Patents

Literature

131results about How to "Resolve resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pour point depressing and viscosity reducing composition for heavy oil, pour point depressing and viscosity reducing agent for heavy oil and preparation method of pour point depressing and viscosity reducing agent

ActiveCN105950127AHigh acid-base stabilityImprove solubilityDrilling compositionAlkyl aminePetroleum

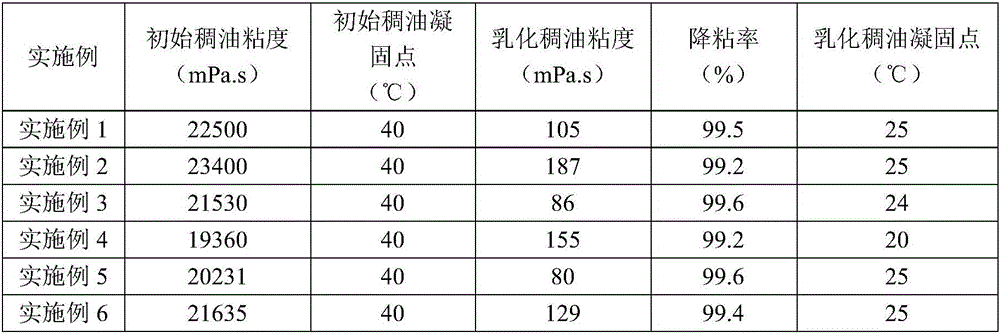

The invention relates to pour point depressing and viscosity reducing composition for heavy oil, a pour point depressing and viscosity reducing agent for the heavy oil and a preparation method of the pour point depressing and viscosity reducing agent, and belongs to the technical field of oil exploitation. The pour point depressing and viscosity reducing composition for the heavy oil comprises components in parts by weight as follows: 25-55 parts of a surfactant, 5-20 parts of a dispersing agent, 15-20 parts of an inhibitor and 20-50 parts of a co-emulsifier, wherein the dispersing agent contains polyoxyethylene alkyl amine, and polyoxyethylene alkyl amine accounts for not lower than 9% of the dispersing agent in percentage by mass. The pour point depressing and viscosity reducing composition for the heavy oil has good emulsifying viscosity reduction functions on the heavy oil with the gum asphalt content of 40% and the freezing point of 40 DEG C, the viscosity reducing rate can be up to 99% or higher and the pour point depressing range can be up to 15 DEG C or higher only through addition of 0.5% by mass of the pour point depressing and viscosity reducing agent product, and the problems of high entering-pump resistance of crude oil and difficulty in shaft lifting can be solved very well.

Owner:CHINA PETROLEUM & CHEM CORP +1

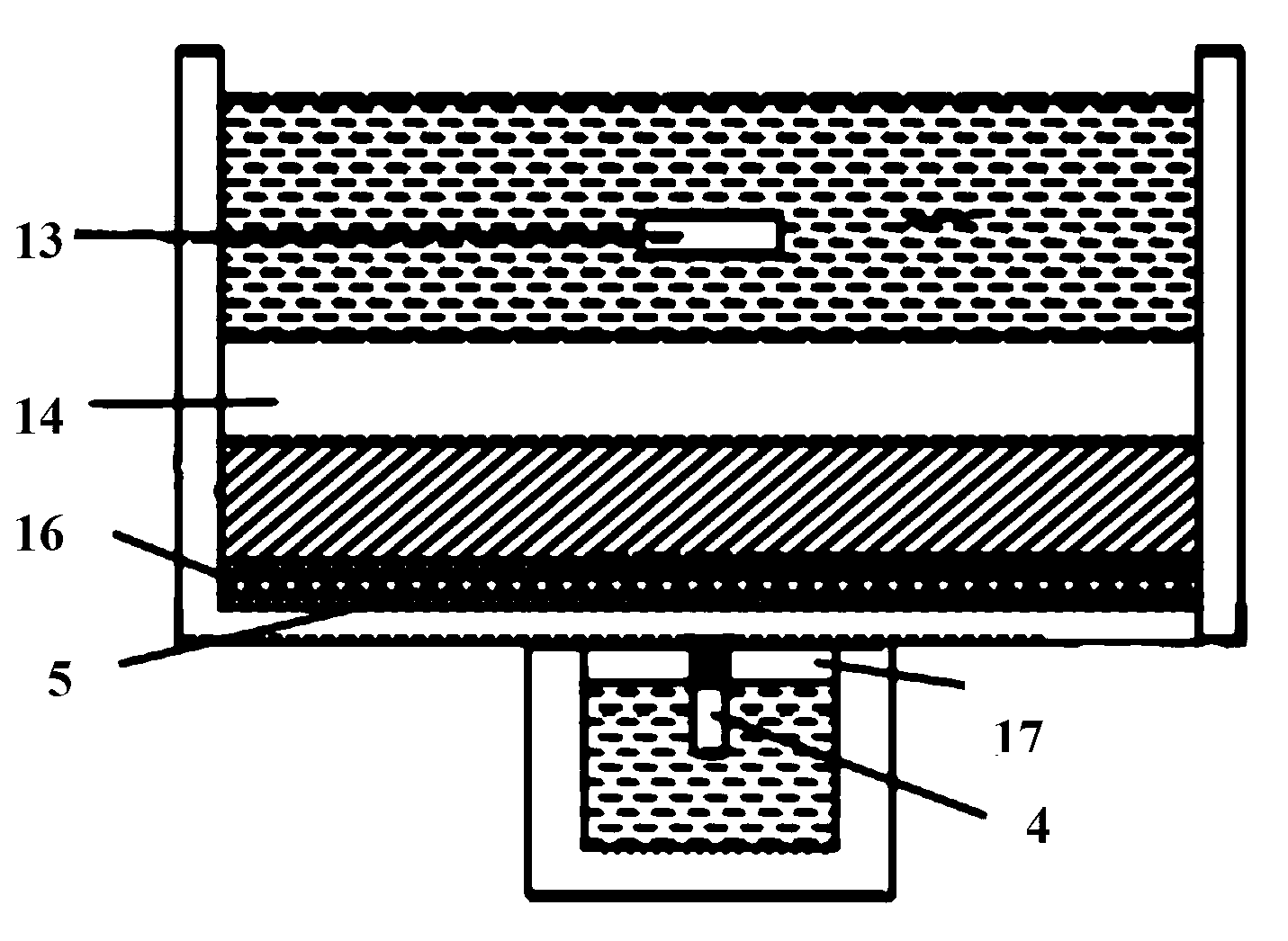

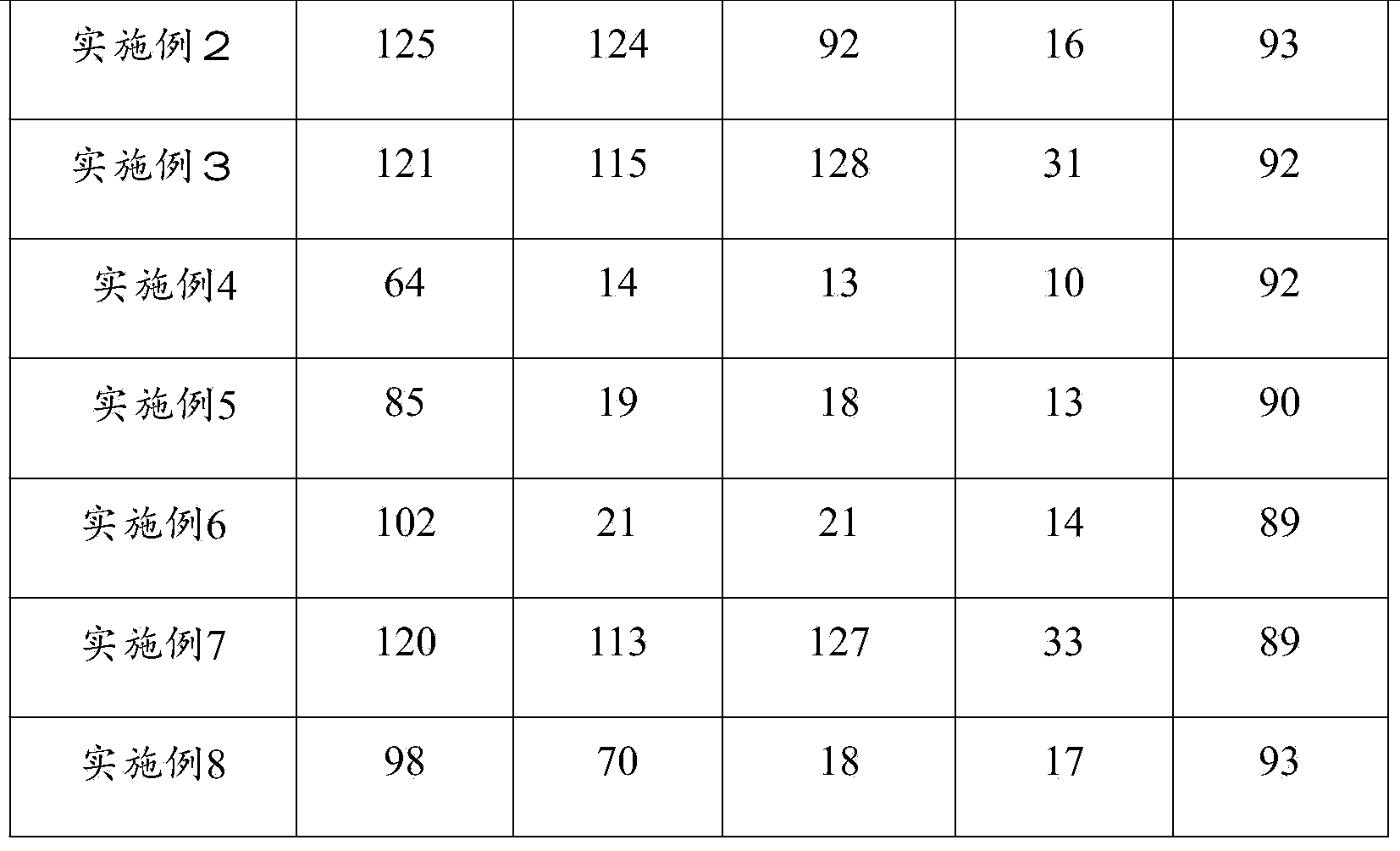

Electroosmosis dewatering method and device of water-containing material

ActiveCN102060427AGuaranteed uptimeIncrease plating areaSludge treatment by de-watering/drying/thickeningElectricityEngineering

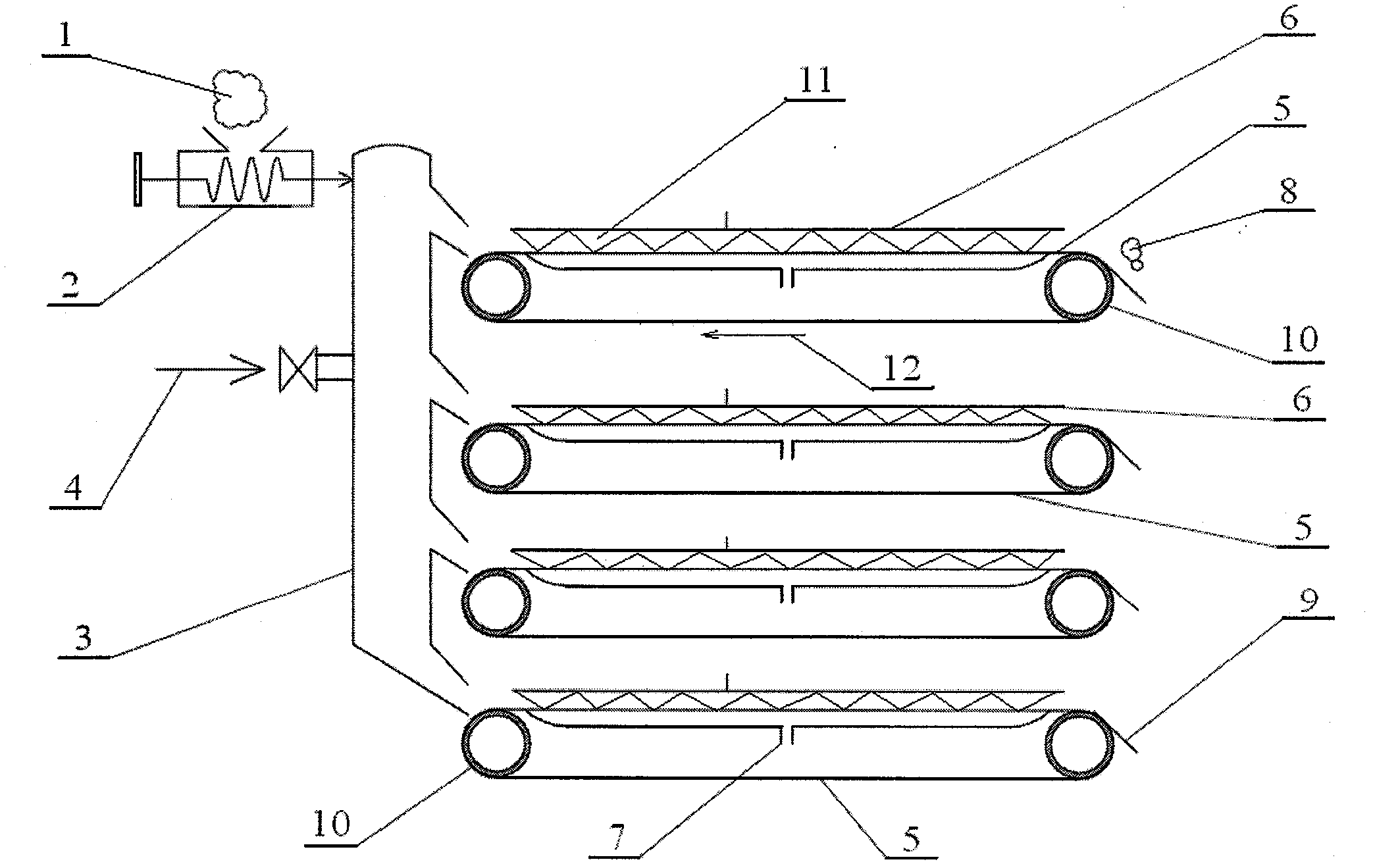

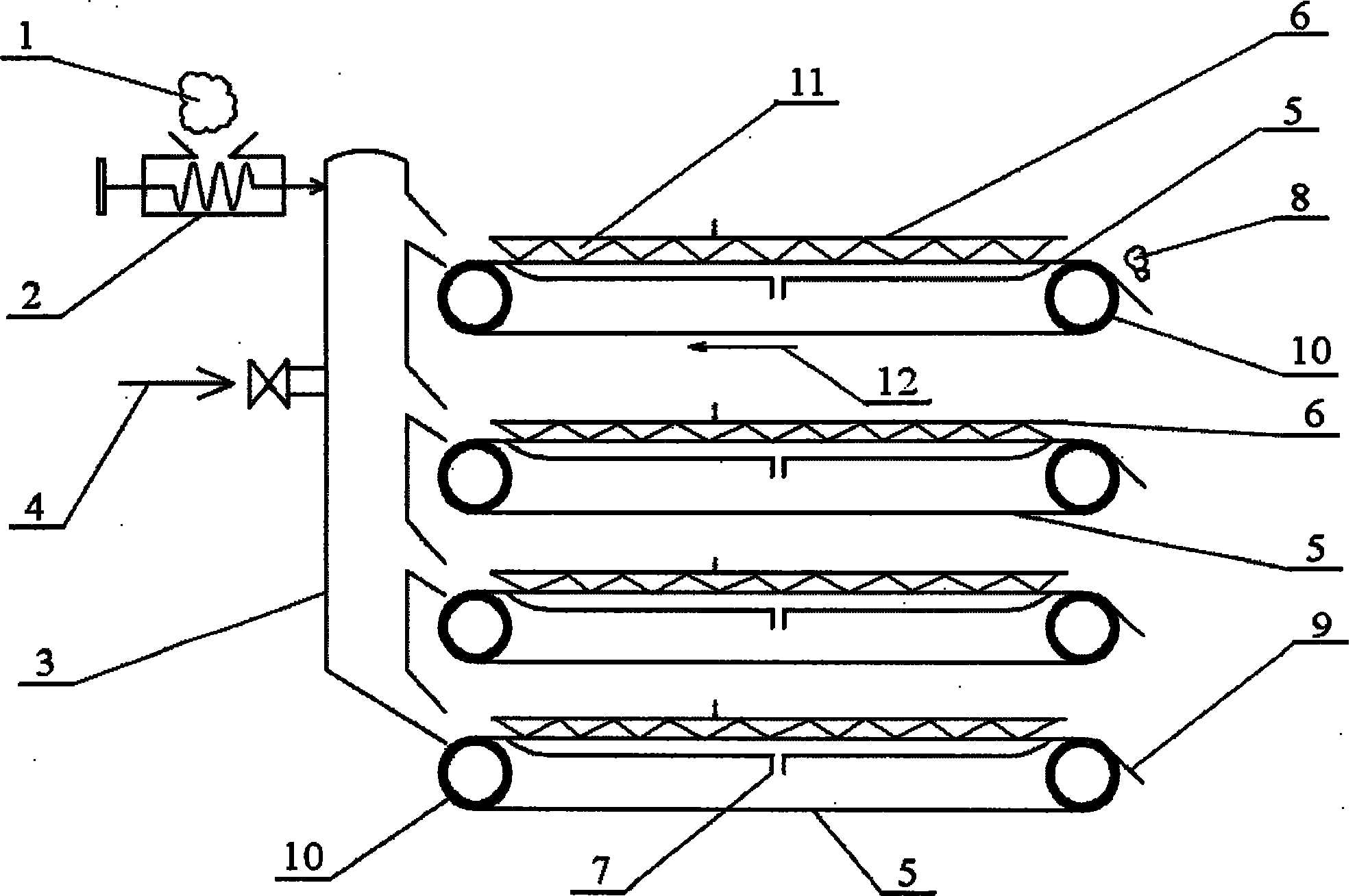

The invention relates to an electroosmosis dewatering method and a device of a water-containing material. In the invention, a water-containing material is dewatered by utilizing a direct-current electric field; an electroosmosis dewatering unit comprises a cathode made of wire mesh capable moving, an anode capable of lifting on the cathode panel along the vertical direction and a subsidiary facility; and the whole dewatering system is provided with multiple layers of units in the direction vertical to the horizontal plane. The device has the characteristics of high space utilization rate, stable running and low cost.

