Patents

Literature

41results about How to "Solve the mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of controlled-release soft capsules for cigarettes

ActiveCN102824887ASolve the mechanical strengthSolve compactnessTobacco preparationTobacco treatmentChemistryOil in water

The invention relates to a preparation method of controlled-release soft capsules for cigarettes. The preparation method comprises the following steps of: dripping an oil-in-water emulsion containing polyvalent metal ions into a film former complex colloid solution as a template, enabling the periphery of the liquid drop template of the oil-in-water emulsion containing the polyvalent metal ions to perform self-assembly on the surface of the liquid drop template in the film former colloid solution through film former colloid particles to form an ordered spherical gel wrapping layer, further cross-linking through the chemical action of the colloid particles and the polyvalent metal ions in the emulsion drops to form a dense and firm film, forming primary products of the soft capsules, and further performing dyeing, drying and dehydration to obtain target capsules. The preparation method disclosed by the invention has the advantages of sufficient mechanical strength and dense structure, higher uniformity, roundness and stability of the capsules in comparison with the ordinary capsules, and great compatibility with smoke gas.

Owner:YUNNAN RES INST OF TOBACCO SCI +1

Porous ceramic-loaded catalyst used for biomass catalytic liquefaction, and preparation method thereof

ActiveCN104844264ASolve the strength problemSolve the problem of easy wear and tearCeramicwareHeat carrierCarnallite

The invention discloses a porous ceramic-loaded catalyst used for biomass catalytic liquefaction, and belongs to the technical field of porous functional ceramic. A natural inorganic catalyst is taken as an active ingredient of the porous ceramic-loaded catalyst, is subjected to smashing, grinding, and screening, and is mixed with a ceramic aggregate, a pore forming agent, and a binder at a mass ratio of 30-40:40-50:5-10:10-15; an obtained mixture is processed so as to obtain a porous ceramic body material; the porous ceramic body material is subjected to drying, sintering, and activation so as to obtain the porous ceramic-loaded catalyst; wherein the active ingredient is one or a combination of a plurality of ingredients selected from dolomite, limestone, diatomite, kaoline, olivine, cordierite, montmorillonite, hydrotalcite, carnallite, beryl, celestite, and gypsum at random, and dolomite and montmorillonite preferably. The porous ceramic prepared via above steps can be taken as a catalyst of biomass pyrolysis liquidation processes and a reactor internal heat carrier at the same time, possesses activity on biomass pyrolysis processes, is capable of increasing bio oil yield, improving bio oil quality, and reducing biomass pyrolysis reaction conditions.

Owner:SHANDONG UNIV OF TECH

Composite nuclear track membrane and preparation method thereof

ActiveCN104001429AImprove surface hydrophilicityHigh mechanical strengthSemi-permeable membranesPolyesterVolumetric Mass Density

The invention discloses a composite nuclear track membrane and a preparation method thereof. The composite nuclear track membrane comprises a polyester nuclear track membrane or a polycarbonate nuclear track membrane, wherein a porous cellulose acetate membrane is composited on one surface of the polyester nuclear track membrane or the polycarbonate nuclear track membrane so as to form the composite nuclear track membrane of which the thickness is 67-160 microns, the aperture of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 1-10 microns, the pore density of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 2*10<5> / cm<2>-2*10<7> / cm<2>, and the thickness of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 7-25 microns. The composite nuclear track membrane has the advantage that the surface hydrophilicity is good, the mechanical strength is high, the membrane thickness is moderate, the automatic operation can be realized easily, the flux of the filtering liquid is high, and the assimilative capacity is strong; the composite membrane is an integer, is not layered and is suitable for fabricating roll type filter cores; the porous cellulose acetate membrane composited on the nuclear track membrane is taken as a pre-filtering layer or a support layer of the nuclear track membrane, so that the problems about mechanical strength and thickness of the membrane are solved, and meanwhile, the a pre-filtering problem of the membrane is solved.

Owner:天津理源科技有限公司

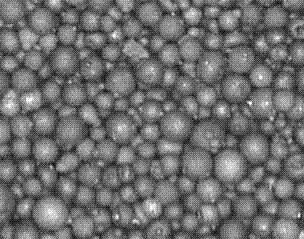

High performance soft magnetic composite Ni-Zn ferrite material

The invention provides a thermal shock resistant Ni-Zn ferrite material with high saturation magnetic flux density. The material provided by the invention is suitable for manufacturing miniaturized power inductance magnetic cores. The material has a main formula composed of the following components and content: 48-50mol% of Fe2O3, 20-25mol% of ZnO, 25-30mol% of NiO, and 2-5mol% of CuO; trace additives comprise: 0.01-0.05wt% of Co2O3, 0.05-0.15wt% of TiO2 and 0.02-0.1% of Bi2O3. A twice wet process is employed to prepare the materials into powder, and the product is prepared by dry pressing molding, high temperature sintering, and electric polarization. The product has the characteristics of high saturation magnetic flux density, high direct current bias and thermal shock resistance, and can simultaneously satisfy the large power and soldering resistance (resistance to instantaneous thermal shock) requirements of small patch (SMD) inductance magnetic cores.

Owner:CYGE ELECTRONIC TECH (HUNAN) CO LTD

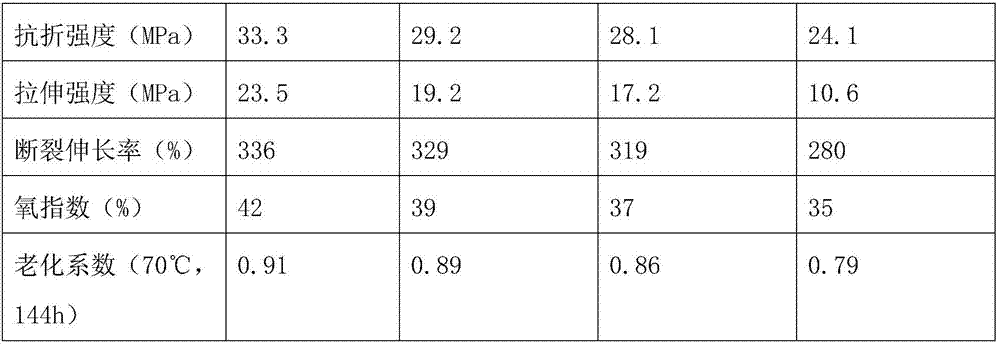

High-voltage transformer substation cable insulating sheath material and preparation method thereof

ActiveCN103524866ASolve flame retardancySolve the mechanical strengthPlastic/resin/waxes insulatorsInsulated cablesWear resistantFumed silica

The invention discloses a high-voltage transformer substation cable insulating sheath material and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 60-80 parts of metallocene linear low density polyethylene, 25-35 parts of isotactic polypropylene, 10-15 parts of EVA, 8-12 parts of aluminum hydroxide, 5-10 parts of magnesium hydroxide, 4-8 parts of zinc stannate, 12-18 parts of siliceous rock powder, 4-6 parts of polyethylene wax, 2-3 parts of terephthalic acid zinc, 1-2 parts of magnesium oxide, 3-5 parts of dimethyl silicone oil, 2-3 parts of basic lead silicate, 5-10 parts of triallyl trimellitate, 1-2 parts of gamma-methacryloxy propyl trimethoxyl silane, 15-25 parts of fumed silica, 10-15 parts of active calcium carbonate, 1-2 parts of an antioxidant 168, and 3-5 parts of a composite filler. The sheath material has excellent mechanical strength and abrasion resistance, can effectively improve the wear resistant ability and the impact resistant ability of a cable sheath, moreover, has good flame retardancy, is low in smoke and is halogen-free, effectively solves contradictions among the flame retardancy, the mechanical strength and the abrasion resistance of the sheath material, prolongs the service life of the sheath, and guarantees normal working of a high-voltage transformer substation cable.

Owner:PANJIN GUANGLIDA ELECTRIC

Preparation method of high-strength high-toughness copper alloy wire for automatic cables

The invention discloses a preparation method of a high-strength high-toughness copper alloy wire for automatic cables. The copper alloy wire comprises the following components by weight percent: 4.0%-6.0% of Al, 1.5%-2.5% of Mn, 1.2%-1.8% of Fe, 0.6%-1.4% of Ni, 0.5%-1.0% of Be, 0.3%-0.6% of Sn, 0.25%-0.45% of Co, 0.1%-0.2% of V, 0.008%-0.016% of Sr, 0.005%-0.015% of Se, 0.03%-0.04% of La, 0.02%-0.03% of Y, 0.01%-0.02% of Pr, 0.005%-0.01% of P and the balance of copper and inevitable impurities. According to the method, the mechanical strength of the copper alloy wire can be greatly enhanced, the ductility of the copper alloy wire is remarkably improved, excellent toughness and plasticity can be kept, and the conflict between the mechanical strength and the toughness of the copper alloy wire is effectively eliminated; meanwhile, the method is simple in production process, low in cost, high in efficiency and easy to control, can achieve large-scale automated production, and has good industrial prospect.

Owner:RUIZHAN TONGLING TECH

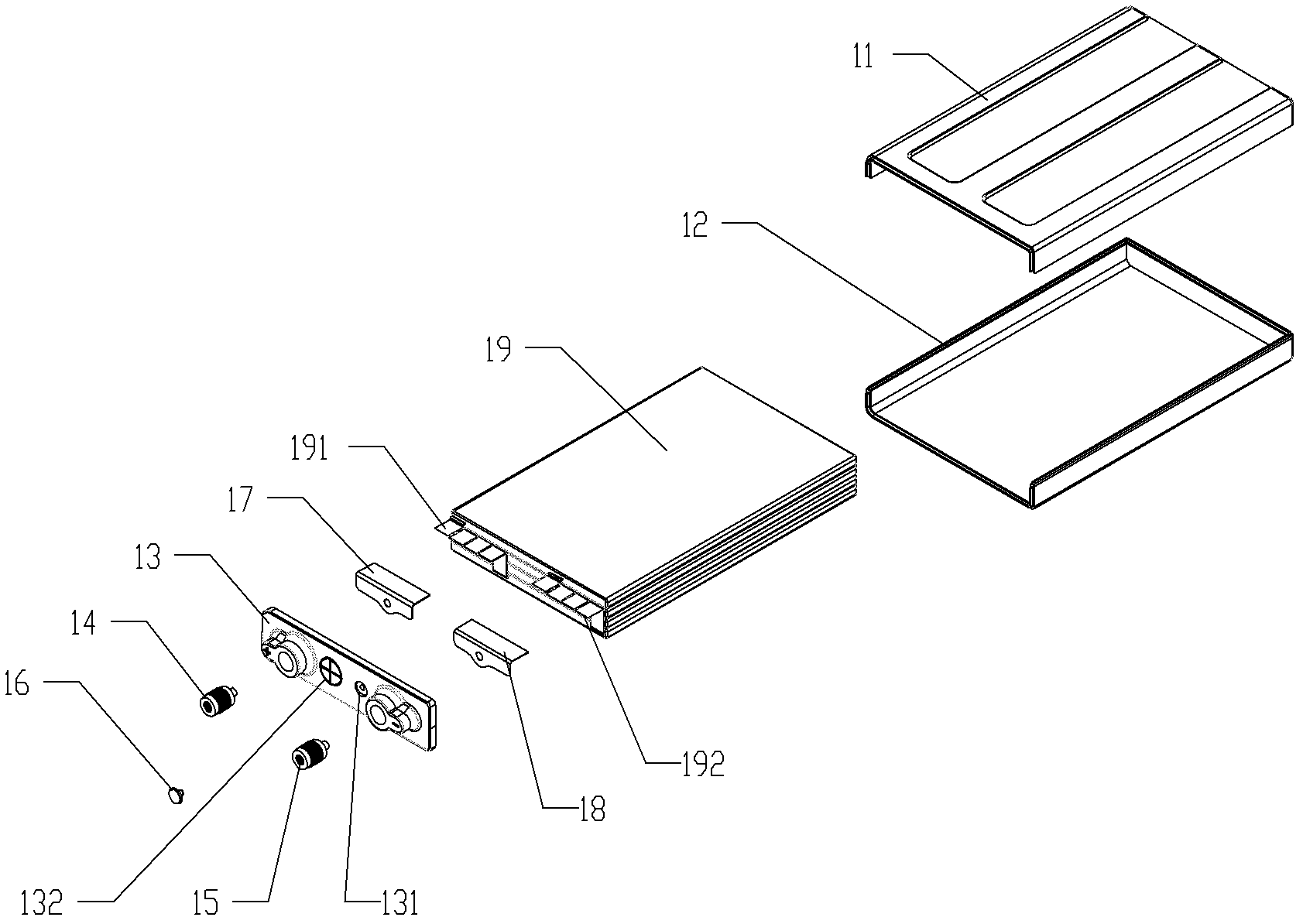

Compound plastic and lithium ion battery and battery pack manufactured by using same and assembling method thereof

InactiveCN102558654ASolve the problem of high-efficiency heat conductionSolve heat conduction efficiency and heat dissipation problemsFinal product manufactureCell component detailsPolyvinylidene fluoridePolypropylene

