Preparation method of samarium-cobalt permanent magnet material

A permanent magnet material, samarium cobalt technology, applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve problems such as deformation, irreversible magnetic loss increase, affecting use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

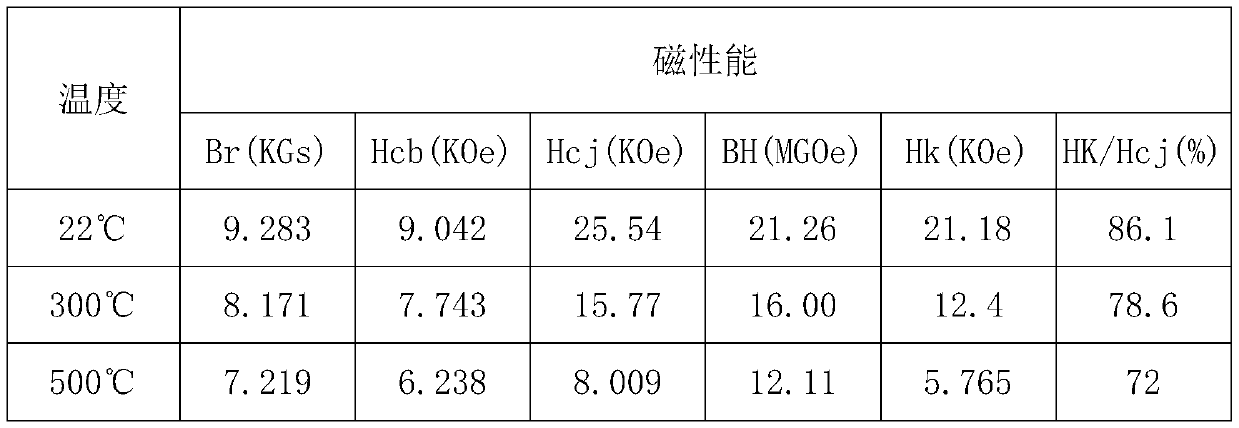

Image

Examples

Embodiment Construction

[0019] Let Sm(Co 0.8 Cu 0.089 Fe 0.088 Zr 0.022 ) 7.17 As an example, the specific implementation manner of the present invention is further described:

[0020] 1 Ingredients: Select high-purity raw materials (Sm / RE≥99.7%, Co≥99.6%, Cu+Ag≥99.95%, Zr+Hf≥99.3%, Fe≥99.75%) according to Sm (Co 0.8 Cu 0.089 Fe 0.088 Zr 0.022 ) 7.17 The atomic ratio is used for batching;

[0021] 2 Melting: put the configured raw materials into the crucible in the order of Fe-Zr-Fe-Co-Cu-Sm, cover the furnace cover and vacuumize, and start heating when the vacuum degree of the melting furnace is ≤7Pa (15KW± 5KW), this process is a pre-heating process, the main purpose is to deeply remove the residual air and moisture of raw materials, crucible and furnace wall, etc., to prevent the oxidation of raw materials from affecting the atomic ratio of each element. Stop vacuuming when preheating to a vacuum degree of ≤5Pa, and fill the furnace with Ar gas of -0.06±0.03MPa (to prevent the volatiliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com