Raw material vertical mill external circulation system and process

A raw material vertical mill and circulation system technology, which is applied in swirling devices, grain processing, etc., can solve the problems of insufficient powder selection capacity, large amount of powder returning, and increased gas flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

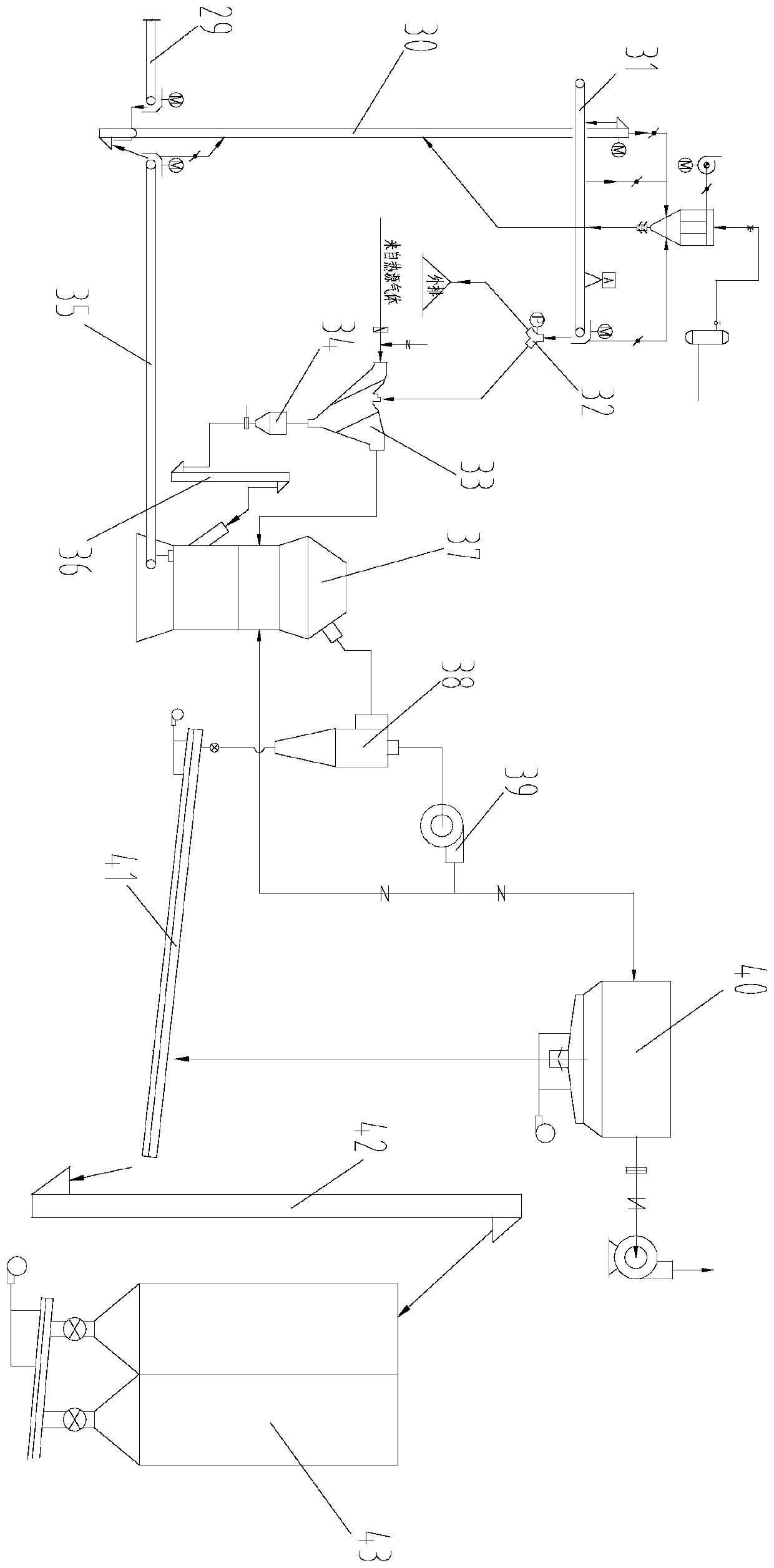

[0023] Such as figure 1 As shown, this embodiment discloses a raw meal vertical mill external circulation system, including a batching belt conveyor 29, a feeding hoist 30, a feeding transmission mechanism 31, a feeding tee 32, a V-shaped powder separator 33, and a buffer bin 34 ;Outgoing mill belt conveyor 35; Feeding hoist 36, external circulation roller vertical mill 37, cyclone 38, circulation fan 39 and bag filter 40, finished product air delivery chute 41, storage hoist 42, finished product warehouse 43.

