Patents

Literature

278results about How to "Solve the durability problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

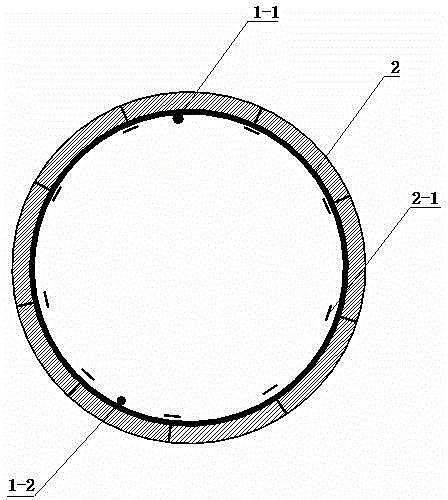

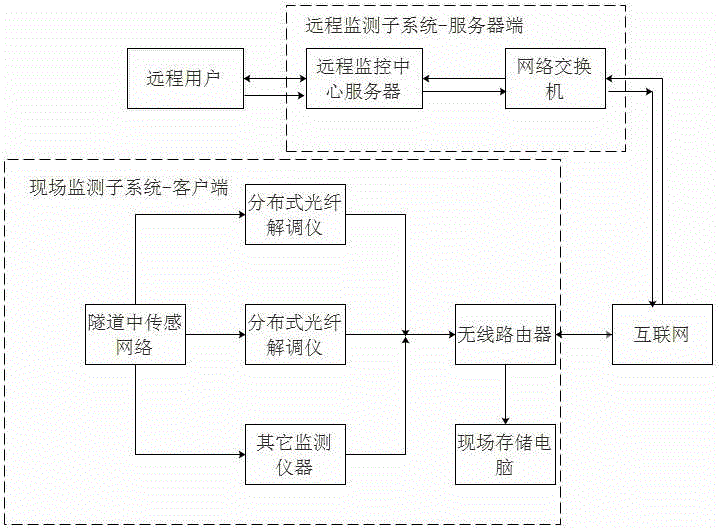

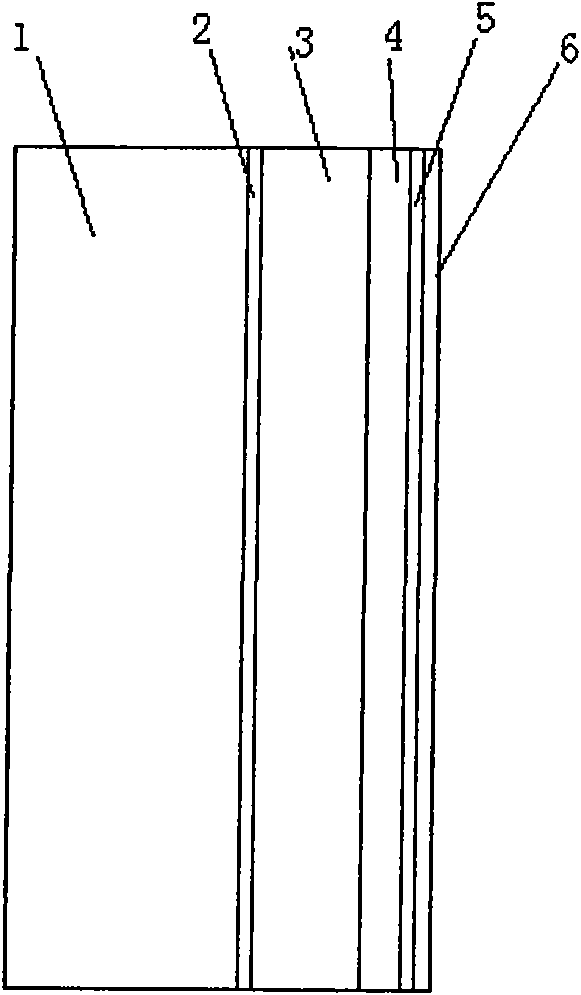

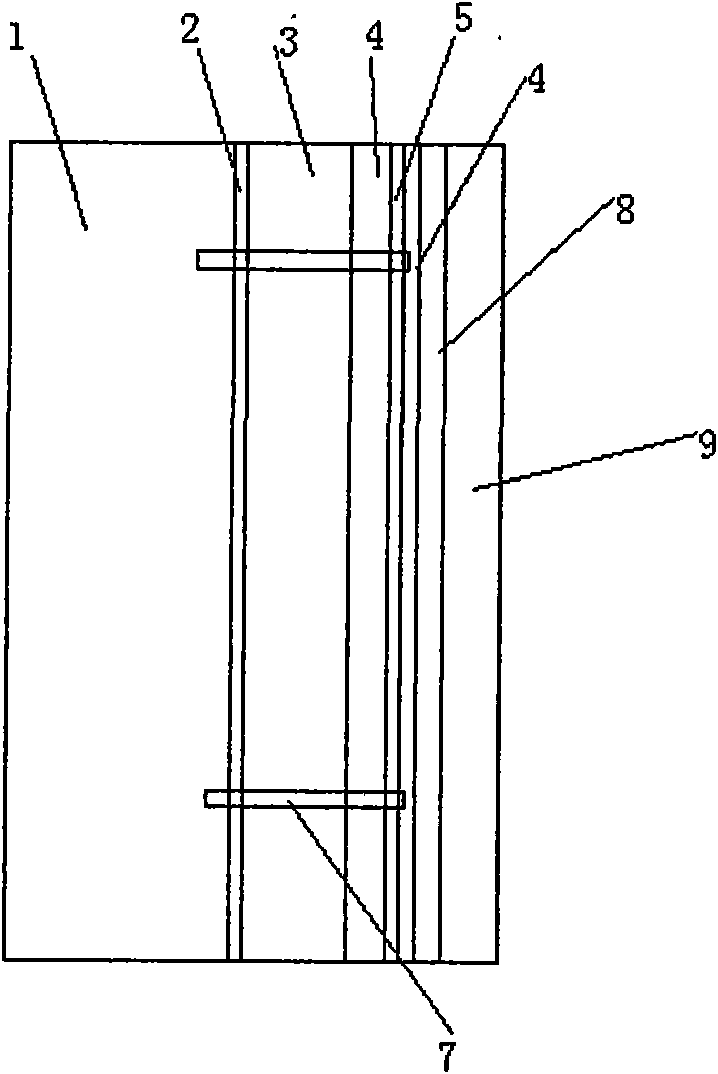

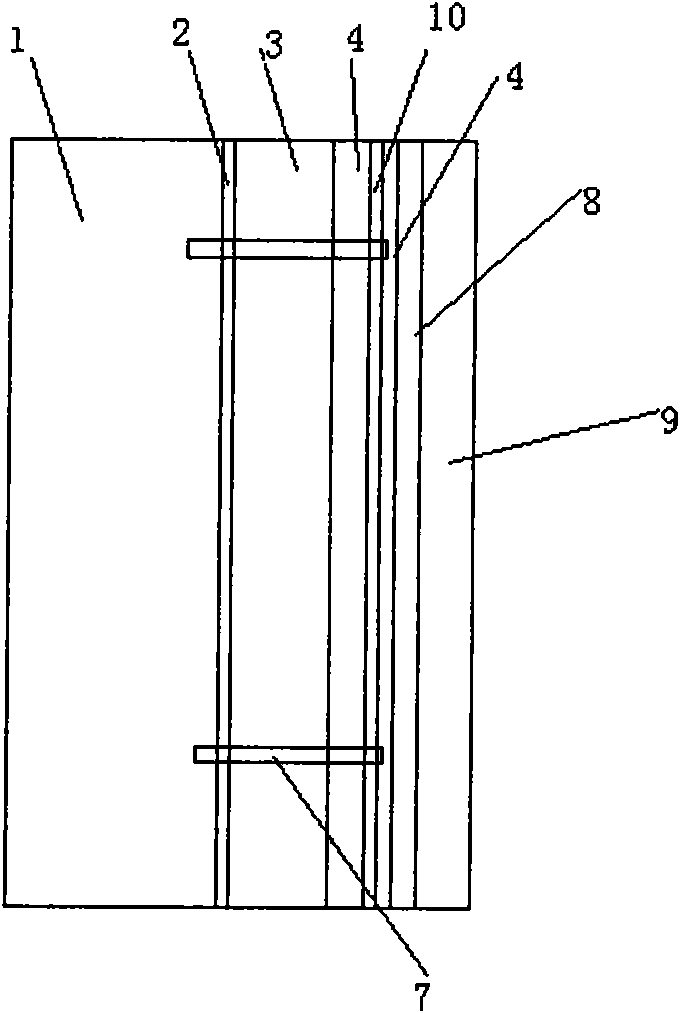

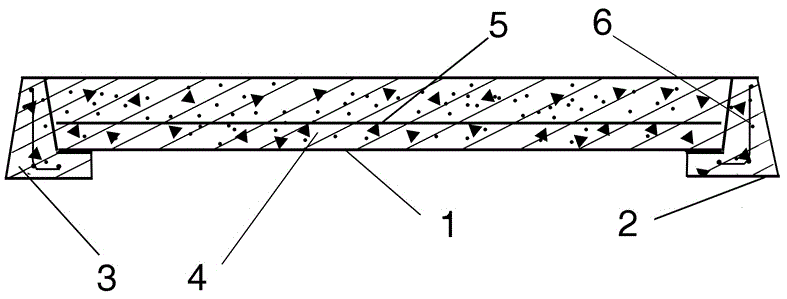

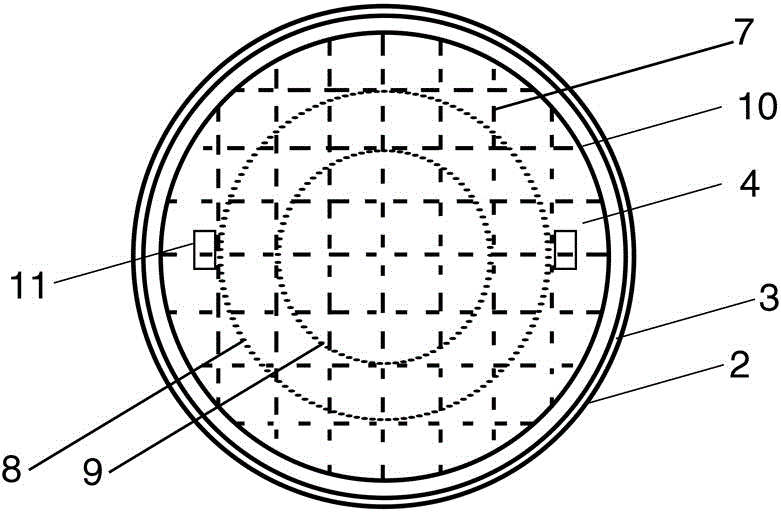

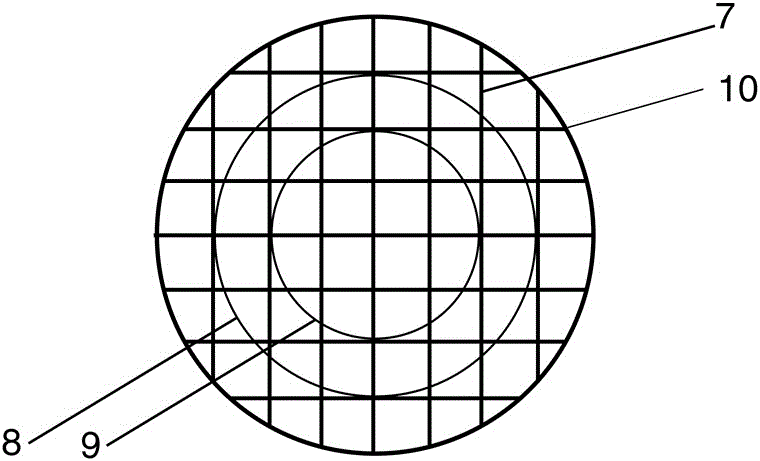

Tunnel structure monitoring system and tunnel structure monitoring method based on distributed long-gauge fiber bragg grating

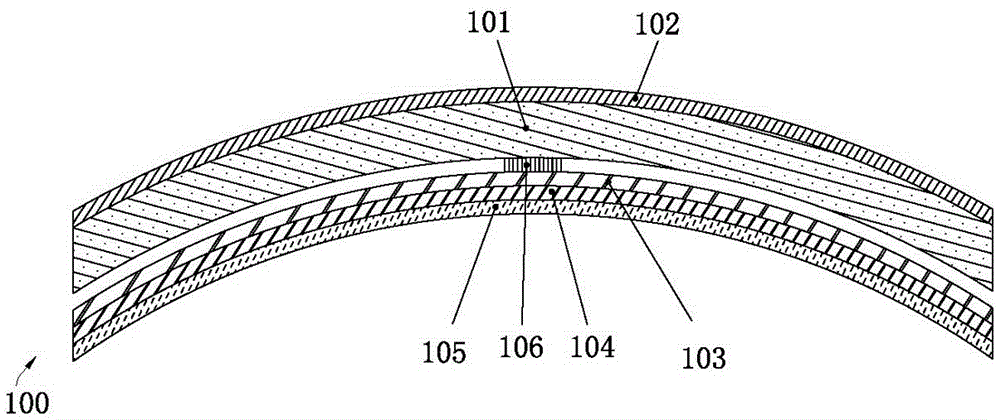

The invention discloses a tunnel structure monitoring system and a tunnel structure monitoring method based on a distributed long-gauge fiber bragg grating. The system comprises distributed long-gauge fiber bragg grating sensors which are comprehensively distributed in a monitored range along the axial direction and the cross section of a tunnel; and longitudinal sedimentation of the tunnel and change conditions of various ring joints of the shield tunnel are monitored. The method comprises the following steps of arranging the distributed long-gauge fiber bragg grating sensors; and acquiring, transmitting and processing data. By the tunnel structure monitoring system and the tunnel structure monitoring method based on the distributed long-gauge fiber bragg grating, full-life monitoring on a tunnel structure in a construction period and a running period can be carried out, and longitudinal sedimentation, convergence deformation, joint deformation, duct piece internal force, strain and the like of the tunnel structure are dynamically monitored in real time.

Owner:SOUTHEAST UNIV +2

Anti-radiation concrete produced from slag aggregate, and production method thereof

InactiveCN103224369ATotal momentum downReduce the degree of stratificationSolid waste managementSlagTackifier

