Patents

Literature

123results about How to "Solve the packaging problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741AHigh quality light weight, compressive strengthLight in massCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

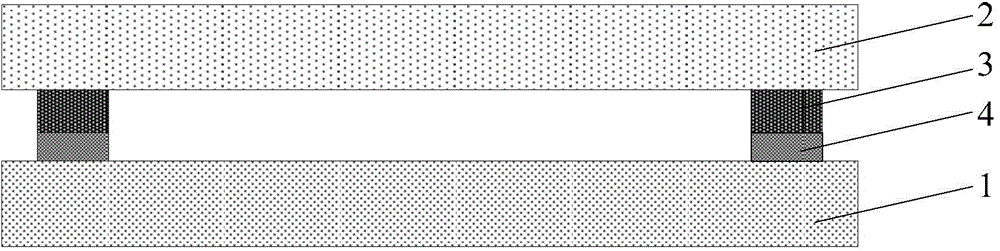

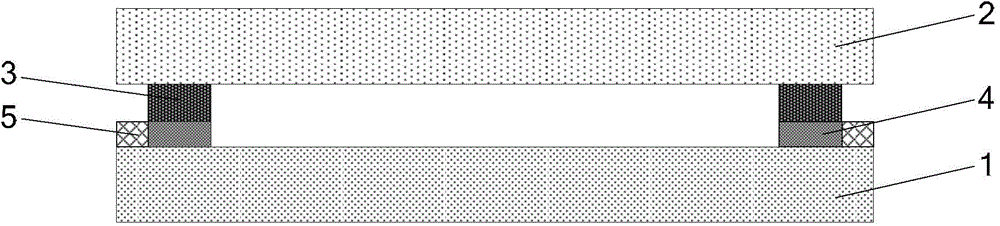

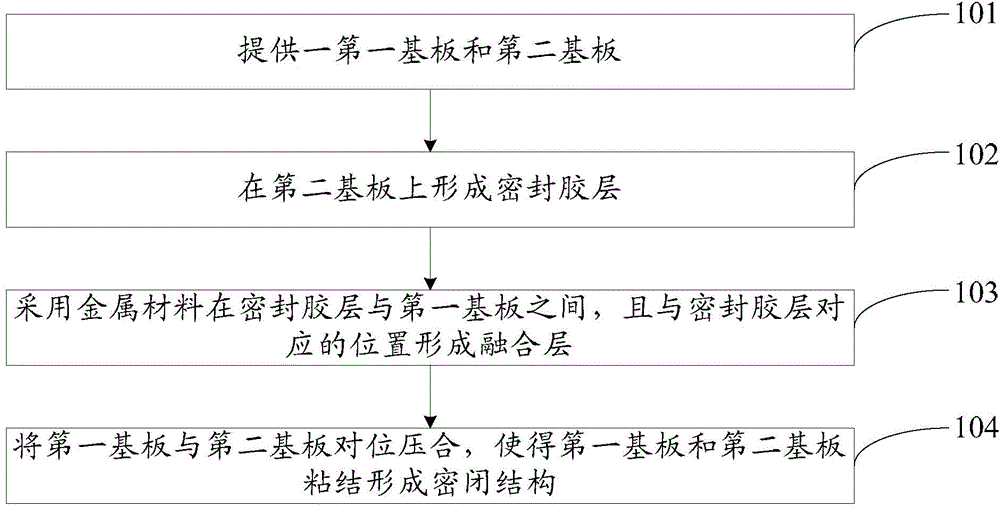

Display panel and production method thereof and display device

ActiveCN104617128ASolve the packaging problemReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMetallic materials

An embodiment of the invention provides a display panel and a production method thereof and a display device and relates to the display technical field. The problem that the encapsulation of encapsulation substrates and array substrates of display panels can only be implemented through special glass materials by special a method is solved, the production cost is reduced, the production time is reduced, and accordingly the production efficiency is improved. The display panel comprises a first substrate and a second substrate which is opposite to and attached to the first substrate; a sealing glue layer is arranged between the first substrate and the second substrate; the sealing glue layer is used for bonding the first substrate and the second substrate to form a closed structure; the display panel also comprises a fusing layer which is arranged between the sealing glue layer and the first substrate corresponding to the sealing glue layer; the fusing layer is formed by metal materials. The display panel and the production method thereof and the display device are applied to the production technical process of the display panel.

Owner:BOE TECH GRP CO LTD

Novel predatory mite production method

ActiveCN104222011ASolve mass feedingSolve Collection IssuesHorticulture methodsAnimal husbandryCollection methodsOrganism

The invention relates to a novel predatory mite production method. The novel predatory mite production method is characterized by including a spider mite breeding method, first-time breeding and continuous breeding methods for predatory mites, a predatory mite separating collection method, a predatory mite packaging method and a cultivating matrix treatment and reutilization method. The novel predatory mite production method has the advantages that the problem about mass breeding of the predatory mites is solved, the method is time saving, labor saving and simple and convenient to operate, breeding cost can be reduced by at least 10% once again, and a great quantity of predatory mite resources can be provided for biological prevention and control of pests.

Owner:SAFE BEST & NECESSARY BEIJING BIOTECH CO LTD

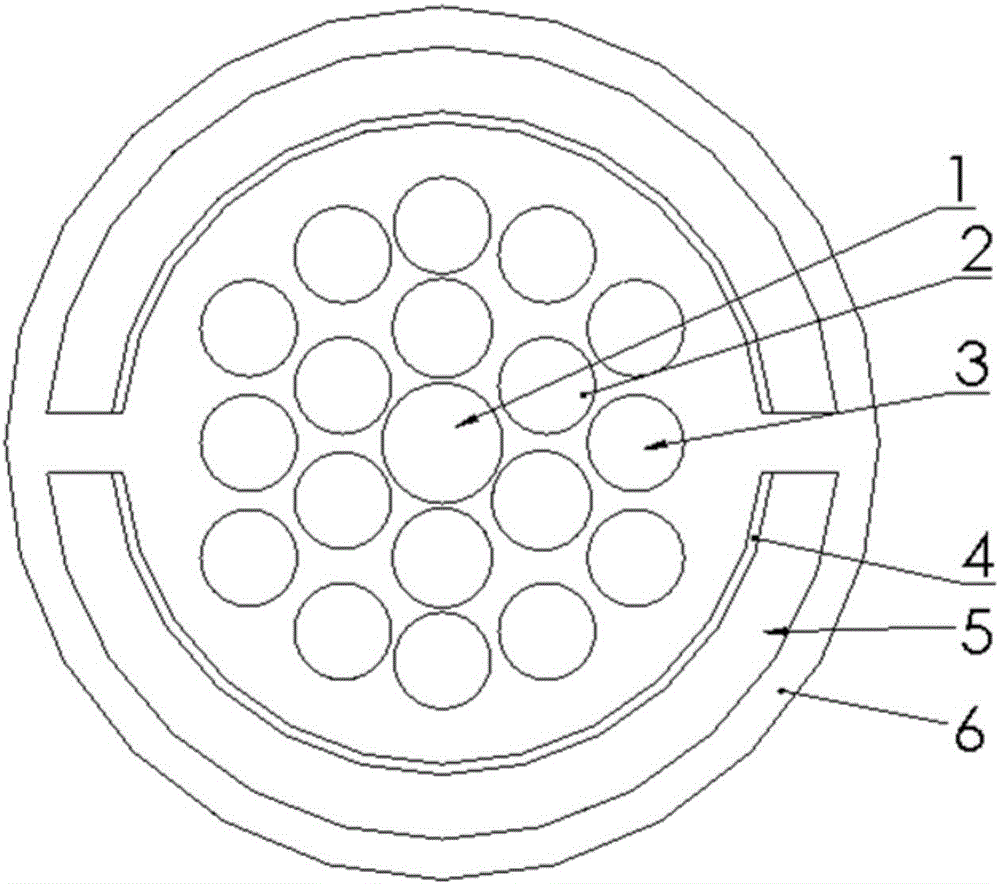

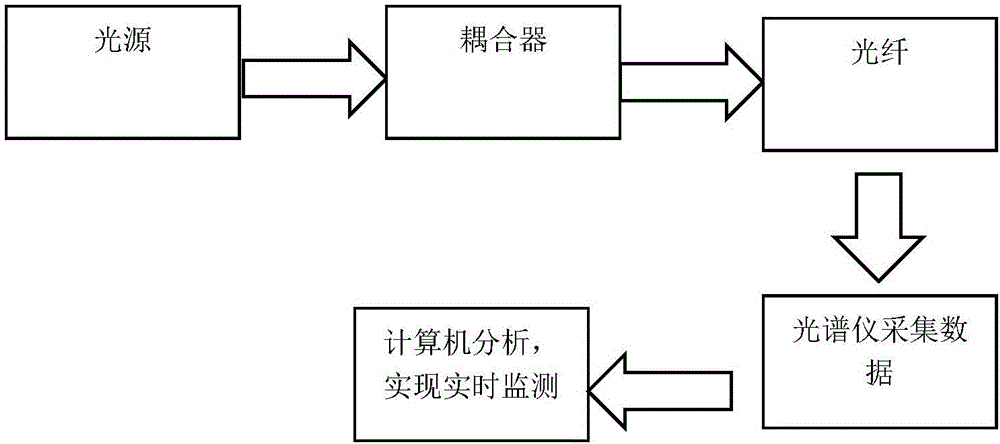

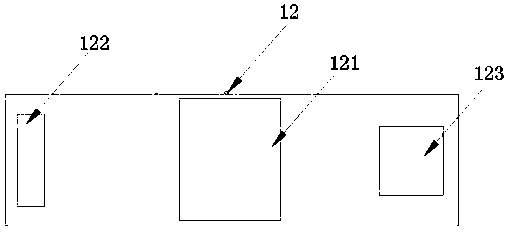

Optical fiber sensor and device based on plasma resonance

InactiveCN106770057AStable structureEasy to manufactureMaterial analysis by optical meansLiquid mediumPlasma resonance

The invention discloses an optical fiber sensor and device based on plasma resonance. The optical fiber of the sensor is internally provided with a plurality of layers of air holes, and the air holes include a central air hole, a first air hole layer, a second air hole layer and a fan annular air hole which are formed from inside to outside, wherein each of the first air hole layer and the second air hole layer contains a plurality of independent air holes; the central air hole is formed in the center of the optical fiber, the first air hole layer, the second air hole layer and the fan annular air hole are arranged symmetrically with the central air hole as a symmetrical center, each of the first air hole layer and the second air hole layer has a hexagonal shape, and the side of the fan annular air hole, adjacent to the center, is coated with a film; and the central air hole and the second air hole layer are filled with air mediums, the first air hole layer is filled with a metal medium, and the fan annular air hole is filled with a liquid medium to be detected. The optical fiber sensor has the advantages of simple manufacture, high sensitivity and better comprehensive performance, the detection range of the sensor can be effectively enlarged, and wider application demands can be met.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Copolymer solid electrolyte for dye sensitized cell and production method thereof

InactiveCN101483104ASolve the packaging problemImprove thermal stabilityLight-sensitive devicesFinal product manufactureSensitized cellHYDROSOL

A polymeric compound solid electrolyte for dye sensitization batteries and method for making same, including a polymer matrix, a redox couple, a silicone hydride coupling agent containing isocyanate functional groups and functional groups capable of complexing with inorganic sol particles after hydrolyzing, and a metal alkoxy compound generating inorganic sol particles after hydrolyzing, wherein, the inorganic sol particles are complexed with the polymeric matrix through sol gel in situ compounding. In the inventive polymer solid electrolyte, the inorganic sol particles are uniformly dispersed in the polymer matrix, the polymer solid electrolyte has good heat stability, simple and unique preparation method, no requirement of complicated equipment, capability of effectively resolving the packaging problems of sensitization batteries, and good application foreground in the field of dye sensitization batteries.

Owner:上海拓引数码技术有限公司

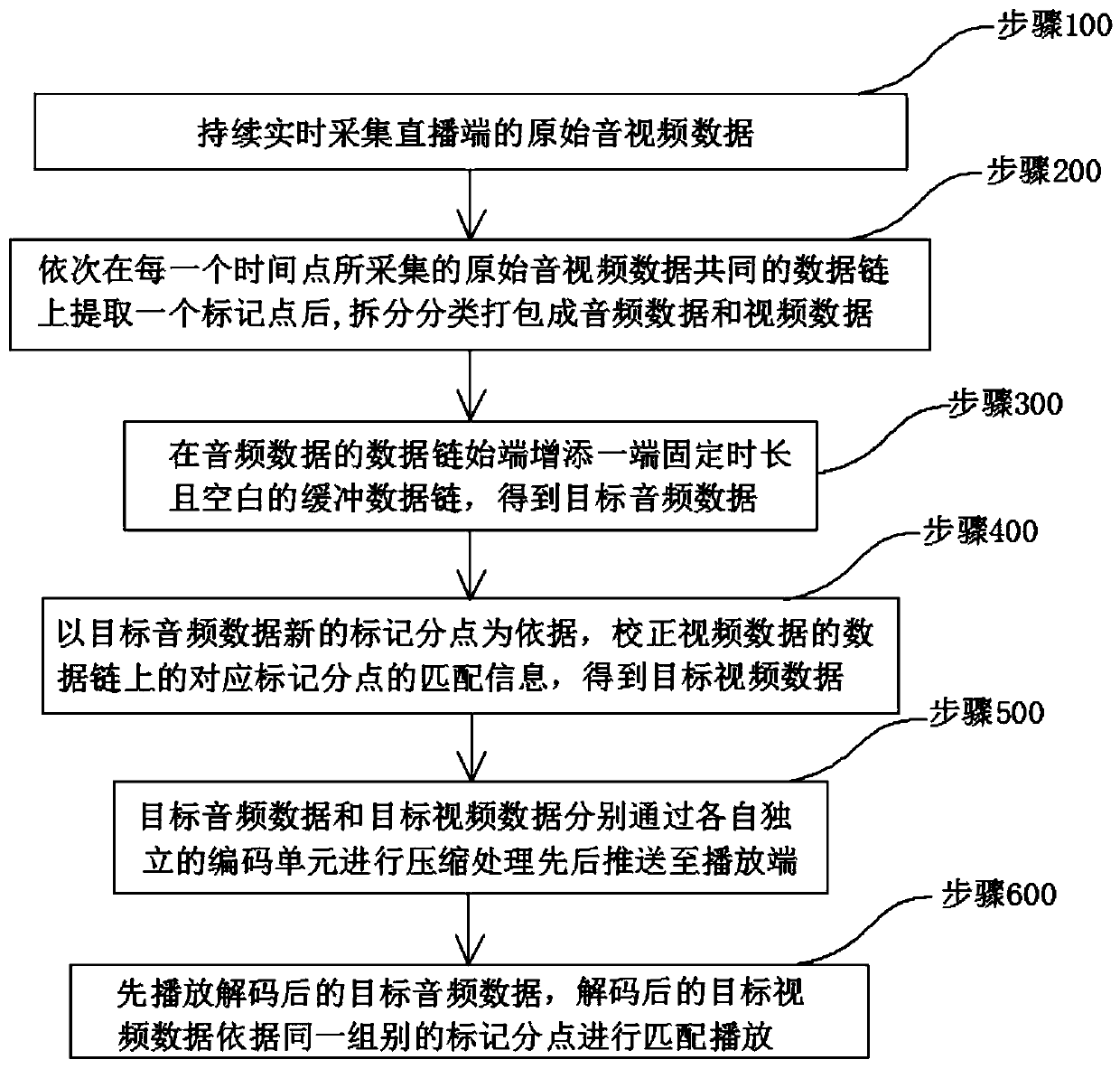

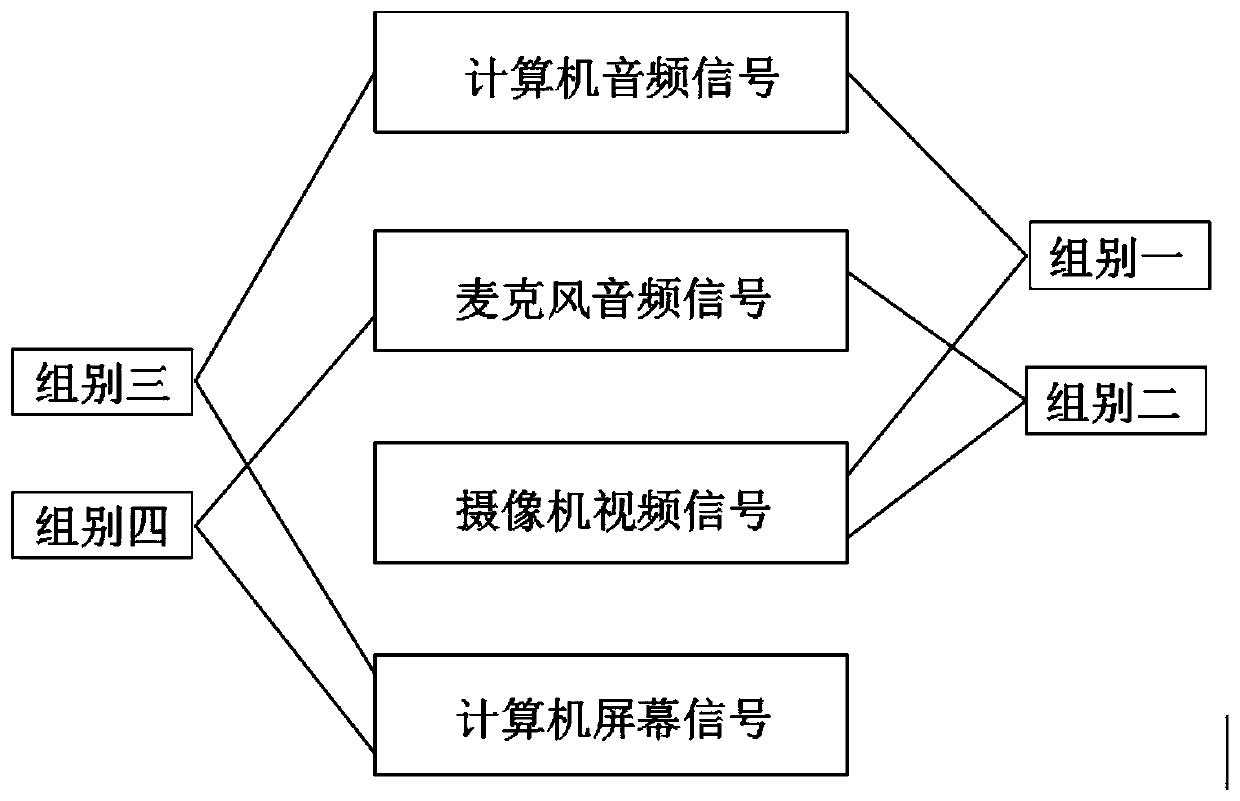

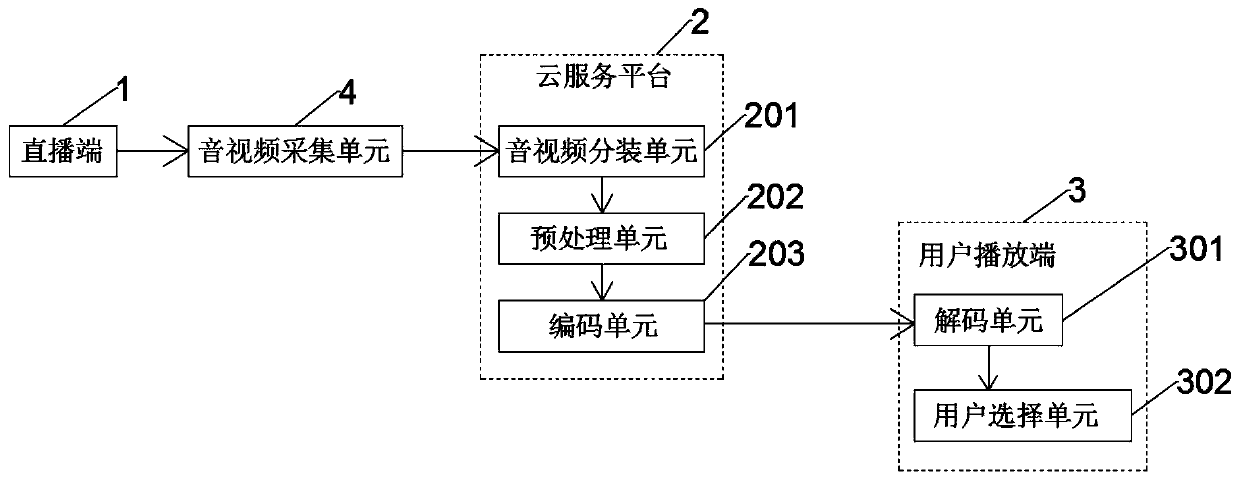

Data transmission method and transmission device for live video broadcasting

ActiveCN110072137AGuaranteed normal broadcastShorten the timeSelective content distributionFault toleranceComputer hardware

The embodiment of the invention discloses a data transmission method and a transmission device for live video broadcasting. The transmission method comprises the following steps: continuously collecting original audio and video data of a live broadcast end in real time; sequentially classifying and packaging the original audio and video data into audio data and video data on time, marking the datachains of the audio data and the video data as two groups according to the same position mark, and adding a buffer data chain with a fixed time length and a blank at the beginning end of the data chain of the audio data to obtain target audio data; remarking the video data corresponding to the target audio data to obtain target video data; the target audio and video data being compressed throughrespective independent coding units and being pushed to a playing end in sequence. According to the scheme, the audio signals and the video signals are classified, normal playing of video programs canbe guaranteed, the fault tolerance rate is increased, and intelligent scheduling is achieved.