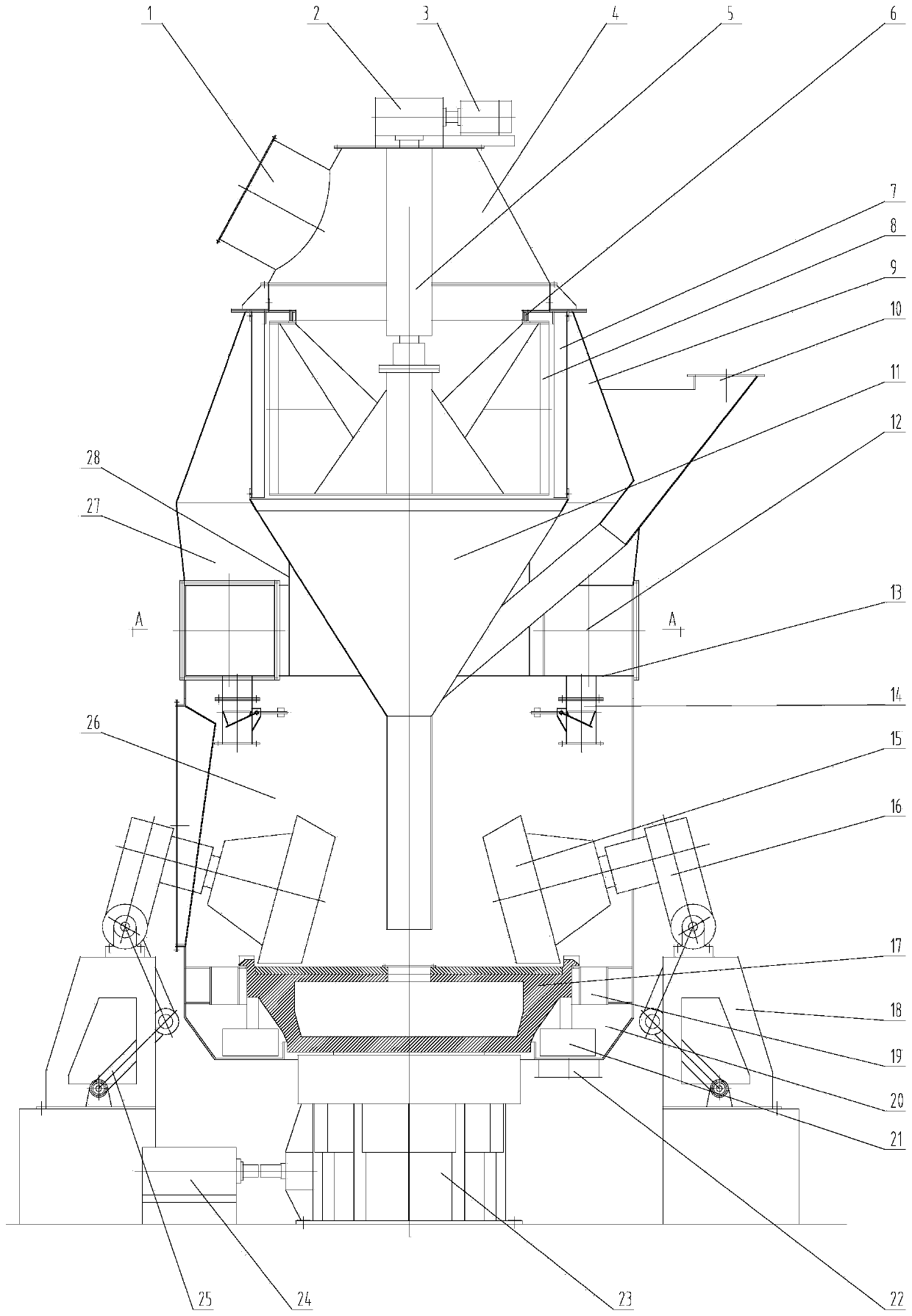

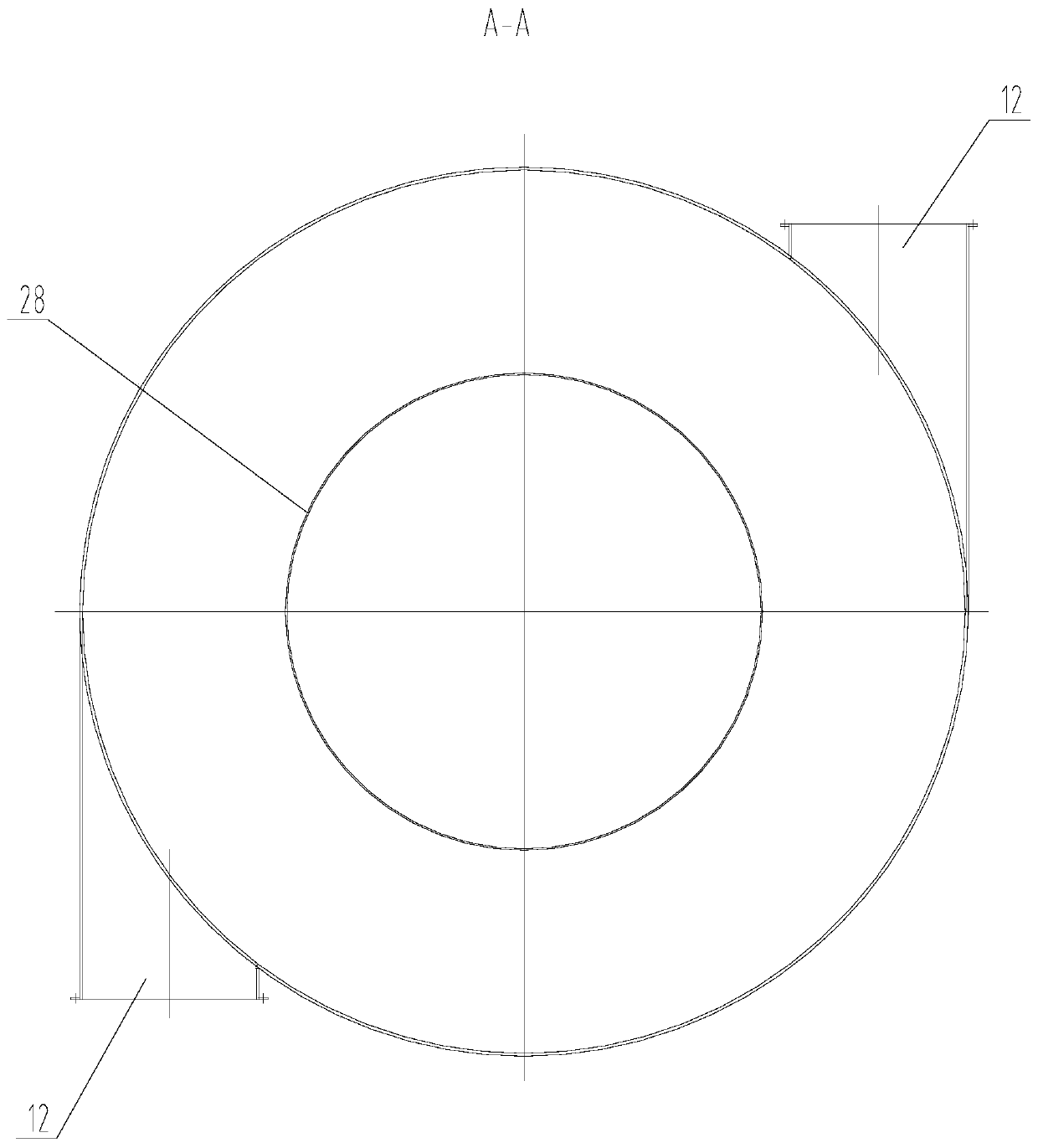

[0024] The outer circulation roller vertical mill 37 includes a lower grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com