Punching machine

A stamping machine and stamping mechanism technology, applied in the field of stamping of rigid workpieces, can solve problems such as troublesome operation, low stamping efficiency, and difficult operation, and achieve the effect of convenient operation and improved stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

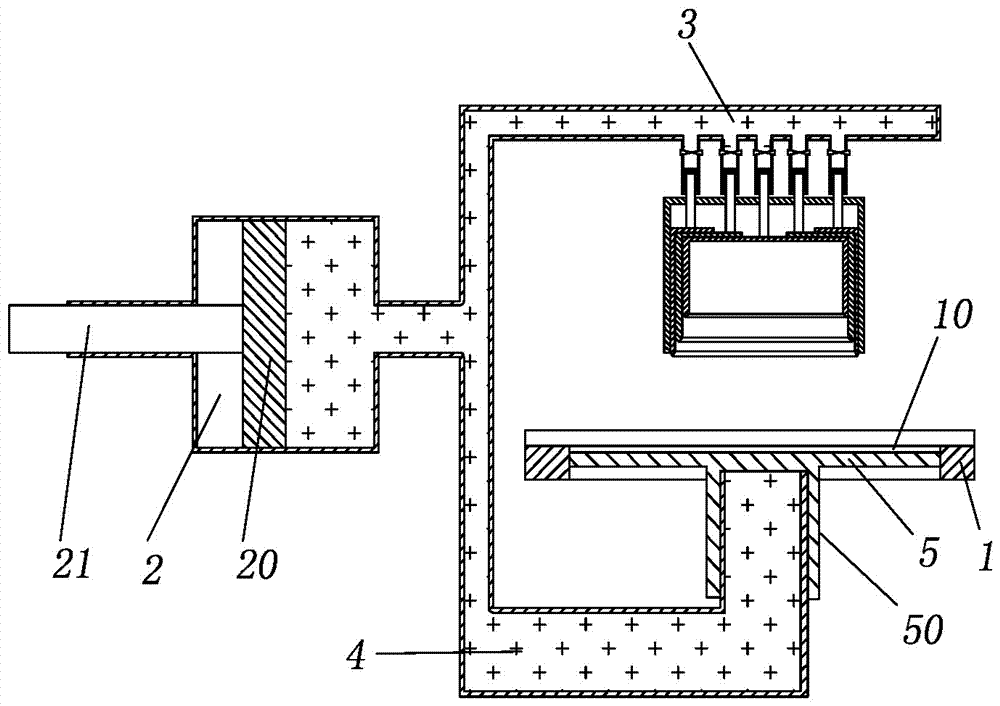

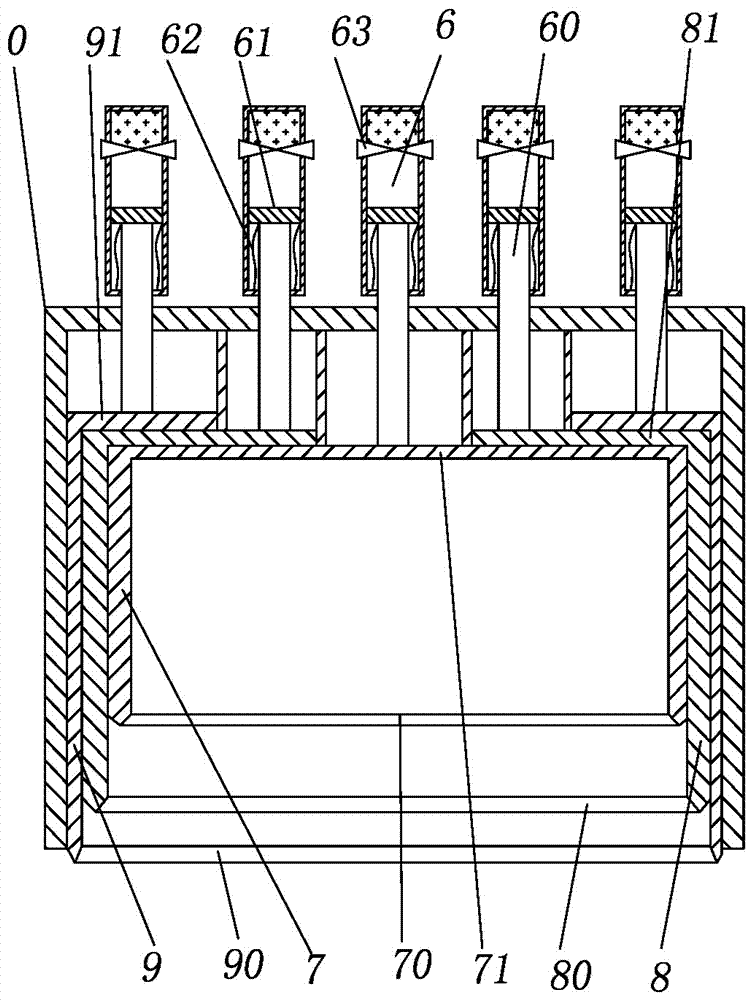

[0021] The reference signs in the drawings of the description include: support plate 1, punching hole 10, oil storage cylinder 2, transverse piston 20, piston rod 21, first branch pipe 3, second branch pipe 4, ejector plate 5, buffer barrel 50, branch Oil pipe 6, connecting rod 60, vertical piston 61, compression spring 62, valve 63, first punching head 7, first punching blade 70, first top plate 71, second punching head 8, second punching blade 80, second The top plate 81 , the third stamping head 9 , the third stamping edge 90 , the third top plate 91 , and the sliding chamber 0 .

[0022] The embodiment is basically as figure 1 As shown: a stamping machine, including a support plate 1, a punching hole 10 is arranged in the support plate 1, and an ejection mechanism, a stamping mechanism, and an oil storage cylinder 2 for storing hydraulic oil; the oil storage cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com