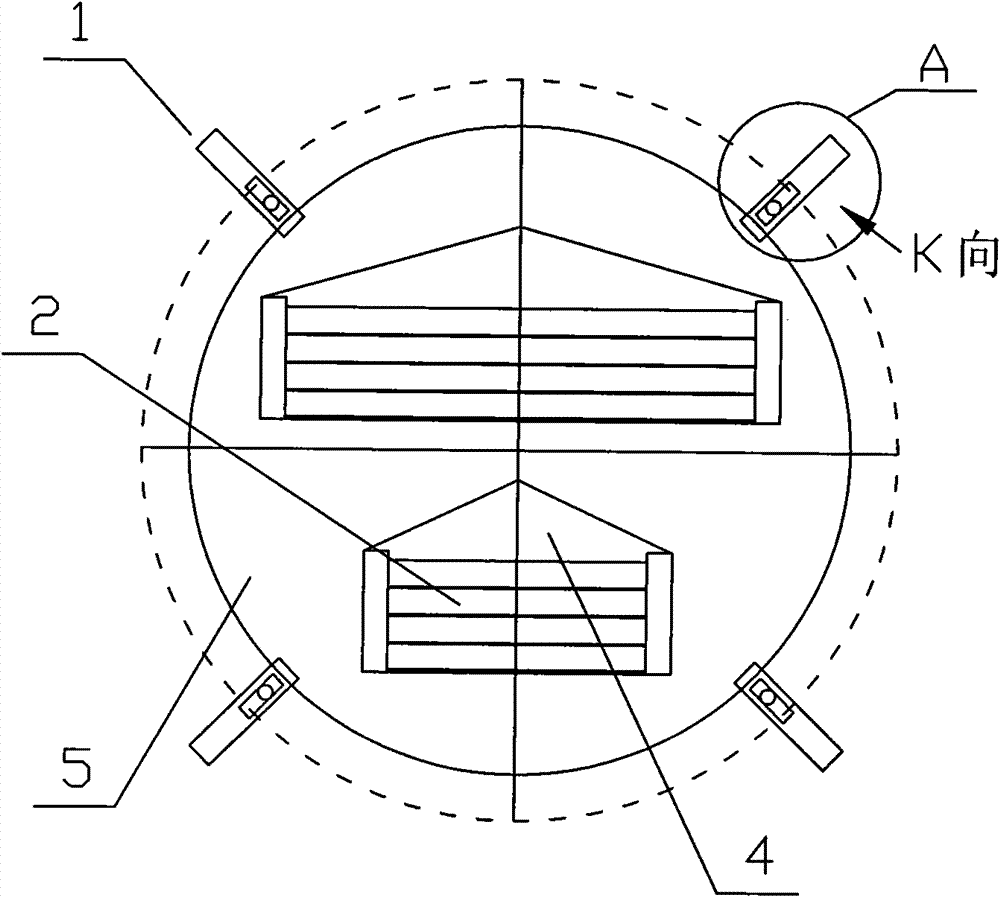

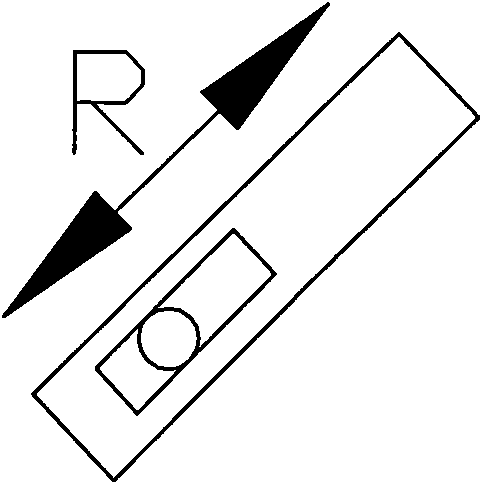

The invention discloses a dual CAN bus fire-fighting linkage intelligent control system which comprises a single main control box (1), N isolators (2), N power supply boxes (3) and N window openers (4). The power supply boxes (3) supply power to each isolator (2) and each window opener (4). The system is connected with the N window openers (4) in parallel through a power line ring net (13), a CAN signal line ring net I (11) and a CAN signal line II (12); and each isolator (2) uses the CAN signal line ring net I (11) to timely collect and inspect the status information of each window opener (4) and feedback to the main control box (1), and the status information is displayed in the main control box (1) in real time. The system effectively unify the model and the type of the window openers, and is convenient for installation and debugging; and the system can realize model unification, flexible networking, intelligent synchronization and stroke adjustment of one or more groups of window openers, thereby enhancing user experience satisfaction, and urban intelligence control strategies and levels.

