Adjustable mould holder and powder forming and shaping machine with mould holder

A shaping machine and adjustable technology, which is applied in the field of formwork, can solve problems such as the error of metal powder rebound force, and achieve the effect of reducing processing cost, low processing cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

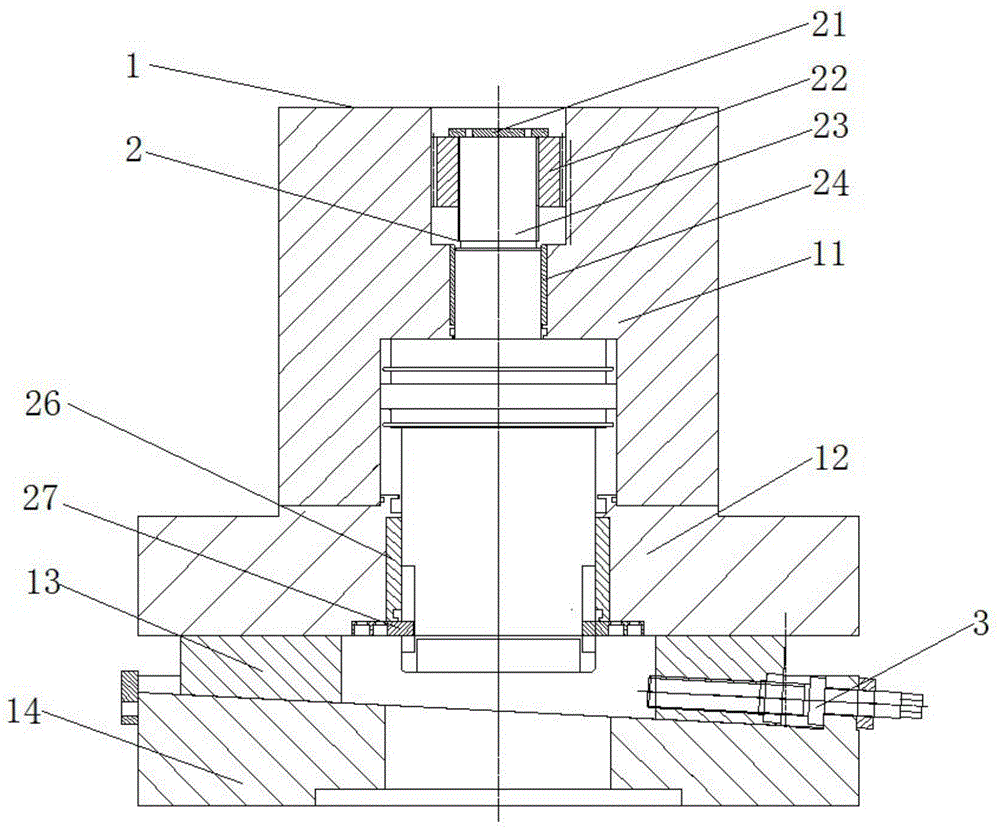

Image

Examples

Embodiment 1

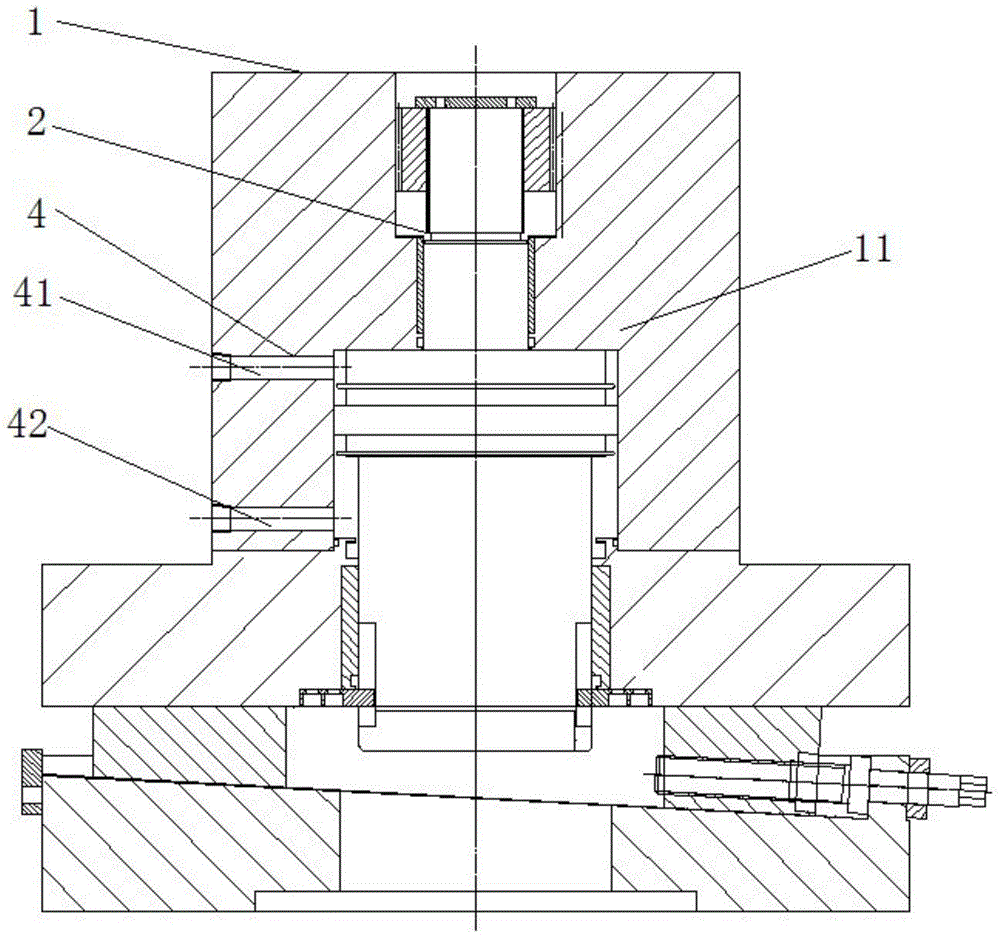

[0037] As the formwork described above, the present embodiment differs from it in that, see image 3 As shown, it is a structural schematic diagram of Embodiment 1 of the adjustable formwork in the present invention; the formwork also includes an oil delivery unit 4, and the oil delivery unit 4 includes a first oil pipe 41 and a second oil pipe 42 , the first oil pipe 41 and the second oil pipe 42 penetrate one side of the top stop plate 11, one end communicates with a hydraulic oil pump (not shown in the figure), and the other end communicates with the stroke unit 2 and the die The gap between the frame bracket 1 unit is used to adjust the stroke of the stroke unit 2, and also can reduce the friction between the stroke unit 2 and the mold frame bracket 1, prolong the service life of the mold frame, and It can buffer the impact force generated by the formwork during use, and also protect the formwork.

Embodiment 2

[0039] As the formwork described above, the present embodiment differs from it in that, see Figure 4 As shown, it is a schematic structural diagram of the second embodiment of the adjustable formwork in the present invention; the formwork also includes a second adjustment unit 5, a guide post 6 and a guide sleeve 