Patents

Literature

154results about How to "Solve high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-component high-temperature-resisting adhesive for assembling loudspeaker and preparation method thereof

ActiveCN103725206AImprove high temperature resistanceSolve high temperature resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesivePlasticizer

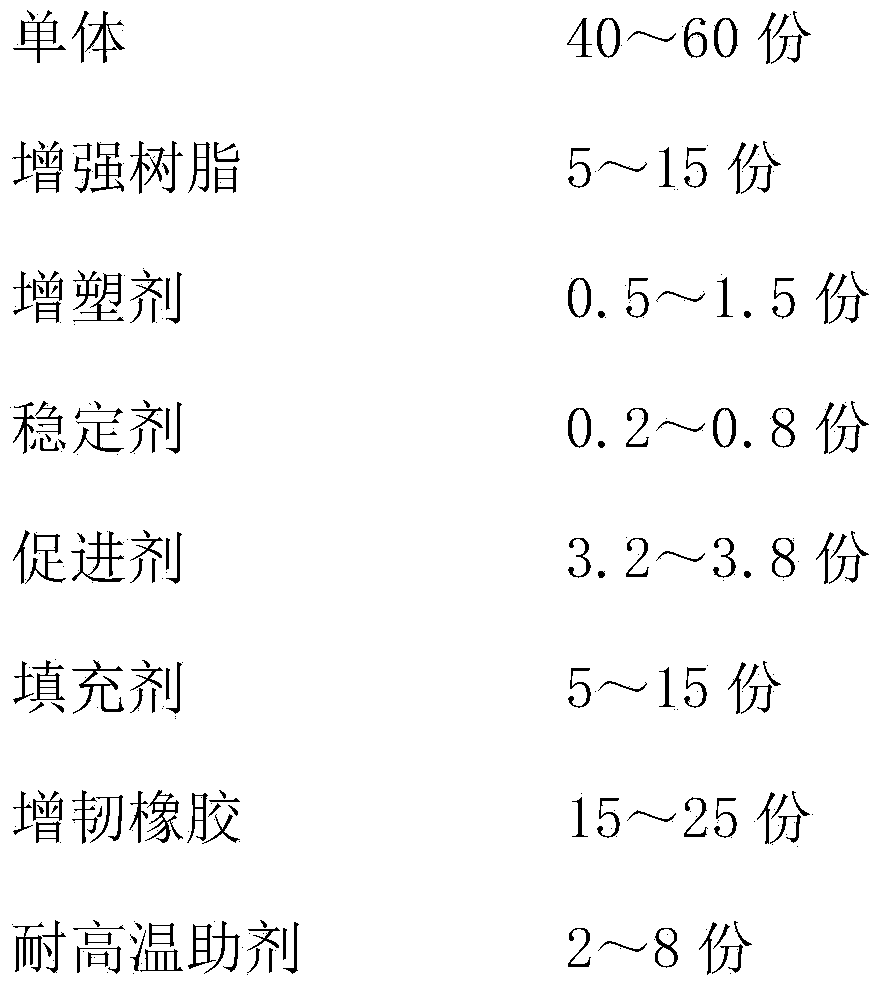

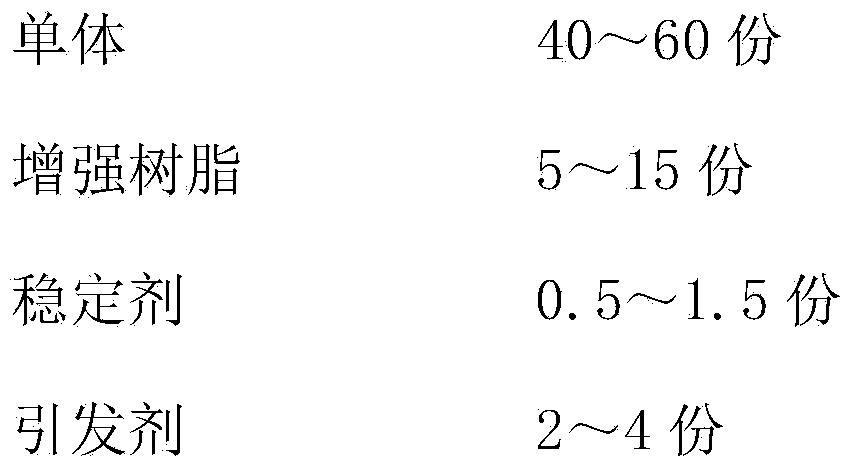

The invention discloses a two-component high-temperature-resisting adhesive for assembling a loudspeaker. The two-component high-temperature-resisting adhesive comprises a main agent and a curing agent, wherein the main agent comprises the following ingredients in parts by weight: 40 to 60 parts of monomer, 5 to 15 parts of reinforcing resin, 0.5 to 1.5 parts of plasticizer, 0.2 to 0.8 part of stabilizer, 3.2 to 3.8 parts of promoter, 5 to 15 parts of filler, 15 to 25 parts of toughening rubber and 2 to 8 parts of high-temperature-resisting additive; the curing agent comprises the following ingredients in parts by weight: 40 to 60 parts of monomer, 5 to 15 parts of reinforcing resin, 0.5 to 1.5 parts of stabilizer, 2 to 4 parts of initiator, 5 to 15 parts of filler, 5 to 15 parts of toughening rubber and 4 to 8 parts of high-temperature-resisting additive. The adhesive can be cured at normal temperature, and the high-temperature-resisting effect is good.

Owner:江苏东禾电声配件有限公司

Alkali-activated slag powder geopolymer mortar for structure reinforcement and preparation method thereof

The invention discloses alkali-activated slag powder geopolymer mortar for structure reinforcement and a preparation method thereof. The alkali-activated slag powder geopolymer mortar for structure reinforcement is prepared from, by weight, 150-210 parts of slag powder, 0-60 parts of fly ash, 400-700 parts of sand, 190-240 parts of water glass and 25-50 parts of solid sodium hydroxide. The preparation method comprises the following steps that the slag powder, the fly ash and the sand are mixed to be uniform according to the proportions; solid sodium hydroxide particles are dissolved in the corresponding amount of the water glass according to the proportion; sodium hydroxide-dissolved water glass is added into well-mixed dry materials, and stirring is conducted continuously to be uniform; the well-stirred alkali-activated slag powder geopolymer mortar is used for building structure reinforcement; the alkali-activated slag powder geopolymer mortar has high compressive strength, good adhesive property with concrete and fiber cloth materials and a wide fluidity range and can adapt to the situation of reinforcing building structures through a fiber cloth bonding method or a grouting pouring method.

Owner:SHANGHAI JIUJIAN REINFORCEMENT TECH

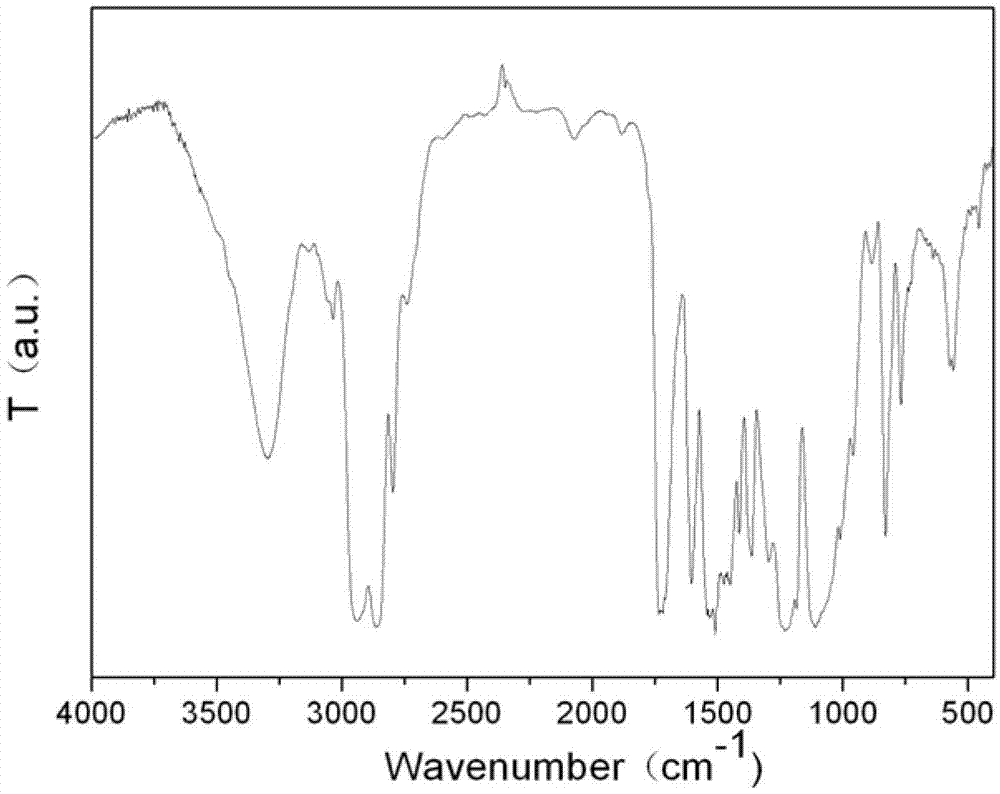

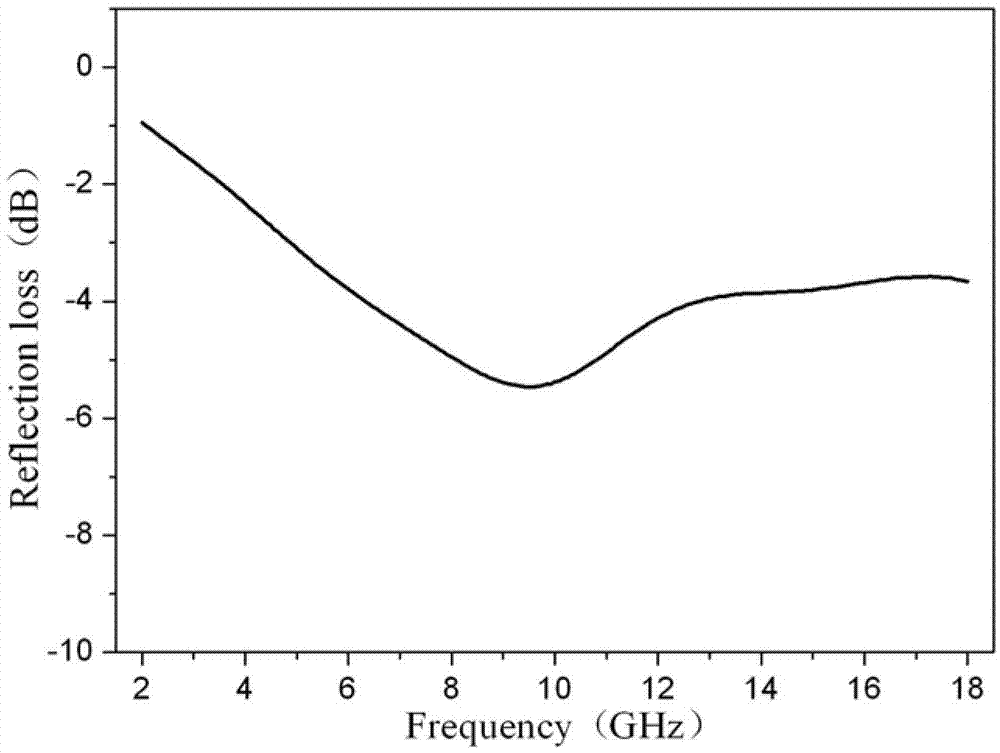

High-temperature resistance radar wave absorbing coating and preparation method thereof

ActiveCN103073981ALight in massThe overall thickness is thinPolyurea/polyurethane coatingsRadiation-absorbing paintsEpoxyCyclohexanone

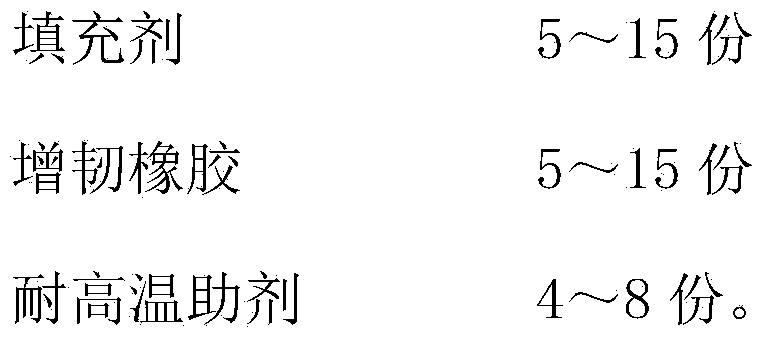

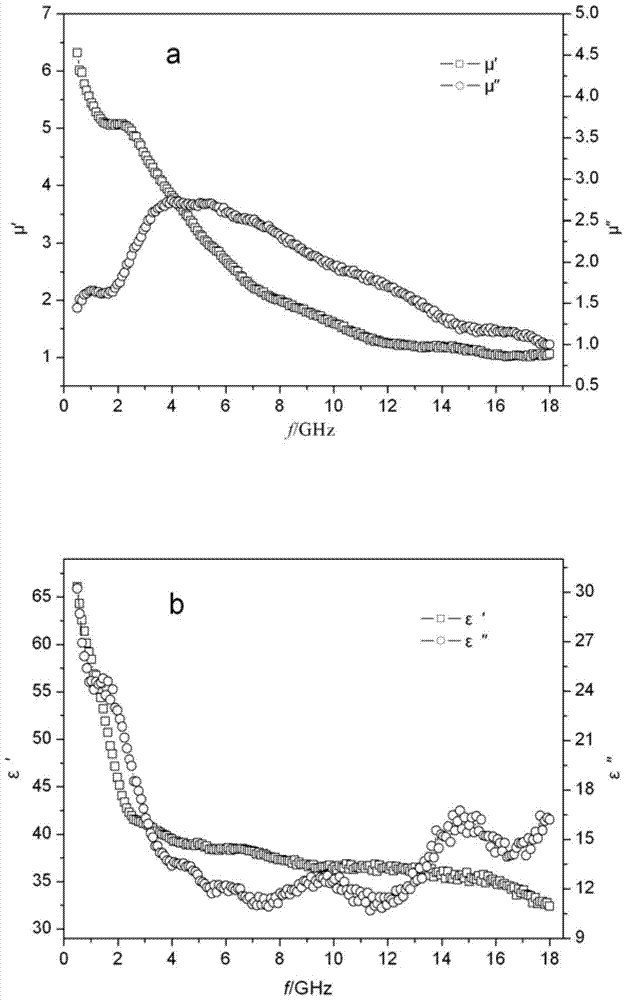

The invention discloses a high-temperature resistance radar wave absorbing coating and a preparation method thereof, and relates to an electromagnetic wave absorbing coating. The absorbing coating comprises the following components: carbonyl iron powder, epoxy resin, polyurethane prepolymer, silane coupling agent and mixed ketone organic solvent, and particularly comprises the following components in part by weight: 65-69 parts of carbonyl iron powder, 19-22 parts of epoxy resin, 30-33 parts of polyurethane prepolymer, 0.4-0.8 parts of KH560 silane coupling agent and 25-35 parts of butanone and cyclohexanone mixed solvent. The absorbing coating provided by the invention can be applied to a wide range of frequency bands, and the application frequency of the absorbing coating can achieve a loss effect of more than minus 3.5 dB in a range of X, Ku wave bands (8-18 GHz).

