High-temperature high-pressure hydraulic recoverable packer

A high-temperature, high-pressure, packer technology, applied in the direction of sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of poor pressure resistance, non-recyclable, poor high-temperature resistance, etc., to solve the problem of non-recyclable, Unblocking is simple and the effect of improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

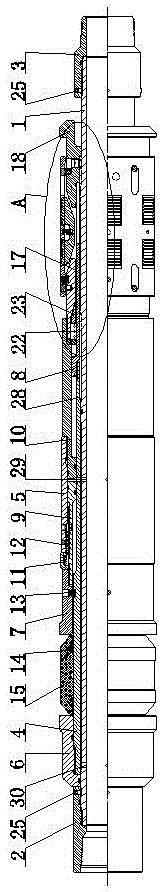

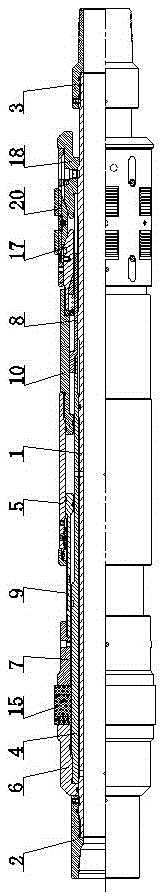

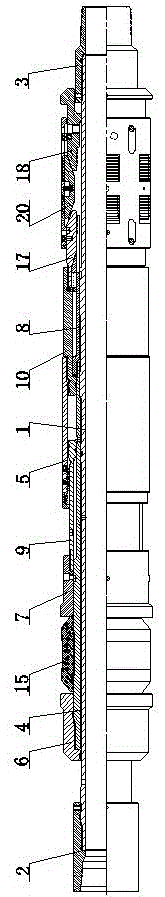

[0020] The high-temperature and high-pressure hydraulic recoverable packer is composed of an inner central pipe 1, an upper joint 2, a lower joint 3, an outer central pipe 4, a cylinder liner 5, an upper guide ring 6 and a lower guide ring 7: one end of the inner central pipe 1 is threaded The upper joint 2 is installed, and the other end of the inner central pipe 1 is threaded with a lower joint 3; Screw 25 connection. The inner central tube 1 and the outer central tube 4 are provided with corresponding pressure transmission holes 29 , and the inner central tube 1 on one side of the pressure transmission holes 29 is provided with a bypass hole 30 . When the packer is unsealed, the inner center pipe 1 and the outer center pipe 4 are staggered, and when the bypass hole 30 is connected to the outside, the bypass hole 30 can balance the pressure inside and outside the inner center pipe 1 to prevent the inner center pipe from 1 Deformed under compression, the packer is effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com