Press stroke and die setting height adjusting mechanism

A technology of mold height and adjustment mechanism, applied in the field of presses, can solve the problems of unstable structure, easy failure, time-consuming and labor-intensive, etc., and achieve the effect of compact body layout and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

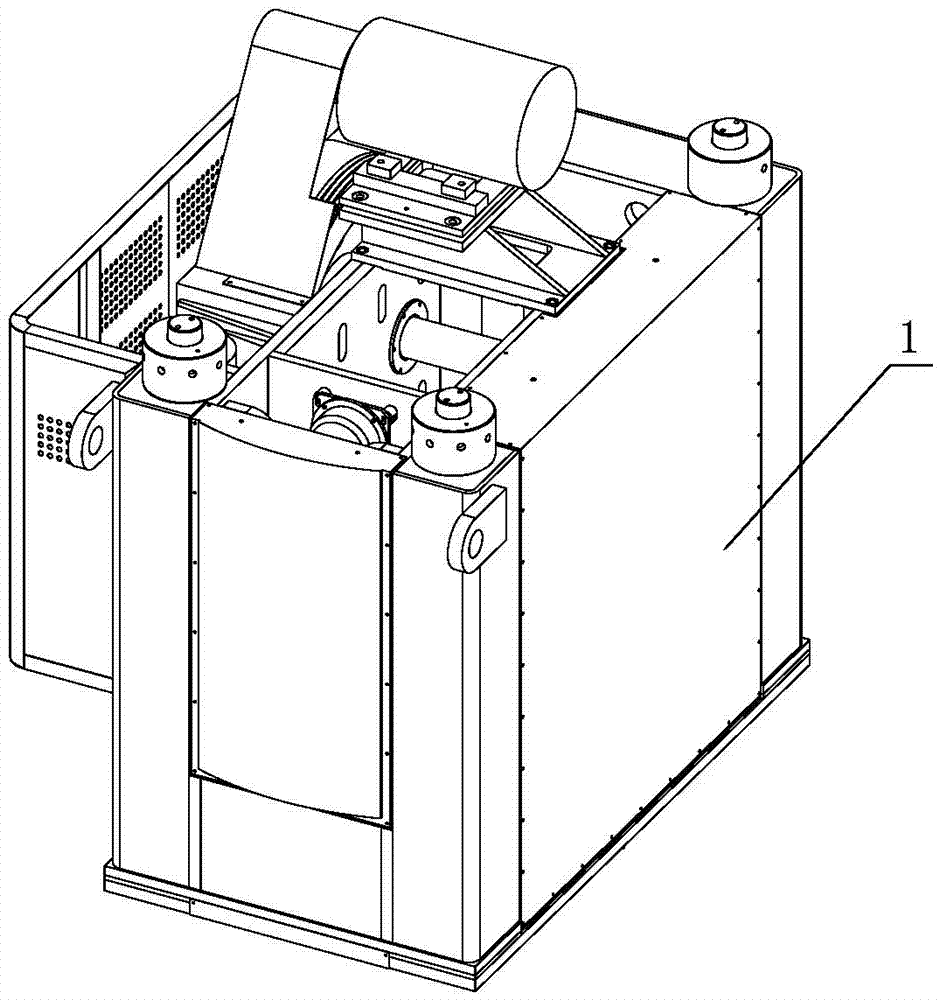

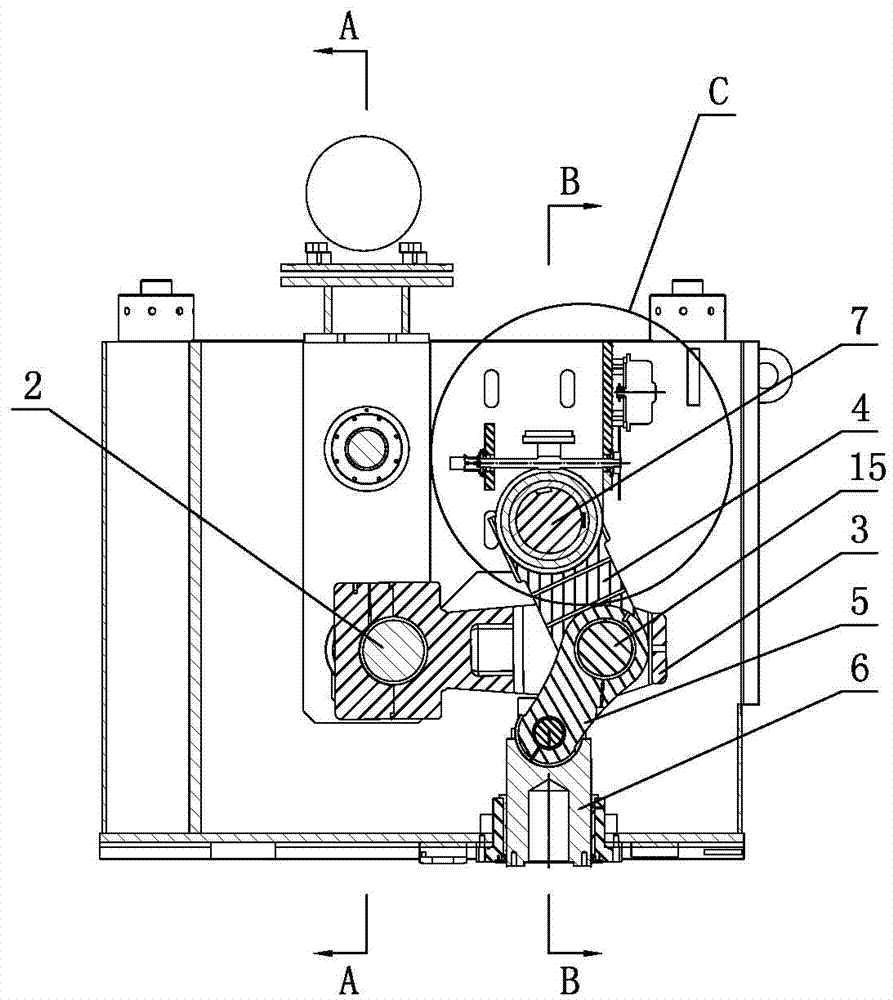

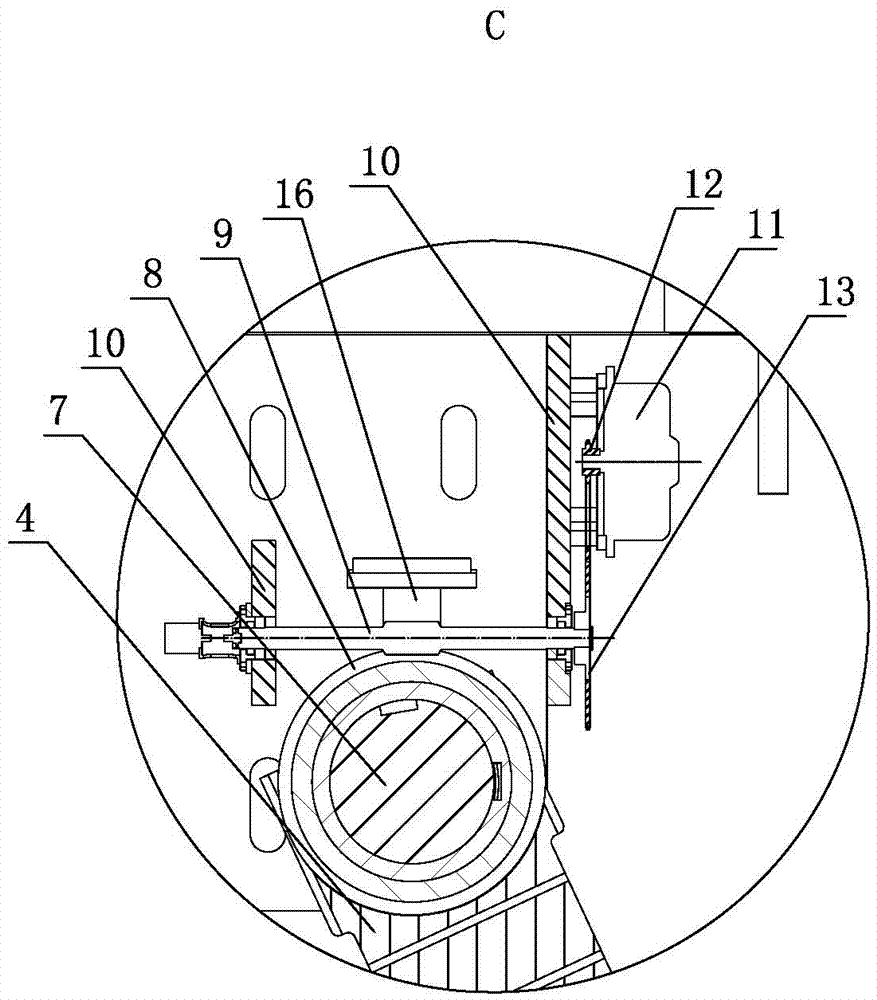

[0024] Such as Figure 1-10, is a press stroke and die height adjustment mechanism, including a fuselage beam 1, a rotatable crankshaft 2 is arranged horizontally on the fuselage beam 1, a connecting rod 3 is arranged on the connecting rod journal of the crankshaft 2, and a connecting rod The ends of 3 are respectively hinged with an upper toggle 4 and a lower toggle 5, and the lower end of the lower toggle 5 is hinged with a vertically movable guide post 6, and the lower end of the guide post 6 is provided with a slider. The toggle lever 4 is provided with a rotatable eccentric shaft 7, the eccentric shaft 7 is parallel to the rotation axis of the crankshaft 2, the upper end of the upper toggle lever 4 is fixedly connected with the eccentric section 701 of the eccentric shaft 7, and the main section of the eccentric shaft 7 is provided with a worm gear 8. A rotatable worm 9 is arranged on the beam 1 of the fuselage. The axis of the worm 9 is perpendicular to the rotation axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com