Patents

Literature

31results about How to "Guaranteed aperture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ce-Zr-Al-based composite oxide rare earth oxygen-storage material and preparation method thereof

InactiveCN103084161AImprove high temperature anti-aging abilityHigh temperature anti-aging abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAging resistanceCerium

The invention relates to a Ce-Zr-Al-based composite oxide rare earth oxygen-storage material and a preparation method thereof. The Ce-Zr-Al-based composite oxide rare earth oxygen-storage material is a composite oxide composed of cerium oxide, zirconium oxide, aluminum oxide and other rare earth oxides other than cerium oxide with a weight percentage of: 15-65% of cerium oxide, 12-55% of zirconium oxide, 5-50% of aluminum oxide, 4-10% of other rare earth oxides other than cerium oxide. Compared with conventional products, the interaction between alumina and Ce-Zr-based composite oxide is strengthened through the surface treatment for alumina, and the homogeneity between alumina and Ce-Zr-based composite oxide is adequately guaranteed. Through selection and compounding of a precipitant and controlling the precipitation end, the yield of the product is ensured. By adding a surface-treating agent, aperture and pore volume of the precipitate precursor are ensured to be large after firing, and high temperature aging resistance of the material is improved.

Owner:上海华明高纳稀土新材料有限公司

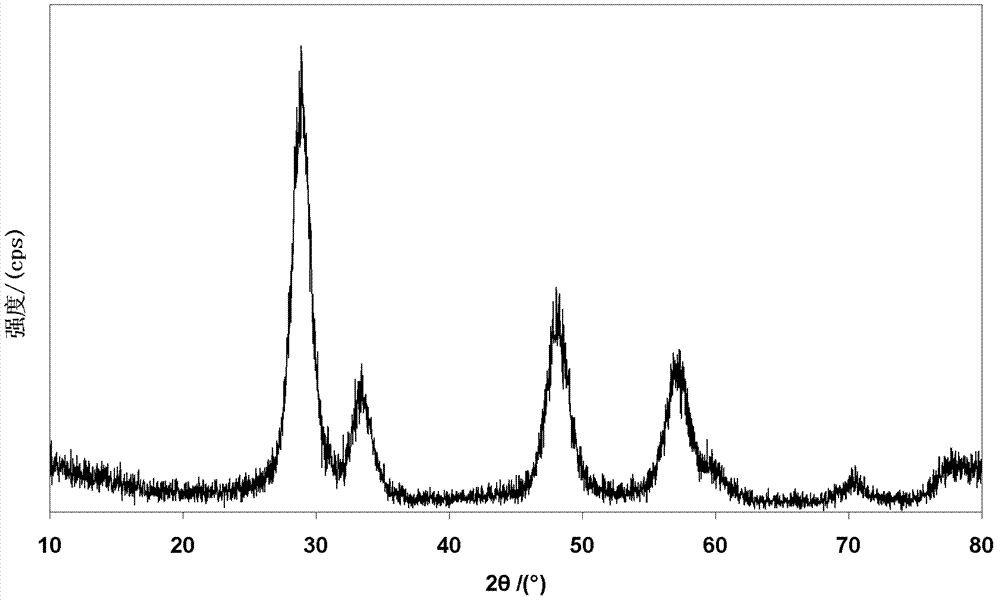

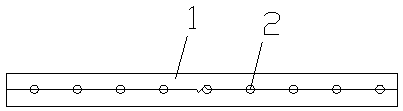

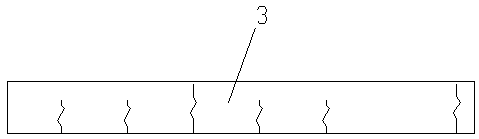

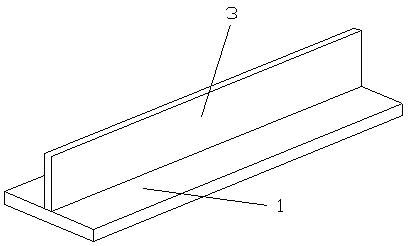

Preparation method of ceramic filtration supporter

ActiveCN101948316AGuaranteed apertureGuaranteed porosityDispersed particle filtrationFiltration separationPore diameterMetallurgy

The invention relates to a preparation method of a ceramic filtration supporter for the filtering dust removal of high temperature gas. The preparation method comprises the steps of mixing materials, formation and firing, the materials include aggregate, high temperature binding agent and pore forming agent, wherein the aggregate is spherical granule aggregate, the formation adopts isostatic compaction with the formation pressure being controlled in a range from 40 to 150 MPa and the firing temperature being controlled in a range from 1000 to 1300 DEG C, and the heat is preserved for 2 to 3 hours. The resultant ceramic filtration supporter has appropriate pore diameter and porosity, good gas permeability, high strength and good overall properties.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

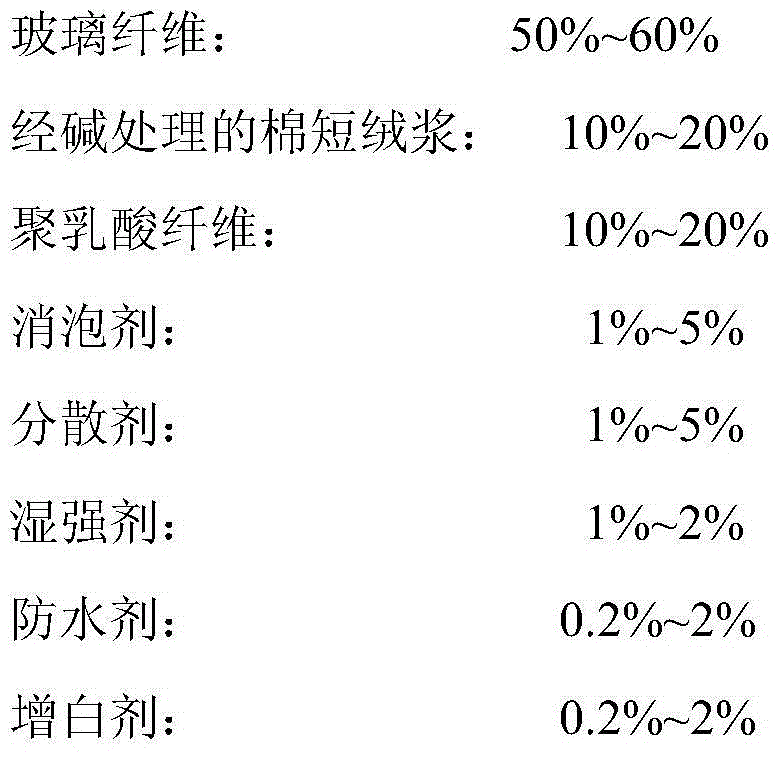

High-precision air filter paper as well as preparation method and application thereof

InactiveCN104878646AHigh porositySmall apertureCellulosic pulp after-treatmentDefoamers additionFiberAir filter

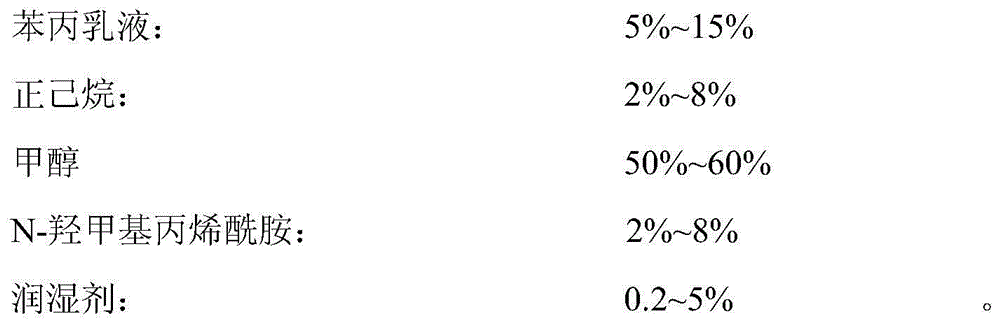

The invention discloses high-precision air filter paper which comprises body paper and an impregnant for impregnating the body paper, wherein the body paper comprises glass fiber, alkali treated cotton linter pulp, polylactic acid fiber, a defoaming agent, a dispersing agent, a wet strength agent, a waterproof agent and a brightener; the impregnant comprises phenolic resin, styrene-acrylic emulsion, normal hexane, methanol, N-hydroxymethyl acrylamide and a wetting agent. The invention further discloses a preparation method of the high-precision air filter paper. Through the preparation method, the obtained high-precision air filter paper has the characteristics of relatively high filter precision, relatively low filter resistance, relatively high pollutant carrying capacity, long service life and good quality stability.

Owner:杭州特种纸业有限公司

Electrostatic air filter paper and preparation method thereof

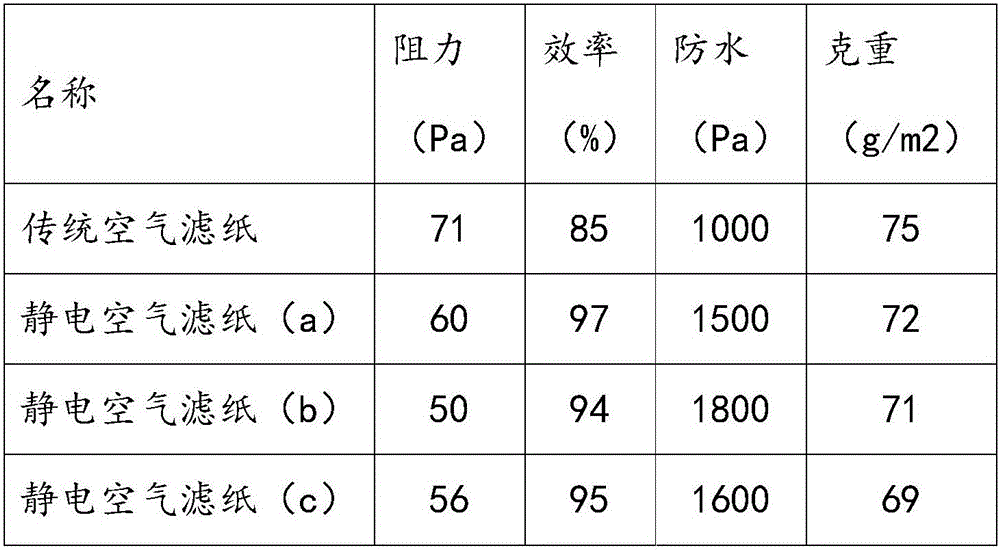

ActiveCN106283891ALow air resistanceEffective filteringPaper/cardboardFiltration separationGlass fiberEmulsion

The invention discloses electrostatic air filter paper. The electrostatic air filter paper is prepared from polypropylene / polyester composite, chopped glass fiber cotton, modified nano cellulose and waterproof emulsion. The invention also discloses a preparation method of the electrostatic air filter paper. The preparation method comprises the following steps: firstly, beating; secondly, dispersing; thirdly, mixing pulp; fourthly, forming; fifthly, hot pressing; sixthly, impregnating; seventhly, drying. The electrostatic air filter paper obtained by the preparation method disclosed by the invention has the characteristics of higher filtering efficiency, relatively-low filtering resistance and good quality stability.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Microporous carbon aerogel and preparation method thereof

ActiveCN106976864AMaintain integrityPrevent structural collapseCarbon preparation/purificationCarbon dioxideParticle-size distribution

