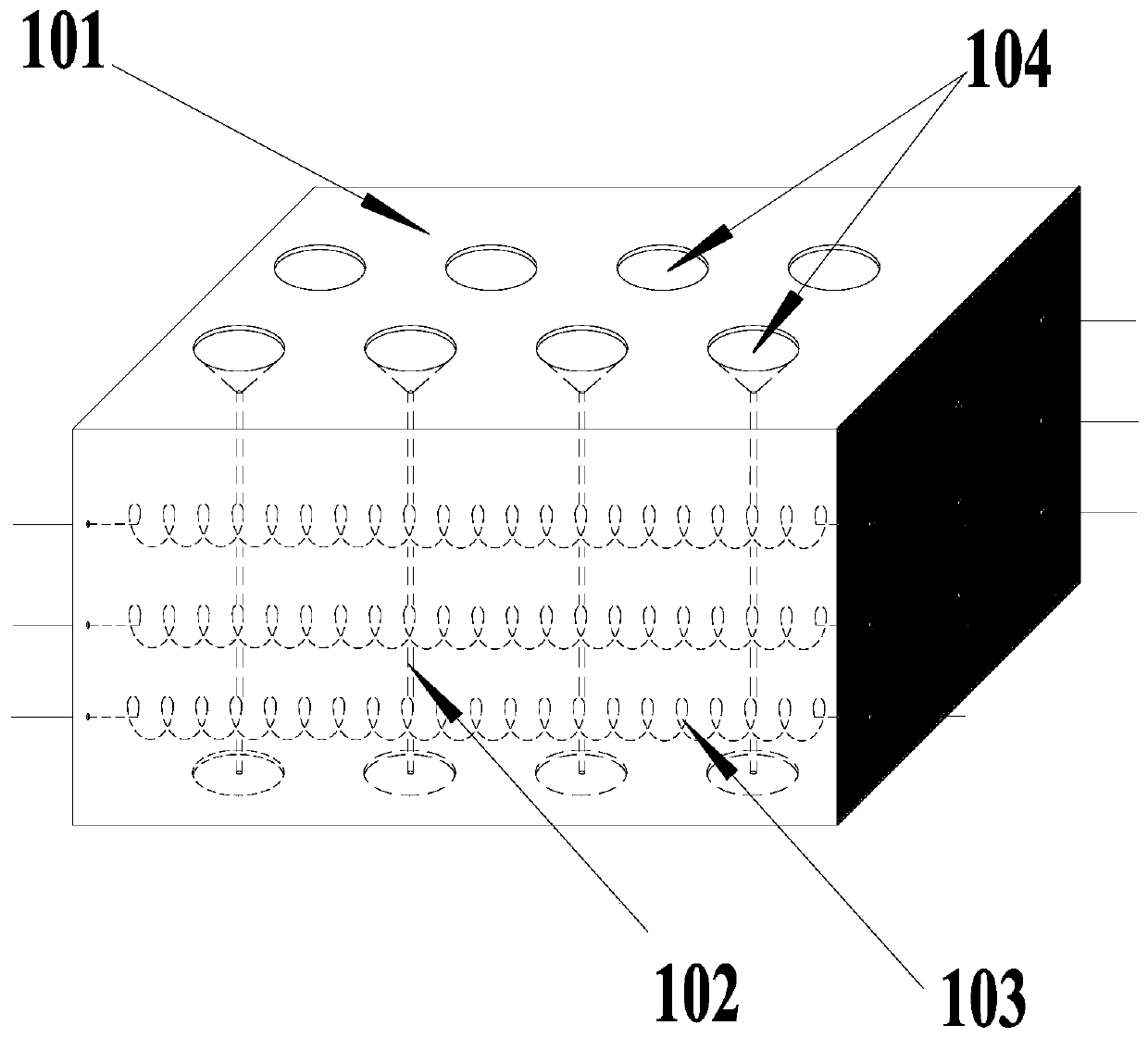

Porous ceramic catalytic oxidizer, preparation method thereof and multipurpose efficient air purification device

A catalytic oxidizer and porous ceramic technology, applied in the environmental field, can solve the problems of secondary pollution, low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

