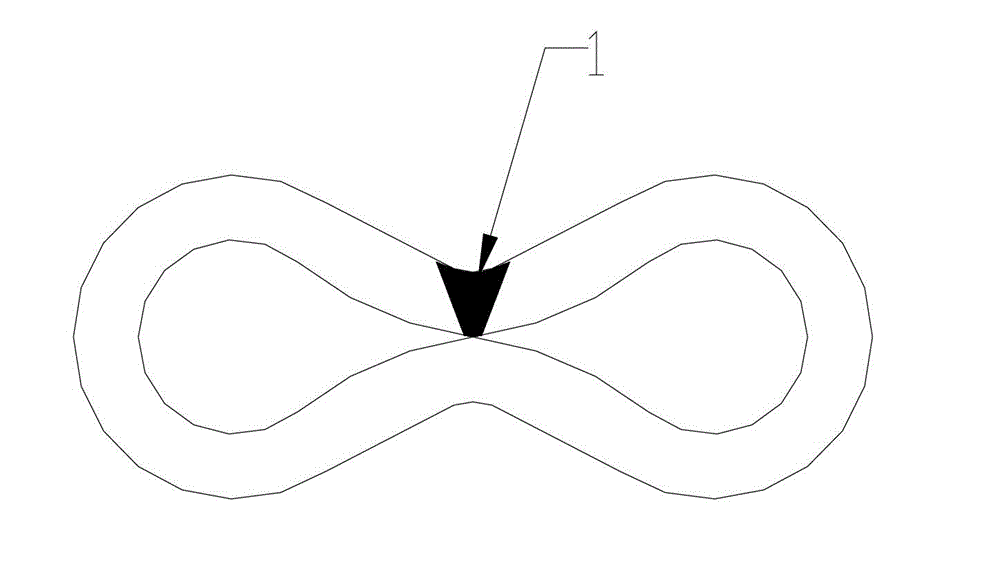

Forming die for machining method for high-strength transverse 8-shaped parts

A processing method and high-strength technology, applied in the field of metal stamping processing, can solve the problems such as difficulty in guaranteeing the precision and strength of mold processing, and the short service life of "∞"-shaped parts, so as to achieve the advantages of convenient operation for employees, stable stamping process, and improved precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