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

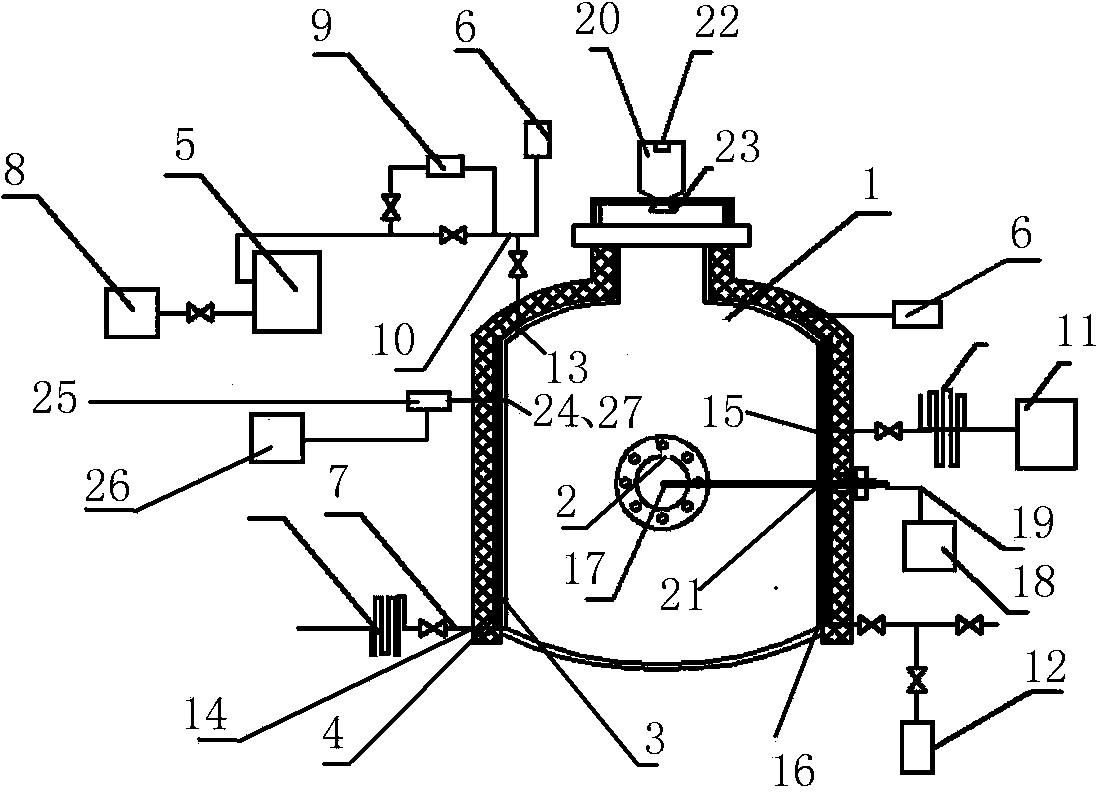

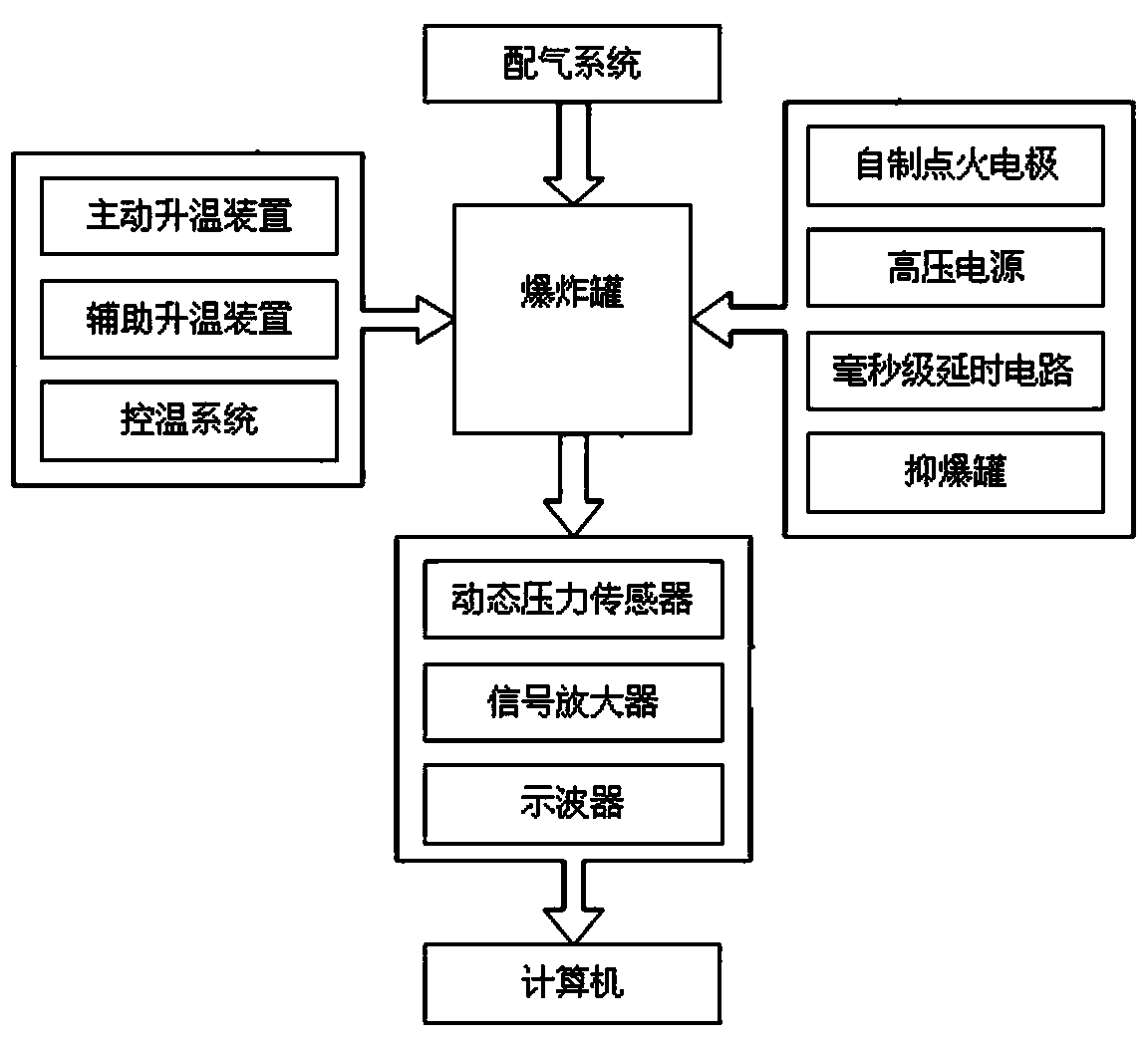

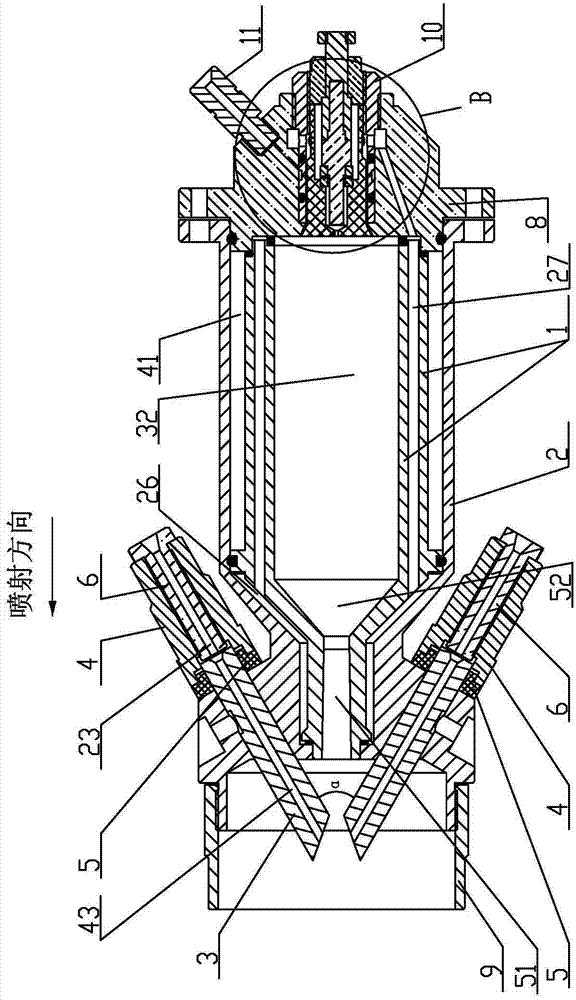

Combustible liquid vapor explosion and explosion suppression characteristic test system

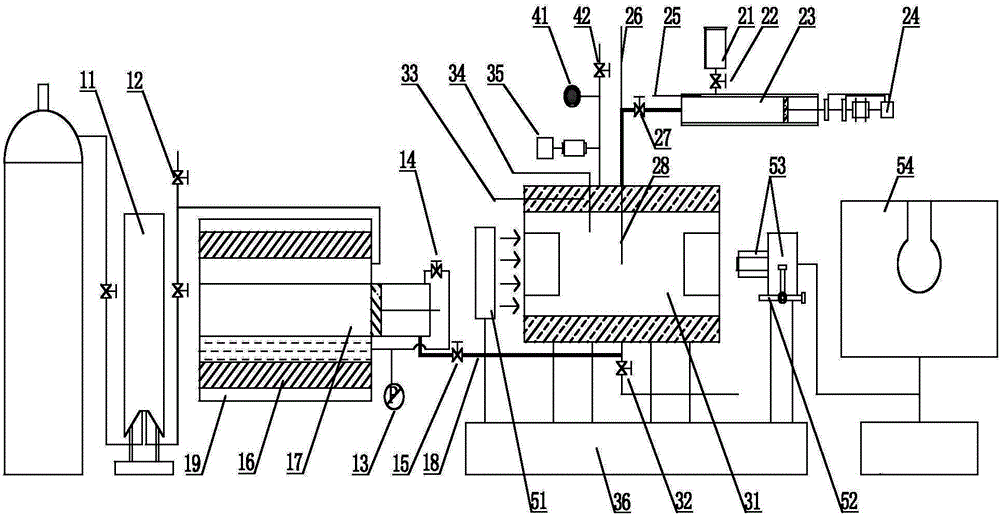

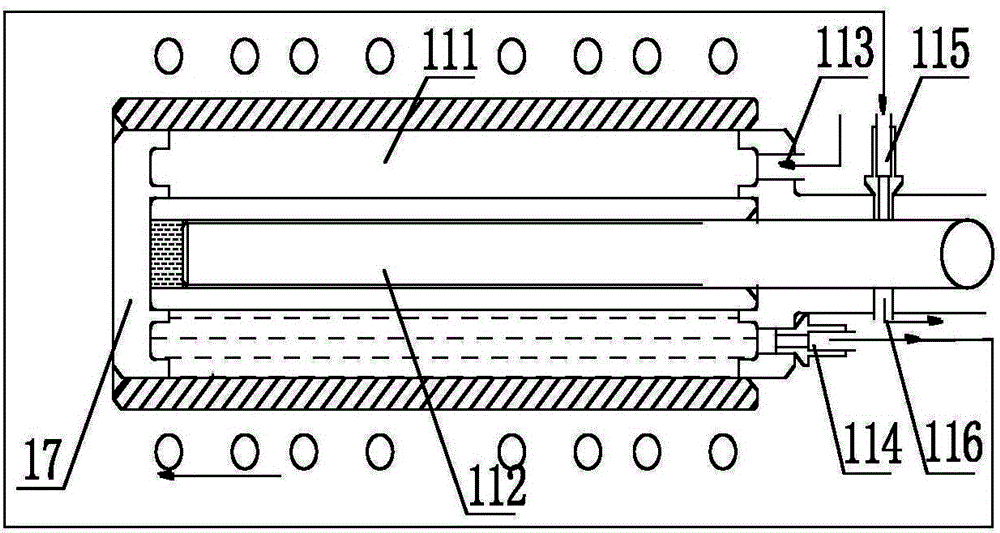

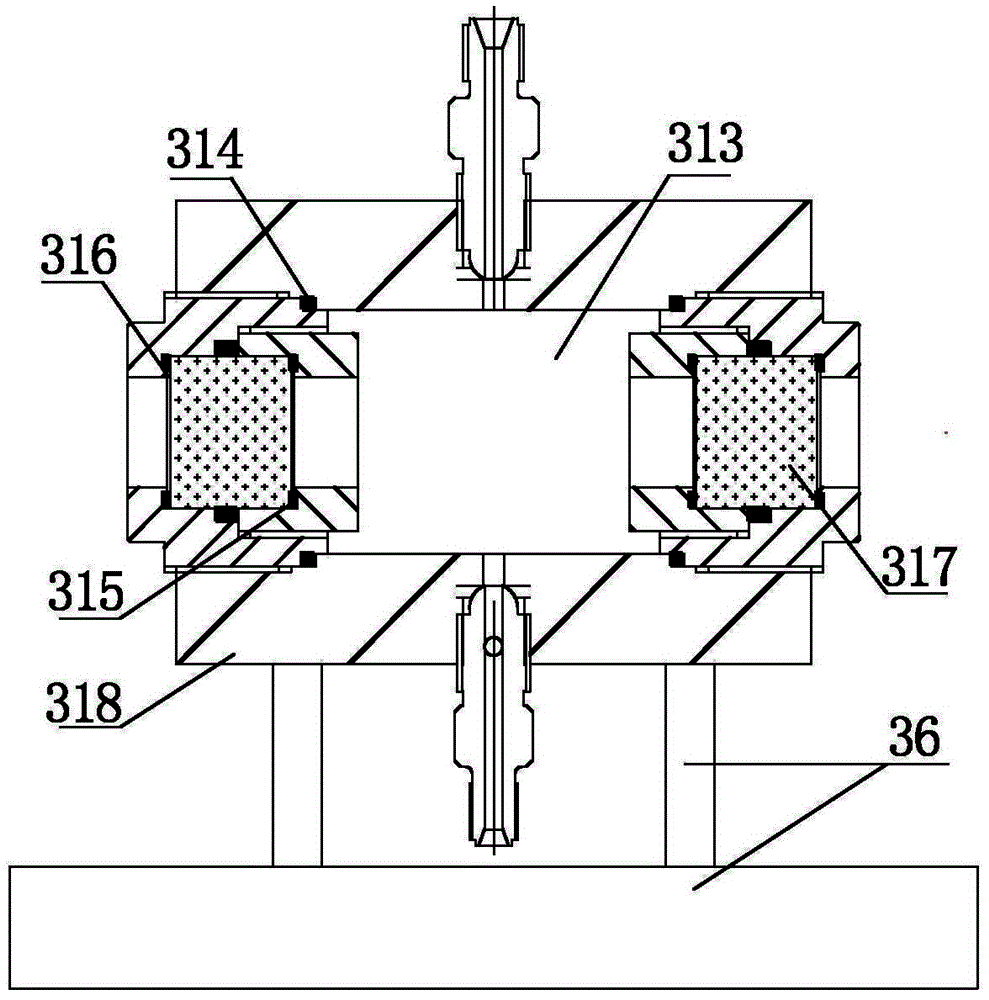

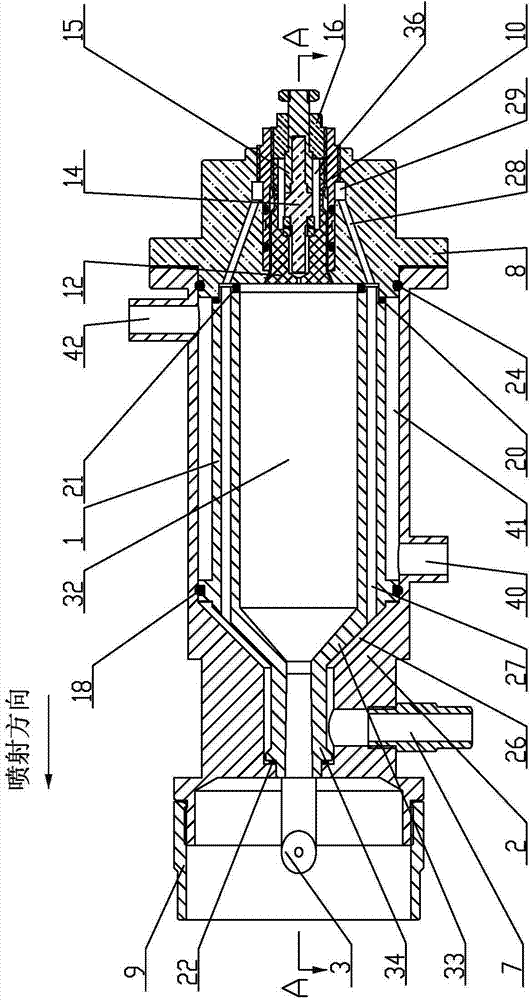

InactiveCN103364531AFunctional DiversificationSimple processing capacityFuel testingIgnition delayEngineering

The invention discloses a combustible liquid vapor explosion and explosion suppression characteristic test system. The system comprises an explosion tank, a double heating temperature-control system, a gas distribution system, a double ignition delay explosion suppression system, and a data test and acquisition system. The explosion tank is provided with a window and six through holes. The explosion tank is covered by a heating sheet of the double heating temperature-control system on the explosion tank. An insulation material is covered on the heating sheet. The temperature-control system is connected with the heating sheet and an air heater. An air compressor of the gas distribution system communicates with a through hole I through the air heater, an ejector, and an ejector pipe. A gas discharge pipe communicates with a through hole II. A vacuum pump communicates with a through hole III. A static pressure sensor communicates with a through hole IV. An ignition electrode of the double ignition delay explosion suppression system is arranged in the explosion tank, and is connected with a delay circuit and a high-voltage power source through the through hole V. An explosion suppression tank is arranged on the top of the explosion tank. A gas generator is arranged in the explosion suppression tank. A nozzle is arranged on the bottom of the explosion suppression tank. A dynamic pressure sensor of the data test and acquisition system is arranged on the through hole VI, and is connected with an oscilloscope through a signal amplifier. The system provided by the invention has the advantages of simple application, multiple test functions, and high precision.