Owner:徐州大亚自动装备有限公司

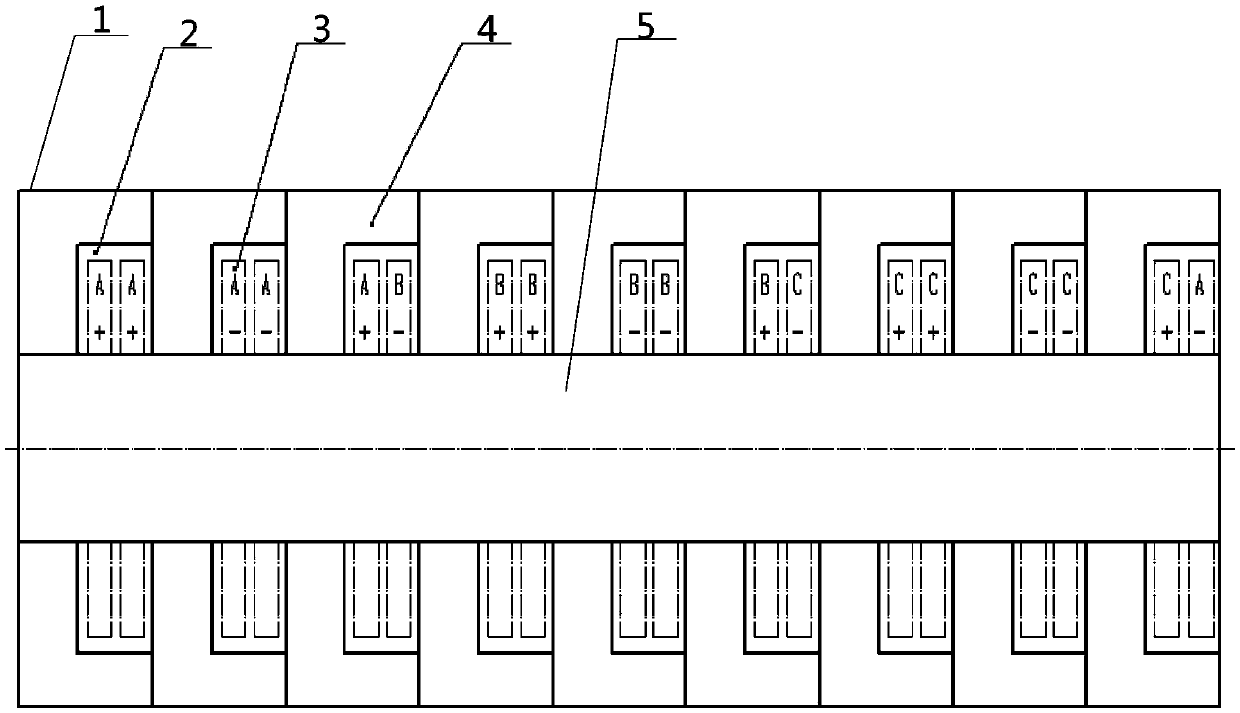

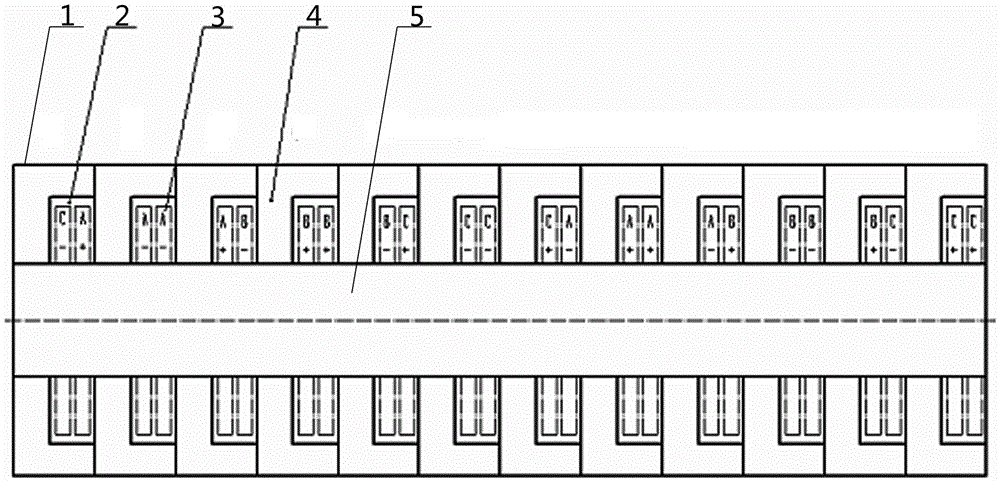

Three-phase permanent-magnet linear motor octupole nine-slot stator winding

InactiveCN105515334AReduce torque fluctuationImprove efficiencyPropulsion systemsWindings conductor shape/form/constructionFailure rateWave shape

The invention discloses a three-phase permanent-magnet linear motor octupole nine-slot stator winding which is characterized in that the three-phase permanent-magnet linear motor octupole nine-slot stator winding comprises a stator winding which is of an octupole nine-slot winding structure in a fractional-slot concentrated winding; the stator winding is composed of a plurality of stator winding units connected in series; each stator winding unit includes nine toothed slots; the winding units are embedded into the toothed slots according to certain rules and are connected in series according to the phase; double winding units are embedded into each toothed slot; and the length of each stator winding unit corresponds to four pairs of poles of a three-phase permanent-magnet linear motor rotor. The stator winding has a simple structure, and the manufacturing process is simple. The slot filling factor is improved; the output of the three-phase permanent-magnet linear motor is increased; the efficiency of the motor is improved; the back electromotive force waveform is good; the cogging torque and torque ripple are reduced; smooth operation of the three-phase permanent-magnet linear motor is ensured; the vibration of the motor is weakened; and the failure rate of the motor is reduced.

Owner:杨超

Adjustable punching mechanism

The invention discloses an adjustable punching mechanism which comprises a main board, a punching needle, a rotary wheel, a cam driven element and a triangular rod. The main board is provided with a drive end and a punching end; the punching needle is arranged at the punching end through a slider in an up-down sliding mode; the rotary wheel is arranged at the drive end in a rotary mode, and the rotary wheel is provided with a plurality of position-adjustable cams. Flanges of the cams can be adjusted in the peripheral direction extending out of the rotary wheel, and the cams can be fixed through fixing assemblies. The cam driven element is hinged to the main board, one end of the cam driven element is limited to the position where the cam driven element can be clamped to the flanges of the cams through an elastic device, and the other end of the cam driven element is provided with a sliding groove. The triangular rod is hinged to the main board. One end of the triangular rod is arranged in the sliding groove in a sliding mode, and the other end of the triangular rod is movably connected with the slider through an ejector rod. By means of the mechanism, circulating punching can be carried out, the sizes of materials to be punched are not limited, material punching can be continuously conducted, and punching efficiency is high.