Owner:YIXING NENGDA ENVIRONMENTAL PROTECTION TECHCO

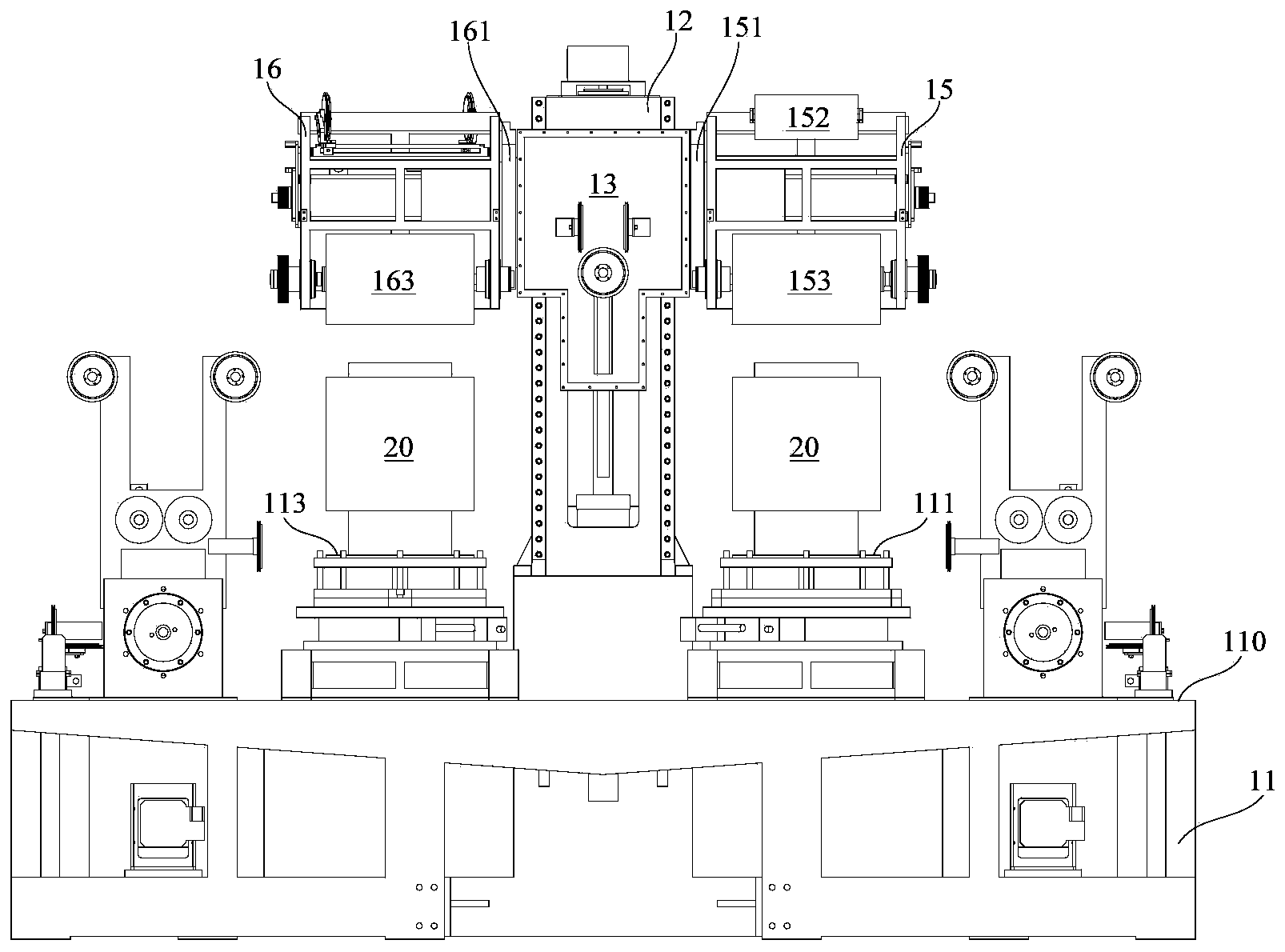

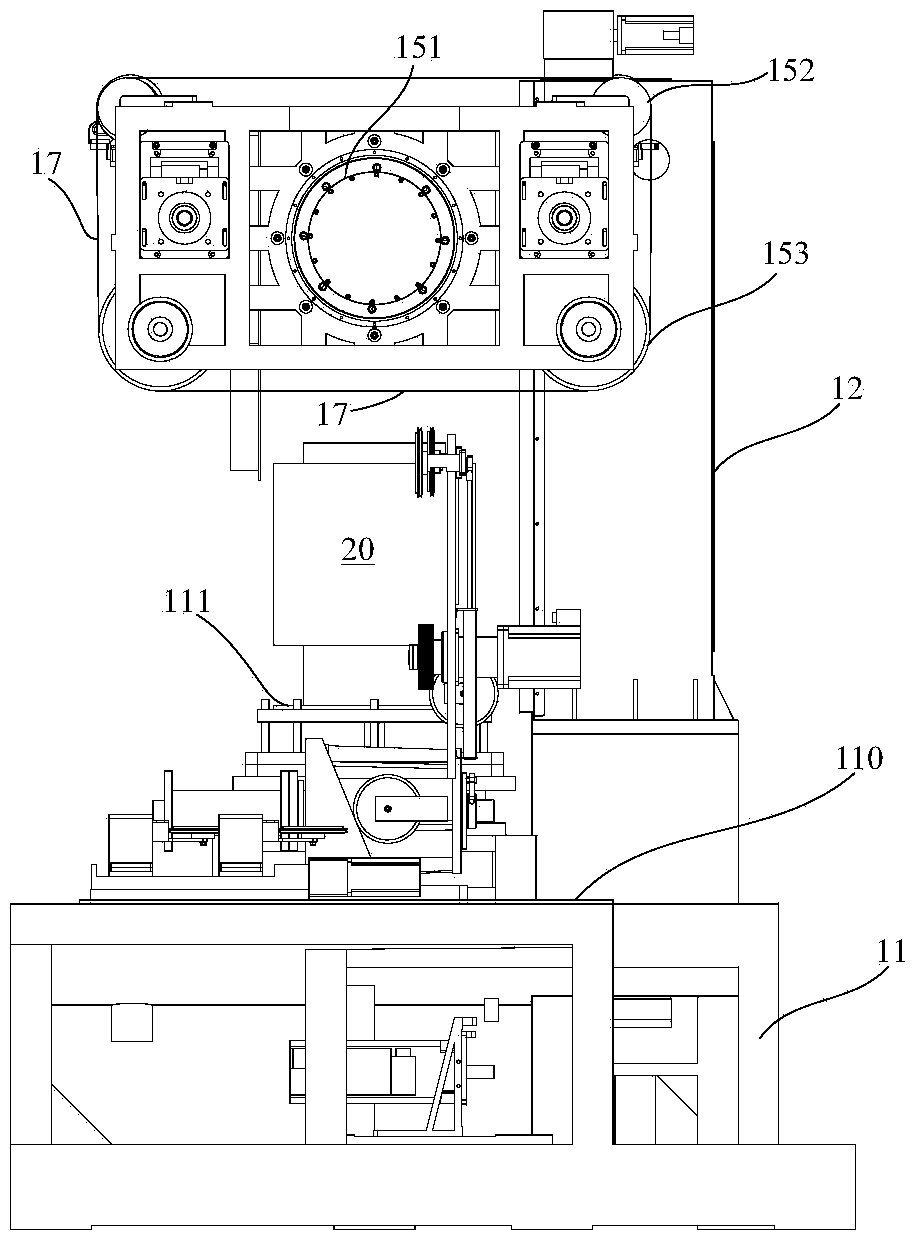

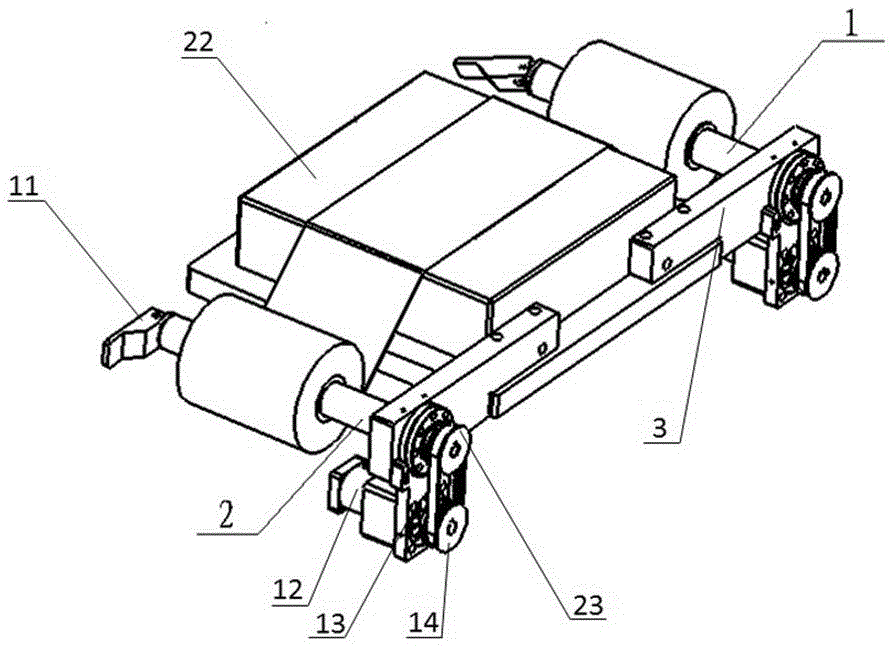

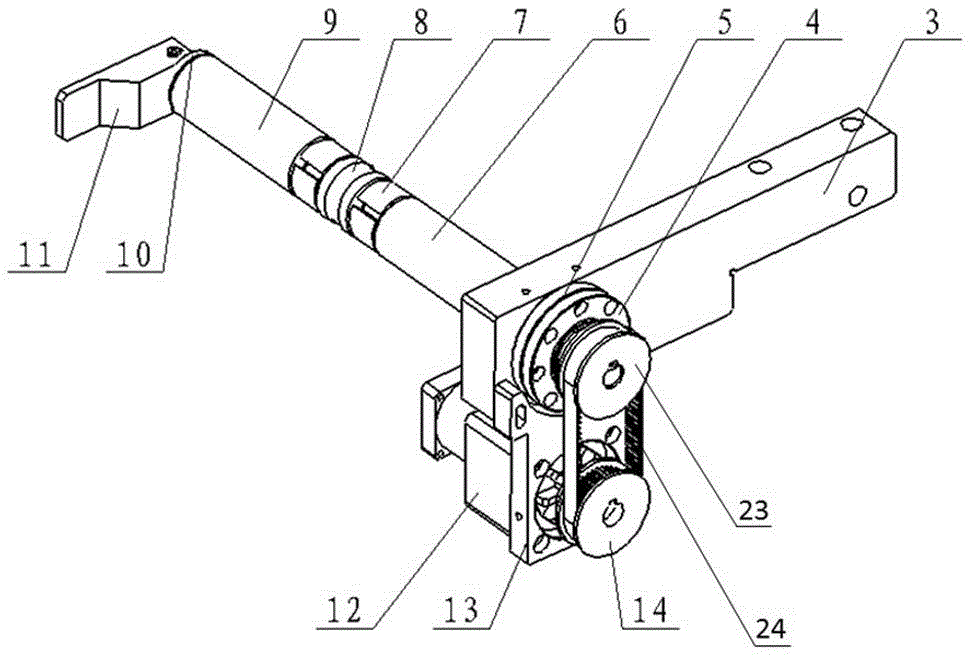

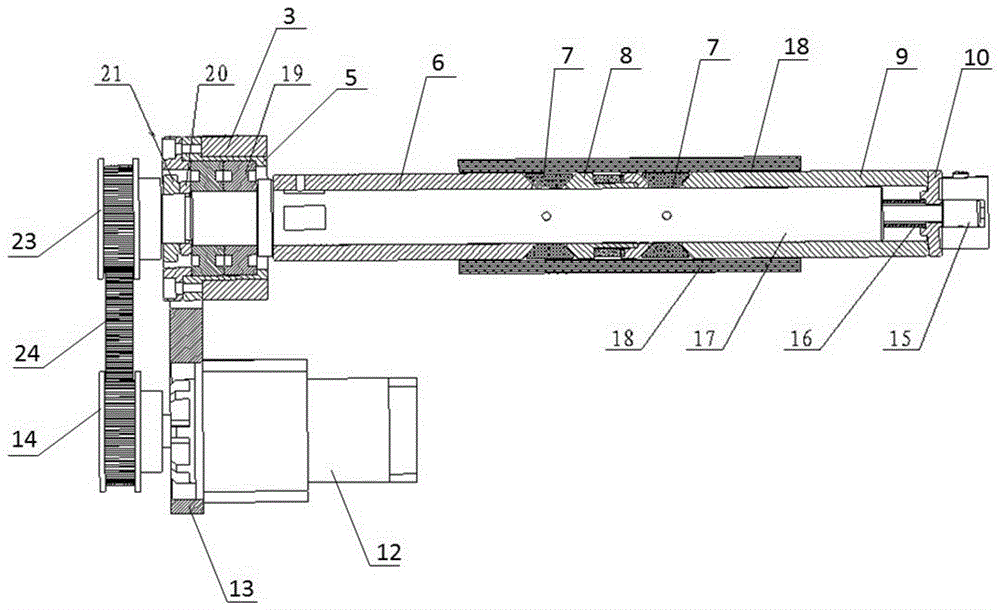

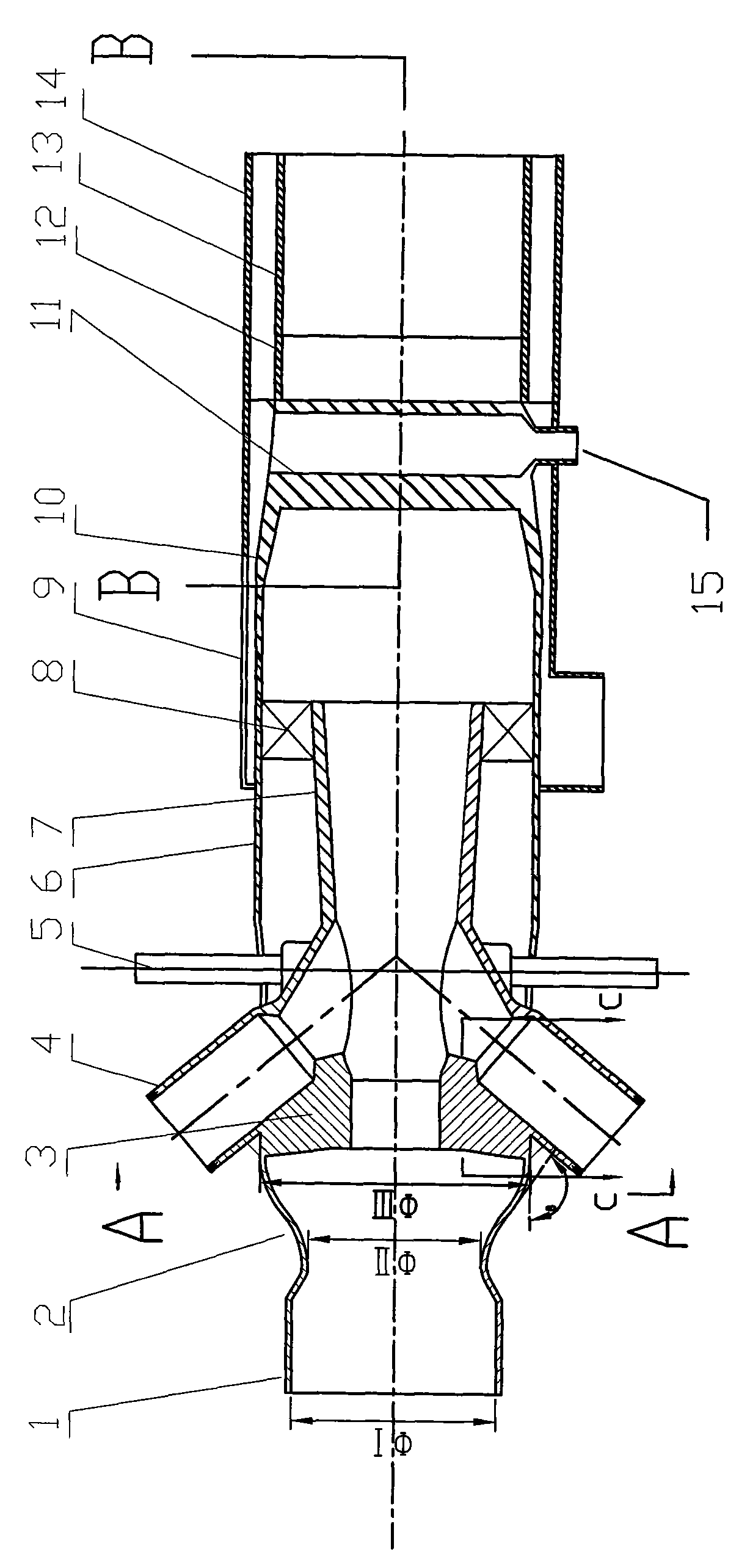

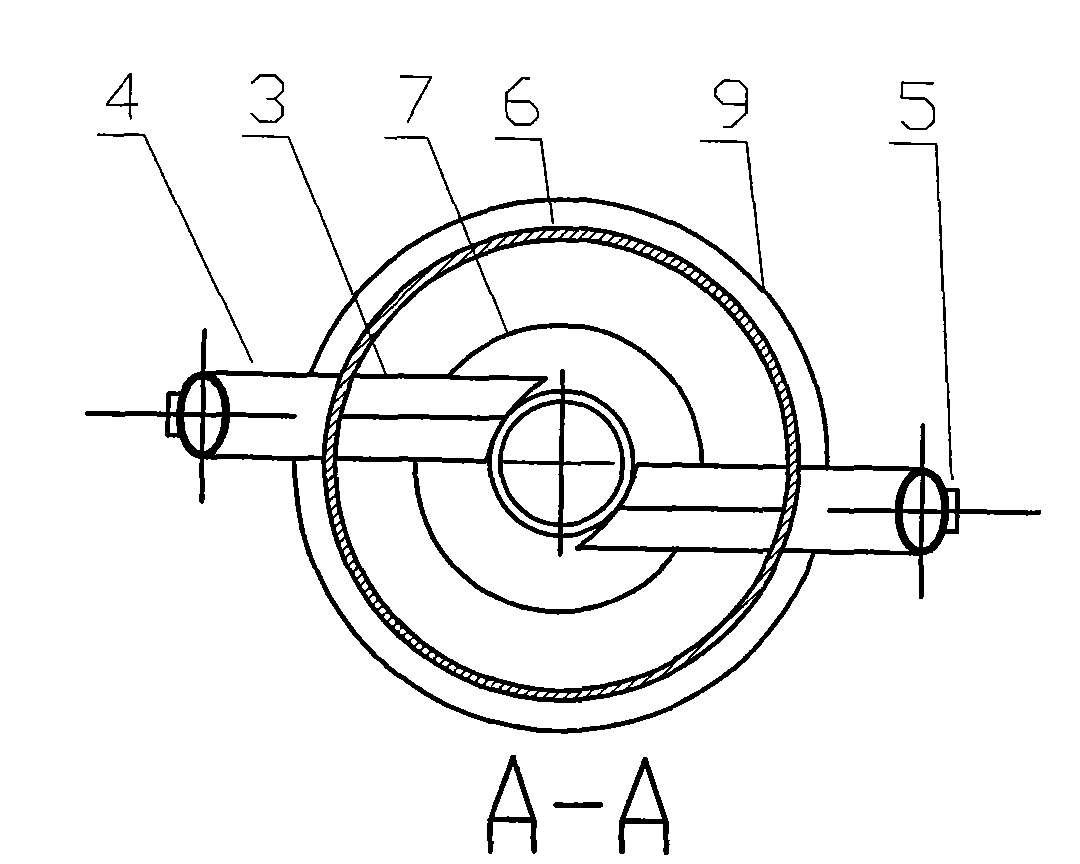

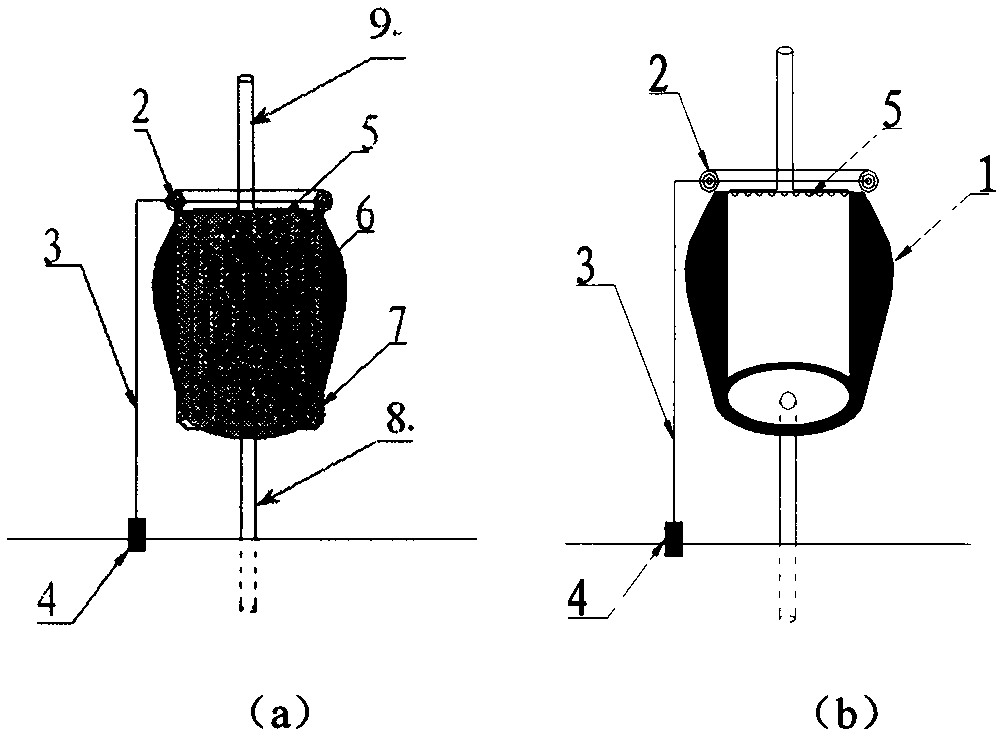

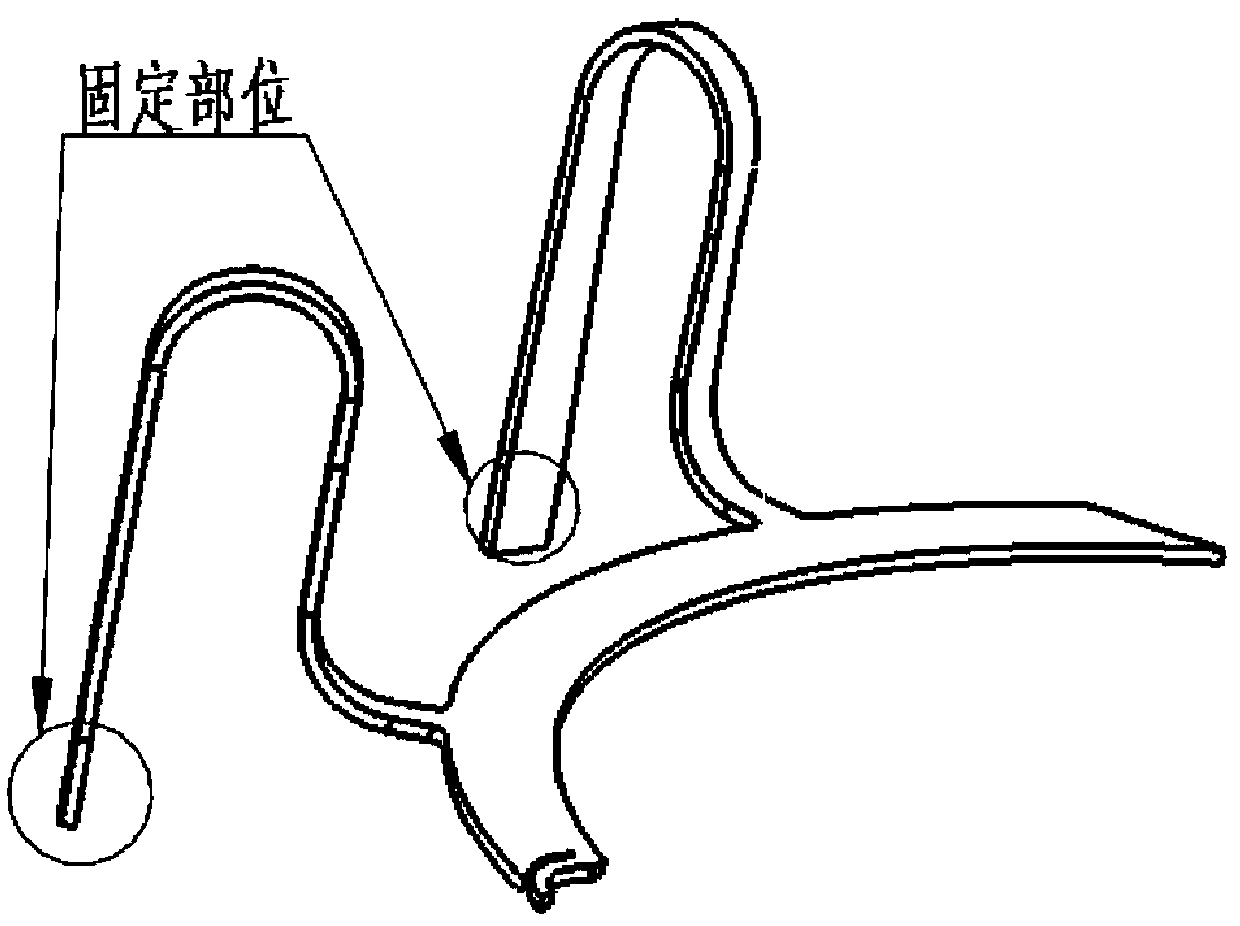

Diamond wire squaring machine

ActiveCN103921360AResolve resistanceSolve cutting difficultiesFine working devicesCouplingEngineering

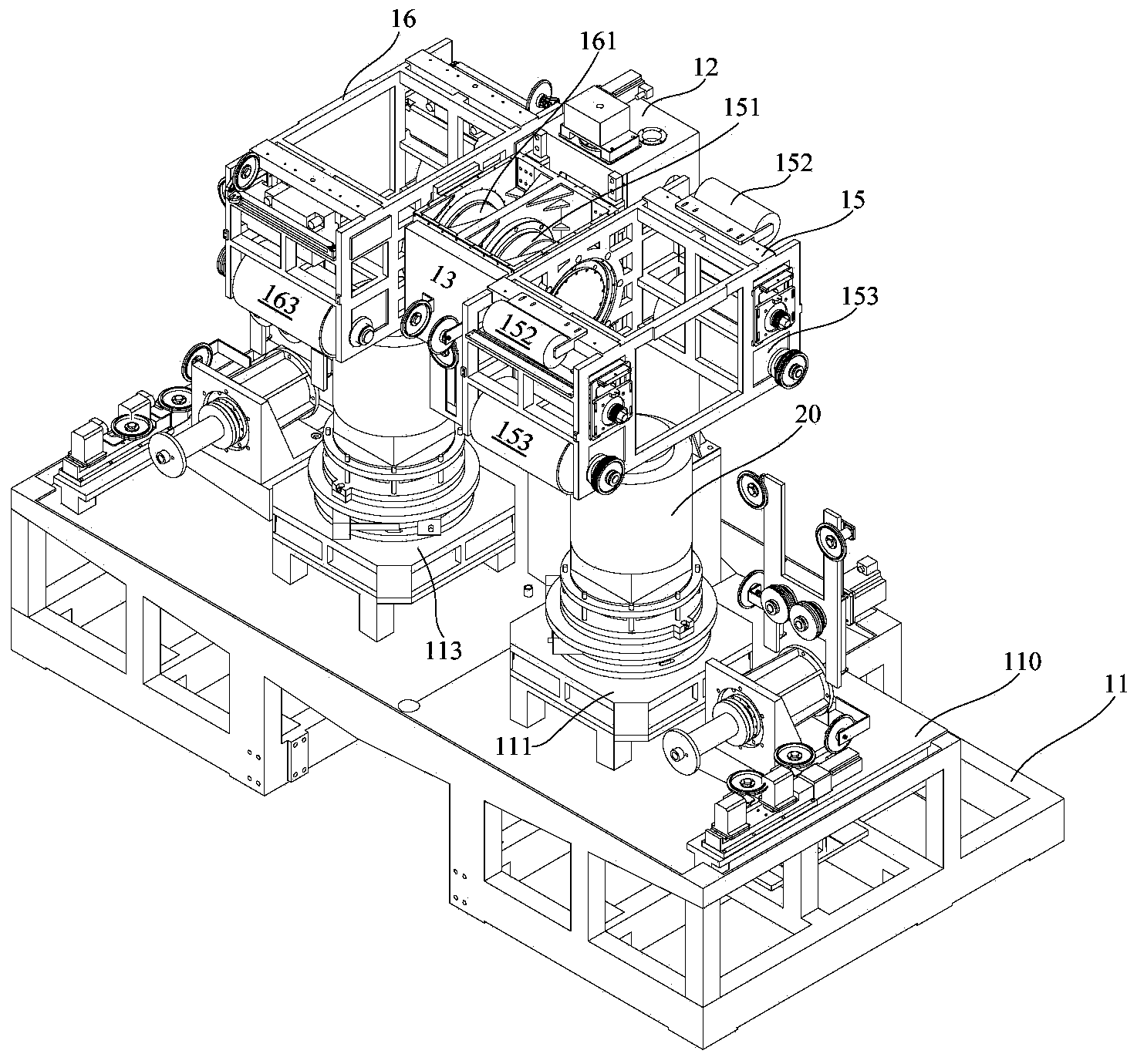

The invention provides a diamond wire squaring machine which comprises a rack. The rack is provided with a rack platform, two workbenches, a supporting stand column, a turning-connection support and two wire stands, wherein the two workbenches and the supporting stand column are arranged on the rack platform, the turning-connection support is arranged on the supporting stand column in a lifting mode, and the two wire stands are connected to the two sides of the turning-connection support in a coupling and rotating mode. Each wire stand is provided with a cutting roller, a server motor and a diamond wire which is wound on the cutting roller. Any wire stand rotates relative to the turning-connection support in a coupling mode to drive the diamond wire to alternatively and obliquely cut machined parts on the workbenches relative to the horizontal line, the entire cutting process is smooth, control is easy, the cutting time is greatly shortened, and the cutting precision and the cutting efficiency are improved.

Owner:海宁市日进科技有限公司

High-temperature gas-solid ceramic filter tube and preparation method

The invention provides improvement of ceramic filter tubes for high-temperature gas purification, and is characterized in that a high-temperature binder for sintering comprises two or more than two of magnesium oxide, strontium oxide, calcium oxide, potassium oxide-containing minerals, kaolin or clay, and trace rare earth, and mainly forms a liquid-phase silicate high-temperature binder above 1200 DEG C. The contradiction between binding strength of a filter tube support body and filtration flux and resistance drop is well coordinated and solved; the obtained filter tube support body not only meets the requirements for transport, installation, and using strength, but also has a high filtration flux and low filtration resistance. When the filter tube has rupture strength of not less than 26 MPa, and a filtration flux of 55 m3 / hm2, the resistance drop is 850-950 Pa or lower; the consistency for finished product batch production is good; and the performance difference is less than 10%.

