Patents

Literature

69results about How to "Stamping stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

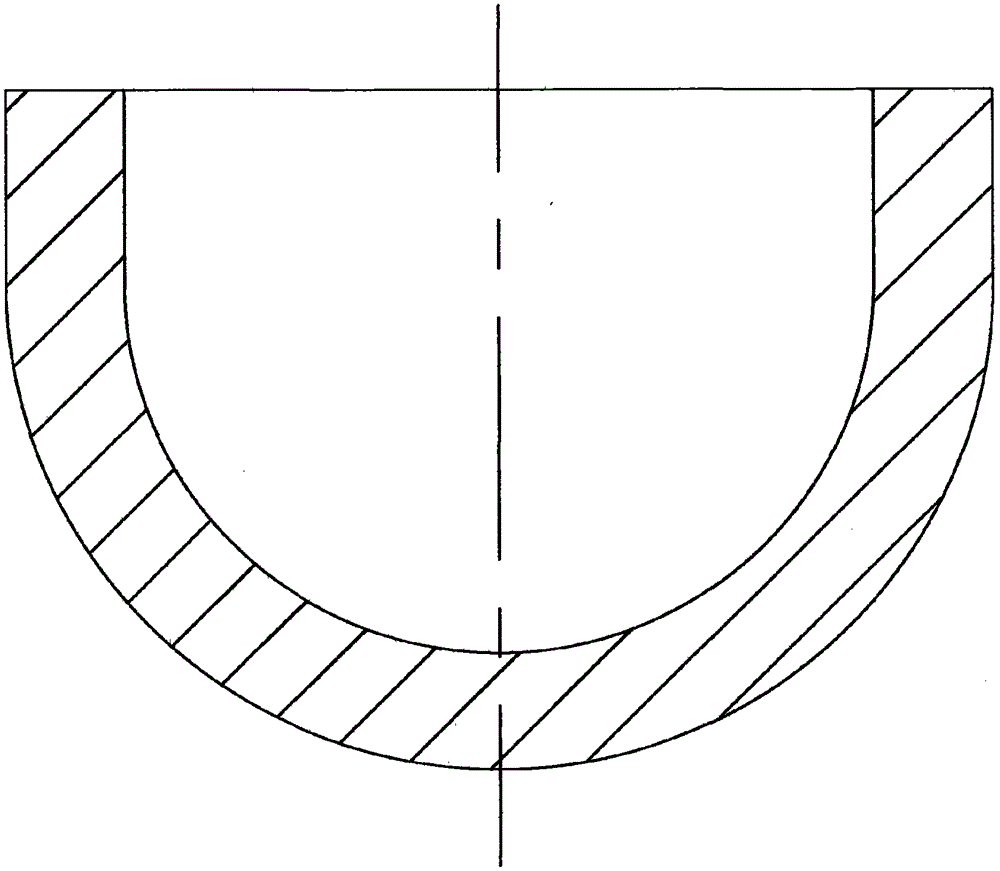

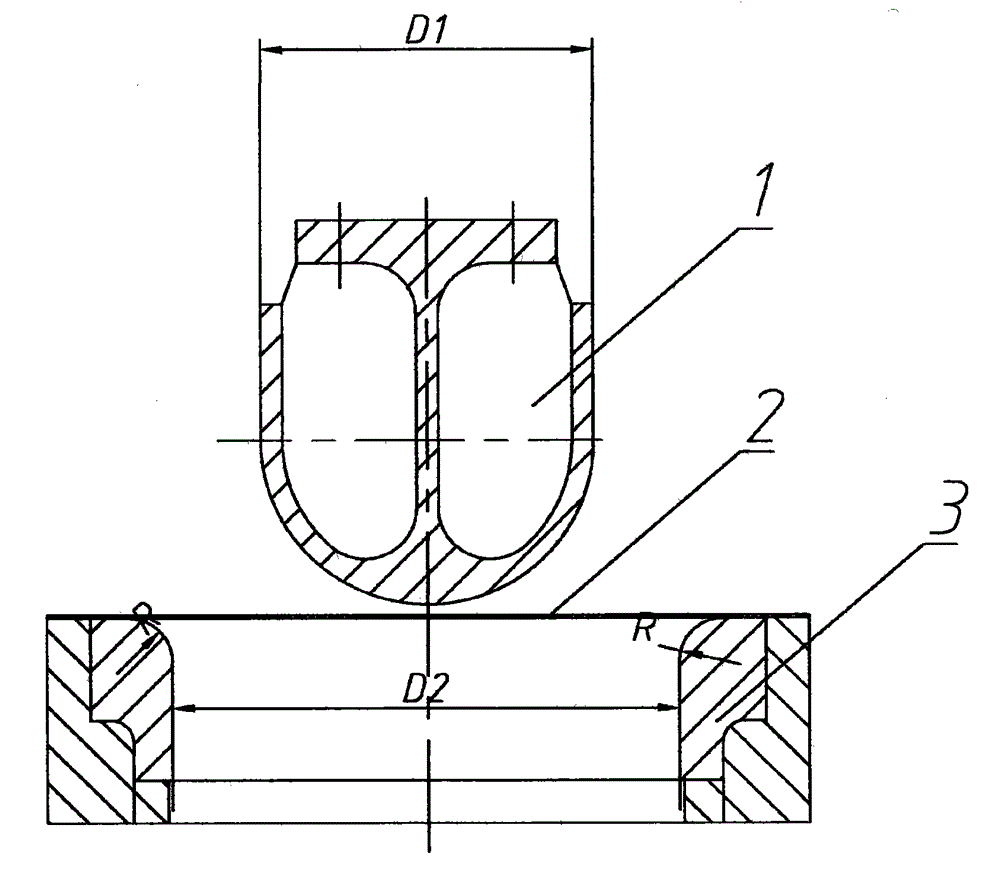

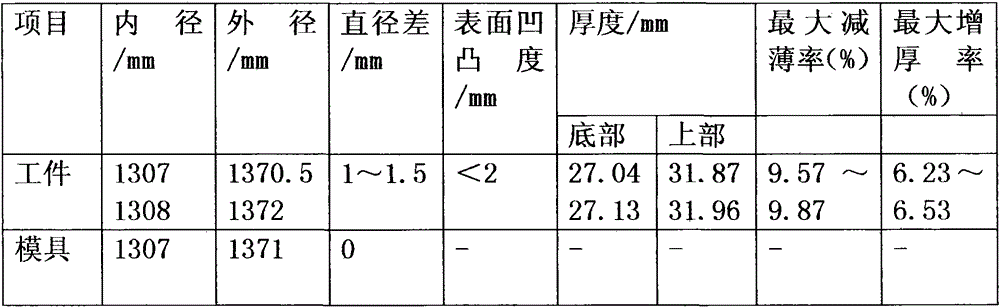

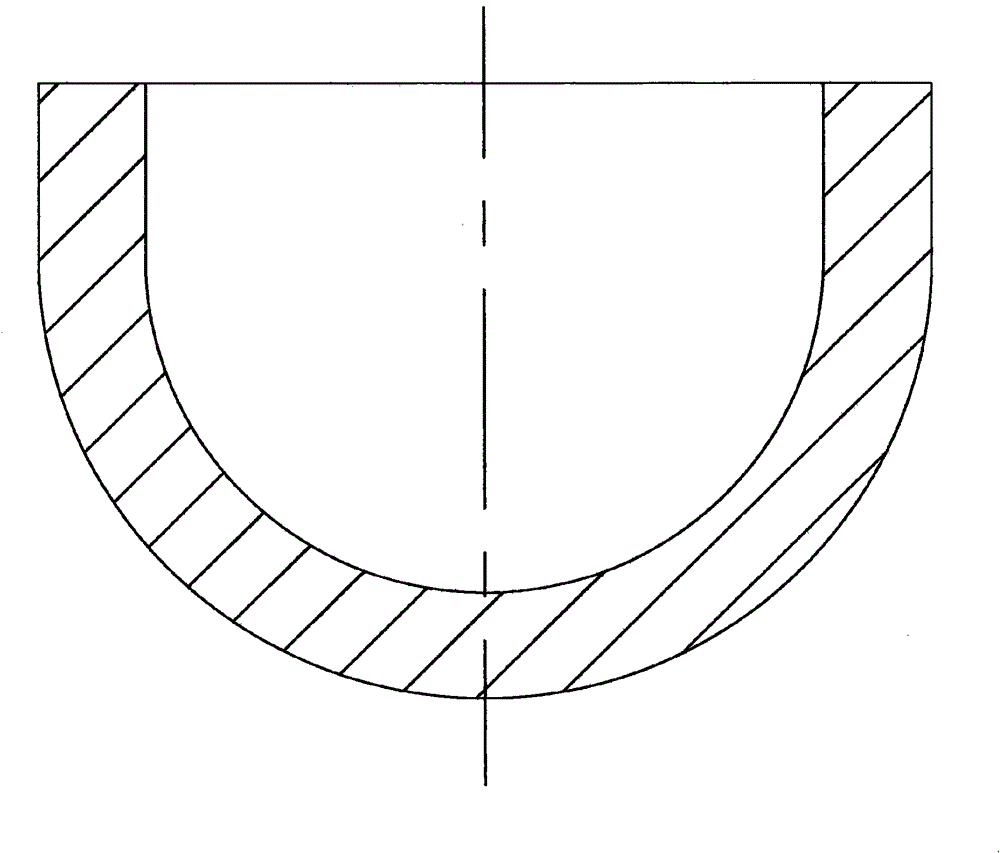

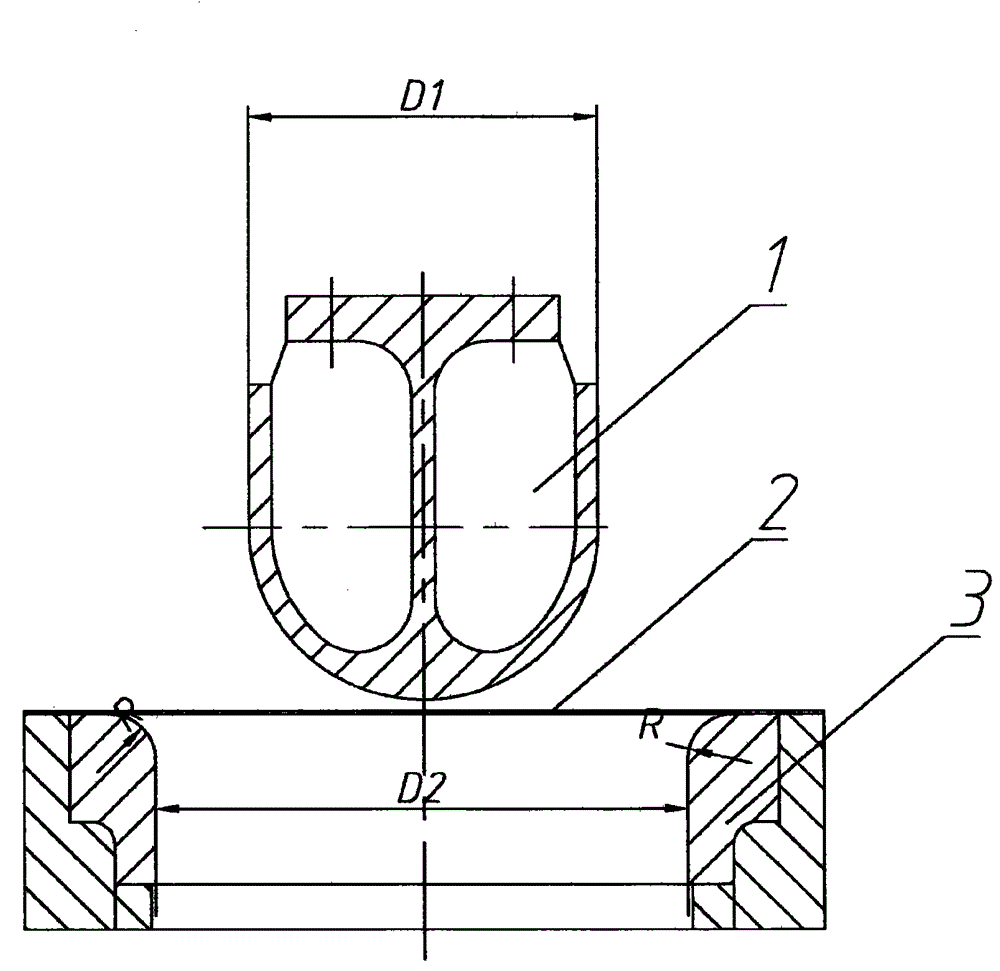

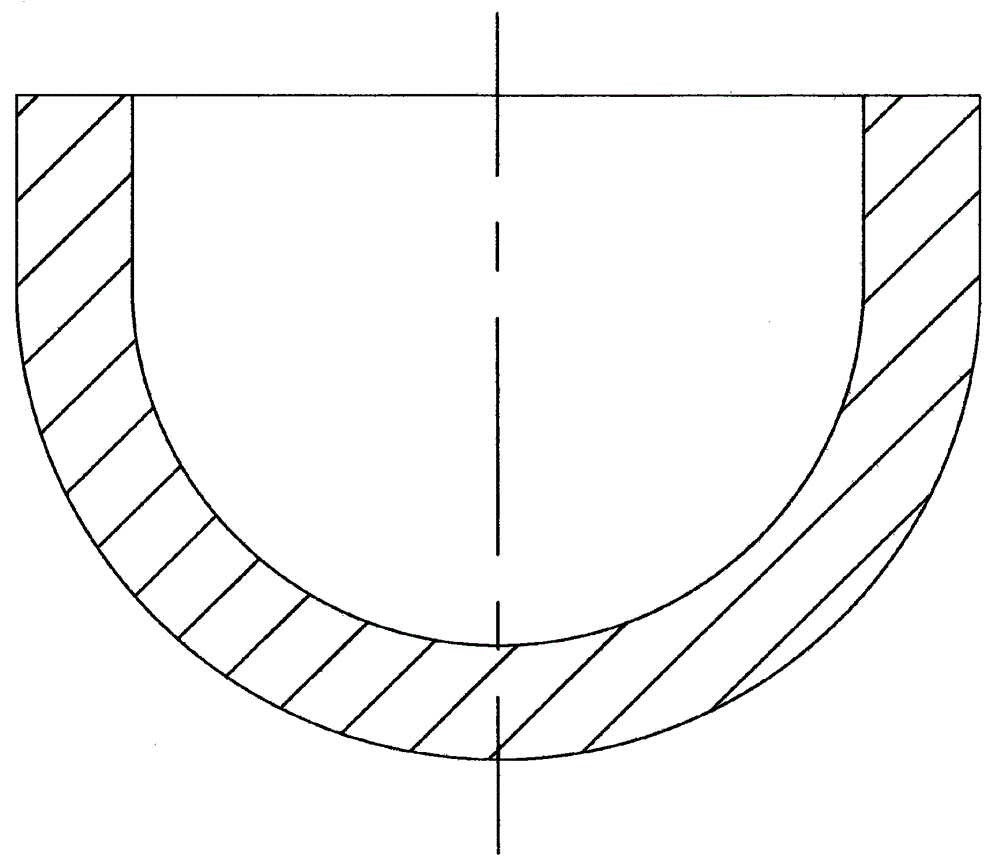

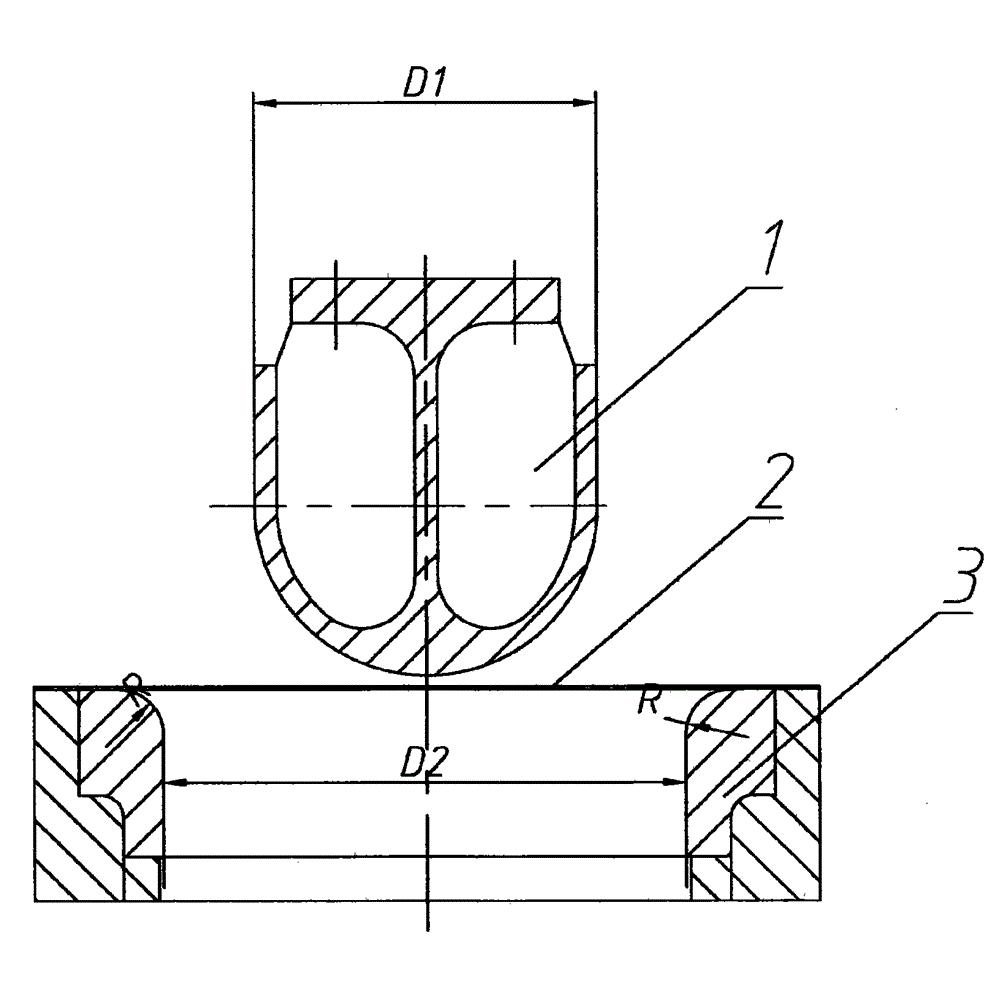

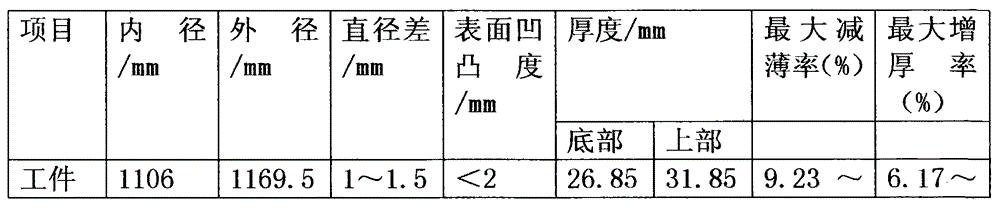

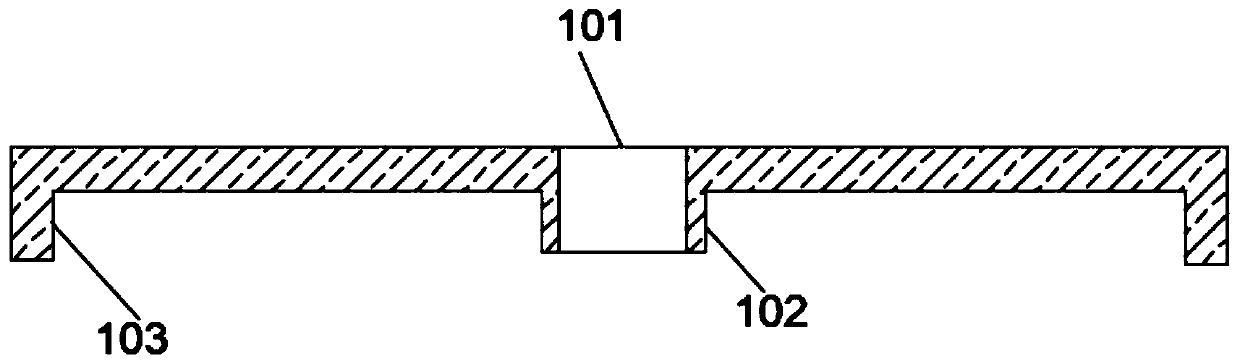

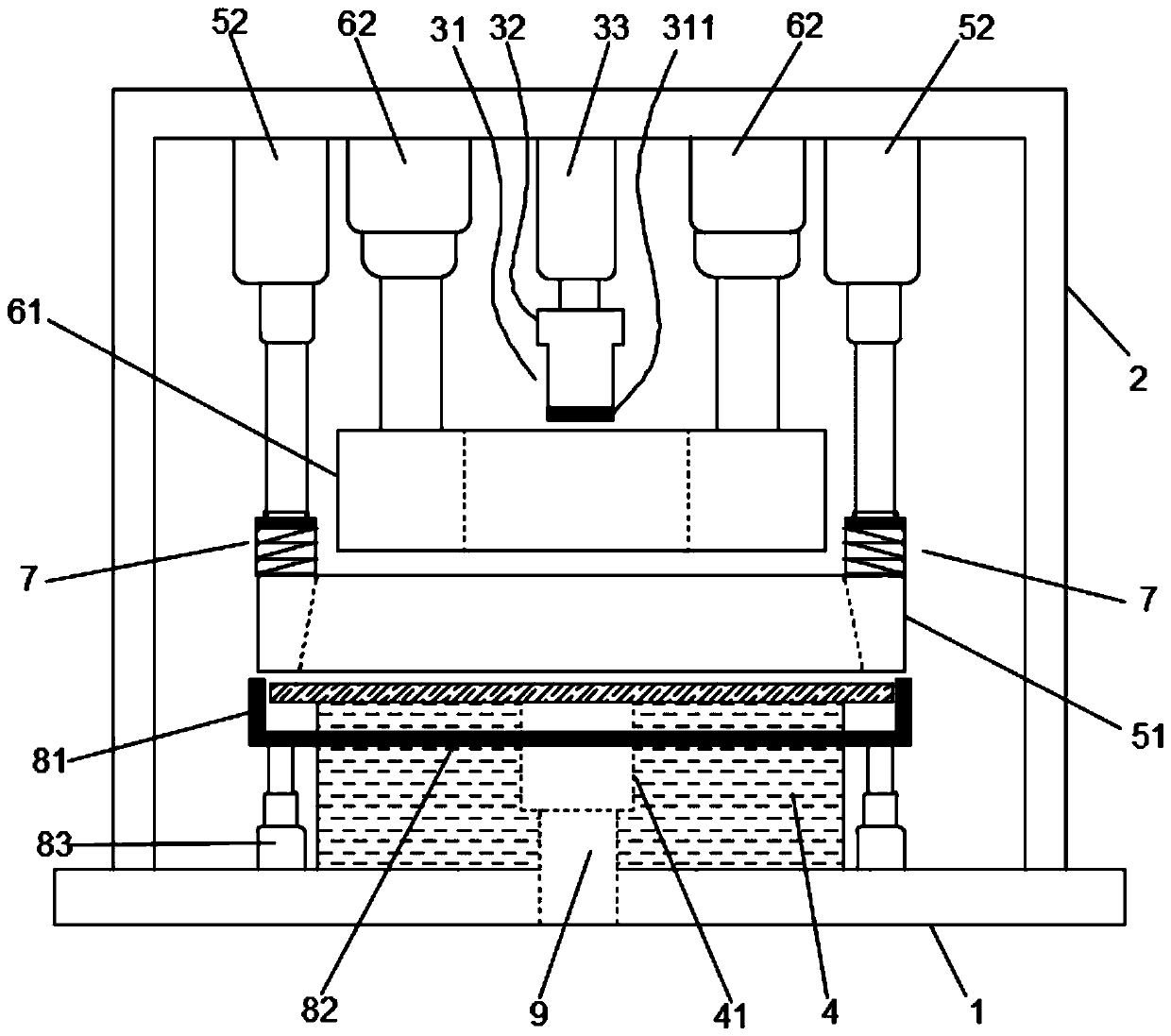

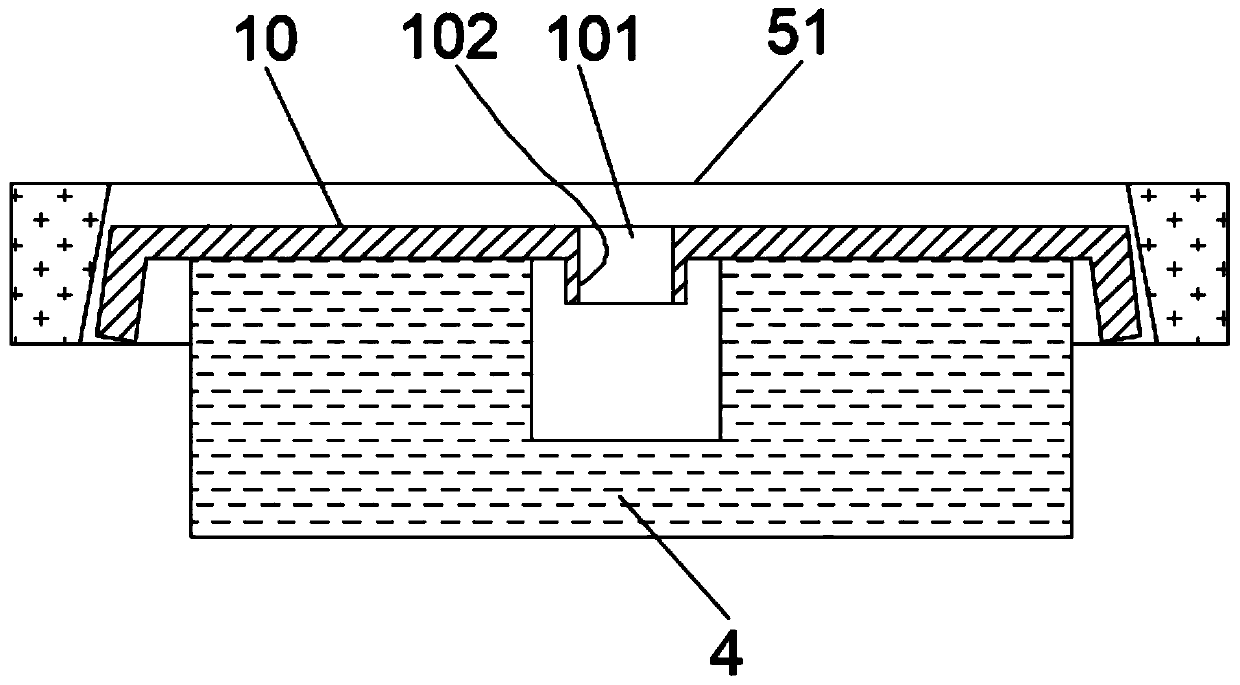

Manufacturing method for nickel composite board end sockets

The invention relates to a metal material machining technology and manufacturing method, in particular to a manufacturing method for nickel composite board end sockets. The manufacturing method comprises the steps of designing a die; calculating the diameter of an upper die pressure head, the diameter of an outlet of a lower die pull ring, the gap between an upper die and a lower die and the circular bead of the lower die pull ring; splicing composite boards; carrying out penetrant flaw detection; carrying out ultrasonic detection; polishing and cleaning the die; carrying out earlier stage processing of blanks; carrying out heating through a natural gas furnace; carrying out stamping forming, wherein three-time forming is adopted for the forming technology; carrying out spinning forming; cutting grooves; carrying out acid dipping; carrying out polishing; carrying out penetrant flaw detection and ultrasonic detection; stacking the end sockets. By means of the method, the stamping process is stable, transformation is even and smooth, a determined hot working system is feasible, the technology parameters are reasonable, control over the dimension of workpieces is good, metal streamline distribution is reasonable, and performance is stable.