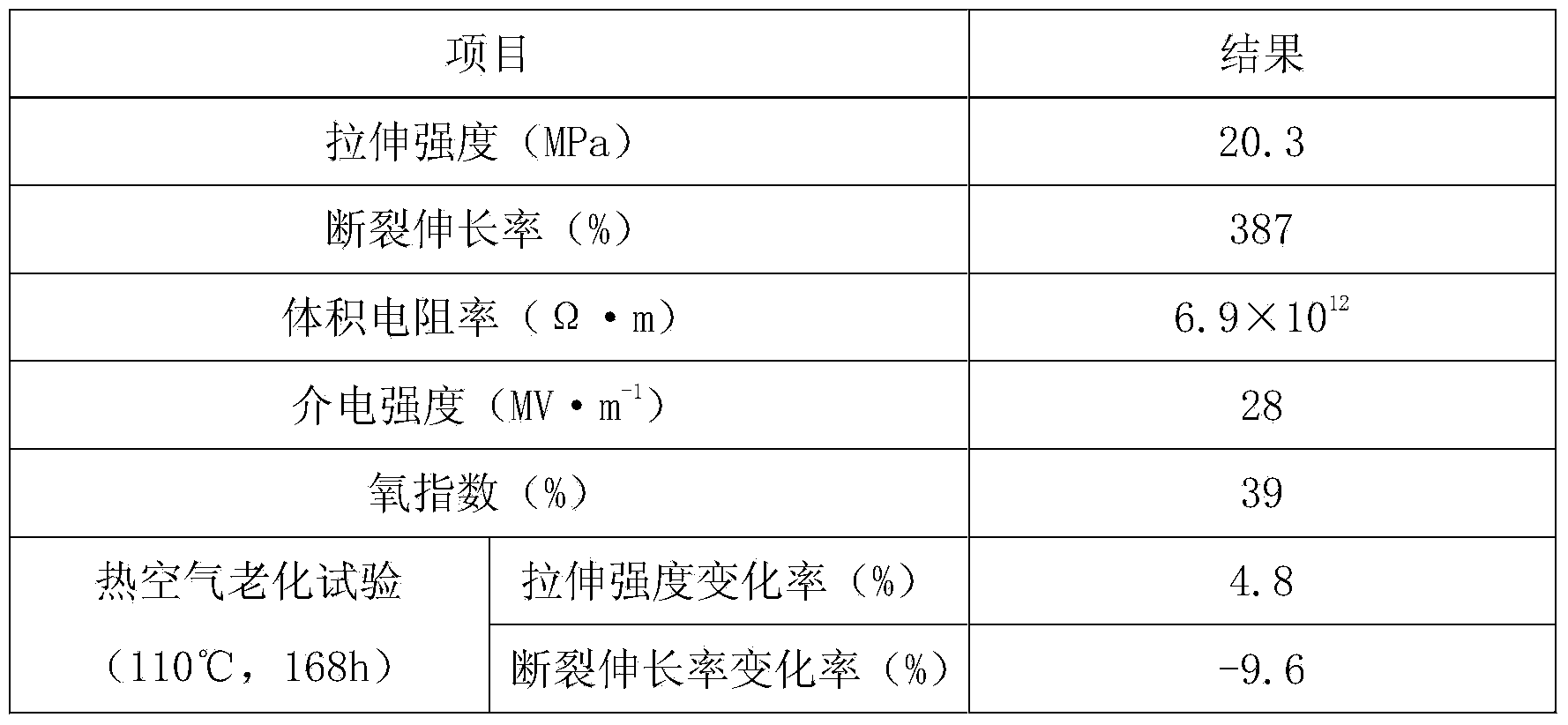

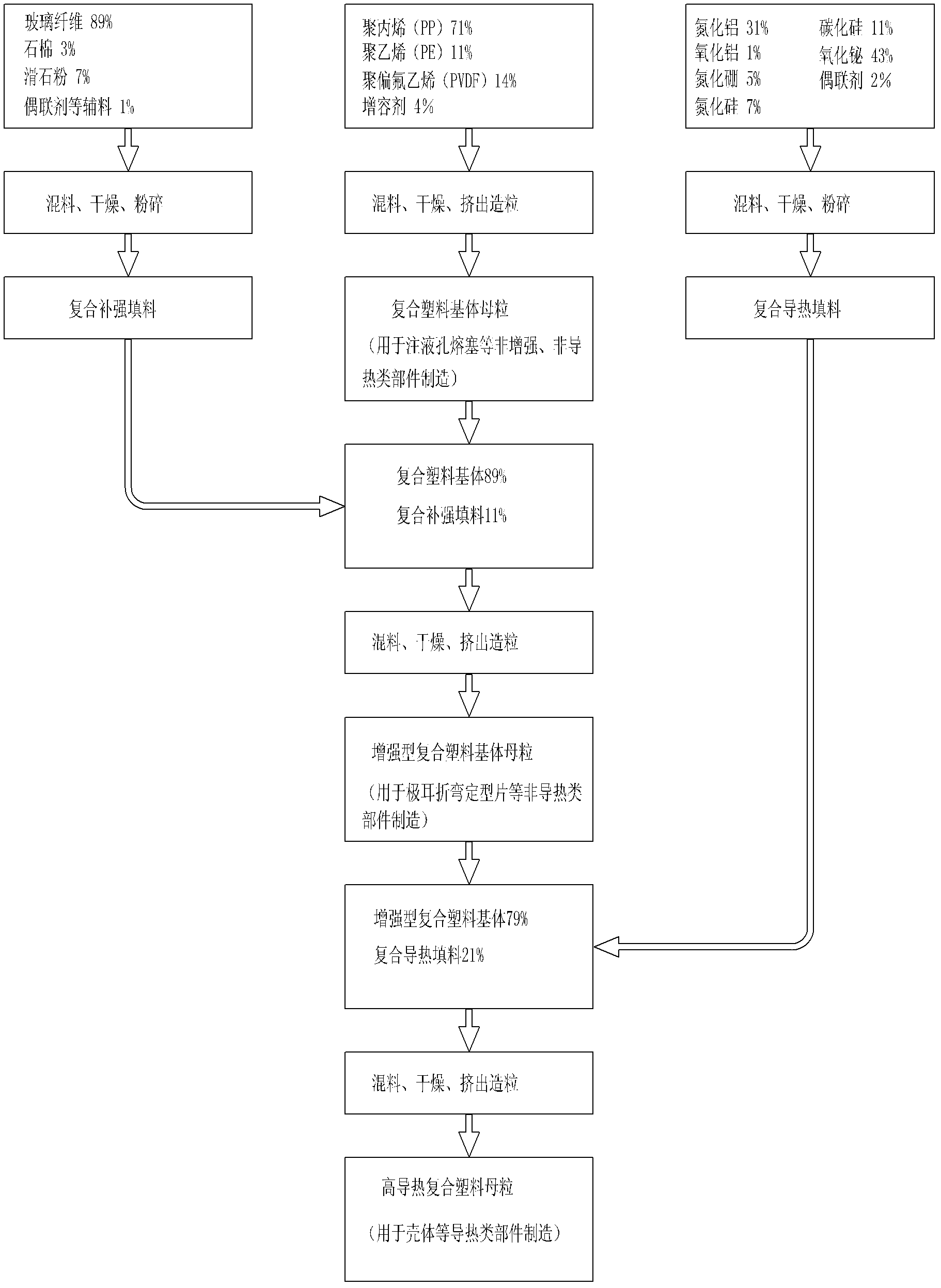

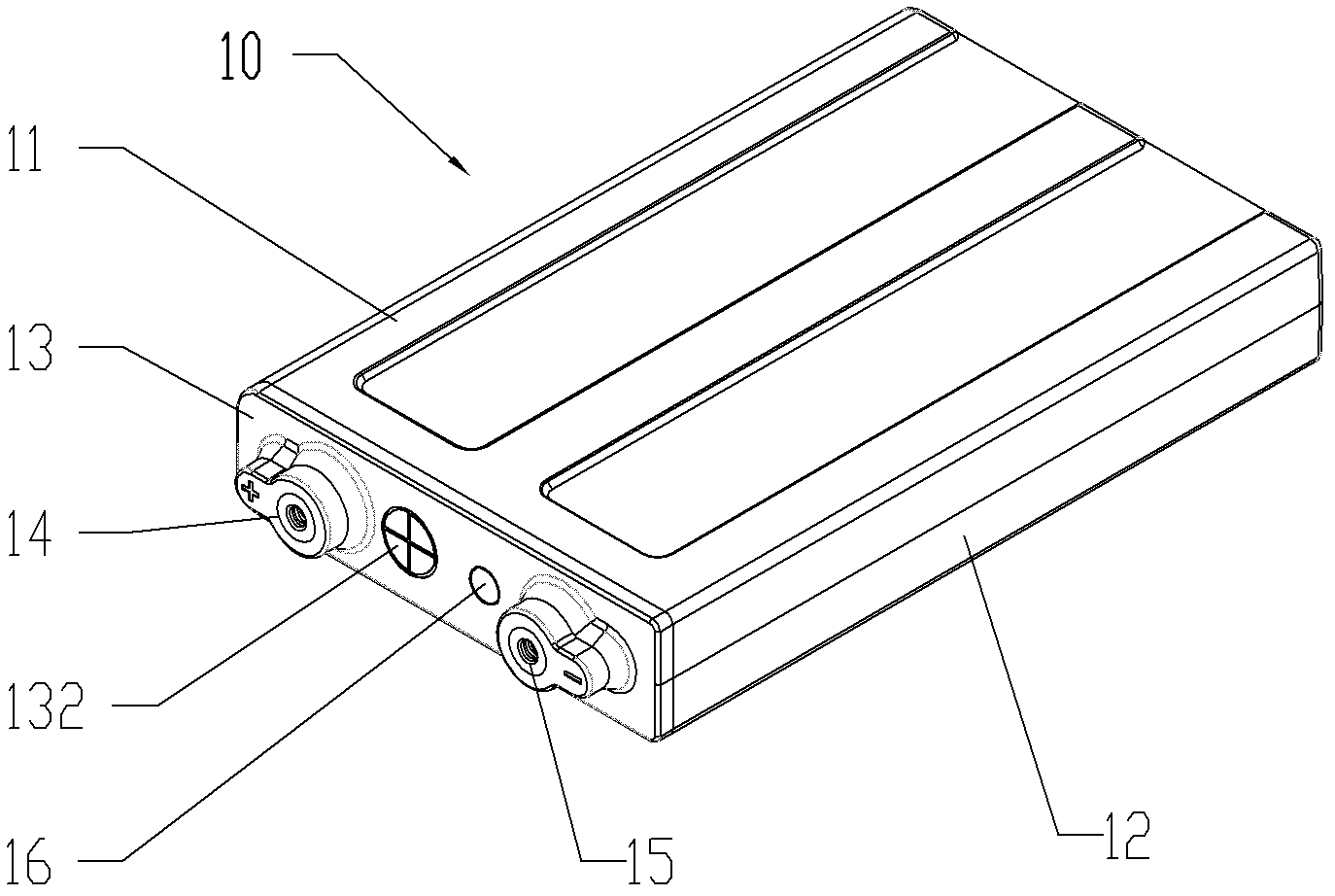

The invention relates to compound plastic and a lithium ion battery and a battery pack manufactured by using the same and an assembling method thereof. The compound plastic disclosed by the invention comprises the following components in percentage by mass: 30-98 percent of a compound plastic substrate, 1-50 percent of a compound reinforcing material and 1-50 percent of a compound heat conducting filler, wherein the compound plastic substrate comprises the following components in percentage by mass: 0-100 percent of polypropylene, 0-100 percent of polyethylene and 0-10 percent of polyvinylidene fluoride. The invention further provides a lithium ion battery and a battery pack manufactured by using the compound plastic and an assembling method thereof. According to the compound plastic and the lithium ion battery and the battery pack manufactured by using the same and the assembling method thereof, the high requirements of a lithium ion battery encapsulating shell on technical conditions such as heat conductivity, mechanical strength, size stability, corrosion resistance, insulating strength, reliability, service life and the like are fully met.

