Roll type vertical mill

A vertical mill, roller technology, applied to the roller vertical mill. It can solve the problems of large energy consumption and increase the amount of discharged materials, and achieve the effects of improving service life, reducing dust concentration, reducing air volume and wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

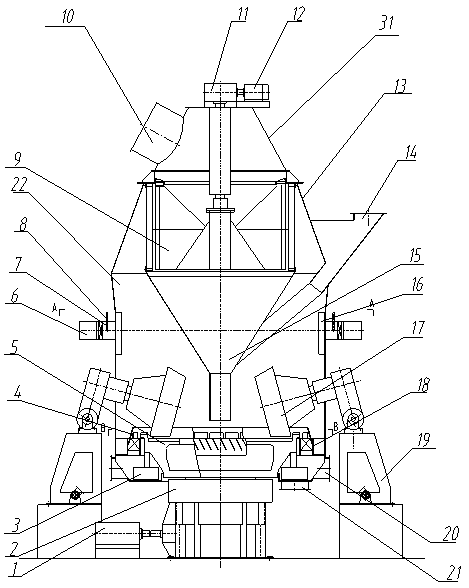

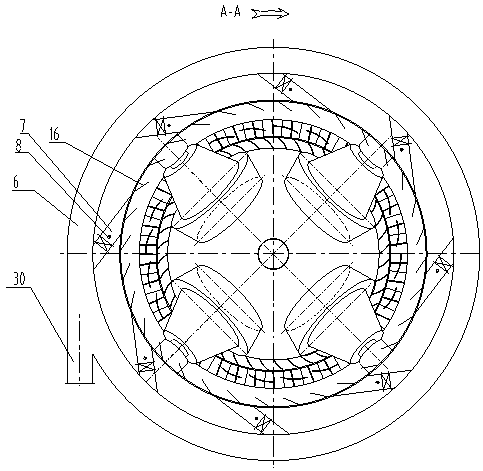

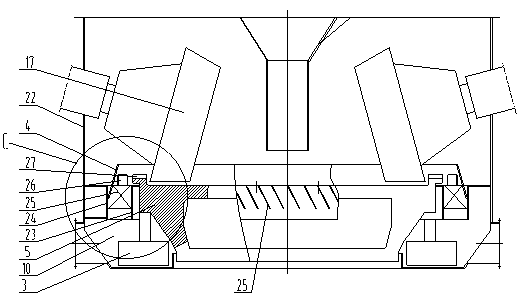

[0035] Such as figure 1 with figure 2 Described a kind of vertical roller mill, comprises mill shell 22, is provided with grinding disc 5 and grinding roller 17 in described mill housing 22, and described grinding disc is installed on the vertical speed reducer 2, by The motor 1 provides power to the vertical reducer 2 .

[0036] The grinding rollers 17 are arranged on the support 19 and evenly distributed around the periphery of the mill shell 22 . A nozzle ring 18 is arranged between the outer circumference of the grinding disc 5 and the mill housing 22, and an air inlet 20 is also arranged on the mill housing 22 at the bottom of the nozzle ring 18, and the gas enters the air inlet 20 to the mill housing 22 An annular airflow is formed inside and passes through the nozzle ring 18; the lower part of the nozzle ring 18, specifically at the bottom of the mill housing 22, is provided with a discharge port 21 for discharging the particles from the mill housing 22, and around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com