Owner:GUANGXI UNIV

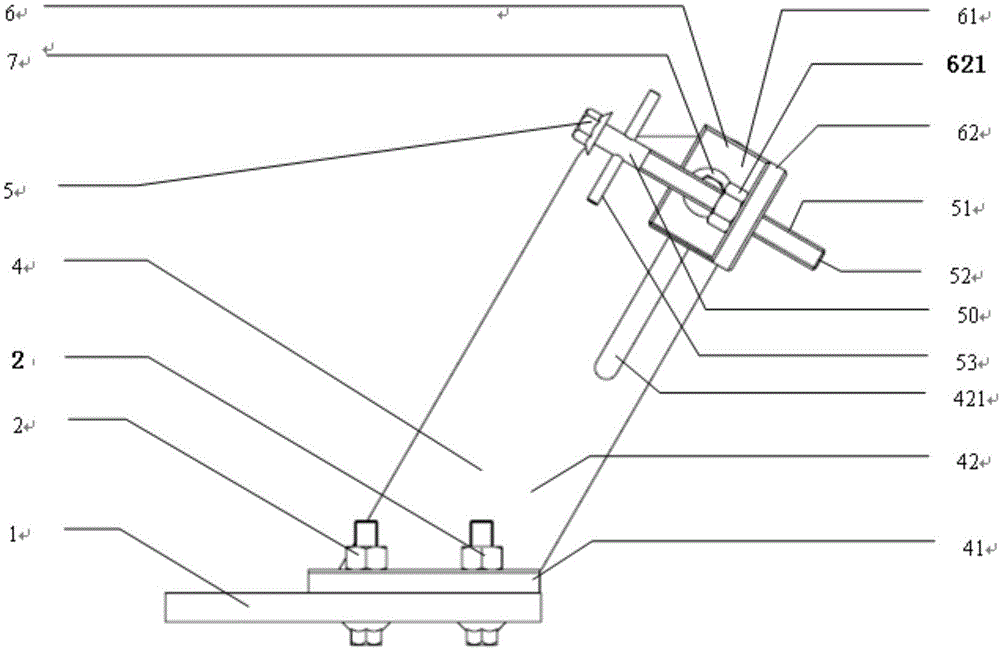

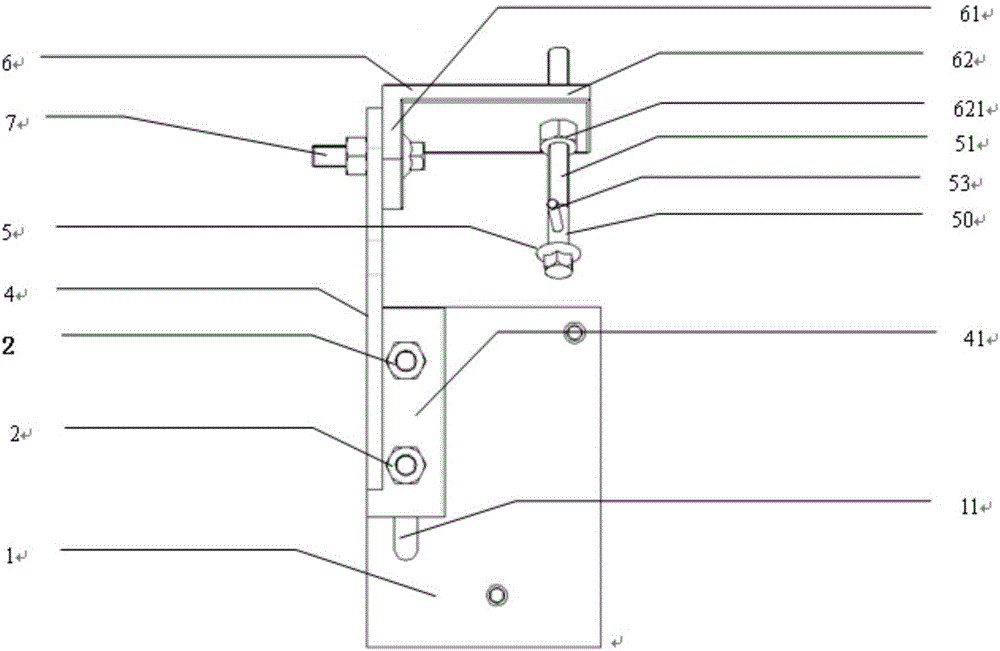

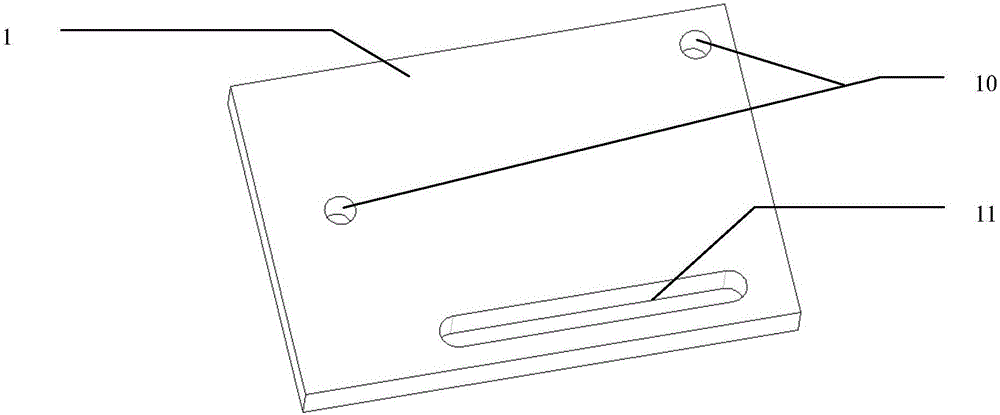

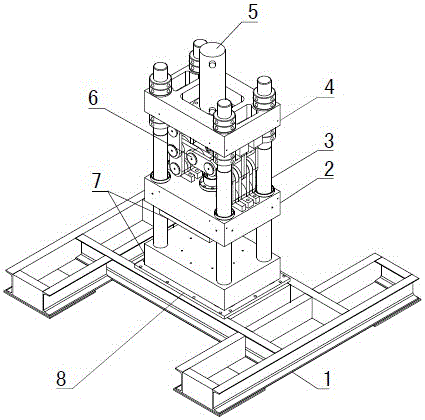

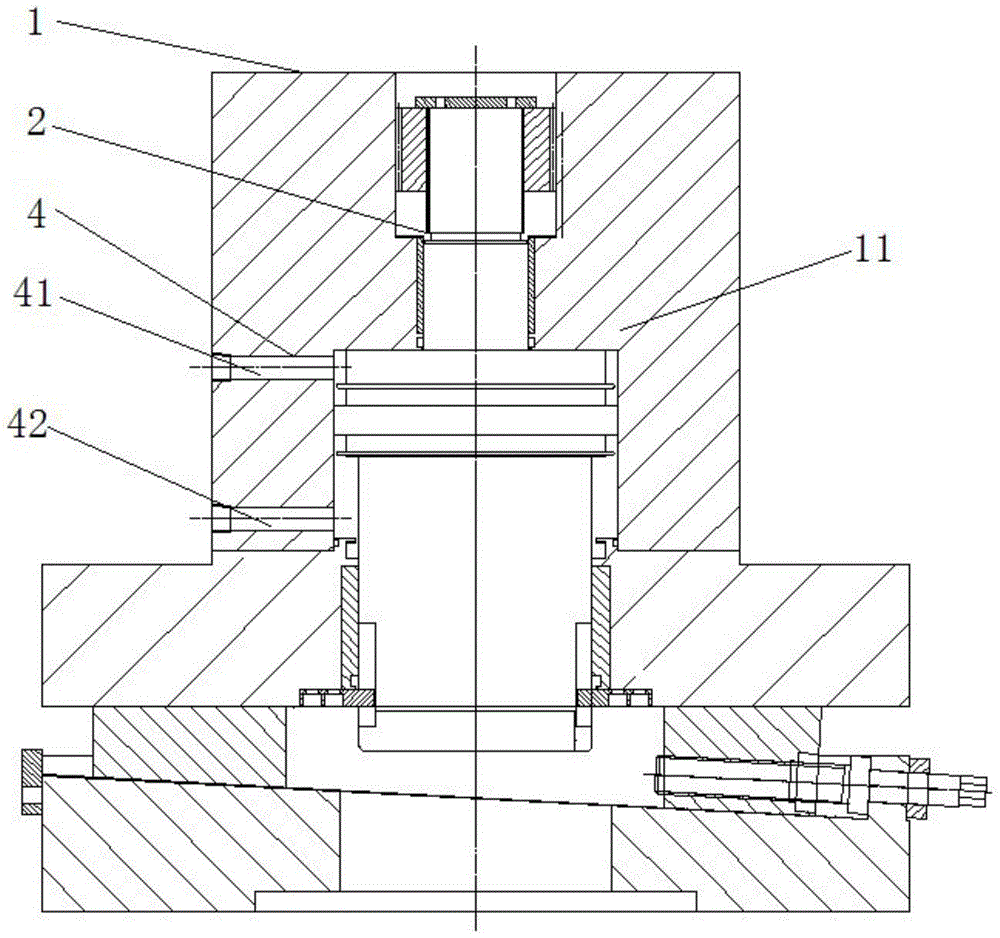

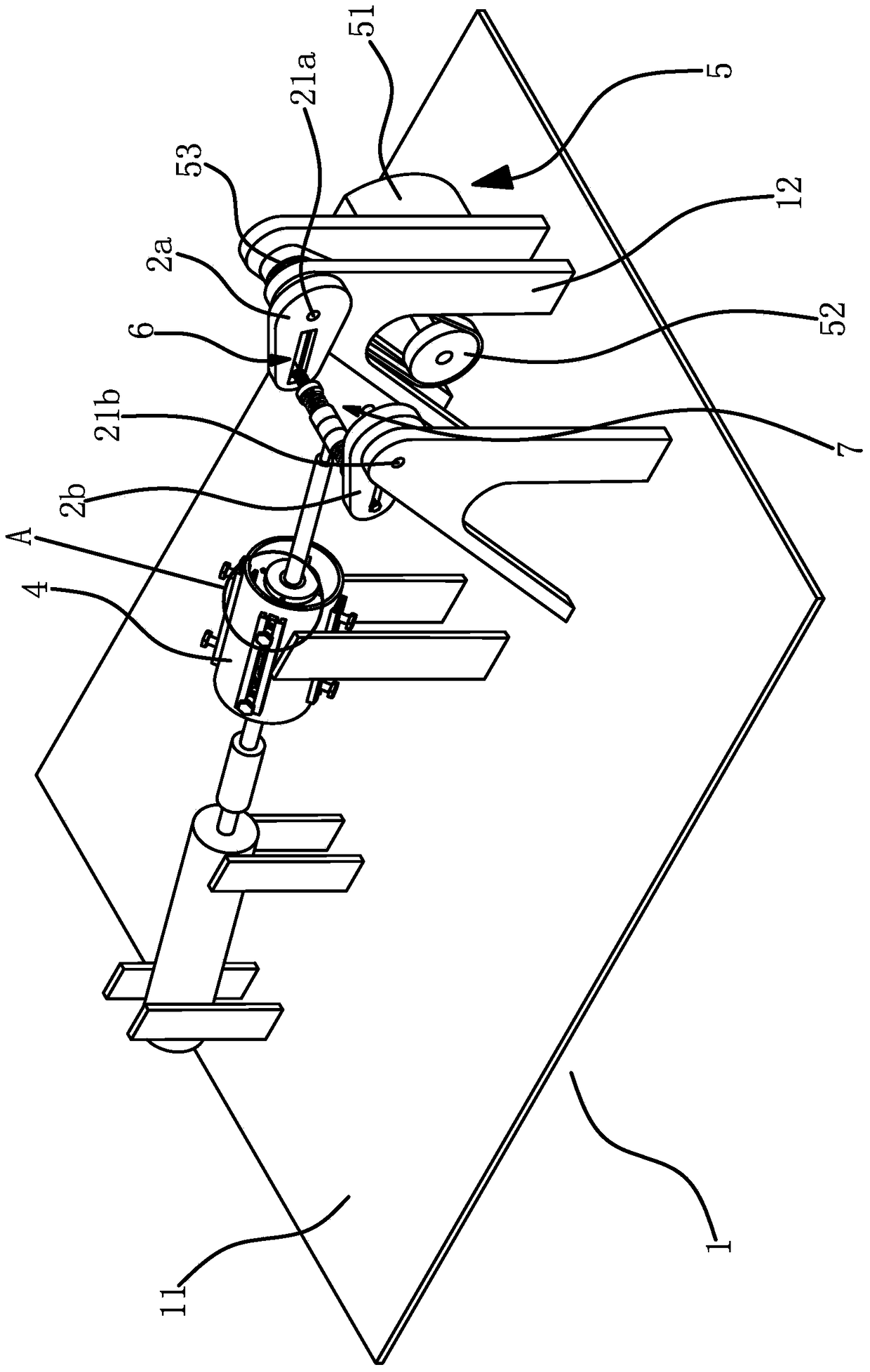

A device for adjusting electronic accelerator pedal for engine bench test

The invention discloses a device for adjusting an electronic accelerator pedal in an engine bench test, comprising a base (1), a support side plate (4), an adjustment rod (5) and an adjustment rod support plate (6): The assembly hole (10) of the electronic accelerator pedal; the supporting side plate includes a connecting portion (41) and a supporting portion (42) protruding upwards and obliquely to the right from one side of the connecting portion; the adjusting rod supporting plate includes an assembling portion (61) And the mounting part (62) protruding vertically outward from one side of the assembly part; the supporting side plate is fixedly connected with one side of the base through its connecting part in an adjustable position; the adjusting rod supporting plate is connected with the supporting side plate through its fitting part One side of the upper part of the support part can be fixedly connected in an adjustable position; the adjusting rod is rotatably connected to the mounting part of the adjusting rod support plate, and its right end surface (52) protrudes from the mounting part of the adjusting rod support plate. The invention can precisely adjust the stroke of the electronic throttle.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Ten-pole twelve-slot stator winding of three-phase permanent magnet linear motor

InactiveCN105406683AGreat effortAdjust strokePropulsion systemsWindings conductor shape/form/constructionManufacturing technologyWave shape