Owner:李松 +1

High-strength waterproof material for high-speed railways and preparation method thereof

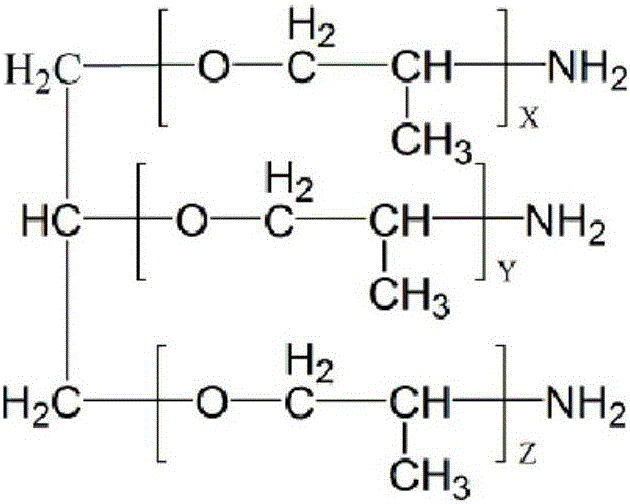

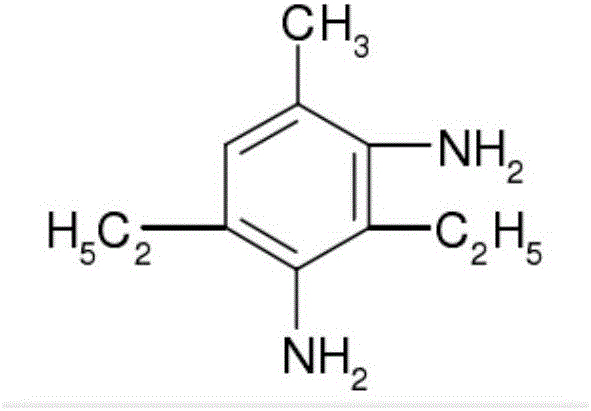

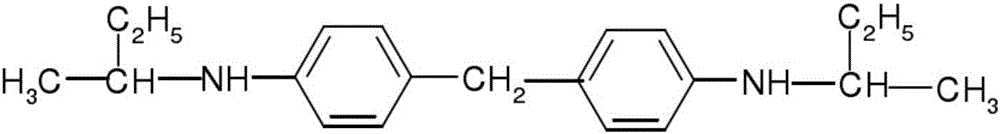

InactiveCN106118431AHigh strengthGood physical and mechanical propertiesFireproof paintsPolyurea/polyurethane coatingsTemperature resistanceMechanical property

The invention discloses a high-strength high-speed iron waterproof material and a preparation method thereof. The high-strength high-speed iron waterproof material includes component A and component B, and component A is prepared from the following raw materials in parts by weight: polyether polyol 95‑105 parts, 1‑10 parts of plasticizer, 10‑20 parts of bis(4‑isocyanatophenyl) methane, 3‑30 parts of graphene / methanesulfonic acid solution, 5‑50 parts of additives; component B It is prepared from the following raw materials in parts by weight: 50-80 parts of amino-terminated polyether, and 20-40 parts of amine chain extender. The present invention optimizes the type and amount of amino-terminated polyether and amine chain extender suitable for high-strength high-speed iron waterproof materials through reasonable proportioning, and has excellent physical and mechanical properties, temperature resistance, weather resistance, chemical medium resistance and Outstanding wear resistance, convenient construction and high efficiency.

Owner:上海基典防水科技有限公司

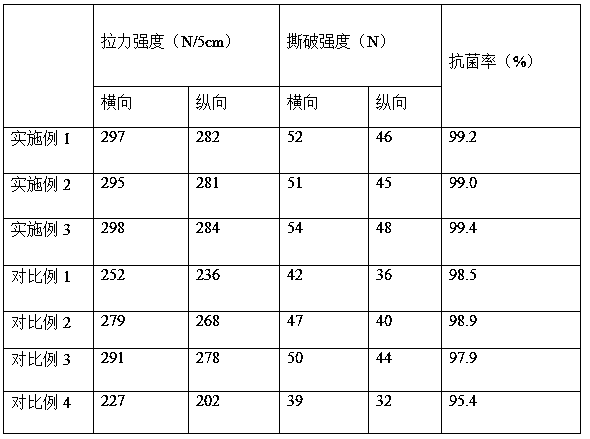

Preparation method of high strength antibacterial non-woven fabric

InactiveCN110079999AImprove barrier propertiesGood oil resistanceFibre typesNon-woven fabricsCross-linkNonwoven fabric

The invention discloses a preparation method of high strength antibacterial non-woven fabric. The method comprises the following steps: step one, adding 50 to 60 parts of polypropylene into a calcining furnace, increasing the temperature to 220 to 280 DEG C till polypropylene is completely molten, adding 10 to 20 parts of modified liquid, increasing the stirring rotate speed to 200 to 300r / min, stirring for 10 to 20min, then adding 5 to 10 parts of rice hull powder, and 1 to 4 parts of polytriazole resin, continuously stirring for 20 to 30min, and then adding 2 to 4 parts of lignin. The methodhas the advantages that polypropylene is taken as a base material, hemicellulose has excellent oxygen barrier property and oil resistance, methylcellulose has excellent mechanical property, the hemicellulose and the methylcellulose are cross-linked, the added nanometer titanium dioxide is taken as an antibacterial agent, and formed crosslinking modified liquid has tough and soft properties.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