Owner:无锡市前洲西塘锻压有限公司

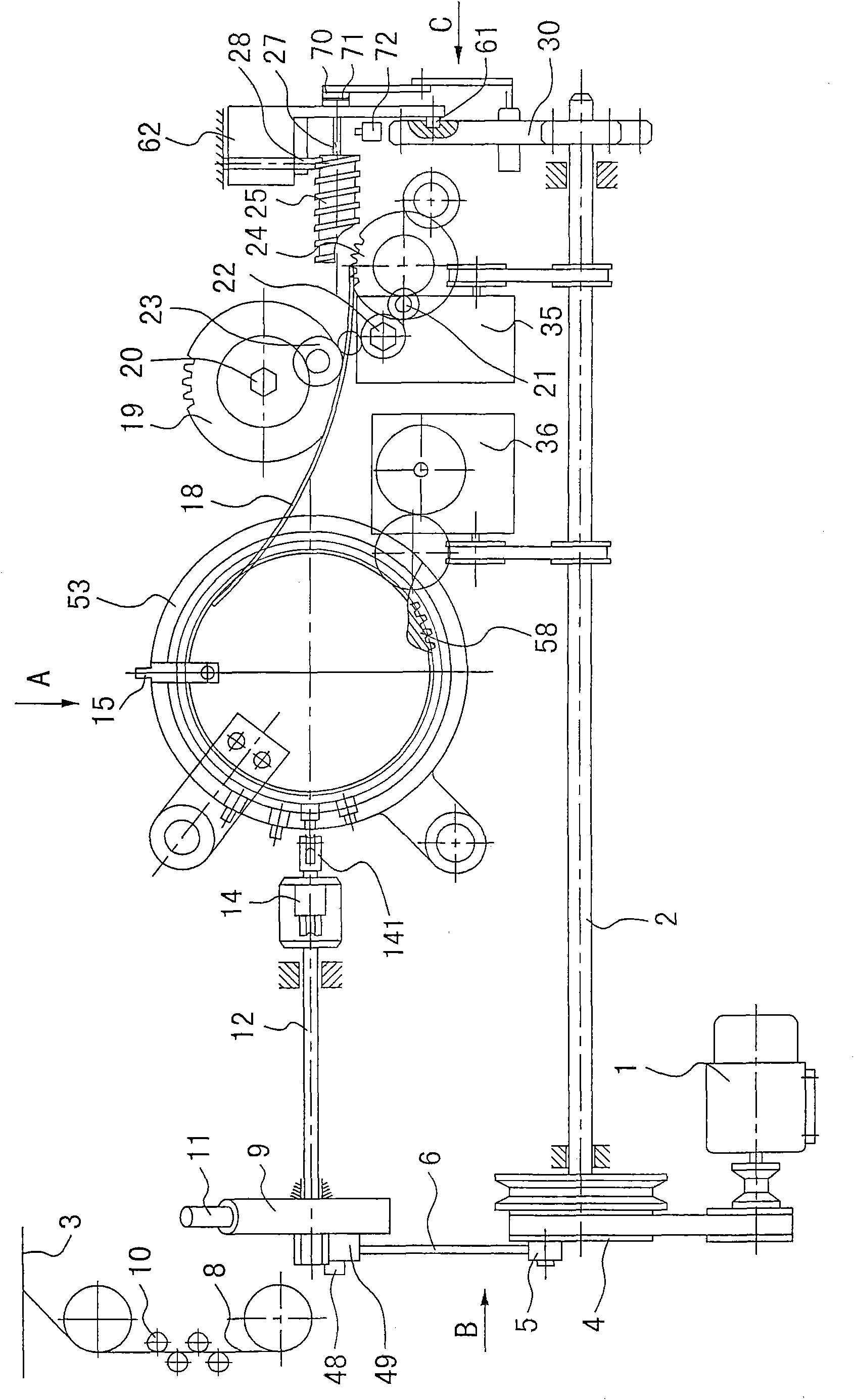

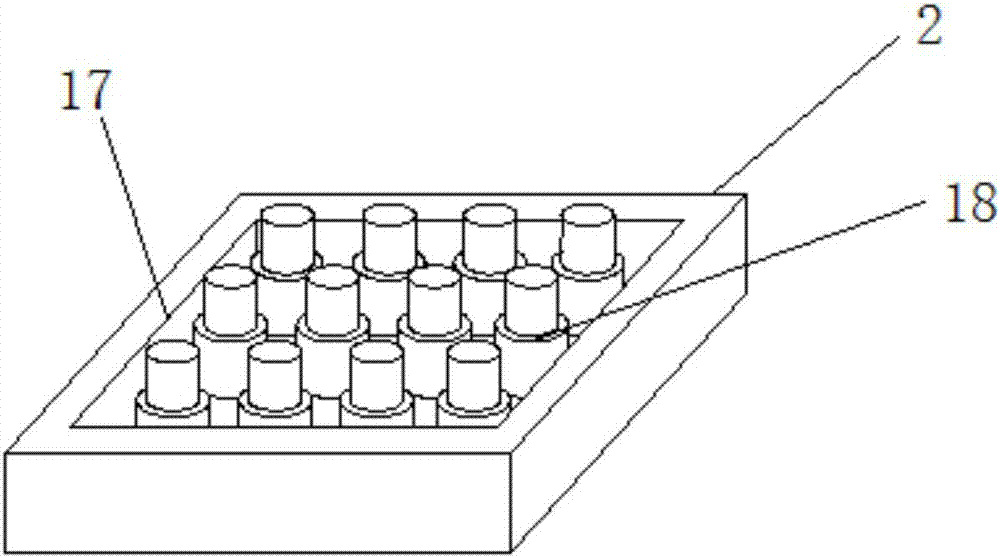

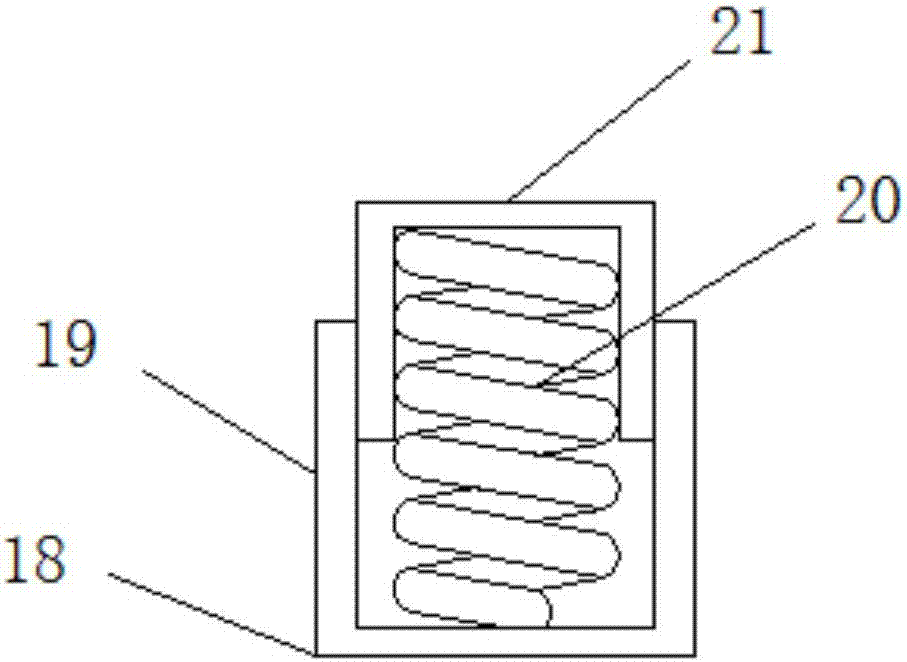

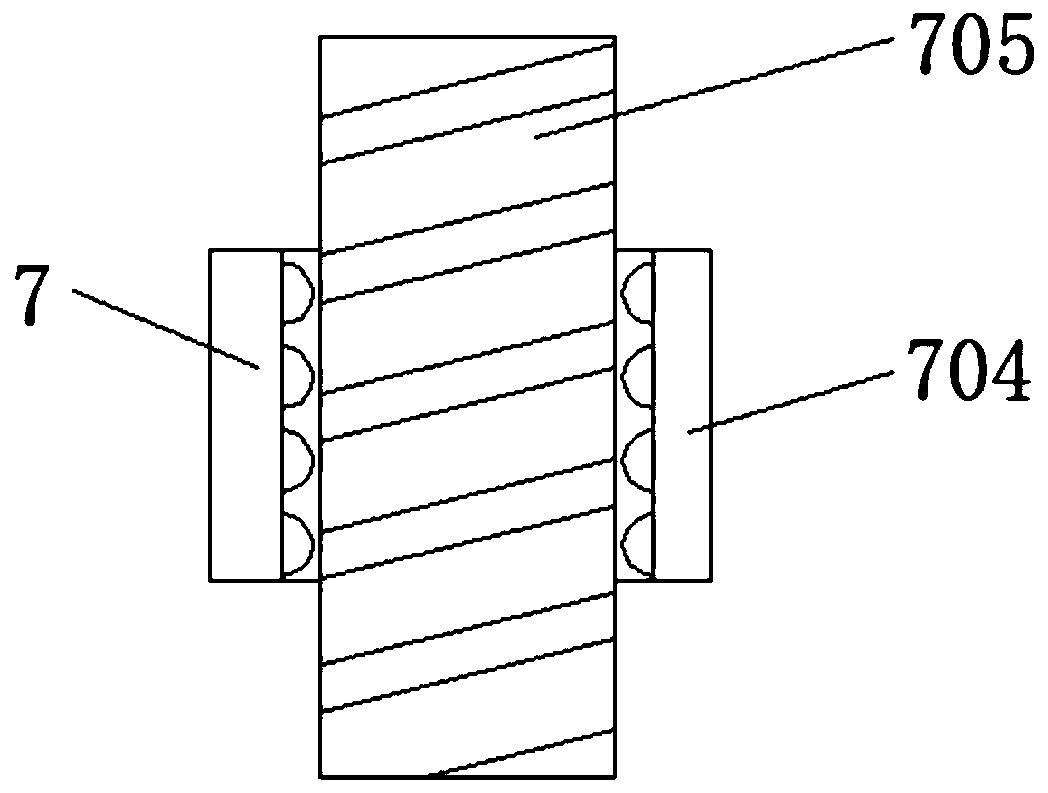

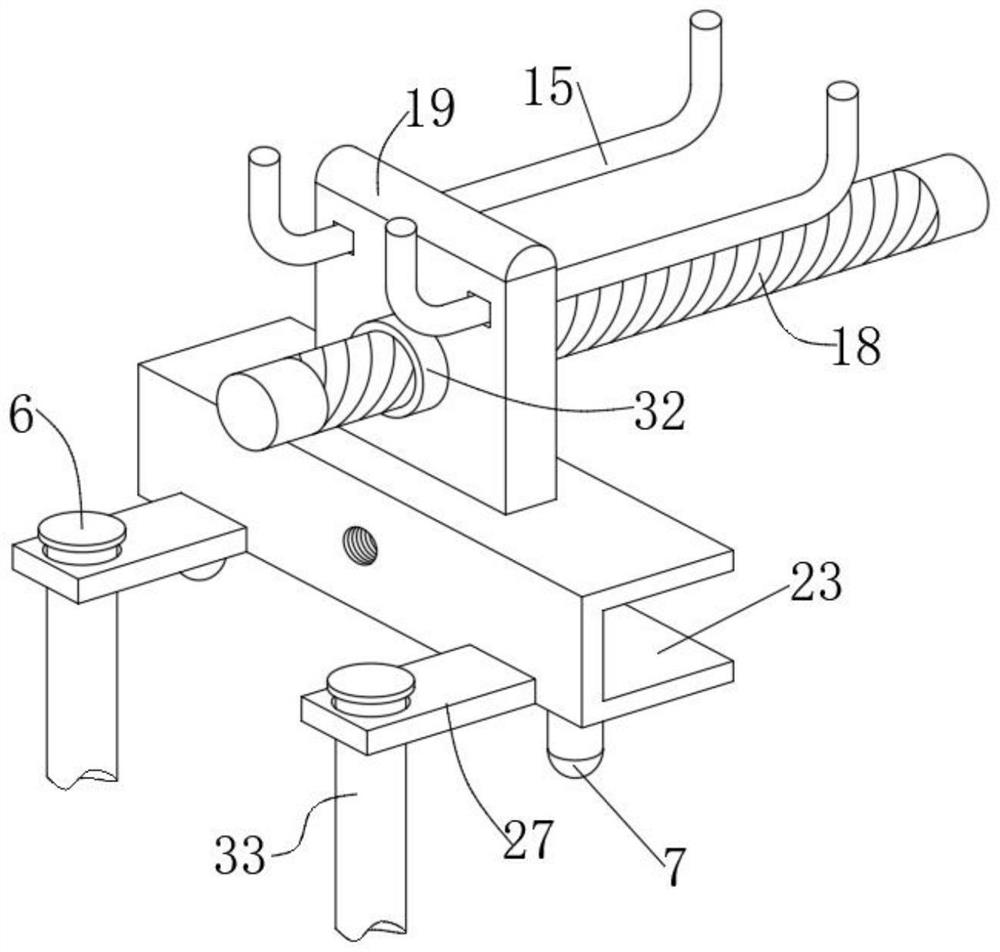

Automatic forming machine for plastic wires

The invention discloses an automatic forming machine for plastic wires, which comprises a main shaft driven by a motor, a wire inlet mechanism driven by the main shaft, a wire pre-profiling mechanism,a shaping and regulating mechanism and a forming and cutting mechanism. The wire inlet mechanism comprises a swing axle, a swing stem is arranged on the swing axle, the head of the swing stem is provided with a wire wrapping head, and wires are wound on the wire wrapping head; the wire pre-profiling mechanism comprises double turntables arranged on a stander, wrapping posts are arranged in the double turntables respectively, the wires are wound on the wrapping posts by the wire wrapping head, the double turntables are provided with circle diameter regulating devices, one side of the double turntables is provided with a guide plate, and the wound wires are led out from the guide plate; the shaping and regulating mechanism comprises an upper drive plate, a lower drive plate and double screws, wherein the upper drive plate and the lower drive plate are arranged on the stander, and a thread pitch regulating device is arranged between the double screws; and the wires which are shaped and regulated enter the forming and cutting mechanism which comprises a fixed die arranged between the double screws, a stamping head is arranged above the fixed die, fixture blocks are arranged under thefixed die at the two sides, the fixed die is matched with the stamping head and the fixture blocks, the stamping head and the fixture blocks are driven by the stamping device, and a tangent device isarranged at the end of the fixed die.