Owner:湖南琴岛网络传媒科技有限公司

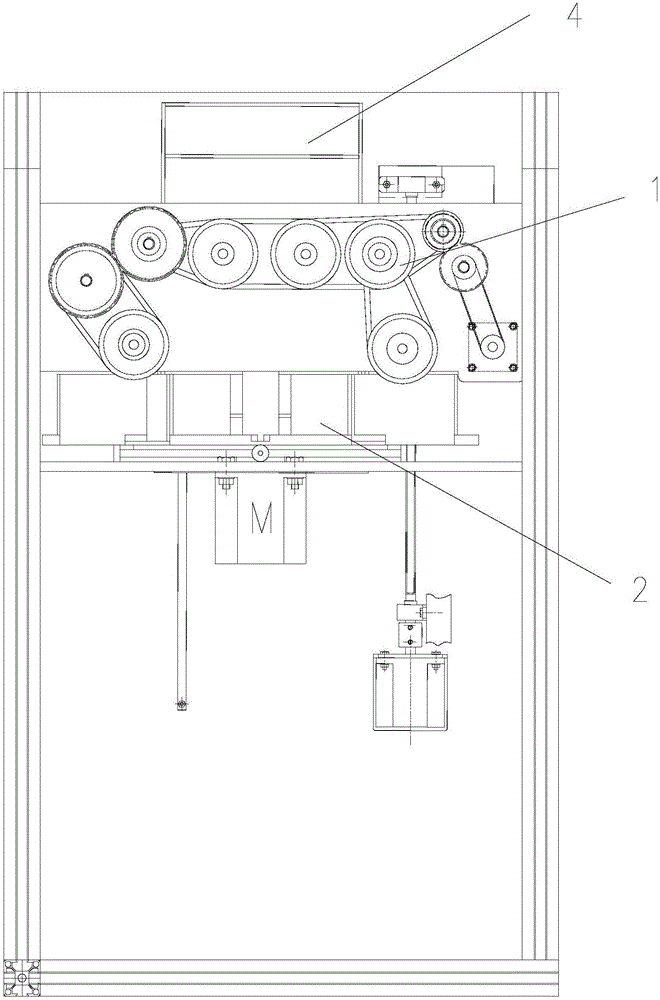

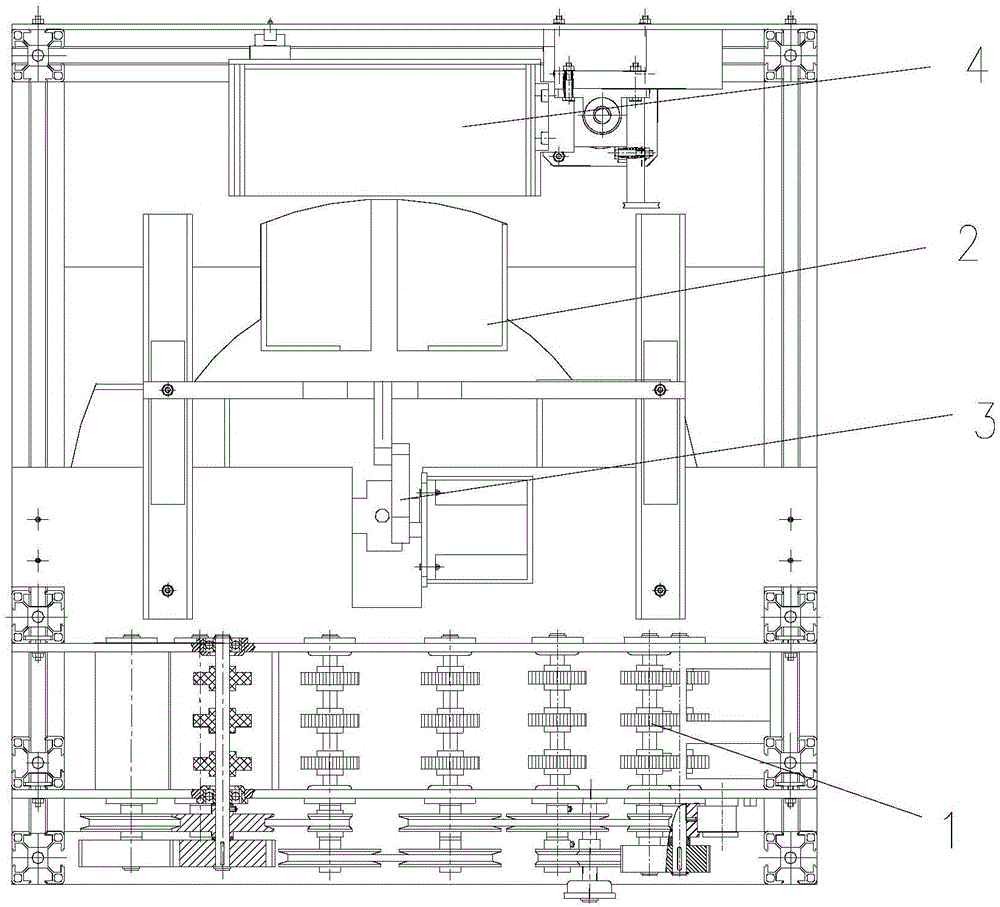

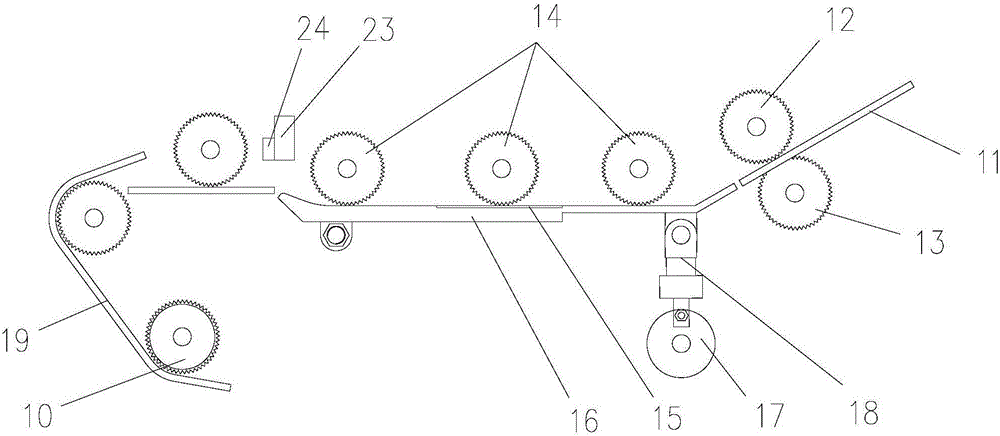

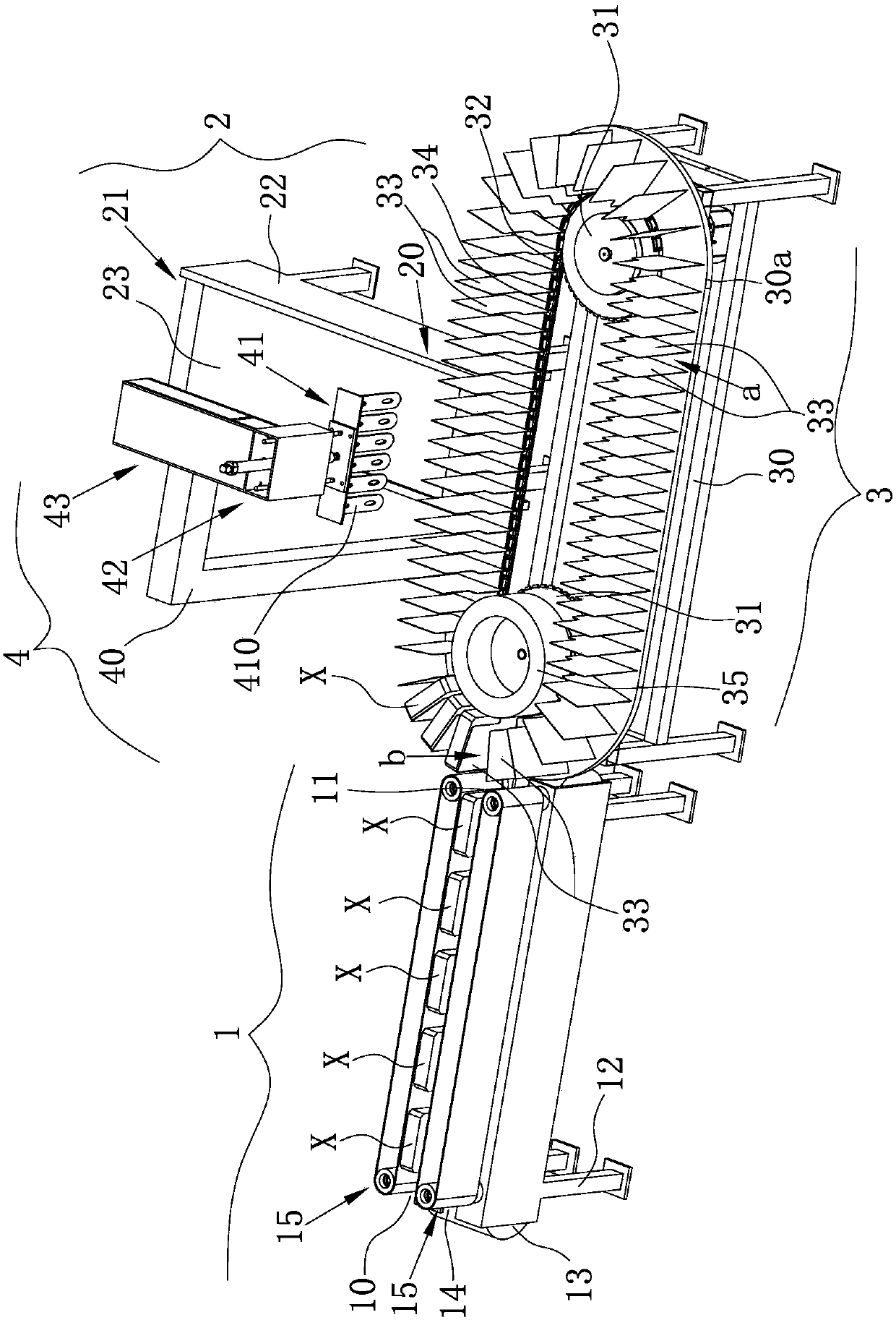

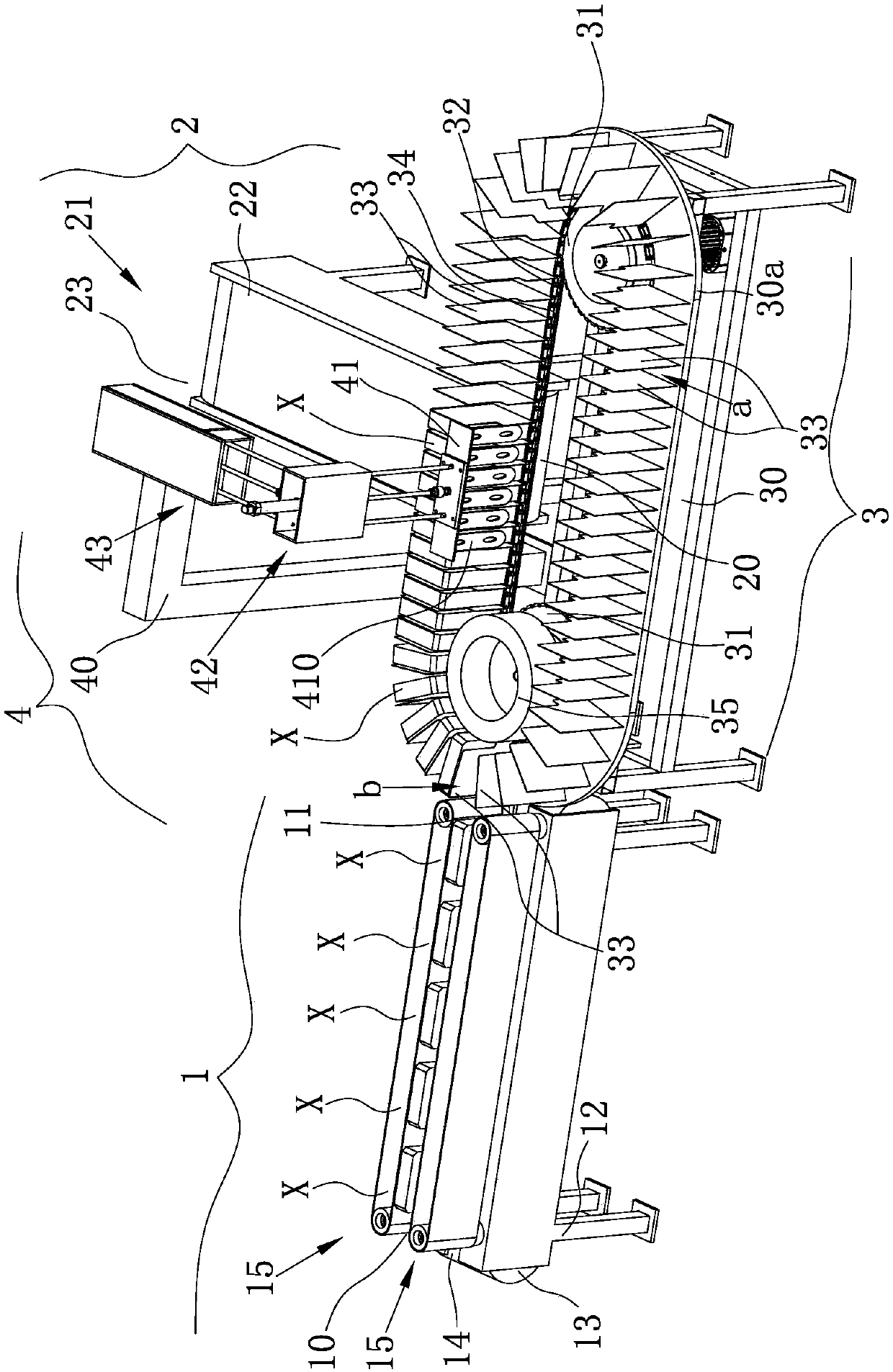

Intelligent fed-paper-money counting and sorting machine

ActiveCN105869273ATo achieve the initial flattening effectGuaranteed accuracyCoin/currency accepting devicesEngineeringHinge joint

The invention discloses an intelligent fed-paper-money counting and sorting machine, which comprises a frame, a bill input mechanism and a bill sorting mechanism, wherein the bill input mechanism and the bill sorting mechanism are mounted on the frame; the bill input mechanism comprises a bill input plate, a rocking plate and a bill output plate; the bill input plate and the bill output plate are fixedly arranged on the frame; the rocking plate is connected between an outlet end of the bill input plate and an inlet end of the bill output plate; an outlet end of the rocking plate is connected onto the frame in a hinging manner; the bottom of an inlet end of the rocking plate is connected with a rocking mechanism; the rocking mechanism drives the rocking plate to move up and down along a hinge joint; multiple groups of rocking plate bill twiddling wheel sets are arranged above the rocking plate; when the inlet end of the rocking plate rises to a highest position, the rocking plate is in contact with the rocking plate bill twiddling wheel sets; multiple bill output bill twiddling wheel sets are mounted above the bill output plate; the outlet end of the bill output plate is provided with bill output wheels; paper money is guaranteed to be capable of being conveyed from the outlet end of the bill input plate to the bill output wheels at the outlet end of the bill output plate by intervals between every two adjacent rocking plate bill twiddling wheel sets, an interval among the rocking plate bill twiddling wheel sets and the bill output bill twiddling wheel sets and intervals between every two adjacent bill output bill twiddling wheel sets. By using the intelligent fed-paper-money counting and sorting machine, the pretreatment can be carried out on wrinkled and superimposed paper money; the process of manually collecting and arranging the paper money is greatly saved; the labor cost is saved.

