Patents

Literature

32results about How to "Solve the pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

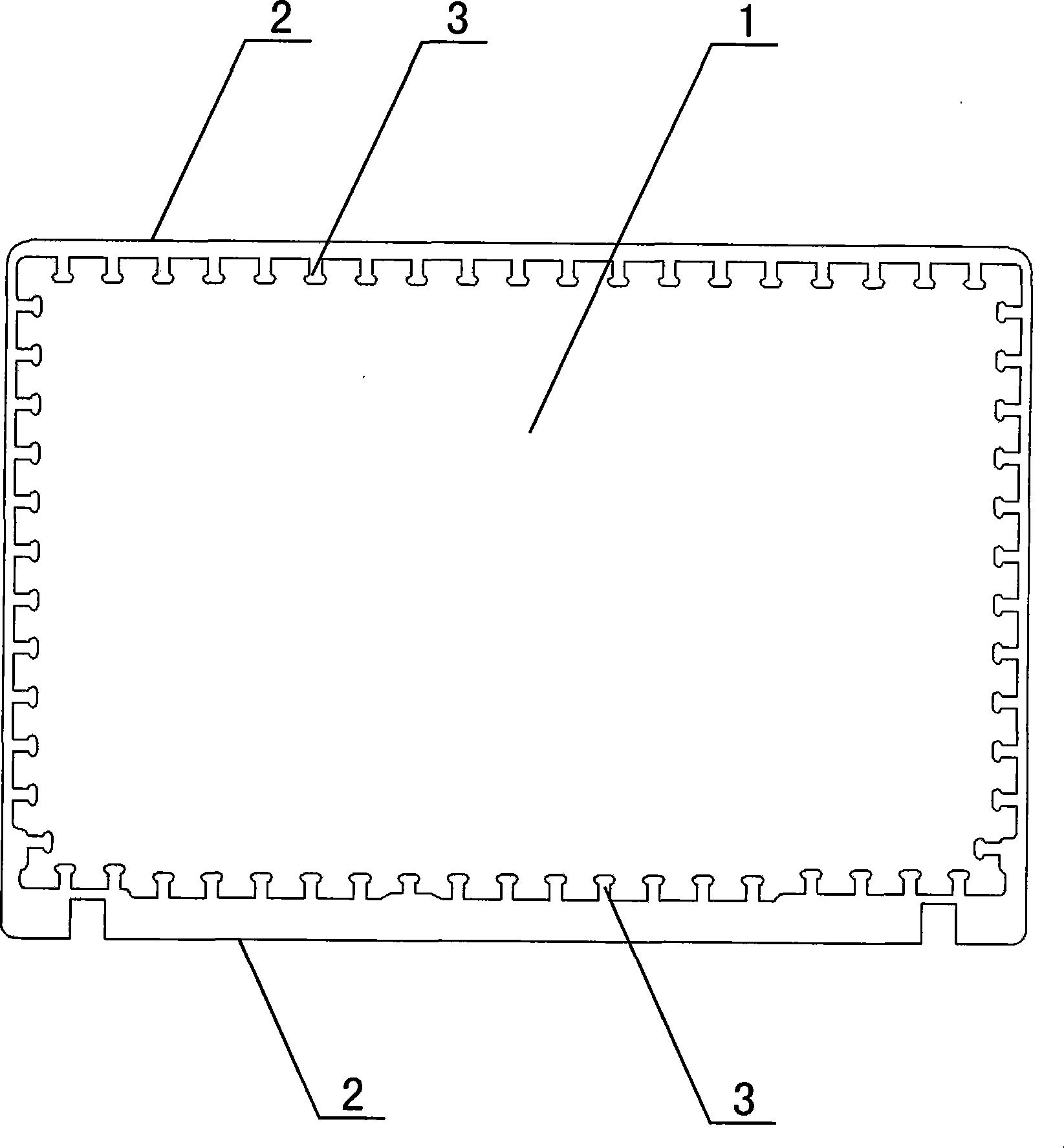

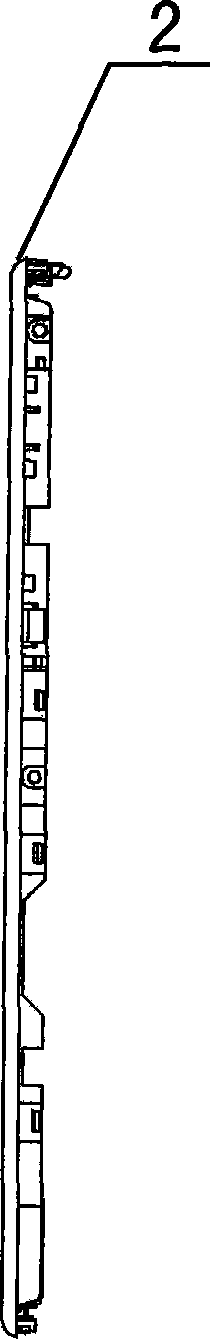

Upper casing of portable computer of magnalium material and plastic and preparation thereof

InactiveCN101387897ADoes not affect the communication effectSolve the pressure resistanceLamination ancillary operationsDigital data processing detailsWork in processCommunication effects

Disclosed are an upper casing of an outer casing of a handheld computer and a manufacturing method thereof. The upper casing is combined by magnesium aluminum alloy materials and plastics, and is made of high-quality magnesium aluminum alloy materials which are casted or pressed into a magnesium aluminum alloy panel with curved edges at the surrounding. After going through passivating treatment, the magnesium aluminum alloy panel is placed in a plastic die of the upper casing of the outer casing of the handheld computer to inject through a hot pressing injection machine, thereby enabling the periphery of the magnesium aluminum alloy panel to be stably combined with plastics to form a semi-finished product. The semi-finished product is manufactured into the upper casing of the outer casing of the handheld computer which is combined by the magnesium aluminum alloy materials and the plastics after scientific polishing and finishing. The upper casing of the outer casing of the handheld computer which is manufactured by combining the characteristics of the magnesium aluminum alloy materials and the plastics achieves the communication effect of pressure resistance, strong impact resistance, not being easy to deform, and not affecting wireless operation, meets the requirements of modern information society, overcomes shortages of non-pressure-resistance, non-wear-resistance and easy deformation of the outer casing of the plastic outer casing of the handheld computer, and also overcomes the shortage that the outer casing of the handheld computer manufactured by the integral magnesium aluminum alloy materials affects wireless operation.

Owner:李远发

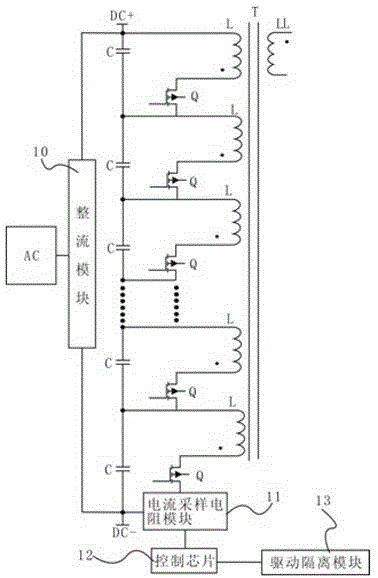

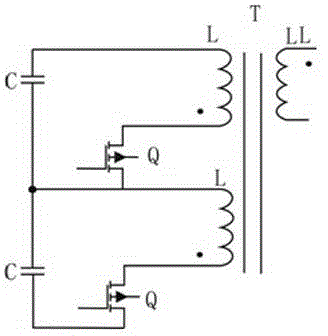

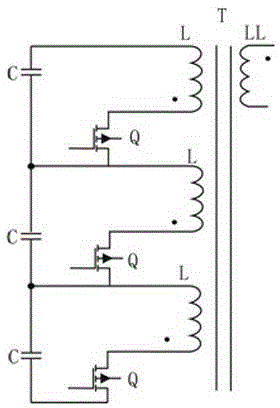

Multilevel high-voltage flyback type switch power supply

ActiveCN103944435AImprove reliabilityImprove stability and reliabilityAc-dc conversionDc-dc conversionCapacitanceTransformer

The invention discloses a multilevel high-voltage flyback type switch power supply comprising a rectification module, a current sampling resistor module, a control chip, a driving isolation module, a transformer, n stages of series-connected capacitors and n stages of MOS tubes, wherein n is a natural number which is greater than or equal to 2. The transformer is provided with multiple stages of primary coils, and the multiple stages of capacitors are connected in series, i.e. various types of voltage n-diving, such as voltage averaging, voltage tri-sectioning, voltage quartering, etc., are performed on the inputted high voltage so that n+1 stages of level input can be realized, voltage withstood by each stage of the primary coil is reduced, voltage withstood by each stage of the MOS tube is reduced, and thus current withstood by each stage of MOS tube is reduced. The structure of the switch power supply is improved, and a mode of input power is converted into the mode of series connection of multistage voltage and low current so that a problem that high voltage withstanding cannot be realized and heating is severe due to direct series connection of the MOS tubes is solved, the problem that the MOS tubes cannot withstand high current is also solved simultaneously, and thus application range of the switch power supply is widened.

Owner:SUZHOU WEICHUANG ELECTRICAL EQUIP TECH

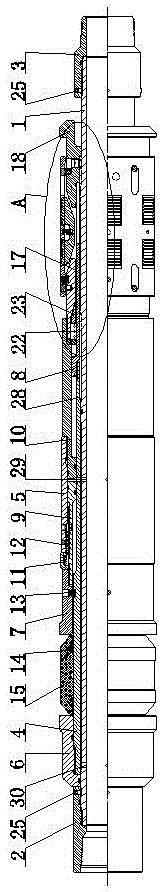

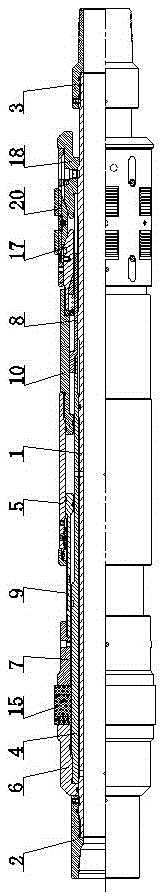

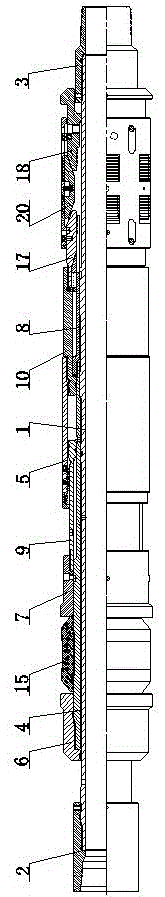

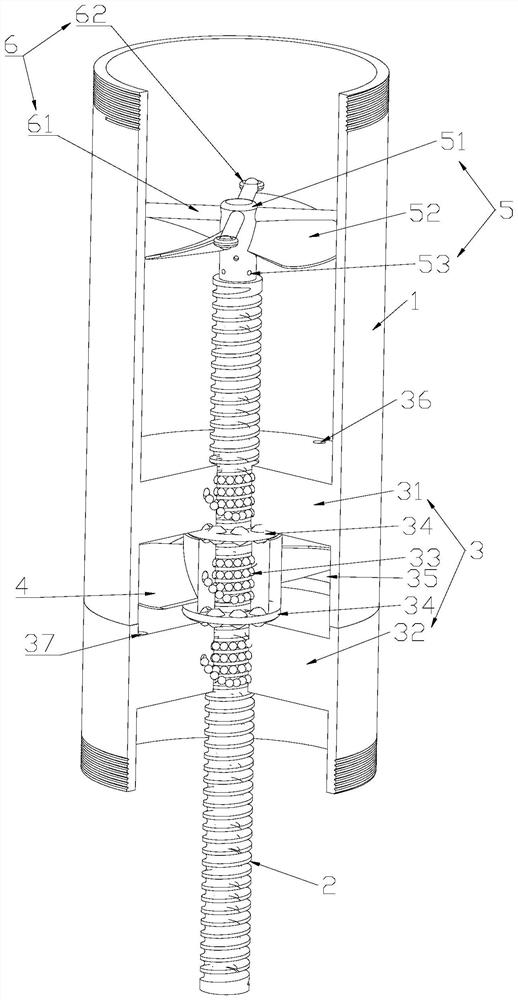

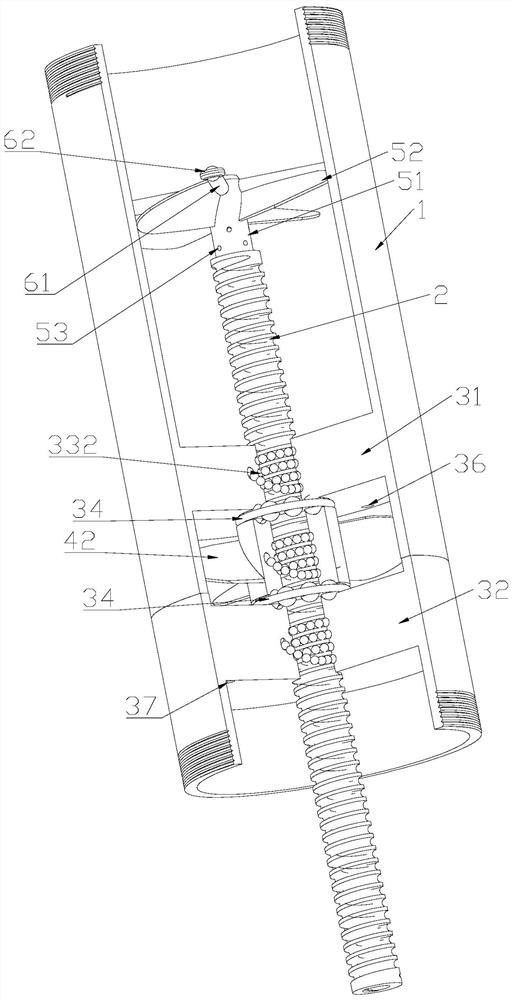

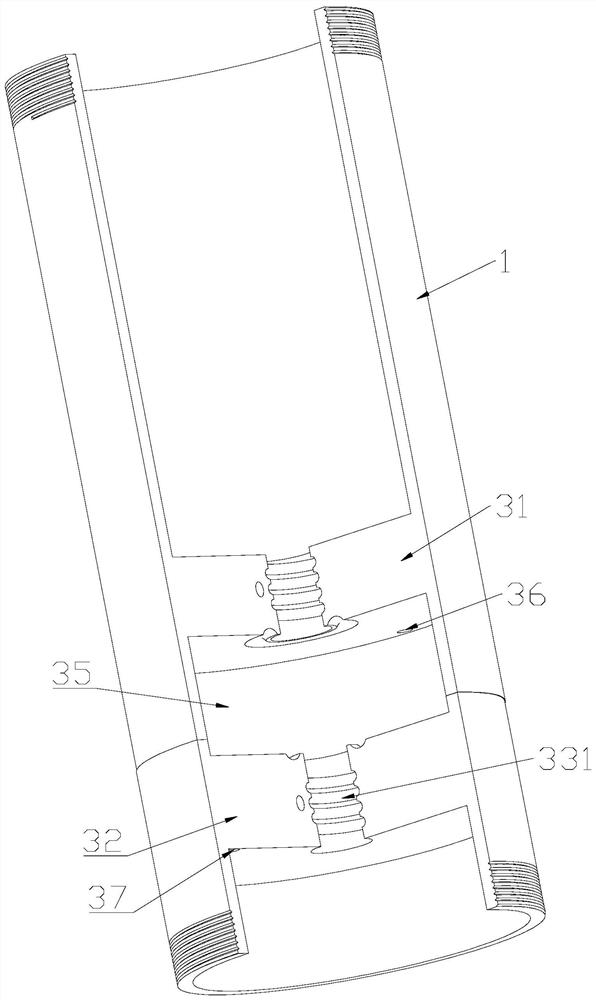

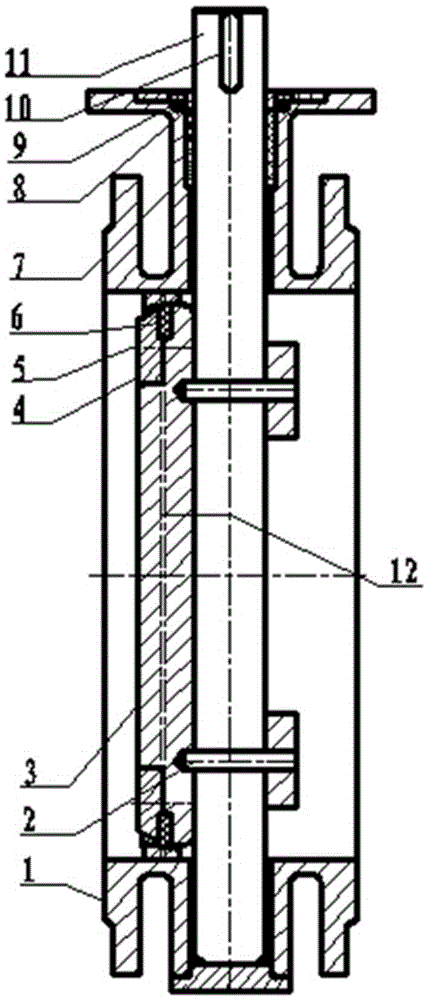

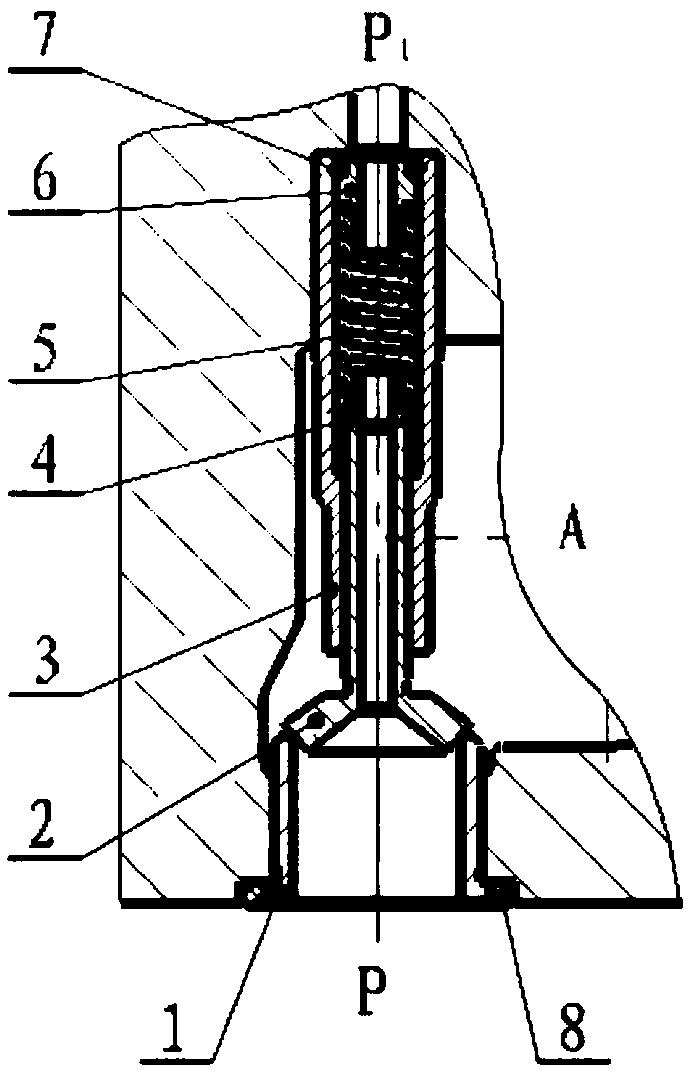

High-temperature high-pressure hydraulic recoverable packer

ActiveCN105545246ACompact structureLong-lasting and effective settingSealing/packingUpper jointWell stimulation

The invention relates to a high-temperature high-pressure hydraulic recoverable packer, and belongs to the field of oil and gas well borehole operation tools. The packer is composed of an upper joint, a lower joint, an outer center pipe, a cylinder sleeve, an upper guide ring and a lower guide ring. The upper joint is mounted at one end of an inner center pipe through a thread, and the lower joint is mounted at the other end of the inner center pipe through a thread. The outer center pipe and a release claw are mounted at the position, between the upper joint and the lower joint, of the inner center pipe, and an upper piston and a lower piston are mounted on the outer center pipe through the cylinder sleeve. The lower guide ring is nailed at the position, at one side of the cylinder sleeve, of the outer center pipe through a shear pin. The upper guide ring is mounted at the position, at one side of the lower guide ring, of the outer center pipe through a thread. The packer is compact in structure. A setting and unsetting structure is ingenious in design. The problem that an existing packer is unrecyclable, poor in compression resistance and poor in high temperature resistance is solved, and the high-temperature high-pressure hydraulic recoverable packer is especially suitable for operation of all kinds of well stimulation such as production, single-layer fracturing and separate-layer fracturing of deep wells and appraisal wells.