The invention discloses a ten-pole twelve-slot stator winding of a three-phase permanent magnet linear motor. The ten-pole twelve-slot stator winding comprises a stator winding, wherein the stator winding is of a twelve-tooth-socket winding structure in a fractional-slot concentrated winding, the stator winding is formed in a way that a plurality of stator winding units are connected in series, A, B and C three-phase windings installed in the twelve tooth sockets in each stator winding unit are arranged according to a certain rule, and double windings are embedded into each tooth socket; and the three-phase permanent magnet linear motor corresponding to the length of each stator winding unit is five pairs of poles. Therefore, the stator winding designed by the invention has the advantages of being simple in structure, simple in manufacture technology and favorable for improving slot space factor, increasing motor capacity, improving motor efficiency, bringing good back emf waveform and reducing tooth socket torque and torque fluctuation, so that the three-phase permanent magnet linear motor can stably operate, motor vibration is weakened, and the fault rate of the motor is lowered.

Owner:杨超

An adjustable punching mechanism

The invention discloses an adjustable punching mechanism, which comprises: a main board, on which a driving end and a punching end are arranged; a punching needle, which is arranged on the punching end in a manner capable of sliding up and down through a slider; A wheel, which is rotatably mounted on the driving end, is provided with a plurality of position-adjustable cams on the wheel, wherein the flanges of the cams can be adjusted in the direction extending out of the periphery of the wheel, and can be adjusted by the fixing assembly. The cam is fixed; the cam follower is hinged on the main board, and one end of the cam follower is limited by an elastic device to a position that can be