Patents

Literature

92results about How to "Solve flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen free flame retardant nylon 6 composite with high CTI value and preparation method thereof

InactiveCN101812231AHigh CTI valueImprove flame retardant performancePolymer scienceFlexural strength

The invention discloses a halogen free flame retardant nylon 6 composite with high CTI value and a preparation method thereof. The composite comprises the following components by mass percent: 643.5-68.8wt.% of nylon, 10-12wt.% of fire retardant, 7-19wt.% of fire retardant synergetic inorganic packing, 8-12% wt.% of toughening agent, 1-3wt.% of bulking agent, 5-10% wt.% of enhance inorganic filler and 0.2-0.5wt.% of anti-oxygen which are prepared into the compound by a high speed premixing dispersing primary extrusion processing. The disclosed composite has as high as 550V CTI value and UL 94V-0 level excellent fire resistance; simultaneously, the polymer has good mechanical property by a comprehensive modified technique, wherein the tensile strength reaches 70.5Mpa, the bending strength reaches 90.7MPa and the impacting strength of a gap reaches 28.1kJ / m2. The invention solves the problem that the flaming resistant and high CTI value are difficult to satisfy simultaneously; the inventive 6 nylon compound is very suitable for preparing a low-pressure vacuum contactor, a transformer coil framework, a high-temperature resistant relay, a breaker, a high voltage electrical apparatus, a handle and a thin wall electronic and electrical appliance elements, and the like.

Owner:BEIJING UNIV OF CHEM TECH

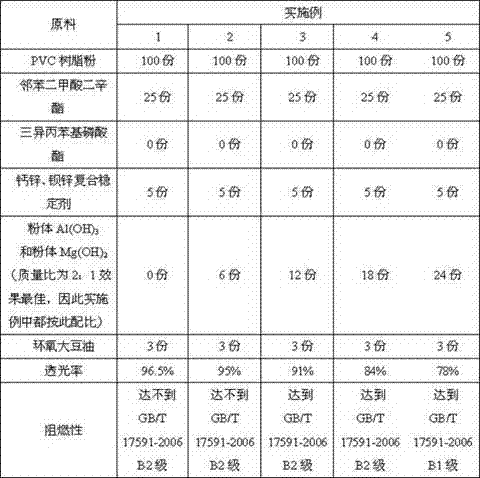

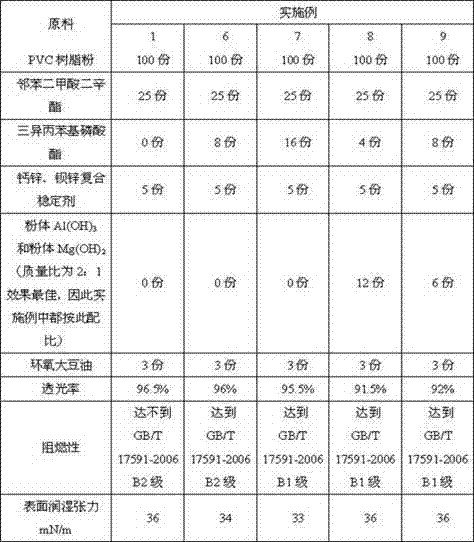

Flame-retardant transparent floor film and production technology thereof

The invention relates to a flame-retardant transparent floor film and a production technology thereof. The flame-retardant transparent floor film is prepared by treating the following main raw materials in parts by weight: 100 parts of PVC (Poly Vinyl Chloride) resin powder, 15 to 30 parts of a main plasticizer, 4 to 8 parts of a fire-retardant plasticizer, 4 to 6 parts of a stabilizer, 6 to 12 parts of an inorganic filler, and 2 to 4 parts of epoxidized soybean oil by a PVC die rolling technology. By adopting the flame-retardant transparent floor film and the production technology thereof, the conflict between the flame retardant performance, the transparence and the jet-printing performance is solved; the inorganic fillers are adopted, thus micromolecules separated by the liquid fire-retardant plasticizers are easily absorbed, and ideal transparence and the jet-printing performance can be provided for the product under efficient flame retardant performance; in addition, the generation of phenomena of wheel adhering, albinism and hard coiling can be effectively avoided by utilizing the flame-retardant transparent floor film; and simultaneously, the flame-retardant transparent floor film is excellent in wear resistance.

Owner:ZHEJIANG BOTAI PLASTIC

Method for manufacturing composite fabric automobile roof

ActiveCN101987599ASolve flame retardancyAddressing Pollution ResistanceSevering textilesHeating/cooling textile fabricsFiberAlcohol

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

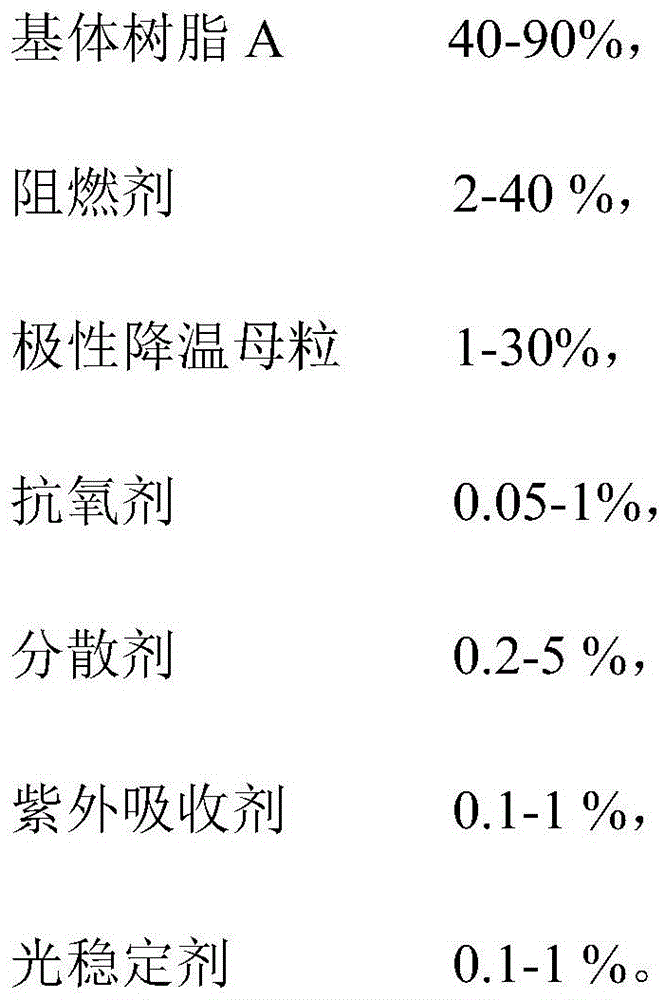

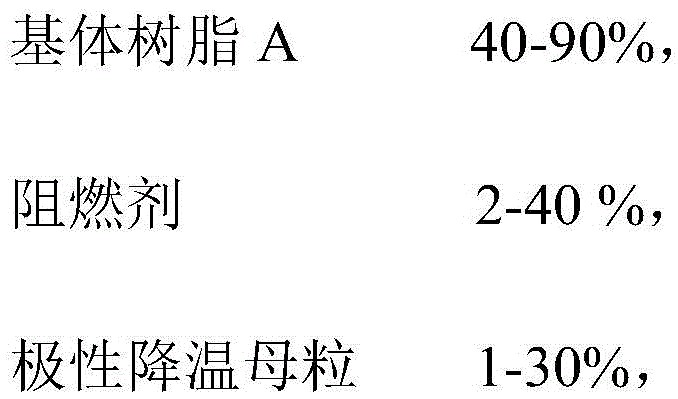

Soft PP flame retardant with ultrahigh fluidity

The invention discloses a soft PP flame retardant with ultrahigh fluidity. The soft PP flame retardant is prepared from 40-90% by mass of a base resin, 2-40% of a flame retardant, 1-30% of polar cooling master batches, 0.05-1% by mass of an antioxidant, 0.2-5% by mass of a dispersant, 0.1-1% by mass of a UV absorbent and 0.1-1% by mass of a light stabilizer. The soft PP flame retardant has low hardness, a good hand feeling, a low processing temperature, a narrow molecular weight distribution range, spinning easiness, good toughness, no precipitation, aging resistance, excellent mechanical properties, good adhesion to polyester, polyethylene and polypropylene, short consumption time, high production efficiency, production convenience, industrial production feasibility and good application prospect in a PP flame-retardant non-woven fabric.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

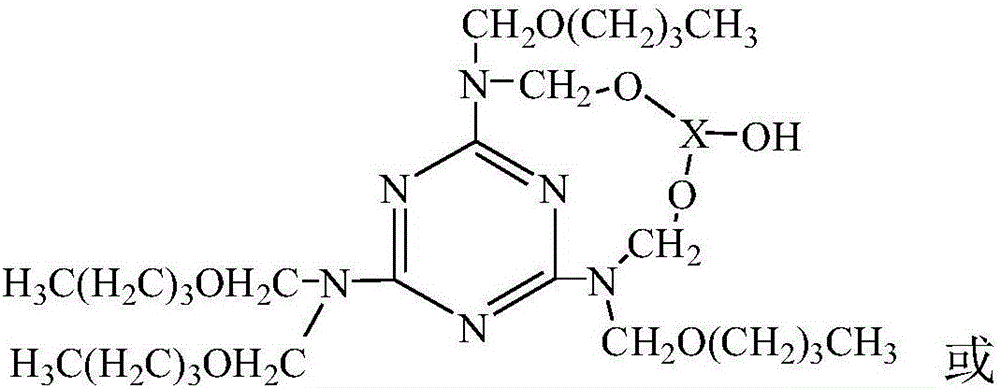

Branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on triazine ring structure and preparation method of copolyester

ActiveCN104710604AIncrease melt viscosityImprove flame retardant performanceNitrogenNetwork structure

The invention discloses branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on a triazine ring structure. The copolyester is prepared by conducting random copolymerization on structure units expressed as formulae I, II and III or structure units expressed as formulae I, II, III and IV according to a conventional method. The intrinsic viscosity [eta] of the prepared branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester is 0.41-1.10 dL / g; the extreme oxygen index is 24.5-38.0%; the vertical combustion grade is between V-2 and V-0; the peak heat release rate p-HRR in a cone heat test is 247-643 kW / m<2>. According to the copolyester, a modified monomer of the triazine ring structure is introduced, and then copolymerized with polyester to form a unique ternary branched cross-linking network structure; the modified monomer of the triazine ring structure contains the flame-retardant element nitrogen, so that the melt viscosity of the copolyester in combustion can be improved; the copolyester is capable of releasing nitrogen and quickly forming an expanded char layer with excellent heat and oxygen insulation effects; especially, a phosphorus-nitrogen synergism effect can be generated when the copolyester is used together with the conventional phosphorus-containing flame-retardant agent; the flame-retardant performance and the melt-dropping-resistant effects can be more excellent; the selected monomer is low in price; the preparation process is mature; the operation is simple and convenient; the industrialized large-scale production is liable to implement.

Owner:SICHUAN UNIV

Multi-functional polyethylene tube and manufacturing method thereof

The invention discloses a multi-functional polyethylene tube and a manufacturing method thereof, belonging to a polymer composite material. The multi-functional polyethylene tube is prepared by blending and modifying the following raw materials in parts by mass: 30-50 parts of high-density polyethylene (HDPE), 70-90 parts of ultrahigh molecular weight polyethylene (UHMWPE), 10-15 parts of polyoctene rubber (TOR), 1.5-2.0 parts of nano rare earth beta-nucleating agent, 1.0-1.5 parts of dicumyl peroxide (DCP), 3-5 parts of silicone polymer flame retardant and 3-5 parts of color masterbatch. The invention has the advantage that the problems of low-temperature brittleness, abrasive resistance, corrosion resistance, ageing resistance, heat resistance, processability, flame retardancy, and the like of the polyethylene tube are solved. The invention can be widely applied to the fields of water supply and drainage, sewage discharge, oil gas, coal power, mining industry, gas supply, heating, chemical industry, power communication, ocean, dredging, and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

High-voltage transformer substation cable insulating sheath material and preparation method thereof

ActiveCN103524866ASolve flame retardancySolve the mechanical strengthPlastic/resin/waxes insulatorsInsulated cablesWear resistantFumed silica

The invention discloses a high-voltage transformer substation cable insulating sheath material and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 60-80 parts of metallocene linear low density polyethylene, 25-35 parts of isotactic polypropylene, 10-15 parts of EVA, 8-12 parts of aluminum hydroxide, 5-10 parts of magnesium hydroxide, 4-8 parts of zinc stannate, 12-18 parts of siliceous rock powder, 4-6 parts of polyethylene wax, 2-3 parts of terephthalic acid zinc, 1-2 parts of magnesium oxide, 3-5 parts of dimethyl silicone oil, 2-3 parts of basic lead silicate, 5-10 parts of triallyl trimellitate, 1-2 parts of gamma-methacryloxy propyl trimethoxyl silane, 15-25 parts of fumed silica, 10-15 parts of active calcium carbonate, 1-2 parts of an antioxidant 168, and 3-5 parts of a composite filler. The sheath material has excellent mechanical strength and abrasion resistance, can effectively improve the wear resistant ability and the impact resistant ability of a cable sheath, moreover, has good flame retardancy, is low in smoke and is halogen-free, effectively solves contradictions among the flame retardancy, the mechanical strength and the abrasion resistance of the sheath material, prolongs the service life of the sheath, and guarantees normal working of a high-voltage transformer substation cable.