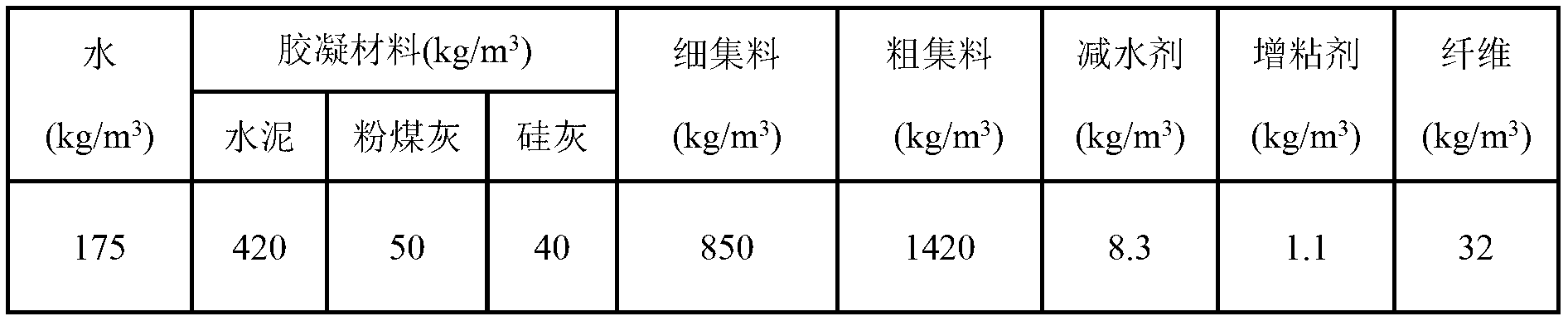

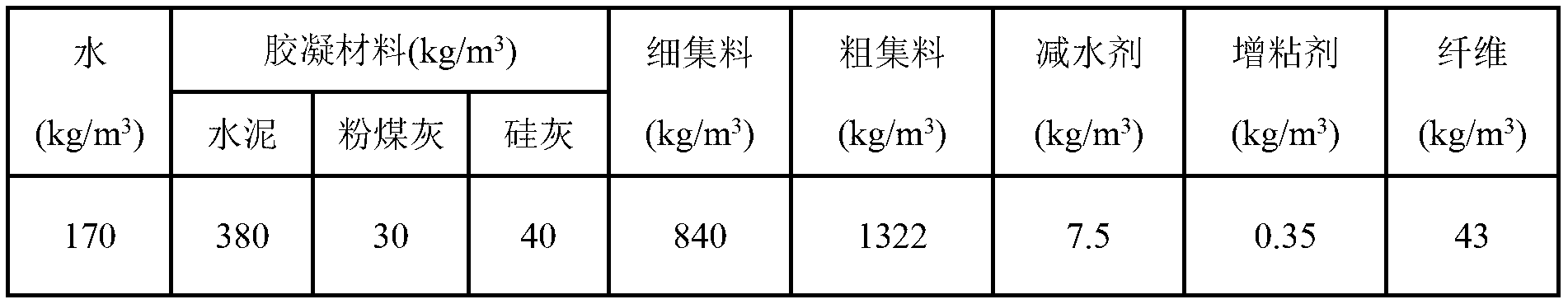

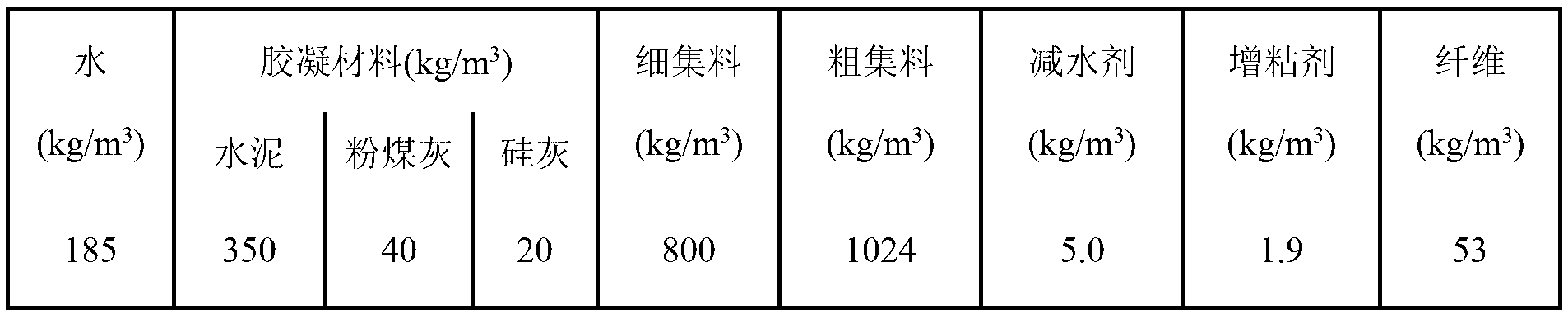

The invention relates to anti-radiation concrete produced from slag aggregate, and a production method thereof so as to effectively consume and utilize mineral waste, and improve an anti-radiation performance and durability of concrete. The anti-radiation concrete produced from slag aggregate comprises the following raw materials, by weight, 140-190 parts of water, 350-630 parts of a cementing material, 750-850 parts of a fine aggregate, 1000-1500 parts of a coarse aggregate, 0.35-1.9 parts of a tackifier, 2.1-7.5 parts of a water reducing agent, and 30-70 parts of fibers, wherein the cementing material comprises cement and a mineral admixture, the mineral admixture comprises silicon ash and fly ash, the cementing material comprises 300-500 parts by weight of the cement, 20-60 parts by weight of the silicon ash and 30-70 parts by weight of the fly ash, the coarse aggregate is a high titanium heavy slag coarse aggregate, the fine aggregate comprises high titanium heavy slag sand and lead powder according to a mass ratio of 1:0.2-3.0, the tackifier is methyl cellulose ether, and the fibers are one or a plurality of material selected from polypropylene fibers, steel fibers and lead fibers.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

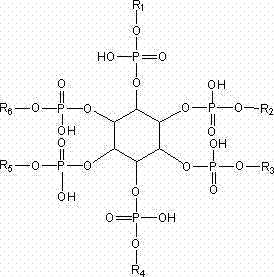

Phosphorus and nitrogen containing flame-retardant finishing agent and flame-retardant cellulose fiber fabric preparation method

InactiveCN108049173AAvoid defects that release toxic substancesSolve the problem of not being washedHeat resistant fibresVegetal fibresNitrogenPhytic acid

The invention discloses a phosphorus and nitrogen containing flame-retardant finishing agent and a flame-retardant cellulose fiber fabric preparation method. The flame-retardant finishing agent is a mixed solution of ammonium phytate, urea and dicyandiamide. A preparation method of the flame-retardant finishing agent comprises the following steps: firstly, utilizing phytic acid and nitrogen containing compound as raw materials to synthesize flame retardant ammonium phytate; secondly, dissolving the synthesized flame retardant ammonium phytate into water and adding the certain amount of the urea and the certain amount of a crosslinking agent to prepare a flame-retardant finishing agent with a corresponding concentration; finally, utilizing a padding-drying-baking finishing technology to apply the flame-retardant finishing agent to flame-retardant finishing of cellulose fiber / fabric. The flame-retardant finishing agent disclosed by the invention has the advantages that greenness and environmental friendliness are achieved in the utilized raw materials, a finishing technology is simple and easy to operate, and no any toxic and harmful matters to the human body and the environment is not generated in an operational process and a using process; the finished cellulose fiber / fabric has the advantages of excellent flame retardance, good washing resistance and wide market application prospect.

Owner:TIANJIN POLYTECHNIC UNIV

Mobile phone shell with 3D structure and processing technology thereof

The invention discloses a mobile phone shell with a 3D structure. The shell comprises a surface shell body and a bottom shell body. The surface shell body and the bottom shell body comprise sheet material layers which are made of a transparent material and possess outer transparent surfaces and inner transparent surfaces, hardening layers which form on the outer transparent surfaces and possess a predetermined thickness, local printing layers which form at any local positions of the inner transparent surfaces, texture transfer printing layers which form on the inner transparent surfaces and cover the local printing layers, vacuum electroplated layers and printing ink layers, wherein the vacuum electroplated layers and the printing ink layers are successively superimposed with the texture transfer printing layers. The invention also discloses a processing technology. By using the mobile phone shell with the 3D structure, on one hand, the shell possesses light transmittance performance which is similar to the light transmittance performance of glass, simultaneously can bear a large impact force and can not be fragmented so that a durability problem during a usage process is solved, and the shell accords with human engineering of a hand portion of a person and satisfies a customized demand of a consumer; on the other hand, through the above technology, mass production in industry is realized and production cost is reduced.

Owner:东莞市汇诚塑胶金属制品有限公司

Self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and insulated wallboard

ActiveCN102249641ASolve insulation problemsSolve fire resistanceSolid waste managementCement mortarStearate

A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and an insulated wallboard solve technical problem in a prior art that self-leveling cement mortar with weak waterproofness causes weak insulation effect of an insulated wallboard. A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover is employed as a technique. Ingredients of the self-leveling cement mortar dry powder comprise a compound impervious component; and the impervious component is prepared by mixing a redispersible high-molecular polymer and one of an organosilicon waterproof agent and a stearate, or a mixture of the two, and accounts for 0.6-4.3wt% of the self-leveling cement mortar dry powder. A special impervious ingredient is added to enhance compactness, microdilatancy and low dry shrinkage property of the cement based self-leveling mortar, so as to substantially increase waterproof function and endurance of the cement based self-leveling mortar. Therefore, a problem that a cladded super-light foaming cement sheet material loses insulation function due to water penetration and problems of flame resistance and endurance are solved fundamentally.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

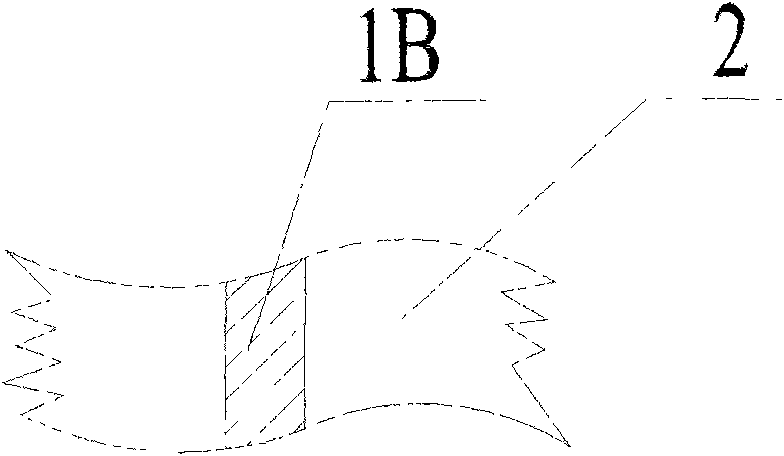

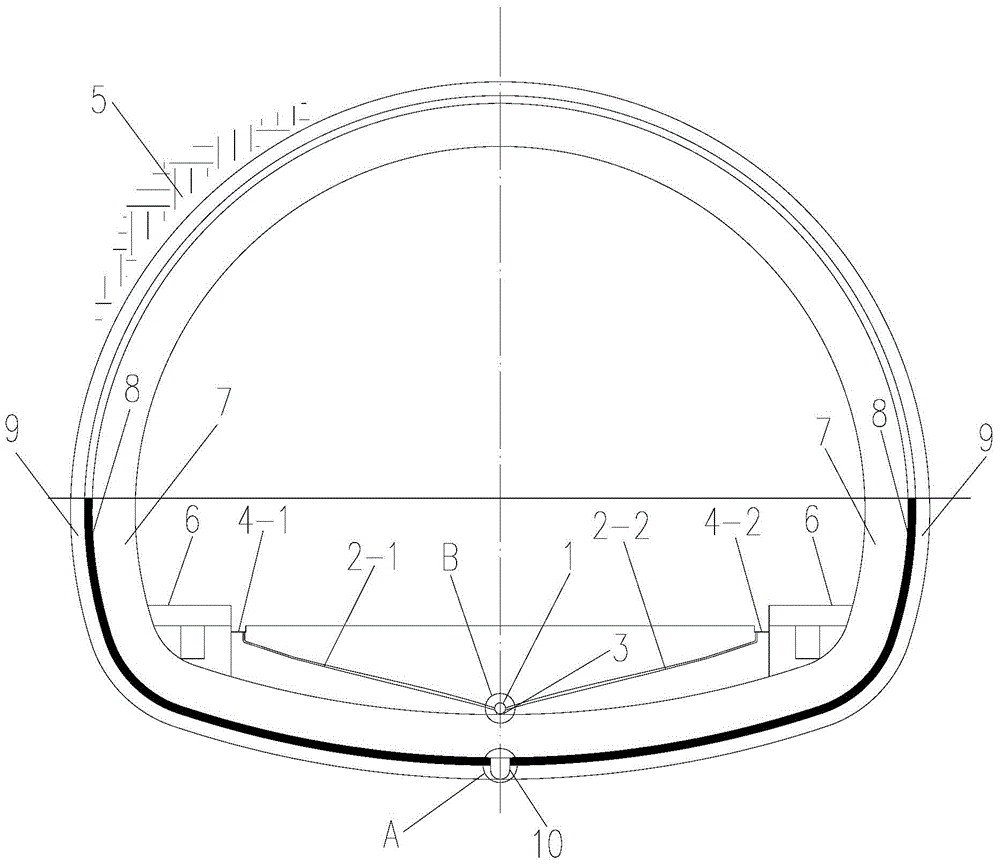

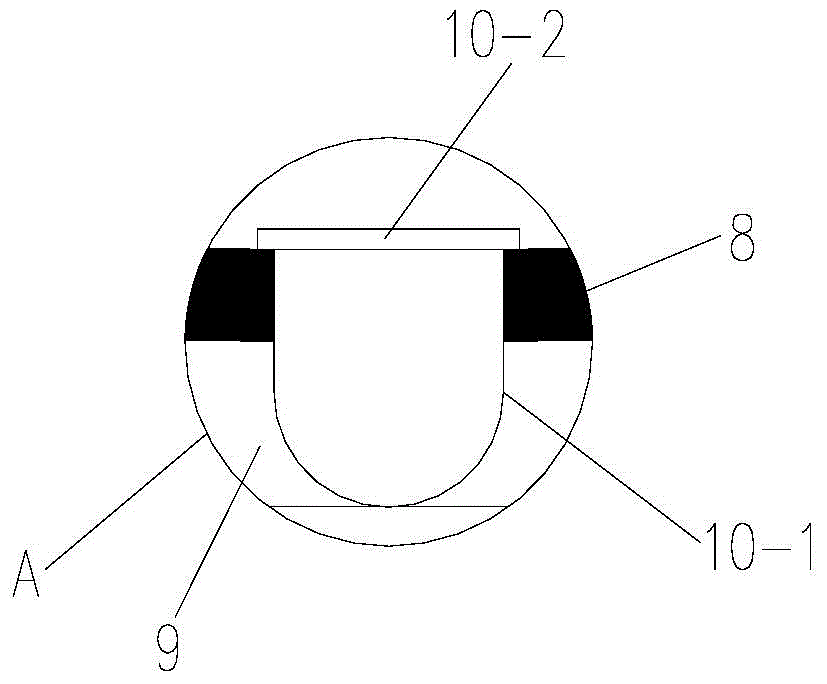

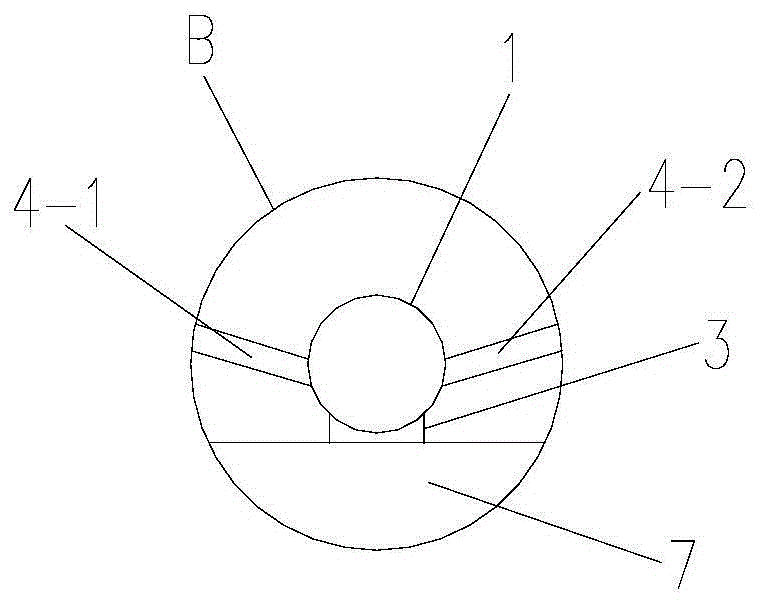

Tunnel diversion composite type waterproof and drainage system as well as construction method and use method thereof

InactiveCN104806272ASimple structureNovel and reasonable designUnderground chambersDrainageFrost heavingWater pipe

The invention discloses a tunnel diversion composite type waterproof and drainage system which comprises a surrounding rock waterproof and drainage system and a tunnel internal drainage system, wherein the surrounding rock waterproof and drainage system comprises a waterproof and drainage layer and a surrounding rock water drainage and collection pipe; the waterproof and drainage layer consists of multiple waterproof and drainage plates arranged in a butting manner; the surrounding rock water drainage and collection pipe consists of a concrete prefabricated pipe and a cover plate; the tunnel internal drainage system comprises a left water collecting tank, a right water collecting tank, a tunnel internal water drainage and collection pipe, a left drainage pipe and a right drainage pipe; the tunnel internal water drainage and collection pipe is arranged on a water collecting pipe base. The invention also discloses a construction method and a use method for the tunnel diversion composite type waterproof and drainage system. According to the tunnel diversion composite type waterproof and drainage system as well as the construction method and the use method thereof disclosed by the invention, the convenience for construction is realized; the diversion of surrounding rock waterproof and drainage and tunnel internal waterproof and drainage is realized, two functions of resisting water and draining water are integrated, the overall waterproof and drainage effects of the integral tunnel are improved, and the difficult problems of tunnel crack, leakage, frost heaving, water logging or icing and the like of a tunnel can be thoroughly solved.

Owner:XIAN UNIV OF SCI & TECH

Core-shell type fluorinated acrylate fabric water repellent and preparation method thereof

ActiveCN103788303AExcellent water and oil repellencyDoes not affect breathabilityFibre treatmentEmulsionMoisture permeability

The invention relates to a core-shell type fluorinated acrylate fabric water repellent which comprises the components by weight percent: 25-50% of monomer, 50-75% of deionized water, an initiator and an emulsifying agent, wherein the weight of the initiator is 0.5-1.5% of the total weight of the monomer, and the weight of the emulsifying agent is 1.0-3.5% of total weight of the monomer. A preparation method of the water repellent comprises the steps of respectively preparing shell emulsion and core emulsion, and then dripping the shell emulsion and the initiator into the core emulsion for reaction to obtain the core-shell type fluorinated acrylate fabric water repellent. The core-shell type fluorinated acrylate fabric water repellent is applied to water and oil repellent finishing of the fabric, so that the fabric has excellent water and oil repellent property, and the problems that the existing water and oil repellent is poor in use durability, low in fastness and the like in the aspect of wearability can be solved; furthermore, the performances such as air permeability, moisture permeability and the like of the fabric are not influenced, and the environmental pollution is not caused.