engaged with the flange of the cam, and the other end is provided with a chute; and a triangular rod, whose Hinged on the main board, one end of the triangular rod is slidably set in the chute, and the other end is movably connected with the slider through a push rod; this mechanism can carry out circular drilling, and does not limit the size of the material to be punched. The material can be punched continuously, so that the punching efficiency is higher.

Owner:GUANGXI UNIV

Clutch capping device of linear pump capping machine

A clutch cap screwing device of a linear pump cap screwing machine comprises a rack front side plate, torque cap screwing components, rotating driving components, a centering linear driving adjusting mechanism, sliding seats, sliding guide rails and a rack rear side plate. The two sliding guide rails are horizontally and fixedly mounted on the rack front side plate and the rack rear side plate in parallel, the two sliding seats are mounted on the two sliding guide rails in a sleeved mode, the torque cap screwing components are mounted on the lower end faces of the sliding seats, the rotating driving components are mounted on the upper end faces of the sliding seats, the rotating driving components drive the torque cap screwing components, the centering linear driving adjusting mechanism is arranged between the rack front side plate and the rack rear side plate, and a driving motor of the centering linear driving adjusting mechanism is connected with the sliding seats. The clutch cap screwing device of the linear pump cap screwing machine solves the problem of manual cap screwing, a flow process of continuous linear cap screwing can be achieved, a great amount of man power is saved, cap screwing efficiency is high and is 100 times that of manual cap screwing, and the aesthetic standards of people for diversified bottle bodies are met.