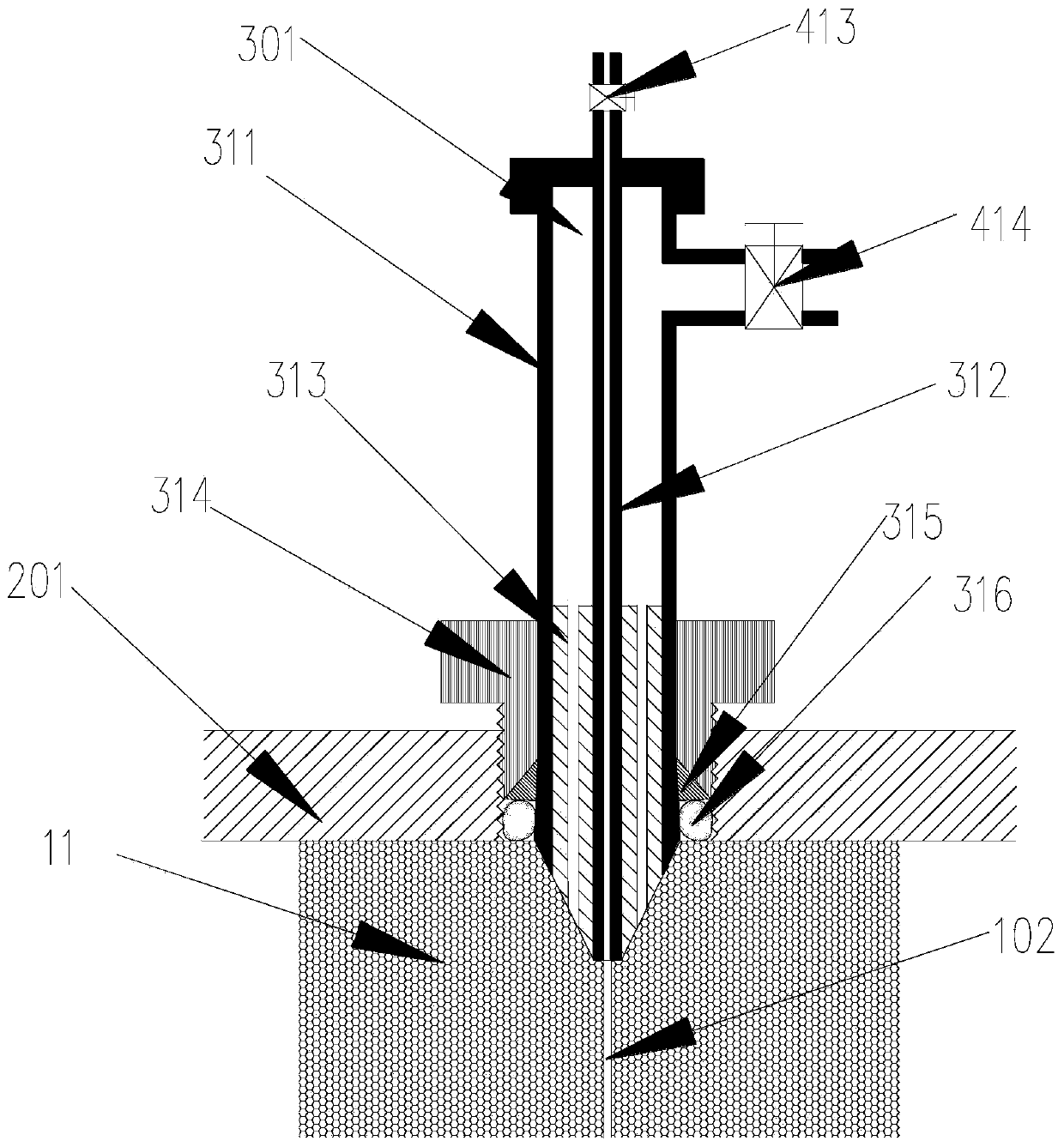

[0098] A preparation of a multipurpose high-efficiency air purification device (1), comprising the following steps:

[0099] 1. Preparation of Porous Ceramic Catalytic Oxidizer (1)

[0100] (1) get 5000g 325 purpose diatomaceous earth, be immersed in the sulfuric acid solution of 0.5mol / L of the hydrogen peroxide containing 10% (mass percentage) in excess, heat and boil to keep 10min, solid-liquid separation, diatomaceous earth is washed with water to near neutrality to obtain the diatomite after removing impurities and expanding the pores;

[0101] Soak the diatomite after removing impurities and expanding the pores in an aqueous solution containing 100g / L of urea, 10g / L of acetic acid and 50g / L of citric acid, a chelating dispersant, ultrasonically vibrate for 20min, and place it in a ventilating valve. In a closed container, evacuated, the vacuum degree was -0.09MPa, kept for 120min, opened the vent valve to restore the pressure in the container to normal pressure, stood f...

Embodiment 2

[0120] A preparation of a multipurpose high-efficiency air purification device (2), comprising the following steps:

[0121] 1. Preparation of Porous Ceramic Catalytic Oxidizer (2)

[0122] Steps (1) and (2) operate according to steps (1) and (2) of Example 1.

[0123] (3) with embodiment 1, difference is: add 3750g 325 purpose kaolin;

[0124] Steps (4) and (5) operate according to steps (4) and (5) of Example 1.

[0125] (6) with embodiment 1, difference is: the cotton thread after step (5) processing is cut into the section of 150mm, take 10;

[0126] (7) Same as Example 1.