Owner:章金魁

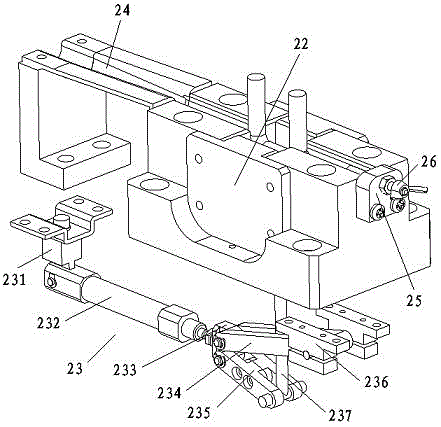

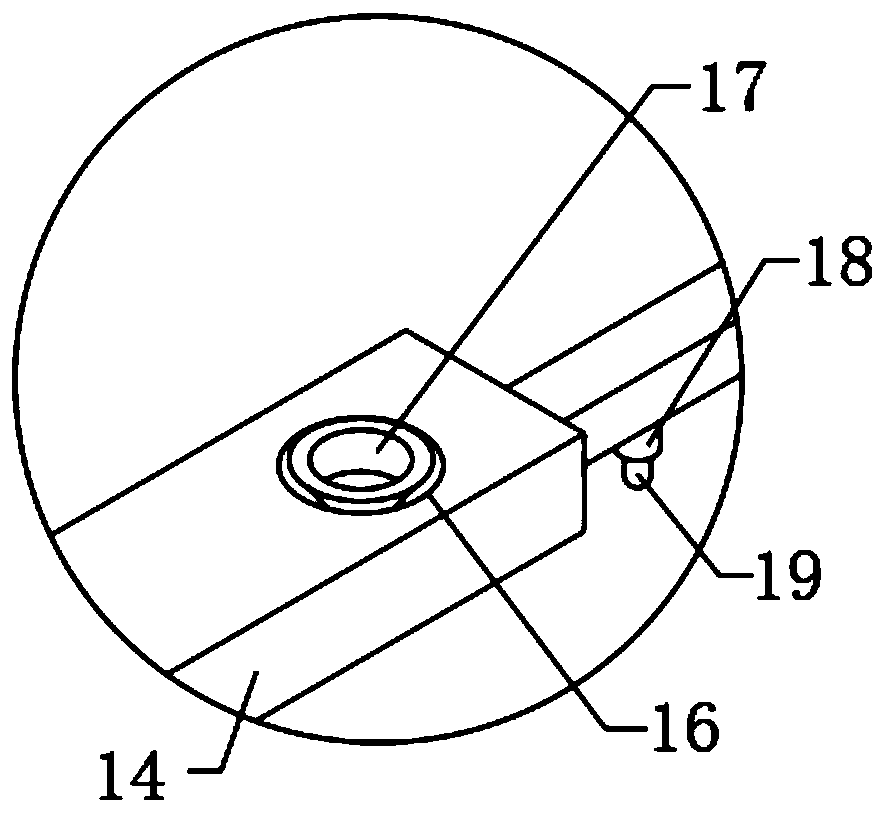

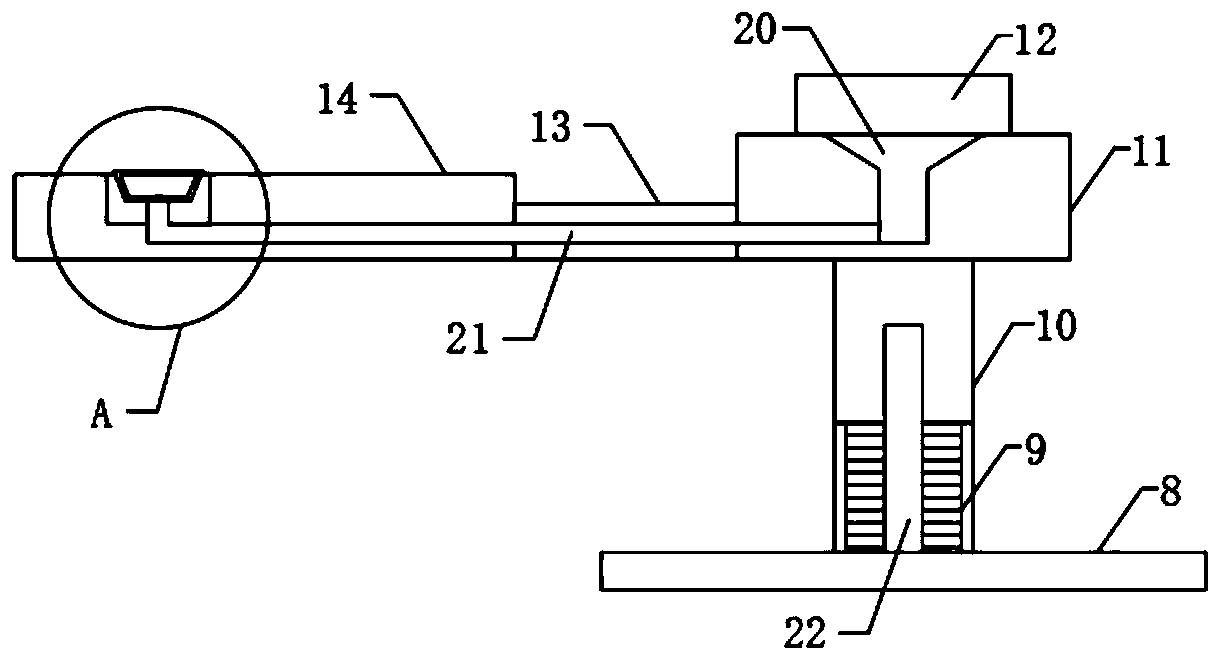

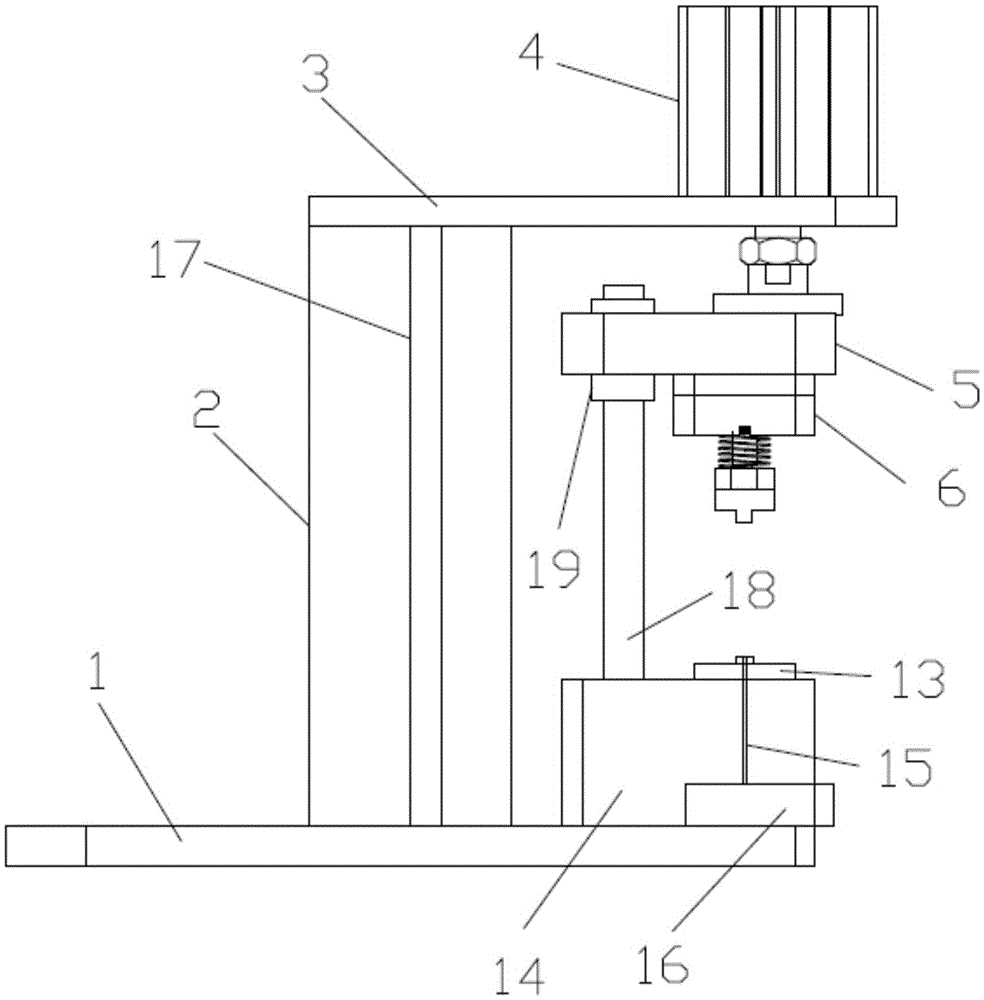

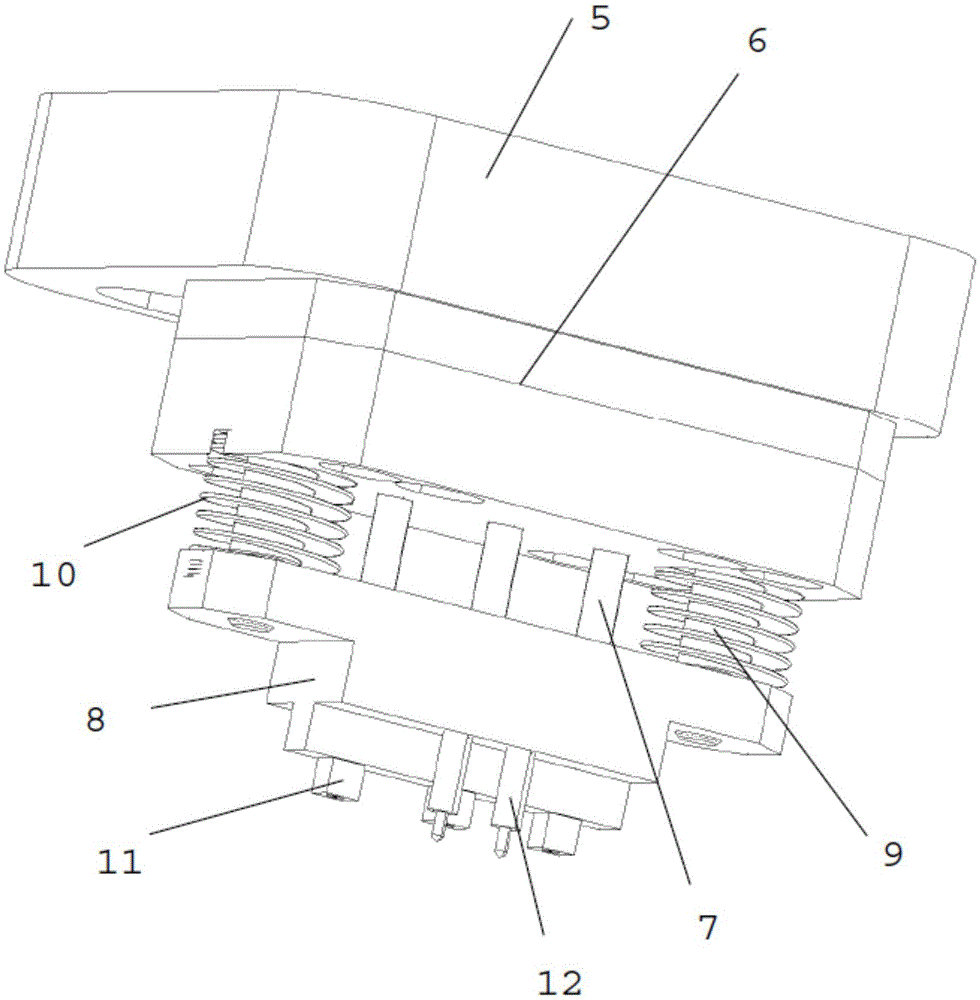

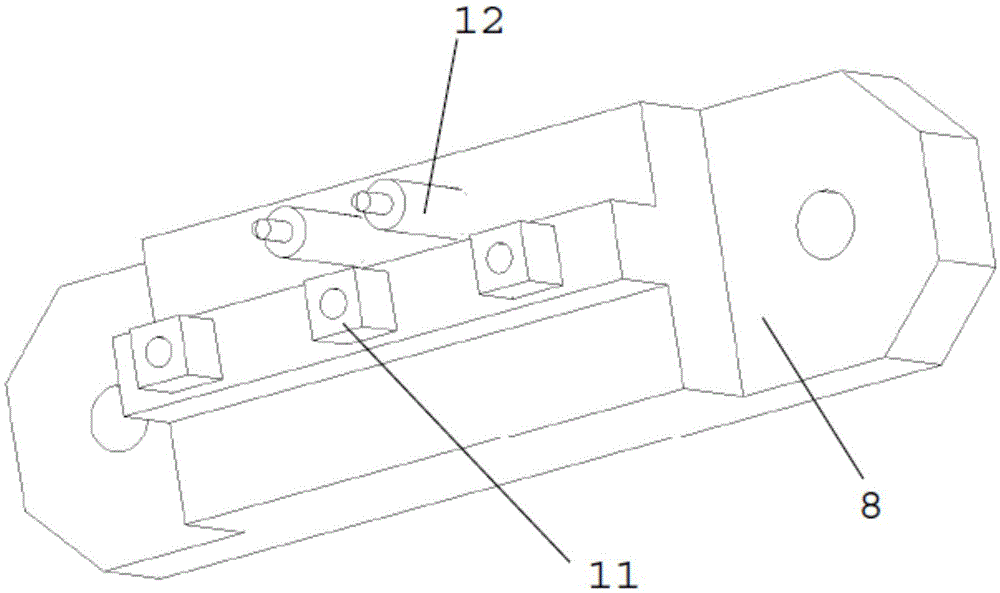

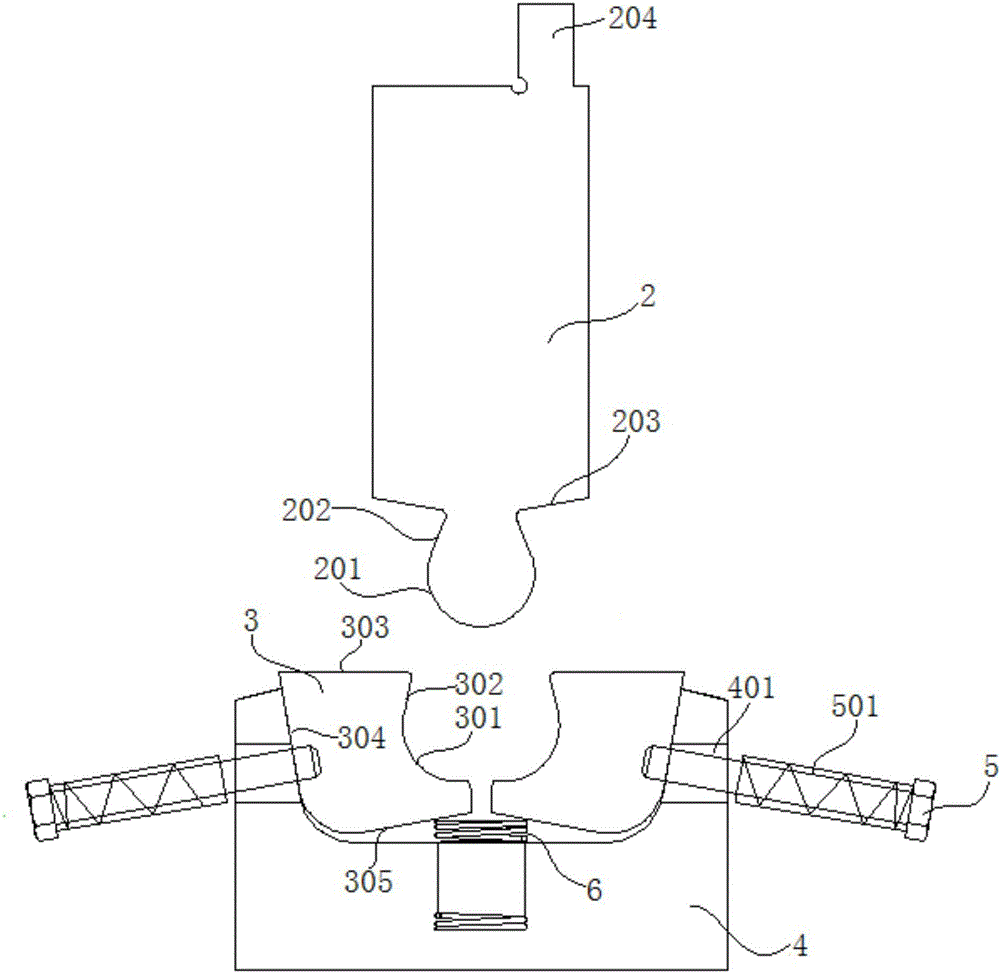

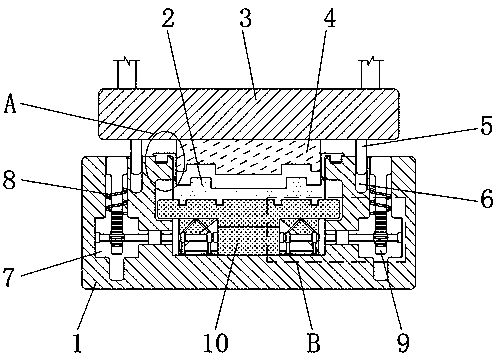

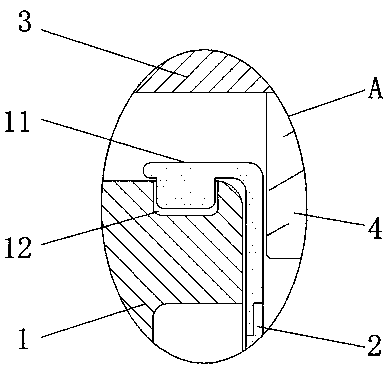

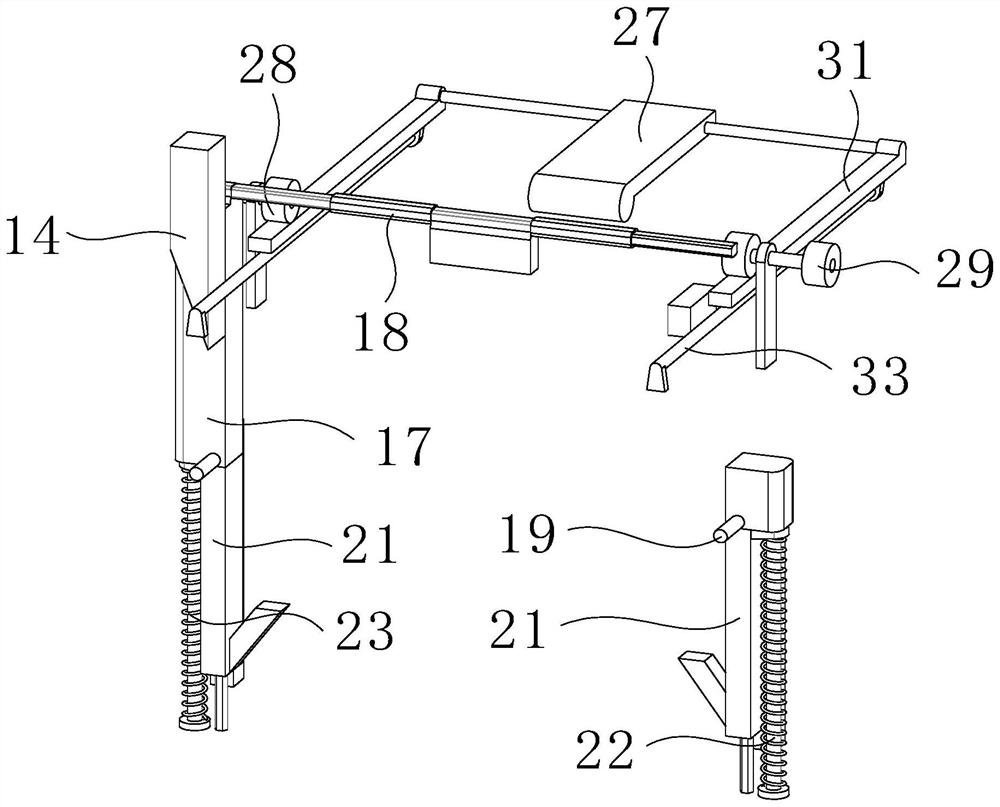

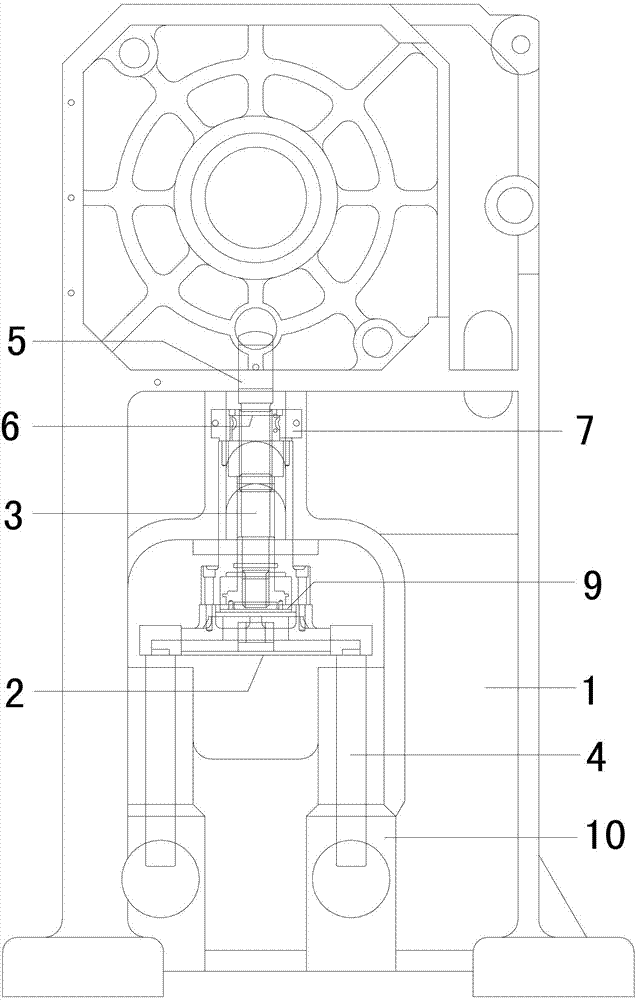

Bending mechanism for automobile door lock latch production line

InactiveCN105728587ACompact structureStamping stabilityShaping toolsVehicle componentsProduction lineCopper

The invention discloses a bending mechanism for an automobile door lock latch production line. The bending mechanism for the automobile door lock latch production line comprises a machine base, a lower bending and stamping die, a material push assembly, a bending and guiding sliding groove, a screw mounting block, a butterfly-shaped screw, guide columns, an upper top plate, a bending and lifting air cylinder, a floating joint, a lifting plate, bending bolts, an upper pressing plate, bending and buffering springs, guide sleeves and an upper bending and stamping die. The lower bending and stamping die is mounted on the upper plane of the machine base. The material push assembly is mounted on the lower plane of the machine base. A copper column mounting groove is formed in the upper end of the lower bending and stamping die. The front portion of the butterfly-shaped screw is inserted into the copper column mounting groove. A piston rod of the bending and lifting air cylinder is fixedly connected with the lifting plate through the floating joint. The lifting plate is connected with the upper pressing plate through the bending bolts. The four guide sleeves are mounted on the upper pressing plate. The guide columns penetrate the guide sleeves. The upper bending and stamping die is mounted on the lower plane of the upper pressing plate. By means of the manner, the bending mechanism is compact in structure, stable in stamping, low in product rejection rate and high in production efficiency.

Owner:SUZHOU HONGPU PRECISION MOLD

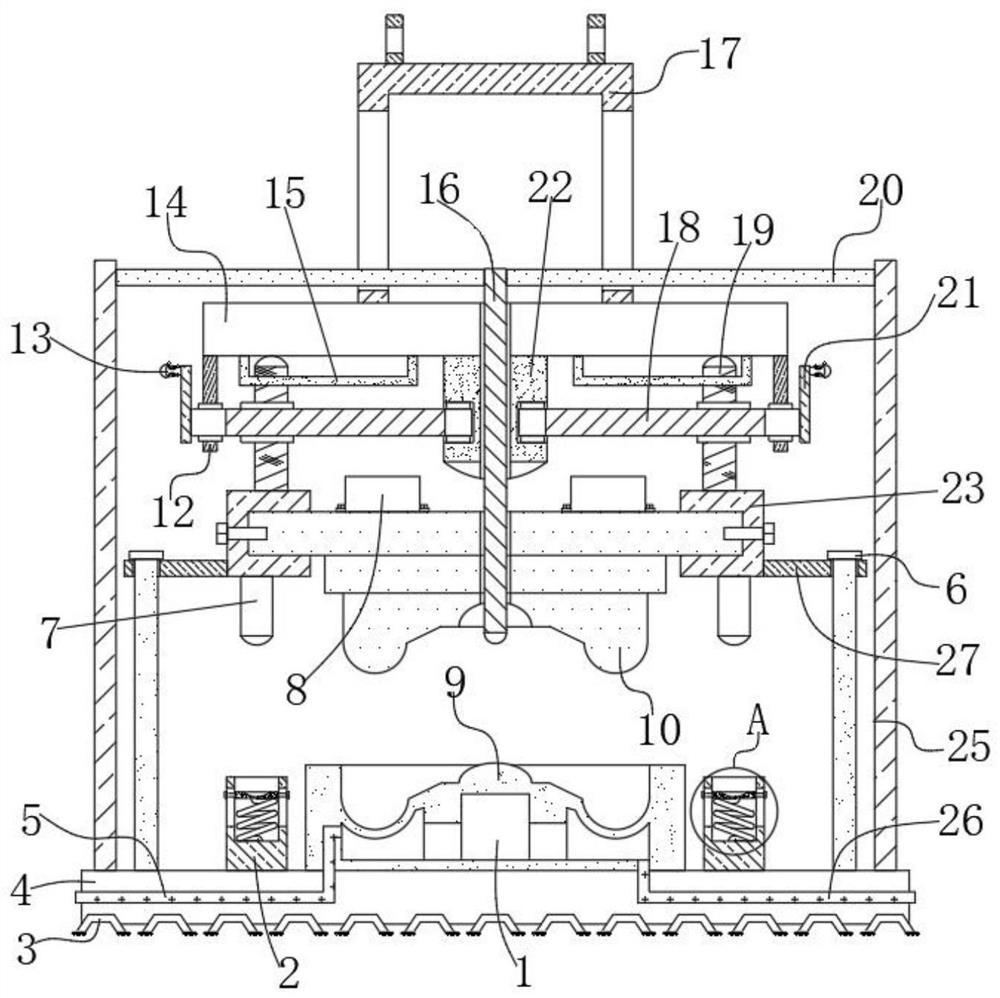

Punching machine

The invention relates to the technical field of punching of rigid workpieces, in particular to a punching machine. The punching machine comprises a supporting plate. A punching hole is formed in the supporting plate. The punching machine further comprises an ejector mechanism, punching mechanisms and an oil storage cylinder for storing hydraulic oil. The oil storage cylinder communicates with a first branch pipe and a second branch pipe located below the first branch pipe. The oil storage cylinder is internally and slidably connected with a transverse piston. The transverse piston is connected with a piston rod. The ejector mechanism comprises an ejector plate and a buffer bucket connected with the lower portion of the ejector plate. The number of the punching mechanisms is two. Each punching mechanism comprises a punching head, a connecting rod, a vertical piston and an oil separating pipe. The sizes of the punching heads of all the punching mechanisms are different. According to the technical scheme, the punching machine is characterized in that punching head replacing and punched part picking are very convenient, and the punching efficiency is improved advantageously.

