High-temperature resistant isolating membrane and preparation method thereof

A technology of isolation film and high temperature resistance, which is applied in the field of compression molding of rubber-grade composite materials, which can solve the problems of high thermal shrinkage rate and high temperature resistance, and achieve the effects of good flexibility, good physical entanglement and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

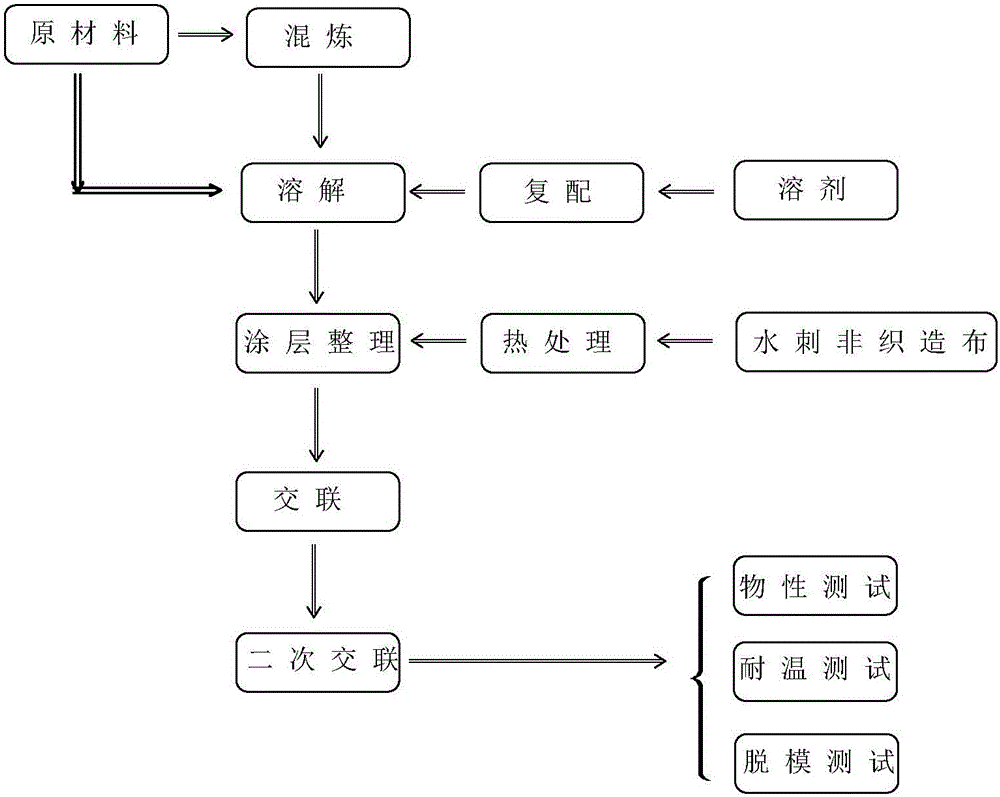

Method used

Image

Examples

Embodiment 1

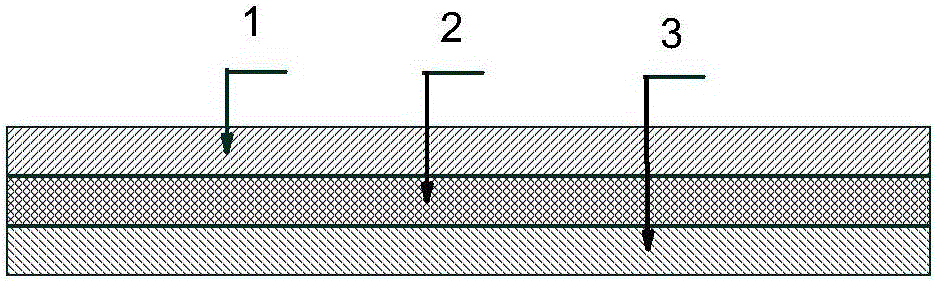

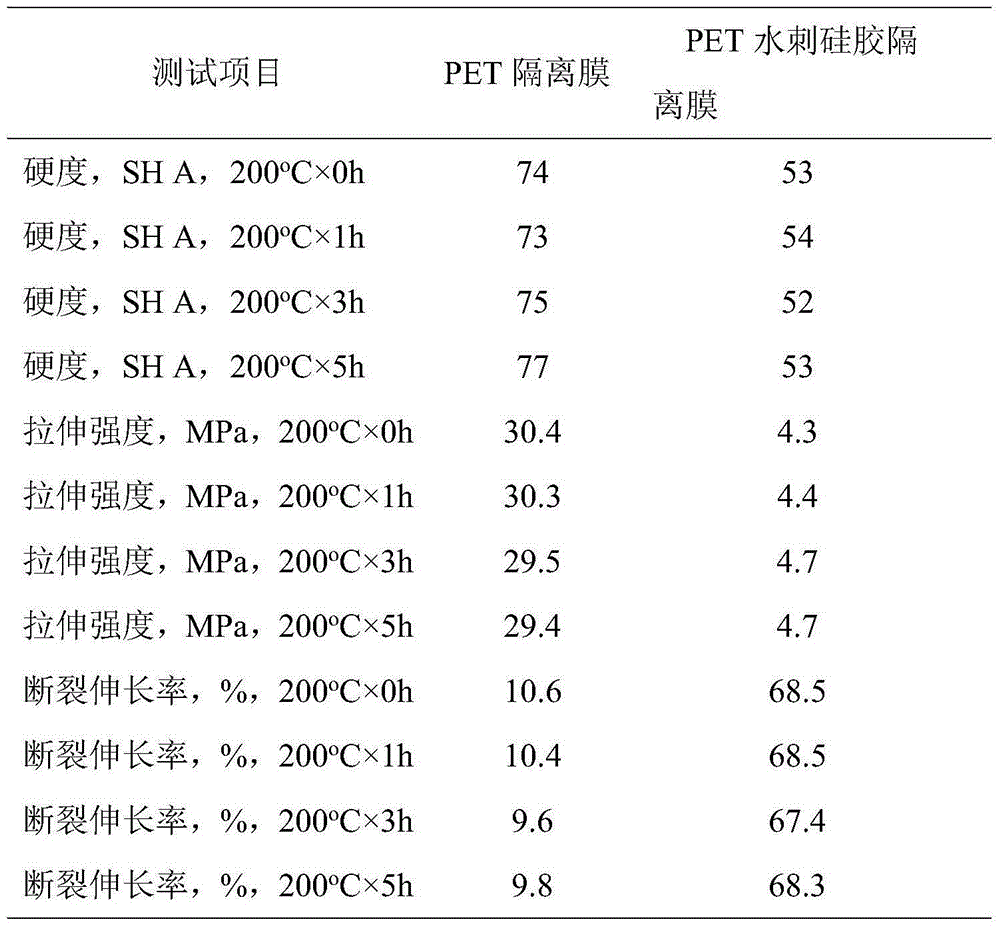

[0060] A high-temperature-resistant isolation film includes a substrate and silicone rubber isolation coatings coated on both sides of the substrate. Product structure such as figure 1 shown. The base material adopts spunlace nonwoven fabric, and the spunlace nonwoven fabric is made of PET, aromatic polyamide, carbon fiber, polyimide, polyphenylene sulfide, polyparaphenylene benzobisoxazole nonwoven fabric A sort of. PET is preferred.

[0061] The main function of the spunlaced nonwoven fabric is to act as a reinforcement of silicone rubber, and at the same time make the silicone rubber penetrate and rivet the fiber web for reinforcement, improve the bonding strength of the silicone rubber and the fiber web, and improve the physical and mechanical properties and service life of the silicone rubber. . The thickness of spunlace reinforced nonwoven fabric is 0.05-2mm, the fiber used has high temperature resistance and thermal stability, and the fiber length is generally 5-30m...