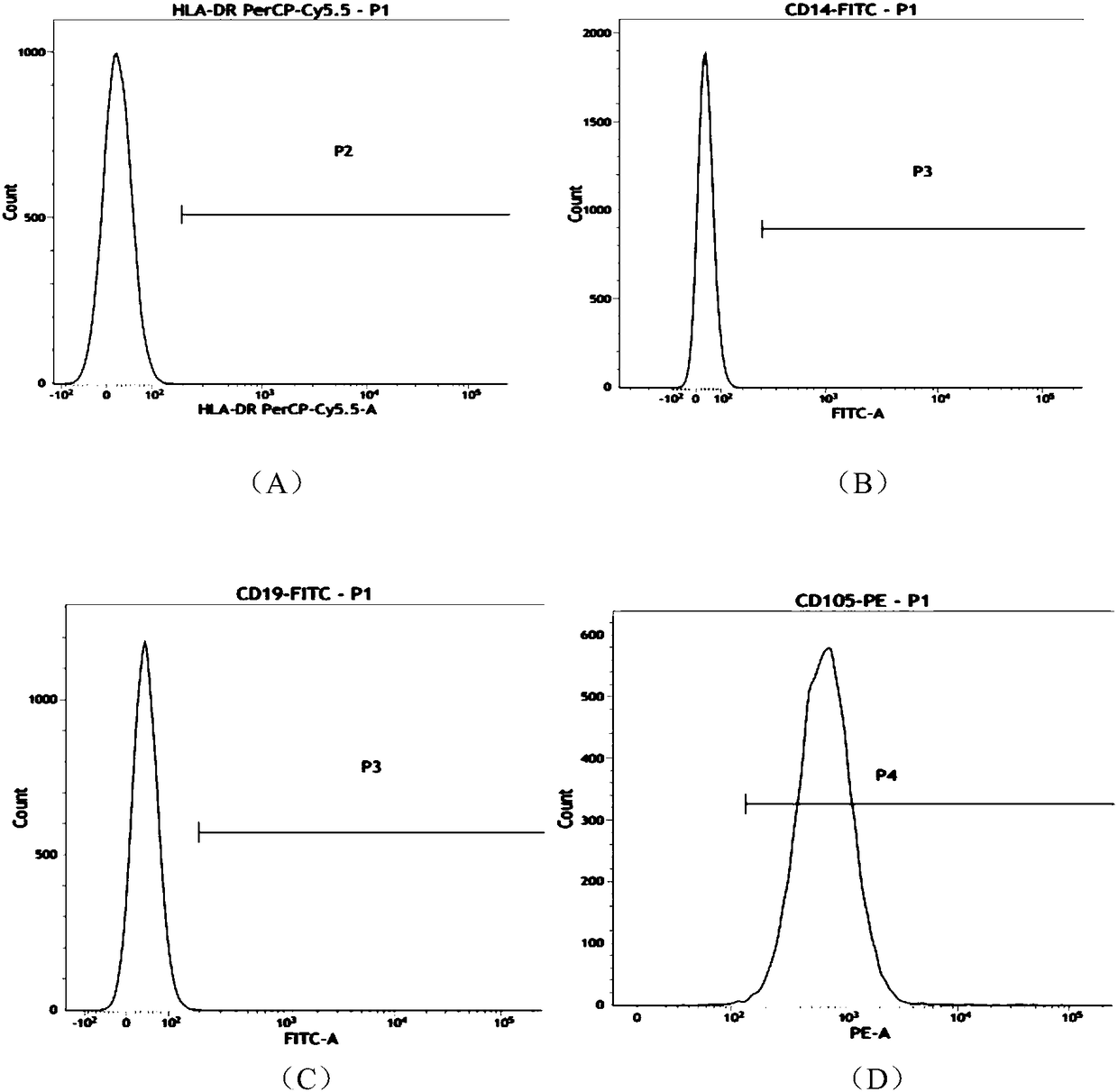

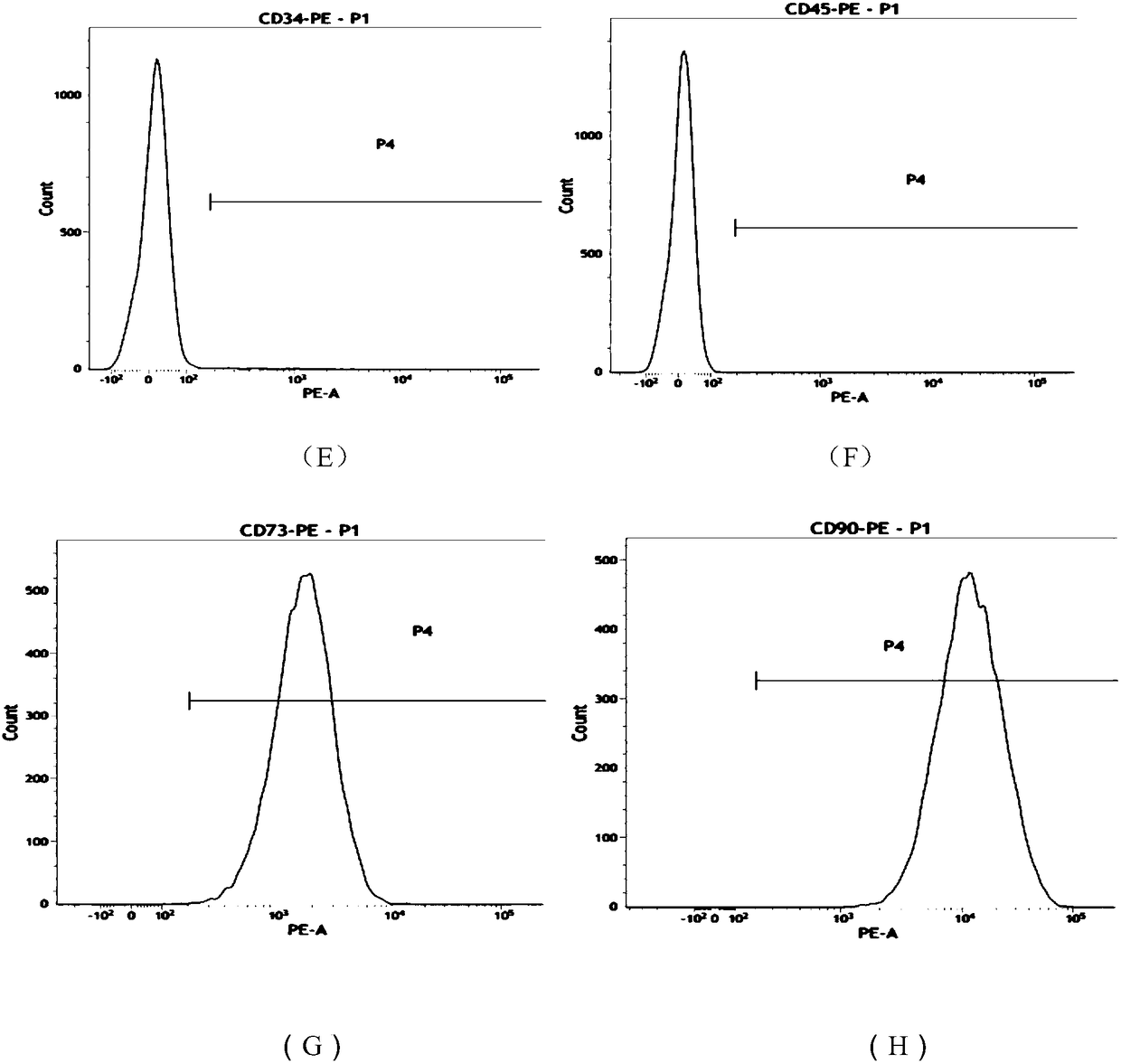

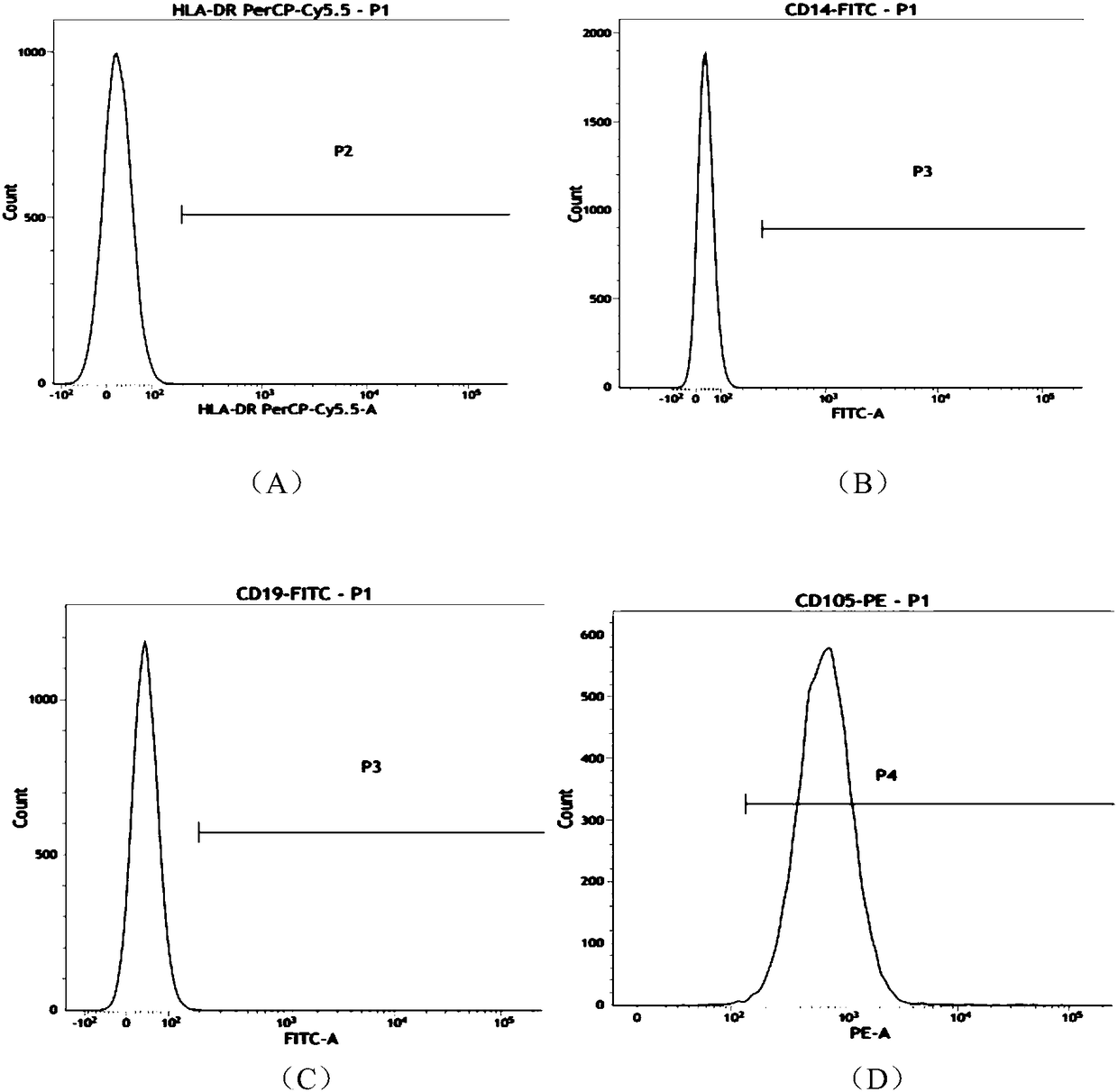

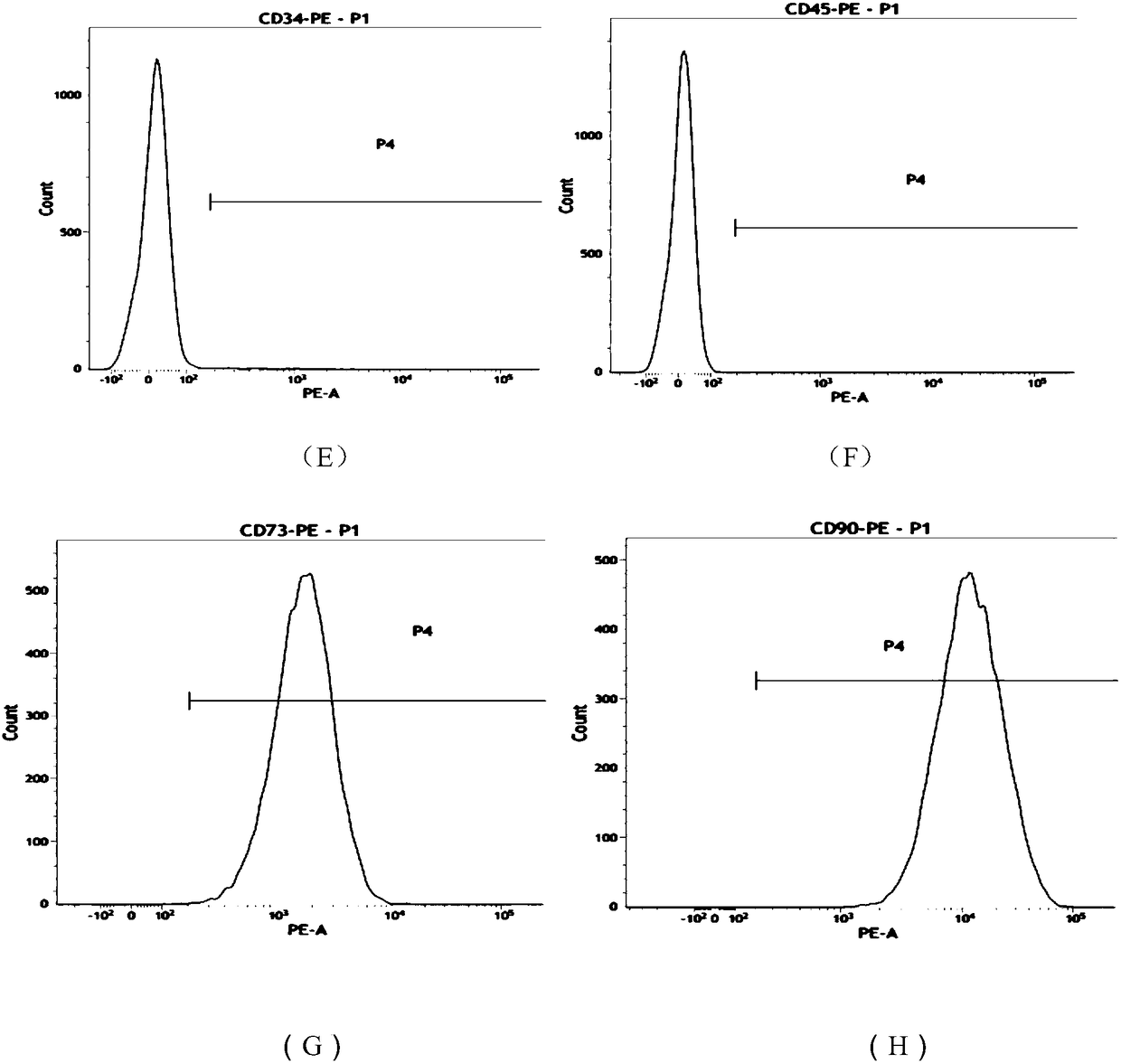

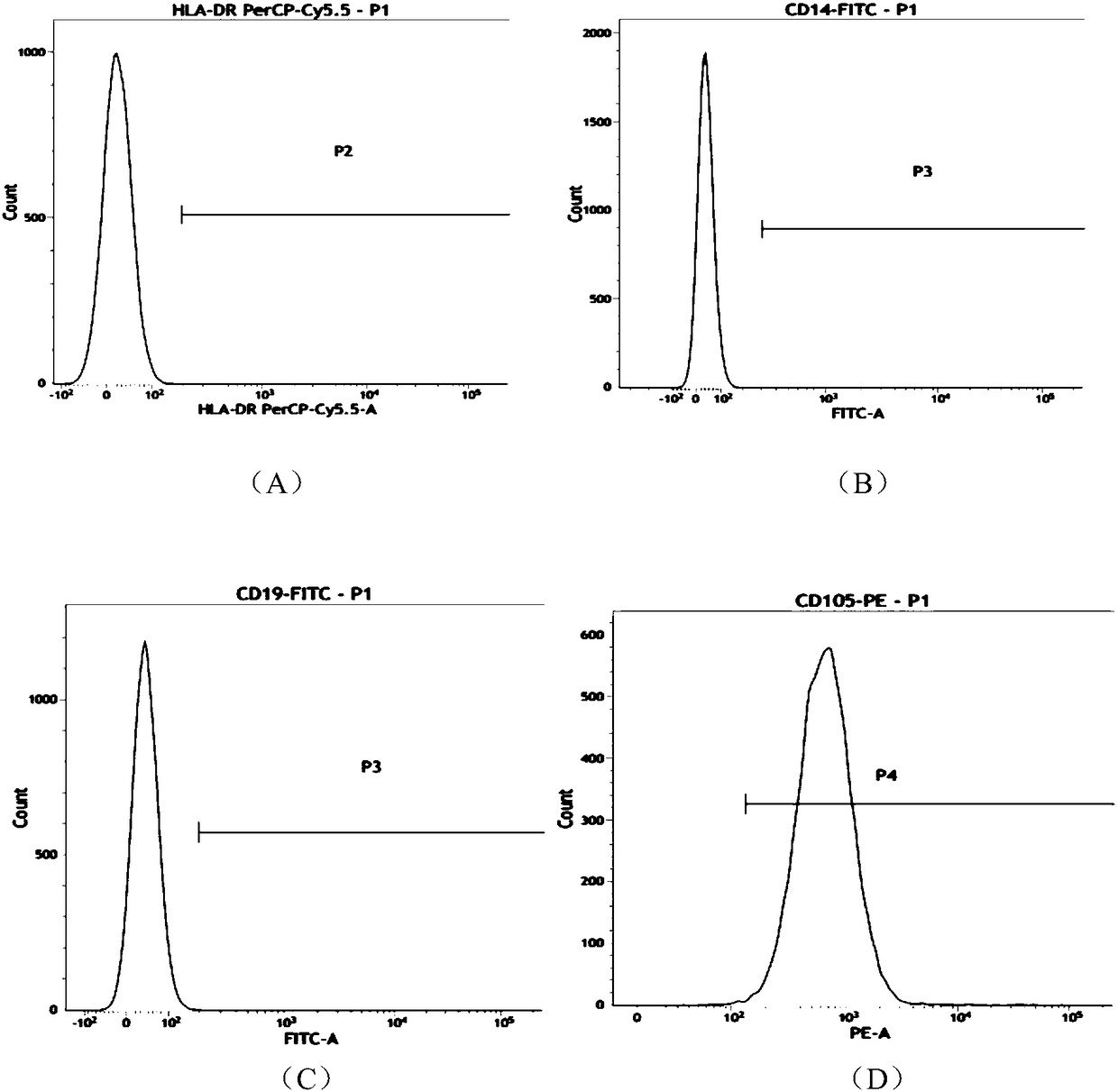

Application of stem cell composition in skin injury treatment medicine

InactiveCN108057116AGood synergySpeed up the repair processPeptide/protein ingredientsAerosol deliverySkin InjuryCytokine

The invention discloses a use of a kit in the preparation of a medicine. The medicine is for treating full thickness skin injuries. The kit includes: a first reagent including an exosome and a cytokine; and a second reagent including a biological scaffold and a stem cell. The kit can effectively promote the repairing of skin injuries and the healing of skin wounds.