Owner:荆州市赛瑞能源技术有限公司

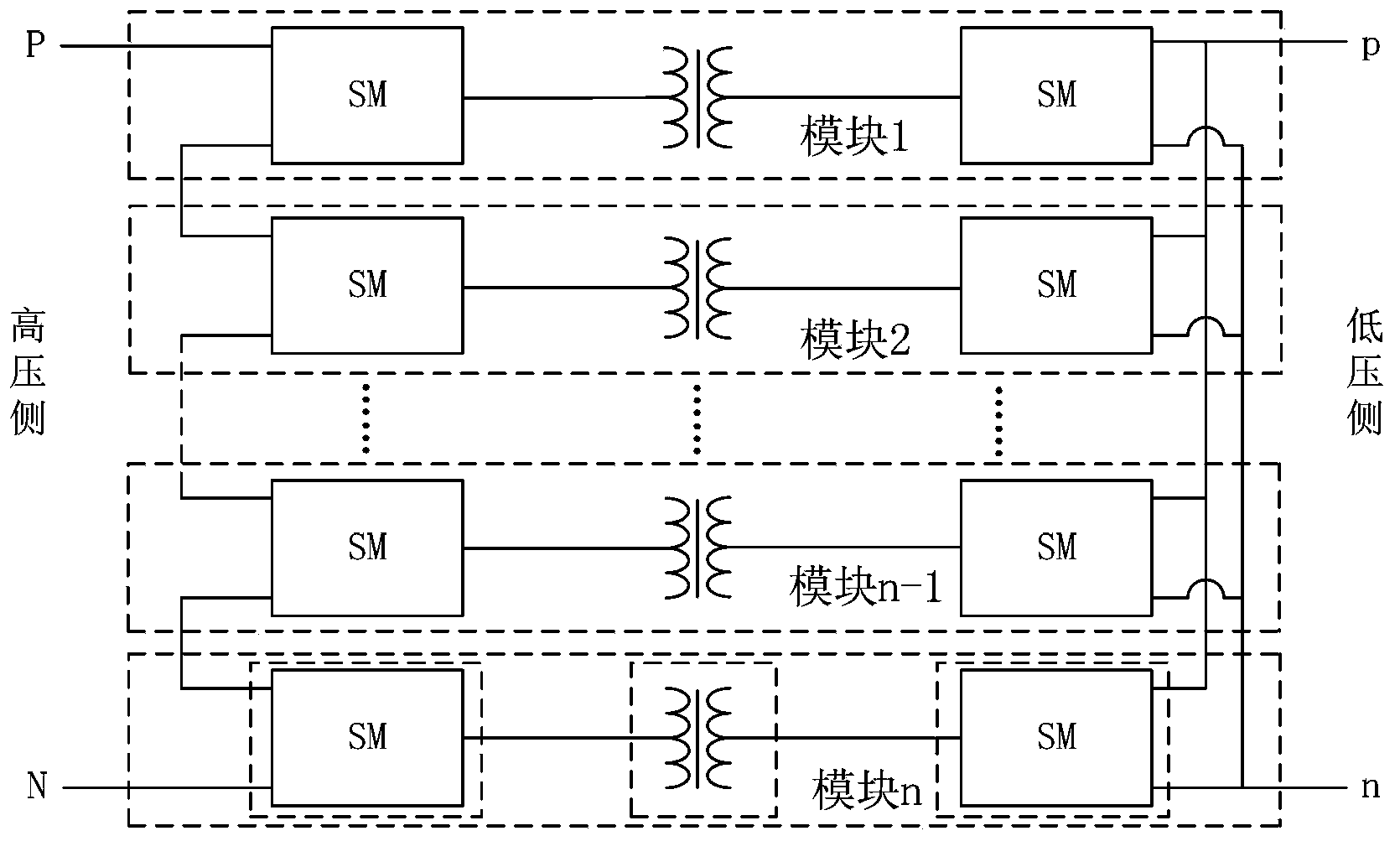

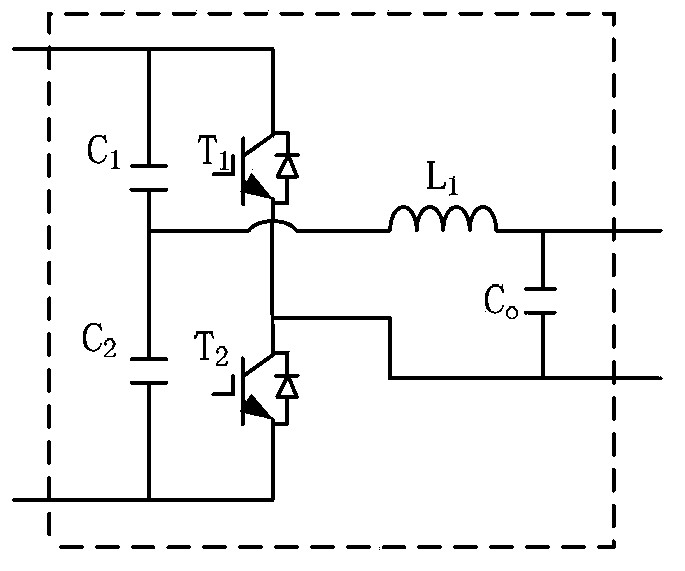

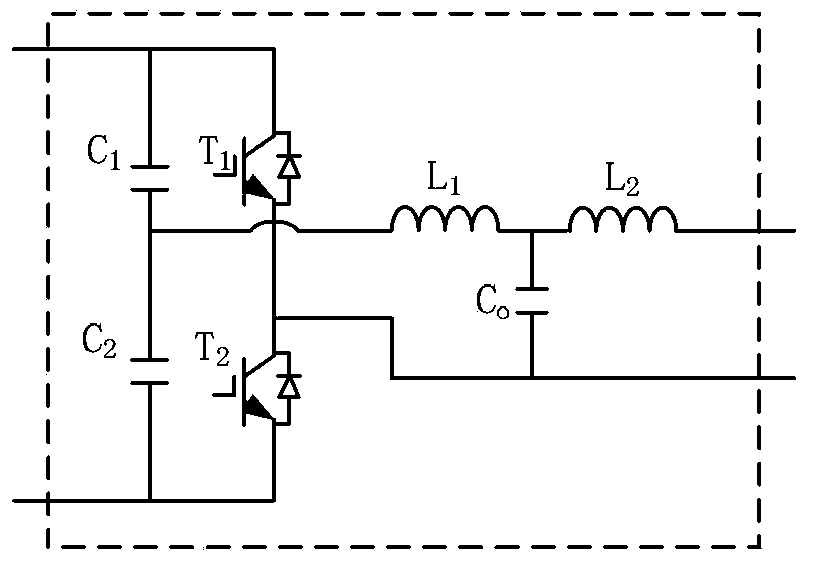

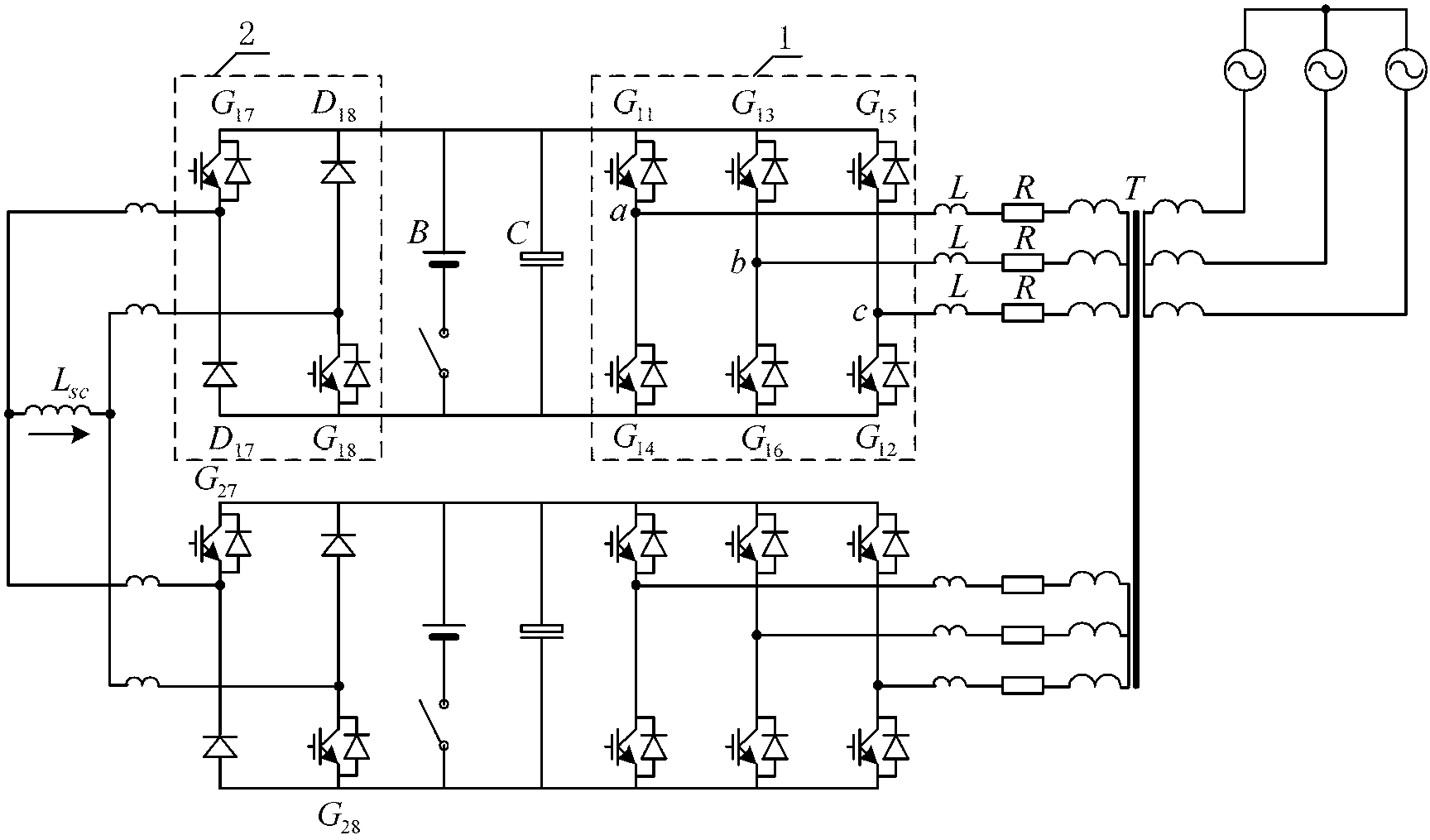

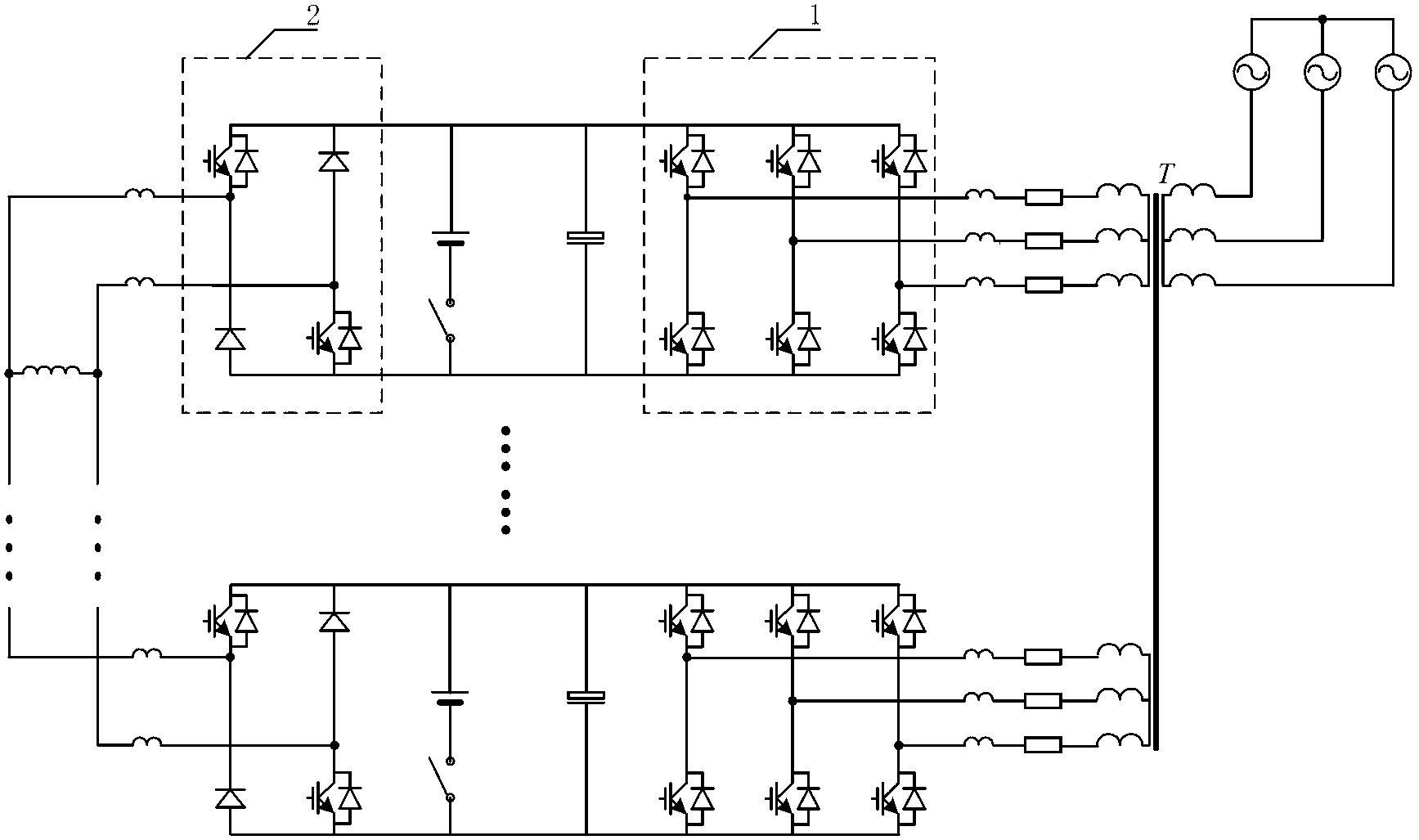

Modularized device for conversion between high-voltage direct current and direct current

InactiveCN103441676ASolve the pressure resistanceSolve the pressure equalization problemApparatus with intermediate ac conversionLow voltageTransformer

The invention discloses a modularized device for conversion between high-voltage direct current and direct current. The modularized device for conversion between the high-voltage direct current and the direct current comprises at least two direct-current-direct-current conversion modules which are the same in structure, wherein the input ends of all the direct-current-direct-current conversion modules are connected in series in sequence in the forward direction and then are arranged between a positive pole and a negative pole of a high-voltage side in a connected mode, and the output ends of all the direct-current-direct-current conversion modules are connected in series or in parallel or in a series-parallel mode according to the voltage class requirement of a low-voltage side, and then are arranged between a positive pole and a negative pole of the low-voltage side in a connected mode. Each direct-current-direct-current conversion module comprises a high-voltage side converter module, a low and medium frequency sine wave transformer and a low-voltage side converter module, wherein the output end of each high-voltage side converter module is connected with an input winding of each low and medium frequency sine wave transformer, and an output winding of each low and medium frequency sine wave transformer is connected with the input end of each low-voltage side converter module. The modularized device for conversion between the high-voltage direct current and the direct current can solve the problems of voltage resistance and voltage sharing of switching devices on the high-voltage side, improve the transmission capacity, and have a certain application prospect in places with high-voltage input high power.