Owner:ZHONGBEI UNIV

High-temperature and high-pressure interfacial tension measurement device and method

InactiveCN104155217ASolve the need for high pressure resistanceSolve high temperature resistanceSurface tension analysisSapphire windowMeasurement device

Owner:TIANJIN UNIV

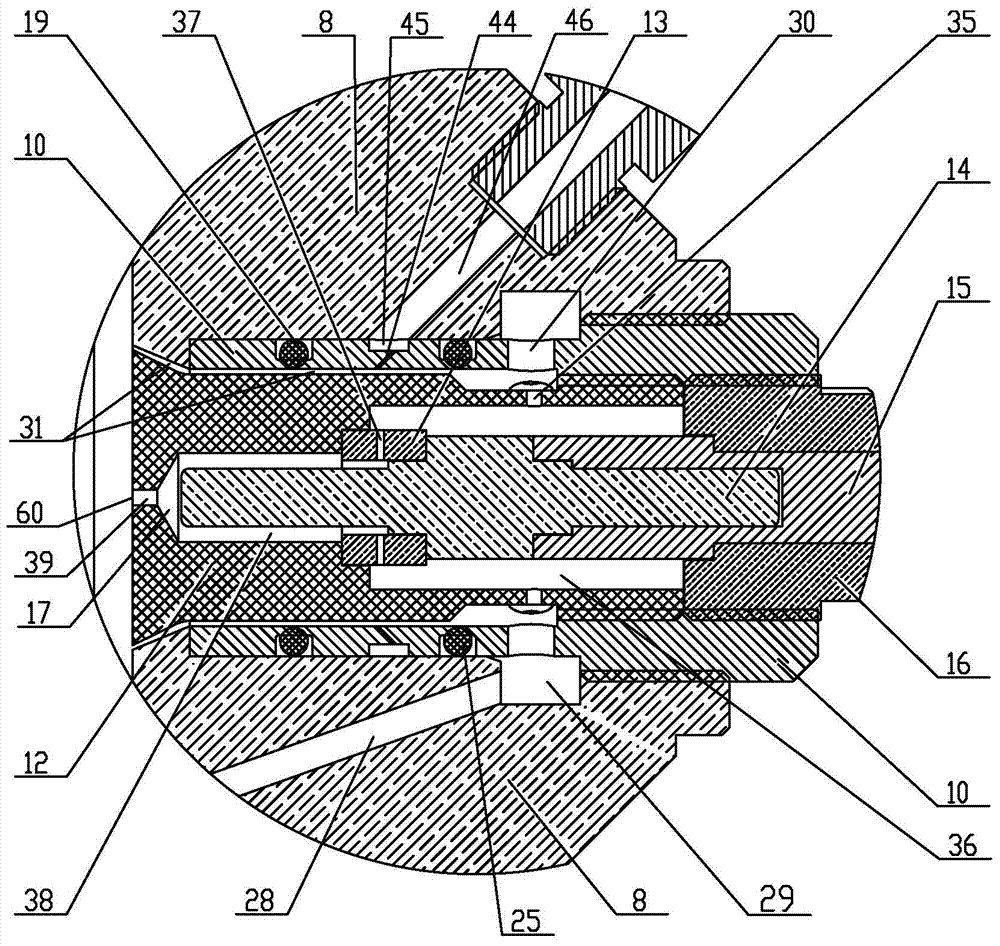

High-speed gas-electric arc composite thermal spraying method and spray gun used in same

ActiveCN104498862AReduces severe oxidation problemsQuality improvementMolten spray coatingLiquid spraying apparatusKeroseneSpray coating

The invention discloses a high-speed gas-electric arc composite thermal spraying method and a spray gun used in the same. The thermal spraying method comprises the following steps: igniting an annular high-speed jet oil-gas mixed flow obtained by mixing kerosene and compressed air by virtue of an air plasma ignition manner; continuously burning the oil-gas mixed flow fully, accelerating to form a supersonic gas and then spraying to a wire material; and electrifying the wire material for arc starting and melting, atomizing and accelerating the wire material under the action of the supersonic gas jet flow, and depositing on the surface of a to-be-sprayed part to form a coating layer. On the basis of the thermal spraying method disclosed by the invention, the wire material subjected to arc melting can be used for realizing efficient spraying on the surface of the to-be-sprayed part under the action of the low-oxygen-content supersonic gas formed when the compressed air supports the combustion of kerosene, and an obtained spray coating layer is good in quality.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

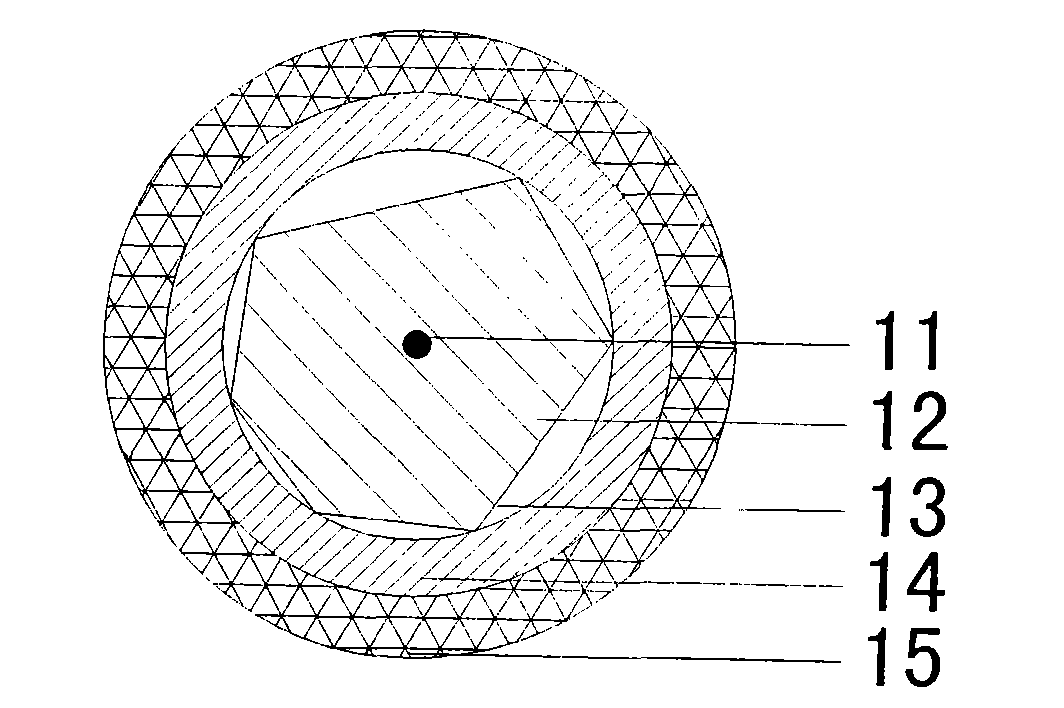

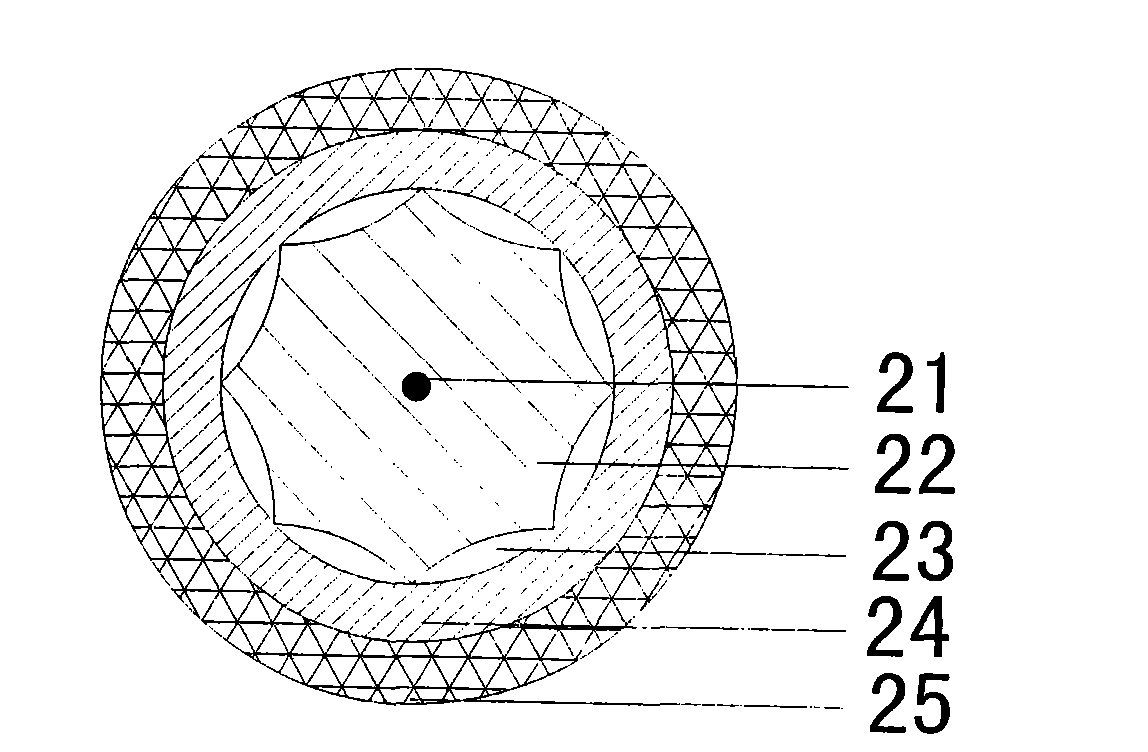

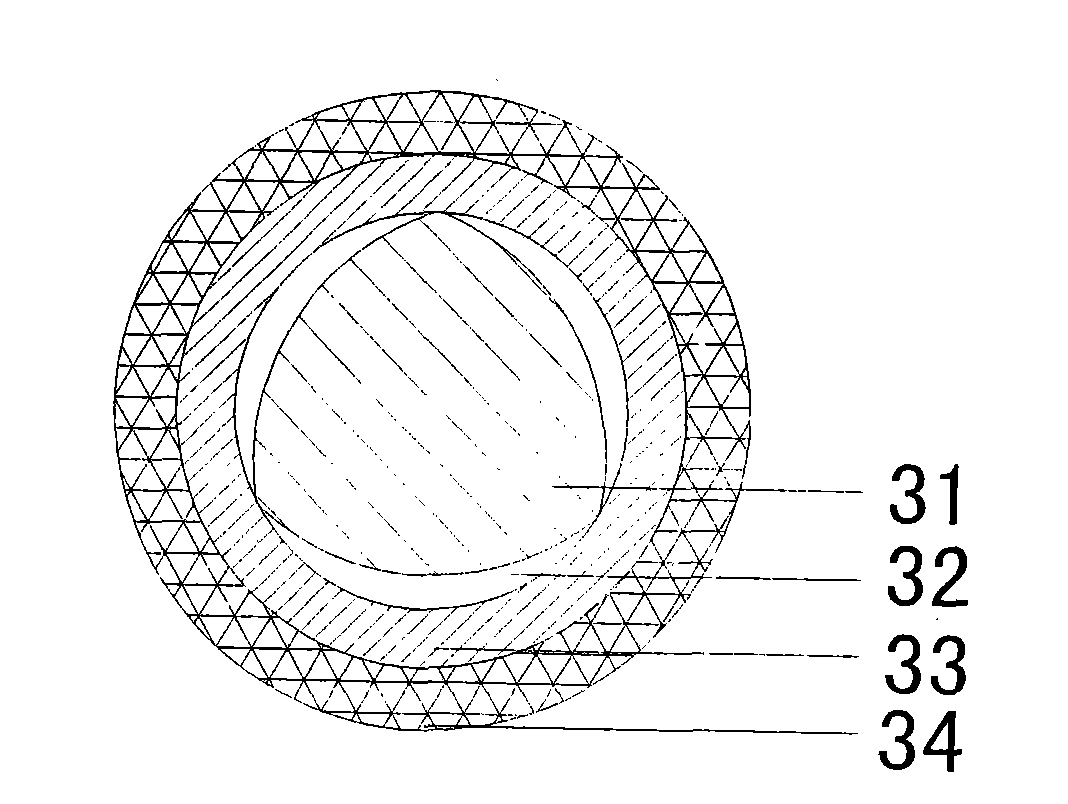

Realization method of air gap clad optical fiber

InactiveCN102654603AImprove cladding coupling efficiencyIncrease numerical apertureOptical fibre with multilayer core/claddingOptical waveguide light guideHigh power lasersCoupling efficiency

The invention relates to a double-clad active optical fiber. Aiming at the defects in the prior art, the invention provides a realization method of an air gap clad optical fiber. The realization method adopts air as an optical cladding layer and adopts a core layer with a novel structure, so that the realization method can be used for improving an energy transmitting optical fiber or a photonic crystal optical fiber of an air cladding layer; the manufacturing process is simplified, the manufacturing cost is reduced and the pumping coupling efficiency is improved. The realization method is characterized in that the optical fiber is formed by a core layer with a polygonal section, the air cladding layer, an inner protection layer with a circular section, and an outer protection layer with a circular section in sequence from inside to outside; the core layer is connected with the inner wall of the inner protection layer with the circular section through the top of a polygonal structure; and an air gap between the inner protection layer and the core layer is the air cladding layer of the optical cladding layer. The double-clad active optical fiber solves the problem of low numerical pore diameters of the conventional high-energy transmission optical fiber and a double-clad optical fiber, and the high-temperature resistance of a low-refractive-index coating material, can improve the structure and the performance of the air cladding layer of the photonic crystal optical fiber, improves the optical fiber production efficiency, and greatly propels application of the optical fiber on the aspects of kilowatt and myriawatt high-energy transmission, a high-power laser system and the like.

