Electrostatic air filter paper and preparation method thereof

An air filter paper and electrostatic technology, applied in the field of filter paper, can solve the problems of unsatisfactory filtration performance and high price (cost), and achieve the effects of improving paper quality, long service life, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

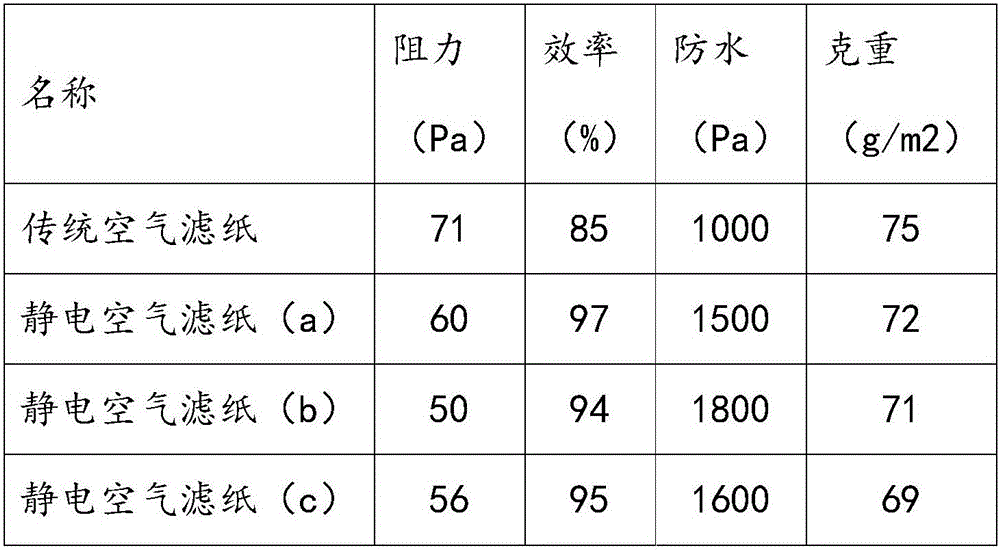

Image

Examples

Embodiment 1

[0028] 1) Beating: 50 parts of polypropylene / polyester fiber composite fibers with a diameter of 5um were beaten using a Volt type beater, and the Canadian freeness of the slurry was controlled to be 100;

[0029] 2) Dispersion: use a high shear disperser to disperse 20 parts of alkali-free glass fibers with a diameter of 0.2 μm;

[0030] 3) Slurry preparation: import the slurry obtained in steps 1) and 2) into the slurry preparation tank, and evenly add 5 parts of modified nanocellulose with a diameter of 3nm and 5 parts of fluorocarbon water repellent, wherein the modified nano Cellulose is obtained by hydrophobic modification of nanocellulose, and the degree of substitution of hydrophobic groups is 0.10;

[0031] 4) Molding: The mixed slurry obtained in step 3) is wet-molded through a paper sample extractor, and the quantitative control is 40g / m 2 ;

[0032] 5) Hot pressing: hot pressing the paper sample obtained in step 4) through a flat vulcanizing machine, the hot pres...

Embodiment 2

[0038] 1) beating: use a volt type beating machine to beat 60 parts of polypropylene / polyester fiber composite fibers with a diameter of 15um, and control the Canadian freeness of the slurry to be 200;

[0039] 2) Dispersion: use a high shear disperser to disperse 25 parts of alkali-free glass fibers with a diameter of 0.6 μm;

[0040] 3) Slurry preparation: import the slurry obtained in steps 1) and 2) into the slurry preparation tank, and evenly add 8 parts of modified nano-cellulose with a diameter of 6nm and 10 parts of fluorocarbon water repellent, wherein the modified nano-cellulose Cellulose is obtained by hydrophobic modification of nanocellulose, and the degree of substitution of hydrophobic groups is 0.20;

[0041] 4) Molding: the mixed slurry obtained in step 3) is wet-molded through a paper sample extractor, and the quantitative control is 60g / m 2 ;

[0042] 5) Hot pressing: hot pressing the paper sample obtained in step 4) through a flat vulcanizing machine, the...

Embodiment 3

[0048] 1) Beating: Utilize a volt beater to beat 68 parts of polypropylene / polyester fiber composite fibers with a diameter of 19um, and control the Canadian freeness of the slurry to be 150;

[0049] 2) Dispersion: use a high shear disperser to disperse 30 parts of alkali-free glass fibers with a diameter of 1.0 μm;

[0050] 3) Slurry preparation: import the slurry obtained in steps 1) and 2) into the slurry preparation tank, and evenly add 9.5 parts of modified nano-cellulose with a diameter of 10nm and 13 parts of fluorocarbon water repellent, wherein the modified nano-cellulose Cellulose is obtained by hydrophobic modification of nanocellulose, and the degree of substitution of hydrophobic groups is 0.25;

[0051] 4) Molding: the mixed slurry obtained in step 3) is wet-molded through a paper sample extractor, and the quantitative control is 50g / m 2 ;

[0052] 5) Hot pressing: hot pressing the paper sample obtained in step 4) through a flat vulcanizing machine, the hot pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com