Owner:NR ELECTRIC CO LTD +1

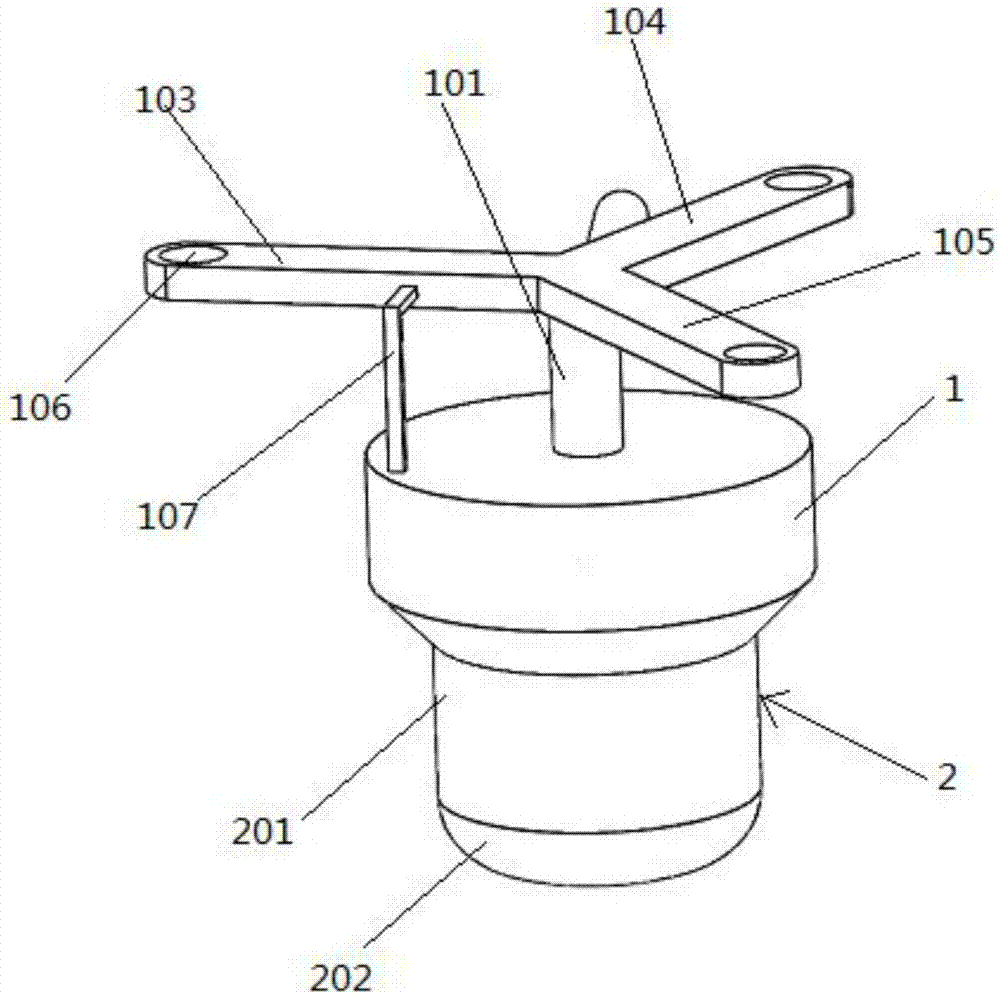

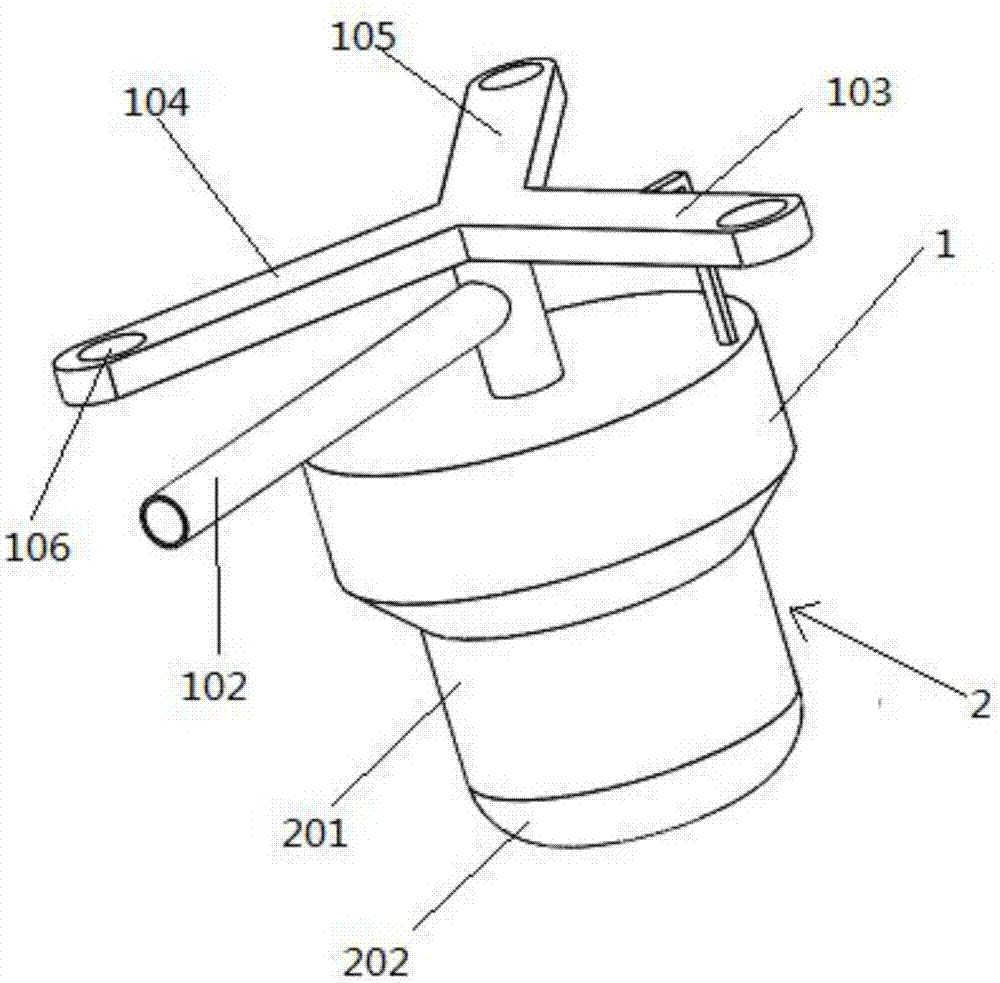

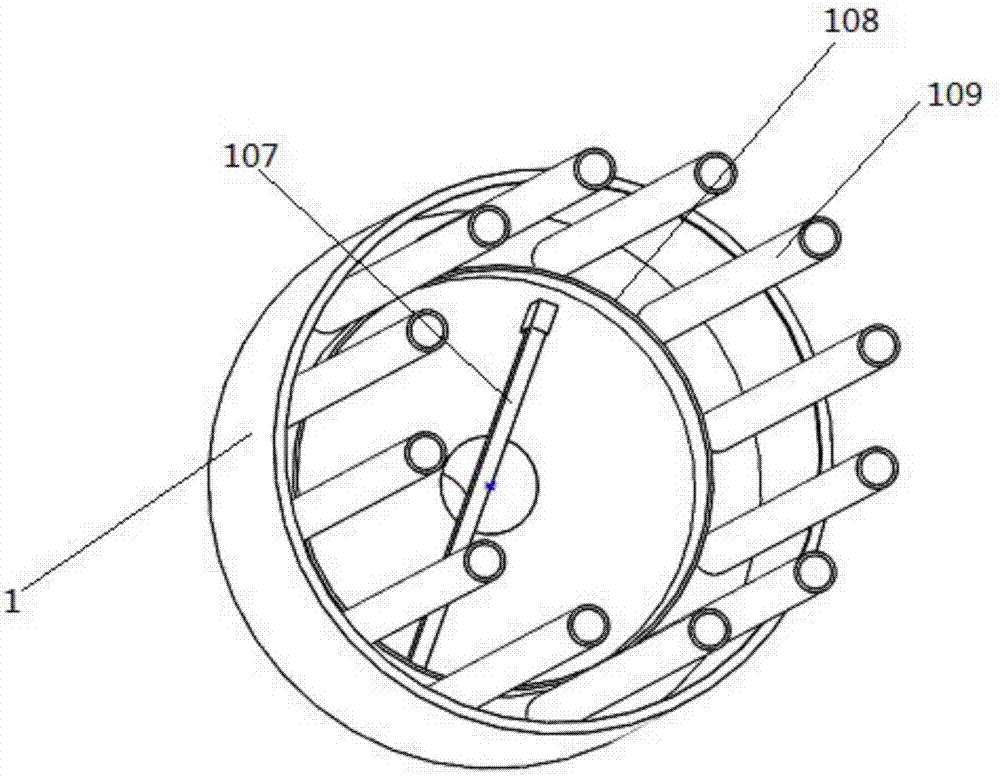

Radial horizontal well sealing device, drilling equipment and drilling method

ActiveCN112963110ASolve the pressure resistanceSolve the problem of low temperature resistanceLiquid/gas jet drillingDirectional drillingThermodynamicsWell drilling

The invention provides a radial horizontal well sealing device, drilling equipment and a drilling method, and relates to the technical field of geological drilling equipment. The radial horizontal well sealing device comprises a sealing shell, an injection pipe, a sealing element, a power feeding mechanism and a rotary drilling mechanism; the sealing element is of an active rolling type dynamic sealing structure and is arranged between the sealing shell and the injection pipe; the rotary drilling mechanism and the power feeding mechanism both adopt high-pressure jet fluid as a power source so as to transmit rotary power and feeding power to the injection pipe; and the drilling equipment comprises an oil pipe, a steering gear, a jet drill bit and a sealing device. By virtue of the sealing device, static friction sealing is changed into dynamic friction sealing, passive sealing is changed into active sealing, and the sealing device has the advantages of reducing drilling cost, being long in service life of equipment, high in drilling efficiency and the like, is also suitable for high-temperature and high-pressure stratums and can avoid the problem that traditional static friction sealing fails.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

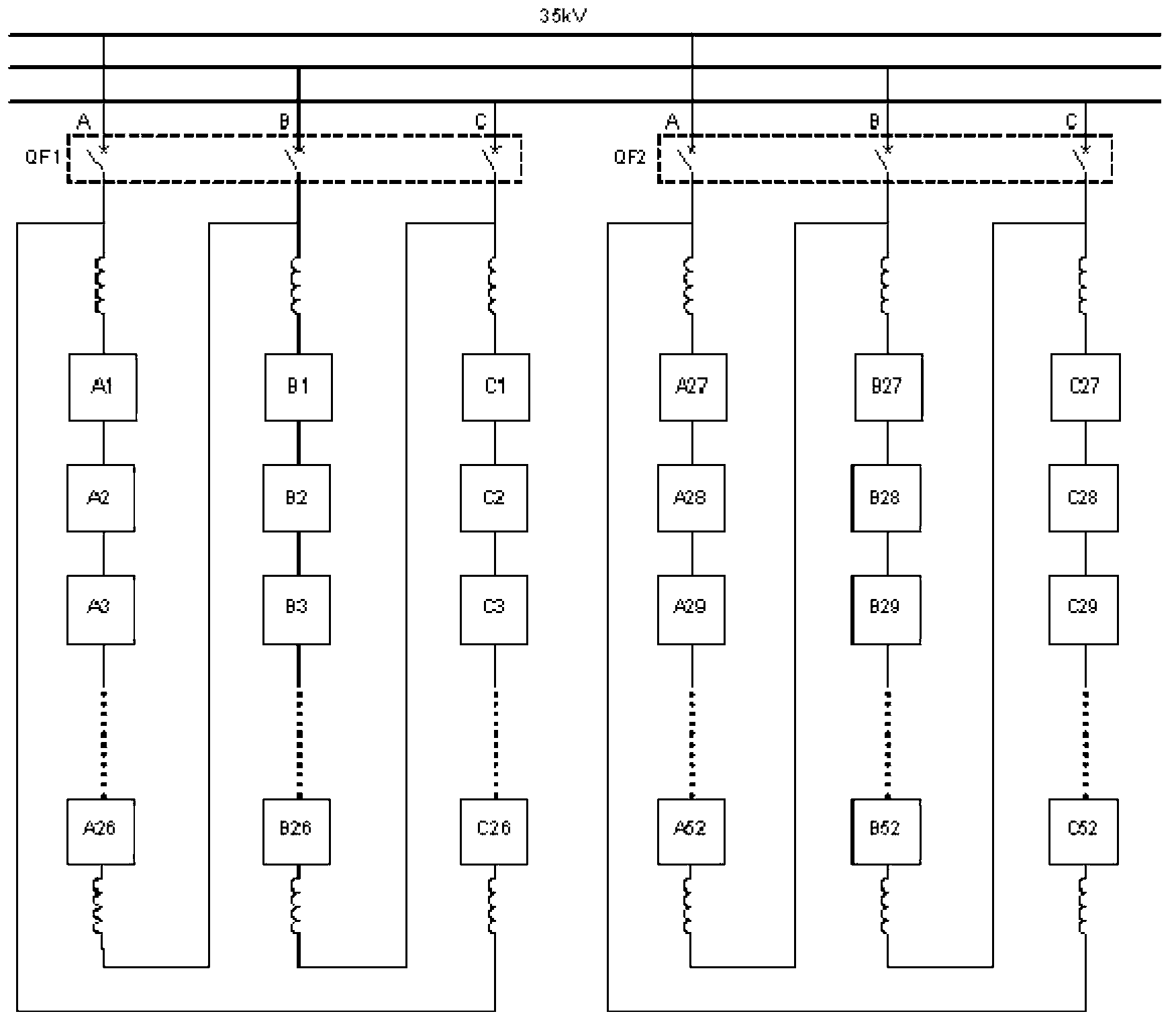

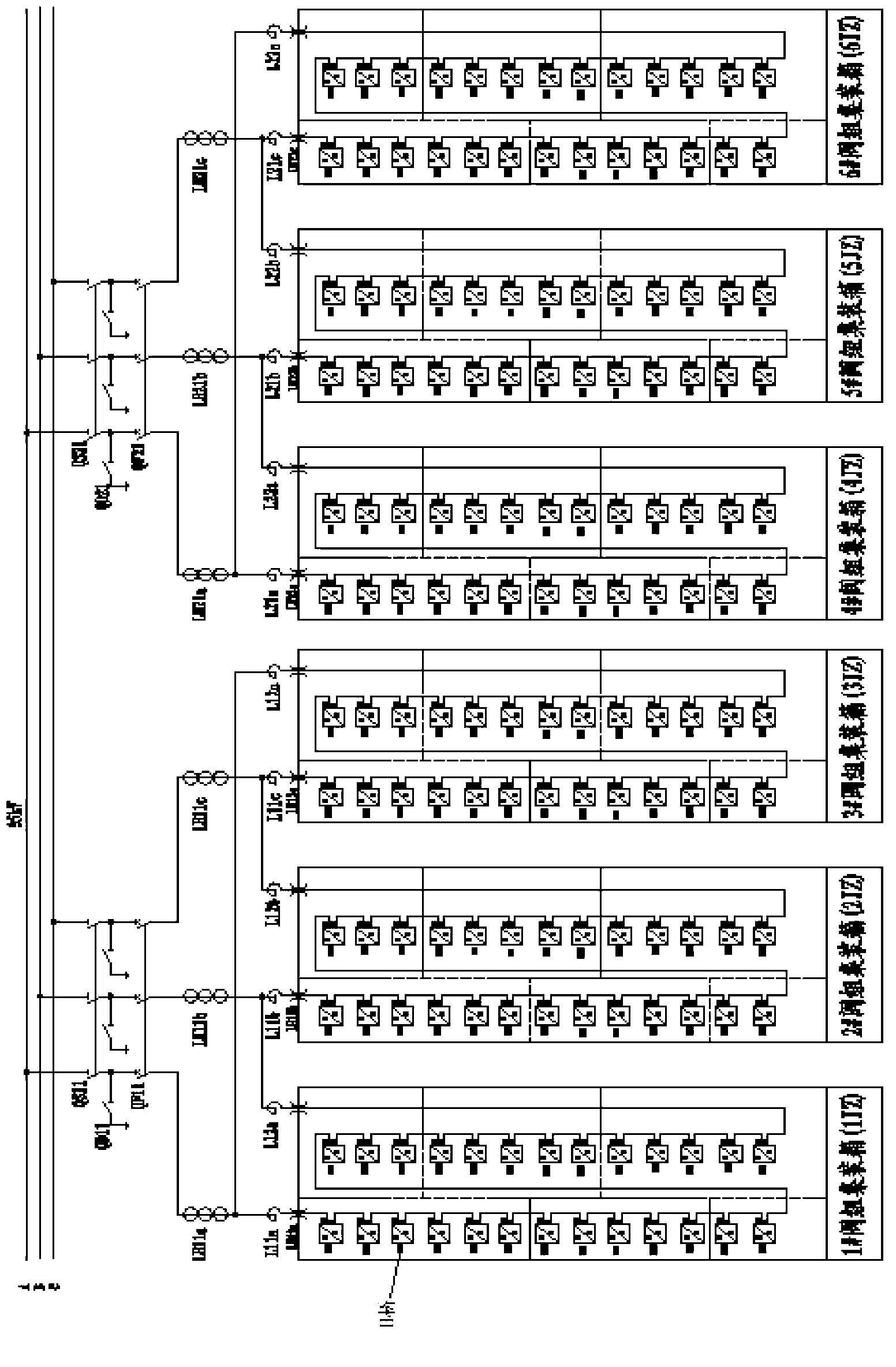

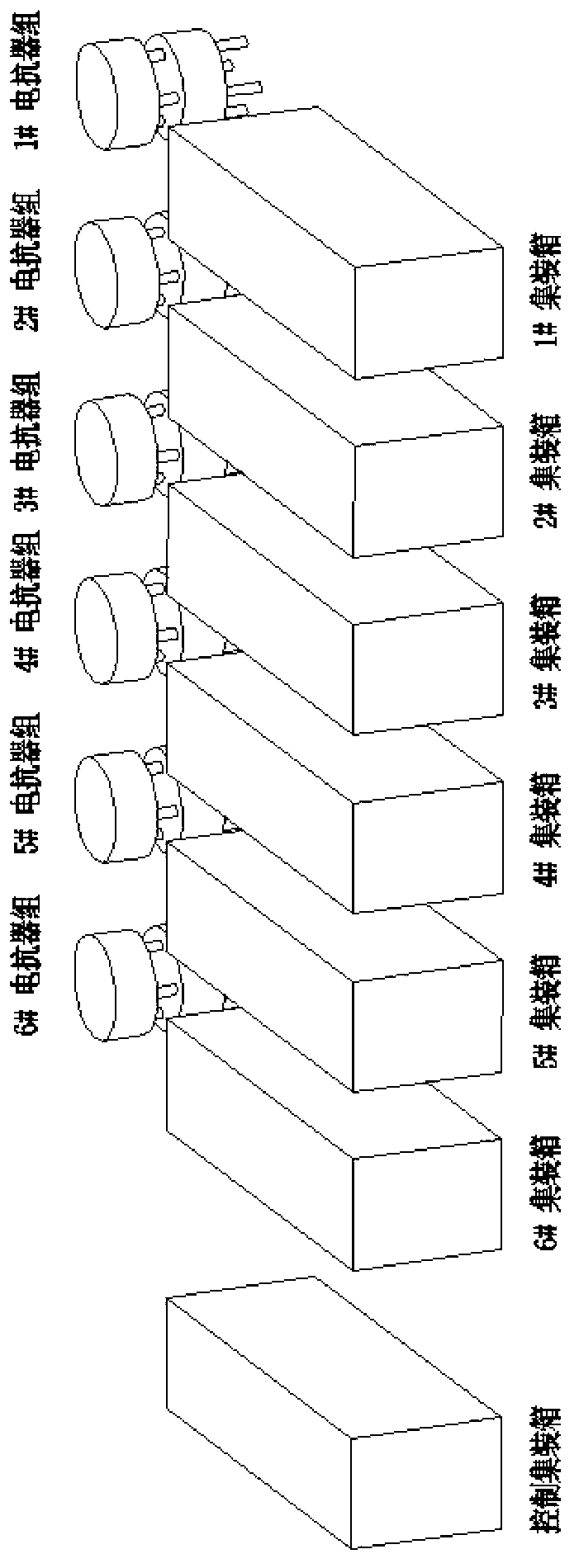

Movable high-voltage high-capacity chained STATCOM system container structure

ActiveCN102842858AGuaranteed accuracyGuaranteed reasonablenessFlexible AC transmissionSubstation/switching arrangement cooling/ventilationPower gridEngineering

A movable high-voltage high-capacity chained STATCOM system container structure comprises two chained STATCOM systems which are connected in parallel, each system comprises a three-phrase chained H bridge power unit group, and each three-phrase chained H bridge power unit group comprises a plurality of H bridge power units which are connected in series. Two ends of the each three-phrase chained H bridge power unit group are respectively provided with an electric reactor, and the each three-phrase chained H bridge power unit group is installed in a valve group container. The two electric reactors of the each three-phrase chained H bridge power unit group are placed up and down, and arranged outside the valve group container. The two systems which are connected in parallel are directly hung into a 35 kilovolt power grid respectively through a high-voltage switch QF1 and a high-voltage switch QF2. The total number of chained STATCOM system containers is seven. In the seven chained STATCOM system containers, six chained STATCOM system containers are valve group containers and one chained STATCOM system container is a controlling container. The movable high-voltage high-capacity chained STATCOM system container structure is low in manufacturing cost and good in heat dissipation, and brings convenience to mass production of STATCOM with different voltages and different capacities. In addition, the movable high-voltage high-capacity chained STATCOM system container structure is compact in structure, convenient to install, adjust, maintain, disassemble and transport, simple to place and install in the open air, convenient for power expansion and safe operation, and capable of satisfying the requirement of high-capacity installation.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

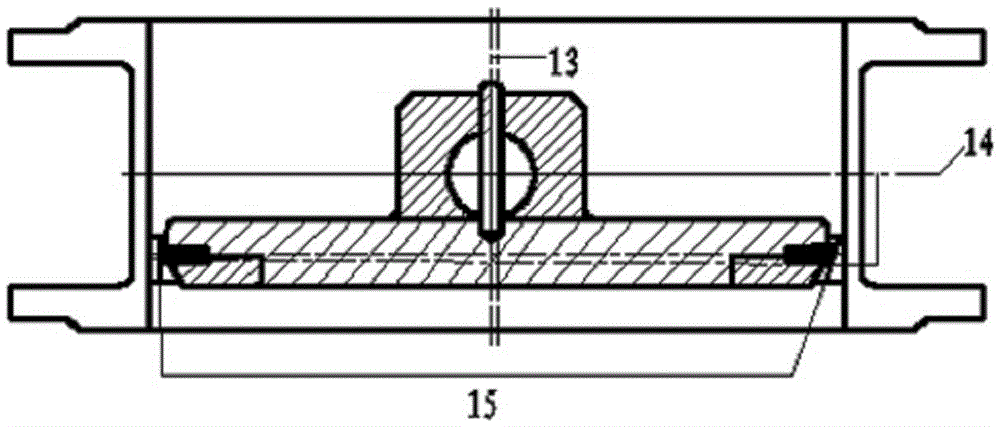

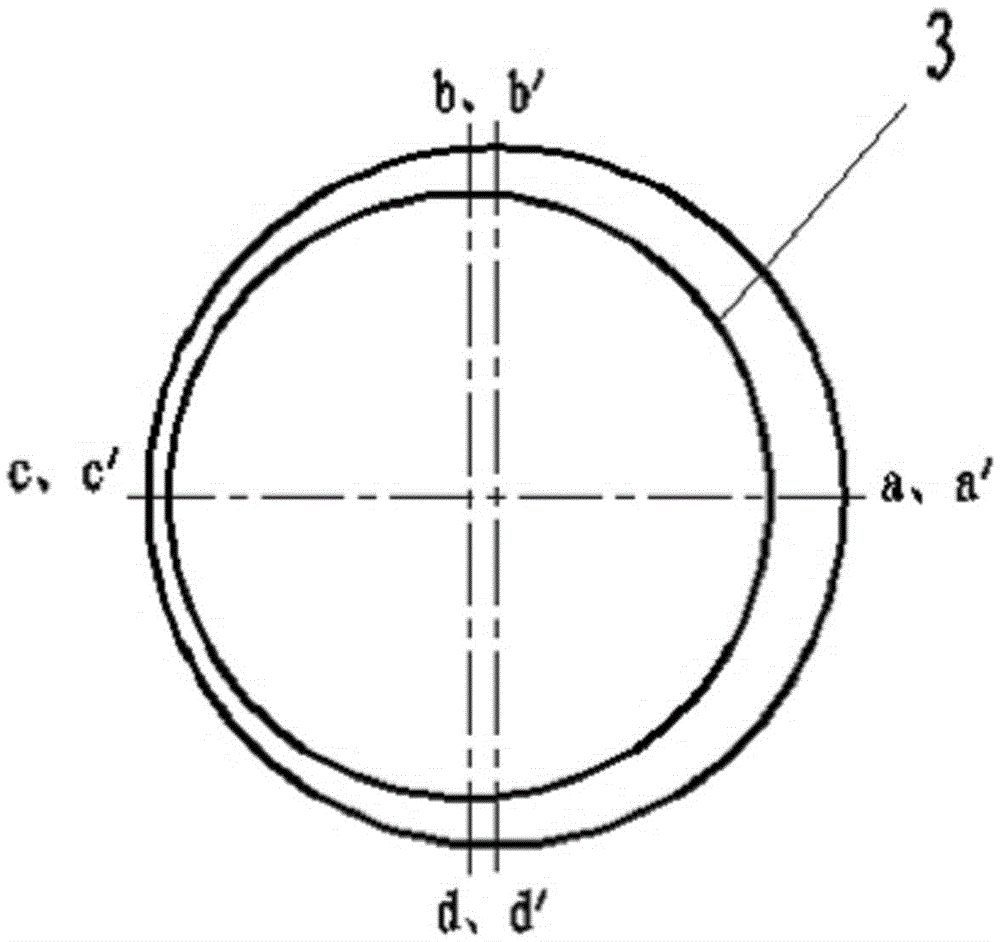

Four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve

The invention discloses a four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve which comprises a butterfly plate assembly consisting of a valve body, a valve shaft, a valve plate, a stack and a valve plate pressure ring, wherein the valve plate is arranged in the valve body and fixed on the valve shaft through a pin; a stuffing box is arranged on the upper part of the valve body; and a transmission mechanism is arranged on the stuffing box. The four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve is characterized in that the valve plate has a four-dimensional four-eccentric structure, wherein the valve plate of the four-dimensional four-eccentric structure is located with four surfaces of a valve base of the valve body, i.e., surfaces a, b, c and d of a diagonal-dimensional valve base and surfaces a', b', c' and d' of a valve plate diagonal-dimensional stack are correspondingly arranged together according to an assembly position so as to form a sealing structure; a sealing angle alpha of the assembled c-c' is 1 degree, and the degree is changeless, and is a designed angle. The four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve is reasonable in structure, wide in scope of application, long in service lifetime, free of leakage, relatively low in manufacturing cost, convenient in mounting, and high in qualified rate; and safety cost is greatly reduced.