Owner:TXSTAR LASER TECH SHANGHAI CO LTD

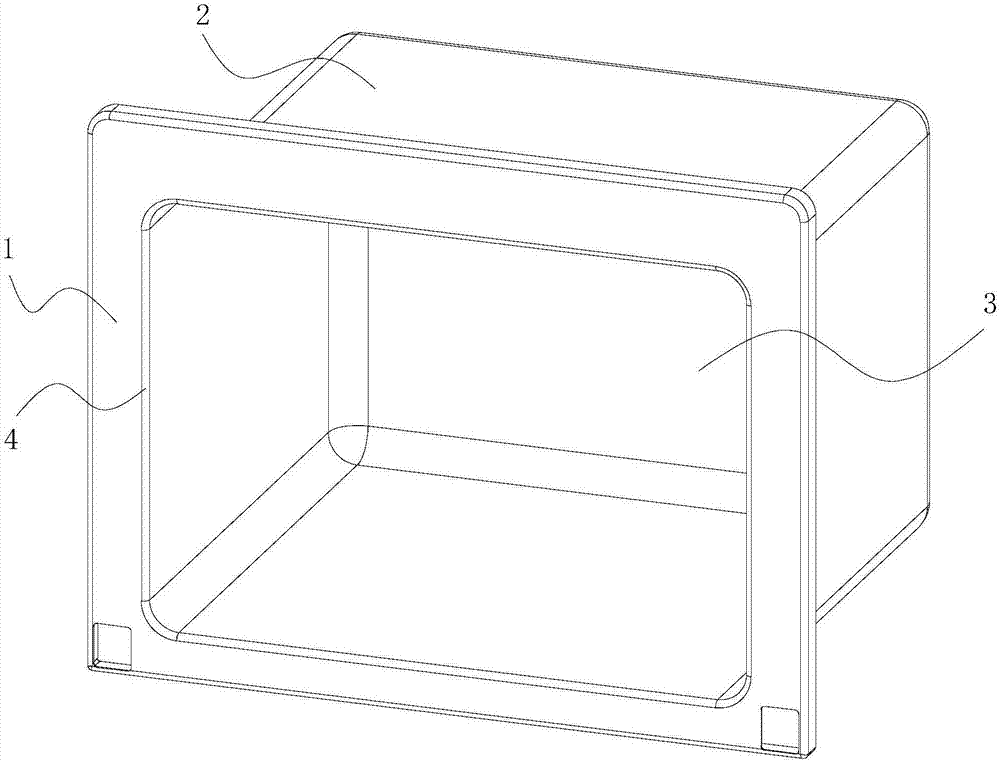

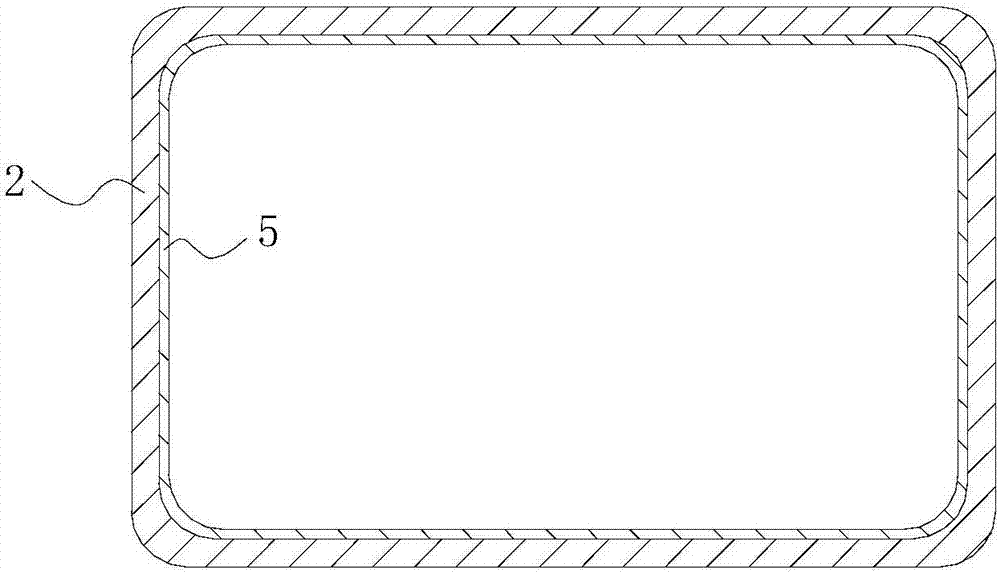

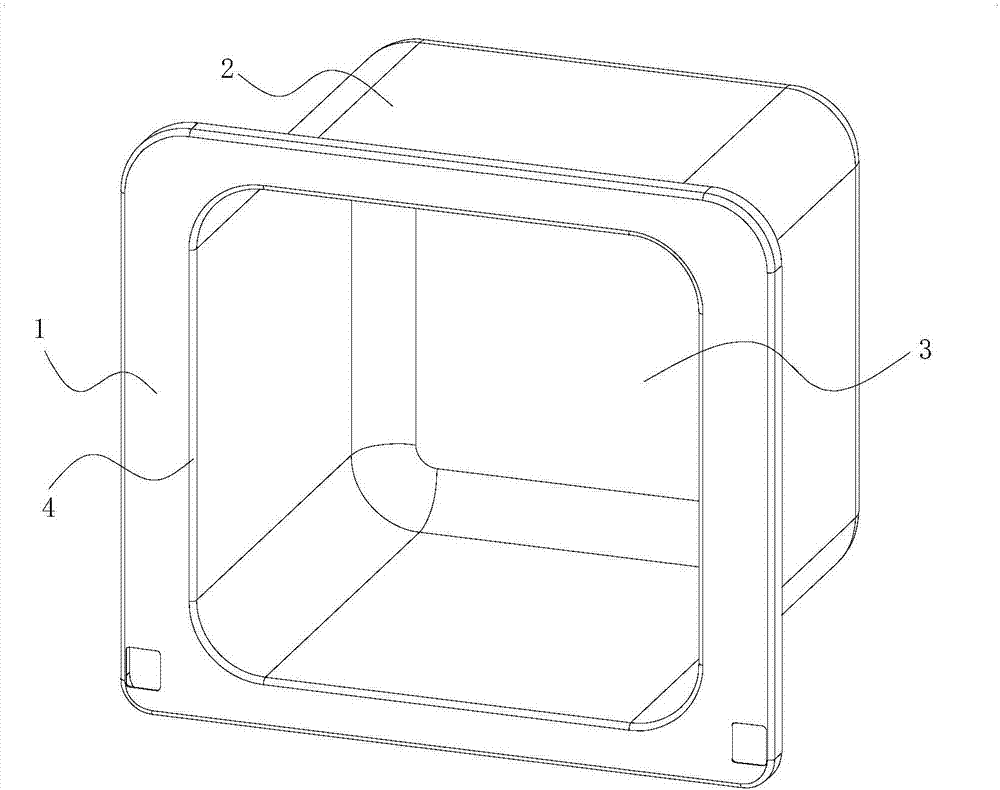

Cavity applying steam oven and steam oven

InactiveCN107485304AImprove air tightnessImprove rust resistanceCooking-vessel materialsSteam cooking vesselsSS - Stainless steelSilica gel

The invention discloses a cavity applying a steam oven. The cavity is formed by stretching and forming whole metal. The cavity comprises a front installation plate, a U-shaped frame and a rear plate, the cavity is formed by stretching and forming the front installation plate, the U-shaped frame and the rear plate at a time, the inner surface of the cavity formed by integrated stretching and forming is coated with an inorganic glassy material, and a metallic matrix of the cavity and the inorganic glassy material are used for coating and sticking through an enameling technology. The invention further provides the steam oven with the cavity. The cavity obtained by integrated stretching and forming is low in mold cost, no splicing gap exists, the consumption of sealing silica gel can be lowered, the sealing performance is good, the surface of the cavity can be completely covered with the inorganic glassy material, the rusting problem is eliminated, an enameled pressed steel plate is adopted for replacing expensive 304 stainless steel, the whole oven cost can be lowered, meanwhile the problems of yellowing and not resisting high temperature can be solved, the 400 DEG C or more high-temperature self-cleaning function can be achieved, and the problem that an existing steam oven is hard to clean is solved.

Owner:广东天倬智能家居有限公司

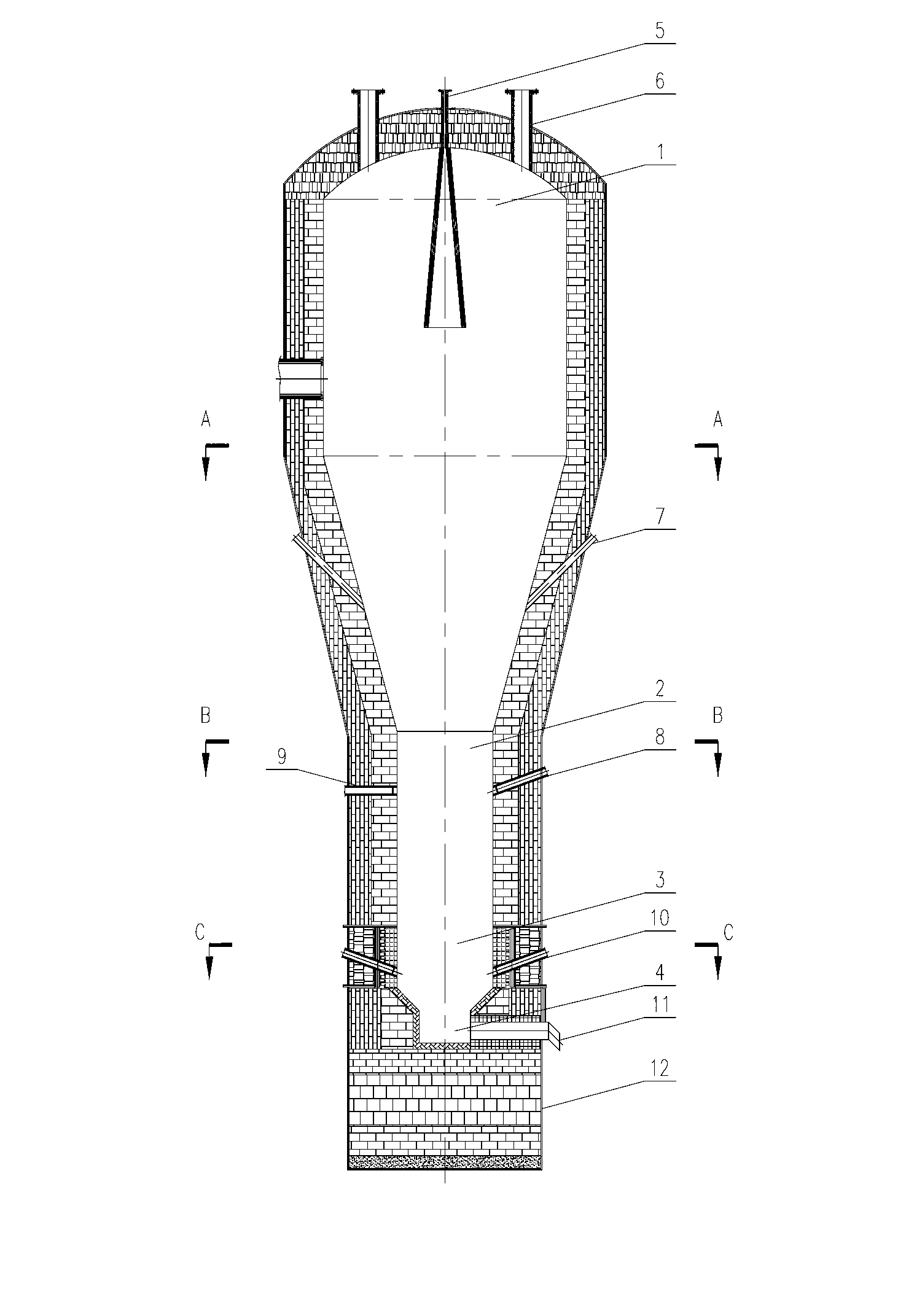

Method for preparing calcium carbide and synthetic gas via flameless oxidation heating method, and calcium carbide reactor

ActiveCN103011164AExtended service lifeIncrease reaction rateCalcium carbideFixed-bed gasificationMixed gasInternal heating

The invention discloses a method for preparing calcium carbide and a synthetic gas via a flameless oxidation heating method, and a calcium carbide reactor, and solves problems of influencing time and effect of calcium carbide reaction caused by uneven heat distribution of the calcium carbide and the synthetic gas prepared by a conventional method and non-uniform particle size of materials entering a reaction chamber. In the method, flameless combustion in the reaction chamber is realized by controlling oxygen content in a mixed gas passing into the reaction chamber; and problems of non-uniform particle size of materials in the reaction chamber is solved by designing feeding particle size at two feeding ports. The reactor enables heat distribution in the chamber to be more uniform through the improvement of oxygen burners of the reaction chamber and a vaporizing chamber. The method is simple in process, is safe and reliable, has more uniform heat distribution, high calcium carbide reaction efficiency and high calcium carbide purity, low loss to furnace walls, the content of the generated synthetic gas is over 7 times that a conventional electrothermal method, and at the same time, consumption rate of raw materials and fuels is low.