Owner:HUNAN UNIV

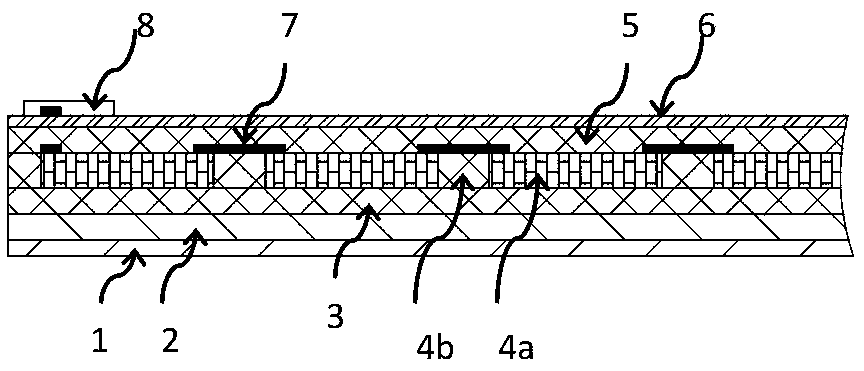

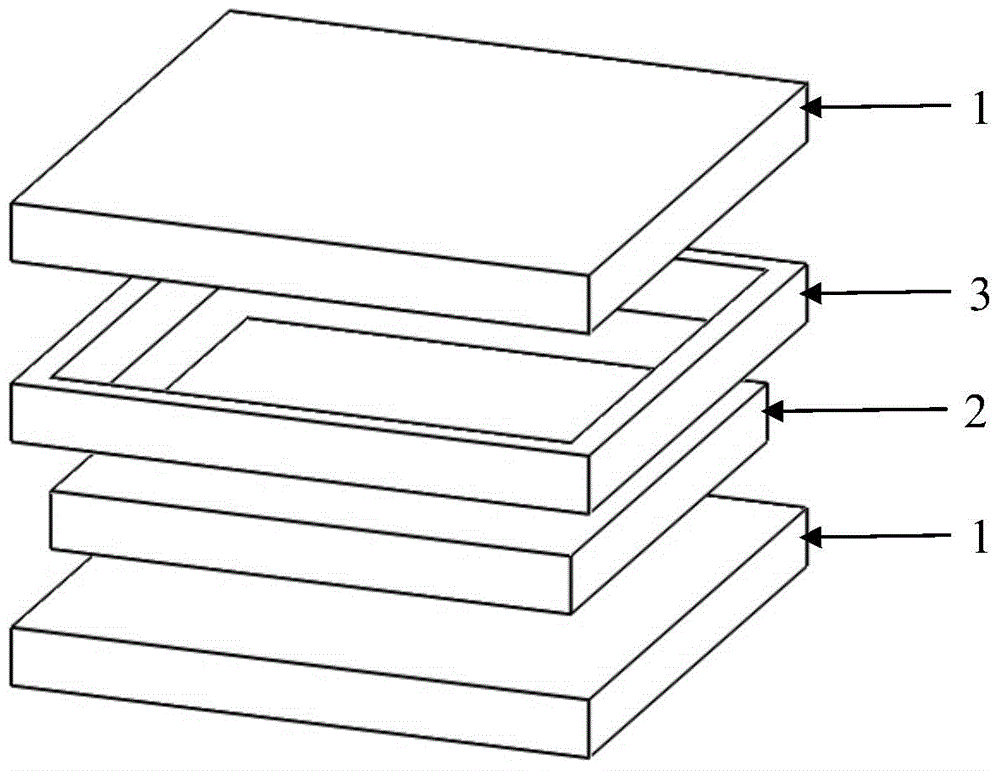

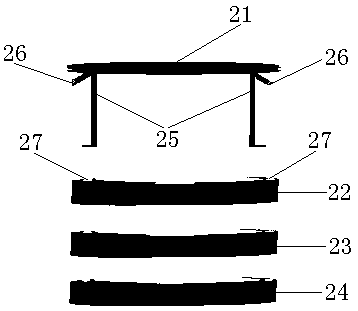

Photovoltaic module based on perovskite solar cells and packaging method thereof

ActiveCN108922973AIncrease power generationImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEngineering

The invention provides a photovoltaic module based on perovskite solar cells and a packaging method thereof. The photovoltaic module comprises a laminated piece and a frame arranged around the laminated piece, wherein the laminated piece comprises a protection layer, a first bonding layer, a perovskite solar cell string, a filling layer, a second bonding layer and a back plate layer which are overlapped in order, the perovskite solar cell string comprises a plurality of perovskite solar cells, a bottom electrode of one cell is connected with a top electrode of an adjacent cell, or bottom electrodes of adjacent two cells are connected and top electrodes of the adjacent two cells are connected, and a space between the adjacent cells is filled with the filling layer.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

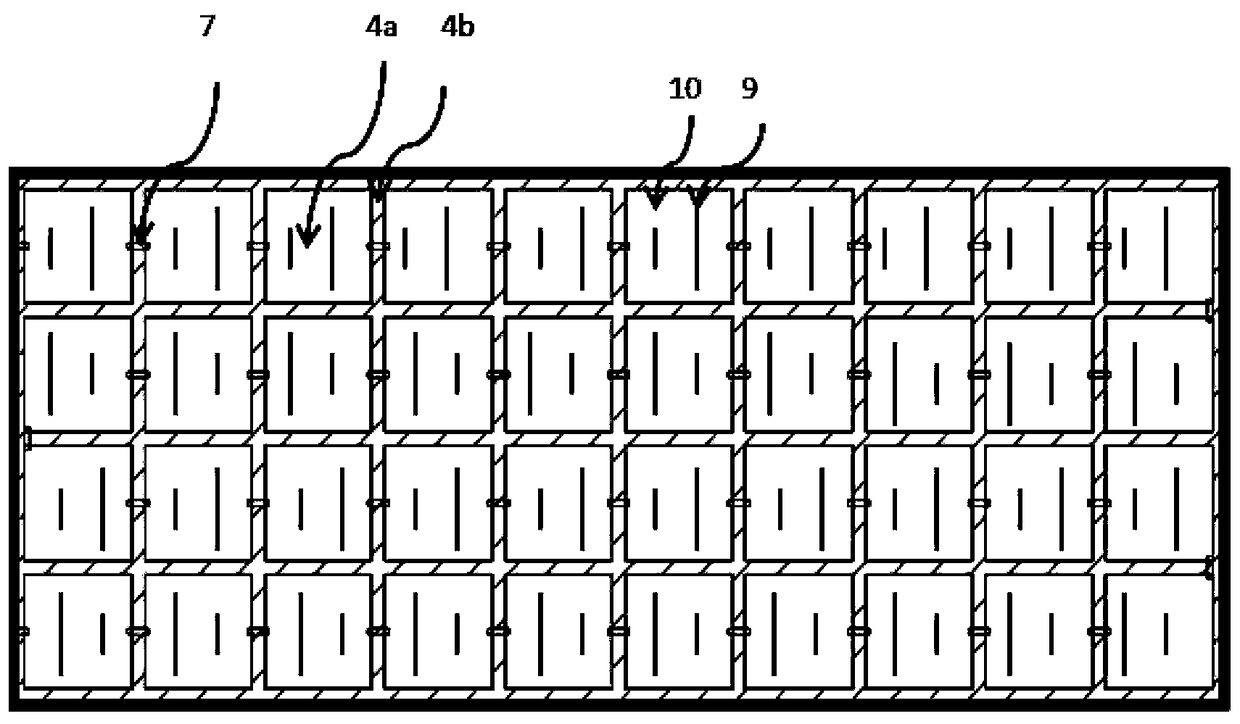

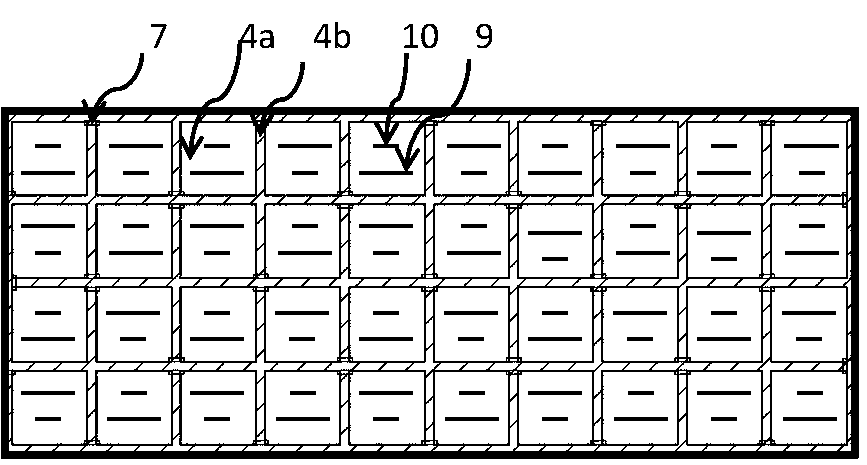

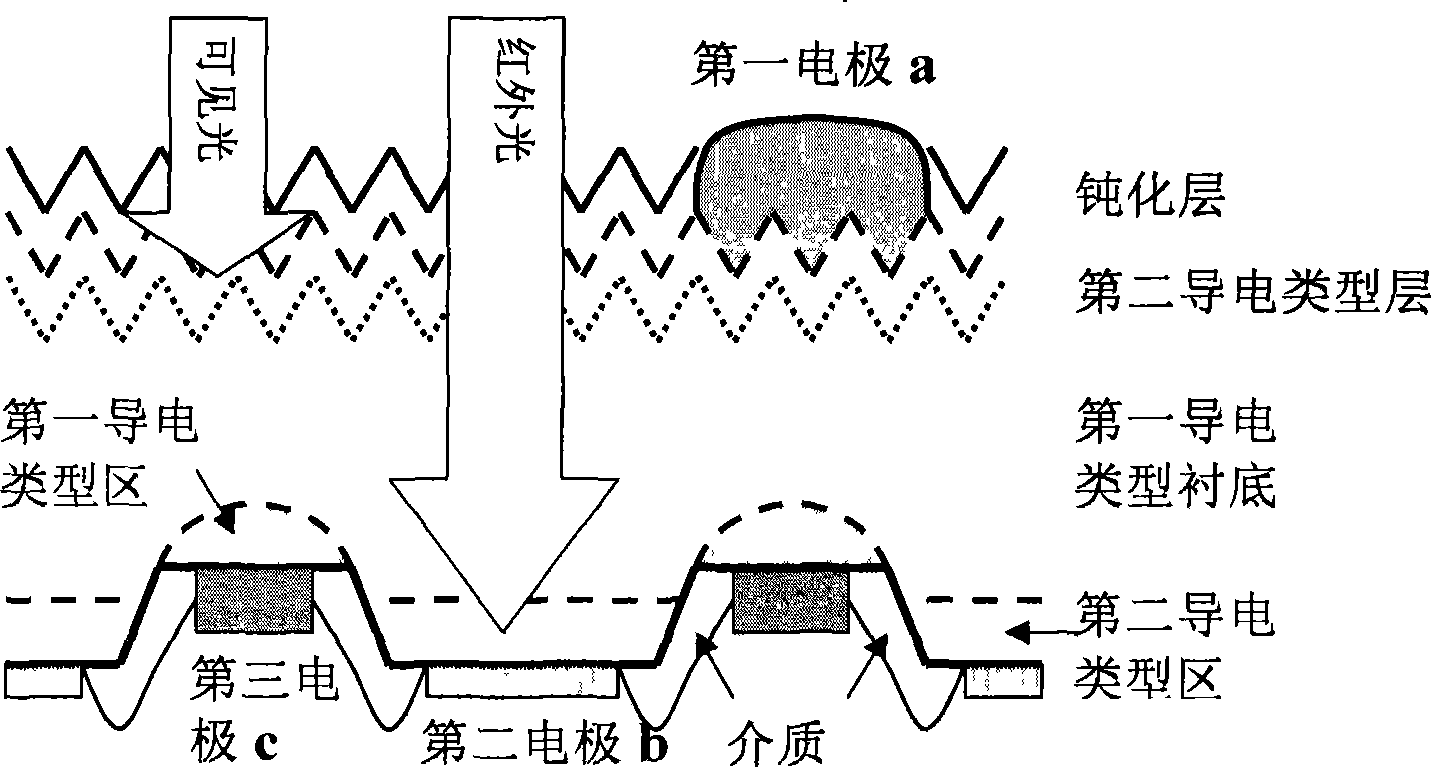

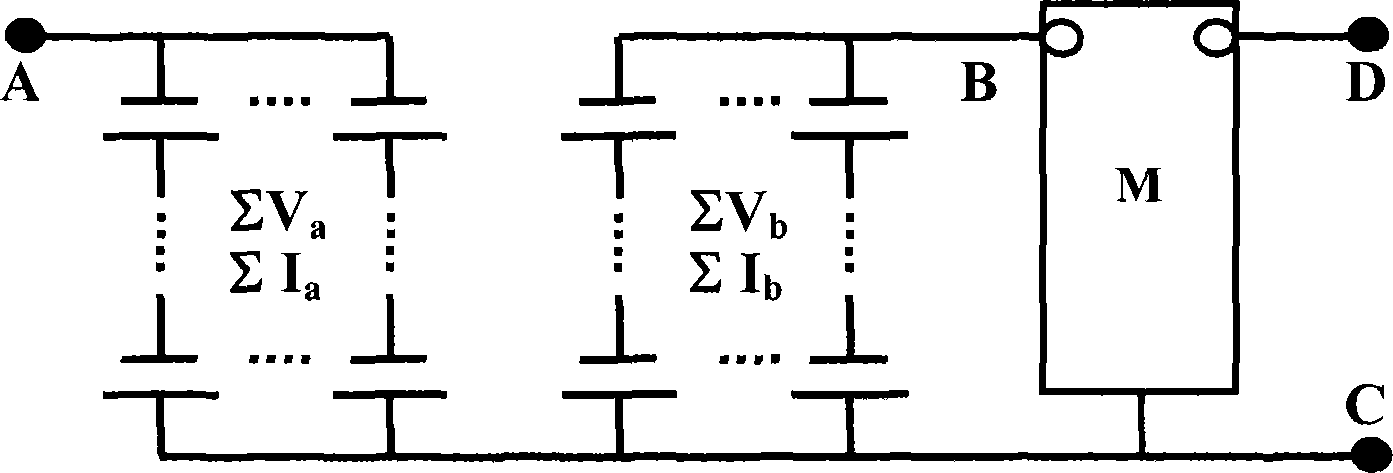

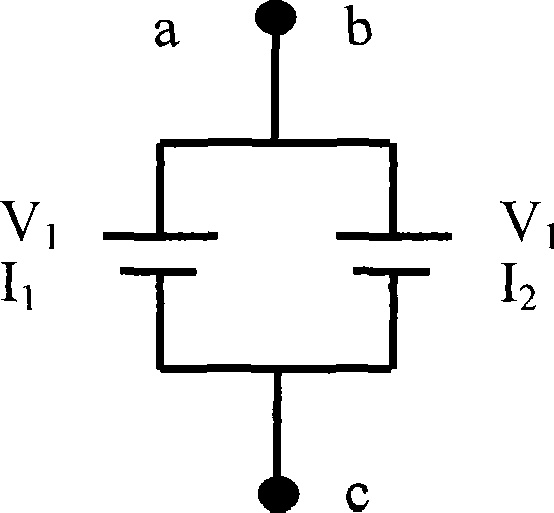

Binode solar battery and preparation method thereof

InactiveCN102054889AImprove photovoltaic efficiencyPromote absorptionFinal product manufacturePhotovoltaic energy generationCharge carrierEngineering

The invention discloses a binode solar battery and a preparation method thereof. The binode solar battery comprises a first conduction type substrate; a light-receiving surface second conduction type layer and a medium passivation layer which are sequentially arranged on the light-receiving surface of the first conduction type substrate, wherein the surface of the medium passivation layer is a matte surface; a back light surface second conduction type area and a back light surface first conduction type area which are alternately formed on the back light surface of the first conduction type substrate; a first electrode which is formed on the light-receiving surface second conduction type layer; a second electrode which is formed on the back light surface second conduction type area; a third electrode which is formed on the back light surface first conduction type area; and a back light surface insulating medium layer which is formed between the second electrode and the third electrode. By adopting the invention, the contradiction between sufficient light absorption and limited diffusion distance of a small amount of current carriers is avoided, and the inconsistent contradiction between the light absorbing area and the current carrier collecting area of back contact battery is avoided, thereby improving the battery efficiency.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