Owner:黄一立

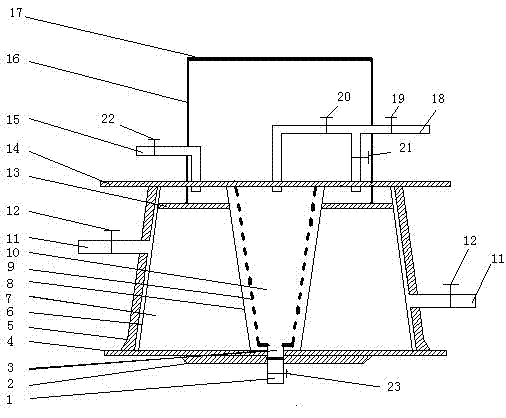

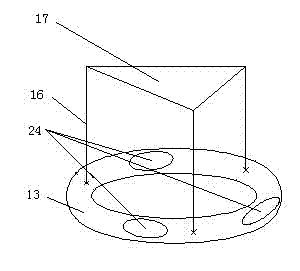

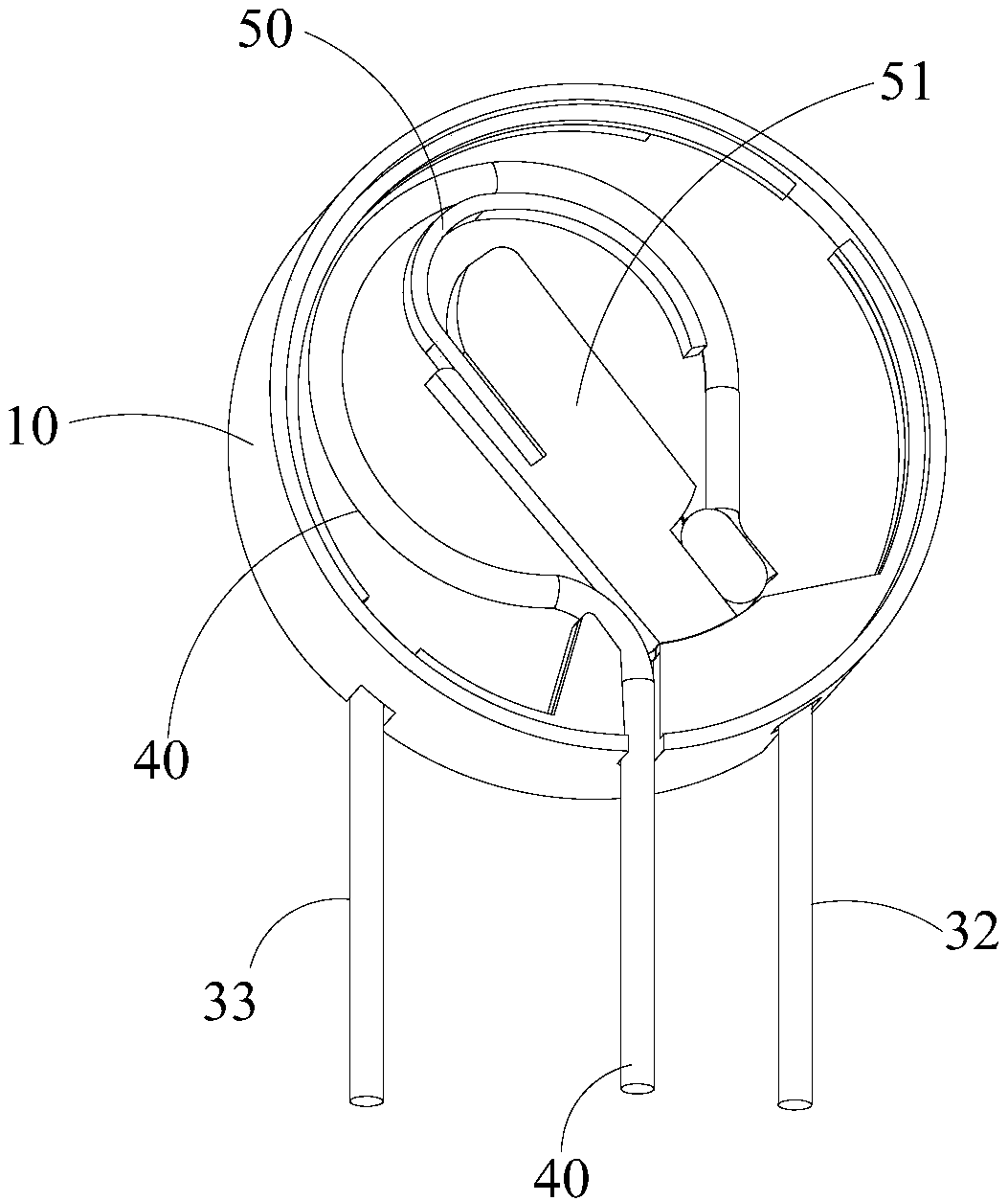

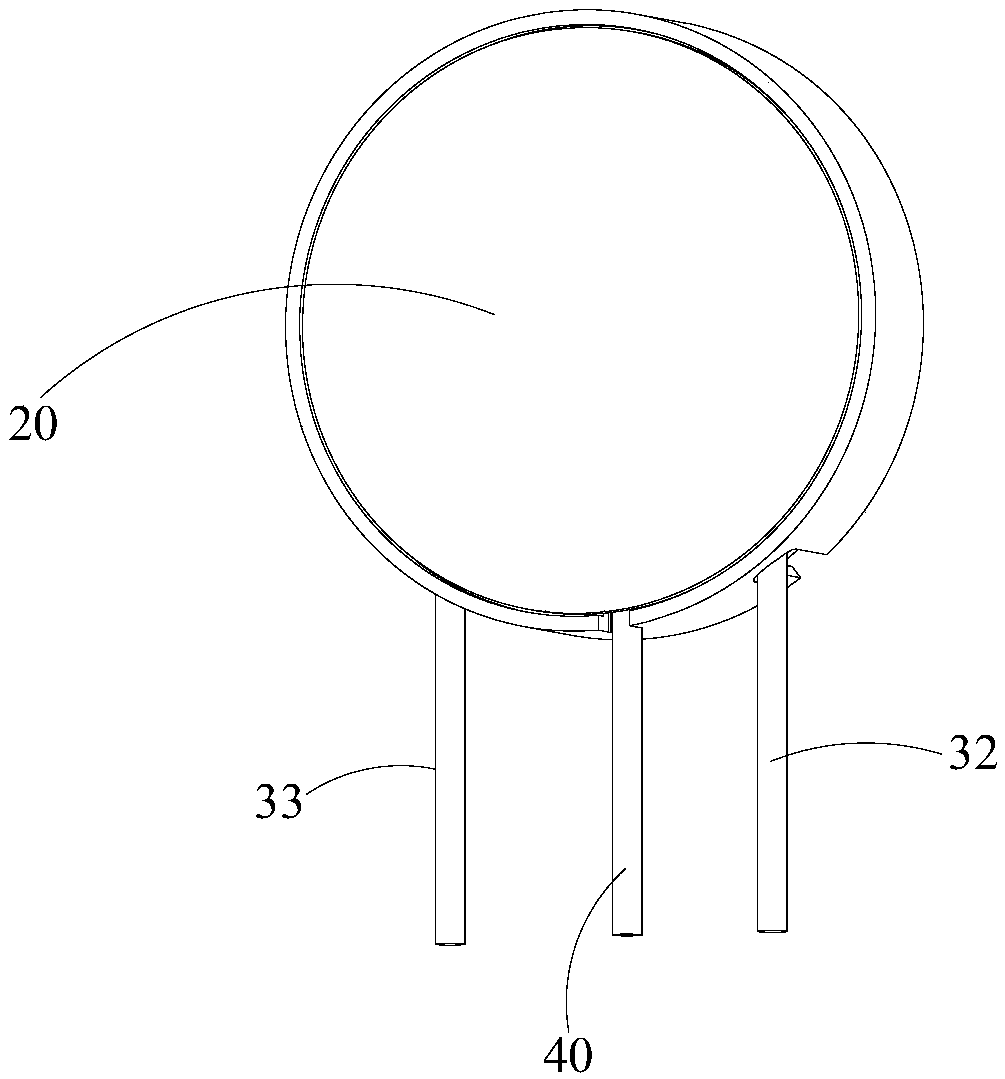

Sheathed circular truncated cone type filter press

ActiveCN102728119AImprove pressure resistanceSolve the pressure resistanceMembrane filtersStationary filtering element filtersStructural engineeringFilter press

The invention discloses a sheathed circular truncated cone type filter press which comprises an outer circular truncated cone-shaped sleeve and an inner circular truncated cone-shaped sleeve, wherein the inner circular truncated cone sleeve is arranged at the middle part of the outer circular truncated cone sleeve; a filter press rubber sleeve is arranged on the inner wall of the outer circular truncated cone-shaped sleeve; a plurality of small holes are formed in the inner circular truncated cone-shaped sleeve; filtering cloth is arranged on the outer wall of the inner circular truncated cone-shaped sleeve; air inlet pipes are arranged at two sides of the outer circular truncated cone-shaped sleeve respectively; an inner sleeve water outlet pipe is arranged at the bottom of the inner circular truncated cone-shaped sleeve; a discharging plate is arranged at the upper part of a circular truncated cone-shaped filtering chamber; a plurality of discharging holes are formed in the discharging plate; a feeding pipe which is communicated with the inside part of the outer circular truncated cone-shaped sleeve is arranged at one side an upper cover; high pressure air inlet pipes which are respectively communicated with the inside parts of the inner circular truncated cone-shaped sleeve and the outer circular truncated cone-shaped sleeve are arranged at the other side of the upper cover; and a water outlet pipe of the filter press machine connected with an inner sleeve water outlet pipe is arranged on a bottom cover. The filter press dehydration is implemented through high pressure gas; fine coal grains are retained inside the circular truncated cone-shaped chamber to be formed as filter cakes; the filter cakes are discharged by opening the bottom cover automatically; the whole filter press process is simple and easy to implement with few maintenance and high efficiency; the solid and liquid separation effect is good; and the energy consumption is low.

Owner:CHINA UNIV OF MINING & TECH

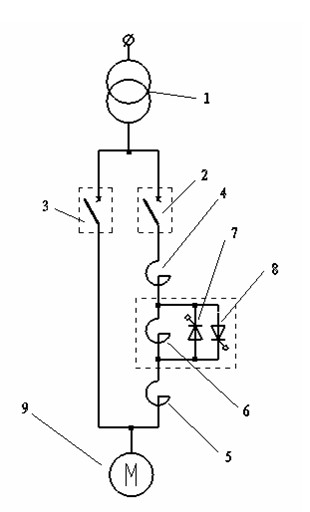

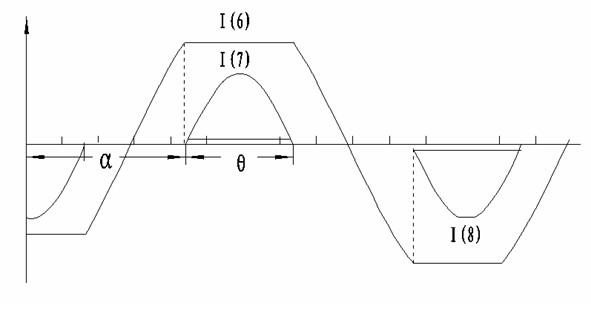

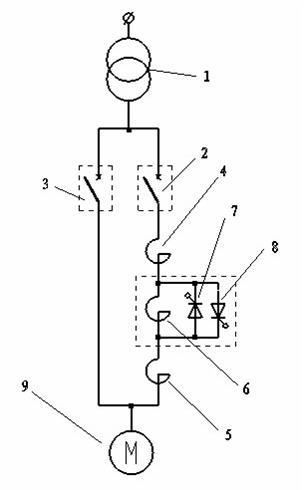

High-voltage soft start main circuit

ActiveCN102611362AReduce pressure requirementsSmall flow capacity requirementHarmonic reduction arrangementPolyphase induction motor starterHarmonicThyratron

The invention relates to a high-voltage soft start main circuit, which belongs to the technical field of high-voltage motor soft starting. The input end of a high-voltage starting switch (2) is connected with a high-voltage grid (1), and the output end is connected with a front reactor (4); a reactor (6) is in parallel connection with a forward transistor (7) and a reverse transistor (8); the parallel-connected end of the reactor (6), the forward transistor (7) and the reverse transistor (8) are connected with the front reactor (4) and the other end is connected with a rear reactor (5); and the other end of the rear reactor (5) is connected with a motor (9). By connecting voltage regulating reactors with antiparallel transistors in parallel and serially connecting phase control reactors in the up-down direction, the high-voltage soft start main circuit provided by the invention can overcome the disadvantages of a variable reactor in the prior art, such as high manufacture cost, complex structure, multiple faults, large maintenance cost, and the content of current harmonics is reduced remarkably. The transistor assembly only needs to bear a lower end voltage and regulate a portion of current, so that the voltage regulator has much lower requirement for the through-current capability of the transistor, thereby greatly lowering the cost.

Owner:BIG PAWER ELECTRICAL TECH XIANGYANG

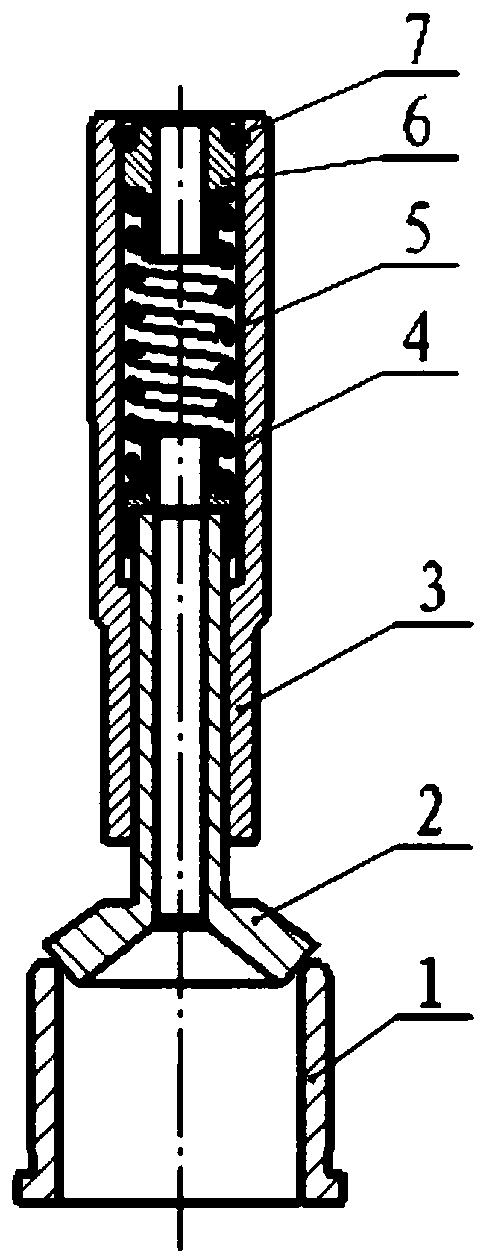

Insertion type pre-pressing valve

ActiveCN109237056ASolution volumeSolve the problem that the spool is easy to get stuckLift valveEngineeringControl valves

The invention relates to an insertion type pre-pressing valve, belongs to the technical field of control valves, and mainly solves the technical problem that an existing pre-pressing valve is large involume, has an easily stuck valve element, is poor in pressure resistance and easily damaged during installation and disassembly. According to the technical scheme, the insertion type pre-pressing valve comprises a valve seat, the valve element, a guide sleeve, a first spring seat, a spring, a second spring seat and a wire retaining ring, wherein the valve seat is a hollow cylinder, the lower endof the outer side of the valve seat is provided with an excircle step, so that the valve seat is limited in a valve body; the valve element is composed of a cone frustum and a hollow cylinder guide rod, and the valve element is arranged at the upper end of the valve seat; the guide sleeve is a hollow cylinder, the hollow cylinder guide rod of the valve element is arranged in a guide hole in the lower middle portion of the guide sleeve, the first spring seat is arranged at the top end of the hollow cylindrical guide rod of the valve element, the spring is arranged on the first spring seat, thesecond spring seat is arranged on the spring, and the wire retaining ring is arranged in a retaining ring groove formed in the upper portion of a spring mounting hole of the guide sleeve.

Owner:TAIZHONG GRP YUCI HYDRAULIC IND

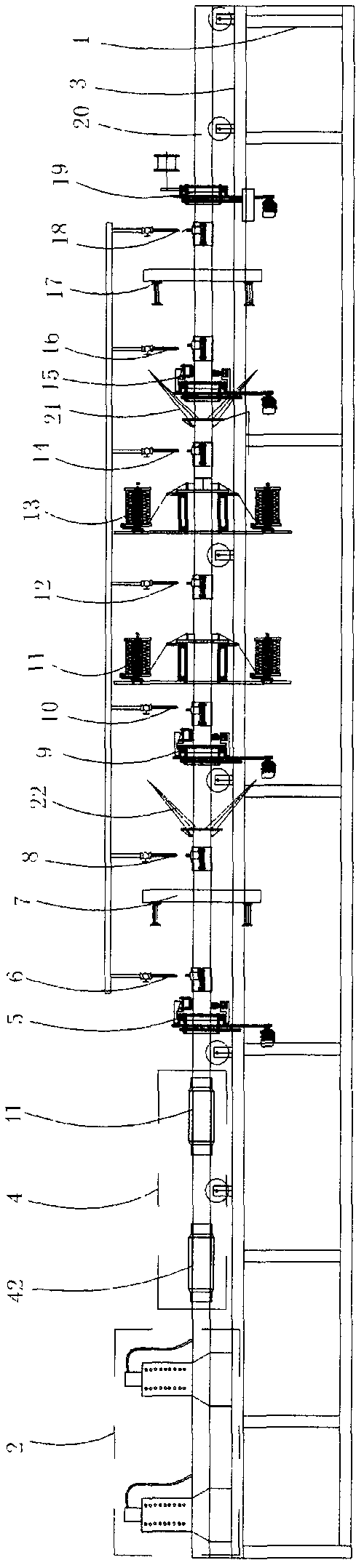

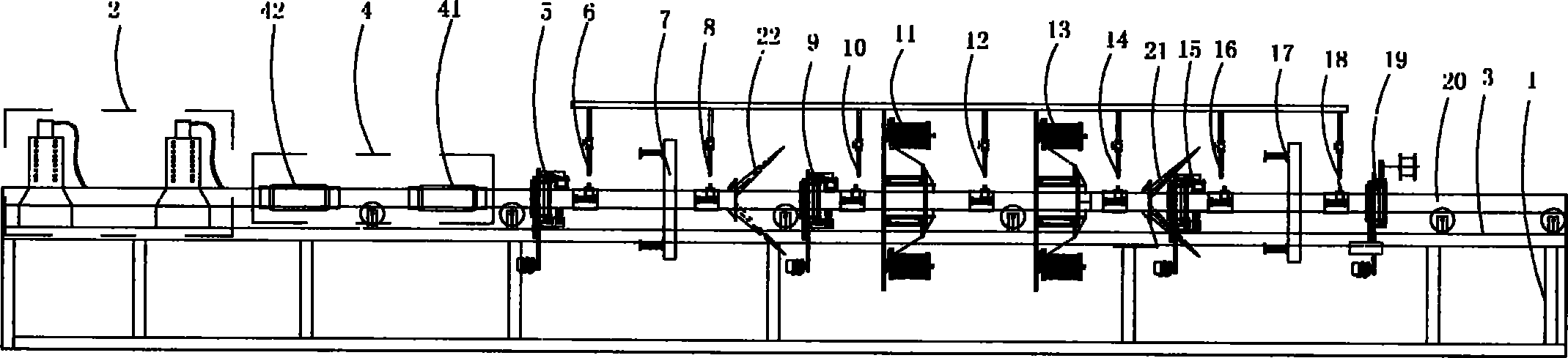

Device for production of corrosion-resisting glass fiber-reinforced plastic pipe

The invention discloses a device for production of a corrosion-resisting glass fiber-reinforced plastic pipe. The device comprises a support, traction devices arranged on the support, a transmission belt rotatingly connected to the traction devices, and other parts of die cavity devices, a first glue-brushing device, a first glue-injection port, a first weaving device, a second glue-injection port, a first linear-yarn device, a second glue-brushing device, a third glue-injection port, a circumferential-yarn left-turn winding device, a forth glue-injection port, a circumferential-yarn right-turn winding device, a fifth glue-injection port, a second linear-yarn device, a third glue-brushing device, a sixth glue-injection port, a second weaving device, a seventh glue-injection port and an internal felt-coating device, wherein the other parts are orderly arranged on the transmission belt and mold core bodies which are synchronous with the transmission belt and moves along a direction the same as the movement direction of the transmission belt are arranged on the transmission belt. The device provided by the invention has a simple structure and is provided with the mold core bodies which is synchronous with the transmission belt of the traction devices and moves along a direction the same as the movement direction of the transmission belt and synchronous traction of the mold core bodies and traction devices is realized. Therefore, corrosion resistance and pressure resistance of the corrosion-resisting glass fiber-reinforced plastic pipe are improved; quality is very stable; appearance is beautiful; and practical applicability is high.