Owner:宁波信基机械科技有限公司

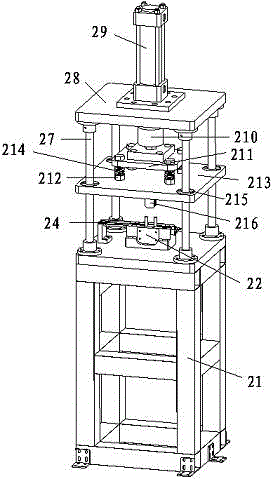

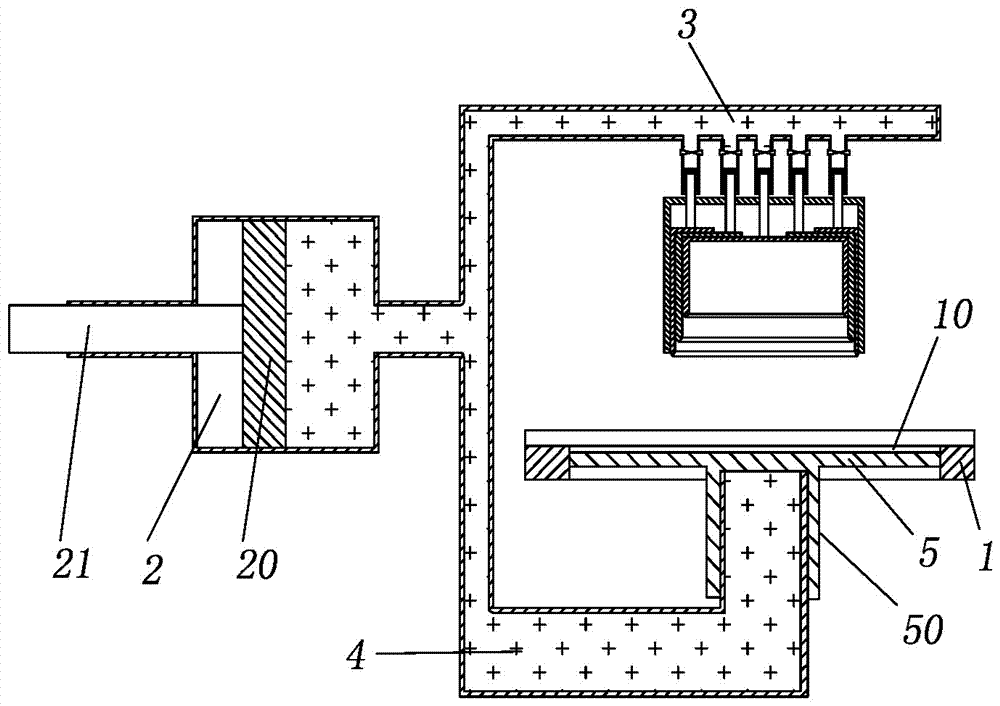

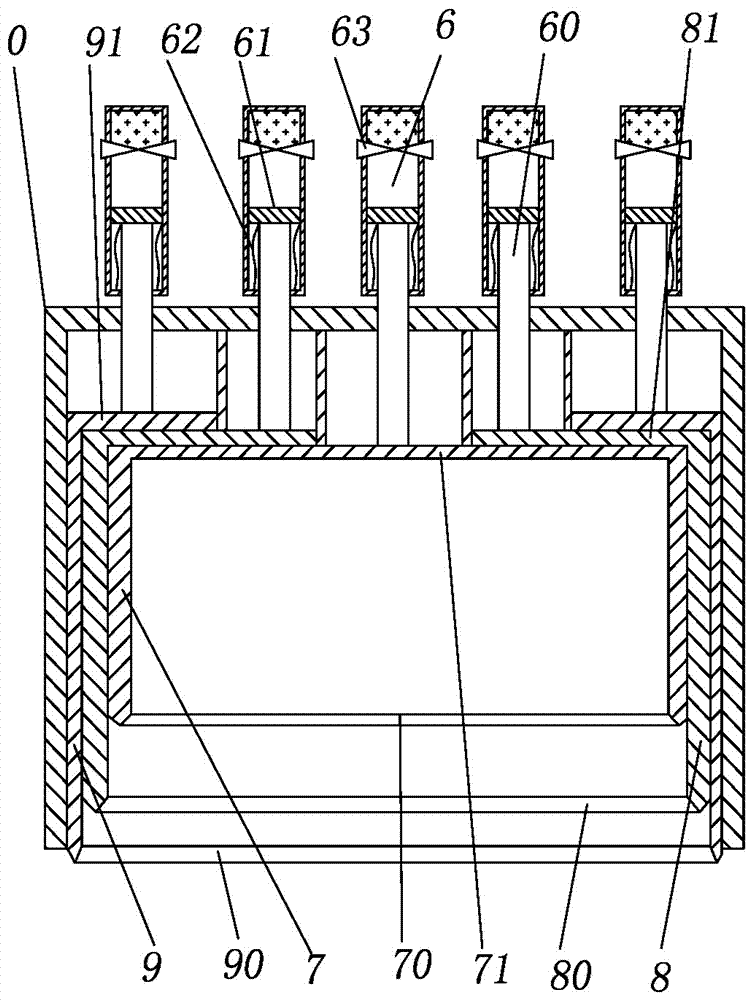

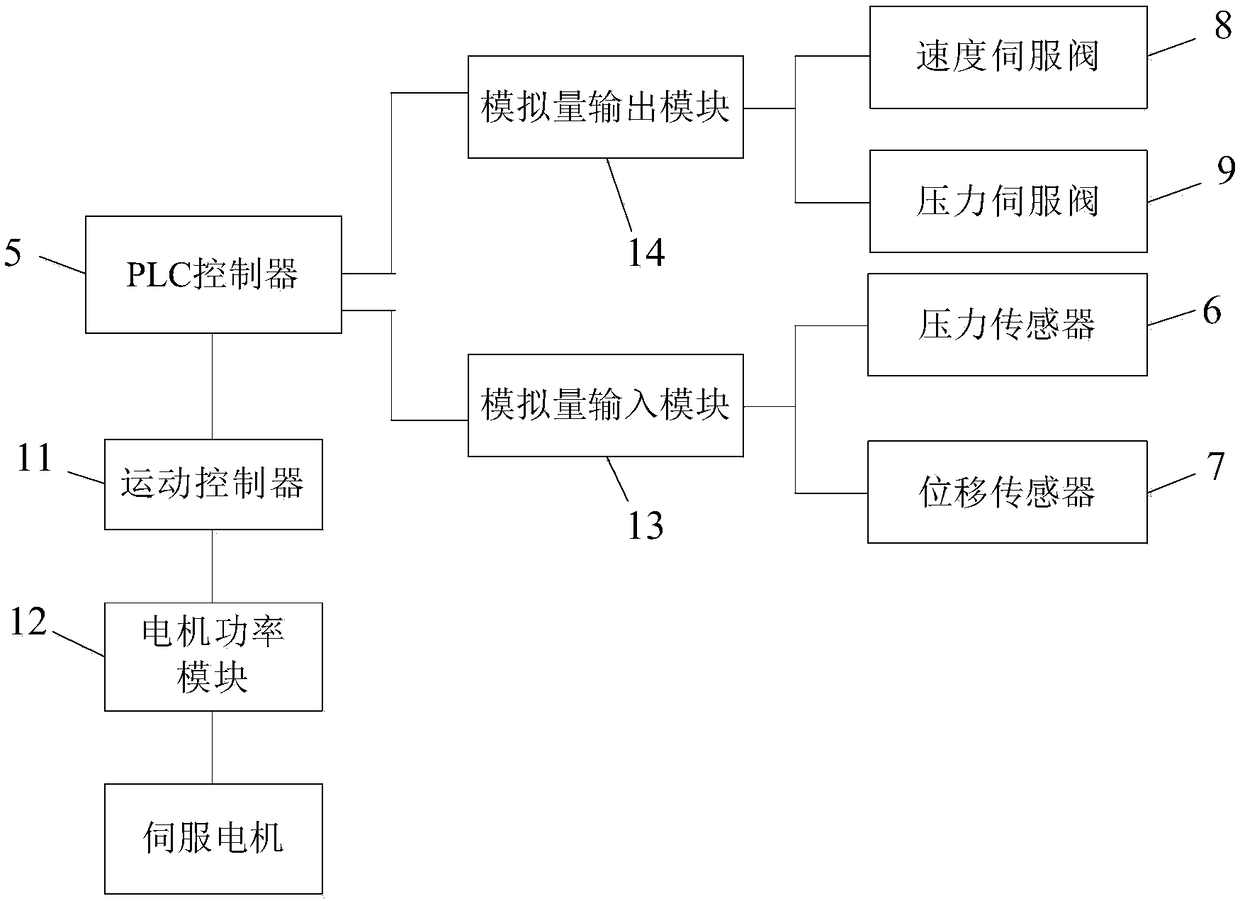

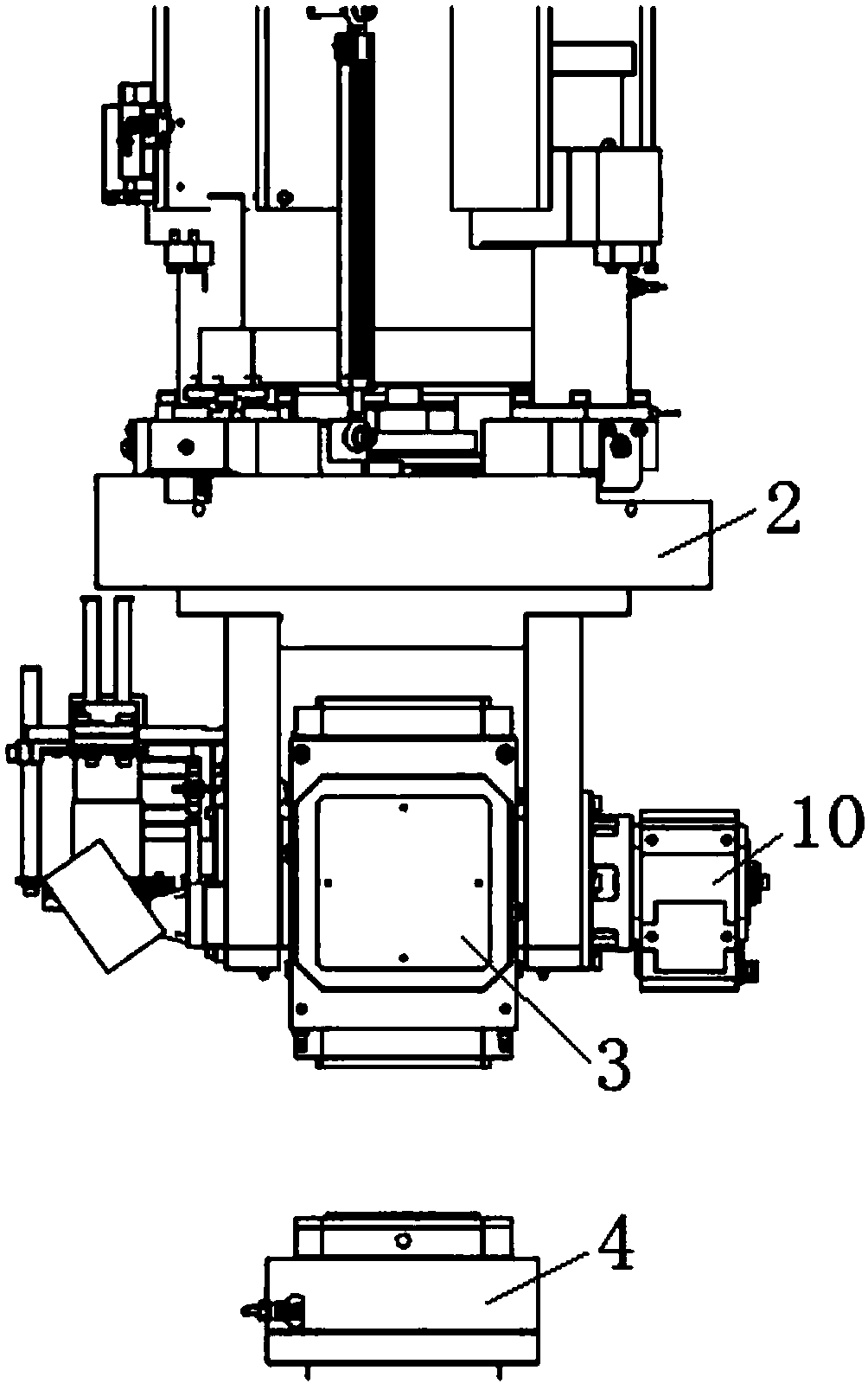

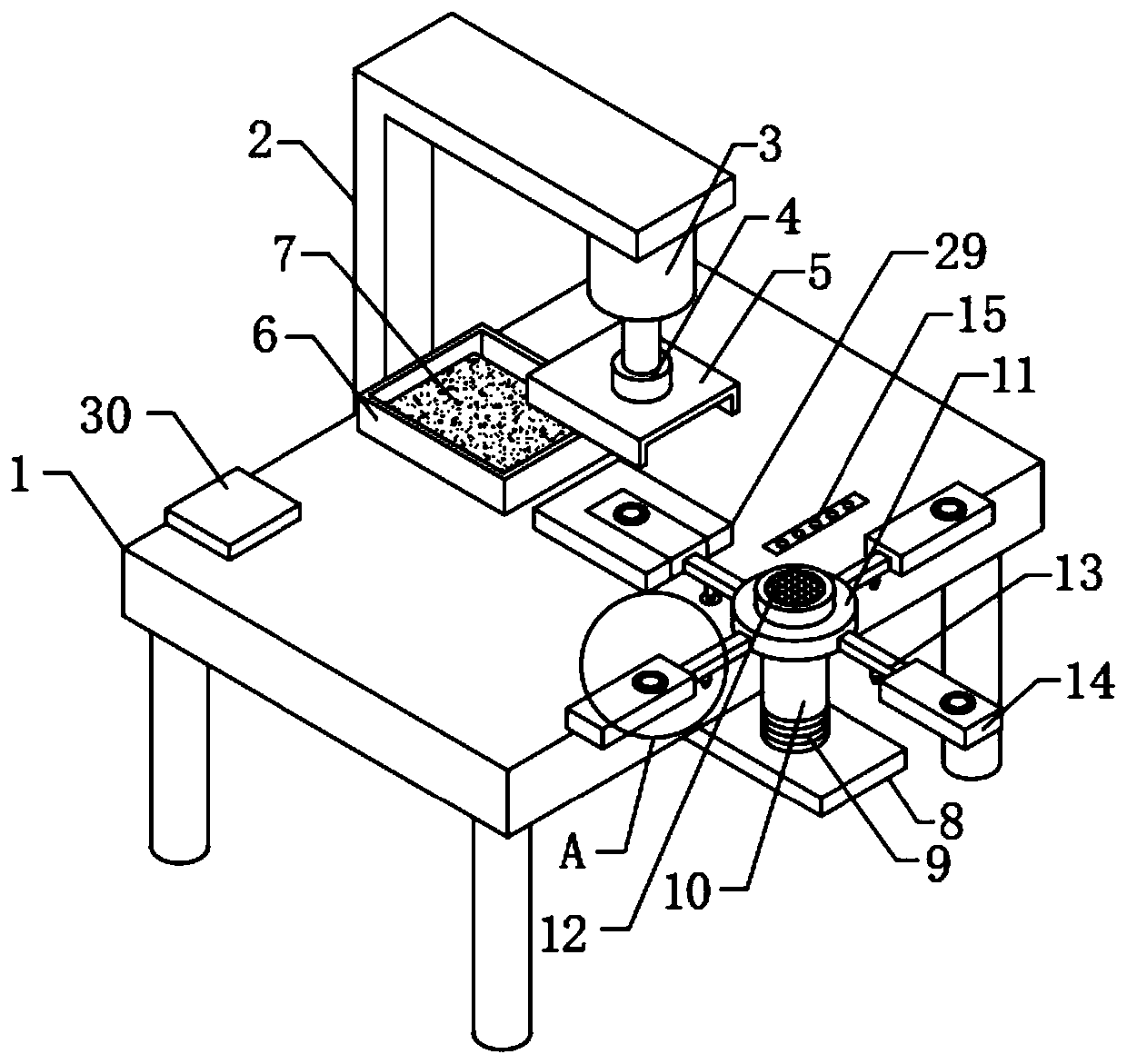

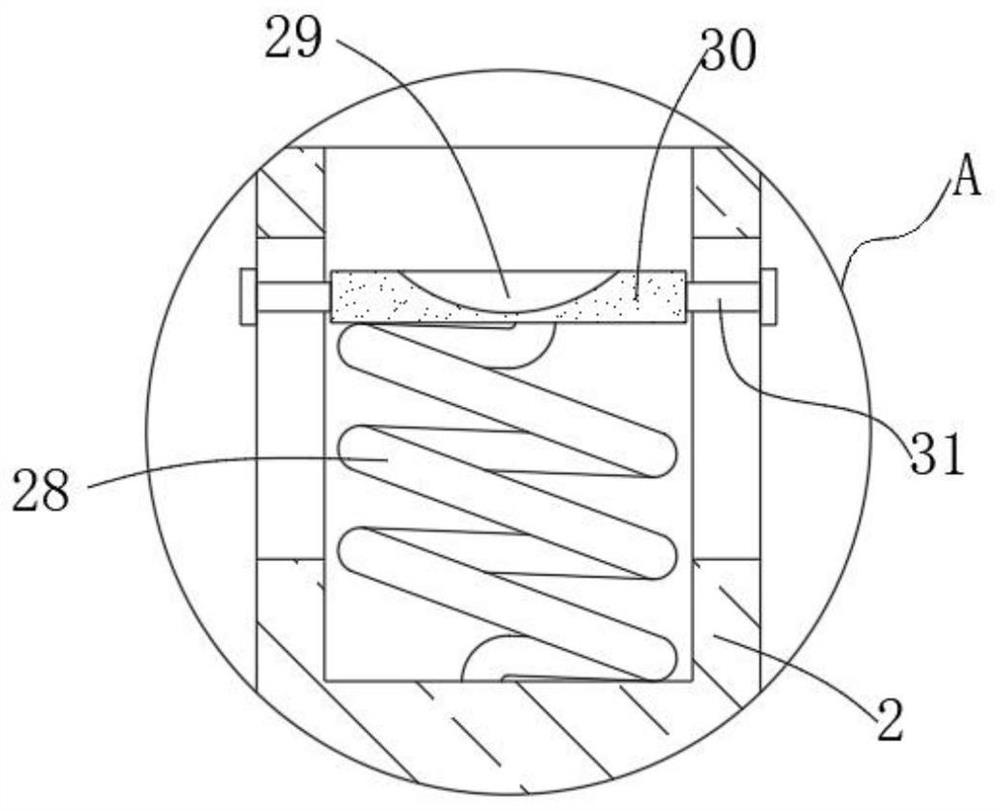

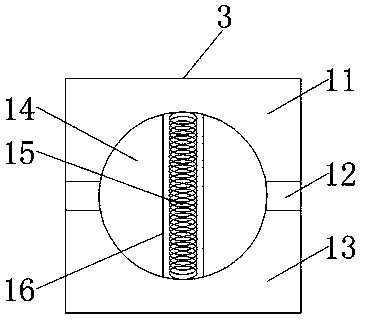

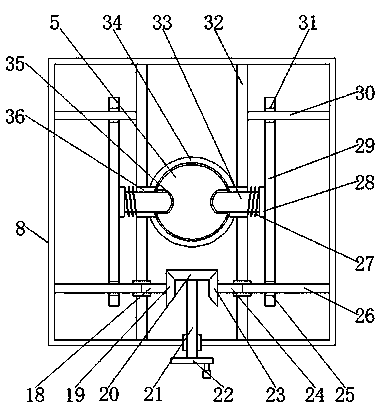

Metal thin net punching formation device

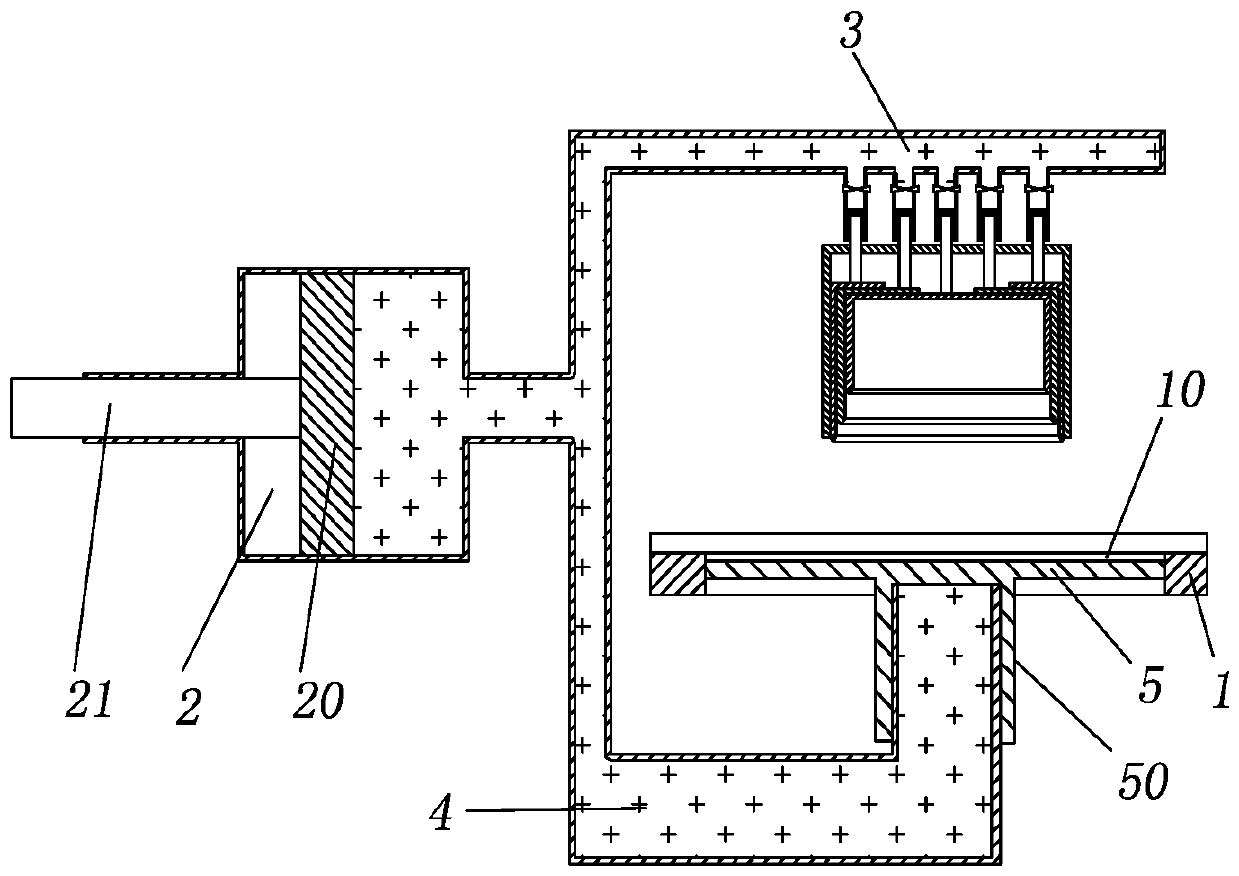

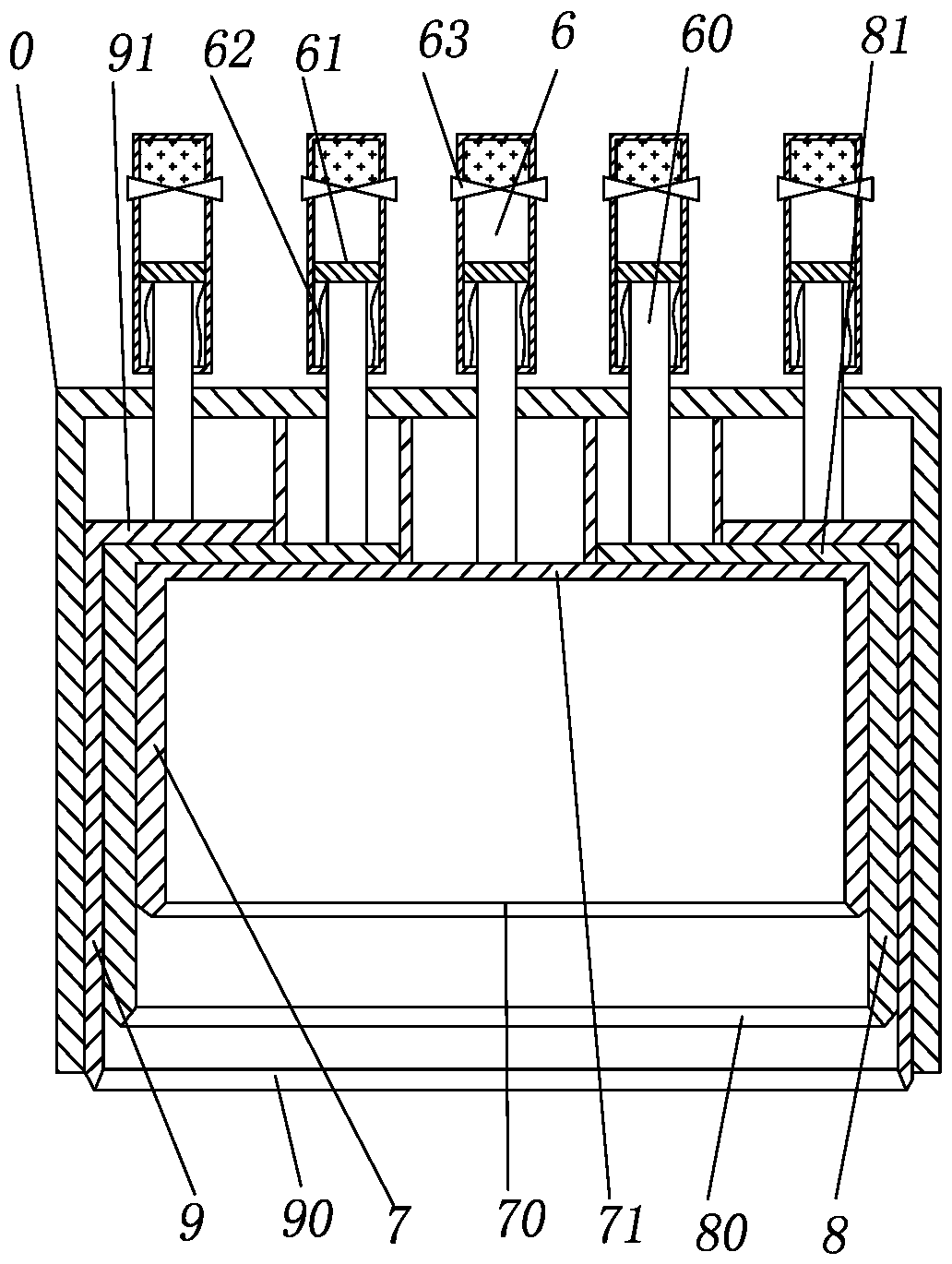

InactiveCN108620483AStamping stabilityImprove efficiencyShaping toolsPunch pressHuman–machine interface