Owner:常州市金坛晨光轻工机械有限公司

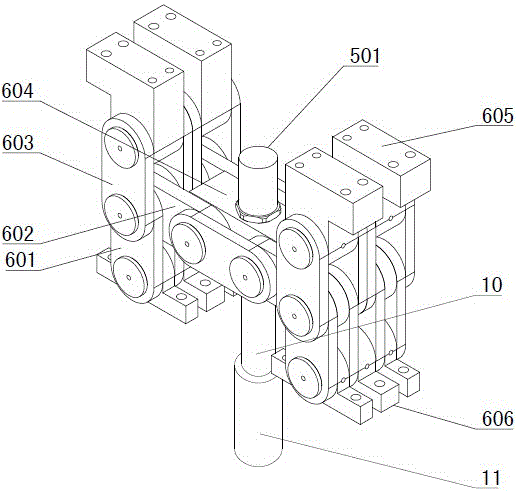

booster press

The invention provides a variable-speed pressurizing mechanism and a variable-speed tail end pressurizing press, and belongs to the field of pressure devices. The variable-speed pressurizing mechanism is characterized by comprising a connection block (604), two hinge mechanisms and a guide device, wherein the two hinge mechanisms are symmetrically hinged to the two sides of the connection block (604), and the guide device is used for guiding the connection block (604); each hinge mechanism comprises an output rod (601), an input rod (602) and an oscillating rod (603) which are hinged together in a star shape; the hinge mechanisms are hinged to the connection block (604) through the input rods (602); the output rods (601), the input rods (602) and the oscillating rods (603) oscillate in the same plane or in parallel planes; the free ends of the output rods (601) are power output ends. The variable-speed pressurizing mechanism is stable in work, can achieve variable-speed pressurizing, and guides output pressure; the variable-speed tail end pressurizing press is small in occupied area in work, generates low noise in work, and is high in energy utilization rate.

Owner:山东多星电器有限公司

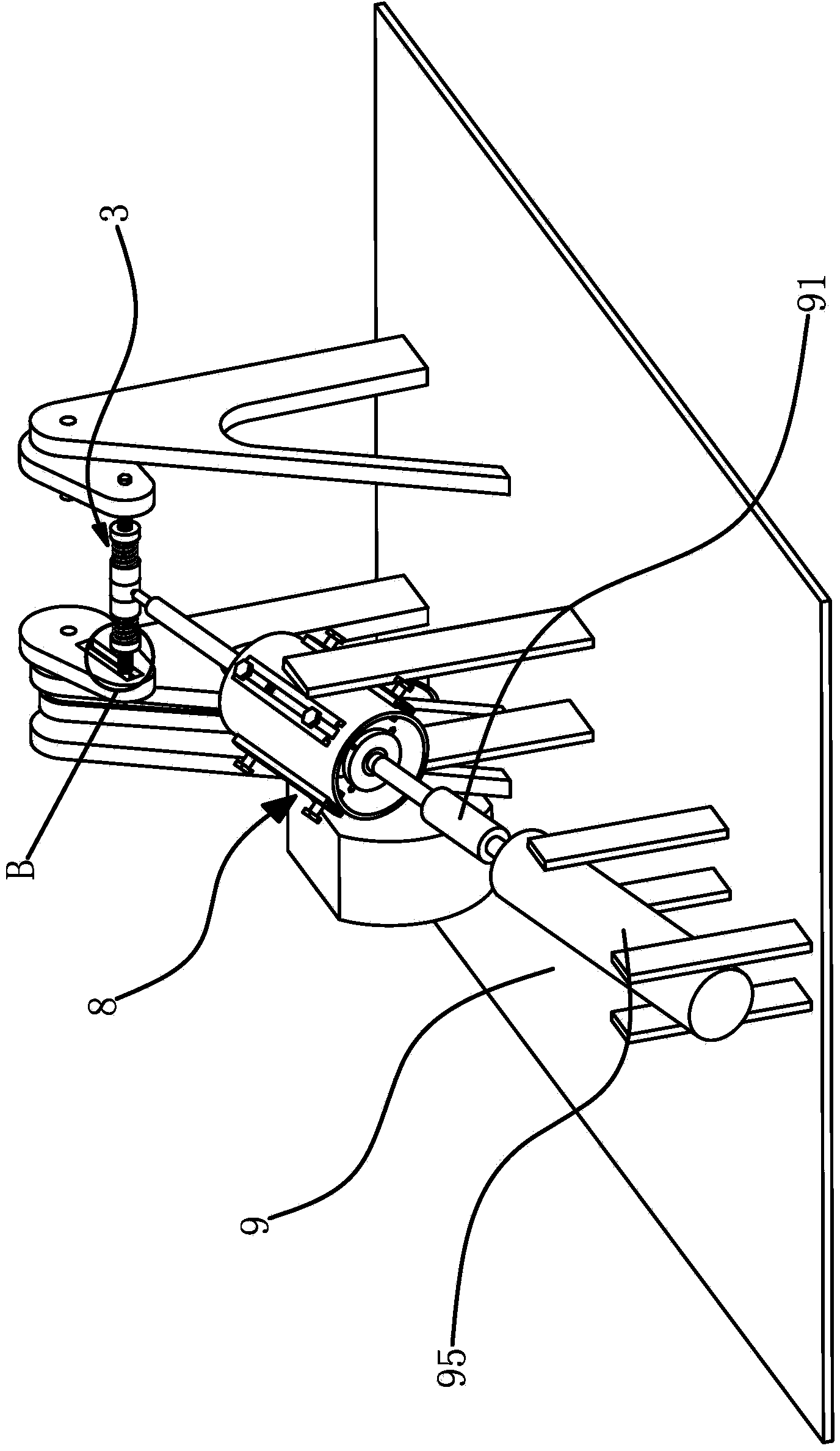

An adjustable mold base and powder forming and shaping machine with the mold base

Owner:宁波汇众粉末机械制造有限公司

Hot powder splashing prevention device for dredging kiln

ActiveCN101907407BPrevent sprayingAdjust strokeIncrustation removal devicesEngineeringMechanical engineering

The invention provides a hot powder splashing prevention device for dredging a kiln. The device comprises a bottom plate and clamping feet positioned on the edge of the bottom plate, wherein the bottom plate is provided with a kiln dredging hole; the outer side of the kiln dredging hole is provided with a detachable baffle plate; and the inner side of the bottom plate is provided with a curtain baffle which covers the kiln dredging hole. The device can effectively prevent hot powder from splashing and have certain effect of blocking powdery powder and heat waves at the same time, and can effectively adjust the stroke of dredging an air pipe and ensure the personal safety of operating personnel.

