Gas valve

A technology for air valves and valve seats, which is applied in the field of dry-running air valves, and can solve problems such as temperature rise of valve components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

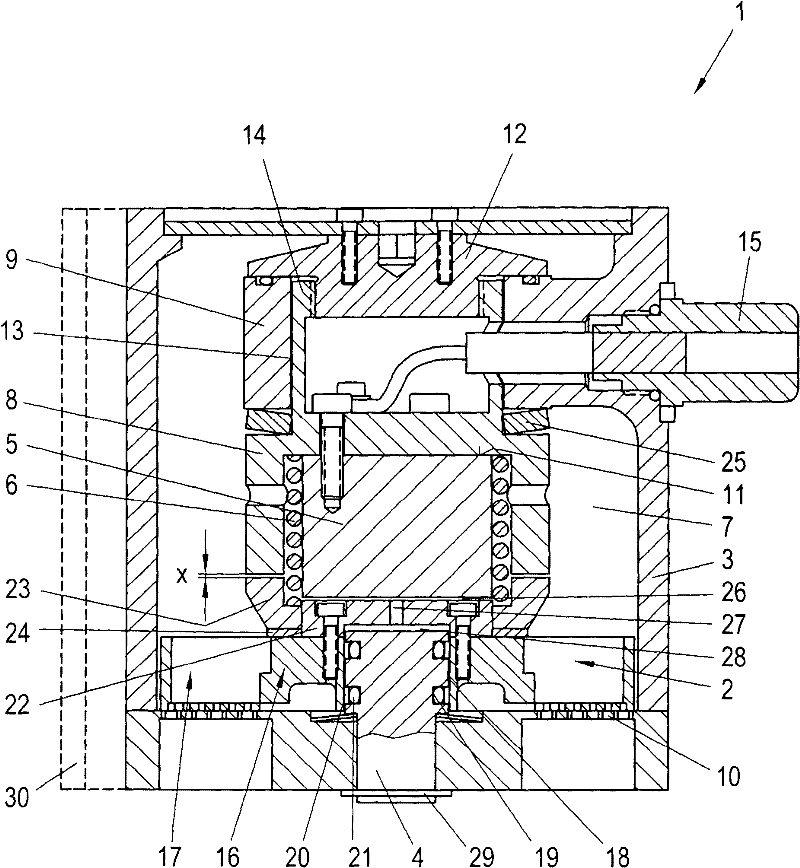

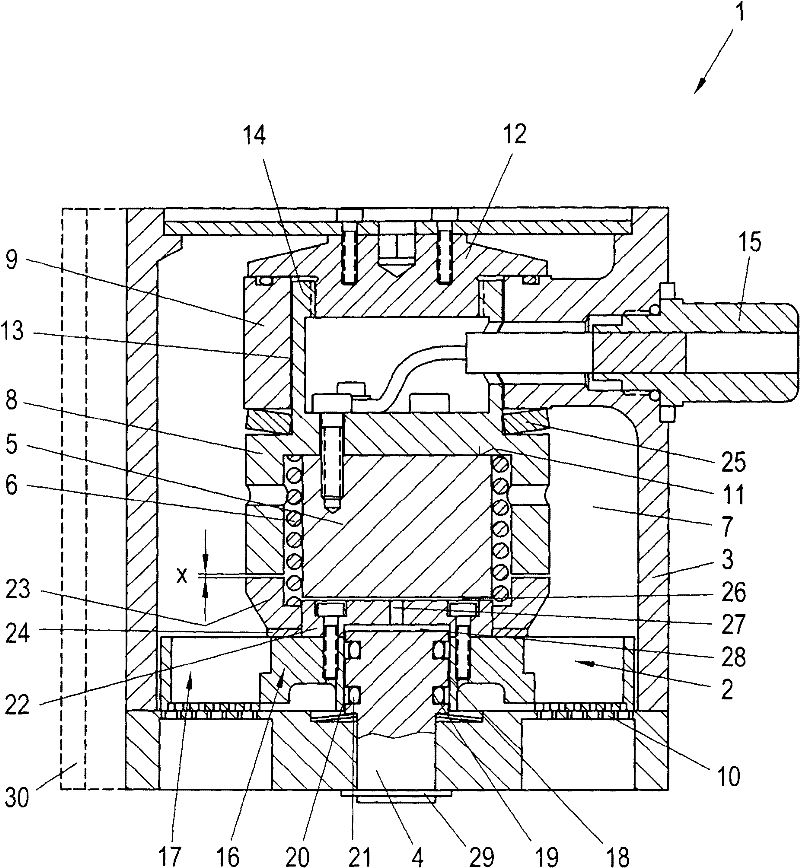

[0018] as in figure 1 As shown in , the gas valve 1 according to the invention comprises a housing 3 in which an intermediate part 9 is arranged. At one axial end of the gas valve 1 there is a valve seat 10 which thus simultaneously forms the gas outlet of the gas valve 1 . The valve seat can be part of the housing 3 . Here, a gas inlet is provided at the opposite axial end of the gas valve 1 . The gas valve 1 shown here is therefore axially flowed through. However, it is of course equally possible that the gas can also be supplied radially at suitable points in the housing 3 .

[0019] An adjusting element 8 is arranged in the intermediate part 9 . The adjusting part 8 is here guided and supported in a recess 13 of the intermediate part 9 and is held by the thread 14 of the adjusting nut 12 at the axial end facing away from the valve seat 10 . The adjusting nut 12 bears axially against the axial end of the intermediate part 9 here. The adjusting element 8 can thus be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com