Tape replacing method for under-well main roadway tape conveyor

A technology of belt conveyors and conveyor belts, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low belt efficiency and manpower consumption, improve work efficiency, improve work efficiency, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

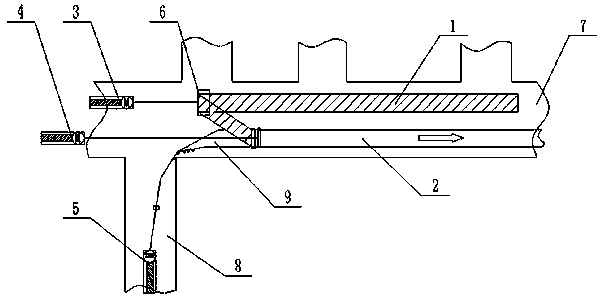

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below in conjunction with the examples, but the scope of protection is not limited thereto.

[0017] After the belt conveyor is stopped, disconnect the upper belt at about 100 meters from the tail, and vulcanize the old tape head and the new tape head prepared in advance for about 12 hours. The length of the overlapping part of the old and new tapes is 400 meters; , the part of new adhesive tape 1 is hung on a diameter of six meters on the drum 6, and the drum 6 is connected with a 14-ton auxiliary towing winch 3 by a steel wire rope, and the auxiliary towing winch 3 drags the drum 6 to rotate by a wire rope; the new adhesive tape 1 Along with the rotation of drum 6, gradually move to the upper belt roller 2 position of belt conveyor; when the above steps are completed, stop the auxiliary drag winch 3. At this time, the old adhesive tape 9 on the lower belt idler of the belt conveyor is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com