Owner:PANJIN GUANGLIDA ELECTRIC

Preparation method of structural flame-retardant polyurethane soft foam

InactiveCN105199069AReduce manufacturing costHas structural flame retardant propertiesPolymer sciencePtru catalyst

The invention provides a preparation method of structural flame-retardant polyurethane soft foam, which comprises the following steps: reacting phenol and formaldehyde to obtain a liquid resol, reacting with melamine to obtain a hydroxymethylated melamine-phenolic resin, initiating the ring-opening polymerization between the hydroxymethylated melamine-phenolic resin and epoxy chloropropane by using a co-initiator to obtain a nitrogenous structural flame-retardant polyether glycol, mixing the nitrogenous structural flame-retardant polyether glycol and other polyether glycols to obtain a base resin, adding a catalyst, a foam stabilizer, a flame retardant and a foaming agent to form a component A, quickly mixing with a component B isocyanate uniformly, pouring into a mold, and foaming to obtain the structural flame-retardant polyurethane soft foam. The limited oxygen index of the obtained foam is 28.1-29.3%, the maximum horizontal combustion velocity is not greater than 70mm / minute, the horizontal combustion time is 75-85 seconds, the average combustion length is less than 50mm, and the apparent density is 35.2-40.3 kg / m<3>.

Owner:SHANGHAI INST OF TECH

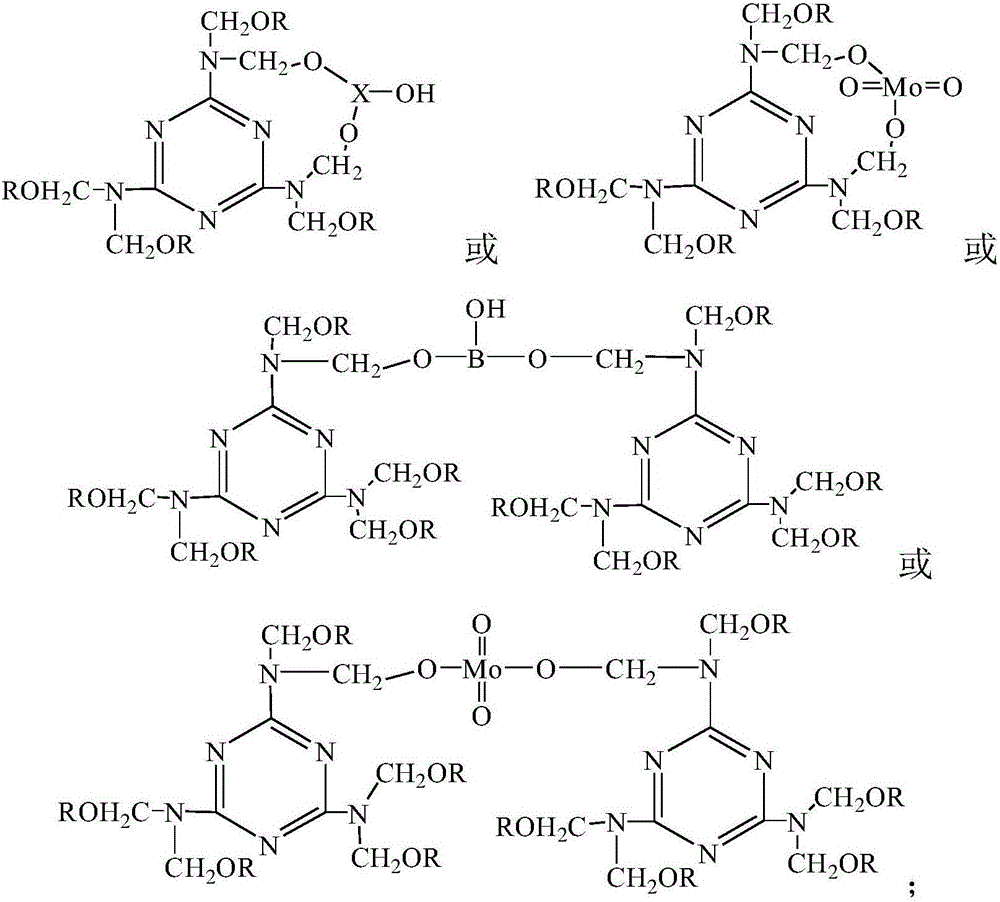

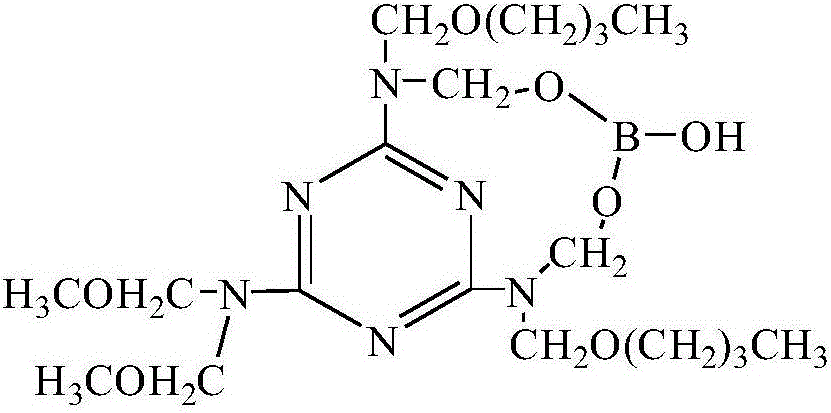

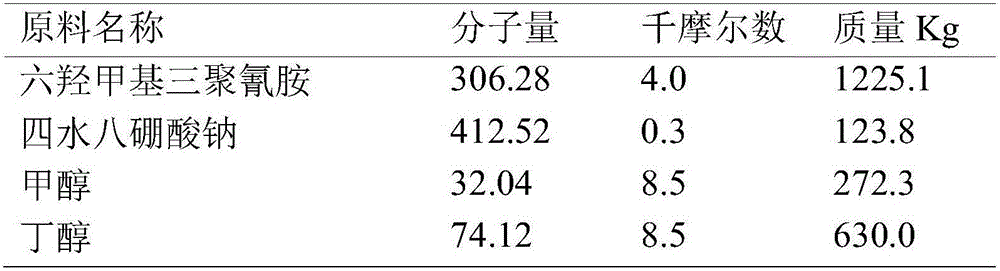

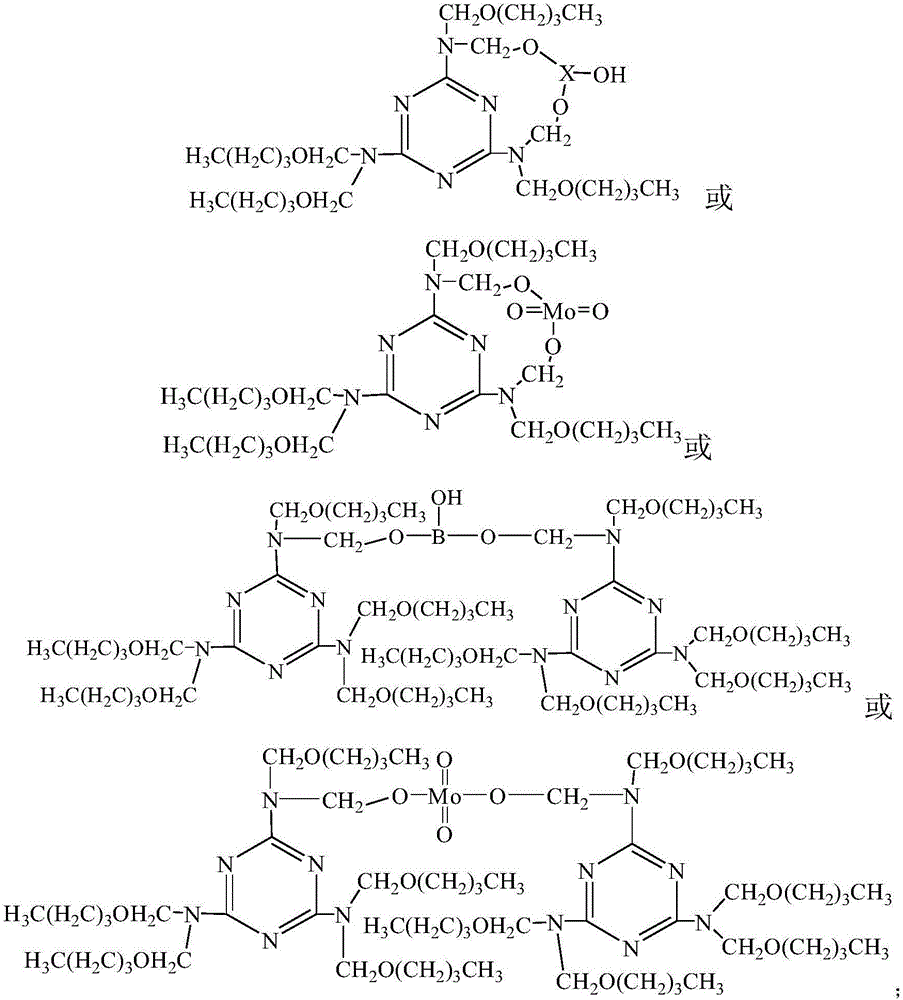

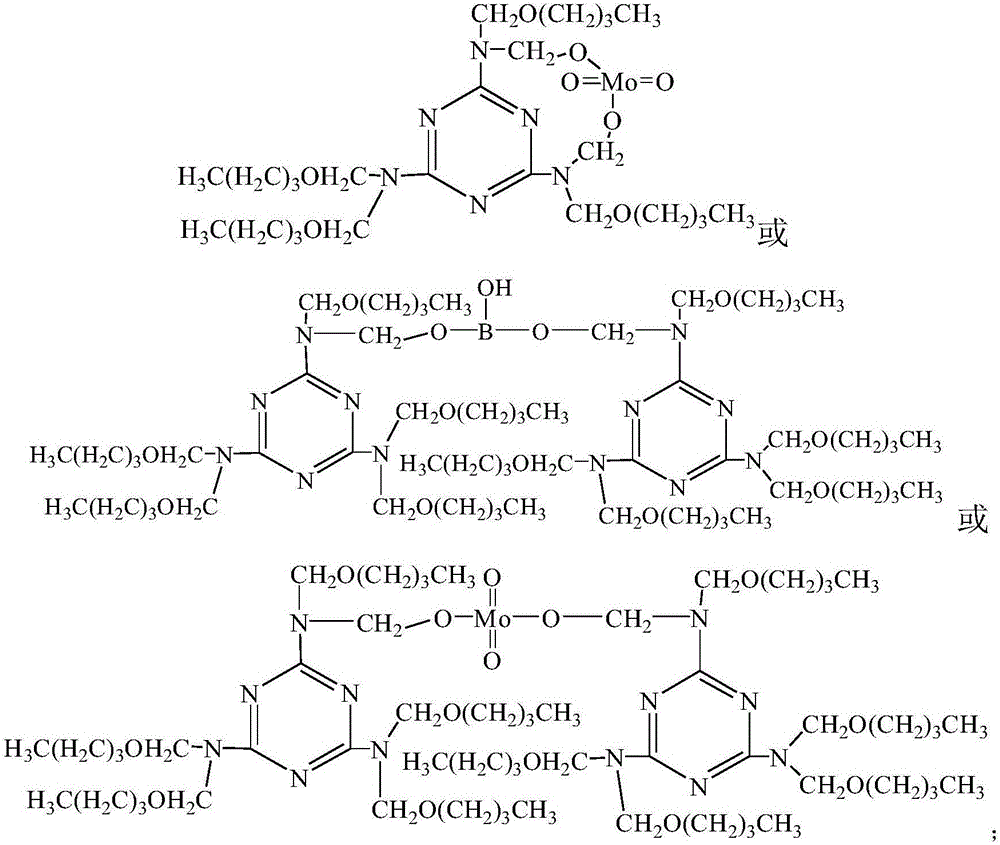

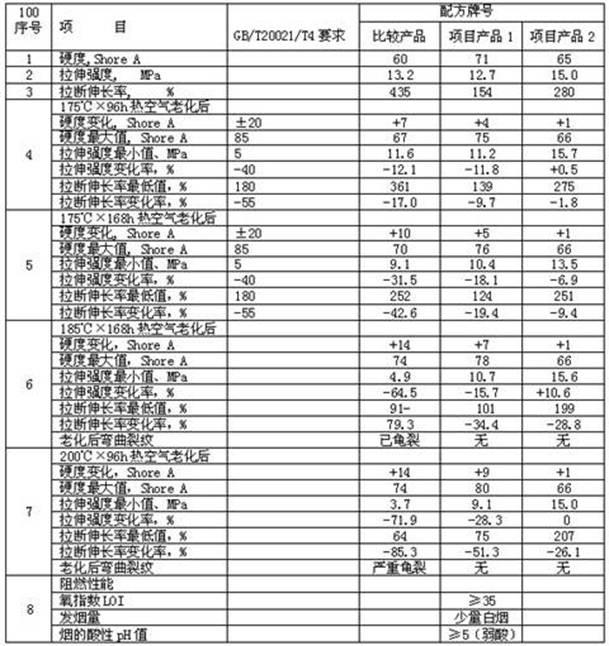

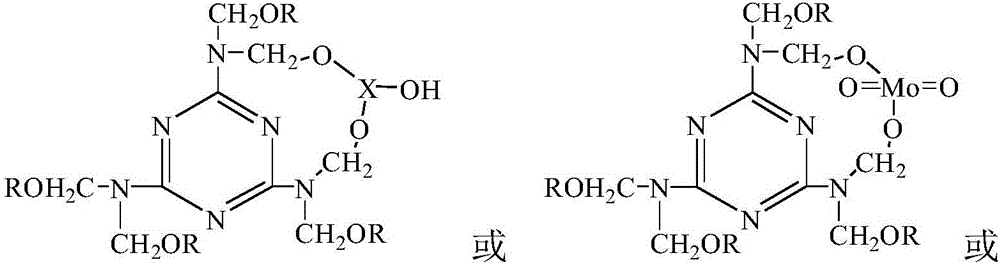

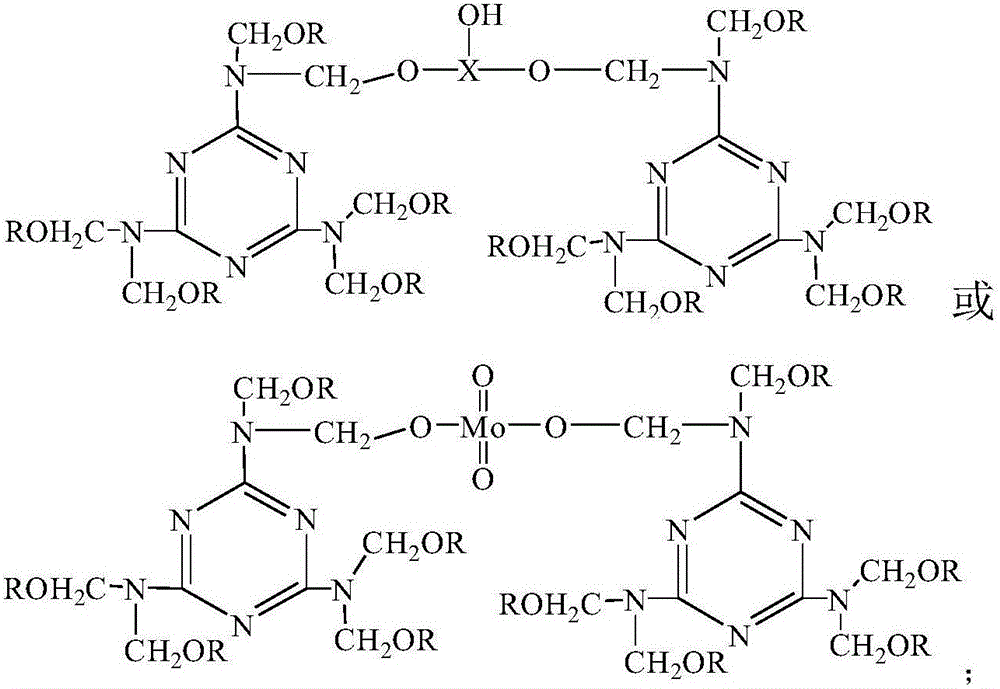

Inorganic hybridized mixed-etherified melamine resin and preparation method thereof

ActiveCN106349267AImprove high temperature resistanceImprove flame retardant performanceGroup 3/13 element organic compoundsGroup 6/16 organic compounds without C-metal linkagesCross-linkHybrid compound

The invention belongs to the technical field of inorganic hybridized polymer materials and particularly relates to inorganic hybridized mixed-etherified melamine resin and a preparation method thereof. The preparation method mainly includes steps: (1) etherification reaction, to be more specific, adding hexamethylol melamine, methyl alcohol and butyl alcohol into a reactor, and performing thermal reaction to obtain tetra-etherified or penta-etherified melamine resin; (2) alkali neutralization; (3) hybridization reaction; (4) distillation for removing residual methyl alcohol and butyl alcohol; (5) cooling and filtering to obtain a finished product. The inorganic hybridized mixed-etherified melamine resin prepared according to the method has advantages that by hybridization cross-linking reaction with inorganic hybrid compounds, high-temperature flame-retardant elements such as boron, molybdenum and stibium are added into amino resin generated finally, and accordingly high temperature resistance and flame retardation of the amino resin are improved, and the resin is mainly applied to preparation of combined polyether and paint.