Owner:ZHEJIANG ZHONGYI GLASS FIBER REINFORCED PLASTIC

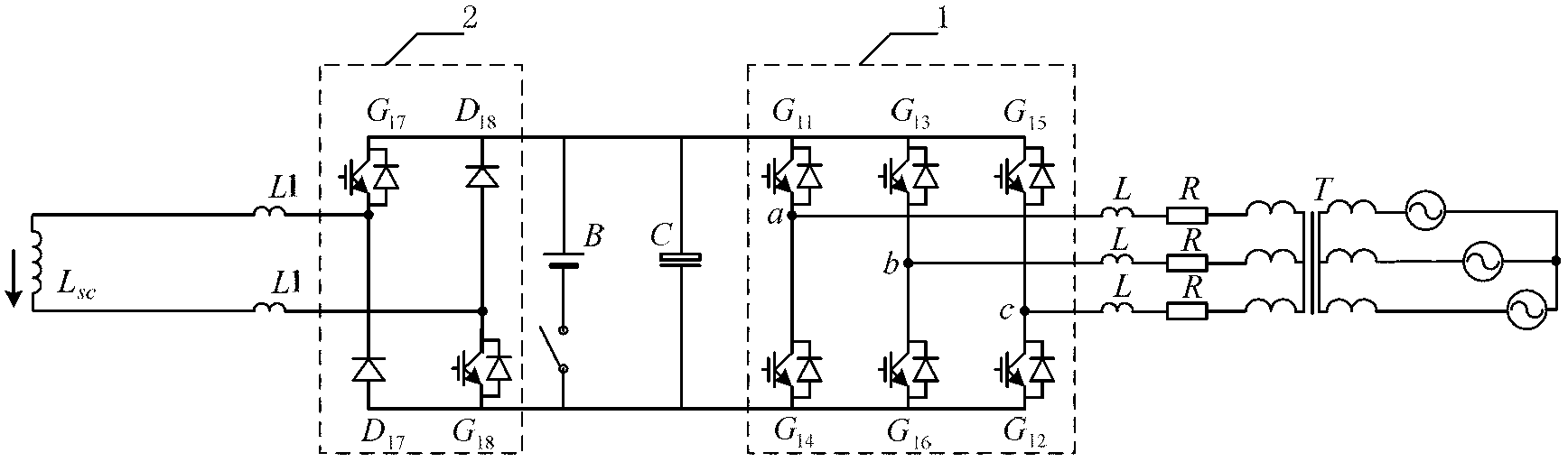

High-capacity combined converter used for electric energy storage

InactiveCN102709937AFlow fastSolve the pressure resistanceSingle network parallel feeding arrangementsAc network load balancingTransformerAlternating current

The invention discloses a high-capacity combined converter used for the electric energy storage, comprising two-level three-phase voltage source type converters (VSC), a chopper and a superconducting inductor; alternating current sides of the two-level three-phase voltage source type converters are connected mutually through an equivalent inductance resistor LR, and then connected to a power grid through multiple groups of coil transformers T; direct current sides are linked to a voltage-stabilizing capacitor C and an equivalent storage battery B in parallel, and then linked with the two-quadrantal chopper in series; the two-quadrantal chopper is connected with the superconducting inductor through a flat wave inductor L1 to form a bidirectional voltage source type converter. For adopting the method of cascading two-level three-phase voltage source type converters and matching up with the chopper, the discharging and charging controls of the superconducting magnet are realized, the rapid flow of energy can be flexibly realized, and the harmonic wave content is effectively reduced; furthermore, the pressure resistance, the flow resistance and other problems of a switch tube in the process of high power conversion are solved, the circulation problem existing in the prior art is avoided, and the high power conversion is realized.

Owner:XIAN UNIV OF TECH

Casting technology of vermicular graphite cast iron full-hydraulic redirector body shell cast

InactiveCN109202013AWell formedHigh precisionFoundry mouldsProcess efficiency improvementGraphiteWear resistance

The invention provides a casting technology of a vermicular graphite cast iron full-hydraulic redirector body shell cast and relates to the technical field of cast production. The method includes: manufacturing a mold, smelting components and removing impurities, supplying components, performing vermicularizing inoculation, performing pouring shaping, performing cooling shaping, and cleaning off the sand. The method guarantees that the vermicularizing rates of different parts on the same cast are differed by 5-10%, which satisfies the requirement on vermicularizing rate uniformity of the full-hydraulic redirector body shell cast. The technology can solve the defects of oil leakage, explosion, heavy weight, poor wearing resistance and pressure resistance, short service life, poor manufacturability of the cast and the like of a full-hydraulic redirector body shell.

Owner:ANHUI DATIAN CASTING

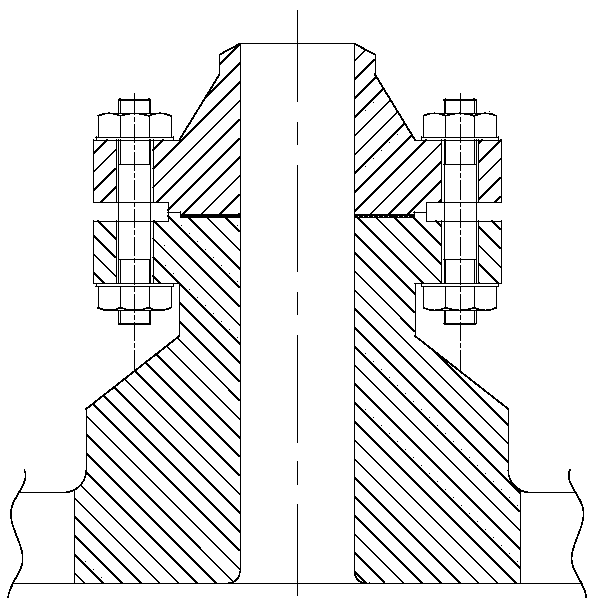

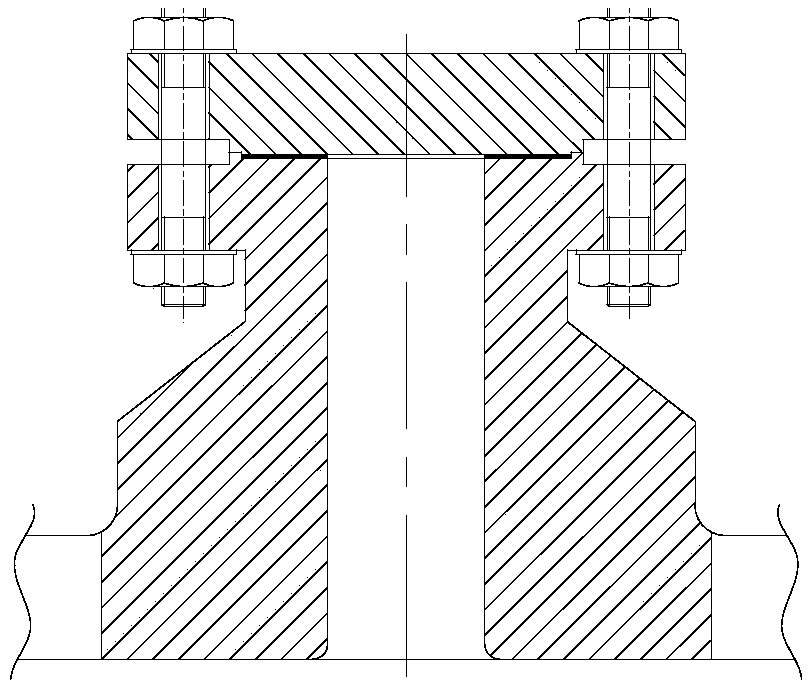

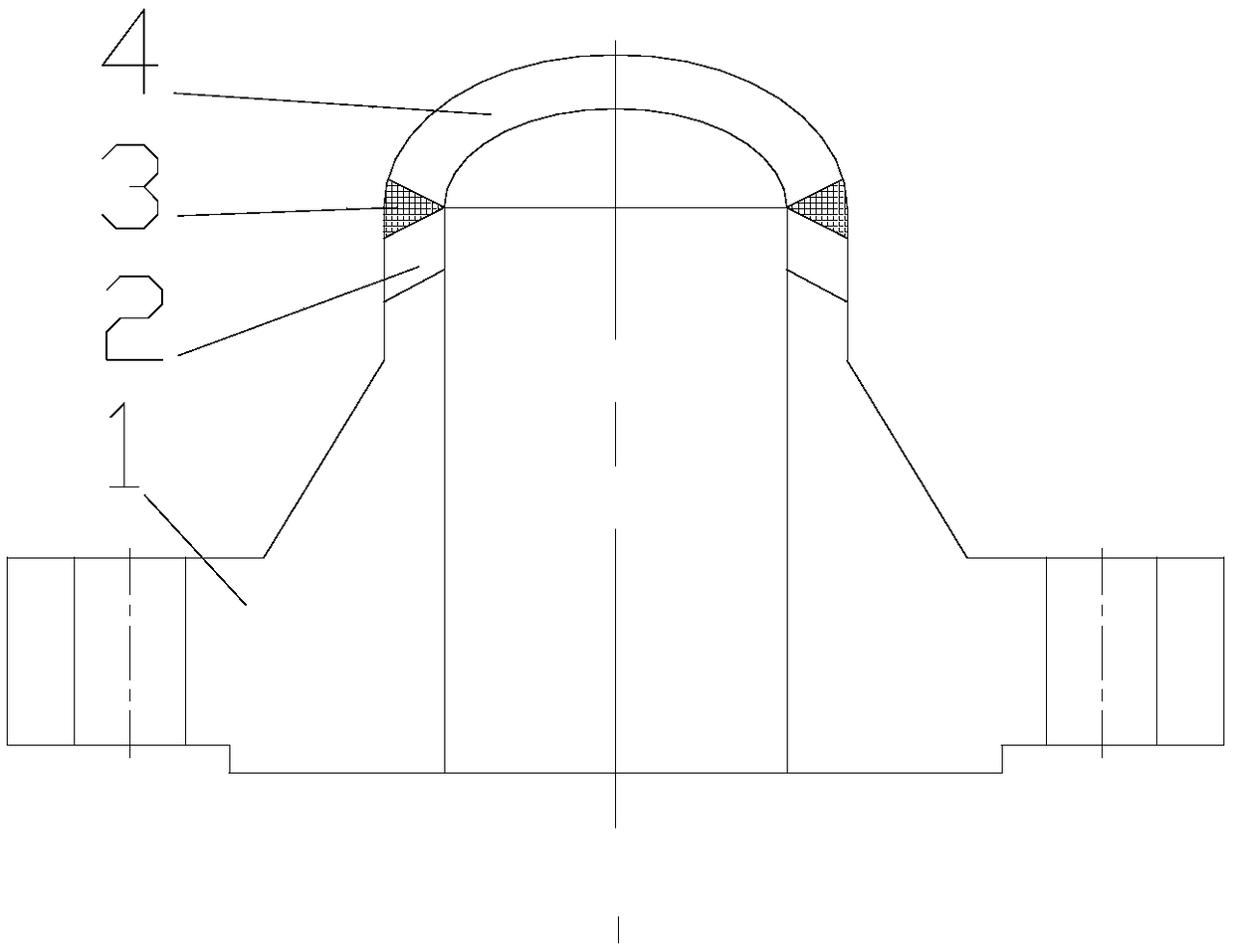

Manufacturing method of long-neck flange water-pressing sealing cover structure

InactiveCN109396756ASolve the problem of not being able to participateSolve the pressure resistanceEngineeringFlange

The invention provides a manufacturing method of a long-neck flange water-pressing sealing cover structure. The manufacturing method of the long-neck flange water-pressing sealing cover structure mainly solves the problem that the long-neck flange cannot participate in a pressure-resistant test, the strength and the sealing performance of the long-neck flange cannot be tested, and materials cannotbe fully utilized by a conventional pressure-bearing equipment. The manufacturing method of the long-neck flange water-pressing sealing cover structure is composed of the long-neck flange1, a water pressure allowance2, a connecting weld joint3 and an end cover4. The sealing surface form of the lower end of the long neck flange1 is not limited; the end cover4 can be in the form of various forms ofconvex seal heads or flat plates; the end cover 4 is not provided with a hole or is provided with a threaded hole or is welded with a connector for pressing or installing a pressure gauge; the waterpressure allowance2 is at the end part of the inner circle or the groove end of the long-neck flange1, and reservation of the water pressure allowance is carried out when the long-neck flange1 is purchased and processed, after the pressure-bearing test of the pressure-bearing equipment is qualified, the water pressure allowance is processed and removed. The method is novel, practical, advanced andfeasible.

Owner:HARBIN BOILER

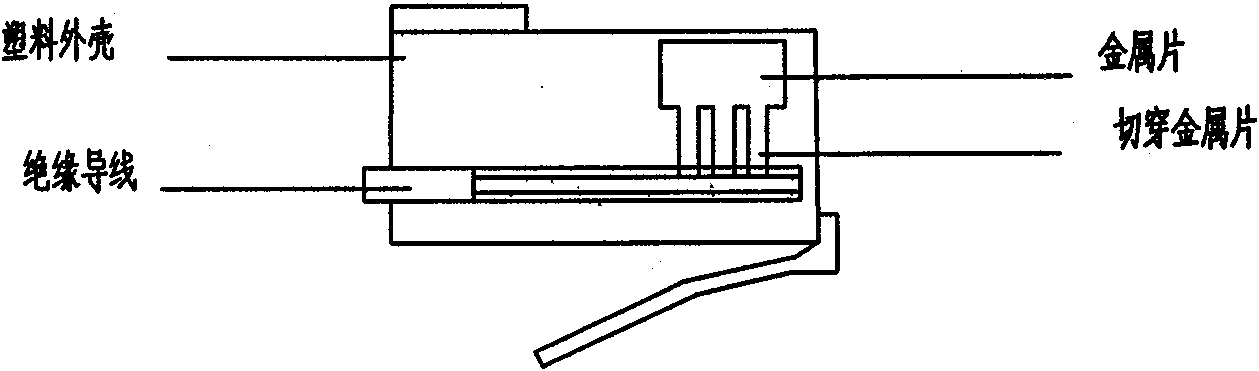

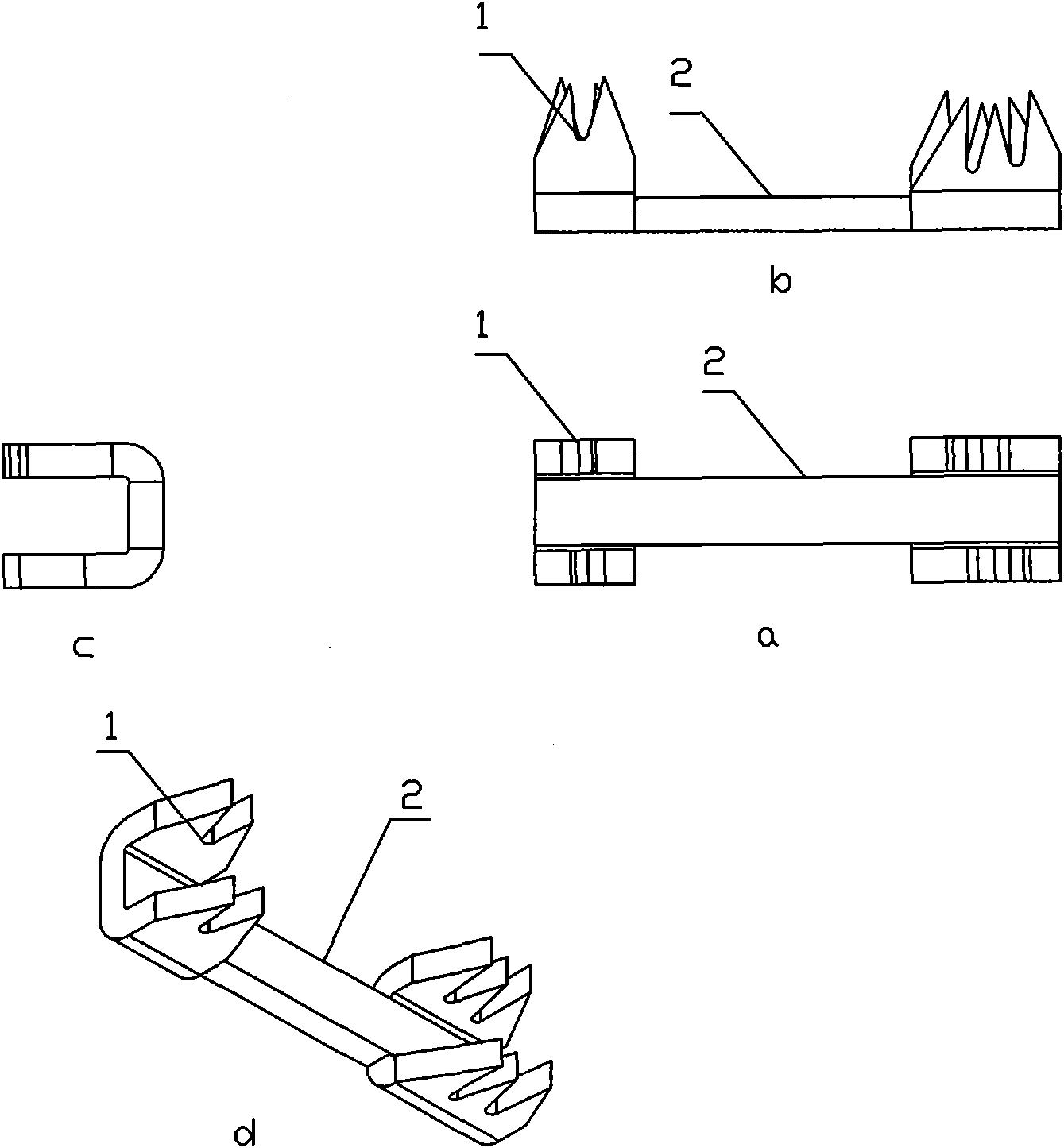

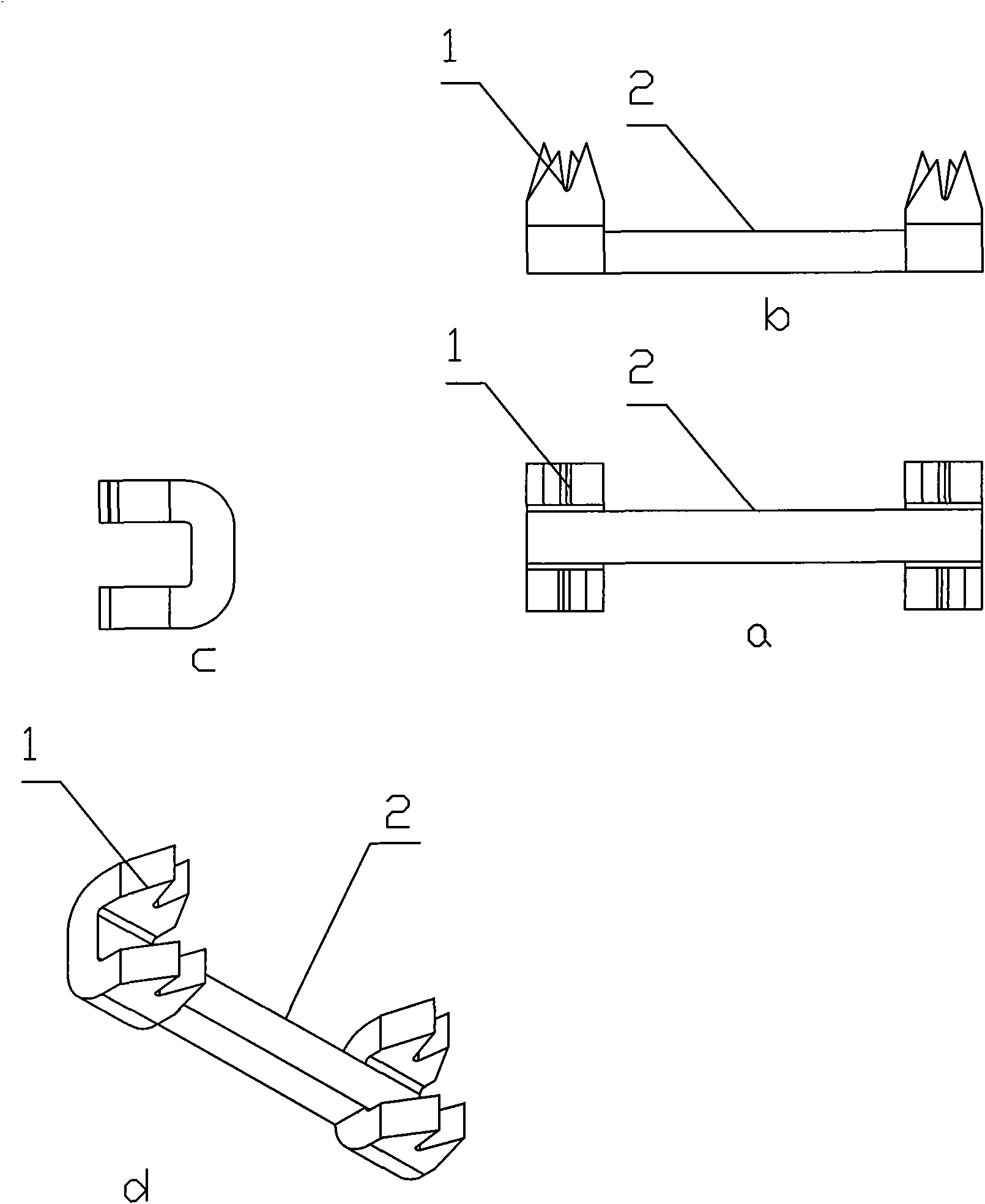

Piercing connecting conductor and device for connecting or tapping insulated wire thereof

InactiveCN101958470AHigh mechanical strengthSolve the carrying capacityContact members penetrating/cutting insulation/cable strandsClamped/spring connectionsState of artInsulation layer

The invention discloses a piercing connecting conductor. The piercing connecting conductor comprises a connecting conductor, wherein the connecting conductor is prepared from a conductive material; the two ends of the connecting conductor are respectively provided with at least one piercing contact; and the piercing contacts are electrically connected with the connecting conductor and used to pierce the insulation layer of a wire under the pressure. Two or more insulated wires can perform insulation joint or tapping without peeling off the insulation layers of the insulated wires in advance or cutting off the insulated wires; and meanwhile, the problems of the prior art such as low carrying current, low pressure resistance, narrow application area, less metal contact pieces and low piercing resistance can be solved simultaneously.