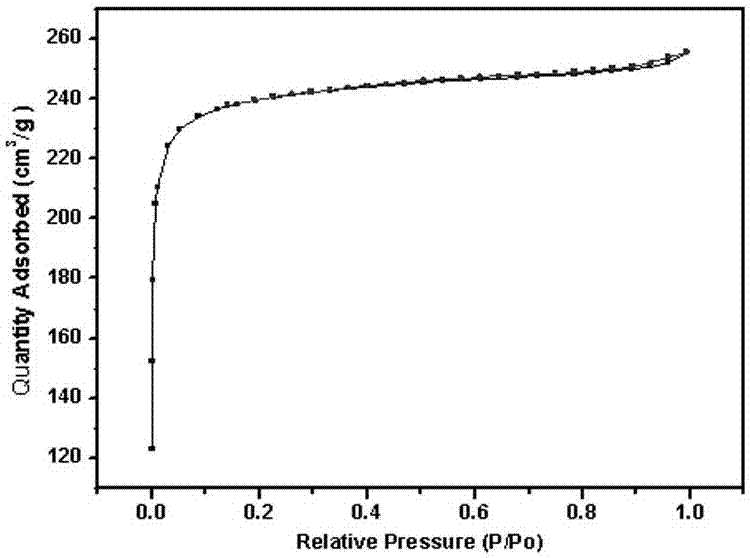

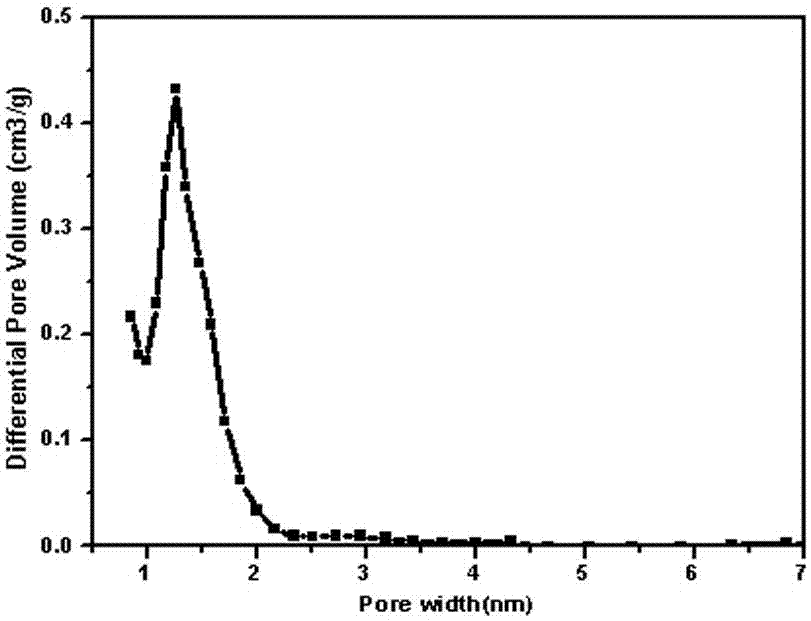

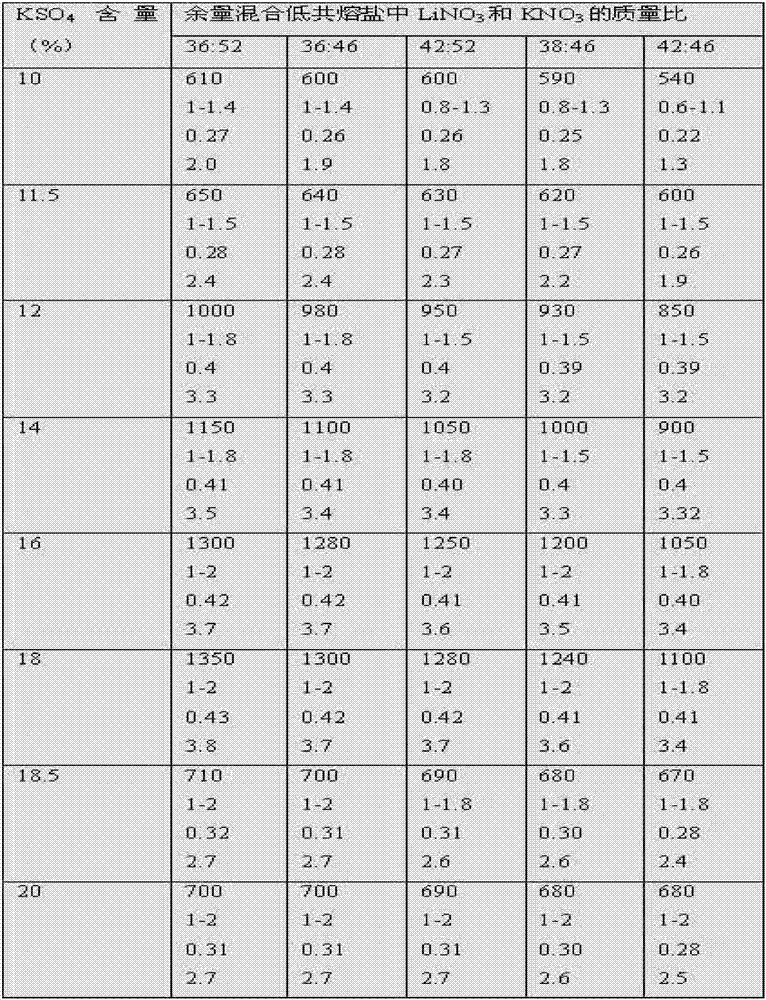

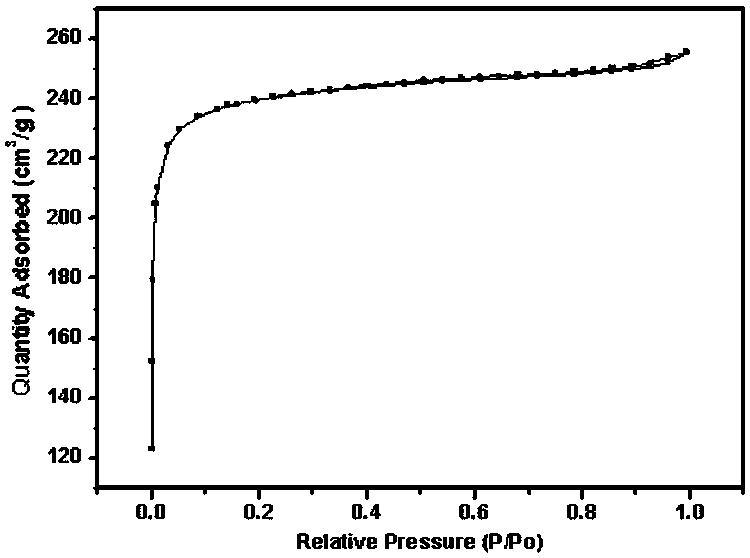

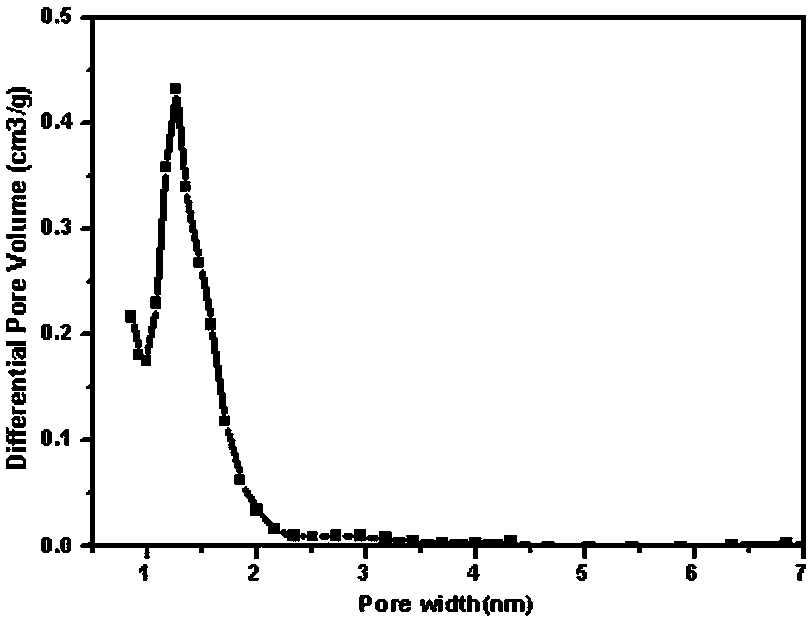

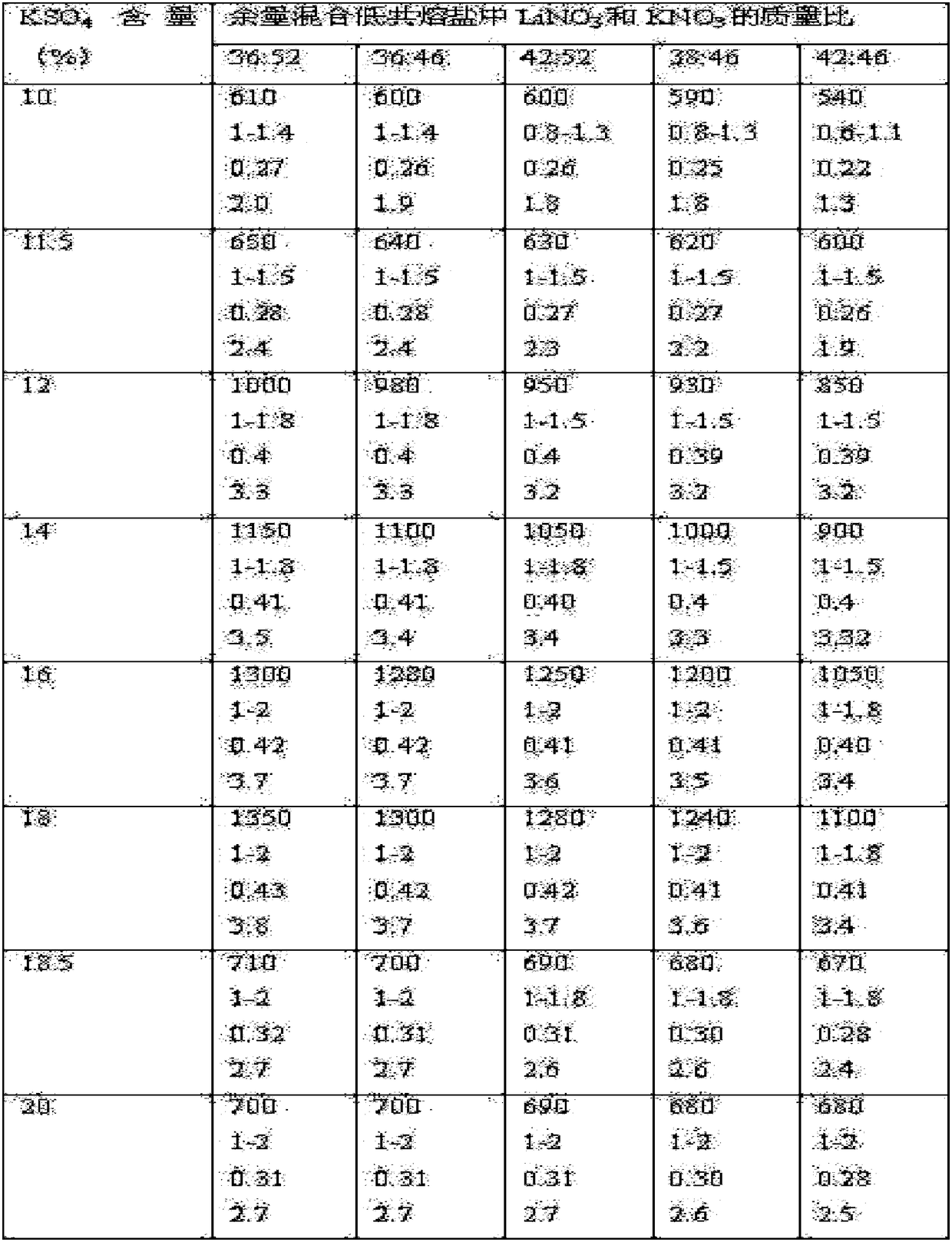

The invention relates to microporous carbon aerogel and a preparation method thereof. The microporous carbon aerogel is prepared by adding mixed eutectic molten salt composed of LiNO3, KNO3 and K2SO4 in a step of preparing organic wet gel; parameters include that specific surface area is 850-1350m2 / g, pore size distribution is 1-2nm, pore volume is 0.38-0.43cm3 / g, and adsorption amount of CO2 at normal temperature and normal pressure is 3.2-3.8mmol / g. The microporous carbon aerogel prepared by the method is high in specific surface area, narrow in pore size distribution range, large in pore volume and high in ability of adsorbing carbon dioxide. The preparation method is simple in steps, convenient to operate, low in production cost, short in process time and environment-friendly.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