Owner:广东奕美化工科技有限公司

Polyphenyl plate thinly plastered external insulation system of outer wall

InactiveCN101575880ASolve the cracking problemSolve shrinkage deformationCovering/liningsSolid waste managementGlass fiberStress concentration

The invention relates to a polyphenyl plate thinly plastered external insulation system of an outer wall, comprising a wall structure layer. The polyphenyl plate thinly plastered external insulation system of the outer wall is characterized in that the wall structure layer is sequentially provided with a heat insulation layer, a crack-resistant protection layer and a finishing coat outside the wall structure layer , wherein the insulation layer is formed by bonding slurry and flame-resistant type expansion polyphenyl plate; the crack-resistant protection layer is formed by crack-resistant mortar and glass fiber alkali-resistant grids; the finishing coat is outer wall flexible putty; tray rivets are arranged on the glass fiber alkali-resistant grids and connected with the wall structure layer; and the finishing coat is formed by crack-resistant mortar, flexible tile bonding agent and tile. The invention has the advantages of solving a the problems of cracking between the crack-resistant protection layer and the finishing coat, the stress concentration and the shrinkage distortion of the insulation layer and the crack-resistant protection layer, and the ageing resistance and durability of the crack-resistant protection layer and the finishing coat.

Owner:上海浩赛干粉建材制品有限公司

High-strength sintered brick and production method

The invention provides a low-cost, good-wearability, high-intensity sintered brick, comprising: granulated blast furnace titanic slag 30-80 wt%; gangue or coal cinder 15-30wt%; sand 0-20wt%; clay or shale 0-42 wt%; and mineralizer 0-15wt%, where the TiO2 content of the granulated blast furnace titanic slag is 15-25%. And its producing method comprises the following steps of: 1) airing and then screening gas mud, converter mud, vanadium-containing slag and granulated blast furnace titanic slag; and crushing the clay, shale and sand; 2) weighing raw materials, and feeding them into a mixing mill or double axis blender; 3) making semidry pressure molding or extrusion molding on blank materials and obtaining brick blanks; 4) firing the brick blanks in a reducing or oxidizing atmosphere at 1000- 1100deg.C. And it has good wearability and low cost. And the invention utilizes the granulated blast furnace titanic slag in 30-80%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

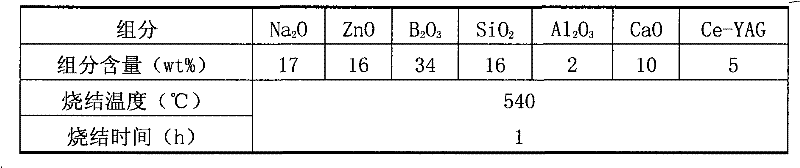

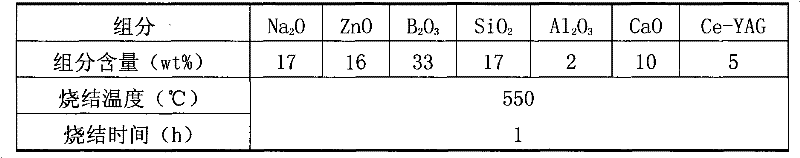

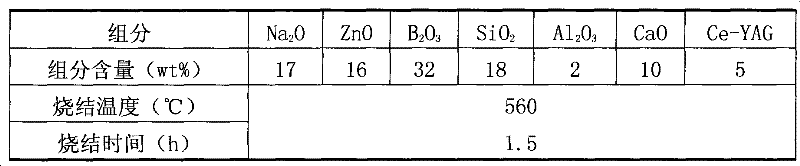

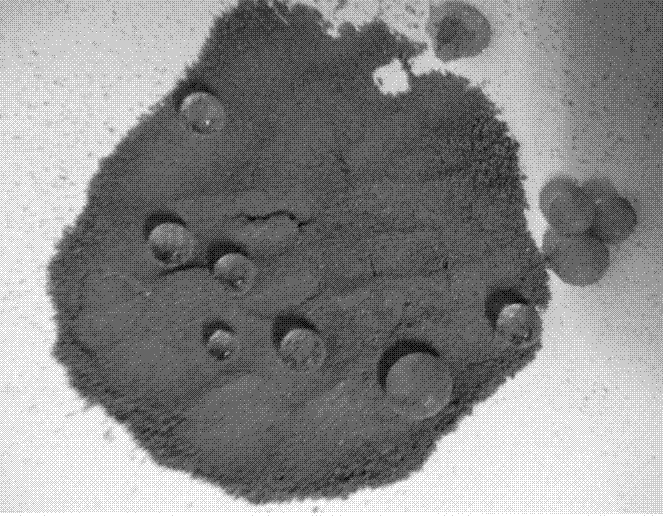

Fluorescent glass with low melting point for white light LED and preparation method thereof

The invention relates to a low-melting-point fluorescent glass for white light LEDs and a preparation method thereof. Low-melting fluorescent glass for white light LEDs, characterized in that it is prepared from raw materials containing Na2O, ZnO, B2O3, SiO2, Al2O3, CaO, MgO, K2O and Ce-YAG components; the mass percentage of each component is: Na2O: 1-20%, ZnO: 0-20%, B2O3: 20-40%, SiO2: 10-30%, Al2O3: 1-25%, CaO: 0-10%, MgO: 0-4%, K2O : 0-1.5%, Ce-YAG: 5-30%. The preparation method is firstly to prepare low-melting-point glass by melting method, mix low-melting-point glass powder and fluorescent powder, and obtain low-melting-point fluorescent glass after sintering. The fluorescent glass obtained by the method has both the good luminescence performance of the crystal material and the excellent stability performance of the glass material. It can be used in white light LED devices to solve the problems of poor color stability and durability of current white light LEDs.

Owner:WUHAN UNIV OF TECH

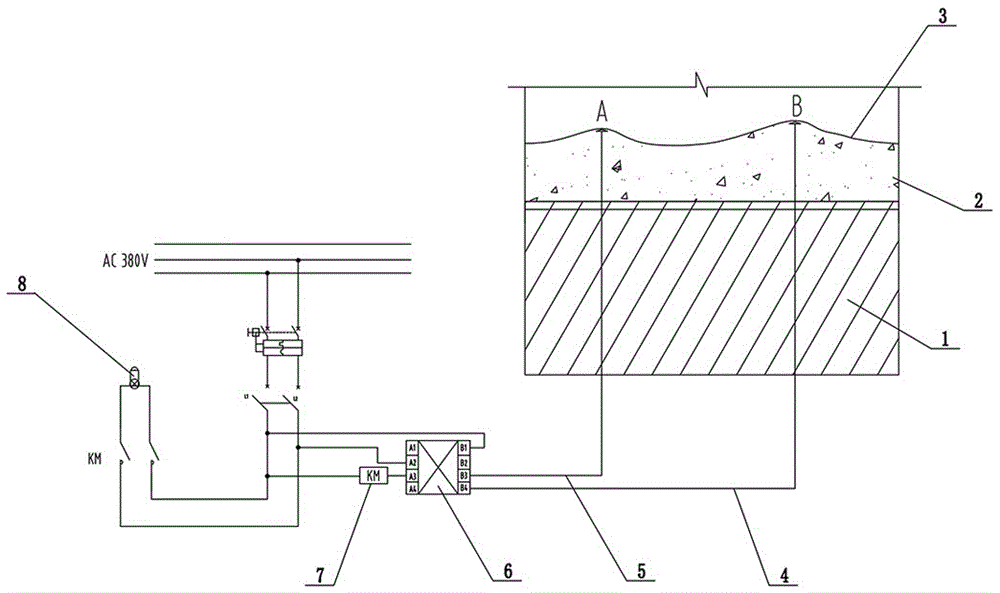

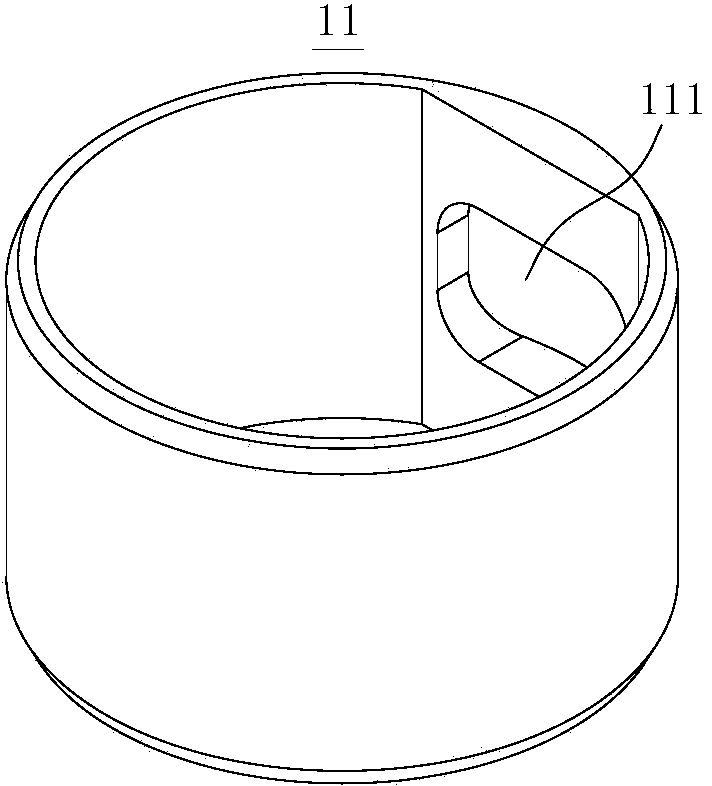

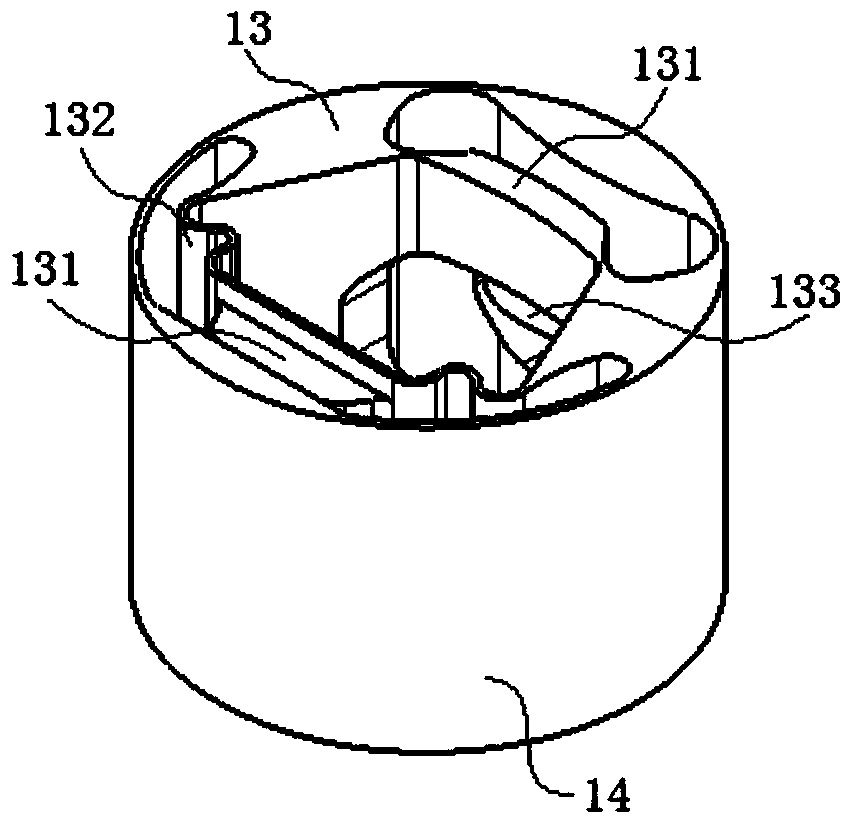

Anti-void monitor for tunnel lining concrete vault

InactiveCN106327731AReasonable structureEnsuring physical qualityUnderground chambersElectric transmission signalling systemsStructural engineeringEngineering

The invention discloses an anti-void monitor for a tunnel lining concrete vault. The anti-void monitor is used for preventing voids from being generated in the tunnel vault and is installed inside a distribution box of a tunnel lining trolley, and a liquid level relay, a contactor and an audible and visual alarm are arranged on a control circuit; one port of the liquid level relay is embedded into the highest point of the lining vault through a wire, and the other port of the liquid level relay is embedded into the second highest point of the lining vault through a wire; the highest point and the second highest point of the vault are communicated through vault lining water-entraining concrete, the contactor on the control circuit controls the audible and visual alarm to be started, concrete reaches the highest point, the concrete is poured to the vault without voids, and then the audible and visual alarm can give an alarm in a communicated mode. The anti-void monitor for the tunnel lining concrete vault is reasonable in structure, safe and reliable, monitors concrete pouring in real time, effectively prevents vault voids from being generated, guarantees the entity quality of the concrete, and effectively achieves structure safety and durability of the concrete.

Owner:CHINA RAILWAY TUNNEL GRP ROAD & BRIDGE ENG CO LTD

Composite gelling material and its preparation method

InactiveCN1868954AHigh activityGood dispersionSolid waste managementCement productionSlagBlast furnace

Owner:WUHAN UNIV OF TECH

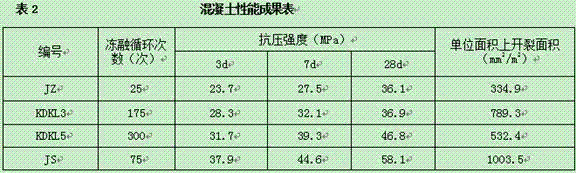

Concrete anti-freezing and anti-cracking agent

The invention discloses a concrete anti-freezing and anti-cracking agent. The concrete anti-freezing and anti-cracking agent is formed by mixing 95 parts by weight of hydrophobic modified mica powder with 5 parts of nano silicon dioxide. Hydrophobic modified mica is prepared by a method comprising the following steps: first step, drying white mica or bronze mica; step two, pulverizing the white mica or the bronze mica into flaky micro-powder of which the granularity is 80 mu m, the screen residues are 15% or below and the thickness is 2.5 mu m; and third step, after mixing a silane coupling agent, methylsilicone oil and white mica powder or bronze mica powder which is prepared in the second step according to a formula, carrying out modification treatment on the mixture at the temperature of 150 DEG C, and the pulverizing the mixture to obtain the finished hydrophobic modified mica powder. The shrinkage of the concrete added with the anti-freezing and anti-cracking agent is greatly reduced, and the anti-cracking property is greatly improved.