Owner:XIAN OCAME ELECTRIC

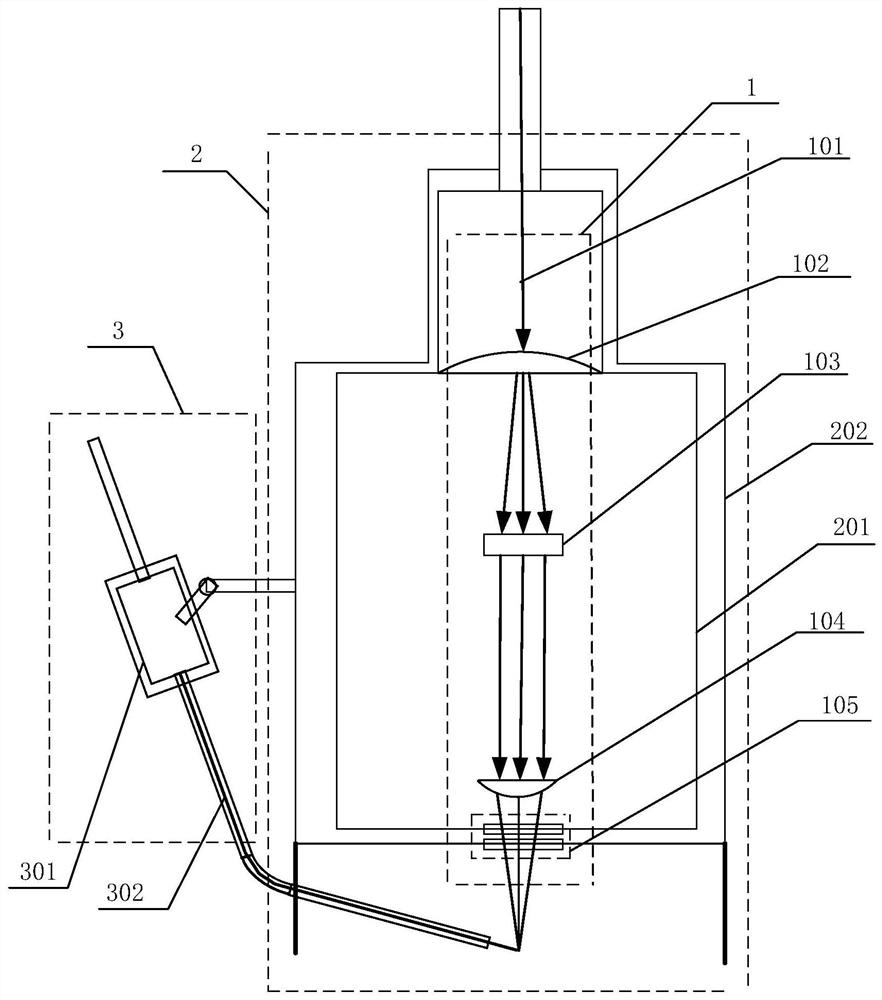

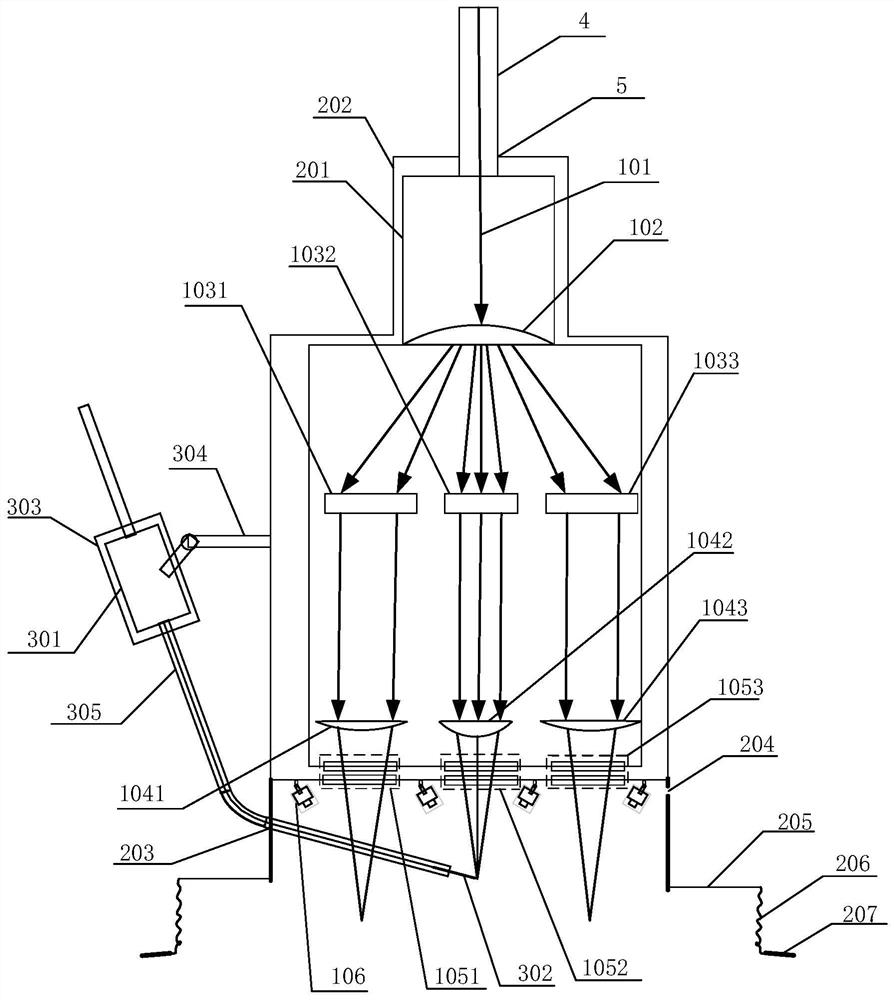

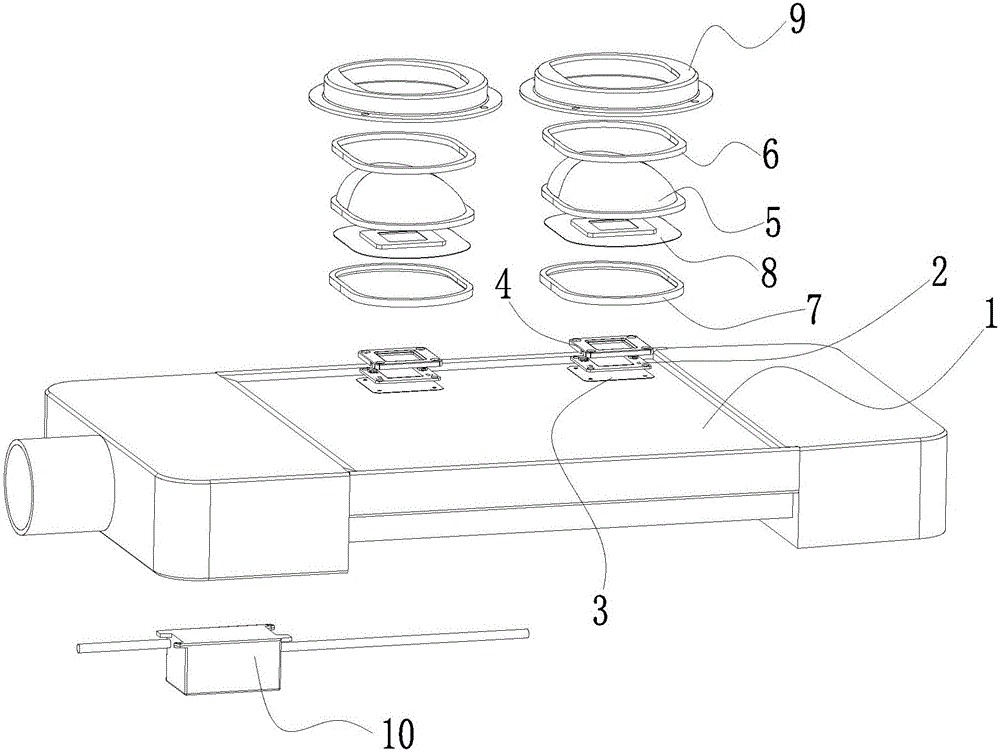

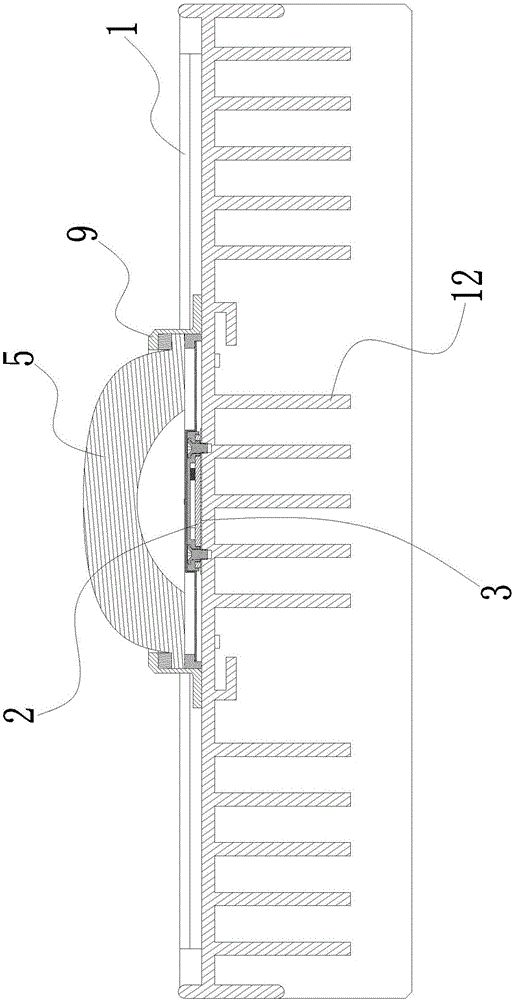

Multifunctional underwater welding laser head

ActiveCN112355472ASolve the waterproof problemSolve the pressure resistanceLaser beam welding apparatusBeam splitterLaser soldering

The invention provides a multifunctional underwater welding laser head. The problem that in a traditional laser welding method, due to poor waterproofness and pressure resistance of a laser head, thewelding effect is poor is solved. The multifunctional underwater welding laser head comprises a welding mechanism, a welding shell and a wire feeding mechanism. The welding mechanism comprises a laser, a spectroscope, a collimating mirror, a focusing mirror and a light transmitting element, and the output end of the laser sequentially penetrates through the spectroscope, the collimating mirror, the focusing mirror and the light transmitting element to reach a welding part. The welding shell comprises a laser head shell and a waterproof sealing cover. The wire feeding mechanism comprises a wirefeeder and a welding wire, the welding wire is arranged at the output end of the wire feeder, the wire feeding mechanism is arranged outside the waterproof sealing cover, and the welding wire penetrates through the waterproof sealing cover to reach the welding part. The multifunctional underwater welding laser head can be widely applied to the technical field of laser welding.

Owner:HARBIN INST OF TECH AT WEIHAI

Nano PVC material and preparation method thereof

InactiveCN108864611AGood compression, wear resistance and aging resistanceImprove corrosion resistanceMethacrylateTin dioxide

The invention discloses a nano PVC material and a preparation method thereof. The nano PVC material is prepared from the following ingredients in parts by weight: 100 to 120 parts of purified water, 10 to 30 parts of emulsifying agent, 5 to 20 parts of isobutyl methacrylate, 15 to 30 parts of nano inorganic particle, 0.5 to 4.5 parts of free radical initiator, 4 to 10 parts of tin dioxide, 15 to 30 parts of ethyl alcohol, 40 to 90 parts of vinyl chloride, 20 to 60 parts of PC, 4 to 10 parts of poly vinyl chloride resin, 3 to 6 parts of zinc oxide, 5 to 10 parts of cyclobutene terephthalic acid, 2 to 8 parts of stabilizer, 1 to 5 parts of plasticizer and 1 to 6 parts of coupling agent. The preparation method of nano PVC material comprises the following steps: S1, adding 100 to 120 parts ofpurified water and 10 to 30 parts of emulsifying agent into a reactor and evenly stirring to form nano blend A. According to the preparation method disclosed by the invention, nanoparticles and PVC polymer are mixed; thus, the prepared PVC material has good performance of compression resistance, abrasion resistance and ageing resistance.

Owner:安徽启慧信息科技有限公司

Anti-explosion and antistatic LED inspection hole lamp

ActiveCN107152637ASimple structural designSolve static problemsLighting support devicesProtective devices for lightingEngineeringLED lamp

The invention discloses an anti-explosion and antistatic LED inspection hole lamp. The anti-explosion and antistatic LED inspection hole lamp comprises a lamp box and an anti-explosion box, wherein the lamp box is connected together with the anti-explosion box through thread fit; a connection pipe connected with the lamp box in a penetrating manner is fixed to the upper end of the lamp box, and a threading pipe is connected to the connection pipe in a penetrating manner; the connection pipe is rotationally fixed to a fixed support through a ball; a conducting rod is connected to a first support, the lower end of the conducting rod is inserted into the lamp box and connected with a conducting boss, the conducting boss is fixed to the top of the lamp box, and LED lamp pipes which are uniformly distributed are arranged between the conducting boss and the box wall of the lamp box; and the anti-explosion box is composed of a stainless steel lampshade and a tempered glass lampshade, and the stainless steel lampshade is located above the tempered glass lampshade. The anti-explosion and antistatic LED inspection hole lamp disclosed by the invention is simple in structural design, solves the problem that the LED lamp generates static electricity to be damaged during a use process, improves the use safety, prolongs the service life of the LED lamp, further solves the problems of low pressure resistance and low sealing performance of the LED lampshade, and has open fire-isolation and anti-explosion effects.

Owner:YANYANG LAMP SET TIANCHANG CITY

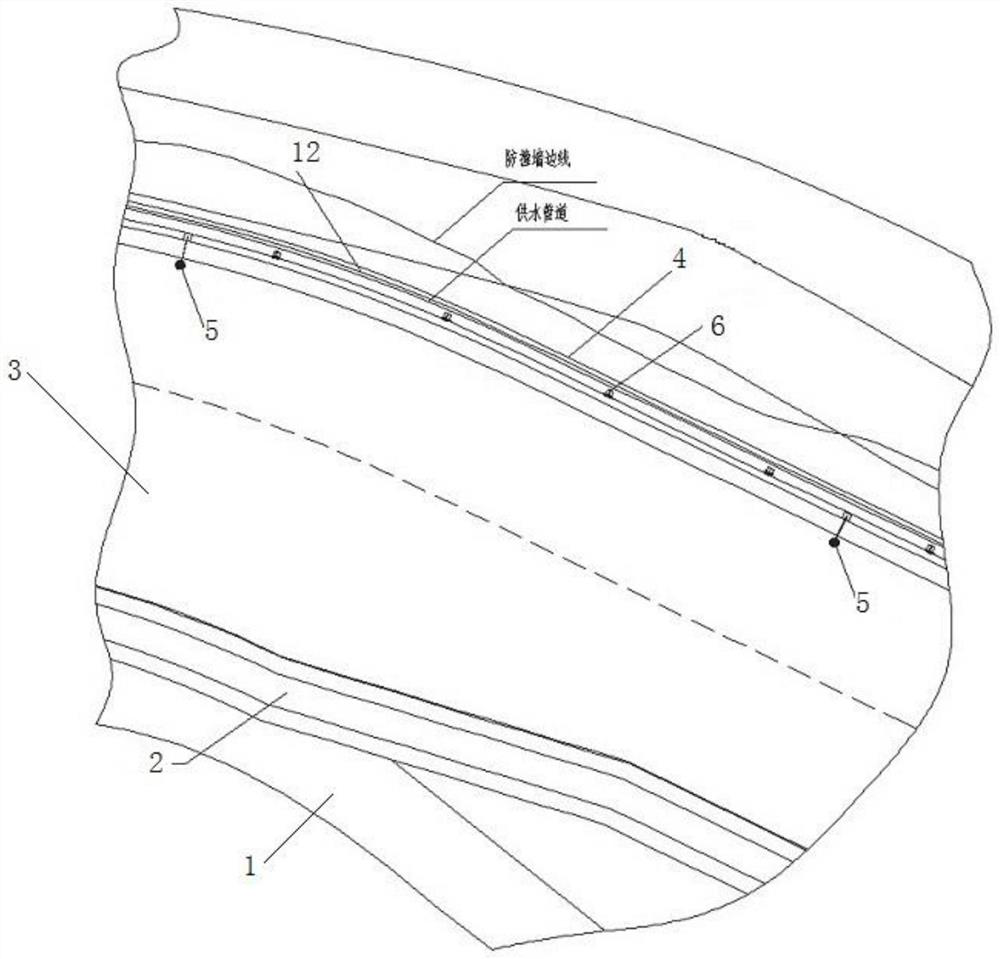

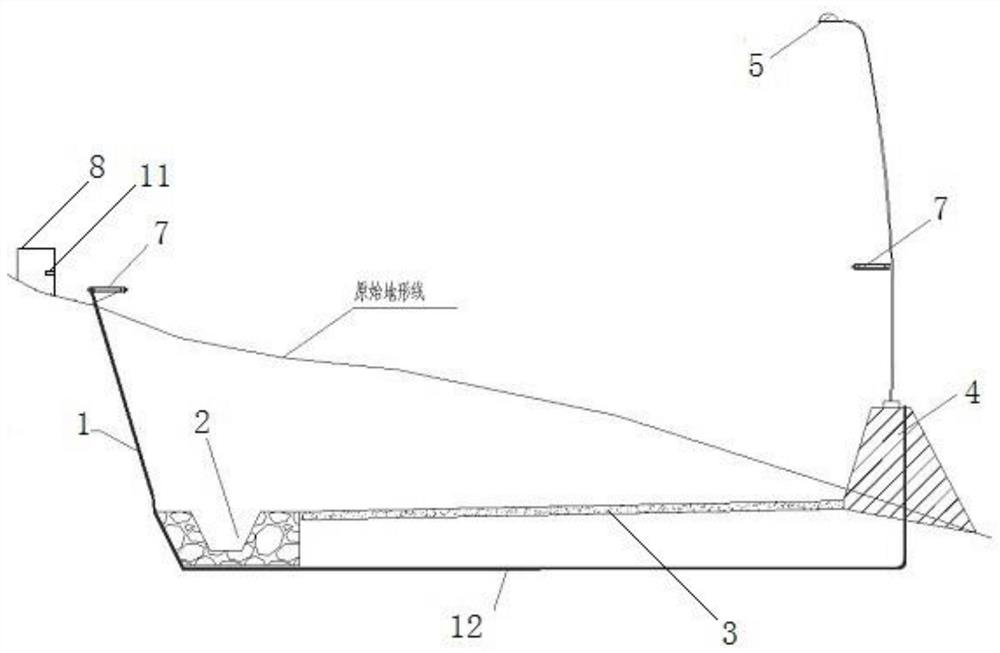

Road side adhesive pavement construction method for inhibiting flying dust and realizing environment-friendly transportation

ActiveCN112482155AResolution cycleSolve the pressure resistanceIn situ pavingsClimate change adaptationAdhesiveArchitectural engineering

The invention discloses a road side adhesive pavement construction method capable of inhibiting flying dust and realizing environment-friendly transportation, which is characterized by comprising a lower curing treatment layer construction process and an upper curing treatment layer construction process, the lower curing treatment layer construction process comprises the steps of gravel layer preparation, construction lofting, mixture preparation and mixing, paving and leveling, rolling and curing. According to the upper curing treatment layer construction process, cement and a curing agent are adopted for mixing, secondary stirring is carried out using a stirring machine, and shaping, rolling and curing are carried out; according to the road bonding adhesive pavement obtained after the road side adhesive pavement construction method capable of inhibiting flying dust and achieving environment-friendly transportation, due to the existence of a road bonding adhesive, a mine transport vehicle is firmer under overpressure under heavy-load transportation, meanwhile, the road bonding adhesive pavement can effectively inhibit flying dust, and the dust falling effect is achieved. The problems that the construction period of the cement pavement is long and the asphalt pavement is not pressure-resistant are solved, and the situation that the cement pavement and the asphalt pavement are prone to raise dust is avoided.

