Conductor coated with high-temperature-resisting insulation layer

A technology of insulation coating and insulation coating layer, which is applied in the field of high temperature resistant insulation coating conductors, can solve the problems of low temperature resistance level, loss of insulation performance, etc., and achieve the effect of solving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe in detail the technical content, achieved objectives and effects of the present invention, the following will be described in detail in combination with the embodiments.

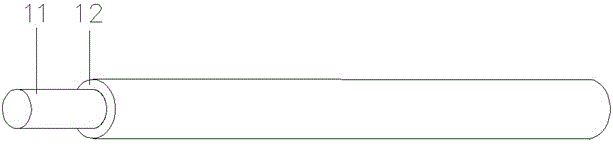

[0014] see figure 1 According to the present invention, the conductor 11 with high temperature resistant insulation coating, the high temperature resistant insulation coating layer 12 on the conductor 11 is an alumina coating layer.

[0015] Preferably, the conductor 11 is a metal or a metal alloy conductor such as an aluminum conductor or a copper conductor.

[0016] In this embodiment, the conductor 11 is in a cylindrical shape, and the conductor 11 and the high temperature resistant insulating coating 12 form an electric wire. The cross-section of the conductor 11 may also be in the shape of a cuboid. In this case, the conductor 11 and the high-temperature-resistant insulating coating 12 form a bus bar. The shape of the conductor 11 is not limited to the above two, and can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com