Owner:YELLOW RIVER ENG CONSULTING +1

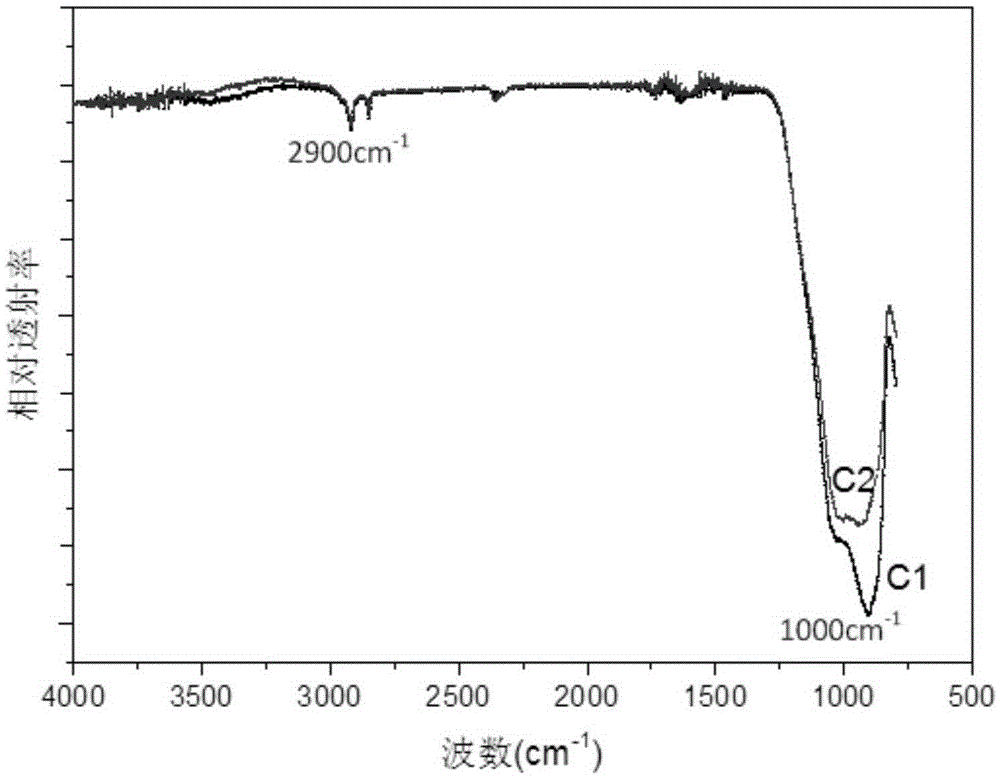

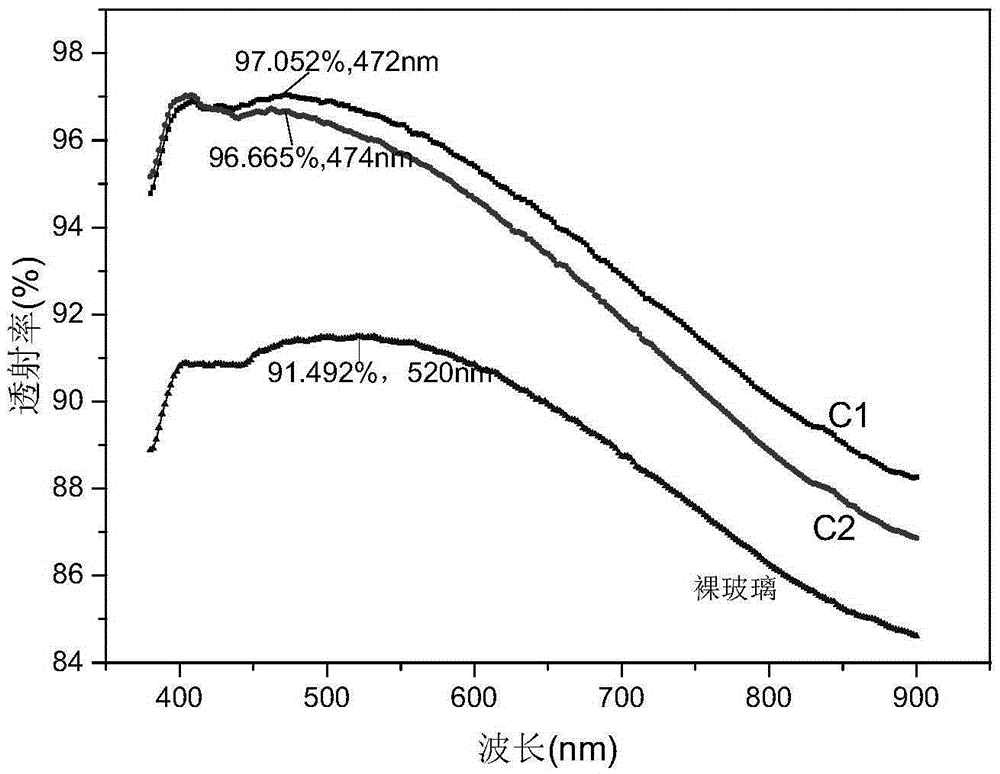

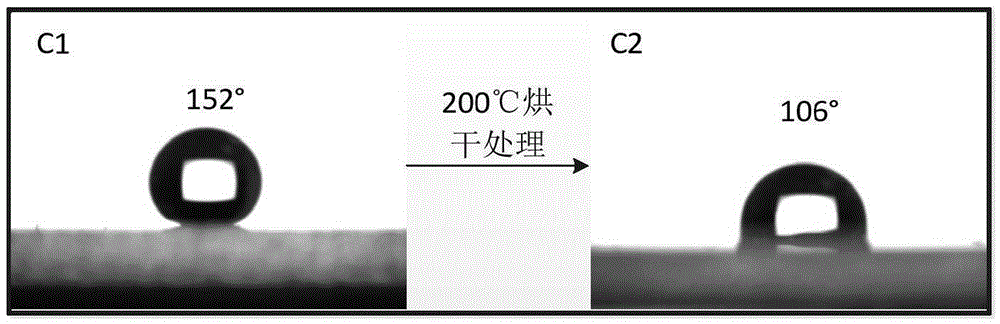

Super-hydrophobic high-transmittance SiO2 anti-reflecting thin film and preparation method thereof

The invention relates to a super-hydrophobic high-transmittance SiO2 anti-reflecting thin film and a preparation method thereof; a hybrid sol doped with trimethylchlorosilane is prepared by a sol-gel method; the surface of a glass slide is cleaned; a plating film is formed on the surface of the glass slide by a dip-coating method, and the super-hydrophobic high-transmittance SiO2 anti-reflecting thin film is obtained after the plating film is dried. Compared with the prior art, the preparation method has the advantages of simple manufacturing process and low cost, and the obtained sol has good uniformity and can be used for large-area film forming. Due to relatively high transmission, incident light transmission can be improved and the solar cell efficiency can be improved when the anti-reflecting thin film is used on a photovoltaic glass cover plate. Moreover, because the thin film has good hydrophobicity and has good self cleaning ability, the thin film is suitable for outdoor humid environments.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

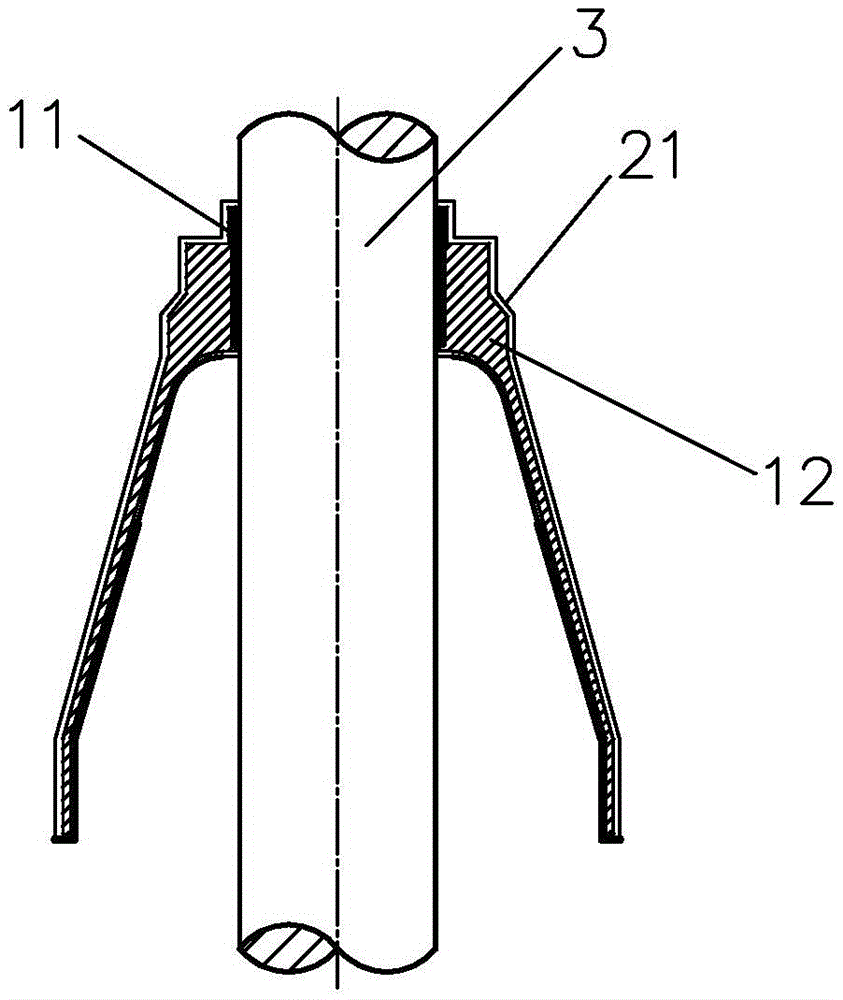

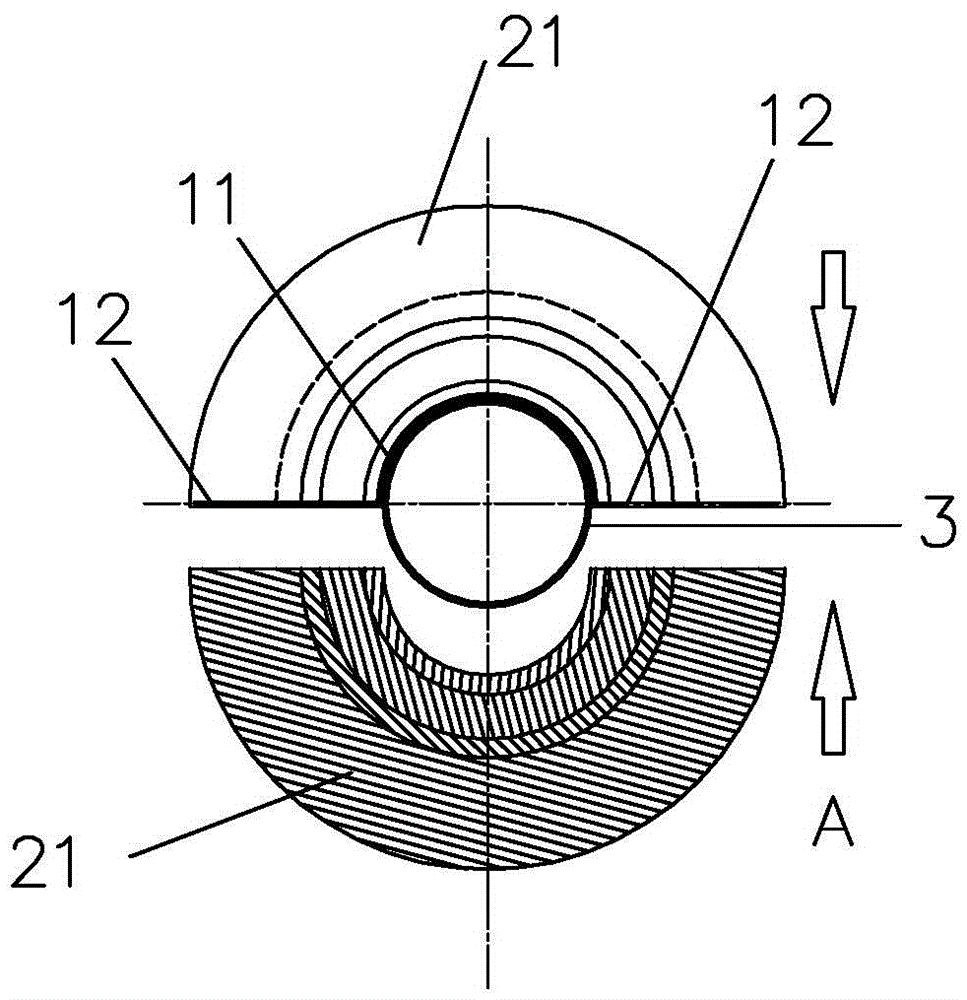

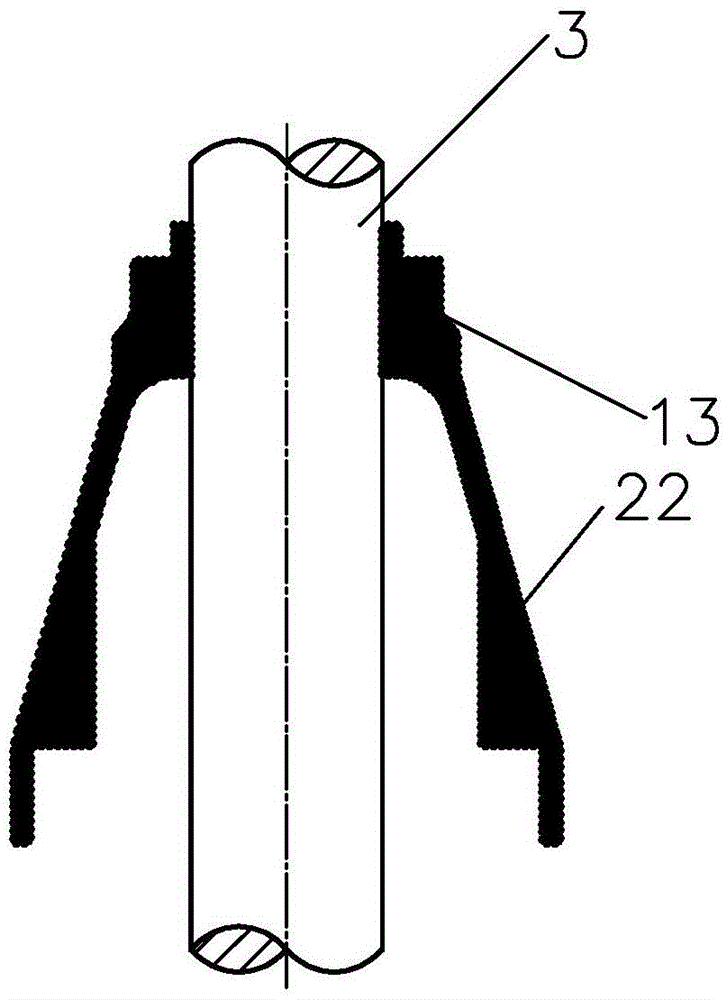

Electrical hot melting waterproof cover and method for achieving waterproof sealing of cable waterproof cover

ActiveCN105463983AIncreased durabilityImprove reliabilityCable-stayed bridgeBridge structural detailsHot meltMaterials science

The invention discloses an electrical hot melting waterproof cover which is suitable for a cable which takes a hot melting material as an outermost layer sheath pipe. The electrical hot melting waterproof cover comprises waterproof cover bodies located on the outer side of the cable sheath pipe and heating elements, and the heating elements comprise the heating element used for connecting the waterproof cover bodies with the sheath pipe into a whole through hot melting and the heating element used for connecting the two-half-type waterproof cover bodies together through hot melting. In an assembling state, the heating elements are inlaid into the cover body mouths or edges of the waterproof cover bodies, and after heating is performed, the waterproof cover bodies and the sheath pipe are connected into a whole through hot melting to form the electrical hot melting waterproof cover; the electrical hot melting waterproof cover comprises the two-half-type waterproof cover bodies, a whole integrated electrical hot melting waterproof cover body and a whole detachable electrical hot melting waterproof cover body according to the difference of the waterproof cover structures. In a using state, the electrical hot melting waterproof cover and the cable are connected together through hot melting welding, the condition that the sealing durability and reliability of an existing waterproof cover and a cable protecting cover are not enough can be improved, the waterproof problem of an embedded pipe at the beam end is permanently solved, the service life of the cable is prolonged, and the maintenance cost of the cable in the using process is lowered.