Owner:SOUTH CHINA INSTITUDE OF BIOMEDICINE

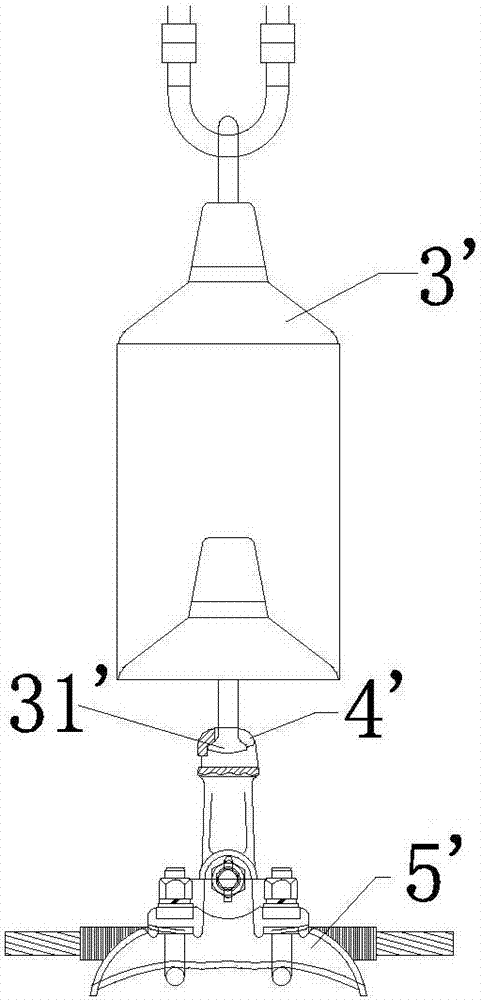

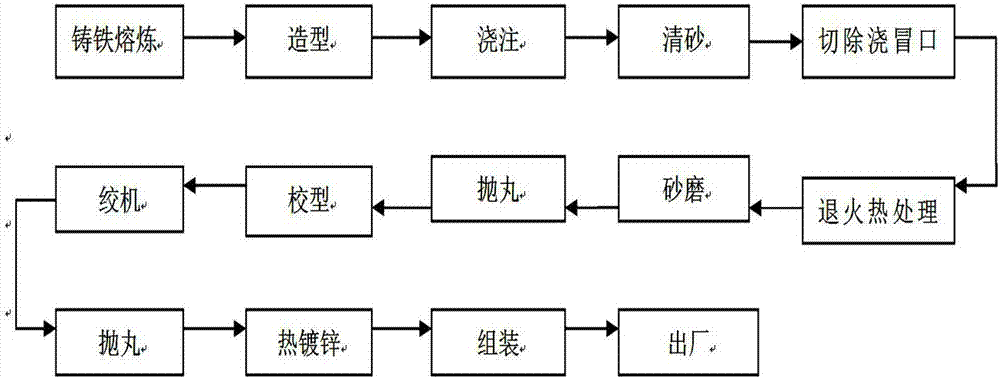

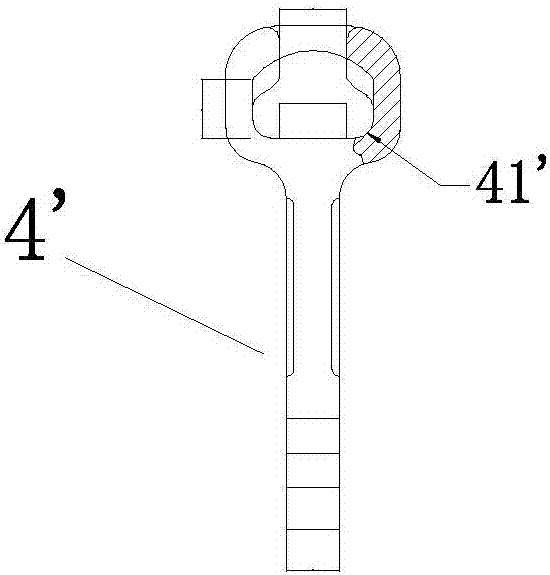

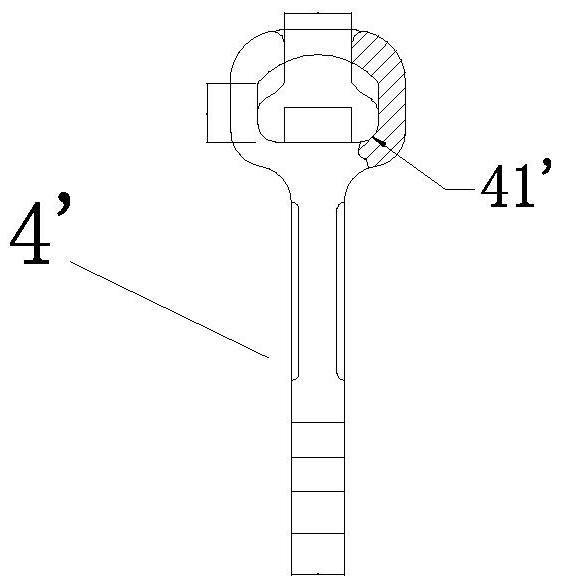

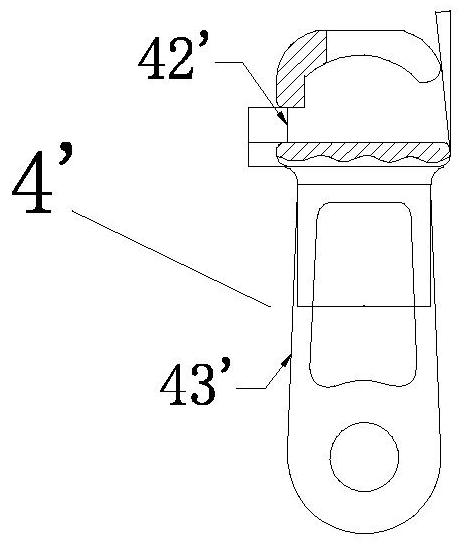

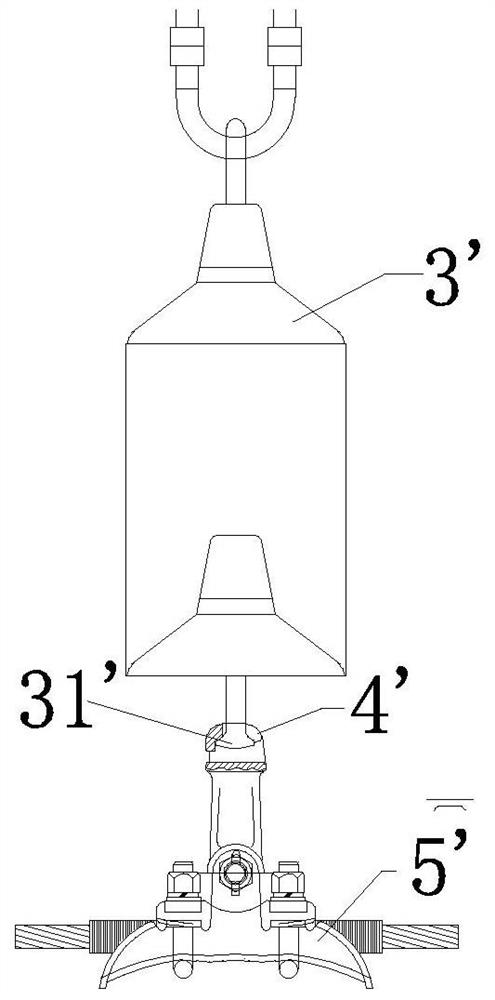

Processing method for forged socket clevis

ActiveCN107234198ASimple structural designSolve the mechanical strengthMetal-working apparatusPunchingUltimate tensile strength

The invention provides a processing method for a forged socket clevis. The processing method is characterized by comprising the following processes of: A, feeding; B, upsetting to prepare blank; C, integrally forging a product outline; D, cutting raw edges; E, punching socket holes, wherein a dually-linked socket punching mould of the forged socket clevis is adopted; F, grinding burrs; and G, performing hot galvanizing. Carbon structural steel with a trade mark of Q235A is selected during feeding. In order to overcome the defects in the prior art of the socket clevis, materials are reasonably selected, the product structural design is improved, and casting is changed into an integral forging production process; and the mould is selected to solve the problem that product mechanical strength is affected by casting internal defects and the problems that a production process is high in energy consumption, has pollution on environment, and is low in working efficiency.

Owner:SICHUAN PROVINCE FUXING ELECTRIC MFG CO LTD

Novel application of stem cells and secretions thereof in treatment of skin burns and scalds

InactiveCN108066750AGood synergyPromote proliferationPeptide/protein ingredientsMammal material medical ingredientsMedicineSkin Injury

The invention discloses a novel application of a kit in preparation of a drug for treating skin defects caused by burns and scalds. The kit comprises a first reagent and a second reagent, wherein thefirst reagent comprises an exosome and cell factors, and the second reagent comprises a biological scaffold and stem cells. The kit can effectively promote repair of skin injuries and healing of skinwounds.

Owner:SOUTH CHINA INSTITUDE OF BIOMEDICINE

Material for electric meter shell and preparation method thereof

InactiveCN107286531AImprove fire resistanceHigh mechanical strengthPolyvinyl chlorideDimethyl siloxane

The invention provides a material for an electric meter shell and a preparation method thereof, belonging to the field of electric materials. The material for the electric meter shell comprises the following raw materials by weight: polyvinyl chloride, polyethylene, methyl methacrylate, glass fiber, polycarbonate, polylactic acid, decabromodiphenylethane, polydimethylsiloxane, chitin, silicon nitride powder, silicon carbide powder, sodium succinate, talcum powder, barium sulfate, graphite powder, chromium carbide powder, boron nitride, alumina silicate, kaolin, polyamide resin, acetal resin, a flame retardant, a plasticizer, a coupling agent, a heat stabilizer, a light stabilizer and a lubricant. The preparation method comprises the following steps: (1) weighing of the above raw materials; and (2) centrifugation, melting, addition into a mold, shaping and cutting. The material and the preparation method thereof provided by the invention overcomes the problem that conventional materials for the electric meter shell need to be further improved and strengthened in mechanical strength, thermal stability and flame retardation.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

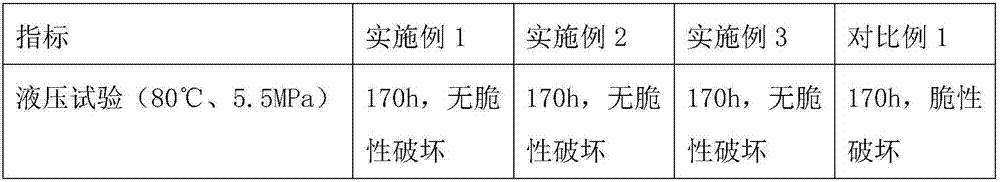

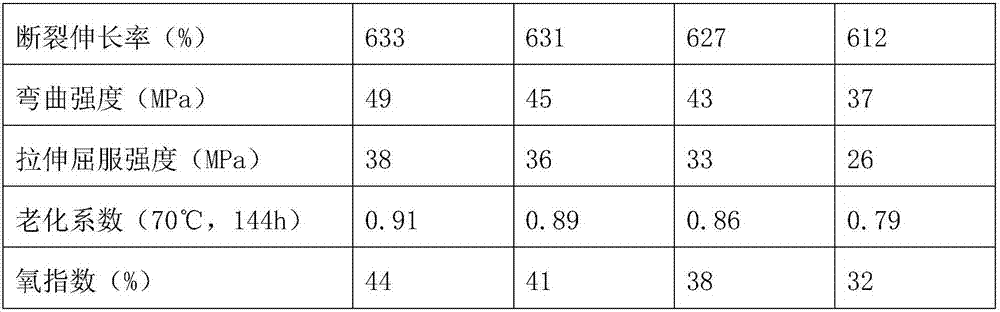

Water feeding pipe and preparation method thereof

InactiveCN107286458ASolve the mechanical strengthSolve flame retardancyLow-density polyethyleneAntioxidant

The invention provides a water feeding pipe and a preparation method thereof and relates to the technical field of plastic pipes. The water feeding pipe comprises, by weight, metallocene linear low density polyethylene, chromium carbonate, fumed silica, nano-active calcium carbonate, metallocene linear low density polyethylene wax, phthalate, gamma-aminopropyltriethoxysilane, rose essential oil, dibutyltin dilaurate, a modifying aid, aluminum hydroxy distearate, hollow glass microbeads, aluminum hydroxide, nano zirconium carbide, aluminum silicate, glass fibers, a thermal stabilizer, a photo-stabilizer, an antioxidant, a compatilizer, and a plasticizer. The preparation method includes the steps of: 1) weighing raw materials; 2) performing granulation; 3) performing mixing, kneading, cooling, extrusion and shaping. The water feeding pipe has high mechanical strength, good flame retarding property, good toughness and good anti-aging performance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

New method for preparing epidermal defect treating drug

The invention discloses uses of a kit in preparation of drugs, wherein the drugs are used for treating epidermal defects, and the kit comprises a first reagent and a second reagent, the first reagentcomprises exosome and cytokine, and the second reagent comprises a biological scaffold and stem cells. According to the present invention, the kit can effectively promote the repair of epidermal damage and the healing of skin wound surfaces.

Owner:SOUTH CHINA INSTITUDE OF BIOMEDICINE

Novel kit containing stem cell

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY +1

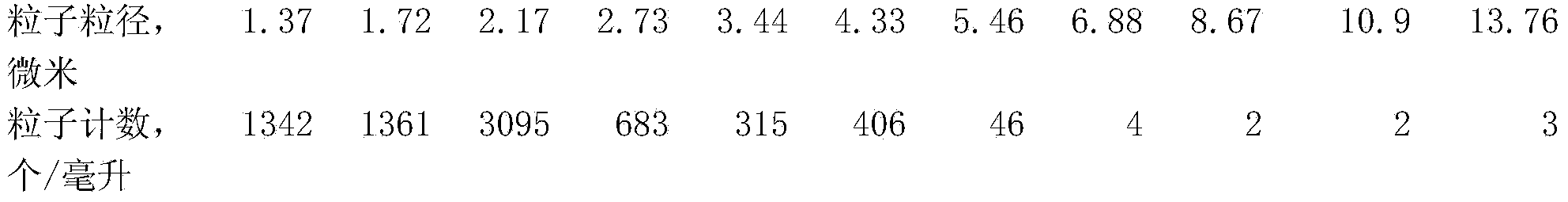

Macromolecule engram phosphoric acid/polyacrylic acid/calcium alginate multi-hybrid polymer micro-sphere and preparation method thereof