Owner:重庆派昂科技发展有限公司

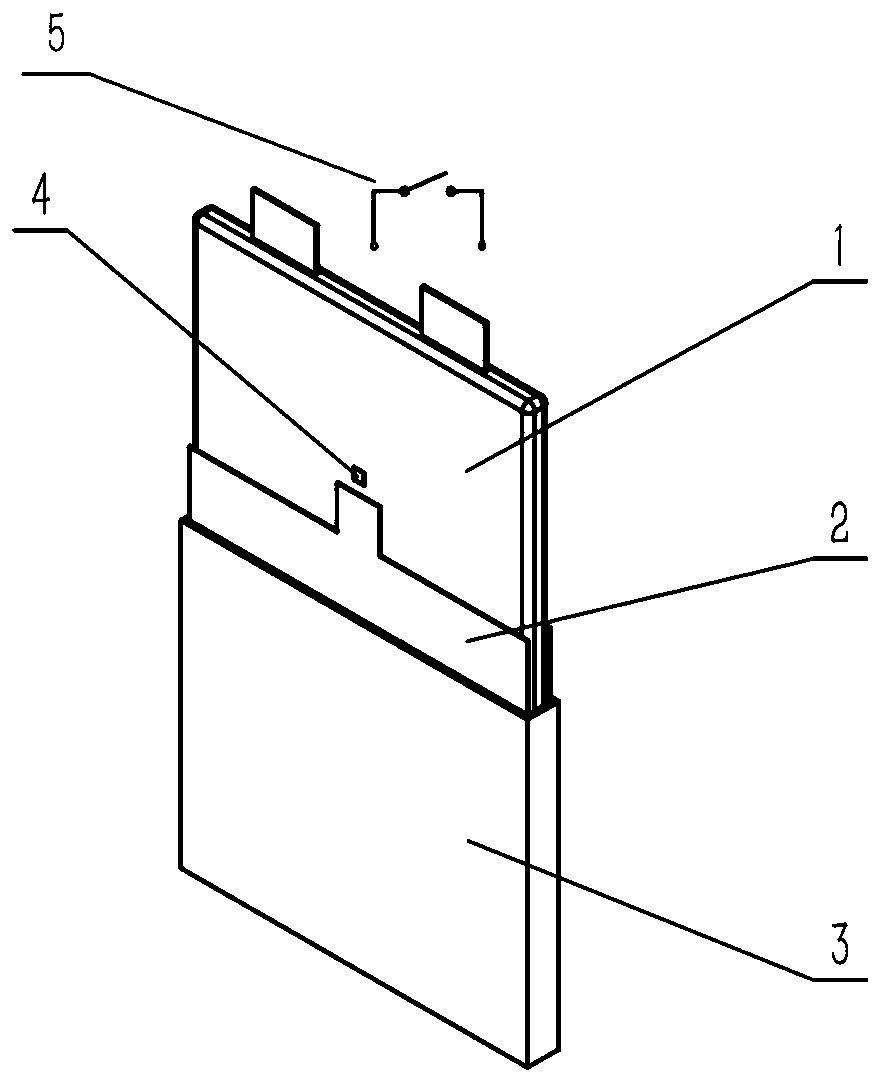

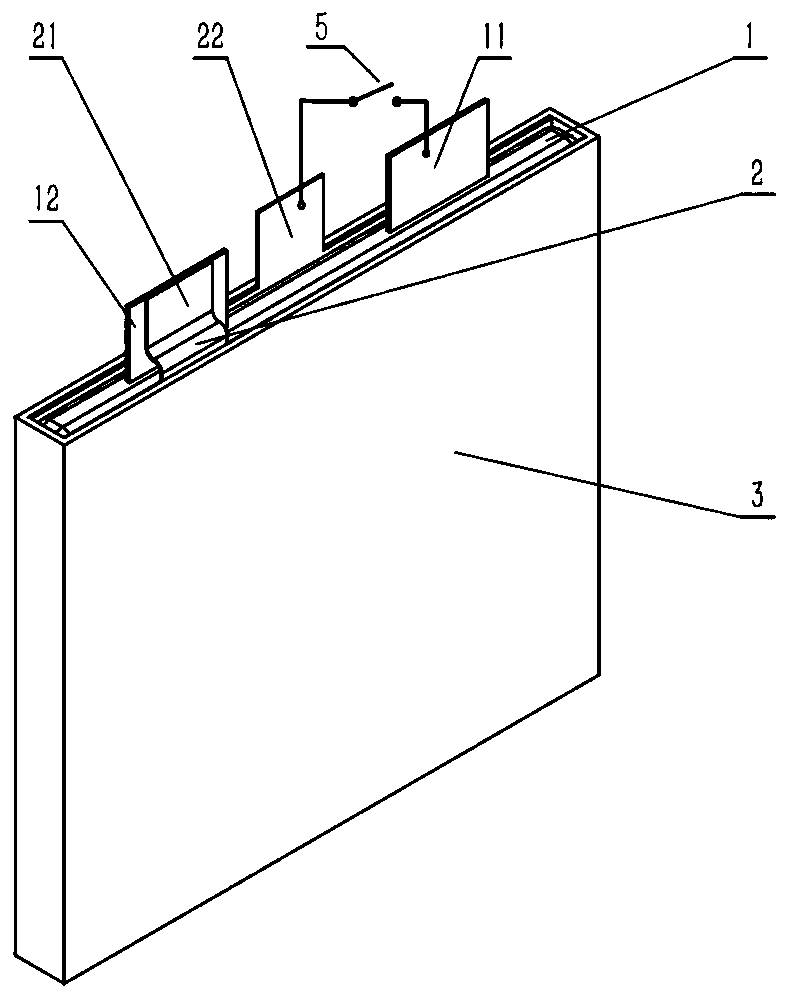

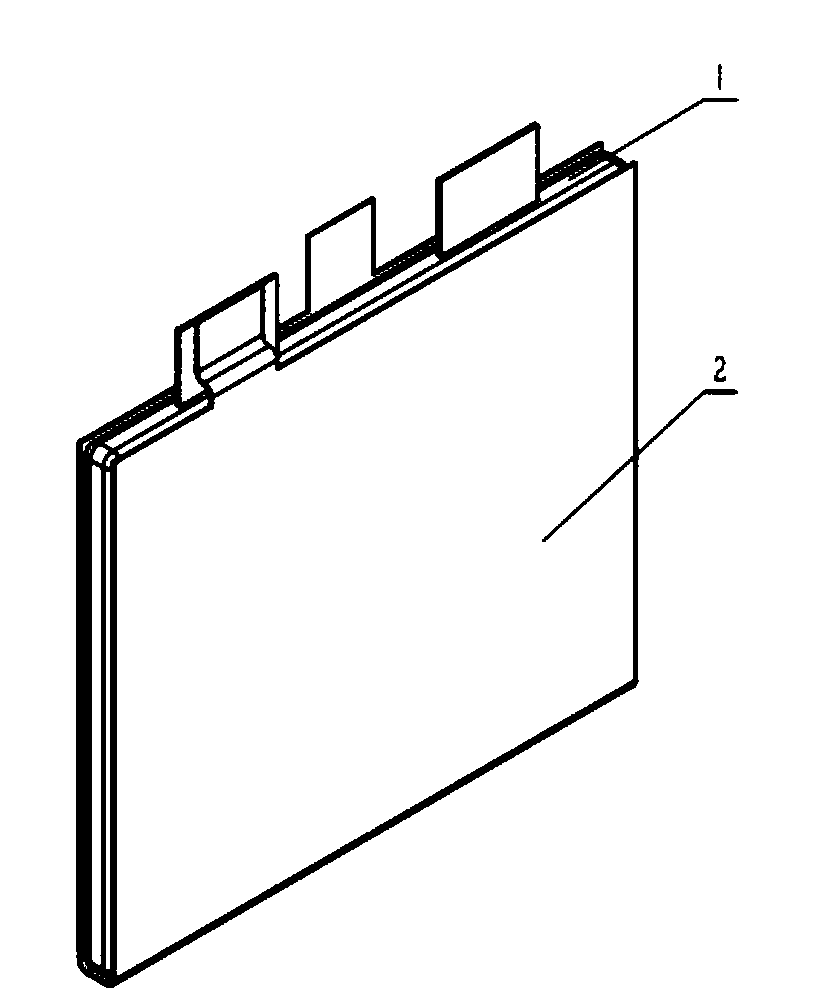

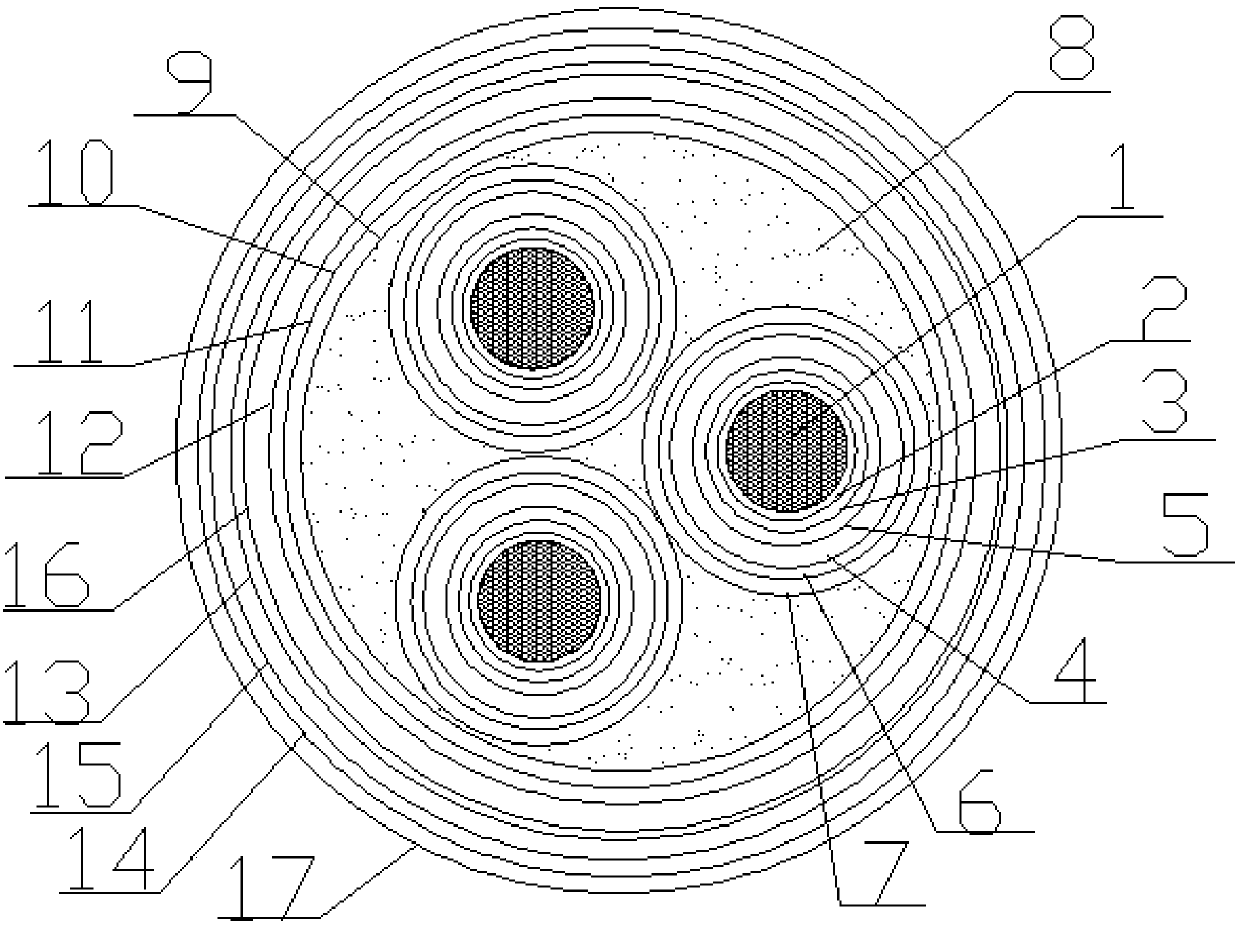

Battery self-heating and heat preserving device

ActiveCN110299580AFix Heating ProblemsEfficient self-preheating and heat preservationSecondary cellsPower batteryJoule

The invention discloses a battery self-heating and heat preserving device. The battery self-heating and heat preserving device comprises a power battery monomer, a heating diaphragm, an aerogel shell,a temperature sensor and a switching circuit. The outer surface of the power battery monomer is coated with the heating diaphragm. The outer surface of the heating diaphragm is coated with the aerogel shell. The temperature sensor is arranged on the power battery monomer, and the temperature sensor is arranged between the power battery monomer and the heating diaphragm. The temperature sensor andthe switching circuit are connected by a signal line. Every two of the power battery monomer, the heating diaphragm and the switching circuit are connected with each other. The switching circuit is used to connect the power battery monomer and the heating diaphragm to form a heating hoop. The heating diaphragm is used to generate heat by the Joule heat effect and heat the power battery monomer bythe heat conduction effect. By adopting the battery self-heating and heat preserving device provided by the invention, batteries can be efficiently self-preheated and kept warm under low temperatureconditions, and the charging and discharging performance of batteries can be enhanced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Transformer sound insulation shell material and preparation method thereof

The invention discloses a transformer sound insulation shell material and a preparation method thereof, which belong to the field of materials and solve the problem of poor sound insulation effect of existing materials. The preparation method specifically comprises the following steps of adding bakelite, epoxy resin, glass fibers, chemigum, polyvinyl chloride resin, cenosphere, expanded vermiculite, calcium carbonate, diatomaceous earth, silicone oil and antioxygen into a container, stirring for 15 to 20 minutes at the rotating speed of 1600 to 1900 r / min, uniformly mixing, then adding dichloromethane, continuously stirring for 5 to 10 minutes, adding acetic acid at last, stirring for 5 to 10 minutes at the rotating speed of 2000 to 2200 r / min, pouring raw materials which are uniformly mixed into a mold, solidifying for 60 to 80 minutes at the temperature of 65 to 75 DEG C, cooling and demolding, so as to obtain the transformer sound insulation shell material. The preparation method has the advantages of simplicity, easiness in operation and low production cost and can be widely used for transformer shell and case materials.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Inorganic hybrid butylated melamine resin and production method thereof