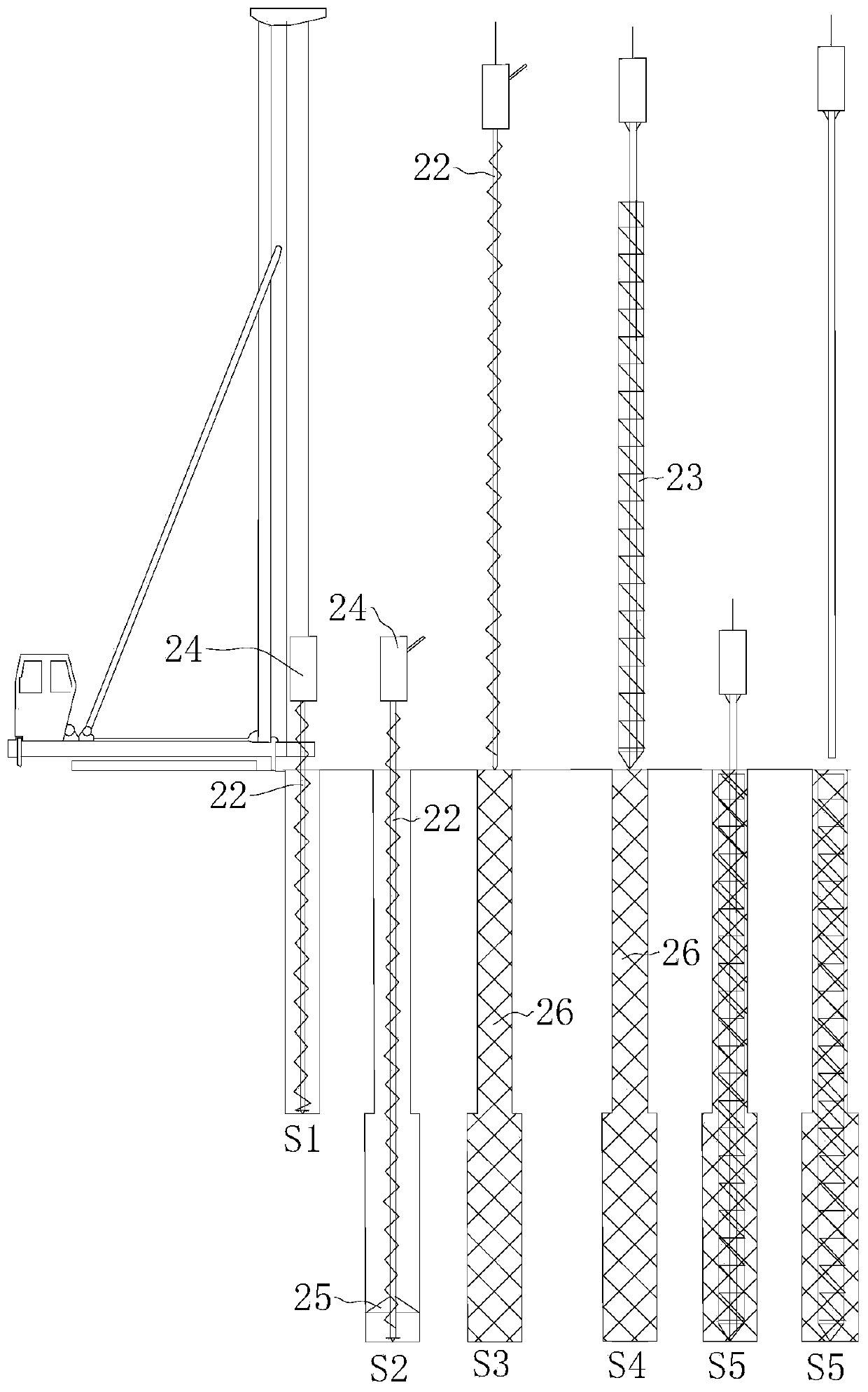

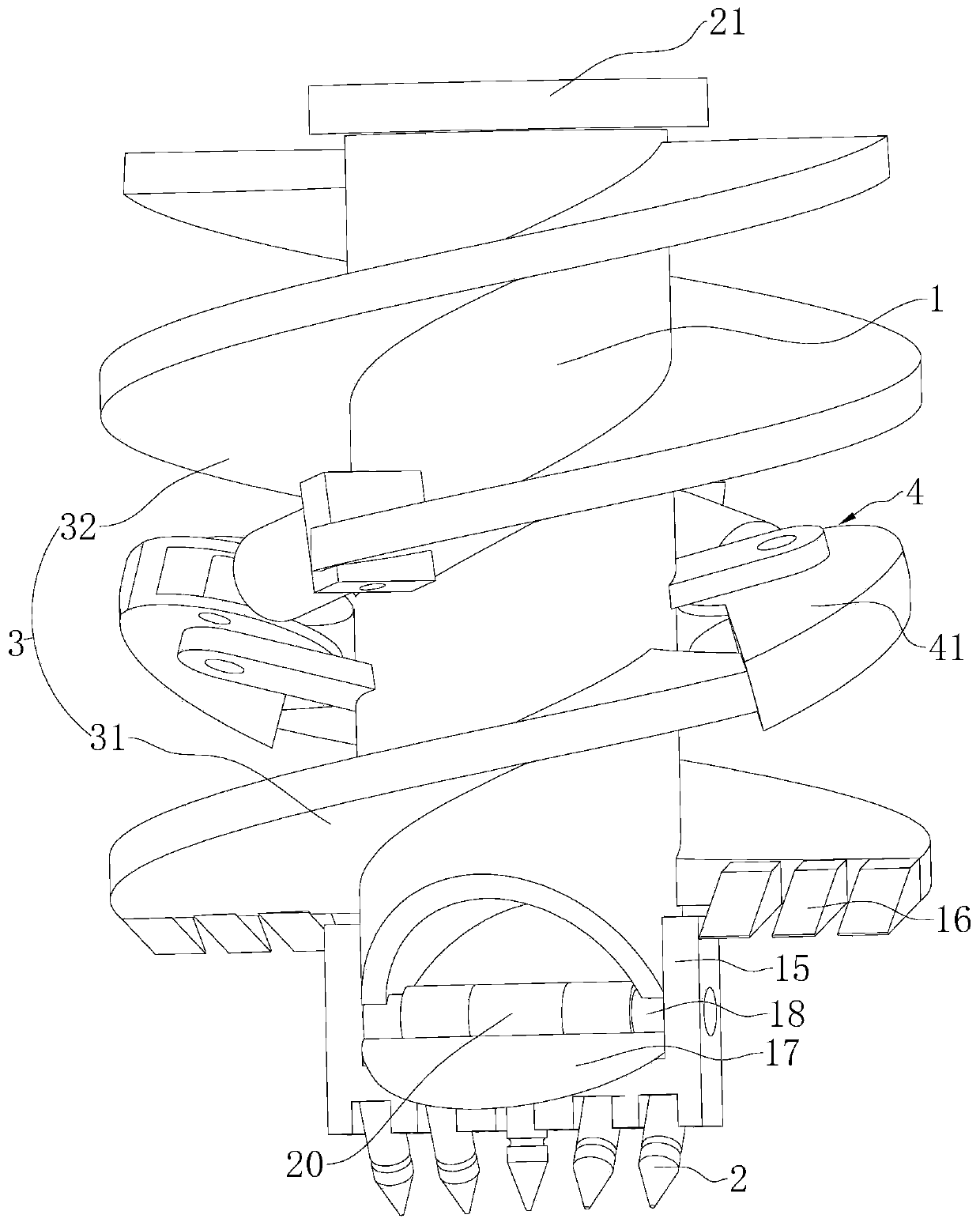

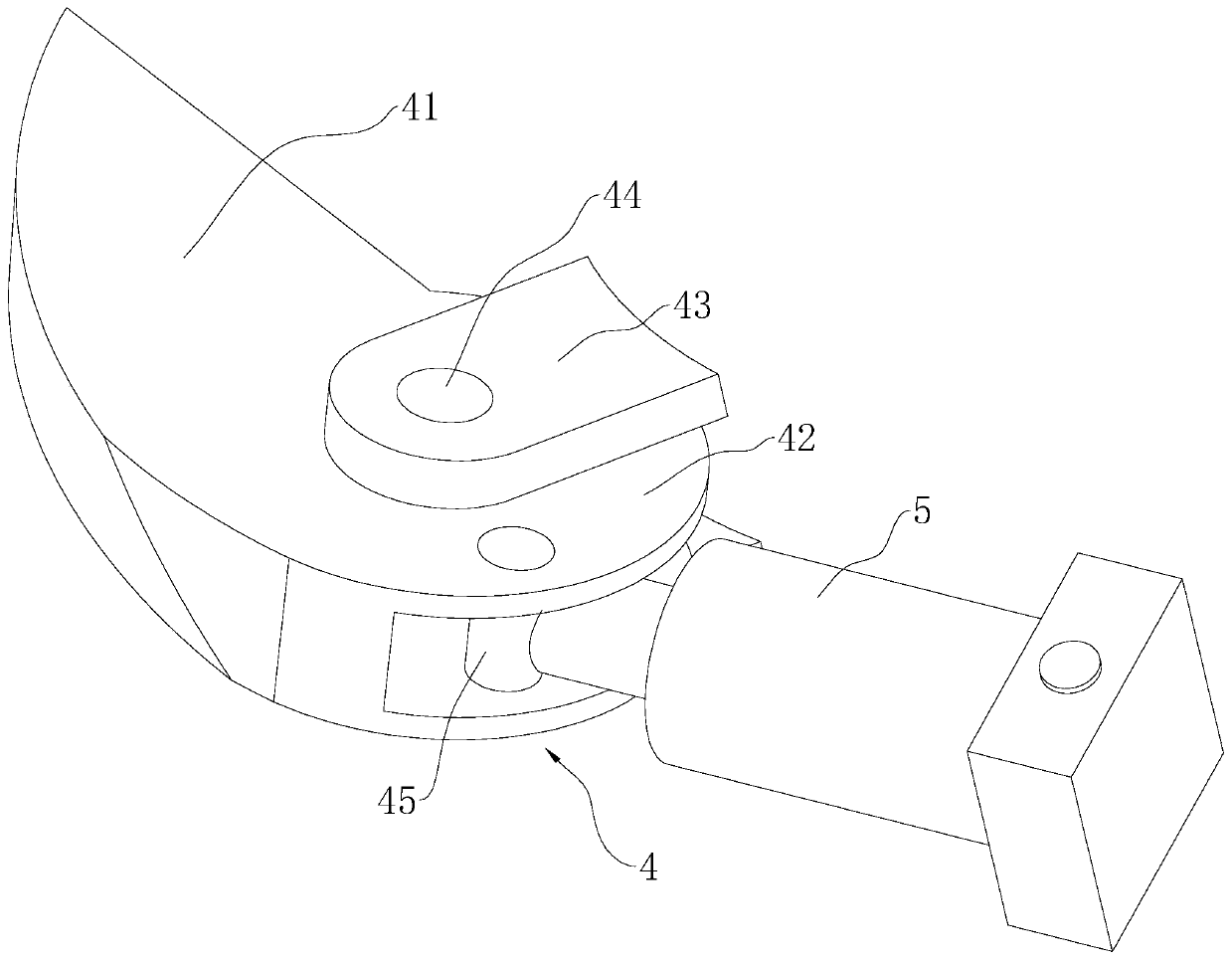

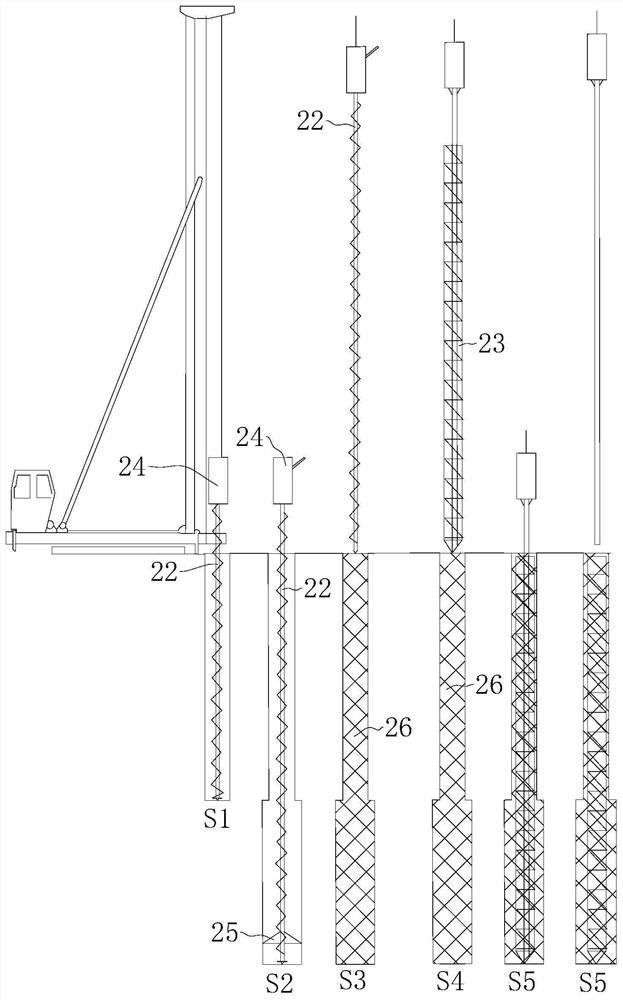

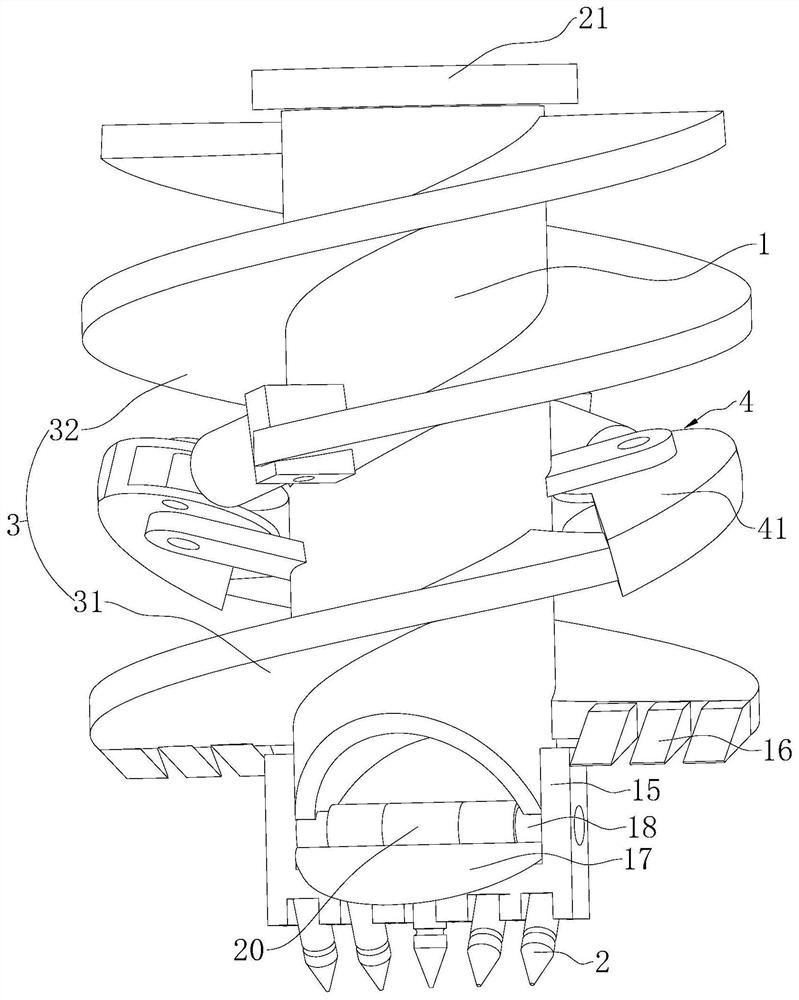

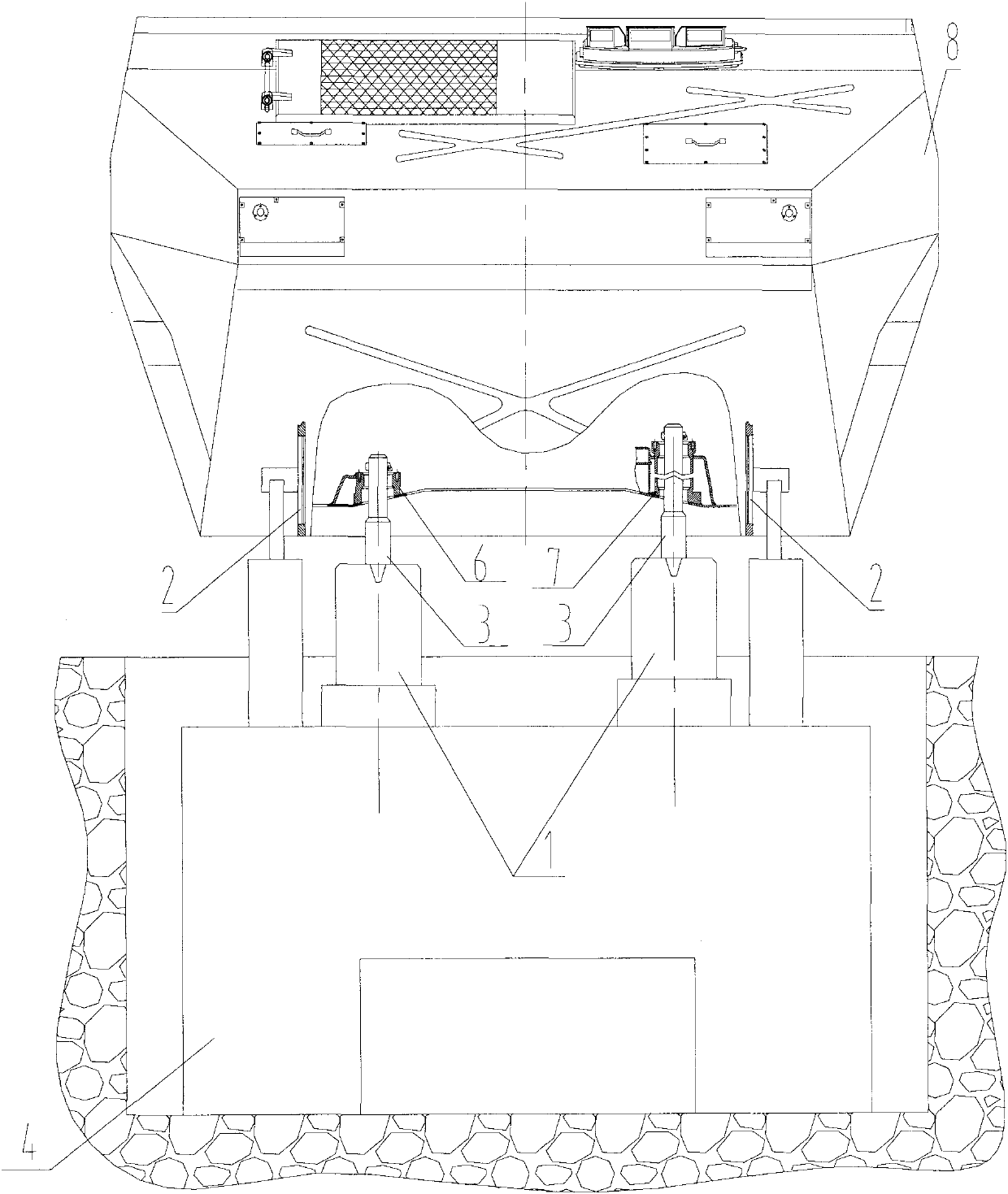

Construction method of long auger drilling guncreting expanded bore pile

ActiveCN111535301ASimple and fast operationImprove work efficiencyDrill bitsDrilling rodsRebarDrill bit

The invention relates to a construction method of a long auger drilling guncreting expanded bore pile, and belongs to the technical field of pile foundation construction. The construction method comprises the following steps that S1, a straight hole is drilled; S2, a bottom expansion drill bit carries out expansion construction on an expansion head at the pile end; S3, concrete is poured into a pile hole through drill rods and the bottom expansion drill bit in a pressure manner, after pouring of a bottom expansion hole part is completed, the bottom expansion drill bit shifts up and down, and concrete on the bottom expansion hole part is stirred again; S4, the bottom expansion drill bit is closed, a drill is lifted up, and concrete is poured into the pile hole continuously in a pressure manner till the drill is lifted to the ground; S5, a vibrator is used for placing a reinforcement cage into the pile hole; and S6, after pile forming, maintaining is carried out, and checking is carriedout. The construction method has the effects that construction is convenient, stability between the expanded bore pile and soil is enhanced, and the bearing capacity of the expanded bore pile is guaranteed.

Owner:江西中恒地下空间科技有限公司

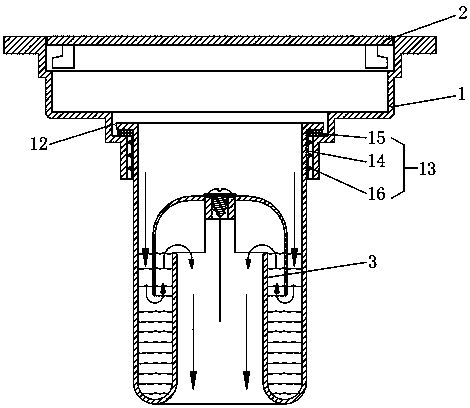

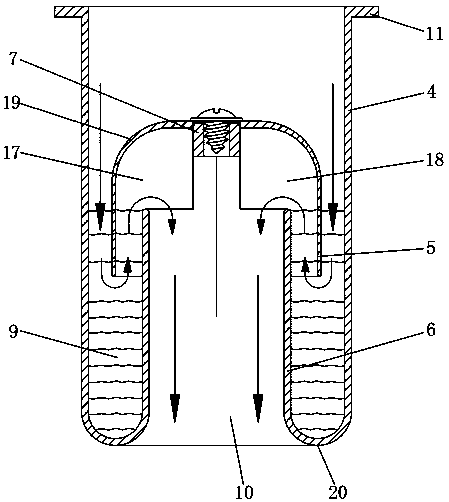

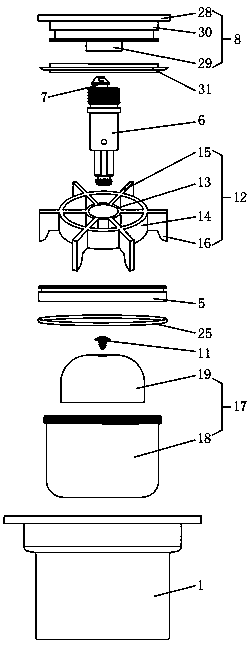

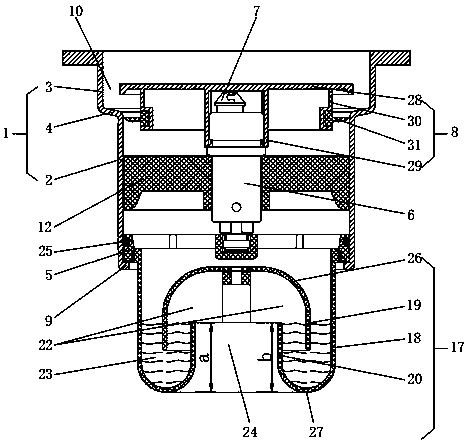

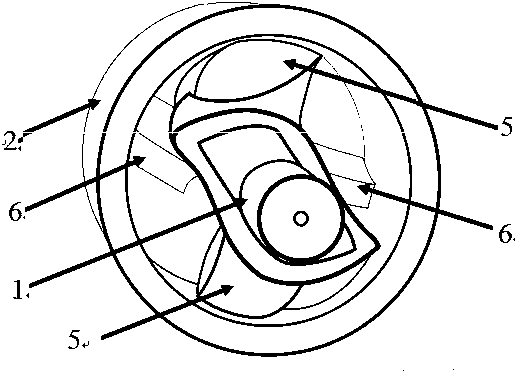

Stink-leaking prevention device and floor drain with stink-leaking prevention device thereof

The invention discloses a stink-leaking prevention device, which includes a water draining pipe and a diversion cover. The lower end of the water draining pipe is bended towards the inner part and towards the upper part in the axis direction to form a water collecting pipe; the upper end of the water collecting pipe is provided with a sealed plate, a plurality of water draining holes are formed inthe lateral wall of the water collecting pipe, a water collecting cavity is formed between the space of the external wall of the water collecting pipe and the internal wall of the water draining pipe, and internal holes of the water collecting pipe are water outlet poles; and the diversion cover is installed on the sealed plate, and free ends of the diversion cover are mounted in the water collecting cavity. According to the stink-leaking prevention device, the function of the stink-leaking prevention is better achieved, and at the same time, the speed of water draining is greatly improved. The invention further discloses a floor drain with stink-leaking prevention device.

Owner:台州信各灵卫浴科技有限公司

Double-layer deodorant floor drain

PendingCN110042910AAchieve the purpose of double-layer deodorizationTo achieve the purpose of deodorizationSewerage structuresFlangePetroleum engineering

The invention discloses a double-layer deodorant floor drain. The double-layer deodorant floor drain includes a floor drain body, the floor drain body includes a lower barrel body and an upper barrelbody, the inner diameter of the upper barrel body is larger than the inner diameter of the lower barrel body, and the upper barrel body is connected with the lower barrel body by a step plate, a valvedeck assembly is arranged in the lower barrel body of the floor drain body and includes a fixing plate, a jumping valve and a valve deck, wherein the jumping valve is fixed to the fixing plate, the valve deck is arranged on a jumping head of the jumping valve, the fixing plate abuts against a flange block at the bottom end of the lower barrel body, the valve deck can seal or open the upper end ofthe lower barrel body, and the upper surface of the valve deck is always lower than or is flush with the top surface of the upper barrel body; intervals are arranged between the outer side surface ofthe valve deck and the inner wall of the upper barrel body; and a supporting seat further fixedly sleeves the jumping valve. According to the double-layer deodorant floor drain, double deodorant grantee is arranged, thus the deodorant effect of the whole floor drain is greatly improved, and meanwhile, compared with an existing floor drain, the drainage speed of the double-layer deodorant floor drain can help the floor drain launch more quickly.

Owner:台州信各灵卫浴科技有限公司

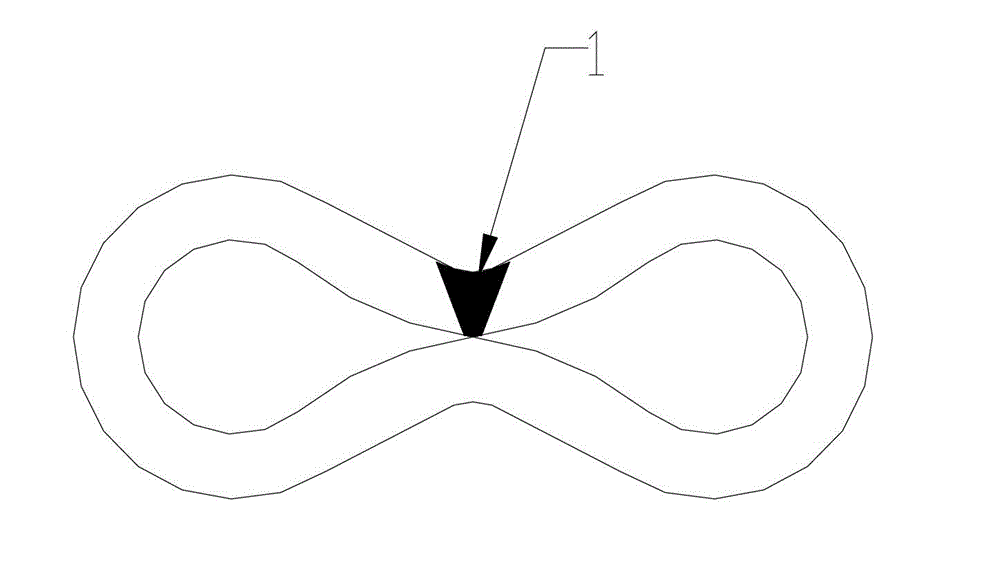

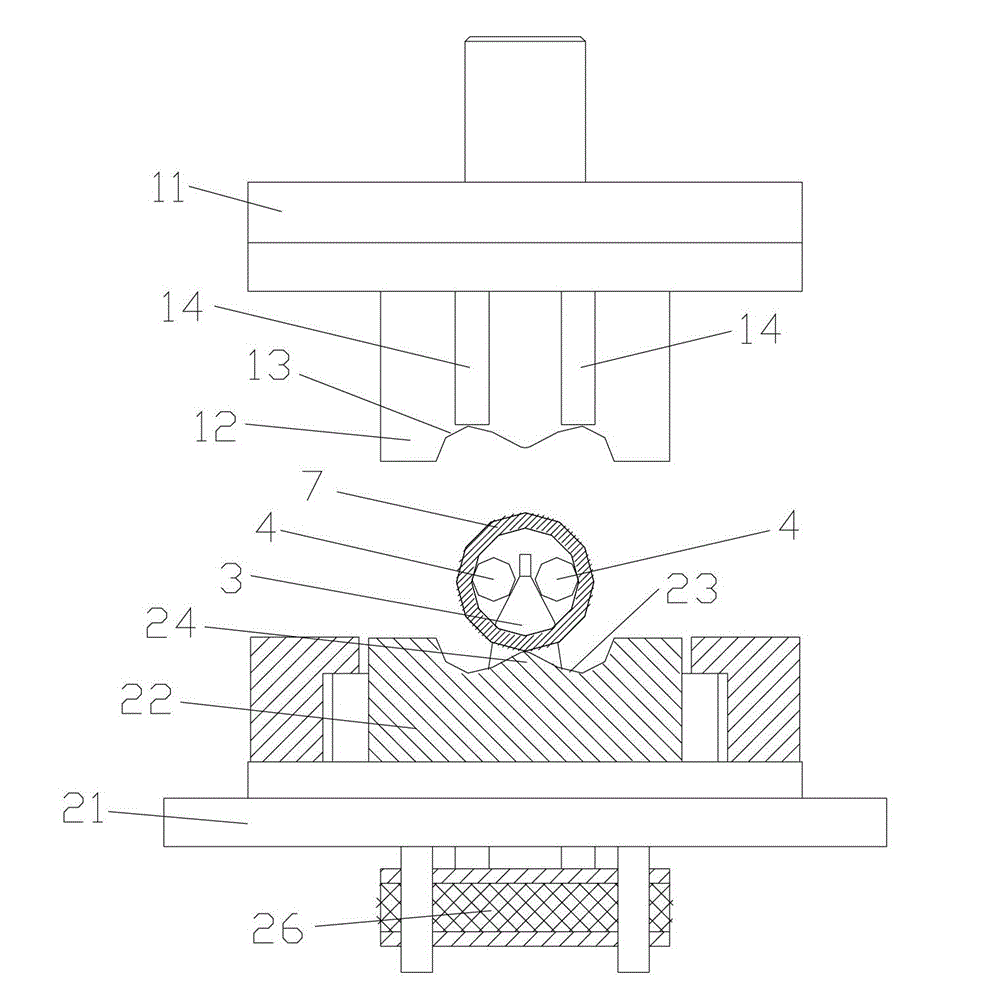

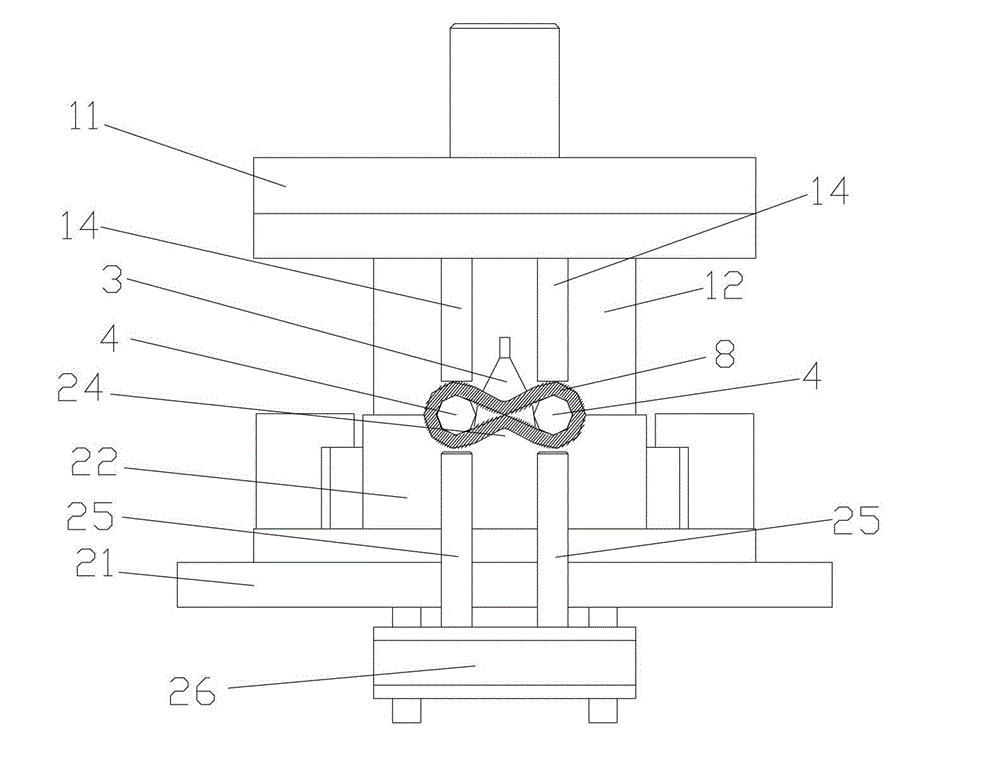

Forming die for machining method for high-strength transverse 8-shaped parts

ActiveCN102974701AExtended service lifeGuaranteed long lifespan issuesShaping toolsStripping-off devicesHigh intensityEngineering

The invention discloses a forming die for a machining method for high-strength transverse 8-shaped parts. The forming die comprises an upper template, an upper die fixed on the upper template, a lower template and a lower die fixed on the lower template, wherein the upper die is provided with an upper die cavity; the lower die is provided with a lower die cavity; the upper die cavity is matched with the lower die cavity to form a transverse 8-shaped inner cavity; a guide plate and a pair of locating rods moving relative to the guide plate are arranged in two side cavities on the lower die adapted with the middle position of the lower die cavity respectively; and the locating rods are clamped between the guide plate and the inner wall of a metal tube. The forming die solves the problems that the machining accuracy of the current die cannot be ensured easily and the machined transverse 8-shaped parts have a short service life, and meets the requirement of a customer better.