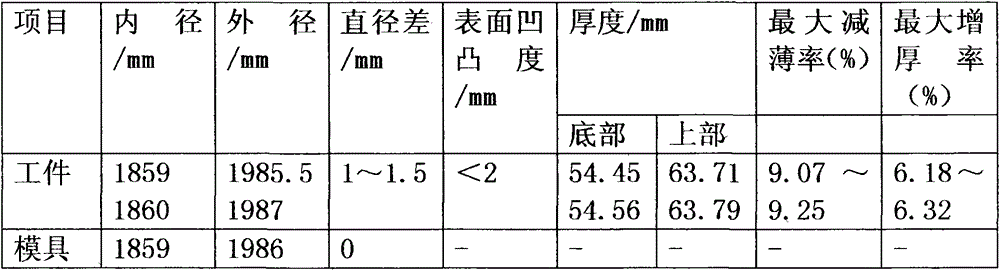

The invention belongs to the technical field of punching machine equipment, and in particular, relates to a metal thin net punching formation device. The metal thin net punching formation device comprises a human-computer interface, an upper punch, a punching mold, a lower punch, a PLC, a pressure sensor, a displacement sensor, a speed servo valve, a pressure servo valve and a servo motor; the displacement sensor sends a detected punching distance of the upper punch to the PLC; the PLC analyzes the punching distance of the upper punch, and then, controls the speed servo valve to adjust the punching speed of the upper punch; the pressure sensor sends detected punching pressure of the upper punch to the PLC; and the PLC analyzes the punching pressure, and then, controls the pressure servo valve to adjust the punching pressure of the upper punch. The metal thin net punching formation device is simple in structure, convenient to set, stable and reliable in operation and wide in applicationrange, can autonomously set punching parameters, is controllable in punching process, and guarantees the product quality.

Owner:NANJING BANKNOTE MINTING +1

Manufacturing method for nickel board end sockets

The invention relates to a metal material machining technology and manufacturing method, in particular to a manufacturing method for nickel board end sockets. The manufacturing method comprises the steps of designing a die; calculating the diameter of an upper die pressure head, the diameter of an outlet of a lower die pull ring, the gap between an upper die and a lower die and the circular bead of the lower die pull ring; splicing nickel boards; carrying out penetrant flaw detection; detecting the hardness; carrying out stress relief annealing processing on the nickel boards; polishing and cleaning the die; carrying out earlier stage processing of blanks; carrying out stamping forming, wherein three-time cold forming is adopted for the forming technology; cutting grooves; carrying out acid dipping; carrying out polishing; carrying out penetrant flaw detection; stacking the end sockets. By means of the method, the stamping process is stable, transformation is even and smooth, a determined hot working system is feasible, the technology parameters are reasonable, control over the dimension of workpieces is good, metal streamline distribution is reasonable, and performance is stable.

Owner:无锡市前洲西塘锻压有限公司

Stamping equipment for bus duct machining and fixing method of stamping equipment for bus duct machining

InactiveCN111531009AQuick fixEasy to fixShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

The invention discloses stamping equipment for bus duct machining and fixing method of the stamping equipment for the bus duct machining. The stamping equipment comprises a stamping table, an L-shapedinstalling frame is fixedly connected to the middle of one side wall of the stamping table, an air cylinder is fixedly installed on one side wall of the top of the L-shaped installing frame, a connecting block is in transmission connection with the output end of the air cylinder, an upper mold is fixedly connected to the bottom end of the connecting block, a first lower mold is connected to the middle of the top end of the stamping table in a clamped mode, a storage box is connected to one side of the top end of the stamping table in a sliding mode, a sponge block is fixedly connected to themiddle of the inner wall of the bottom end of the storage box, and an installing plate is fixedly connected to one side of the bottom end of the stamping table. According to the stamping equipment forthe bus duct machining and the fixing method of the stamping equipment for the bus duct machining, a rotating plate is arranged, by means of cooperation of multiple connecting rods and multiple second lower molds, multiple stamping materials can be placed in the area outside the air cylinder, hands are prevented from being crushed by the air cylinder, safety is higher, and the multiple stamping materials can be rapidly and stably fixed by means of cooperation of multiple suction cups and multiple air guide pipes.

Owner:镇江西杰电气有限公司

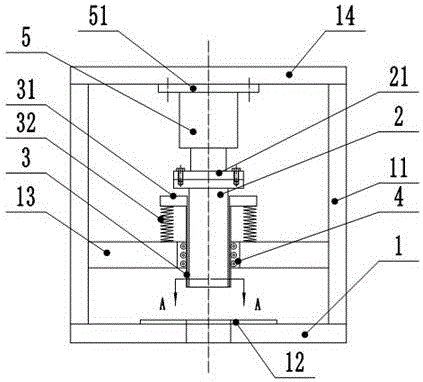

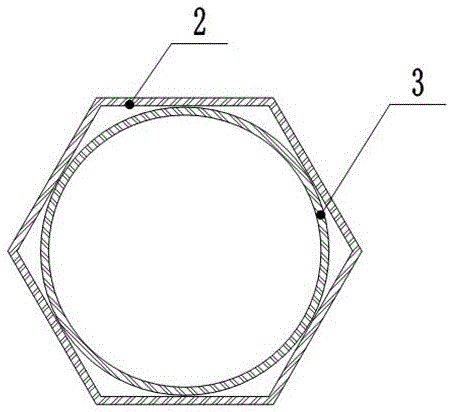

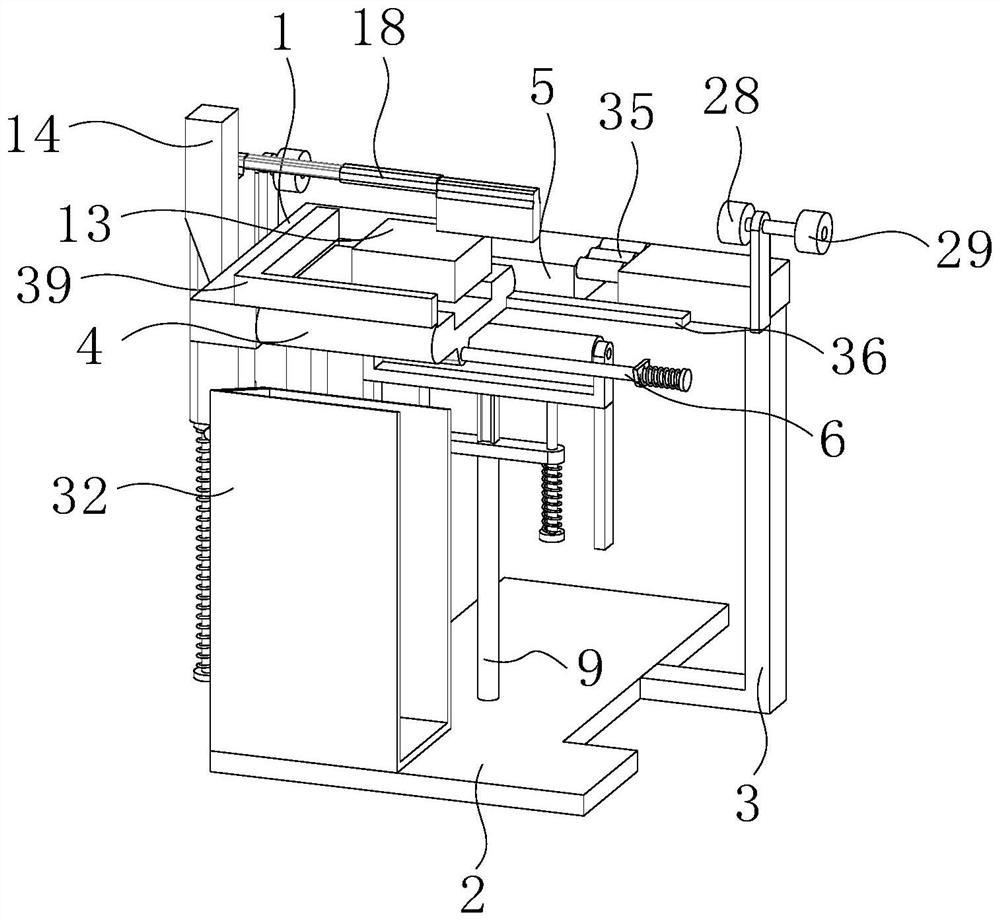

Glass plate perforating device

ActiveCN106426573AImprove efficiencyStamping stabilityStone-like material working toolsPunchingMachining process

The invention relates to a perforating device, and discloses a glass plate perforating device. The glass plate perforating device comprises a support. The support comprises a working platform for containing pieces to be punched. Longitudinal supporting arms are arranged on the two sides of the working platform. A middle cross beam is transversely connected between the two supporting arms and provided with a through hole. A sliding sleeve is mounted in the through hole, and a puncher pin is arranged in the sliding sleeve in a matched manner and comprises an inner round puncher pin body and a hexagonal puncher pin body. The inner round puncher pin body is sleeved with the hexagonal puncher pin body and is internally tangent to the hexagonal puncher pin body. The upper end of the hexagonal puncher pin body is connected with a mounting plate, and springs are connected between the mounting plate and the middle cross beam. According to the technical scheme, in the machining process, a pushing air cylinder moves continuously downwards and cannot stop in the middle, and therefore the efficiency of the punching process is higher; and the pushing air cylinder directly drives the puncher pin to carry out punching, the puncher pin is matched in the sliding sleeve mounted on the cross beam and cannot deflect in the advancing process, and therefore the punching process is more stable, and clamping is avoided.

Owner:重庆市笙建玻璃有限公司

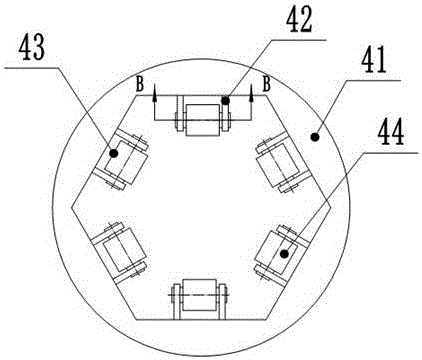

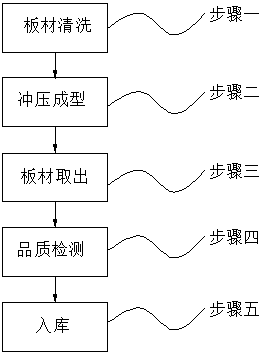

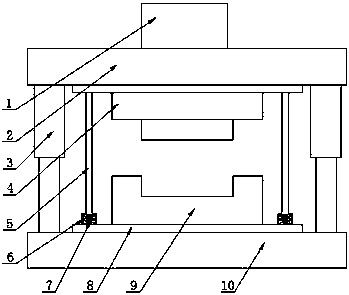

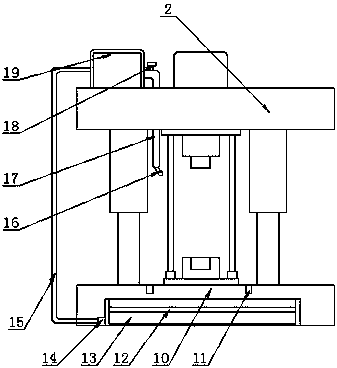

Machining equipment and process for explosion-proof electric apparatuses

InactiveCN108580632AEasy to rinseEasy to recycle waterCleaning using liquidsEjection devicesWater dischargeSprayer

The invention discloses a machining equipment and process for explosion-proof electric apparatuses. The machining equipment comprises a cylinder, an upper bottom plate, a piston rod, a convex die, a guide column, a second spring, a limiting block and a centre; a water tank is installed inside the lower bottom plate, a control panel is operated to open an electric control valve, water inside the water tank flows to a high-pressure sprayer through a water discharge pipe, plates on a concave die are washed through the high-pressure sprayer, water flows into the water tank via a water inlet and then is filtered through a filter screen, finally, a water pump operates, and the water in the water tank is pumped into the water tank through a water return pipe, so that the plates are cleaned conveniently, water recycling is facilitated, and the water resource is saved; the cylinder operates, the piston rod is controlled to retract, then the convex die is driven to descend to punch the plates placed in the concave die, the guide column moves up and down in a guide sleeve in the punching process, a first spring is driven to extend or retract, accurate positioning is achieved conveniently, andmeanwhile, the punching process can be more stable due to a buffer effect.

Owner:山西长城电气股份有限公司

U type/V type part stamping device and technology thereof

ActiveCN108311573AStamping realizationPrevent rotationShaping toolsEngineeringMechanical engineering

The invention discloses a U type / V type part stamping device and a technology thereof. The U type / V type part stamping device comprises a base plate, a first side plate and a second side plate are fixedly connected to the two sides of the upper surface of the base plate, two transverse plates are fixedly connected to the right side face of the first side plate, and the opposite faces of the two transverse plates are fixedly connected with the top end and the bottom end of a first sliding rod. According to the U type / V type part stamping device and the technology thereof, two U type stamping plates or two V type stamping plates get close to U type parts or V type parts needing to be stamped, stamping of the U type parts or V type parts is completed, stamping of the U type parts or V type parts is achieved through the device and the technology, an enterprise does not need to purchase other stamping devices, the enterprise production cost is reduced, and enterprise development is facilitated; and meanwhile, manual replacement of other stamping devices for stamping parts is not needed, the time of a worker is saved, and the working efficiency of the worker is improved.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

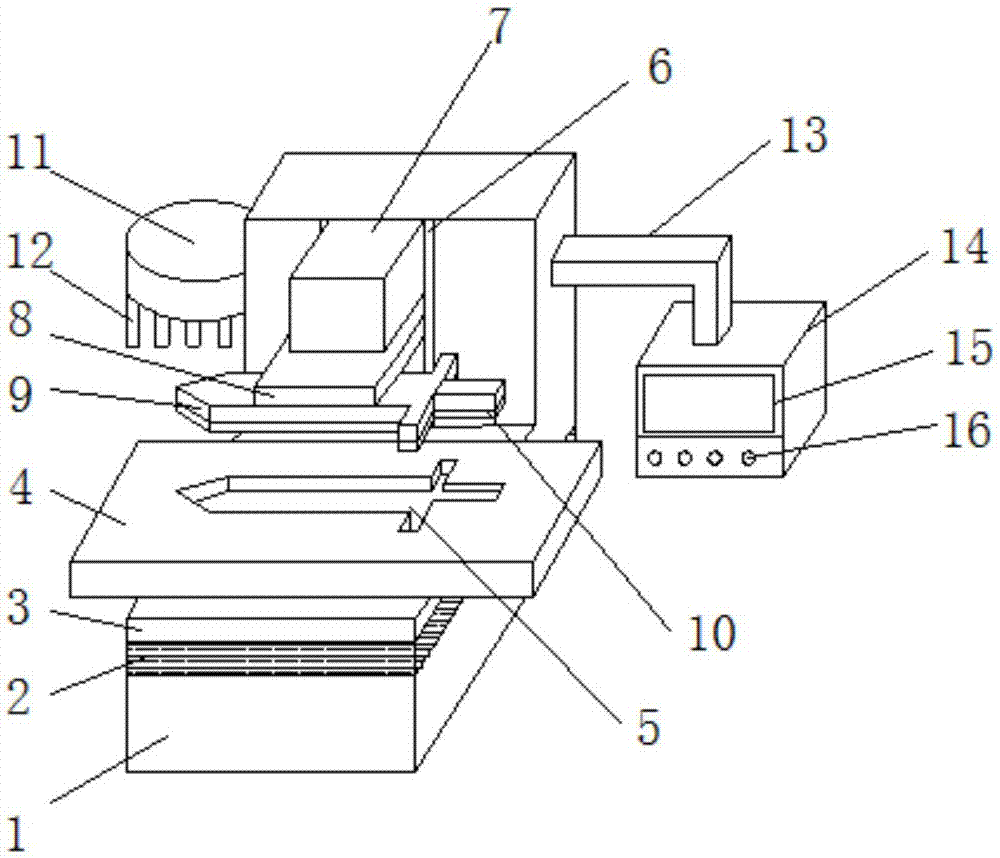

Rough blank stamping device of Longquan sword

The invention provides a preparing process of the Longquan sword. The process comprises following steps that archaized low-sulfur white iron is selected to serve as a raw material, a rough blank stamping device is adopted to stamp the archaized low-sulfur white iron to form the early form of the Longquan sword, and rough hammering, fine hammering, shaping, quenching, polishing, tempering, carving,shaving and assembling are carried out. The traditional Longquan sword making process is improved, the performance of pig iron is changed, the archaized low-sulfur white iron raw material is adopted,the Longquan sword suitable for a dance studying person with the sword for keeping health for use, and the Longquan sword has the beneficial effects that the sword body has strength and toughness; the rear tail of the sword body is elastic, and free in stretching; thirdly, the sword body is bright; fourthly, t he archaized low-sulfur white iron raw material is adopted, and it is ensured that themade Longquan sword is resistant to wear and oxidation and not prone to rusting.

Owner:浙江精龙刀剑有限公司

Manufacturing method for nickel-copper end sockets

The invention relates to a metal material machining technology and manufacturing method, in particular to a manufacturing method for nickel-copper end sockets. The manufacturing method comprises the steps of designing a die; calculating the diameter of an upper die pressure head, the diameter of an outlet of a lower die pull ring, the gap between an upper die and a lower die and the circular bead of the lower die pull ring; polishing and cleaning the die; carrying out earlier stage processing of blanks; carrying out heating through a natural gas furnace; carrying out stamping forming, wherein three-time forming is adopted for the forming technology; carrying out spinning forming; cutting grooves; carrying out acid dipping; carrying out polishing; carrying out penetrant flaw detection; stacking the end sockets. By means of the method, the stamping process is stable, transformation is even and smooth, a determined hot working system is feasible, the technology parameters are reasonable, control over the dimension of workpieces is good, metal streamline distribution is reasonable, and performance is stable.