Owner:SINOHYDRO BUREAU 9

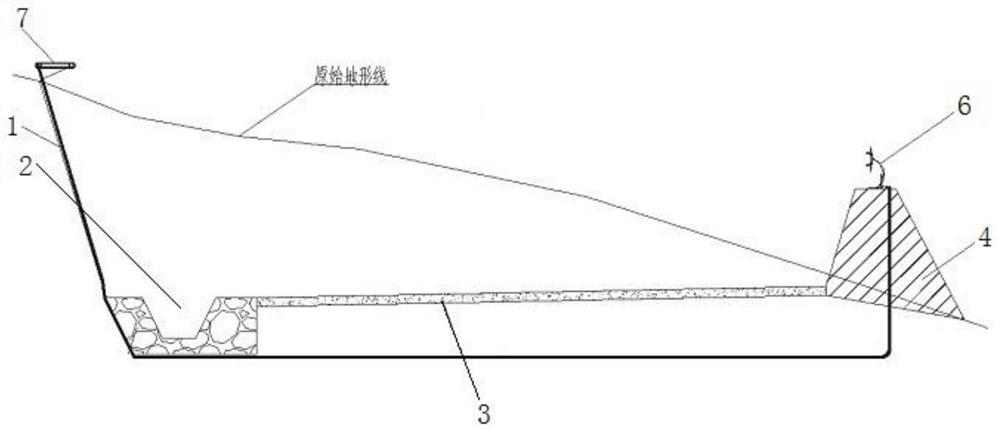

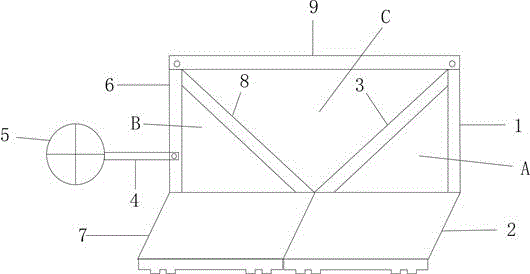

Automotive multi-triangular-framework protection equipment with impact resistant function

InactiveCN105172718AFix stability issuesSolve the pressure resistancePedestrian/occupant safety arrangementBumpersControl systemEngineering

The invention belongs to the field of automotive accessories and provides automotive multi-triangular-framework protection equipment with an impact resistant function. The automotive multi-triangular-framework protection equipment comprises a buffer body 1, a moving resisting body 2, a support body 3, a pushing rod 4, a control system 5, a buffer body 6, a moving resisting body 7, a support body 8 and a support body 9. The automotive multi-triangular-framework protection equipment is characterized in that the buffer body 1, the moving resisting body 2 and the support body 3 form a triangular framework A; the buffer body 6, the moving resisting body 7 and the support body 8 form a triangular framework B; the support body 3, the support body 8 and the support body 9 form a triangular framework C. The automotive multi-triangular-framework protection equipment has the characteristics of good stability, ruggedness and pressure resistance; impact from opposite automobiles is prevented and blocked through counter-acting force of the triangular framework structures and ground, the retarding brake effect is good, and the safety factor is high.

Owner:蒋科化

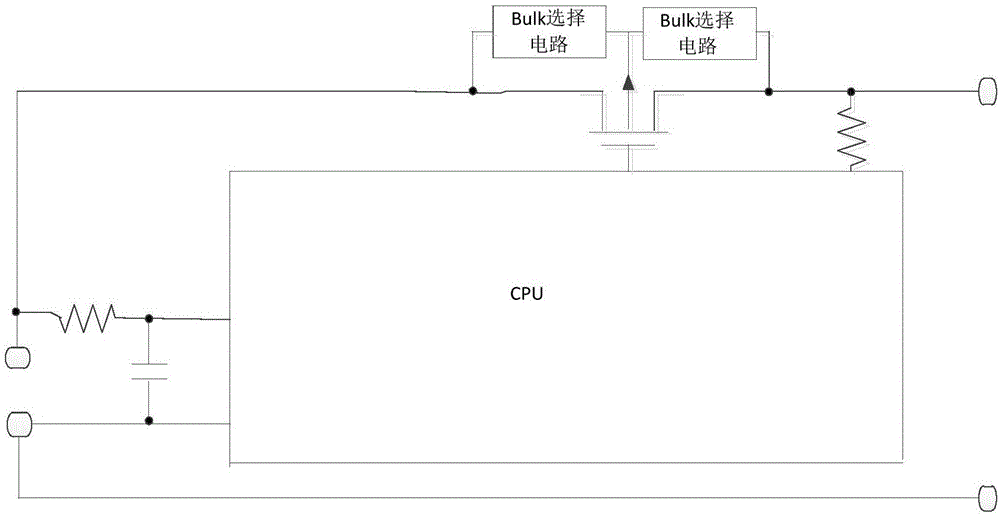

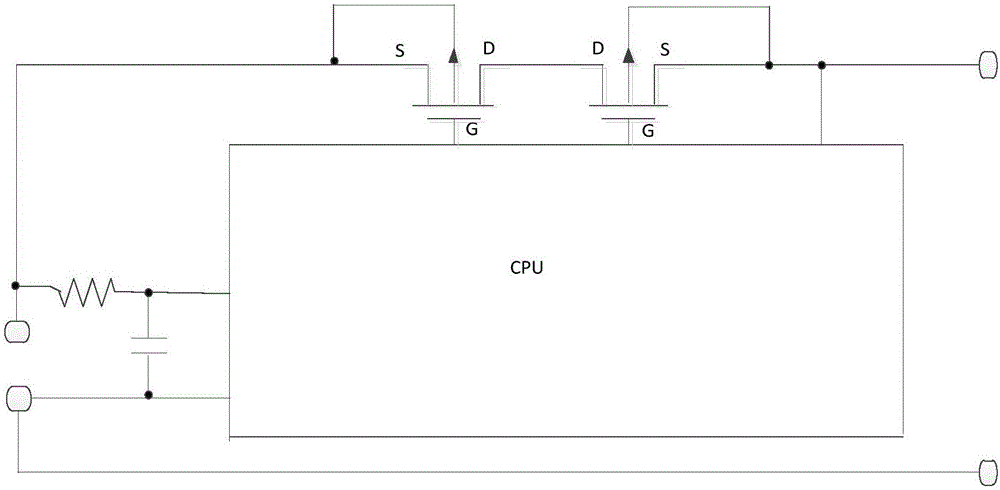

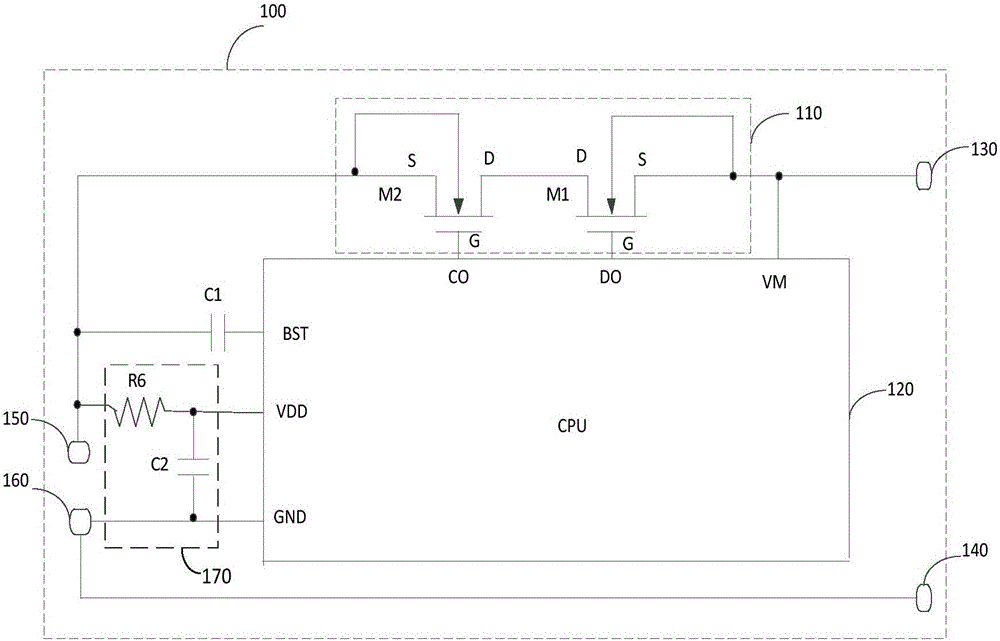

Battery protection circuit and lithium battery circuit

PendingCN106849290AImprove practicalitySolve the costElectric powerBattery overcurrent protectionBattery chargePower flow

The invention provides a battery protection circuit and a lithium battery circuit, and relates to the technical field of battery charging / discharging protection. The battery protection circuit comprises a charging / discharging circuit, a controller, a power source anode interface, a power source cathode interface, a battery anode interface and a battery cathode interface. The charging / discharging circuit comprises a first power pipe and a second power pipe. The controller is provided with a first driving port, a second driving port, a first power source port, a second power source port and a grounding port, and is integrated with a reverse connection protection circuit. When the power source anode interface is connected to a power source cathode, the reverse connection protection circuit opens a current channel between a power source and the controller; when the battery anode interface is connected to a battery cathode, the reverse connection protection circuit opens the current channel between a battery and the controller. Through the design, the problem which exists in an existing battery protection technology that the reliability is low since a short circuit is likely to occur in the production and using process is solved.

Owner:成都拓尔微电子有限责任公司

LED (light-emitting diode) street lamp

InactiveCN106287447ASolving the problem of surge failureSolve the pressure resistanceMechanical apparatusElectric circuit arrangementsEngineeringElectrical bonding

The invention discloses an LED (light-emitting diode) street lamp which comprises a lamp body, a power supply mechanism, a light engine, a mica spacer, a separator and a glass lens, wherein the light engine is arranged on the surface of the lamp body, the mica spacer is arranged between the light engine and the surface of the lamp body, the separator is arranged at the top of the light engine, the glass lens covers the surface of the lamp body corresponding to the light engine, and the power supply mechanism is electrically connected with the light engine. The LED street lamp has the advantages that a lightning arrester is additionally connected between the light engine and an external wire, lightning resistance is higher than 10KV, a mica plate is added between the light engine and a radiator to function in radiating and insulating, a plastic cover is arranged between the light engine and a screw, a fixing hole of the light engine is fixed by the plastic cover in an insulating manner, the problem of failure due to surge of an existing light engine is solved, and the problems of insufficient voltage resistance and electro-migration of the light engine are solved.

Owner:YANGJIANG LIQIAO TECH

Formula for novel auxiliary agent capable of improving TPV

InactiveCN109721857AEffective crosslinkingImprove flame retardant performanceCross-linkVulcanization

The invention discloses a formula for a novel auxiliary agent capable of improving TPV. The formula comprises the following raw materials by weight: 60 to 70 parts of EPDM rubber, 14 to 16 parts of anethylene-vinyl acetate copolymer, 11 to 13 parts of polyethylene, 10 to 12 parts of chlorinated polyvinyl chloride, 7 to 9 parts of polypropylene, 5 to 7 parts of chitosan antibacterial microspheres,1 to 2 parts of a flame retardant, 2 to 3 parts of a cross-linking agent, 0.3 to 0.5 part of sulfur, 0.5 to 1 part of naphthenic oil, 0.2 to 0.4 part of an ultraviolet absorber and 0.3 to 0.5 part ofa lubricant. According to the formula provided by the invention, through addition of the ethylene-vinyl acetate copolymer, the processing technology of the TPV can be improved, and the TPV has stronger adaptability in the process of production; meanwhile, through addition of the polyethylene, the TPV after production can be greatly improved in modulus and is improved in the performance of poor compression deformation resistance, and the problems of difficult processing and poor modulus and compression deformation resistance of the TPV for a long time are solved; and the ethyl acetate end of the ethylene-vinyl acetate copolymer has good fusion effect with the polypropylene, so a softening effect is exerted on vulcanization of the EPDM rubber and the polypropylene.

Owner:东莞捷佳塑胶科技有限公司

Wallboard containing PVC modified material and preparation method thereof

InactiveCN109096645AImprove heat resistanceSolve the pressure resistanceChemistryEnvironmentally friendly

The invention discloses a wallboard containing a PVC modified material and a preparation method thereof. The wallboard comprises, by weight parts, 100-120 parts of purified water, 5-10 parts of maleicanhydride, 15-30 parts of emulsifier, 15-30 parts of ethanol, 20-40 parts of environmentally friendly plasticizer, 4-10 parts of polyvinyl chloride resin, 20-60 parts of vinyl chloride polymer, and 15-40 parts of sponge cells. The preparation method includes the following steps: step S1 of preparation of a PVC modified component: adding, by weight parts, 100-120 parts of purified water, 15-30 parts of emulsifier and 15-30 parts of ethanol to a reactor, stirring evenly, and forming a blend A. The purpose of the wallboard is to provide the wallboard containing the PVC modified material and thepreparation method thereof to solve the problems of poor gas permeability, poor strength, no toughness, no environmental protection caused by the addition of formaldehyde and other auxiliaries.

Owner:安徽启慧信息科技有限公司

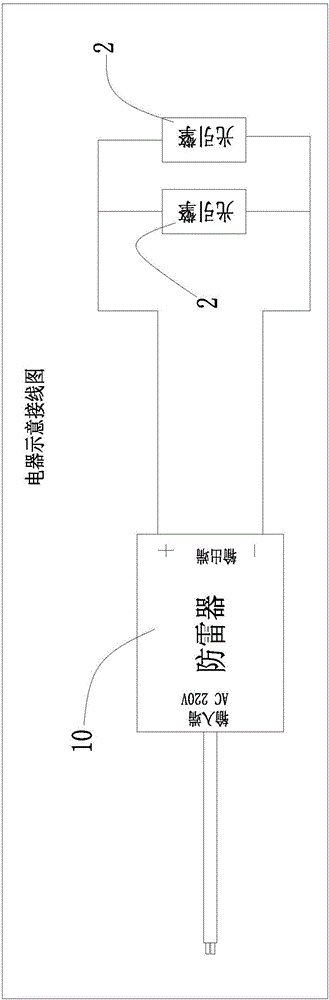

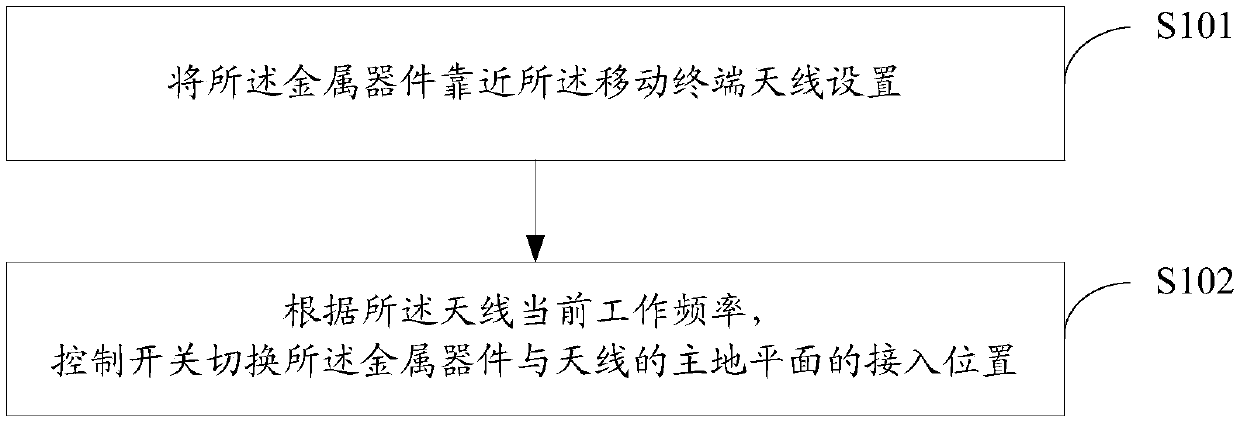

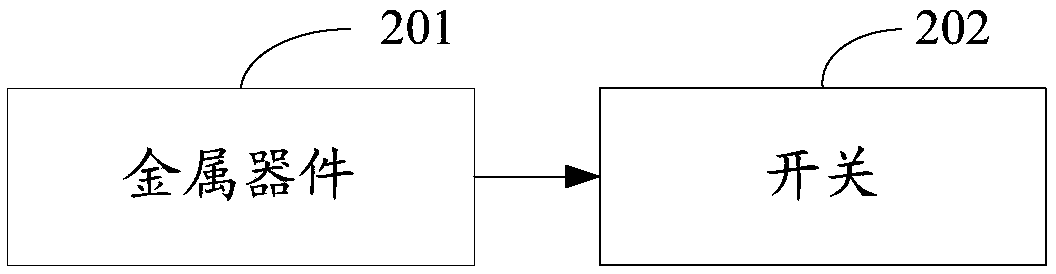

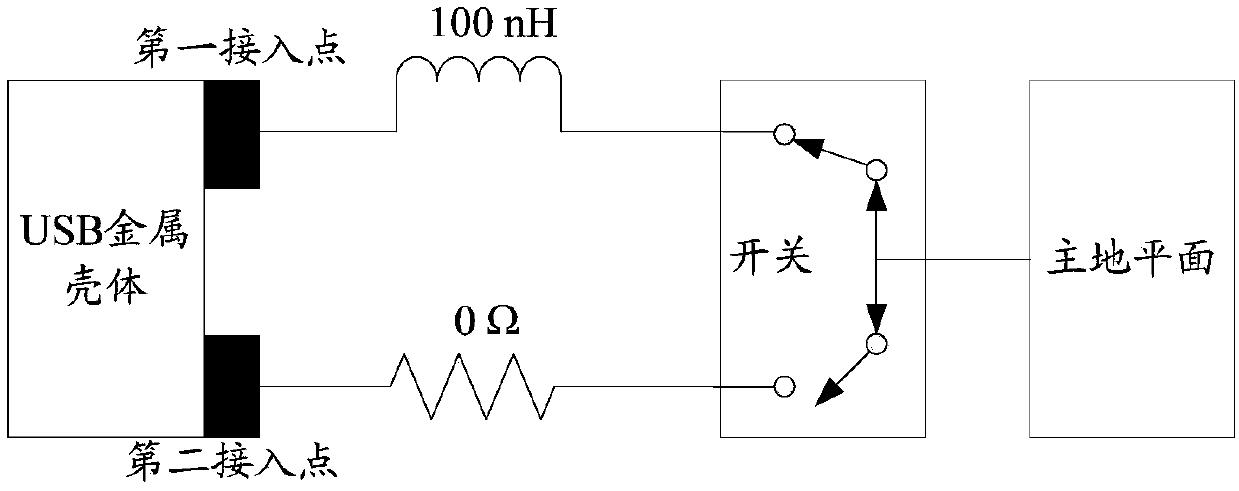

Method, device and apparatus for improving antenna efficiency of mobile terminal and storage medium

ActiveCN110943279ASolve lossSolve the pressure resistanceAntenna supports/mountingsAntennas earthing switches associationEngineeringGround plane

The invention discloses a method, device and apparatus for improving antenna efficiency of a mobile terminal, and a storage medium, and relates to the technical field of mobile terminals, and the method comprises the steps: enabling a metal part to be close to an antenna of the mobile terminal; and controlling a switch to switch the access position of the metal part anda main ground plane of the antenna according to the current working frequency of the antenna.