Owner:黄山鼎奇链传动股份有限公司

Graphene composite photocatalytic ultrafiltration membrane and preparation method thereof

ActiveCN110813110AImprove hydrophilicityImprove pollutionMembranesPhysical/chemical process catalystsPhoto catalysisCarboxylic group

The invention discloses a graphene composite photocatalytic ultrafiltration membrane, and a preparation method thereof. The preparation method comprises the following steps: firstly, blending grapheneoxide and polysulfone to prepare a membrane; improving the hydrophilic and anti-pollution capabilities of the ultrafiltration membrane by utilizing the graphene oxide; then, taking a dispersion liquid of aminated titanium dioxide and water as a solidification liquid to carry out suction filtration and solidification on the semi-solidified ultrafiltration membrane; crosslinking amino groups of aminated titanium dioxide with carboxyl groups of carboxylated graphene oxide in the curing process, so that the binding force of titanium dioxide nanoparticles and the membrane is improved through physical and chemical dual effects, and the problem of loss of photocatalytic particles in a traditional photocatalytic ultrafiltration membrane is solved.

Owner:江苏晖尔利电子科技有限公司

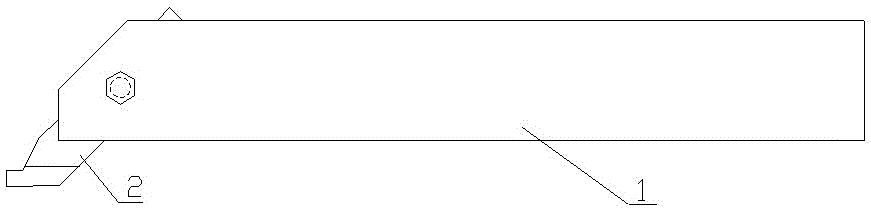

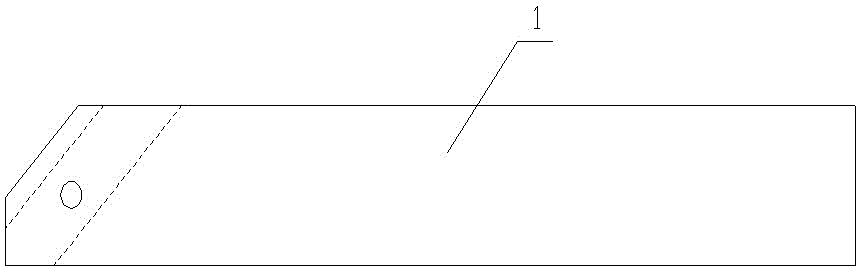

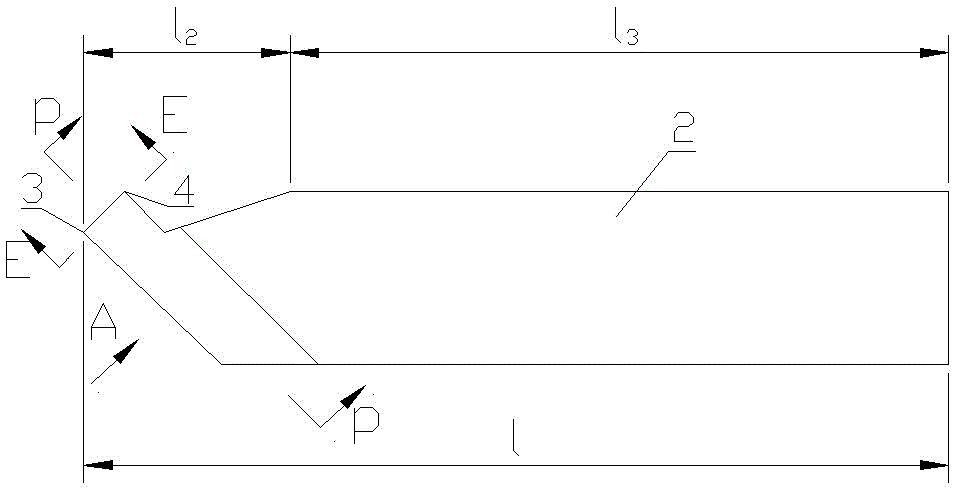

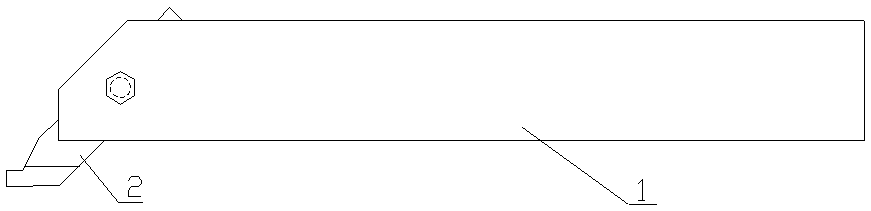

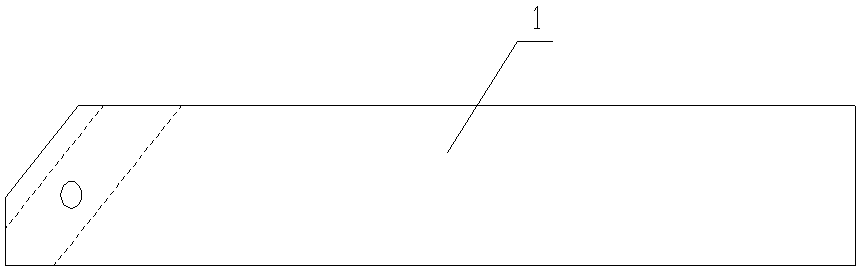

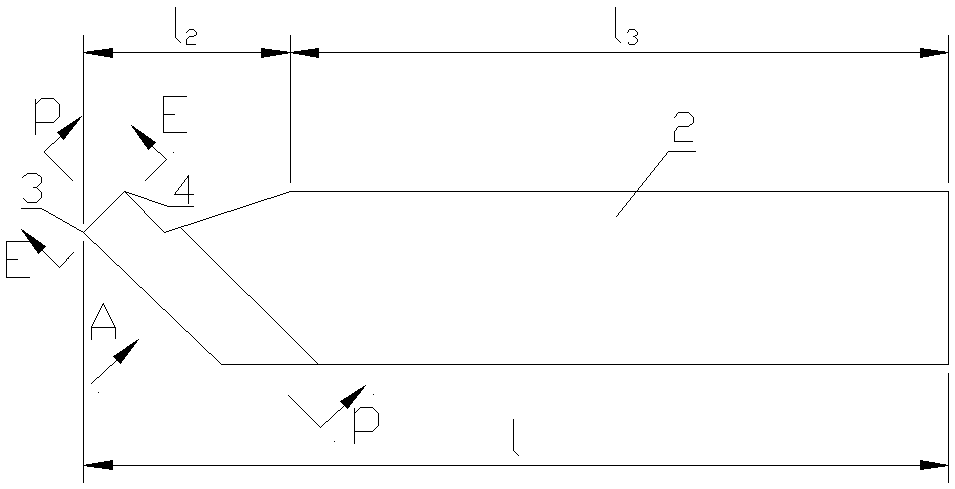

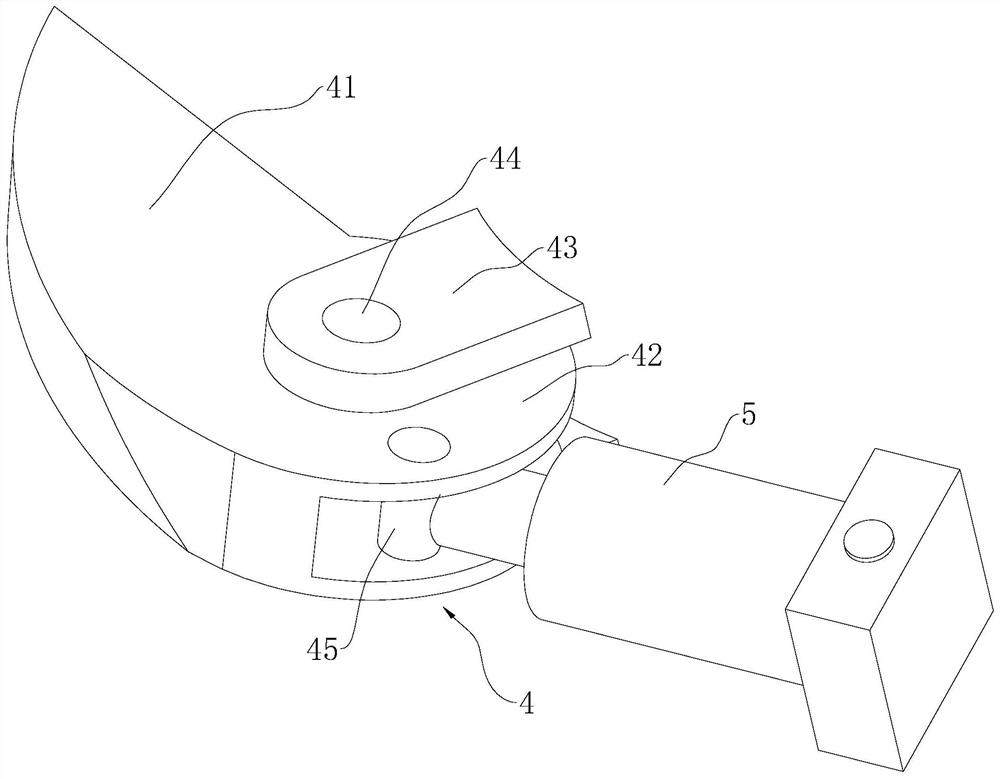

Cutter for lathe machining of flat-bottom holes

The invention relates to a cutter for lathe matching of flat-bottom holes of discs. The cutter comprises a cutter bar and a cutter body. The cutter bar is a square strip, the cutter body is a three-edge flat lathe cutter fixedly mounted in an oblique square hole of the cutter bar. A left cutting edge and a right cutting edge are arranged on the left and right sides of a front cutting edge of the point of the cutter body, and an arc groove is arranged between the left and right cutting edges. The front cutting edge is set with an initial cut-in rake angle, an included angle between the initial cut-in rake angle and a front cutting edge rake angle is angle gamma, and the initial cut-in rake angle is connected with the arc groove between the left cutting edge and the right cutting edge. The cutter is simple in structure and high in strength of the cutter body; efficient machining of large-flat-bottom holes can be realized, and design requirements on aperture, roughness and the like are met effectively.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

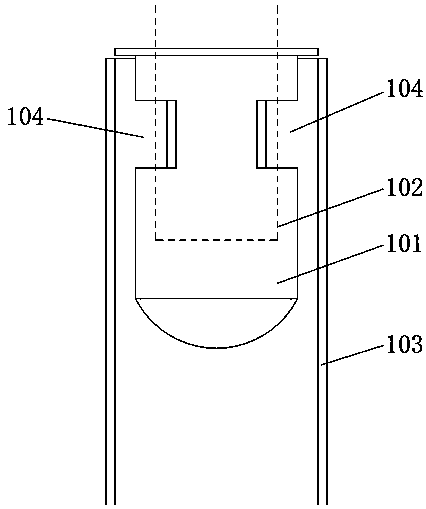

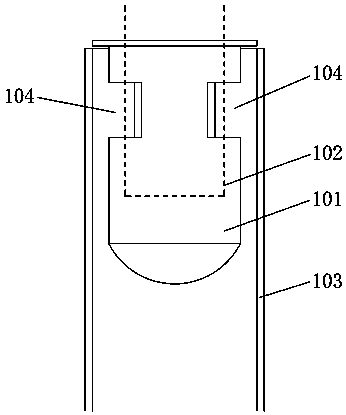

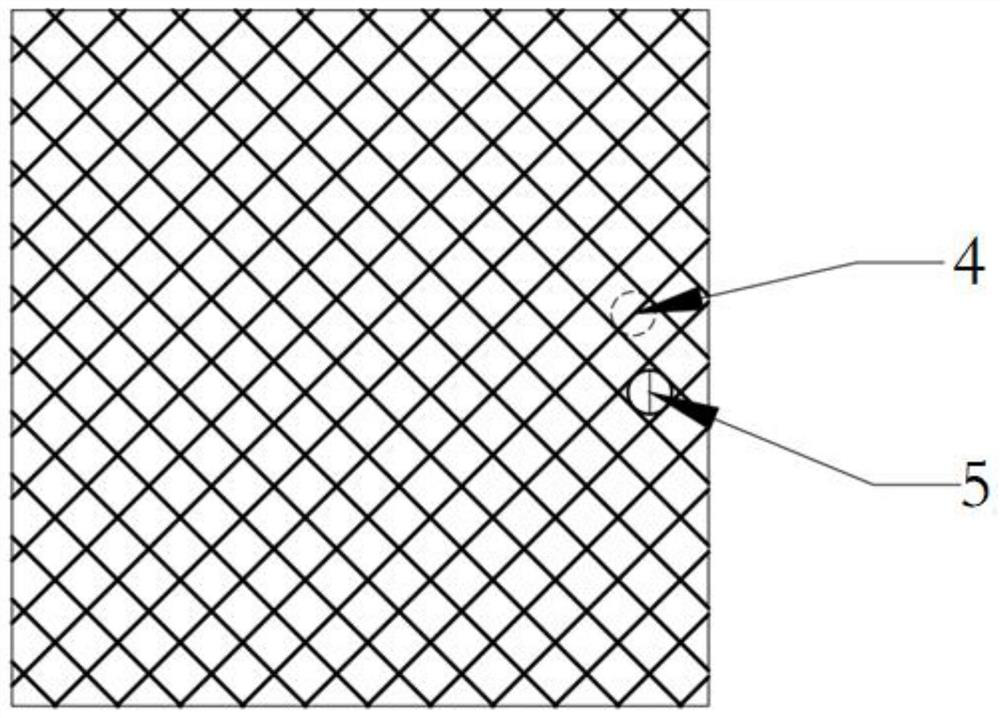

Bone trabecula structure

ActiveCN112022444AGuaranteed StrengthSmooth shippingBone implantJoint implantsBone TrabeculaeBone ingrowth

The invention relates to the technical field of medical prostheses, and provides a bone trabecula structure. The bone trabecula structure comprises a bone trabecula structure body, the bone trabeculastructure body is composed of a plurality of mutually-staggered trabeculae, and the mutually-staggered trabeculae form bone trabecula structure holes; a hole structure is arranged in each bone trabecula structure body, each hole structure comprises a plurality of side face holes and a plurality of transverse holes, and the multiple side face holes and the multiple transverse holes are mutually crossed; and part of the multiple side face holes are perpendicular to the axis of each bone trabecula structure body, and part of the multiple side face holes are obliquely arranged. The bone trabeculastructure has the beneficial effects that pores are designed in the transverse directions and the longitudinal directions of the trabeculae of the bone trabecula structure body, so that the strength of the bone trabecula structure is guaranteed, the intercommunity is improved, nutrients and other substances can be transported more smoothly, the metabolic site area is increased, the bone ingrowth progress is quicker, and the bone ingrowth effect is firmer.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