Owner:LIUZHOU OVM STRUCTURE INSPECTION TECH

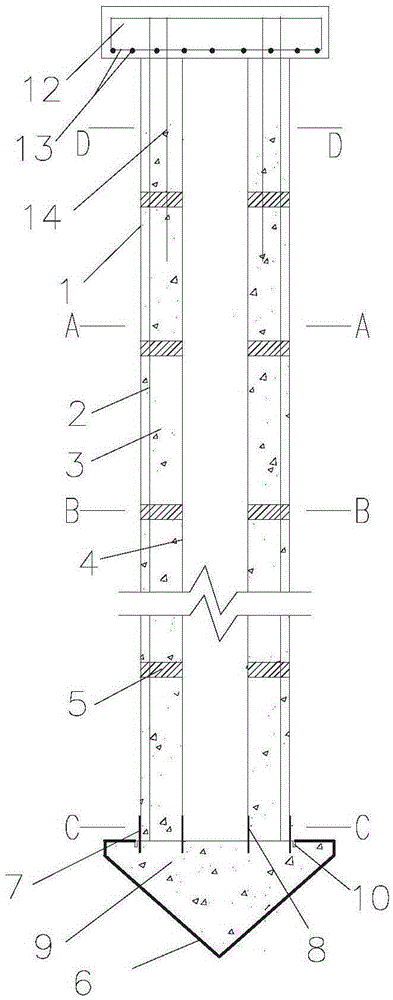

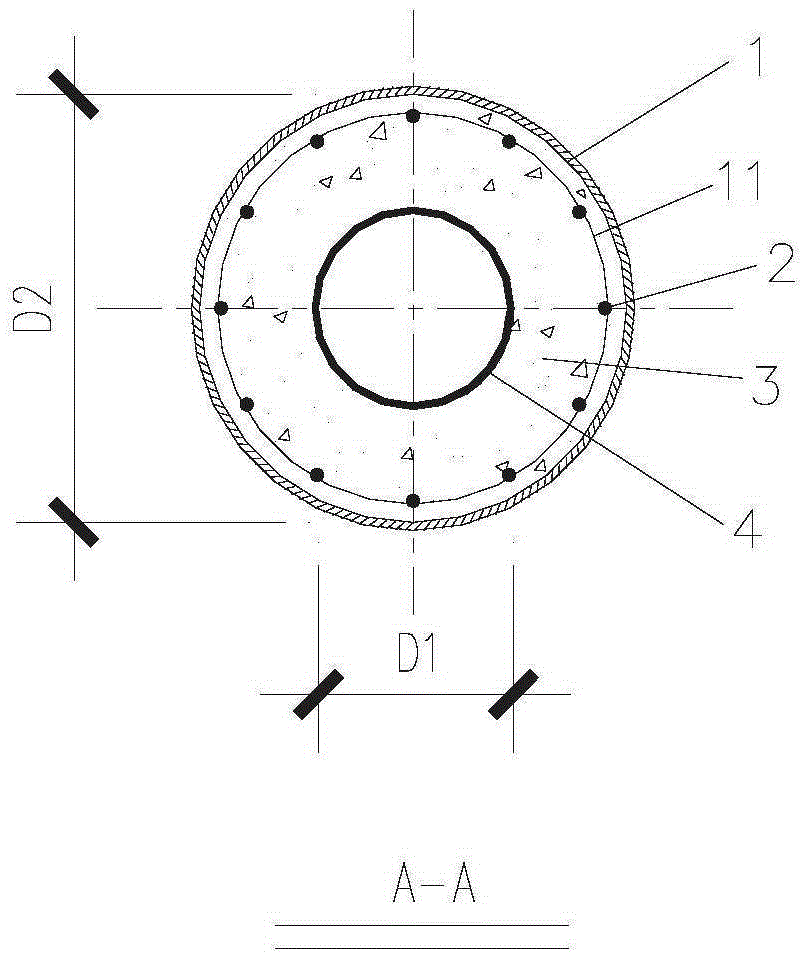

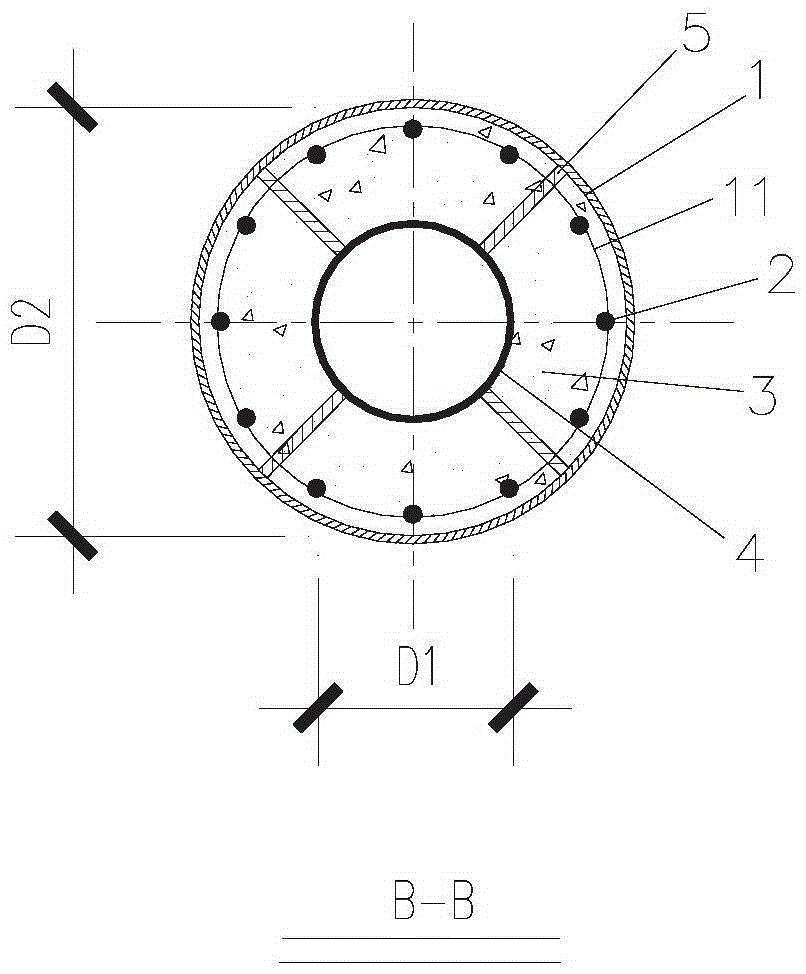

FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

InactiveCN105386443AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses an FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile which is mainly formed by an FRP pipe, a round reinforcement cage framework, a thick-wall steel pipe and recycled concrete. The round reinforcement cage framework and the thick-wall steel pipe are arranged in the FRP pipe, and the round reinforcement cage framework, the thick-wall steel pipe and the FRP pipe are arranged concentrically. The recycled concrete is poured in annular space between the FRP pipe and the thick-wall steel pipe. The bearing capacity and deformation resisting capacity of the single pile can be greatly improved through the built-in thick-wall steel pipe. The wrapping FRP pipe can effectively prevent a pile body from being corroded, and the durability of the pile body is improved. Meanwhile, the FRP pipe and spiral stirrups are combined to restrain the inner recycled concrete, and the bearing force of the compounding pile is further improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated. In a word, the compounding hollow recycled concrete pile has the advantages of being good in pile forming quality, high in bearing force, good in deformation resisting capacity and durability, small in influence on the environment, high in construction speed and the like.

Owner:GUANGXI UNIV

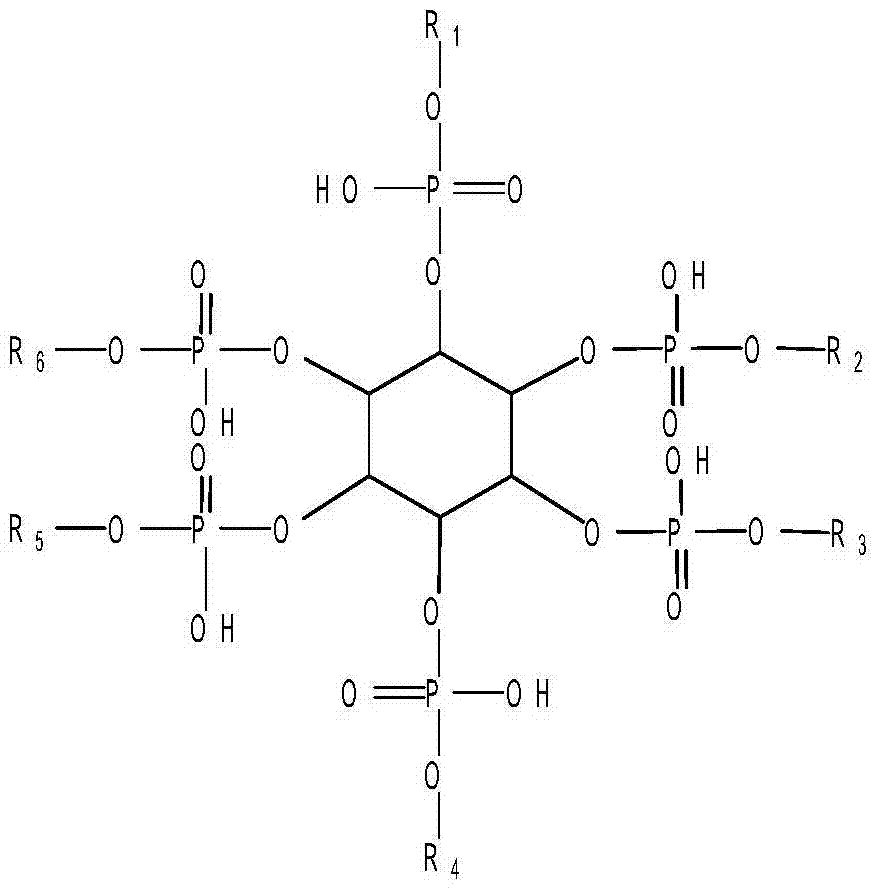

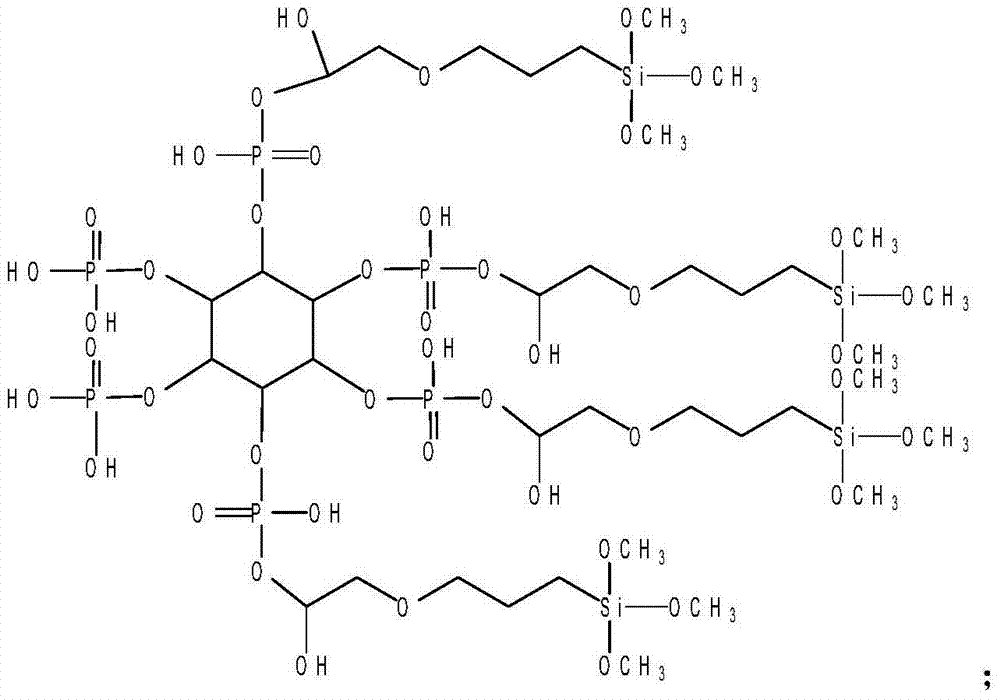

Preparation method of flame-retardant cotton fabric

ActiveCN104264467ASolve the durability problemSimple processGroup 5/15 element organic compoundsVegetal fibresFire retardantSilanes

The invention discloses a preparation method of a flame-retardant cotton fabric. The preparation method comprises the following steps: adding natural phytic acid compounds and gamma-epoxy propoxy trimethoxy silane into an organic solvent, stirring and reacting for 0.5-2 hours at 50-80 DEG C to obtain a flame-retardant finishing liquid, soaking a cotton fabric into the flame-retardant finishing liquid for 8-15 minutes, then soaking and rolling twice, then drying the cotton fabric at 60-90 DEG C, baking the cotton fabric for 2-8 minutes at 150-180 DEG C, and finally performing water washing, soaping and drying. The preparation method disclosed by the invention adopts natural phytic acid as a reaction raw material, a prepared flame-retardant textile cannot release free formaldehyde, the problem of formaldehyde release of most of current flame retardants can be solved, gamma-epoxy propoxy trimethoxy silane is introduced into flame retardant molecules, the prepared flame retardants contain a plurality of reactive groups, and the problem of flame-retardant finishing durability of the cotton fabric can be solved. The technical scheme disclosed by the invention is simple in process and convenient to operate, and has wide application prospects.

Owner:新乡市新科防护科技有限公司

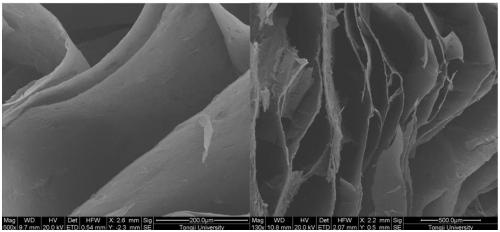

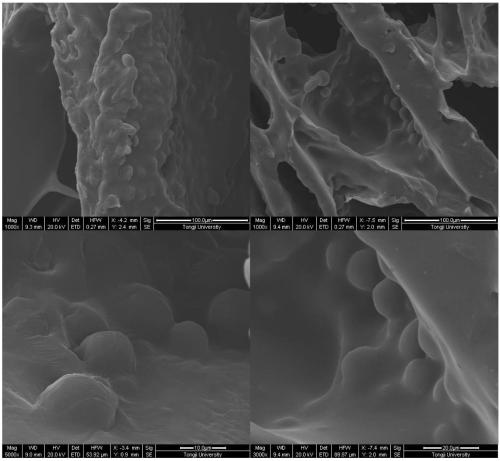

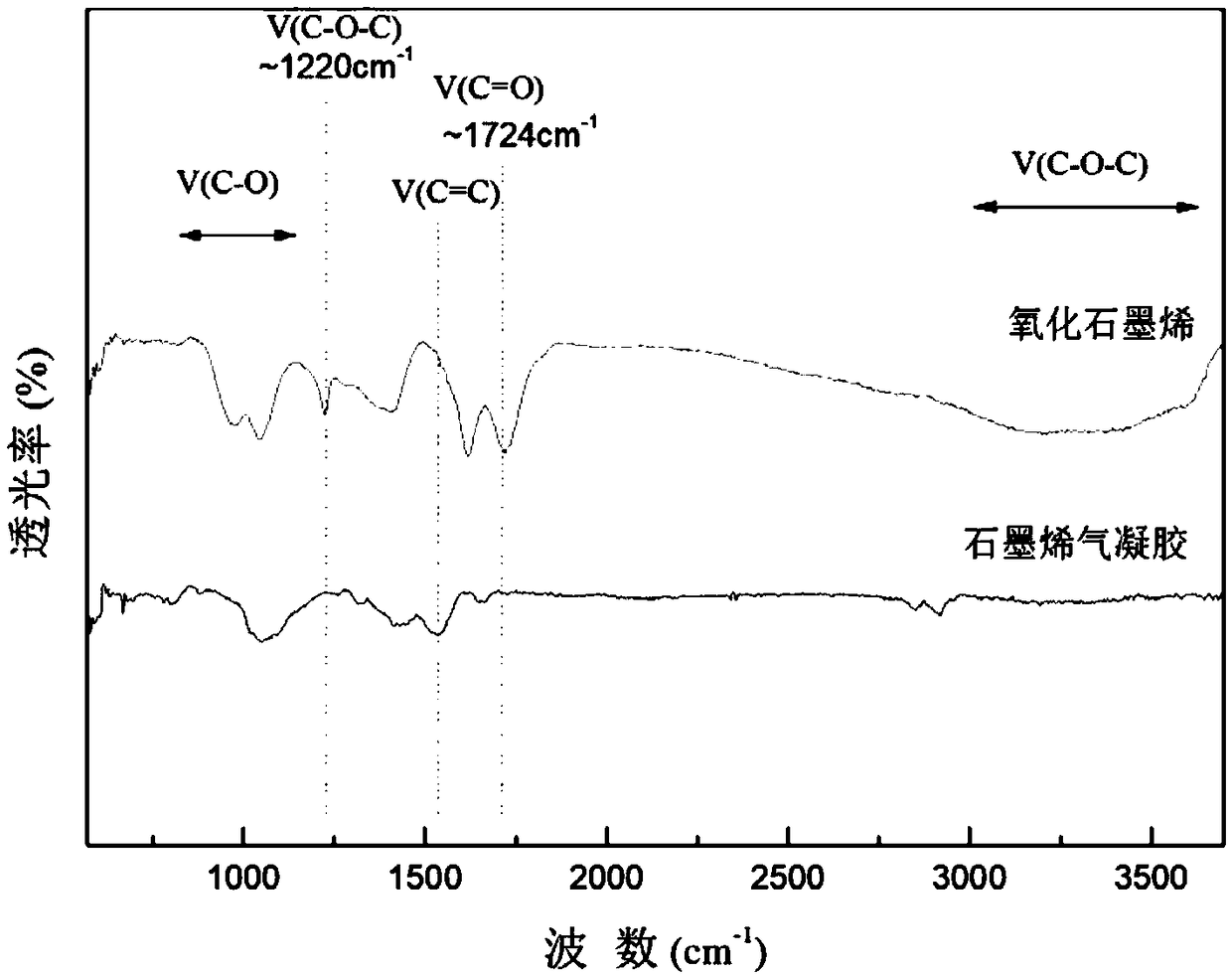

Graphene elastic polymer phase-change composite material and preparation method thereof

ActiveCN109385254ASolving Dispersion ProblemsSolve the durability problemHeat-exchange elementsFreeze-dryingMechanical property

The invention relates to a graphene elastic polymer phase-change composite material and a preparation method thereof. Firstly, a graphene aerogel is obtained through a hydrothermal reduction, then a graphene oxide solution is mixed with a phase-change material, phase-change microcapsules are prepared through a Pickering emulsion method, and finally, the phase-change microcapsules in certain proportions and an elastic polymer emulsion mixed solution are compounded with the graphene aerogel through vacuum impregnation, and subjected to vacuum freeze-drying to obtain the graphene elastic polymerphase-change composite material. Compared with the prior art, the graphene aerogel is taken as a skeleton to provide thermal conductive modification for the composite material, and a packaging environment is provided for the phase-change material through a complicated pore structure, therefore, two technical bottlenecks of high leakage possibility and poor thermal conductivity of the phase-changecomposite material can be effectively solved; an elastic polymer is compounded to reinforce the graphene skeleton, and is capable of providing excellent mechanical properties for the composite material while further packaging the phase-change material, and then energy storage application can be realized under special conditions.

Owner:TONGJI UNIV

Use of plastic film or plastic composite film as architecture component protective film or decorative film

InactiveCN1884753AConstruction is inconvenientSolve the durability problemBuilding insulationsTectorial membraneComposite film

The invention relates to the application of plastic film or plastic composite film, used as building element protective film or decorating film, wherein the invention coats adhesive or polymer on the surface of building element, then adheres the plastic film or plastic composite film on the said surface. The invention has the advantages that: it can prolong the service life of decorate element, with low cost and simple operation, while the polymer is made by mixing adhesive and other stuff on site.

Owner:吴淑环

Antibacterial and antifungal agent, preparation method thereof and antibacterial and antifungal method

ActiveCN105494429AAntibacterialSolve the durability problemBiocideDead animal preservationToxicityChemistry

The invention discloses an antibacterial and antifungal agent, a preparation method thereof and an antibacterial and antifungal method. The antibacterial and antifungal agent comprises the following raw materials in parts by weight: 0.5 to 5 parts of antibacterial metal salt, 15 to 52 parts of photocatalytic oxide, 60 to 70 parts of diatomite, and 10 to 15 parts of organic antifungal component. The antibacterial and antifungal agent has excellent antibacterial and antifungal capacities and antibacterial and antifungal durability at the same time, is low in toxicity and production cost, and can be applied to various materials, such as coating, diatom ooze, putty, mortar, and plastics.