Owner:宜兴市鑫帝豪高科陶瓷厂

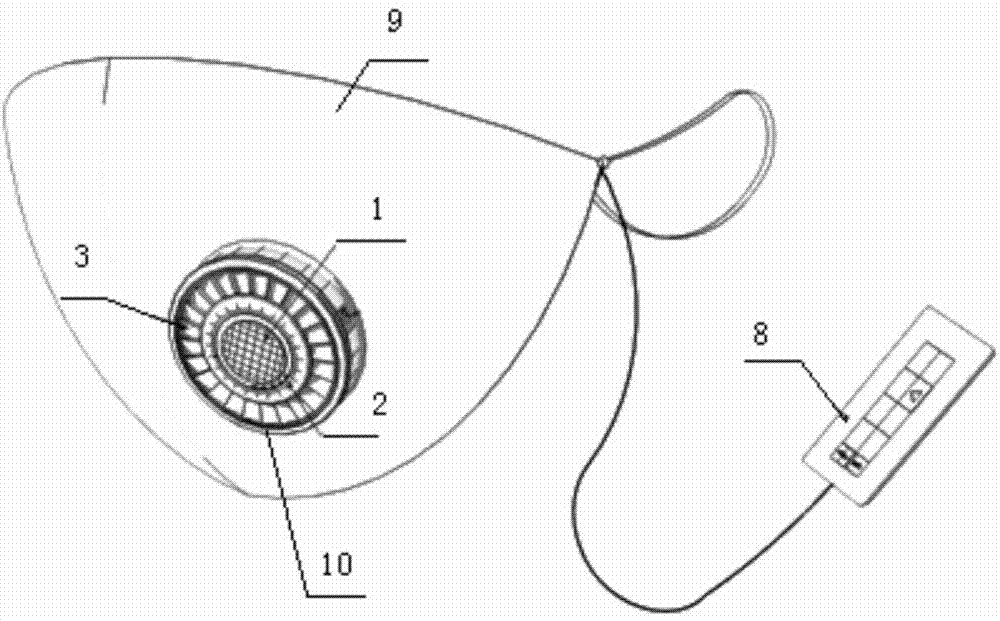

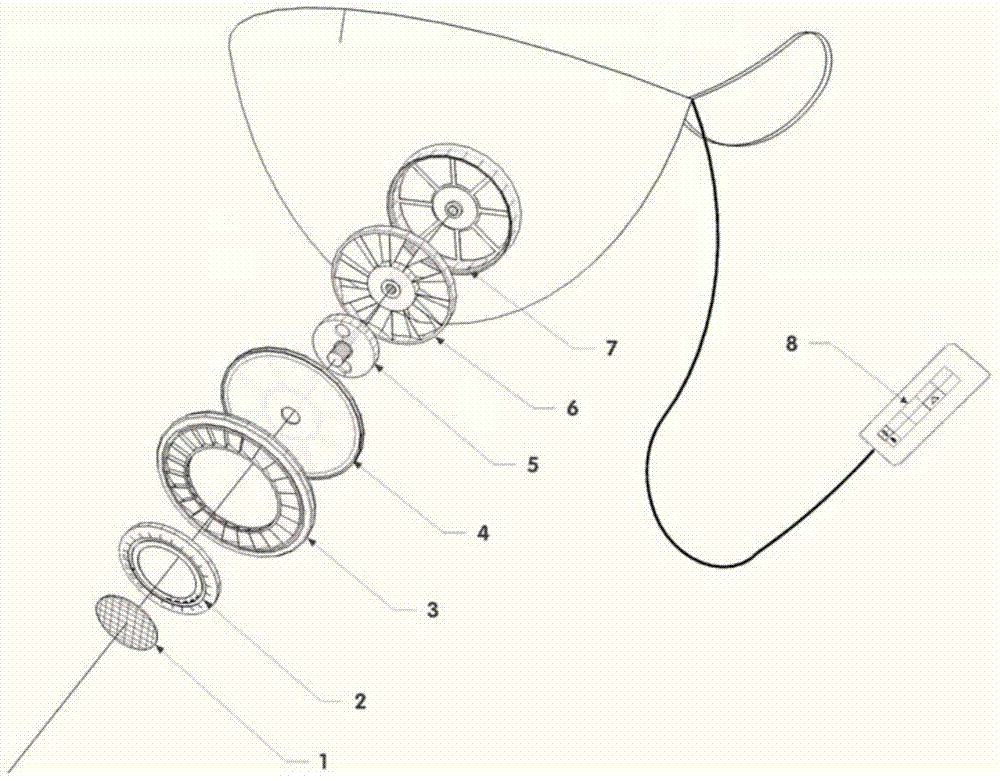

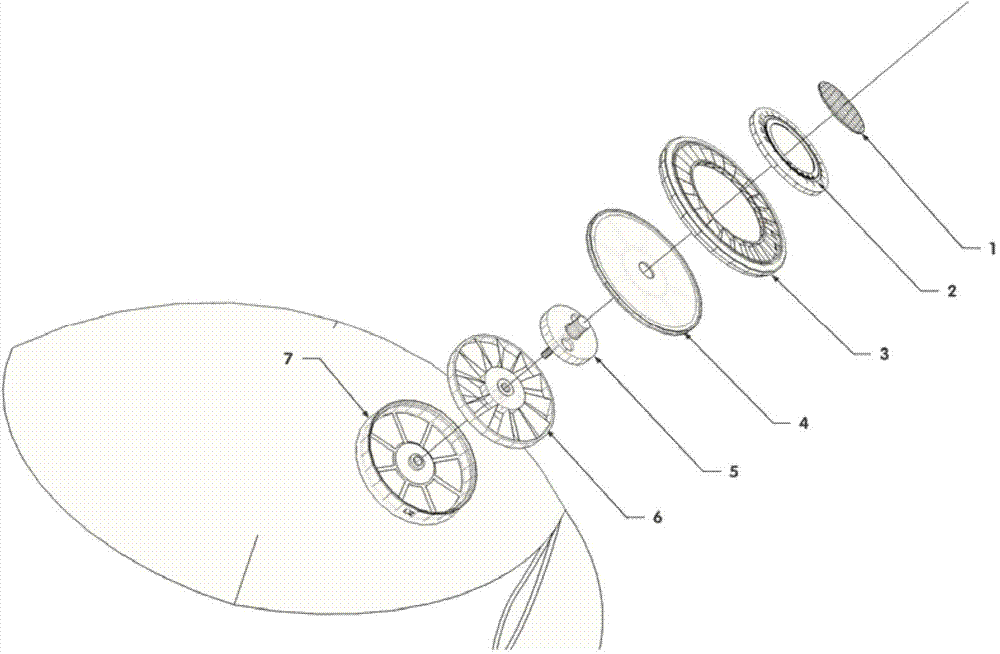

Anti-dust respirator with intelligent breathing ring

InactiveCN104705842ASimple structureSolve efficiency problemsProtective garmentMagnetic bearingRespirator

The invention provides an anti-dust respirator with an intelligent breathing ring. According to the technical scheme, the anti-dust respirator comprises a respirator body and the intelligent breathing ring, wherein the respirator body and the intelligent breathing ring are detachably connected in a spirally buckled mode. The respirator body is provided with a breathing ring base. A fixed shaft is arranged at the center of the breathing ring base. The exterior of the intelligent breathing ring is in a transparent organic plastic cylinder shape. The intelligent breathing ring internally comprises a flow guide fan blade, a magnetic bearing motor, a filter cotton web, a flow guide grating cover and a filter efficacy ring. The filter efficacy ring is connected with the flow guide grating cover in a buckled mode. The two ends of the magnetic bearing motor are connected with the filter cotton web and the flow guide fan blade respectively. The end of the filter cotton web is embedded into the outer ring of the flow guide grating cover. The end of the flow guide fan blade is connected with the breathing ring base. The breathing ring base, the flow guide fan blade, the magnetic bearing motor, the filter cotton web, the flow guide grating cover and the filter efficacy ring are connected into a whole through the fixed shaft of the breathing ring base in a penetrating and sleeving mode, driven by the magnetic bearing motor and assembled into a small fan through mechanical connection and leads filtered air into the respirator body. The anti-dust respirator with the intelligent breathing ring is simple in structure, the plastic parts are low in weight, assembling, maintaining and replacing are convenient, and the anti-dust respirator has remarkable economic benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

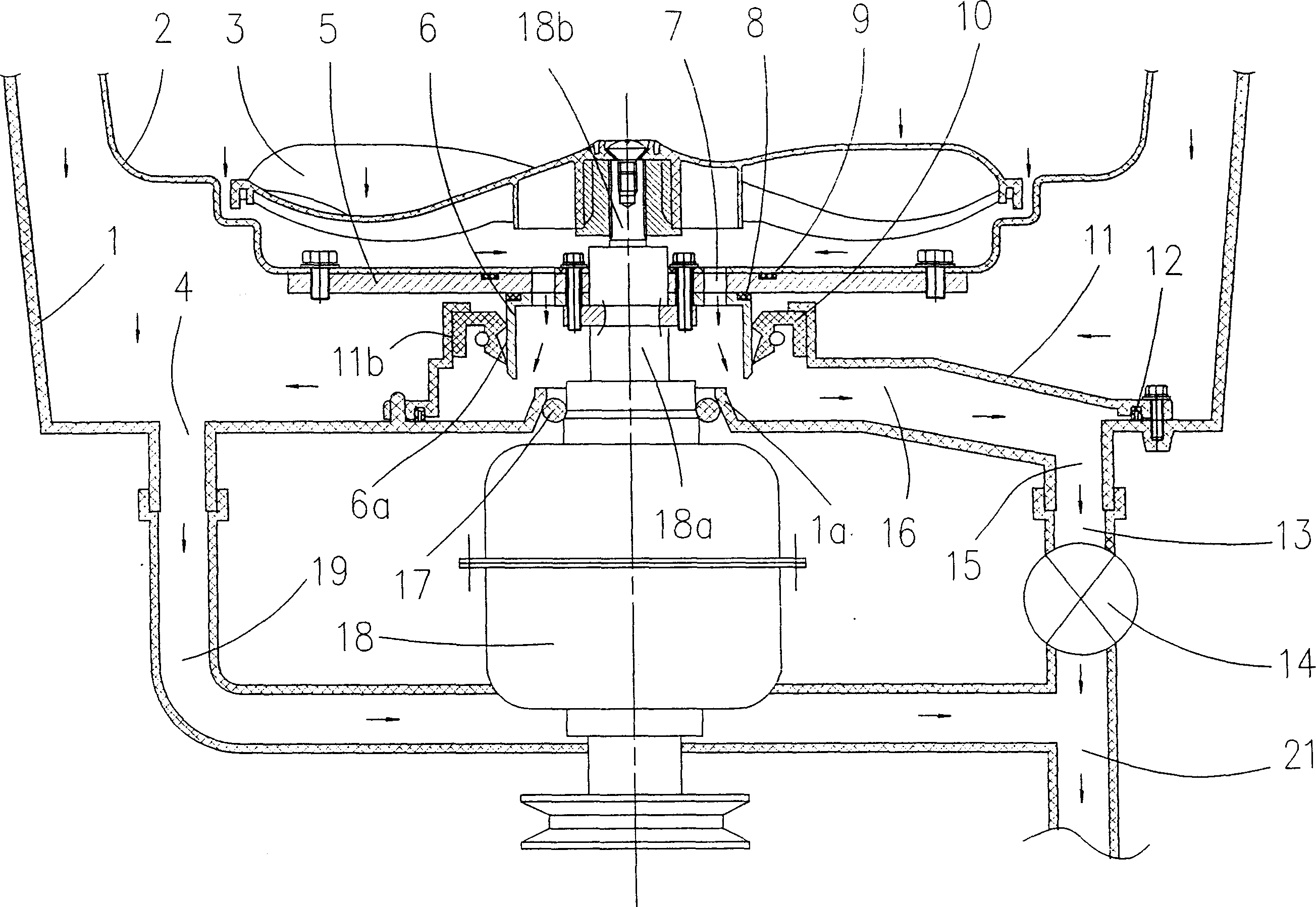

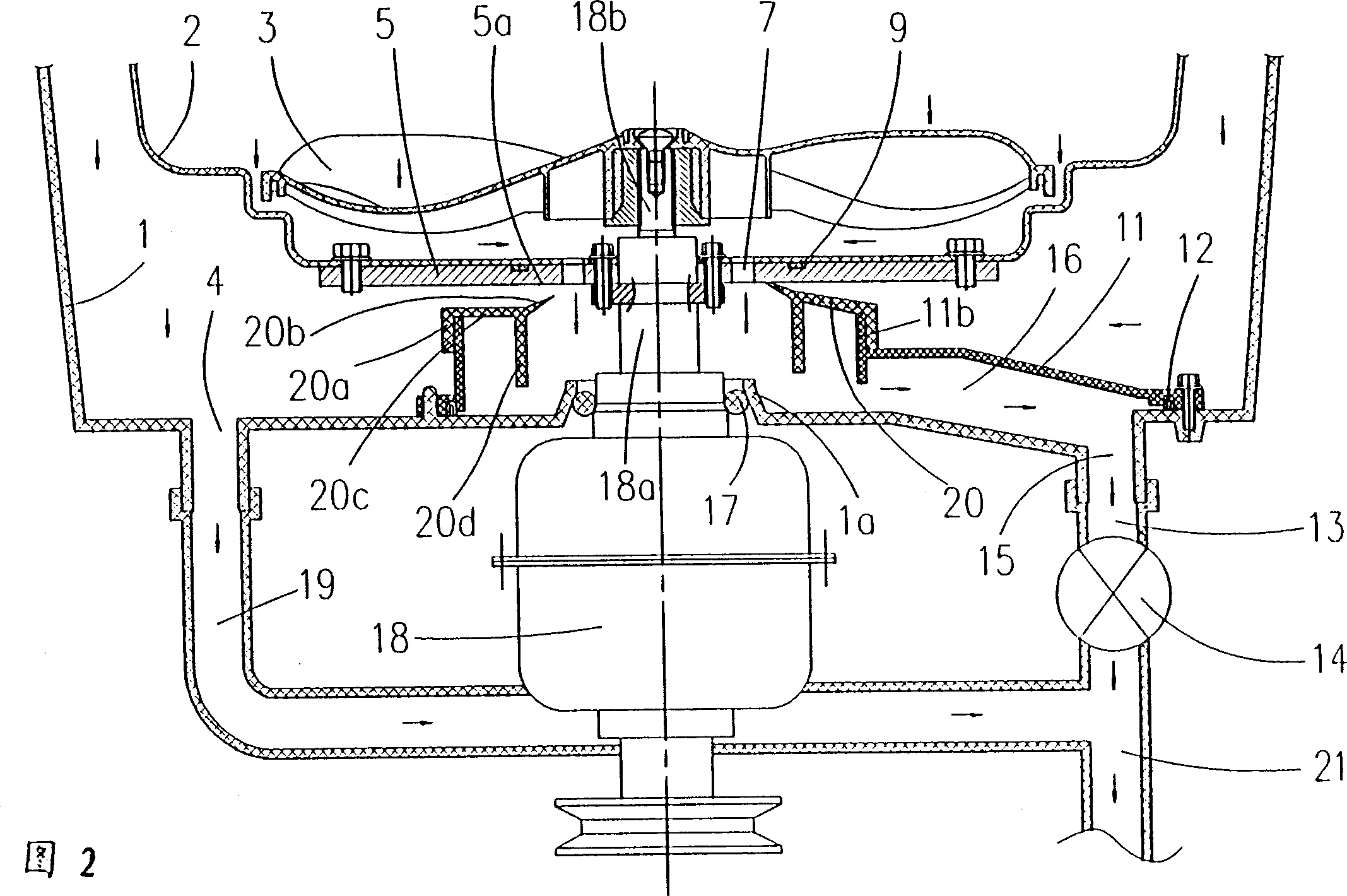

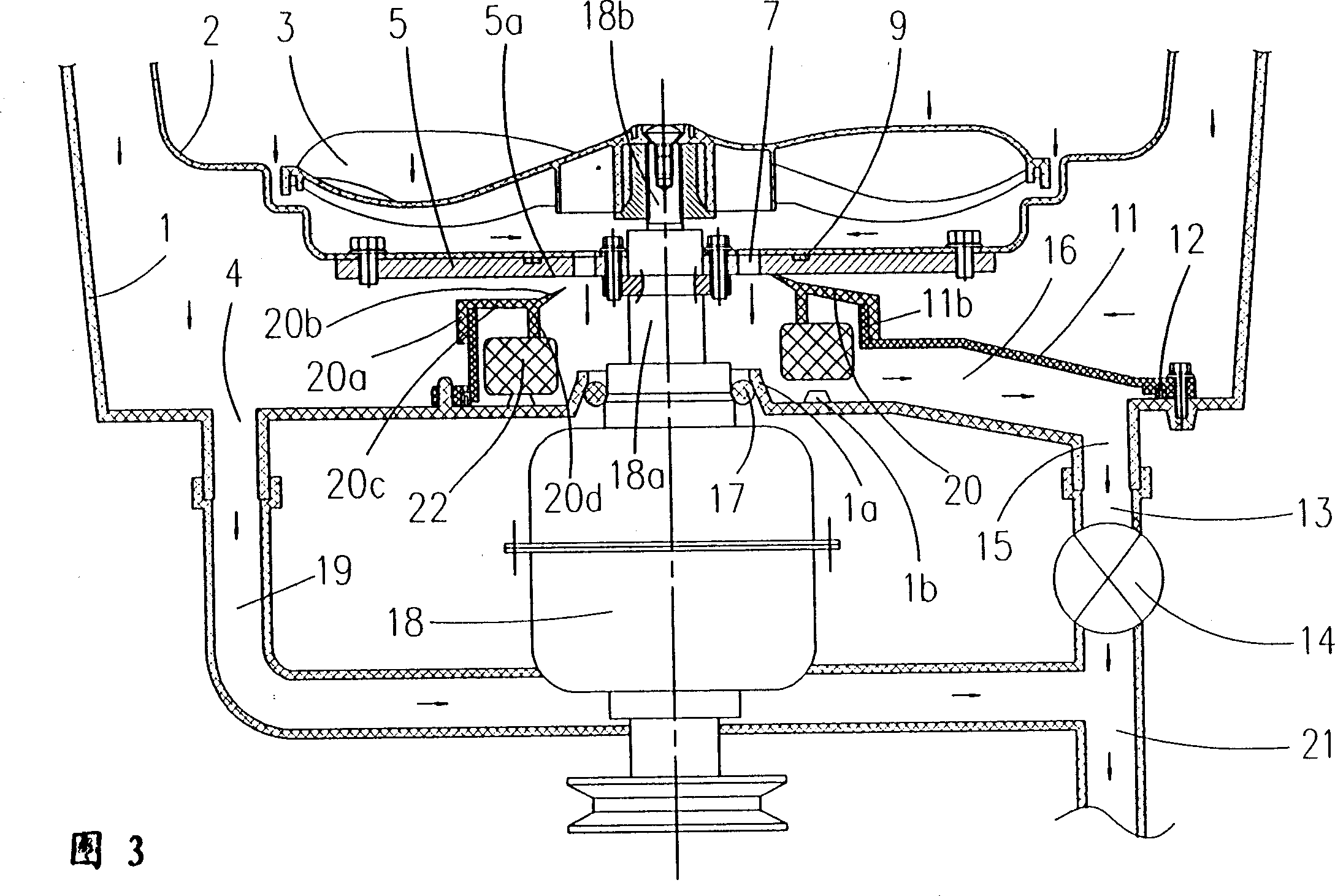

Float sealing structure for water-saving automatic washer

InactiveCN1548613AResolve frictionSolve the noiseEngine sealsOther washing machinesWater savingEngineering

The float sealing structure for water-saving automatic washer includes sealing hood, tray, draining cavity comprising outer tub, sealing hood and tray, and sealing part. It features that the sealing part is made of elastic material and has through hole in the center, outer edge and inner edge around the through hole. Of the edges, one is fixed and connected hermetically with the sealing surface, and the other is suspended with one protrudent lip for pressing the sealing surface under the action of buoyancy. The central through hole of the sealing part is jacketed onto the dewatering shaft, and the sealing part has at least one ring water pressure action surface to form end sealing under the action of the buoyancy of the water draining cavity.

Owner:叶小舟

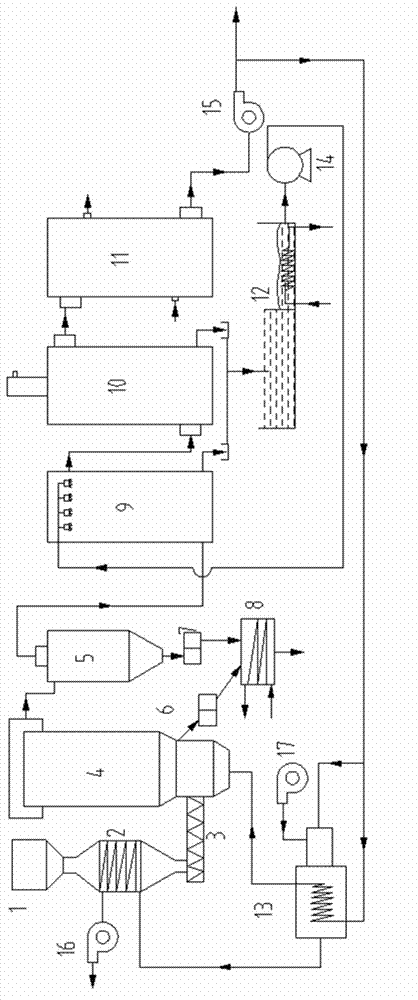

Lignite complete cycle high-efficiency dry distillation quality improving system and method

ActiveCN102925179ASolve efficiency problemsResolve resistanceDirect heating destructive distillationSpecial form destructive distillationIntercoolerEngineering

The invention provides a lignite complete cycle dry distillation quality improving system and method. A bottom outlet of a vertical drying furnace of the lignite complete cycle dry distillation quality improving system is connected with a spiral charging machine, the outlet of the spiral charging machine is connected with a fluidization dry distillation furnace; the bottom of the fluidization dry distillation furnace is connected with a coal gas outlet of a hot blast heater, the top of the fluidization dry distillation furnace is connected with a cyclone dust collector; the feeding hole of the fluidization dry distillation furnace is connected with the spiral charging machine, the discharge hole of fluidization dry distillation furnace is an overflow port in the side wall at the bottom, and the fluidization dry distillation furnace is connected with a gas-solid heat exchanger by virtue of a first U-shaped seal valve; the outlet of the cyclone dust collector is connected with a spray tower, the bottom of the cyclone dust collector is connected with the gas-solid heat exchanger by virtue of a second U-shaped seal valve; the discharge hole of the spray tower is connected with the feeding hole of an electrical tar precipitator, liquid at the bottom of the spray tower and liquid at the bottom of the electrical tar precipitator are converged and then are communicated into a mechanical clarification tank; and the discharge hole at the upper part of the electrical tar precipitator is connected with the feeding hole of an intercooler, and the discharge hole of the intercooler is connected with a pressurization fan. The lignite complete cycle dry distillation quality improving method provided by the invention is a direct contact heat exchange process and has the characteristics of full heat exchange and high thermal efficiency.