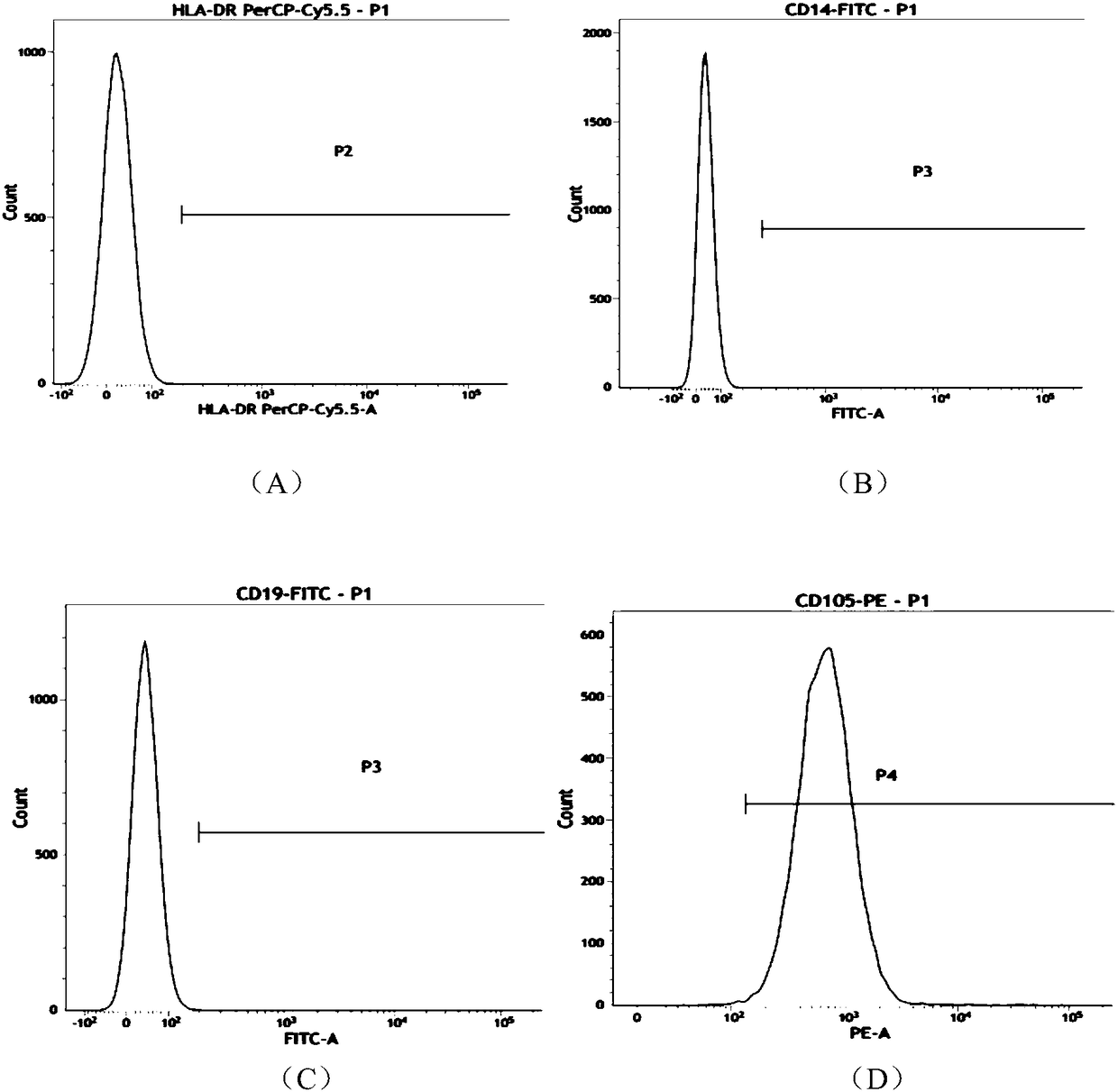

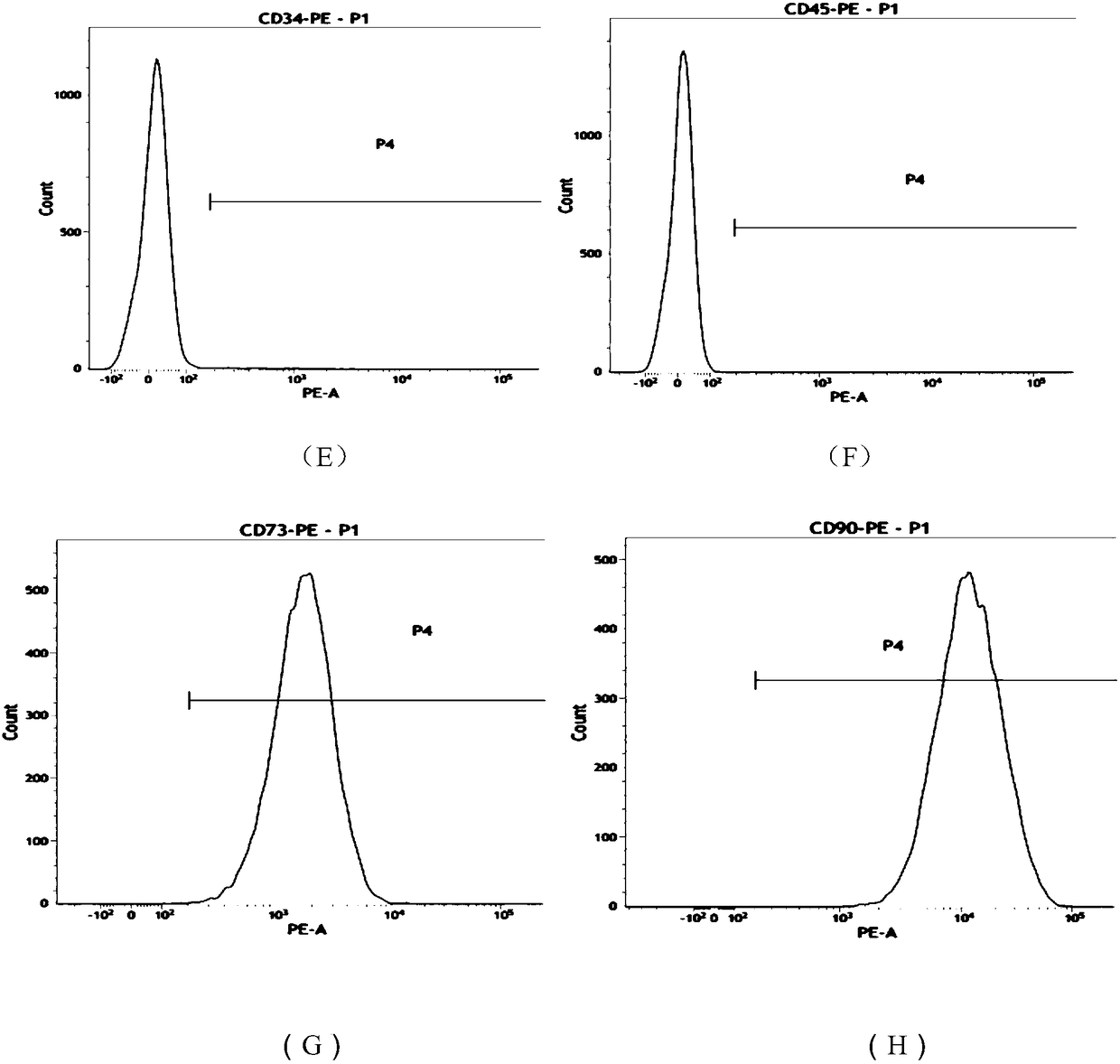

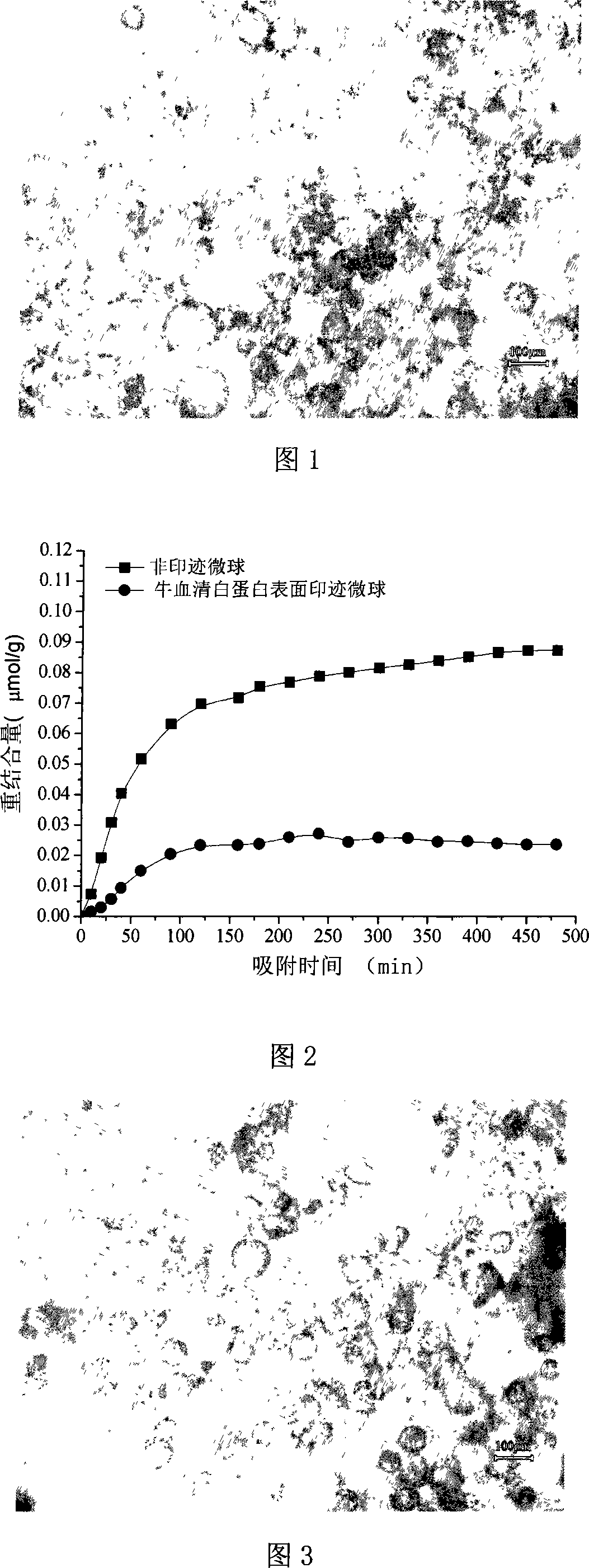

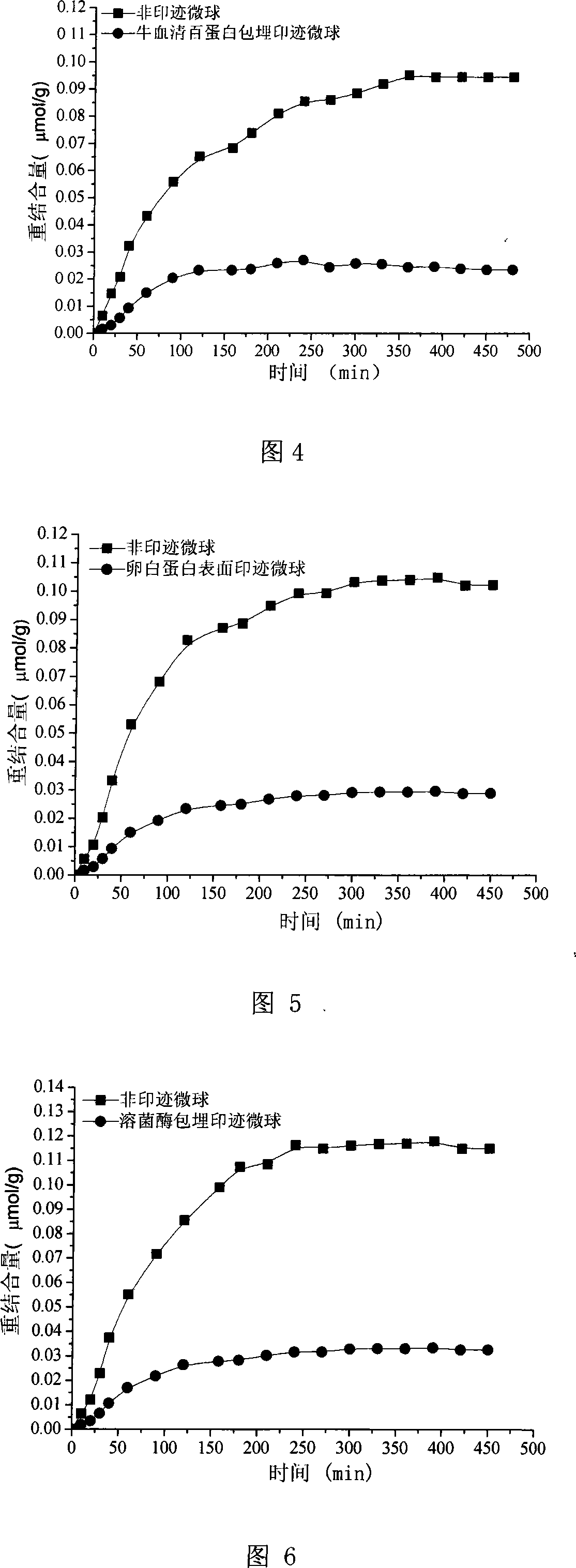

The invention relates to a macromolecular engram of multiple hybridigation polymeric compound microsphere of phosphoric acid / polyacrylic acid / calcium alginate and process for preparation. The protein engram of multiple hybridigation polymeric compound microsphere of phosphoric acid or polyacrylic acid or calcium alginate comprises the following raw materials and parts by weight: 20%-40% of calcium alginate, 1%-10% of diammonium phosphate, 0.5%-5% of poly-sodium acrylate, 50%-65% of calcium chloride and 0.1%-10% of protein. The prepared multiple hybridigation polymeric compound microsphere of phosphoric acid or polyacrylic acid or calcium alginate is tested by protein multiple binding, the test result indicates that the multiple binding content of engram microsphere can reach at least 3 times of the multiple binding content of non-engram microsphere which protein is not added, the result of electric conductivity titration and infrared spectrum testing indicate that a model multiple hybridigation component is produced under the joint action of diammonium phosphate, calcium alginate and CaCl2. The invention is simple and easy in the process for preparation and easy controllable in process of reaction and the like, the invention solves the shortcomings of low in mechanical strength and engram efficiency of the pure calcium alginate and astable in property and the like, thereby the applying foreground is wide.