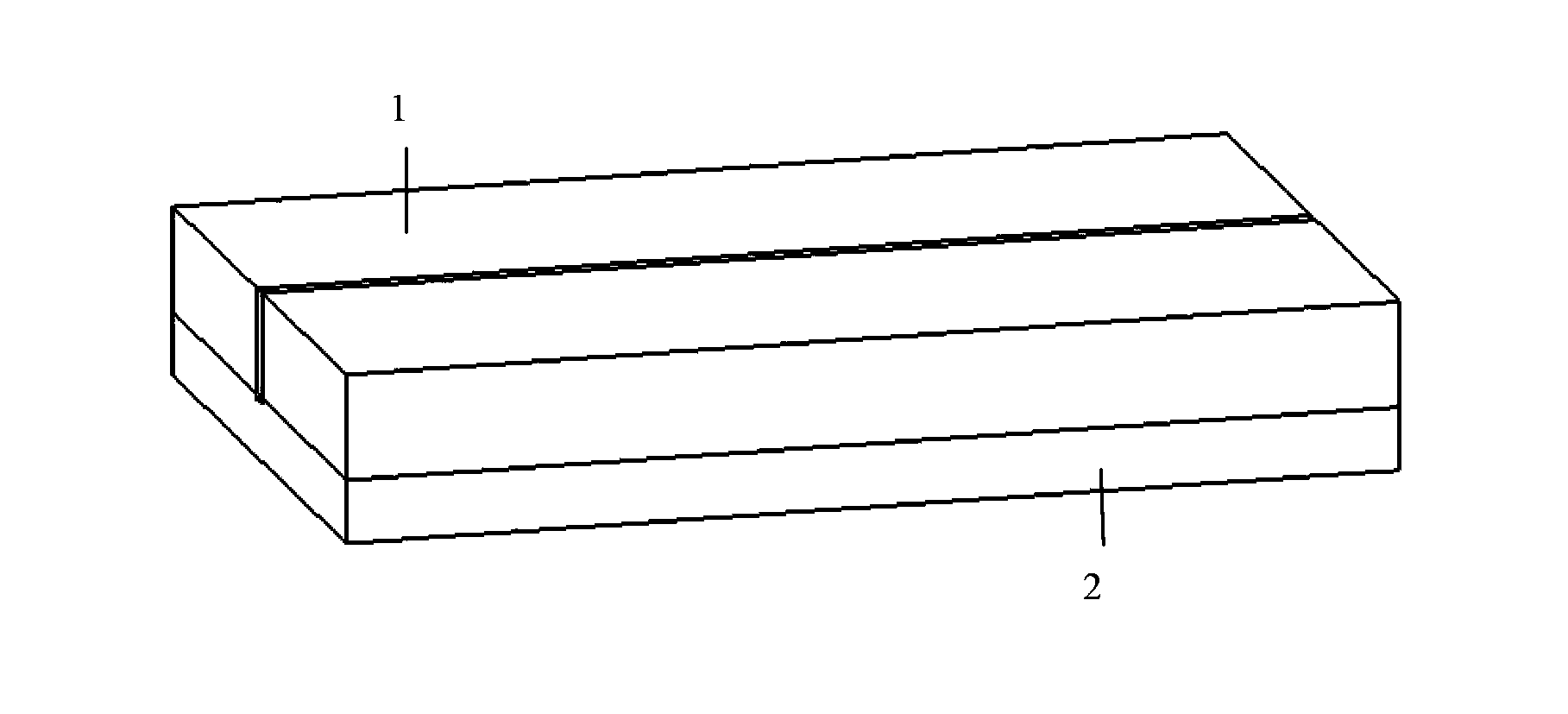

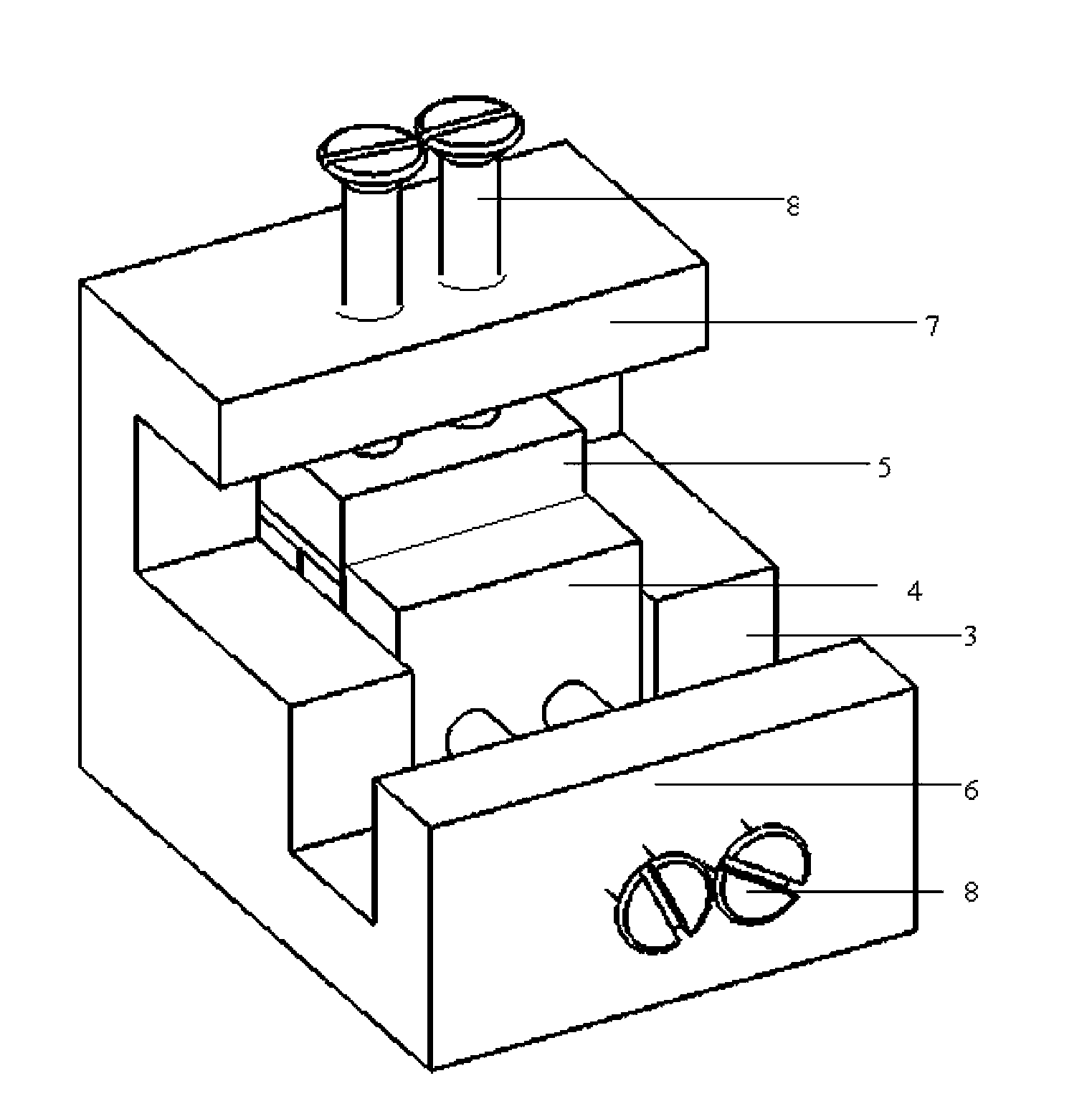

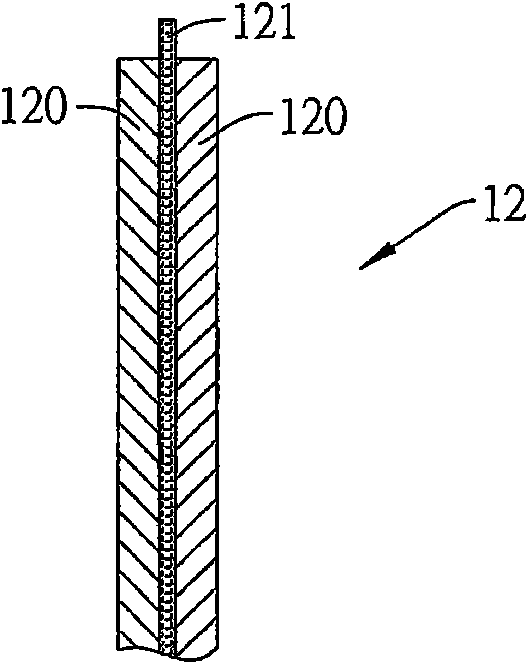

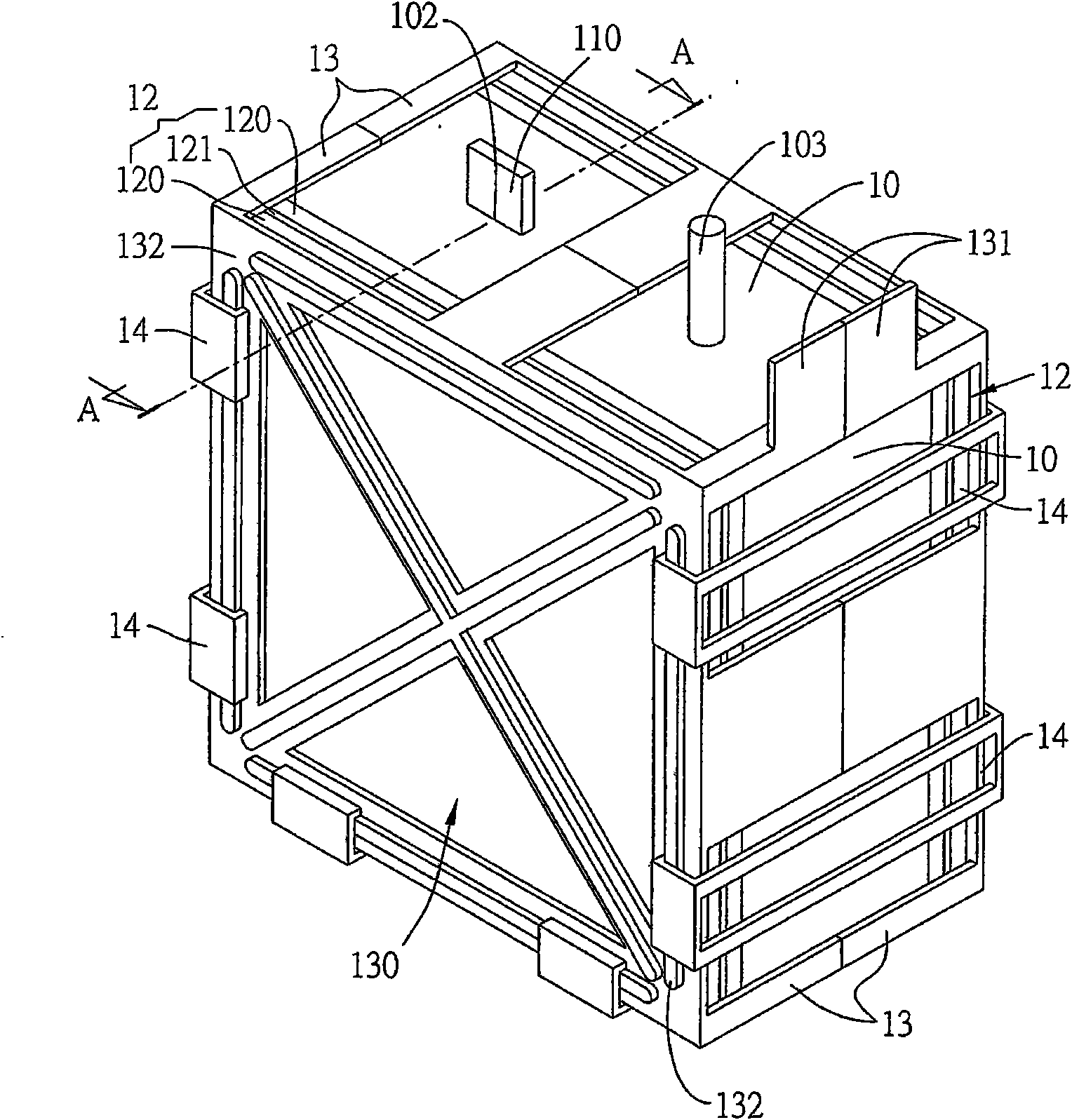

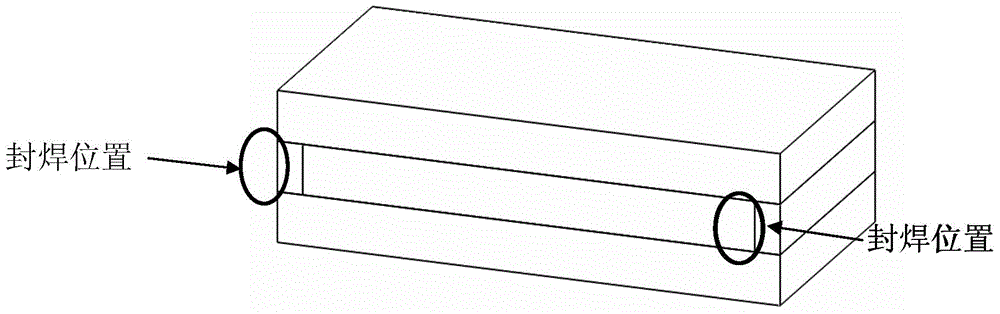

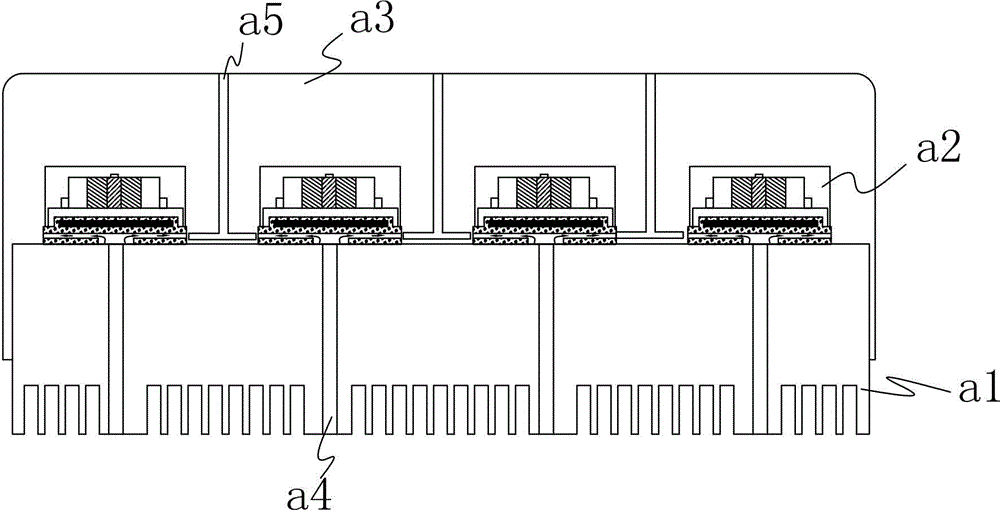

Double-sided packaging method of high-power laser bar and sintering fixture used for high-power laser bar packaging

ActiveCN104078834AAchieve double-sided sinteringAvoid the smile phenomenonLaser detailsSemiconductor laser structural detailsPunchingHigh power lasers

The invention relates to a double-sided packaging method of a high-power laser bar. The method comprises the following steps that (1) the end face of the light-emitting surface of the high-power laser bar is made to be flush with the end faces of the side faces of two first heat sinks through punching along a sintering fixture; (2) one of the first heat sinks is welded onto one side face of the high-power laser bar, and the other first heat sink is welded onto the other side face of the high-power laser bar; in the welding process, the sintering fixture is used for making the two first heat sinks to be flush with each other and clamping the two first heat sinks. According to the double-sided packaging method of the high-power laser bar, the light-emitting surface of the high-power laser bar is perpendicular to the sintering fixture and is tightly attached to a heating body of the sintering fixture downwards, therefore, the light-emitting surface of the high-power laser bar is completely flush with the edges of the first heat sinks, and the smile phenomenon caused due to the fact that thermal stress is not well processed is effectively avoided. The packaging method can be used for horizontal GS stacks and can also be used for vertical arrays, and the application range is relatively wide.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Battery device and packaging, dismounting and recovering method of same

InactiveCN101944623AEasy to packFast packFuel and primary cellsFuel cells disposal/recyclingRecovery methodBiochemical engineering

The invention relates to a battery device and a packaging, dismounting and recovering method of same. The method comprises the following steps of: firstly, arranging an anode conducting assembly in a reaction tank frame, and protruding an anode conducting bump out of the reaction tank frame; subsequently, respectively covering a first opening and a second opening of the reaction tank frame by using two groups of cathode conducting assemblies to form a reaction area capable of accommodating electrolyte; subsequently, laying a metal fixing part on the surfaces of the cathode conducting assemblies and the reaction tank frame; and finally, fastening the metal fixing part by using a fastener. Thus, the battery device provided by the invention for a user has the characteristics of simple structure, rapid packaging, dismountability and recyclability through special structural design, and thus, the problems of difficult packaging and dismounting, difficult recovering and the like caused by complex structure of the traditional battery device are solved.

Owner:OPEN MINDER GROUP

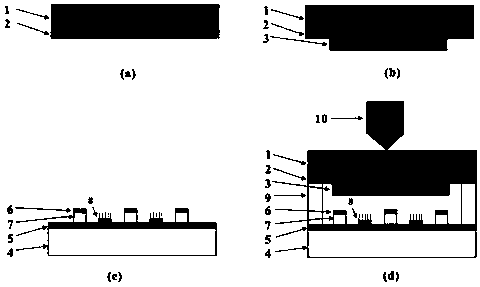

Method for directly manufacturing cold cathode flat plate X-ray detector on scintillator and structure thereof

ActiveCN109346488ASolve integrationSolve the packaging problemSolid-state devicesRadiation controlled devicesElectrical conductorAnode

The invention discloses a method for directly manufacturing a cold cathode flat plate X-ray detector on a scintillator. The method comprises the following process steps of (1) preparing an anode electrode on the scintillator; (2) preparing a photoconductor on the anode electrode; (3) preparing a cold cathode substrate; (4) mutually insulating and fixing one side, which is prepared with the photoconductor, of the scintillator and one side, which is prepared with a cold cathode, of the cold cathode substrate through an isolator; and (5) retaining a vacuum state between the scintillator and the cold cathode substrate. The invention simultaneously discloses the cold cathode flat plate X-ray detector prepared by the abovementioned method. The scintillator in the invention possesses the functionof a substrate support and the function of converting an X-ray into a visible light; photon scattering can be effectively avoided; the problem of integration of the scintillator on the X-ray detectoris solved; and the X-ray imaging function can be implemented by use of an addressable cold cathode electron source.

Owner:SUN YAT SEN UNIV

Packaging method of wide cold-rolling stainless steel coil

ActiveCN101693480AImprove packaging qualitySo as not to damageFlexible coversWrappersCardboardEngineering

The invention relates to a packaging method of a wide cold-rolling stainless steel coil, aiming at improving the packaging quality of the wide stainless steel coil. The packaging method comprises the following steps: selecting an inner paper angle protector and an outer paper angle protector according to the size of the inner diameter and the outer diameter of the coil; respectively wrapping one circle of paper angle protector on the inner ring and the outer ring of the coil; filling a cardboard tube in an inner core of the coil; selecting a packaging plastic cloth cover according to the size of the outer diameter of the coil, completely wrapping the coil with wire-adding film-laminating compound paper; wrapping an inner protection board and then wrapping an outer inner protection board; wrapping an inner protection angle and an outer protection angle and protection boards at two side ends, wherein the inner protection angle and the outer protection angle are made of cold-rolling galvanized plates, and according to the coil weight, the quantity of coil core-passing belts is 5-6 when the coil weight is more than 5t, and the quantity of coil core-passing belts is 3-4 when the coil weight is less than or equal to 5t; and wrapping 3-5 packaging belts in the circumference direction of the coil, wherein two belts must be wrapped on an outer protection angle ring, and the left are uniformly wrapped on the outer protection board.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

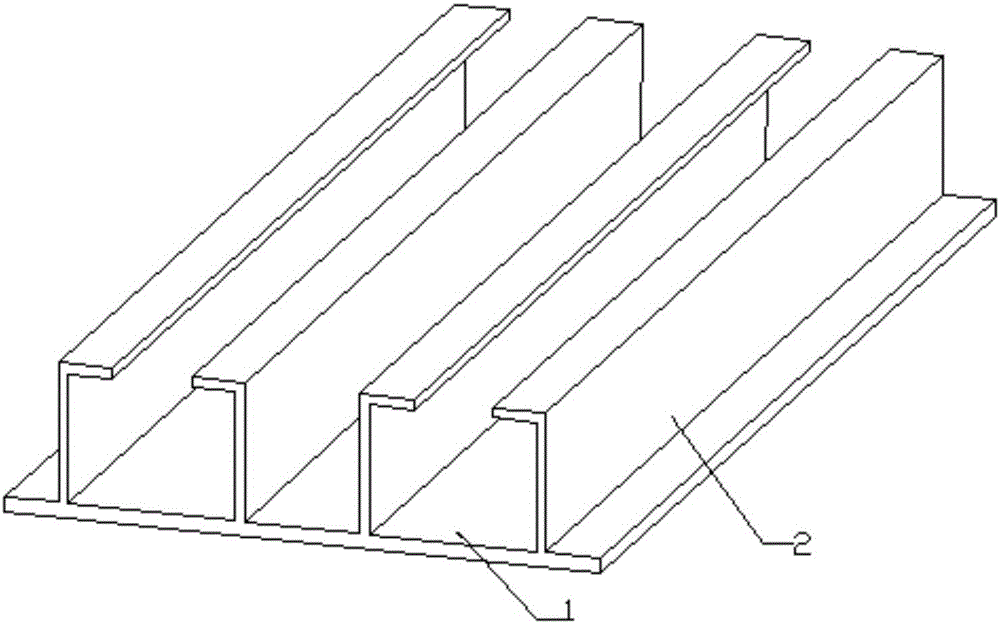

Encapsulation method for integral molding of stringer panel structure

The invention belongs to a resin-based composite material molding technology, and relates to an encapsulation method for integral molding of a stringer panel structure. For the stinger panel structure which cannot be encapsulated without being opened after stringer molds are assembled, before a stringer upper flange shape mold is assembled, an auxiliary material and a vacuum film which are arranged between stringers are positioned between the stringers in advance to be attached to the mold, and after the edges of the two sides of the vacuum film are sealed, the two ends are reserved to be sealed with the outer side vacuum film, namely, the panel shape mold after the mold assembling is completed; the problem that after the upper flange shape mold is assembled, a non-opening area of a cavity between the stringers cannot be encapsulated is solved, and the auxiliary material and vacuum film bridging phenomenon caused by the fact that vacuumizing cannot be operated after encapsulation is avoided.