Owner:BEIJING PURENERGY TECH DEV

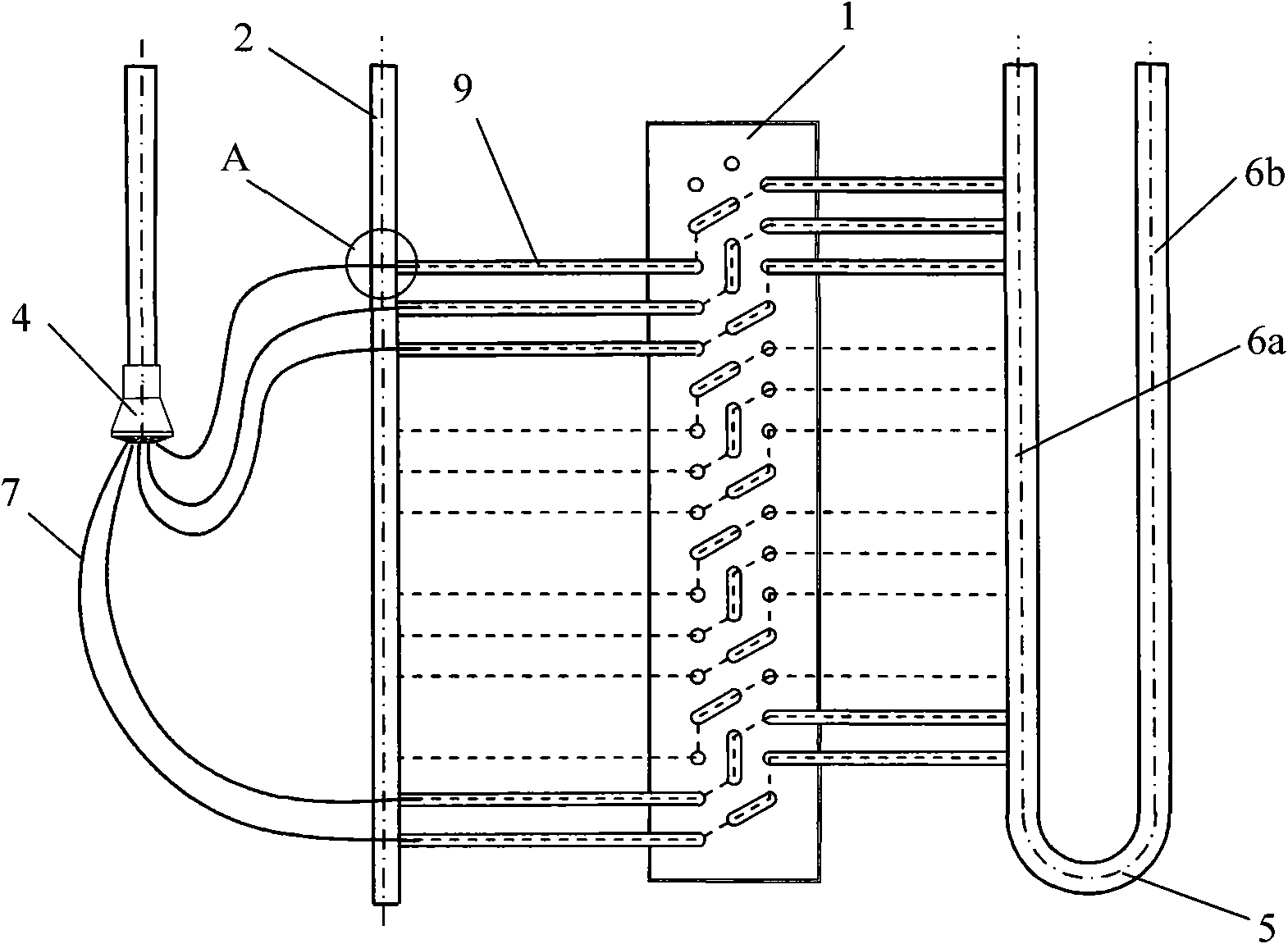

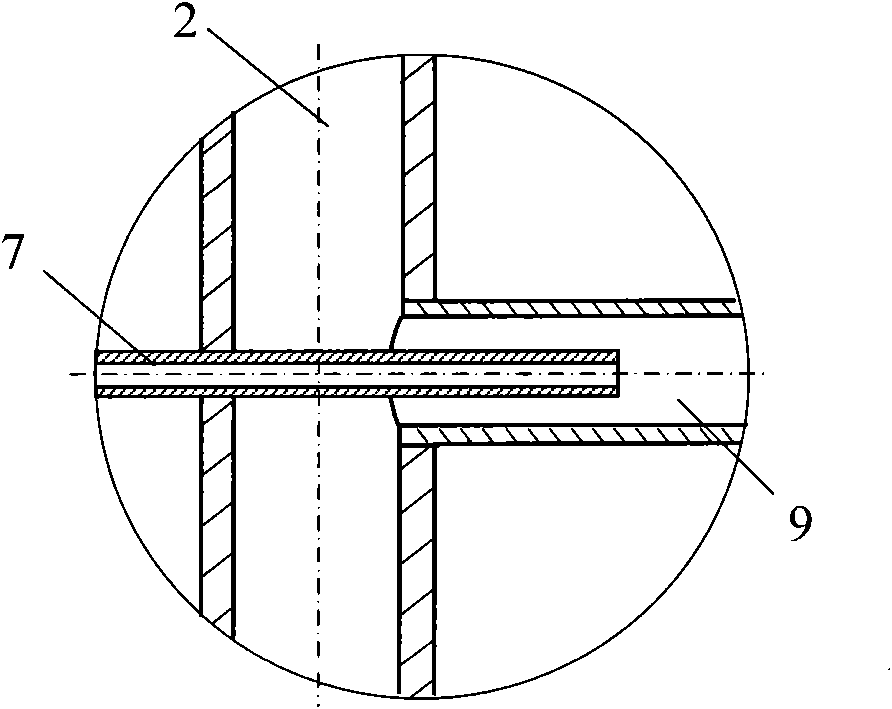

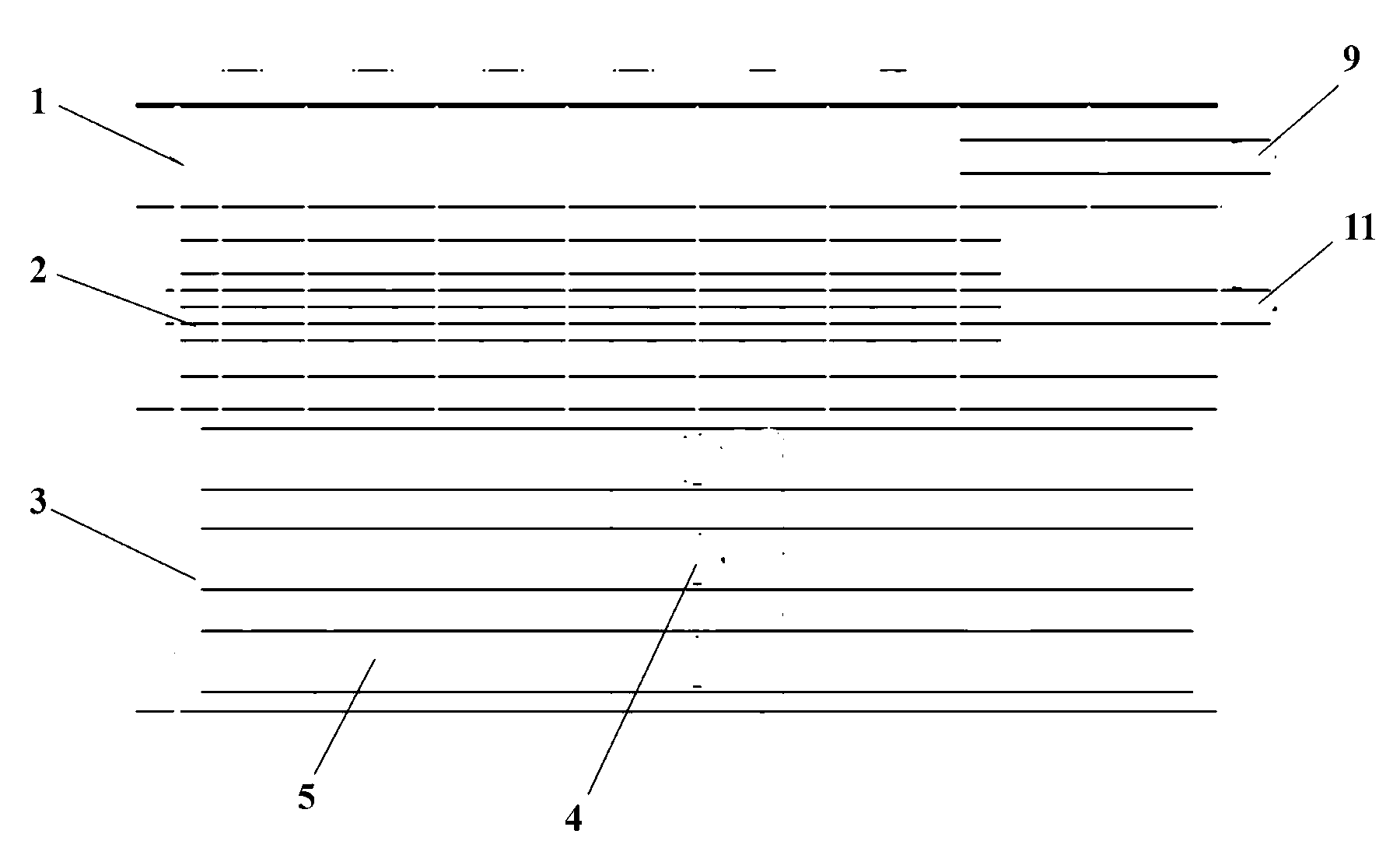

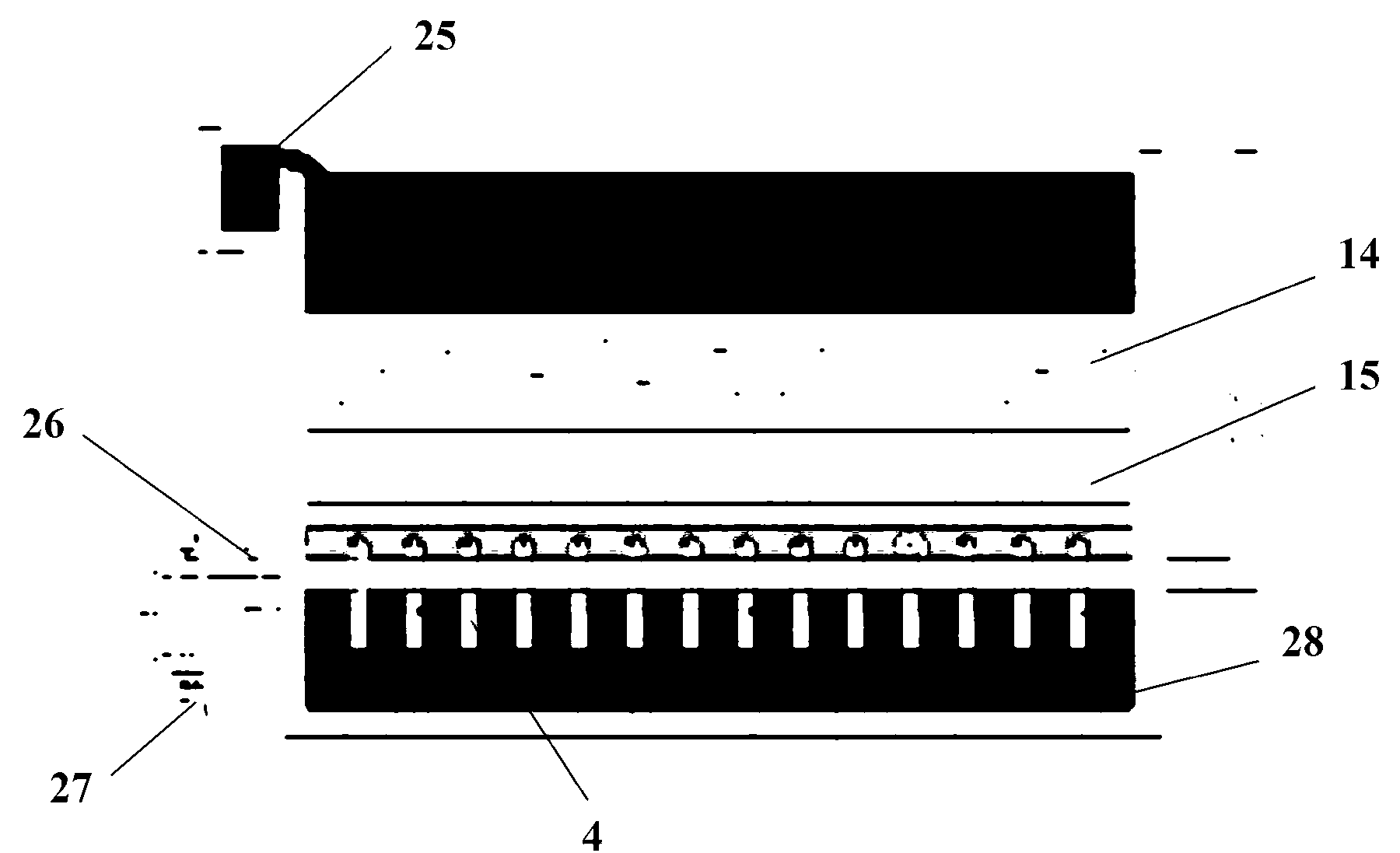

Special evaporator for heat-pipe refrigerating hybrid air-conditioner

InactiveCN101818972AImprove reliabilityImprove energy savingEvaporators/condensersAir conditioning systemsEngineeringAir conditioning

A special evaporator for a heat-pipe refrigerating hybrid air-conditioner contains a finned pipe heat exchanger, a gas collecting pipe, a liquid distribution head, a liquid distribution pipe and a heat exchange pipe. The special evaporator is characterized in that a liquid collecting pipe is arranged between the heat exchange pipe and the liquid separating pipe, and the liquid separating pipe runs through the liquid collecting pipe to insert and stretch into the heat exchange pipe; the gas collecting pipe adopts a U-shaped pipe which is composed of a first rising vertical pipe, a second rising vertical pipe and an oil return bend pipe; and the heat exchange pipe is communicated with the first rising vertical pipe through the finned pipe heat exchanger. The special evaporator of the invention realizes the fusion of performance and safety of a vapor compression refrigerating mode and a heat-pipe natural circulation mode on the same evaporator through a special pipeline design, ensures oil return safety of the vapor compression refrigerating mode, and reduces the pipe resistance of the evaporator. The evaporator which is applicable to the heat-pipe refrigerating hybrid air-conditioning unit has simple structure, low cost and obvious effect, thus effectively solving the problems of oil return and resistance reduction of the unit, and improving the operating reliability and high efficiency.

Owner:TSINGHUA UNIV +1

Integrated water purification device and water purification method

InactiveCN103007625ASolve easy blockageSolve the dirty cleaning of the filter materialMultistage water/sewage treatmentFiltration circuitsFlocculationPurification methods

The invention relates to an integrated water purification device and a water purification method. The device comprises a flocculation basin, an inclined plate sedimentation basin and a non-overflowing double-layered filter material filtering tank which are sequentially connected in series, wherein the filtering tank comprises a filter material layer, a supporting layer, a water distribution and gas distribution assembly and a water distribution water channel which is vertically arranged along the middle part of the filtering tank; the water distribution and gas distribution assembly comprises a water collection pipe row which is horizontally arranged, and a vertical pipe row which is vertically arranged; the upper ends of all vertical pipes are communicated with water collection pipes in the water collection pipe row and the lower ends of all the vertical pipes are communicated with the water distribution water channel; a water discharging hole is formed in the bottom of each water collection pipe, and an air exhausting hole and a washing air hole are sequentially formed in the middle part and the top of each water collection pipe; and an air inlet small hole is formed in the lower middle part of each vertical pope. According to the integrated water purification device and the water purification method, the problems that a filtering head of a double-layered filter material filtering tank is easy to block, a filter material cannot be washed, a mud ball is deposited, the filtering material is lost, the construction cost is high, the maintenance is complicated ant the like can be solved; the construction period is short, a land is saved and the construction cost is low; and the water supply requirements of countryside villages and towns, and industrial and mining enterprises, and beauty spots, which are far away from cities can be met.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

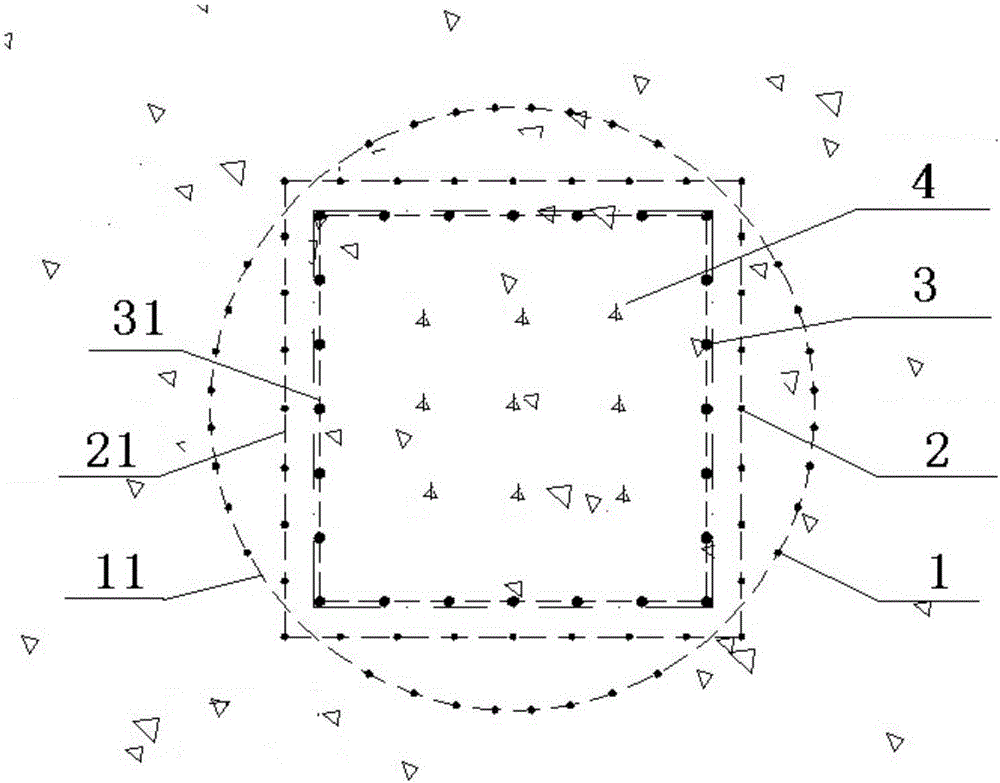

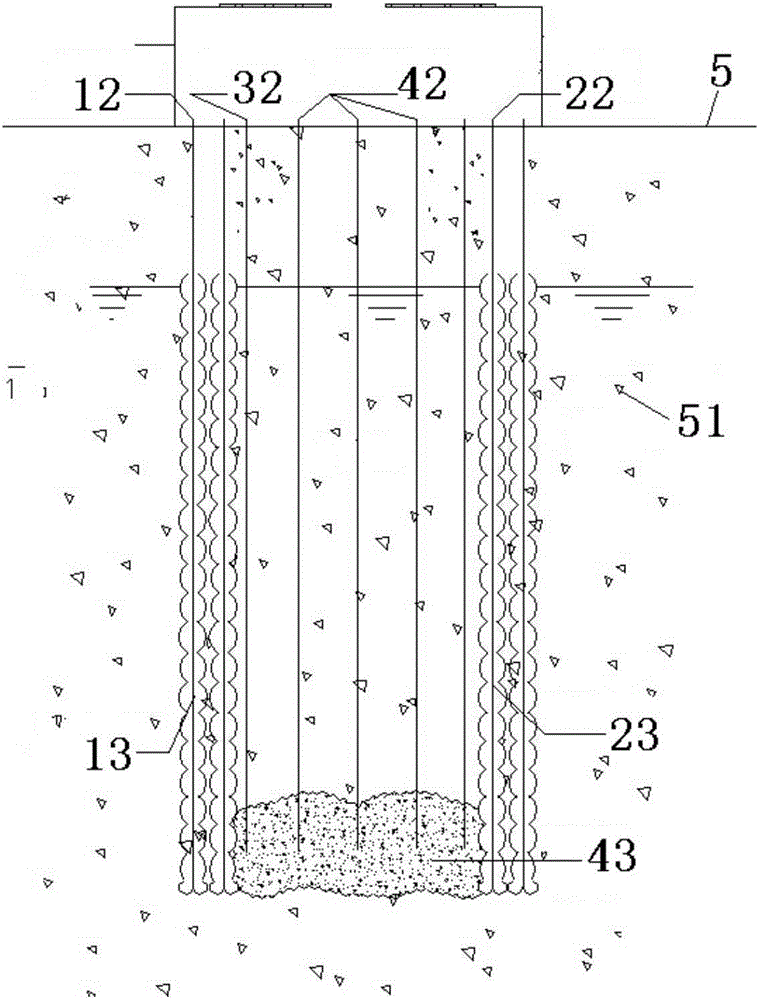

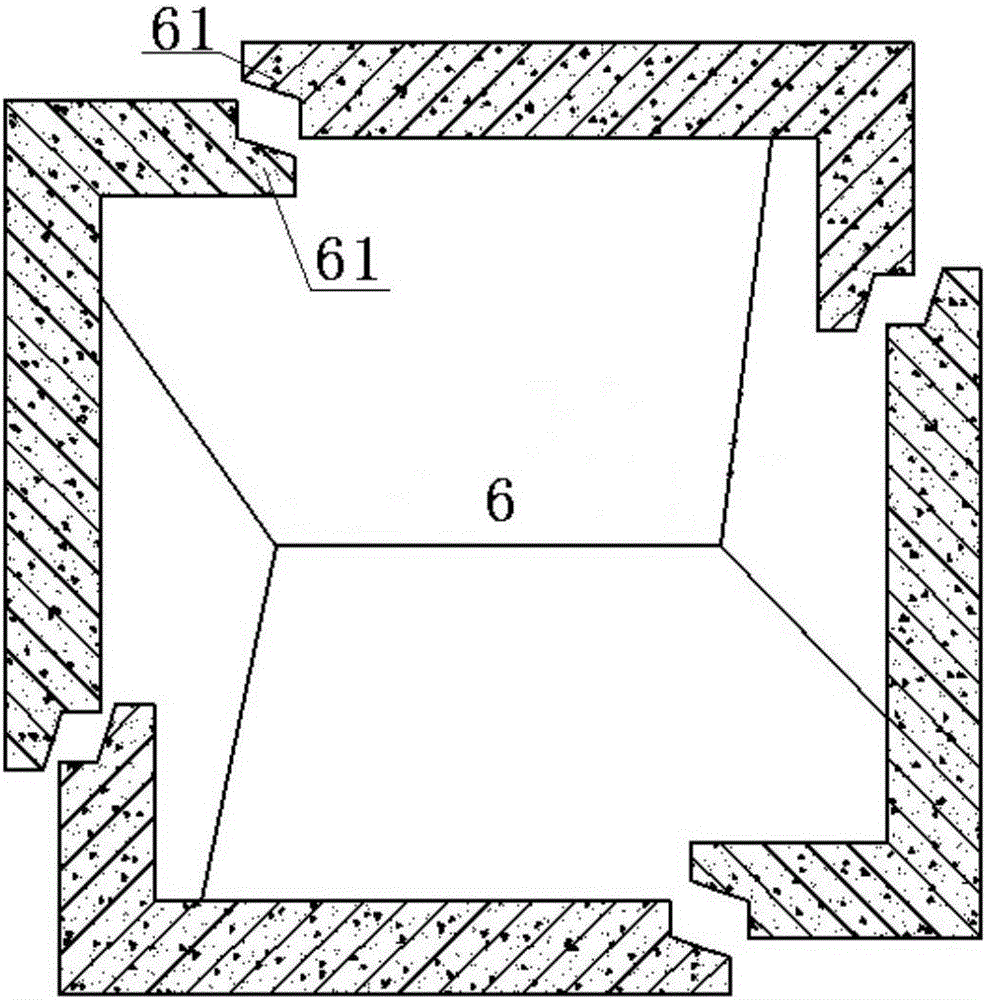

Prefabricated underground silo compound shaft construction method and silo structure

ActiveCN106088154AReduce the internal force of the rectangular sectionReduce settlementArtificial islandsUnderwater structuresEngineeringSilo

The invention relates to the field of underground silo facilities, in particular to a prefabricated underground silo compound shaft construction method and a silo structure which effectively improve the underground silo construction efficiency and greatly reduce the construction cost. The prefabricated underground silo compound shaft construction method comprises the following steps that a, paying off is firstly carried out in a silo building site to locate and arrange drill holes; b, freezing operation and bottom grouting are carried out; c, splicing assembly is carried out to form shaft structures; d, shoe leg heating pipes in shoe leg structures are used for hydrothermal circulation; e, structure shaft components are assembled step by step to form new shaft structures till the preset depth is achieved; f, bottom plates and supporting plates are mounted; g, all drill hole openings in the ground are closed; and h, debugging and running are completed, and construction is finally completed. The prefabricated underground silo compound shaft construction method and the silo structure are high in construction reliability and construction speed and especially suitable for being used in fields with the short construction period and limited construction space.

Owner:黄竟强

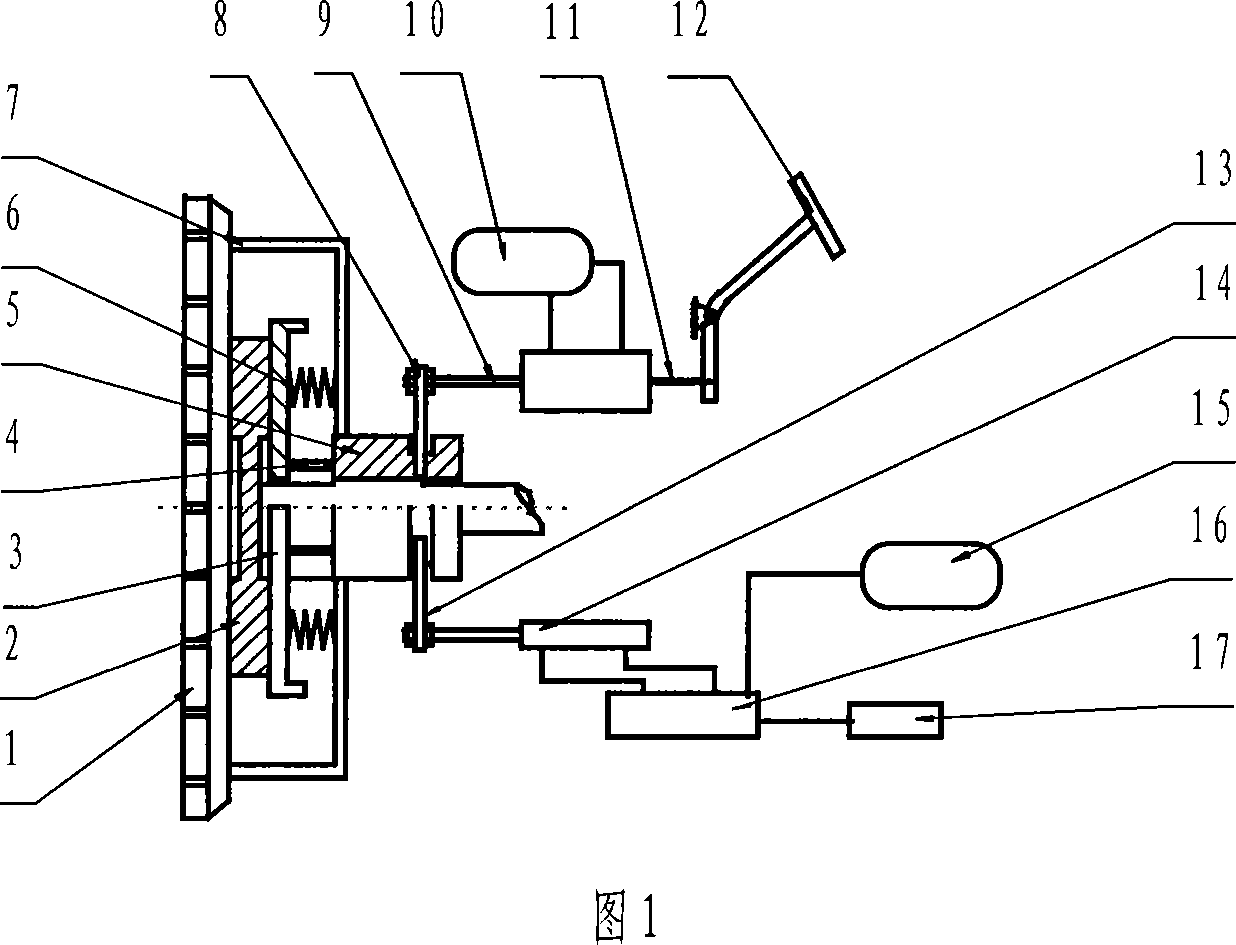

Auxiliary automatic separator for clutch of hydraulic mixed power city bus

InactiveCN101020412AGood energy saving effectEasy to operateBraking element arrangementsGas pressure propulsion mountingEngine powerClutch

The present invention relates to one kind of auxiliary automatic separator for clutch of hydraulic mixed power city bus. The present invention can ensure the independent operation of engine power or hydraulic power in mixed power city bus without mutual interference and resistance, and make mixed power city bus possess excellent energy saving effect and excellent operation smoothness.

