Device and method for manufacturing high temperature resistant displacement sensor probe based on planar coil

A technology of displacement sensors and planar coils, which is applied in the direction of inductance/transformer/magnet manufacturing, measuring devices, and electrical devices, etc., to achieve the effects of ensuring sensitivity, prolonging service life, and strong magnetic field density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

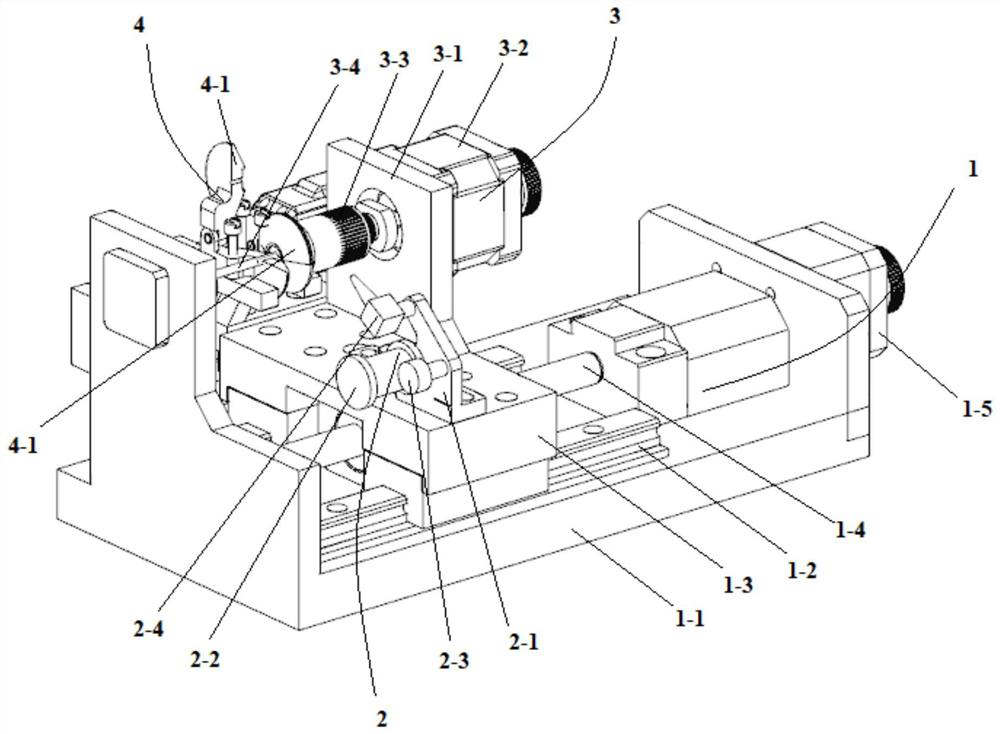

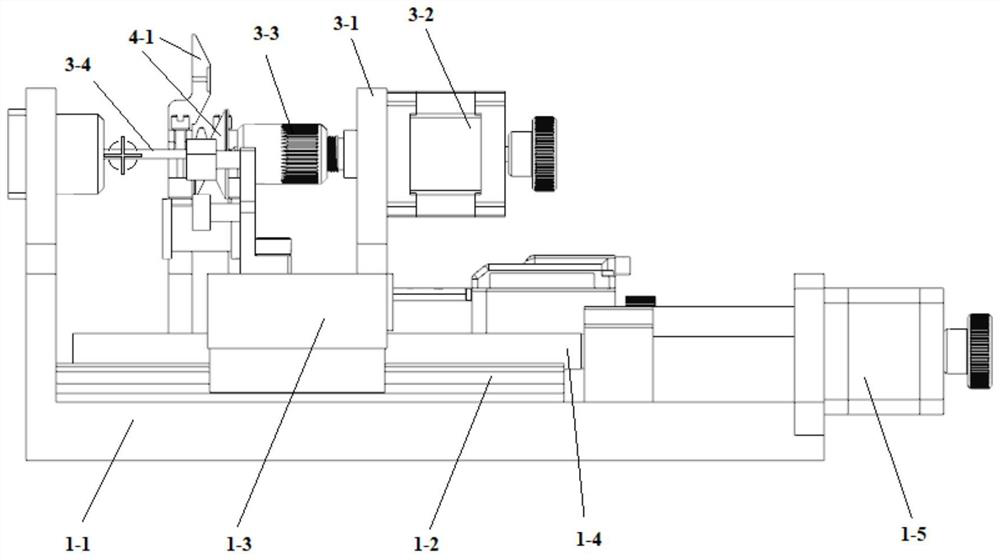

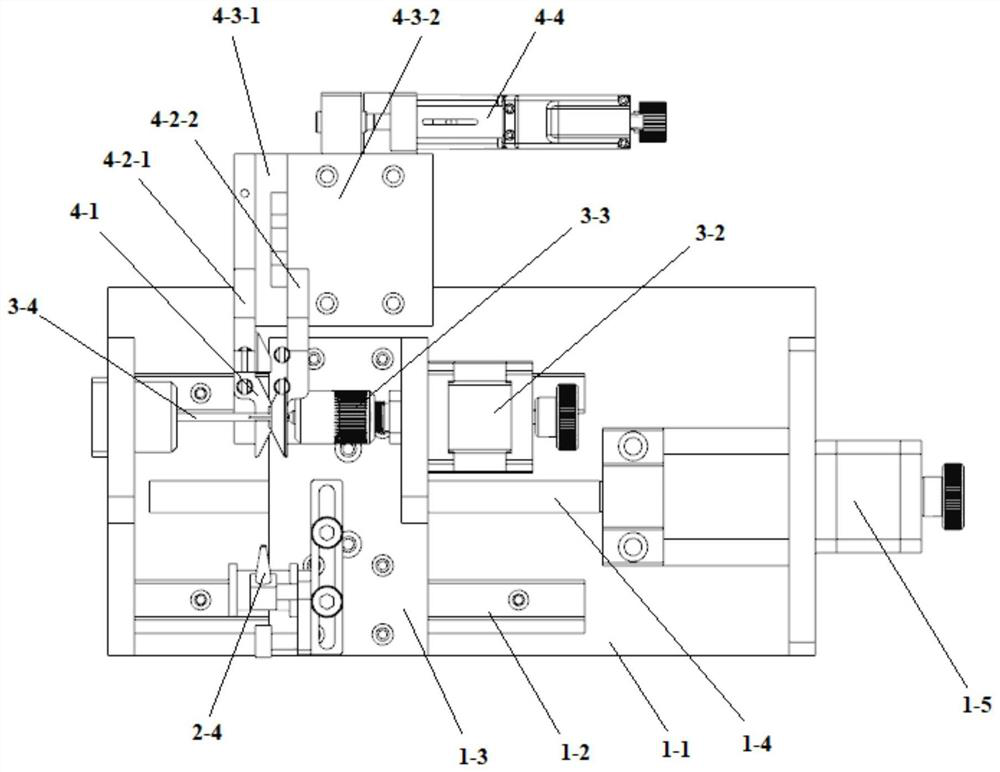

[0052] This embodiment provides a high-temperature-resistant displacement sensor probe manufacturing device based on a planar coil, which includes a displacement control unit 1, a wire feeding unit 2 and a winding drive unit 3 arranged on the displacement control unit 1, and can communicate with the winding drive unit 3. Disassemble and install the planar coil fixing unit 4; the displacement control unit 1 includes a base 1-1, a slide rail 1-2 located on the base 1-1, which is installed on the slide rail 1-2 and can move along the slide rail 1-2 The moving displacement platform 1-3, the displacement shaft 1-4 that runs through the displacement platform 1-3 and is parallel to the slide rail 1-2, and the motor 1-5 connected with the displacement shaft 1-4; the wire feeding unit 2 includes a The fixed seat 2-1 on the displacement platform 1-3, the large wire wheel 2-2, the small wire wheel 2-3 and the wire feeding cone 2-4 located on the fixed seat 2-1; the winding drive unit 3 in...

Embodiment 2

[0062] This embodiment provides a method for manufacturing a high-temperature-resistant displacement sensor probe based on a planar coil. The method uses the device in Embodiment 1 for manufacturing, and specifically includes the following steps:

[0063] Step 1: Wrap the metal wire, the raw material of the planar coil, on the large wire wheel, pass through the wire feeding cone after being tensioned by the small wire wheel, and pass the metal wire through the through hole of the fixing clip along the winding shaft and fix it on the winding shaft ;

[0064] Step 2: Adjust the position of the wire feeding unit and the winding drive unit through the motor; then adjust the relative position of the fixed clip and the winding shaft in the planar coil fixing unit through the displacement controller, so that the winding shaft passes through the through hole of the fixed clip ;

[0065] Step 3: Adjust the position between the first bracket and the second through the displacement cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com