Owner:MCC BAOSTEEL TECH SERVICE

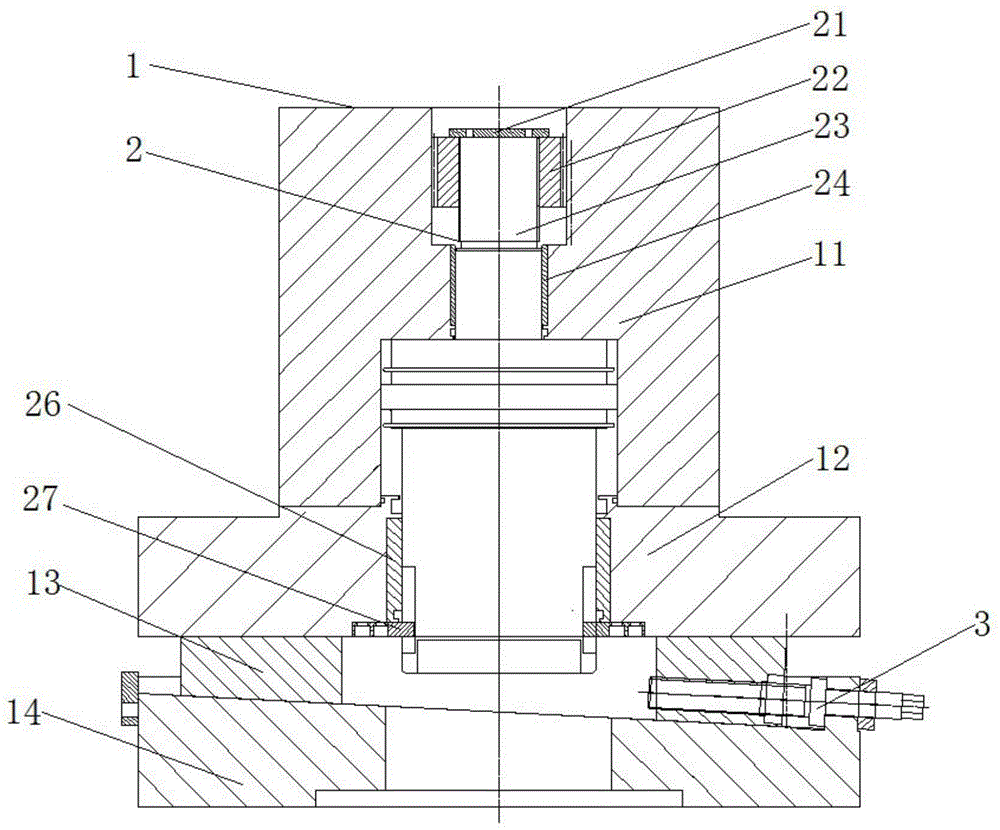

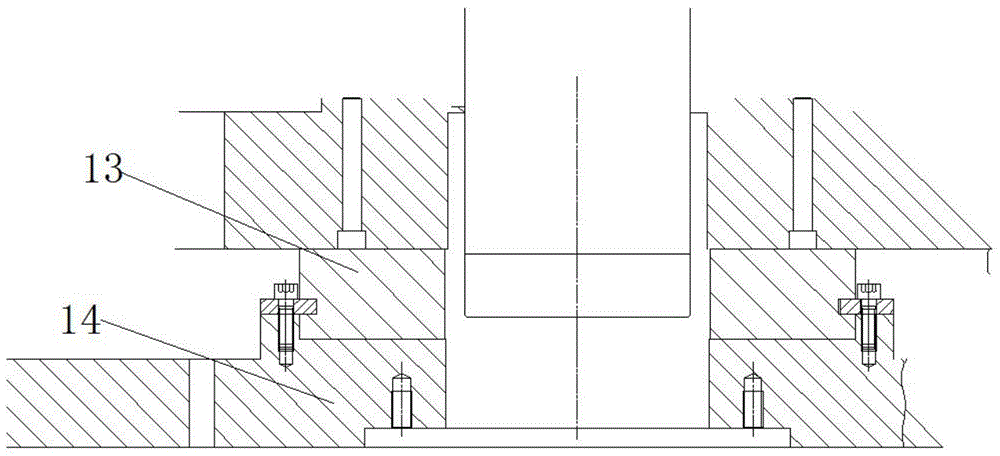

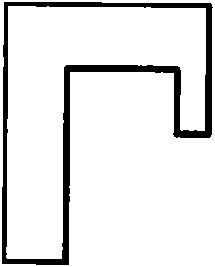

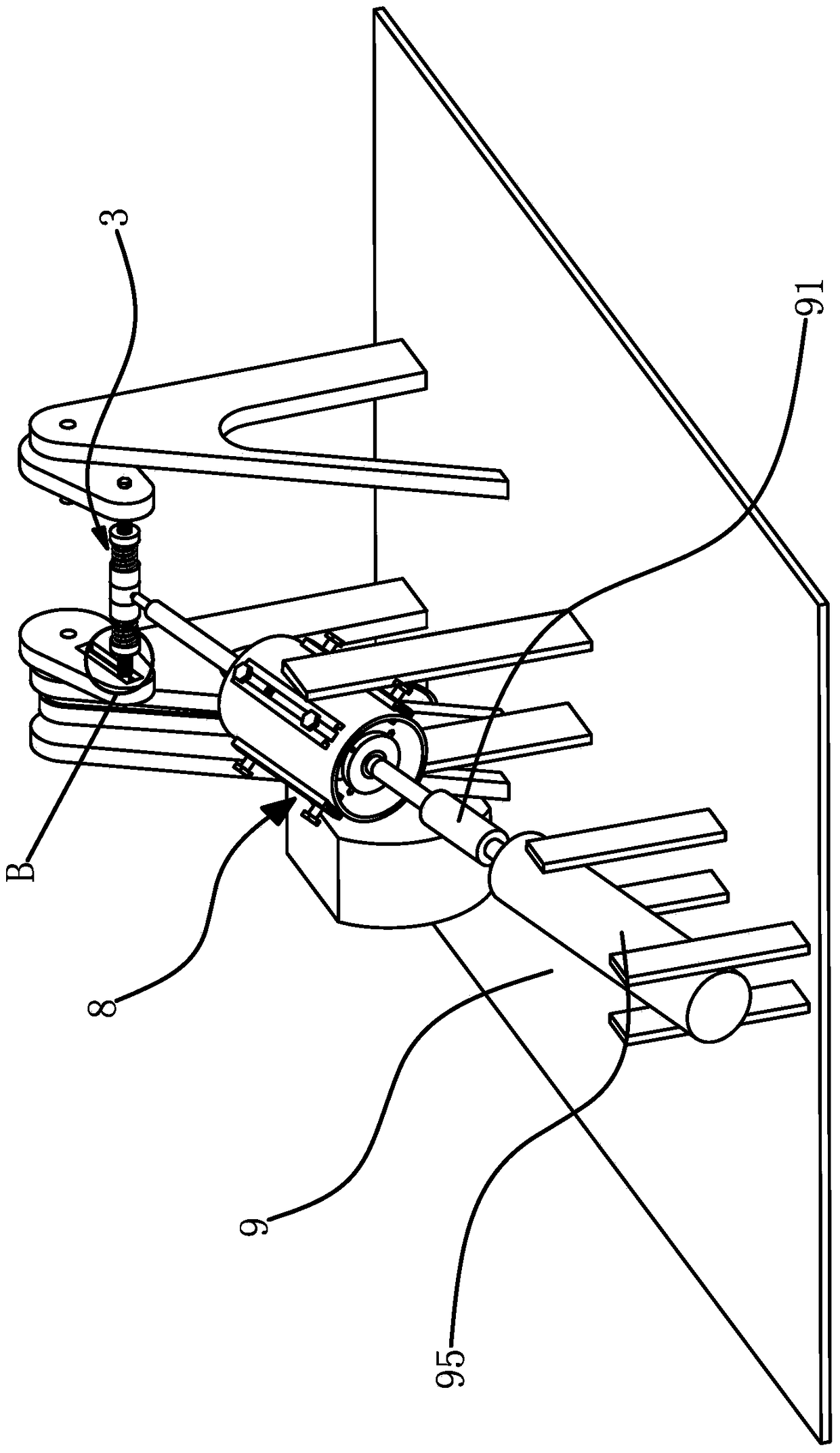

Adjustable mould holder and powder forming and shaping machine with mould holder

The invention provides an adjustable mould holder and a powder forming and shaping machine with the mould holder. The mould holder comprises a mould holder support, a stroke unit and a first adjustment unit; the stroke unit is connected with the mould holder support and is used in forming of a workpiece; and the first adjustment unit is connected with the mould holder support and is used to adjust stroke of the mould holder. The first adjustment unit in the adjustable mould holder is used to solve the problem of a micro height difference which exists between a workpiece while one-step forming and a finished product and which is resulted from machining precision of the mould holder or an error generated due to existing of a metal powder resilience force in a machining process after workpiece one-step forming, and the first adjustment unit finely adjusts the stroke of the mould holder in this way to enable a machining precision requirement to be achieved at the next time of workpiece forming. The structure of the first adjustment unit is simple, operation is convenient, and stability while workpiece stamping is high; and time for adjusting the stroke of the mould holder is short, rigidity is good, and reliability is good.

Owner:宁波汇众粉末机械制造有限公司

A fatigue test device for vvt engine piston

ActiveCN103868684BGuaranteed Fatigue TestGuaranteed accuracyMachine part testingVariable valve timingEngineering