Owner:SHANGHAI SHENZHOU VEHICLE RES & DEV

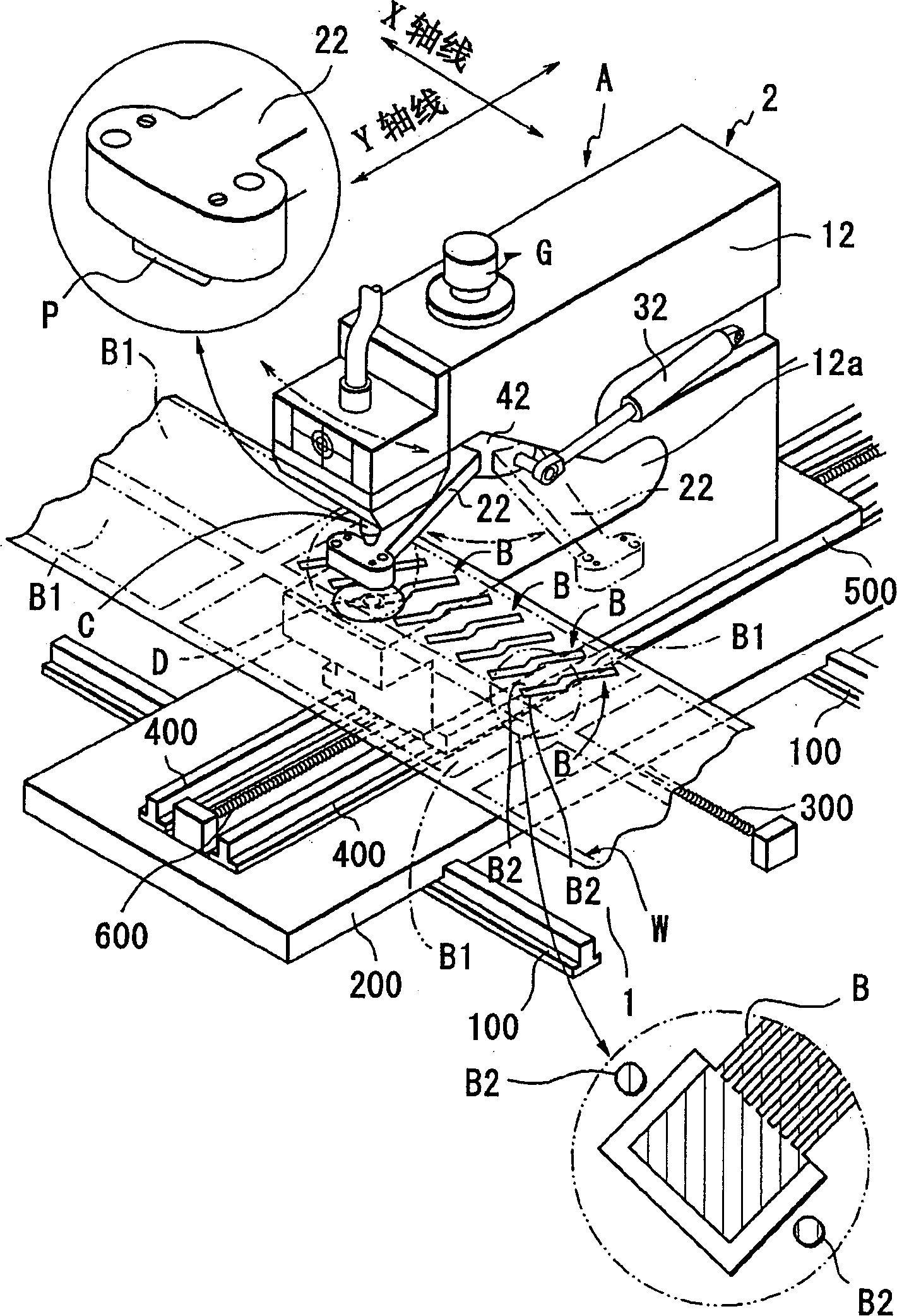

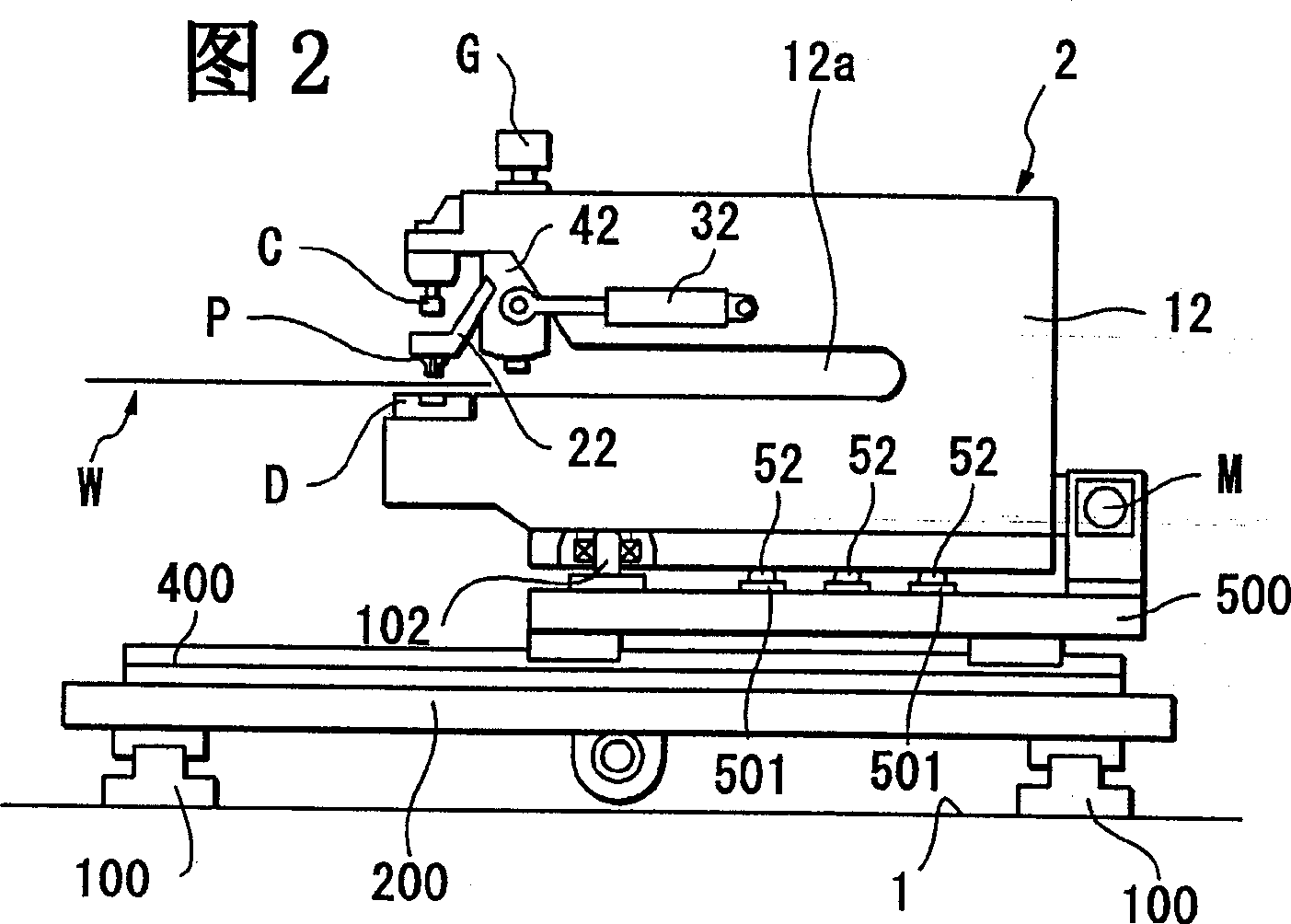

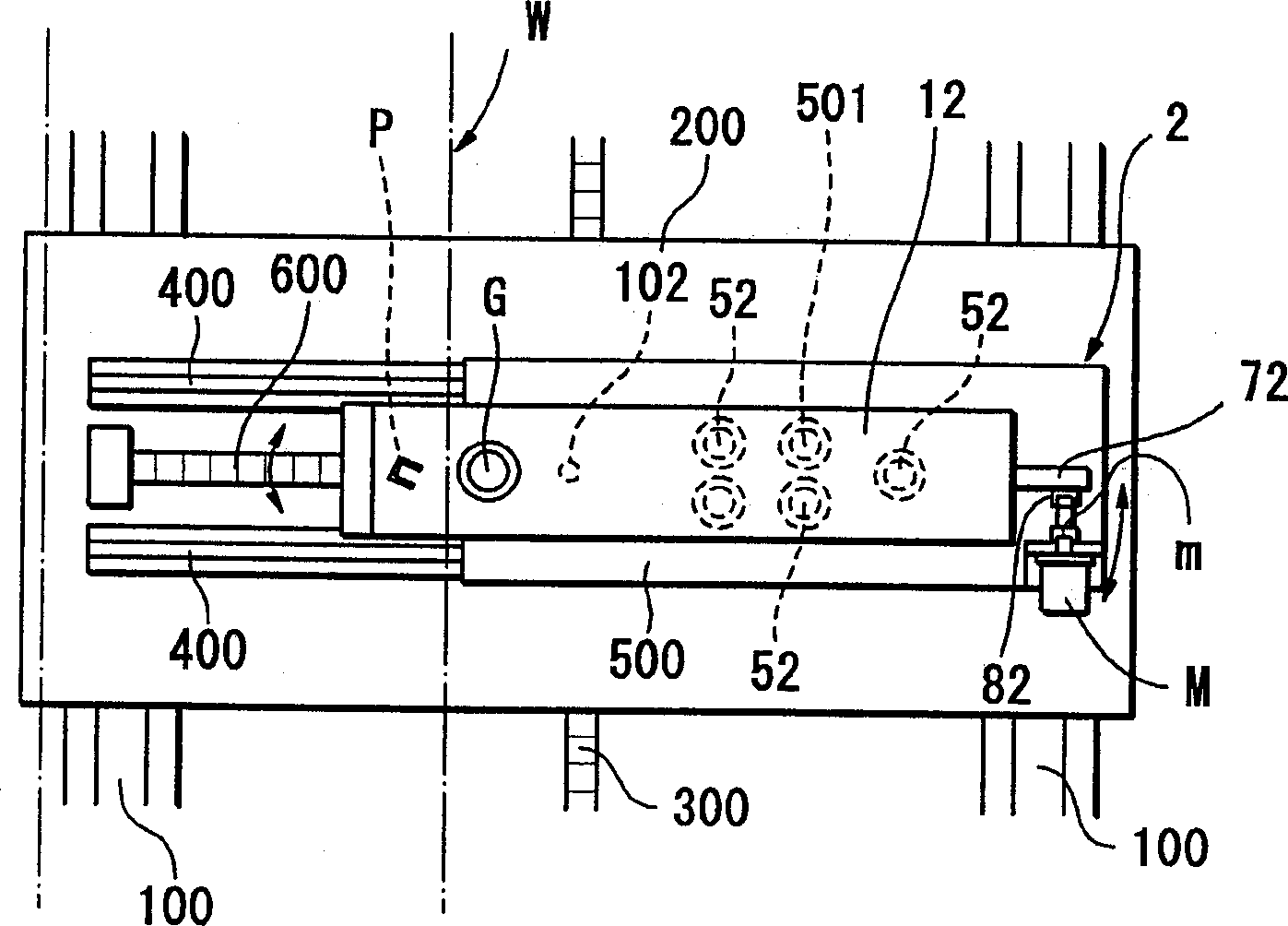

Punching device for workpiece with flexibility

InactiveCN1404970ACorrect misalignmentEasy to punchMetal working apparatusPunchingImaging processing

The invention provides a punching device for a flexible workpiece capable of punching a flexible workpiece with high precision even if the position of the noncircular part of the flexible workpiece to be punched is displaced in a theta direction by more than a predetermined angle. While the coordinate values of the centers of reference points B2 and B2 whose images are picked up by a camera C and subjected to image processing (binarization) and image data subjected to graying process are being varied and displaced relative to the coordinate values of the centers of the reference points previously inputted to an image processor as teaching data, and relative to the image data of the outer periphery of an end of a product B subjected to graying process, a punching part 2 is controlled to move in the theta direction and in the directions of X and Y axes, or the workpiece is controlled to move in the theta direction as the punching part is controlled to move in the directions of the X and Y axes, whereby the coordinate values are matched for punching.

Owner:UHT CORP

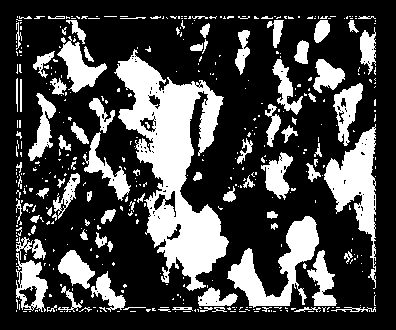

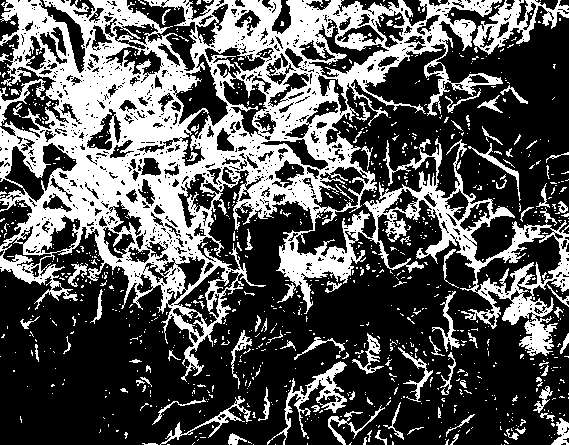

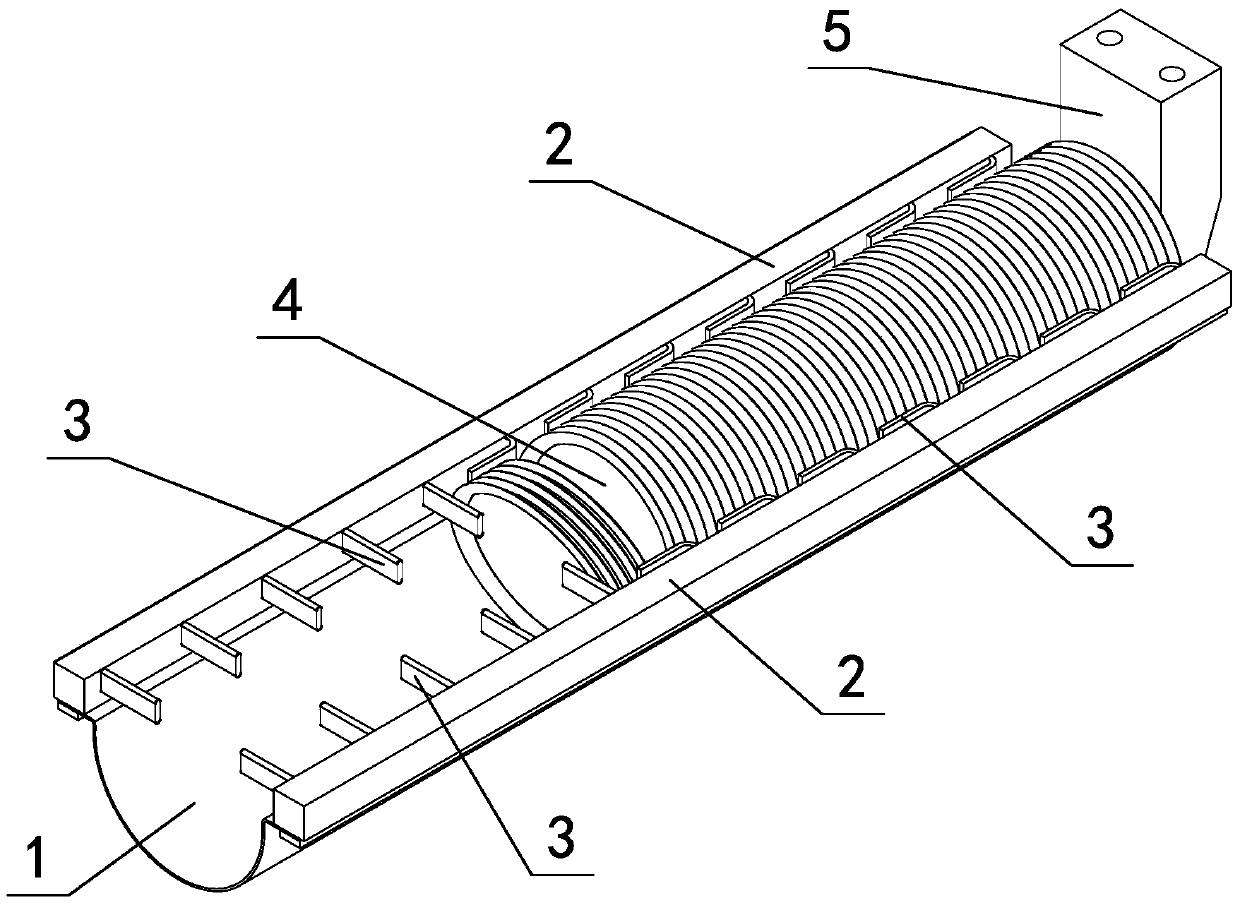

Low-resistance wear-resistance teflon microporous membrane and preparation method

ActiveCN104043347AReduce resistanceImprove wear resistanceSemi-permeable membranesFiberLow resistance

The invention discloses a low-resistance wear-resistance teflon microporous membrane and its preparation method. The teflon microporous membrane has a unique microstructure which is composed of banded nodes which are parallelly arranged and fine fiber used for connecting the nodes. The method comprises the following steps: 1) uniformly mixing teflon resin and an auxiliary agent oil, curing in a constant temperature oven, prepressing, extruding and calendering to prepare a base band; 2) drying and degreasing the above base band, and stretching in the direction parallel to the length of the base band; 3) carrying out loosing processing on the above longitudinally-stretched membrane in a heat-treatment oven at a certain loosing ratio; and 4) stretching the above sintered membrane at the temperature higher than melting point of teflon in the direction perpendicular to the length of the base band and sintering and shaping. The prepared PTFE microporous membrane material has excellent properties such as low resistance, good abrasion resistance, high puncture strength and the like, and can be applied in multiple fields of industrial dedusting, clothing, dust collectors, liquid-phase filtering, water treatment and the like.

Owner:浙江净膜环保有限责任公司

Paper rolling mechanism for printing machine

The invention discloses a paper rolling mechanism for a printing machine. The paper rolling mechanism comprises two parts including a paper feeding part and a paper receiving part; the paper feeding part and the paper receiving part are fixed to the two ends of a working table of the printing machine, and roll paper is conveyed through the paper feeding part, is pulled by the working table of the printing machine to the paper receiving part, and is tightly pasted to the working table of the printing machine; the paper feeding part and the paper receiving part are fixed to a single arm support plate on the working table of the printing machine in a single cantilever manner and are independently driven by driving devices to rotate; and expanding devices are arranged inside paper cores on the paper feeding part and the paper receiving part. According to the paper rolling mechanism for the printing machine, single cantilever structures are adopted, the structure is simple, and operation is convenient; and the expanding devices are arranged on the paper rolling mechanism, the roll paper can be fixed from the interior of the paper cores, the problem that the paper cores are not tightly clamped is effectively solved, the problem that resistance exists during rotation of the paper receiving part is solved, and the using effect of the paper rolling mechanism for the printing machine is improved.

Owner:THE 45TH RES INST OF CETC

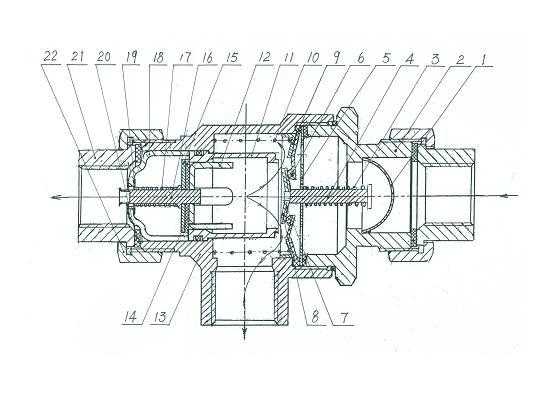

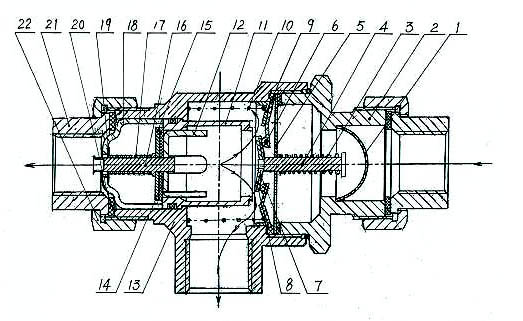

Low-resistance self-discharge backflow preventer

ActiveCN101852302AReduce lossesSmall flow resistanceCheck valvesMultiple way valvesMechanical engineeringSelf-discharge

The invention relates to the technical field of valves, in particular to a low-resistance self-discharge backflow preventer, solving the problems of instable work, poor safety performance, large energy loss and complicated structure of the traditional backflow preventer. The low-resistance self-discharge backflow preventer comprises a valve body and a valve cap arranged at one end of a water inlet of the valve body and is characterized in that a water discharge opening is arranged at the middle of the valve body; a sleeve is arranged at the core part of the valve body at the water discharge opening; a circular blade and a spring seat are arranged at one end of the valve body towards the water inlet of the valve body; a third spring is arranged between the outside diameter of the sleeve and the inside diameter of the valve body; a first one-way valve is arranged at the core part of the valve cap; one end of the first one-way valve is matched with the sleeve; a second one-way valve is arranged at one end of the sleeve towards a water outlet of the valve body; and the second one-way valve comprises a four-claw sliding valve and the matching part of the sliding valve and the sleeve is the width of four claws. The invention has the advantages of high partition safety, small loss for a tap when a medium passes through the preventer and effective prevention on the pollution caused by the backflow.

Owner:HANGZHOU CHUNJIANG VALVE

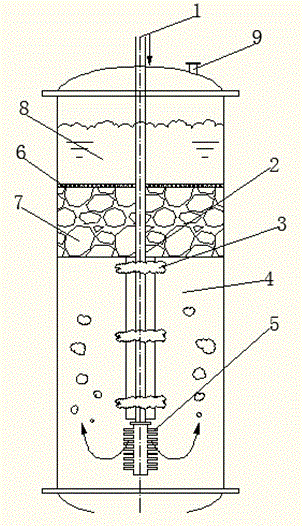

Gas-lifting type two-phase partition membrane bioreactor

ActiveCN105536512AReduce energy consumptionHigh trafficDispersed particle separationAir quality improvementMembrane bioreactorBiological membrane

The invention provides a gas-lifting type two-phase partition membrane bioreactor and belongs to the technical field of industrial organic waste gas purification. The bioreactor comprises a shell, a gas inlet and an exhaust funnel; the bioreactor is characterized in that the gas inlet is formed in the center of the upper end of the shell, and the exhaust funnel is arranged at the upper end of the shell; the shell is internally provided with a tail gas area, a microorganism reaction area and an aqueous phase area in sequence from top to bottom, the exhaust funnel is communicated with the tail gas area, and a biological membrane is arranged between the microorganism reaction area and the tail gas area; the shell is further internally provided with a gas pipe, the gas pipe is arranged at the central axis of the shell and sequentially penetrates through the tail gas area, the biological membrane and the microorganism reaction area, the upper end of the gas pipe is communicated with the gas inlet, and the lower end of the gas pipe is located at the bottom of the aqueous phase area. The bioreactor combines characteristics of the two-phase partition biotechnology and characteristics of the membrane biotechnology, is compact, simple, novel in structure and high in innovation, has the advantages of being thorough in destruction, free of secondary pollution, comparatively simple in procedure and the like and is an ideal organic waste gas purification means.

