Double liquid phase groove type distributor

A distributor and two-phase technology, applied in distillation separation, separation method, dispersed particle separation, etc., can solve the problem that the quality of the product cannot meet the requirements, and it can only overflow on the top of the secondary distribution tank, and the product cannot be reached. Quality requirements and other issues, to achieve the effect of easy manufacturing and on-site installation, excellent gas-liquid distribution effect, and a wide range of operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

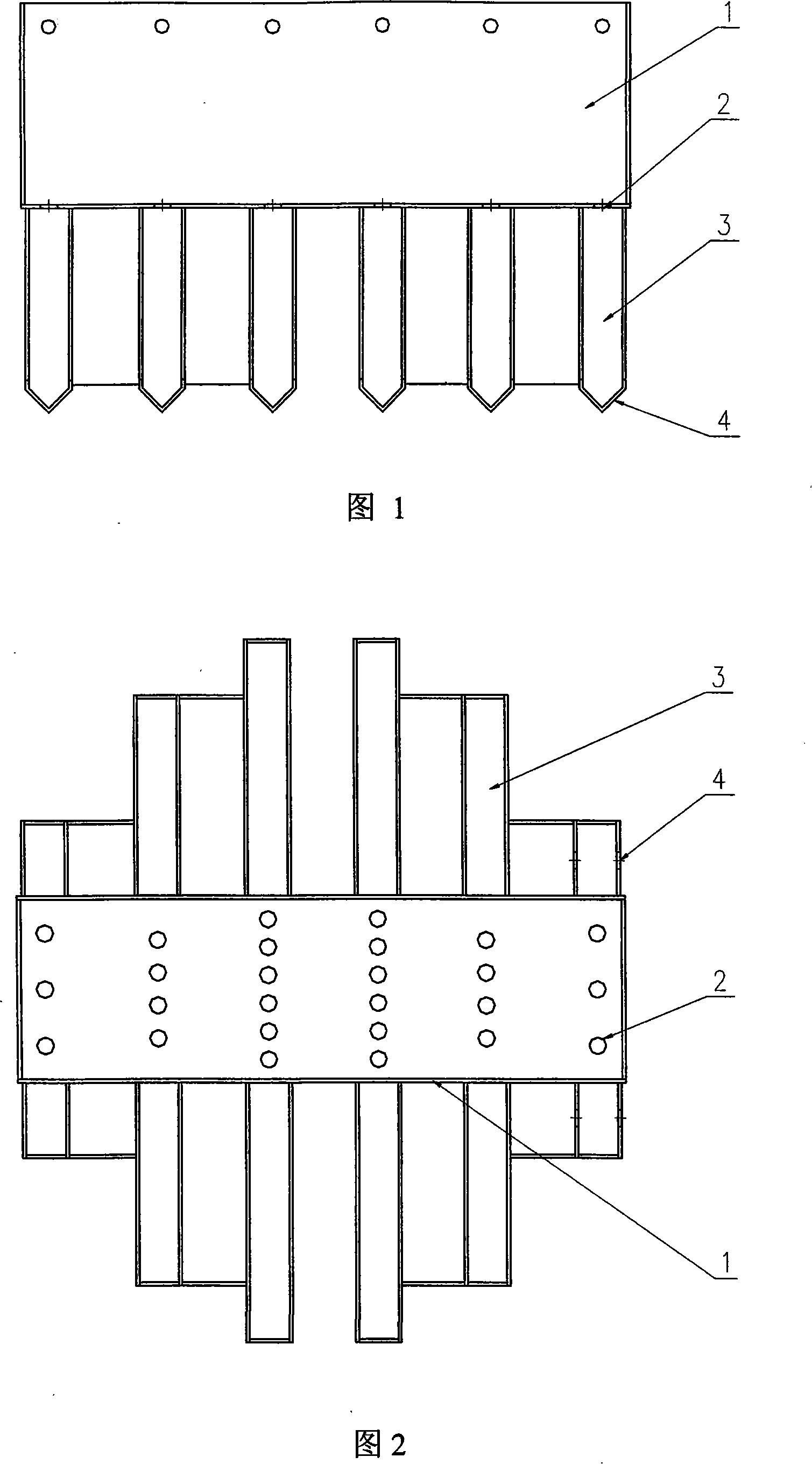

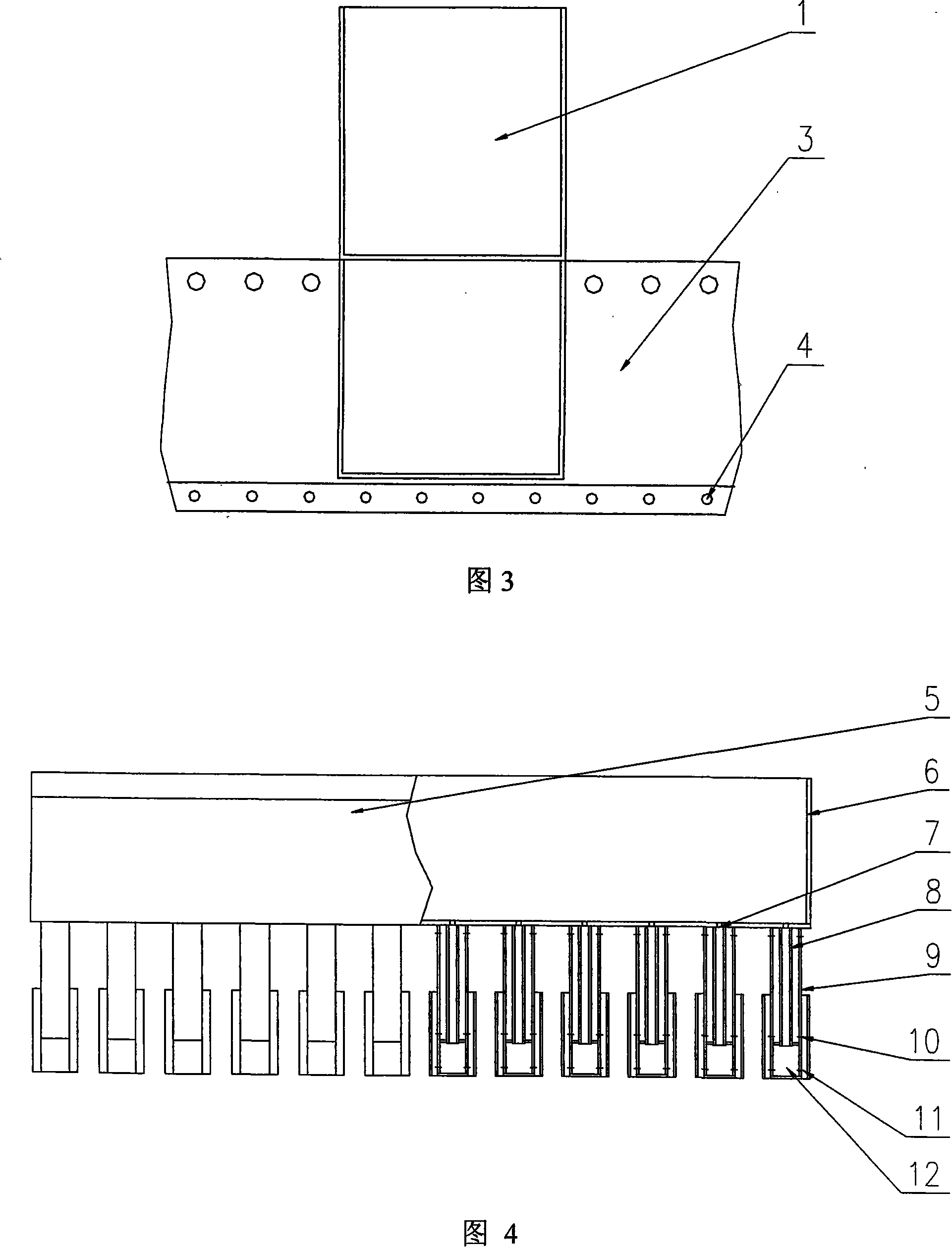

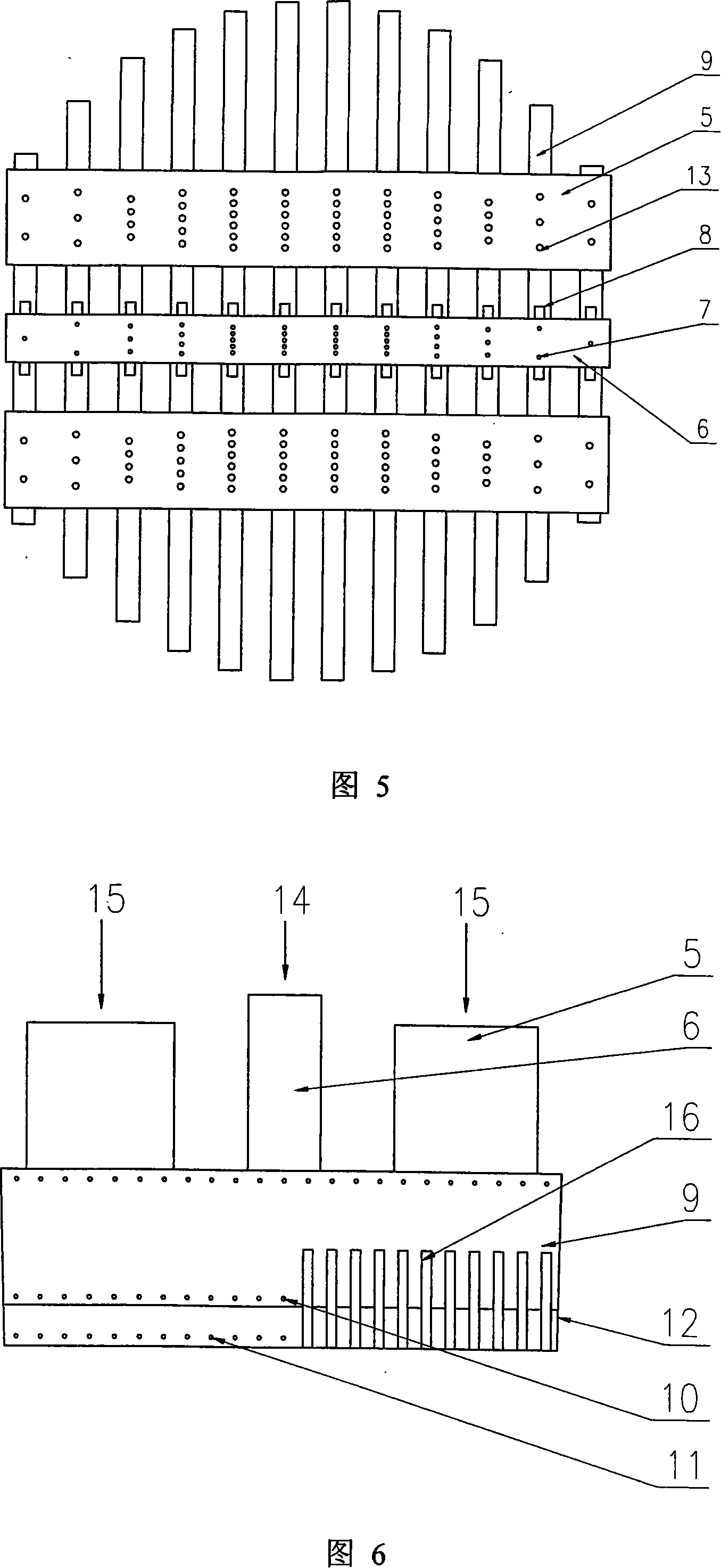

[0032] As shown in Fig. 4, Fig. 5, Fig. 6 and Fig. 7, the present invention is a two-liquid phase trough distributor realized by the following technical scheme. The distributor includes a rectangular first-level main groove and a second-level distribution groove. Below the first-level main groove is a second-level distribution groove arranged in an array perpendicular to it. The first-level main tank is composed of 2 to 4 single-tank boxes, and the second-level distribution tank is composed of two single-chamber tanks that respectively withstand two different liquids. Corresponding to the center position of the secondary distribution tank along the length direction of the first-level main tank body, different numbers of liquid separation holes are opened in proportion to the bottom of the tank body, and the respective liquids are respectively introduced into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com