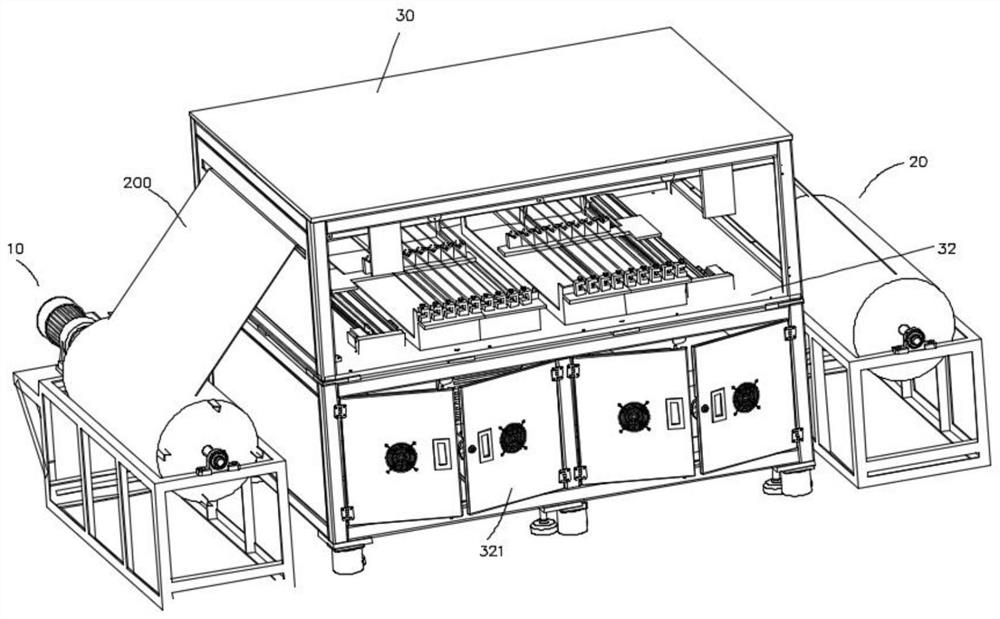

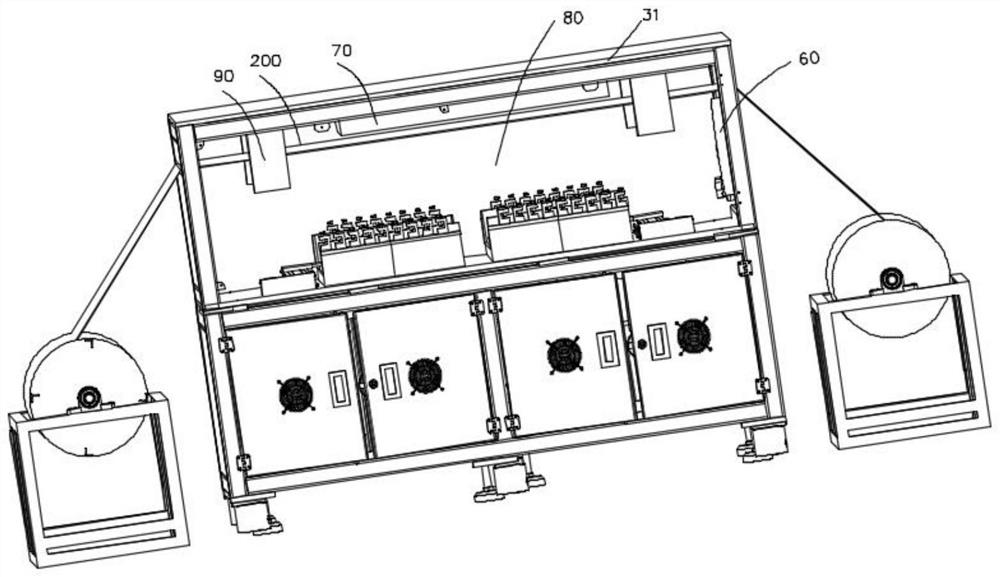

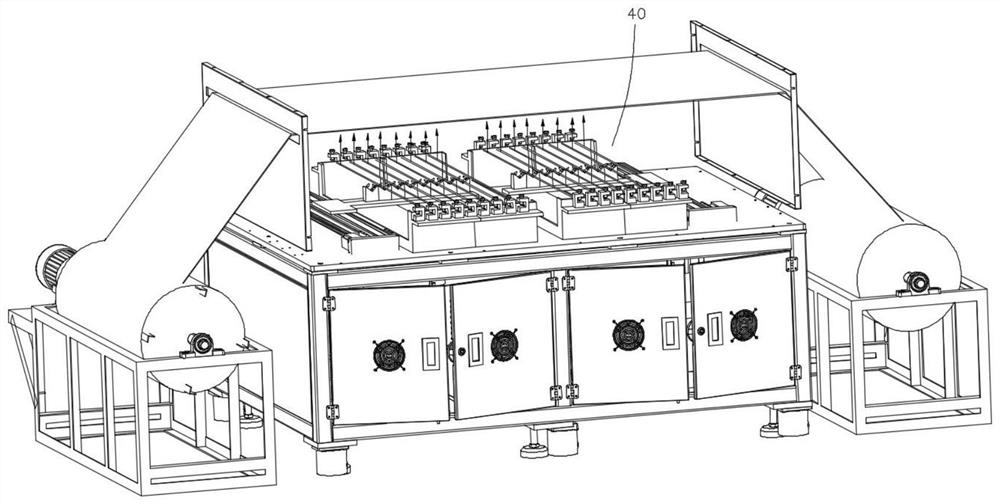

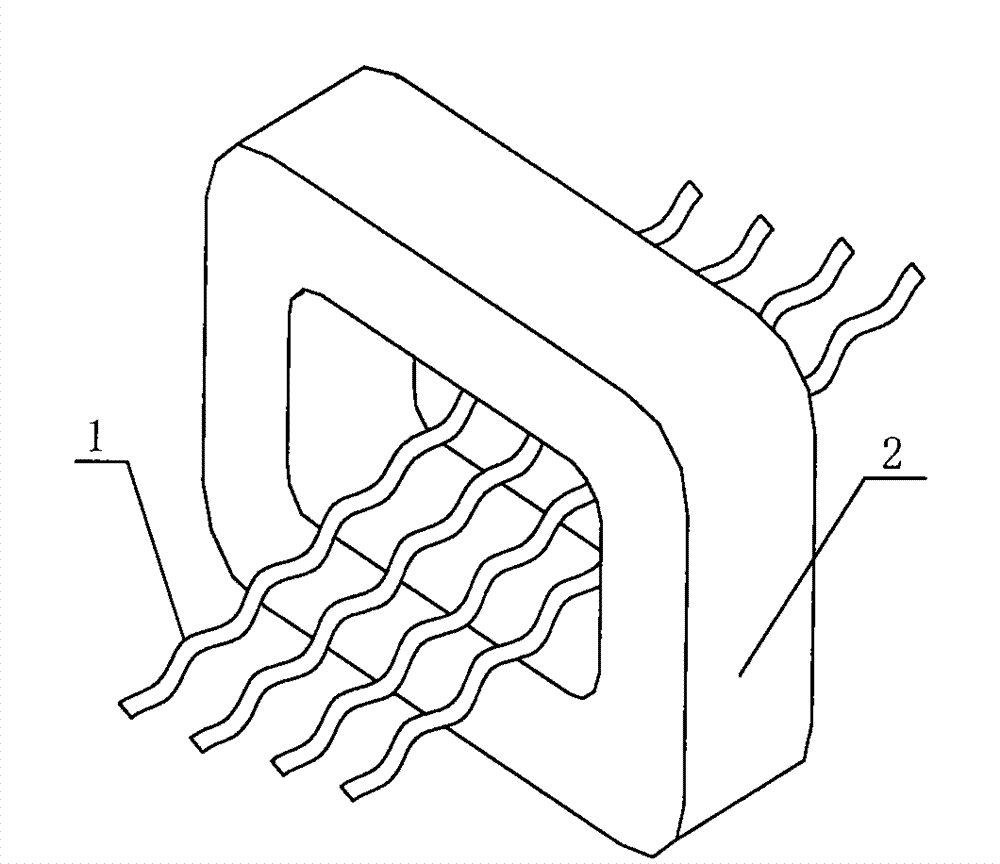

Nanofiber filter layer production device

The invention discloses a nanofiber filter layer production device. The device comprises an unwinding end, a winding end, a mounting shell, a reciprocating dropping mechanism and a high-pressure device, the reciprocating liquid dropping mechanism comprises a plurality of rope bodies, a plurality of liquid drop discharging devices, a fixing plate and a side driving piece, the unwinding end and thewinding end are distributed on the two sides of the mounting shell, a base material is wound by the winding end after being released by the unwinding end, the base material moves along the high-pressure section, the reciprocating liquid dropping mechanism drops material liquid drops to the rope body, and the material liquid drops are drawn upwards under the action of the high-pressure section andcover the base material. The high-pressure device forms upward power, a liquid outlet spray head is positioned below the side of the rope body, the liquid outlet spray head discharges liquid along theside face of the rope body, the liquid moves upwards under the action of the high-pressure section, the liquid drops contact with the lower portion of the rope body and then are drawn upwards, the contact area of the liquid drops and the rope body is increased, the drawing effect is good, the filtering effect of the nanofiber layer is improved, and meanwhile the problem of shielding interferenceis solved through inclined liquid discharging.

Owner:江苏纳易环保科技有限公司

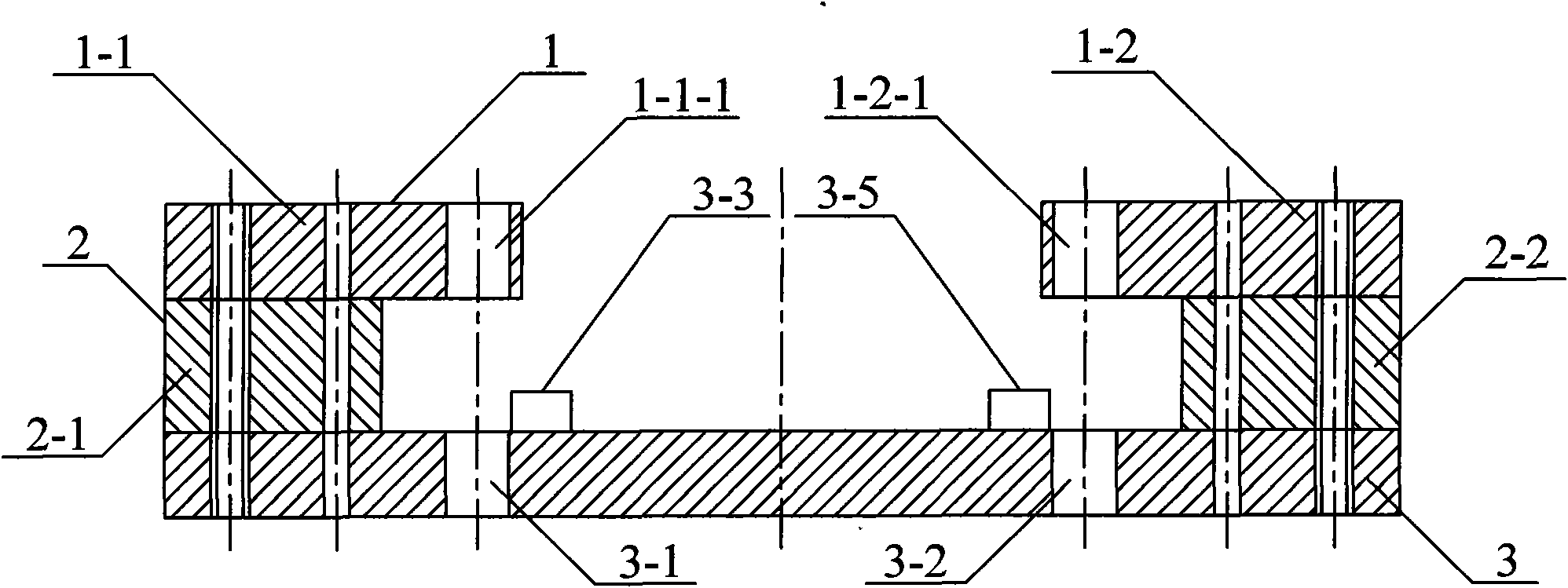

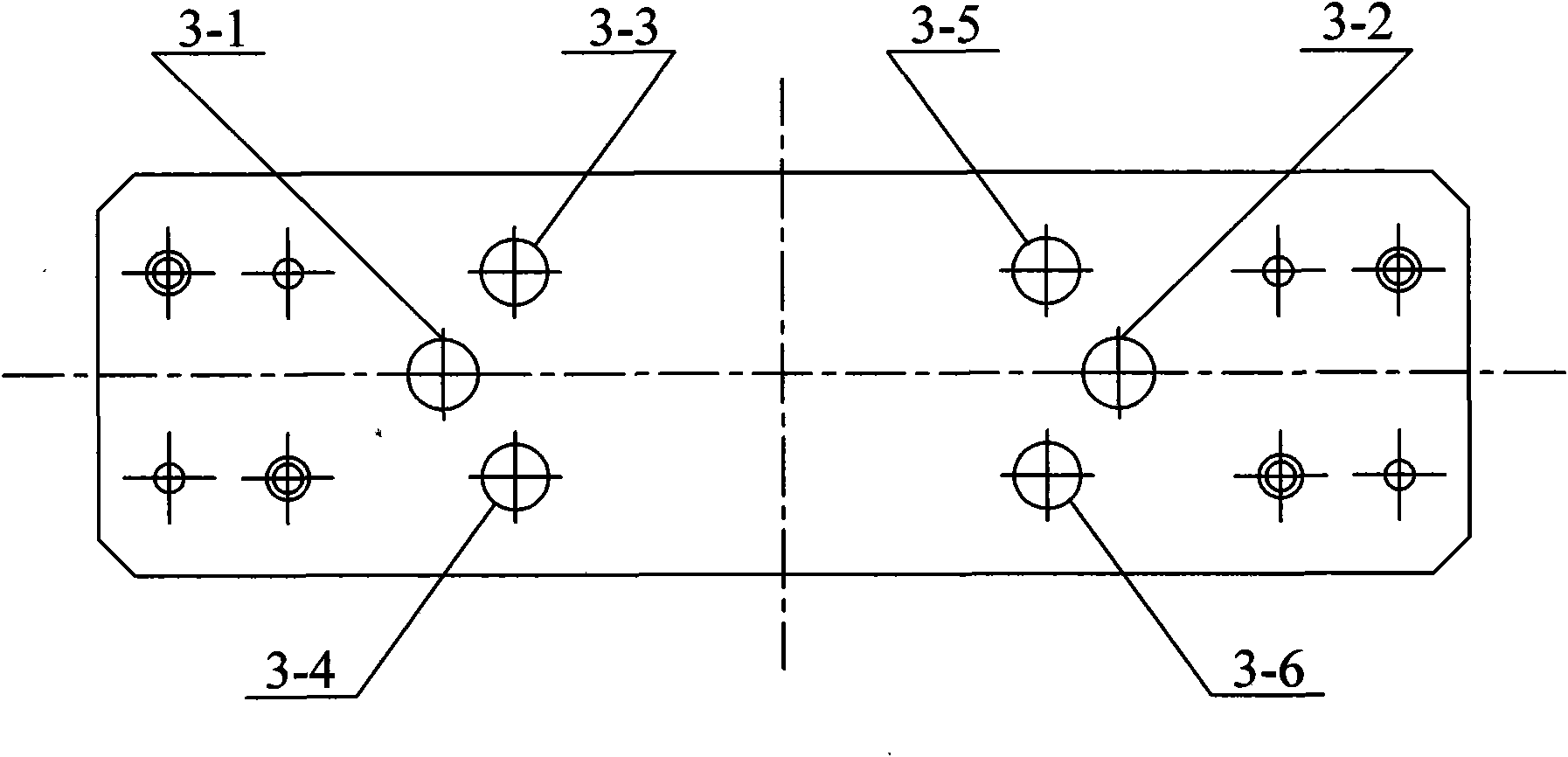

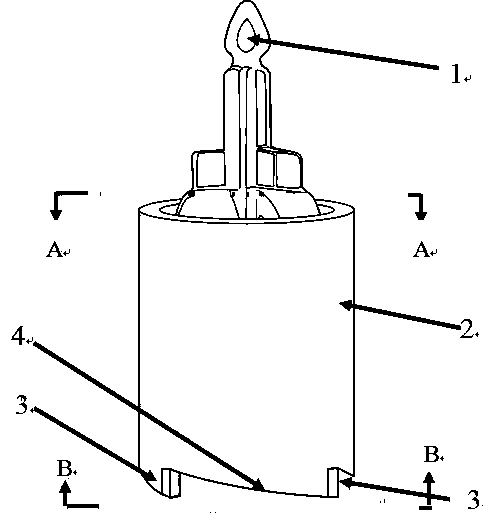

Drill jig for processing positioning holes of bead-fixed ring

InactiveCN101664817AGuaranteed apertureGuaranteed machining accuracyDrill jigsDrill holeEnvironmental geology

The invention discloses a drill jig for processing positioning holes of a bead-fixed ring. By using the drill jig to process positioning holes of the bead-fixed ring, the processing precisions of apertures and pitches of the positioning holes can be ensured. The drill jig comprises an upper mould, a middle mould and a lower mould, wherein the upper mould is fixedly connected with the lower mould through the middle mould; a space is left between the upper mould and the lower mould; the upper mould drill holes are arranged on the upper mould, and the lower mould drill holes corresponding to theupper mould drill holes are arranged on the lower mould; and a positioning pin is arranged at an upper side surface of the lower mould, which can be matched with a bead-fixed hole of the bead-fixed ring.