Owner:AVIC COMPOSITES

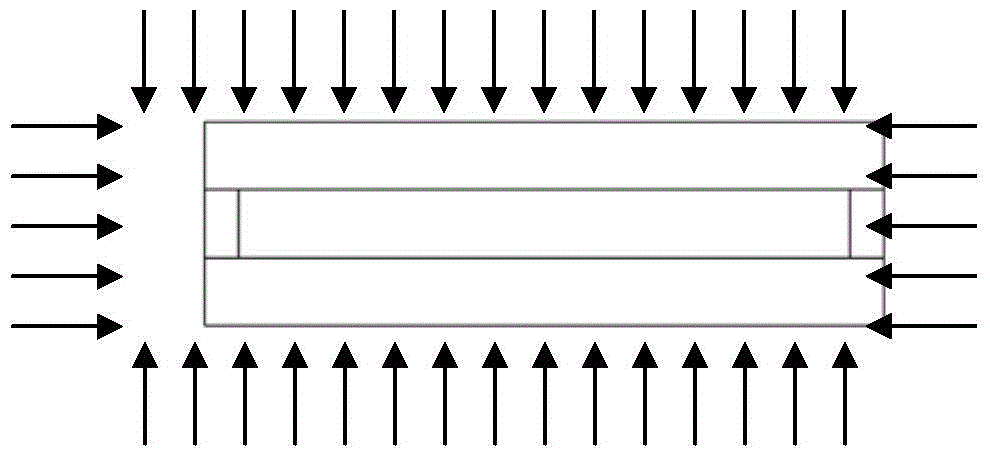

Cu-W/Cu-Cu composite board preparation method

InactiveCN104625623AHigh thermal conductivityImproved coefficient of thermal expansionBinding forceNanotechnology

The invention provides a Cu-W / Cu-Cu composite board preparation method. According to the method, based on sealing weld and hot isostatic pressure technologies, structure optimization is conducted on sandwich composite materials, and finally near-net formed products are prepared. The Cu-W / Cu-Cu composite board preparation method is short in technological process, near-net in forming, especially suitable for large-scale industrial production and high in composite interlamination binding force, the strength and thermal property of the composite materials are guaranteed effectively, and the heat dissipation problem of high-dissipation-power electronic devices can be solved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

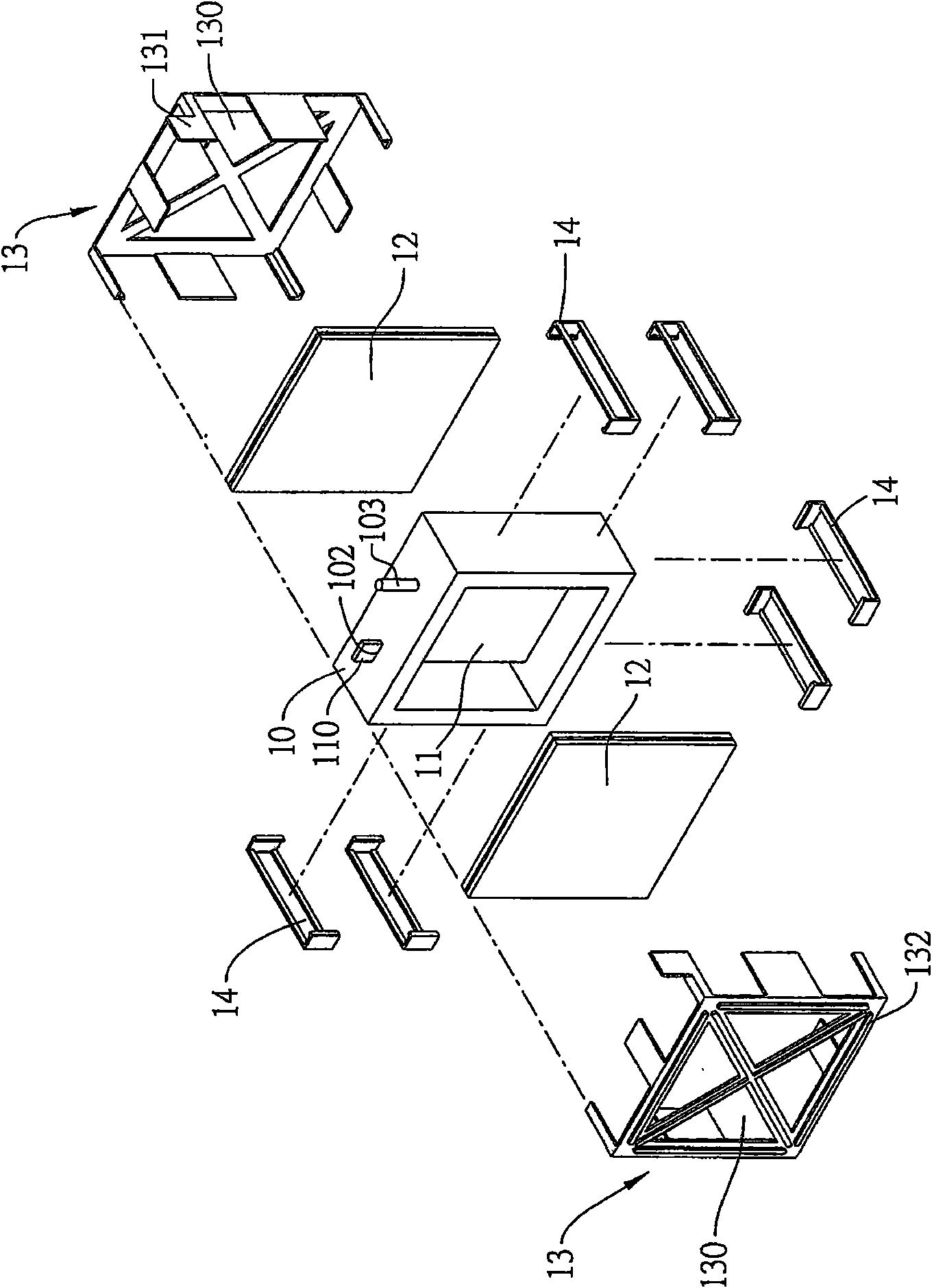

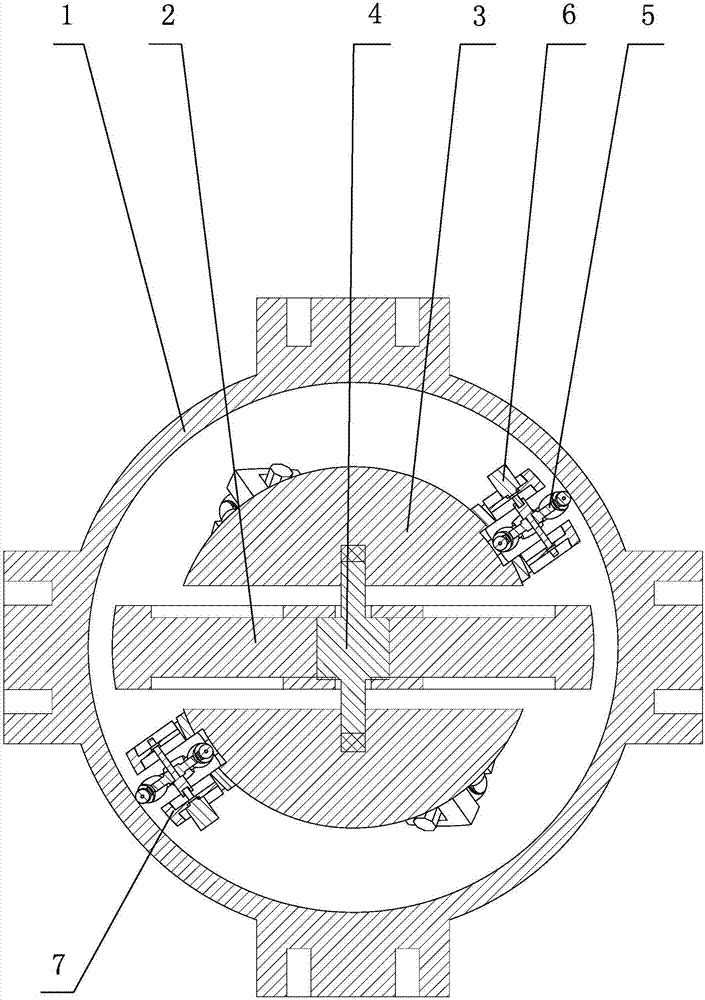

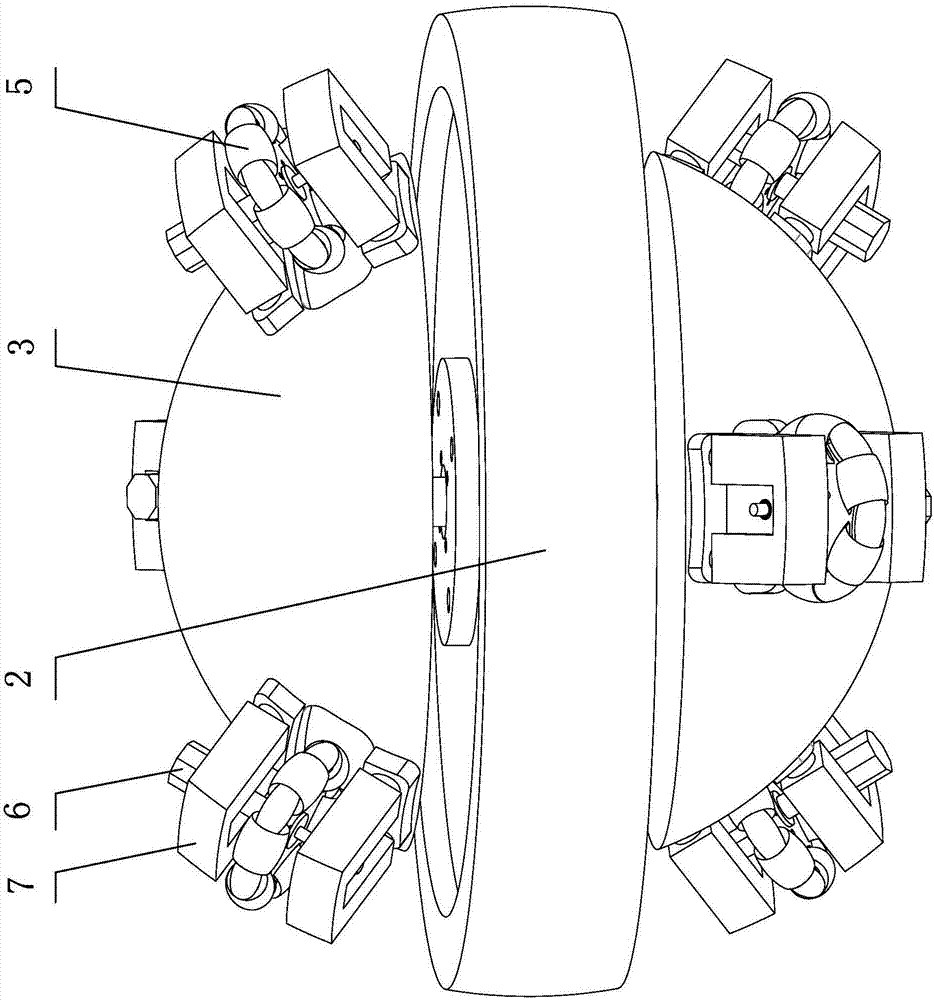

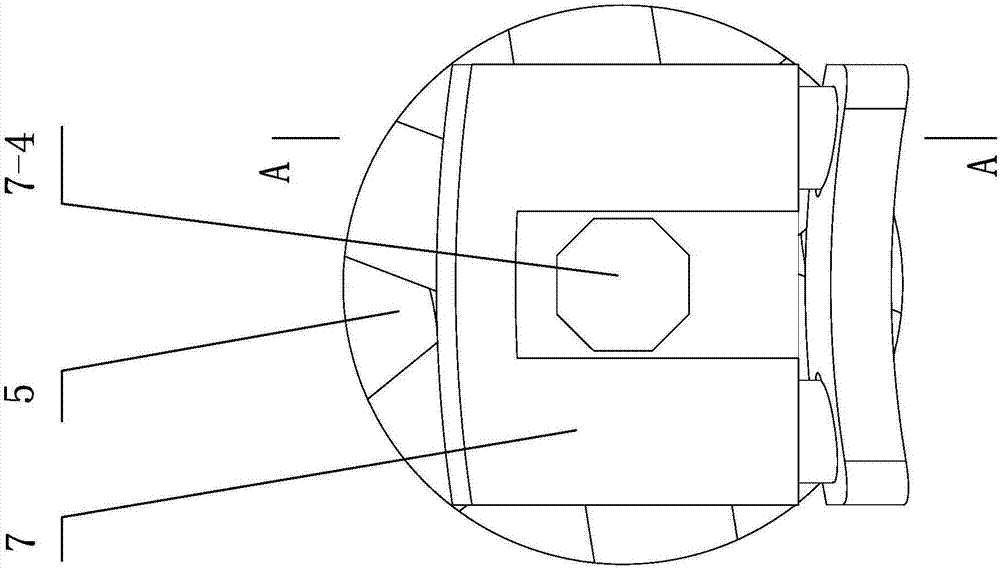

Totally-enclosed type spherical all-directional gyroscope mechanism and operation method thereof

ActiveCN107131874ASolve the packaging problemCompact structureRotary gyroscopesGyroscopeElectric machinery

The invention discloses a totally-enclosed type spherical all-directional gyroscope mechanism and an operation method thereof. The totally-enclosed type spherical all-directional gyroscope mechanism comprises an outer spherical shell which is fixedly arranged on an equipment machine body and a horizontal rotor which is arranged in the outer spherical shell, wherein the horizontal rotor is arranged between upper and lower arc-shaped spherical bodies; spherical centers of the upper and lower arc-shaped spherical bodies are concentric with the outer spherical shell; the horizontal rotor is internally provided with a double-axis model airplane motor; upper and lower rotary shafts of the double-axis model airplane motor are connected with the upper and lower arc-shaped spherical bodies respectively; each of the upper and lower arc-shaped spherical bodies is provided with three all-directional wheels to form three pairs of upper and lower wheel trains; each all-directional wheel is mounted on the corresponding arc-shaped spherical body through a corresponding elastic wheel frame and each all-directional wheel is tightly pressed on an inner wall of the outer spherical shell in the radial direction under the action of an elastic force of the corresponding elastic wheel frame; each wheel frame is provided with a motor for driving the corresponding all-directional wheel to rotate. By adopting the totally-enclosed type spherical all-directional gyroscope mechanism, the sealing problem of a mechanical gyroscope is solved; the totally-enclosed type spherical all-directional gyroscope mechanism has the characteristics of compact structure and safety and reliability.