Owner:无锡市前洲西塘锻压有限公司

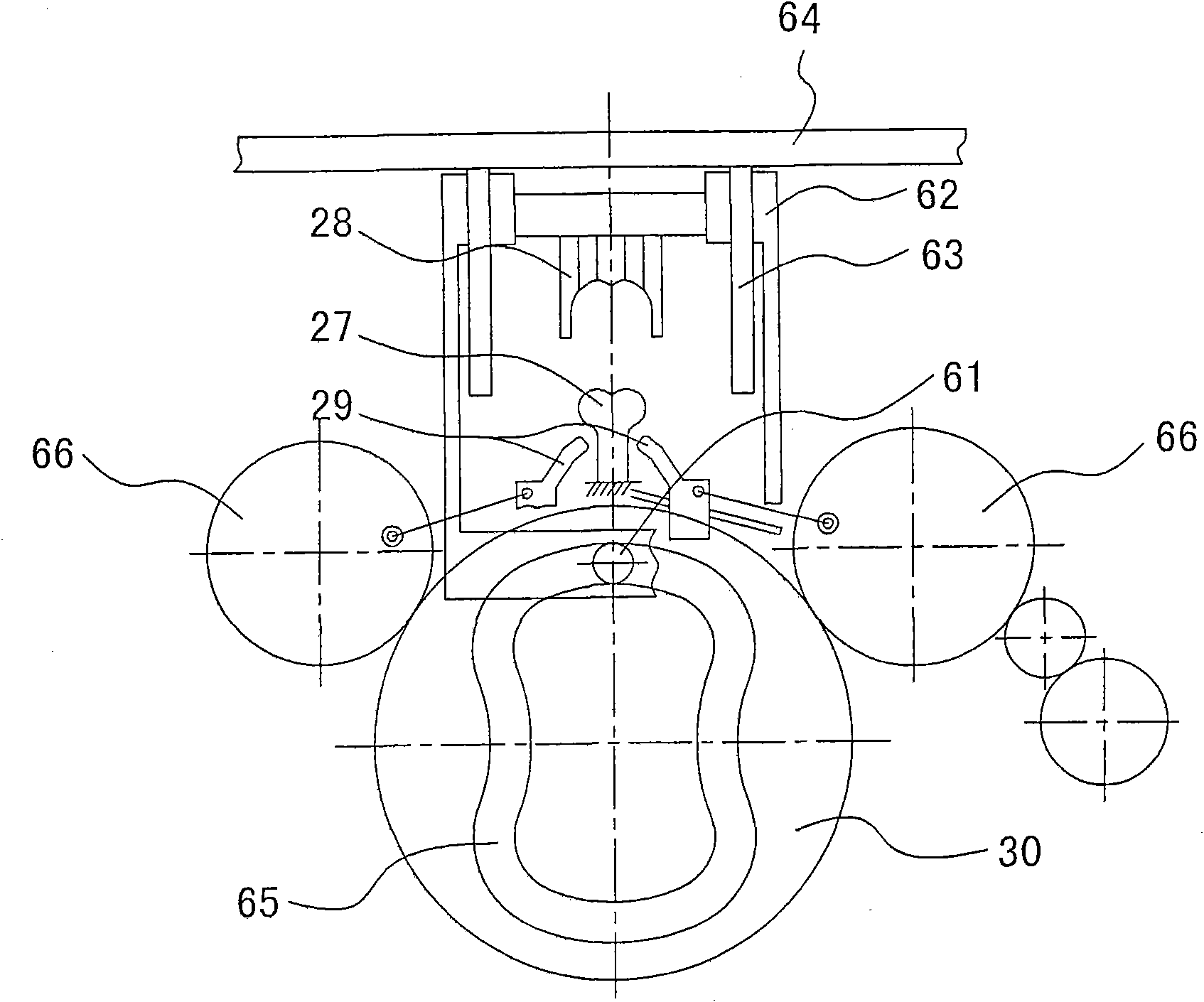

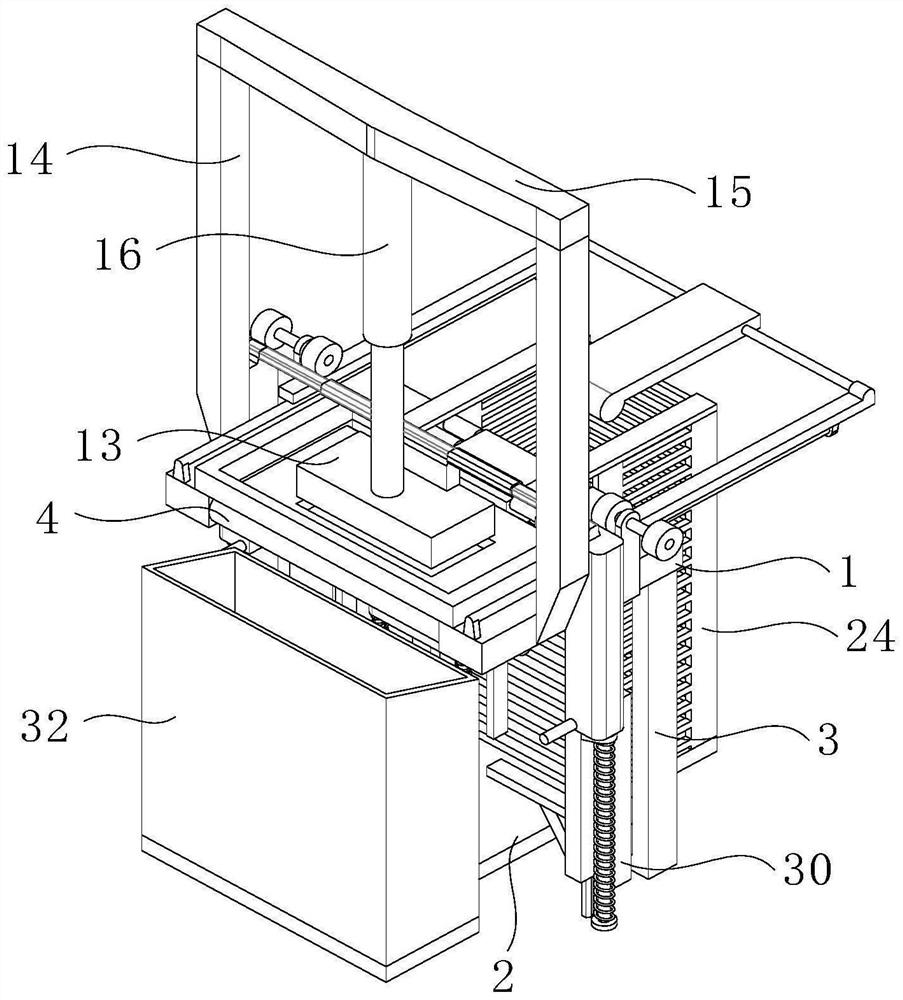

Automatic punching and bending device for filter element end covers

PendingCN110802165AStamping stabilityMetal-working feeding devicesPositioning devicesPunchingAnnular cutter

The invention discloses an automatic punching and bending device for filter element end covers. The automatic punching and bending device comprises a workbench, a portal frame, a first punching module, a lower forming part, a second punching module and a pressing part, wherein the portal frame, the first punching module, the lower forming part, the second punching module and the pressing part areconnected with the workbench; the lower forming part is fixed to the workbench, and a punching groove is formed in the middle of the lower forming part; the pressing part is positioned above the groove wall of the punching groove; the first punching module comprises a first punching head, a forming boss and a first air cylinder, the first punching head is arranged at the lower end of the first punching module, the first air cylinder is fixed to the portal frame, and an annular cutter is arranged at the end, close to a sheet material to be punched, of the punching head; and the second punchingmodule comprises a second punching head and air cylinders driving the second punching head to move downwards, and the second punching head can move to the outer side of the lower forming part and thenare clamped with the lower forming part. According to the automatic punching and bending device, multiple processes of piecing, bending, punching and the like of the filter element end covers are carried out intensively on the device, so that a processing device does not need to be replaced in the processing process of the filter element end covers, and then the processing efficiency is effectively improved.

Owner:江苏宏仕达环保科技有限公司

Cutting equipment for mechanical arm meter bottom cover production

InactiveCN112620458AStamping stabilityEasy accessMetal-working feeding devicesGrinding machinesPistonStructural engineering

The invention belongs to the technical field of cutting equipment, particularly relates to cutting equipment for mechanical arm meter bottom cover production, and provides the following scheme for solving the problems that when an existing mechanical meter bottom cover is subjected to punch forming, manual positioning is needed during general feeding, operation is troublesome, and feeding is inconvenient due to the fact that the bottom cover is embedded in a die groove during material taking. The equipment comprises an operation table, two symmetrically-arranged supporting plates are fixedly installed at the top of the operation table, the same top plate is fixedly installed at the tops of the two supporting plates, an air cylinder is fixedly installed at the bottom of the top plate, an upper die base is fixedly installed on a piston of the air cylinder, a lower die base is fixedly installed at the top of the operation table, a die groove is formed in the top of the lower die base, and a buffer groove is formed in the inner wall of the bottom of the die groove. The equipment is easy to operate and convenient to use, materials can be rapidly clamped and positioned, meanwhile, pressing and fixing can be conducted during stamping, material taking is convenient, and people can use the equipment conveniently.

Owner:深圳市金三维实业有限公司

High-precision connection point punching and breaking device

InactiveCN105127272AEasy to collectStamping stabilityMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a high-precision connection point punching and breaking device. The device comprises a base, wherein a frame is arranged at one side of the surface of the base; an air cylinder is arranged on the frame, is vertically arranged downward and is connected with a guide plate; an upper die base is arranged at the bottom of the guide plate; punches are arranged at the bottom of the upper die base; the surfaces of the punches are sleeved by an upper die sleeve; guide pillars are arranged on the upper die sleeve, penetrate through the upper die base and are arranged in the guide plate; limiting slots are formed in the guide plate; limiting bulges are arranged at the tops of the guide pillars; the limiting slots are matched with the limiting bulges for limiting; the guide pillars between the upper die base and the upper die sleeve are also sleeved by pressure springs; locating guide sleeves matched with the punches are arranged at the bottom of the upper die sleeve; locating pins are also arranged at one sides of the locating guide sleeves; and a lower die core matched with the punches for stamping is arranged on a base below the punches and is arranged on a lower die platform. The device has a simple structure, good punching and breaking effects and high punching and breaking efficiency and has the effect of effectively saving the labor cost.

Owner:SUZHOU SUOLIWANG NEW ENERGY TECH CO LTD

Environment-friendly punch oil prepared from waste rolling oil

InactiveCN107523391AImprove performanceTo achieve the purpose of recyclingLubricant compositionEcological environmentAntioxidant

The invention relates to environment-friendly punch oil prepared from waste rolling oil. The environment-friendly punch oil comprises the waste rolling oil, thickening agents, extreme-pressure anti-wear agents, oily agents and antioxidants. The environment-friendly punch oil has the advantages that excellent lubricating effects can be realized by the environment-friendly punch oil, the environment-friendly punch oil is excellent in anti-wear performance and is environment-friendly regenerative lubricating oil, the aluminum processing cost can be effectively reduced, and environmental protection pressures can be relieved; the environment-friendly punch oil is harmless for human bodies and ecological environments in use procedures.

Owner:熵遇(上海)新材料科技有限公司

Metal continuous punching die

InactiveCN111589958AStamping stabilityEasy dischargeShaping toolsMechanical energy handlingPunchingStructural engineering

The invention discloses a metal continuous punching die. A bottom plate, a die body, a punching plate and a fixing plate are included. The die body is arranged at the top end of the bottom plate. Discharging structures are arranged at the two ends of the outer wall of the die body. The fixing plate is arranged at the bottom end in the die body. Stable structures are arranged on the two sides of the top end of the bottom plate. Connecting rods are arranged at the bottom end of the top plate. Damping structures are arranged at the bottom ends of the connecting rods. The punching plate is arranged at the bottom ends of the damping structures. Through the arrangement of the stable structures, when the die needs to be punched, an external power source is conducted at the time, a servo motor isstarted and drives a rotation rod to rotate, the rotating rotation rod makes screws rotate through a belt, drive blocks can slide on the screws up and down, and accordingly the metal punching effect is achieved; and under the action of the two screws, a more stable effect can be achieved during impacts.

Owner:广州百畅信息科技有限公司

Automobile part stamping die

The invention provides an automobile part stamping die. The automobile part stamping die comprises a base, supporting frames are arranged on the two sides of the base, a mounting frame is arranged atthe tops of the supporting frames, a hydraulic cylinder for stamping is arranged on the mounting frame, a stamping head is arranged at the output end of the hydraulic cylinder, a stamping groove is formed in the middle of the base, and a through hole is formed in the bottom of the stamping groove. The area of the through hole is smaller than that of the stamping groove, a sliding groove is formedin the base, the sliding groove communicates with the side wall of the stamping groove, and the depth of the sliding groove is smaller than that of the stamping groove. A die switching device is arranged at the end, away from the stamping groove, of the sliding groove. The scheme of the automobile part stamping die is convenient for module replacement, simple to operate and high in efficiency.