Owner:WUJIANG SHUANGJING BEARING

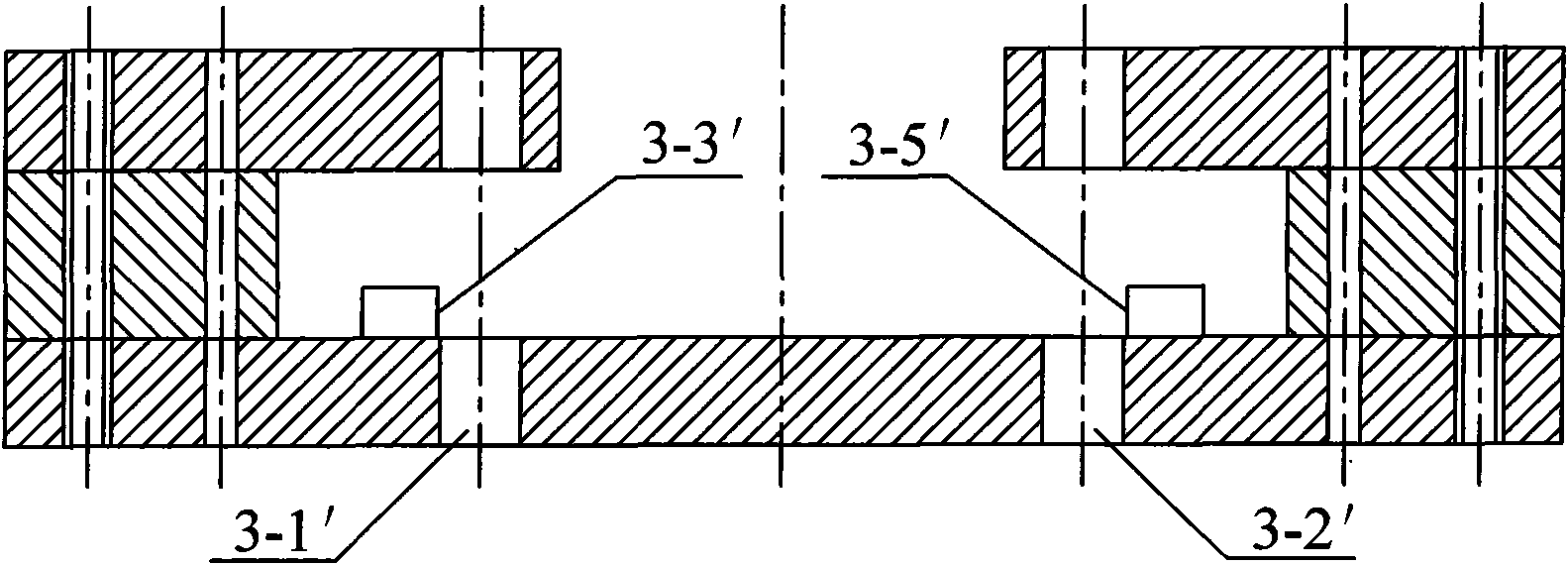

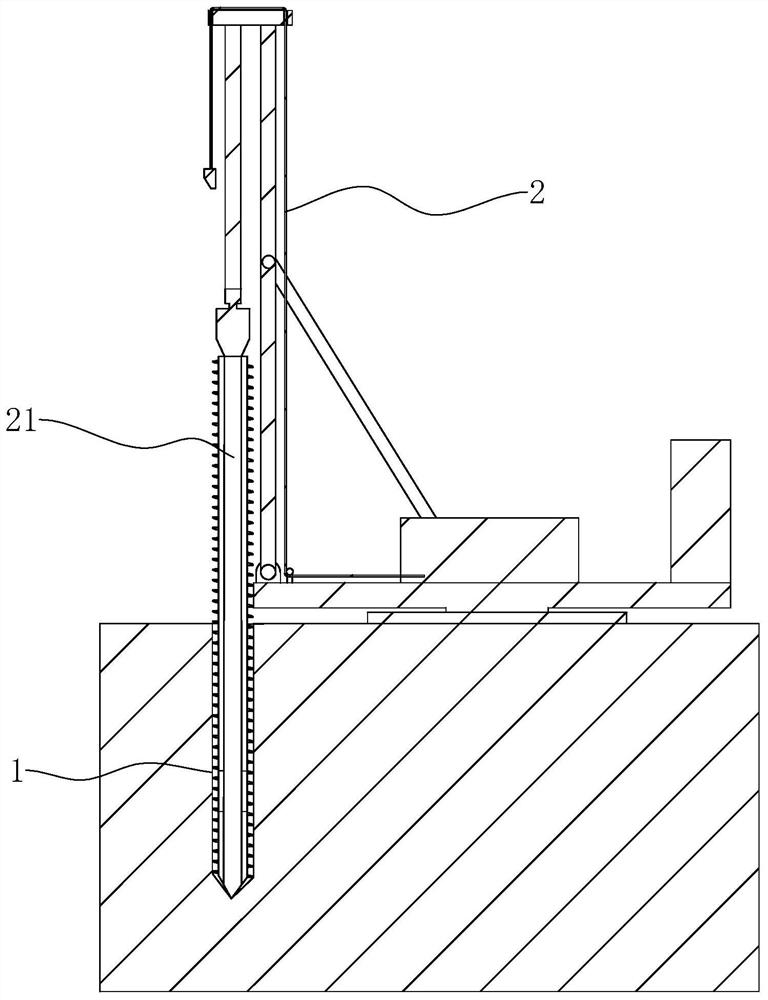

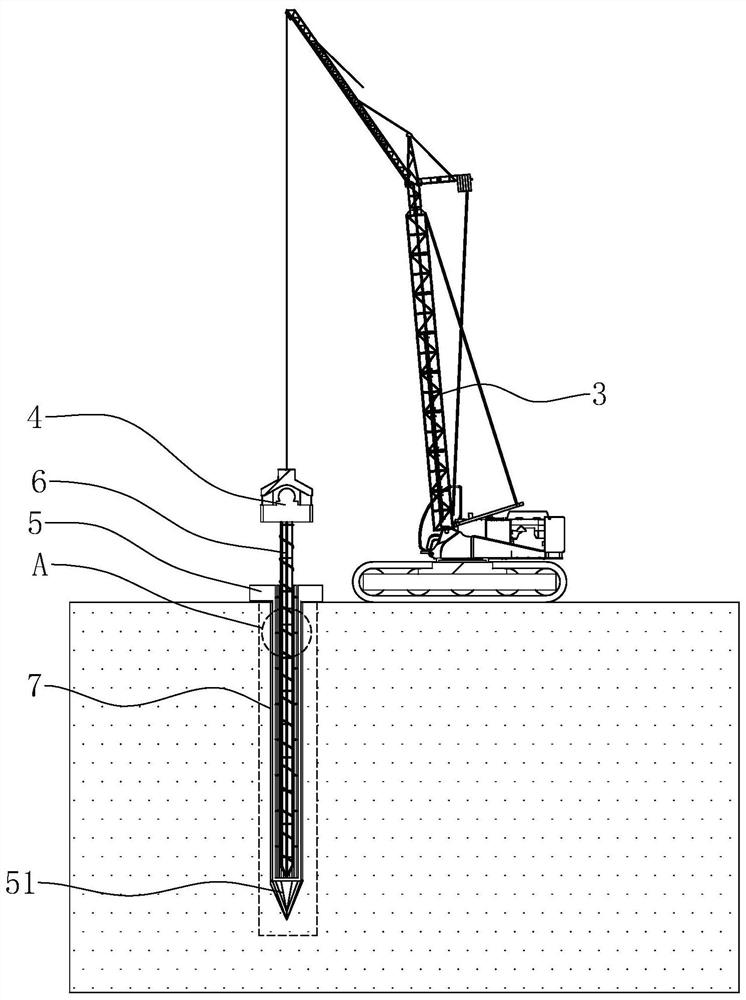

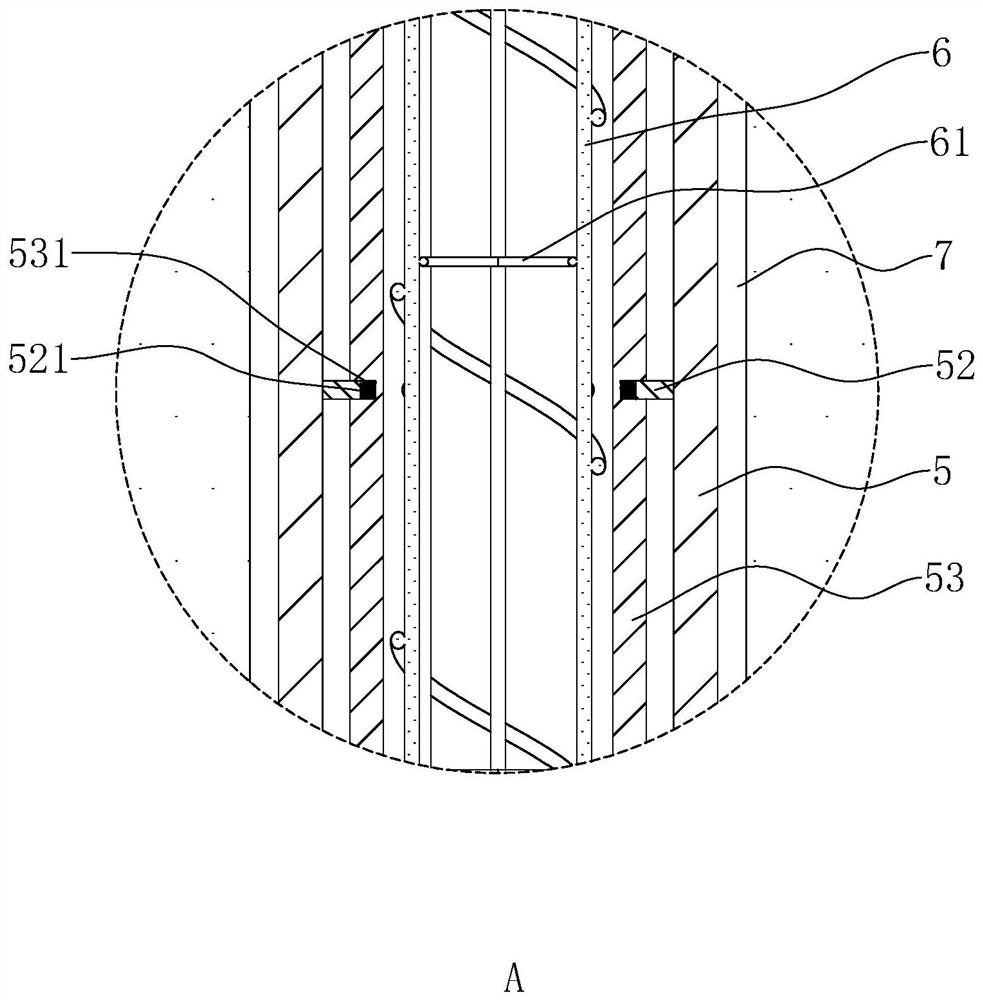

Construction Technology of Long Spiral Cast-in-situ Pile with Vibration and Tube Follower

This application relates to the technical field of foundation engineering, and discloses the construction process of long spiral cast-in-situ piles with vibration and pipe, including the following construction steps: step 1, preparation before construction; step 2, drilling into holes; step 3, concrete pouring; step 4, Hammering of the steel casing; step five, placing the reinforcement cage; step six, secondary pouring of concrete and removal of the steel casing. This application uses the pipe pile of the pile driver to pour concrete mortar in the borehole, which can ensure the borehole diameter and avoid the collapse of the hole, and then use the vibrating hammer to hammer the casing into the original pile position filled with concrete mortar. The uncondensed concrete at the original pile position is squeezed around to expand the pile diameter, increase the diameter of the pile foundation and the degree of integration with the ground, thereby improving the bearing strength and stability of the pile foundation.

Owner:湖北中南岩土工程有限公司

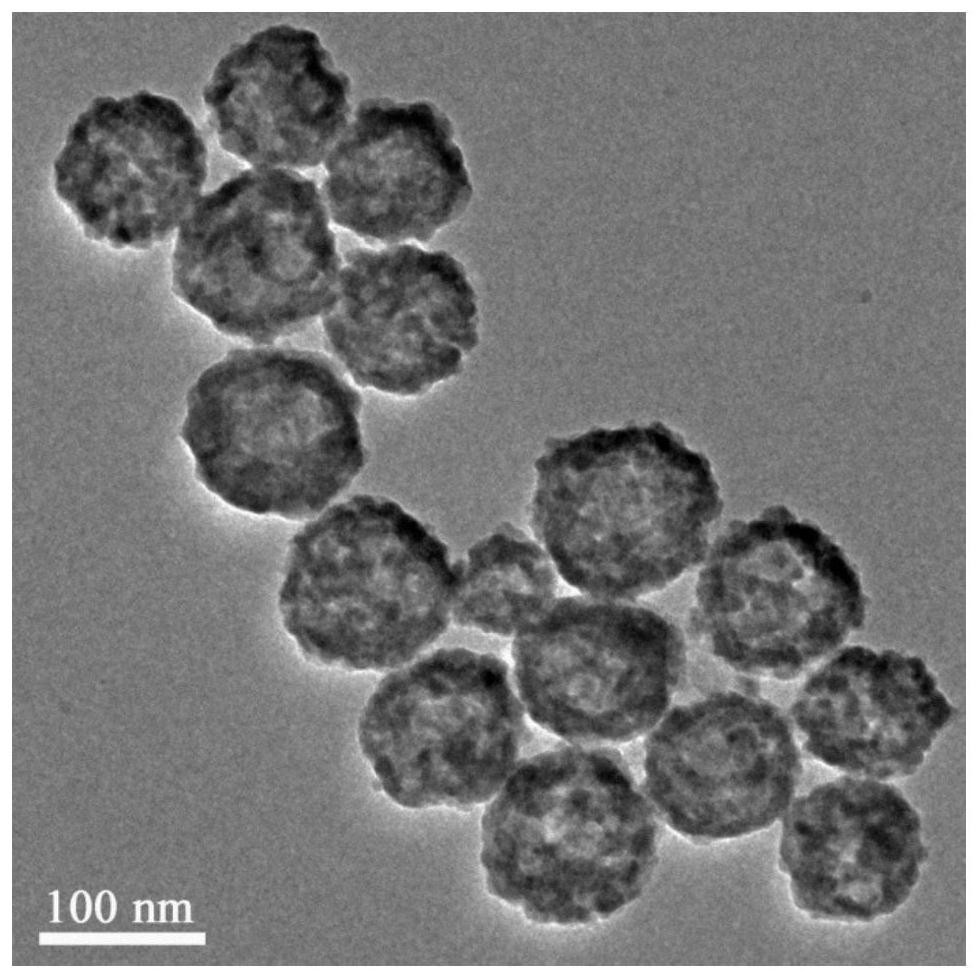

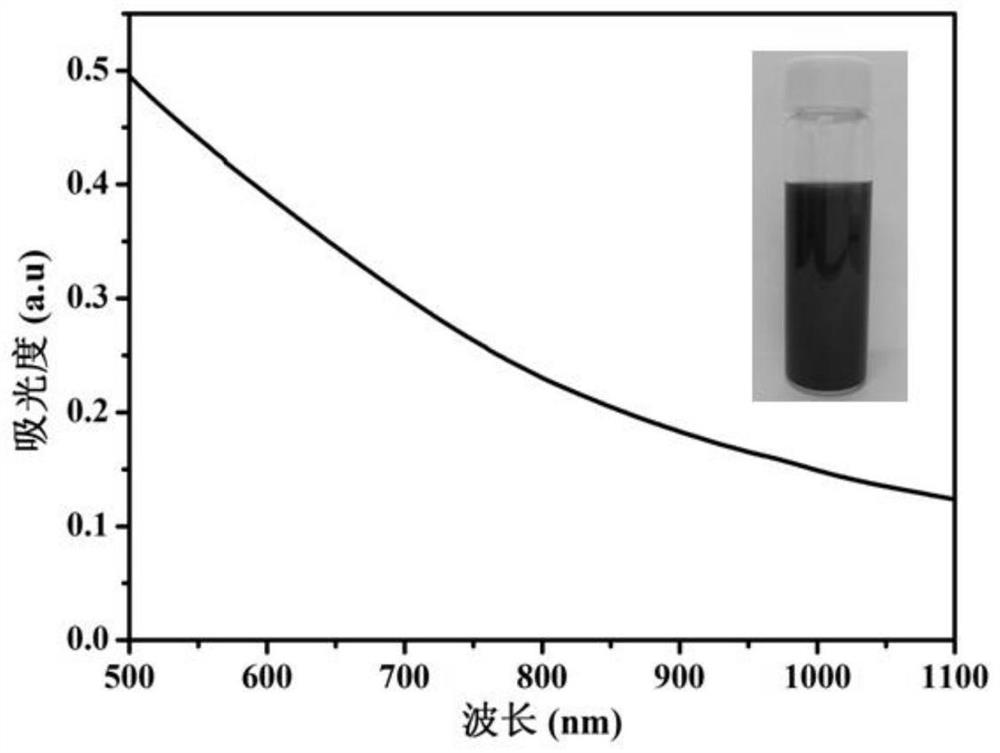

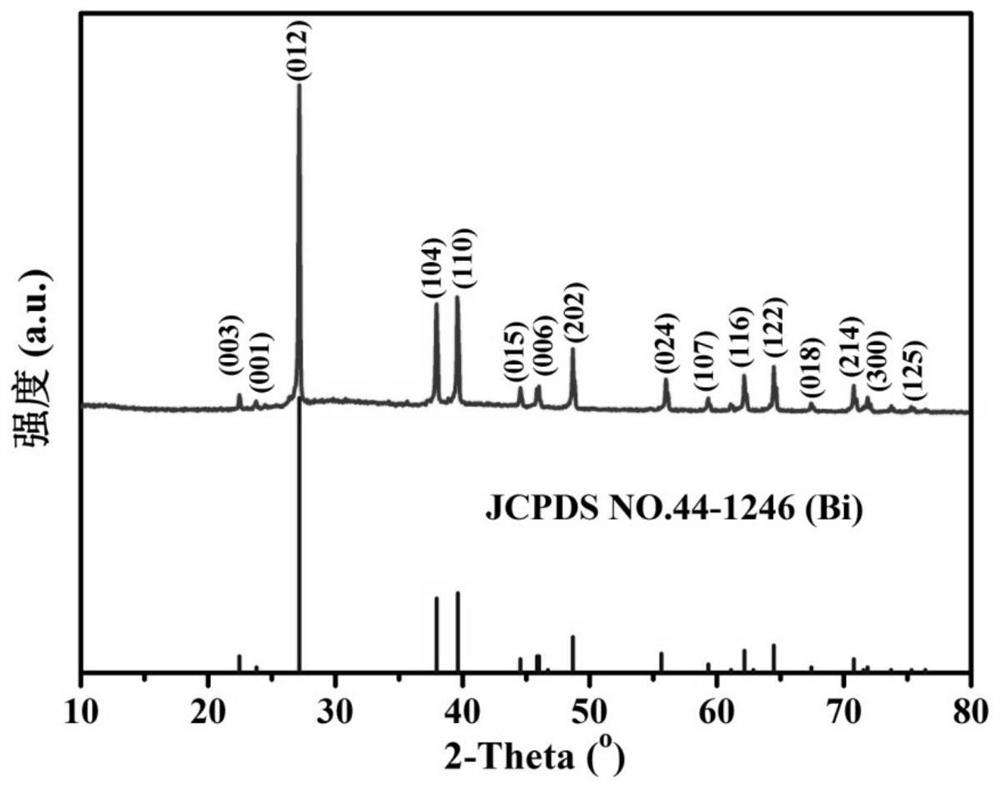

A kind of porous bismuth nano microsphere and its preparation method and application

ActiveCN109157531BGood biocompatibilityImprove biological characteristicsOrganic active ingredientsPowder deliveryMicrosphereGlycerol

The invention belongs to the field of multifunctional nanomaterials and particularly relates to porous bismuth nano-microspheres as well as a preparation method and an application thereof. A hydrophilic surface modifier is attached to the surfaces of the porous bismuth nano-microspheres, and three-dimensional through multi-pore structures are distributed in the microspheres. The preparation methodof the porous bismuth nano-microspheres comprises steps as follows: a molybdenum oxide template, bismuth salt and the hydrophilic surface modifier are uniformly dispersed in a mixed solution of glycerin and other alcohol solvents, a reflux reaction is performed, and the generated solid bismuth nano-microspheres are attached to the surface of the molybdenum oxide template; after the molybdenum oxide template is removed by alkali liquor, a solvothermal reaction is performed in a dimethyl sulfoxide solution, and the porous bismuth nano-microspheres are produced. The prepared porous bismuth nano-microspheres have radiopotentiation activity, photothermal conversion characteristic, drug loading activity and biocompatibility, achieve the synergistic therapeutic effect of radiotherapy, photothermic therapy and drug therapy, and have the application prospect of serving as a tumor diagnosis and treatment agent.

Owner:SHANGHAI UNIV OF ENG SCI

A graphene composite photocatalytic ultrafiltration membrane and preparation method thereof

ActiveCN110813110BImprove hydrophilicityImprove pollutionMembranesPhysical/chemical process catalystsOrganic chemistryPhoto catalysis

In the present invention, the membrane is first prepared by blending graphene oxide and polysulfone, and the hydrophilicity and anti-pollution ability of the ultrafiltration membrane are improved by using graphene oxide, and then the dispersion liquid of aminated titanium dioxide and water is used as a coagulation liquid for semi-curing The ultrafiltration membrane is solidified by suction filtration, and the amino groups of aminated titanium dioxide are cross-linked with the carboxyl groups of carboxylated graphene oxide during the curing process, so that the combination of titanium dioxide nanoparticles and the membrane is improved through physical and chemical dual effects, and the traditional optical solution is solved. The loss of photocatalytic particles in the catalytic ultrafiltration membrane.