Owner:GUILIN UNIV OF ELECTRONIC TECH

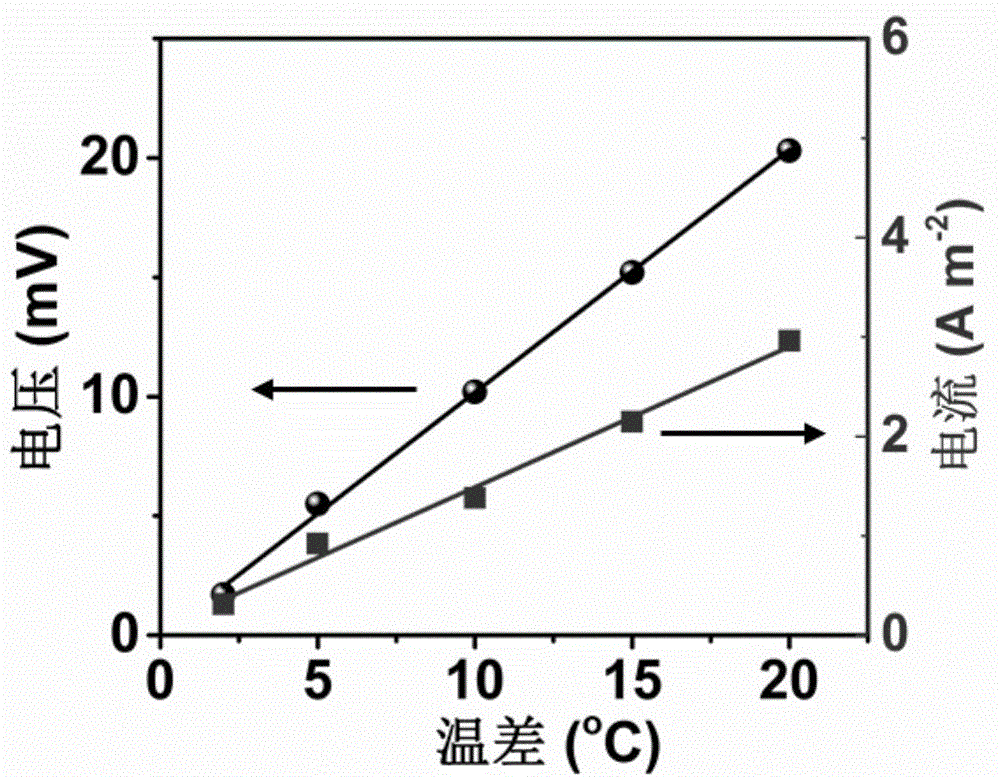

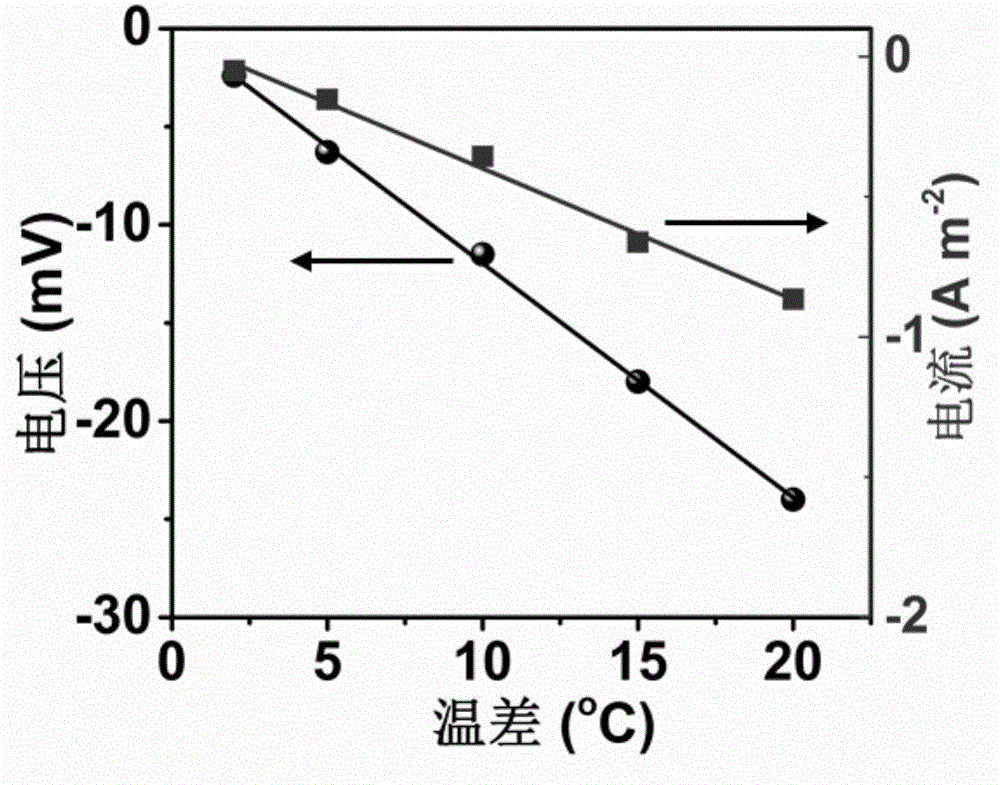

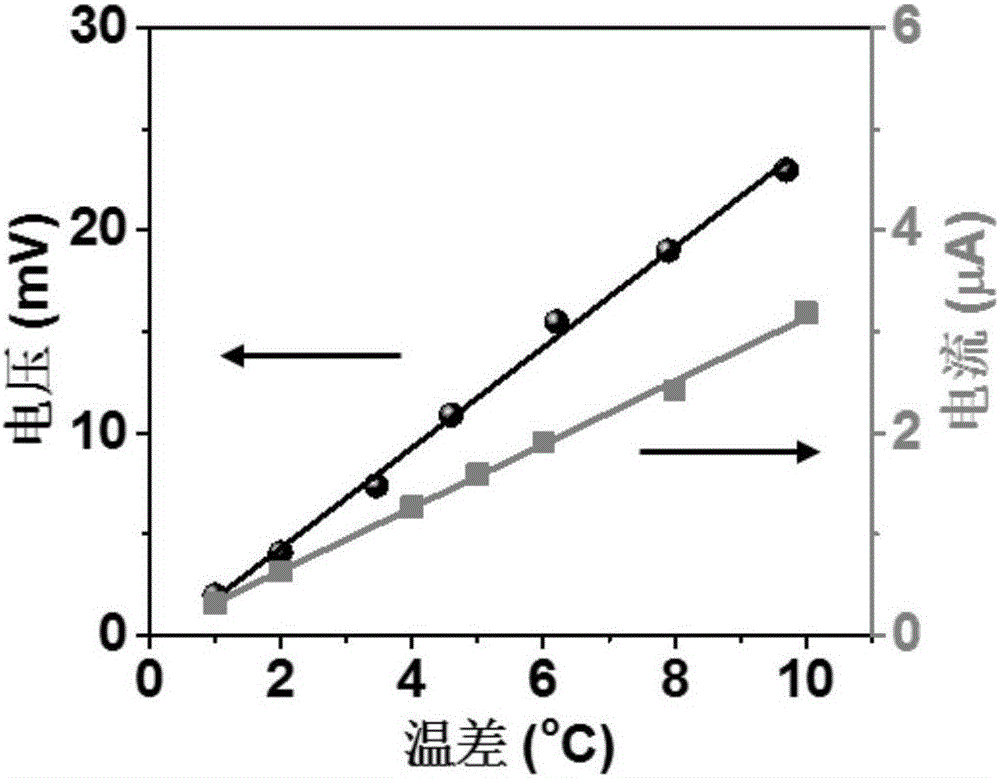

Preparation methods for thermoelectric colloid material and thermoelectric device, and product

InactiveCN106299102AEasy to packageImprove Seebeck coefficientThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentFlexible electronicsSolid-state

The invention discloses preparation methods for a thermoelectric colloid material and a thermoelectric device, and a product. After a polymer solution is mutually mixed with a redox electrolyte, a product is subjected to curing process to prepare the thermoelectric colloid; the thermoelectric colloid regulates and controls a thermoelectric-chemical Seebeck coefficient and thermoelectric output performance by changing the redox electrolyte; the thermoelectric colloid has flexible and tensile characteristics, so that the thermoelectric colloid can be prepared into a required solid-state shape through a mould; the solid-state thermoelectric colloid is applicable to large-area packaging and integrating; the thermoelectric device is prepared by packaging and integrating the thermoelectric colloid and electrodes; and by adoption of the thermoelectric device, low-dimension heat energy can be effectively converted into electric energy, so that the thermoelectric device has wide application prospect in flexible electronic devices and wearable equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

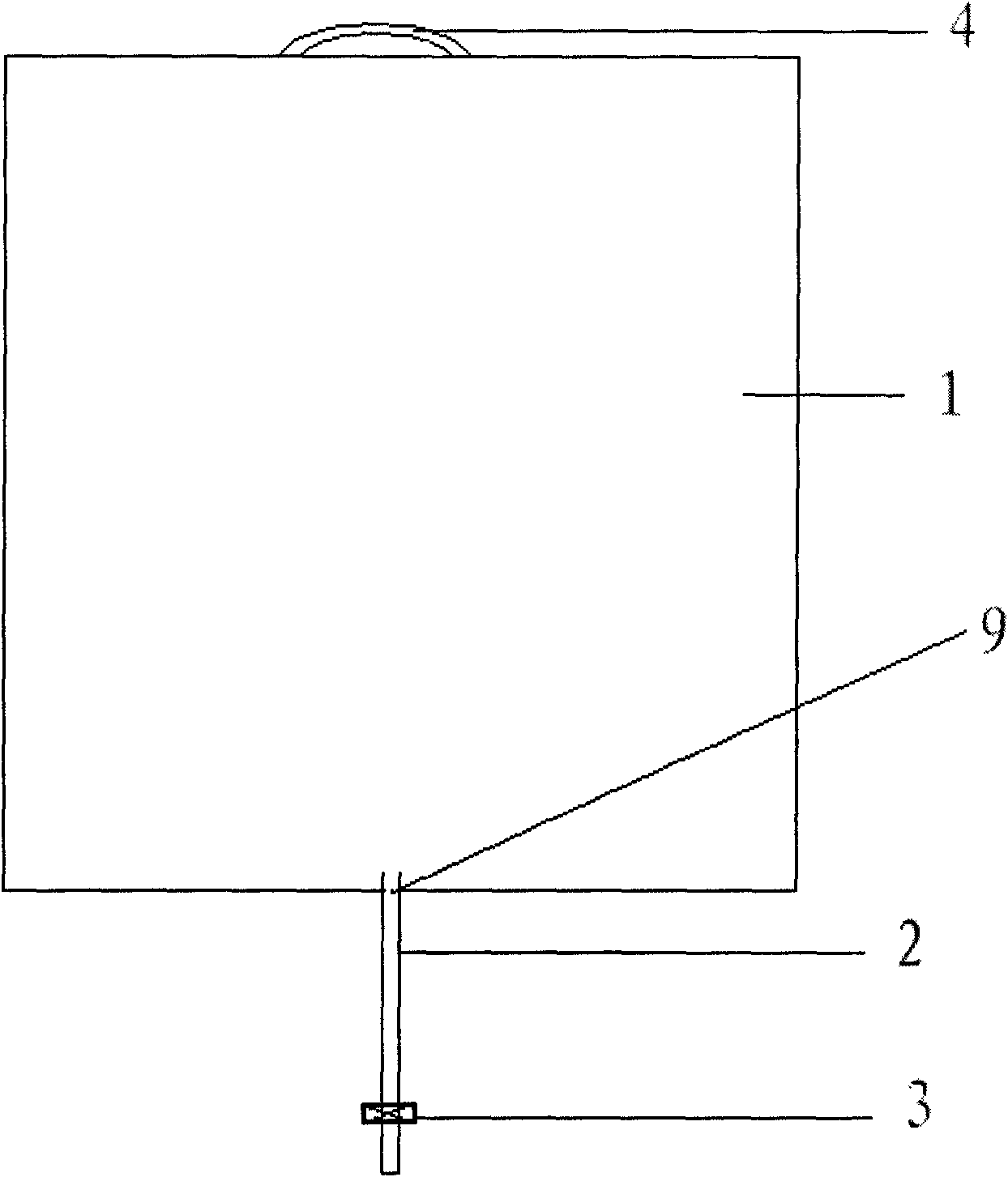

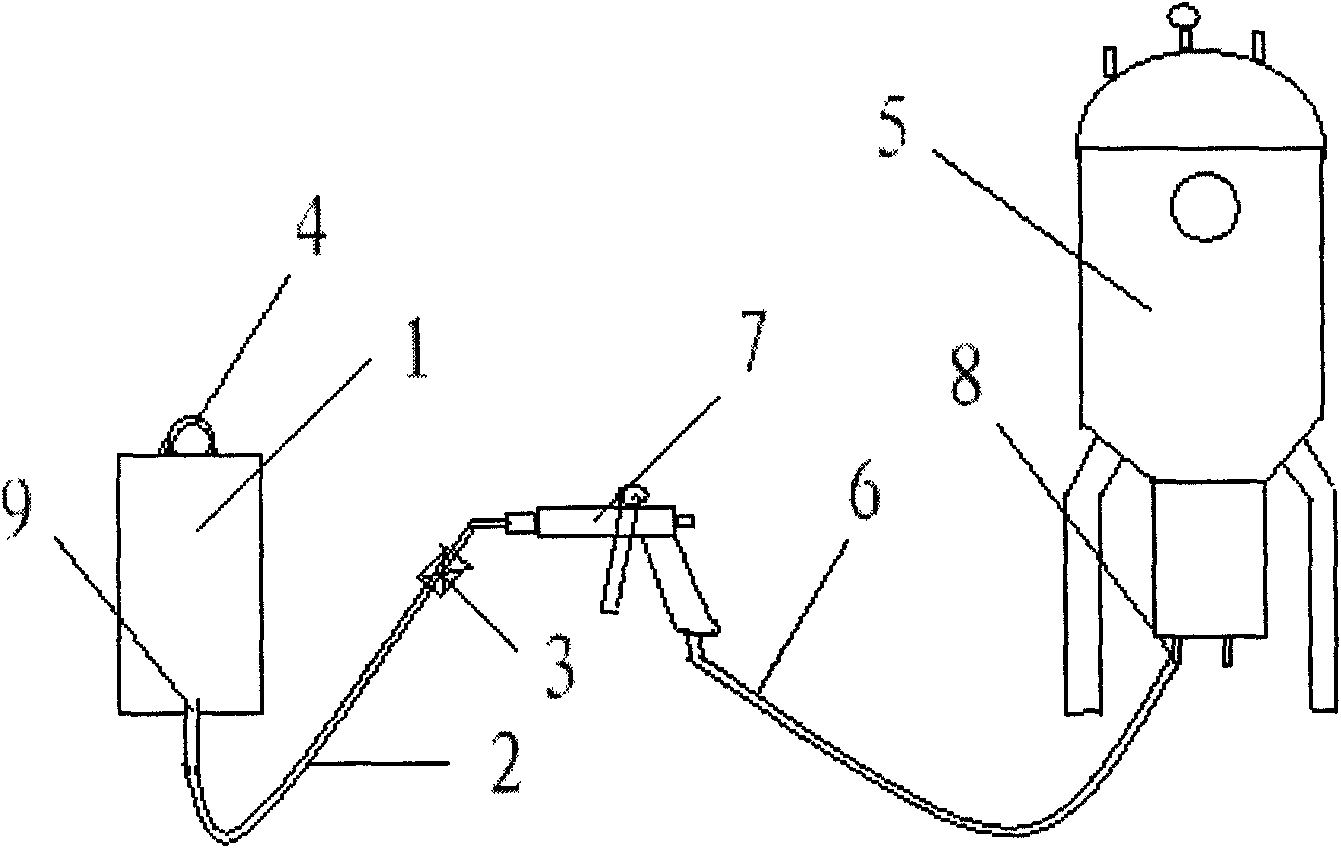

Edible mushroom liquid strain packaging bag device and application method thereof

The invention discloses an edible fungus liquid strain packaging bag device and an application method thereof. The lower bottom of the bag is provided with a bacterial liquid inlet and outlet, which is sealed and fixedly communicated with a conduit, and a liquid stop valve is installed at the lower end of the conduit; The upper end is provided with a hanging hole; application method: the high-pressure water gun is fixedly connected with the high-pressure conduit; Sterilized plastic bags. This invention makes up for the gap in the field of edible fungus liquid strains, and is a new product and application method that has never appeared in this technical field; the device of the present invention is used to package edible mushroom liquid strains, which has the advantages of simple and convenient packaging operation, low strain pollution It has the advantages of low yield and long storage time of strains, and the liquid strains are easy to transport, store and disperse after being packed in plastic bags.

Owner:谢日禄

LED lamp casting material adhered outdoors

InactiveCN101592317AExpand the scope of applicationSolve the packaging problemPoint-like light sourceProtective devices for lightingEngineeringAntistatic agent

The invention relates to an LED lamp casting material adhered outdoors, which can be realized low cost and application to outdoors on the basis of improving the LED material adhered indoors. The technical proposal is that the invention is characterized by being made of ethoxyline resin, anti-static agent and uvioresistant material and light stabilizer.

Owner:LEYARD

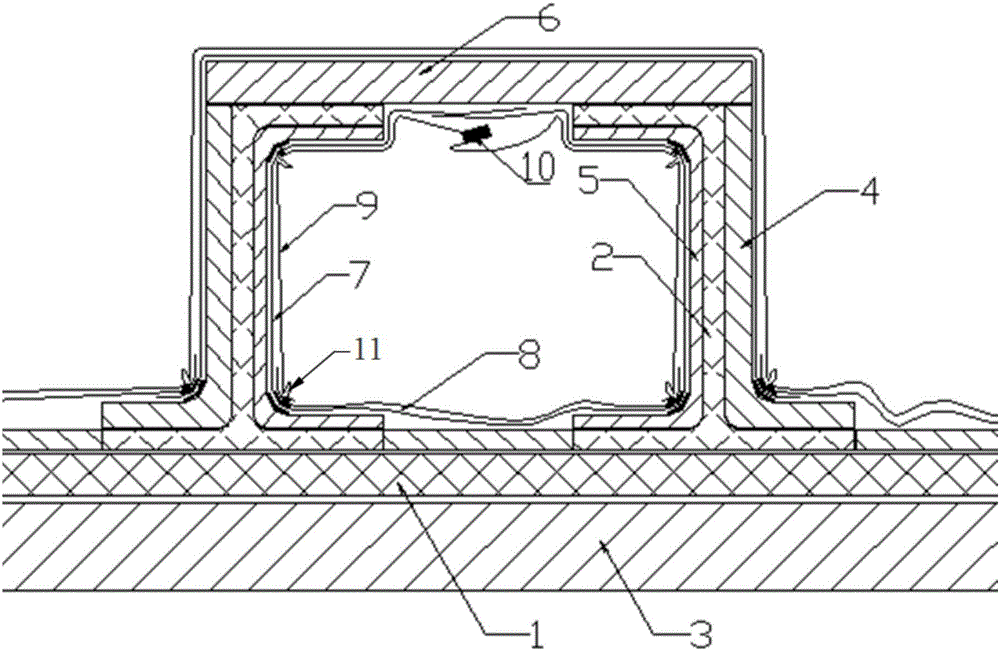

Self-cooling high-power integral LED package

ActiveCN105405952AThe degree of homogenization of current density is improvedSolve the packaging problemSemiconductor devicesEngineeringCooling channel

The invention discloses a self-cooling high-power integral LED package, which comprises a metal cooling base, wherein a plurality of LED epitaxial wafers are arranged on the metal cooling base; each LED epitaxial wafer comprises a metal substrate; an inlet opening is formed in the bottom surface of the metal substrate; outlet openings are formed in two side surfaces of the metal substrate; and the two outlet openings are communicated with the inlet opening. According to the self-cooling high-power integral LED package, the problem of integral package is solved; and through arrangement of cooling holes and cooling channels, the self-cooling function is achieved.

Owner:GUANGDONG UNIV OF SCI & TECH

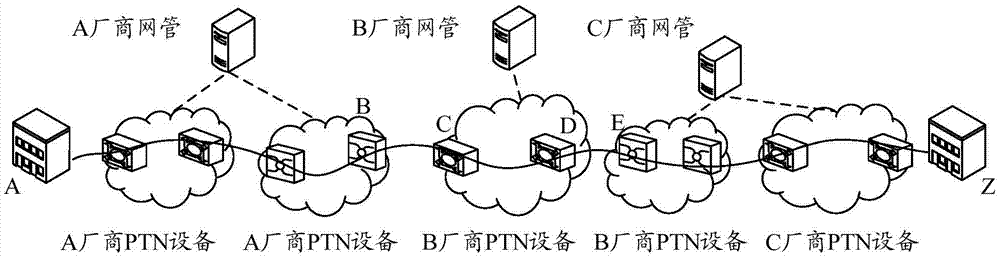

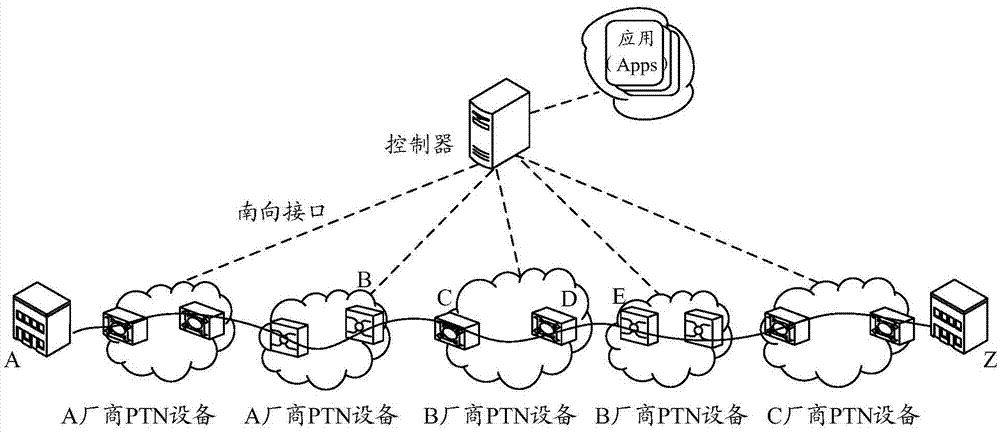

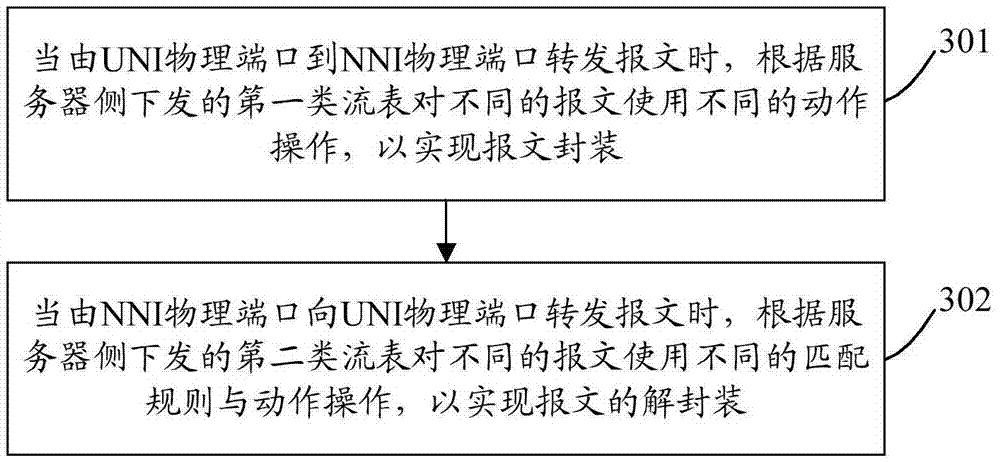

Message conversion method, message conversion device, and message conversion system

ActiveCN106961412AImplement decapsulationSolve the packaging problemTransmissionComputer hardwareNetwork-to-network interface

The invention discloses a message conversion method. The message conversion method comprises steps that when messages are forwarded from a user network interface (UNI) physical port to a network-to-network interface (NNI) physical port, different messages are operated by different motions according to a first-class flow table issued by a server side, and a message packaging is realized; when the messages are forwarded from the NNI physical port to the UNI physical port, the different messages are operated by different matching rules and the different motions according to a second-class flow table issued by the server side, and then the unpacking of the messages is realized. The invention also discloses a message conversion device and a message conversion system at the same time. By adopting the technical scheme provided by the invention, the problem of the prior art of inability of directly using a standard OpenFlow protocol for packet message forwarding is solved.