ActiveCN106243300AImprove high temperature resistanceImprove flame retardant performancePolyurea/polyurethane coatingsEpoxy resin coatingsCross-linkHybrid compound

The invention belongs to the technical field of inorganic hybrid polymeric materials, and especially relates to an inorganic hybrid butylated melamine resin and a production method thereof. The production method mainly comprises the following steps: 1, carrying out an etherification reaction: adding hexamethylolmelamine and butanol to a reaction kettle, and carrying out a heat insulation reaction to obtain tetraetherified or pentaetherified melamine resin; 2, neutralizing with an alkali; 3, carrying out a hybrid reaction; 4, distilling to remove residual butanol; and 5, cooling and filtering to obtain the finished product. A hybrid cross-linking reaction with an inorganic hybrid compound makes boron, molybdenum, antimony and other high temperature-resistant flame retardation elements be introduced to finally generate amino resin, so the high temperature resistance and the flame retardation performance of the amino resin are improved, and the obtained amino resin is mainly used to prepare combined polyether, paints and coatings.

Owner:重庆派昂科技发展有限公司

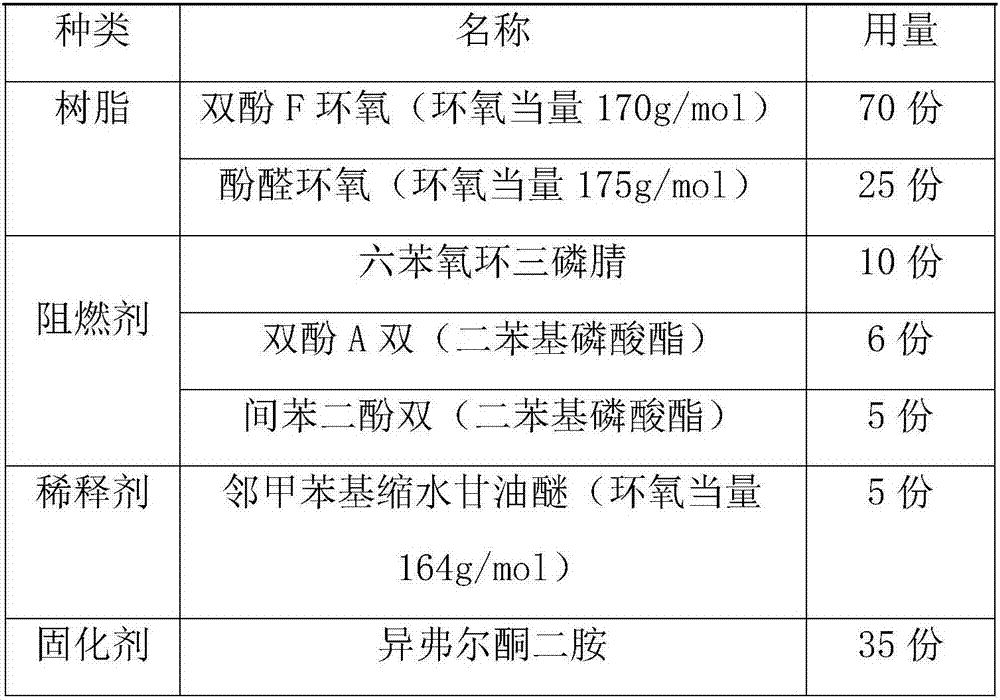

Low-temperature type flame retardant epoxy resin adhesive and preparation method thereof

InactiveCN105885754ASolve difficult to cureSolve flame retardancyNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyNitrogen

The invention discloses a low-temperature type flame retardant epoxy resin adhesive and a preparation method thereof. The preparation method comprises the following steps of mixing epoxy resin, epoxy resin thinner, defoaming agent, and toughener, and uniformly stirring, so as to obtain a component A; mixing phenolic modified amine, accelerant and coupler, and uniformly stirring, so as to obtain a component B; finally, uniformly mixing the raw materials of component A and component B, so as to obtain the low-temperature type flame retardant epoxy resin adhesive. The low-temperature type flame retardant epoxy resin adhesive has the advantages that the phenolic hydroxyl, thiocarbonyl and secondary amino group type low-temperature active groups and the phosphorus-nitrogen synergistic flame retardant elements are contained, so that the low-temperature experiment and halogen-free flame retardant effects are realized; the construction is convenient, the odor is little, the applicable period is long, the heat discharging is stable, the flame retardant property is excellent, the low-temperature and quick-curing effects are realized, the adhering with a substrate is good, and the impact-resistant property is realized; the problems of difficulty in curing and failure to self flame retardancy at low temperature in the existing epoxy resin adhesive are solved, the preparation method is simple, and the control and industrialization are easy.