Owner:CHINA BUILDING MATERIALS ACAD

Waterproof and oilproof soil-release fabric and production method thereof

InactiveCN103046382ASimple processing methodIncrease productivityBiochemical fibre treatmentSingeingCotton fibrePolyester

The invention discloses a waterproof and oilproof soil-release fabric and a production method thereof. In the fabric, the content of cotton fibers is 40%-85%, and the waterproof and oilproof soil-release fabric is obtained by forming a grey fabric from cotton / spandex wrap yarns with a twist coefficient being 1.45-4.55 and polyester yarns with the twist coefficient being 35-195, dyeing the grey fabric and then processing the dyed fabric by using a fluorinated acrylate finishing solution; in addition, at least one type of yarns in weft yarns of the fabric is the cotton / spandex wrap yarns; and after being washed for 20 times according to a standard JIS, the waterproof property, the oilproof property and the soil-release property of the fabric are all above grade 3.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

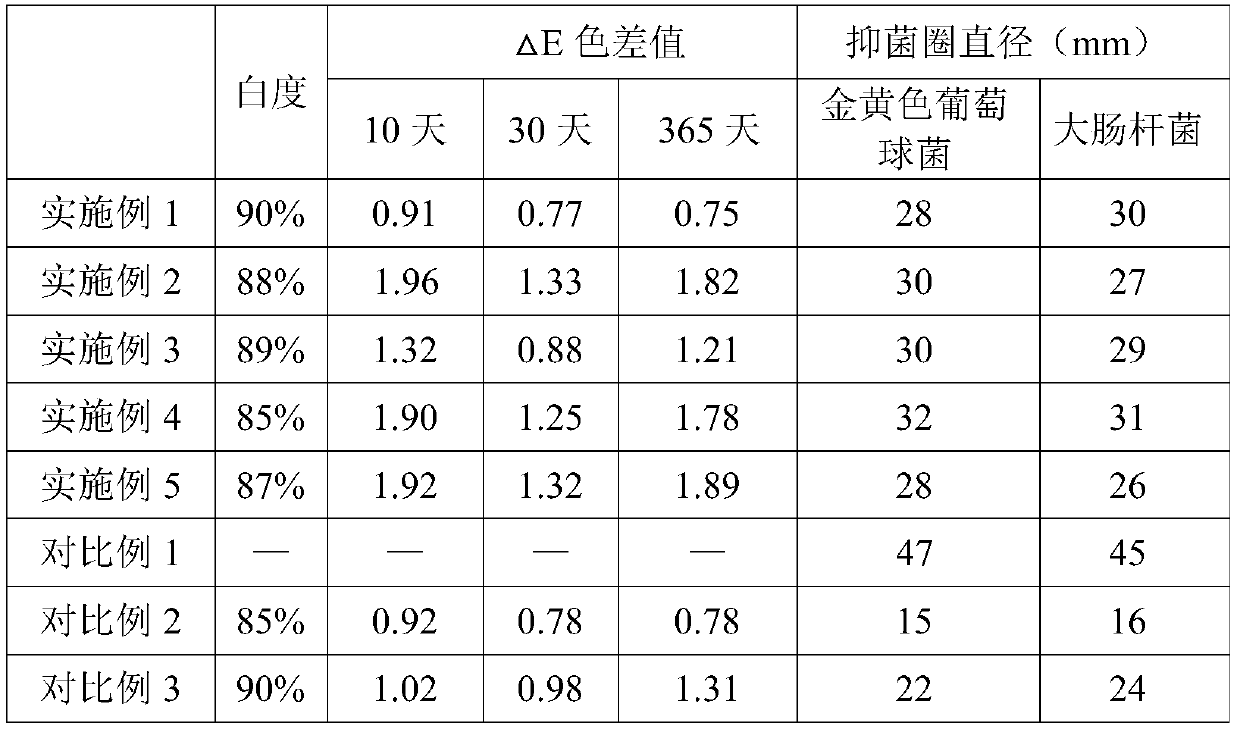

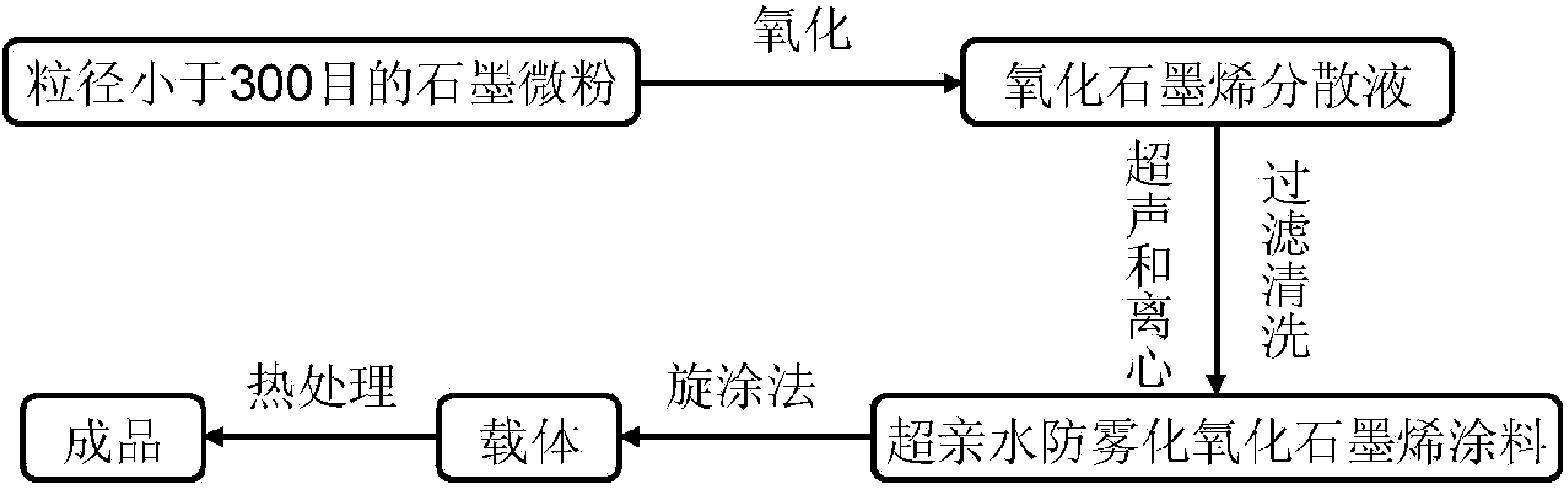

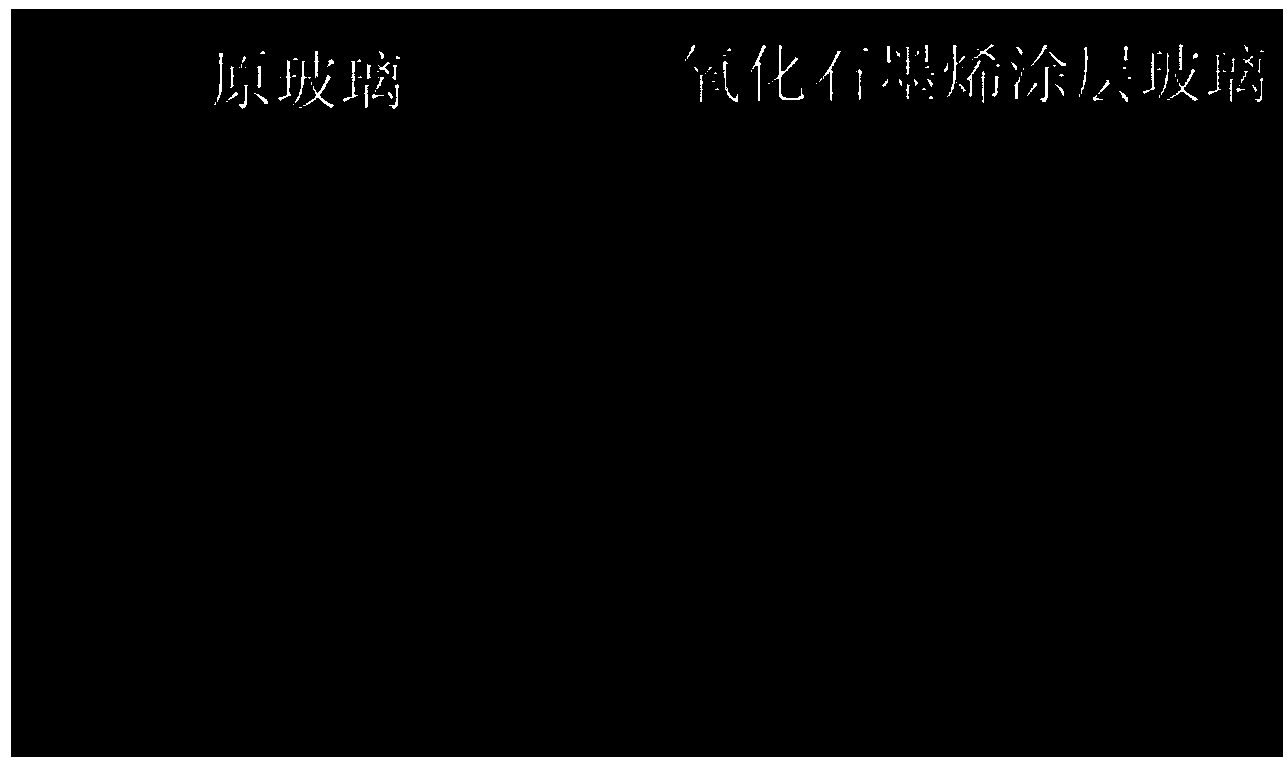

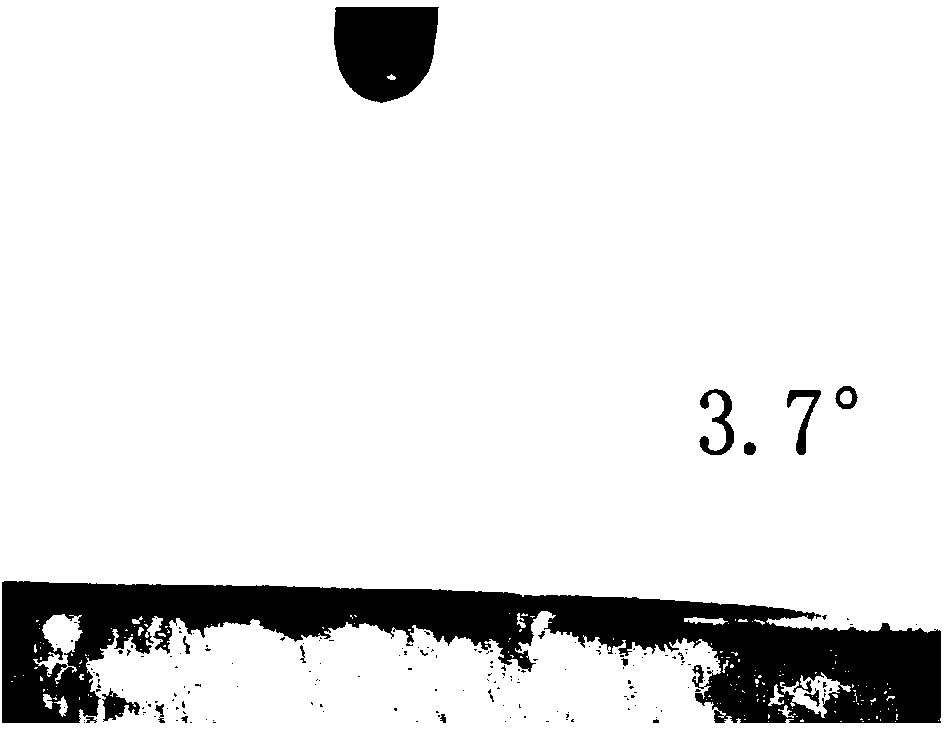

Super-hydrophilic anti-fogging oxidized graphene coating, preparation method and application thereof

ActiveCN104231684AImprove performanceIncreased durabilityPretreated surfacesCoatingsGraphene coatingFiltration

The invention discloses a preparation method of a super-hydrophilic anti-fogging oxidized graphene coating. The preparation method comprises the following steps: taking graphene micro powder as a raw material, adopting a wet chemical oxidation method to prepare oxidized graphene dispersion liquid, and carrying out filtration, rinsing, ultrasonic dispersion and centrifugal separation to obtain the super-hydrophilic anti-fogging oxidized graphene coating. In addition, the invention further discloses a method of adopting the coating to prepare a super-hydrophilic anti-fogging oxidized graphene coating layer. The preparation method disclosed by the invention is simple in technology, low in cost, green and environment-friendly, and easy in operating condition control. The obtained oxidized graphene coating is excellent in performance, wide in application range, and capable of being applied to relatively transparent common glass or organic transparent carrier. The prepared super-hydrophilic anti-fogging oxidized graphene coating layer has the excellent characteristics of super-hydrophilicity, anti-fogging property, high strength, long durability, high transmission of light and the like. The preparation method of the super-hydrophilic anti-fogging oxidized graphene coating effectively solves the problem that the existing coating layer is poor in anti-fogging effect and durability, and is favorable to promote application and development of the super-hydrophilic technology.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Bridge pier anti-collision component based on FRP and polyurethane foam filled honeycomb-shaped rubber concrete

PendingCN111593691ASolve the stiffness problemSolve the costBridge structural detailsBridge materialsHoneycombRoad surface

The invention discloses a bridge pier anti-collision component based on FRP and polyurethane foam filled honeycomb rubber concrete, wherein the bridge pier anti-collision component is arranged on theouter side of a bridge pier lower structure, and the bridge pier lower structure is a bridge pier and road surface connecting structure; the pier anti-collision component comprises an FRP sleeve, a polyurethane foam layer and a rubber concrete layer. The anti-collision component and a bridge pier adopt an integral forming construction technology; the whole anti-collision structure adopts a honeycomb buffer layer and a concrete filling layer, wherein the honeycomb buffer layer is composed of an FRP sleeve, a polyurethane foam layer and a rubber concrete layer. When the component is impacted, animpact buffer area, an impact force deformation area and an impact force constraint area are formed, so that the impact energy is dispersed in the circumferential direction of a honeycomb buffer layer composed of an FRP sleeve-polyurethane foam layer and a rubber concrete layer, and dual protection is conducted on a vehicle and a bridge lower structure. The component is integrally formed, the cost is low, the structure is simple, and later maintenance is facilitated.

Owner:BEIJING MUNICIPAL CONSTR +2

After finishing method for permanently improving hygiene performance of superfine fiber synthetic leather base cloth

ActiveCN102140763ARealize a high degree of simulationImprove hygieneBiochemical fibre treatmentFermentationAlkaline proteaseFiber

The invention relates to an after finishing method for permanently improving the hygiene performance of superfine fiber synthetic leather base cloth, which comprises the following steps of: pretreating the surface of the superfine fiber synthetic leather base cloth by using a treating agent; hydrolyzing collagen by using alkaline protease; and grafting the hydrolyzed collagen to the primarily modified surface of the superfine fiber synthetic leather base cloth by using a crosslinking agent. The surface of the superfine fiber synthetic leather base cloth is covalently modified by collagen macromolecules, the hygiene performance of the superfine fiber synthetic leather base cloth is permanently improved by the collagen, the aim of highly simulating superfine fiber synthetic leather is fulfilled, and the problems of a poor improving effect and low durability in the prior art are solved.