Owner:WUHUAN ENG

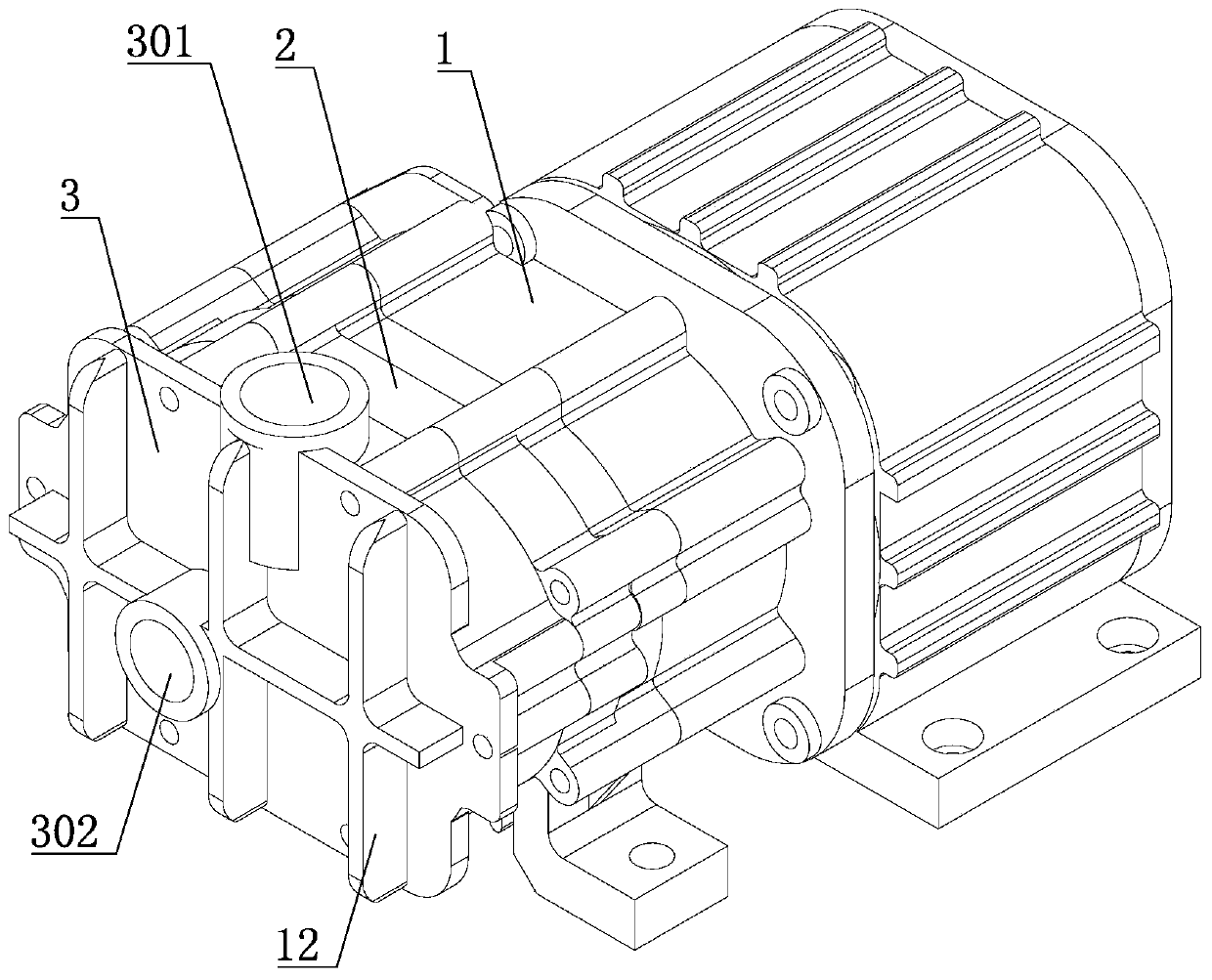

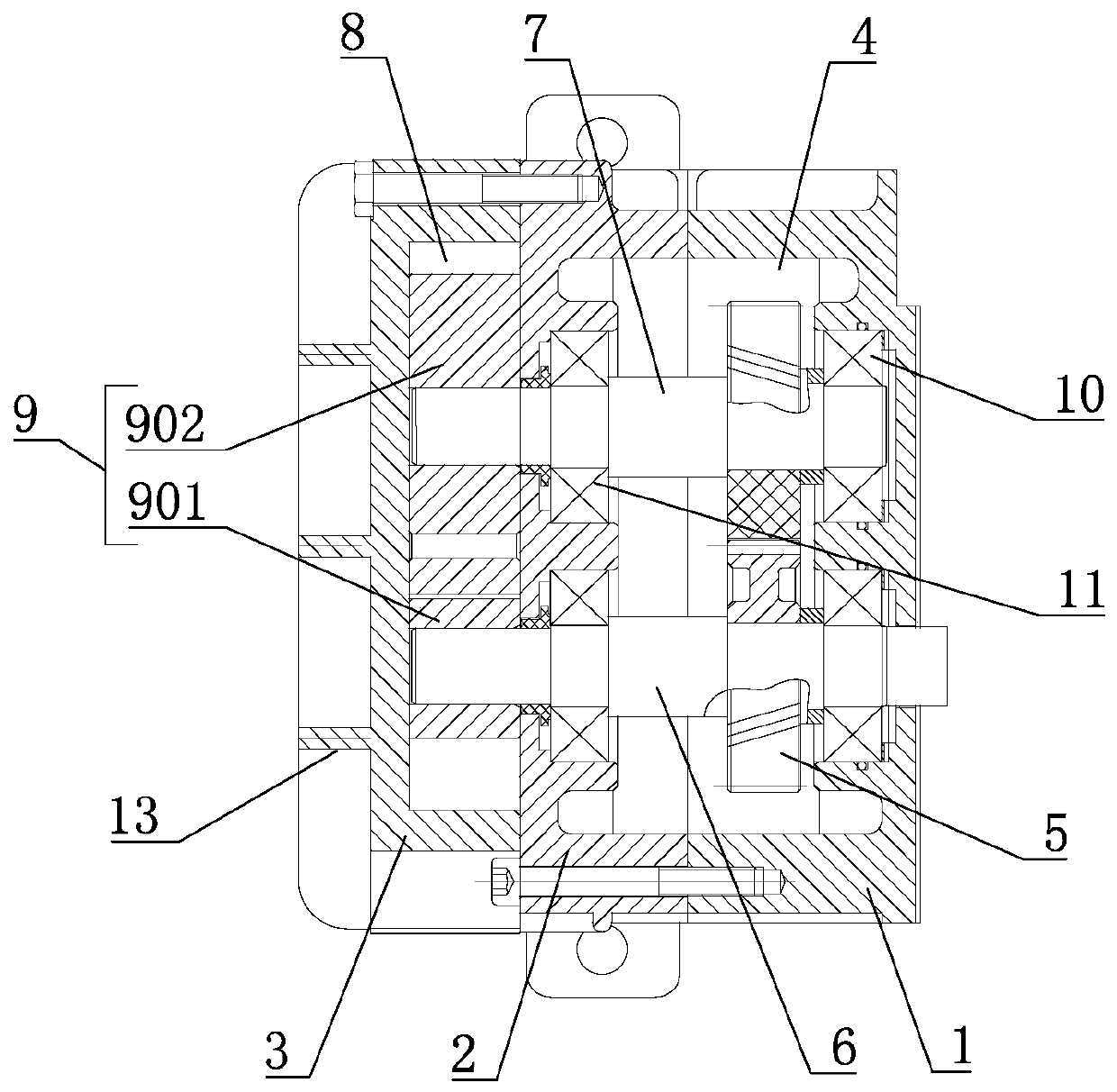

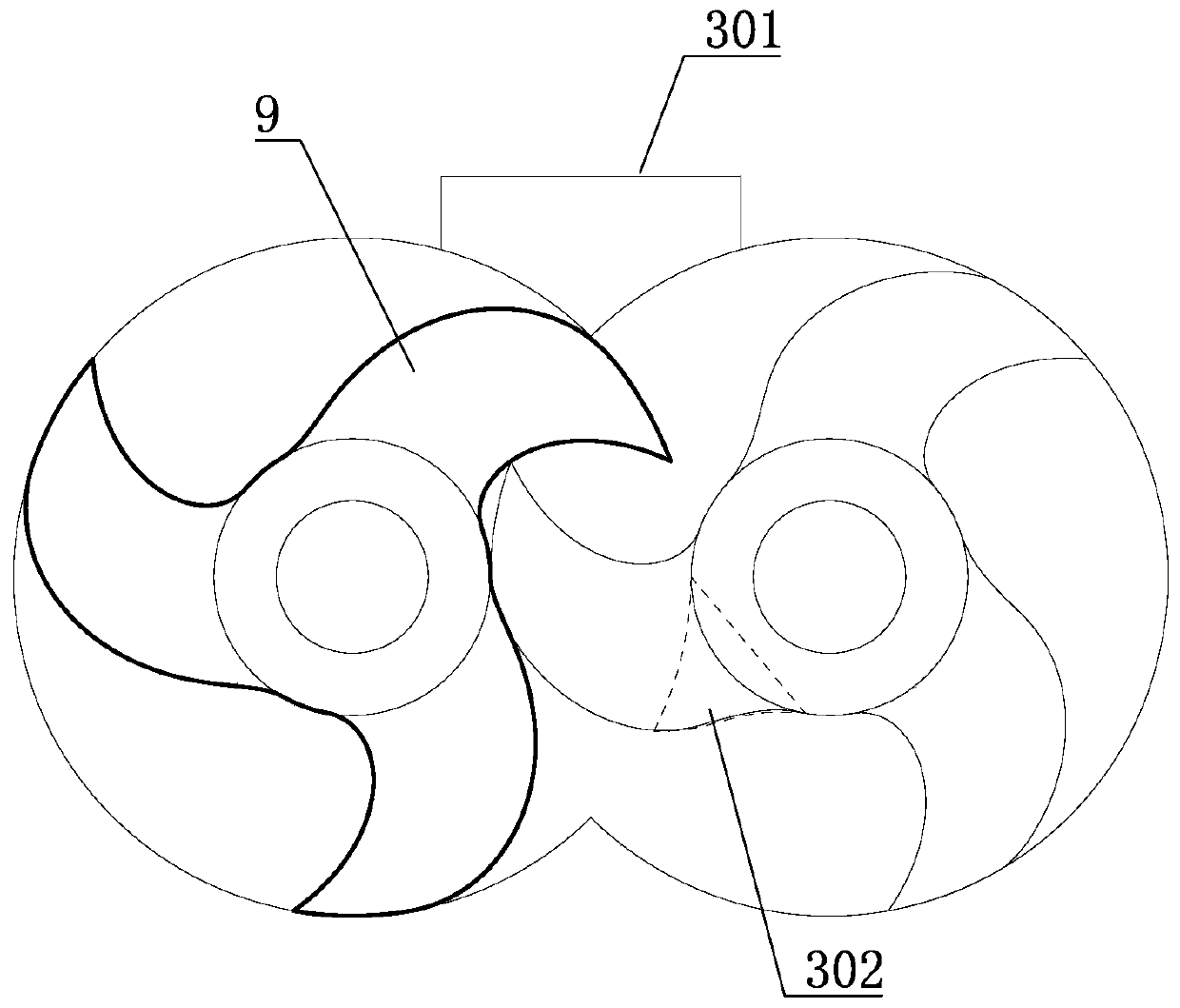

Claw type hydrogen circulating pump

PendingCN110319004AReasonable structural designReduce noiseRotary piston pumpsRotary piston liquid enginesLow noiseHydrogen

The invention relates to a claw type hydrogen circulating pump. The claw type hydrogen circulating pump comprises a first shell body, a bearing end cover connected with the first shell body, and a second shell body connected with the bearing end cover, wherein a gear chamber is formed between the first shell body and the bearing end cover, two self-lubricating gears which are meshed with each other are arranged in the gear chamber, and no lubricating oil exists in the gear chamber; the two self-lubricating gears are correspondingly connected with a driving shaft and the driven shaft; a rotor chamber is formed between the bearing end cover and the second shell body, and two mutually matched three-jaw rotors are arranged in the rotor chamber. According to the claw type hydrogen circulating pump, the synchronous gears of the rotors adopt a novel technology of non-metal self-lubricating, and has the characteristics of high temperature resistance and no need of lubrication, therefore, lubricating oil does not need to be added in the gear chamber, the oil-free operation of the hydrogen circulating pump is realized, and the problem of the lubricating oil leakage is fundamentally solved; and moreover, the self-lubricating gears of non-metal material further has the advantages of wear resistance and low noise, the replacement maintenance of the lubricating oil is not needed, and equivalently, the maintenance-free of the gears is realized.

Owner:烟台东德氢能技术有限公司

Scratch-resistant black heat transfer printing ink and preparation method thereof

ActiveCN103725090AAnti-scratch guaranteeDoes not affect heat dissipationInksAnodic oxidationChemistry

The invention discloses a scratch-resistant black heat transfer printing ink and a preparation method thereof. The printing ink comprises the following components in percent by weight: 25-35 percent of epoxy resin, 5-8 percent of phenolic resin, 3.5-5.0 percent of a curing agent, 45-60 percent of a heat conducting filling material, 10-12 percent of a coloring agent and 0.5-0.7 percent of an additive. The printing ink has a rigidity larger than 6 H after being roasted and pressed to meet the scratch-resistant requirement of Al-based copper-clad plate production and manufacturing, has the thermal conductivity reaching 1.5 W to facilitate the radiating of an Al-based copper-clad plate compared with an anodic oxidation film and a PET protecting film, and has a maximum bearing temperature of 230 DEG C and maximum pressure of 100 kg / cm<2>, and therefore, a novel method for using the heat transfer printing ink is found, the radiating function of the Al-based copper-clad plate is not affected while the aluminium surface is prevented from scratching. The heat transfer printing ink is a new measure for protecting the aluminium surface of the Al-based copper-clad plate.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

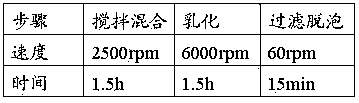

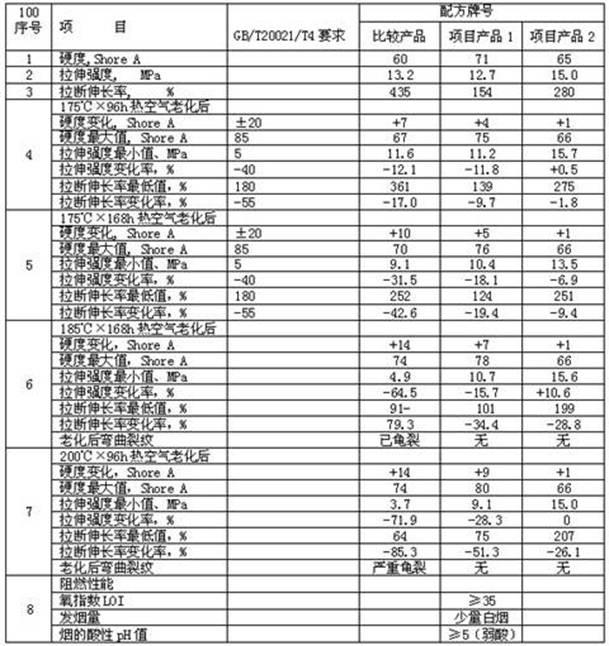

Composition as well as preparation method and application thereof

ActiveCN103146084ASolve high temperature resistanceSolve the requestOther chemical processesPolyoxymethyleneStearic acid

The invention provides a composition as well as a preparation method and an application thereof. The composition is prepared from the following raw materials in parts by weight: 100+0.5 parts of EPDM (Ethylene-Propylene-Diene Monomer), 6+ / -0.01 parts of activated zinc oxide, 0.5+ / -0.01 part of stearic acid, 3+ / -0.01 parts of antiager RD, 2+ / -0.01 parts of anti-fog wax, 1.2+ / -0.01 parts of rubber dispersant, 30+ / -0.5 parts of carbon black N330, 35+ / -0.5 parts of carbon black N550, 12+ / -0.5 parts of softener, 4.5+ / -0.005 parts of DCP (dicumyl peroxide) and 0.45+ / -0.005 parts of vulcanizing agent POM (polyoxymethylene). The composition can be used for preparing high temperature resistant and atomized materials, so that the composition has the high temperature resistant and atomized requirements, so that the defects that in the prior art, the high temperature resistant time is not long, the atomization and the temperature resistance cannot achieve simultaneously, and the performances after heat resistance are obviously reduced are solved. The composition can be widely applied to the automobile industry and the electron industry, the production efficiency is improved, and the time and resource are saved.

Owner:厦门市金汤橡塑有限公司

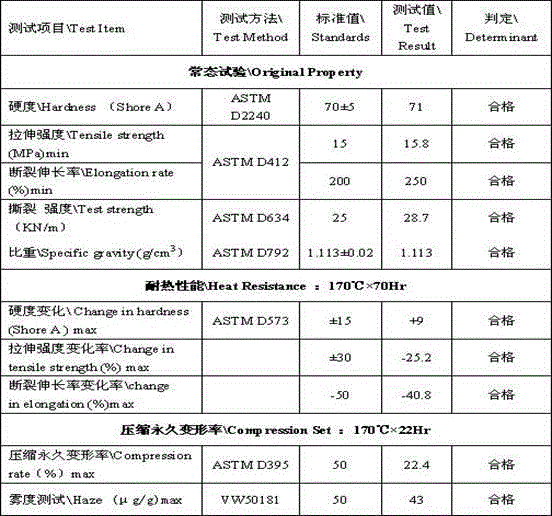

Dry-method coating layer production technology for label cloth

InactiveCN104195829ASolve sheddingSolve high temperature resistanceFibre treatmentWinding machineNonwoven fabric

The invention discloses a dry-method coating layer production technology for label cloth. The dry-method coating layer production technology comprises the steps of mixing raw materials, such as water-borne polyacrylate, a crosslinking agent, a filler, a wetting dispersant, a thickening agent, a flatting agent and auxiliary resin, according to a certain ratio, and stirring the raw materials and water through a stirrer to prepare a coating layer material; uniformly coating non-woven cloth with the coating layer material through a label cloth coating machine; drying the label cloth by a dryer; cooling the label cloth through refrigeration equipment; and after the label cloth is wound by a winding machine, splitting the label cloth through a cutter, and packaging the label cloth through a packaging machine. According to the dry-method coating layer production technology for the label cloth, the quality of the coating layer material is improved, the processing working procedures are reduced, the cost is lowered, and the production efficiency is improved.

Owner:HUZHOU KAIEN COATING

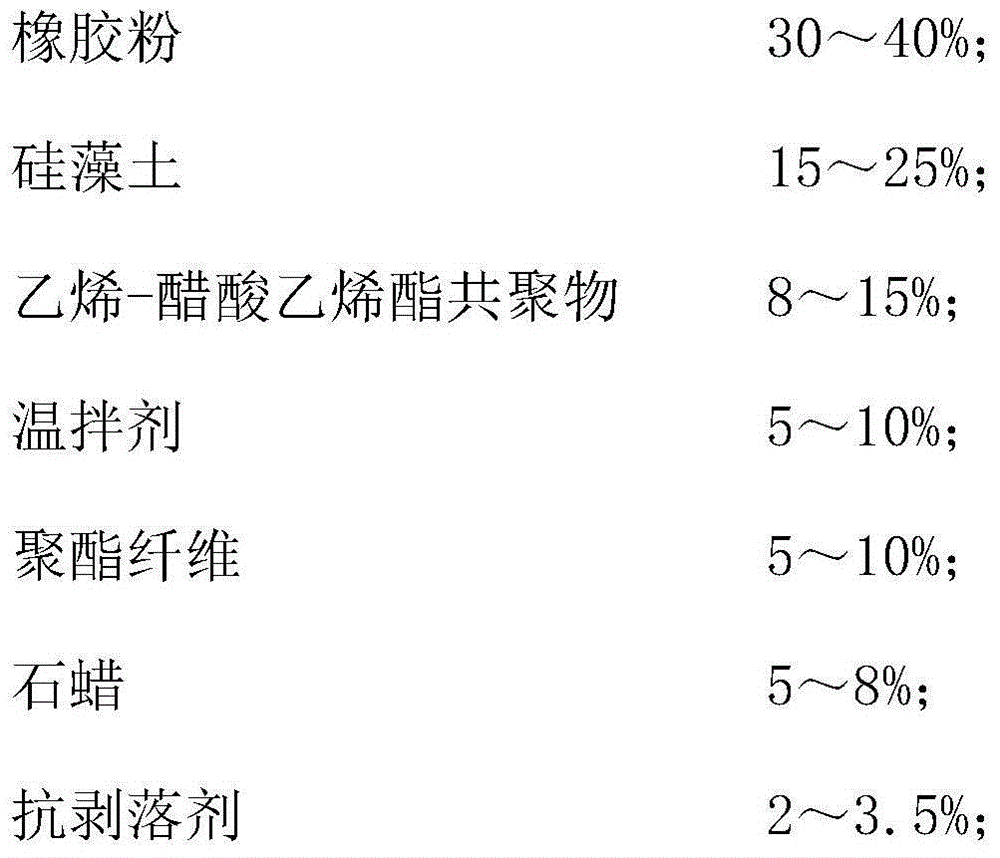

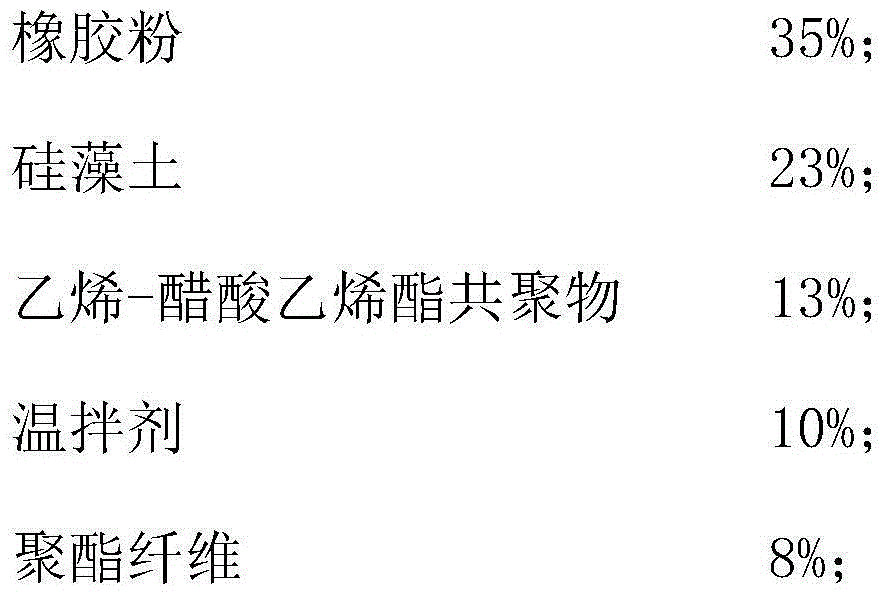

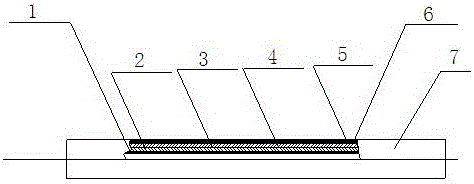

Warm-mixing SMA (styrene maleic anhydride)-modified asphalt concrete modified particle and preparation method thereof

InactiveCN104592773AAchieve comprehensive road performanceSolve shipping problemsClimate change adaptationBuilding insulationsPolyesterFiber

The invention discloses a warm-mixing SMA (styrene maleic anhydride)-modified asphalt concrete modified particle. The warm-mixing SMA-modified asphalt concrete modified particle comprises the following components in percentage by mass: 30-40% of rubber powder, 15-25% of diatomite, 8-15% of an ethylene-vinyl acetate copolymer, 5-10% of a warm-mixing agent, 5-10% of polyester fibers, 5-8% of paraffin and 2-3.5% of an anti-stripping agent, based on 100% in total. The invention further discloses a preparation method of the modified particle. According to the warm-mixing SMA-modified asphalt concrete modified particle disclosed by the invention, additives with different modifying functions are physically co-mixed and chemically modified and mixed to prepare the modified particle which is used for paving high-grade asphalt pavement, so that a conventional SBS (styrene butadiene styrene) asphalt modifying technology production process is replaced, the problems in transportation, storage and the like of the SBS modified asphalt are solved, the investment, the pollution and the energy consumption are reduced, the comprehensive road performances of the asphalt pavement are improved, the service life of the pavement is prolonged, the road construction cost and the maintenance cost are reduced, and the economic value and the social benefits are extremely high.