Owner:SHANGHAI UNIV

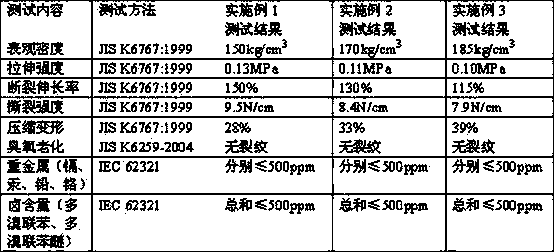

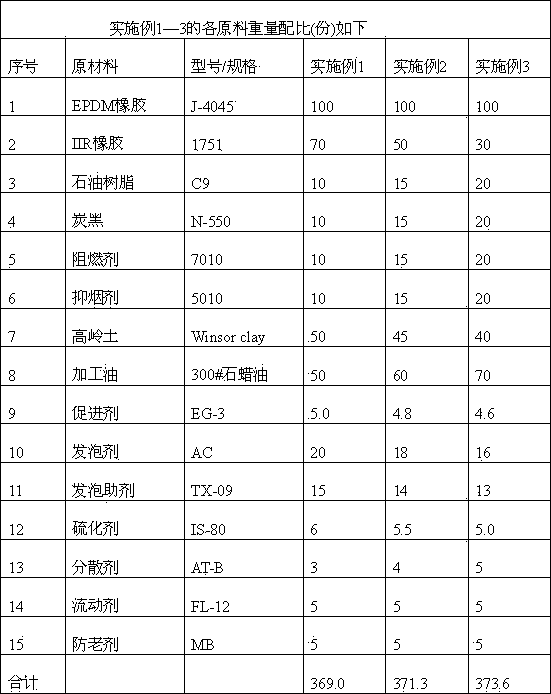

Flame-retardant and slow-rebounded ethylene-propylene-diene-terpolymer rubber porous foaming material and preparation method thereof

The invention relates to a foaming material, and in particular relates to a flame-retardant and slow-rebounded ethylene-propylene-diene-terpolymer rubber porous foaming material and a preparation method thereof. The flame-retardant and slow-rebounded ethylene-propylene-diene-terpolymer rubber porous foaming material with the characteristics of light weight, low smoke, flame retardance, strong shock absorption, small compression deformation, ageing resistance and the like is prepared in a crosslinking and foaming manner according to a proper formula and a proper process. The foaming material is widely applied to various filed of national economy such as engine sealing and shock absorption in automobile industry; leakproof sealing and wall sound absorption in construction industry; rail padding in rail transit; fin sealing in shipping industry, and the like.

Owner:YIBAO FUJIAN POLYMER MATERIALS

Combination material of insulation boards for producing building outer walls and preparation method thereof

The invention relates to a combination material of polyurethane insulation boards for producing building outer walls by using a continuous method and a preparation method thereof. The combination material is composed of a component A and a component B, a weight ratio of the component A to the component B is 1:1-1.3, wherein the component A is composed of the following components, by weight, of 20-40% of polyether polyol A, 15-35% of polyether polyol B, 10-20% of polyether polyol C, 1.0-3.0% of foam stabilizer, 1.0-3.0% of chemical foaming agent, 10-20% of physical foaming agent, 0.5-3.5% of catalytic agent and 10-20% of fire retardant, and the component B is polymethyl polyphenyl polyisocyanates. The preparation method of the combination material comprises stirring and mixing all components in the component A in proportion, and then mixing the component A with the component B. Polyurethane foams made of the combination material are low in heat conductivity coefficient, good in leakproofness, excellent in flame retardant property, good in product stability and capable of completely meeting requirements for polyurethane outer wall boards.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

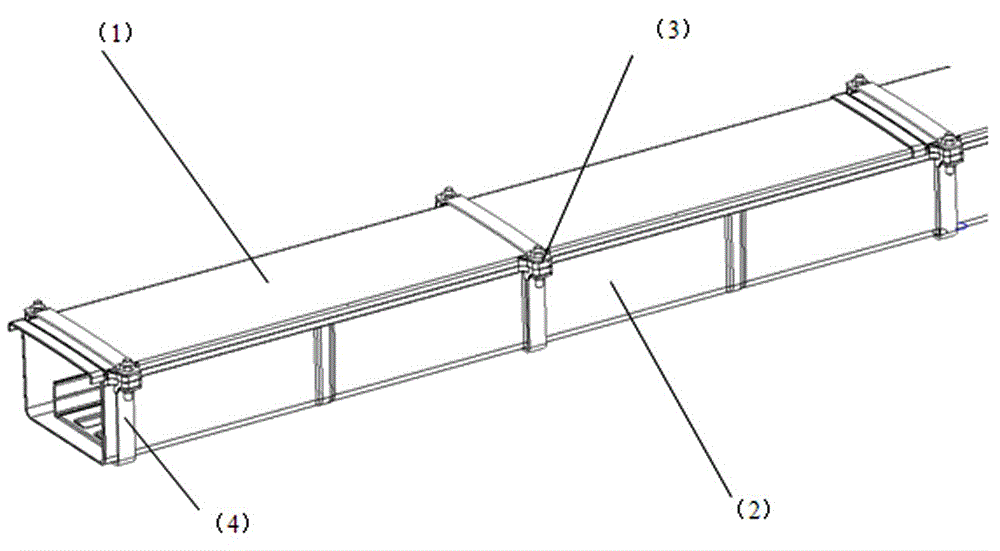

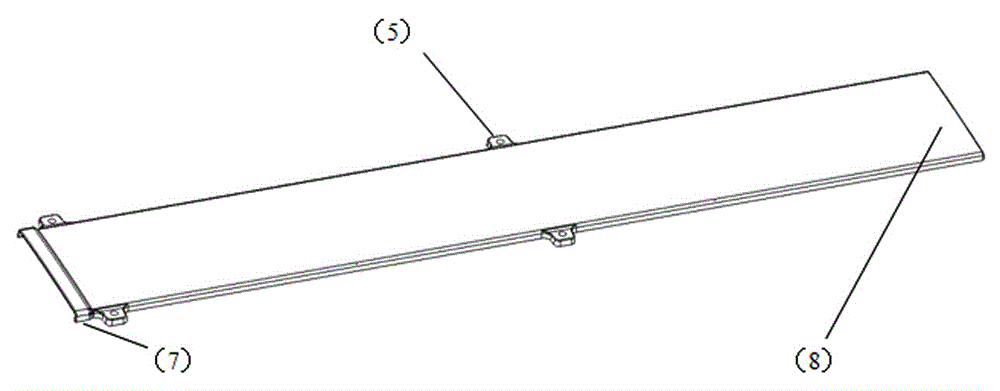

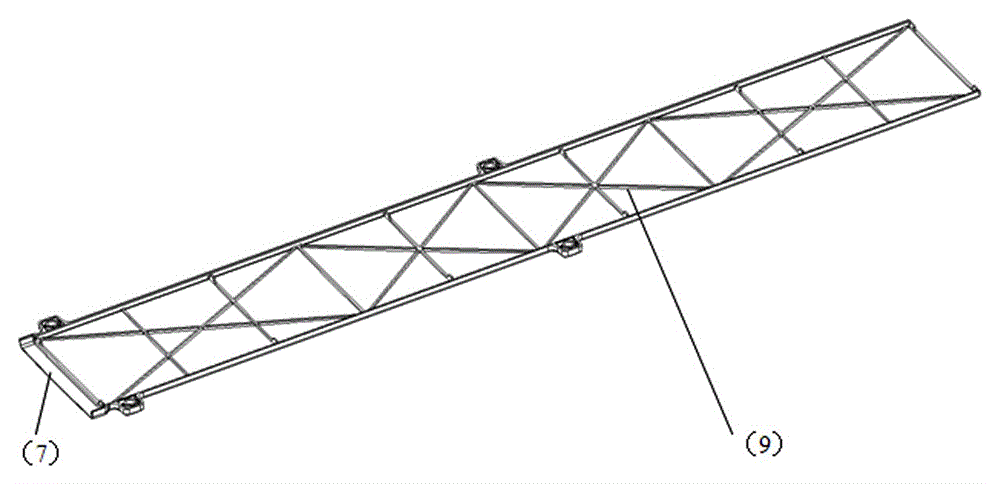

High-strength composite cable trough for railway and preparation process

InactiveCN105001608AMeet the requirements of relevant construction standardsSolve flame retardancyElectrical apparatusGlass fiberAlkali free

The invention relates to a high-strength composite cable trough for a railway and a preparation process. The technical scheme is as follows: the high-strength composite cable trough comprises a trough cover and a trough body made from composite materials, a supporting frame and fastening bolts, wherein the trough body adopts a rectangular trough-type structure with an open top; the trough cover adopts a rectangular structure and is mounted at the top of the trough body; trough cover hanger structures are arranged on two sides of the trough cover; trough body hanger structures are arranged on two sides of the trough body; the trough cover and the trough body are sequentially connected end to end and assembled and then are fixed through the supporting frame; and the supporting frame consists of an upper part and a lower part. The beneficial effects are as follows: a sheet molding compound (SMC) is taken as a raw material and subjected to high-temperature curing and pressing through a forming mold to form the high-strength composite cable trough. The SMC is prepared by taking unsaturated polyester resin as a base material, taking alkali-free non-twist glass fibers as reinforcement materials and fully mixing the base material and the reinforcement materials with inorganic fillers, assistants and the like, so that the problems of a product in aspects of fire retardancy, insulation, high strength and the like are solved, and the high-strength composite cable trough is convenient to transport and mount and long in service life, and fully meets related standard requirements of railway construction.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

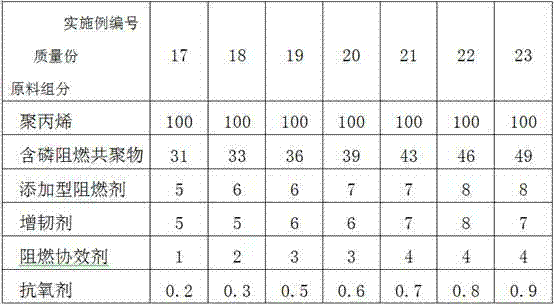

Flame retardant polypropylene composition for salivating method sheet materials and manufacture method thereof

ActiveCN102532709ASolve the strength problemSolve flame retardancyPolymer scienceStrength of materials

The invention discloses a flame retardant polypropylene composition for salivating method sheet materials. The flame retardant polypropylene composition is characterized by consisting of the following ingredients in parts by mass: 100 mass parts of polypropylene, 30 to 50 mass parts of phosphoric flame retardant copolymers, 5 to 8 mass parts of additive flame retardants, 5 to 8 mass parts of tougheners, 1 to 5 mass parts of flame retardant synergistic agents and 0.1 to 1 mass part of antioxidants. A preparation method of the flame retardant polypropylene composition comprises the steps that: the phosphoric flame retardant copolymers are prepared; all ingredients of the composition are put into a mixing machine to be uniformly mixed, then, the melt extrusion is carried out by an extruding machine, in addition, the melt temperature is controlled to be 160 to 200 DEG C, the bar pulling and the grain cutting are carried out, and the flame retardant polypropylene composition for the salivating method sheet materials is prepared. The flame retardant polypropylene composition has good compatibility with polypropylene base bodies, the influence on the mechanical performance and the thermal performance of the material is small, and the flame retardant performance and the tearing resistance performance of the polypropylene material are particularly improved. The flame retardant polypropylene composition can be widely applied to the insulation manufacture in the fields of electronic appliances, office electric appliances, vehicles, instrument apparatuses and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

High strength and wear resistant aromatic composite material, preparation method and application thereof

The invention relates to the field of materials, in particular to a high strength and wear resistant aromatic composite material, a preparation method and application thereof. The composite material includes: 65-85 parts of an aromatic polymer, 5-20 parts of ceramic filler and 10-30 parts of fiber. According to the invention, polyether ketone, polyether sulfone, polyether ether ketone and other aromatic polymers are adopted as the matrix resin to effectively improve the mechanical properties, thermal stability, corrosion resistance and the like of the product. The adding of the ceramic fillerinto the aromatic polymer matrix not only can improve the thermal conductivity coefficient of the product, but also can improve the product strength, and endows the product with the advantages of wearresistance, high hardness, flame retardance, aging resistance, environmental protection, etc. The high strength and wear resistant aromatic composite material provided by the invention has the characteristics of convenient shaping, simplicity and high efficiency, can achieve one-time shaping, and also can be used for secondary processing. The product has high degree of design freedom, is suitablefor large-scale production, and well solves the problems of low strength, poor hardness, no flame retardance, signal shielding and the like of the shells and shell components in existing electronic products, wearable equipment or household appliances.