Owner:重庆智者炎麒科技有限公司

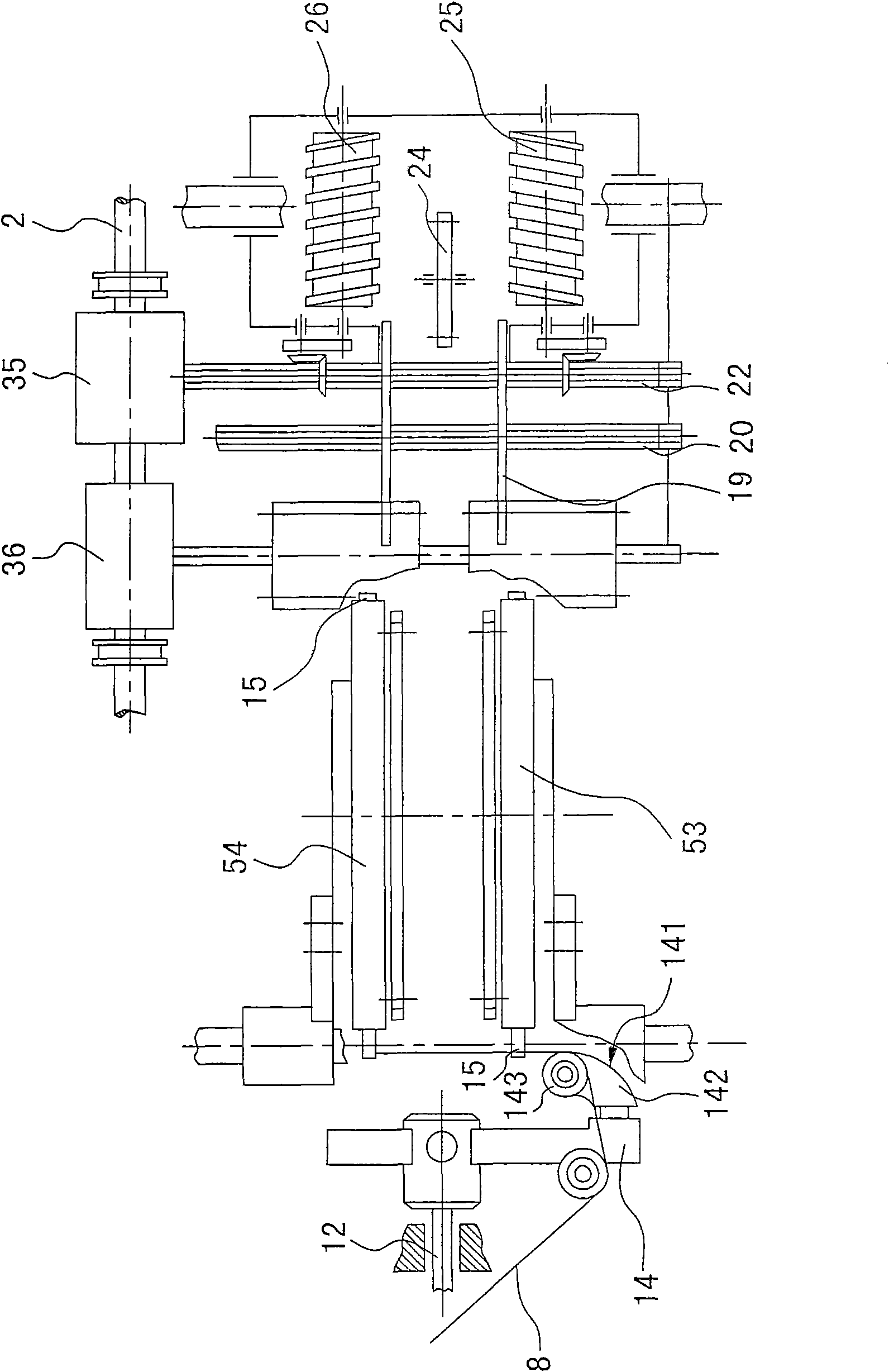

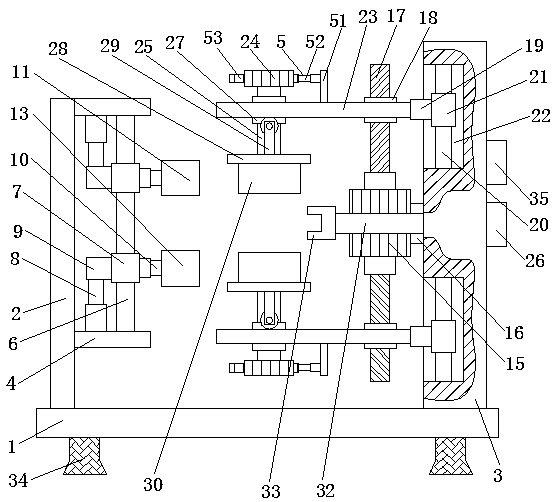

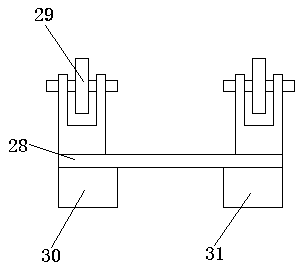

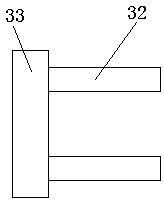

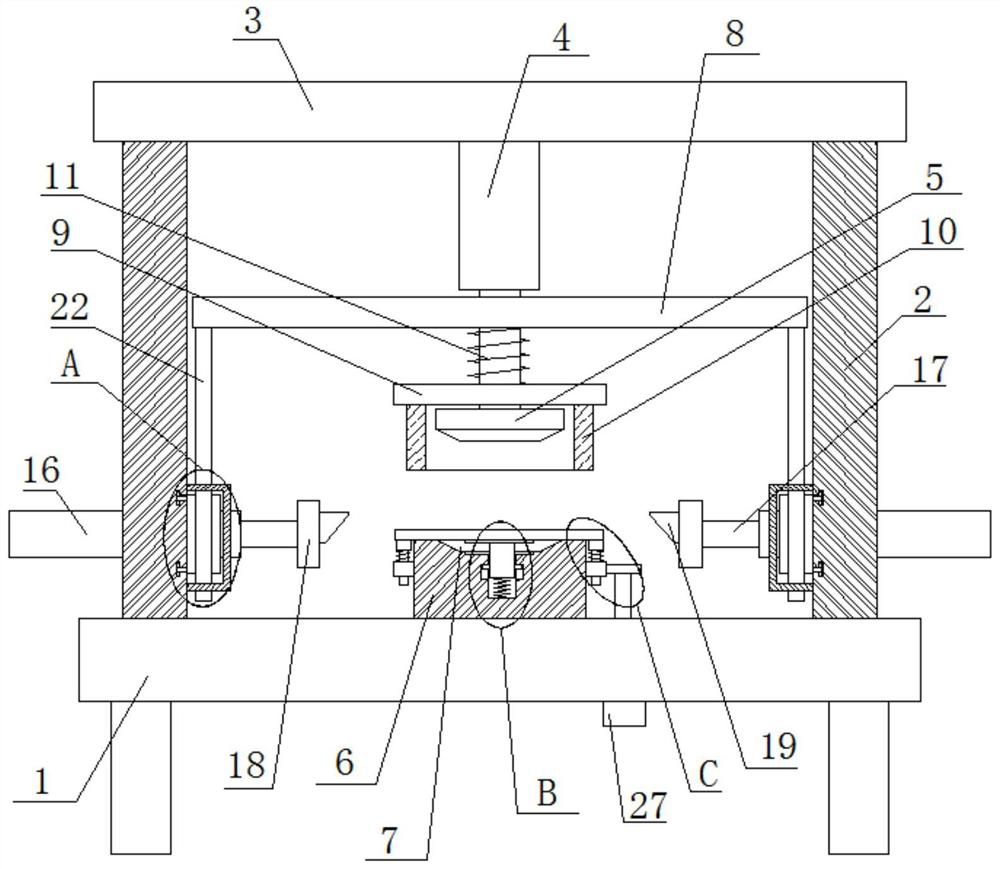

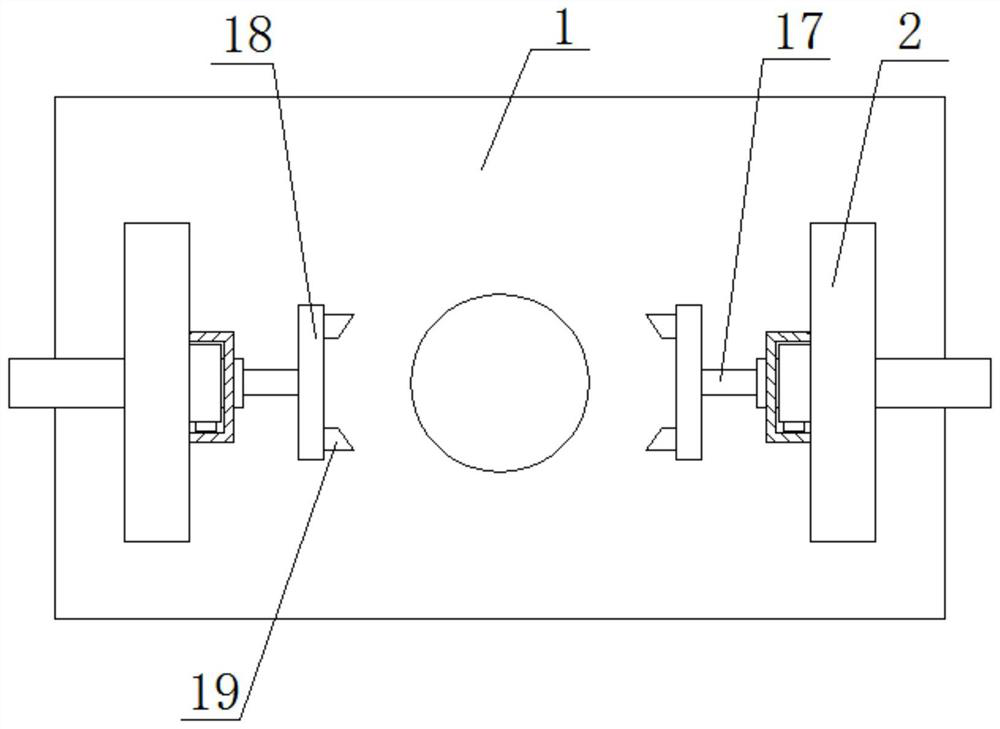

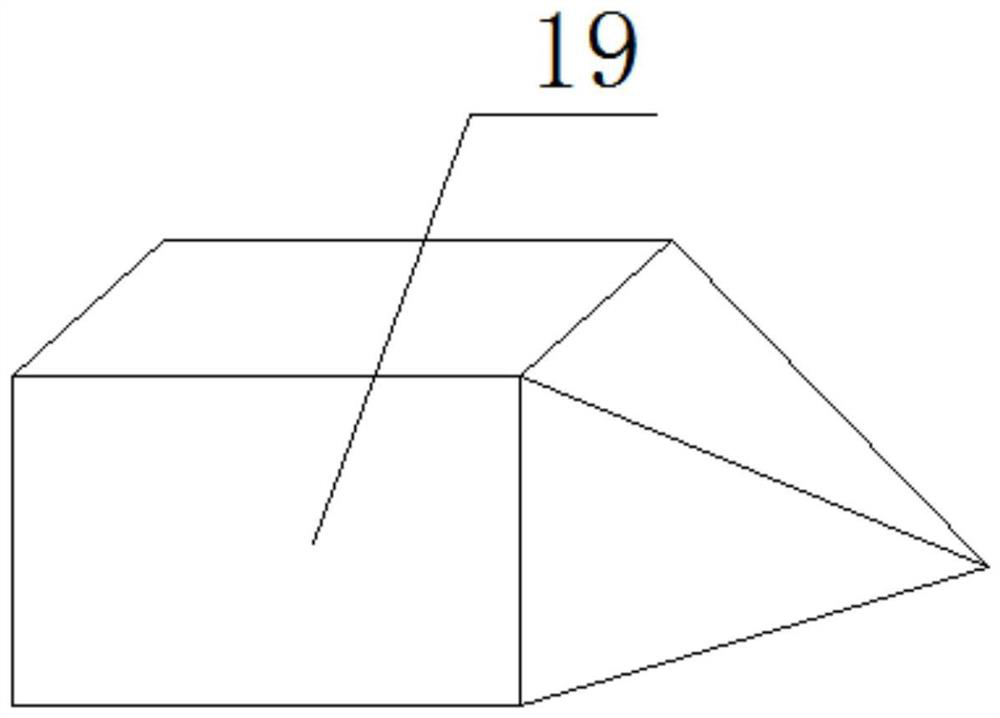

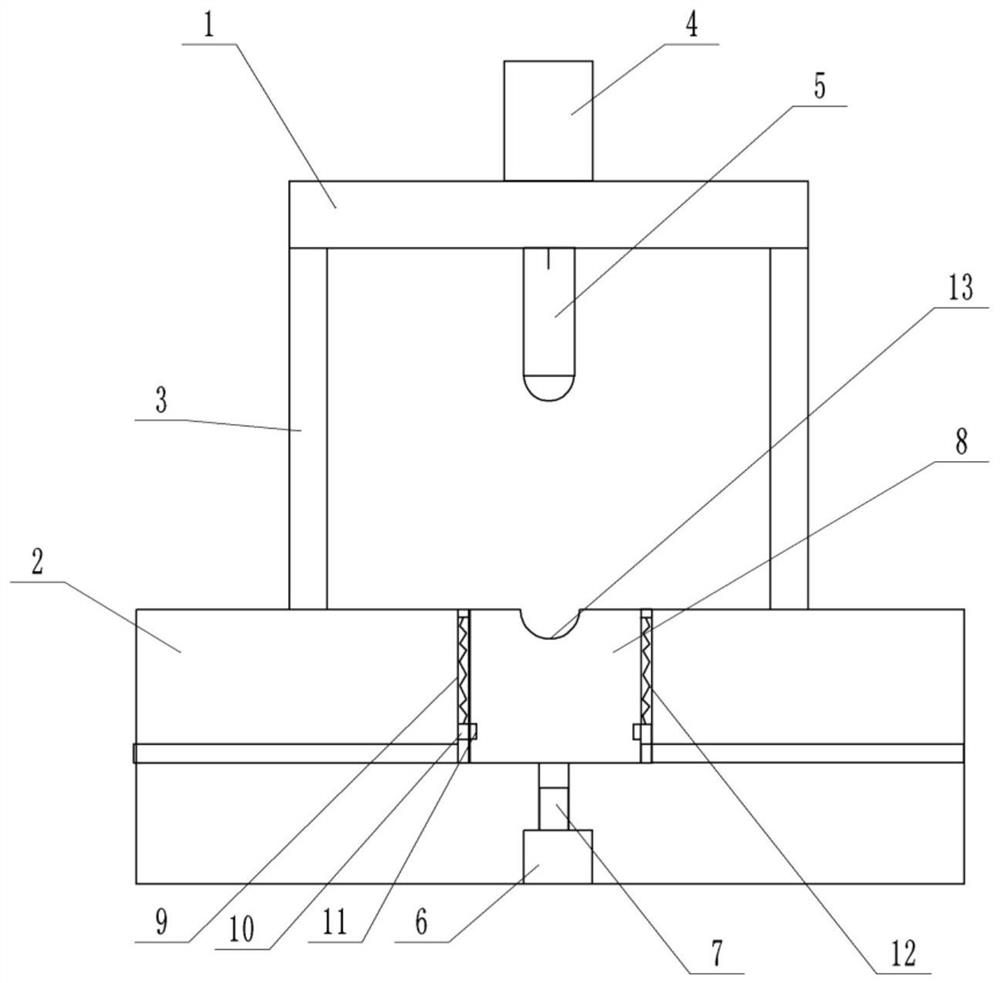

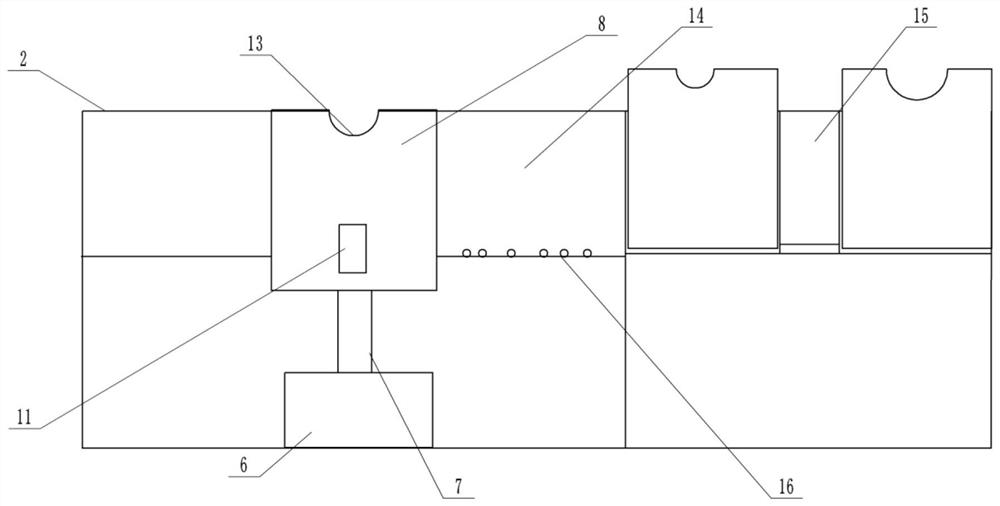

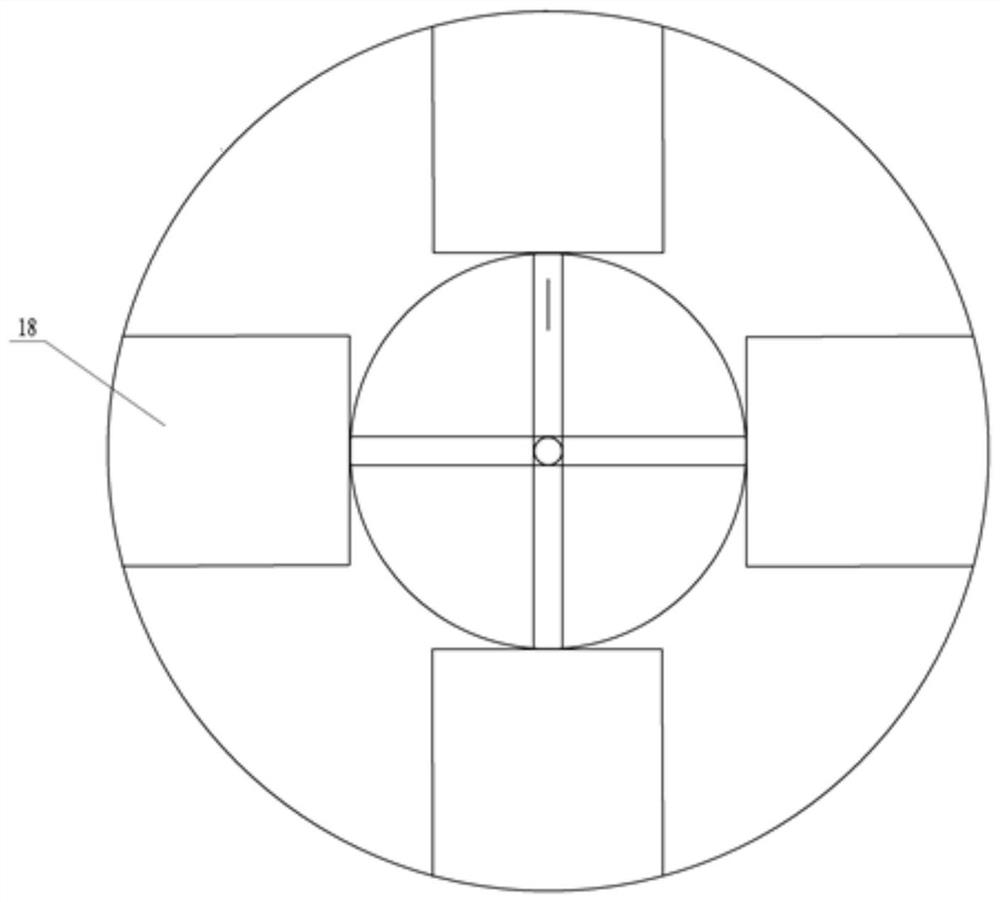

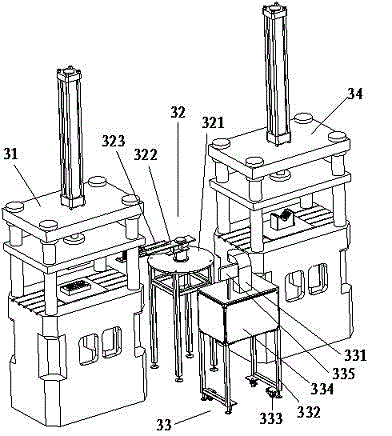

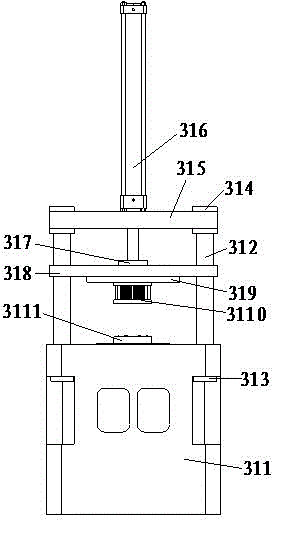

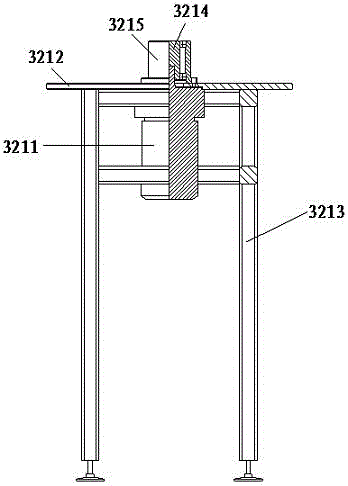

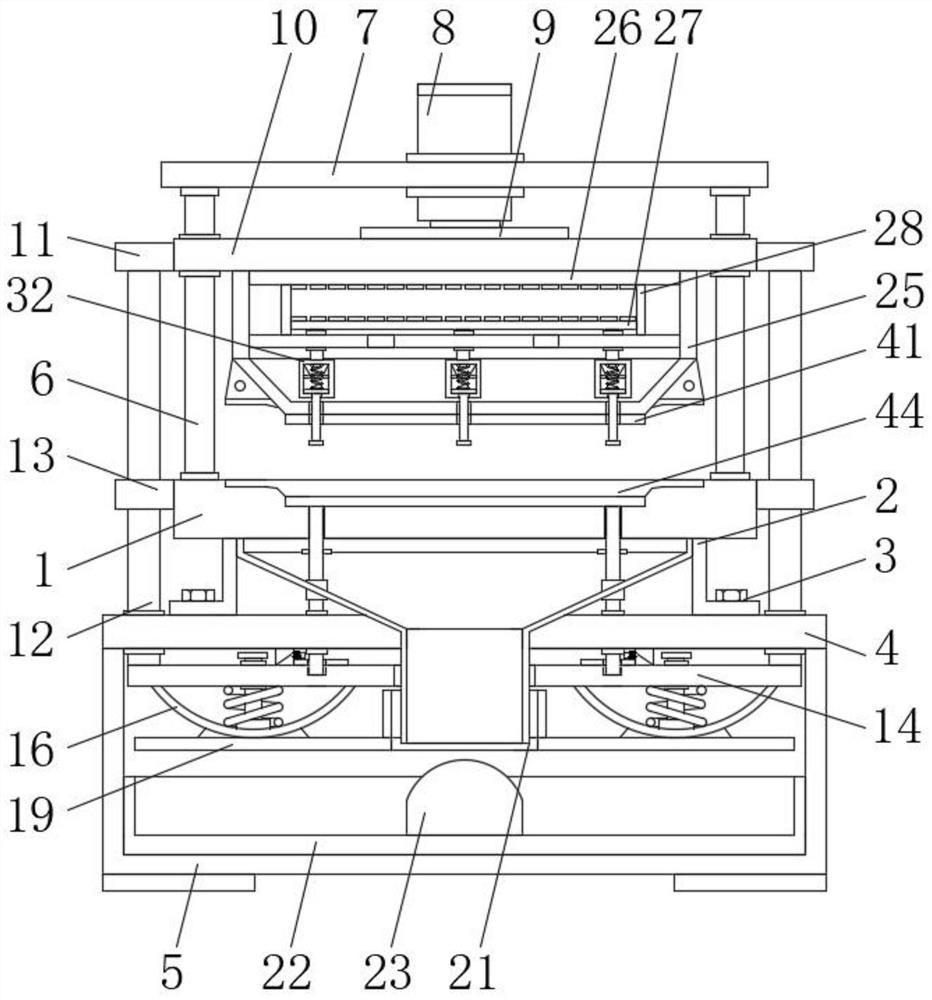

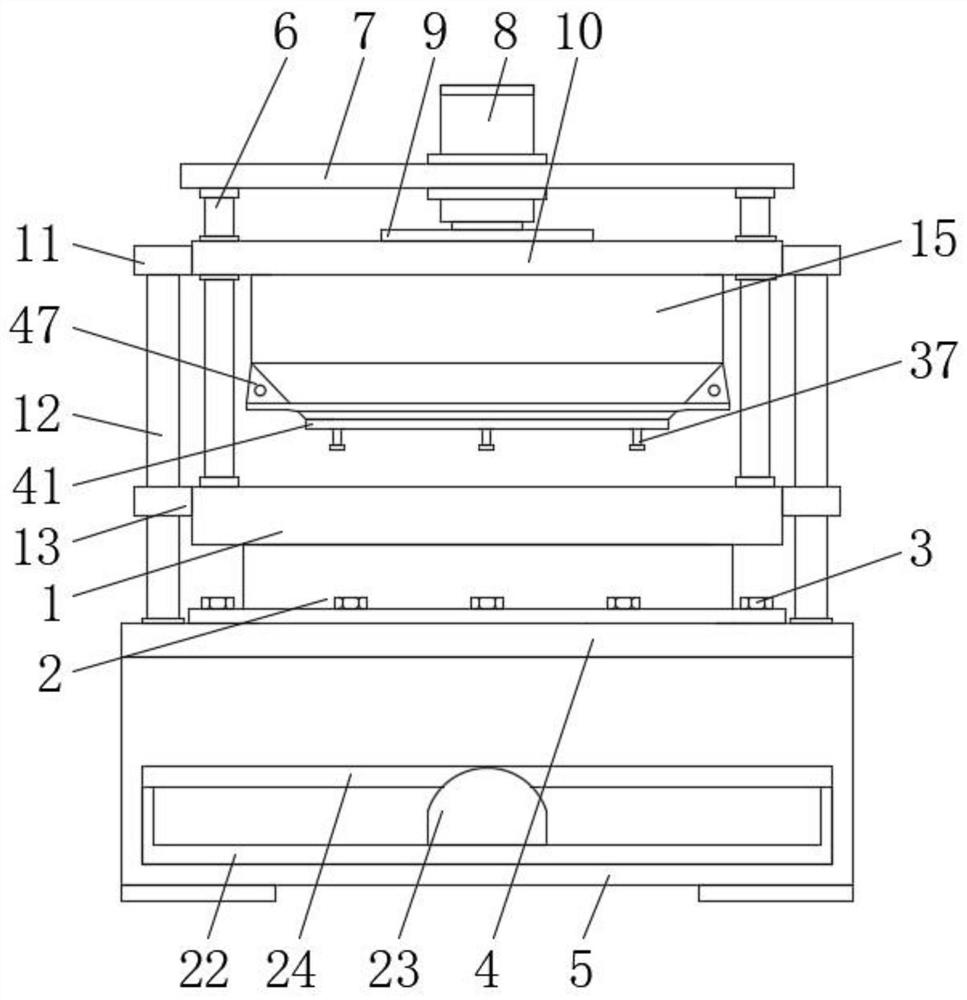

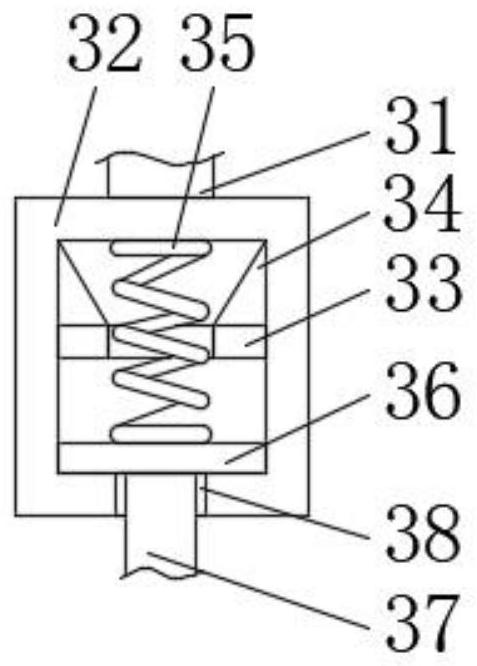

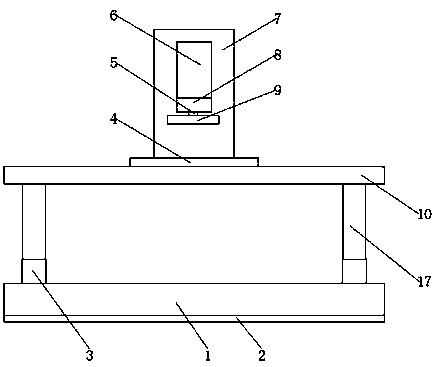

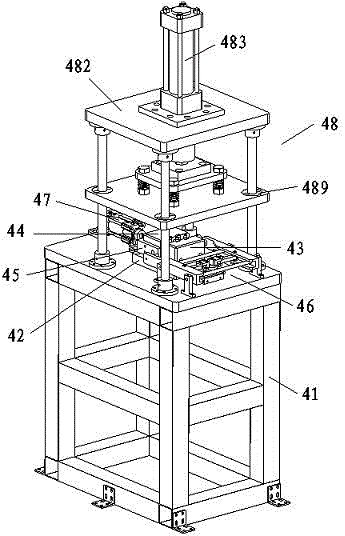

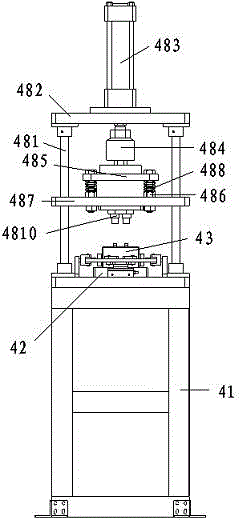

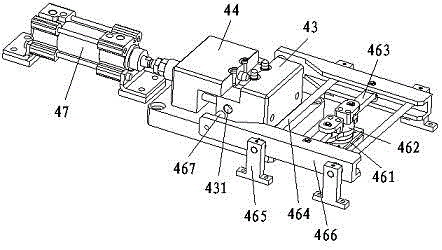

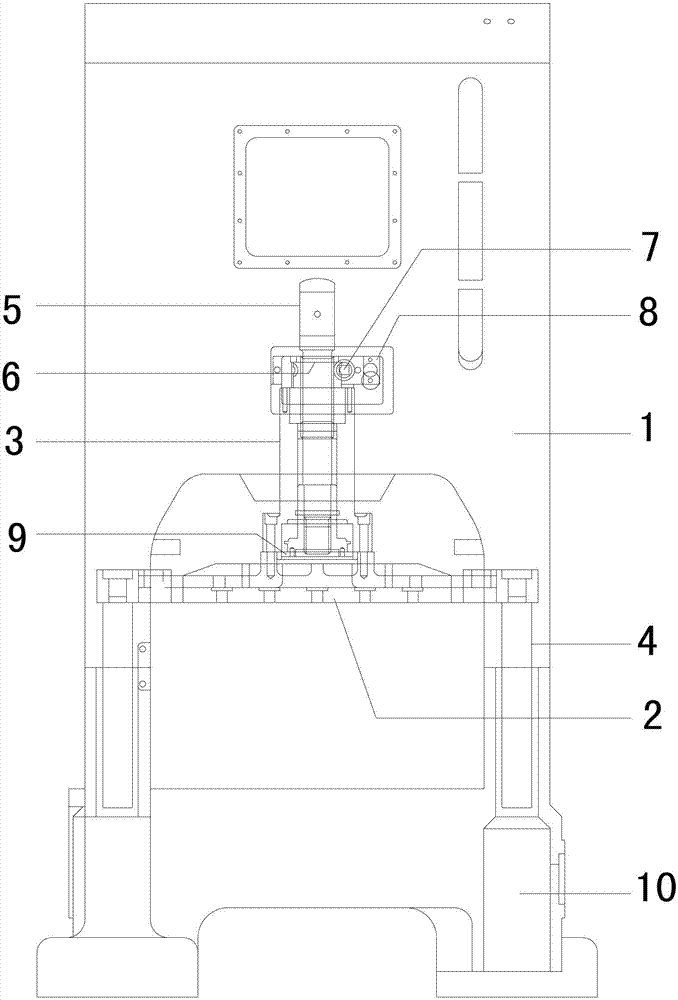

Stamping detection mechanism of stamping-welding line

The invention discloses a stamping detection mechanism of a stamping-welding line. The stamping detection mechanism comprises a punching device, a stamping switching device, a stamping detection device and a bending flanging device; the punching device, the stamping switching device and the bending flanging device are transversely mounted side by side on the floor in a factory; the stamping detection device is disposed in the front of the stamping switching device; the punching device comprises a base, a tie post, a lock ring, a lock disc, an upper ejector plate, a punching cylinder, a punching check disc, an upper pressure plate, an upper die mounting plate, an upper punching ide, a lower punching die and a punching base plate; the upper pressure plate is provided with the punching cylinder; a piston rod of the punching cylinder is connected with the punching check disc which is fixed to the upper pressure plate; the lower plane of the upper pressure plate is provided with the upper die mounting plate; the upper punching die is fixed to the lower plane of the upper die mounting plate; the punching check disc is fixed to the upper pressure plate; the lower plane of the upper pressure plate is provided with the upper die mounting plate; the upper punching die is fixed to the lower plane of the upper die mounting plate; the upper punching die corresponds to the lower punching die in position. The stamping detection mechanism has the advantages that stamping is stable, product scrap rate is low, and production efficiency is high.