Owner:ZHEJIANG HENGSHENG TECH

Automobile hydraulic-braking hose and manufacturing method thereof

InactiveCN105757364ASolve high temperature resistanceSolve low temperature resistanceThermal insulationFlexible pipesIsolation layerEngineering

The invention discloses an automobile hydraulic-braking hose and a manufacturing method thereof. The automobile hydraulic-braking hose comprises a rubber hose body of a multi-layer composite structure, the rubber hose body comprises an inner rubber layer, a first braided layer, an insulating layer, a second braided layer, a bonding layer and an outer rubber layer sequentially from inside to outside, wherein the first braided layer is arranged outside the inner rubber layer, the insulating layer is added outside the first braided layer, the second braided layer is arranged outside the insulating layer, the bonding layer is added outside the second braided layer, and the outer rubber layer is extruded outside the bonding layer. The properties, such as expansion, fatigue, tensile strength and pulse, of the automobile hydraulic-braking hose are optimized, resistant high temperature is increased from 100 DEG C to 120 DEG C, resistant low temperature is decreased from -45 DEG C to -57 DEG C, resistant ozone is increased from 50 ppm to 200 ppm, and adhesive force between the outer rubber layer and the second braided layer is increased from 5 N / cm to 15 N / cm.

Owner:NANJING ORIENTLEADER TECH CO LTD

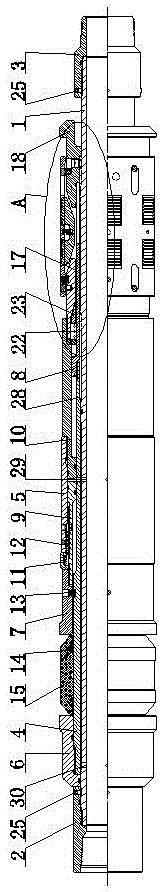

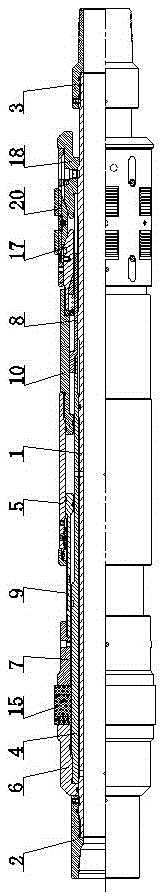

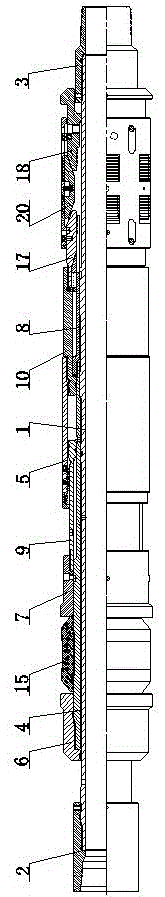

High-temperature high-pressure hydraulic recoverable packer

ActiveCN105545246ACompact structureLong-lasting and effective settingSealing/packingUpper jointWell stimulation

The invention relates to a high-temperature high-pressure hydraulic recoverable packer, and belongs to the field of oil and gas well borehole operation tools. The packer is composed of an upper joint, a lower joint, an outer center pipe, a cylinder sleeve, an upper guide ring and a lower guide ring. The upper joint is mounted at one end of an inner center pipe through a thread, and the lower joint is mounted at the other end of the inner center pipe through a thread. The outer center pipe and a release claw are mounted at the position, between the upper joint and the lower joint, of the inner center pipe, and an upper piston and a lower piston are mounted on the outer center pipe through the cylinder sleeve. The lower guide ring is nailed at the position, at one side of the cylinder sleeve, of the outer center pipe through a shear pin. The upper guide ring is mounted at the position, at one side of the lower guide ring, of the outer center pipe through a thread. The packer is compact in structure. A setting and unsetting structure is ingenious in design. The problem that an existing packer is unrecyclable, poor in compression resistance and poor in high temperature resistance is solved, and the high-temperature high-pressure hydraulic recoverable packer is especially suitable for operation of all kinds of well stimulation such as production, single-layer fracturing and separate-layer fracturing of deep wells and appraisal wells.

Owner:荆州市赛瑞能源技术有限公司

Laser cladding rare-earth modified iron-based ceramic composite long-service-life high-wear-resistance corrosion-resistant marine equipment piston rod coating and preparation process thereof

InactiveCN110318051AReduce porosityHigh surface hardnessMetallic material coating processesPiston rodsCeramic compositeRare earth

The invention discloses a laser cladding rare-earth modified iron-based ceramic composite long-service-life high-wear-resistance corrosion-resistant marine equipment piston rod coating and a preparation process thereof. The coating comprises the following components of, in percentage by mass, 15%-19% of Cr, 1%-2% of Mn, 5%-8% of Mo, 1%-2% of W, 11%-16% of B, 2%-5% of C, 1%-3% of Si, 8%-10% of ceramic powder, 0.5%-2% of rare earth oxide powder and the balance Fe. By taking the coating as a cladding material, laser cladding is adopted to obtain the laser cladding rare-earth modified iron-based ceramic composite long-service-life high-wear-resistance corrosion-resistant marine equipment piston rod coating, the coating has excellent wear resistance and corrosion resistance, the coating is highin surface hardness, is strong in binding force with a matrix material, and can bear large loads, and the problems that an existing coating is easy to peel off and corrode and is used in the wearingenvironment are effectively solved; and the coating has the advantages that the production cost is low, the preparation method and process is stable, performance is stable, and the coating is suitablefor large-scale application on fresh water and marine equipment facilities.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

Fuel-cell ceramic proton exchange membrane and preparation method thereof

ActiveCN104393318ASolve high temperature resistanceSolve the problem of longevityFinal product manufactureSolid electrolyte fuel cellsFuel cellsElectro conductivity

The invention relates to a fuel-cell ceramic proton exchange membrane and a preparation method thereof. Concretely, a nano-level ceramic particle with fixed shape is employed for preparing a ceramic membrane with a double-layer continuous structure, and the ceramic membrane is used as the fuel-cell ceramic proton exchange membrane. The proton exchange membrane has the advantages of high proton electric conductivity, simple film forming process, low cost, high working temperature and long service life, and is suitable for industrial production of fuel batteries and market popularization application.

Owner:深圳国氢新能源科技有限公司

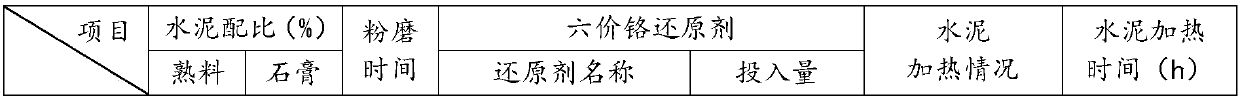

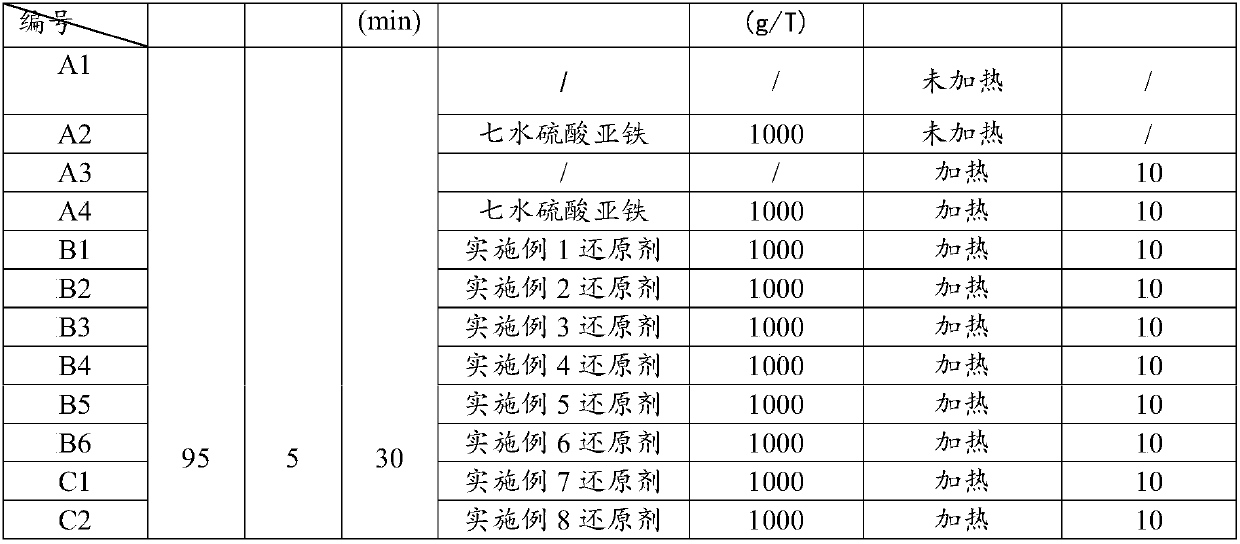

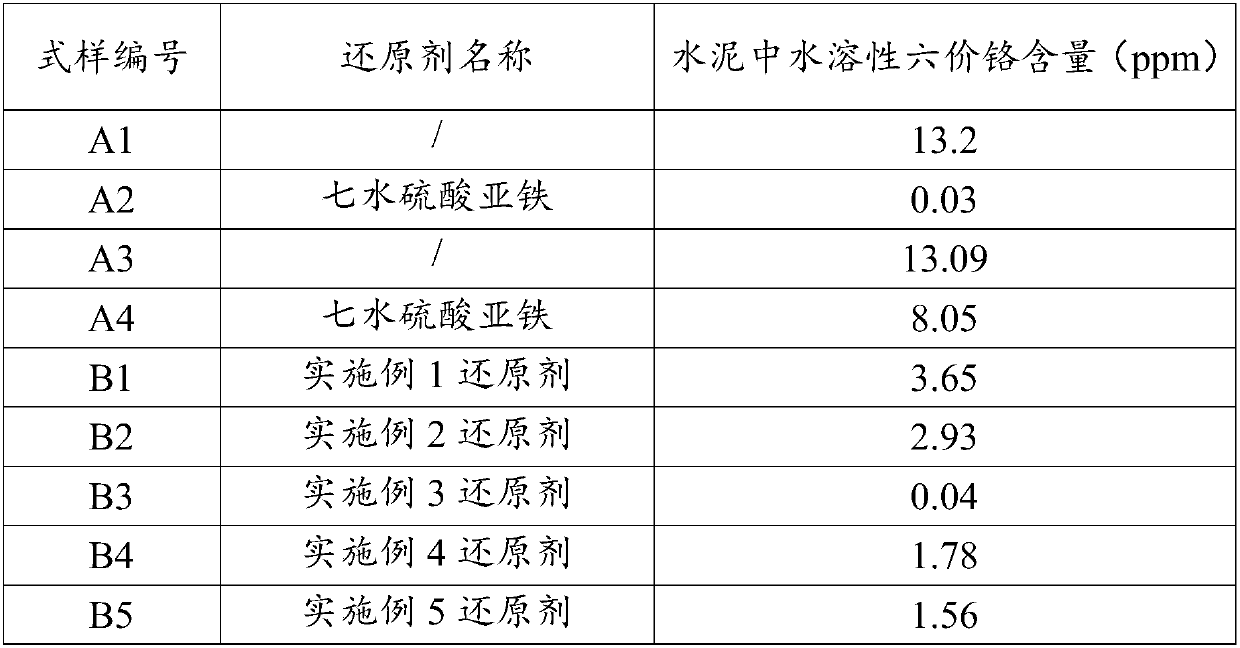

Hexavalent chromium reducing agent and preparation method thereof

ActiveCN107915420APrevent Oxygen OxidationSolve the problem of low temperature resistance and poor stabilitySolubilityHexavalent chromium

The invention provides a hexavalent chromium reducing agent and a preparation method thereof. The reducing agent contains the following components in parts by weight: 50-90 parts of an iron-based reducing agent, 0.57-3.6 parts of nanometer zero-valent iron and 0.9-7.1 parts of a dispersing agent. According to the hexavalent chromium reducing agent provided by the invention, an iron-based reducingagent is uniformly packaged by a dispersing agent solution containing nanometer zero-valent iron particles, and very high reaction activity is achieved by mixing nanometer zero-valent iron with the iron-based reducing agent, so that hexavalent chromium in the reducing agent solution can be rapidly reduced; dispersing agent molecules are capable of stabilizing nanometer zero-valent iron and packaging the iron-based reducing agent, so that the oxidation of the iron-based reducing agent by oxygen in the air is prevented, the hexavalent chromium reducing agent has a moisture preserving function, and the situations that because the partial water-entraining iron-based reducing agent is dehydrated under a high temperature condition, the solubleness is reduced, and the iron-based reducing agent isunlikely to participate in the reducing reaction of hexavalent chromium are prevented.