Owner:大连疆宇新材料科技有限公司

Halogen-free high-flame-retardant cable

ActiveCN103093873AImprove mechanical propertiesStrong copper resistanceRubber insulatorsInsulated cablesElastomerRubber material

The invention discloses a halogen-free high-flame-retardant cable. An insulation layer of the cable comprises an outer insulation layer and an inner insulation layer which are formed by a double-layer coextrusion method. The tension strength of the outer insulation layer is larger than or equal to 13.8MPa, the broken elongation of the outer insulation layer is larger than or equal to 300%, and the inner insulation layer is made of high-flame-retardant rubber materials. The outer insulation layer comprises 100 parts of vinyl copolymer and / or ethylene propylene diene monomer rubber, 60-150 parts of halogen-free flame retardant, 1-10 parts of compatilizer, 0.1-5 parts of antioxidants, 0.1-5 parts of lubricants, 0-20 parts of polymer elastic bodies and 0-3 parts of coupling agents. The inner insulation layer comprises 100 parts of vinyl copolymer and / or ethylene propylene diene monomer rubber, 80-250 parts of halogen-free flame retardant, 1-10 parts of compatilizer, 0.1-5 parts of antioxidants, 0.1-5 parts of lubricants, 0-20 parts of polymer elastic bodies and 0-3 parts of coupling agents. The cable is stretch-resistant, excellent in waterproof performance and abrasion resistance and high in flame-retardant level.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Anticorrosive paint

InactiveCN102504674ANo change in flame retardancyConductivity unchangedAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention relates to an anticorrosive paint which comprises epoxy resin, carbon substances, metal and oxides thereof, a flame retardant, a heat insulating material, additives, a mixed solvent and a curing agent substance, wherein the epoxy resin is flame-retardant epoxy resin which is an additive flame-retardant epoxy resin formed by combination of common epoxy resin and the flame retardant or a reactive flame-retardant epoxy resin formed by combination of flame-retardant epoxy resin with a flame-retardant element and an inorganic flame retardant.

Owner:XIAN RUIJINYUAN ENERGY TECH

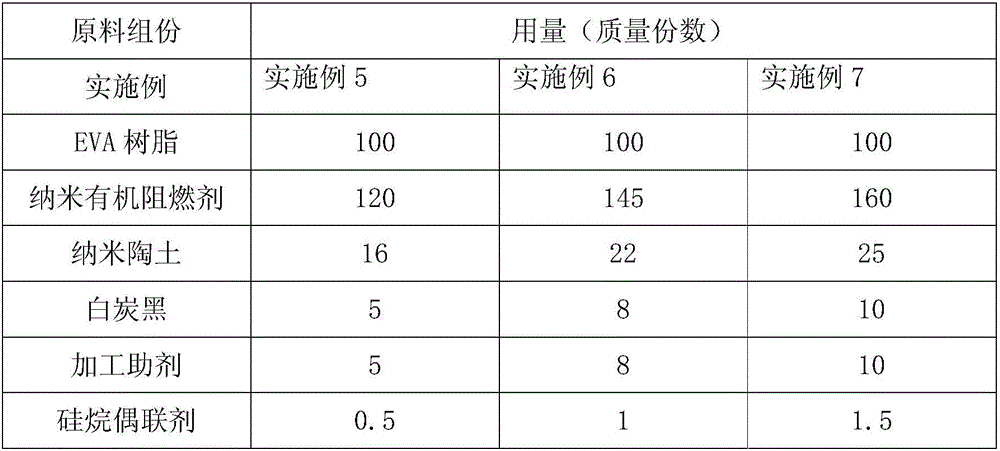

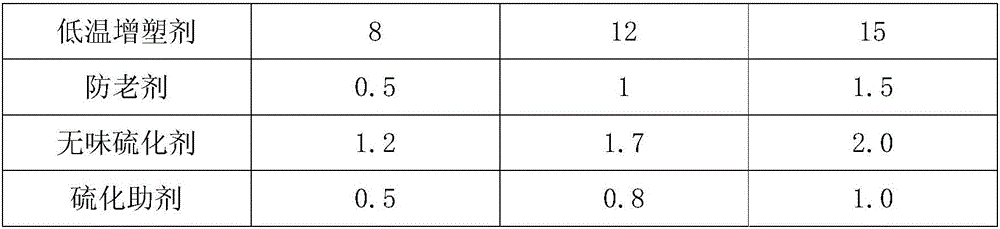

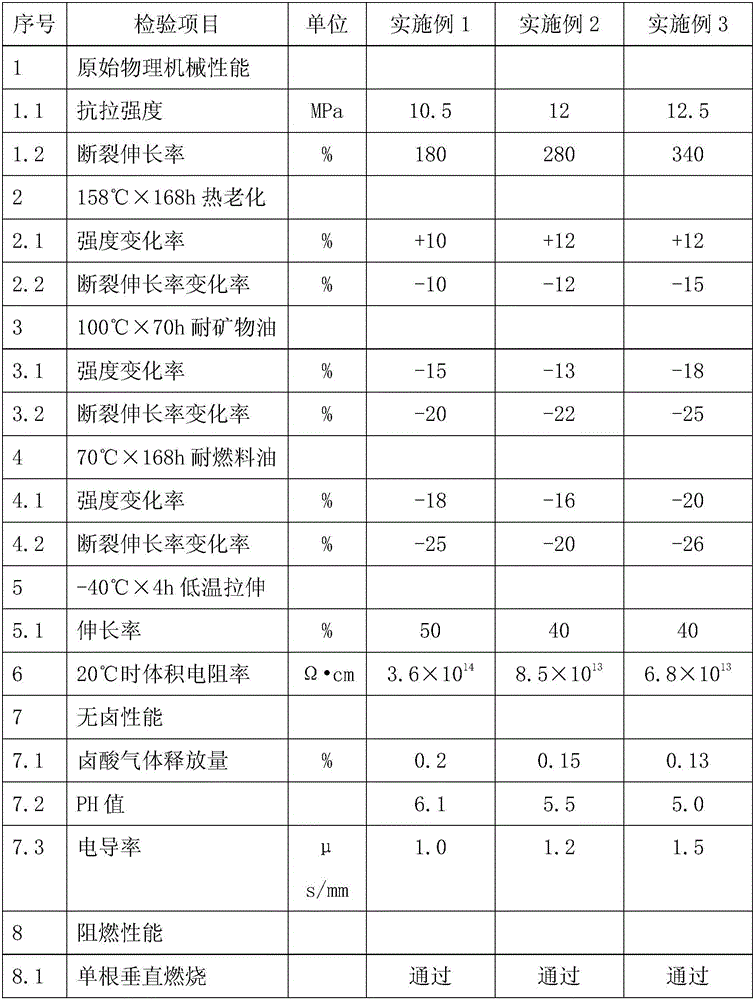

Oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material and preparation method thereof

ActiveCN106220985ASolve flame retardancyAddress mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePower cable

The invention relates to an oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material and a preparation method thereof, and belongs to the technical field of power cables. The oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material is prepared from the following components in parts by weight: 90 to 110 parts of EVA resin, 100 to 160 parts of a nanoscale organic flame retardant, 5 to 10 parts of white carbon black, 15 to 25 parts of nano-pottery clay, 5 to 10 parts of a processing auxiliary agent, 0.5 to 2 parts of a silane coupling agent, 8 to 15 parts of a low-temperature plasticizer, 0.5 to 1.5 parts of an anti-ageing agent, 1.2 to 2.0 parts of a tasteless vulcanizing agent and 0.5 to 1.0 part of a vulcanizing auxiliary agent. The preparation method comprises the following steps: 1, plastifying: plastifying EVA resin particles for 5 to 8 minutes in an internal mixer, scrolling down and allowing standing still; 2, mixing: plastifying the primarily plastified EVA resin for 0.5 to 1.5 minutes; adding the processing auxiliary agent, the silane coupling agent, the nano-pottery clay and the white carbon black and mixing for 4 to 6 minutes; adding the nanoscale organic flame retardant, the low-temperature plasticizer and the anti-ageing agent and mixing for 5 to 7 minutes; adding the tasteless vulcanizing agent and the vulcanizing auxiliary agent in a later period. The invention has the advantages that the oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material has excellent fire resistance, high mechanical property, high insulating property and high elasticity; the process is simple, the operation is convenient, the control is accurate, and the product is stable.