Embodiment 2

[0074] Preparation of embodiment 2 functional silicone rubber (raw material adopts solid silicone rubber)

[0075] The solid silicone rubber is mixed on an open mill to prepare the silicone rubber with required functions.

[0076] Adjust the front and rear roll speed ratio (1.1-1.3) of the mill: 1, control the roll temperature to no more than 50°C, and mix for about 30 minutes. First adjust the roller spacing to about 1.0mm, add 10kg of solid silicone rubber to cover the rollers; then gradually increase the roller spacing by 1-5mm, and add 4kg of precipitated silica, 4kg of fumed silica, and two 0.5kg of phenylsilanediol, 0.5kg of (hydroxyl) silicone oil, 0.06kg of iron oxide, and finally add 0.05kg of dicumyl peroxide, reduce the roller distance to about 1.0mm, and thin pass 5-10 times. After the next film is parked for 24 hours, it is ready to use.

Embodiment 3

[0077] The preparation of embodiment 3 functional silicone rubber (raw material adopts A, B two-component liquid silicone rubber)

[0078] The two-component liquid silicone rubber is mixed in a high-speed mixer to prepare the silicone rubber with the desired function.

[0079] In a high-speed mixer, add 30kg of liquid silicone rubber component A, 3kg of component B, 5kg of diphenylsilanediol, and stir at high speed for 5 minutes, then add 10kg of fumed white carbon black, 0.06kg of iron oxide, and continue stirring for 10 minutes. Transport to a three-roll mill for grinding for 20 minutes and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com