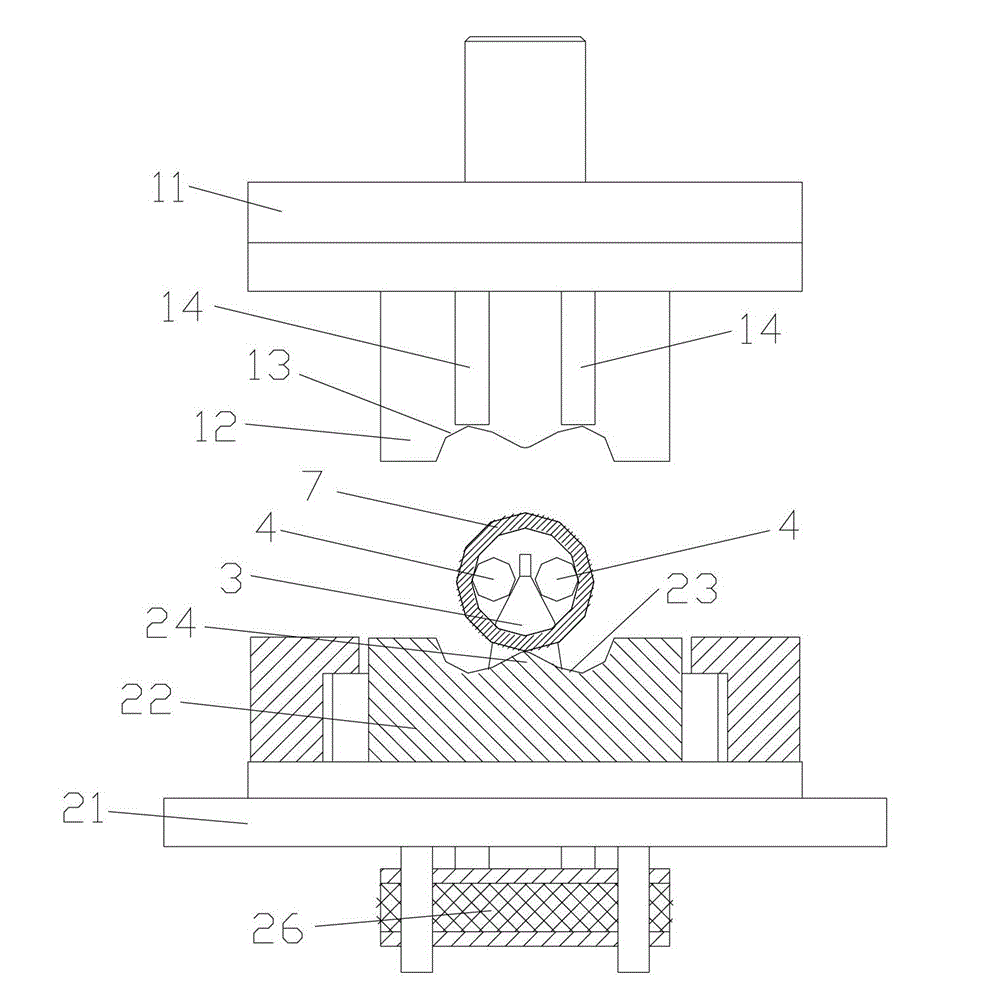

[0017] Example 1, please refer to Figures 1 to 3 , the molding die that is used for high-strength " ∞ " shape part processing method, comprises upper template 11, the upper mold 12 that is fixed on the upper template 11, lower template 21 and the lower mold 22 that are fixed on the lower template 21, described upper mold 12 is provided with an upper mold cavity 13, and the lower mold 22 is provided with a lower mold cavity 23. The upper mold cavity 13 and the lower mold cavity 23 cooperate to form a "∞"-shaped inner cavity; the lower mold cavity 22 is adapted to the lower mold cavity 23 The cavities on both sides of the middle position are respectively provided with a guide plate 3 and a pair of positioning rods 4 movable relative to the guide plate 3. The positioning rods 4 are stuck between the guide plate 3 and the inner wall of the metal pipe 7; , the positioning rod 4 can roll down along the edge of the guide plate 3, and finally fall into the "∞"-shaped inner cavity.

...

Embodiment 2

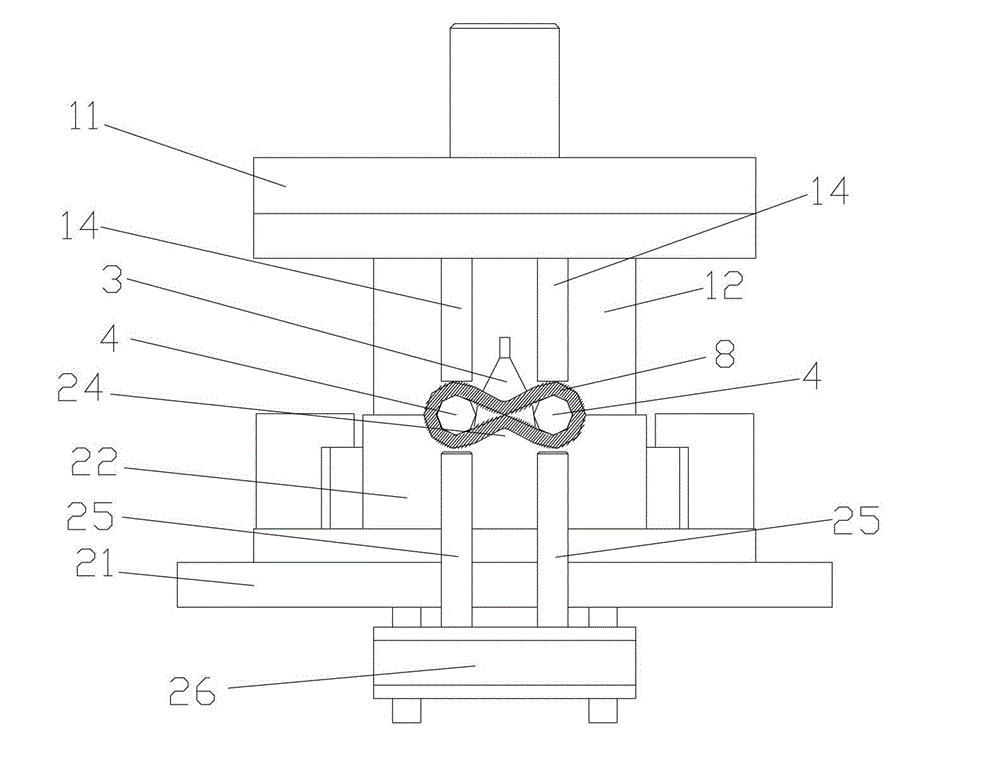

[0024] Please also refer to Figures 4 to 6 As shown, a support column 5 is also provided on the outside of the guide plate 3, and a compression spring 6 for controlling the stroke of the support column 5 is provided between the support column 5 and the lower template 21. The positioning rod 4 is placed on the support column 5, and the rest are the same as in embodiment 1. .

[0025] Place the heat-treated metal tube 7 on the lower mold 22 of the molding die, clamp the positioning rod 4 between the guide plate 3 and the inner wall of the metal tube 7, and place the positioning rod 4 on the support column 5, start the button, and the upper mold 12 goes down, when the upper die 12 presses the metal tube 7, the support column 5 goes down under the action of the compression spring 6, and the metal tube 7 is deformed at the same time, the positioning rod 4 rolls down along the edge of the guide plate 3, and finally falls into the "∞ "In the inner cavity of the font, the mold is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com