Owner:YANGZHOU UNIV

Can cap tipping prevention device

ActiveCN105501909ASmall elastic resistancePouring won'tConveyorsConveyor partsProduction lineEngineering

The invention discloses a can cap tipping prevention device which is arranged on a horizontal cap collection groove of a can cap production line, wherein mounting seats are arranged at the cap collection groove from notches at the two sides of the cap collection groove along the length direction of the cap collection groove; elastic can blocking strips are horizontally arranged at one side, facing to the cap collection groove, of each mounting seat in a spaced manner; one end of each can blocking strip is fixed to one mounting seat correspondingly; the other ends of the can blocking strips are overhung and stretch into the cap collection groove; and the projected lengths of the overhung parts of the can blocking strips on the cross section of the cap collection groove are 30-45% of the width of an opening of the cap collection groove. With the adoption of the can cap tipping prevention device, the problems that in a can collection process in the prior art, can cap tipping happens easily, thereby resulting in that can caps are scratched, a cap pushing resisting force is increased, and a manipulator can not complete a can cap grabbing task can be solved effectively. The can cap tipping prevention device can prevent can caps from tipping effectively, the production efficiency is improved, the product quality is ensured, and the can cap tipping prevention device has very high practical values.

Owner:YIWU EASY OPEN END INDAL CORP

Inferior coal micro-oil ignition combustor

InactiveCN101603683AExtended service lifeSolve easy burnsPilot flame ignitersPulverulent fuel combustion burnersCycloneCombustion chamber

An inferior coal micro-oil ignition combustor comprises a streamlined air powder separation ring, a bidirectional cyclone oil combustor, a wing-shaped anti-friction block, a primary dense-phase coal powder combustion chamber, a secondary dilute-phase coal powder combustion chamber, a V-shaped cavity backflow blunt body, a circumferential cooling bellows and the like, employs a principle of gas-solid two phase flow separation, a principle of oil flame two-way cyclone ignition, backflow high-temperature flue gas of a blunt body, a principle of energy repeated utilization, a principle of coal powder graded ignition and energy gradual enlargement, forms a power field with low air speed, high density, strong eddy flow, strong backflow in the combustor, and creates favorable condition for firing coal powder, so as to effectively solve the problems of firing difficulty and low burn-out ratio of inferior coal. The combustor is capable of igniting inferior coal of 4 to 10 tons by using oil capacity of 150kg / h, which has an oil-saving ratio more than 80%, service life more than 4 years, and is beneficial for popularization in related industries.

Owner:范昌 +2

Ultra-fine fibre adsorption face fabric and manufacturing method thereof

The invention relates to an adsorption material made of superfine fibers and widely used in the cleaning field and the manufacturing method thereof. The prior adsorption material has poor absorptivity and water absorbability and has snagging and aging problems. The invention provides a superfine fiber adsorption material and the manufacturing method thereof. The superficial loops of the inventive product are arranged in high and low rows alternately. The raw materials of high and low row loops are respectively superfine fiber / nylon composite yarn and elastic distorted polyester yarn, with a twist of 300-700. The manufacturing method comprises a twisting step in which the superfine fiber / nylon composite yarn and elastic distorted polyester yarn are twisted respectively in opposite directions; and a dyeing step which includes opening treatment and addition of hydrophilic softener. The inventive product has strong water absorbability and adsorptivity, is easy to clean after dirt cleaning, and has good anti-aging property.

Owner:HAINING LIDA WARP KNITTING CLOTH IND CO LTD

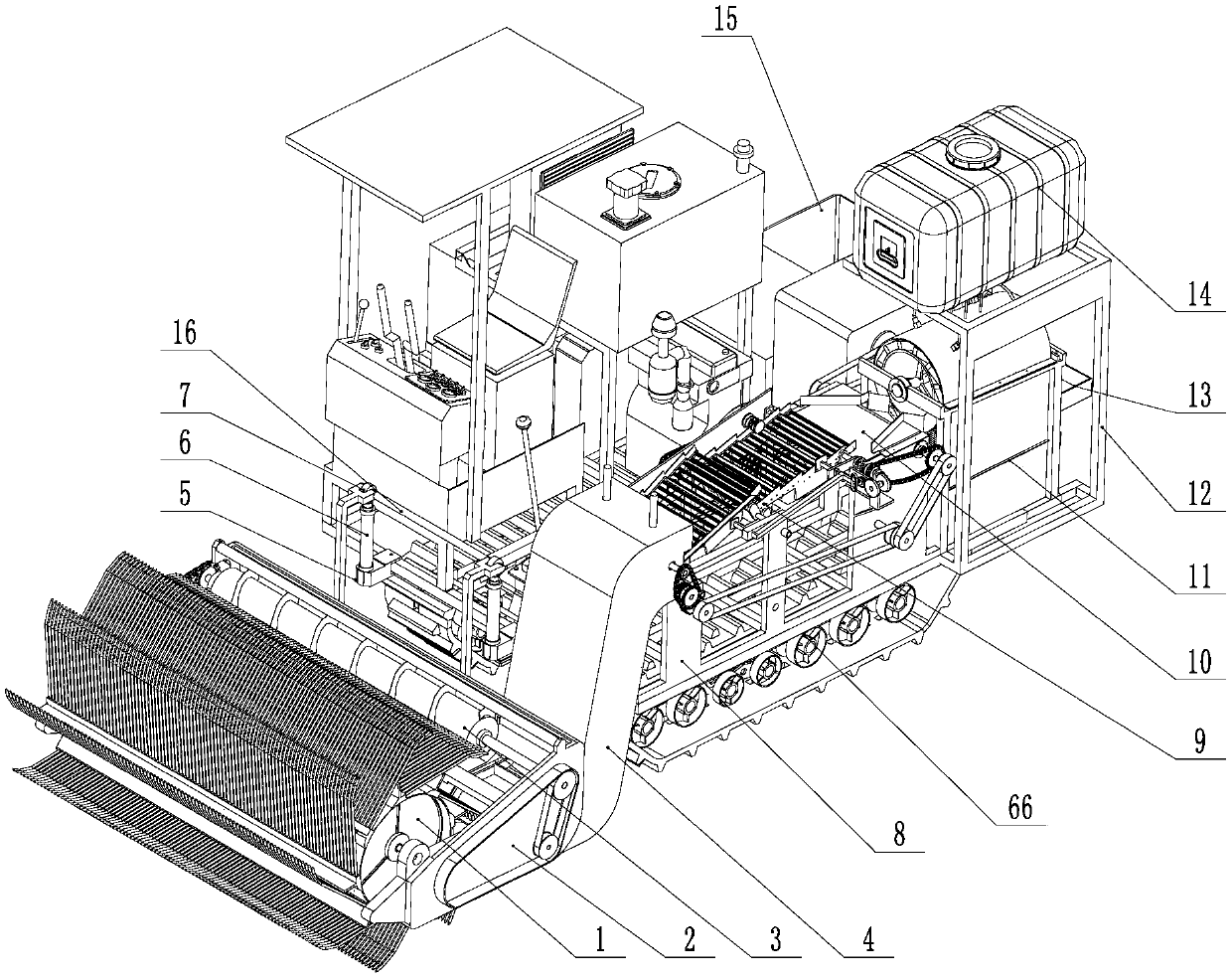

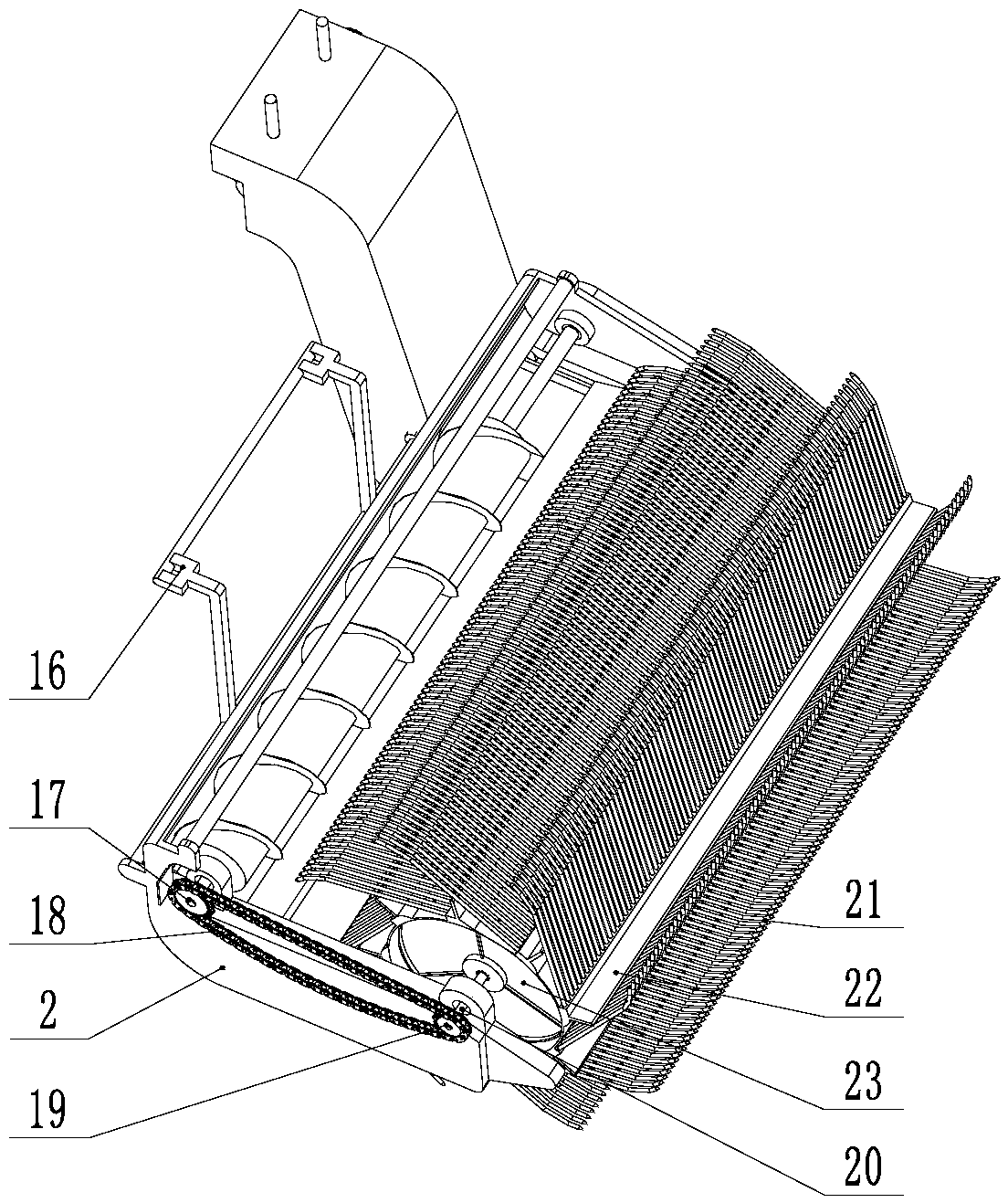

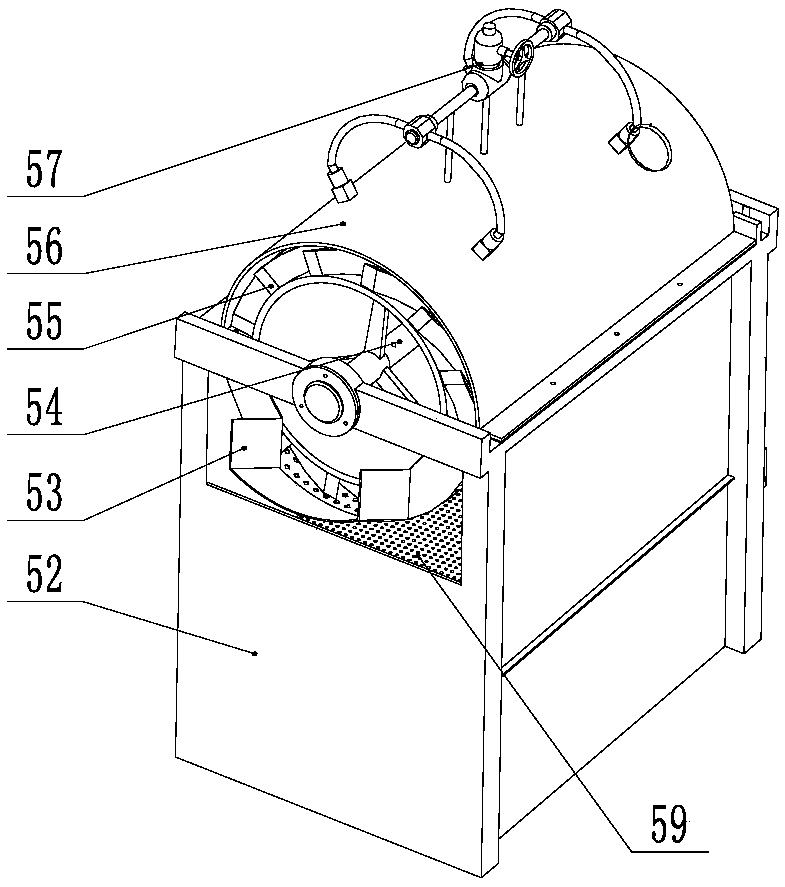

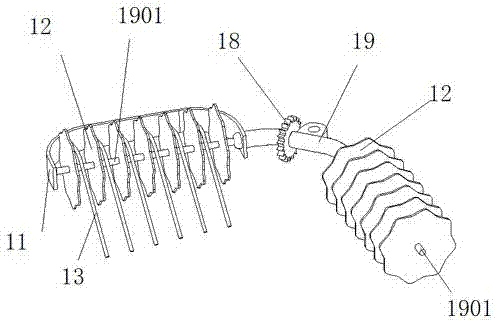

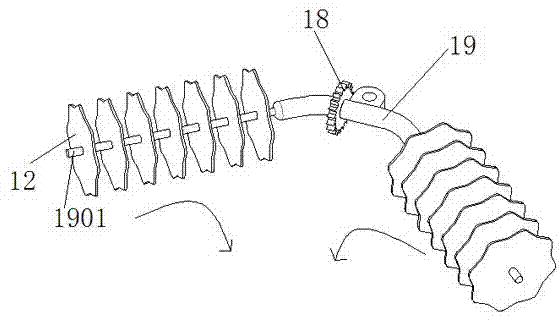

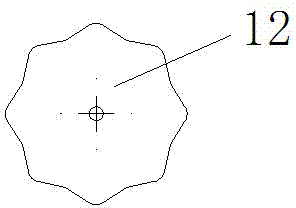

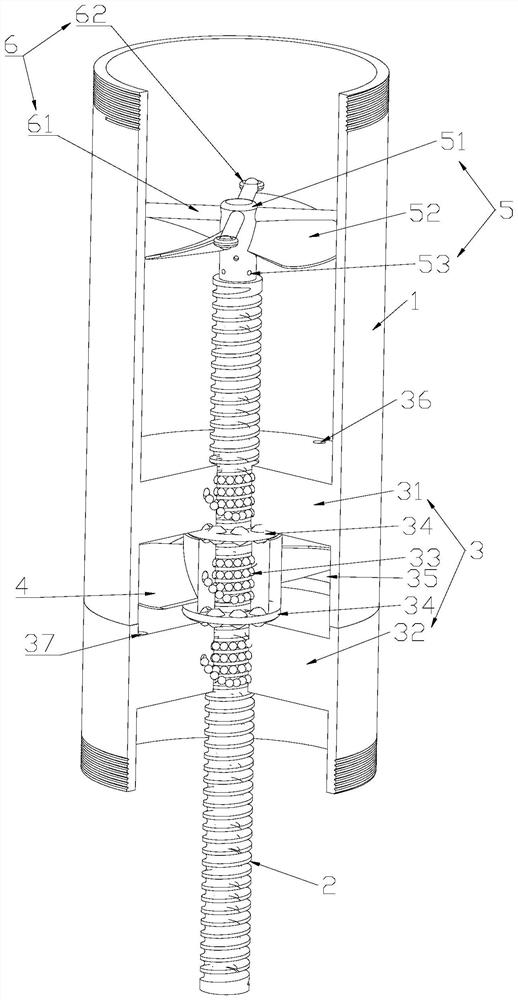

Caterpillar water chestnut combine harVester

ActiveCN108668603ASolve the problem of serious soil congestionResolve resistanceDigger harvestersCaterpillarRasp

The inVention discloses a caterpillar water chestnut combine harVester, which comprises a chassis, a walking system arranged below the chassis, a digging system arranged in front of the chassis, a two-way Vibration separation system arranged aboVe the chassis, a cleaning system and a hydraulic lifting system arranged behind the chassis, wherein a lifting cross beam welded at the tail end of the digging system is connected with the hydraulic lifting system. The two-way Vibration separation deVice comprises a rear throwing motion and a left and a right sieVe of the water chestnuts, when the water chestnuts perform rear throwing motion on a separation sieVe plate, the rasp rod on the separation sieVe plate can increase the friction force between the water chestnuts and the separation sieVe plate to generate a comb brush action and an impact action on the water chestnuts, when the water chestnuts perform a left and right sieVe motion on the separation sieVe plate, the separation sieVe plate generates a Vibration effect on the water chestnuts. By using the harVester, the work of digging, transporting, separating, cleaning, collecting and binning the like can be completed at one time, the harVesting time of the water chestnuts is greatly shortened, the harVesting efficiency is improVed, the damage of the water chestnuts is small during the harVesting process, and the labor intensityof farmers is reduced.