Owner:南通鑫唐纺织印染有限公司

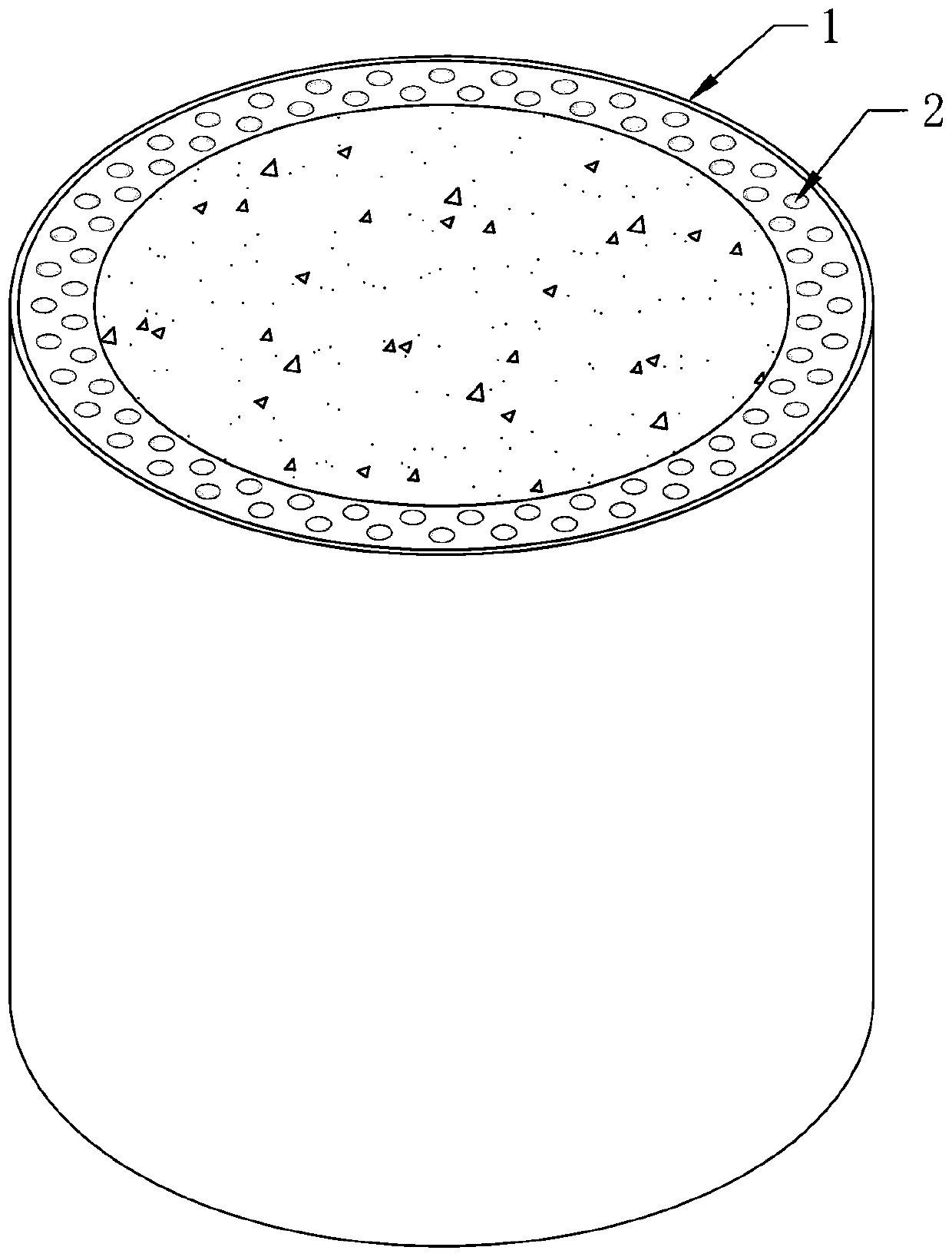

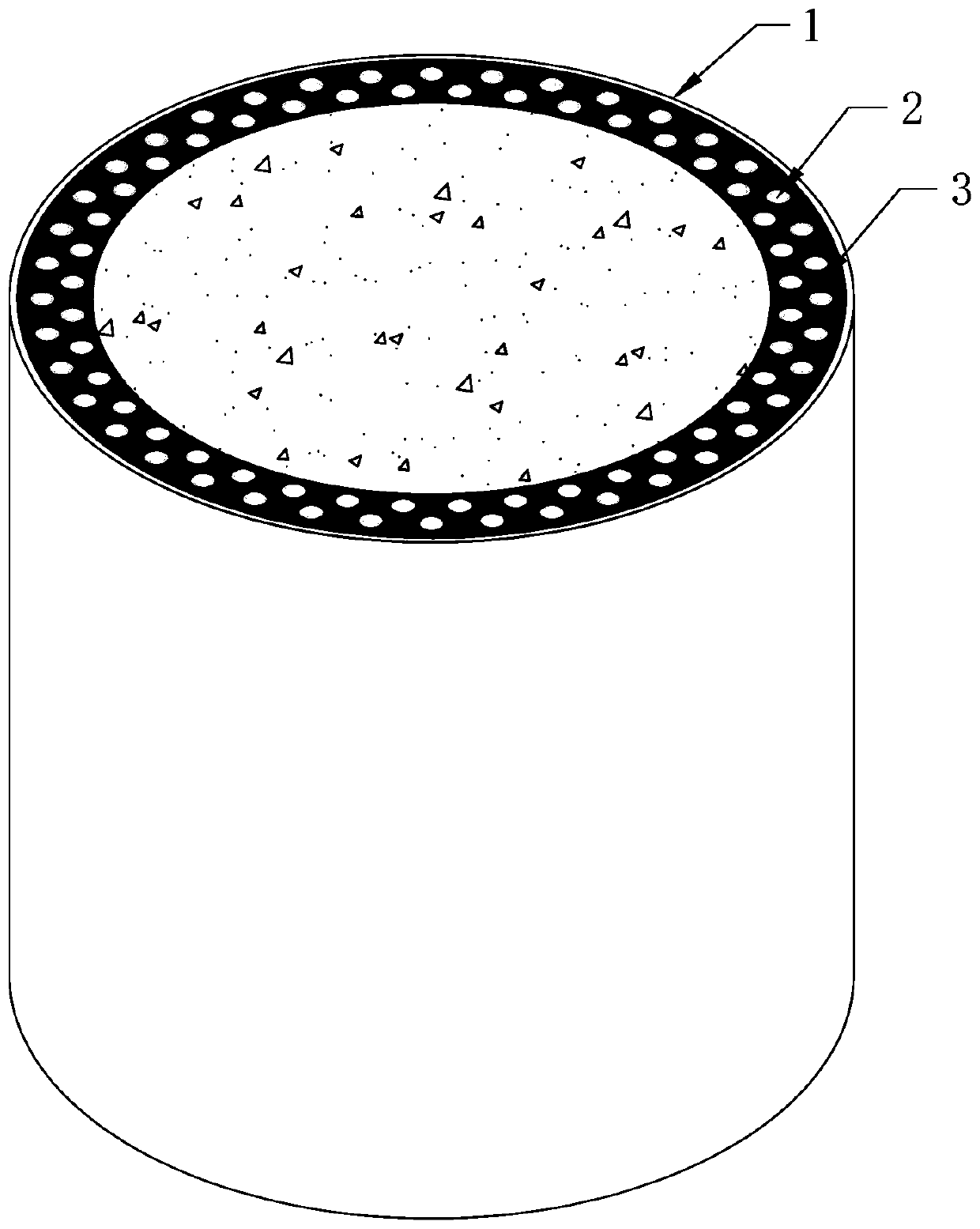

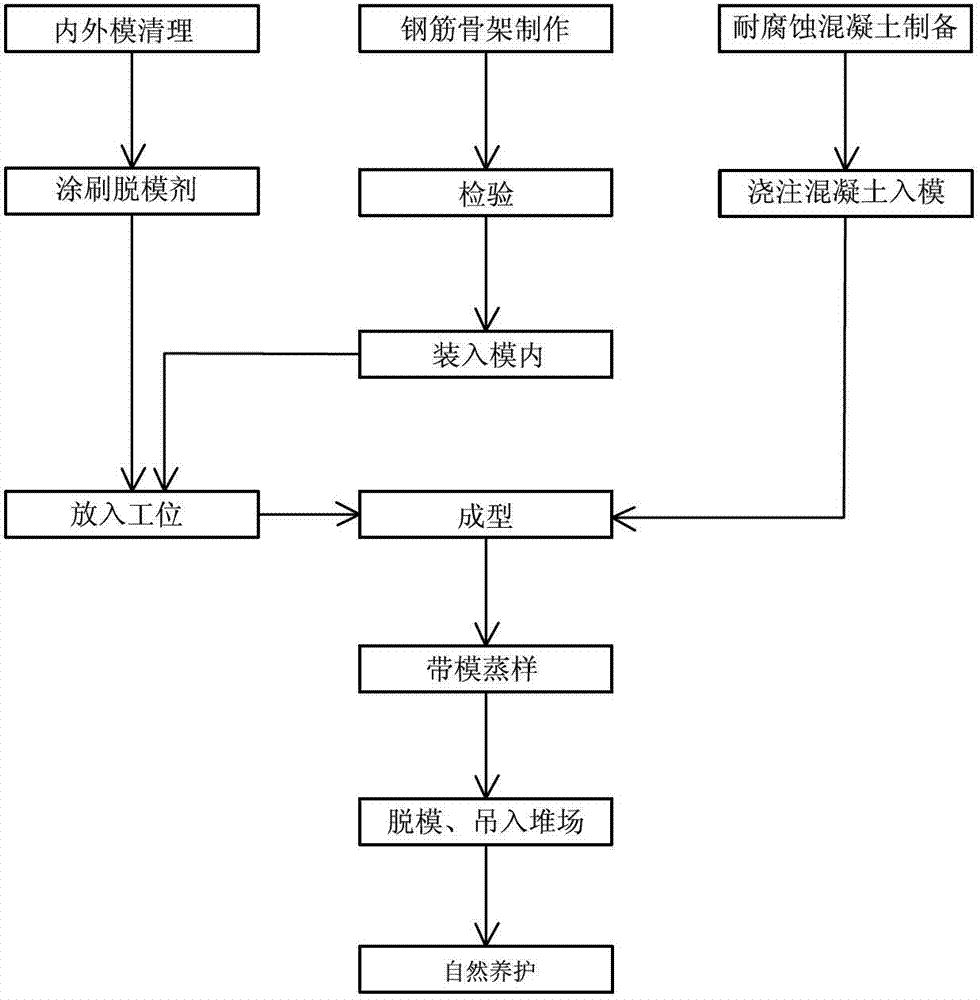

Production technology of anti-corrosion prefabricated reinforced concrete inspection well

InactiveCN103358387AHigh strengthImprove impermeabilitySewerage structuresCeramic shaping apparatusReinforced concreteSlag

The invention discloses a production technology of an anti-corrosion prefabricated reinforced concrete inspection well, which comprises the steps of sequentially cleaning inner and outer molds of the inspection well, coating the inner and outer molds with mold release agents, fabricating and inspecting reinforced skeletons in the anti-corrosion concrete inspection well, filling the inner and outer molds with the reinforced skeletons in the anti-corrosion concrete inspection well, mixing slag powder, coal ash, sand, stone, an excitant, a special additive and water to form anti-corrosion concrete, pouring the anti-corrosion concrete in the inner and outer molds, forming the anti-corrosion concrete by pouring via a hanging roll technology, a vibrating technology and a mandrel vibrating technology, placing the anti-corrosion concrete formed by pouring, and the inner and outer molds into a station, allowing the anti-corrosion concrete formed by pouring, and the inner and outer molds to be subjected to steam-cured treatment, demolding, and transferring the solidified anti-corrosion concrete inspection well to a storage yard for natural curing. The inspection well produced by the technology is high in strength, good in permeability resistance, energy-saving and environment-friendly, and can achieve factory prefabrication, and the service life of the inspection well is longer than that of the common concrete inspection well.

Owner:SUZHOU CONCRETE CEMENT PROD RES INST +1

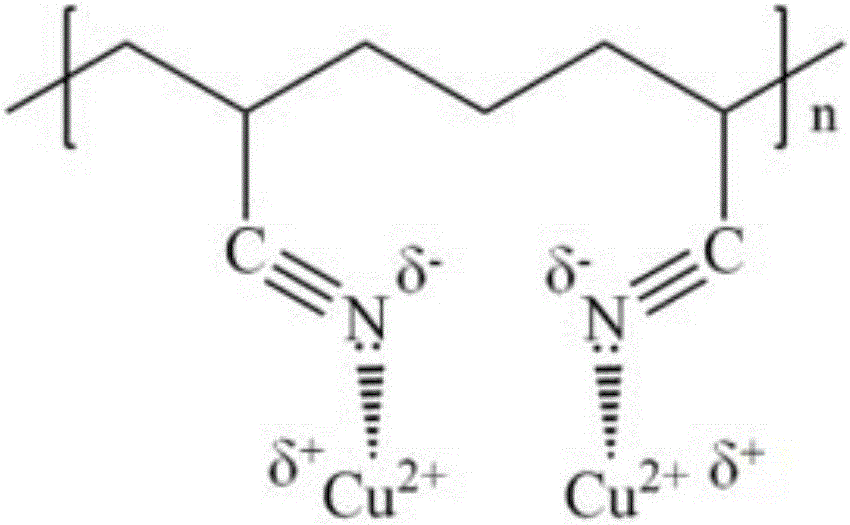

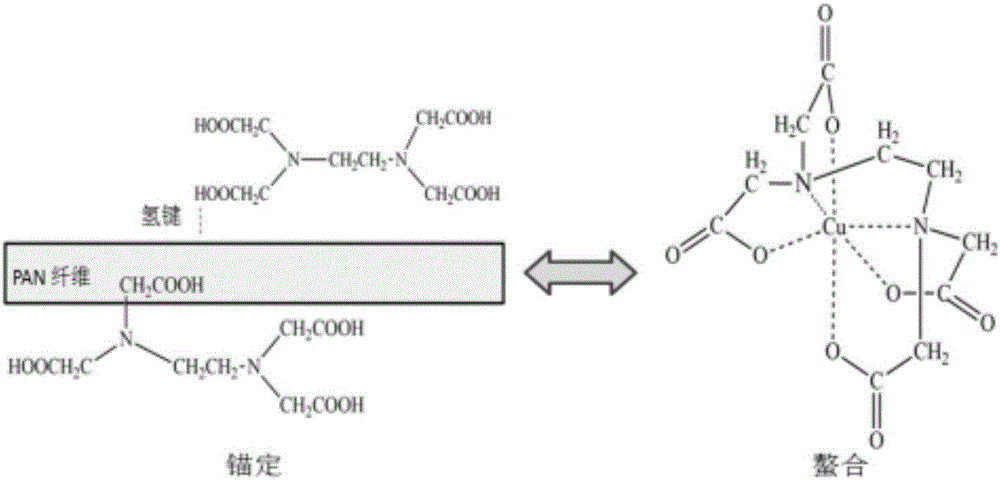

Preparation method of anti-microbial conductive acrylic fiber/copper sulphide complex fiber

InactiveCN106758148ALarge specific surface areaFacilitate depositionFibre typesWater bathsPolymer science

The invention relates to a preparation method of an anti-microbial conductive acrylic fiber / copper sulphide complex fiber. The preparation method comprises the steps of pretreating acrylic fiber; immersing the pretreated acrylic fiber into a copper sulfate solution, stirring, keeping in water bath with the temperature ranging from 40 to 80 DEG C for 1 to 2h, then adding a chelating agent solution, immersing and drying for three times, then adding the obtained acrylic fiber into a sodium sulfide solution, reacting at room temperature for 10 to 30min, cleaning, and drying to obtain the anti-microbial conductive acrylic fiber / copper sulphide complex fiber. The anti-microbial conductive acrylic fiber / copper sulphide complex fiber prepared by the invention not only has favorable antibacterial property, electrical conductivity, binding strength, washing fastness and the like, but also is moderate in preparation conditions, simple in process and low in cost.

Owner:DONGHUA UNIV

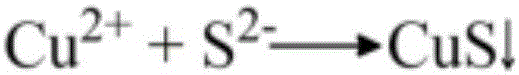

Insulated crack-resistant protective light dry mortar for external thermal insulation of exterior wall and preparation method thereof

The invention discloses insulated crack-resistant protective light dry mortar for external thermal insulation of an exterior wall. The insulated crack-resistant protective light dry mortar comprises the following raw materials by mass percent: 25-35% of cement, 15-25% of vitrified microbead, 8-15% of quartz powder, 5-10% of coal ash floating bead, 1-5% of perlite, 5-15% of rubber particles, 3-10% of metakaolin, 1.0-1.5% of rubber powder, 0.1-0.3% of water reducing agent, 0.2-0.5% of anti-crack fiber, and 0.2-0.4% of cellulose ether, wherein the sum of the components by mass percent is 100%. The preparation method of the dry motor comprises the step of agitating and mixing the weighed raw materials. The using method comprises the steps of agitating and mixing water with the dry motor according to the mass ratio of (4-5):4. By adopting the insulated crack-resistant protective light dry mortar, rubber is added to cement-based crack-resistant protective dry mortar, so that the brittleness of the cement-based protective motor material is improved, the problems that the existing coating mortar is easy to crack and poor in durability are solved, and the thermal insulation and crack-resistant functions are really achieved.