Owner:江苏晖尔利电子科技有限公司

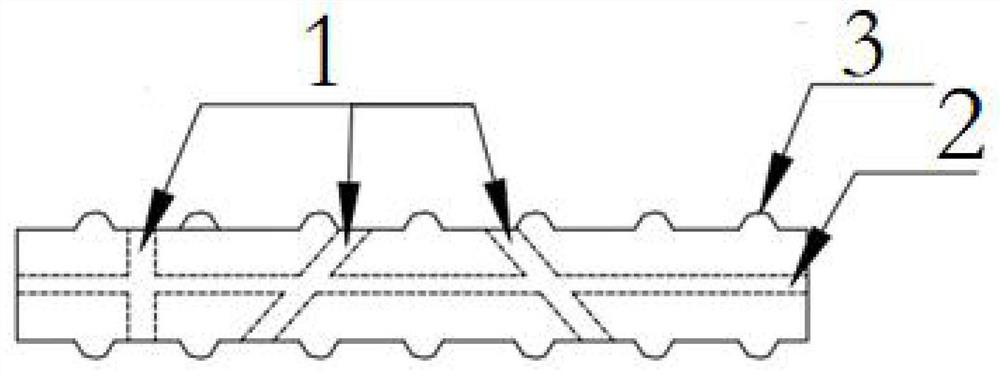

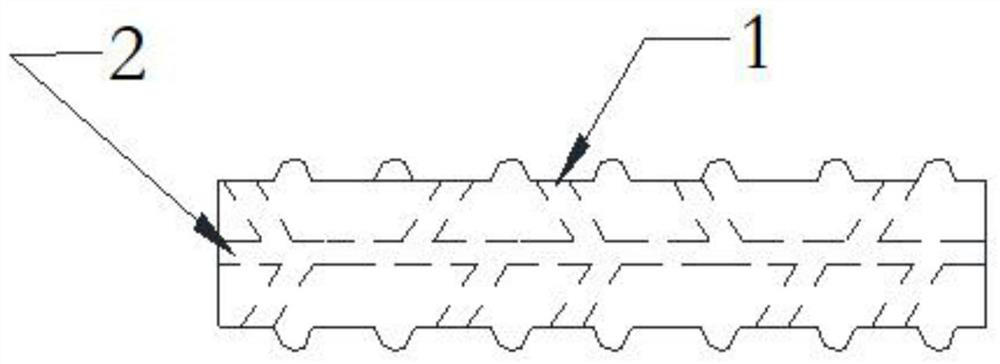

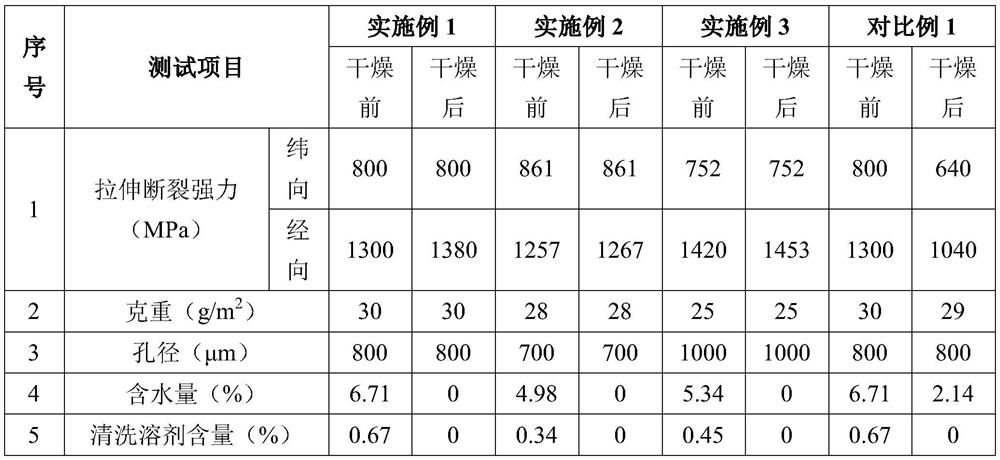

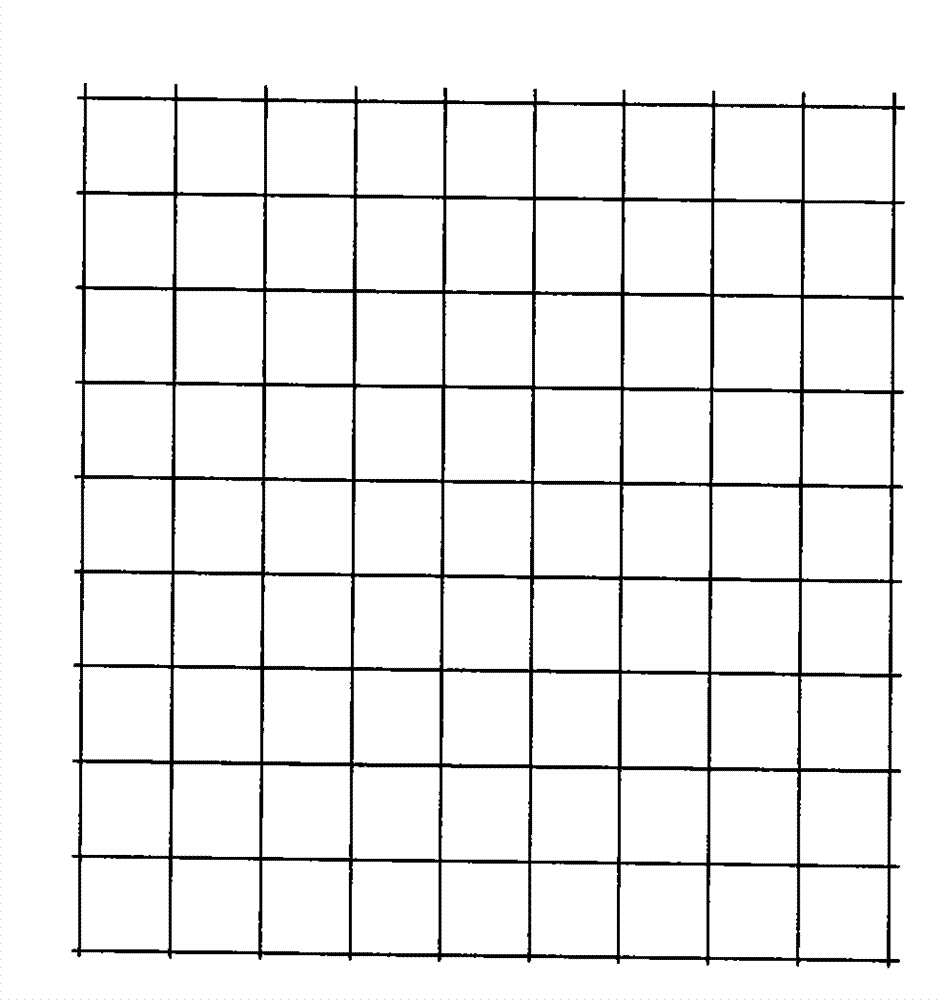

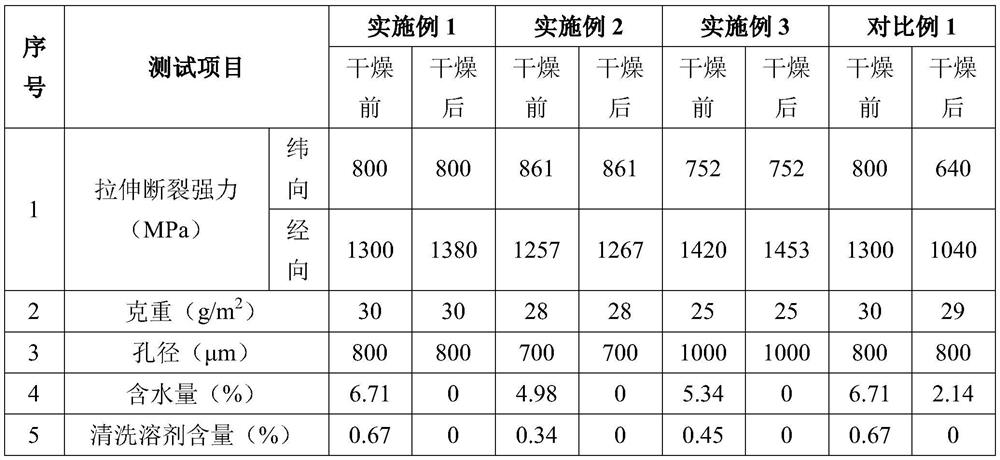

Drying method of polyglycollide warp-knitted supporting net for artificial skin

ActiveCN113670005AMaintain tensile breaking strengthGuaranteed apertureDrying using combination processesDrying solid materials with heatPolyglycolideMaterials science

The invention relates to a drying method of a polyglycollide warp-knitted supporting net for artificial skin. The drying method specifically comprises the steps of carrying out pre-drying, deep drying and fabric stress relaxation in sequence. According to the drying method, water in the polyglycollide warp-knitted supporting net and a residual solvent in the cleaning process can be thoroughly removed, the tensile breaking strength, the aperture, the gram weight and other properties of the polyglycollide warp-knitted supporting net can be effectively kept, and the method has important significance in application of the polyglycollide warp-knitted supporting net to the field of medical artificial skin.

Owner:HAIXI NEW TEXTILE MATERIAL OF JINJIANG IND TECH ACAD

Tool for turning flat-bottomed holes

The invention relates to a cutter for lathe matching of flat-bottom holes of discs. The cutter comprises a cutter bar and a cutter body. The cutter bar is a square strip, the cutter body is a three-edge flat lathe cutter fixedly mounted in an oblique square hole of the cutter bar. A left cutting edge and a right cutting edge are arranged on the left and right sides of a front cutting edge of the point of the cutter body, and an arc groove is arranged between the left and right cutting edges. The front cutting edge is set with an initial cut-in rake angle, an included angle between the initial cut-in rake angle and a front cutting edge rake angle is angle gamma, and the initial cut-in rake angle is connected with the arc groove between the left cutting edge and the right cutting edge. The cutter is simple in structure and high in strength of the cutter body; efficient machining of large-flat-bottom holes can be realized, and design requirements on aperture, roughness and the like are met effectively.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

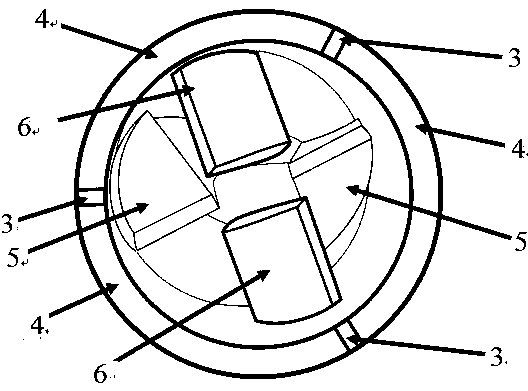

A multi-layer three-dimensional cutter face drill bit for glacier drilling

The invention relates to a drill bit with multilayer stereoscopic tool faces for glacier drilling exploration. The drill bit is characterized in that a drill bit body is connected with upper-layer tool bits, the upper-layer tool bits are positioned in a drill body which is in the shape of a barrel, three-position tool bits and bottom spiral contact surfaces of the drill body are arranged on the lower portion of the barrel, 45-degree included angles are formed between the three-position tool bits and the bottom spiral contact surfaces of the drill body, and the three-position tool bits are equidistantly separated from one another by 120-degree angles at the bottom of the barrel. Lower-layer tool bits are positioned on the inner lower portion of the barrel and are connected with the wall of the barrel, 135-degree included angles are formed by the lower-layer tool bits and the wall of the barrel, and planes where the lower-layer tool bits are located intersect with planes where the upper-layer tool bits are located. The drill bit has the advantages that the drilling operation stability and safety can be improved owing to the bottom spiral contact surfaces of the drill body, the service life of the drill bit can be prolonged owing to the upper-layer tool bits and the lower-layer tool bits, the stone and ice crushing capacity of the drill bit can be enhanced by the upper-layer tool bits and the lower-layer tool bits, and the ice crushing perpendicular upward detachment and the diameters of drilled holes can be guaranteed by the aid of the drill body which is in the shape of the barrel.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

A Construction Method for Bottom Expansion Pile with Pressure Grouting Concrete with Long Helical Drilling

The present invention involves a long spiral drilling rhombus pressure irrigation concrete expansion bottom pile construction method. It belongs to the technical field of pile foundation construction. The steps are as follows: S1, direct holes; S2, expansion drills to expand construction piles to expand the head; S3,, S3,, S3, S3, After the drill rod and the bottom drill, the bottom of the pile hole is irrigated and irrigated the concrete, and after the pouring part of the expansion hole is poured, the bottom and lower position of the drilling bits are shifted to rehabilitate the concrete expansion hole. Diamond, and continue to irrigate concrete in the pile holes until the drill is lifted to the ground; S5, use the vibrator to place the steel cage towards the pile hole; S6. After the pile is fired, it is maintained and inspected. The present invention has a convenient construction, enhances the stability between the bottom piles and the soil, and ensures the effect of the loading capacity of the bottom pile.

Owner:江西中恒地下空间科技有限公司

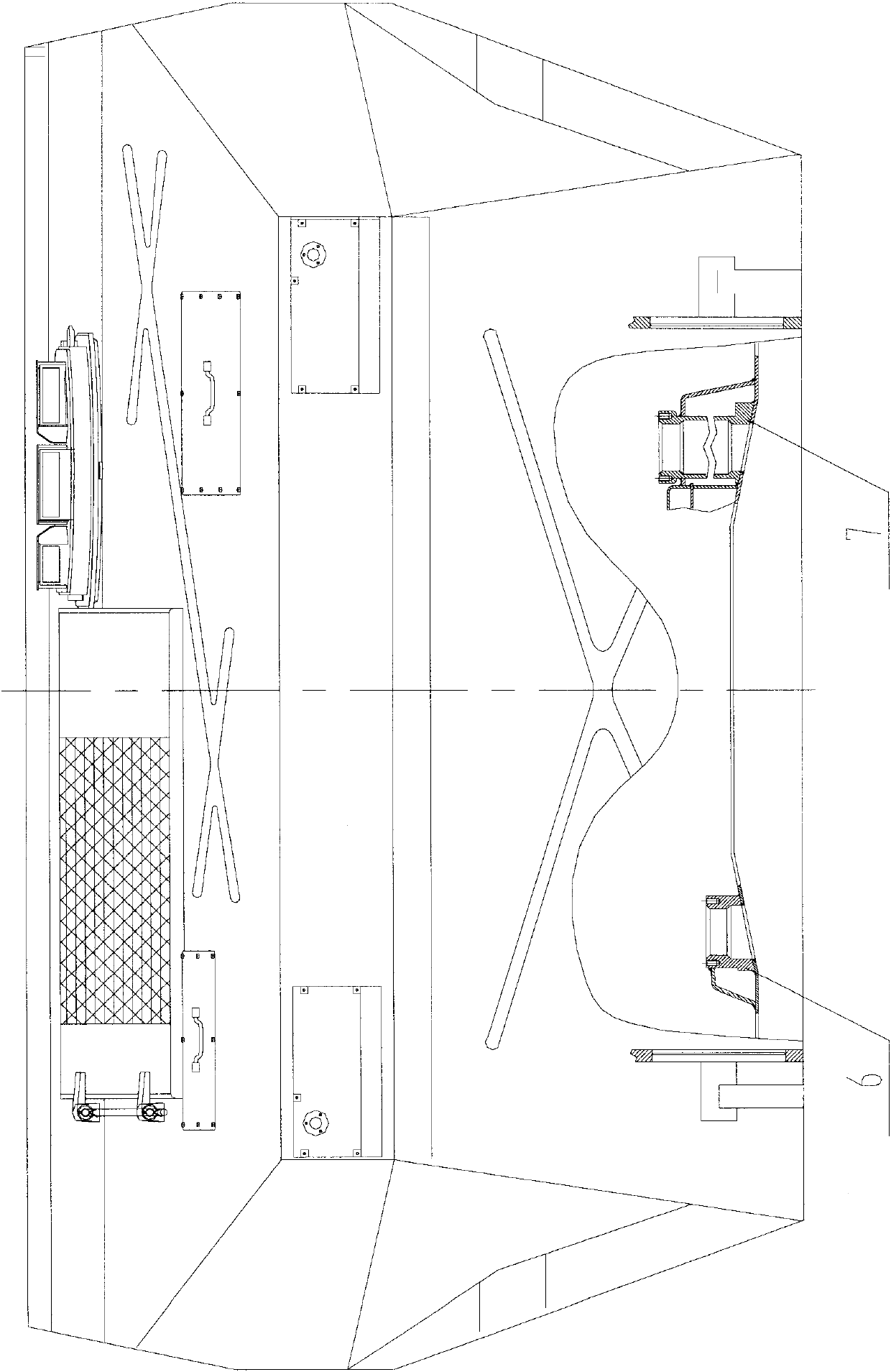

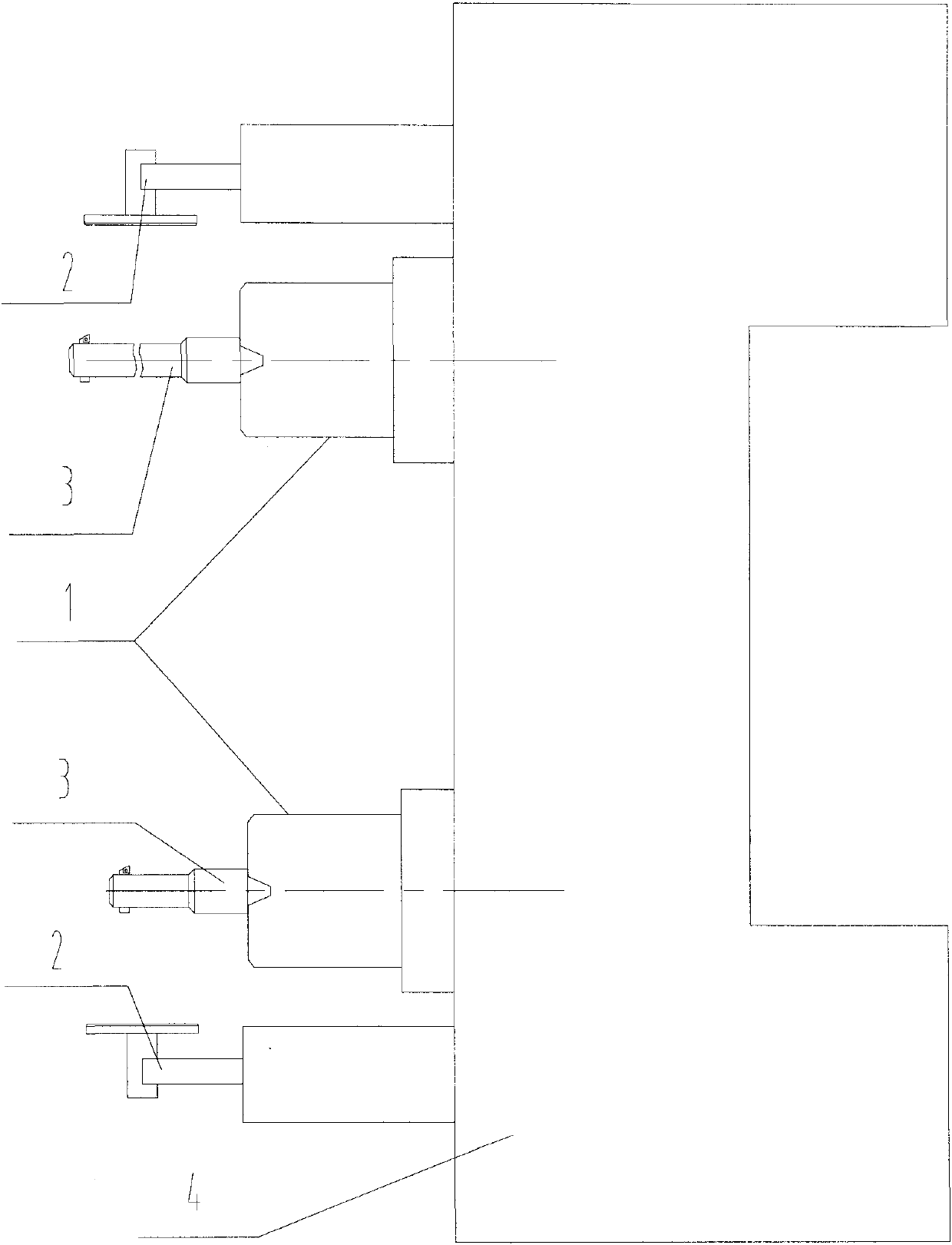

Construction technology of cantilever beam push-pull frame for jack-up drilling platform