Owner:HUAZHONG AGRI UNIV

Underwear steel ring sleeve and method for manufacturing underwear

Owner:KAIPING KELIAN KNITTERS DEV

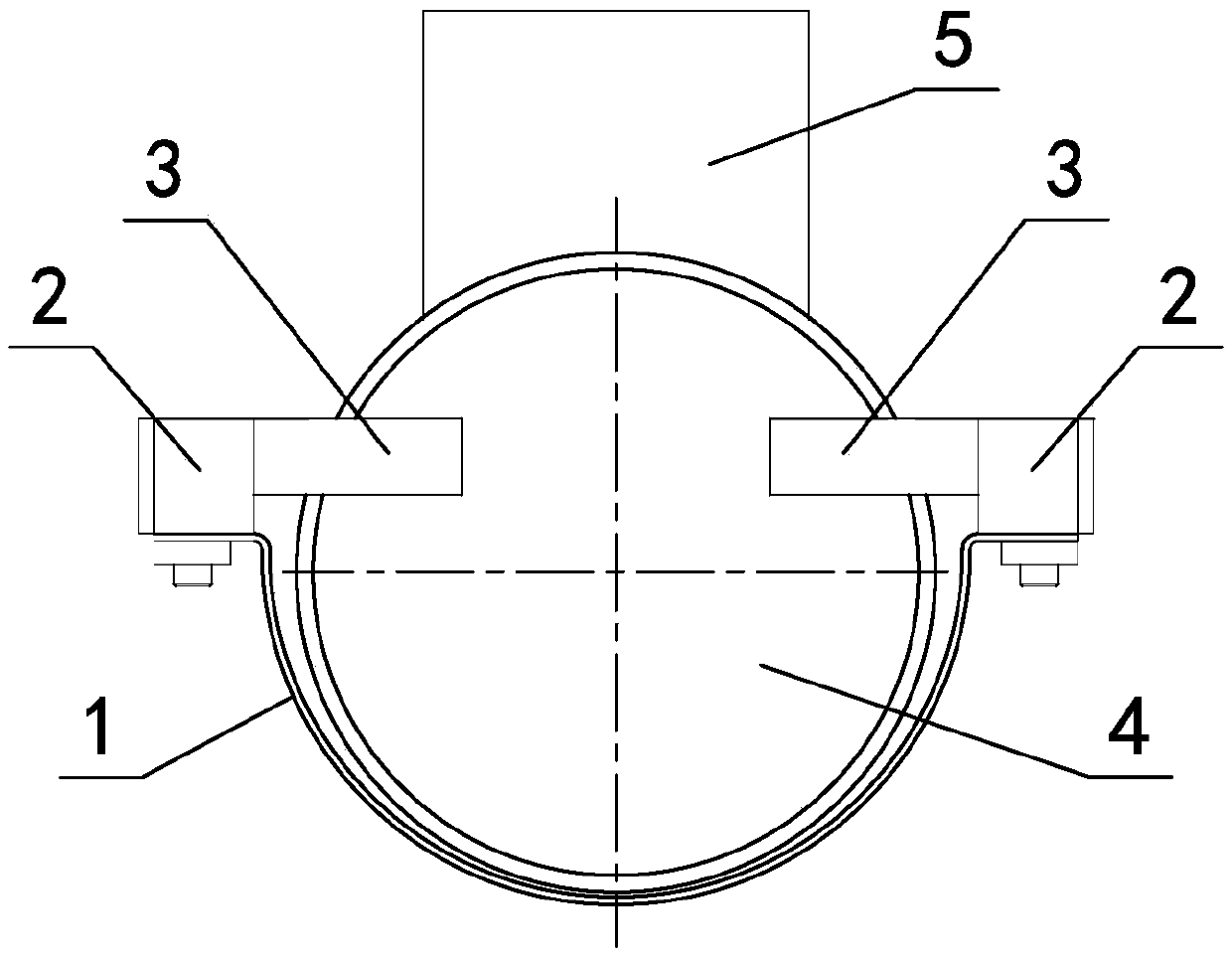

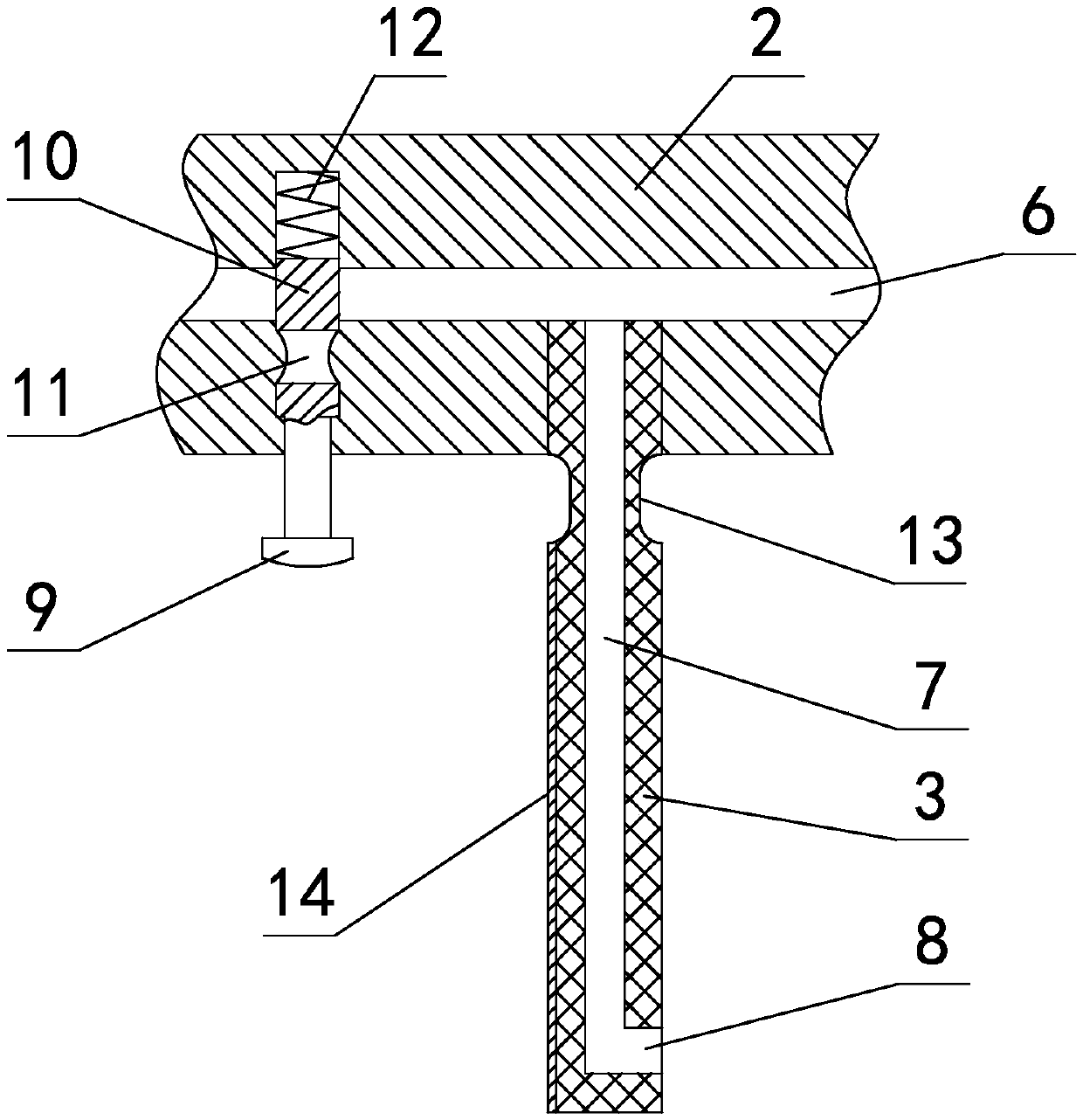

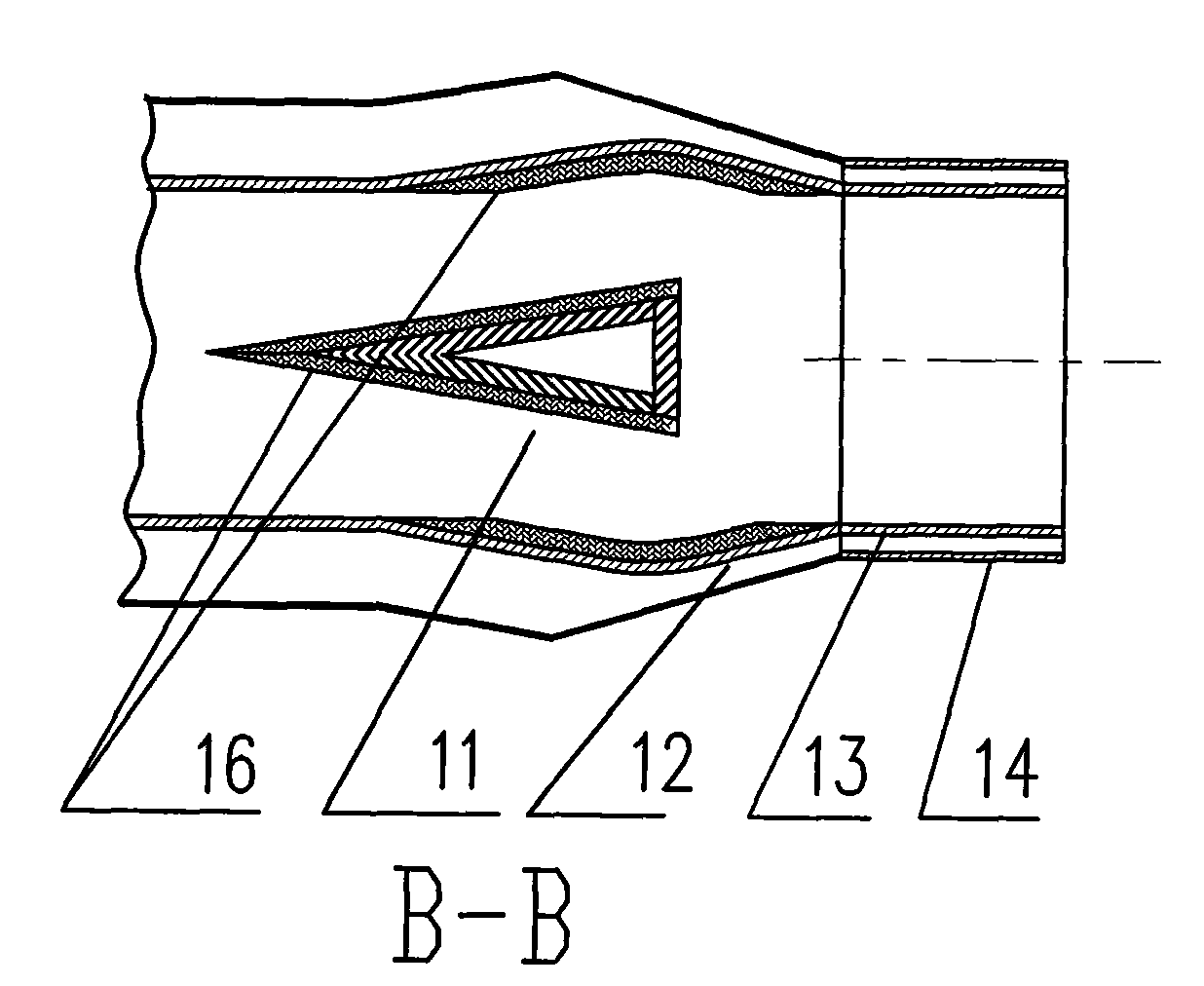

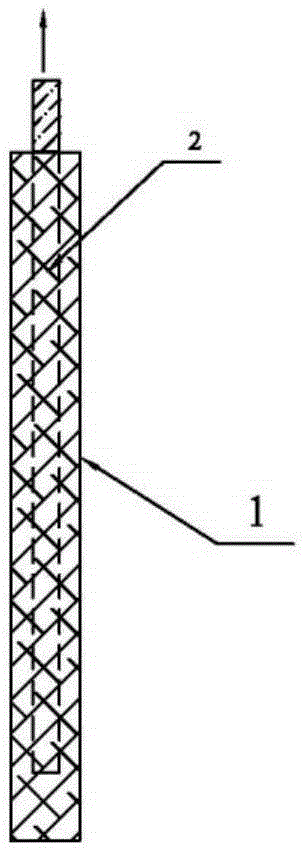

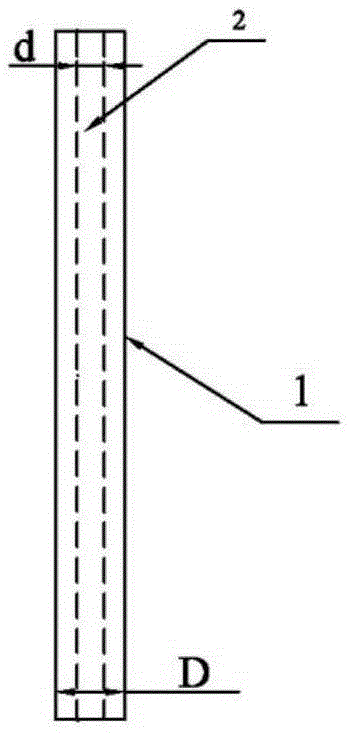

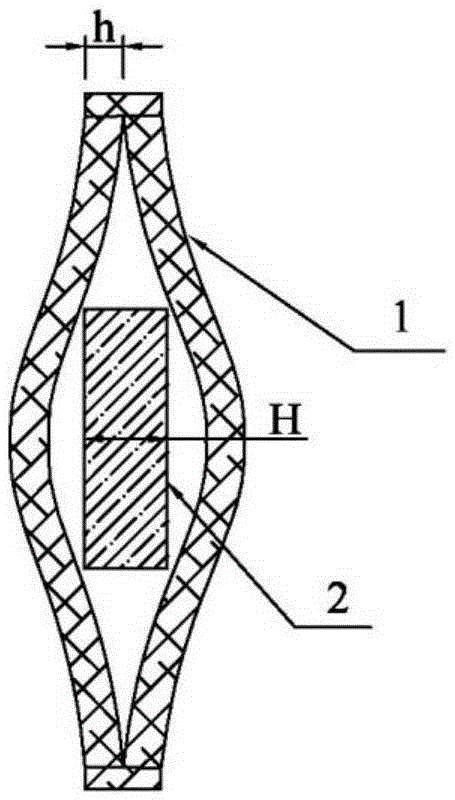

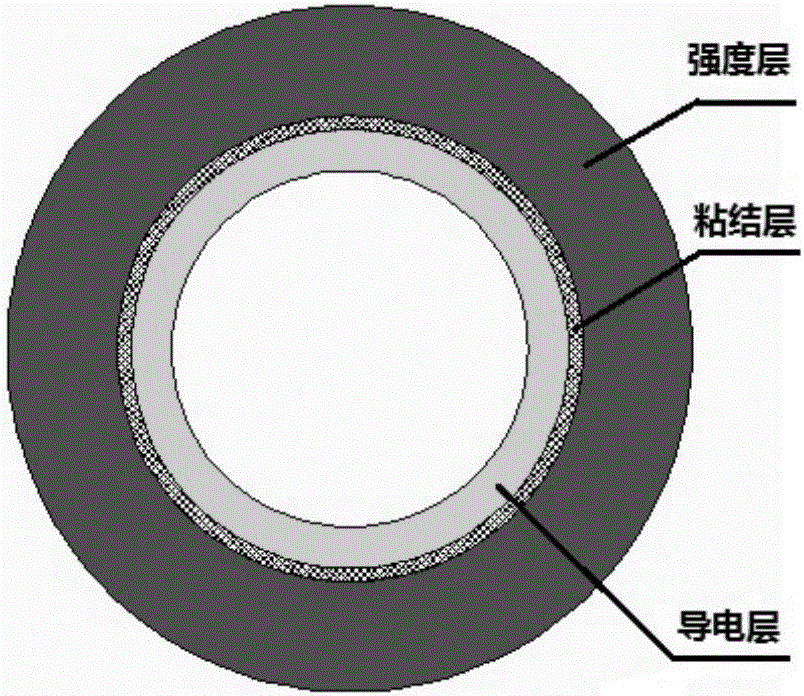

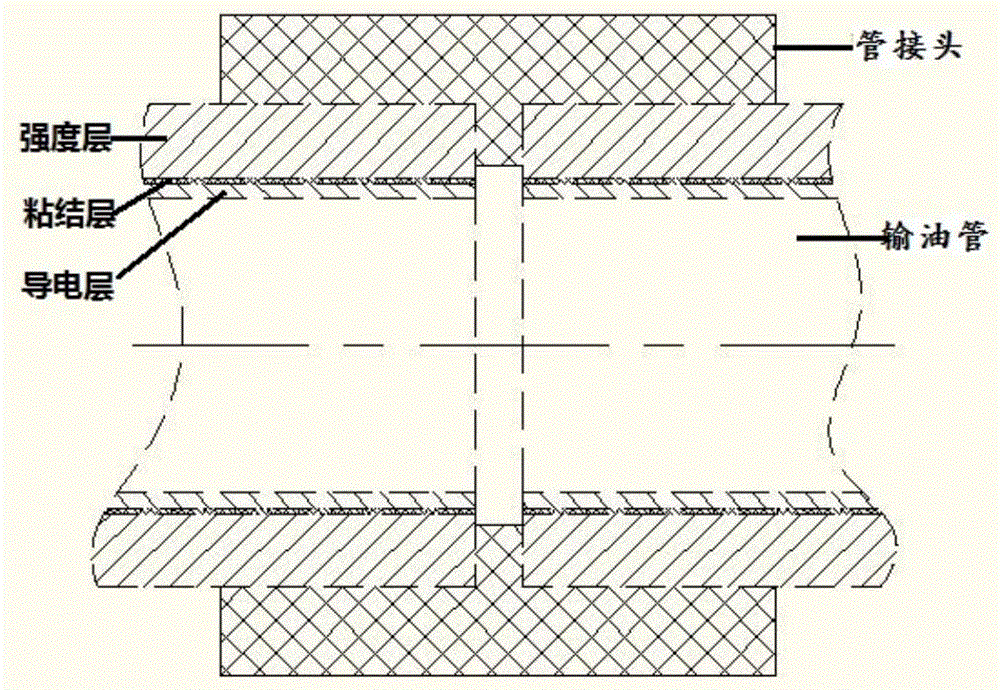

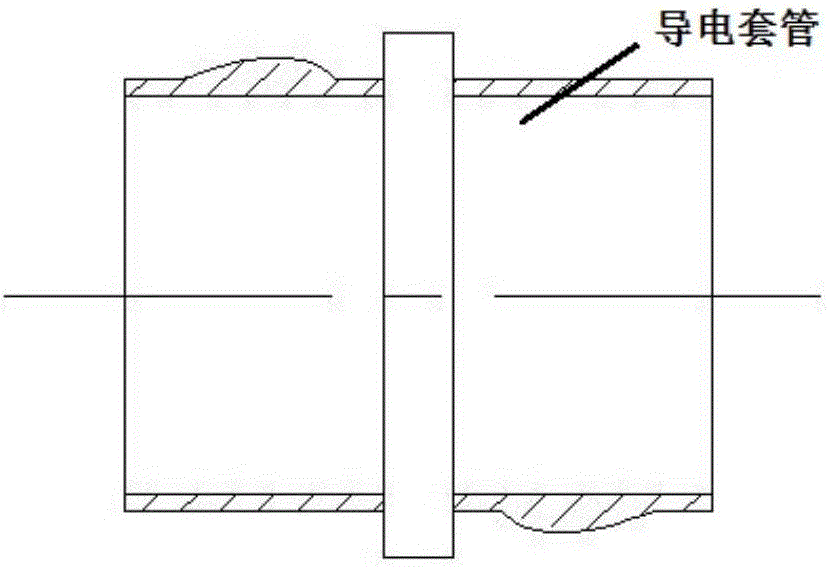

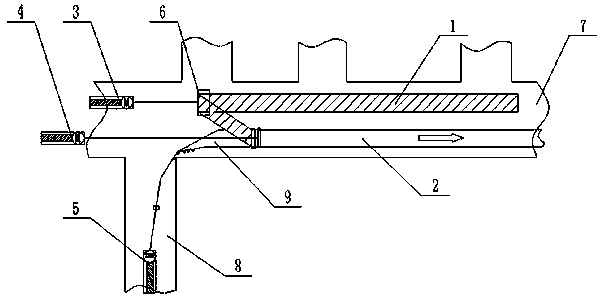

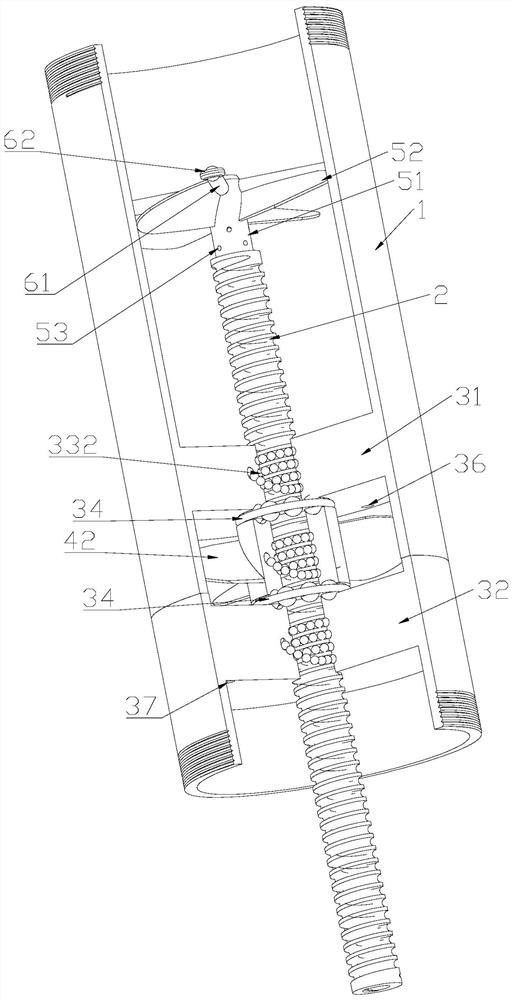

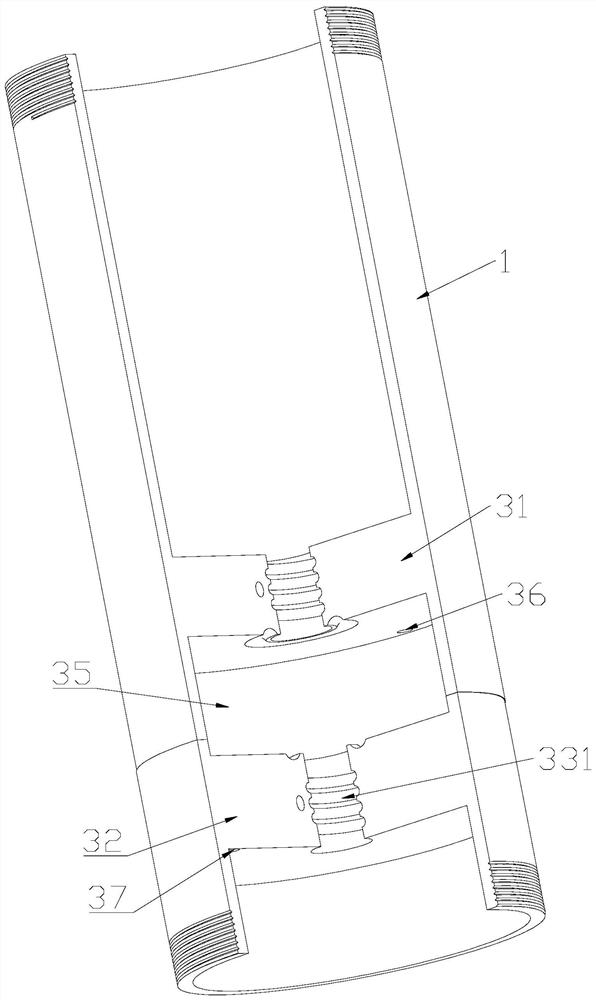

Polymer oil delivery pipe connector for achieving static electricity guiding and removing by communicating seam allowance end face radial keys in axial direction

ActiveCN106567972ASolve the problem that electrostatic conduction cannot be achievedResolve resistancePipe-jointsElectrostatic chargesElectrical connectionPolymer

The invention provides a polymer oil delivery pipe connector for achieving static electricity guiding and removing by communicating seam allowance end face radial keys in the axial direction. The polymer oil delivery pipe connector is characterized by comprising a polymer pipe body (1); an inward convex ring body (2) is arranged inside the polymer pipe body (1); the two end faces of the ring body (2) serve as seam allowance faces which abut against the ends of polymer oil delivery pipes to be connected; a conducting ring (3) is bonded to the inner surface of the ring body (2); the multiple radial keys (4) used for communicating conducting layers of the two polymer oil delivery pipes to be connected in the axial direction are arranged on the end faces of the two sides of the conducting ring (3); grooves (5) matched with the radial keys (4) in dimension are machined in the opposite positions of the end faces of the polymer oil delivery pipes to be connected; and through electrical connection generated by cooperation of the radial keys (4) and the grooves (5), the conducting layers communicate with each other after the polymer oil delivery pipes are connected. The polymer oil delivery pipe connector is simple in structure, and oil delivery resistance and accumulation of static electricity are avoided.

Owner:JIANGSU UNIV

Tape replacing method for under-well main roadway tape conveyor

The invention discloses a tape replacing method for an under-well main roadway tape conveyor, and relates to the technical field of mine transporting mechanical equipment. The problems that the under-well main roadway tape conveyor is low in efficiency of replacing tapes and consumes manpower are solved. The method comprises the steps that two tape heads of new and old tapes are in overlapping joint; the new tape is hung on a roller, the roller is connected with an auxiliary towing winch, and the auxiliary towing winch rotates by dragging the roller; the new tape gradually moves to a conveyingbelt position on the upper portion of the tape conveyor along with the rotation of the roller, the auxiliary towing winch stops working, the conveyed old tape on the lower portion of the tape conveyor is connected with a main towing winch, the main towing winch pulls the old tape, and under the pulling ofthe old tape, the new tape is gradually replaced to a belt carrier roller on the tape conveyor; the method solves the problem of the towing resistance of the winches and greatly increases the work efficiency, the work loading of the main towing winch is reduced, and the work safety is improved.

Owner:山西天地王坡煤业有限公司

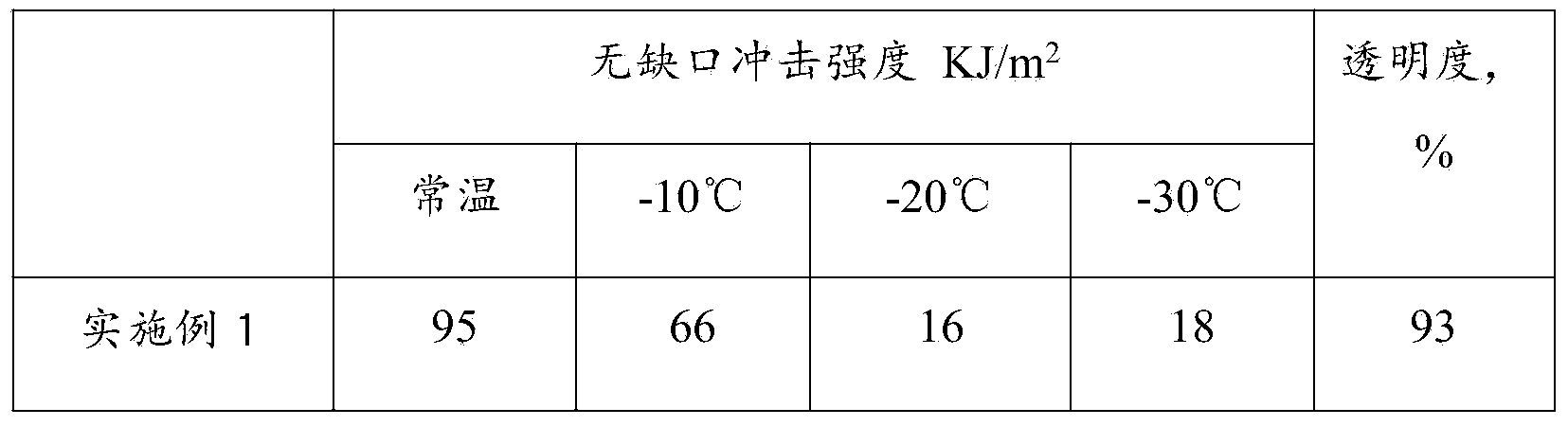

Low-temperature-resistant polypropylene clothing packaging film and preparation method thereof

The invention discloses a low-temperature-resistant polypropylene clothing packaging film composed of the following components in percentage by weight: 75-92wt% of homo polypropylene, 7.5-22wt% of modified polypropylene and 0.5-3wt% of adhesion preventive, wherein modified polypropylene is composed of a repeating unit of isotactic polypropylene and 6-22% of irregularly-distributed ethylene. The low-temperature-resistant polypropylene clothing packaging film disclosed by the invention is resistant to low temperature, high in transparency and good in anti-blocking property; in addition, the well-chosen non-migration particle adhesion preventive is adopted, and the problems of high friction resistance, opening difficulty and easiness for powder leakage of a single layer of film, caused by the addition of modified polypropylene, are solved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Closed urinal

The invention provides a urinal, in particular a closed urinal. The closed urinal is characterized in that pedal pressure of a user is used to enable roller shutters to be opened, and the roller shutters are closed under the function of a spring when a user leaves a pedal. When the user goes to a toilet, the user can not see waste water used for flushing the toilet. Therefore, the closed urinal can be applied to an occasion where the waste water is used to flush the toilet, effectively solves the problem that the user has conflicted emotion due to poor waste water quality, and achieves a water-saving aim.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Vine-nut placement device and peanut harvester with same

The invention discloses a vine-nut placement device and a peanut harvester with the same. The vine-nut placement device comprises a rack; a placement device drive sprocket is disposed on the rack. The vine-nut placement device is characterized in that placement supports are symmetrically fixedly connected to the left and right of the rack respectively, placement bars are evenly fixed in the placement supports, a rotating shaft is movably connected to each placement support through a bearing, star wheels evenly arranged are fixedly welded on each rotating shaft, the placement device drive sprocket is connected with the rotating shafts, and the rotating shafts drive the star wheels on two sides of the rack to rotate oppositely, namely both rotating diagonally down and inwardly, so that vines and nuts are turned. The invention further provides application of the placement device in single conveyor chain ladders or double conveyor chain ladders, vines and nuts on peanut plants can be automatically turned, less labor is consumed, and the plants can be sun-cured conveniently; the harvest problems that during peanut harvesting, traction resistance is large, many nuts drop, nuts are compressed in sandy soil, the vines and nuts are buried in the sandy soil and sun-curing is inconvenient are solved.