Owner:西安德耐节能科技有限责任公司

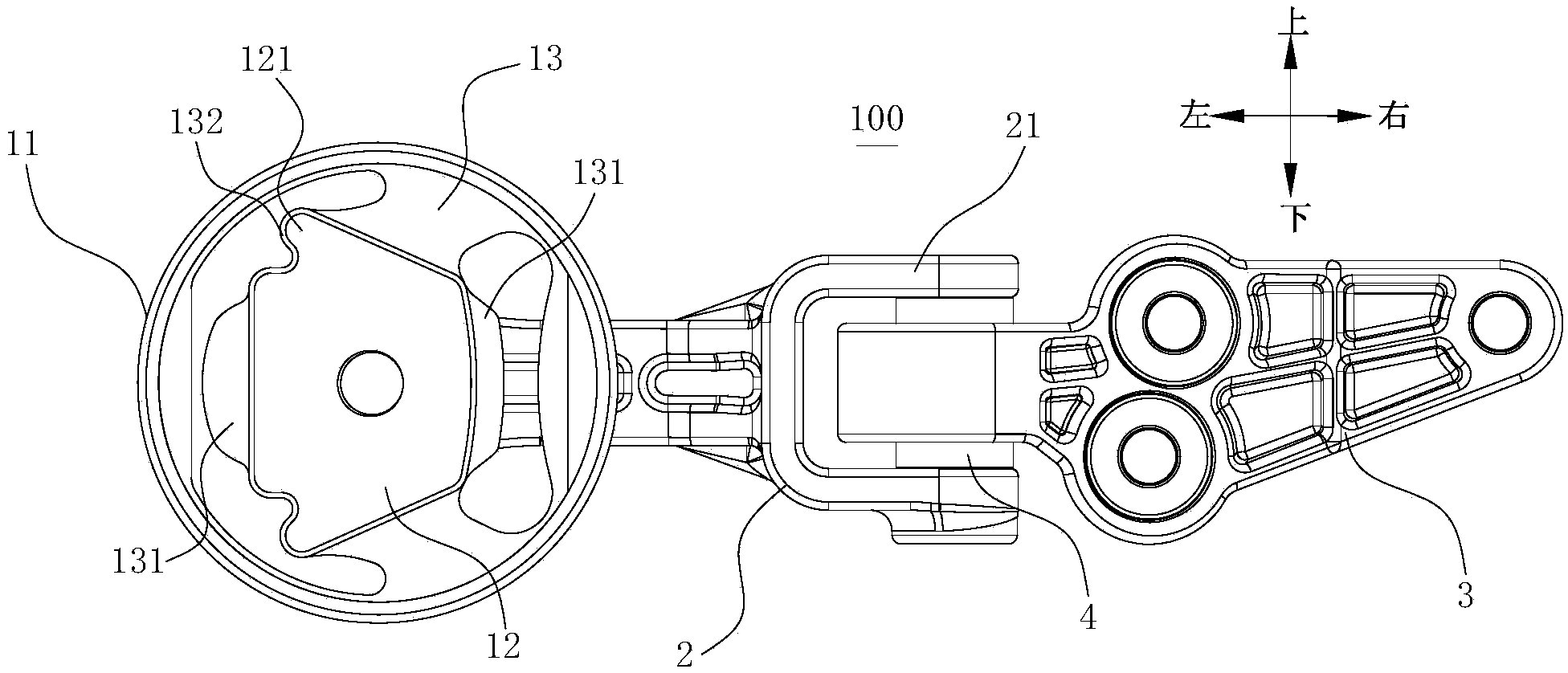

Vehicle and pull rod type suspension device thereof

ActiveCN104070979AExtended service lifeImprove reliabilityJet propulsion mountingInternal combustion mountingEngineeringMechanical engineering

The invention discloses a vehicle and a pull rod type suspension device thereof. The pull rod type suspension device comprises a bush assembly, a connecting rod and a transmission mount bracket, wherein the bush assembly comprises an inner core, a rubber part and an outer tube, the inner core is arranged inside the outer pipe, the rubber part is arranged between the outer pipe and the inner core, the side wall of the outer pipe is provided with a first through hole, and the position on the rubber part, which corresponds to the first opening, is provided with a second through opening; one end of the connecting rod penetrates the first opening of the outer pipe and the second opening of the rubber part to be connected with the inner core, and the connecting rod can swing between two opposite side walls relative to the first opening of the outer pipe; the transmission mount bracket is connected with the other end of the connecting rod. The pull rod type suspension device limits torsional displacement of a power assembly of a vehicle through connection of the connecting rod and the inner core and forming of the first opening for limiting movement of the connecting rod on the outer pipe, and solves the problems of aging inclination and reduction of fatigue durability of the bush assembly.

Owner:GREAT WALL MOTOR CO LTD

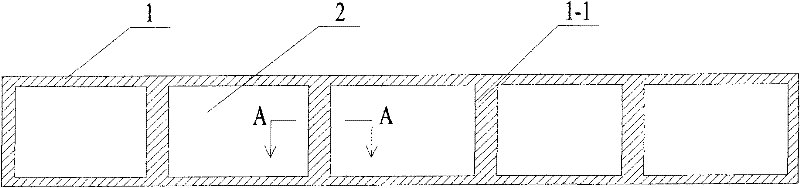

Reactive powder concrete material manhole cover and manufacturing method thereof

ActiveCN106337442ASimple designReduce molding difficultyArtificial islandsCeramic shaping apparatusFire controlRebar

The invention discloses a reactive powder concrete material manhole cover which comprises a manhole cover body and a manhole base. The reactive powder concrete material manhole cover is characterized in that the manhole base is composed of a first reactive powder concrete body and reinforcing steel bars arranged in the first reactive powder concrete body; the manhole cover body is composed of a second reactive powder concrete body in a shape of an inverse circular truncated cone and a reinforcing steel bar supporting body arranged in the second reactive powder concrete body; and the reinforcing steel bar supporting body is formed by a ring-shaped steel hoop, #-shaped reinforcing steel bars, inner annular reinforcing steel bars and outer annular reinforcing steel bars, wherein the two ends of the #-shaped reinforcing steel bars are fixedly connected with the ring-shaped steel hoop or connected with the ring-shaped steel hoop into a whole, the inner annular reinforcing steel bars are fixedly connected with the #-shaped reinforcing steel bars or connected with the #-shaped reinforcing steel bars into a whole, and the outer annular reinforcing steel bars are fixedly connected with the #-shaped reinforcing steel bars or connected with the #-shaped reinforcing steel bars into a whole. A manufacturing method of the manhole cover includes the steps of reinforcement cage manufacturing, reactive powder concrete mixture manufacturing, and manhole cover body and manhole base manufacturing. By means of the reactive powder concrete material manhole cover and the manufacturing method, the manhole cover is excellent in performance, durable in use and capable of being used as municipal engineering public services such as tap water, telecom, electric power, gas, heating power, fire control and environmental sanitation.

Owner:福建诚兴新材料科技有限公司

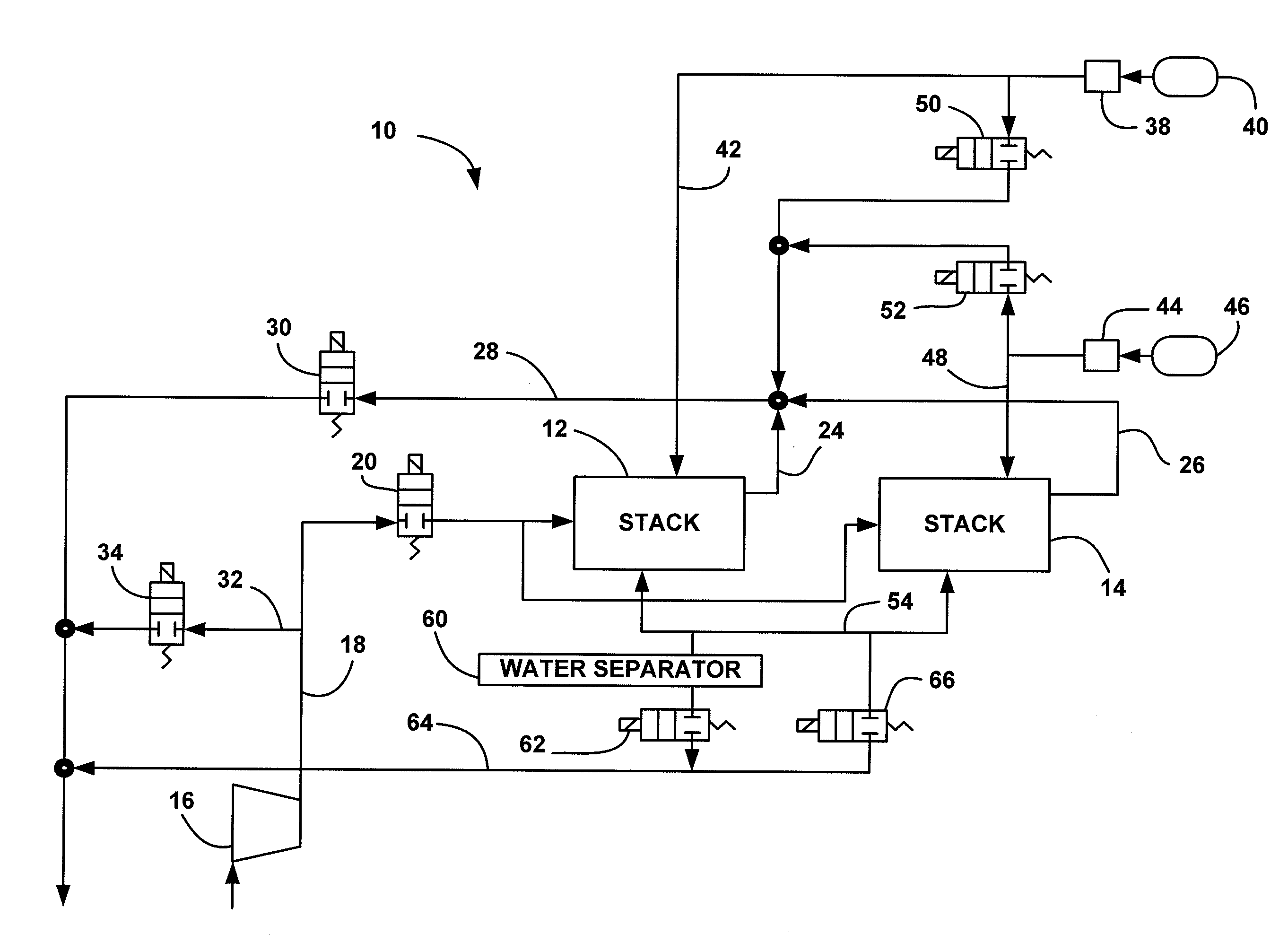

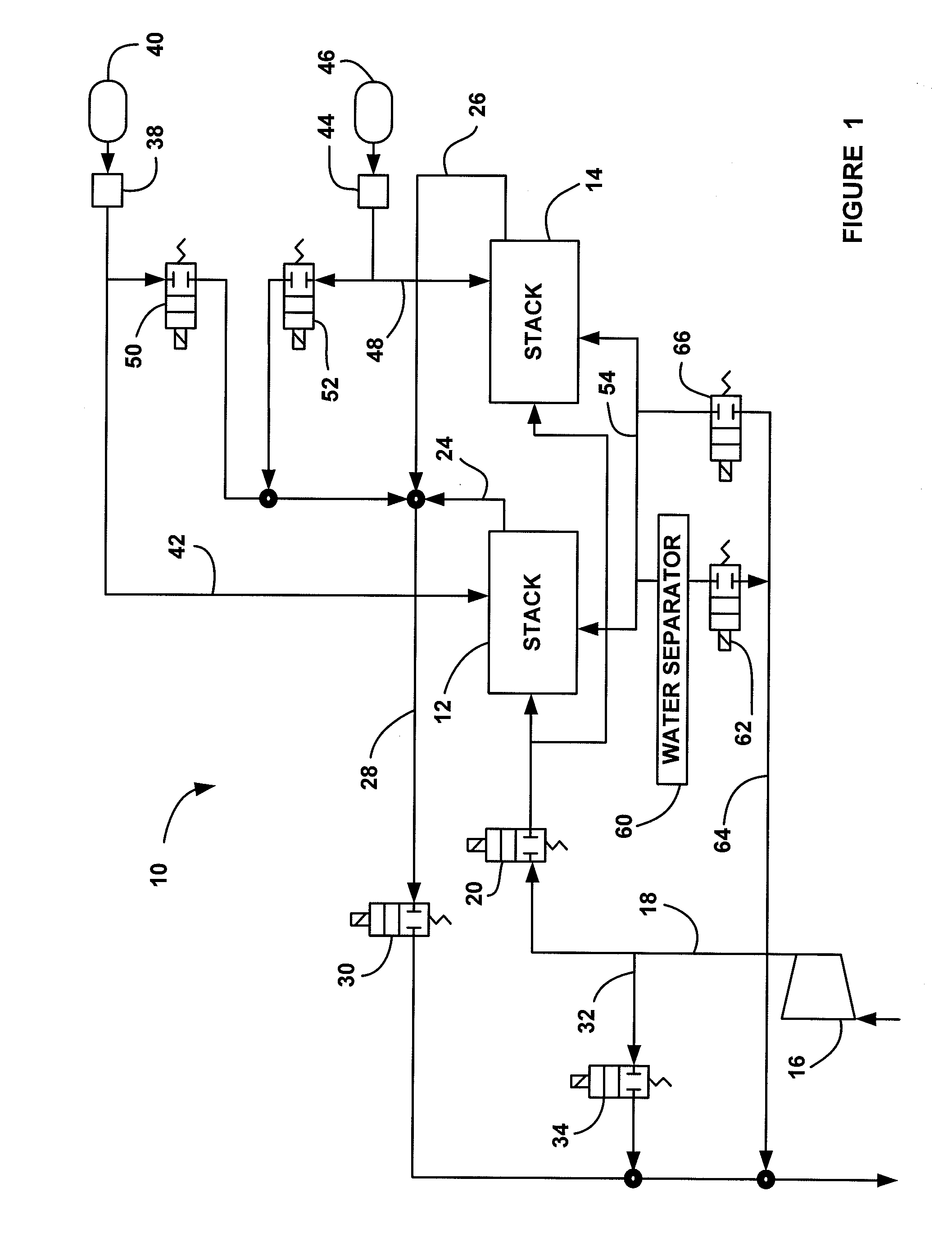

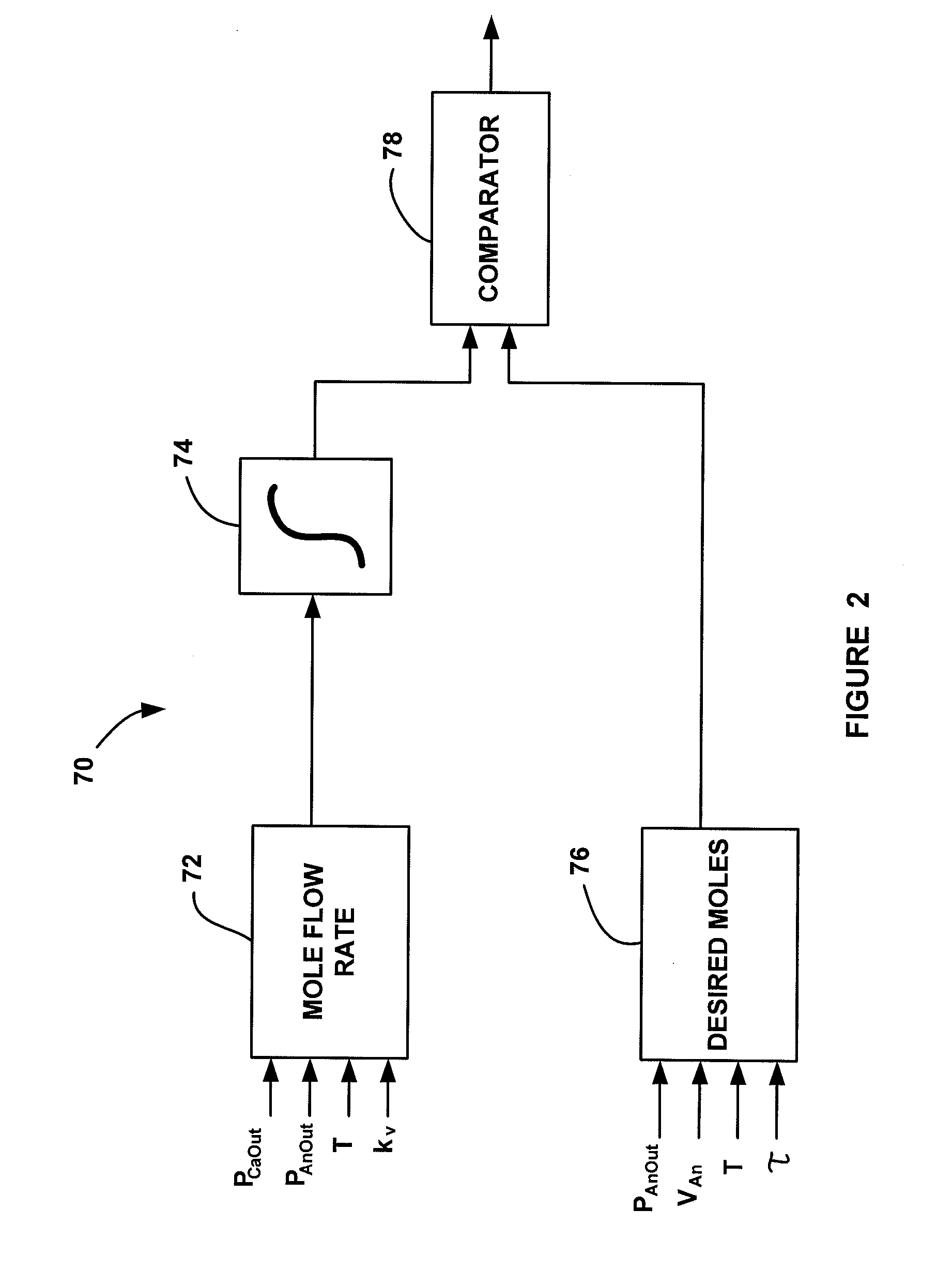

Anode Bleed Control Strategy for Improved Water Management and Hydrogen Utilization

ActiveUS20080312849A1Improve water managementSolve the durability problemVolume flow measuring devicesVolume/mass flow by differential pressureHydrogenFuel cells

A control strategy for bleeding an anode side of fuel cell stack in a fuel cell system that improves water management and addresses durability and performance concerns. The method includes determining when to begin the anode bleed, typically by estimating or measuring the amount of nitrogen in the anode side of the stack. The method also includes determining when to end the anode bleed based on the volume of gas that has been bled. The method determines the mole flow rate of the anode gas flowing through a bleed valve, integrates the mole flow rate to get the number of moles of the gas that have passed through the bleed valve, determines a desired amount of moles to be bled, and ends the bleed when the actual number of moles of the gas equals the desired number of moles of the gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com