Owner:DONGYUAN HONGCHAO TECH

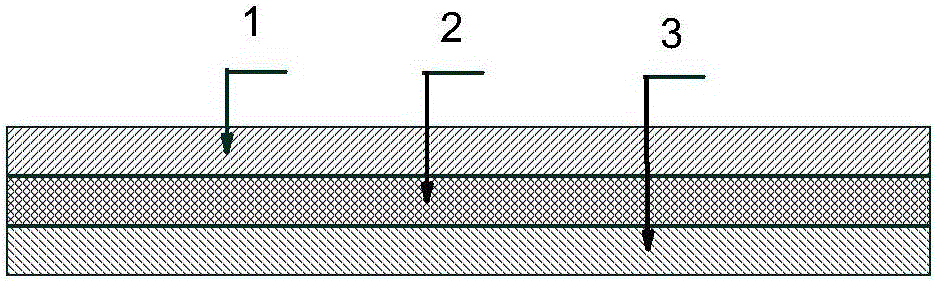

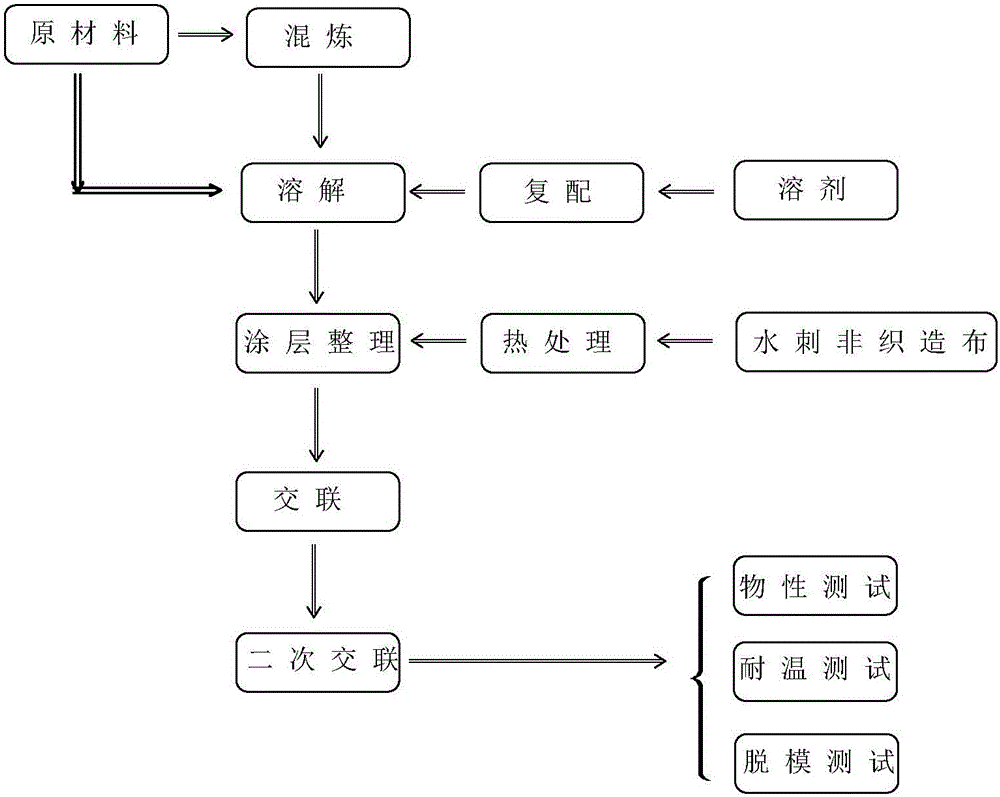

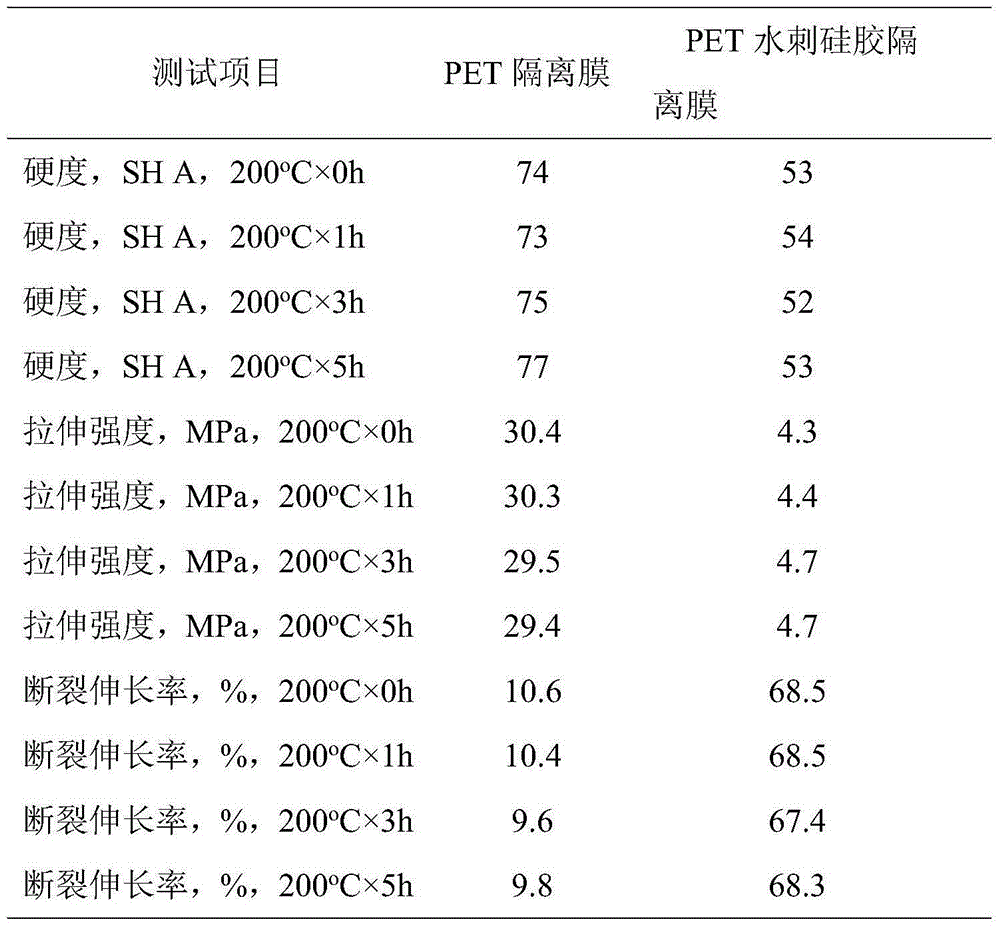

High-temperature resistant isolating membrane and preparation method thereof

ActiveCN105113262ASolve high temperature resistanceImprove flexibilityFibre typesCoatingsFiberEmulsion

The invention discloses a high-temperature resistant isolating membrane and a preparation method thereof. The isolating membrane comprises a base material and silicone rubber isolating coatings coated on two sides of the base material, wherein the base material is spunlace non-woven cloth. The preparation method comprises the following steps: (1) preparation of functional silicone rubber; (2) preparation of a mixture of solvent-type silicone rubber emulsions; (3) heat treatment of the spunlace non-woven cloth, coating finishing, curing and cross linking. The high-temperature resistant isolating membrane has the advantages that (1) the isolating membrane is resistant to high temperature; (2) the isolating membrane is resistant to thermal shrinkage; (3) the isolating membrane can be recycled. As the isolating coatings are mainly made of liquid or solid silicone rubber, and is high in wettability and physical entanglement property to fiber of the non-woven cloth, the isolating membrane is integral after curing under the action of a cross-linking agent, is prevented from peeling off and layering, is relatively high in overall strength, excellent in flexibility, and is still resistant to aging and damage after being recycled.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

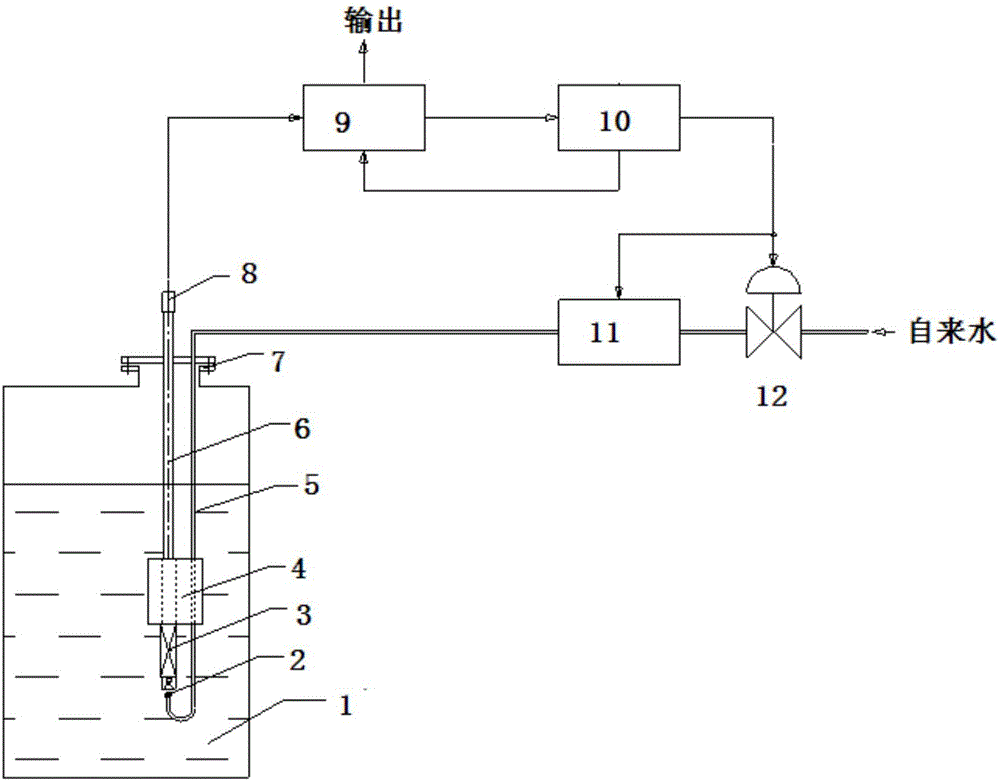

Online measurement device for measuring pH value of leached neutralizing tank slurry of uranium ore hydrometallurgical mill

InactiveCN106770577ASolve acid and alkali corrosion resistanceSolve high temperature resistanceMaterial electrochemical variablesAutomatic controlMeasurement device

The invention provides an online measurement device for measuring a pH value of leached neutralizing tank slurry of a uranium ore hydrometallurgical mill. The device comprises a pH sensor for measuring the pH value, a pH converter for converting a measurement signal and an automatic cleaning device. The composite pH sensor suitable for a medium system is selected, the device with a regular automatic cleaning function is added for the pH sensor on such a basis, and a cleaning controller is regularly and automatically controlled to control an electromagnetic valve to be opened and closed and control a booster pump to be started and stopped to realize automatic cleaning of the composite pH sensor through a pH converter computer system. According to the device, the measurement accuracy is less than or equal to + / -0.1pH when the pH value of the leached neutralizing tank slurry is measured by a certain uranium ore hydrometallurgical mill, and the requirement of an industrial production site on accurate measurement of the pH value of the leached slurry is met.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

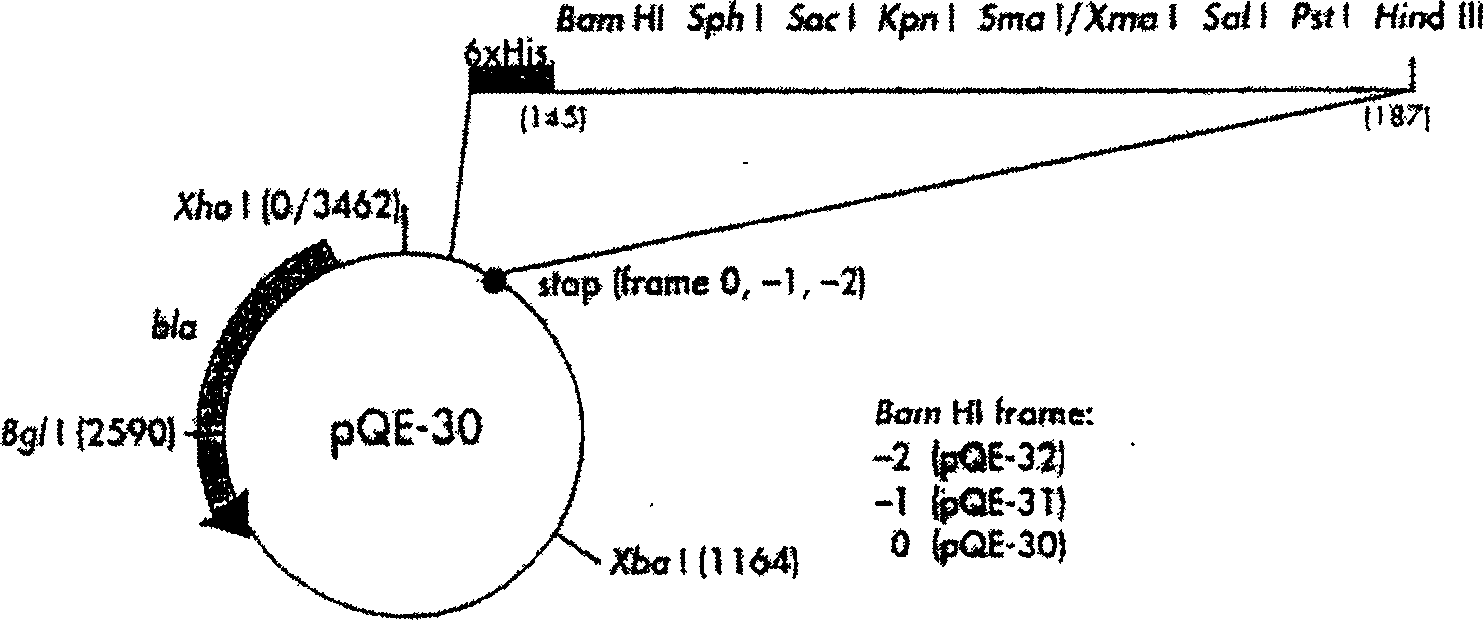

Heat-resistant phytase, clone and expression of gene

InactiveCN1552872AAdd new traitsSolve high temperature resistanceBacteriaHydrolasesBiotechnologyPhytase

Heat resistant phytase and its gene clone and expression are disclosed to solve low heat resistance of the prior phytase, loss of its nutrition and waste on adding surplus nutrition. The technological scheme includes screening natural heat resistant strain of phytase, cloning its gene that has 1152 nucleotides, 383 encoding amino acids with 26 amino acids at the end N as signal peptides in total length, cut point of the signal peptides locating at rear of +26 lactamine, establishing engineering strain of heat resistant phytase gene (SDLiuTP01) to express gene products. The said phytase has biological activity at wide temperature range to promote plant growth, to increase soil fertility, not to damage crop quality, to degrate insoluble phosphorus in food and feed to increase use of phosphorus and to reduce organic phosphorous pollution.

Owner:TIANJIN NORMAL UNIVERSITY +1

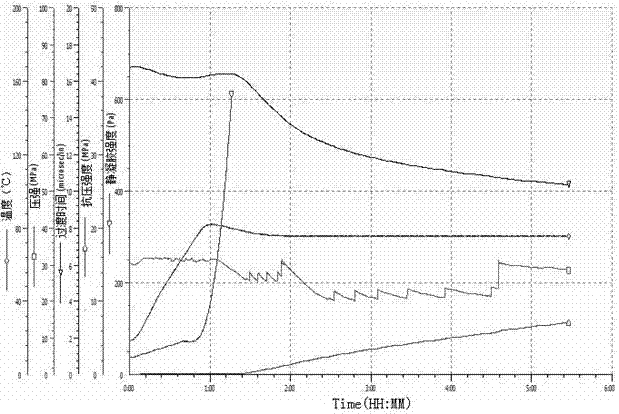

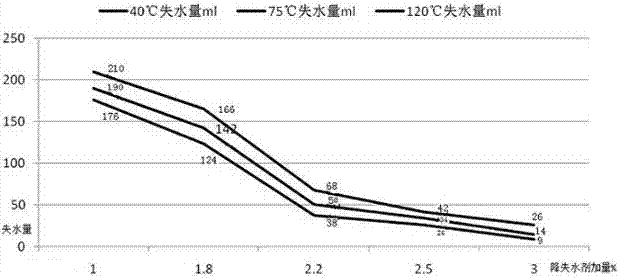

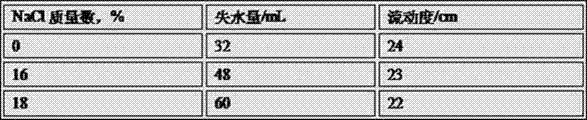

Acrylic fluid loss agents for oil well cement as well as preparation method and application of acrylic fluid loss agents

InactiveCN107325799ASolve high temperature resistanceSolve the problem of poor salt resistanceDrilling compositionSealing/packingCalcium formateTransition time

The invention provides acrylic fluid loss agents for oil well cement as well as a preparation method and an application of the acrylic fluid loss agents. The acrylic fluid loss agents for the oil well cement are prepared from components in percentage by weight as follows: 15-20 parts of acrylic polymers, 45%-50% of calcium formate, 20%-25% of sodium sulfate and the balance of triethanolamine. The water retention and wide-spectrum acrylic polymer fluid loss agents are particularly applicable to high-temperature and high-salt oil-layer well cementation and have the comprehensive properties including low fluid loss, temperature resistance, salt resistance, wide temperature use range, high gas channeling prevention capability and the like. The acrylic fluid loss agents can effectively control fluid loss of cement slurry, prevent free water from entering the stratum and ensure the bonding quality of set cement with the interface, also has a function of channeling prevention in the stratum and guarantees the well cementation quality. A formed cement slurry system has good fluidity and has no thixotropy when left to stand; fluid loss of the cement slurry is small, the sedimentation stability is good, and the compressive strength is high; the thickening transition time is short, and the thickening curve type is normal; the acrylic fluid loss agents have the comprehensive properties including temperature resistance, salt resistance, wide temperature use range, high gas channeling prevention capability and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

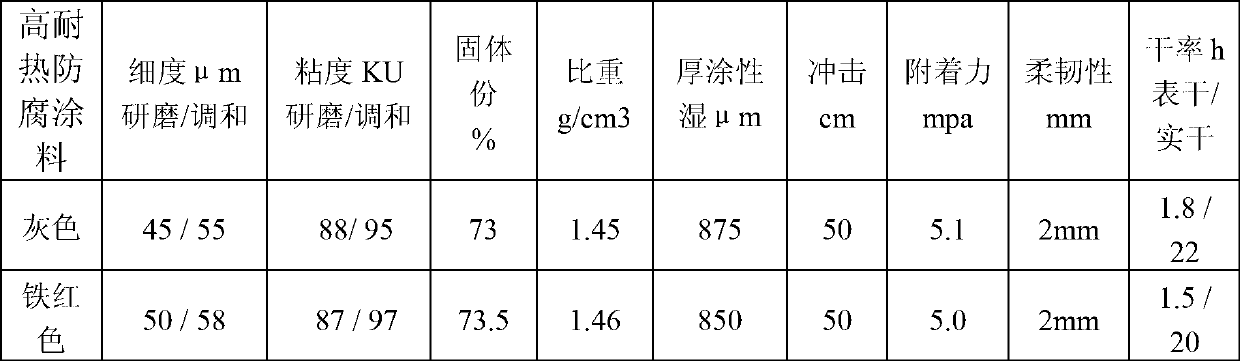

High temperature resistant anticorrosive paint and preparation technology thereof

ActiveCN102993916AImprove anti-corrosion performanceSolve high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPliability

The invention discloses a high temperature resistant anticorrosive paint which comprises a main agent and a curing agent, wherein the main agent comprises novolac epoxy resin F-51, diluent, a pigment filler and an auxiliary agent; the invention also disclosed a preparation technology of the paint, and the method comprises the following steps of: blending, grinding, mixing and the like. The high temperature resistant anticorrosive paint is used for solving the problems of high temperature resistance and anticorrosion after long-term immersion of a pipeline or a hot water tank in the boiling water environment, and the inner wall coating formed by the paint is high temperature resistant, high in corrosion resistance, thick in coating and good in flexibility; meanwhile, the high temperature resistant anticorrosive paint can be cured at the room temperature, has no special requirements for the construction environment and technology, has no strict requirements for the treatment of the surface of a metal substrate, and is good in construction performance, thus greatly lowering the construction cost and being widely applied to the inner walls of various heat accumulation tanks and hot water pipelines.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

High-temperature resistant halogen-free fire-retarding rubber conveyer belt rubber material and conveyer belt made thereof

ActiveCN101993557ASolve high temperature resistanceSolve flame retardancyConveyorsRubber materialEngineering

The invention relates to a high-temperature resistant halogen-free fire-retarding rubber conveyer belt rubber material which is high temperature resistant and fire-retarding and a conveyer belt made thereof. The rubber material comprises the following components: 90 to 110 parts of high-temperature resistant rubber, 170 to 190 parts of halogen-free fire retardant, 35 to 45 parts of reinforcing additive, 7 to 13 parts of thinker, 3.5 to 5.5 parts of vulcanizing agent, 1.5 to 2.5 parts of anti-aging agent A, 1.0 to 2.0 parts of anti-aging agent B and 1.0 to 2.0 parts of promoter. The components can be added or reduced according to a ratio. The invention has the advantages that: two main technical drawbacks in terms of high-temperature resistance and halogen-free and fire-retarding properties of the conventional products of the rubber conveyer belt industry are overcome; the application, used to lack, of the rubber material of the rubber conveyer belt products under halogen-free, fire-retarding and high temperature-resistance conditions is realized; the use safety of the conveyer belt products is improved considerably; and the service life of the products is prolonged.