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

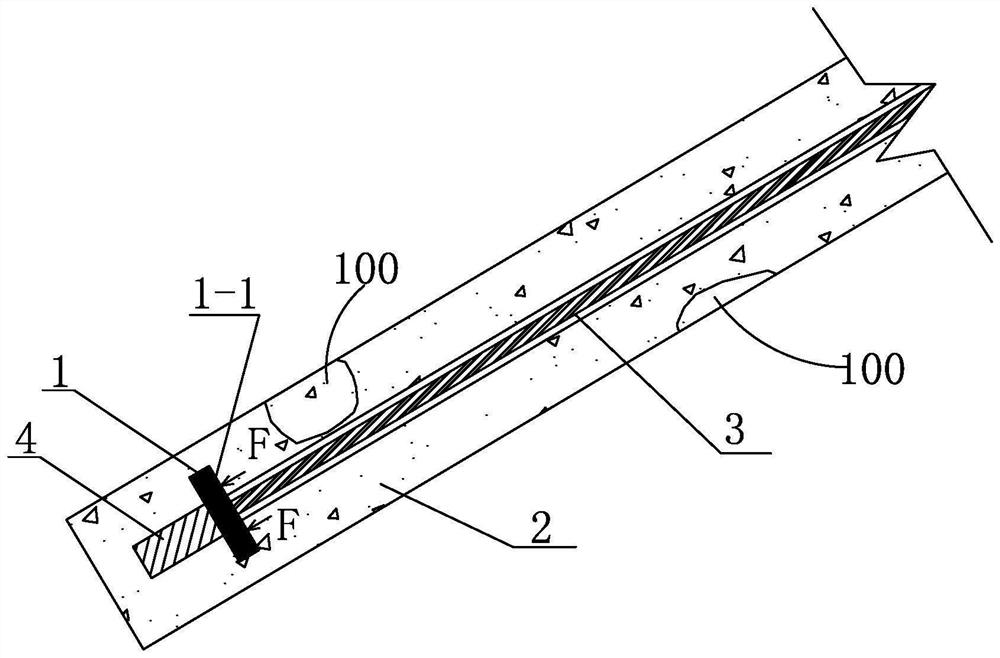

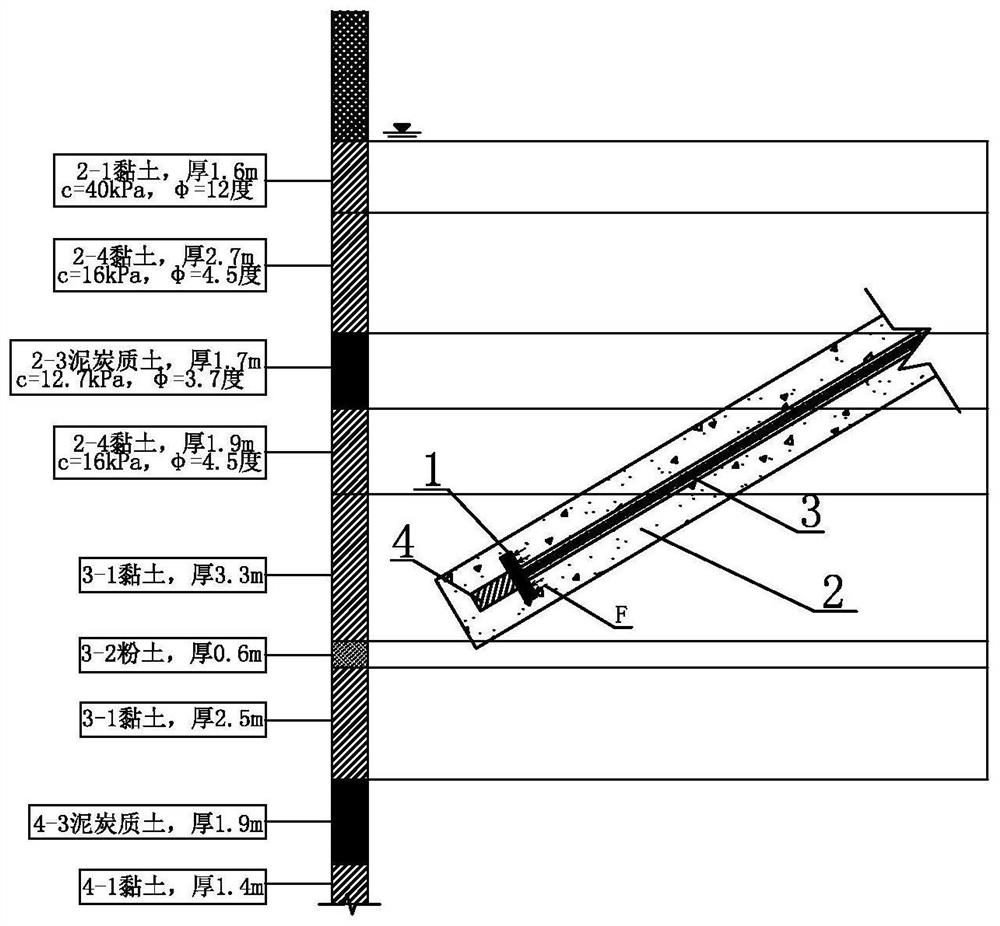

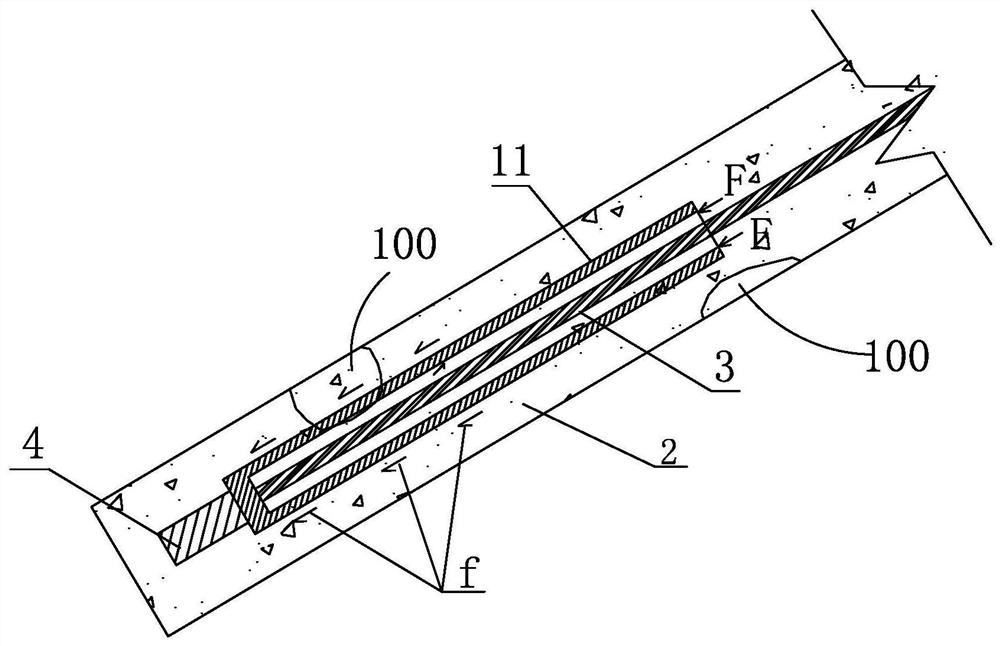

Carrier unbonded steel strand anchor cable

PendingCN112854212AIncrease the lengthGuaranteed apertureBulkheads/pilesArchitectural engineeringFoundation engineering

The invention relates to a carrier unbonded steel strand anchor cable, and belongs to the technical field of ground anchors special for foundation engineering. The anchor cable comprises an unbonded steel strand used for being inserted into an underground drilled hole, a locking anchorage device and a carrier, wherein the locking anchorage device is attached to one end face of the carrier; the carrier extends in the longitudinal direction of the steel strand to form a long-strip-sleeve shape; the steel strand penetrates into the long-strip-sleeve, and one end of the steel strand penetrates through one end face of the carrier and then is fixedly connected with the locking anchorage device; and the length of the carrier is far larger than the diameter of the hole. According to the anchor cable, due to the fact that the outer wall of the sleeve of the carrier is bonded and fixed to surrounding cement, the anchoring force of the anchor cable can be improved, or the hole diameter of the drilled hole is reduced under the condition that the anchoring force of the anchor cable is guaranteed, and the anchor cable can adapt to complex and changeable stratum structures.

Owner:SUZHOU NG FOUND ENG

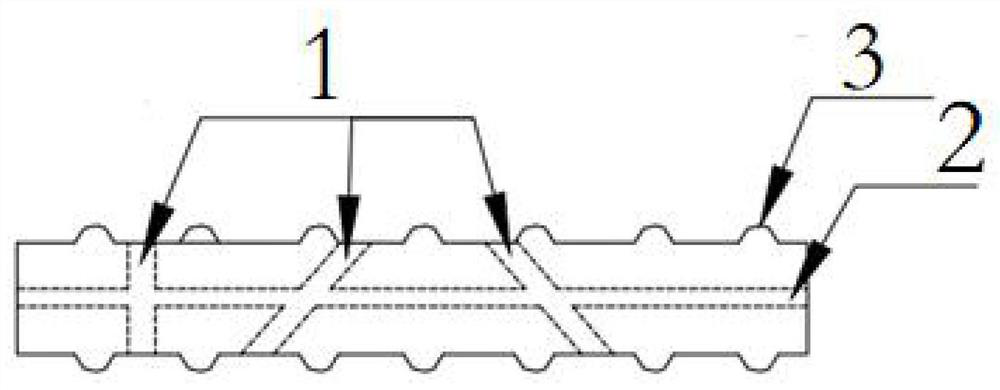

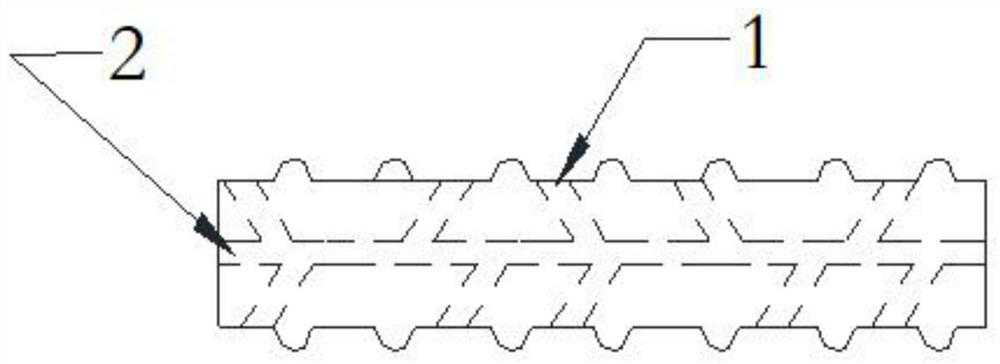

Manufacturing method of metal woven screen

The invention discloses a manufacturing method of a metal woven screen, which successively comprises the following steps: carrying out pressing and pre-springing on steel wires by a knurling wheel; simultaneously carrying out high-frequency quenching or mid frequency quenching on a plurality of steel wires after pre-springing, and then tempering so as to enable the hardness of the steel wires to be HRC42-52; and weaving the steel wires after the heat treatment into a screen. The invention greatly improves the wear-resisting property of the screen, prolongs the service life of the screen, can carry out the high-frequency quenching or the mid frequency quenching on a plurality of steel wires at the same time, and greatly improve the production efficiency. The heat treatment is carried out before woven, thereby improving the abrasive resistance of the screen, avoiding the looseness of the screen in the process of heat treatment, ensuring the evenness of aperture, and reaching the national GBT standard.

Owner:上海锦荣矿山机械有限公司

Drying method of polyglycolide warp knitted support net for artificial skin

ActiveCN113670005BMaintain tensile breaking strengthGuaranteed apertureDrying using combination processesDrying solid materials with heatPolyglycolideMaterials science

The invention relates to a drying method for a polyglycolide warp-knitted support net for artificial skin, specifically performing pre-drying, deep drying and fabric stress relaxation successively. The present invention can completely remove the moisture in the polyglycolide warp-knitted support net and the solvent remaining in the cleaning process, and can effectively maintain the properties of the polyglycolide warp-knitted support net such as tensile breaking strength, pore diameter, and grammage, It is of great significance for the application of polyglycolide warp knitted support net in the field of medical artificial skin.

Owner:HAIXI NEW TEXTILE MATERIAL OF JINJIANG IND TECH ACAD

Processing method of steering vertical axle seat of 8×8 wheeled armored vehicle

ActiveCN111183713BGuaranteed positionGuaranteed apertureArmoured vehiclesBoring/drilling machinesAgricultural engineeringMachine tool

The invention relates to a processing method for a steering vertical shaft seat of a wheeled armored vehicle, in particular to a precision processing method for a steering vertical shaft seat of an 8×8 wheeled armored vehicle. Through a special processing machine tool, the method of processing the vertical shaft seat by reverse pulling is adopted, which solves the technical problems such as the high rework probability of the vertical shaft seat of the steering shaft seat and the welding deformation of the shaft seat hole. The processing process is as follows: install the special processing machine tool under the ground level, install the wheeled armored vehicle on the positioning and clamping device of the special processing machine tool, make the boring tool pass through the bottom hole of the vertical shaft seat from bottom to top, and make the boring tool go from Up and down movement completes the machining of the shaft seat hole. In the process of processing, a special measuring device is used to realize the measurement with a tool, and the diameter of the boring tool is adjusted according to the measurement data to complete the machining of the vertical shaft seat. The invention avoids the structural limitation of the 8×8 wheeled infantry fighting vehicle, and completes the machining of the vertical shaft seat from bottom to top on the outside of the vehicle, ensures the position and aperture of the vertical shaft seat, and reduces the rework probability of the vertical shaft seat.

Owner:内蒙古第一机械集团股份有限公司

a trabecular structure

ActiveCN112022444BGuaranteed StrengthSmooth shippingBone implantJoint implantsBone TrabeculaeDentistry

The invention relates to the technical field of medical prosthesis and provides a bone trabecular structure. It includes: a trabecular bone structure body, the trabecular bone structure body is composed of a number of interlaced trabeculae, and the interlaced trabeculae form a trabecular bone structure hole; a hole structure is arranged inside the trabecular bone structure body , the hole structure includes a number of side holes and a number of transverse holes, and a number of side holes intersect with a number of the transverse holes; wherein, some of the side holes are arranged perpendicular to the axis of the trabecular structure body, and some Several side holes are arranged obliquely. The beneficial effect of the present invention is that: the body of the trabecular bone structure is designed with holes in the transverse and longitudinal directions of the trabecular bone, which not only ensures the strength of the trabecular bone structure, but also increases the intercommunication, so that nutrients and other substances can be transported more smoothly, increasing the The site area for metabolism is reduced, the progress of bone ingrowth is accelerated, and the effect of bone ingrowth is more reliable.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

A kind of photocatalytic ultrafiltration membrane and preparation method thereof

ActiveCN110813109BImprove bindingGuaranteed apertureMembranesPhysical/chemical process catalystsNanoparticlePhysical chemistry

The invention provides a photocatalytic ultrafiltration membrane and a preparation method thereof, specifically, by adding TiO 2 The dispersion of nanoparticles and water is used as a coagulation liquid to filter and solidify the semi-cured ultrafiltration membrane. Compared with the prior art, TiO is fixed on the cured ultrafiltration membrane. 2 The method has better binding force and solves the problem of loss of photocatalytic particles existing in traditional photocatalytic ultrafiltration membranes.

Owner:TAIZHOU QINGRUN ENVIRONMENTAL PROTECTION TECH CO LTD

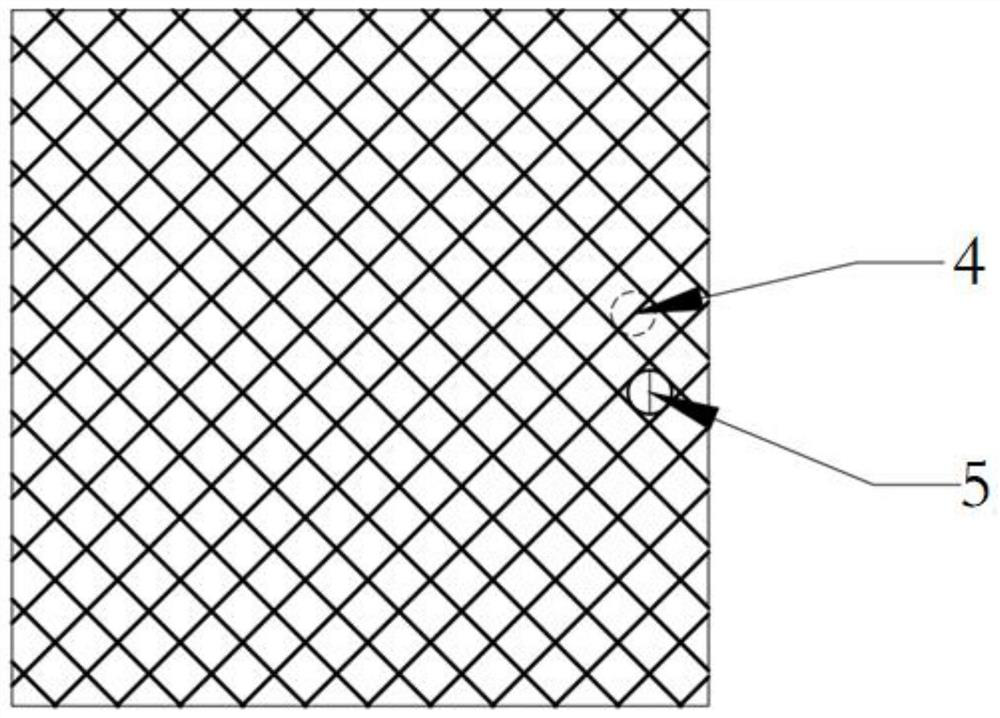

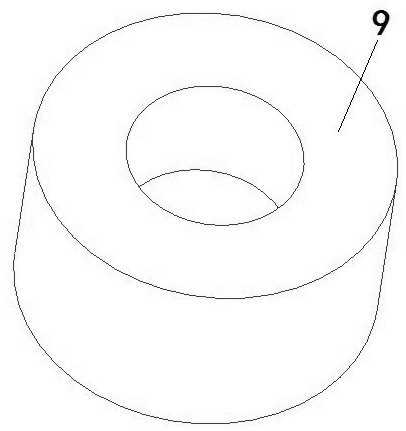

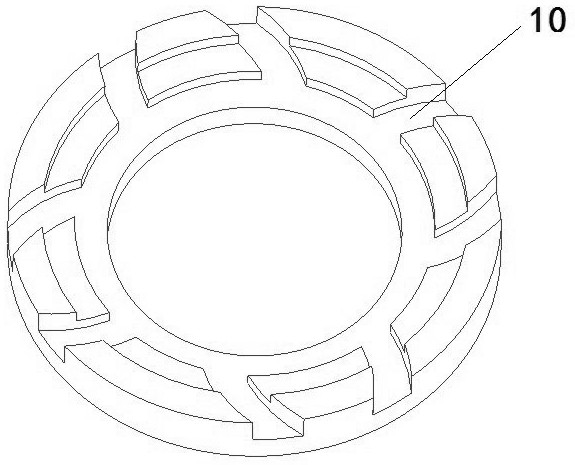

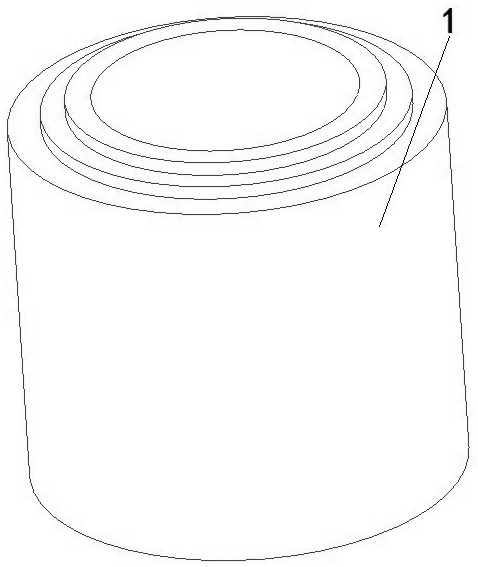

A kind of non-hard rock coring bit and its processing technology

ActiveCN114458161BIncrease the outer diameterEasy to excludeDrill bitsMining engineeringGeological exploration

The invention relates to a non-hard rock coring drill bit and a processing technology thereof, belonging to the technical field of drill bits for geological exploration. The technical solution is: positive water ports (4) and anti-water ports (5) are arranged alternately at the end of the drill bit steel body (1), the protrusions between the adjacent positive water ports and anti-water ports are tire blocks, and the tire blocks include tire blocks one (2) and tire block two (3); between the adjacent positive water outlet and reverse water port opposite to the spiral direction is tire block one (2), and the adjacent positive water port (4) and reverse water port (5) opposite to the spiral direction There are tire blocks two (3) in between, and tire block one and tire block two are arranged alternately on the circumference of the end of the steel body of the drill bit. Beneficial effects of the present invention: convenient manufacture, reasonable structure, reduced occurrence of collapse and sticky drills; reduced frequent replacement of drill bits in soft rock formations, improved drilling efficiency and reduced drilling costs, through the actual use of on-site machines, The purpose of the invention is achieved, and the problem of difficult coring in soft rock formations in the technical field of drilling for geological exploration is solved.

Owner:TANGSHAN JINSHI SUPER ABRASIVE

A kind of microporous carbon aerogel and preparation method thereof

ActiveCN106976864BImprove adsorption capacityLarge specific surface areaCarbon preparation/purificationMolten saltParticle-size distribution

The invention relates to microporous carbon aerogel and a preparation method thereof. The microporous carbon aerogel is prepared by adding mixed eutectic molten salt composed of LiNO3, KNO3 and K2SO4 in a step of preparing organic wet gel; parameters include that specific surface area is 850-1350m2 / g, pore size distribution is 1-2nm, pore volume is 0.38-0.43cm3 / g, and adsorption amount of CO2 at normal temperature and normal pressure is 3.2-3.8mmol / g. The microporous carbon aerogel prepared by the method is high in specific surface area, narrow in pore size distribution range, large in pore volume and high in ability of adsorbing carbon dioxide. The preparation method is simple in steps, convenient to operate, low in production cost, short in process time and environment-friendly.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com