Owner:CHINA MOBILE COMM GRP CO LTD

Preparation process for high-purity low-arsenic hydroxyethylidene diphosphonic acid

ActiveCN103509051ARealize continuous online productionMild process control conditionsGroup 5/15 element organic compoundsThio-Ethylic acid

The invention relates to a preparation process for high-purity low-arsenic hydroxyethylidene diphosphonic acid. The preparation process comprises the following steps: with phosphorus trichloride, acetic acid and ammonium thioacetate as raw materials, controlling process conditions at first, reacting acetic acid with phosphorus trichloride in a reaction vessel to produce hydroxyethylidene diphosphonic acid and adding ammonium thioacetate in the process of the reaction; and then subjecting an obtained material to concentration and air flushing to remove impurities, adding ammonium thioacetate and carrying out arsenic removal and centrifugation so as to obtain the high-purity low-arsenic hydroxyethylidene diphosphonic acid. According to the invention, scientific technology is employed for product purification, no other substance like a crystal nucleus and a crystallization promoter is added, so no new impurity is introduced. Hydroxyethylidene diphosphonic acid in the high-purity low-arsenic hydroxyethylidene diphosphonic acid prepared in the invention is more than 95%, and arsenic content in the high-purity low-arsenic hydroxyethylidene diphosphonic acid is less than 2 ppm; the preparation process overcomes problems in packaging, transporting and on-site application of liquid hydroxyethylidene diphosphonic acid and broadens the application fields of the high-purity low-arsenic hydroxyethylidene diphosphonic acid.

Owner:HENAN QINGSHUIYUAN TECH

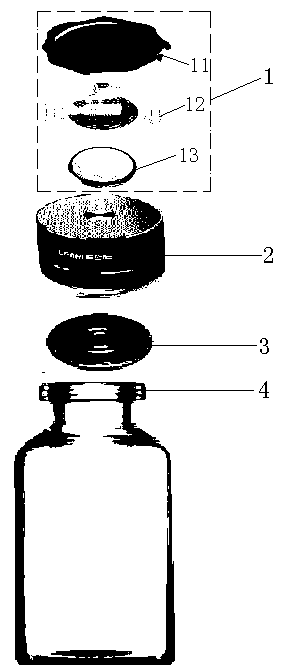

Micro-electronic label code bottle cap

PendingCN109823690ARealize real-time monitoring functionAchieve positioningLocking devicesPenicillinEngineering

The invention discloses a micro-electronic label code bottle cap. The bottle cap is used for penicillin bottle seal and penicillin bottle inner assigned environment value monitoring, and the bottle cap is composed of a top cap layer, a code lock layer and a rubber layer which are sequentially stacked from top to bottom. The lower edge of the code lock layer is provided with a coincidence convex port corresponding to a convex port in the outer edge of a penicillin bottle. The coincidence convex port and the convex port are sleeved and fixed together through an aluminum ring. The top cap layer is fixed to the upper end face of the code lock layer, and the rubber layer is fixed to the lower end face of the code lock layer. The rubber layer is used for sealing the penicillin bottle. The code lock layer is used for encrypting and locking the penicillin bottle. The top cap layer is used for monitoring the inner assigned environment value of the penicillin bottle, and the top cap layer is used for data interaction with the outside and bottle cap positioning. By means of the micro-electronic label code bottle cap, interior and exterior isolation of the penicillin bottle can be achieved, and the seal function is achieved; and the interior temperature of the penicillin bottle can be monitored as well, and safety of medicines in the whole penicillin bottle is enhanced.

Owner:中义(泰州)医药科技有限公司

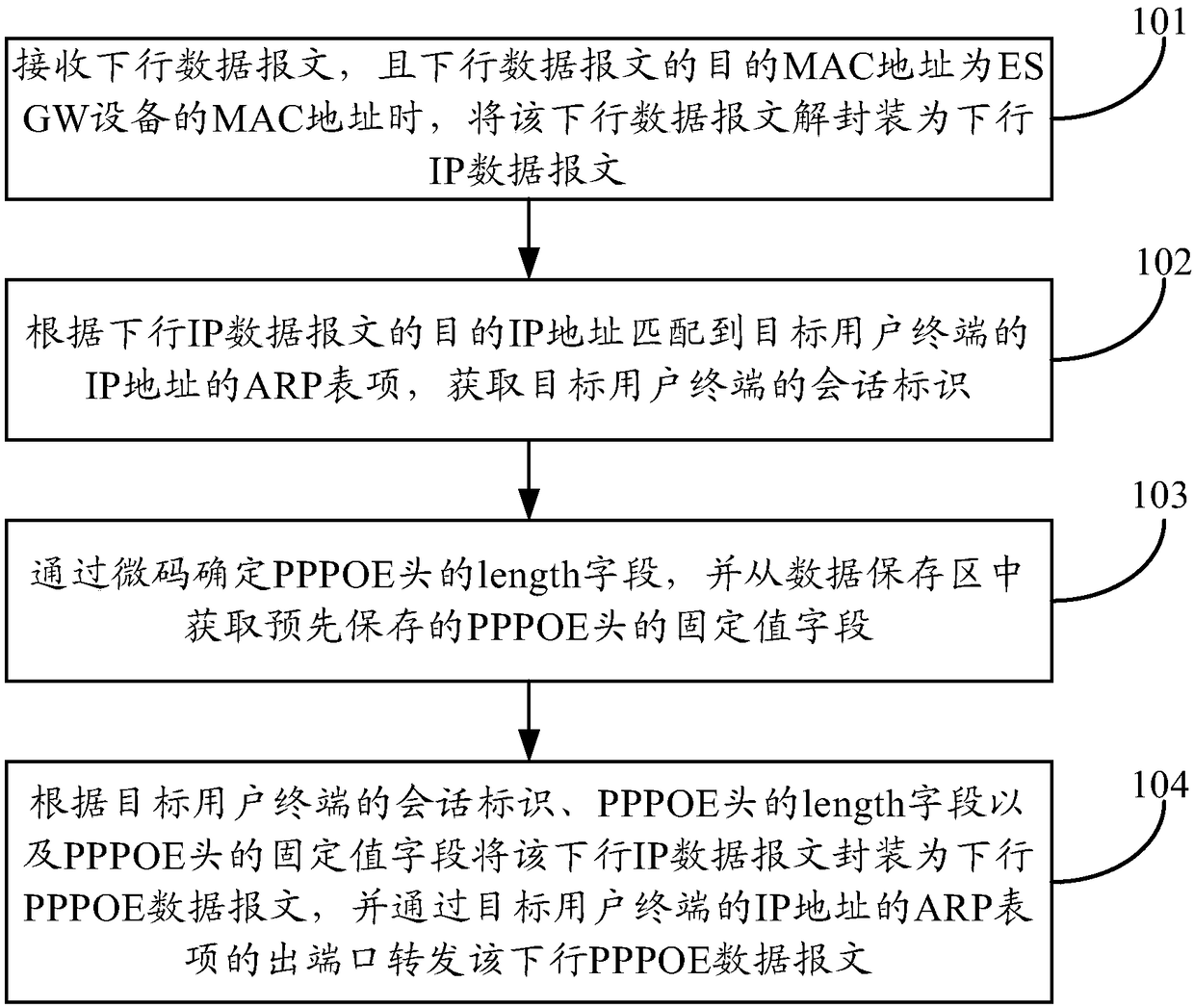

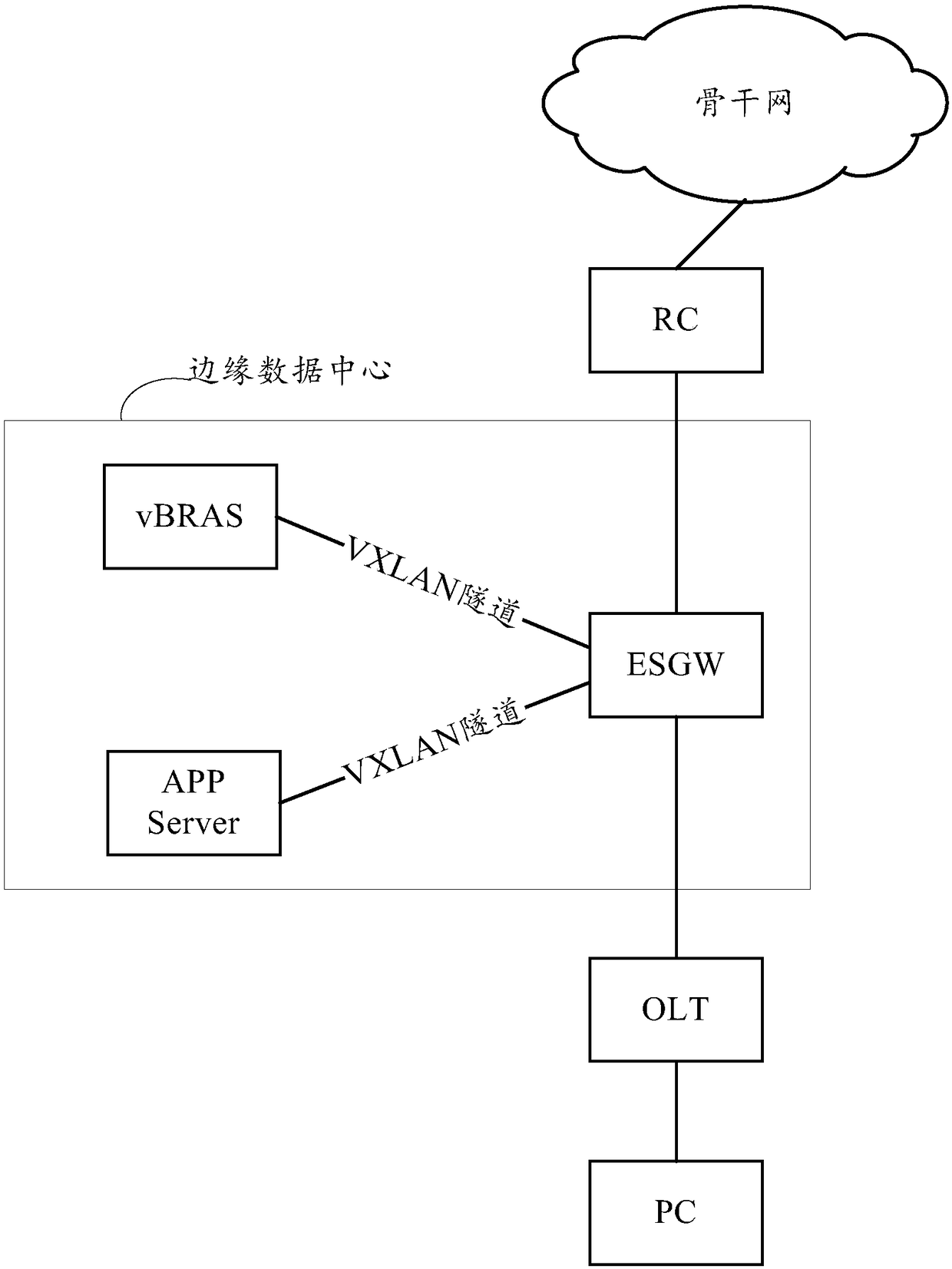

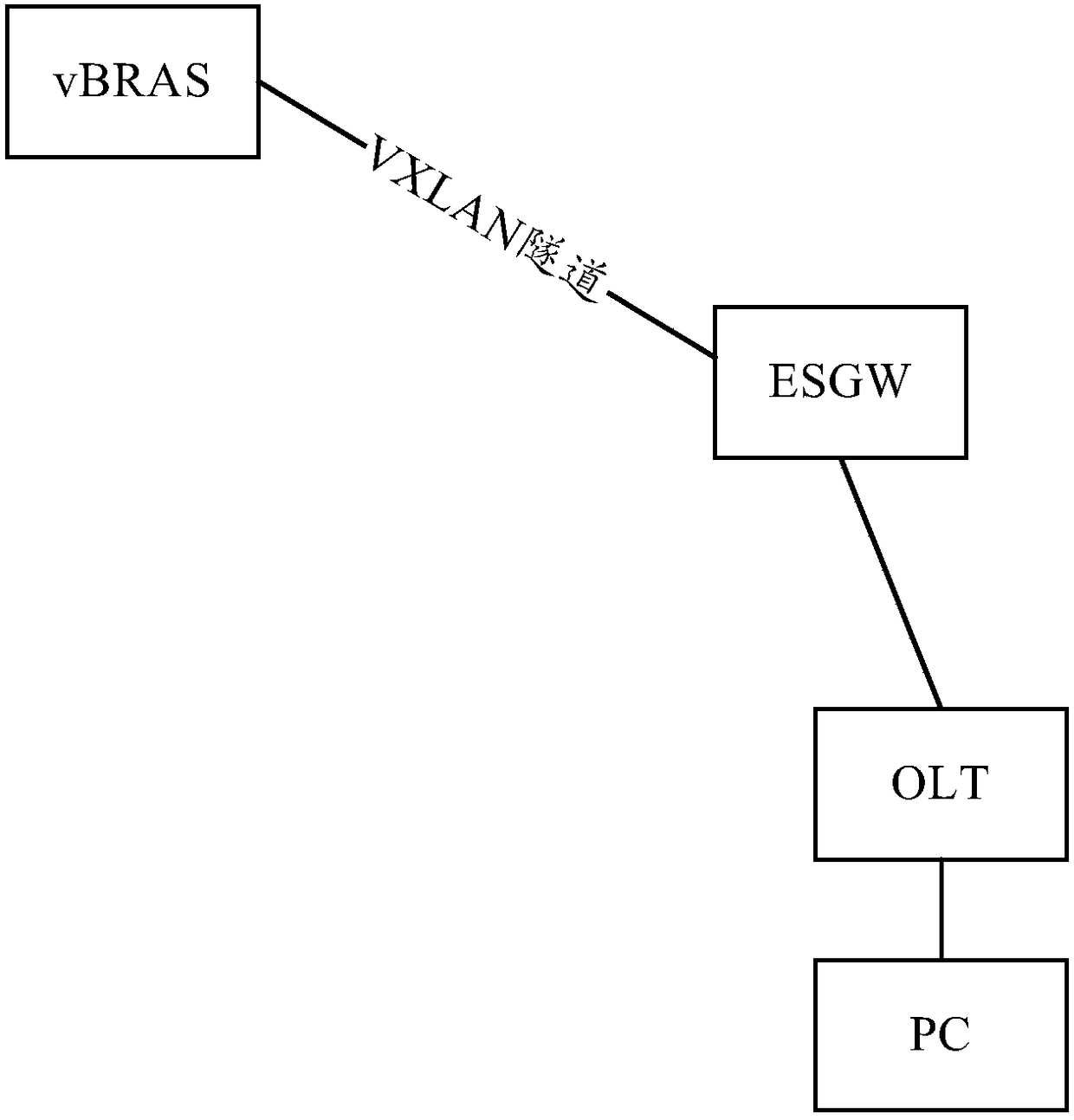

Message forwarding method and apparatus

The invention provides a message forwarding method and apparatus. The method comprises the following steps: receiving a downlink data message, and when the destination MAC address of the downlink datamessage is an MAC address of an ESGW device, de-packaging the downlink data message into a downlink IP data message; matching an ARP table entry of an IP address of a target user terminal according to a target IP address of the downlink IP data message, and obtaining a session identifier of the target user terminal; determining a length field of a PPPOE header via a microcode, and obtaining a pre-stored fixed value field of the PPPOE header from a data storage area; packaging the downlink IP data message into a downlink PPPOE data message according to the session identifier of the target userterminal, the length field of the PPPOE header and the fixed value field of the PPPOE header, and forwarding the downlink PPPOE data message through an outlet port of the ARP table entry of the IP address of the target user terminal. By application of the message forwarding method and apparatus provided by the embodiment of the invention, the PPPOE package of three-layer forwarding messages of agateway device can be implemented.

Owner:NEW H3C TECH CO LTD

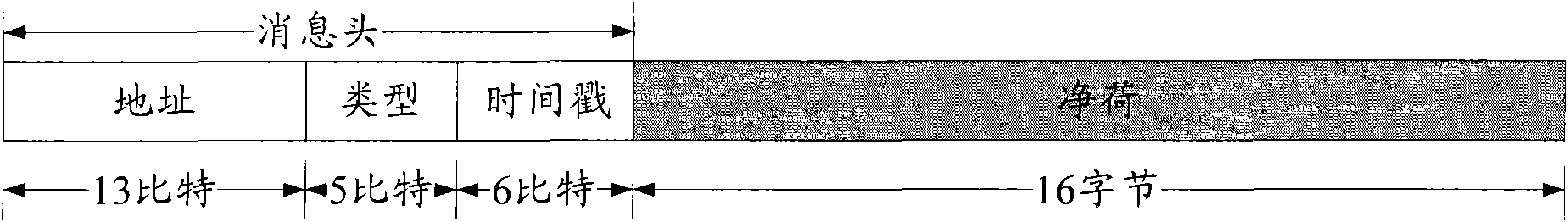

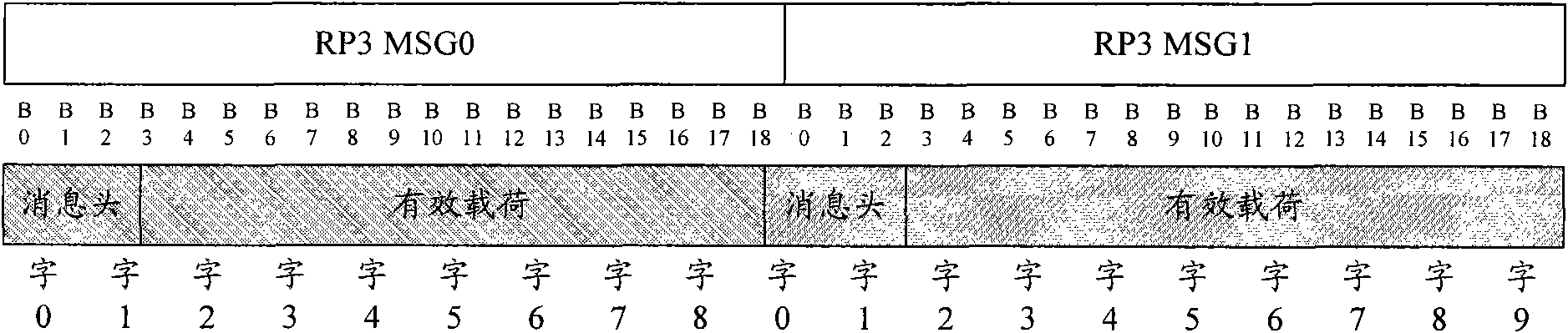

Method and device for transmitting open base station architecture initiative reference point 3 messages

InactiveCN102065395ASolve the packaging problemEasy to sendNetwork traffic/resource managementInformation formatBase station

The invention discloses a method and a device for transmitting an open base station architecture initiative reference point 3 (OBSAI RP3) messages. The method comprises the following steps of: splicing two OBSAI RP3 messages; and sequentially transmitting the two spliced OBSAI RP3 messages in a way of taking each word as a unit. In the method and the device, the OBSAI RP3 messages can be simply and conveniently transmitted.