Owner:重庆市荣昌区富民生产力促进中心有限公司

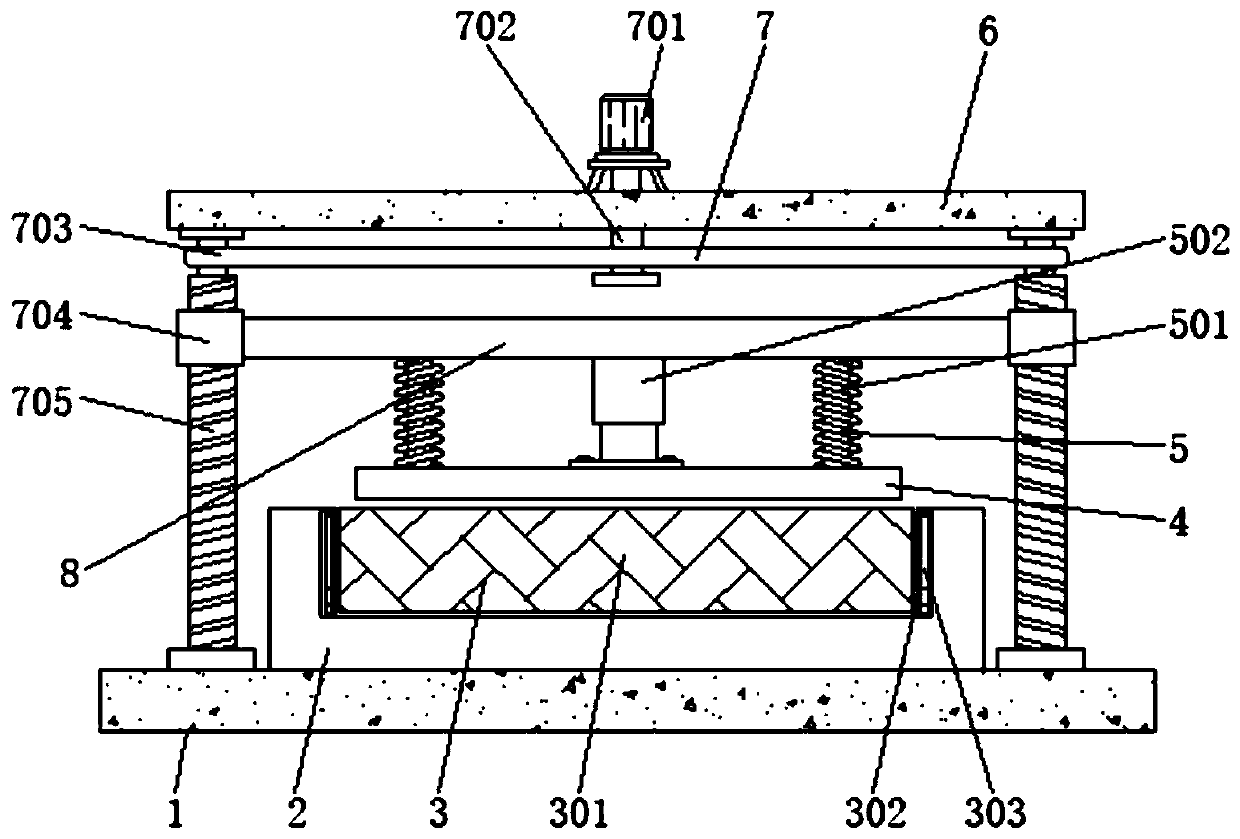

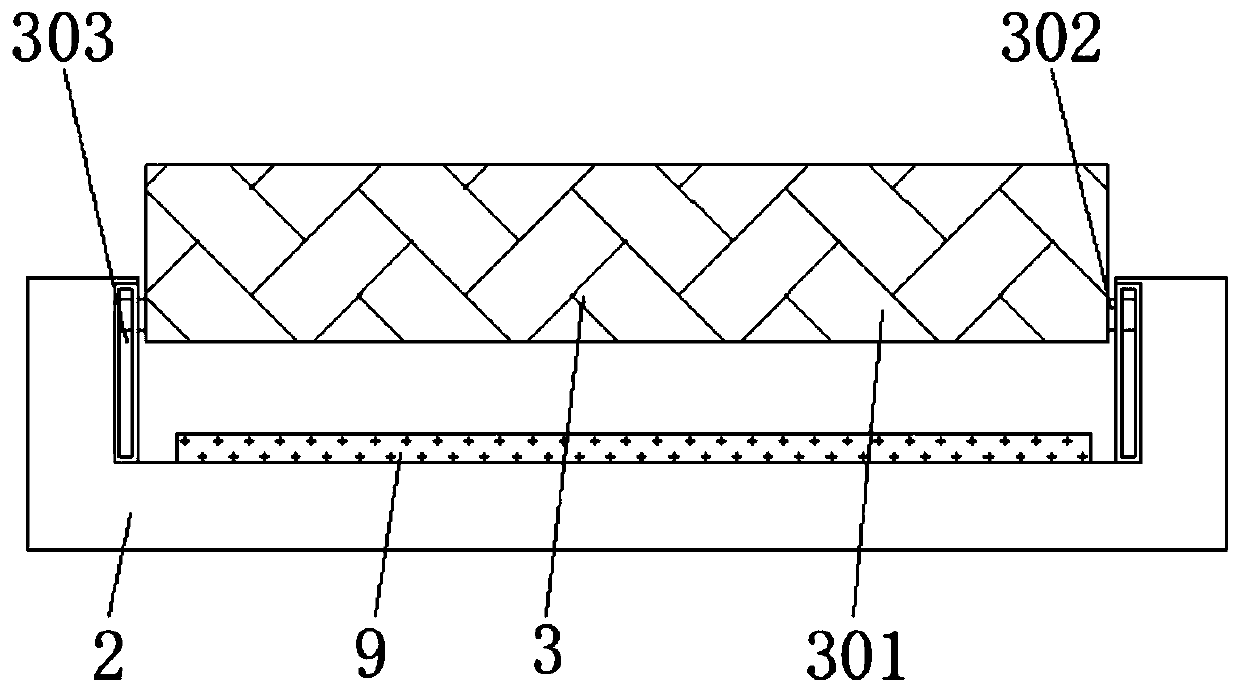

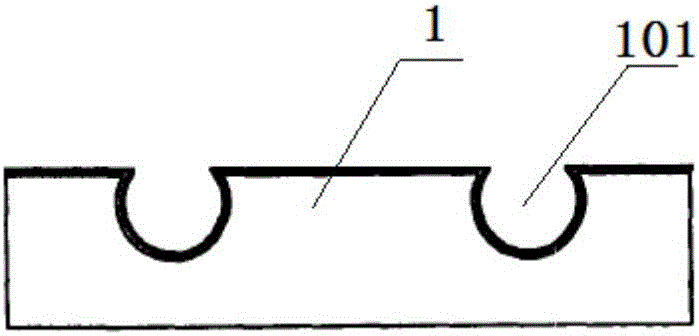

Floor heating pipeline groove forming method

ActiveCN106391874ALimited rotation trajectoryImprove buffering effectShaping toolsWrinkle skinEngineering

The invention discloses a floor heating pipeline groove forming method, and relates to the field of forming combination molds special for floor heating pipeline grooves. The floor heating pipeline groove forming method includes the following steps that (1) a mold is installed; (2) feeding is performed; (3) stamping is conducted, two forming blocks are subjected to acting force of a heat conduction layer blank and can rotate towards the middle part to be folded synchronously under the combined effect of compressed springs at the two sides of a lower mold base and a supporting spring at the bottom of a U-shaped groove, and a protruding part can be wrapped by bending the heat conduction layer blank; and (4) resilience is carried out, the protruding part can enter the gap located between the two forming blocks completely when an upper mold reaches the maximum stroke, and the heat conduction layer blank can wrap the protruding part completely; and then, the two forming blocks rotate towards the two sides to be separated synchronously, and the heat conduction layer blank can be ejected out. By means of the floor heating pipeline groove forming method, the function of precisely processing the floor heating pipeline grooves at a time in a wrinkle-free mode is achieved, and dimensional consistency of the floor heating pipeline grooves in the length direction is guaranteed.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Cooling demoulding equipment for stamping mould

PendingCN113814326APrevent thinningStamping stabilityShaping toolsStripping-off devicesPhysicsEngineering

The invention discloses cooling demoulding equipment for a stamping mould, which comprises a bottom plate; a lower mould is fixed to the outer wall of the top of the bottom plate through bolts; a cooling cavity is formed in the lower mould; communicated first pipe holes are formed in the side wall, close to the top, of the cooling cavity and the side wall of the bottom plate; cold inlet pipes are fixedly connected into the first pipe holes; the side wall, close to the bottom, of the cooling cavity and the side wall of the bottom plate are provided with communicated second pipe holes; cold outlet pipes are fixedly connected into the second pipe holes; the top of the bottom plate is provided with an upper mould mechanism; the upper mould mechanism is located over the lower mould; the outer wall of the top of the bottom plate is provided with four buffering mechanisms; and the four buffering mechanisms are located at the four corners close to the lower mould correspondingly. According to the cooling demoulding equipment of the stamping mould in the invention, the equipment has a cooling function for assisting unloading and an unloading function; therefore, after stamping, a stamped workpiece can be rapidly blanked; manual stripping is avoided; and the use convenience of the equipment is improved.

Owner:蒋敏龙

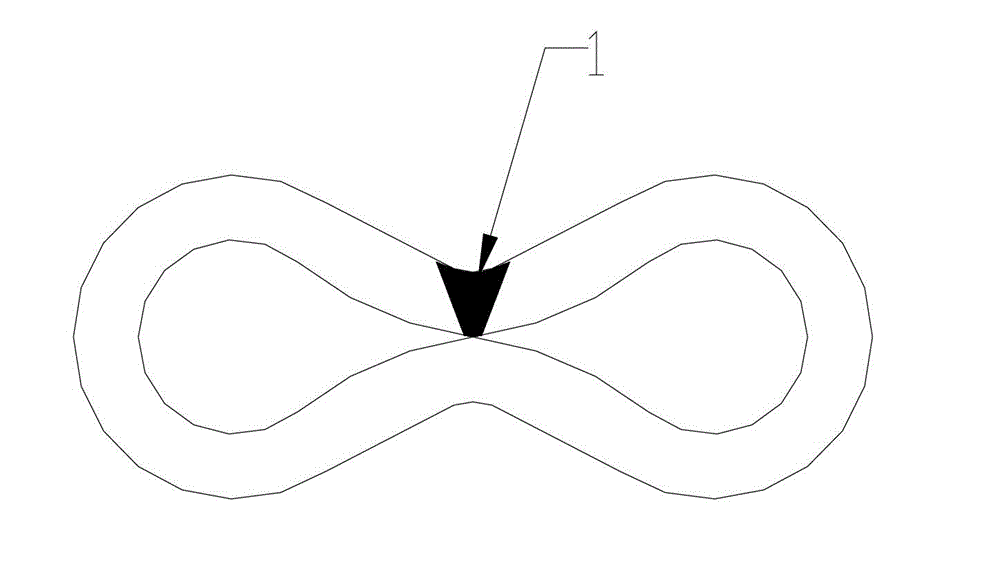

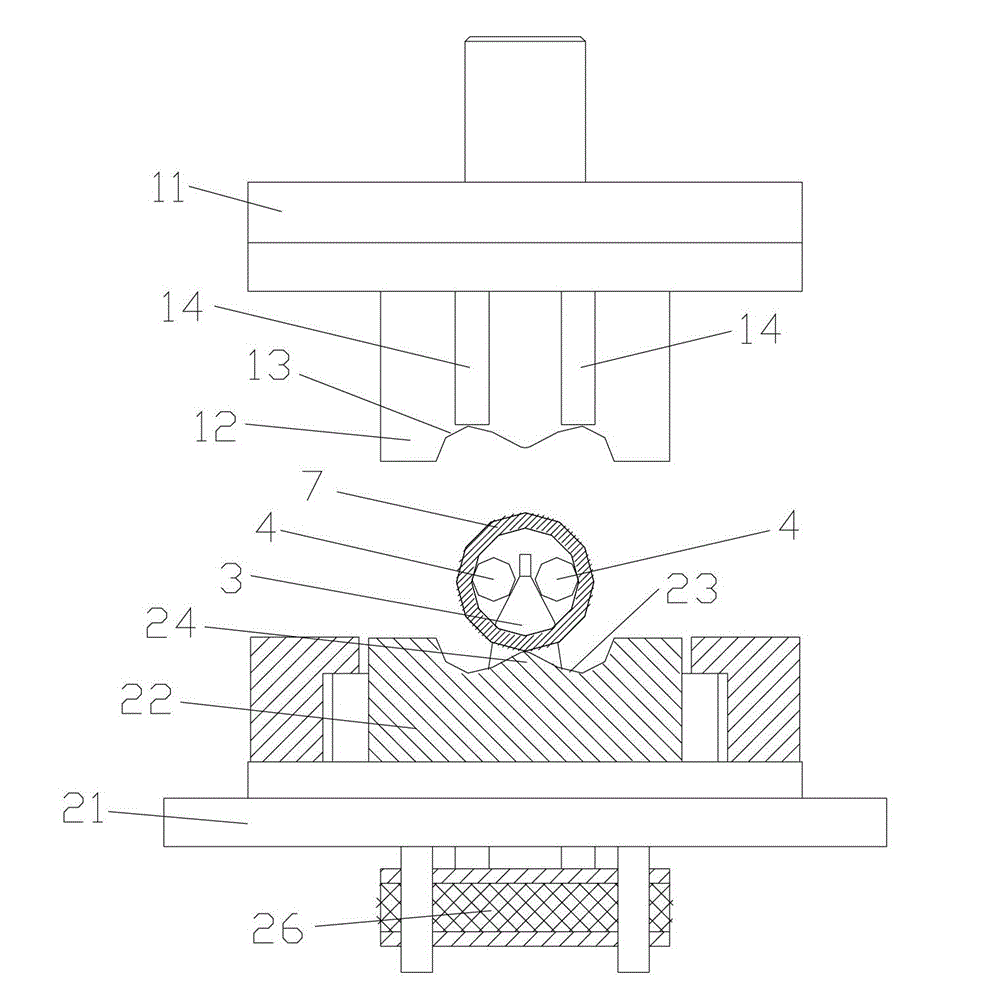

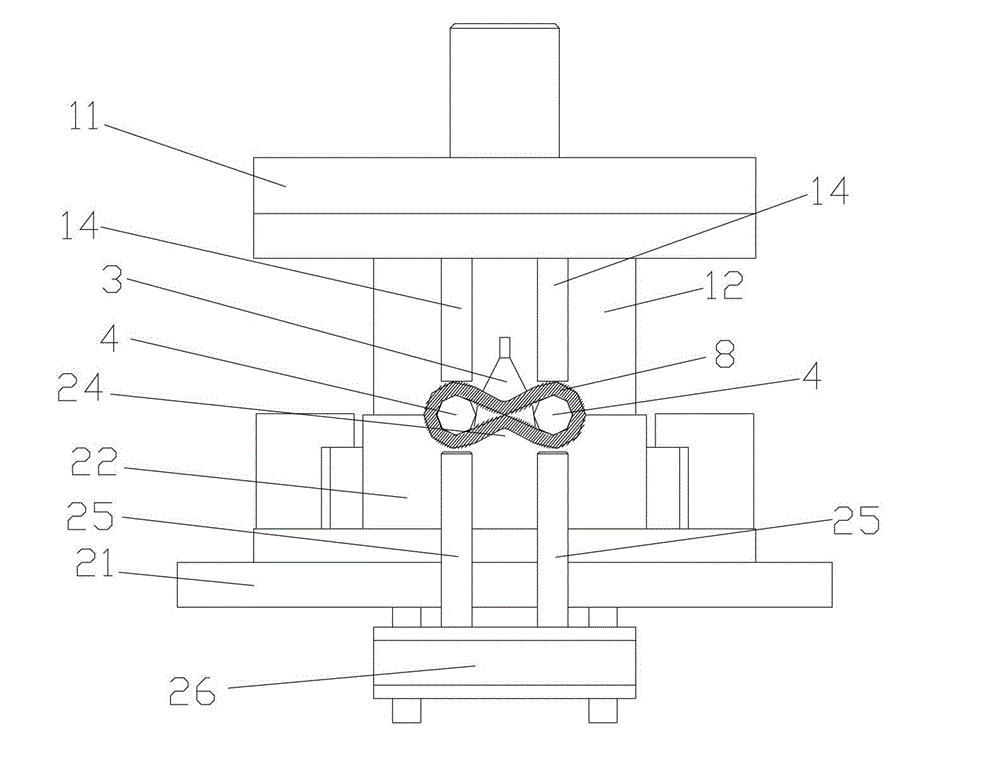

Forming die for machining method for high-strength transverse 8-shaped parts

ActiveCN102974701AExtended service lifeGuaranteed long lifespan issuesShaping toolsStripping-off devicesHigh intensityEngineering

The invention discloses a forming die for a machining method for high-strength transverse 8-shaped parts. The forming die comprises an upper template, an upper die fixed on the upper template, a lower template and a lower die fixed on the lower template, wherein the upper die is provided with an upper die cavity; the lower die is provided with a lower die cavity; the upper die cavity is matched with the lower die cavity to form a transverse 8-shaped inner cavity; a guide plate and a pair of locating rods moving relative to the guide plate are arranged in two side cavities on the lower die adapted with the middle position of the lower die cavity respectively; and the locating rods are clamped between the guide plate and the inner wall of a metal tube. The forming die solves the problems that the machining accuracy of the current die cannot be ensured easily and the machined transverse 8-shaped parts have a short service life, and meets the requirement of a customer better.

Owner:黄山鼎奇链传动股份有限公司

Damage-prevention ejection part for stamping die

The invention discloses a damage-prevention ejection part for a stamping die. The ejection part comprises a lower die, wherein a die body groove is formed in the upper surface of the lower die, a supporting body is arranged in the die body groove, the outer side of the upper surface of the supporting body is arranged in a displacement groove, the displacement groove is formed in the inner wall ofthe die body groove, a supporting block is arranged at the lower end of the supporting body, and the lower surface of the supporting body is connected to the upper ends of supporting and jacking structures. According to the damage-prevention ejection part for the stamping die, a stamped formed part can be easily ejected out of the die conveniently through the structure similar to a scissor jack, compared with the way adopting the lever principle for saving labor in the prior art, more labor is saved, so that the stamped formed part can be easily taken out of the die by a worker conveniently, so that the stamped part can be stably jacked up through a plurality of the structure similar to the scissor jack, the ejected part can be stably used, and the situation that the ejected part is damaged in the using process is avoided.

Owner:安徽容纳新能源科技有限公司

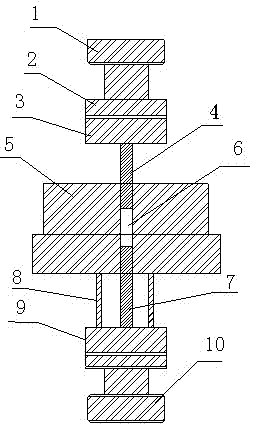

Punching die for producing hard alloy saw-tooth tool bit

The invention relates to a punching die for producing a hard alloy saw-tooth tool bit, comprising a die body, an upper punch seat, a lower punch seat, an upper punch and a lower punch, wherein the upper punch and the lower punch are respectively installed on the upper punch seat and the lower punch seat, an upper fixing sheet and a lower fixing sheet are respectively arranged between the upper punch seat and the upper punch as well as between the lower punch seat and the lower punch; the upper punch is sleeved on the upper fixing sheet; the lower punch is sleeved on the lower fixing sheet; annular pad forks are also sleeved at two sides of the lower punch; the die body is placed on the upper end faces of the annular pad forks; a die cavity is formed by the upper end face of the lower punch and the die body; and the upper punch is correspondingly arranged above the die cavity. Because the annular pad forks, the upper fixing sheet and the lower fixing sheet are arranged, the punching die for producing the hard alloy saw-tooth tool bit has simple structure and is convenient for mounting and dismounting; when the punching die is produced, the damage to the lower punch, caused by stress concentrated on the lower punch, is avoided by means of the annular pad forks through stamping the upper punch and the lower punch in one step, and the stamping is stable, therefore, the production efficiency is greatly improved, the maintenance cost is saved, and the product quality is enhanced.

Owner:昆山长鹰硬质材料科技股份有限公司

Die plate groove punching machine for chip machining

InactiveCN113909395AStamping stabilityMetal-working feeding devicesStripping-off devicesEngineeringMachining

The invention provides a die plate groove punching machine for chip machining, and relates to the field of chip machining. The die plate groove punching machine for chip machining comprises a workbench and a supporting table, the workbench is located above the supporting table, the workbench and the supporting table are fixedly connected through two supporting frames, a through hole is formed in the upper surface of the workbench, a shaping block is arranged in the through hole, a supporting shaft is elastically hinged to the bottom face of the workbench, the bottom face of the shaping block is fixedly connected to the outer surface of the supporting shaft in a sleeving manner, a pushing frame is arranged at the position, behind the supporting shaft, below the shaping block , and a fixing frame is arranged below the pushing frame. According to the die plate groove punching machine for chip processing, by arranging a vertical plate, a lifting rod, an angle plate, a feeler lever and a material pushing rod, the pushing frame pushes the shaping block upwards, so that the shaping block rotates to be inclined to enable materials on the upper portion to fall off, when the material pushing rod moves leftwards, the material at the uppermost portion in a discharging box is pushed to move forwards to the shaping block, and therefore, the materials can be continuously fed, punched and discharged.

Owner:黄高升

punching machine

Owner:宁波信基机械科技有限公司

Stamping die for automobile chassis

InactiveCN113020427AEven by forceNo cloggingShaping toolsMetal-working feeding devicesStamping processAutomotive engineering

The invention discloses a stamping die for an automobile chassis, and belongs to the technical field of stamping dies. The stamping die for the automobile chassis comprises a clamping fixed die, the lower surface of the clamping fixed die is fixedly connected with the upper surface of a mounting connecting piece, and the lower surface of the inner wall of the mounting connecting piece is fixedly connected with the upper surface of a supporting connecting plate through a plurality of mounting screws. According to the stamping die for the automobile chassis, reinforcing rings and mounting rods are arranged, the reinforcing rings are matched with the multiple mounting rods in the stamping process so that uniform stress can be kept under the action of a second sealing plate, uniform stress of all stamping positions of raw materials during stamping is kept, stamping is made stable, deformation is not prone to occurring, and the raw materials are kept to be pressed and positioned downwards. And along with the continuous pressing process until stamping is completed, the mounting rods can rapidly strip off the raw materials in the rapid resetting process after stamping and hole forming are completed, waste materials are discharged after being rapidly separated, the situation of stamping waste material blockage is avoided, stamping and discharging integration is completed, and the operation stability and efficiency are improved.

Owner:吴国洪

Hardware machining punch press capable of being maintained conveniently

InactiveCN108817213APromote repairEasy to disassembleShaping toolsPressesPunch pressArchitectural engineering

The invention provides a hardware machining punch press capable of being maintained conveniently, and relates to the field of hardware machining equipment. The hardware machining punch press comprisesa base, the bottom of the base is fixedly connected with an anti-slip under layer, and anti-slip stripes are formed in the bottom of the anti-slip under layer. Damping devices are fixedly connected to the four corners of the top of the base separately, and support columns are fixedly connected to the tops of the damping devices. A top plate is fixedly connected to the tops of the support columns,and a manipulation platform is fixedly connected to middle of the top of the top plate. According to the hardware machining punch press capable of being maintained conveniently, mounting plates can be subjected to certain limiting action through limiting springs and limiting rings on the outer sides of limiting tubes, so that the mounting plates are not over-adjusted, the situation that clampingcolumns are damaged caused by the excessive adjustment of the mounting plates is effectively prevented, and the service life of an installation device is effectively prolonged. Through the damping devices at the top of the base, the huge vibration generated during the operation of the punch press can be buffered and absorbed, and the noise generated by the punch press can be obviously lowered.

Owner:扬州市普锐泰新材料有限公司

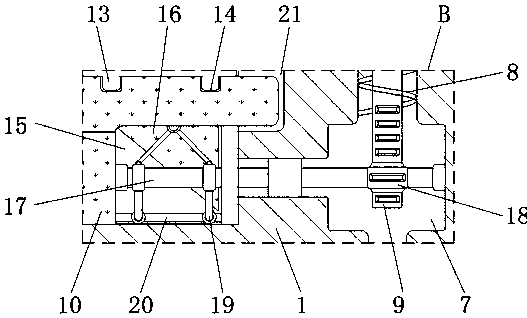

Stamping mechanism for automobile door lock catch production line

The invention discloses a stamping mechanism for an automobile door lock catch production line. The stamping mechanism for the automobile door lock catch production line comprises a stamping machine base, a base plate, a stamping and fixing die, a stamping and guiding die, a guiding and limiting plate, a clamping and locating assembly, a stamping push-pull air cylinder and a stamping assembly. The base plate is mounted on an upper flat plate on the stamping machine base. The stamping and fixing die and the stamping and guiding die are mounted on the base plate. The lower portions of the opposite inner side faces of the stamping and fixing die and the stamping and guiding die are connected through a pin bolt in a located manner. Limiting holes are formed in the two ends of the stamping and fixing die. The clamping and locating assembly is arranged at the front end of the stamping and fixing die. The stamping push-pull air cylinder is mounted on the position, at the rear end of the stamping and guiding die, of the upper flat plate of the stamping machine base. A piston rod of the stamping push-pull air cylinder is fixedly connected with the stamping and guiding die. The stamping assembly is arranged above the stamping and fixing die and the stamping and guiding die. By means of the manner, the stamping mechanism is compact in structure, stable in stamping, low in product rejection rate and high in production efficiency.

Owner:蚌埠安知知识产权运营有限公司

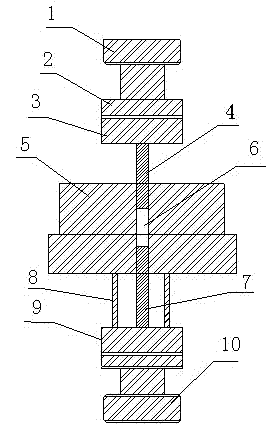

Planar-type punching machine with five-guide-rod structure

The invention provides a planar-type punching machine with a five-guide-rod structure. The five-guide-rod structure is composed of a lathe bed with a sliding block. A steel pipe is arranged above the sliding block. An adjusting screw and a transmission device are installed above the steel pipe. Guide posts are arranged below the sliding block in an abutted mode. The guide posts are respectively support four corners of the sliding block in an abutted mode. The steel pipe, the guide posts and the sliding block are of integrated structures. The guide posts and the steel pipe are arranged at the top and the bottom of the sliding block to form a five-guide-rod structure. When the planar-type punching machine works, a stress punching point is located in the middle of the sliding block, guidance quality with a same force around the sliding block is obtained, and therefore the stress point of the sliding block is enabled to be stable, and the stress of stamping products is enabled to be uniform and stable. The problem that a stress point of the exiting annular guide post on a steel pipe is not uniform and stable is solved. Progressive contributions on the stamping industry are made.

Owner:广东虹瑞智能设备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com