Owner:浙江顺豪新材料有限公司

Wet-wax crazy-horse resin for processing leather surface and preparing method thereof

InactiveCN101429577ASolve Crazy Horse DiscolorationSolve high temperature resistanceLeather surface finishingStrong acidsSizing

The invention discloses a wet wax crazy horse resin for treating the surface of leather and a manufacturing method thereof. The wet wax crazy horse resin comprises the following compositions in weight portion: 80 to 120 portions of PU resin, 60 to 100 portions of dimethylfomamide, 50 to 90 portions of toluene, 10 to 20 portions of wax powder, 3 to 7 portions of methyl organosilicon, 5 to 15 portions of hydroxyl organosilicon and 6 to 12 portions of acrylic powder; The process comprises the following steps: (1) according to mixture ratio, a toluene solution and a dimethylfomamide solution are mixed, are put to the wax powder and are fully stirred; (2) the methyl organosilicon and the hydroxyl organosilicon are stirred; (3) the mixture mixed in step two is put to a solution obtained in step one and is fully and evenly stirred for 8 minutes; and (4) the solution obtained in step three is added with the acrylic powder and is evenly stirred for 5 minutes to obtain the finished product. The wet wax crazy horse resin for treating the surface of leather and the manufacturing method have the following advantages: the wearing resistance, scratch resistance, flexing resistance, color fastness and other requirements of the resin reach the national standard; the resin solves the problems of discoloring of crazy horse, high-temperature embossing resistance and sizing time in the prior art; water drenching resistance and water pressure resistance reach the standard; the solvent resistance and strong acid and alkali resistance reach the standard; and the external wetting variation resistance and temperature variation resistance reach the standard.

Owner:沈雪峰

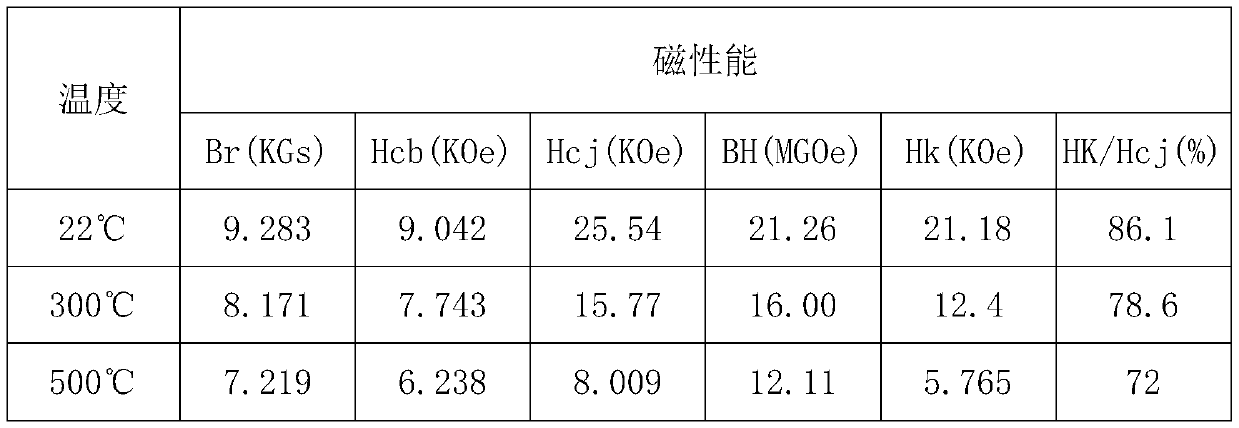

Preparation method of samarium-cobalt permanent magnet material

InactiveCN110957089ASolve high temperature resistanceSolve the problem of high coercivity at room temperatureInductances/transformers/magnets manufactureMagnetic materialsIngotTemperature resistance

The invention discloses a preparation method of a samarium-cobalt permanent magnet material. The preparation method comprises the following steps: material preparation is carried out according to Sm (Co <1-u-v-w> Cu Fe <v> Zr <w>) z, wherein u = 0.08-0.09, v = 0.08-0.09, w = 0.02-0.03 and z = 7.1-7.2; the prepared raw materials are sequentially put into a vacuum induction melting furnace according to the sequence of Fe-Zr-Fe-Co-Cu-Sm to be subjected to high-temperature melting, samarium-cobalt alloy ingots with uniform components are obtained, the alloy ingots are subjected to coarse crushing, intermediate crushing and jet milling step-by-step crushing, and finally powder with the mixed particle size SDM within the range of 3.2-3.8 microns is obtained; the powder is pressed in a vertical pressing mode, and then a pressed blank is obtained through isostatic pressing; and the pressed blank is placed in a vacuum sintering furnace to be sintered, subjected to solid solution and aged.On the premise of not adding trace elements (Mn, Er and the like), the problems of high temperature resistance and high coercive force at the room temperature of 500 DEG C of the 2: 17 type samarium-cobalt permanent magnet can be solved through the combination of five metals including metal cobalt (Co), metal samarium (Sm), metal iron (Fe), metal copper (Cu) and metal zirconium (Zr) and process control of the process.

Owner:杭州科德磁业有限公司

Release agent for scratch-resistant high temperature-resistant OPP (Oriented Polypropylene) heat transfer film and preparation method thereof

InactiveCN103497613AImproves UV resistanceIncrease UVDuplicating/marking methodsCoatingsMicrocrystalline waxOrganic solvent

The invention discloses a release agent for a scratch-resistant high temperature-resistant OPP (Oriented Polypropylene) heat transfer film. The release agent is prepared from the following raw materials in parts by weight: 30-60 parts of polymethyl methacrylate, 10-30 parts of nanometer titanium dioxide, 5-10 parts of scratch-resistant auxiliary agent, 3-5 parts of dilauryl thiodipropionate and 50-100 parts of organic solvents. The invention also discloses a preparation method of the release agent. According to the release agent for the scratch-resistant high temperature-resistant OPP heat transfer film, the polymethyl methacrylate is modified by the nanometer titanium dioxide, good scratch-resistant property is achieved through addition of a microcrystalline wax or Nano-R 1003 serving as the scratch-resistant auxiliary agents, and good high temperature-resistant property can be obtained by addition of the dilauryl thiodipropionate. The obtained release agent can be used for a preparation process of the heat transfer film and the prepared heat transfer film has the functions of ultraviolet prevention, scratch resistance, high temperature resistance and the like; the obtained OPP heat transfer film can be used in the fields of heat transfer printing, optics, advertising graphics, and the like.

Owner:太仓市鸿运包装材料有限公司

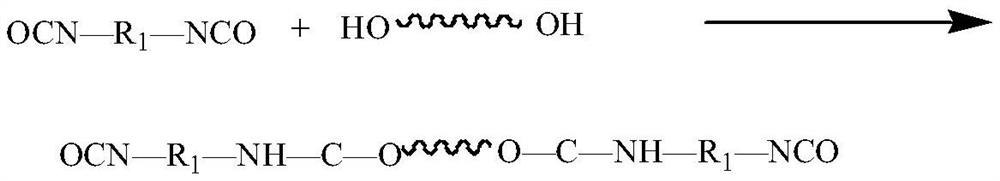

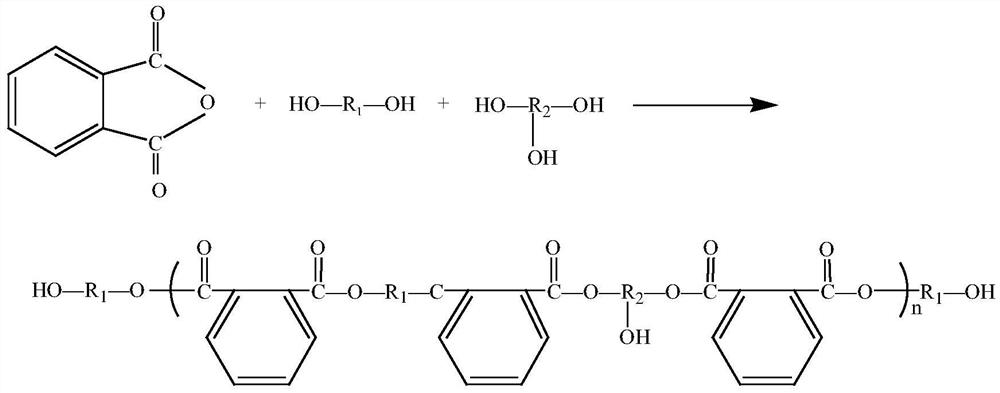

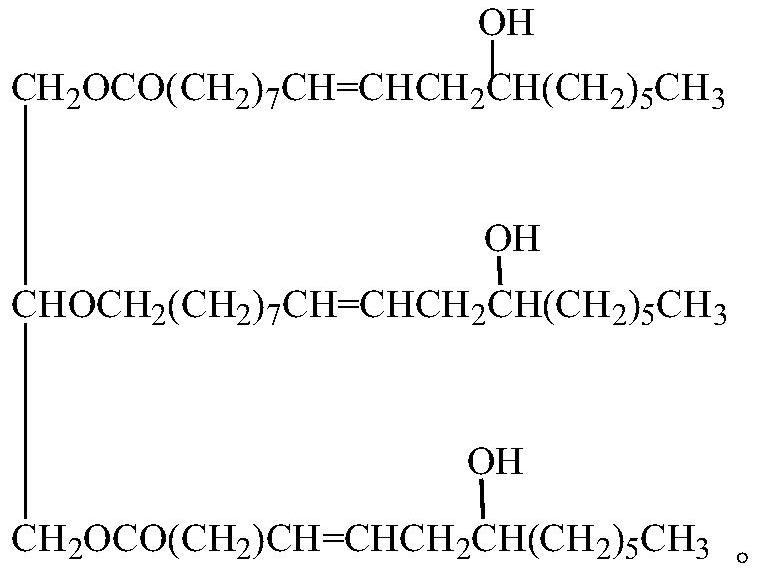

Two-component solvent-free polyurethane adhesive and preparation method thereof

PendingCN113583611ALow viscositySolve viscosityPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to the technical field of polyurethane adhesives, in particular to a two-component solvent-free polyurethane adhesive and a preparation method thereof. The two-component solvent-free polyurethane adhesive is composed of a component A and a component B according to the mass ratio of 1: 1 to 3: 2. The component A is an isocyanate-terminated prepolymer prepared through a reaction of polyisocyanate and polyether glycol. The component B is castor oil modified polyester polyol prepared by reacting castor oil with phthalic anhydride, small molecular dibasic acid and small molecular dihydric alcohol under the action of a catalyst. The two-component solvent-free polyurethane adhesive has low viscosity, high shear strength and high flame retardant property, and overcomes the defects of poor adhesive strength and poor high temperature resistance of a polyurethane adhesive in a flexible package.

Owner:GUANGDONG HERUN PRECISION METAL MATERIALS CO LTD

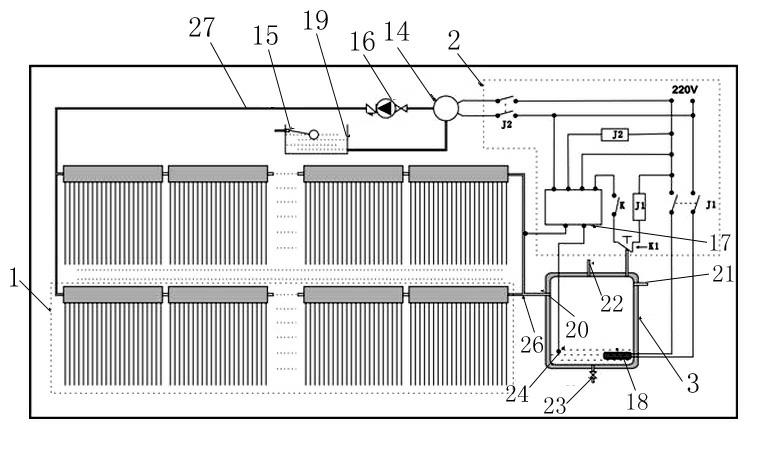

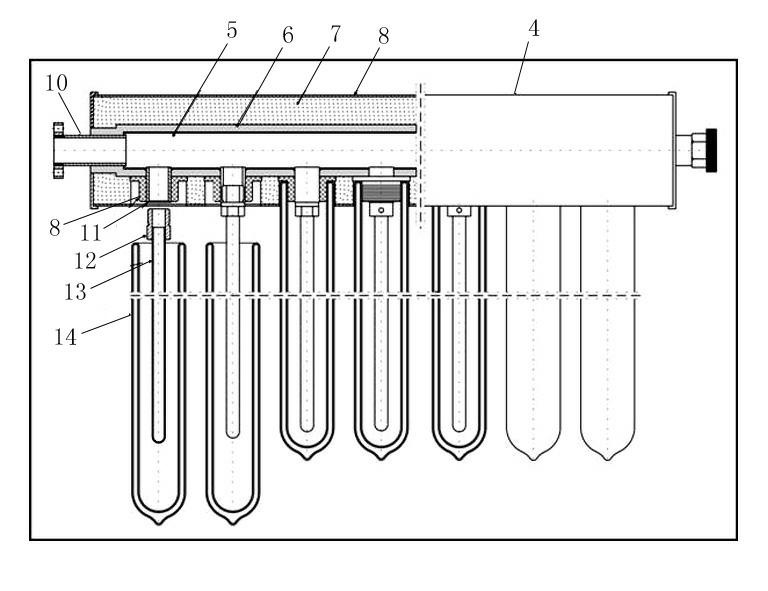

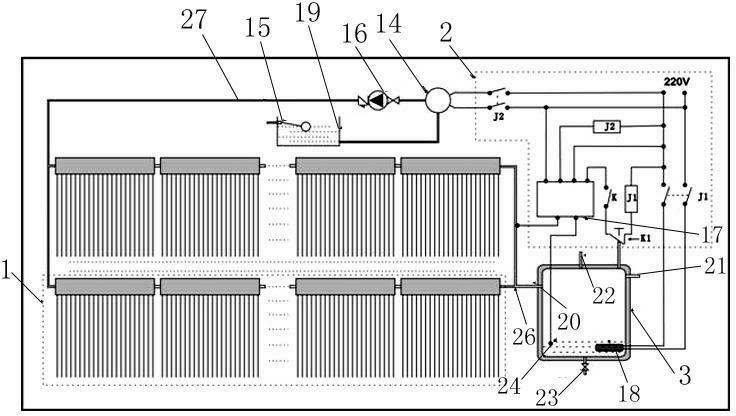

Solar vapor generating system

InactiveCN102620271ASolve high temperature resistanceSolve the problem of heat collection efficiencySolar heating energySteam generation heating methodsThermodynamicsHeat conducting

The invention discloses a solar vapor generating system mainly comprising a plurality of solar heat collectors, a controller and a vapor storage barrel, wherein each solar heat collector mainly comprises a connecting box, a heat conducting pipe and a vacuum heat collecting pipe; the solar heat collectors are connected in series to form a group of heat collecting clusters, each connecting box comprises a main runner arranged in a shell of a box body, at least one heat insulating layer is arranged outside the main runner, two ends of the main runner are provided with connecting ports, the main runner is provided with a plurality of T-shaped seats for connecting the heat conducting pipes, and elastic sealing seats connected with the vacuum heat collecting pipes are sleeved outside the T-shaped seats; the connecting boxes are mutually connected in series through the connecting ports to form a group of heat collecting clusters; a water inlet connection port of the connecting box at the most significant end of each heat collecting cluster is connected with a water pump with a one-way valve through a pipeline; the heat collecting clusters are connected to the vapor storage barrel through pipelines; and a plurality of the heat collecting clusters are connected in parallel to increase the air output. The solar vapor generating system has the characteristics of reasonable and compact structure, convenience in use and installation, high in heat collecting efficiency, capability of continuously generating vapor with high capacity for use, long service life, low using cost and the like.

Owner:HANGZHOU TIANBA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com