Owner:TIANJIN UNIV

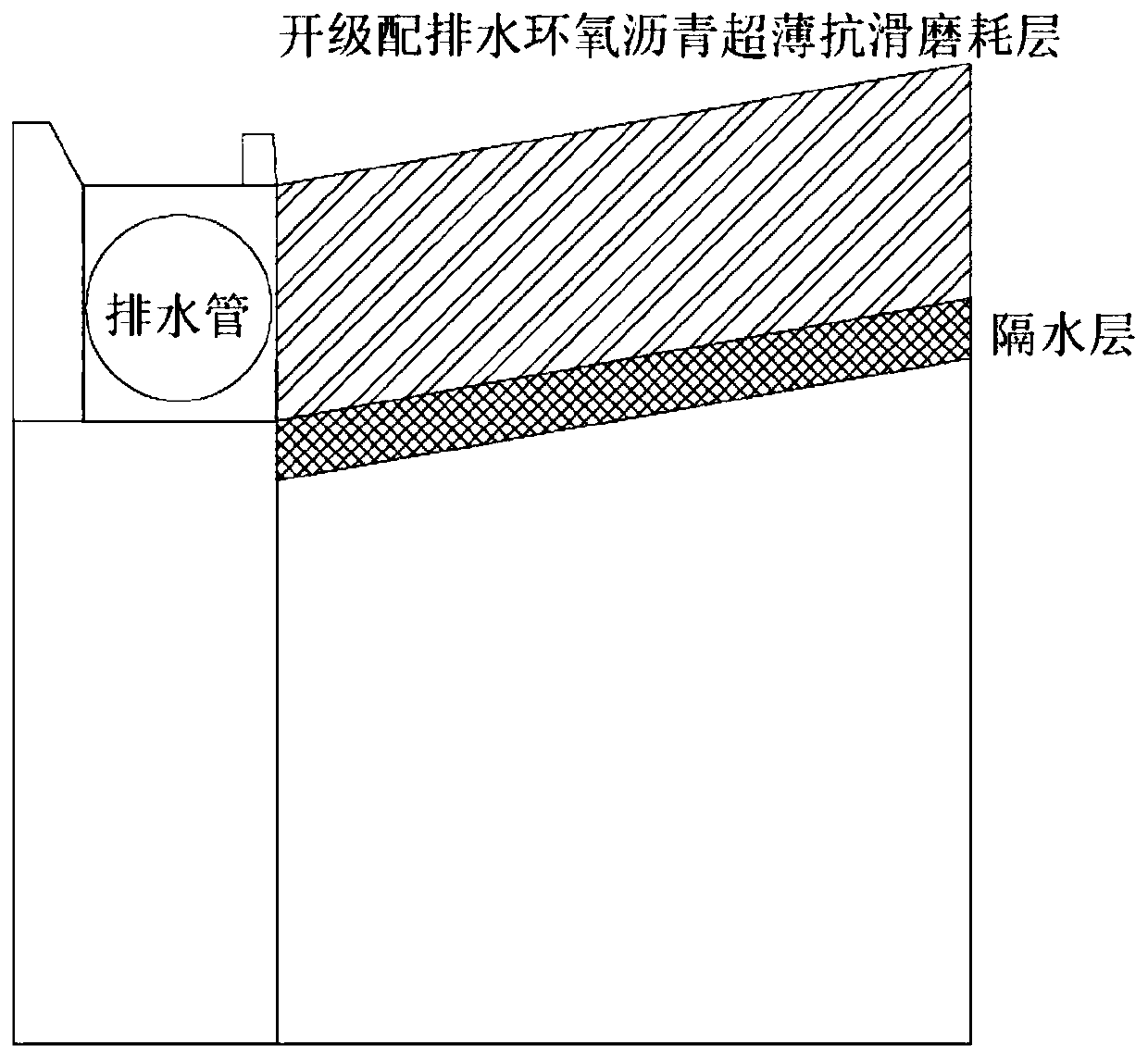

Ultrathin anti-skid wearing layer and pavement with wearing layer

InactiveCN111003969ASolve the mechanical strengthSolve the durability problemIn situ pavingsPaving gutters/kerbsPolymer chemistryGeotechnical engineering

The invention provides an open-graded drainage type epoxy asphalt ultrathin anti-skid wearing layer which is composed of an open-graded epoxy asphalt mixture with the porosity ranging from 15% to 20%,and the total thickness of the open-graded drainage type epoxy asphalt ultrathin anti-skid wearing layer is about 1 cm. According to the anti-skid wearing layer, epoxy asphalt is adopted to replace common asphalt and thermoplastic modified asphalt, so that the problem that the mechanical strength and durability of a thermoplastic asphalt mixture are reduced due to the comprehensive action of cyclic load, temperature stress and water is solved; the open-graded asphalt mixture with the porosity of 15%-20% is used for achieving the effect of surface drainage, the phenomenon of water drifting generated when an automobile runs at a high speed is reduced, the contact area of a tire and a road surface is increased, and the skid resistance of the asphalt wearing layer is improved; the maximum nominal particle size of the aggregate is 4.75 mm, the thickness of the open graded asphalt surface layer is controlled to be about 1 cm, theultrathin anti-skid wearing layer is formed, the constructioncost is reduced, and the construction recovery time is shortened.

Owner:SOUTHEAST UNIV

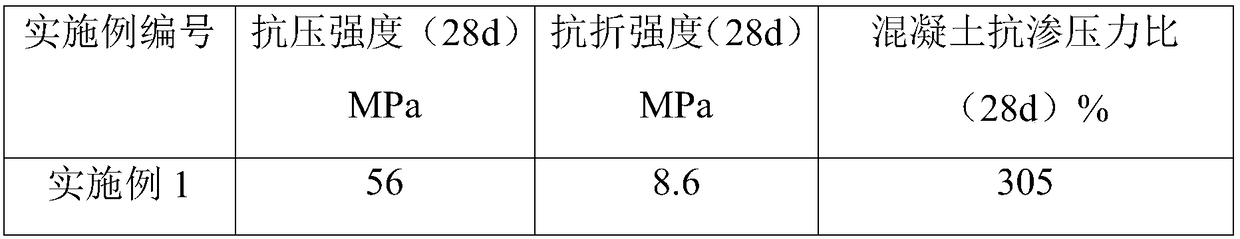

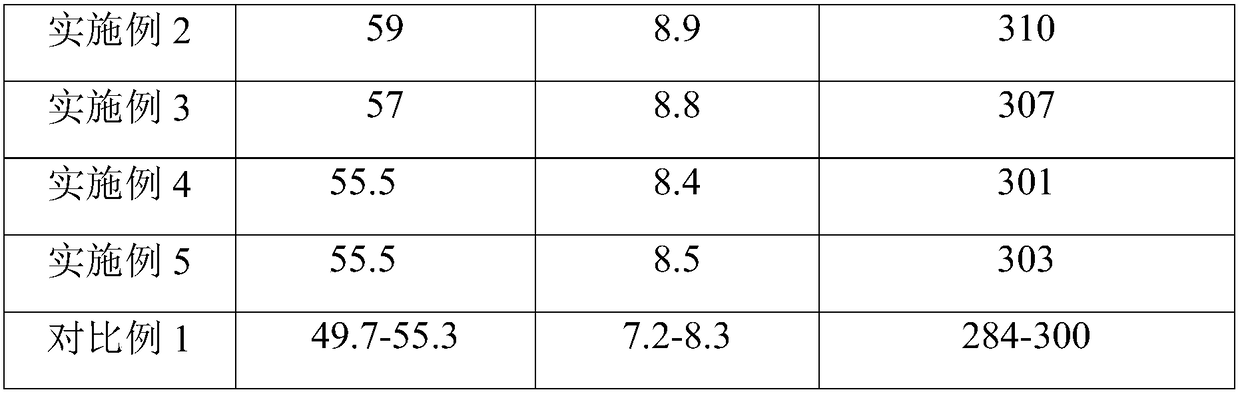

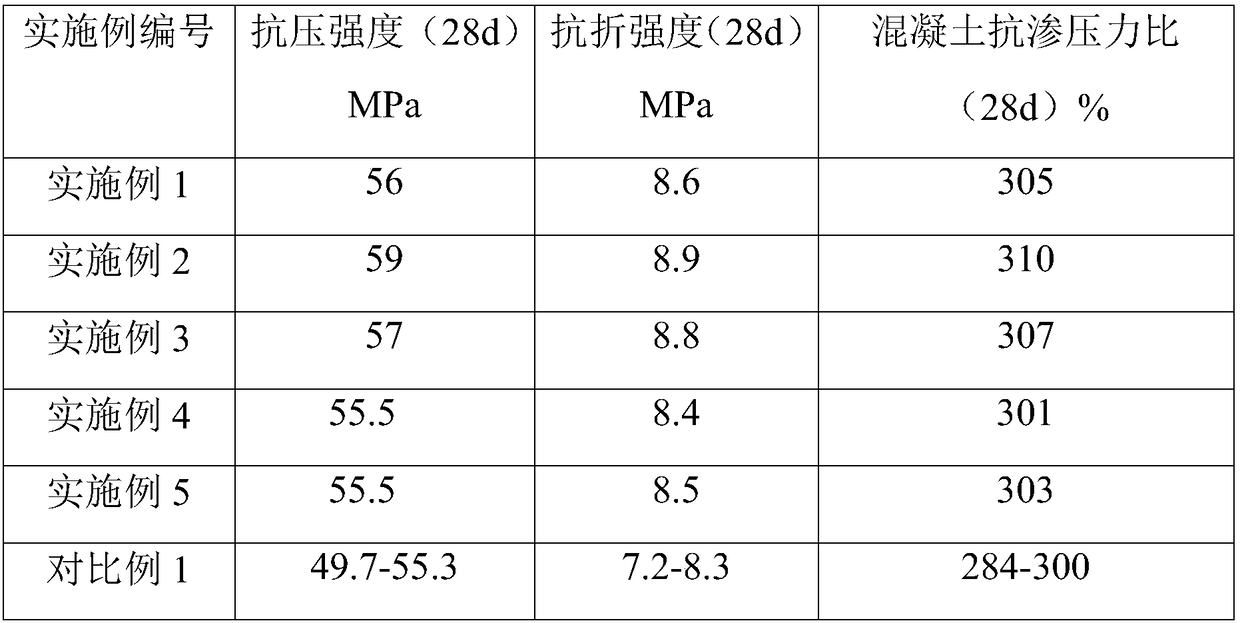

Concrete material containing active additive

The invention discloses a concrete material containing an active additive. The concrete material comprises Portland cement, the active additive, sodium silicate, quartz sand and water, wherein the active additive comprises material A, material B and material C; the material A is made with allophane and potassium carbonate; the material B is made with tartaric acid, maleic acid, ammonium formate, calcium metaaluminate, oxalic acid, sodium tartrate and calcium chloride; the material C is made with sodium silicate, sodium citrate, zinc formate, calcium carbonate, potassium carbonate, sodium acetate trihydrate, calcium formate, calcium metaaluminate and calcium chloride. The problem that traditional concrete material has insufficient overall mechanical strength and anti-permeability performance is solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Metal soft solder for vacuum glass

PendingCN113666649ASolve the mechanical strengthEven expansion and contractionCeramic materialsMechanical strength

The invention discloses a metal soft solder for vacuum glass in the field of brazing materials. The metal soft solder comprises a solid strip-shaped body, and the surface of the body is coated with a nano light absorption material. According to the invention, the problem that the mechanical strength of the vacuum glass is seriously influenced due to great residual thermal stress existing in the sealing of metal soft solder for the vacuum glass in the prior art can be solved.

Owner:四川英诺维新材料科技有限公司

Preparation method of immobilized catalytic particle metal felt for producing biodiesel

ActiveCN108212179AImprove conversion rateSimple processPhysical/chemical process catalystsFatty acid esterificationBiodieselEthanol

The invention discloses a preparation method of an immobilized catalytic particle metal felt for producing biodiesel, aiming at solving the problems of an existing catalyst that the stability is poor,the service life is short and the catalytic efficiency is low. The preparation method comprises the following steps: carrying out ultrasonic washing on the metal felt with absolute ethyl alcohol andwater, and drying; preparing ZrOCl2.8H2O and nitrate into a mixed water solution; stirring and adding ammonia water until the pH (Potential of Hydrogen) is 9 to 10, so as to obtain flocculent sediment; standing at room temperature; then filtering and washing until no Cl<-> exists so as to obtain a filter cake; drying and grinding to obtain a powdered material; adding the powdered material into anH2SO4 solution to form a mixture; adding the dried metal felt into the mixture; after immersing, drying; roasting under an inert atmosphere at 400 to 600 DEG C for 3 to 7h to obtain the immobilized catalytic particle metal felt. The immobilized catalytic particle metal felt prepared by the preparation method has the advantages of high catalytic efficiency and mechanical strength, good stability and long service life; the preparation method has a simple technology and industrialized production is easy to realize.