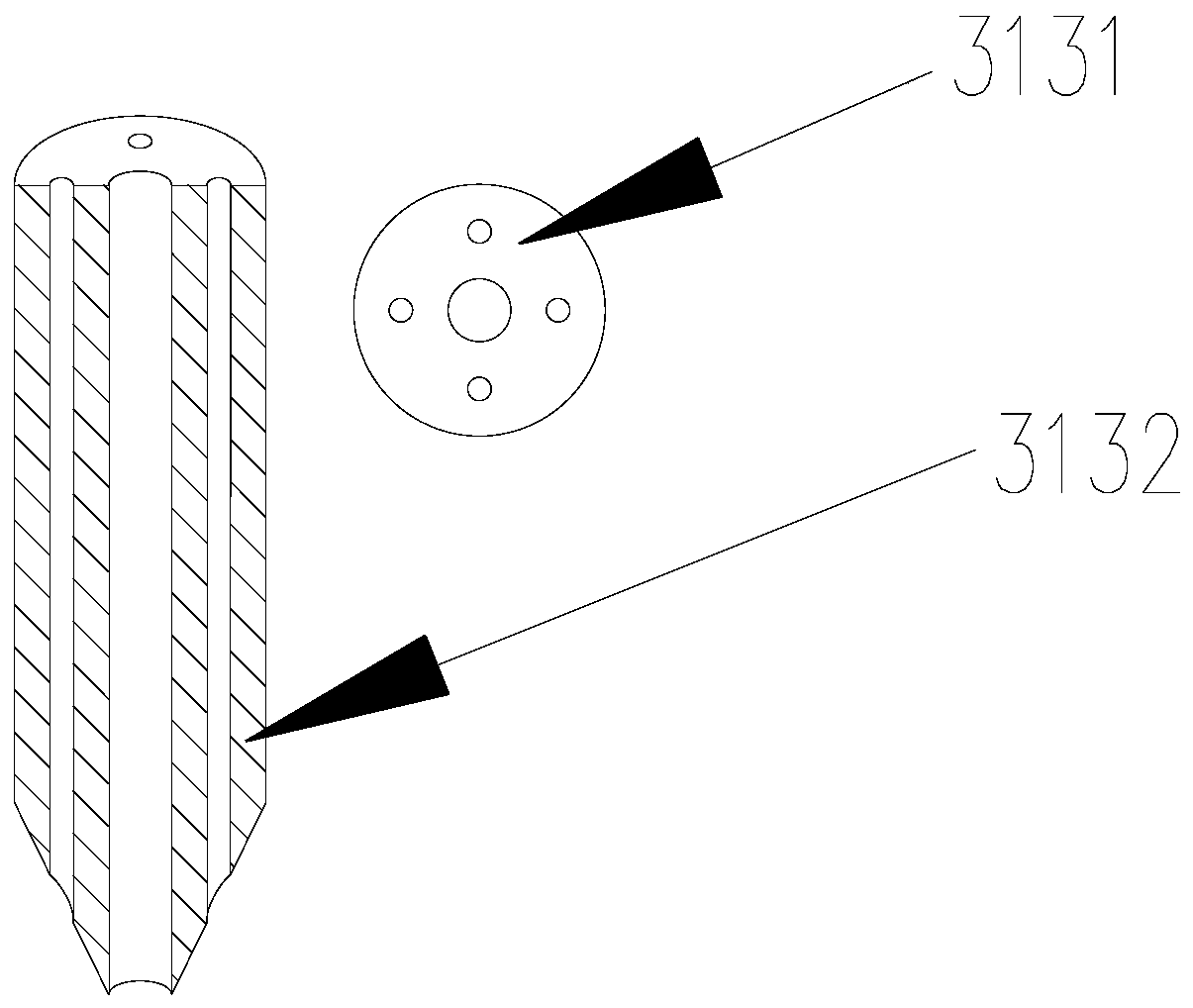

[0127] (8) Take iron-chromium-aluminum alloy wire with a wire diameter of 0.6 mm, place it in a 0.8 mol / L sodium hydroxide solution at 55 ° C, soak it for 5 min, wash off the surface lye with water, and dry it; the subsequent spiral body preparation is the same as the implementation Example 1, the difference is that the helical body is properly stretched so that the distance between the helical wir...

Embodiment 3

[0139] A preparation of a multipurpose high-efficiency air purification device (3), comprising the following steps:

[0140] 1. Preparation of Porous Ceramic Catalytic Oxidizer (3)

[0141] Steps (1) and (2) operate according to steps (1) and (2) of Example 1.

[0142] (3) with embodiment 1, difference is: add 3750g 325 purpose kaolin;

[0143] Steps (4) and (5) operate according to steps (4) and (5) of Example 1.

[0144] (6) with embodiment 1, difference is: the cotton thread after step (5) processing is intercepted length is 150mm section, get 20;

[0145] (seven) with embodiment 1;

[0146] (8) Same as Example 1, the difference is: take the iron-chromium-aluminum alloy wire with a wire diameter of 0.6 mm, place it in the sodium hydroxide solution of 1 mol / L at 50 ° C, and soak it; The spacing is 4mm, and the 100mm long helix is intercepted;

[0147] (9) with embodiment 1, difference is: adding 100 purpose sponge iron 900g, 200 purpose iron powder 1750g and containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com