Owner:正阳县创鑫机械有限公司

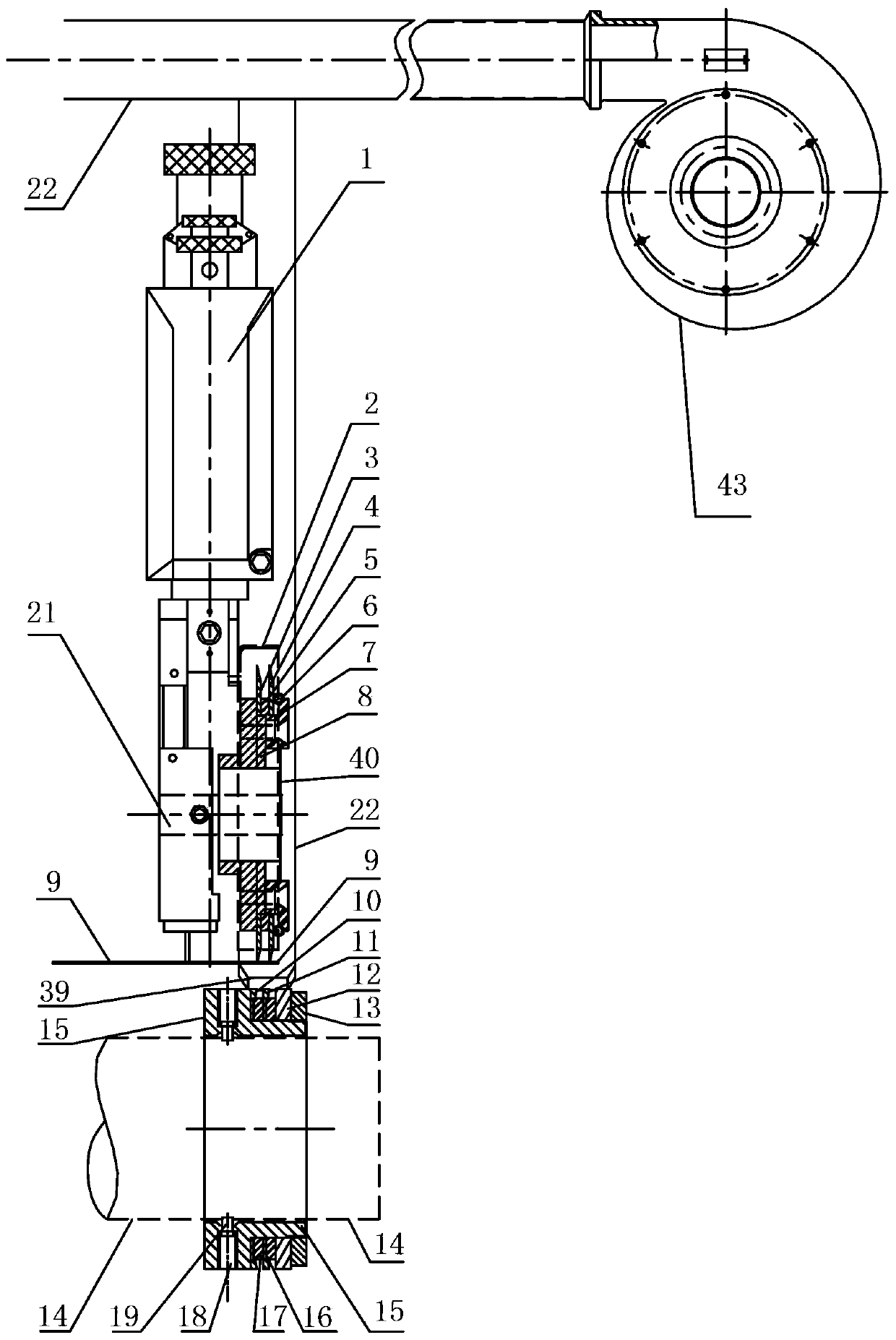

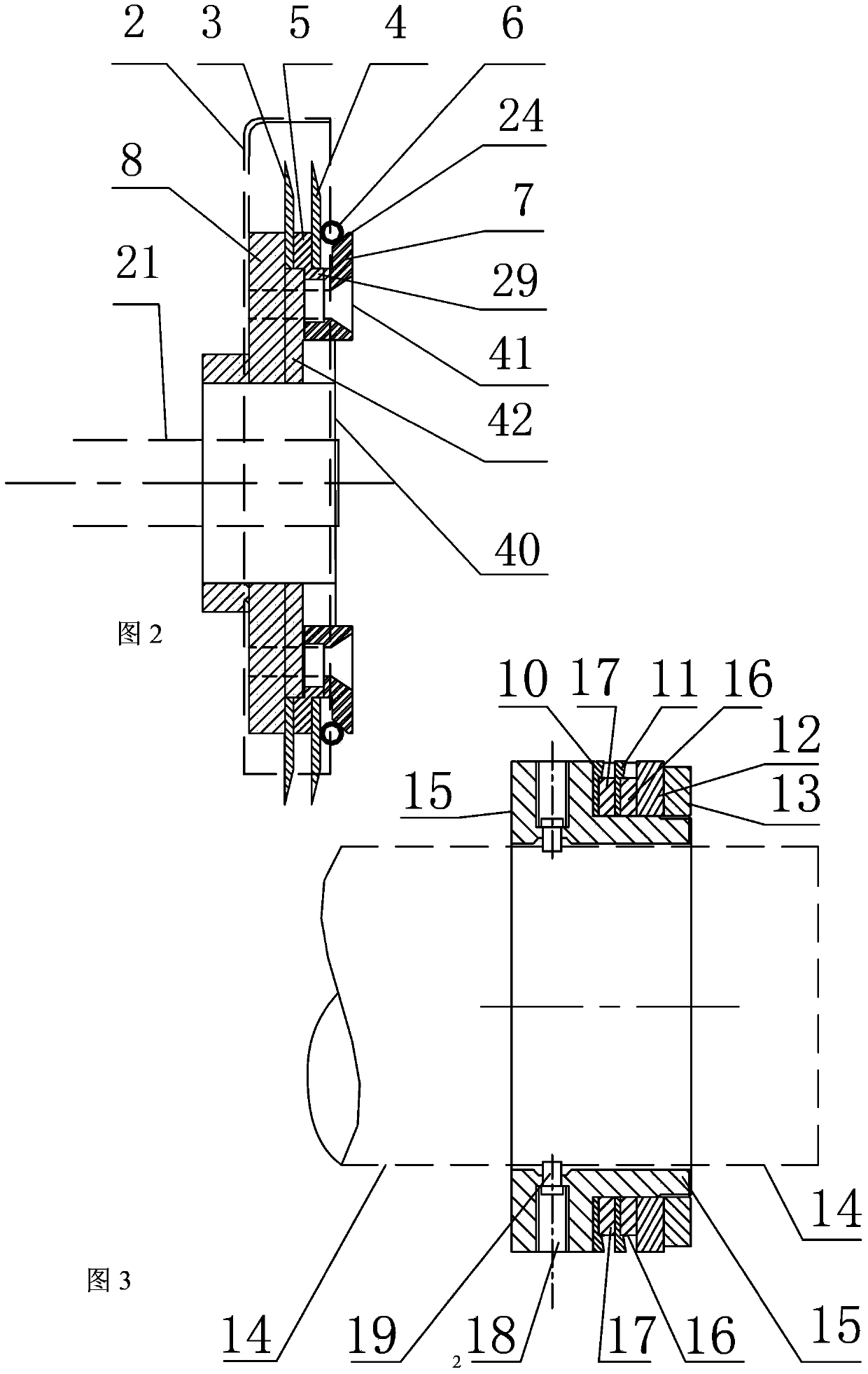

Radial horizontal well sealing device, drilling equipment and drilling method

ActiveCN112963110ASolve the pressure resistanceSolve the problem of low temperature resistanceLiquid/gas jet drillingDirectional drillingThermodynamicsWell drilling

The invention provides a radial horizontal well sealing device, drilling equipment and a drilling method, and relates to the technical field of geological drilling equipment. The radial horizontal well sealing device comprises a sealing shell, an injection pipe, a sealing element, a power feeding mechanism and a rotary drilling mechanism; the sealing element is of an active rolling type dynamic sealing structure and is arranged between the sealing shell and the injection pipe; the rotary drilling mechanism and the power feeding mechanism both adopt high-pressure jet fluid as a power source so as to transmit rotary power and feeding power to the injection pipe; and the drilling equipment comprises an oil pipe, a steering gear, a jet drill bit and a sealing device. By virtue of the sealing device, static friction sealing is changed into dynamic friction sealing, passive sealing is changed into active sealing, and the sealing device has the advantages of reducing drilling cost, being long in service life of equipment, high in drilling efficiency and the like, is also suitable for high-temperature and high-pressure stratums and can avoid the problem that traditional static friction sealing fails.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

High-speed automatic soft trademark cutting machine

ActiveCN103433973ASolve the requestSolve the problem of not being able to turn white on the same sideMetal working apparatusWaste material

The invention relates to a high-speed automatic soft trademark cutting machine for cutting a precise printed piece in a high speed. The high-speed automatic soft trademark cutting machine is characterized by comprising an upper knife assembly, a bed knife assembly and a trash cleaning device, wherein the upper knife assembly is provided with two upper knives, an outer upper knife is not axially fixed, and the position of the outer upper knife is regulated by a tension spring on the outer side of the upper knife assembly; the bed knife assembly is provided with two bed knives corresponding to the two upper knives; a trash cleaning hole of the trash cleaning device faces a position between the bed knife assembly and the upper knife assembly and is used for absorbing cutting trashes. According to the high-speed automatic soft trademark cutting machine, a traditional cutting concept is broken through, and the contradiction between over-high requirements on the cutting precision and the cut whitened sides which are arranged on the same side in a cutting process of the high-speed automatic soft trademark cutting machine is changed by utilizing a double-knife cutting structure; furthermore, the two knives are arranged accordantly and can be compositely mounted and singly exchanged; a structure in which coordination faces of the tension spring and a cover plate are cooperated is smartly utilized on the arrangement of the outer upper knife, so that an axial free motion space is formed on the outer upper knife, and the production speed and efficiency and the product quality are substantially improved.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

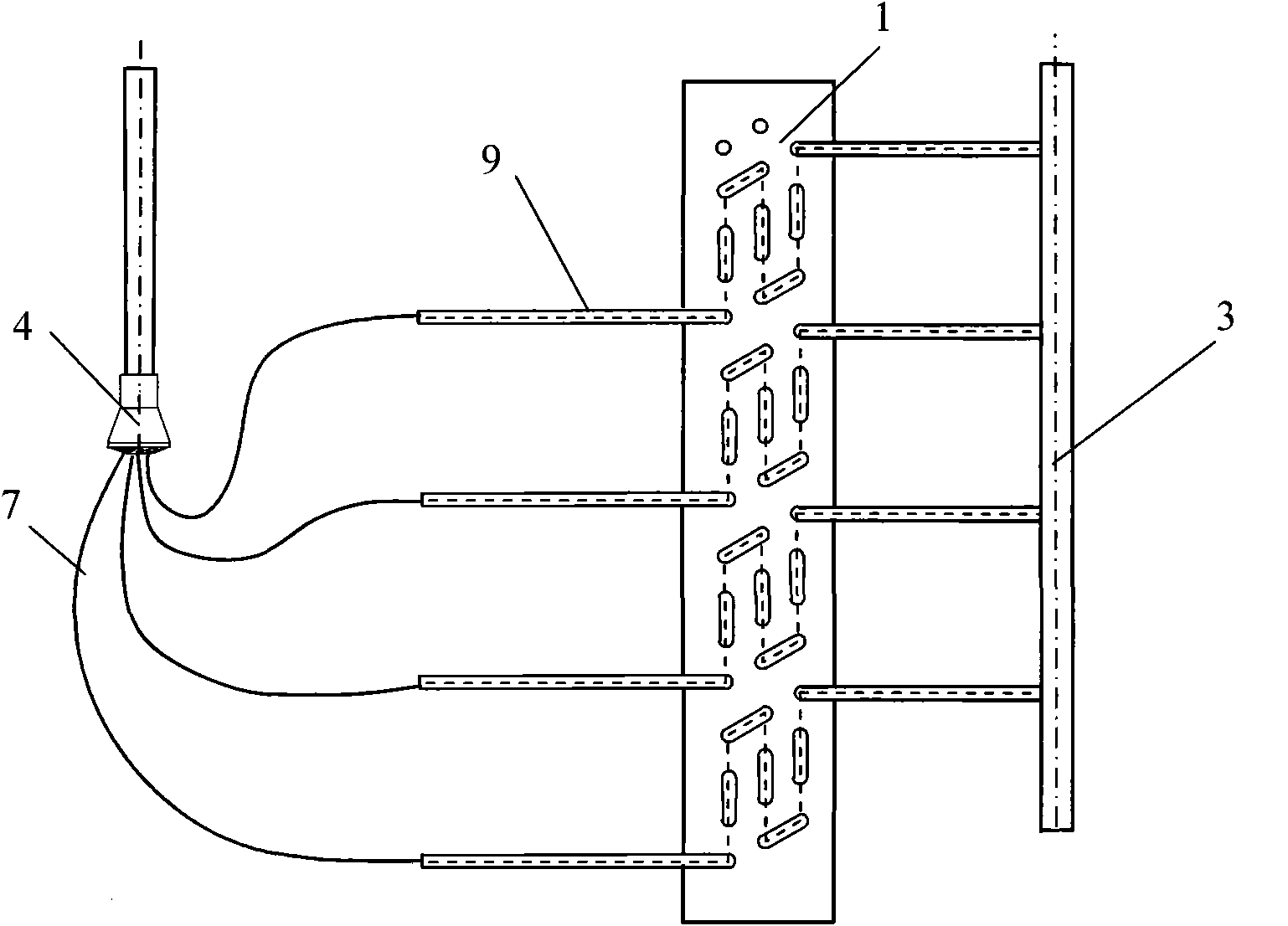

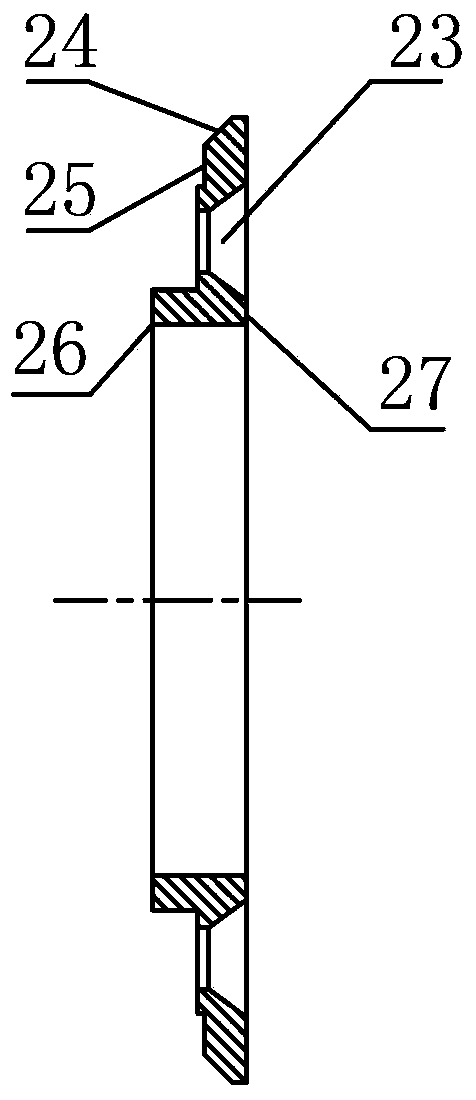

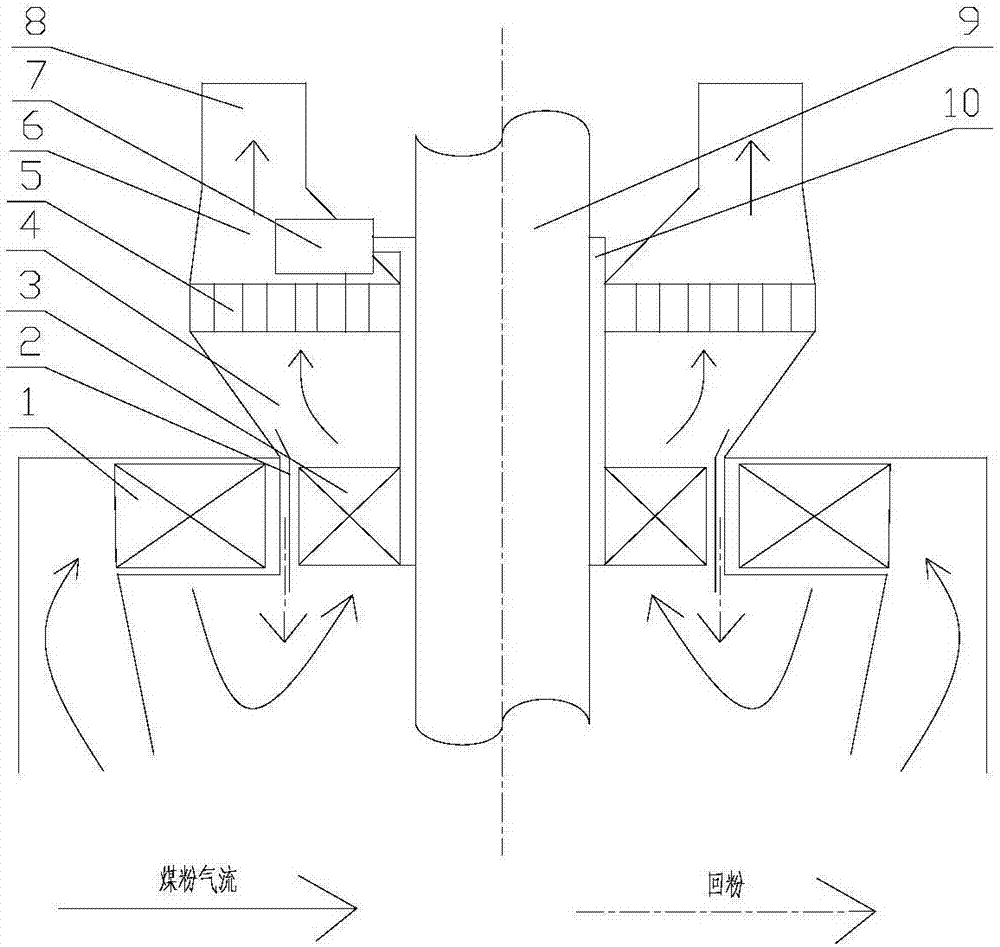

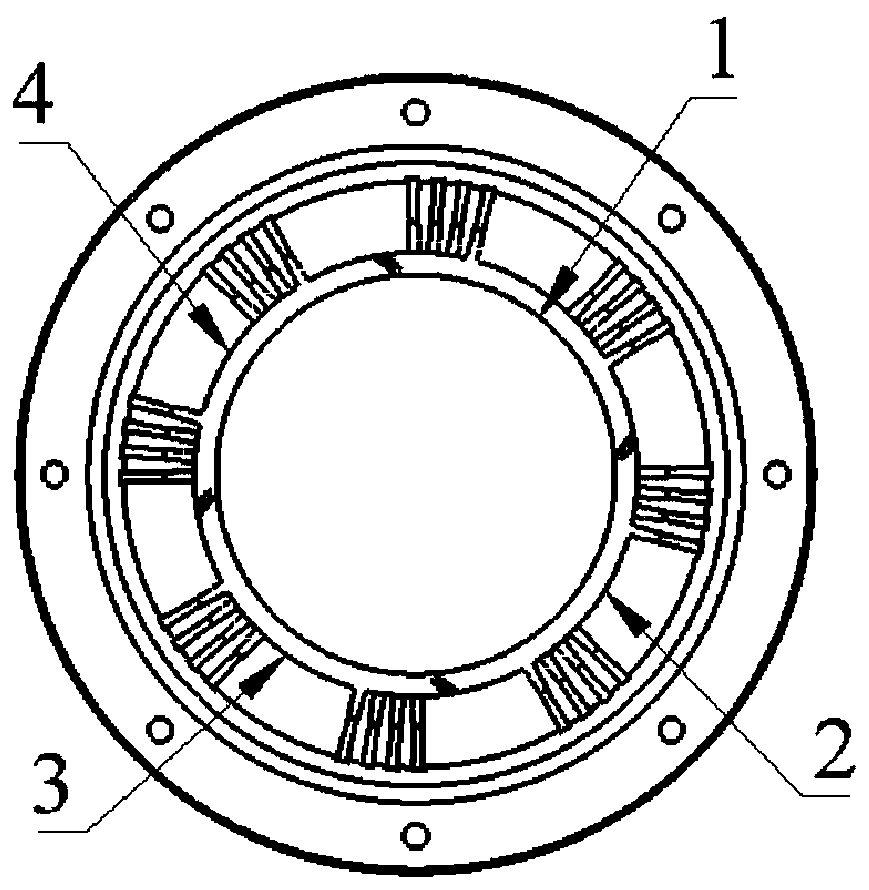

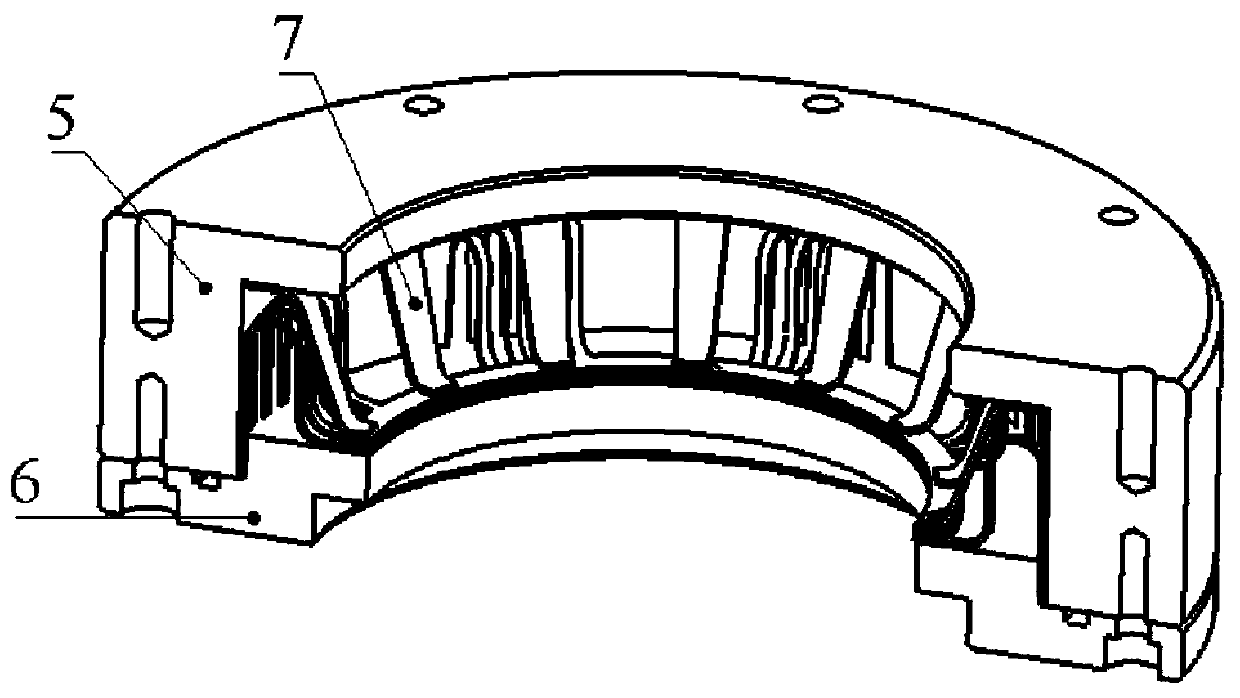

Rotary type variable frequency pulverized coal deep separation and uniform distribution device and method for medium speed coal mill

ActiveCN107470009AImprove depth separationReduce partial throttling lossesGrain treatmentsCoalType variable

The invention discloses a rotary type variable frequency pulverized coal deep separation and uniform distribution device and method for a medium speed coal mill. The rotary type variable frequency pulverized coal deep separation and uniform distribution device is characterized in that a separating and mixing conical section sleeves the side surface of a coal dropping pipe in a noncontact manner; a residual rotation elimination and uniform distribution grid and a plurality of axial flow blades are arranged in the separating and mixing conical section in sequence from top to bottom; a finished pulverized coal airflow outlet of a separator communicates with the bottom opening of the separating and mixing conical section; the top opening of the separating and mixing conical section communicates with a pulverized coal pipe through a pulverized coal pipe inlet conical section; an annular coarse pulverized coal return passage partition is positioned in the separating and mixing conical section and positioned between the separating and mixing conical section and the axial flow blades; the annular coarse pulverized coal return passage partition and the inner wall of the separating and mixing conical section form an annular coarse pulverized coal return passage; the top opening of the annular coarse pulverized coal return passage is positioned above the axial flow blades; and the bottom opening of the annular coarse pulverized coal return passage is positioned below the axial flow blades. According to the rotary type variable frequency pulverized coal deep separation and uniform distribution device and method for the medium speed coal mill, the problem of a greater distribution deviation in the pulverized coal quantity of the pulverized coal pipe is fundamentally solved, the deep separation of pulverized coal is realized, and the quality of pulverized coal is higher.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

Vane type high-temperature high-pressure gas (liquid) elastic dynamic sealing device and preparation method

PendingCN111336254AImprove sealingReduce manufacturing costEngine sealsWelding apparatusHoneycombEngineering

The invention discloses a vane type high-temperature high-pressure gas (liquid) elastic dynamic sealing device to further improve the sealing effect and prolong the service life. The dynamic sealing device comprises a base shell, an upper cover and a plurality of layers of sealing fins, wherein a lap of groove is formed in the integral inner side of the base shell and the upper cover; the arc shaped sections of every two adjacent sealing fin units of each layer of sealing fins in all layers of sealing fins are connected end to end to form an entire circle; the arc shaped sections and a shaft form radial elastic contact; the multiple layers of sealing fins are sequentially stacked at the entire circle; and the sealing fin units of every two adjacent layers of sealing fins are arranged in astaggered manner in the circumferential direction to cover port gaps between every two adjacent arc shaped sections, and the bending parts of all layers of sealing fins are correspondingly distributedat the port gaps. The vane type high-temperature high-pressure gas (liquid) elastic dynamic sealing device is better than labyrinth seal, honeycomb seal and brush seal in sealing effect, is lower than brush seal in manufacturing cost and technology difficulty and is higher than brush seal in product leakproofness and reliability.

Owner:西安丁杰精密机械制造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com