Owner:ZTE CORP

Terminal structure of MOSFET device and preparation method and application of terminal structure

PendingCN111725300ASolve the pressure resistanceSolve the leakSemiconductor/solid-state device manufacturingSemiconductor devicesCarbide siliconMOSFET

The invention relates to a terminal structure of an MOSFET device and a preparation method and application of the terminal structure. The terminal structure comprises more than one group of silicon carbide groove rings which are arranged on the periphery of an MOSFET device chip and are sequentially distributed from inside to outside, the silicon carbide groove rings are closed rings; the siliconcarbide groove ring on the innermost side is connected with the low potential of a chip; the silicon carbide groove ring on the outermost side is a cut-off ring, and the potential of the cut-off ringis connected with a scribing channel of the chip. According to the terminal structure of the MOSFET device, the silicon carbide groove is connected with the low potential of the chip at the inner side, so that the formation of a reverse channel is effectively inhibited, and electric leakage can be inhibited; the silicon carbide groove is connected with the high potential of the scribing channel onthe outer side, the isolation effect can be enhanced, and the closed annular design can prevent an electric leakage channel from being formed between the inner side and the outer side, so that the problems of voltage resistance and electric leakage of the MOSFET device are solved.

Owner:SHENZHEN RUI ZHI CHEN TECH

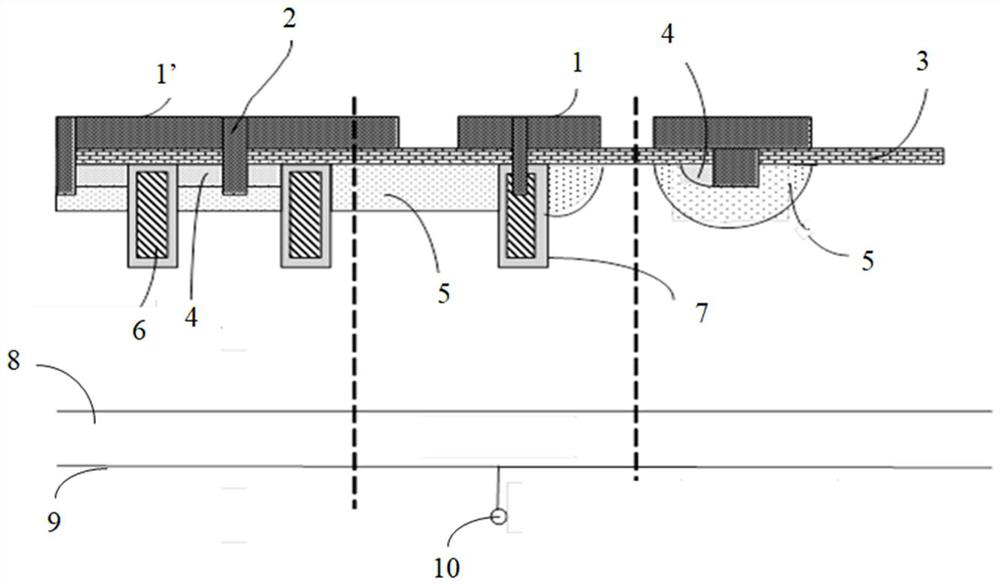

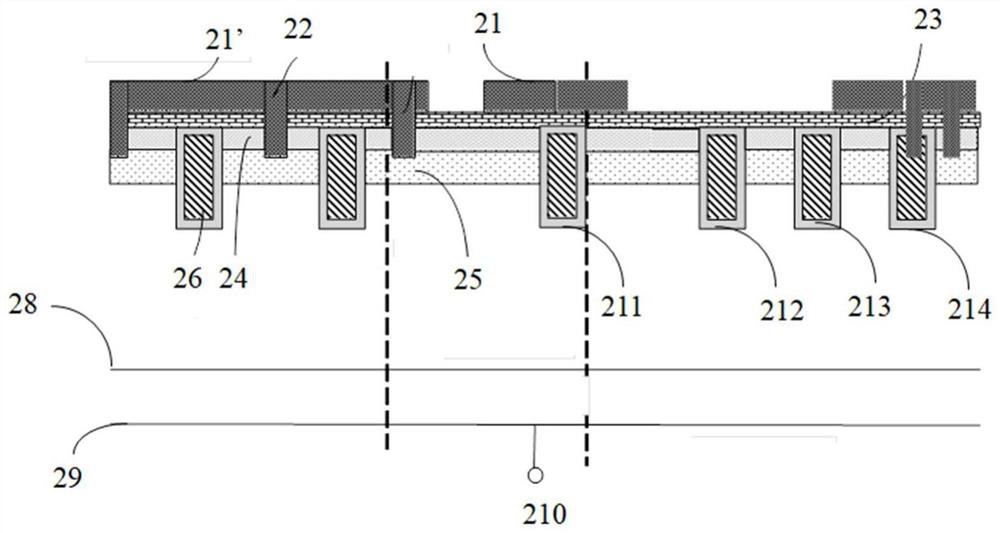

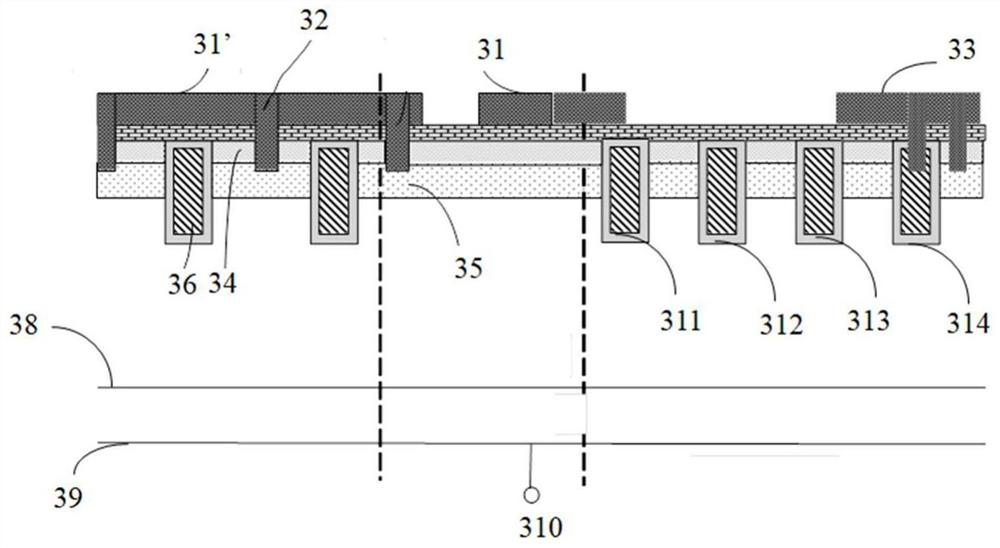

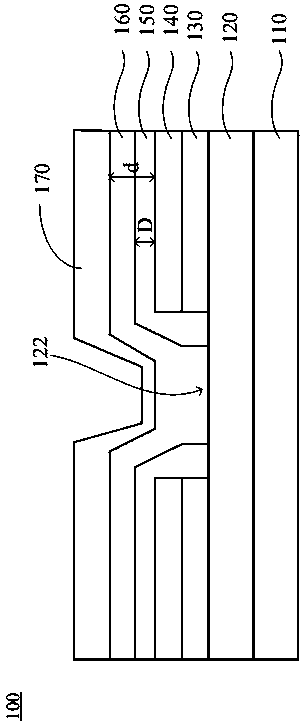

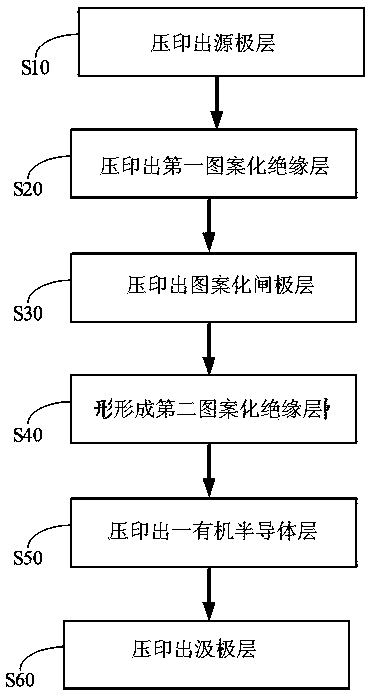

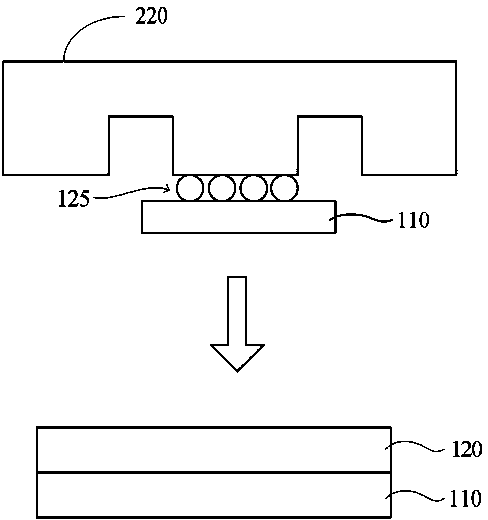

Manufacturing method of vertical organic thin film transistor

InactiveCN102299260BSolve the pressure resistanceSolve the characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerOrganic semiconductor

The invention discloses a vertical organic thin film transistor and a manufacturing method thereof. The vertical organic thin film transistor comprises a source electrode layer, a first patterned insulation layer, a patterned gate electrode layer, a second patterned insulation layer, an organic semiconductor layer and a drain electrode layer, wherein the first patterned insulation layer is arranged on the source electrode layer, the patterned gate electrode layer is correspondingly arranged on the first patterned insulation layer, the second patterned insulation layer has the preset thickness and is covered on the patterned gate electrode layer, and the local surface of the source electrode layer is exposed out. The organic semiconductor layer is covered on the second patterned insulation layer and the local surface. The drain electrode layer is arranged on the organic semiconductor layer.

Owner:CPTF VISUAL DISPLAY (FUZHOU) LTD +1

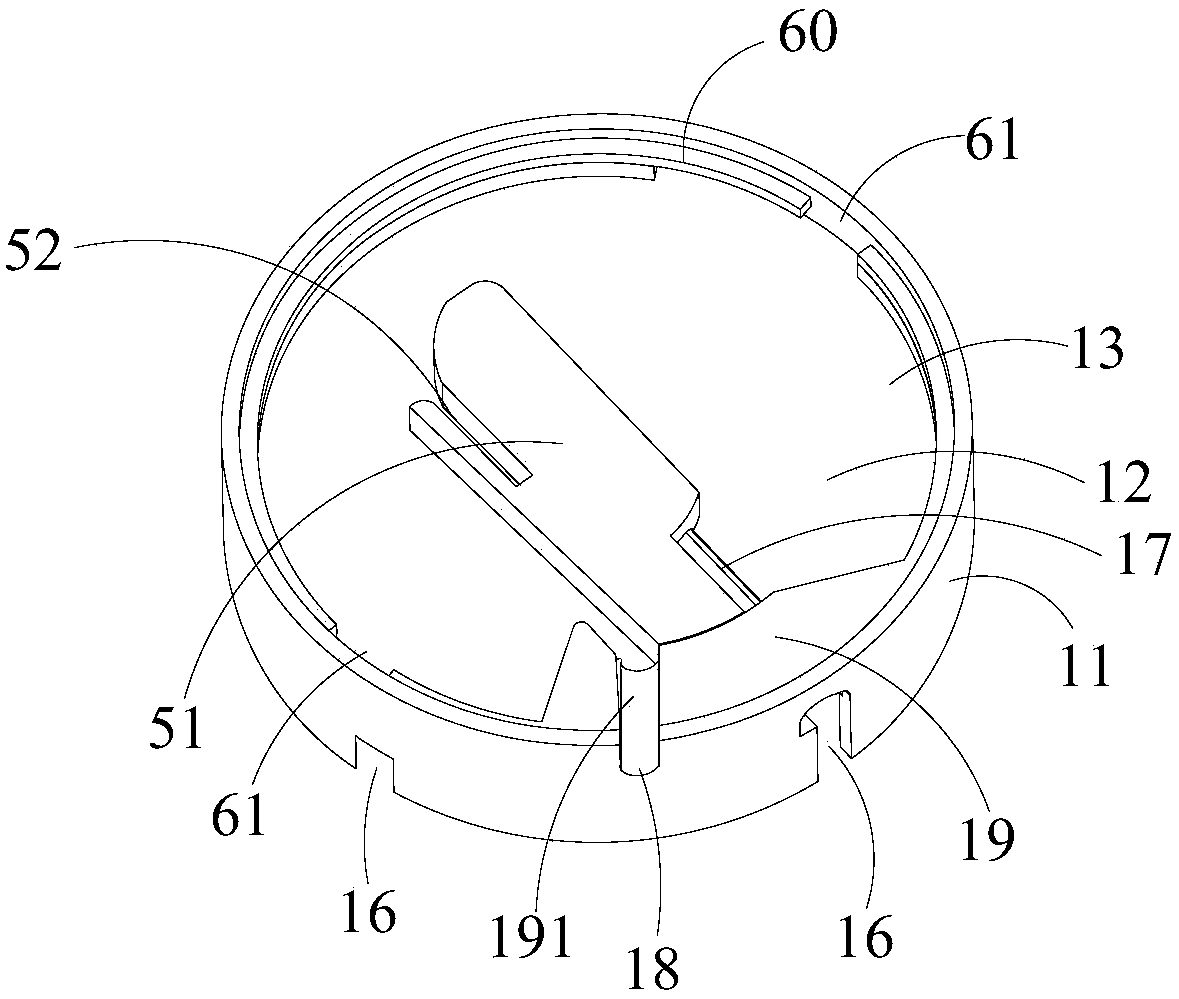

Small mechanical trip type thermal protection piezoresistor

InactiveCN110136905APrevent overheating and fireAvoid safety hazardsOvervoltage protection resistorsResistor detailsElectrical resistance and conductanceMechanical engineering

The invention relates to the technical field of piezoresistors, and provides a small mechanical trip type thermal protection piezoresistor. The piezoresistor comprises a base, a top cover, a pressuresensitive valve plate component and a movable electrode, the front surface of the base is provided with a first holding cavity, the top cover covers the first holding cavity, the back surface of the base is provided with a second holding cavity, the pressure sensitive valve plate component comprises a pressure sensitive valve plate arranged in the second holding cavity and first and second electrodes respectively clamped at the front surface and the back surface of the pressure sensitive valve plate and extended out of the second holding cavity, the first holding cavity is internally providedwith a window configured to allow part of the first electrode to be exposed, the movable electrode is elastic, the inner end of the movable electrode is extended into the first holding cavity, bent, then arranged at the window and welded and fixed with the exposed portion of the first electrode, and the outer end of the movable electrode is extended out of the first holding cavity. The technical problems of the large volume, the complex structure and the limited application occasions of the mechanical trip type thermal protection device in the prior art are solved.

Owner:陆饶丹

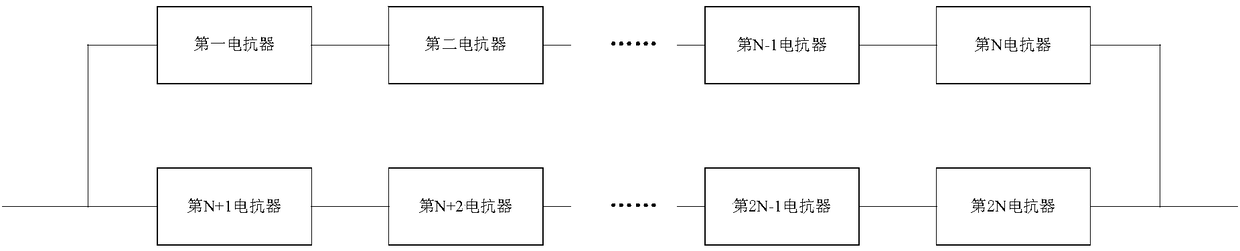

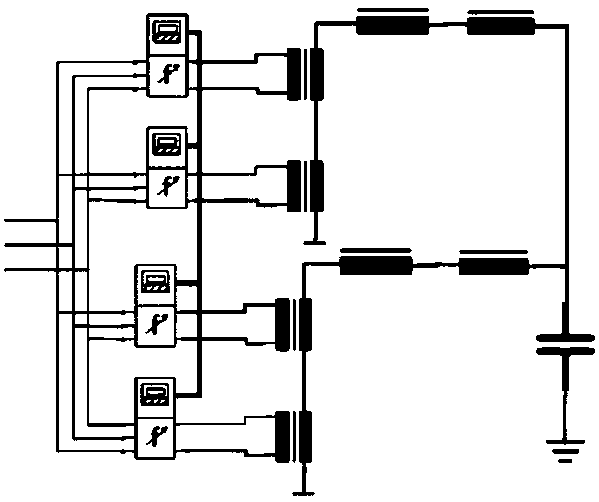

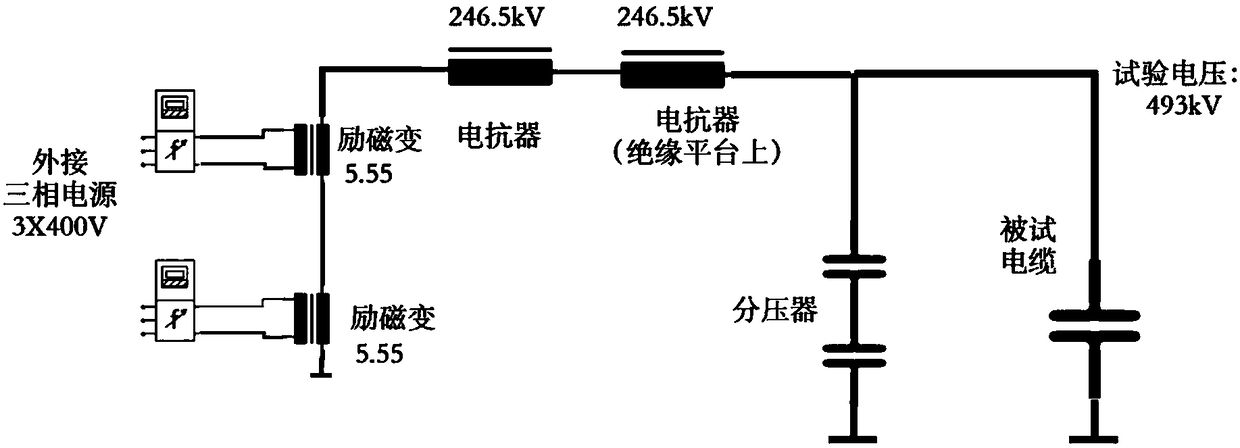

Test equipment

InactiveCN108152643AMeet capacity requirementsSolve the pressure resistanceElectrical testingVoltageTest facility

The invention discloses test equipment. The test equipment comprises a first reactor, a second reactor,..., an Nth reactor, an (N+1)th reactor,..., a 2Nth reactor, wherein the first reactor to the Nthreactor are connected in series to form a first branch, the (N+1)th reactor to the 2Nth reactor are connected in series to form a second branch, the first branch and the second branch are connected in parallel, and N is a natural number. According to the invention, the test equipment achieves a technical effect of meeting voltage and capacity requirements of a voltage withstand test of an engineering project.

Owner:STATE GRID BEIJING ELECTRIC POWER +2

Conductor coated with high-temperature-resisting insulation layer

InactiveCN104361925ASolve temperature resistanceSolve the pressure resistanceInsulated cablesInsulated conductorsCopper conductorInsulation layer

The invention discloses a conductor coated with a high-temperature-resisting insulation layer. The high-temperature-resisting insulation layer on the conductor is an aluminum oxide coating layer. The conductor is an aluminum conductor, a copper conductor or a metal alloy. When the conductor is in a cylindrical shape, the conductor and the high-temperature-resisting insulation layer form an antenna. When the conductor is in a cuboid shape, the conductor and the high-temperature-resisting insulation layer form a busbar. The high-temperature-resisting insulation layer is an aluminum oxide coating layer, aluminum oxide can be resistant to high temperature higher than 2000 DEG C, and therefore the temperature resistance and the pressure resistance can be well achieved. The aluminum oxide coating layer can be made thin.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com