Owner:ZTE CORP

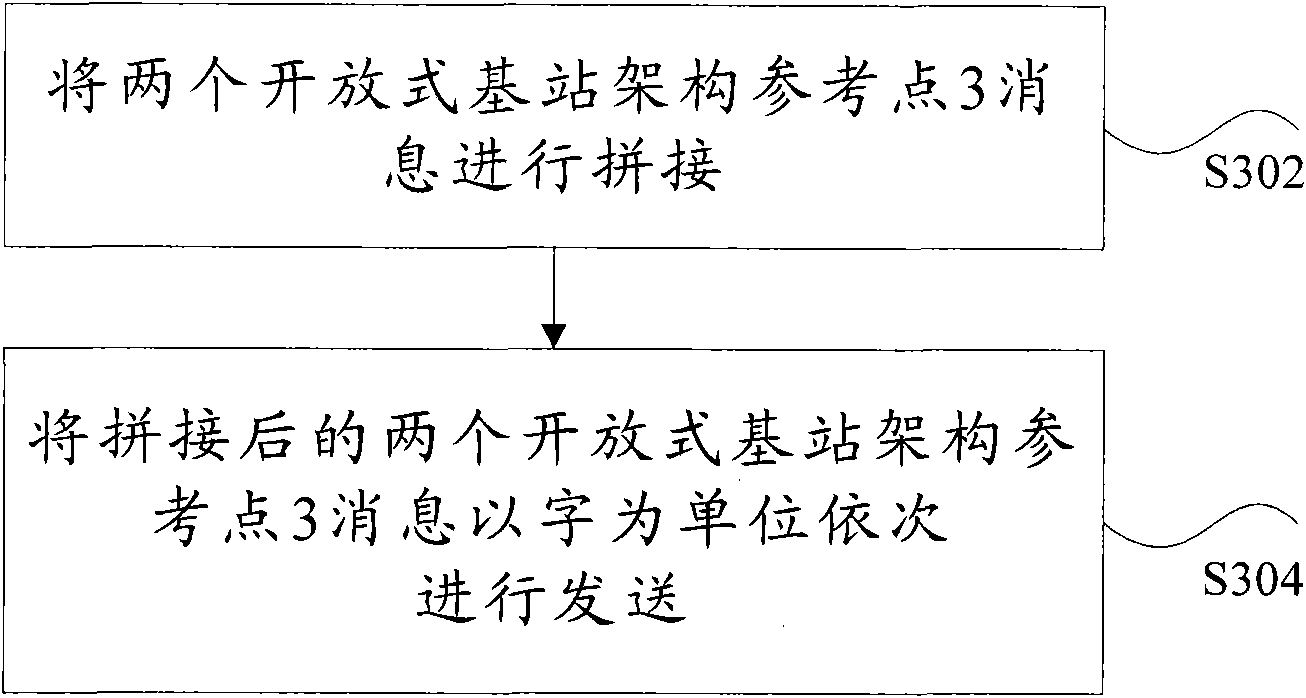

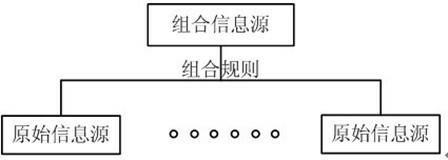

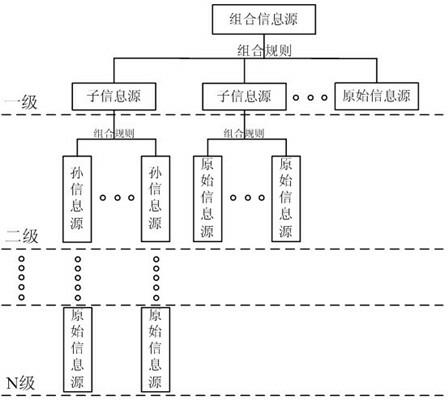

Combination method for combined information source and combined access method for Internet of things information source

The invention discloses a combination method for a combined information source and a combined access method for an Internet of things information source. The methods are based on the combined information source. The combined access method for the Internet of things information source mainly comprises the following steps that: an information user transmits an information source access request to an information source center; the information source center judges the attribute of an information source, directly accesses an access interface of the information source, acquires information and feeds the information back to the information user if the information source is an original information source, and then finishes the access, and if the information source is the combined information source, the information user acquires and combines the information of the combined information source by utilizing combination rules stored by the information source center and access interfaces for subordinate information sources forming the combined information source, and feeds the information back to the information user. By the methods, a transmitted data volume in the access of the Internet of things information source can be greatly reduced, network pressure can be alleviated, and difficulty in the development of technologies and information acquisition, which is related to the Internet of things can be lowered, so that a practical and reliable means is provided for the rapid and sound development of an Internet of things technology.

Owner:CHENGDU BITNUM TECH

Production and manufacturing technology of silicon nitride ceramic tiny component

InactiveCN106631041AImprove performance indicatorsIncrease productivityCeramic shaping apparatusManufacturing technologyMicrometer

The invention discloses a production and manufacturing technology of a silicon nitride ceramic tiny component. The technology comprises the following steps of preparing materials for production including ceramic main powder, a sintering auxiliary agent, heterogeneous particles, a defoaming agent, deionized water and a bonding agent; mixing the heterogeneous particles into deionized water; adding the defoaming agent to prepare uniform slurry; mixing the ceramic main powder into the uniform slurry; performing drying after the uniform stirring; then, crushing the materials into powder A; adding the bonding agent into the powder A; using a sweet dumpling rolling method for manufacturing a required workpiece; using a plastic bath ceramic biscuit encapsulation method for performing encapsulation; adding the sintering auxiliary agent; using a firstly higher and then lower heat insulation measure for performing sintering treatment on the workpiece. The comprehensive measures of the crystal grain refining, micrometer toughening and nanometer reinforcement, the firstly higher and then lower heat insulation method and the like are used for improving the performance index of the silicon nitride ceramic. The plastic bath encapsulation method is used for solving the encapsulation problem of the biscuit in a complicated shape; the production efficiency of the tiny workpiece encapsulation is greatly improved.

Owner:张海波

Curing time-controllable solid-state electrolyte and preparation method thereof

InactiveCN108597883AImprove photoelectric conversion efficiencyFacilitate large-scale packagingLight-sensitive devicesPhotovoltaic energy generationPrepolymerIn situ polymerization

The invention discloses a curing time-controllable solid-state electrolyte and a preparation method thereof. The curing time-controllable solid-state electrolyte comprises a polyurethane prepolymer, aliquid-state electrolyte and an additive, wherein the polyurethane prepolymer is prepared by addition polymerization reaction of isocyanate and dihydric or polyhydric alcohol, the liquid-state electrolyte comprises iodate, iodine and an organic solvent, the additive is an amine, pyridine or imidazole nitrogen-containing compound, and the mass ratio of the polyurethane prepolymer and the liquid-state electrolyte is 1:(1-10). The pyridine or imidazole compound is added into the polyurethane prepolymer capable of in-situ polymerization, on one hand, the photoelectric conversion efficiency of a battery can be improved; and on the other hand, the solid-state electrolyte is suitable for a dye-sensitized solar cell, large-scale package of the battery is facilitated, probability is provided for industrialization of the dye-sensitized solar cell, and the solid-state electrolyte has good application prospect in the field of the dye-sensitized solar cell.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

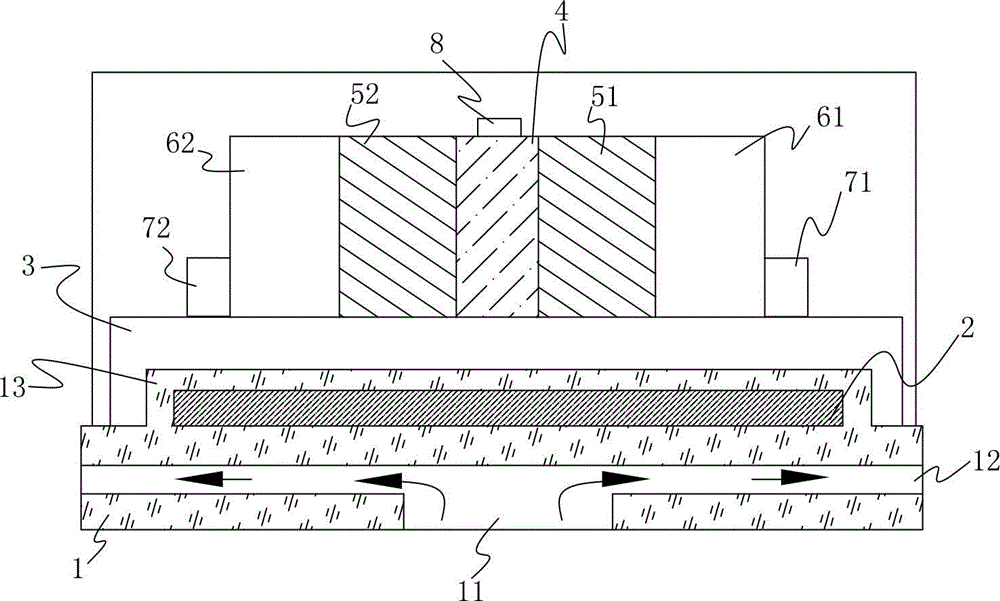

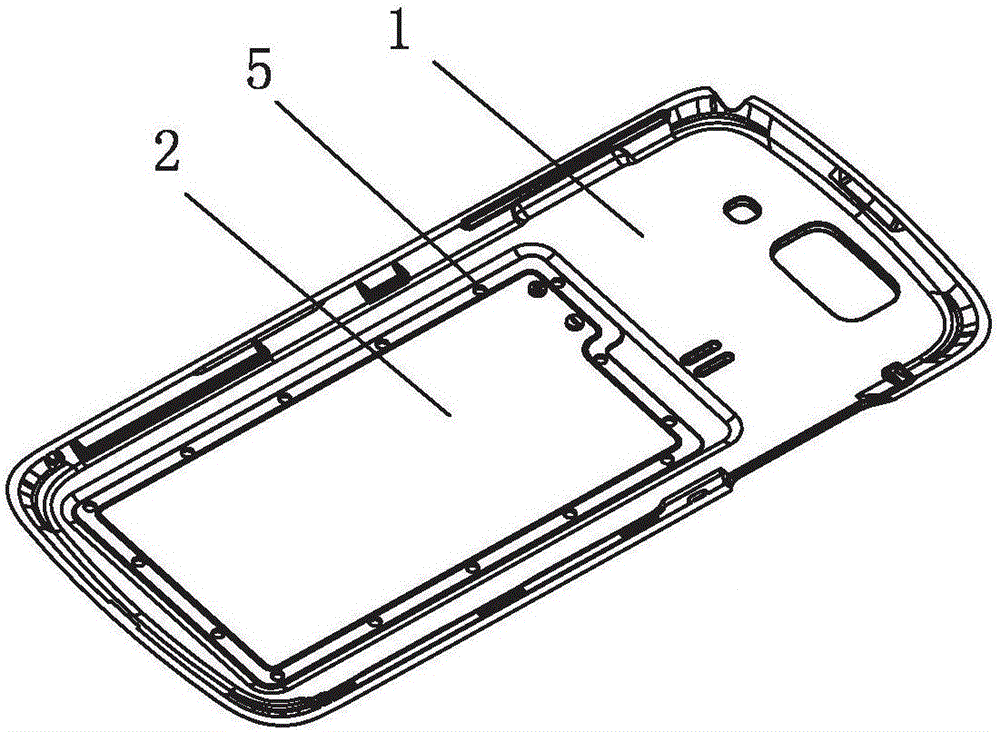

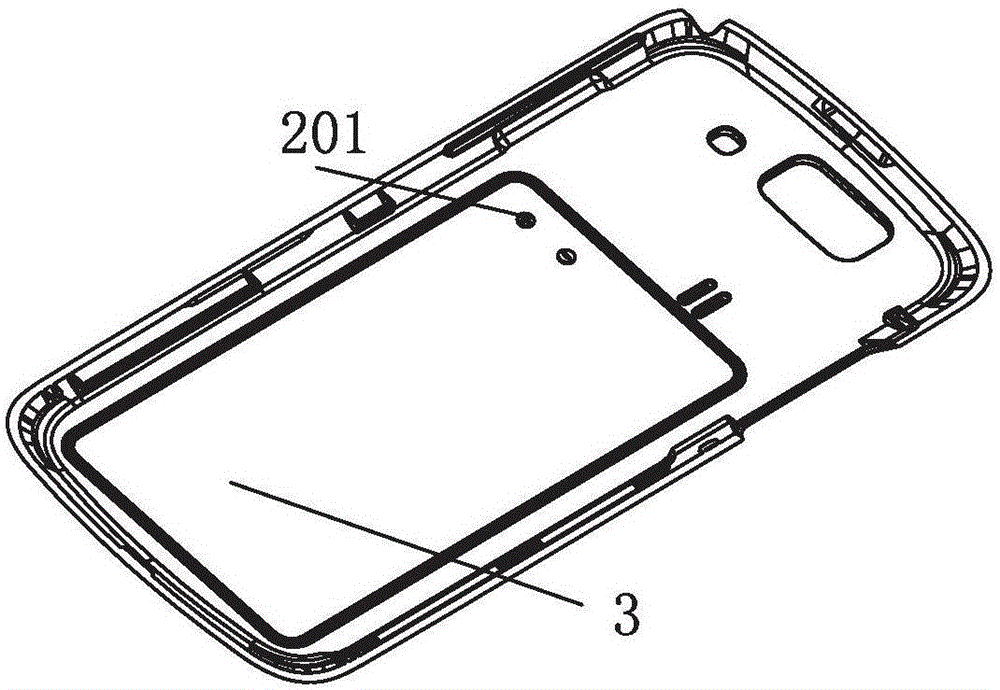

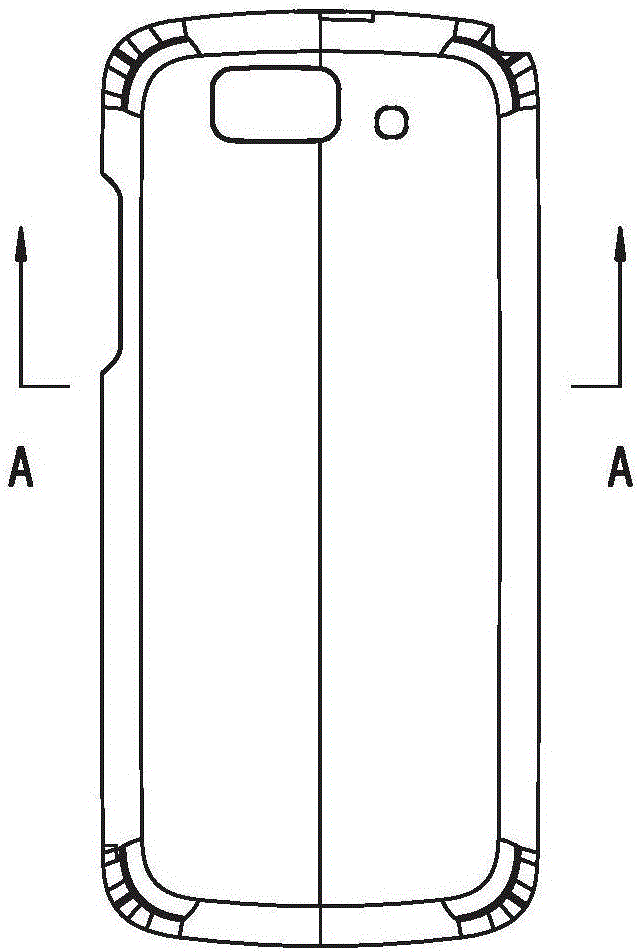

Ultra-thin waterproof shell and battery integrally molded structure, manufacture apparatus and manufacture method

ActiveCN106572613ASolve the packaging problemSolve high temperature resistanceSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsManufactured apparatusEngineering

The invention relates to an ultra-thin waterproof shell and battery integrally molded structure, a manufacture apparatus and a manufacture method. The ultra-thin waterproof shell and battery integrally molded structure includes a plastic shell and a flexible battery which is integrally injected and molded at the inner side of the plastic shell; one side of the flexible battery, which is opposite to the of the plastic shell, is covered with waterproof silica gel; a feed through hole is formed in the waterproof silica gel; at least one positioning through hole which pass through the two sides of the flexible battery is formed in the flexible battery; and one part of the plastic shell extends to the one side of the flexible battery through the positioning through holes so as to be molded as the fixing structure of the flexible battery. In the manufacture apparatus, a second mold portion is provided with movable positioning pins; and the movable positioning pins are configured to be controllably inserted into the positioning through holes in the flexible battery and to controllably retreat from the positioning through holes in the flexible battery. The ultra-thin integrally molded structure has good water waterproof performance and flexibility. Various surface treatment can be performed on the ultra-thin integrally molded structure.

Owner:DONGGUAN HUAQING OPTICAL TECH

Automatic arranging conveying system facilitating product stacking or packing

ActiveCN107745950AIncrease labor costAverage efficiencyPackagingStacking articlesEngineeringMechanical engineering

The invention relates to an automatic arranging conveying system facilitating product stacking or packing. The automatic arranging conveying system comprises a charging conveying unit, a discharging conveying unit, a connection unit and a mechanical material taking unit, wherein the charging conveying unit is provided with a charging inlet and a discharging outlet; products are located between thecharging inlet and the discharging outlet at intervals and are conveyed out of the discharging outlet one by one; the discharging conveying unit is provided with an inlet and an outlet; the productsare moved from the inlet to the outlet; the connection unit is used for connecting the discharging outlet with the inlet so that the products can be automatically arranged and moved to the inlet; andthe mechanical material taking unit is located at the inlet and can move the arranged products from the connection unit to the inlet according to demanded quantities. The products can be moved to a stacking system or a packing system according to the set numbers accurately, personnel operation is not needed for the whole process, thus, the problem of missing packing of the products is completely solved, meanwhile, implementation is convenient, and the cost is low.

Owner:SUZHOU HAGONG ZHONGZHI AUTOMATIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com