Owner:天津金山电线电缆股份有限公司

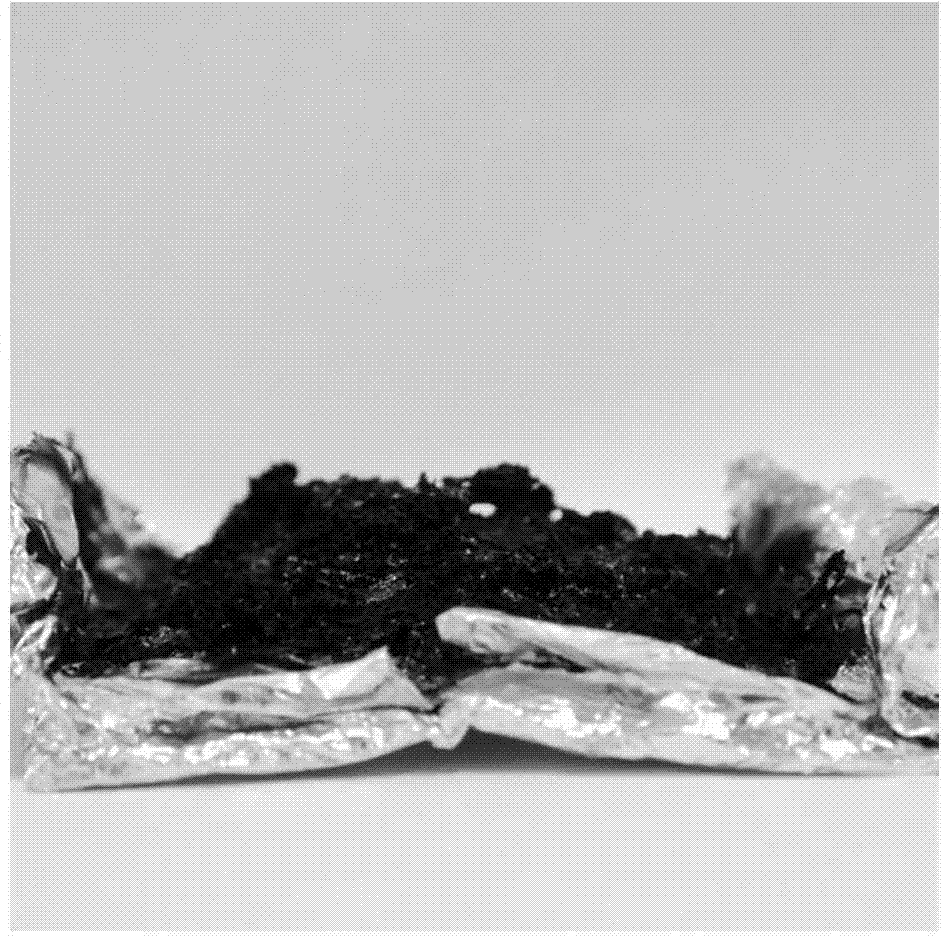

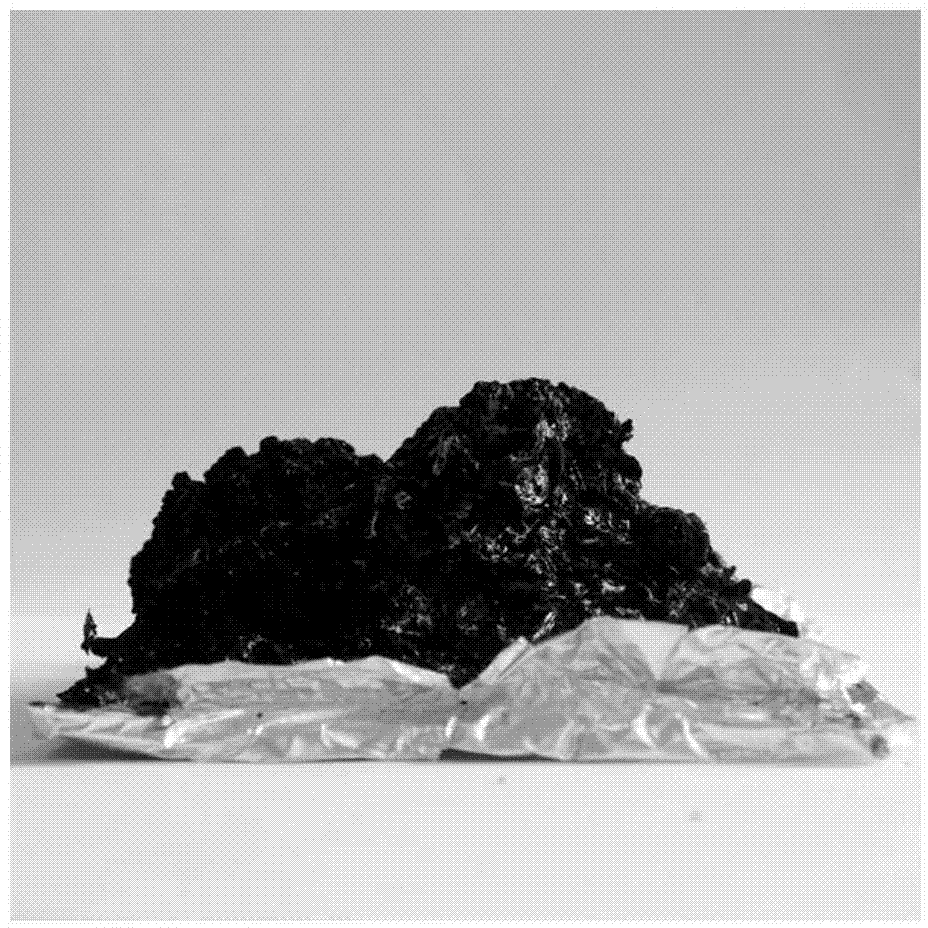

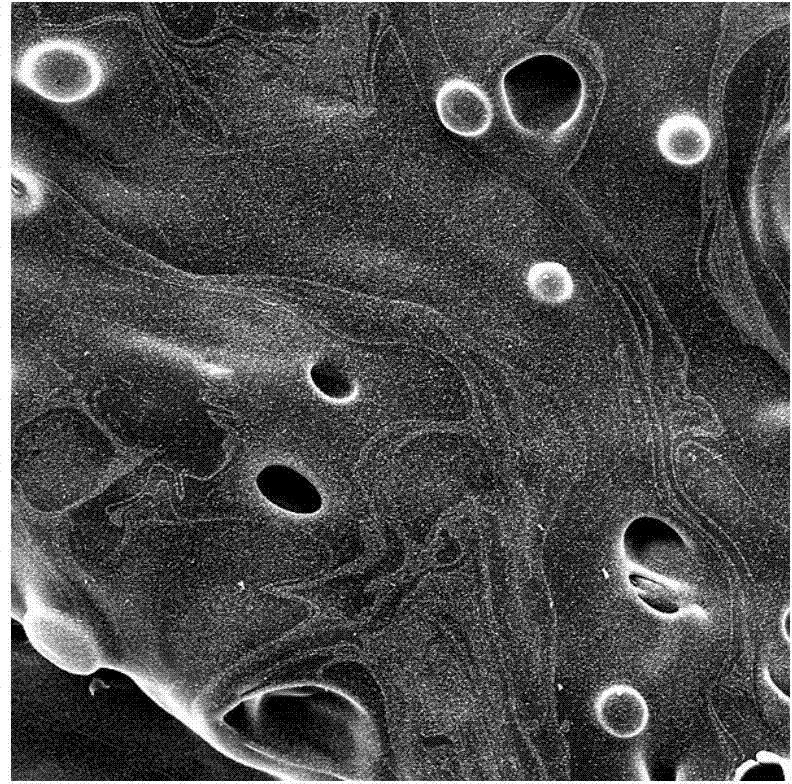

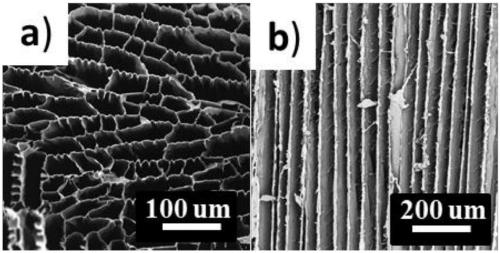

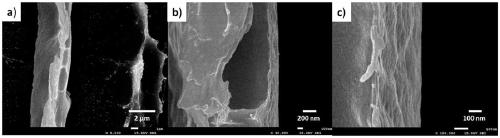

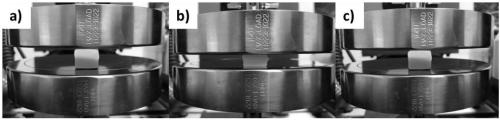

Flexible high flame retardant biologic aerogel material and preparation method thereof

ActiveCN109485910AAnisotropicImprove mechanical propertiesCoatingsPolymer scienceLimiting oxygen index

The invention discloses a preparation method of a flexible high flame retardant biologic aerogel material. The preparation method comprises the following steps: preparing a biomass macromolecular solution; uniformly mixing the biomass macromolecular solution with a synthesized resin precursor solution to obtain a mixed solution, then quickly placing the mixed solution at -20 to -200 DEG C to be cooled in a single direction and freezing the mixed solution to a solid; and finally, freezing and drying the solid in a freeze dryer to obtain a biologic aerogel and crosslinking the biologic aerogel in a dried vacuum environment or a dried alkaline vacuum environment at 150-200 DEG C for 0.5-50 h to obtain the flexible high flame retardant biologic aerogel material. The material has anisotropic mechanical property, has high axial strength and has rebound resilience radially. The pore wall of the material has a porous structure, and the aerogel prepared by the porous material has an ultralow heat conductivity coefficient which is 0.002-0.02W / (m.K). The density of the material is 16-181 kg / m<3>, the extreme oxygen index is 24.0-39.0%, the peak heat release rate is 55.6-245.6 kW / m<2>, and thecontact angle of the aerogel is 60-148 degrees.

Owner:SICHUAN UNIV

Medium-voltage fire-resistant power cable

InactiveCN107564612AExcellent flame retardantImprove fire resistancePlastic/resin/waxes insulatorsInsulated cablesFiberFirestop

The invention discloses a medium-voltage fire-resistant power cable, which comprises a cable core, wherein the cable core is formed by twisting a plurality of wire cores; each wire core comprises a conductor, a shielding layer, an insulating layer and an insulating shielding layer; the shielding layers, insulating layers and the insulating shielding layer are arranged outside the corresponding conductors; each conductor is formed by twisting a plurality of copper core conductors; a thermal insulating layer is also arranged outside each insulating layer; one insulating shielding layer is arranged outside each thermal insulating layer; a metal shielding layer wraps the outside of each insulating shielding layer; a fire-resistant layer is arranged outside each metal shielding layer; the partsamong the plurality of wire cores are filled with fillers; a ceramic fiber tape, an adiabatic cooling layer, a steel tape firestop layer, an oxygen barrier layer, an inner sheath and an outer sheathwrap the outside of the cable core; and the outer sheath wraps the inner sheath through a lubricating layer. The medium-voltage fire-resistant power cable is simple in structure, and has good flame retardant property and fire resistance; the voltage level of the cable is improved on the basis of ensuring the flexibility and the large-length processing performance of the cable; and safe and reliable operation of a power system is ensured.

Owner:JIANGSU PUCAO TECH CO LTD

High-temperature resistant halogen-free fire-retarding rubber conveyer belt rubber material and conveyer belt made thereof

ActiveCN101993557ASolve high temperature resistanceSolve flame retardancyConveyorsRubber materialEngineering

The invention relates to a high-temperature resistant halogen-free fire-retarding rubber conveyer belt rubber material which is high temperature resistant and fire-retarding and a conveyer belt made thereof. The rubber material comprises the following components: 90 to 110 parts of high-temperature resistant rubber, 170 to 190 parts of halogen-free fire retardant, 35 to 45 parts of reinforcing additive, 7 to 13 parts of thinker, 3.5 to 5.5 parts of vulcanizing agent, 1.5 to 2.5 parts of anti-aging agent A, 1.0 to 2.0 parts of anti-aging agent B and 1.0 to 2.0 parts of promoter. The components can be added or reduced according to a ratio. The invention has the advantages that: two main technical drawbacks in terms of high-temperature resistance and halogen-free and fire-retarding properties of the conventional products of the rubber conveyer belt industry are overcome; the application, used to lack, of the rubber material of the rubber conveyer belt products under halogen-free, fire-retarding and high temperature-resistance conditions is realized; the use safety of the conveyer belt products is improved considerably; and the service life of the products is prolonged.

Owner:浙江顺豪新材料有限公司

Material for electric meter shell and preparation method thereof

InactiveCN107286531AImprove fire resistanceHigh mechanical strengthPolyvinyl chlorideDimethyl siloxane

The invention provides a material for an electric meter shell and a preparation method thereof, belonging to the field of electric materials. The material for the electric meter shell comprises the following raw materials by weight: polyvinyl chloride, polyethylene, methyl methacrylate, glass fiber, polycarbonate, polylactic acid, decabromodiphenylethane, polydimethylsiloxane, chitin, silicon nitride powder, silicon carbide powder, sodium succinate, talcum powder, barium sulfate, graphite powder, chromium carbide powder, boron nitride, alumina silicate, kaolin, polyamide resin, acetal resin, a flame retardant, a plasticizer, a coupling agent, a heat stabilizer, a light stabilizer and a lubricant. The preparation method comprises the following steps: (1) weighing of the above raw materials; and (2) centrifugation, melting, addition into a mold, shaping and cutting. The material and the preparation method thereof provided by the invention overcomes the problem that conventional materials for the electric meter shell need to be further improved and strengthened in mechanical strength, thermal stability and flame retardation.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

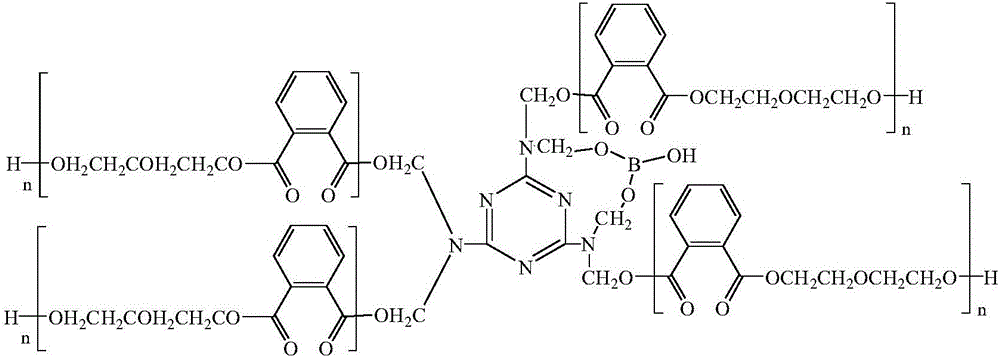

Inorganic hybrid polyester polyol etherified melamine resin and preparation method thereof

ActiveCN106243335AImprove high temperature resistanceImprove flame retardant performanceFireproof paintsPolyurea/polyurethane coatingsPolyesterCross-link

The invention belongs to the technical field of inorganic hybrid polymers and especially relates to inorganic hybrid polyester polyol etherified melamine resin and a preparation method thereof. The preparation method mainly comprises the following steps: (1) etherification reaction: adding hexamethylolmelamine and polyester polyol into a reaction vessel to carry out a thermal reaction so as to obtain tetraetherified or pentaetherified melamine resin; (2) alkali neutralization; (3) hybridization reaction; (4) cooling and filtering to obain the finished product. Through the above method, the inorganic hybrid polyester polyol etherified melamine resin is prepared. By hybridization cross-linking reaction with an inorganic hybrid compound, high-temperature-resistant fire retardant elements such as boron, molybdenum, antimony, etc. are introduced into the finally produced amino resin polyol such that high temperature resistance and flame retardant property of amino resin polyol are enhanced. The product of the invention is mainly used in preparation of premixed polyols and paint coating.