The invention provides a fatigue test device for a VVT (Variable Valve Timing) engine piston and belongs to the technical field of engine test equipment. The problem that the test data of the present fatigue test device is not accurate enough is solved. The fatigue test device for the VVT engine piston comprises a frame, wherein a first cam is in rotating connection with the frame through a rotating shaft; a connecting shaft is vertically connected with a side face of the first cam; a distance-adjusting structure is arranged between the connecting shaft and the cam; a sleeve is fixedly connected with the frame; the rotating shaft is connected with a driving structure; a detecting structure for detecting the coaxiality of a cylinder sleeve and the piston is also arranged on the frame; an adjusting structure for adjusting the coaxiality of the cylinder sleeve and the piston is arranged on the sleeve and the connecting shaft. The fatigue test device for the VVT engine piston can be used for performing a fatigue test under the condition that the coaxiality of the cylinder sleeve and the piston is ensured. The accuracy of the test data is increased.

Owner:ZHEJIANG FUJIEDE AUTOMOTIVE SYST CO LTD

Hot powder splashing prevention device for dredging kiln

The invention provides a hot powder splashing prevention device for dredging a kiln. The device comprises a bottom plate and clamping feet positioned on the edge of the bottom plate, wherein the bottom plate is provided with a kiln dredging hole; the outer side of the kiln dredging hole is provided with a detachable baffle plate; and the inner side of the bottom plate is provided with a curtain baffle which covers the kiln dredging hole. The device can effectively prevent hot powder from splashing and have certain effect of blocking powdery powder and heat waves at the same time, and can effectively adjust the stroke of dredging an air pipe and ensure the personal safety of operating personnel.

Owner:MCC BAOSTEEL TECH SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com