Owner:HENAN INST OF ENG

Electric wire and cable material and preparation method of same

The invention provides an electric wire and cable material and a preparation method of same and relates to the field of electricity materials. The electric wire and cable material includes, by weight, polyvinyl chloride resin, methyl vinyl silicon rubber, ethylene-vinyl acetate copolymer, nano-active calcium carbonate, color powder, polyethylene wax, talcum powder, ceramic fibers, floating beads, brown corundum, a plasticizer, a compatilizer, a flame retarding agent, an antioxidant, a photostabilizer, and a thermal stabilizer. The preparation method includes the steps of: 1) weighing raw materials; 2) stirring the raw materials in a high-speed mixing machine; 3) stirring the raw materials in a cold-stirring machine; 4) feeding the raw materials in a granulator. The preparation method solves the problems of insufficient flame-retarding property, mechanical strength, toughness and anti-aging property of electric wire and cable materials in the prior art.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Spot welding method for reinforcing rib of corrugated sheet of corrugated oil tank

InactiveCN104759748ASolve oil leakageSolve the mechanical strengthTransformers/inductances coolingInductances/transformers/magnets manufactureFuel tankAtmospheric pressure

The invention discloses a spot welding method for a reinforcing rib of a corrugated sheet of a corrugated oil tank. The spot welding method specifically comprises the steps that a long arm welding machine is adopted, after voltage and air pressure are adjusted, spot welding is conducted at the reinforcing rib, formed through pressing, of the corrugated sheet in the length direction of the reinforcing rib at the interval of 40-50 mm, and then the spot welding of the reinforcing rib of the corrugated sheet of the corrugated oil tank is completed. By the adoption of the spot welding method, a corrugated wing will not deform and can bear the mechanical strength of 50 kPa which is far larger than a nationally regulated value, the oil injection amount can be reduced, and the problem that the oil tank leaks oil can be solved.

Owner:JIANGSU ZHONGRONG ENVIRONMENTAL PROTECTION

Preparation method of concrete material containing active additive

ActiveCN109133836ASolve the mechanical strengthImprove waterproof performanceCalcium formateZinc formate

The invention discloses a preparation method of a concrete material containing an active additive. The preparation method includes: mixing allophane, potassium carbonate powder and hydrochloric acid solution, carrying out first heating and second heating in sequence, and grinding to obtain material A; mixing tartaric acid, maleic acid, ammonium formate, calcium metaaluminate, oxalic acid, sodium tartrate, and calcium chloride, drying, screening, calcining, and grinding to obtain material B; mixing sodium silicate, sodium citrate, zinc formate, calcium carbonate, potassium carbonate, sodium acetate trihydrate, calcium formate, calcium metaaluminate, and calcium chloride, drying, screening, calcining, and grinding to obtain material C; mixing the material A, the material B and the material C, calcining, and carrying out secondary tempering to obtain the active additive; mixing Portland cement, the active additive, sodium silicate, quartz sand, and water to obtain the concrete material. The problem that traditional concrete materials have insufficient overall mechanical strength and anti-permeability performance is solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Low-temperature oxidation curing process of secondary particles

ActiveCN111482128AAvoid thermal bondingSimple processGranulation in stationary drums/troughsGranulation with special binding agentsThermal fluidsGranulation

The invention discloses a low-temperature oxidation curing process for secondary particles. The process is as follows: transferring a secondary particle hot material which is just granulated into a cooling kettle under the protection of inert atmosphere from a high-temperature kettle, cooling the secondary particle hot material by adopting circulating heat-conducting oil, and closing the circulating heat-conducting oil when the temperature is reduced to 320-270 DEG C so as to naturally cool the secondary particle hot material; when the secondary particle hot material is cooled to 250 DEG C, changing the inert atmosphere into the oxygen atmosphere, performing oxidation curing treatment on the secondary particle hot material, and when the temperature is reduced to the room temperature, performing discharging. The process has the advantages of simple process, low energy consumption, environmental protection, strong toughness of cured secondary particles and high mechanical strength.

Owner:HUNAN SHINZOOM TECH

A preparation method of high-strength and high-conductivity copper alloy wire for automobile wire and cable

InactiveCN104046813BHigh mechanical strengthSolve the mechanical strengthCopperUltimate tensile strength

The invention discloses a method for preparing a high-strength and high-conductivity copper alloy wire for an automotive electric wire and cable. The copper alloy wire comprises the following component elements in percentage by weight: 1.5-2.5% of Zn, 0.8-1.6% of Cr, 0.5-1.0% of Ni, 0.3-0.6% of Mn, 0.25-0.35% of Ag, 0.1-0.2% of Ti, 0.04-0.08% of Nb, 0.03-0.05% of Sb, 0.015-0.025% of B, 0.005-0.015% of Te, 0.03-0.04% of Ce, 0.02-0.03% of Tm, 0.005-0.01% of S, 0.003-0.005% of P and the balance of copper and inevitable impurities. By virtue of the method disclosed by the invention, the mechanical strength of the copper alloy wire can be greatly improved while the excellent electrical conductivity is maintained, and the problem of the contradiction between the mechanical strength and electrical conductivity of the copper alloy wire is effectively solved; the method has the advantages of rapid preparation, simple process, environment friendliness, low cost, high efficiency and convenience in control, and the automatic mass production can be achieved.

Owner:铜陵新辰汽车制造有限公司

A composite material for artificial teeth and its preparation method and application

ActiveCN103976883BMeet needsSolve the mechanical strengthImpression capsDentistry preparationsSelective laser sinteringMicrocrystalline wax

The invention discloses a composite material for artificial teeth and a selective laser sinter molding method and an application thereof. The method includes raw materials, a powder preparation method and a material molding method. The raw materials contain polymethyl methacrylate, hydroxyapatite nano-particles, an emulsifier, microcrystalline wax and paraffin. The powder preparation method comprises the following steps: firstly carrying out lipophilic modification on the hydroxyapatite nano-particles by a wax emulsification method and then preparing a polymethacrylate powder material doped with the hydroxyapatite nano-particles by hot-melting mechanical agitation and crushing ball milling. According to the molding method, a polymethacrylate powder is molded by a selective laser sintering technology. By the adoption of the artificial teeth dedicated composite material with a composite bioactivity, the problem that traditional artificial teeth have insufficient mechanical strength and poor compatibility can be solved effectively. In addition, as the selective laser sinter molding technology is provided, preparation time of artificial teeth is shortened greatly, teeth replacement cycle is minimized for patients, and requirements of doctors and patients on artificial teeth are met.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Low temperature oxidation curing process of secondary particles

ActiveCN111482128BSolve the mechanical strengthAvoid thermal bondingGranulation in stationary drums/troughsGranulation with special binding agentsPhysical chemistryThermal fluids

The invention discloses a low-temperature oxidative solidification process of secondary particles, which transfers the hot material of the secondary particles which has just completed the granulation process from a high-temperature kettle into a cooling kettle under the protection of an inert atmosphere, and uses circulating heat conduction oil to heat the secondary particles. Cool the material, and when the temperature drops to 320~270°C, turn off the circulating heat conduction oil to let the secondary particle heat material cool down naturally; when the temperature of the secondary particle heat material cools down to 250°C, change the inert atmosphere to an oxygen atmosphere. The secondary particle hot material is oxidized and cured, and the material can be unloaded when the temperature drops to room temperature. The invention has the advantages of simple process, low energy consumption, environmental protection, strong toughness and high mechanical strength after the secondary particles are cured.

Owner:HUNAN SHINZOOM TECH

Processing method of forged bowl head hanging plate

ActiveCN107234198BSimple structural designSolve the mechanical strengthMetal-working apparatusPunchingUltimate tensile strength

The invention provides a processing method for a forged socket clevis. The processing method is characterized by comprising the following processes of: A, feeding; B, upsetting to prepare blank; C, integrally forging a product outline; D, cutting raw edges; E, punching socket holes, wherein a dually-linked socket punching mould of the forged socket clevis is adopted; F, grinding burrs; and G, performing hot galvanizing. Carbon structural steel with a trade mark of Q235A is selected during feeding. In order to overcome the defects in the prior art of the socket clevis, materials are reasonably selected, the product structural design is improved, and casting is changed into an integral forging production process; and the mould is selected to solve the problem that product mechanical strength is affected by casting internal defects and the problems that a production process is high in energy consumption, has pollution on environment, and is low in working efficiency.

Owner:SICHUAN PROVINCE FUXING ELECTRIC MFG CO LTD

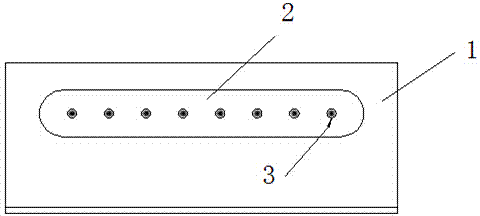

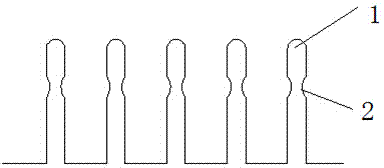

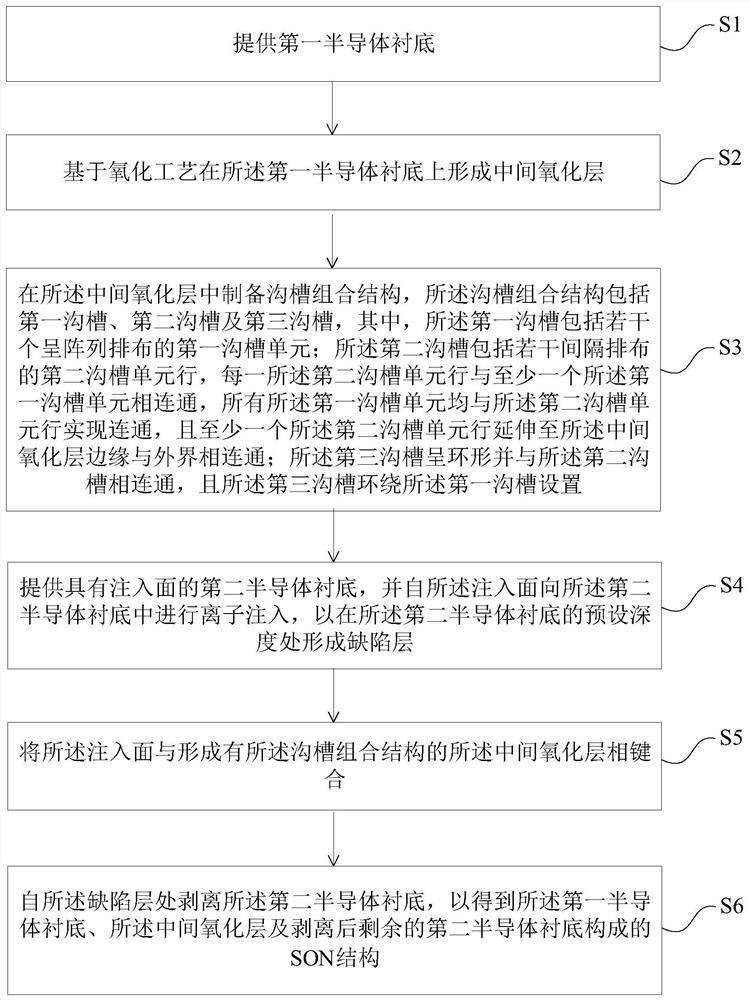

Son structure and its preparation method

ActiveCN112701128BSolve the mechanical strengthSame internal and external pressureSolid-state devicesSemiconductor/solid-state device manufacturingCrystallographyThermal dilatation

The invention provides a SON structure and a preparation method thereof. The preparation method includes: providing a first semiconductor substrate; forming an intermediate oxide layer on the first semiconductor substrate; A groove combination structure of a groove and an annular third groove, the second groove communicates with the first groove and includes a cell row extending to the end of the middle oxide layer; a defect layer is formed in the second semiconductor substrate; bonding the second semiconductor substrate to the middle oxide layer; peeling off the second semiconductor substrate from the defect layer. The invention provides a method for preparing SON in a non-vacuum state. A groove combination structure is prepared in the intermediate oxide layer formed by an oxidation process. The combination of the first groove, the second groove and the third groove is equivalent to a cavity structure. The middle window pattern is connected with the ring groove through strip grooves, and a certain number of strip grooves extend to the edge of the silicon wafer to communicate with the outside air to ensure consistent internal and external pressure, and at the same time solve the problem of gas pressure in the cavity. Thermal expansion and vacuum cause mechanical strength problems.

Owner:上海烨映微电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com