Owner:CHANGZHOU JUMBO ENERGY SAVING TECH CO LTD

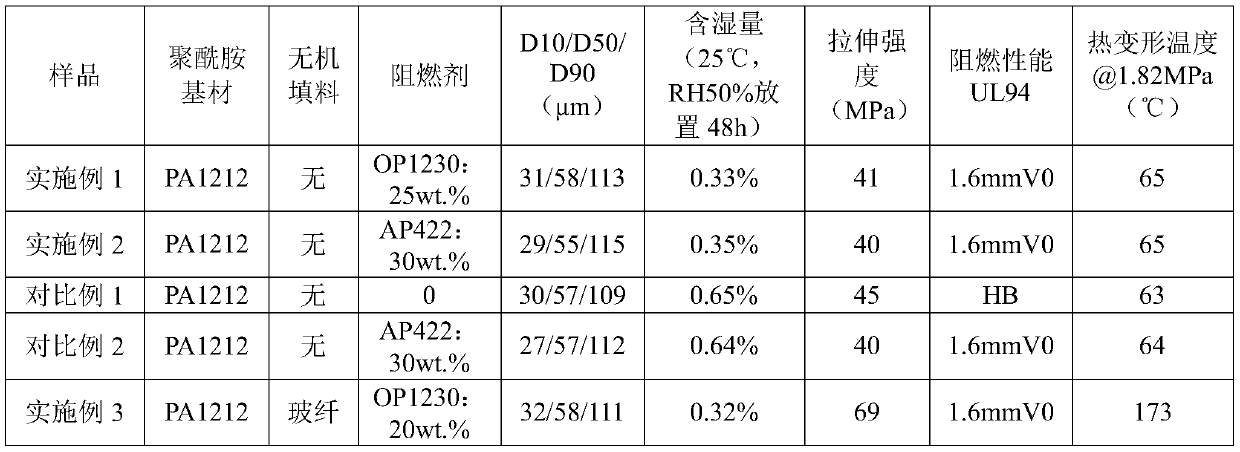

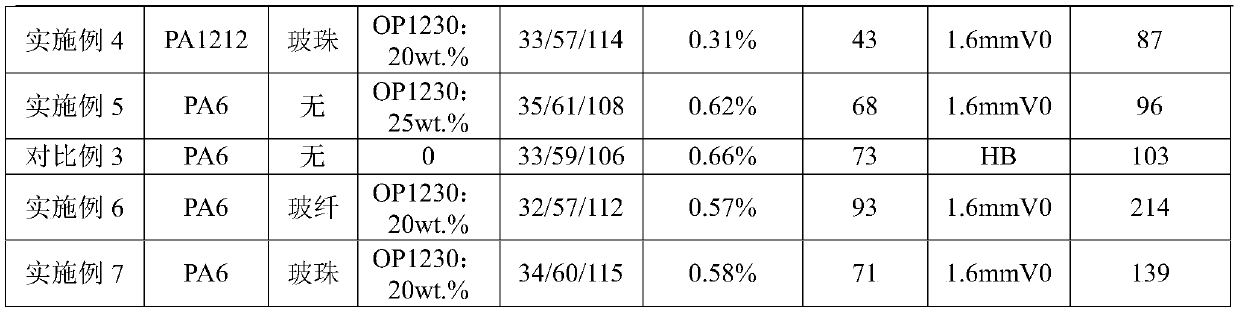

Preparation method of polyamide flame-retardant material for laser sintering

ActiveCN110330790AImprove mechanical propertiesResolve separabilityAdditive manufacturing apparatusSelective laser sinteringAntioxidant

The invention provides a preparation method of a polyamide flame-retardant material for laser sintering, and the method comprises the following steps: adding dried polyamide resin, a flame retardant,an antioxidant, a compatilizer and an inorganic filler into a screw extruder for extrusion granulation to prepare polyamide flame-retardant particles, wherein the polyamide flame-retardant particles comprise, by mass, 34-87.9 wt.% of polyamide resin, 10-30 wt.% of the flame retardant, 0.1-1 wt.% of the antioxidant, 2-5 wt.% of the compatilizer and 0-30 wt.% of the inorganic filler; the polyamide flame-retardant particles are prepared into polyamide flame-retardant power through a cryogenic crushing process, and the polyamide flame-retardant power is dried and screened to obtain the polyamide flame-retardant powder with the particle size ranging from 30 to 100 microns; the polyamide flame-retardant powder and a power flow aid are evenly mixed to prepare the polyamide flame-retardant powdermaterial for selective laser sintering, wherein the polyamide flame-retardant powder material comprises, by mass, 99 wt.% to 99.8 wt.% of the polyamide flame-retardant powder and balance of the powerflow aid, and the powder flow aid is a hydrophobic flow aid with an organically-treated surface. The flame retardant is tightly combined with polyamide, is not easy to separate from each other, and has good flame retardant performance.

Owner:HUNAN FARSOON HIGH TECH CO LTD

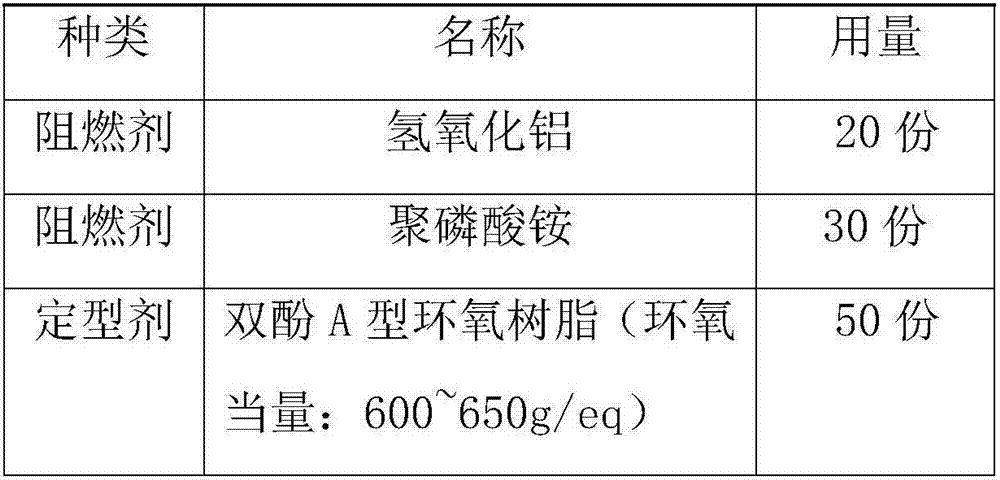

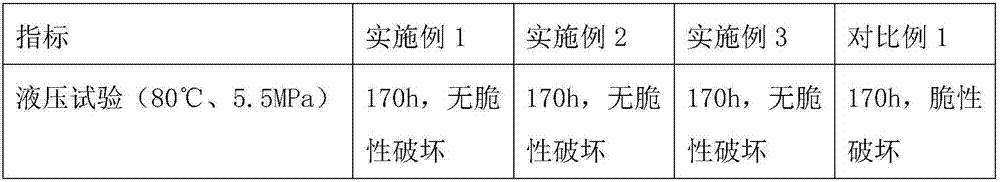

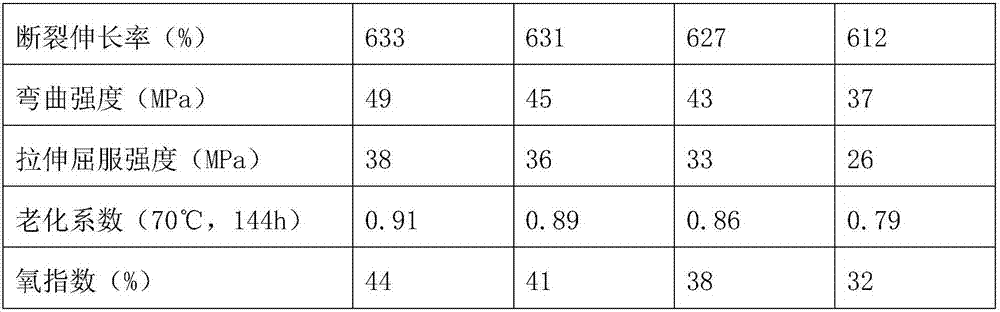

Preparation method of carbon fiber liquid molded carbon fiber composite material with no halogen, low toxicity and high flame resistance

The invention discloses a preparation method of a carbon fiber liquid molded carbon fiber composite material with no halogen, low toxicity and high flame resistance. The method comprises the following steps: 1) preparation of a flame retardant setting powder; 2) uniform spreading of the flame retardant setting powder on the surface of a carbon fiber fabric; 3) high temperature setting; and 4) fabric layer setting, and liquid molding process manufacturing. The preparation method of the carbon fiber liquid molded carbon fiber composite material with no halogen, low toxicity and high flame resistance is characterized in that a powdery high-efficiency flame retardant is mixed with a setting agent to form the flame retardant setting powder, and the flame retardant setting powder is used as a flame retardant setting agent to set the carbon fiber fabric in order to solve the flame retardation problem and reach the fabric setting effect. The carbon fiber composite material prepared from flame-retardant or non-flame-retardant resin through a liquid molding technology has a high flame retardation level, and can reach the highest requirements of Germany flame retardant standards DIN5510-2:2009, that is, the combustion property reaches S4, the smoke density reaches SR2, the droplet characteristic reaches ST2, and the smoke toxicity FED is not more than 1.

Owner:HENGSHEN

Water pipe used in pipeline engineering and preparation method thereof

The invention provides a water pipe used in pipeline engineering and a preparation method thereof, and relates to the technical field of plastic pipes. The water pipe used in pipeline engineering includes the following raw materials in parts by weight: SG-3 type PVC resin, aluminum borate whiskers, acetyl Calcium acetone, 1,2‑polybutadiene, talc, silica gel, polysulfone resin, polyamide resin, polyurethane rubber, phenolic resin, graphite powder, ceramic fiber, nano silicon carbide, 2,6‑di tert-butyl-p-cresol, flame retardant, plasticizer, compatibilizer, heat stabilizer, light stabilizer and curing agent; the preparation method comprises the following steps: (1) weighing raw materials, (2) mixing, (3) ) Melt molding, cooling and shaping. The invention solves the deficiencies of the existing water pipes in flame retardancy, heat resistance and strength.

Owner:ANHUI MEILAN LANDSCAPE ENG CO LTD

Water feeding pipe and preparation method thereof

InactiveCN107286458ASolve the mechanical strengthSolve flame retardancyLow-density polyethyleneAntioxidant

The invention provides a water feeding pipe and a preparation method thereof and relates to the technical field of plastic pipes. The water feeding pipe comprises, by weight, metallocene linear low density polyethylene, chromium carbonate, fumed silica, nano-active calcium carbonate, metallocene linear low density polyethylene wax, phthalate, gamma-aminopropyltriethoxysilane, rose essential oil, dibutyltin dilaurate, a modifying aid, aluminum hydroxy distearate, hollow glass microbeads, aluminum hydroxide, nano zirconium carbide, aluminum silicate, glass fibers, a thermal stabilizer, a photo-stabilizer, an antioxidant, a compatilizer, and a plasticizer. The preparation method includes the steps of: 1) weighing raw materials; 2) performing granulation; 3) performing mixing, kneading, cooling, extrusion and shaping. The water feeding pipe has high mechanical strength, good flame retarding property, good toughness and good anti-aging performance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com