7, wherein the second adjustment The unit 5 runs through the middle top plate 12 and the two upper punches 14, and is respectively fixed with the middle top plate 12 and the two upper punches 14, and the guide sleeve 7 is connected with the two upper punches 14. The guide post 6 passes through the middle top plate 12 , the two upper punches 14 and the guide sleeve 7 , and is fixed with the middle top plate 12 .

[0040] The second adjustment unit 5 includes a cover 51, a worm gear 52, a worm 53, a second piston rod 54, a first sleeve 55, a second sleeve 56, a first base 57, a second The base 58 and the base cover 59, wherein the cover 51, the first sleeve 55 and the...

Embodiment 3

[0043] As the formwork described above, the present embodiment differs from it in that, see Figure 5 As shown, it is a simple structural block diagram of powder forming and shaping machine in the present invention; and in combination Figure 6 As shown, it is a structural block diagram of the frame body described in the present invention; and Figure 7 As shown, it is a specific structural block diagram of the powder forming and shaping machine in the present invention; the powder forming and shaping machine also includes a frame body 8, and the frame body 8 is used to carry the mold base to complete the described Basic operation of powder molding and shaping machines. The frame body 8 includes a support 81, a female mold 82 and a forming mold frame 83, wherein one end of the female mold 82 is connected with the mold frame, and the other end is connected with the forming mold frame 83. connected for filling metal powder; the forming mold frame 83 is connected with the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com